Page 1

Low Cost 10-Bit, 6-Channel Output

FEATURES

High voltage drive to within 1.3 V of supply rails

Output short-circuit protection

High update rates

Fast, 100 Ms/s, 10-bit input data update rate

Low static power dissipation: 0.7 W

Includes STBY function

Voltage-controlled video reference (brightness) and

full-scale (contrast) output levels

INV bit reverses polarity of video signal

3.3 V logic, 9 V to 18 V analog supplies

High accuracy voltage outputs

Laser trimming eliminates the need for adjustments

Flexible logic

STSQ/XFR allow parallel AD8383 operation at various

resolutions

Fast settling into capacitive loads

30 ns settling time to 0.25% into 150 pF load

Slew rate 460 V/µs

Available in 48-lead 7 mm × 7 mm LFCSP package

APPLICATIONS

LCD analog column driver

PRODUCT DESCRIPTION

The AD8383 provides a fast, 10-bit latched decimating digital

input that drives six high voltage outputs. 10-bit input words are

sequentially loaded into six separate, high speed, bipolar DACs.

Flexible digital input format allows several AD8383s to be used

in parallel for higher resolution displays. STSQ synchronizes

sequential input loading, XFR controls synchronous output

updating, and R/L controls the direction of loading as either

left-to-right or right-to-left. Six channels of high voltage output

drivers drive to within 1.3 V of the rail. For maximum flexibility,

the output signal can be adjusted for dc reference, signal

inversion.

Decimating LCD DecDriver

AD8383

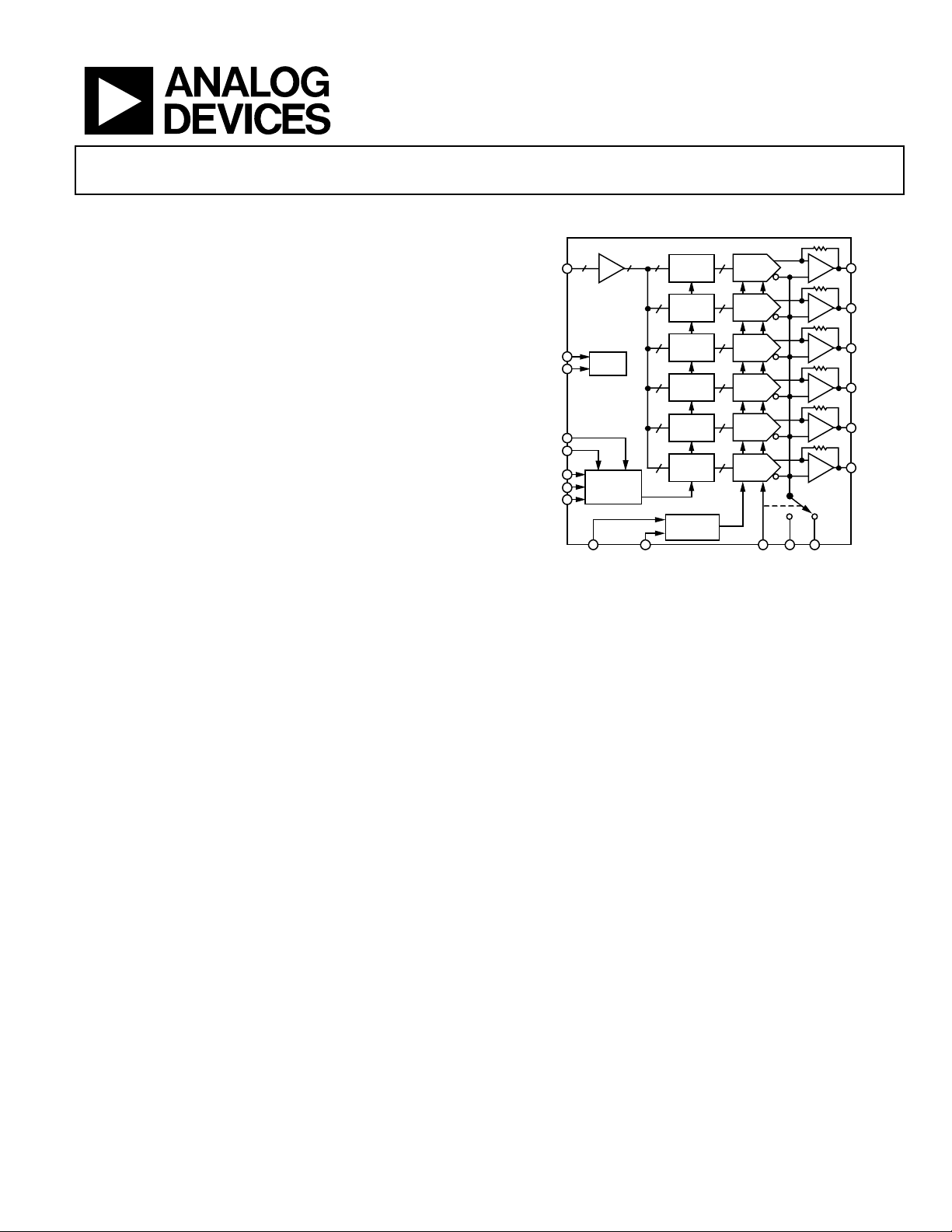

FUNCTIONAL BLOCK DIAGRAM

1010

10 10

DB(0:9)

STBY

BYP

R/L

E/O

CLK

STSQ

XFR

AD8383

SEQUENCE

CONTROL

VREFHI

BIAS

VREFLO

2-STAGE

LATCH

10 10

2-STAGE

LATCH

10 10

2-STAGE

LATCH

10 10

2-STAGE

LATCH

10 10

2-STAGE

LATCH

10 10

2-STAGE

LATCH

SCALING

CONTROL

Figure 1

The AD8383 is fabricated on the 26 V, fast bipolar XFHV

process developed by Analog Devices, Inc. This process

provides fast input logic, bipolar DACs with trimmed accuracy

and fast settling, high voltage, precision drive amplifiers on the

same chip.

