Low Noise, Low Gain Drift, G = 2000

+IN–

–FIL

V

Data Sheet

FEATURES

Fixed gain of 2000

Access to internal nodes provides flexibility

Low noise: 1.5 nV/√Hz input voltage noise

High accuracy dc performance

Gain drift: 10 ppm/°C

Offset drift: 1 μV/°C

Gain accuracy: 0.2%

CMRR: 130 dB min

Excellent ac specifications

Bandwidth: 3.5 MHz

Slew rate: 40 V/μs

Power supply range: ±4 V to ±18 V

8-pin SOIC package

ESD protection >5000 V (HBM)

Temperature range for specified performance:

−40°C to +85°C

Operational up to 125°C

APPLICATIONS

Sensor interface

Medical instrumentation

Patient monitoring

GENERAL DESCRIPTION

The AD8428 is an ultralow noise instrumentation amplifier

designed to accurately measure tiny, high speed signals. It

delivers industry-leading gain accuracy, noise, and bandwidth.

All gain setting resistors for the AD8428 are internal to the part

and are precisely matched. Care is taken in both the chip pinout

and layout. This results in excellent gain drift and quick settling

to the final gain value after the part is powered on.

The high CMRR of the AD8428 prevents unwanted signals

from corrupting the signal of interest. The pinout of the AD8428

is designed to avoid parasitic capacitance mismatches that can

degrade CMRR at high frequencies.

Instrumentation Amplifier

AD8428

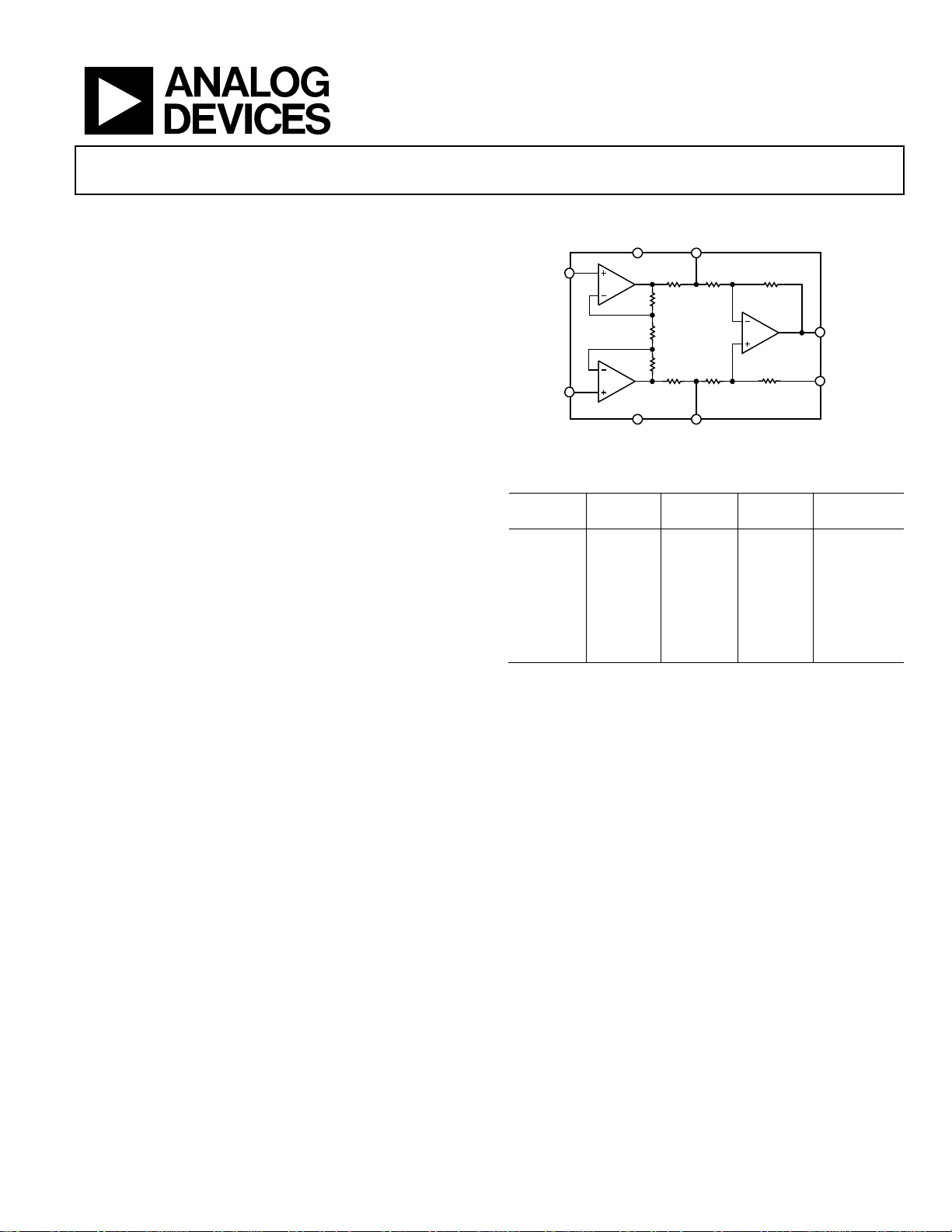

FUNCTIONAL BLOCK DIAGRAM

+

S

IN

6kΩ 6kΩ

3kΩ

30.15Ω

3kΩ

6kΩ 6kΩ

–V

+FIL

S

Figure 1.

