450 MHz, Triple 16 × 5

S

FEATURES

Large, triple 16 × 5 high speed, nonblocking switch array

Pin compatible with the

arrays) and the

Differential or single-ended operation

Supports sync-on common-mode and sync-on color

operating modes

RGB and HV outputs available for driving monitor directly

G = +4 operation (differential input to differential output)

Flexible power supplies: +5 V or ±2.5 V

Logic ground for convenient control interface

Serial or parallel programming of switch array

High impedance output disable allows connection of

multiple devices with minimal loading on output bus

Adjustable output CM and black level through external pins

Excellent ac performance

Bandwidth: 450 MHz

Slew rate: 1650 V/μs

Settling time: 4 ns to 1% to support 1600 × 1200 @ 85Hz

Low power of 2.3 W

Low all hostile crosstalk

−82 dB @ 5 MHz

−47 dB @ 500 MHz

Wide input common-mode range of 4 V

Reset pin allows disabling of all outputs

Fully populated 26 × 26 ball PBGA package

(27 mm × 27 mm, 1 mm ball pitch)

Convenient grouping of RGB signals for easy routing

APPLICATIONS

RGB video switching

KVM

Professional video

GENERAL DESCRIPTION

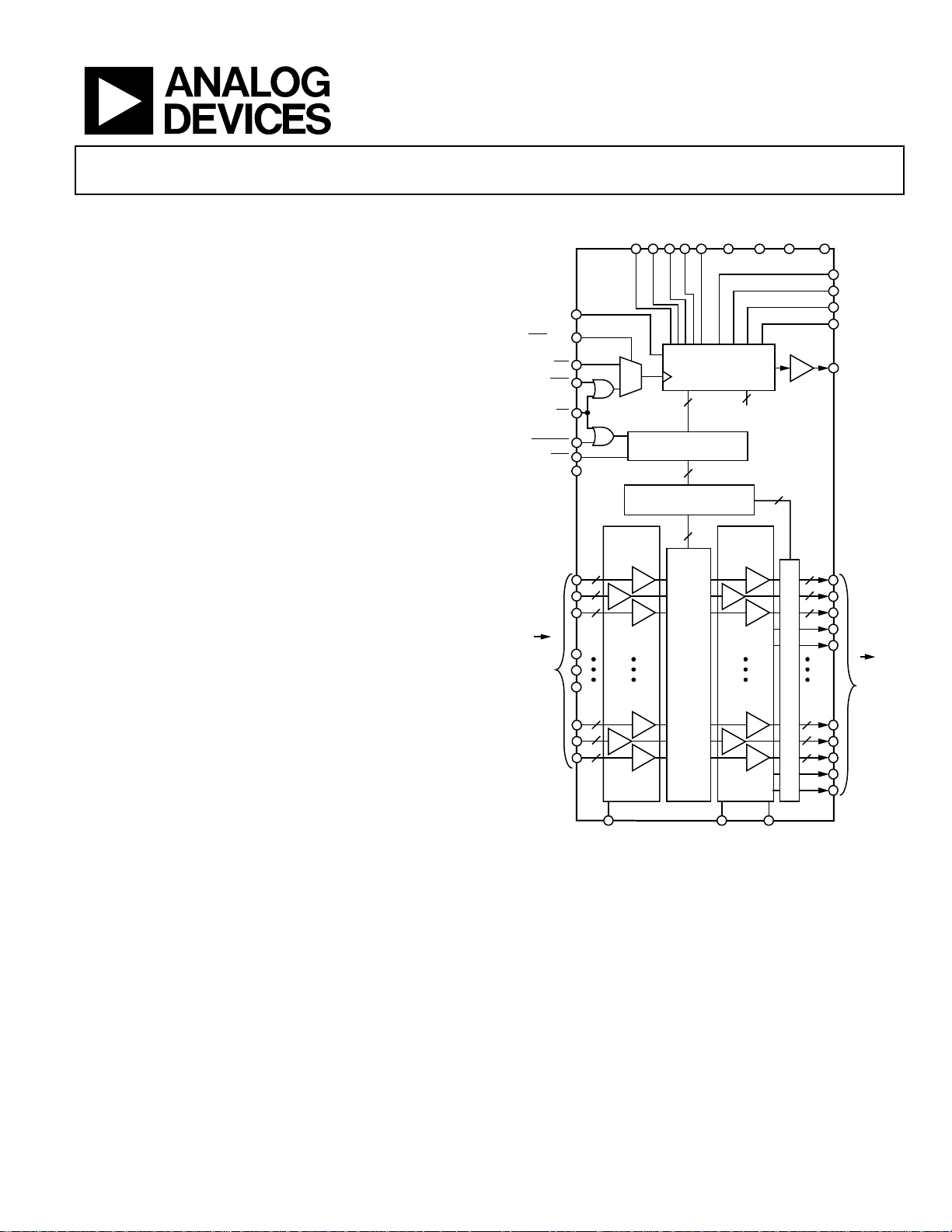

The AD8178 is a high speed, triple 16 × 5 video crosspoint switch

matrix. It supports 1600 × 1200 RGB displays @ 85 Hz refresh rate,

by offering a 450 MHz bandwidth and a slew rate of 1650 V/µs.