The AD8383 dissipates 0.7 W nominal static power. The STBY

pin reduces power to a minimum with fast recovery.

The AD8383 is offered in a 48-lead, 7 mm × 7 mm × 0.85 mm

LFCSP package and operates over the commercial temperature

range of 0°C to 85°C.

DAC

DAC

DAC

DAC

DAC

DAC

INV V1 V2

VID0

VID1

VID2

VID3

VID4

VID5

®

04513-0-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

Page 2

AD8383

TABLE OF CONTENTS

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 5

Maximum Power Dissipation ..................................................... 5

Pin Configuration and Function Descriptions............................. 6

Timing Diagrams.............................................................................. 7

Theory of Operation ........................................................................ 8

Transfer Function and Analog Output Voltage ........................ 8

Applications....................................................................................... 9

External VBIAS Generation........................................................ 9

REVISION HISTORY

Revision 0: Initial Version

PCB Design for Good Thermal Performance........................ 10

Thermal Pad Design .................................................................. 10

Thermal Via Structure Design.................................................. 11

Solder Masking........................................................................... 11

Reference PCB Design............................................................... 11

Estimated Junction Temperature ............................................. 12

Outline Dimensions....................................................................... 14

Ordering Guide .......................................................................... 14

Rev. 0 | Page 2 of 16

Page 3

AD8383

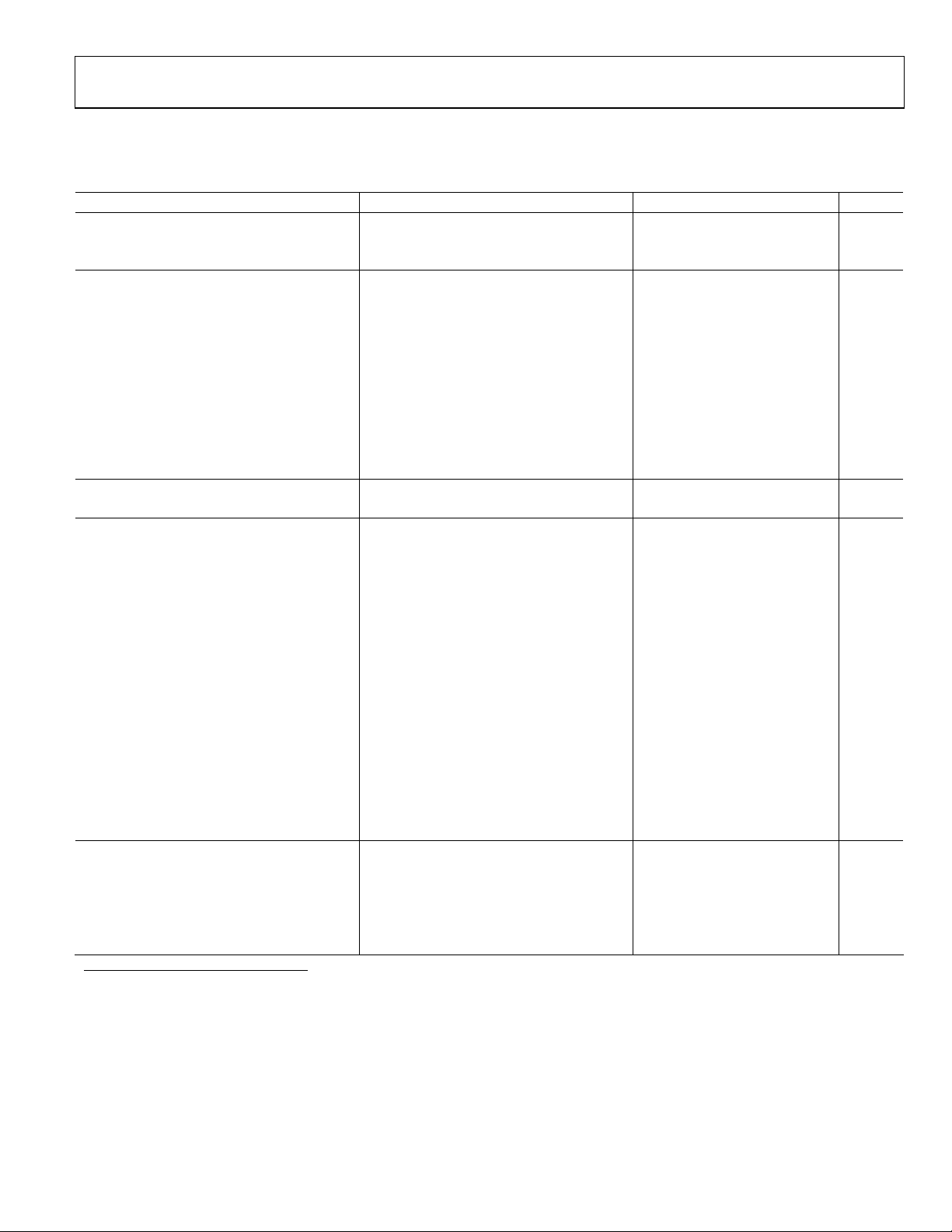

SPECIFICATIONS

Table 1. @25°C, AVCC = 15.5 V, DVCC = 3.3 V, T

unless otherwise noted

Parameter Conditions Min Typ Max Unit

VIDEO DC PERFORMANCE

1

VDE –7.5 +7.5 mV

VCME –3.5 +3.5 mV

REFERENCE INPUTS

V1, V2 Range 5 AVCC – 4 V

V2 to V1 Range –0.25 V

V1 Input Current +0.2 µA

V2 Input Current –7.5 µA

VREFHI Range VREFHI ≥ VREFLO VREFLO AVCC V

VREFLO Range VREFHI ≥ VREFLO V1 – 0.5 AVCC – 1.3 V

VREFHI Input Resistance To VREFLO 20 kΩ

VREFLO Bias Current –0.2 µA

VREFHI Input Current 125 µA

VFS Range

2

RESOLUTION

Coding Binary 10 Bits

DIGITAL INPUT CHARACTERISTICS

Maximum Input Data Update Rate

3

CLK to Data Setup Time 0 ns

CLK to STSQ Setup Time 1 ns

CLK to XFR Setup Time 1 ns

CLK to Data Hold Time 3 ns

CLK to STSQ Hold Time 3 ns

CLK to XFR Hold Time 3 ns

CLK High Time 3 ns

CLK Low Time 2.5 ns

C

IN

I

IH

I

IL

IIL, CLK 1.2 µA

V

IH

V

IL

V

TH

VIDEO OUTPUT CHARACTERISTICS

Output Voltage Swing AVCC – VOH, VOL – AGND 1.1 1.3 V

CLK to VID Delay

4

INV to VID Delay 50% of VIDx 10.4 12.4 14.4 ns

Output Current 100 mA

Output Resistance 22 Ω

1

VDE = Differential Error Voltage = Common-Mode Error Voltage. See section. Theory of Operation

2

VFS = 2 × (VREFHI – VREFLO).

3

Maximum input transition time (10% to 90%) = 0.8/(2f) where f is the operating CLK rate.

4

Measured from 50% of falling CLK edge to 50% of output change. Measurement is made for both states of INV.

T

MIN

= 0°C, T

MIN

to T

, DAC Code 450 to 800

MAX

= 75°C, VFS = 5 V, VREFLO = V1 = V2 = 7 V,

MAX

0 5.5 V

100 Ms/s

3 pF

0.05 µA

0.6 µA

2 V

0.8 V

1.5 V

50% of VIDx 10.0 12.0 14.0 ns

Rev. 0 | Page 3 of 16

Page 4

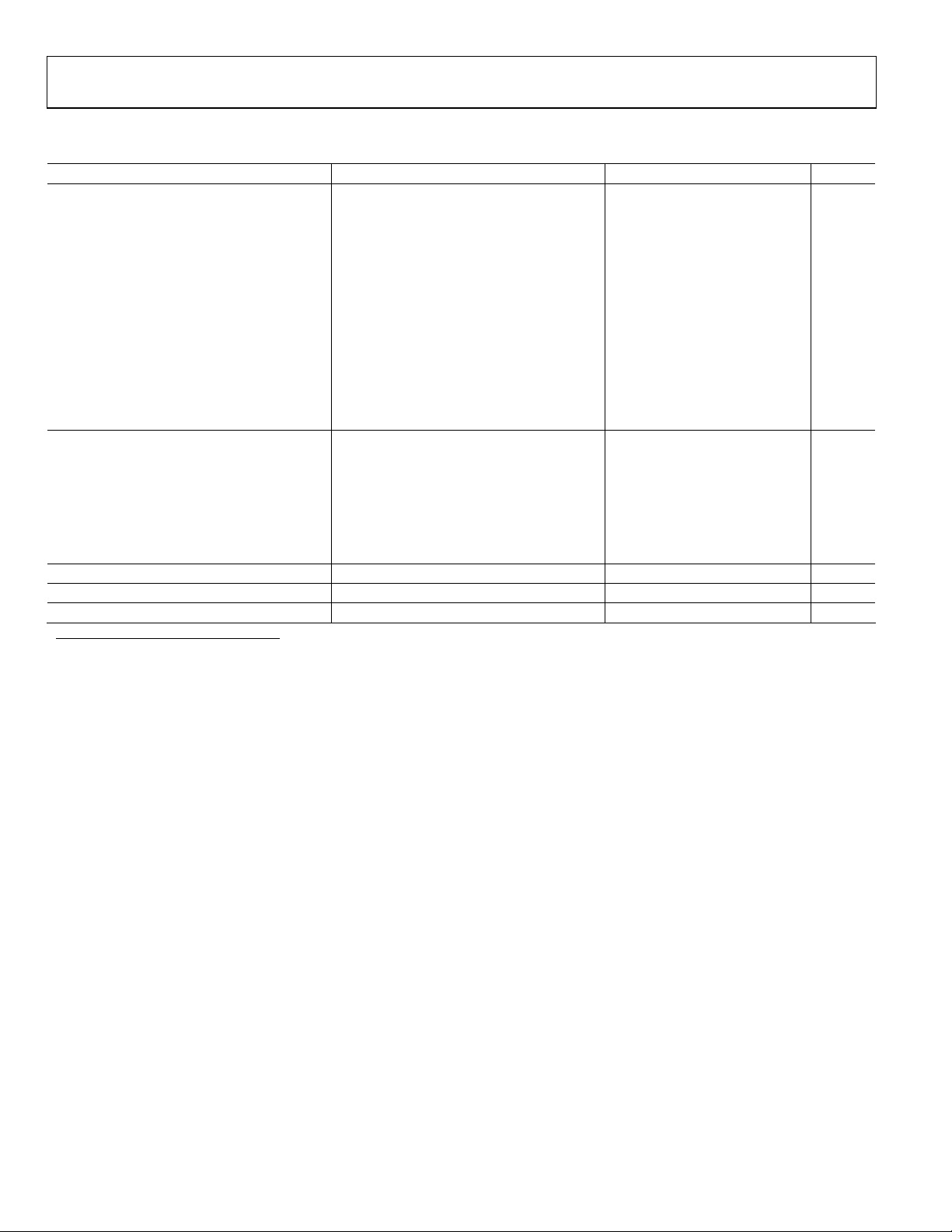

AD8383

SPECIFICATIONS (continued)