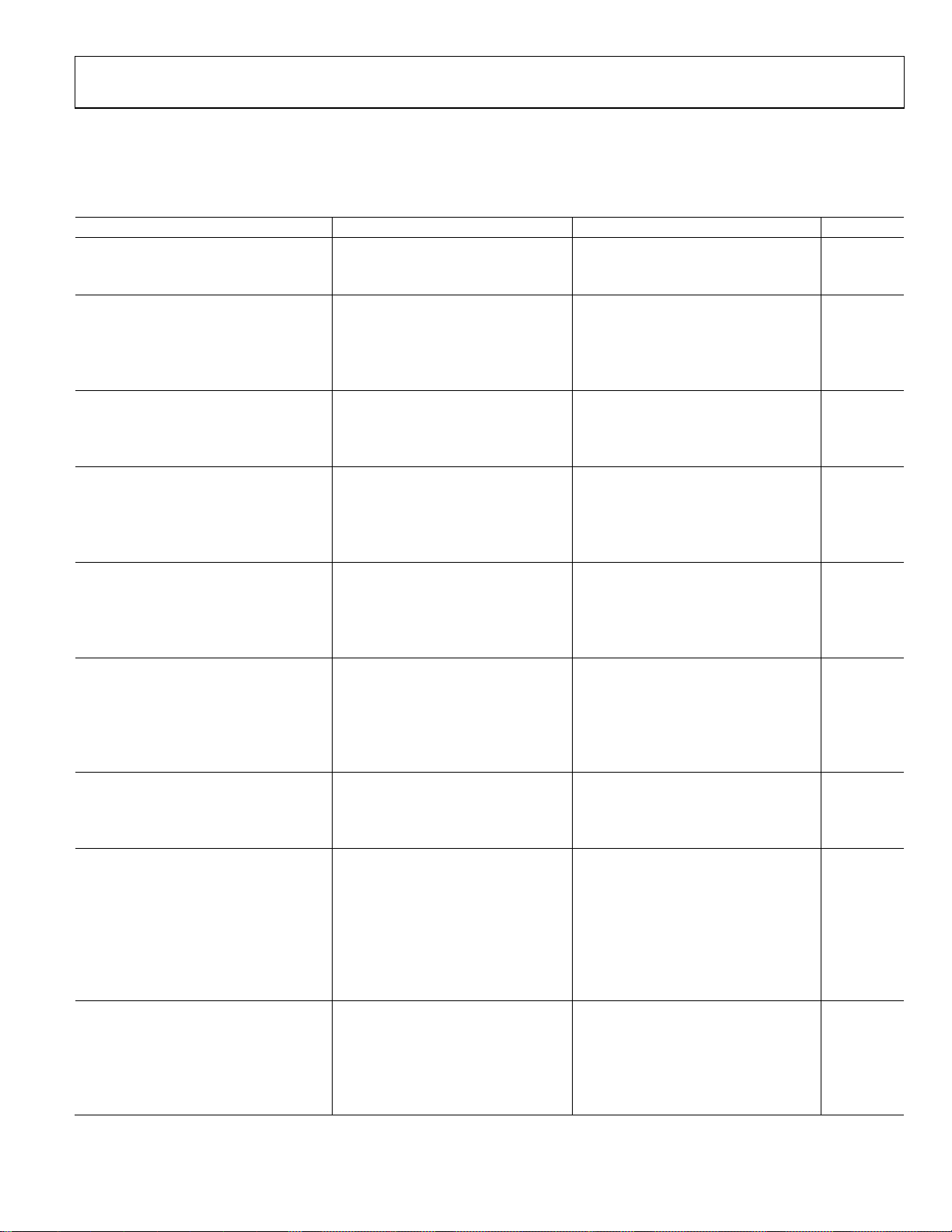

Table 1. Instrumentation Amplifiers by Category1

GeneralPurpose

Zero

Drift

Military

Grade

AD8220 AD8231 AD620 AD627 AD8428

AD8221 AD8290 AD621 AD623 AD8429

AD8222 AD8293 AD524 AD8235

AD8224 AD8553 AD526 AD8236

AD8228 AD8556 AD624 AD8426

AD8295 AD8557 AD8226

AD8227

1

See www.analog.com for the latest instrumentation amplifiers.

The AD8428 is one of the fastest instrumentation amplifiers

available. The circuit architecture is designed for high bandwidth

at high gain. The AD8428 uses a current feedback topology for

the initial preamplifier gain stage of 200, followed by a difference

amplifier stage of 10. This architecture results in a 3.5 MHz

bandwidth at a gain of 2000 for an equivalent gain bandwidth

product of 7 GHz.

The AD8428 pinout allows access to internal nodes between the

first and second stages. This feature can be useful for modifying

the frequency response between the two amplification stages,

thereby preventing unwanted signals from contaminating the

output results.

The performance of the AD8428 is specified over the industrial

temperature range of −40°C to +85°C. It is available in an 8-lead

plastic SOIC package.

