Page 1

10-Bit, 12-Channel Output

FEATURES

High voltage drive

To within 1.3 V of supply rails

Output short-circuit protection

High update rates

Fast, 100 Ms/s 10-bit input data update rate

Static power dissipation: 1.4 W

Voltage-controlled video reference (brightness), offset,

and full-scale (contrast) output levels

INV bit reverses polarity of video signal

3.3 V logic, 9 V to 18 V analog supplies

High accuracy voltage outputs

Laser trimming eliminates the need for adjustments or

calibration

Flexible logic

XFR allows parallel AD8386 operation

Fast settling into capacitive loads

35 ns settling time to 0.25% into 150 pF load

Slew rate 400 V/μs

Available in 64-lead 9 mm × 9 mm LFCSP_VQ

GENERAL DESCRIPTION

The AD8386 provides a fast, 10-bit, latched, decimating digital

input that drives 12 high voltage outputs. Input words with

10 bits are loaded sequentially into 12 separate high speed,

bipolar DACs. Flexible digital input format allows several

AD8386s to be used in parallel in high resolution displays.

The output signal can be adjusted for dc reference, signal

inversion, and contrast for maximum flexibility.

BYP

VRH

VRH

VRL

DB(0:9)

R/L

CLK

XFR

INV

GCTL

GSW

TSW

SDI

SCL

SEN

SVRH

SVRL

SVRL

Decimating LCD Driver

AD8386

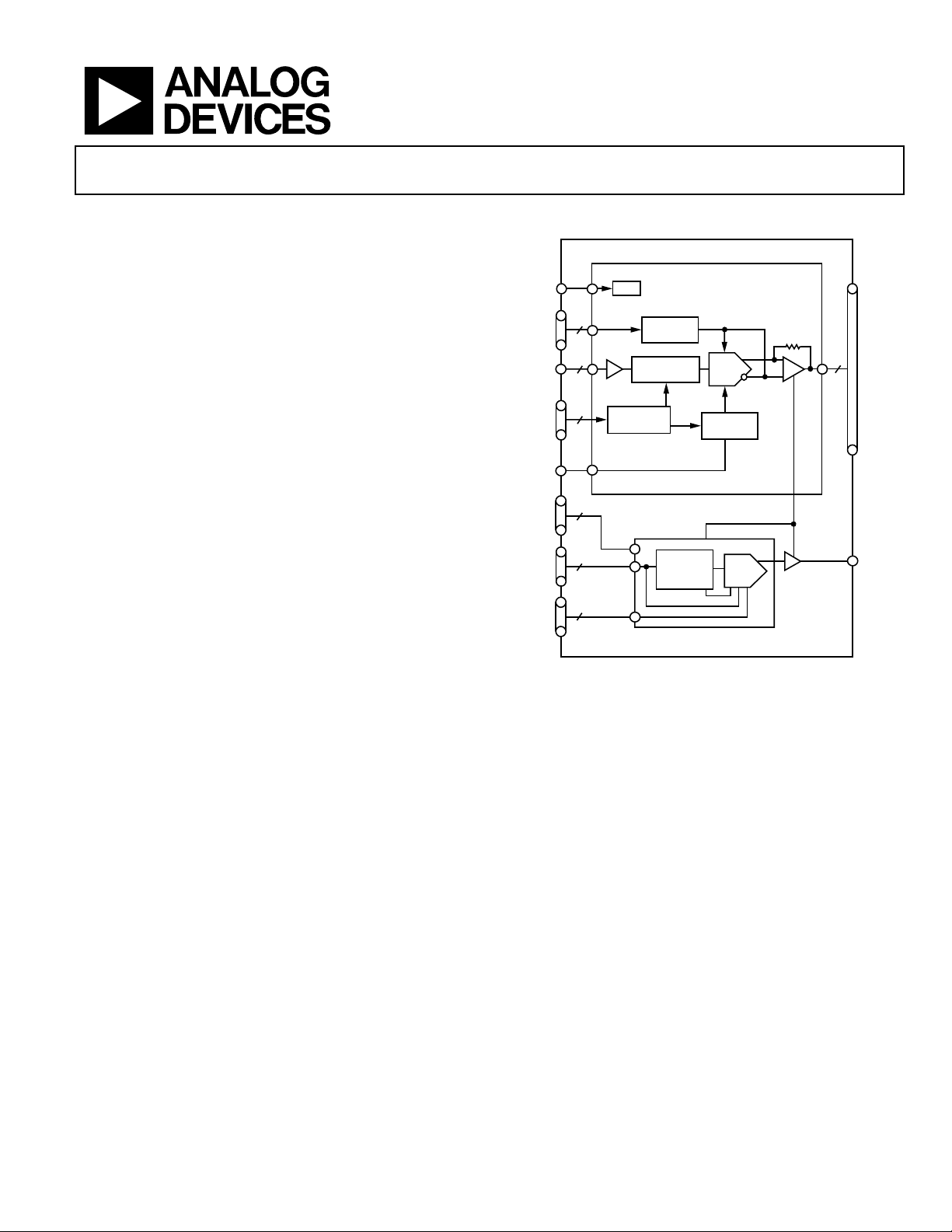

FUNCTIONAL BLOCK DIAGRAM

BIAS

2

10

3

3

3

2

SCALING

CONTROL

TWO-STAGE

LATCH

SEQUENCE

CONTROL

12-BIT

SHIFT

REGISTER

Figure 1.

10-BIT

DACs

INV

CONTROL

8-BIT

DAC

AD8386

VID0

VID1

VID2

VID3

VID4

12

VID5

VID6

VID7

VID8

VID9

VID10

VID11

VAO

05687-001

The AD8386 is fabricated on ADI’s fast bipolar, 26 V XFHV

process, which provides fast input logic, bipolar DACs with

trimmed accuracy and fast settling, high voltage, precision

drive amplifiers on the same chip.