With −82 dB of crosstalk and −90 dB isolation (@ 5 MHz), the

AD8178 is useful in many high speed video applications.

The AD8178 supports two modes of operation: differential-in

to differential-out mode with sync-on CM signaling passed

through the switch and differential-in to differential-out mode

with CM signaling removed through the switch. The output CM

and black level can be conveniently set via external pins.

AD8175 and AD8176 (16 × 9 switch

AD8177 (16 × 5 switch array)

Video Crosspoint Switch

AD8178

FUNCTIONAL BLOCK DIAGRAM

D0 D1 D2 D3 D4VPOSVNEGVDD DGND

AD8178

SERIN

ER/PAR

WE

CLK

CS

UPDATE

RST

CMENC

R

G

B

16 x RGB

CHANNELS

R

G

B

1

0

INPUT

RECEIVER

G = +2

2

2

2

2

2

2

VBLK VOCM_CMENCON VOCM_CMENCOFF

45-BIT SHIFT

REGISTER WITH

5-BIT PARALLEL

LOADING

25

PARALLEL L ATCH

25

DECODE

5 × 5:16 DECODERS

80

SWITCH

MATRIX

G = +2

20

NO

CONNECT

OUTPUT

BUFFER

G = +1

5

ENABLE/DISABL E

Figure 1.

The outputs can be used single-ended in conjunction with

decoded H and V outputs to drive a monitor directly.

The independent output buffers of the AD8178 can be placed

into a high impedance state to create larger arrays by paralleling

crosspoint outputs. Inputs can be paralleled as well. The AD8178

offers both serial and a parallel programming modes.

The AD8178 is packaged in a fully-populated 26 × 26 ball

PBGA package and is available over the extended industrial

temperature range of −40°C to +85°C.

A0

A1

A2

CLR

SEROUT

SET INDIVIDUAL, OR

RESET ALL OUTPUTS T O OFF

2

2

2

2

2

2

R

G

B

H

V

CHANNELS

5 x RGB, HV

R

G

B

H

V

06608-001

0

Rev.

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

AD8178

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Timing Characteristics (Serial Mode) ....................................... 5

Timing Characteristics (Parallel Mode).................................... 6

Absolute Maximum Ratings............................................................ 7

Thermal Resistance ...................................................................... 7

Power Dissipation......................................................................... 7

ESD Caution.................................................................................. 7

REVISION HISTORY

7/07—Revision 0: Initial Version

Pin Configurations and Function Descriptions............................8

Truth Table and Logic Diagram ............................................... 17

Equivalent Circuits......................................................................... 19

Typical Performance Characteristics........................................... 21

Theory of Operation ...................................................................... 26

Applications Information.............................................................. 27

Operating Modes........................................................................ 27

Programming.............................................................................. 28

Differential and Single-Ended Operation............................... 29

Outline Dimensions....................................................................... 38

Ordering Guide .......................................................................... 38

Rev. 0 | Page 2 of 40

AD8178

SPECIFICATIONS

VS = ± 2.5 V at TA = 25°C, G = +4, RL = 100 Ω (each output), VBLK = 0 V, output CM voltage = 0 V, differential I/O mode, unless

otherwise noted.

Table 1.