120kΩ

120kΩ

AD8428

Low

Power

OUT

REF

Low

Noise

09731-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

AD8428 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 5

Thermal Resistance ...................................................................... 5

ESD Caution .................................................................................. 5

Pin Configuration and Function Descriptions ............................. 6

Typical Performance Characteristics ............................................. 7

REVISION HISTORY

10/11—Revision 0: Initial Version

Theory of Operation ...................................................................... 13

Architecture ................................................................................ 13

Filter Terminals ........................................................................... 13

Reference Terminal .................................................................... 13

Input Voltage Range ................................................................... 14

Layout .......................................................................................... 14

Input Bias Current Return Path ............................................... 15

Input Protection ......................................................................... 15

Radio Frequency Interference (RFI) ........................................ 16

Calculating the Noise of the Input Stage ................................. 16

Outline Dimensions ....................................................................... 18

Ordering Guide .......................................................................... 18

Rev. 0 | Page 2 of 20

Data Sheet AD8428

SPECIFICATIONS

VS = ±15 V, V

Table 2.

Parameter Test Conditions/Comments Min Typ Max Unit

COMMON-MODE REJECTION RATIO (RTI) VCM = ±10 V

CMRR, DC to 60 Hz 130 dB

CMRR at 50 kHz 110 dB

NOISE (RTI) VIN+, VIN− = 0 V

Voltage Noise f = 1 kHz 1.3 1.5 nV/√Hz

f = 0.1 Hz to 10 Hz 40 50 nV p-p

Current Noise f = 1 kHz 1.5 pA/√Hz

f = 0.1 Hz to 10 Hz 150 pA p-p

VOLTAGE OFFSET

Input Offset, V

Average TC TA = −40°C to +85°C 1 μV/°C

Offset RTI vs. Supply (PSRR) 120 dB

INPUT CURRENT

Input Bias Current 200 nA

Over Temperature TA = −40°C to +85°C 250 pA/°C

Input Offset Current 50 nA

Over Temperature TA = −40°C to +85°C 20 pA/°C

DYNAMIC RESPONSE

−3 dB Small Signal Bandwidth 3.5 MHz

Settling Time to 0.01% 10 V step 0.75 μs

Settling Time to 0.001% 10 V step 1.4 μs

Slew Rate 40 50 V/μs

GAIN

First Stage Gain 200 V/V

Subtractor Stage Gain 10 V/V

Total Gain Error V

Tot al G ain Nonlinearity V

Total Gain vs. Temperature 10 ppm/°C

INPUT

Impedance (Pin to Ground)

Input Operating Voltage Range VS = ±4 V to ±18 V −VS + 2.5 +VS − 2.5 V

Over Temperature TA = −40°C to +85°C −VS + 2.5 +VS − 2.5 V

OUTPUT

Output Swing RL = 2 kΩ −VS + 1.7 +VS − 1.2 V

Over Temperature TA = −40°C −VS + 2.0 +VS − 1.3 V

T

Output Swing RL = 10 kΩ −VS + 1.7 +VS − 1.0 V

Over Temperature TA = −40°C −VS + 1.8 +VS − 1.2 V

T

Short-Circuit Current 30 mA

REFERENCE INPUT

RIN 132 kΩ

IIN V

Voltage Range −VS +VS V

Reference Gain to Output 1 V/V

Reference Gain Error 0.01 %

= 0 V, TA = 25°C, G = 2000, RL = 10 k, unless otherwise noted.

REF

100 μV

OSI

= −10 V to +10 V 0.2 %

OUT

= −10 V to +10 V 5 ppm

OUT

1

1||2 GΩ||pF

= +85°C −VS + 1.6 +VS − 1.1 V

A

= +85°C −VS + 1.4 +VS − 0.9 V

A

+, VIN− = 0 V 6.5 μA

IN

Rev. 0 | Page 3 of 20

AD8428 Data Sheet

Parameter Test Conditions/Comments Min Typ Max Unit

FILTER TERMINALS

2

R

6 kΩ

IN

Voltage Range −VS +VS V

POWER SUPPLY

Operating Range ±4 ±18 V

Quiescent Current 6.5 6.8 mA

Over Temperature TA = −40°C to +85°C 8 mA

1

The differential and common-mode input impedances can be calculated from the pin impedance: Z

2

To calculate the actual impedance, see Figure 1.

DIFF

= 2(Z

); ZCM = Z

PIN

/2.

PIN

Rev. 0 | Page 4 of 20

Data Sheet AD8428

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Supply Voltage ±18 V

Output Short-Circuit Current Duration Indefinite

Maximum Voltage at −IN, +IN1 ±VS

Maximum Voltage at −FIL, +FIL ±VS

Differential Input Voltage1 ±1 V

Maximum Voltage at REF ±VS

Storage Temperature Range −65°C to +150°C

Specified Temperature Range −40°C to +85°C

Maximum Junction Temperature 140°C

ESD

Human Body Model 5000 V

Charged Device Model 1250 V

Machine Model 400 V

1

For voltages beyond these limits, use input protection resistors. See the

Input Protection section for more information.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 4. Thermal Resistance

Package θJA Unit

8-Lead SOIC_N 121 °C/W

ESD CAUTION

Rev. 0 | Page 5 of 20

AD8428 Data Sheet

A

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

D8428

–IN

1

–FIL

2

+FIL

3

+IN

4

TOP VIEW

(Not to Scale)

Figure 2. Pin Configuration

Table 5. Pin Function Descriptions

Pin No. Mnemonic Description

1 −IN Negative Input Terminal.

