Page 1

Fast, High-Voltage Drive, 6-Channel Output

a

DecDriver™ Decimating LCD Panel Driver

FEATURES

High-Voltage Drive to Within 1.3 V of Supply Rails

24 V Supply for Fast Output Voltage Drivers

High Update Rates: Fast 75 Ms/s 10-Bit Input Word Rate

Low Power Dissipation, 550 mW with Power-Down

Voltage Controlled Video Reference and Full-Scale

(Contrast) Output Levels

INV Bit Reverses Polarity of Video Signal

Nominal 3.3 V Logic and 15 V Analog Supplies

Flexible Logic

Addressable or Sequential Channel Loading

STSQ/CS Allow Parallel AD8380 Operation for XGA

and Greater Resolution

Drives Capacitive Loads

26 ns Settling Time to 1% Up to 150 pF Load

Slew Rate 270 V/s

Available in 44-Lead MQFP

APPLICATIONS

Poly Si LCD Panel Analog Column Driver

DB [0:9]

CLK

STSQ/CS

XFR

E/O

R/L

A[0:2]

STBY

BYP

VREFHI

VREFLO

AD8380

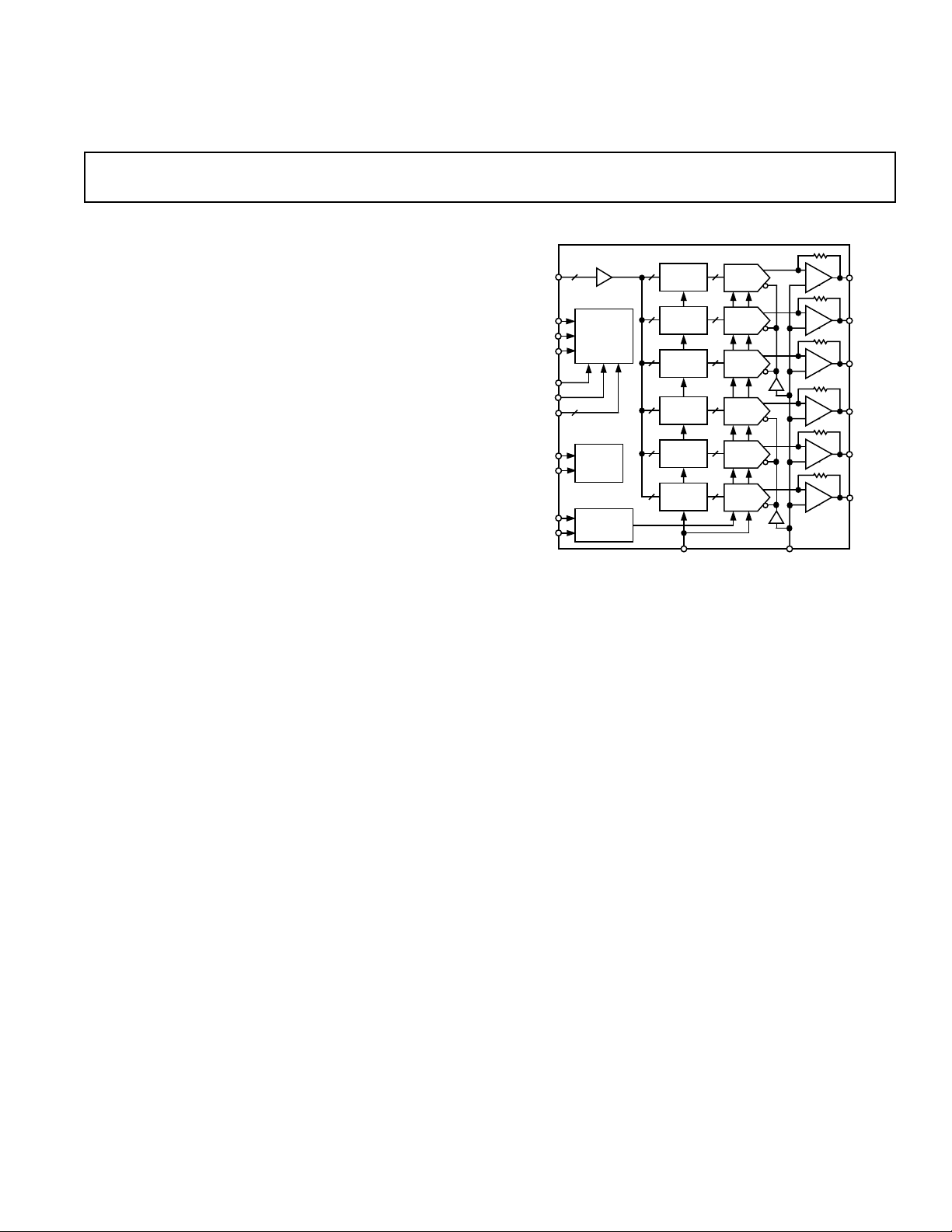

FUNCTIONAL BLOCK DIAGRAM

10

CHANNEL

SELECTOR

3

BIAS

SCALING

CONTROL

AD8380

10

10

10

10

10

1010

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

INV VMID

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

VID0

VID1

VID2

VID3

VID4

VID5

PRODUCT DESCRIPTION

The AD8380 provides a fast, 10-bit latched decimating digital

input that drives 6-channel high voltage drive outputs. The 10bit input word is sequentially muxed into six separate high speed,

bipolar DACs. Flexible digital input formats allow several

AD8380s to be used in parallel for higher resolution displays.

STSQ/CS, in conjunction with 3-bit addressable channel-loading

pins, allows loading of the digital words either sequentially or

randomly, and R/L control sets loading as either left to right, or

vice versa. 6-channel high voltage output drivers drive to within

1.3 V of the rails to rated settling time. The output signal can be

adjusted for dc signal reference, signal inversion or contrast for

maximum flexibility.

The AD8380 is fabricated on ADI’s XFCB26 fast bipolar 26 V

process, providing fast input logic, trimmed accuracy bipolar

DACs and fast settling, high voltage precision drive amplifiers

on the same chip.

The AD8380 dissipates nominally 0.55 W of static power. STBY

pin reduces power to a minimum, with fast recovery.

The AD8380 is offered in a 44-lead 10 × 10 × 2.0 mm MQFP

package and operates over the commercial temperature range of

0°C to 85°C.