Parameter Conditions Min Typ Max Unit

VIDEO OUTPUT DYNAMIC PERFORMANCE T

Data Switching Slew Rate 20% to 80% 460 V/µs

Invert Switching Slew Rate 20% to 80% 560 V/µs

Data Switching Settling Time to 1% 19 24 ns

Data Switching Settling Time to 0.25% 30 50 ns

Invert Switching Settling Time to 1% VO = 10 V Step 75 120 ns

Invert Switching Settling Time to 0.25% VO = 10 V Step 250 500 ns

Invert Switching Overshoot VO = 10 V Step 100 200 mV

CLK and Data Feedthrough

All-Hostile Crosstalk

5

6

Amplitude 40 mV p-p

Duration 20 ns

DAC Transition Glitch Energy Code 511 to Code 512 0.3 nV-s

POWER SUPPLY

DVCC, Operating Range 3 3.3 3.6 V

DVCC, Quiescent Current 20 28 mA

AVCC, Operating Range 9 18 V

Total AVCC Quiescent Current 40 48 mA

STBY AVCC Current STBY = H 0.15 0.45 mA

STBY DVCC Current STBY = H 3.5 5 mA

OPERATING TEMPERATURE RANGE, T

AMBIENT TEMPERATURE RANGE

OPERATING TEMPERATURE RANGE, T

A

7

J

5

Measured on two outputs differentially as CLK and DB(0:9) are driven and STSQ and XFR are held low.

6

Measured on two outputs differentially as the other four outputs make a full-scale transition for both states of INV.

7

Operation at 85°C ambient temperature requires a thermally optimized PCB layout (see Application Notes), minimum airflow of 200 lfm, input clock rate not

exceeding 100 MHz, black-to-white transition ≤4 V, C

C, MIN

to T

, VO = 5 V Step, CL = 150 pF

C, MAX

10 mV p-p

Ambient Temperature 0 75 °C

0 85 °C

100% tested 25 125 °C

≤150 pF.

L

Rev. 0 | Page 4 of 16

Page 5

AD8383

ABSOLUTE MAXIMUM RATINGS

Table 2. AD8383 Stress Ratings

Parameter Rating

Supply Voltages

AVCCx – AGNDx 18 V

DVCC – DGND 4.5 V

Input Voltages

Maximum Digital Input Voltages DVCC + 0.5 V

Minimum Digital Input Voltages DGND – 0.5 V

Maximum Analog Input Voltages AVCC + 0.5 V

Minimum Analog Input Voltages AGND – 0.5 V

Internal Power Dissipation

LFCSP Package @ 25°C Ambient 3.8 W

Operating Temperature Range 0°C to 85°C

Storage Temperature Range –65°C to +125°C

Lead Temperature Range (Soldering 10 sec) 300°C

8

Stresses above those listed under the Absolute Maximum

Ratings may cause permanent damage to the device. This is a

stress rating only; functional operation of the device at these or

any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to the

absolute maximum ratings for extended periods may reduce

device reliability.

8

48-Lead LFCSP Package:

= 26°C/W (Still Air): JEDEC STD, 4-layer board with 0 CFM airflow

θ

JA

= 20°C/W

θ

JC

= 11.0°C/W in Still Air

ψ

JB

MAXIMUM POWER DISSIPATION

Junction Temperature

The maximum power that can be safely dissipated by the

AD8383 is limited by its junction temperature. The maximum

safe junction temperature for plastic encapsulated devices as

determined by the glass transition temperature of the plastic is

approximately 150°C. Exceeding this limit temporarily may

cause a shift in the parametric performance due to a change in

the stresses exerted on the die by the package. Exceeding a

junction temperature of 175°C for an extended period can

result in device failure.

Overload Protection

The AD8383 employs a 2-stage overload protection circuit that

consists of an output current limiter and a thermal shutdown.

The maximum current at any one output of the AD8383 is

internally limited to 100 mA, average. In the event of a momentary short-circuit between a video output and a power supply

rail (AVCC or AGND), the output current limit is sufficiently

low to provide temporary protection.

The thermal shutdown debiases the output amplifier when the

junction temperature reaches the internally set trip point. In the

event of an extended short-circuit between a video output and a

power supply rail, the output amplifier current continues to

switch between 0 mA and 100 mA typical with a period

determined by the thermal time constant and the hysteresis of

the thermal trip point. The thermal shutdown provides longterm protection by limiting the average junction temperature to

a safe level.

Operating Temperature Range

Production testing guarantees a minimum thermal shutdown

junction temperature (T

) of at least 125°C.

J

To ensure operation at T

maximum power dissipation as described in the Applications

section.

Exposed Paddle

The die paddle must be soldered to AVCC for reliable electrical

operation.