2 −FIL Negative Filter Terminal.

3 +FIL Positive Filter Terminal.

4 +IN Positive Input Terminal.

5 −VS Negative Power Supply Terminal.

6 REF Reference Voltage Terminal. Drive this terminal with a low impedance voltage source to level-shift the output.

7 OUT Output Terminal.

8 +VS Positive Power Supply Terminal.

+V

8

S

OUT

7

REF

6

–V

5

S

09731-002

Rev. 0 | Page 6 of 20

Data Sheet AD8428

TYPICAL PERFORMANCE CHARACTERISTICS

TA = 25°C, VS = ±15 V, V

1200

1000

800

600

HITS

400

200

= 0 V, RL = 10 kΩ, unless otherwise noted.

REF

N = 5170

MEAN = 2.12

SD = 7.332

1600

1400

1200

1000

800

HITS

600

400

200

NONINVERTING I

INVERTING I

BIAS

N = +5171

MEAN = –10.8

SD = +6.67496

N = +5171

MEAN = –10.2

SD = +6.52901

BIAS

0

–40 –20 40200

V

(µV)

OSI

Figure 3. Typical Distribution of Input Offset Voltage, VS = ±5 V

1400

N = +5169

1200

1000

800

HITS

600

400

200

0

–40 –20 40200

V

(µV)

OSI

MEAN = –2.57

SD = +7.31066

Figure 4. Typical Distribution of Input Offset Voltage, VS = ±15 V

1400

1200

1000

800

HITS

600

400

200

N = 5166

MEAN = 0.398

SD = 0.42707

0

–60 –40 –20 40200

09731-003

I

BIAS

(nA)

09731-006

Figure 6. Typical Distribution of Input Bias Current

1000

800

600

HITS

400

200

0

–8 –6 –4 6042–2

09731-004

I

OFFSET (nA)

BIAS

N = +5171

MEAN = –0.53

SD = +1.41655

09731-007

Figure 7. Typical Distribution of Input Bias Current Offset

1200

N = +3487

MEAN = –53.9

1000

800

600

HITS

400

200

SD = +86.7774

0

–3 –2 –1 3120

V

OSI

DRIFT (µV)

Figure 5. Typical Distribution of Input Offset Voltage Drift

09731-005

Rev. 0 | Page 7 of 20

0

–600 –400 200 4000–200

GAIN ERROR (µV/V)

Figure 8. Typical Distribution of Gain Error, Gain = 2000,

V

= ±15 V, RL = 10 kΩ

S

09731-008

AD8428 Data Sheet

15

VS = ±15V

10

5

0

–5

–10

INPUT COMMON-MODE VOLTAGE (V)

–15

–15 –10 –5 0 5 10 15

VS = ±12V

VS = ±5V

OUTPUT VO LTAGE (V )

Figure 9. Input Common-Mode Voltage vs. Output Voltage,

= ±5 V, VS = ±12 V, VS = ±15 V

V

S

09731-009

72

66

60

54

48

42

36

30

24

GAIN (dB)

18

12

6

0

–6

–12

100 1k 10k 100k 100M1M 10M

FREQUENCY (Hz)

Figure 12. Gain vs. Frequency

09731-014

18

16

14

12

10

8

6

INPUT BIAS CURRENT (nA)

4

2

0

–14 14

–11.8V

+12V

–12 –10 –8 –6 –4 –2 0 2 4 6 8 10 12

COMMON-MODE VOLTAGE (V)

Figure 10. Input Bias Current vs. Common-Mode Voltage,

= ±15 V

V

S

140

120

100

80

60

PSRR (dB)

40

20

0

0.1 1 1M100k10k1k10010

FREQUENCY (Hz)

+PSRR

–PSRR

Figure 11. PSRR vs. Frequency

170

160

150

140

130

120

CMRR (dB)

110

100

90

80

09731-010

1 10 100 1k 10k 100k 1M

FREQUENCY (Hz)

GAIN = 2000

09731-015

Figure 13. CMRR vs. Frequency

120

GAIN = 2000

110

100

90

80

70

60

50

CMRR (dB)

40

30

20

10

0

09731-011

1 10 100 1k 10k 100k 1M

FREQUENCY (Hz)

09731-016

Figure 14. CMRR vs. Frequency, 1 kΩ Source Imbalance

Rev. 0 | Page 8 of 20

Data Sheet AD8428

5

4

3

2

1

0

–1

CHANGE IN INPUT OFFSET VOLTAGE (µV)

–2

0 120

10 20 30 40 50 60 70 80 90 100 110

Figure 15. Change in Input Offset Voltage (V

WARM-UP TIME (Seconds)

OSI

) vs. Warm-Up Time

09731-017

70

REPRESENTATIVE DATA NORMALI ZED AT 25°C

60

50

40

30

20

10

CMRR (nV/V)

0

–10

–20

–30

–25–105 203550658095110

–40 125

TEMPERATURE ( °C)

Figure 18. CMRR vs. Temperature, Normalized at 25°C

09731-020

15

10

5

0

–5

–10

–15

INPUT BIAS CURRENT (nA)

–20

–25

–30

–40 125

IOS

IB+

IB–

NORMALIZ ED AT 25°C

–25–105 203550658095110

TEMPERATURE ( °C)