DecDriver is a trademark of Analog Devices, Inc.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

Page 2

AD8380–SPECIFICATIONS

(@ 25ⴗC, AVCC = 15 V, DVCC = 3.3 V, T

otherwise noted)

= 0ⴗC, T

MIN

= 85ⴗC, unless

MAX

Model Conditions Min Typ Max Unit

VIDEO DC PERFORMANCE

1

T

to T

MIN

MAX

VDE DAC Code = 450 to 800 –7.5 +1 +7.5 mV

VCME DAC Code = 450 to 800 –3.5 +0.5 +3.5 mV

Scale Factor Error DAC Code = 0 to 1023 –0.25 +0.25 %

Offset Error DAC Code = 0 to 1023 –7 +1 +7 mV

REFERENCE INPUTS

VMID Range

2

6 7 7.5 V

VMID Bias Current 3 µA

VFS Range VFS = 2 × (VREFHI–VREFLO) 1 5 6 V

VREFHI VREFLO +0.5 AVCC – 2.5 AVCC V

VREFLO VMID – 0.5 VREFHI – 2.5 VREFHI – 0.5 V

VREFHI Input Resistance to VREFLO 3.3 kΩ

VREFLO Bias Current 0.2 µA

VREFHI Input Current

3

VFS = 5 V 750 µA

RESOLUTION

Coding Binary 10 Bits

DIGITAL INPUT CHARACTERISTICS

Input Data Update Rate 75 Ms/s

Clock to Data Setup Times: t

Clock to STSQ Setup Times: t

Clock to XFR Setup Times: t

1

3

5

Maximum CLK Rise and Fall Time, t

Clock to A[0:2] Hold Times: t

Clock to Data Hold Times: t

Clock to STSQ Hold Times: t

Clock to XFR Hold Times: t

Clock to A[0:2] Setup Times: t

C

IN

I

IN

V

IH

V

IL

V

TH

9

2

4

6

8

7

Threshold Voltage 1.4 V

1ns

1ns

1ns

4ns

4ns

4ns

4ns

4ns

1ns

3pF

0.6 µA

2.0 V

0.8 V

VIDEO OUTPUT CHARACTERISTICS

Output Voltage Swing AVCC – VOH, VOL – AVEE 1.1 1.3 V

CLK to VID Delay

4

50% of VIDx 13.5 15.5 17.5 ns

Output Current 30 mA

VIDEO OUTPUT DYNAMIC PERFORMANCE T

MIN

to T

MAX

, VO = 5 V Step,

CL = 150 pF, RS = 25 Ω

Data Switching Slew Rate 270 V/µs

Invert Switching Slew Rate 625 V/µs

Data Switching Settling Time to 1%

Data Switching Settling Time to 0.25% 35 65 ns

Invert Switching Settling Time to 1%

Invert Switching Settling Time to 0.25% 85 100 ns

CLK Feedthrough

All-Hostile Crosstalk

6

7

5

5

26 32 ns

30 40 ns

2 5 mV p-p

Amplitude 95 mV p-p

Glitch Duration 40 ns

POWER SUPPLY

Supply Rejection (VDE) +VS = 15 V ± 1 V 1 mV/V

DVCC, Operating Range 3 5.5 V

DVCC, Quiescent Current 22 35 mA

AVCC, Operating Range 9 24 V

Total AVCC Quiescent Current 33 44 mA

STBY AVCC Current STBY = H 0.5 5 mA

STBY DVCC Current STBY = H 0.1 5 mA

OPERATING TEMPERATURE RANGE 0 85 °C

NOTES

1

For definitions of VDE and VCME, see the Transfer Function section. Scale factor error is expressed as percentage of VFS.