Parameter Conditions Min Typ Max Unit

DYNAMIC PERFORMANCE

−3 dB Bandwidth 200 mV p-p 450 MHz

2 V p-p 420 MHz

Gain Flatness 0.1 dB, 200 mV p-p 17 MHz

Propagation Delay 2 V p-p 1.3 ns

Settling Time 1% , 2 V step 4 ns

Slew Rate, Differential Output 2 V step 1650 V/μs

2 V step, 10% to 90% 1450 V/μs

Slew Rate, RGB Common Mode 1 V step , 10% to 90% 300 V/μs

Slew Rate, HV Outputs Rail-to-rail, TTL load 400 V/μs

NOISE/DISTORTION PERFORMANCE

Crosstalk, All Hostile f = 5 MHz −82 dB

f = 10 MHz −74 dB

f = 100 MHz −56 dB

f = 500 MHz −47 dB

Off Isolation, Input-Output f = 10 MHz, RL = 100 Ω, one channel −90 dB

Input Voltage Noise 0.01 MHz to 50 MHz 50 nV/√Hz

DC PERFORMANCE

Gain Error 1 %

Gain Matching R, G, B same channel 0.5 %

Gain Temperature Coefficient 32 ppm/°C

OUTPUT CHARACTERISTICS

Output Offset Voltage CMENC on or off 20 mV

Temperature coefficient 58 μV/°C

Output Offset Voltage,

RGB Common Mode

Temperature coefficient −16 μV/°C

Output Impedance Enabled, differential 1.5 Ω

Disabled, differential 2.7 kΩ

Output Disable Capacitance Disabled 2 pF

Output Leakage Current Disabled 1 μA

Output Voltage Range No load, differential 4 V p-p

Output Current Short circuit 45 mA

INPUT CHARACTERISTICS

Input Voltage Range,

Differential Mode

Input Voltage Range,