1.2

0.8

0.4

0

–0.4

–0.8

–1.2

–1.6

–2.0

–2.4

Figure 16. Input Bias Current and Input Offset Current vs. Temperature

250

200

150

100

50

0

–50

GAIN ERROR (µV/V)

–100

–150

REPRESENTATI VE DATA NORMALIZED AT 25°C

–200

–25–105 203550658095110

–40 125

TEMPERATURE ( °C)

Figure 17. Gain Error vs. Temperature, Normalized at 25°C

9.0

8.5

8.0

7.5

7.0

6.5

SUPPLY CURRENT (mA)

INPUT OFFSET CURRENT ( nA)

09731-018

6.0

5.5

5.0

–25–105 203550658095110

–40 125

TEMPERATURE ( °C)

09731-021

Figure 19. Supply Current vs. Temperature

50

40

30

20

10

0

–10

–20

–30

SHORT-CIRCUIT CURRENT (mA)

–40

–50

09731-019

–40 125

I

SHORT+

I

SHORT–

–25–105 203550658095110

TEMPERATURE ( °C)

09731-022

Figure 20. Short-Circuit Current vs. Temperature

Rev. 0 | Page 9 of 20

AD8428 Data Sheet

V

V

V

100

90

80

70

60

50

40

SLEW RATE (V/µ s)

30

20

10

0

–40 125

–25–105 203550658095110

TEMPERATURE ( °C)

Figure 21. Slew Rate vs. Temperature, VS = ±15 V

+SR

–SR

09731-023

+

S

–0.4

–40°C +25°C +85°C +125°C

–0.8

–1.2

+2.0

+1.6

+1.2

OUTPUT VO LTAGE SWING (V)

+0.8

REFERRED TO SUPPLY VOLTAGES

+0.4

–V

S

56789101112131415 1716

4

SUPPLY VOLTAGE (±V

)

S

Figure 24. Output Voltage Swing vs. Supply Voltage, RL = 10 kΩ

09731-026

100

90

80

70

60

–SR

50

40

SLEW RATE (V/µ s)

30

+SR

20

10

0

–40 125

–25–105 203550658095110

TEMPERATURE ( °C)

Figure 22. Slew Rate vs. Temperature, VS = ±5 V

+

S

–0.5

–1.0

–1.5

–2.0

–2.5

+2.5

+2.0

INPUT VOLTAGE (V)

+1.5

+1.0

REFERRED TO SUPPLY VOLTAGES

+0.5

–V

S

46810 18161412

SUPPLY VOLTAGE (±VS)

Figure 23. Input Voltage Limit vs. Supply Voltage

–40°C

+25°C

+85°C

+125°C

+

S

–0.4

–40°C +25°C +85°C +125°C

–0.8

–1.2

+2.0

+1.6

+1.2

OUTPUT VOLT AGE SWING (V)

+0.8

REFERRED TO SUPPLY VOLTAGES

+0.4

–V

S

5 6 7 8 9 10 11 12 13 14 15 1716

4

09731-024

SUPPLY VOLTAGE (±V

)

S

09731-027

Figure 25. Output Voltage Swing vs. Supply Voltage, RL = 2 kΩ

15

–40°C

10

+25°C

+85°C

+125°C

5

0

–5

OUTPUT VOLTAGE SWING (V)

–10

–15

100 1k 10k 100k

09731-025

LOAD (Ω)

09731-028

Figure 26. Output Voltage Swing vs. Load Resistance, VS = ±15 V

Rev. 0 | Page 10 of 20

Data Sheet AD8428

V

+

S

–0.5

–1.0

–1.5

+1.5

+1.0

OUTPUT VOLTAGE SWING (V)

REFERRED TO SUPPLY VOLTAGES

+0.5

–V

S

0.01 0.1 1 10

Figure 27. Output Voltage Swing vs. Output Current, VS = ±15 V

–40°C +25°C +85°C +125° C

OUTPUT CURRENT (mA)

20nV/DIV 1s/DIV

09731-029

09731-032

Figure 30. 0.1 Hz to 10 Hz RTI Voltage Noise

20

15

10

5

0

–5

–10

GAIN NONLINEARITY (5 ppm/DIV)

–15

–20

–10–8–6–4–2 0 2 4 6 108

OUTPUT VO LTAGE (V)

Figure 28. Gain Nonlinearity, RL = 10 kΩ

100

10

GAIN = 2000

GAIN = 2000

16

15

14

13

12

11

10

9

8

7

NOISE (pA/√Hz)

6

5

4

3

2

1

09731-030

1 10 100 1k 10k 100k

FREQUENCY (Hz)

09731-033

Figure 31. Current Noise Spectral Density vs. Frequency

NOISE (nV/√Hz)

1

0.1

0.1 1 10 100 1k 10k 100k

FREQUENCY (Hz)

Figure 29. RTI Voltage Noise Spectral Density vs. Frequency

50pA/DI V 1s/DIV

09731-031

Figure 32. 0.1 Hz to 10 Hz Current Noise

09731-034

Rev. 0 | Page 11 of 20

AD8428 Data Sheet

5V/DIV

752ns TO 0.01%

1408ns TO 0. 001%

0.002%/DIV

1µs/DIV

TIME (µs)