2

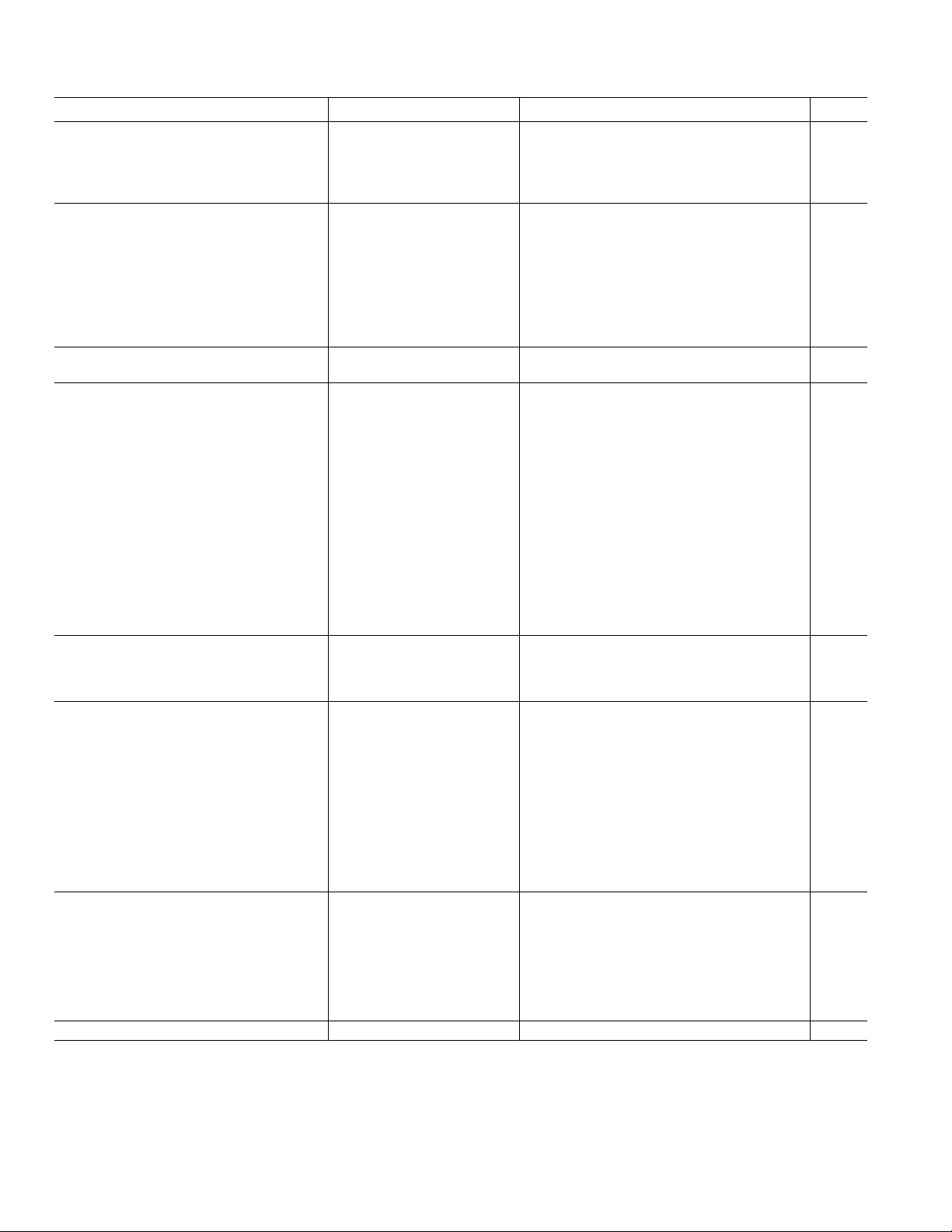

See Figure 1 for valid ranges of VMID.

3

VREFHI Input Current = (VREFHI – VREFLO)/(VREFHI Input Resistance) = 2.5 V/3.3 kΩ.

4

Delay time from 50% of falling CLK edge to 50% of output change. Measurement is made for both states of INV.

5

For best settling time results, use minimum series output resistance, RS of 25 Ω.

6

An output channel is selected, and glitch is monitored as CLK is driven. STSQ and XFR are set to logic low.

7

Input data is loaded such that any five output channels change by VFS (i.e., 5 V), and the sixth unselected channel is monitored. Measurement is made for both states of INV.

Specifications subject to change without notice.

–2–

REV. B

Page 3

AD8380

VFS – Volts

6 7.5

VMID – Volts

6

4.5

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Description

1 NC No Connect.

2–11 DB[0:9] Video Data Inputs. DB9 is the MSB.

12 E/O Even/Odd data select, input latches are loaded at the falling edge of CLK if E/O is low or

rising edge if E/O is high.

13 R/L Determines starting point of internally generated channel-loading sequence.

R/L Low (when address = 111) loads from Channel 0 up to Channel 5.

14 INV When high, analog video outputs are above the VMID setpoint. See Figure 3.

15, 16 DVEE, DVCC Digital Supplies. Nominally 3.3 V and 0 V, respectively.

17, 20, 22, 24,

26, 28, 30, 32,

34, 37, 38 AVCCxxx, AVEExxx Analog Supplies. Nominally 15 V and 0 V, respectively.

18 STBY Stand By. When high, all digital and analog circuits are “debiased” and the power dissipation

drops to a minimum.

19 BYP An external capacitor connected from here to V

21 VMID Externally supplied voltage applied here sets the midpoint reference for the video output.

23, 25, 27, 29,

31, 33 VID5–VID0 Analog Video Outputs.

36, 35 VREFHI, VREFLO Voltage between these pins sets DAC full-scale range. An external reference must be applied

and should be common to all devices to ensure best tracking.

39–41 A[0:2] 3-bit channel address for addressable loading of the digital input latches.

42 STSQ/CS STSQ to start internal sequencing or Chip Select to enable addressable channel addressing.

See functional description. Used in conjunction with A[0:2].

43 XFR If XFR = HIGH at the rising edge of CLK, data is transferred to the DACs on the next falling

edge of CLK. See Figures 4, 6, 7, and 8.

44 CLK Master Clock Input.

will help to ensure rapid DAC settling time.

EE

CHANNEL SELECTION FUNCTIONALITY

There are two channel selection modes, addressed channel

loading, (in which the user directly controls which DAC is

loaded), and internally sequenced loading (in which the user

controls the direction and clock phase in which the loading

proceeds).

ADDRESSED CHANNEL LOADING:

When channel address (A0, A1, A2) = 000 through 101, the

video data is loaded into Channels 0 through 5. (STSQ/CS

functions as “Chip Selection” this case.)

INTERNALLY SEQUENCED LOADING:

When channel address = 111 the video data is loaded in a

sequence determined internally. The sequencing is initiated by

a pulse applied to STSQ/CS input. The count proceeds from

0 to 5 if R/L is LOW or from 5 to 0 if R/L is HIGH.

DAC TRANSFER FUNCTION

V

= VMID + VFS × (1 – N/1023); if INV is HIGH,

OUT

= VMID – VFS × (1 – N/1023); if INV is LOW

V

OUT

where VFS = 2 × (VREFHI – VREFLO)

MAXIMUM OUTPUT VOLTAGE

The maximum output signal swing is constrained by the output

voltage compliance of the DACs and the output dynamic range

of the output amplifiers. The minimum voltage allowed at the

outputs of the DACs is about 6 V. This constrains the minimum

value of VMID to be 6 V. The output amplifiers will swing and

settle cleanly, as described on the specification page, for output

voltages within 1.5 V from each supply voltage rail.

For a given value of V

, the voltage required to saturate the

MID

video output voltages defines the maximum usable full-scale

voltage. For example, if VMID is less than AVCC/2, the maximum value of VFS is (VMID – 1.5 V). If VMID is greater than

AVCC/2, the maximum useful VFS is (AVCC – 1.5 – VMID).

Figure 1 graphically describes these limiting factors.

Figure 1. Valid Range for VMID with Respect to VFS

(AVCC = 15 V)

REV. B

–3–

Page 4

AD8380

ABSOLUTE MAXIMUM RATINGS

Supply Voltage AVCC–AVEE . . . . . . . . . . . . . . . . . . . . . 26 V

Internal Power Dissipation

2

1

Quad Flat Package (S) . . . . . . . . . . . . . . . . . . . . . . . 1.7 W

Output Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Associated Text

Storage Temperature Range . . . . . . . . . . . . –65°C to +125°C

Operating Temperature Range . . . . . . . . . . . . . . 0°C to 85°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . . 300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Specification is for device in free air:

44-Lead MQFP Package: θJA = 73°C/W (Still Air), where PD = (TJ – TA)/θJA.

θJC = 22°C/W.