See the Applications section for details regarding use of the

exposed paddles to dissipate excess heat.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

this product features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

Rev. 0 | Page 5 of 16

< 125°C, it is necessary to limit the

J

Page 6

AD8383

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

CLK

XFR

STSQNCNC

4847464544

V1

AVCCDAC

AGNDDACVREFHI

4342414039

VREFLO

V2

38

AGND0

37

1

NC

DB0

2

DB1

3

DB2

4

DB3

5

DB4

6

DB5

7

DB6

8

DB7

9

10

DB8

11

DB9

NC

12

13

E/O

NC = NO CONNECT

PIN 1

INDICATOR

14

R/L

(Not to Scale)

15

16

INV

DGND

AD8383

TOP VIEW

7mm × 7mm

17

18NC19

DVCC

AVCCBIAS

20

STBY

21

22

BYP

AGNDBIAS

23

NC

24

NC

36

35

34

33

32

31

30

29

28

27

26

25

VID0

AVCC0,1

VID1

AGND1,2

VID2

AVCC2,3

VID3

AGND3,4

VID4

AVCC4,5

VID5

AGND5

04513-0-002

Figure 2. 48-Lead LFCSP Pin Configuration

Table 3. Pin Function Descriptions

Pin Name Function Description

DB(0:9) Data Input 10-Bit Data Input. MSB = DB(0:9).

CLK Clock Clock Input.

STSQ Start Sequence

The state of STSQ is detected on the active edge of CLK. A new data loading sequence begins on

the next active edge of CLK after STSQ is detected HIGH.

The active CLK edge is the rising edge when E/O is held HIGH. It is the falling edge when E/O is

held LOW.

R/L Right/Left Select

A new data loading sequence begins on the left with Channel 0 when this input is LOW, and on

the right with Channel 5 when this input is HIGH.

E/O Even/Odd Select

The active CLK edge is the rising edge when this input is held HIGH and the falling edge when

this input is held LOW. Data is loaded sequentially on the rising edges of CLK when this input is

HIGH and on the falling edges when this input is LOW.

XFR Data Transfer

XFR is detected and a data transfer is initiated on a rising CLK edge when this input is held HIGH.

Data is transferred to the video outputs on the next rising CLK edge after XFR is detected.

VID0–VID5 Analog Outputs These pins are directly connected to the analog inputs of the LCD panel.

V1, V2 Reference Voltages The voltage applied between these pins set the reference levels of the analog outputs.

VREFHI,

Full-Scale References The voltage applied between these pins sets the full-scale output voltage.

VREFLO

INV Invert

When this pin is HIGH, the analog output voltages are above VMID. When LOW, the analog

output voltages are below VMID. VMID is a hypothetical reference level set by the voltages

applied to V1 and V2. VMID is equal to (V1 + V2)/2.

DVCC Digital Power Supply Digital Power Supply.

DGND Digital Supply Return This pin is normally connected to the analog ground plane.

AVCCx Analog Power Supplies Analog Power Supplies.

AGNDx Analog Supply Returns Analog Supply Returns.

BYP Bypass A 0.1 µF capacitor connected between this pin and AGND ensures optimum settling time.

STBY Standby When HIGH, the internal circuits are debiased and the power dissipation drops to a minimum.

Rev. 0 | Page 6 of 16

Page 7

AD8383

TIMING DIAGRAMS

t

CLK LOW

t

CLK HIGH

V

TH

V

TH

= 1.65V

= 1.65V

04513-0-003

CLK

DB(0:9)

STSQ

XFR

CLK

DB(0:9)

t

CLK HIGH

VTH = 1.65V

t

HOLD

V

TH

t

HOLD

= 1.65V

t

SKEW

t

SETUP

t

SETUP

Figure 3. Timing Diagram, Even Mode (E/O = HIGH)

t

CLK LOW

V

= 1.65V

TH

t

t

SKEW

SETUP

V

TH

t

HOLD

= 1.65V

STSQ

XFR

t

SETUP

t

HOLD

SETUP

t

HOLD

V

V

= 1.65V

TH

= 1.65V

TH

04513-0-004

t

Figure 4. Timing Diagram, Odd Mode (E/O = LOW)

Rev. 0 | Page 7 of 16

Page 8

AD8383

[

THEORY OF OPERATION

TRANSFER FUNCTION AND ANALOG OUTPUT VOLTAGE

The DecDriver has two regions of operation: where the video

output voltages are either above or below a reference voltage

VMID, and where VMID = (V1 + V2)/2. The transfer function

defines the analog output voltage as the function of the digital

input code as follows:

n

–1)(

–1)(

⎞

for INV = LOW

⎟

1023

⎠

n

⎞

for INV = HIGH

⎟

1023

⎠

⎛

×=

FSV – V1nVIDx

⎜

⎝

⎛

×+=

VFS2VnVIDx

⎜

⎝

To best correlate transfer function errors to image artifacts, the

overall accuracy of the DecDriver is defined by two parameters,

VDE and VCME.

VDE, the differential error voltage, measures the difference

between the rms value of the output and the rms value of the

ideal. The defining expression is

nVDE ×

=

)(

][ ]

2

−−−

)()(

n1VnVOUTP2VnVOUTN

−−

1023

⎞

⎟

⎠

⎛

1

⎜

⎝

VFS

where n = input code

VFS = 2 × (VREFHI – VREFLO)

A number of internal limits define the usable range of the

analog output voltages, VIDx, as shown in Figure 5.