Common Mode

CMR, RGB Input ΔV

ΔV

CM Gain, RGB Input ΔV

ΔV

Input Capacitance Any switch configuration 2 pF

Input Resistance Differential 3.33 kΩ

Input Offset Current 1 μA

CMENC on or off 10 mV

1 V p-p

V

= 1 V p-p ±2.25 V p-p

IN

/ΔV

, ΔV

OUT, DM

OUT, DM

OUT, CM

OUT, CM

/ΔV

/ΔV

/ΔV

IN, CM

IN, CM

IN, CM

IN, CM

= ±0.5 V, CMENC off –62 dB

IN, CM

, ΔV

= ±0.5 V, CMENC on −45 dB

IN, CM

, ΔV

= ±0.5 V CMENC off −70 dB

IN, CM

, ΔV

= ±0.5 V, CMENC on 0 dB

IN, CM

Rev. 0 | Page 3 of 40

AD8178

Parameter Conditions Min Typ Max Unit

SWITCHING CHARACTERISTICS

Enable On Time

Switching Time, 2 V Step

UPDATE to 50% output

50%

UPDATE to 50% output

50%

POWER SUPPLIES

Supply Current V

, outputs enabled, no load 460 mA

POS

Outputs disabled 290 mA

V

, outputs enabled, no load 460 mA

NEG

Outputs disabled 290 mA

D

, outputs enabled, no load 4 mA

VDD

Supply Voltage Range 4.5 to 5.5 V

PSR ΔV

ΔV

OUT, DM

OUT, DM

/ΔV

/ΔV

POS

NEG

, ΔV

= ±0.5 V −55 dB

POS

, ΔV

= ±0.5 V −55 dB

NEG

OPERATING TEMPERATURE RANGE

Temperature Range Operating (still air) −40 to +85 °C

θJA Operating (still air) 15 °C/W

80 ns

70 ns

Rev. 0 | Page 4 of 40

AD8178

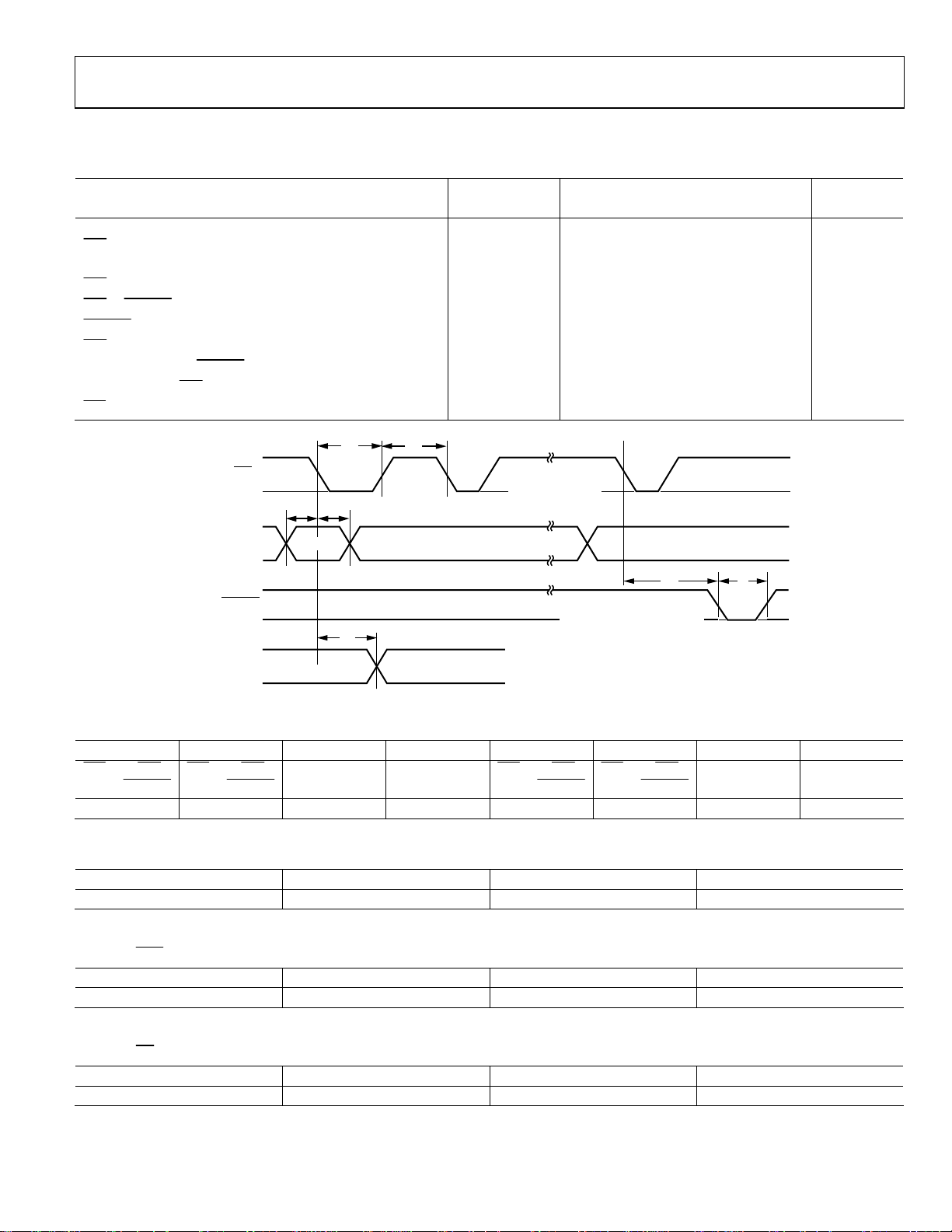

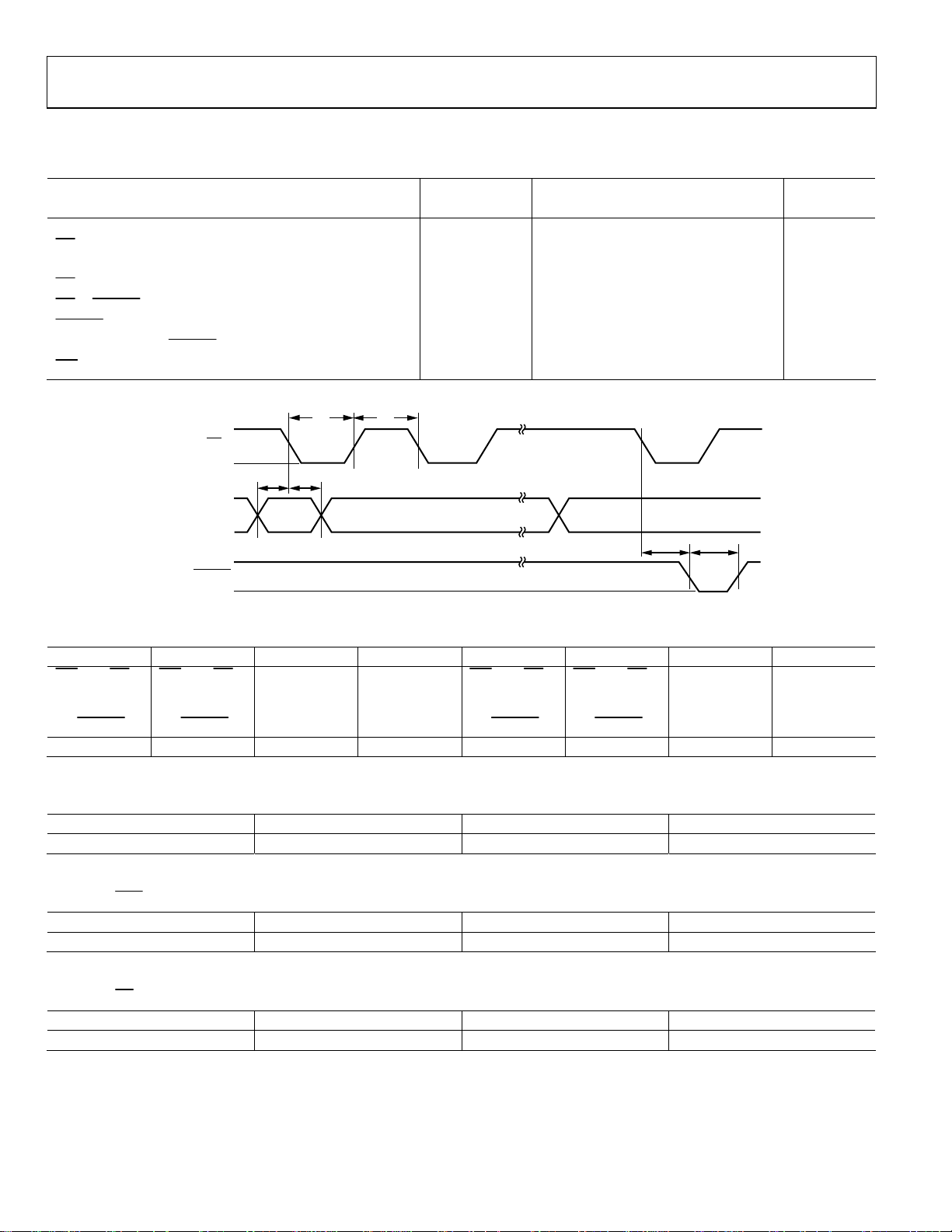