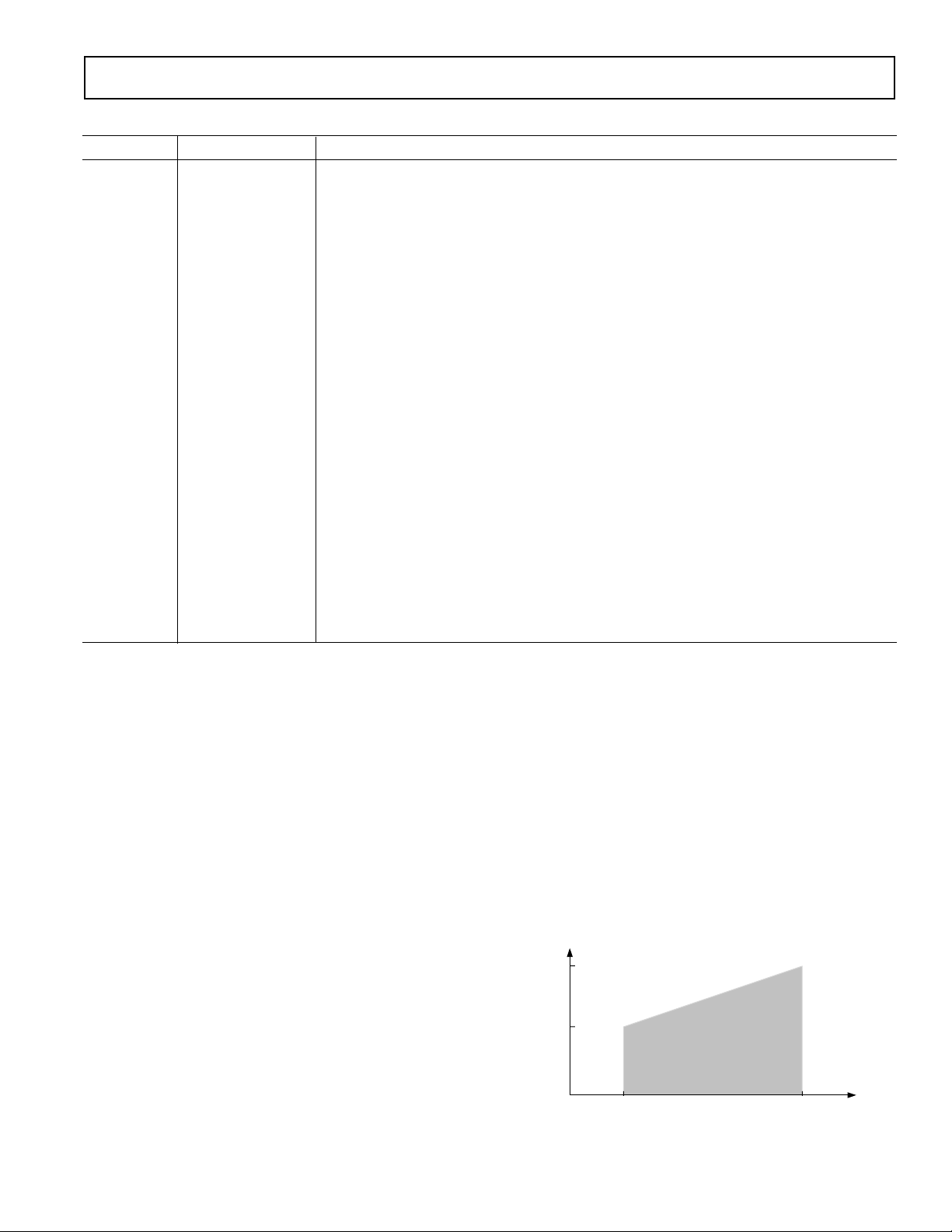

PIN CONFIGURATION

CLK

XFR

1

NC

2

DB0

3

DB1

4

DB2

5

DB3

6

DB4

7

DB5

8

DB6

9

DB7

10

DB8

(MSB) DB9

NC = NO CONNECT

11

STSQ/CSA0A1A2AVCCDAC

44 43 42 41 40 39 38 37 36 35 34

PIN 1

IDENTIFIER

AD8380

TOP VIEW

(Not to Scale)

12 13 14 15 16 17 18 19 20 21 22

INV

R/L

E/O

DVEE

DVCC

AVCC BIAS

AVEEDAC

BYP

STBY

VREFHI

VREFLO

AVEE0

VMID

AVEE5

AVEE BIAS

33

32

31

30

29

28

27

26

25

24

23

VID0

AVCC0,1

VID1

AVEE1,2

VID2

AVCC2,3

VID3

AVEE3,4

VID4

AVCC4,5

VID5

MAXIMUM POWER DISSIPATION

The maximum power that can be safely dissipated by the

AD8380 is limited by the associated rise in junction temperature.

The maximum safe junction temperature for plastic encapsulated

devices is determined by the glass transition temperature of the

plastic, approximately 150°C. Exceeding this limit temporarily

may cause a shift in parametric performance due to a change in

the stresses exerted on the die by the package. Exceeding a junction temperature of 175°C for an extended period can result in

device failure.

Output Short Circuit Limit

The AD8380’s internal short circuit limitation is not sufficient to

protect the device in the event of a direct short circuit between a

video output and a power supply voltage rail (V

or VEE). Tem-

CC

porary short circuits can reduce an output’s ability to source or

sink current and, therefore, impact the device’s ability to drive a

load. Short circuits of extended duration can cause metal lines to

fuse open, rendering the device nonfunctional.

To prevent these problems, it is recommended that a series

resistor of 25 Ω or greater be placed as close as possible to the

AD8380’s video outputs. This will serve to substantially reduce

the magnitude of the fault currents and protect the outputs from

damage caused by intermittent short circuits. This may not be

enough to guarantee that the maximum junction temperature

(150°C) is not exceeded under all conditions. To ensure proper

operation, it is necessary to observe the maximum power derating curve in Figure 2 below.

3.0

TJ, MAX = 150ⴗC

2.5

2.0

1.5

1.0

MAXIMUM POWER DISSIPATION – Watts

0.5

10 20 30 40 50 60 70

AMBIENT TEMPERATURE – ⴗC

800

90

Figure 2. Maximum Power Dissipation vs. Temperature

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD8380JS 0°C to 85°C 44-Lead MQFP S-44A

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD8380 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–4–

WARNING!