AVCC

2V

V2 + V

FS

V2

V

MID

VIDx (V)

V1

V1 – V

FS

AGND

Figure 5. Transfer Function, VIDx vs. Input Code, Internal Limits and Usable Output Voltage Range

REFHI–VREFLO

INV = HIGH

V

= (V1+V2)/2

MID

INV = LOW

0 1023

INPUT CODE

VCME, the common-mode error voltage, measures ½ the dc

bias of the output. The defining expression is

1

⎡

≥ 1.3V

0 ≤ VFS≤ 5.5V

5V ≤ V2 ≤ (AVCC – 4)

0 ≤ VFS≤ 5.5V

≥ 1.3V

INTERNAL LIMITS AND

USABLE VOLTAGE RANGES

)(

⎢

212

⎣

9V ≤ AVCC ≤ 18V

5V ≤ V1 ≤

(AVCC – 4)

()

04513-0-005

+=

–)()(

nVOUTPnVOUTNnVCME

+

2V1V

⎤

⎥

2

⎦

Rev. 0 | Page 8 of 16

Page 9

AD8383

V

APPLICATIONS

The V1 and V2 inputs in these systems are tied together and are

normally connected to VCOM, as shown in Figure 6.

AD8383

VCOM

V2

V1

04513-0-006

Figure 6. Standard Connection Diagram

The transfer function of the AD8383 is shown in Figure 7 for

V2 = V1 = VCOM.

VFS = 5V

VCOM

VBIAS = 1V

VBIAS = 1V

VFS = 5V

1023820

RESERVED

CODE

RANGE

COM = 7V

R2 = 1kΩ

R1 = 6kΩ

AVCC = 15.5V

VZ = 5.1V

–IN

V+

VCOM

AD8132

V–

+IN

DVCC = 3.3V

3

5

4

6

V2 = 8V

V1 = 6V

V2

V1

1

2

8

Figure 8. High Accuracy Reference Circuit

VFS = 4V

V2

VCOM

V1

VFS = 4V

VBIAS = 1V

VBIAS = 1V

1023

AD8383

04513-0-008

04513-0-007

Figure 7. Output Transfer Function for Standard Connection

EXTERNAL VBIAS GENERATION

In systems that require improved brightness resolution and

higher accuracy, the V1 and V2 inputs, connected to external

voltage references, provide the necessary VBIAS while allowing

the full code range to be used for gamma correction.

V1 sets the white drive voltage while INV = LOW and V2 sets

the white drive voltage while INV = HIGH. V1 and V2 are

defined as

V1 = VCOM – VBIAS

V2 = VCOM + VBIAS

To ensure a symmetrical ac driving voltage, the difference

between V2 and VCOM must be equal to the difference

between VCOM and V1.

(V2 – VCOM) = (VCOM – V1)

The circuit in Figure 8 ensures symmetry to within 1 mV with a

minimum component count. Bypass capacitors are not shown

for clarity.

The transfer function and the input symmetry error of the

AD8383 are shown in Figure 9 when the circuit of Figure 8 is

used to generate VBIAS.

THE AD8383, IN THE APPLICATIONS

CIRCUIT SHOWN, TYPICALLY PRODUCES

A SYMMETRICAL OUTPUT AT 85°C WHEN

ITS SUPPLY, (V+) – (V–), IS AT 7.2V.

04513-0-009

Figure 9. Transfer Function for High Accuracy Reference Applications

8.75

7.50

6.25

5.00

3.75

2.50

1.25

0.00

–1.25

–2.50

–3.75

(V2 + V1)/2 – VCOM (mV)

–5.00

–6.25

–7.50

–8.75

TYPICAL ASYMMETRY AT THE OUTPUTS OF THE

AD8383 VERSUS ITS POWER SUPPLY FOR THE

APPLICATION CIRCUIT

5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7

TA = 85°C

V

+

– V– (V)

TA = 25°C

Figure 10. Accuracy for High Accuracy Reference Applications

04513-0-010

Rev. 0 | Page 9 of 16

Page 10

AD8383

PCB DESIGN FOR GOOD THERMAL PERFORMANCE

The total maximum power dissipation of the AD8383 is partly

dependent on load. In a 6-channel 60 Hz XGA system running

at a 65 MHz clock rate, the total maximum power dissipation is

1.08 W at an LCD panel input capacitance of 150 pF.

At the maximum specified clock rate of 100 Ms/s, the total

maximum power dissipation can exceed 2 W for large capacitive

loads, as shown in Table 4.

Although the maximum safe operating junction temperature is

higher, the AD8383 is 100% tested at a junction temperature of

125°C. Consequently, the maximum guaranteed operating

junction temperature is 125°C. To limit the maximum junction

temperature at or below the guaranteed maximum, the package,

in conjunction with the PCB, must effectively conduct heat

away from the junction.

The AD8383’s LFCSP package is designed to provide superior

thermal characteristics, partly achieved by an exposed die

paddle on the bottom surface of the package. In order to take

full advantage of this feature, the exposed paddle must be in

direct thermal contact with the PCB, which then serves as a

heat sink.

THERMAL PAD DESIGN

Thermal performance of the AD8383 varies logarithmically

with the contact area between the exposed thermal paddle and

the thermal pad on the top layer of the PCB. See Figure 11.

The θ

(of the AD8383 mounted on a standard JEDEC PCB) is

JA

reduced by approximately 40% as the contact area increases

from 0% (no thermal pad) to 50%. It approaches its specified

value as the contact area (on the JEDEC standard PCB)

approaches 100%.