The AD8386 dissipates 1.4 W nominal static power.

The AD8386 is offered in a 64-lead 9 mm × 9 mm LFCSP_VQ

package and operates over the commercial temperature range of

0°C to 85°C.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 © 2005 Analog Devices, Inc. All rights reserved.

Page 2

AD8386

TABLE OF CONTENTS

Features.............................................................................................. 1

Reference and Control Input Descriptions............................. 13

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

DecDriver® Section ....................................................................... 3

Serial Interface Section ................................................................ 5

Absolute Maximum Ratings............................................................ 6

Maximum Power Dissipation ..................................................... 6

Overload Protection..................................................................... 6

Exposed Paddle............................................................................. 6

ESD Caution.................................................................................. 6

Operating Temperature Range ................................................... 7

Pin Configuration and Function Descriptions............................. 8

DecDriver Block Diagram and Timing........................................ 10

Serial Interface Block Diagram and Timing ............................... 12

Transfer Function and Analog Output Voltage...................... 13

Accuracy...................................................................................... 14

3-Wire Serial Interface............................................................... 14

Output Operating Modes.......................................................... 14

Overload Protection................................................................... 14

Applications..................................................................................... 15

Optimized Reliability with the Thermal Protection Circuit 15

Operation in High Ambient Temperature.............................. 15

Power Supply Sequencing ......................................................... 15

Grounded Output Mode During Power-Off.......................... 15

Typical Application Circuits ..................................................... 16

PCB Design for Optimized Thermal Performance ............... 17

AD8386 PCB Design Recommendations ............................... 17

Outline Dimensions....................................................................... 19

Ordering Guide .......................................................................... 19

Functional Description.................................................................. 13

REVISION HISTORY

8/05—Revision 0: Initial Version

Rev. 0 | Page 2 of 20

Page 3

AD8386

SPECIFICATIONS

DECDRIVER® SECTION

At 25°C, AVCC = 15.5 V, DVCC = 3.3 V, T

Table 1.

Parameter Conditions Min Typ Max Unit

VIDEO DC PERFORMANCE

1

VDE DAC Code 450 to 800 −7.5 +7.5 mV

VCME DAC Code 450 to 800 −3.5 +3.5 mV

VIDEO OUTPUT DYNAMIC PERFORMANCE T

Data Switching Slew Rate 20% to 80%, VO = 5 V step 400 V/μs

Invert Switching Slew Rate 20% to 80%, VO = 10 V step 560 V/μs

Data Switching Settling Time to 1% 24 35 ns

Data Switching Settling Time to 0.25% 35 50 ns

Invert Switching Settling Time to 1% 80 130 ns

Invert Switching Settling Time to 0.25% 250 500 ns

Invert Switching Overshoot 10 V Step 100 200 mV

CLK and Data Feedthrough

All-Hostile Crosstalk

2

3

Amplitude 50 mV p-p

Glitch Duration 30 ns

DAC Transition Glitch Energy DAC code 511 to 512 0.6 nV-s

VIDEO OUTPUT CHARACTERISTICS

Output Voltage Swing AVCC − VOH, VOL − AGND 1.1 1.3 V

Output Voltage—Grounded Mode 200 mV

Data Switching Delay: t

INV Switching Delay: t

4

9

5

10

Output Current 100 mA

Output Resistance 29 Ω

REFERENCE INPUTS

VRL Range VRH ≥ VRL 5.25 AVCC − 4 V

VRH Range VRH ≥ VRL VRL AVCC V

VRH – VRL Range VFS = 2 × (VRH − VRL) 0 2.75 V

VRH Input Resistance To VRL 20 kΩ

VRL Input Current −45 μA

VRH Input Current 125 μA

RESOLUTION

Coding Binary 10 Bits

DIGITAL INPUT CHARACTERISTICS

CIN 3 pF

IIH 0.05 μA

IIL −2 μA

VIH 2 V

VIL 0.8 V

VTH 1.65 V

IIH TSW 330 μA

IIL TSW −2 μA

TSW R

10 kΩ

PULLDOWN

A MIN

= 0°C, T

= 85°C, VRH = 9.5 V, VRL = 7 V, unless otherwise noted.

A MAX

T

A MIN

A MIN

to T

to T

A MAX

, CL = 150 pF

A MAX

15 mV p-p

5 V step 12 14 16 ns

10 V step 15 17 19 ns

Rev. 0 | Page 3 of 20

Page 4

AD8386

Parameter Conditions Min Typ Max Unit

DIGITAL TIMING CHARACTERISTICS T

Maximum Input Data Update Rate 100 Ms/s

Data Setup Time: t1 1 ns

XFR Setup Time: t3 0 ns

INV Setup Time: t11 0 ns

Data Hold Time: t2 3.5 ns

XFR Hold Time: t4 4.5 ns

INV Hold Time: t12 4 ns

CLK High Time: t7 6 ns

CLK Low Time: t8 4 ns

1

VDE = differential error voltage. VCME = common-mode error voltage. Full-scale output voltage = VFS = 2 × (VRH − VRL). See the Accuracy section.

2

Measured on two outputs differentially as CLK and DB (0:9) are driven and XFR is held low.

3

Measured on two outputs differentially as the others are transitioning by 5 V. Measured for both states of INV.

4

Measured from 50% of rising CLK edge to 50% of output change. Measurement is made for both states of INV.

5

Measured from 50% of rising CLK edge, which follows a valid XFR, to 50% of output change. See Figure 6 for the definition.