ESD SENSITIVE DEVICE

REV. B

Page 5

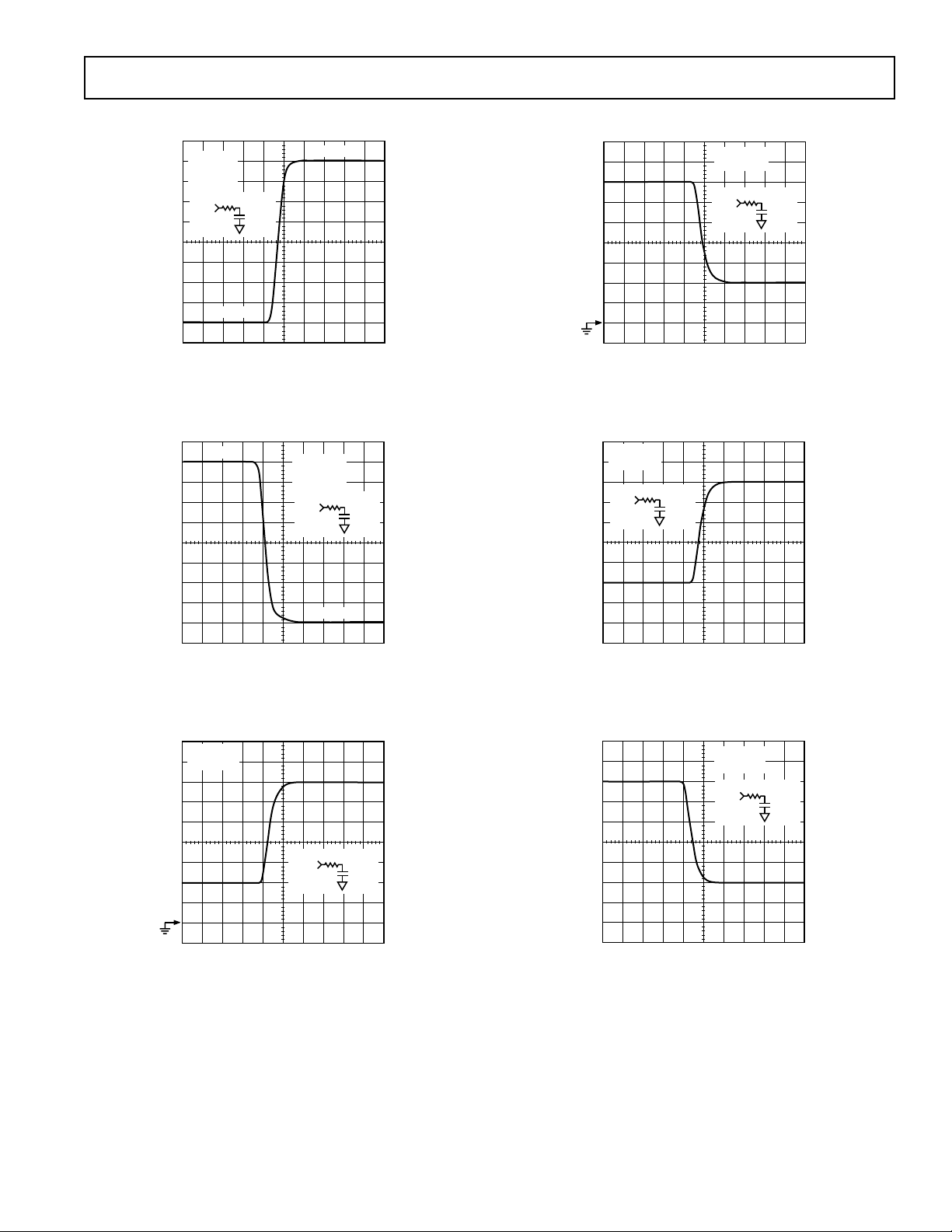

Typical Performance Characteristics–AD8380

20ns/DIV

VMID = 7V

VFS = 5V

VMID

1V/DIV

25⍀

C

L

150pF

VIDX

VMID – VFS

20ns/DIV

VMID = 7V

VFS = 5V

VMID

1V/DIV

25⍀

C

L

150pF

VIDX

VMID + VFS

20ns/DIV

VMID = 7V

VFS = 5V

VMID

1V/DIV

25⍀

C

L

150pF

VIDX

VMID + VFS

VMID + VFS

1.25V/DIV

VMID – VFS

CODE = 0

VMID = 7V

VFS = 5V

25⍀

VIDX

INV = L

C

L

150pF

20ns/DIV

INV = H

TPC 1. Invert Switching 10 V Step Response (Rise) at C

VMID + VFS

1.25V/DIV

INV = H

CODE = 0

VMID = 7V

VFS = 5V

25⍀

VIDX

C

L

150pF

TPC 4. Data Switching Full-Scale Step Response (Fall) at

L

CL, INV = L

VMID – VFS

20ns/DIV

INV = L

TPC 2. Invert Switching 10 V Step Response (Fall) at C

VMID = 7V

VFS = 5V

VMID

1V/DIV

VMID – VFS

20ns/DIV

VIDX

25⍀

C

L

150pF

TPC 3. Data Switching Full-Scale Step Response (Rise) at

CL, INV = L

TPC 5. Data Switching Full-Scale Step Response (Rise) at

L

, INV = H

C

L

TPC 6. Data Switching Full-Scale Step Response (Fall) at

CL, INV = H

REV. B

–5–

Page 6

AD8380

VMID = 7V

VFS = 5V

VFS

INV = H

t

= 0

VIDX

VMID

10ns/DIV

25⍀

VMID + VFS

C

L

150pF

VMID+

OUTPUT VOLTAGE ERROR – 1%/DIV

TPC 7. Output Settling Time Response to 1% of Full

Scale (Rising Edge) at C

VMID

OUTPUT VOLTAGE ERROR – 1%/DIV

t = 0

L

VIDX

VMID + VFS

10ns/DIV

VMID = 7V

VFS = 5V

INV = H

25⍀

C

L

150pF

VMID

TPC 8. Output Settling Time Response to 1% of Full

Scale (Falling Edge) at C

L

VMID = 7V

VFS = 5V

INV = H

25⍀

VIDX

VMID + VFS

C

L

150pF

VMID

VMID

t

OUTPUT VOLTAGE ERROR – 0.1%/DIV

= 0

10ns/DIV

TPC 10. Output Settling Time Response to 0.25% of Full

Scale (Falling Edge) at C

7.5

5.5

3.5

1.5

0

VDE – mV

–1.5

–3.5

–5.5

–7.5

06090

10 20 30 40 50 70 80

L

CODE 482

CODE 738

TEMPERATURE – ⴗC

TPC 11. Differential Error Voltage (VDE) vs. Temperature

VMID = 7V

VFS = 5V

VMID + VFS

OUTPUT VOLTAGE ERROR – 0.1%/DIV

INV = H

t = 0

VIDX

VMID

10ns/DIV

25⍀

VMID + VFS

C

L

150pF

TPC 9. Output Settling Time Response to 0.25% of Full

Scale (Rising Edge) at C

L

–6–

3.5

2.5

1.5

CODE 738

0.5

0

–0.5

VCME – mV

–1.5

–2.5

–3.5

06090

10 20 30 40 50 70 80

TEMPERATURE – ⴗC

CODE 482

TPC 12. Common-Mode Error Voltage (VCME) vs.

