Precision, 16 MHz

www.BDTIC.com/ADI

a

FEATURES

Replaces Hybrid Amplifiers in Many Applications

AC PERFORMANCE:

Settles to 0.01% in 350 ns

100 V/s Slew Rate

12.8 MHz Min Unity Gain Bandwidth

1.75 MHz Full Power Bandwidth at 20 V p-p

DC PERFORMANCE:

0.25 mV Max Input Offset Voltage

5 V/ⴗC Max Offset Voltage Drift

0.5 nA Input Bias Current

250 V/mV Min Open-Loop Gain

4 V p-p Max Voltage Noise, 0.1 Hz to 10 Hz

94 dB Min CMRR

Available in Plastic Mini-DIP, Hermetic CERDIP, and

SOIC Packages. Also Available in Tape and Reel in

Accordance with EIA-481A Standard

GENERAL DESCRIPTION

The AD845 is a fast, precise, N channel JFET input, monolithic

operational amplifier. It is fabricated using Analog Devices’

complementary bipolar (CB) process. Advanced laser-wafer

trimming technology enables the very low input offset voltage

and offset voltage drift performance to be realized. This precision, when coupled with a slew rate of 100 V/ms, a stable unity

gain bandwidth of 16 MHz, and a settling time of 350 ns to

0.01%—while driving a parallel load of 100 pF and 500 W—

represents a combination of features unmatched by any FET

input IC amplifier. The AD845 can easily be used to upgrade

many existing designs that use BiFET or FET input hybrid

amplifiers and, in some cases, those which use bipolar input

op amps.

The AD845 is ideal for use in applications such as active filters,

high speed integrators, photodiode preamps, sample-and-hold

amplifiers, and log amplifiers, and for buffering A/D and D/A

converters. The 250 mV max input offset voltage makes offset

nulling unnecessary in many applications. The common-mode

rejection ratio of 110 dB over a ±10 V input voltage range

represents exceptional performance for a JFET input high

speed op amp. This, together with a minimum open-loop

gain of 250 V/mV ensures that 12-bit performance is achieved,

even in unity gain buffer circuits.