A MIN

to T

A MAX

Rev. 0 | Page 4 of 20

Page 5

AD8386

SERIAL INTERFACE SECTION

At 25°C, AVCC = 15.5 V, DVCC = 3.3 V, T

Table 2.

Parameter Conditions Min Typ Max Unit

SERIAL DAC DC PERFORMANCE

DNL SVFS = 5 V −1 +1 LSB

INL SVFS = 5 V −1.5 +1.5 LSB

Output Offset Error −2.0 +2.0 LSB

Scale Factor Error −3.0 +3.0 LSB

SERIAL DAC OUTPUT DYNAMIC PERFORMANCE To 0.5%

VAO Settling Time, t26 C

VAO Settling Time, t26 C

SERIAL DAC OUTPUT CHARACTERISTICS

VAO Maximum SVRH − 1 LSB V

VAO Minimum SVRL V

VAO − Grounded Mode 150 mV

VAO Output Resistance All supplies OFF 75 kΩ

I

±30 mA

OUT

C

Low Range

LOAD

C

High Range

LOAD

REFERENCE INPUTS

SVRH Range SVRL < SVRH SVRL + 1 AVCC − 3.5 V

SVRL Range SVRL < SVRH AGND + 1.5 SVRH − 1 V

SVFS Range 1 8 V

SVRH Input Current SVRS = 5 V 0.1 μA

SVRL Input Current SVRS = 5 V −1.6 −1.3 mA

DIGITAL INPUT CHARACTERISTICS

CIN 3 pF

IIH 0.05 μA

IIL −1 μA

VIH 2.0 DVCC V

VIL DGND 0.8 V

VTH 1.65 V

DIGITAL TIMING CHARACTERISTICS T

SEN to SCL Setup Time, t20 10 ns

SCL, High Level Pulse Width, t21 10 ns

SCL, Low Level Pulse Width, t22 10 ns

SCL to SEN Hold Time, t23 10 ns

SDI Setup Time, t24 10 ns

SDI Hold Time, t25 10 ns

POWER SUPPLIES

DVCC, Operating Range 3 3.3 3.6 V

DVCC, Quiescent Current 54 75 mA

AVCC Operating Range 9 18 V

Total AVCC Quiescent Current 80 100 mA

OPERATING TEMPERATURES

Ambient Temperature Range, T

Ambient Temperature Range, T

1

Output VAO is designed to drive capacitive loads less than 0.002 μF or more than 0.047 μF. Load capacitances in the range 0.002 μF − 0.047 μF cause the output

overshoot to exceed 100 mV.

2

Operation at high ambient temperature requires a thermally optimized PCB layout (see the Applications section). In systems with limited or no airflow, the maximum

ambient operating temperature is limited to 70°C with the thermal protection enabled, VFS = 4 V, data update rate = 85 Ms/s. Operation at 85°C ambient temperature

requires the thermal protection circuit turned disabled (TSW = LOW).

1

1

2

A

2

A

A MIN

= 0°C, T

= 85°C, VRH = 9.5 V, VRL = 7 V, unless otherwise noted.

A MAX

= 100 pF 1 2 μs

L

= 33 μF 15 ms

L

0.002 μF

0.047 μF

to T

A MIN

A MAX

Still air, TSW = HIGH 0 70 °C

Still air, TSW = LOW 0 85 °C

Rev. 0 | Page 5 of 20

Page 6

AD8386

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Supply Voltage

AVCCx − AGNDx 18 V

DVCC − DGND 4.5 V

Input Voltage

Maximum Digital Input Voltage DVCC + 0.5 V

Minimum Digital Input Voltage DGND − 0.5 V

Maximum Analog Input Voltage AVCC + 0.5 V

Minimum Analog Input Voltage AGND − 0.5 V

Internal Power Dissipation

LFCSP @ TA = 25°C 3.7 W

Operating Temperature Range 0°C to 85°C

Storage Temperature Range –65°C to +125°C

Lead Temperature Range

(Soldering 10 sec)

1

300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at these or

any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

1

64-lead VQ_LFCSP:

θJA = 27°C/W in still air (JEDEC STD, 4-layer PCB with 16 vias on Epad)

θJA = 25°C/W @ 200 lfm airflow (JEDEC STD, 4-layer PCB with 16 vias on Epad)

θJA = 24°C/W @ 400 lfm airflow (JEDEC STD, 4-layer PCB with 16 vias on Epad)

ΨJT = 0.2°C/W in still air (JEDEC STD, 4-layer PCB with 16 vias on Epad)

ΨJB = 13.8°C/W in still air (JEDEC STD, 4-layer PCB with 16 vias on Epad)

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the

AD8386 is limited by its junction temperature. The maximum

safe junction temperature for plastic encapsulated devices, as

determined by the glass transition temperature of the plastic, is

approximately 150°C. Exceeding this limit temporarily may

cause a shift in the parametric performance due to a change in

the stresses exerted on the die by the package. Exceeding a

junction temperature of 175°C for an extended period can

result in device failure.

OVERLOAD PROTECTION

The AD8386 overload protection circuit consists of an output

current limiter and a thermal protection circuit.

When TSW is LOW, the thermal protection circuit is disabled,

and the output current limiter is turned on. The maximum

current at any one output of the AD8386 is internally limited to

100 mA average. In the event of a momentary short circuit

between a video output and a power supply rail (AVCC or

AGND), the output current limit is sufficiently low to provide

temporary protection.

When TSW is HIGH, the output current limiter, as well as the

thermal protection circuit, is turned on. The thermal protection

circuit debiases the output amplifier when the junction

temperature reaches the internally set trip point. In the event of

an extended short circuit between a video output and a power

supply rail, the output amplifier current continues to switch

between 0 mA and 100 mA typical with a period determined by

the thermal time constant and the hysteresis of the thermal trip

point. The thermal protection circuit limits the average junction

temperature to a safe level, which provides long-term

protection.