In order to minimize thermal performance degradation of

production PCBs, the contact area between the thermal pad and

the PCB should be maximized. Therefore, the size of the

thermal pad should match the exposed 5.25 mm × 5.25 mm

paddle size. However, if the PCB design rules require a pad-topad clearance of more than 0.3 mm, the size of the thermal pad

may be reduced to 5 mm × 5 mm. Additionally, a second

thermal pad of the same size should be placed on the bottom

side of the PCB. At least one thermal pad should be in direct

thermal (and electrical) contact with the AVCC plane.

50

A thermally effective PCB must incorporate a thermal pad and

45

a thermal via structure. The thermal pad provides a solderable

contact surface on the top surface of the PCB. The thermal via

structure provides a thermal path to the inner and bottom

layers of the PCB to remove heat.

40

(°C/W)

JA

θ

35

30

25

Figure 11. Thermal Performance vs. Contact Area (on a JEDEC PCB)

250 50 75 100

CONTACT AREA (%)

04513-0-011

Table 4. Power Dissipation vs. Load Capacitance and VFS at 100 Ms/s Clock Rate

VFS = 5 V VFS = 4 V

C

(pF) P

LOAD

QUIESCENT

(W) P

(W) P

DYNAMIC

(W) P

TOTAL

(W) P

DYNAMIC

TOTAL

(W)

150 0.7 0.72 1.42 0.58 1.28

200 0.7 0.96 1.66 0.77 1.47

250 0.7 1.20 1.90 0.96 1.66

300 0.7 1.44 2.14 1.15 1.85

Rev. 0 | Page 10 of 16

Page 11

AD8383

THERMAL VIA STRUCTURE DESIGN

Effective heat transfer from the top to the inner and bottom

layers of the PCB requires thermal vias incorporated into the

thermal pad design. Thermal performance increases logarithmically with the number of vias, as shown in Figure 12. With the

AD8383 on a standard JEDEC PCB, θ

value when a total of 16 vias are used. At a via count above 36,

approaches its optimum value as the slope of the curve

θ

JA

approaches zero.

32

30

28

(°C/W)

JA

θ

26

24

reaches its specified

JA

REFERENCE PCB DESIGN

The top copper layer is shown in Figure 13.

7 mm

7 mm

Figure 13. Recommended PCB Landing

The bottom thermal pad forms AVCC plane.

04513-0-013

22

Figure 12. Thermal Performance vs. Number of Vias (on a JEDEC PCB)

1002030

NUMBER OF VIAS

40

04513-0-012

Near optimum thermal performance of production PCBs is

attained when the number of vias is at least 36.

SOLDER MASKING

To minimize the formation of solder voids due to solder flowing

into the via holes (solder wicking), the via diameter should be

small. Solder masking of the via holes on the top layer of the

PCB plugs the via holes, inhibiting solder flow into the holes. To

optimize the thermal pad coverage, the solder mask diameter

should be no more than 0.1 mm larger than the via diameter.

Thermal Pads

Top PCB Layer: 5.25 mm × 5.25 mm

Bottom PCB Layer: 5.25 mm × 5.25 mm

Thermal via structure

Diameter: 0.25 mm

Number of vias: 41

Via Grid Pitch: 0.5 mm

Miscellaneous

Perimeter Pads: 0.5 mm × 0.25 mm

Solder Mask Swell: 0.02 mm

Rev. 0 | Page 11 of 16

Page 12

AD8383

θ

+

(

(

θ, ψ

θJB, ψ

JB

θ

AD8383

CP

T

J

JC

C

JC

θ

JC-BOTTOM

C

JC-BOTTOM

Figure 14. Thermal Equivalent Circuit

ESTIMATED JUNCTION TEMPERATURE

Assuming no heat flows through the sides of the AD8383 package, heat flow from the AD8383 is through two paths. While

part of the total heat generated dissipates through the top of the

case, the remainder flows into the PCB to be dissipated.

Assuming there is no other heat-generating component near the

AD8383, the thermal equivalent circuit of a system that consists

of one AD8383 mounted on a PCB is shown in Figure 14.

The thermal resistance of the top of the case, θ

independent of the system variables, and well defined. θ

depends on the thermal resistance of the molding compound.

, is constant,

JC

JC

C

θ

PCB

PCB

θ

AIR-CASE

T

PCB

T

CASE

PCB

C

AIR-CASE

θ

AIR-PCB

C

AIR-PCB

T

T

A

AMBIENT

04513-0-014

Junction Temperature and Maximum Power Dissipation

In a thermal steady state represented by the simplified schematic shown in Figure 15, heat flow from the die is partly through

the top of the case, causing a temperature drop (T

partly through the PCB, causing a temperature drop (T

The junction temperature is calculated as follows:

TT

CASEJ

PCBCASE

PPP

J

=

T

−

=+=

JC

θ

PCBJC

θ θ

+

TT

−

+

CBP

θ

Tθ T θ Pθθ

PCBJCCASEPCBPCBJC

+

J

PCBJ

– T

)()(

CASE

J

), and

– T

PCB

).

The thermal resistance of the system, θ

, is system dependent

JA

and therefore cannot be properly estimated. Although it is traditional to provide the thermal resistance of a JEDEC reference

system in the data sheet, its value may not be appropriate for all

systems and may result in large errors (>>25%).

The thermal resistance of production PCBs, θ

, depends largely

JC

on the particular PCB design, and, to some extent, the environmental conditions specific to the particular system. Although θ

is traditionally not provided on data sheets, a thermal characterization parameter, ψ

, of a JEDEC reference system is gaining

JB

increasing acceptance. When the PCB thermal design near the

AD8383 closely approximates the PCB of the JEDEC reference

system, θ

approaches ψJB.