CBFET Op Amp

AD845

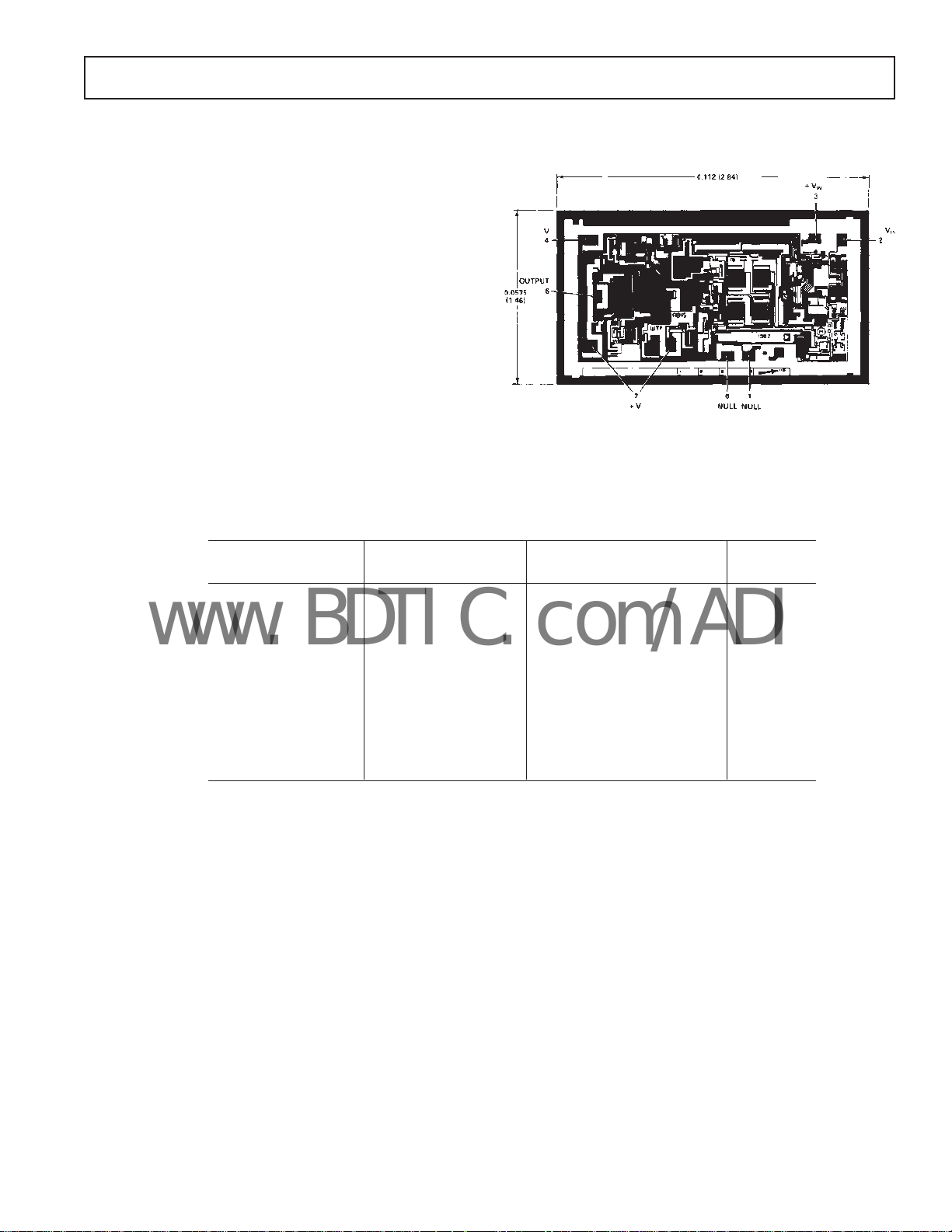

CONNECTION DIAGRAMS

Plastic Mini-DIP (N) Package

and CERDIP (Q) Package

The AD845 conforms to the standard op amp pinout except

that offset nulling is to V+. The AD845J and AD845K grade

devices are available specified to operate over the commercial

0∞C to 70∞C temperature range. AD845A and AD845B

devices are specified for operation over the –40∞C to +85∞C

industrial temperature range. The AD845S is specified to operate over the full military temperature range of –55∞C to +125∞C.

Both the industrial and military versions are available in 8-lead

CERDIP packages. The commercial version is available in an

8-lead plastic mini-DIP and 16-lead SOIC; J and S grade chips

are also available.

PRODUCT HIGHLIGHTS

1. The high slew rate, fast settling time, and dc precision of the

AD845 make it ideal for high speed applications requiring

12-bit accuracy.

2. The performance of circuits using the LF400, HA2520,

HA2522, HA2525, HA2620, HA2622, HA2625, 3550,

OPA605, and LH0062 can be upgraded in most cases.

3. The AD845 is unity gain stable and internally compensated.

4. The AD845 is specified while driving 100 pF/500 W loads.

16-Lead SOIC

(R-16) Package

REV. E

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

AD845–SPECIFICATIONS

www.BDTIC.com/ADI

(@ 25ⴗC and ⴞ15 V dc, unless otherwise noted.)