EXPOSED PADDLE

To ensure optimal thermal performance, the exposed paddle

must be electrically connected to an external plane, such as

AVCC or GND, as described in the

Applications section.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate

on the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 6 of 20

Page 7

AD8386

(

)

OPERATING TEMPERATURE RANGE

The maximum operating junction temperature is 150°C. The

junction temperature trip point of the thermal protection

circuit is 165°C. Production tests guarantee a minimum

junction temperature trip point of 125°C.

Consequently, the maximum guaranteed operating junction

temperature is 125°C when the thermal protection circuit is

enabled and 150°C when the thermal protection circuit is

disabled.

To ensure operation within the specified operating temperature

range, it is necessary to limit the maximum power dissipation as

TT

−

P

DMAX

≈

AirStillJA

09.0 lfminAirflow

AJMAX

()

×−θ

59.0

3.00

STILL AIR

200LFM

400LFM

OVERLOAD

PROTECTION

ENABLED

DISABLED

2.75

2.50

2.25

2.00

720p HDTV

1.75

1.50

QUIESCENT

MAXIMUM POWER DISSIPATION (W)

1.25

1.00

40 45 50 55 60 65 70 75 80 9085 95

65 70 75 80 85 90 95 100 105 115110 120

Figure 2. Maximum Power Dissipation vs. Temperature

AMBIENT TEMPERATURE (°C)

The AD8386 is on a 4-layer JEDEC PCB with a thermally

optimized landing pattern with 16 vias.

The quiescent power dissipation of the AD8386 is 1.4 W.

05687-002

When driving a 12-channel 720p HDTV panel with an input

capacitance of 150 pF, the AD8386 dissipates 1.66 W when

displaying 1 pixel wide alternating white and black vertical lines

generated by a standard 720p HDTV input video.

Conditions include the following:

• AVCC = 15.5 V

• DVCC = 3.3 V

• VFS = 5 V

• C

= 150 pF

L

• f

= 74.25 MHz

PIXEL

• Black-to-white transition = 4 V

• Active video time = 75%

Figure 2 shows these power dissipations.

Rev. 0 | Page 7 of 20

Page 8

AD8386

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

DVCC

DGND

CLK

XFR

INV

R/L

TSTA

AGNDD

AVCCD

VRH

VRH

VRL

AGND0

VID0

AVCC0, 1

VID1

646362616059585756555453525150

49

NC

1

NC

2

DB0

3

DB1

4

DB2

5

DB3

6

DB4

7

DB5

8

DB6

9

DB7

10

DB8

11

DB9

12

SDI

13

SEN

14

SCL

15

GCTL

16

NC = NO CONNECT

PIN 1

INDICATOR

AD8386

TOP VIEW

(Not to Scale)

171819202122232425262728293031

BYP

TSW

GSW

DVCC

DGND

AGNDS

SVRL

SVRL

VAO

SVRH

AVCCS

AGND11

Figure 3. 64-Lead LFCSP_VQ Pin Configuration

VID11

VID10

AVCC10, 11

32

AGND9, 10

48

AGND1, 2

47

VID2

46

AVCC2, 3

45

VID3

44

AGND3, 4

43

VID4

42

AVCC4, 5

41

VID5

40

AGND5, 6

39

VID6

38

AVCC6, 7

37

VID7

36

AGND7, 8

35

VID8

34

AVCC8, 9

33

VID9

05687-003

Rev. 0 | Page 8 of 20

Page 9

AD8386

Table 4. 64-Lead LFCSP_VQ Pin Function Descriptions

Pin No. Mnemonic Function Description

1, 2 NC No Connect No Internal Connection.

3 to 12 DB0 to DB9 Data Input 10-Bit Data Input. MSB = DB(9).

13 SDI Serial Data Input

14 SEN Serial DAC Enable

15 SCL Serial Data Clock Serial Data Clock.

16 GCTL Output Mode Control

17 GSW Output Mode Switch

18 TSW Thermal Switch

19, 64 DVCC Digital Power Supply Digital Power Supply.

20, 63 DGND Digital Ground Digital Supply Return.

21 AGNDS Analog Ground Analog Supply Return.

22, 23, 24 SVRL, SVRH Serial DAC Reference Voltage The voltage applied between these pins sets the serial DAC full-scale voltage.

25 VAO Serial DAC Output This output voltage is updated in the rising edge of the SEN input.

26 AVCCS Analog Power Supply Analog Power Supply.

27 BYP Bypass

28, 32, 36,

40, 44, 48, 52

29, 31, 33, 35,

37, 39, 41, 43,

45, 47, 49, 51

30, 34, 38,

42, 46, 50

53 VRL Video Center Reference

54, 55 VRH Full-Scale Reference The full-scale video output voltage is VFS = 2 × (VRH − VRL).

56 AVCCD Analog Power Supply Analog Power Supply.

57 AGNDD Analog Ground Analog Supply Return.

58 TSTA Test Pin Connect this pin to AGND.

59 R/L Right/Left Select

60 INV Invert

61 XFR Transfer/Start Sequence

62 CLK Clock Video Data Clock.

AGND11 to

AGND0

VID11 to

VID0

AVCC10, 11

to AVCC0, 1

Analog Ground Analog Supply Returns.

Analog Output These pins are directly connected to the analog inputs of the LCD panel.

Analog Power Supply Analog Power Supplies.

While the SEN input is LOW, one 12-bit serial word is loaded into the

serial DAC on the rising edges of the SCL.