Temperature

REV. B

Page 7

AD8380

0.5

0.4

0.3

0.2

0.1

0

DNL – LSB

–0.1

–0.2

–0.3

–0.4

–0.5

0

CODE

896768640512384256128 1024

TPC 13. Differential Nonlinearity (DNL) vs. Code, INV = H

0.5

0.4

0.3

0.2

0.1

0

DNL – LSB

–0.1

–0.2

–0.3

–0.4

–0.5

0

CODE

896768640512384256128 1024

TPC 14. Differential Nonlinearity (DNL) vs. Code, INV = L

0.5

0.4

0.3

0.2

0.1

0

INL – LSB

–0.1

–0.2

–0.3

–0.4

–0.5

0

CODE

896768640512384256128 1024

TPC 16. Integral Nonlinearity (INL) vs. Code, INV = H

0.5

0.4

0.3

0.2

0.1

0

INL – LSB

–0.1

–0.2

–0.3

–0.4

–0.5

0

CODE

1024

896768640512384256128

TPC 17. Integral Nonlinearity (INL) vs. Code, INV = L

7.5

5.0

2.5

0

VDE – mV

–2.5

–5.0

–7.5

0

CODE

TPC 15. Differential Error Voltage (VDE) vs. Code

REV. B

3.5

2.5

0

VCME – mV

–2.5

1024

896768640512384256128

–3.5

0

CODE

1024

896768640512384256128

TPC 18. Common-Mode Error Voltage (VCME) vs. Code

–7–

Page 8

AD8380

VFS = 5V

VMID = 7V

INV = L

= 25⍀

R

1mV/DIV

2V/DIV

S

= 150pF

C

L

CLK

OUTPUT @ CODE 0

20ns/DIV

TPC 19. Clock Switching Transient (Feedthrough) at C

VFS = 5V

VMID = 7V

INV = L

= 25⍀

R

5mV/DIV

2V/DIV

S

= 150pF

C

L

OUTPUT

@ CODE 1023

DATA

VFS = 5V

VMID = 7V

INV = L

= 25⍀

R

2.5V/DIV

20mV/DIV

L

60

40

20

0

–20

PSRR – dB

–40

–60

S

= 150pF

C

L

(QUIET)

TPC 21. All-Hostile Crosstalk at C

VID0,1,2,3,4

VID5

10ns/DIV

L

VOUTP (INV = L)

VOUTN (INV = H)

20ns/DIV

TPC 20. Data Switching Transient (Feedthrough) at C

–80

10k 5M100k

L

TPC 22. AVCC Power Supply Rejection vs. Frequency

FREQUENCY – Hz

1M

–8–

REV. B

Page 9

AD8380

THEORY OF OPERATION

The AD8380 is a system building block designed to directly drive

the columns of poly-silicon LCD panels of the type popularized for use in data projectors. It comprises six channels of

precision 10-bit digital-to-analog converters loaded from a

single, high speed, 10-bit parallel input. Precision current

feedback amplifiers providing well-damped pulse responses

and rapid voltage settling into large capacitive loads buffer the

six outputs. Excellent linearity performance and laser trimming

of scale factors and output offsets at the wafer level ensure low

absolute output errors over all input codes. Tight channel-tochannel matching in high channel count systems is guaranteed

by reliance on an externally-applied voltage reference.

DB [0:9]

CLK

STSQ/CS

XFR

E/O

R/L

A[0:2]

STBY

BYP

VREFHI

VREFLO

10

CHANNEL

SELECTOR

3

BIAS

SCALING

CONTROL

AD8380

10

10

10

10

10

1010

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

2-STAGE

LATCH

INV VMID

DAC

10

DAC

10

DAC

10

DAC

10

DAC

10

DAC

VID0

VID1

VID2

VID3

VID4

VID5

Figure 3. Top Level Block Diagram

Transfer Function

The transfer function of the AD8380 is made up of two regions

of operation, in which the video output voltages are either above

or below an output reference voltage externally applied at the

VMID input.

(VMID + VFS)

INV = H

VOUTN

The region over which the output voltage varies with input code

is defined by the status of the INV input. When INV is low, the

video output voltages rise from (VMID – VFS), (where VFS =

the full-scale output voltage), to VMID as the input code increases

from 0 to 1023. When INV is high, the output voltages drop

from (VMID + VFS) to VMID with increasing code (see

Figure 4).

For each value of input code there are then two possible values

for the output voltage, depending on the status of INV. When

INV is low the output is defined as VOUTP(N) where N refers

to the input code, and the P refers to the positive slope of the

voltage variation with code. When INV is high, the output is

defined as VOUTN(N).

To best correlate transfer function errors to image artifacts, the

overall accuracy of the AD8380 is defined by comparing the output

voltages, VOUTP(N) and VOUTN(N), to each other and to

their ideal values. Two parameters are defined, one dependent

on the difference between the signal amplitudes at a particular

code, and one dependent on their average value. These are VDE

and VCME. Their defining expressions are:

×

VDE = [VOUTN(N) – VOUTP(N)]/2 – [(1 – N/1023)

VFS]

where

N = input code, and VFS = 2 × (VREFHI – VREFLO)

VCME = [[VOUTN(N) +VOUTP(N)]/2 – VMID] × (1/2)

where

VMID = midpoint reference voltage for the video outputs.

Setting the Full-Scale Output

The full-scale output voltage (VFS), which defines the maximum output voltage excursion for a full code input transition, is

defined as twice the voltage difference between the VREFHI and

VREFLO inputs.