TIMING CHARACTERISTICS (SERIAL MODE)

Table 2.

Limit

Parameter Symbol Min Typ Max Unit

Serial Data Setup Time t1 40 ns

t

CLK Pulse Width

Serial Data Hold Time t3 50 ns

CLK Pulse Separation

CLK to UPDATE Delay

UPDATE Pulse Width

CLK to SEROUT Valid

Propagation Delay, UPDATE to Switch On

Data Load Time, CLK = 5 MHz, Serial Mode

RST Time

60 ns

2

t

140 ns

4

t

10 ns

5

t

90 ns

6

t

120 ns

7

80 ns

9 μs

140 200 ns

CLK

SERIN

1 = LATCHED

UPDATE

0 = TRANSPARENT

SEROUT

t

1

0

t1t

1

OUT4 (D4)

0

1

0

2

3

t

7

t

4

LOAD DATA INTO

SERIAL REGISTER

ON FALLING EDGE

OUT4 (D3) OUT0 (D0)

TRANSFER DATA FROM SERIAL

REGISTER TO PARALLEL

LATCHES DURING LOW LEVEL

t

5

t

6

06608-002

Figure 2. Timing Diagram, Serial Mode

Table 3. Logic Levels, VDD = 3.3 V

VIH VIL V

SER/PAR, CLK,

SERIN, UPDATE

SER/PAR, CLK,

SERIN, UPDATE

V

OH

I

OL

SEROUT SEROUT

I

IH

SER/PAR, CLK,

SERIN, UPDATE

I

IL

SER/PAR, CLK,

SERIN, UPDATE

I

OH

OL

SEROUT SEROUT

2.0 V min 0.6 V max 2.8 V min 0.4 V max 20 μA max –20 μA max –1 mA min 1 mA min

Table 4. H and V Logic Levels, V

VOH VOL I

= 3.3 V

DD

I

OH

OL

2.7 V min 0.5 V max –3 mA max 3 mA max

RST

Table 5.

VIH VIL I

Logic Levels, VDD = 3.3 V

I

IH

IL

2.0 V min 0.6 V max −60 μA max −120 μA max

CS

Table 6.