Figure 33. Large Signal Pulse Response and Settling Time,

10 V Step, V

20mV/DIV 1µs/DIV

= ±15 V

S

GAIN = 2000

Figure 34. Small Signal Pulse Response, RL = 10 kΩ, CL = 100 pF

NO LOAD

CL = 500pF

CL = 770pF

09731-035

50mV/DIV 1µ s/DIV

09731-037

Figure 35. Small Signal Pulse Response with Various Capacitive Loads,

No Resistive Load

1800

1600

1400

1200

SETTL ED TO 0.001%

1000

800

600

SETTLING TIME (ns)

400

200

09731-036

0

SETTLED TO 0.01%

2 4 6 8 101214161820

STEP SIZE (V)

09731-038

Figure 36. Settling Time vs. Step Size

Rev. 0 | Page 12 of 20

Data Sheet AD8428

C

THEORY OF OPERATION

OMPENSATION

+V

S

1

–IN

–V

S

II

I

B

A1 A2

C1 C2

NODE 1

R1

3kΩ

–RG

30.15Ω

R

G

V

B

NODE 2

R2

3kΩ

+RG

Figure 37. Simplified Schematic

ARCHITECTURE

The AD8428 is based on the classic 3-op-amp topology. This

topology has two stages: a gain stage (preamplifier) to provide

differential amplification by a factor of 200, followed by a difference amplifier stage to remove the common-mode voltage and

provide additional amplification by a factor of 10. Figure 37

shows a simplified schematic of the AD8428.

The first stage works as follows. To keep its two inputs matched,

Amplifier A1 must keep the collector of Q1 at a constant voltage.

It does this by forcing −RG to be a precise diode drop from −IN.

Similarly, A2 forces +RG to be a constant diode drop from +IN.

Therefore, a replica of the differential input voltage is placed across

the gain setting resistor, R

. The current that flows across this

G

resistance must also flow through the R1 and R2 resistors, creating a gained differential signal between the A2 and A1 outputs.

The second stage is a G = 10 difference amplifier, composed of

Amplifier A3 and Resistors R3 through R8. This stage removes

the common-mode signal from the amplified differential signal.

The transfer function of the AD8428 is

V

= 2000 × (V

OUT

IN+

− V

IN−

) + V

REF

FILTER TERMINALS

The −FIL and +FIL terminals allow access between R3 and R4,

and between R5 and R6, respectively. Adding a filter between

these two terminals modifies the signal gain vs. frequency before

it reaches the second amplifier stage.

Q2Q1

+V

R3

6kΩ

R5

6kΩ

+V

–FIL

2

+FIL

–V

R4

6kΩ

R6

6kΩ

–V

3

S

S

120kΩ

A3

120kΩ

R8

R7

+V

S

7

OUT

+V

S

–V

S

6

REF

–V

S

09731-042

S

S

I

B

COMPENSATION

+V

S

4

+IN

–V

S

REFERENCE TERMINAL

The output voltage of the AD8428 is developed with respect to

the potential on the reference terminal. This is useful when the

output signal must be offset to a precise midsupply level. For

example, a voltage source can be tied to the REF pin to levelshift the output so that the AD8428 can drive a single-supply

ADC. The REF pin is protected with ESD diodes and should

not exceed either +V

For best performance, the source impedance to the REF

terminal should be kept well below 1 Ω. As shown in Figure 37,

the reference terminal, REF, is at one end of a 120 k resistor.

Additional impedance at the REF terminal adds to this 120 k

resistor and results in amplification of the signal connected to

the positive input. The amplification from the additional R

can be calculated as follows:

2 × (120 k + R

Only the positive signal path is amplified; the negative path is

unaffected. This uneven amplification degrades the CMRR of

the amplifier.

V

or −VS.

S

)/(240 k + R

REF

INCORRECT

REF

CORRECT

AD8428

REF

V

+

OP1177

–

Figure 38. Driving the Reference Pin

)

AD8428

REF

REF

09731-043

Rev. 0 | Page 13 of 20

AD8428 Data Sheet

V

INPUT VOLTAGE RANGE

The 3-op-amp architecture of the AD8428 applies gain in the

first stage before removing the common-mode voltage in the

difference amplifier stage. Internal nodes between the first and

second stages (Node 1 and Node 2 in Figure 37) experience a

combination of an amplified differential signal, a common-mode

signal, and a diode drop. This combined signal can be limited by

the voltage supplies even when the individual input and output

signals are not limited. Figure 9 shows the allowable input

common-mode voltage ranges for various output voltages and

supply voltages.

LAYOUT

To ensure optimum performance of the AD8428 at the PCB

level, care must be taken in the design of the board layout. The

pins of the AD8428 are especially arranged to simplify board

layout and to help minimize parasitic imbalance between the

inputs.

AD8428

–IN

1

–FIL

2

+FIL

3

+IN

4

TOP VIEW

(Not to Scale)

Figure 39. Pinout Diagram

Common-Mode Rejection Ratio over Frequency

Poor layout can cause some of the common-mode signals to be

converted to differential signals before reaching the in-amp. Such

conversions occur when one input path has a frequency response

that is different from the other. To maintain high CMRR over

frequency, the input source impedance and capacitance of each

path should be closely matched. Additional source resistance in

the input paths (for example, for input protection) should be

placed close to the in-amp inputs to minimize the interaction

of the inputs with parasitic capacitance from the PCB traces.

Parasitic capacitance at the filter pins can also affect CMRR over

frequency. If the board design has a component at the filter pins,

the component should be chosen so that the parasitic capacitance

is as small as possible.