AD845J/A AD845K/B AD845S

Parameter Conditions Min Typ Max Min Typ Max Min Typ Max Unit

INPUT OFFSET VOLTAGE

1

Initial Offset 0.7 1.5 0.1 0.25 0.25 1.0 mV

T

MIN

to T

MAX

2.5 0.4 2.0 mV

Offset Drift 20 1.5 5.0 10 mV/∞C

INPUT BIAS CURRENT

2

Initial VCM = 0 V 0.75 2 0.5 1 0.75 2 nA

T

MIN

to T

MAX

45/75 18/38 500 nA

INPUT OFFSET CURRENT

Initial VCM = 0 V 25 300 15 100 25 300 pA

T

to T

MIN

MAX

INPUT CHARACTERISTICS

Input Resistance 10

11

3/6.5 1.2/2.6 20 nA

10

11

10

11

kW

Input Capacitance 4.0 4.0 4.0 pF

INPUT VOLTAGE RANGE

Differential ±20 ±20 ± 20 V

Common-Mode ⴞ10 +10.5/–13 ⴞ10 +10.5/–13 ⴞ10 +10.5/–13 V

Common-Mode Rejection VCM = ±10 V 86 110 94 113 86 110 dB

INPUT VOLTAGE NOISE 0.1 Hz to 10 Hz 4 4 4 mV p-p

f = 10 Hz 80 80 80 nV/÷Hz

f = 100 Hz 60 60 60 nV/÷Hz

f = 1 kHz 25 25 25 nV/÷Hz

f = 10 kHz 18 18 18 nV/÷Hz

f = 100 kHz 12 12 12 nV/÷Hz

INPUT CURRENT NOISE f = 1 kHz 0.1 0.1 0.1 pA/÷Hz

OPEN-LOOP GAIN V

= ±10 V

O

R

≥ 2 kW 200 500 250 500 200 500 V/mV

LOAD

R

≥ 500 W 100 250 125 250 100 250 V/mV

LOAD

T

MIN–TMAX

70 75 50 V/mV

OUTPUT CHARACTERISTICS

Voltage R

≥ 500 W ⴞ12.5 ⴞ12.5 ⴞ12.5 V

LOAD

Current Short Circuit 50 50 50 mA

Output Resistance Open Loop 5 5 5 W

FREQUENCY RESPONSE

Small Signal Unity Gain 12.8 16 13.6 16 13.6 16 MHz

Full Power Bandwidth

3

VO = ±10 V

R

= 500 W 1.75 1.75 1.75 MHz

LOAD

Rise Time 20 20 20 ns

Overshoot 20 20 20 %

Slew Rate 80 100 94 100 94 100 V/ms

Settling Time 10 V Step

C

= 100 pF

LOAD

R

= 500 W

LOAD

to 0.01% 350 350 500 350 500 ns

to 0.1% 250 250 250 ns

DIFFERENTIAL GAIN f = 4.4 MHz 0.04 0.04 0.04 %

DIFFERENTIAL PHASE f = 4.4 MHz 0.02 0.02 0.02 Degree

POWER SUPPLY

Rated Performance ±15 ±15 ± 15 V

Operating Range ⴞ4.75 ⴞ18 ⴞ4.75 ⴞ18 ⴞ4.75 ⴞ18 V

Rejection Ratio V

Quiescent Current T

NOTES

1

Input offset voltage specifications are guaranteed after five minutes of operation at TA = 25∞C.

2

Bias current specifications are guaranteed maximum at either input after five minutes of operation at T

3

FPBW = slew rate/2 p V peak.

4

S grade T

All min and max specifications are guaranteed. Specifications shown in boldface are tested on all production units at final electrical test. Results from these tests are

used to calculate outgoing quality levels.

Specifications subject to change without notice.

MIN–TMAX

are tested with automatic test equipment at TA = –55∞C and TA = +125∞C.

= ± 5 to ±15 V 88 110 95 113 88 110 dB

S

MIN

to T

MAX

10 12 10 12 10 12 mA

= 25∞C.

A

–2–

REV. E

AD845

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 18 V

Internal Power Dissipation

2

1

Plastic Mini-DIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.6 W

CERDIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.4 W

16-Lead SOIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 W

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +V

S

Output Short-Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . . . +V

and –V

S

S

Storage Temperature Range

Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .–65∞C to +150∞C

N, R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .–65∞C to +125∞C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . . 300∞C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only, and functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Mini-DIP package: qJA = 100∞C/W; CERDIP package: qJA = 110∞C/W; SOIC

package: qJA = 100∞C/W.

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

METALIZATION PHOTOGRAPH

Dimensions shown in inches and (mm).

Contact factory for latest dimensions.

SUBSTRATE CONNECTED TO +V

S

1

AD845JN 0∞C to 70∞C 8-Lead PDIP N-8

AD845KN 0∞C to 70∞C 8-Lead PDIP N-8

AD845JR-16 0∞C to 70∞C 16-Lead SOIC R-16

AD845JR-16-REEL 0∞C to 70∞CTape and Reel R-16

AD845JR-16-REEL7 0∞C to 70∞CTape and Reel R-16

AD845AQ –40∞C to +85∞C 8-Lead CERDIP Q-8

AD845BQ –40∞C to +85∞C 8-Lead CERDIP Q-8

AD845SQ –55∞C to +125∞C 8-Lead CERDIP Q-8

AD845SQ/883B –55∞C to +125∞C 8-Lead CERDIP Q-8

5962-8964501PA

2

–55∞C to +125∞C 8-Lead CERDIP Q-8

AD845JCHIPS 0∞C to 70∞CDie

NOTES

1

N = Plastic DIP; Q = CERDIP; R = Small Outline IC (SOIC).