A falling edge of this input initiates a loading cycle. While this input is held

LOW, the serial DAC is enabled and data is loaded on every rising edge of

SCL. The output is updated on the rising edge of a valid SEN. A valid

SEN must remain LOW for at least three SCL cycles. While this input is

held HIGH, the control DAC is disabled.

When this input is HIGH, the output mode is determined by the function

programmed into the serial interface. When LOW, the output mode is

controlled by the GSW input.

When GCTL is LOW and this input is HIGH, the video outputs and VAO

operate normally. When GCTL and this input are both LOW, the video

outputs and VAO are asynchronously forced to AGND, regardless of

the function programmed into the serial interface. This function operates

when AVCC power is OFF but requires DVCC power supply to be ON.

When this input is LOW, the thermal protection circuit is disabled. When

HIGH, the thermal protection circuit is enabled. This pin has a 10 kΩ

internal pull-down resistor.

A 0.1 μF capacitor connected between this pin and AGND ensures

optimum settling time.

The voltage applied to this pin sets the video center voltage. The video

outputs are above this reference while the INV = HIGH and below this

reference while INV = LOW.

A new data loading sequence begins on the left with Channel 0 when

this input is LOW, and on the right with Channel 11 when this input is HIGH.

When this input is HIGH, the VIDx output voltages are above VRL. When

LOW, the VIDx outputs voltages are below VRL. The state of INV is latched

on the first rising CLK edge after XFR is detected. The VIDx outputs change

on the rising CLK edge after the next XFR is detected.

The state of XFR is detected on the rising edge of CLK. Data is transferred to

the outputs and a new loading sequence begins on the next rising edge of

CLK after XFR is detected HIGH.

Rev. 0 | Page 9 of 20

Page 10

AD8386

DECDRIVER BLOCK DIAGRAM AND TIMING

TWO-

BYP

DB(0:9)

CLK

XFR

R/L

INV

BIAS

10

SEQUENCE

CONTROL

INV

CONTROL

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

10

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

10

STAGE

LATCH

SCALING

CONTROL

TWO-

TWO-

TWO-

TWO-

TWO-

TWO-

TWO-

TWO-

TWO-

TWO-

TWO-

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

VID0

VID2

VID4

VID6

VID8

VID10

VID1

VID3

VID5

VID7

VID9

VID11

VRL

VRH

Figure 4. AD8386 DecDriver Section

Rev. 0 | Page 10 of 20

05687-004

Page 11

AD8386

CLK

DB(0:9)

XFR

INV

VID(0:11)

VRL + VFS

VRL

t

f

t

8

V

TH

t

1

t

2

V

TH

05687-005

CLK

DB(0:9)

XFR

t

r

t

7

t

1

t

3

t

2

V

t

4

TH

Figure 5. Input Timing

–9 –8 –7 –6 –5 –4 –3 –1 1 2 3 4 5 6 7 8 9 11 13 14 15

t

9

t

MIN

11

t

MAX

11

010

–2

50%

–12, –11, –10, –9, –8, –7, –6, –5, –4, –3, –2, –1

t

9

t

12

PIXELS

12

t

10

0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11

VRL

VRL – VFS

PIXELS

05687-006

Figure 6. Output Timing (R/L LOW)

Table 5.

Parameter Conditions Min Typ Max Unit

Data Setup Time, t1 Input tr, tf = 2 ns 1 ns

Data Hold Time, t2 3.5 ns

XFR Setup Time, t3 0 ns

XFR Hold Time, t4 4.5 ns

CLK High Time, t7 6 ns

CLK Low Time, t8 4 ns

Data Switching Delay, t9 12 14 16 ns

Invert Switching Delay, t10 15 17 19 ns

Invert Setup Time, t11 0

Invert Hold Time, t12 4

ns

ns

Rev. 0 | Page 11 of 20

Page 12

AD8386

SERIAL INTERFACE BLOCK DIAGRAM AND TIMING

SVRH

SVRL

SDI

SCL

SEN

12-BIT SHIFT REGISTER

SDI

CODE

SD0 SD1 SD2 SD3 SD4 SD5 SD6 SD7 SD8 SD9 SD10 SD11

SDI

CODE

8

SELECT LOAD

VAO = SVRL + SDI

SDAC

CONTROL

× (SVRH – SVRL)/256

CODE

VAO

75kΩ

TSW

10kΩ

VIDEO

DACs

GSW

GCTL

SEN

SCL

SDI

D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

VAO

Figure 8. Serial Interface Timing Diagram

THERMAL

SWITCH

12

Figure 7. Serial Interface Block Diagram

05687-008

SEN

SCL

SDI

VAO

12

12

D11

t

22

t

21

t25t

D10

D0

D1

t

20

24

Figure 9. Serial Interface Timing Diagram

t

23

VID(0:11)

t

26

05687-007

05687-009

Table 6.

Parameter Conditions Min Typ Max Unit

SEN to SCL Setup Time, t20 10 ns

SCL, High Level Pulse Width, t21 10 ns

SCL, Low Level Pulse Width, t22 10 ns

SCL to SEN Hold Time, t23 10 ns

SDI Setup Time, t24 10 ns

SDI Hold Time, t25 10 ns

VAO Settling Time, t26 SVFS = 5 V, to 0.5 %, CL = 100 pF 1 2 μs

VAO Settling Time, t26 SVFS = 5 V, to 0.5 %, CL = 33 μF 15 ms

Rev. 0 | Page 12 of 20

Page 13

AD8386

FUNCTIONAL DESCRIPTION

The AD8386 is a system building block designed to

directly drive the columns of LCD microdisplays of the type

popularized for use in projection systems. It has 12 channels of

precision, 10-bit digital-to-analog converters (DACs) loaded

from a single high speed serial input. Precision current feedback

amplifiers, which provide well-damped pulse response and fast

voltage settling into large capacitive loads, buffer the 12 outputs.