VOH VOL I

Logic Levels, VDD = 3.3 V

I

IH

OL

2.0 V min 0.6 V max 100 μA max 40 μA max

Rev. 0 | Page 5 of 40

AD8178

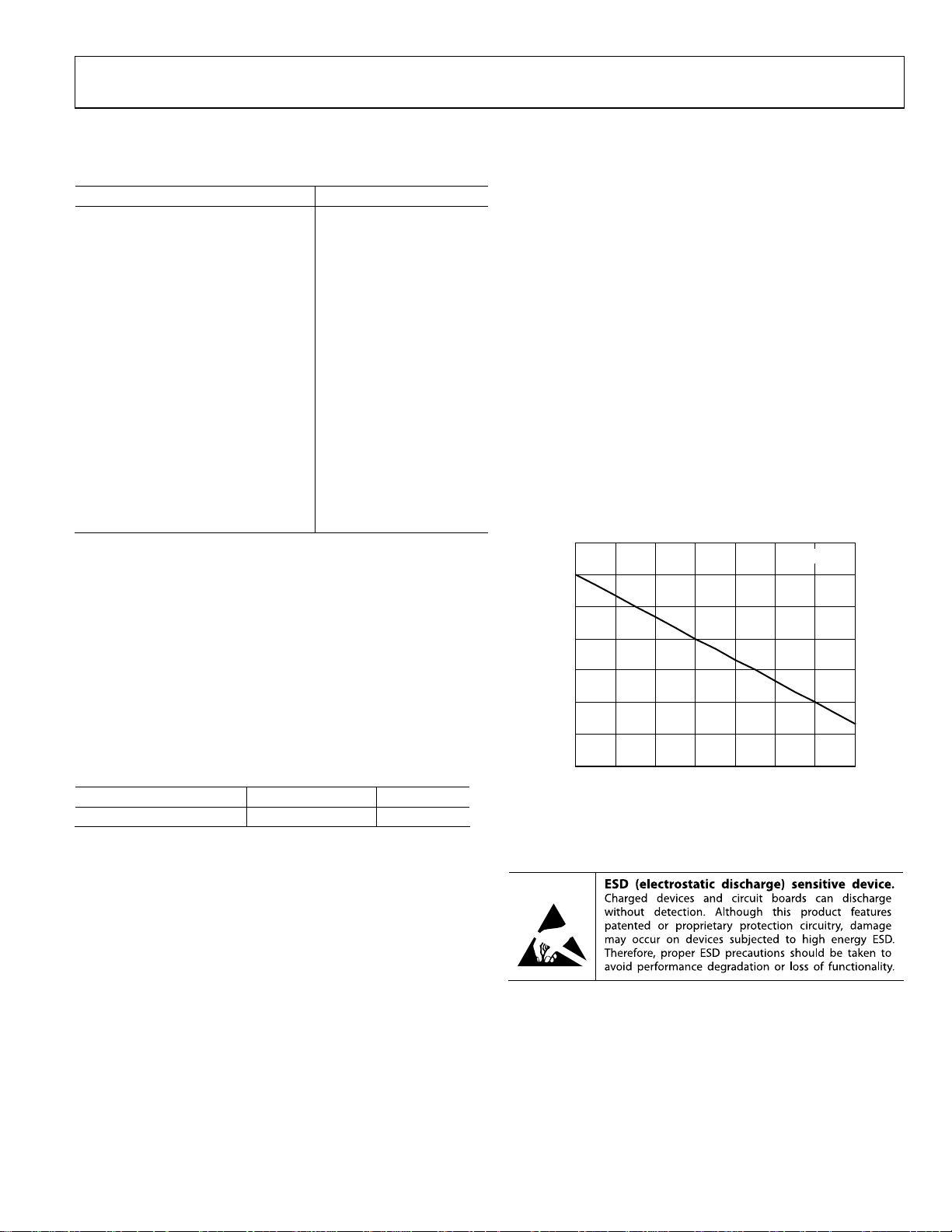

TIMING CHARACTERISTICS (PARALLEL MODE)

Table 7.

Limit

Parameter Symbol Min Typ Max Unit

Parallel Data Setup Time t1 80 ns

t

WE Pulse Width

Parallel Hold Time t3 150 ns

WE Pulse Separation

WE to UPDATE Delay

UPDATE Pulse Width

Propagation Delay, UPDATE to Switch On

RST Time

WE

D0 TO D4

A0 TO A2

1 = LATCHED

0 = TRANSPARENT

UPDATE

t

1

0

t1t

1

0

2

3

t

4

Figure 3. Timing Diagram, Parallel Mode

110 ns

2

t

90 ns

4

t

10 ns

5

t

90 ns

6

80 ns

140 200 ns

t

t

5

6

6608-003

Table 8. Logic Levels, VDD = 3.3 V

VIH VIL V

SER/PAR, WE,

D0, D1, D2, D3,

D4, A0, A1, A2,

A3,

UPDATE

SER/PAR, WE,

D0, D1, D2, D3,

D4, A0, A1, A2,

A3,

UPDATE

V

OH

I

OL

SEROUT SEROUT

I

IH

SER/PAR, WE,

D0, D1, D2, D3,

D4, A0, A1, A2,

A3,

UPDATE

I

IL

SER/PAR, WE,

D0, D1, D2, D3,

D4, A0, A1, A2,

A3,

UPDATE

I

OH

OL

SEROUT SEROUT

2.0 V min 0.6 V max Disabled Disabled 20 μA max −20 μA max Disabled Disabled

Table 9. H and V Logic Levels, V

VOH VOL I

= 3.3 V

DD

I

OH

OL

2.7 V min 0.5 V max –3 mA max 3 mA max

RST

Table 10.

VIH VIL I

Logic Levels, VDD = 3.3 V

I

IH

IL

2.0 V min 0.6 V max −60 μA max −120 μA max

Table 11.

VOH VOL I

CS

Logic Levels, VDD = 3.3 V

I

IH

OL

2.0 V min 0.6 V max 100 μA max 40 μA max

Rev. 0 | Page 6 of 40

AD8178

ABSOLUTE MAXIMUM RATINGS

Table 12.