+V

8

S

OUT

7

REF

6

–V

5

S

09731-044

Power Supplies and Grounding

Use a stable dc voltage to power the instrumentation amplifier.

Noise on the supply pins can adversely affect performance. See

the PSRR performance curves in Figure 11 for more information.

Place a 0.1 µF capacitor as close as possible to each supply pin.

Because the length of the bypass capacitor leads is critical at

high frequency, surface-mount capacitors are recommended. A

parasitic inductance in the bypass ground trace works against

the low impedance created by the bypass capacitor.

As shown in Figure 40, a 10 µF capacitor can be used farther

away from the device. For larger value capacitors, which are

intended to be effective at lower frequencies, the current return

path distance is less critical. In most cases, the 10 µF capacitor

can be shared by other precision integrated circuits.

+

S

REF

10µF

LOAD

V

OUT

09731-045

0.1µF

+IN

AD8428

–IN

0.1µF 10µF

–V

S

Figure 40. Supply Decoupling, REF, and Output Referred to Local Ground

A ground plane layer is helpful to reduce undesired parasitic

inductances and to minimize voltage drops with changes in

current. The area of the current path is directly proportional

to the magnitude of parasitic inductances and, therefore, the

impedance of the path at high frequency. Large changes in

currents in an inductive decoupling path or ground return

create unwanted effects due to the coupling of such changes

into the amplifier inputs.

Because load currents flow from the supplies, the load should

be connected at the same physical location as the bypass capacitor grounds.

Reference Pin

The output voltage of the AD8428 is developed with respect to

the potential on the reference terminal. Ensure that REF is tied

to the appropriate local ground.

Rev. 0 | Page 14 of 20

Data Sheet AD8428

V

V

INPUT BIAS CURRENT RETURN PATH

The input bias current of the AD8428 must have a return path

to ground. When the source, such as a thermocouple, cannot

provide a current return path, one should be created, as shown

in Figure 41.

INCORRECT

+V

S

AD8428

REF

–V

S

TRANSFORMER

+V

S

AD8428

REF

–V

S

THERMOCOUPL E

+V

S

C

f

=

AD8428

C

CAPACITIVEL Y COUPLED

REF

–V

S

HIGH- PASS

2πRC

CAPACITIVEL Y COUPLED

Figure 41. Creating an Input Bias Current Return Path

10MΩ

1

CORRECT

TRANSFORMER

THERMOCOUPL E

C

R

C

R

+V

S

AD8428

–V

S

+V

S

AD8428

–V

S

+V

S

AD8428

–V

S

REF

REF

REF

INPUT PROTECTION

Do not allow the inputs of the AD8428 to exceed the ratings

stated in the Absolute Maximum Ratings section. If these ratings

cannot be adhered to, add protection circuitry in front of the

AD8428 to limit the maximum current into the inputs (see the

I

section).

MAX

I

MAX

The maximum current into the AD8428 inputs, I

on time and temperature. At room temperature, the device can

withstand a current of 10 mA for at least one day. This time is

cumulative over the life of the device.

, depends

MAX

Input Voltages Beyond the Rails

If voltages beyond the rails are expected, use an external resistor

in series with each input to limit current during overload conditions. The limiting resistor at each input can be computed using

the following equation:

VVR−

IN

PROTECT

≥

I

MAX

SUPPLY

Noise sensitive applications may require a lower protection

resistance. Low leakage diode clamps, such as the BAV199, can

be used at the inputs to shunt current away from the AD8428

inputs and, therefore, allow smaller protection resistor values.

To ensure that current flows primarily through the external

protection diodes, place a small value resistor, such as a 33

resistor, between the diodes and the AD8428.

+

+V

R

PROTECT

+

V

V

I

IN+

–

R

PROTECT

+

IN–

–

SIMPLE METHOD LOW NOISE METHOD

S

AD8428

–V

S

R

+

V

IN+

–

R

+

V

IN–

–

PROTECT

PROTECT

S

33Ω

I

–V

S

+V

S

33Ω

–V

S

Figure 42. Protection for Voltages Beyond the Rails

Large Differential Input Voltage at High Gain

If large differential voltages at high gain are expected, use an

external resistor in series with each input to limit current

during overload conditions. The limiting resistor at each input

can be computed using the following equation:

⎛

V

R

PROTECT

Noise sensitive applications may require a lower protection

09731-046

1

2

DIFF

⎜

×≥

⎜

⎝

I

MAX

V1

−

⎞

⎟

R

−

G

⎟

⎠

resistance. Low leakage diode clamps, such as the BAV199,

can be used across the AD8428 inputs to shunt current away

from the inputs and, therefore, allow smaller protection resistor

values.

R

PROTECT

I

+

DIFF

–

R

PROTECT

AD8428

Figure 43. Protection for Large Differential Voltages

+V

S

AD8428

–V

S

09731-048

09731-047

Rev. 0 | Page 15 of 20

AD8428 Data Sheet

V

R

()(

RADIO FREQUENCY INTERFERENCE (RFI)

Because of its high gain and low noise properties, the AD8428 is

a highly sensitive amplifier. Therefore, RF rectification can be a

problem if the AD8428 is used in applications that have strong

RF signal sources present. The problem is intensified if long

leads or PCB traces are required to connect the amplifier to the

signal source. The disturbance can appear as a dc offset voltage

or a train of pulses.