Operating Modes, Control Logic and DAC Latches

Control logic included on the AD8380 chip facilitates channel

loading in ascending or descending order (for image mirroring),

data loading on rising or falling clock edges (for even/odd word

loading), and addressing and loading individual channels (for

system testing or debugging). The on-chip logic makes it easy to

build systems requiring more than six drive channels per color.

DAC latches are of a two-stage master-slave design that guarantees all channel outputs are updated simultaneously.

VMID

VOUTP

VIDEO OUTPUT VOLTAGE

(VMID – VFS)

0 1023

INPUT CODE

INV = L

Figure 4. Definition of Output Transfer Function

REV. B

–9–

Page 10

AD8380

SVGA System Operation

An SVGA system is characterized by the requirement of six

channels of panel drive for each displayed color. Such a system

would use a single AD8380 per color.

With E/O and all address bits A[0:2] set high, channel loading

commences on the first rising edge of CLK following a valid

assertion of the Start Sequence (STSQ) input. The second stage

latches, and therefore the video outputs, are updated on the

first falling edge of the clock following a valid Transfer (XFR)

signal. (See Figure 5 for signal timing details.)

DB[0:9]

CLK

STSQ/CS

XFR

5050

t1t

t

7

2.0V

0.8V

t

t

3

4

2

t

t

5

6

t

2.0V

0.8V

7

Figure 5. Sequenced SVGA Timing (A[0:2] = HIGH, E/O =

HIGH, See Table I

)

Table I. Sequenced SVGA Data Byte to Channel Assignment

Channel Number Data Byte Number

E/O = HIGH VID0 0

R/L = LOW VID1 1

VID2 2

VID3 3

VID4 4

VID5 5

Load Sequence Switching (Right/Left Control)

To facilitate image mirroring, the order in which channels are

loaded can be easily switched. When the voltage on the right/left

control input (R/L) is low, the internal sequencer will load data

starting with Channel 0 and counting up to Channel 5. When

this voltage is high, channel loading will be in reverse order, from

Channel 5 down to Channel 0.

XGA System Operation

In an XGA system, twelve column drivers (two AD8380s) are

required for each color (refer to Figure 6). An “even/odd”

system, in which one AD8380 drives even numbered columns

and another drives odd numbered columns, can be easily implemented as detailed in Figures 7 and 8. A clock at one-half the

pixel rate is applied to the CLK input. Even bytes are loaded on

the rising edge of the clock, while odd bytes are loaded on the

falling edge. Identifying whether a chip is to load on rising or falling

edges is done by setting the proper level on the E/O input.

PANEL

CONTROLLER

CLKIN

IMAGE

PROCESSOR

VIDEO

DB[0:9]

DCLK/2

10

1 COLOR OF ‘EVEN/ODD’ XGA

STSQ_A

STSQ_B

XFR

E/O_A

R/L

INV

E/O_B

STSQ/CS

XFR

E/O

R/L

INV

CLK

STSQ/CS

XFR

E/O

R/L

INV

CLK

AD8380

DEVICE “A”

DB[0:9]

AD8380

DEVICE “B”

DB[0:9]

A[0:2]

VIDEO

OUT

A[0:2]

VIDEO

OUT

DVCC

3

6

DVCC

3

6

Figure 6. Even/Odd: Outputs of Devices A and B are

Configured as Even and Odd Data Channels and Loading

O

Sequence Is Defined by Status of E /

DB[0:9]

(EVEN

STSQ

(EVEN

STSQ

CLK

CHIP)

/

CS

CHIP)

CLK

(ODD

CHIP)

/

CS

(ODD

CHIP)

XFR

A0:A2 = HIGH

10 011 9 10 11

0

t

t

4

3

t

t

4

3

and R/L Inputs

t

1

t

2

t

1

t

2

t

t

5

6

Figure 7. Sequenced Even/Odd XGA Timing, A[0:2] =

HIGH (See Table II)

Table II. Sequenced Even/Odd XGA Data Byte to

Channel Assignment

Data Byte Number

Channel Number R/L = LOW R/L = HIGH

E/O = HIGH VID0 0 10

VID1 2 8

VID2 4 6

VID3 6 4

VID4 8 2

VID5 10 0

E/O = LOW VID0 1 11

VID1 3 9

VID2 5 7

VID3 7 5

VID4 9 3

VID5 11 1

–10–

REV. B

Page 11

DCLK

AD8380

AD8380 INPUT DATA

CLK (AD8380)

/CS (EVEN)

STSQ

/CS (ODD)

STSQ

XFR

AD8380 #1

EVEN CHANNEL

(E/O = HIGH)

(R/L = LOW)

012 4 567893 1011121314 15161718192021222324

0

2

4

6

8

10

12 24

14

16

18

20

0

2

4

6

8

10

22

12

14

16

18

20

22

AD8380 #2

ODD CHANNEL

(E/O = LOW)

(R/L = LOW)

1

3

5

7

9

11

1

3

5

7

9

11

13

15

17

19

21

23

13

15

17

19

21

23

Figure 8. Operation of Even/Odd XGA System

REV. B

–11–

Page 12

AD8380

SXGA and Beyond

Very high resolution display systems can be built using the E/O

XGA system as a model. By using four AD8380s, twenty-four

columns can be driven together for an SXGA display. Two would

be designated for even columns and two for odd. Four separate

STSQ signals would be used to coordinate data loading with a

single XFR to synchronize updating of output voltages.

Using a single external voltage source to drive the VREF inputs

on all drivers for a particular color and a single voltage source

for all their VMID inputs, will guarantee matching for all channels.

The exceptional accuracy of the AD8380’s transfer function will

ensure that high channel count systems can be built without fear of

image artifacts resulting from channel-to-channel matching errors.

Direct Channel Loading

For debug or characterization purposes, it may be desirable to

load data directly into a single channel without requiring exercise

of the STSQ and XFR inputs. This can be done by applying

dc logic high levels to the STSQ and XFR inputs, and addressing

the desired channel through the A[0:2] inputs. Data will then

be loaded into the selected channel on each falling edge of the

CLK signal.

The maximum rate at which a channel can be updated will be

limited by the settling time of the output amplifiers.

Addressed Channel Loading

The direct channel loading method can be extended. Channels

may be loaded in an arbitrary sequence through the use of an

active XFR signal with STSQ set to a high level. Use the A[0:2]

inputs to define the desired channel sequence. Data will be loaded

on the falling edge of CLK into the channel whose address was

valid on the preceding rising edge of CLK. All channel outputs

are then updated together by qualification of a valid XFR signal.