JA

For thermally enhanced packages, the thermal resistance of the

exposed thermal paddle, θ

JC-BOTTOM

, is very low and may

therefore be ignored.

where:

T

is the junction temperature

J

is the temperature of the top of the case (near the output

T

CASE

pins for the AD8383)

is the PCB temperature on the solder side (directly under

T

PCB

the AD8383)

P is the total power dissipated by the AD8383

JB

is the thermal resistance of the top of the case

θ

JC

is the thermal resistance of the PCB

θ

PCB

At a given maximum allowed junction temperature, the

maximum allowed power dissipation is

+

θ θ

⎡

=

P

MAX

⎢

⎣

PCBJC

PCBJC

θθ

For a thermally optimized PCB,

)

T

JMAX

θ

can be replaced with ψ

JC

T

T

θ

CASE

JC

PCB

⎤

−−

⎥

PCB

θ

⎦

PCB

and the equation can be rewritten as

P

MAX

⎡

=

⎢

⎣

)

PCBJC

ψ θ

+

ψθ

JMAX

T

PCBJC

CASE

T

JC

θ

⎤

PCB

T

−−

⎥

PCB

ψ

⎦

Rev. 0 | Page 12 of 16

Page 13

AD8383

θ

P

PCB

θ

PCB

T

PCB

AIR-PCB

Figure 15. Simplified Thermal Equivalent Circuit

P

T

J

T

A

P

P

C

θ

JC

T

CASE

θ

AIR-CASE

04513-0-015

Verification of the Maximum Operating Junction Temperature

In order to verify the system thermal design for compliance

with the maximum operating junction temperature specification, temperature measurements T

CASE

and T

are required at

PCB

the maximum possible total power dissipation in a complete,

fully assembled LCD projection system.

Maximum possible total power dissipation of the AD8383

occurs when the video input to the projector is a pattern with

1-pixel-wide white and black vertical lines. An alternative

pattern that results in the maximum possible total power

dissipation is a 1-pixel checkerboard pattern. The expected total

power dissipation of the AD8383 in a 60 Hz, 6-channel XGA

projector displaying the 1-pixel-wide vertical line or checkerboard pattern is 1.08 W (at AVCC = 15.5 V, VCOM = 7 V, and

LCD capacitance = 150 pF).

Although the case and PCB temperatures are highly dependent

on the PCB design, their measured values are expected to be

similar at approximately 40°C above the ambient (on a typical

PCB with a minimal airflow whose thermal design follows the

recommendations described in this note). The junction temperature then calculates to approximately 10°C above the case and

PCB temperatures. At a 70°C ambient temperature, the junction

temperature is expected to be at approximately 120°C.

The AD8383 has a relatively small thermal mass. In order to

minimize measurement errors due to the thermal mass of the

measuring device, a small-gauge thermocouple or a thermal

probe with a very small thermal mass is required for the measurement of T

CASE

and T

PCB

.

Power-Up and Power-Down Sequencing

As indicated in the Absolute Maximum Ratings, the voltage at

any input pin cannot exceed its supply voltage by more than

0.5 V. To ensure compliance with the Absolute Maximum

Ratings, power-up and power-down sequencing may be

required.

During power-up, initial application of nonzero voltages to any

of the input pins must be delayed until the supply voltage ramps

up to at least the highest maximum operational input voltage.

During power-down, the voltage at any input pin must reach

zero during a period not exceeding the hold-up time of the

power supply.

Failure to comply with the Absolute Maximum Ratings may

result in functional failure or damage to the internal ESD

diodes.

Damaged ESD diodes may cause temporary parametric failures,

which may result in image artifacts. Damaged ESD diodes

cannot provide full ESD protection, thus reducing reliability.

The recommended sequence is

Power ON

1. Apply power to supplies.

2. Apply power to other I/Os.

Power OFF

1. Remove power from I/Os.

2. Remove power from supplies.

VBIAS Generation—V1, V2 Input Pin Functionality

In order to avoid image flicker, a bias voltage of approximately

1 V minimum must be maintained across the pixels of HTPS

LCDs. The AD8383 provides two methods of maintaining this

bias voltage.

Internal Bias Voltage Generation

Standard systems that internally generate the bias voltage

reserve the upper-most code range for the bias voltage and use

the remaining code range to encode the video for gamma

correction.

Rev. 0 | Page 13 of 16

Page 14

AD8383

OUTLINE DIMENSIONS

BSC SQ

PIN 1

INDICATOR

7.00

0.60 MAX

37

36

0.60 MAX

0.30

0.23

0.18

PIN 1

48

INDICATOR

1

5.25

5.10 SQ

4.95

12

13

0.25 MIN

1.00

0.85

0.80

12° MAX

SEATING

PLANE

TOP

VIEW

0.80 MAX

0.65 TYP

0.50 BSC

COMPLIANT TO JEDEC STANDARDS MO-220-VKKD-2

6.75

BSC SQ

0.20 REF

0.50

0.40

0.30

0.05 MAX

0.02 NOM

COPLANARITY

25

0.08

BOTTOM

VIEW

24

5.50

REF

Figure 16. 48-Lead Frame Chip Scale Package [LFCSP]

(CP-48)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD8383ACPZ

9

Z = Pb-free part.

9

0°C to 85°C 48-Lead LFCSP CP-48

Rev. 0 | Page 14 of 16

Page 15

AD8383

NOTES

Rev. 0 | Page 15 of 16

Page 16

AD8383

NOTES

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D03191–0–1/04(0)

Rev. 0 | Page 16 of 16

Loading...

Loading...