Laser trimming at the wafer level ensures low absolute output

errors and tight channel-to-channel matching. Tight part-topart matching in high resolution systems is guaranteed by the

use of external voltage references.

REFERENCE AND CONTROL INPUT DESCRIPTIONS

Data transfer/start sequence control—input data loading,

data transfer.

A valid XFR control input initiates a new six-clock loading

cycle, during which data is transferred to the outputs, and 12

input data-words are loaded sequentially into the 12 internal

channels. Data is loaded on both the rising and falling edges of

CLK. Data loaded from the previous cycle is transferred to the

outputs on the rising CLK edge when the XFR is held HIGH at

the preceding rising CLK edge only. A new loading sequence

begins on the current rising CLK edge when XFR is held HIGH

at the preceding rising CLK edge only.

An internal 10 kΩ pull-down resistor disables the thermal

switch when this pin is left unconnected.

GCTL, GSW controls—output mode control.

Table 7. GTCL, GSW Truth Table

GTCL GSW Action

0 0

All video outputs and VAO are forced near

AGND. While the outputs are disabled, AVCC can

be removed.

0 1 All video outputs and VAO operate normally.

1 X

Output operating mode is controlled by the

serial interface.

TRANSFER FUNCTION AND ANALOG OUTPUT VOLTAGE

The DecDriver has two regions of operation where the video

output voltages are either above or below the reference voltage

VRL. The transfer function defines the video output voltage as

the function of the digital input code as

VIDx(n) = VRL + VFS × (1 − n/1023), for INV = HIGH

VIDx(n) = VRL − VFS × (1 − n/1023), for INV = LOW

where:

n = input code

Right/left control—input data loading.

To facilitate image mirroring, the direction of the loading

sequence is set by the R/L control.

A new loading sequence begins at Channel 0 and proceeds to

Channel 11 when the R/L control is held LOW. It begins at

Channel 11 and proceeds to Channel 0 when the R/L control is

held HIGH.

VRH, VRL inputs—full-scale video reference inputs.

The full-scale output voltage is VFS = 2 × (VRH − VRL).

INV control—analog output inversion.

The analog voltage equivalent of the input code is subtracted

from (VRL + VFS) while INV is held HIGH, and added to

(VRL − VFS) while INV is held LOW.

The state of the INV input is latched on the first rising edge of

CLK, immediately following a valid XFR. The VIDx outputs

invert on the first rising CLK edge, immediately following the

next valid XFR.

TSW control—thermal switch control.

VFS = 2 × (VRH − VRL)

A number of internal limits define the usable range of the video

output voltages, VIDx, shown in

VIDx – VOLTS

AVCC

(VRL + VFS)

VOUTN(n)

INV = HIGH

VRL

INV = LOW

VOUTP(n)

(VRL – VFS)

AGND

0

INPUT CODE (n)

VIDx vs. INPUT CODE

Figure 10. Transfer Function and Usable Voltage Ranges

Figure 10.

≥1.3V

0 ≤ VFS ≤ 5.5V

0 ≤ VFS

5.25V ≤ VRL

≤ 5.5V

≤ (AVCC – 4)

≥1.3V

1023

INTERNAL LIMITS AND

USABLE VOLTAGE RANGES

9V ≤ AVCC

≤ 18V

05687-010

When this input is HIGH, the thermal protection circuit is

enabled. When LOW or left unconnected, the thermal

protection circuit is disabled.

Rev. 0 | Page 13 of 20

Page 14

AD8386

()(

)

ACCURACY

To best correlate transfer function errors to image artifacts, the

overall accuracy of the DecDriver is defined by two parameters,

VDE and VCME.

VDE, the differential error voltage, measures the difference

between the rms value of the output and the rms value of the

ideal. The defining expression is

[]

()

=

nVDE ×

−

2

nnVOUTPnVOUTN

⎛

1

⎜

⎝

−−

1023

⎞

VFS

⎟

⎠

VCME, the common-mode error voltage, measures ½ the dc

offset of the output. The defining expression is

() ()

1

⎡

()

= VRL

nVCME

⎢

⎣

+

22

nVOUTPnVOUTN

⎤

−

⎥

⎦

3-WIRE SERIAL INTERFACE

The serial interface controls the 8-bit serial DAC and the video

output operating mode via a 12-bit serial word. The two most

significant bits (MSB) select the function and the eight least

significant bits (LSB) are the data for the serial DAC.

Table 8. Bit Definitions

Bit Name Bit Functionality

SD (0:7) 8-Bit SDAC Data. MSB = SD7.

SD8 Not Used.

SD9 Not Used.

SD10 VAO Load Selection.

SD11 Output Mode Selection When GCTL = 1.

Table 9. Truth Table @ GCTL = HIGH

SEN SD Action

11 10 9 8

0 0 X X Normal Output Mode. No change to VAO.

0 1 X X Normal Output Mode. Load VAO.

1 0 X X

1 1 X X Grounded Output Mode. Load VAO.

X X X X

Grounded Output Mode. No change to

VAO.

Start a Serial Interface Loading Cycle. No

change to VAO.

Table 10. Truth Table @ GCTL = LOW

SEN SD Action

11 10 9 8

X 0 XXNo Change to VAO.

X 1 XXLoad VAO.

X X X X

Start a Serial Interface Loading Cycle. No

change to VAO.

Serial DAC

The serial DAC is loaded via the serial interface. The output

voltage is determined by

VAO = SVRL + (SVRH − SVRL) × n/256

where n is the SD(0:7) serial input code.