See Figure 9 for timing details.

DB[0:9]

CLK

XFR

A[0:2]

IN THIS CASE, INPUT LATCHES ARE LOADED IN THE ORDER SELECTED

BY A[0:2], THEN DACs ARE UPDATED TOGETHER BY XFR.

50 1 5

t

t

1

2

t

5

t

6

t8t

9

0

Figure 9. Addressed Channel Timing (E/O = HIGH,

STSQ/CS = HIGH)

Standby Mode

A high level applied to the standby (STBY) input will turn off

most of the internal circuitry, dropping the quiescent power

dissipation to a few milliwatts. Since both digital and analog

circuits are debiased, all stored data will be lost. Upon returning

STBY to a low level, normal operation is restored.

APPLICATION

The AD8380 is a mixed-signal, high speed, very accurate device

with multiple channels. In order to realize its specifications, it is

essential to use a properly designed circuit board.

Layout and Grounding

The analog and digital sections of the AD8380 are pinned

out on approximately opposite sides of the package. When

laying out a circuit board, please keep these sections separate

from each other to minimize crosstalk and noise coupling of

the digital input signals into the analog outputs.

All signal trace lengths should be made as short and direct as

possible to prevent signal degradation due to parasitic effects.

Please note that digital signals should not cross or be routed

near analog signals.

It is imperative to provide a solid ground plane under and

around the part. All of the ground pins of the part should be

directly connected to the ground plane with no extra signal

path length. For conventional operation, this includes the

pins DVEE, AVEEDAC, AVEEBIAS, AVEE0, AVEE1,2;

AVEE3,4; and AVEE5. The return currents for any of the signals for the part should be routed close to the ground pin for

that section to prevent stray signals from appearing on other

ground pins.

Power Supply Bypassing

The AD8380 has several power supply and reference voltages

that must be properly bypassed to the ground plane for optimum performance. The bypass capacitor for each supply pin, as

well as VREFHI, VREFLO, and VMID, should be connected as

close as possible to the IC pins and directly to the ground plane.

A 0.1 µF capacitor, preferably a ceramic chip, should be used to

minimize lead length.

To provide low frequency, high current bypassing, larger value

tantalum capacitors should also be used. These should be connected from the supply to ground, but it is not necessary to place

these close to the IC pins. Stray inductance will not greatly affect

their performance. The high current outputs should be bypassed

with these capacitors. It is recommended that two 22 µF tantalum

capacitors be placed from the AVCC supply to ground at either

end of the output side of the IC. AVCCBIAS and AVCCDAC

should each have a 10 µF tantalum bypass capacitor to ground.

See Figure 10.

VREFHI Reference Distribution

In a system that uses more than one AD8380 per color, it is

important that all of the AD8380 devices operate from equal

reference voltages to ensure that the video outputs are well

matched. VREFLO is not a concern due to its high input resistance and very low bias current. Therefore, it is not likely that

there will be significant dc voltage drops in the circuit traces to that

supply. It is recommended to have good local supply bypassing

at each AD8380 from their respective VREFLOs to ground.

The higher input current that flows in the VREFHI circuit

requires that this be laid out more carefully. VREFHI connects

internally to a 20 kΩ resistor for each of the six channels to provide

an input resistance of about 3.3 kΩ. Thus with a (VREFHI –

VREFLO) voltage of 2.5 V (to yield a VFS of 5.0 V ), about

750 µA will flow into each VREFHI circuit.

–12–

REV. B

Page 13

AD8380

2.500V

3.3V

10V

15V

CLK

10

DB[0:9]

XFR

E/O

R/L

STSQ/CS

3

A[0:2]

INV

STBY

0.1F

DVCC

VREFHI VREFLO AVCCDAC AVCCBIAS AVCC0,1 AVCC2,3 AVCC4,5 VMID

DVEE AVEEDAC BYP AVEEBIAS AVEE0

AVEE1,2 AVEE3,4

AVEE5

LOGIC

DAC

BIAS DRIVERS

6

VID0 – VID5

7V

10F

0.1F 0.1F 0.1F 0.1F

0.1F

22F

10F0.1F

R

S

24.9⍀

(TYP FOR 6)

10F 22F10F

0.1F0.1F0.1F

In order to obtain the best matching, the traces to each of the

VREFHI pins of the AD8380s should be connected by an

approximately same length and same width circuit trace in a

“star” configuration. The source of the VREFHI voltage should

be at the center of the “star.” Therefore, the VREFHI currents

for two devices will not share a significant length of circuit trace,

and each trace will provide an approximately equal voltage drop.

In addition, if the VREFHI traces must be long, then the traces

should be widened to minimize differences in the voltage drops

due to differences in the VREFHI input currents of different

AD8380s. The dc resistance of these traces should be less than

100 mΩ. If the VREFHI input current is about 1 mA, then the

voltage drop will be about 100 µV.

For example, if a trace length is 5 in. long (13 cm.), then the

trace width for a 1 oz. copper foil should be wider than 0.025 in.

(0.7 mm) in order to keep the trace impedance below 100 mΩ.

Driving a Capacitive Load

A purely capacitive load can react with output impedance of the

AD8380 resulting in overshoot and ringing in its step response.

To minimize this effect, and optimize settling time, it is recommended that a 25 Ω resistor be placed in series with each of the

driver’s outputs as shown in Figure 10.

Figure 10. Interface Drawing

REV. B

–13–

Page 14

AD8380

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

44-Lead MQFP

(S-44A)

0.041 (1.03)

0.029 (0.73)

SEATING

PLANE

0.010 (0.25)

MAX

0.009 (0.23)

0.005 (0.13)

0.096 (2.45)

MAX

0.083 (2.10)

0.077 (1.95)

1

11

12

0.031 (0.80)

0.530 (13.45)

0.510 (12.95)

0.398 (10.10)

0.390 (9.90)

TOP VIEW

(PINS DOWN)

BSC

SQ

SQ

0.018 (0.45)

0.012 (0.30)

3444

33

0.315 (8.00)

REF

23

22

AD8380–Revision History

Location Page

Data sheet changed from REV. A to REV B.

Single-Channel Block Diagram section and graphic removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

–14–

REV. B

Page 15

–15–

Page 16

C01091–0–4/01(B)

–16–

PRINTED IN U.S.A.

Loading...

Loading...