Parameter Rating

Analog Supply Voltage (V

Digital Supply Voltage (VDD – D

Ground Potential Difference

(V

– D

GND

)

NEG

Maximum Potential Difference

– V

NEG

)

(V

DD

Common-Mode Analog Input Voltage

POS

– V

) 6 V

NEG

) 6 V

GND

+0.5 V to –2.5 V

8 V

– 0.5 V) to

(V

NEG

+ 0.5 V)

(V

POS

Differential Analog Input Voltage ±2 V

Digital Input Voltage VDD

Output Voltage

– 1 V) to (V

POS

NEG

+ 1 V)

(V

(Disabled Analog Output)

Output Short-Circuit Duration Momentary

Storage Temperature Range −65°C to +125°C

Operating Temperature Range −40°C to +85°C

Lead Temperature

300°C

(Soldering, 10 sec)

Junction Temperature 150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

POWER DISSIPATION

The AD8178 is operated with ±2.5 V or +5 V supplies and can

drive loads down to 100 , resulting in a large range of possible

power dissipations. For this reason, extra care must be taken

when derating the operating conditions based on ambient

temperature.

Packaged in a 676-lead BGA, the AD8178 junction-to-ambient

thermal impedance (θ

the maximum allowed junction temperature of the die should

not exceed 150°C. Temporarily exceeding this limit may cause

a shift in parametric performance due to a change in stresses

exerted on the die by the package. Exceeding a junction

temperature of 175°C for an extended period can result in

device failure. The curve in

internal die power dissipations that meet these conditions over

the −40°C to +85°C ambient temperature range. When using

Tabl e 1 3 , do not include external load power in the maximum

power calculation, but do include load current dropped on the

die output transistors.

10

9

8

7

6

) is 15°C/W. For long-term reliability,

JA

Figure 4 shows the range of allowed

TJ = 150°C

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 13. Thermal Resistance

Package Type θJA Unit

PBGA 15 °C/W

ESD CAUTION

5

MAXIMUM DIE POWER (W)

4

3

15 25 35 45 55 65 75 85

AMBIENT TEM PERATURE (°C)