2

See military data sheet.

REV. E

–3–

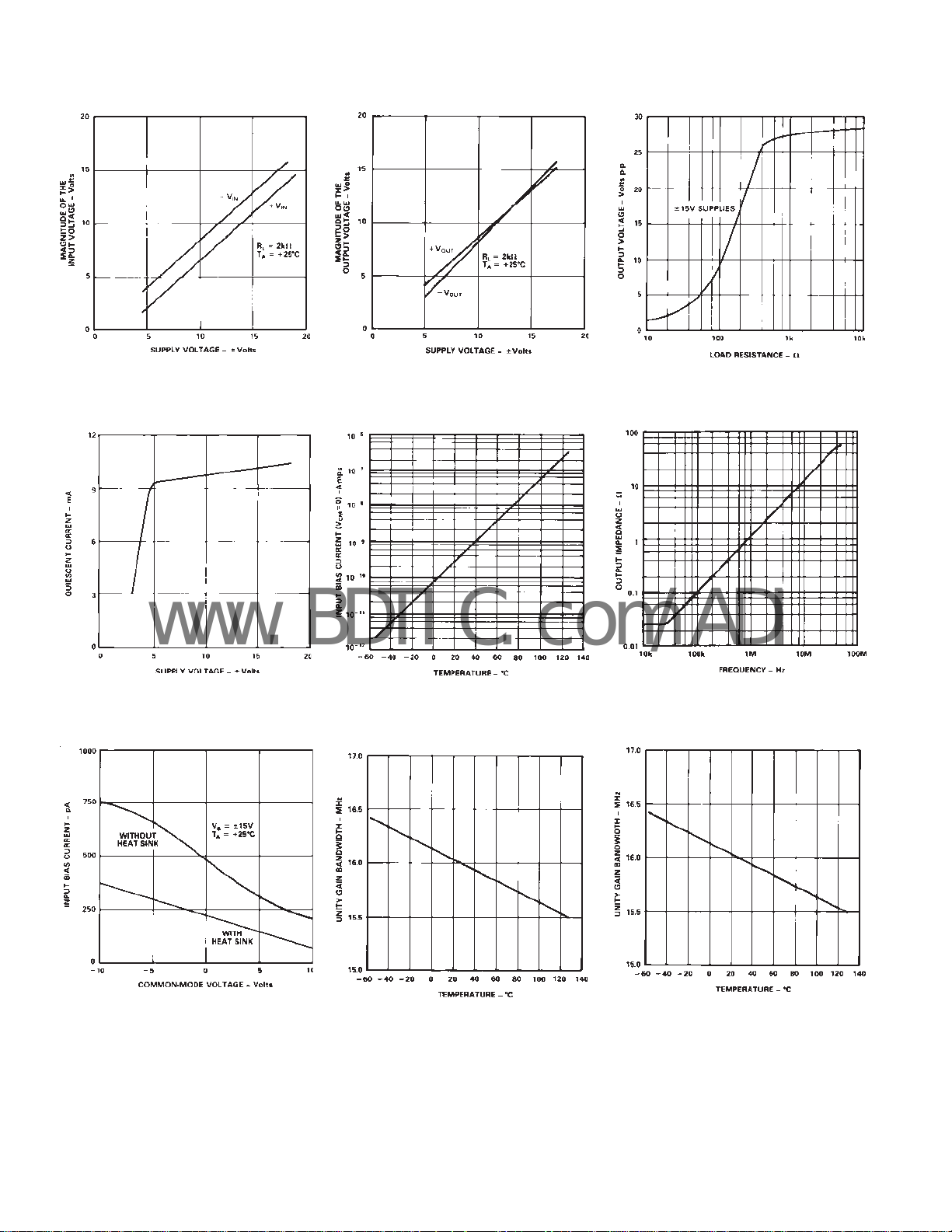

AD845–Typical Performance Characteristics

www.BDTIC.com/ADI

TPC 1. Input Voltage Swing

vs. Supply Voltage

TPC 4. Quiescent Current vs.

Supply Voltage

TPC 2. Output Voltage Swing

vs. Supply Voltage

TPC 5. Input Bias Current vs.

Temperature

TPC 3. Output Voltage Swing

vs. Resistive Load

TPC 6. Magnitude of Output

Impedance vs. Frequency

TPC 7. Input Bias Current vs.