Output VAO is designed to drive capacitive loads less than

0.002 μF or more than 0.047 μF. Load capacitances in the

0.002 μF − 0.047 μF range cause the output overshoot to exceed

100 mV.

OUTPUT OPERATING MODES

In normal operating mode, the voltage of the video outputs is

determined by the inputs.

In grounded output mode, the video outputs are forced to

(AGND + 0.2 V) typ.

OVERLOAD PROTECTION

The overload protection employs current limiters and a thermal

protection circuit to protect the video output pins against accidental

shorts between any video output pin and AVCC or AGND.

The junction temperature trip point of the thermal protection

circuit is 165°C. Production tests guarantee a minimum

junction temperature trip point of 125°C. Consequently, the

operating junction temperature should not rise above 125°C

when the thermal protection circuit is enabled.

For systems that operate at high internal ambient temperatures

and require large capacitive loads to be driven by the AD8386 at

high frequencies, junction temperatures above 125°C may be

required. In such systems, the thermal protection circuit should

either be disabled or a minimum airflow of 200 lfm must be

maintained.

Rev. 0 | Page 14 of 20

Page 15

AD8386

APPLICATIONS

OPTIMIZED RELIABILITY WITH THE THERMAL PROTECTION CIRCUIT

The AD8386 is designed for enhanced reliability through

features that provide protection against accidental shorts that

may occur during PCB assembly repair, such as solder bridging,

or during system assembly, such as a misaligned flat panel cable

in the connector.

While internal current limiters provide short-term protection

against temporary shorts at the outputs, the thermal shutdown

provides protection against persistent shorts lasting for several

seconds. To optimize reliability, the following sequence of

operations is recommended.

Initial Power-Up after PCB Assembly or Repair

Disable grounded output mode and enable thermal protection.

Ensure that the GCTL and GSW pins are LOW and the TSW

pin is HIGH upon initial power-up and remains unchanged

throughout this procedure.

Execute the initial power-up.

•

Identify any shorts at the outputs.

•

•

Power-down, repair shorts, and repeat the initial power-up

sequence until proper system functionality is verified.

Power-Up during Normal Operation

Disable grounded output mode and disable the thermal

protection circuit using either of the following two methods:

POWER SUPPLY SEQUENCING

As indicated in the Absolute Maximum Ratings section, the

voltage at any input pin cannot exceed its supply voltage by

more than 0.5 V. Power-on and power-off sequencing may be

required to comply with the Absolute Maximum Ratings.

Failure to comply with the Absolute Maximum Ratings may

result in functional failure or damage to the internal ESD

diodes. Damaged ESD diodes may cause temporary parametric

failures, which may result in image artifacts. Damaged ESD

diodes cannot provide full ESD protection, reducing reliability.

The following power supply sequencing ensures that the

Absolute Maximum Ratings are not violated.

Power-on sequence is:

Turn ON AVCC and analog reference voltages.

•

•

Turn ON DVCC and digital signals.

Power-off sequence is:

•

Turn OFF AVCC and analog reference voltages.

Turn OFF DVCC and digital signals.

•

GROUNDED OUTPUT MODE DURING POWER-OFF

Certain applications require that the video outputs be held near

AGND during power-down. The following power-off sequence

ensures that the outputs are near ground during power-off and

the Absolute Maximum Ratings are not violated.

•

GCTL = HIGH, TSW = HIGH and serial code

0XXXXXXXXXXX sent immediately following a power-up,

places all outputs into normal operating mode and disables

the thermal protection circuit.

TSW = LOW disables the thermal protection circuit.

•

GCTL = LOW and GSW = HIGH puts all outputs into

normal operating mode.

OPERATION IN HIGH AMBIENT TEMPERATURE

To extend the maximum operating junction temperature of the

AD8386 to 150°C, keep the thermal protection circuit disabled

(TSW = LOW) during normal operation.

Rev. 0 | Page 15 of 20

Enable grounded output mode in one of two ways:

•

GTCL = LOW and GSW = LOW, or GCTL = HIGH

and code 1XXXXXXXXXXX sent via the serial interface.

Turn OFF AVCC and analog reference voltages.

•

•

Turn OFF DVCC and digital signals.

Page 16

AD8386

TYPICAL APPLICATION CIRCUITS

12-CHANNEL

LCD

SEN

VID0

VID1

VID2

VID3

VID4

VID5

VID6

VID7

VID8

VID9

VID10

VID11

VAO

PIXEL

CLK

PROCESSOR

÷2

IMAGE

μP

DB(0:9)

CLK

R/L

XFR

INV

REFERENCES

DB(0:9)

CLK

R/L

XFR

INV

VRH

VRL

SVRH

SVRL

SDI

AD8386

SCL

Figure 11. 12-Channel System

CHANNEL 0

CHANNEL 1

CHANNEL 2

CHANNEL 3

CHANNEL 4

CHANNEL 5

CHANNEL 6

CHANNEL 7

CHANNEL 8

CHANNEL 9

CHANNEL 10

CHANNEL 11

05687-015

PIXEL

CLK

PROCESSOR

÷2

IMAGE

DB(0:9)

CLK

R/L

XFR

INV

DB(0:9)

INV

μP

DB(0:9)

CLK

R/L

XFR

INV

SCL

SDI

SEN

REFERENCES

SCL

SDI

SEN

CLK

R/L

XFR

DB(0:9)