High frequency signals can be filtered with a low-pass filter

network at the input of the instrumentation amplifier, as shown

in Figure 44.

+

S

0.1µF

C

C

L*

33Ω

L*

33Ω

*CHIP FERRIT E BEAD.

1nF

R

C

D

R

10nF

C

C

1nF

0.1µF

Figure 44. RFI Suppression

+IN

AD8428

–IN

–V

The filter limits both the differential and common-mode bandwidth, as shown in the following equations:

DIFF

CM

=

=

uencyFilterFreq

uencyFilterFreq

where C

C

≥ 10 CC.

D

affects the differential signal, and CC affects the common-

D

mode signal. Choose values of R and C

mismatch between R × C

at the positive input and R × CC at

C

1

CCR

+

D

1

RC

π2

C

that minimize RFI. A

C

the negative input degrades the CMRR of the AD8428. By using

a value of C

one order of magnitude larger than CC, the effect

D

of the mismatch is reduced, and performance is improved.

Resistors add noise; therefore, the choice of resistor and capac-

itor values depends on the desired trade-off between noise, input

impedance at high frequencies, and RFI immunity. To achieve

low noise and sufficient RFI filtering, the use of inductive ferrite

beads is recommended (see Figure 44). Using inductive ferrite

beads allows the value of the resistors to be reduced, which helps

to minimize the noise at the input.

10µF

V

OUT

REF

10µF

S

09731-049

)2(π2

C

For best results, place the RFI filter network as close as possible

to the amplifier. Layout is critical to ensure that RF signals are

not picked up on the traces after the filter. If RF interference is

too strong to be filtered, shielding is recommended.

Note that the resistors used for the RFI filter can be the same

as those used for input protection (see the Input Protection

section).

CALCULATING THE NOISE OF THE INPUT STAGE

The total noise of the amplifier front end depends on much

more than the specifications in this data sheet. The three main

contributors to noise are as follows: the source resistance, the

voltage noise of the instrumentation amplifier, and the current

noise of the instrumentation amplifier.

In the following calculations, noise is referred to the input (RTI);

that is, all sources of noise are calculated as if the source appeared

at the amplifier input. To calculate the noise referred to the amplifier output (RTO), simply multiply the RTI noise by the gain of

the instrumentation amplifier.

Source Resistance Noise

Any sensor connected to the AD8428 has some output resistance.

There may also be resistance placed in series with the inputs for

protection from either overvoltage or radio frequency interference.

This combined resistance is labeled R1 and R2 in Figure 45. Any

resistor, no matter how well made, has an intrinsic level of noise.

This noise is proportional to the square root of the resistor value.

At room temperature, the value is approximately equal to

4 nV/√Hz × √(resistor value in k).

SENSO

R1

R2

Figure 45. Source Resistance from Sensor and Protection Resistors

For example, assuming that the combined sensor and protection resistance is 4 k on the positive input and 1 k on the

negative input, the total noise from the input resistance is

22

)

AD8428

=+=×+×

09731-050

HznV/9.816641444

Rev. 0 | Page 16 of 20

Data Sheet AD8428

Voltage Noise of the Instrumentation Amplifier Total Noise Density Calculation

Unlike other instrumentation amplifiers in which an external

resistor is used to set the gain, the voltage noise specification

of the AD8428 already includes the input noise, output noise,

and the R

resistor noise.

G

Current Noise of the Instrumentation Amplifier

The contribution of current noise to the input stage in nV/√Hz

is calculated by multiplying the source resistance in k by the

specified current noise of the instrumentation amplifier in

pA/√Hz.

For example, if the R1 source resistance in Figure 45 is 4 k

and the R2 source resistance is 1 k, the total effect from the

current noise is calculated as follows:

()()

22

=×+×

HznV/2.65.115.14

To determine the total noise of the in-amp, referred to input,

combine the source resistance noise, voltage noise, and current

noise contribution by the sum of squares method.

For example, if the R1 source resistance in Figure 45 is 4 k

and the R2 source resistance is 1 k, the total noise, referred

to input, is

222

=++

HznV/0.112.65.19.8

Rev. 0 | Page 17 of 20

AD8428 Data Sheet

OUTLINE DIMENSIONS

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

SEATING

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

85

1

1.27 (0.0500)

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012-AA

BSC

6.20 (0.2441)

5.80 (0.2284)

4

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.31 (0.0122)

8°

0°

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

1.27 (0.0500)

0.40 (0.0157)

45°

012407-A

Figure 46. 8-Lead Standard Small Outline Package [SOIC_N]

Narrow Body

(R-8)

Dimensions shown in millimeters and (inches)

ORDERING GUIDE

1

Model

AD8428ARZ −40°C to +125°C 8-Lead SOIC_N R-8

AD8428ARZ-RL −40°C to +125°C 8-Lead SOIC_N, 13” Tape and Reel R-8

1

Z = RoHS Compliant Part.

Temperature Range Package Description Package Option

Rev. 0 | Page 18 of 20

Data Sheet AD8428

NOTES

Rev. 0 | Page 19 of 20

AD8428 Data Sheet

NOTES

©2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D09731-0-10/11(0)

Rev. 0 | Page 20 of 20

Loading...

Loading...