Common-Mode Voltage

TPC 8. Short-Circuit Current

Limit vs. Temperature

–4–

TPC 9. Unity-Gain Bandwidth

vs. Temperature

REV. E

AD845

www.BDTIC.com/ADI

TPC 10. Open-Loop Gain and

Phase Margin vs. Frequency

TPC 13. Common-Mode

Rejection vs. Frequency

TPC 11. Open-Loop Gain vs.

Supply Voltage

TPC 14. Large Signal Frequency

Response

TPC 12. Power Supply

Rejection vs. Frequency

TPC 15. Output Swing and

Error vs. Settling Time

TPC 16. Harmonic Distortion

vs. Frequency

REV. E

TPC 17. Input Noise Voltage

Spectral Density

–5–

TPC 18. Slew Rate vs. Temperature

AD845

www.BDTIC.com/ADI

TPC 19. Recommended Power

Supply Bypassing

TPC 22. Unity Gain Follower

TPC 20. AD845 Simplified

Schematic

TPC 23. Unity Gain Follower

Large Signal Pulse Response

TPC 21. Offset Null Configuration

TPC 24. Unity Gain Follower

Small Signal Pulse Response

TPC 25. Unity Gain Inverter

TPC 26. Unity Gain Inverter

Large Signal Pulse Response

–6–

TPC 27. Unity Gain Inverter

Small Signal Pulse Response

REV. E

AD845

www.BDTIC.com/ADI

MEASURING AD845 SETTLING TIME

Figure 1 shows AD845 settling time performance. This measurement was accomplished by driving the amplifier in the unity

gain inverting mode with a fast pulse generator. The input

summing junction was measured using false nulling techniques.

Settling time is defined as the interval of time from the application

of an ideal step function input until the closed-loop amplifier

output has entered and remains within a specified error band.

Components of settling time include:

1. Propagation time through the amplifier

2. Slewing time to approach the final output value

3. Recovery time from overload associated with the slewing

4. Linear settling to within a specified error band

These individual components can be seen easily in Figure 1.

Settling time is extremely important in high speed applications

where the current output of a DAC must be converted to a

voltage. When driving a 500 W load in parallel with a 100 pF

capacitor, the AD845 settles to 0.1% in 250 ns and to 0.01% in

310 ns.

stable, accurately defined gain. Low input bias currents and fast

settling are achieved with the FET input AD845.

Most monolithic instrumentation amplifiers do not have the

high frequency performance of the circuit in Figure 3. The circuit bandwidth is 10.9 MHz at a gain of 1 and 8.8 MHz at a

gain of 10; settling time for the entire circuit is 900 ns to 0.01%

for a 10 V step (Gain = 10).

The capacitors employed in this circuit greatly improve the

amplifier’s settling time and phase margin.

Figure 1. Settling Characteristics 0 V to 10 V Step

Upper Trace: Output of AD845 Under Test (5 V/Div)

Lower Trace: Error Voltage (1 mV/Div)

Figure 2. Settling Time Test Circuit

Figure 3. High Performance, High Speed Instrumentation

Amplifier

Table I. Performance Summary for the 3-Op Amp

Instrumentation Amplifier Circuit

3-Op Amp In-Amp

Small Signal Settling Time

Gain R

1Open 10.9 MHz 500 ns

22 kW 8.8 MHz 500 ns

10 226 W 2.6 MHz 900 ns

100 20 W 290 kHz 7.5 ms

Note: Resistors around the amplifiers’ input pins need to be small enough in

value so that the RC time constant they form, with stray circuit capacitance,

does not reduce circuit bandwidth.

G

Bandwidth to 0.01%

A HIGH SPEED INSTRUMENTATION AMP

The 3-op amp instrumentation amplifier circuit shown in

Figure 3 can provide a range of gains from unity up to 1000 and

higher. The instrumentation amplifier configuration features

high common-mode rejection, balanced differential inputs, and

REV. E

Figure 4. The Pulse Response of the 3-Op Amp

Instrumentation Amplifier. Gain = 1, Horizontal Scale =

0.5 ms/Div and Vertical Scale = 5 V/Div.

–7–

AD845

www.BDTIC.com/ADI

Figure 5. Settling Time of the 3-Op Amp Instrumentation

Amplifier. Horizontal Scale is 200 ns/Div, Vertical Scale,

Positive Pulse Input is 5 V/Div and Output Settling is

1 mV/Div.