INV

Figure 12. 24-Channel System

VRH

AD8386

VRH

AD8386

VRL

VRL

SVRH

SVRH

VID0

VID1

VID2

VID3

VID4

VID5

VID6

VID7

VID8

VID9

VID10

VID11

SVRL

VAO

VID0

SVRL

VID1

VID2

VID3

VID4

VID5

VID6

VID7

VID8

VID9

VID10

VID11

VAO

CHANNEL 0

CHANNEL 1

CHANNEL 2

CHANNEL 3

CHANNEL 4

CHANNEL 5

CHANNEL 6

CHANNEL 7

CHANNEL 8

CHANNEL 9

CHANNEL 10

CHANNEL 11

24-CHANNEL

LCD

CHANNEL 12

CHANNEL 13

CHANNEL 14

CHANNEL 15

CHANNEL 16

CHANNEL 17

CHANNEL 18

CHANNEL 19

CHANNEL 20

CHANNEL 21

CHANNEL 22

CHANNEL 23

05687-016

Rev. 0 | Page 16 of 20

Page 17

AD8386

PCB DESIGN FOR OPTIMIZED THERMAL PERFORMANCE

The total maximum power dissipated by the AD8386 is partly

load dependent. In a 12-channel, 60 Hz XGA system running at

a 65 MHz pixel rate, the total maximum power dissipated is

1.7 W, assuming a 15.5 V analog power supply, a 4 V white-toblack swing, and a 150 pF LCD input capacitance.

To limit the operating junction temperature at or below the

guaranteed maximum, the package in conjunction with the

PCB must effectively conduct heat away from the junction.

The AD8386 package is designed to provide enhanced thermal

characteristics through the exposed die paddle on the bottom

surface of the package. In order to take full advantage of this

feature, the exposed paddle must be in direct thermal contact

with the PCB, which then serves as a heat sink.

A thermally effective PCB must incorporate two thermal pads

and a thermal via structure. The thermal pad on the top PCB

layer provides a solderable contact surface on the top surface of

the PCB. The thermal pad on the bottom PCB layer provides a

surface in direct contact with the ambient air. The thermal via

structure provides a thermal path to the inner and bottom

layers of the PCB to remove heat.

Bottom PCB Layer

It is recommended that the bottom thermal pad be thermally

connected to a plane. The connection should be direct such that

the thermal pad becomes part of the plane.

The use of thermal spokes is not recommended when

connecting the thermal pads or via structure to a plane.

Solder Masking

To minimize the formation of solder voids due to solder flowing

into the via holes (solder wicking), the via diameter should be

small. Optional solder masking of the via holes on the top layer

of the PCB plug the via holes, inhibiting solder flow into the

holes. To optimize the thermal pad coverage, the solder mask

diameter should be no more than 0.1 mm larger than the via

hole diameter.

Pads are set by the customer’s PCB design rules, and thermal

vias are 0.25 mm diameter circular mask, centered on the vias.

Thermal Pad Design

To minimize thermal performance degradation of production

PCBs, the contact area between the thermal pad and the PCB

should be maximized. Therefore, the size of the thermal pad on

the top PCB layer should match the exposed paddle size. The

second thermal pad of at least the same size should be placed on

the bottom side of the PCB. At least one thermal pad should be

in direct thermal contact with a plane, such as AVCC or GND.

Thermal via Structure Design

Effective heat transfer from the top to the inner and bottom

layers of the PCB requires thermal vias incorporated into the

thermal pad design. Thermal performance increases

logarithmically with the number of vias.

Near optimum thermal performance of production PCBs is

attained when tightly spaced thermal vias are placed on the full

extent of the thermal pad only.

AD8386 PCB DESIGN RECOMMENDATIONS

Table 11. Top PCB Layer

Pad Size

Pad Pitch

Thermal Pad Size

Thermal via Structure

0.25 mm × 0.4 mm

0.5 mm

4.7 mm × 4.7 mm

0.25 mm diameter vias on a 0.5 mm grid

05687-011

Figure 13. Land Patter—Top PCB Layer

05687-012

Figure 14. Land Patter—Bottom PCB Layer

05687-013

Figure 15. Solder Mask—Top Layer

Rev. 0 | Page 17 of 20

Page 18

AD8386

0.05

SOLDER MASK

SWELL

0.5

0.4

0.5

9.00

9.00

4.7 SQ CU w/4.8 SQ SOLDER MASK

R 0.05 OPTIONAL FILLETS

VIA ARRAY ON 0.5 GRID

0.25 DRILL, 0.35 SOLDER MASK SWELL

0.25

OPTIONAL FILLETS

R 0.05

Figure 16. Suggested Land Pattern

Dimensions shown in millimeters

Rev. 0 | Page 18 of 20

05285-014

Page 19

AD8386

OUTLINE DIMENSIONS

1.00

0.85

0.80

12° MAX

SEATING

PLANE

BSC SQ

PIN 1

INDICATOR

9.00

0.60 MAX

TOP

VIEW

0.80 MAX

0.65 TYP

0.50 BSC

*

COMPLIANT TO JEDEC STANDARDS MO-220-VMMD

EXCEPT FOR EXPOSED PAD DIMENSION

8.75

BSC SQ

0.20 REF

0.45

0.40

0.35

0.05 MAX

0.02 NOM

49

48

33

32

0.60 MAX

Figure 17. 64-Lead Lead Frame Chip Scale Package [LFCSP_VQ]

9 mm × 9 mm Body, Very Thin Quad (CP-64-1)

Dimensions shown in millimeters

EXPOSED PAD

(BOTTOM VIEW)

7.50

REF

0.30

0.25

0.18

64

17

1

16

PIN 1

INDICATOR

*

4.85

4.70 SQ

4.55

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD8386JCPZ

1

Z = Pb-free part.

1

0°C to 85°C 64-Lead Lead Frame Chip Scale Package (LFCSP_VQ) CP-64-1

Rev. 0 | Page 19 of 20

Page 20

AD8386

NOTES

© 2005 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D05687–0–8/05(0)

Rev. 0 | Page 20 of 20

Loading...

Loading...