DRIVING THE ANALOG INPUT OF AN A/D CONVERTER

An op amp driving the analog input of an A/D converter, such

as that shown in Figure 7, must be capable of maintaining a

constant output voltage under dynamically changing load conditions. In successive approximation converters, the input current

is compared to a series of switched trial currents. The comparison point is diode clamped but may deviate several hundred

millivolts, resulting in high frequency modulation of A/D input

current. The output impedance of a feedback amplifier is made

artificially low by the loop gain. At high frequencies, where the

loop gain is low, the amplifier output impedance can approach

its open-loop value. Most IC amplifiers exhibit a minimum

open-loop output impedance of 25 W due to current limiting

resistors. A few hundred microamps reflected from the change

in converter loading can introduce errors in instantaneous input

voltage. If the A/D conversion speed is not excessive and the

bandwidth of the amplifier is sufficient, the amplifier’s output

will return to the nominal value before the converter makes its

comparison. However, many amplifiers have relatively narrow

bandwidth, yielding slow recovery from output transients. The

Figure 6. Settling Time of the Three Op Amp Instrumentation Amplifier. Horizontal Scale: 200 ns/Div; Vertical

Scale, Negative Pulse Input: 5 V/ Div; Output Settling:

1 mV/Div.

AD845 is ideally suited to drive high resolution A/D converters

with 5 ms or longer conversion times since it offers both wide

bandwidth and high open-loop gain.

Figure 7. AD845 As ADC Unity Gain Buffer

–8–

REV. E

OUTLINE DIMENSIONS

www.BDTIC.com/ADI

AD845

8-Lead Plastic Dual In-Line Package [PDIP]

(N-8)

Dimensions shown in inches and (millimeters)

0.375 (9.53)

0.365 (9.27)

0.355 (9.02)

8

1

0.100 (2.54)

0.180

(4.57)

MAX

0.150 (3.81)

0.130 (3.30)

0.110 (2.79)

0.022 (0.56)

0.018 (0.46)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

COMPLIANT TO JEDEC STANDARDS MO-095AA

BSC

5

4

0.295 (7.49)

0.285 (7.24)

0.275 (6.98)

0.015

(0.38)

MIN

SEATING

PLANE

0.060 (1.52)

0.050 (1.27)

0.045 (1.14)

0.325 (8.26)

0.310 (7.87)

0.300 (7.62)

0.150 (3.81)

0.135 (3.43)

0.120 (3.05)

0.015 (0.38)

0.010 (0.25)

0.008 (0.20)

16-Lead Standard Small Outline Package [SOIC]

Wide Body

(R-16)

Dimensions shown in millimeters and (inches)

10.50 (0.4134)

10.10 (0.3976)

16

1

1.27 (0.0500)

BSC

0.30 (0.0118)

0.10 (0.0039)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

0.51 (0.0201)

0.31 (0.0122)

COMPLIANT TO JEDEC STANDARDS MS-013AA

9

7.60 (0.2992)

7.40 (0.2913)

8

2.65 (0.1043)

2.35 (0.0925)

SEATING

PLANE

10.65 (0.4193)

10.00 (0.3937)

0.33 (0.0130)

0.20 (0.0079)

8ⴗ

0ⴗ

0.75 (0.0295)

0.25 (0.0098)

1.27 (0.0500)

0.40 (0.0157)

ⴛ 45ⴗ

8-Lead Ceramic Dual In-Line Package [CERDIP]

(Q-8)

Dimensions shown in inches and (millimeters)

0.005 (0.13)

PIN 1

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.023 (0.58)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

0.055 (1.40)

MIN

0.100 (2.54) BSC

0.405 (10.29) MAX

MAX

85

1

4

0.070 (1.78)

0.030 (0.76)

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150 (3.81)

MIN

SEATING

PLANE

0.320 (8.13)

0.290 (7.37)

15

0

0.015 (0.38)

0.008 (0.20)

REV. E

–9–

AD845

www.BDTIC.com/ADI

Revision History

Location Page

10/03—Data Sheet changed from REV. D to REV. E.

Renumbered figures and TPCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Universal

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

–10–

REV. E

–11–

www.BDTIC.com/ADI

C00886–0–10/03(E)

www.BDTIC.com/ADI

–12–

Loading...

Loading...