Figure 4. Maximum Die Power Dissipation vs. Ambient Temperature

6608-004

Rev. 0 | Page 7 of 40

AD8178

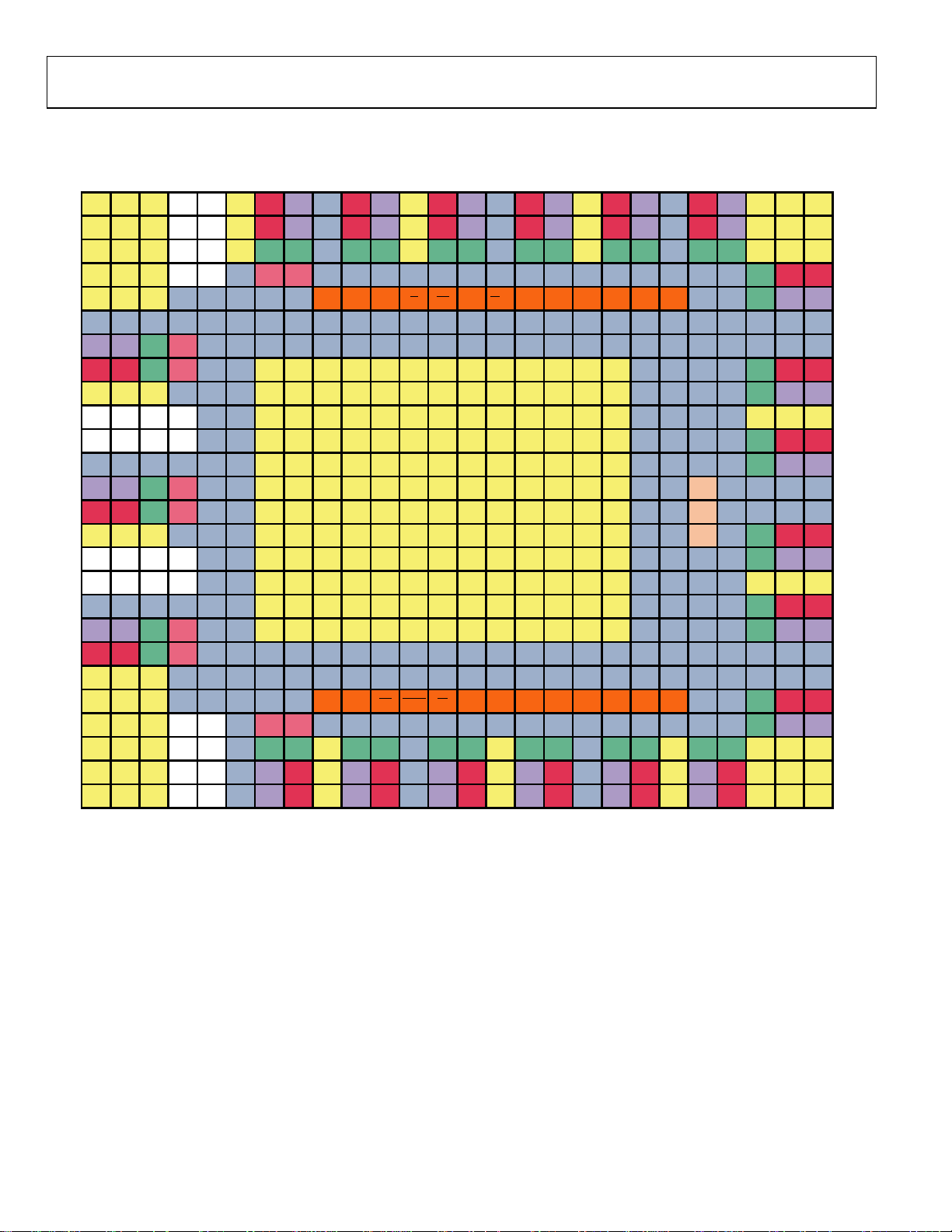

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

2625242322212019181716151413121110987654321

VNEG VNEG VNEG NC NC VNEG OPR4 ONB4 VPOS IPR8 INB8 VNEG IPR9 INB9 VPOS IPR10 INB10 VNEG IPR11 INB11 VPOS IPR12 INB12 VNEG VNEG VNEG

A

VNEG VNEG VNEG NC NC VNEG ONR4 OPB4 VPOS INR8 IPB8 VNEG INR9 IPB9 VPOS INR10 IPB10 VNEG INR11 IPB11 VPOS INR12 IPB12 VNEG VNEG VNEG

B

VNEG VNEG VNEG NC NC VNEG OPG4 ONG4 VPOS IPG8 ING8 VNEG IPG9 ING9 VPOS IPG10 ING10 VNEG IPG11 ING11 VPOS IPG12 ING12 VNEG VNEG VNEG

C

VNEG VNEG VNEG NC NC VPOS H4 V4 VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS IPG13 INR13 IPR13

D

VNEG VNEG VNEG VPOS VPOS VPOS VPOS VPOS DGND VDD

E

VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS

F

ONB3 OPB3 ONG3 V3 VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS

G

OPR3 ONR3 OPG3 H3 VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS IPG14 INR14 IPR14

H

VNEG VNEG VNEG VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS ING14 IPB14 INB14

J

NC NC NC NC VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS VNEG VNEG VNEG

K

NC NC NC NC VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS IPG15 INR15 IPR15

L

VPOS VPOS VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS ING15 IPB15 INB15

M

ONB2 OPB2 ONG2 V2 VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS VPOS VPOS

N

OPR2 ONR2 OPG2 H2 VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VBLK VPOS VPOS VPOS VPOS

P

VNEG VNEG VNEG VPOS VPOS VPOS VNEG VNEG VN EG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS IPG7 INR7 IPR7

R

NC NC NC NC VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS ING7 IPB7 INB7

T

NC NC NC NC VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS VNEG VNEG VNEG

U

VPOS VPOS VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG V NEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS IPG6 INR6 IPR6

V

ONB1 OPB1 ONG1 V1 VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS ING6 IPB6 INB6

W

OPR1 ONR1 OPG1 H1 VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS

Y

VNEG VNEG VNEG VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS

AA

VNEG VNEG VNEG VPOS VPOS VPOS VPOS VPOS DGND VDD RST UPDATE WE CMENC D4 D3 D2 D1 D0 VDD DGND VPOS VPOS IPG5 INR5 IPR5

AB

VNEG VNEG VNEG NC NC VPOS V0 H0 VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS ING5 IPB5 INB5

AC

VNEG VNEG VNEG NC NC VPOS ONG0 OPG0 VNEG ING0 IPG0 VPOS ING1 IPG1 VNEG ING2 IPG2 VPOS ING3 IPG3 VNEG ING4 IPG4 VNEG VNEG VNEG

AD

VNEG VNEG VNEG NC NC VPOS OPB0 ONR0 VNEG IPB0 INR0 VPOS IPB1 INR1 VNEG IPB2 INR2 VPOS IPB3 INR3 VNEG IPB4 INR4 VNEG VNEG VNEG

AE

VNEG VNEG VNEG NC NC VPOS ONB0 OPR0 VNEG INB0 IPR0 VPOS INB1 IPR1 VNEG INB2 IPR2 VPOS INB3 IPR3 VNEG INB4 IPR4 VNEG VNEG VNEG

AF

SEROUT

CS CLK SERIN

2625242322212019181716151413121110987654321

Figure 5. Pin Configuration, Package Bottom View

SER/PAR

A2 A1 A0 CLR VDD DGND VPOS VPOS ING13 IPB13 INB13

VOCM_

CMENCON

VOCM_

CMENCOFF

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

AD

AE

AF

06608-055

Rev. 0 | Page 8 of 40

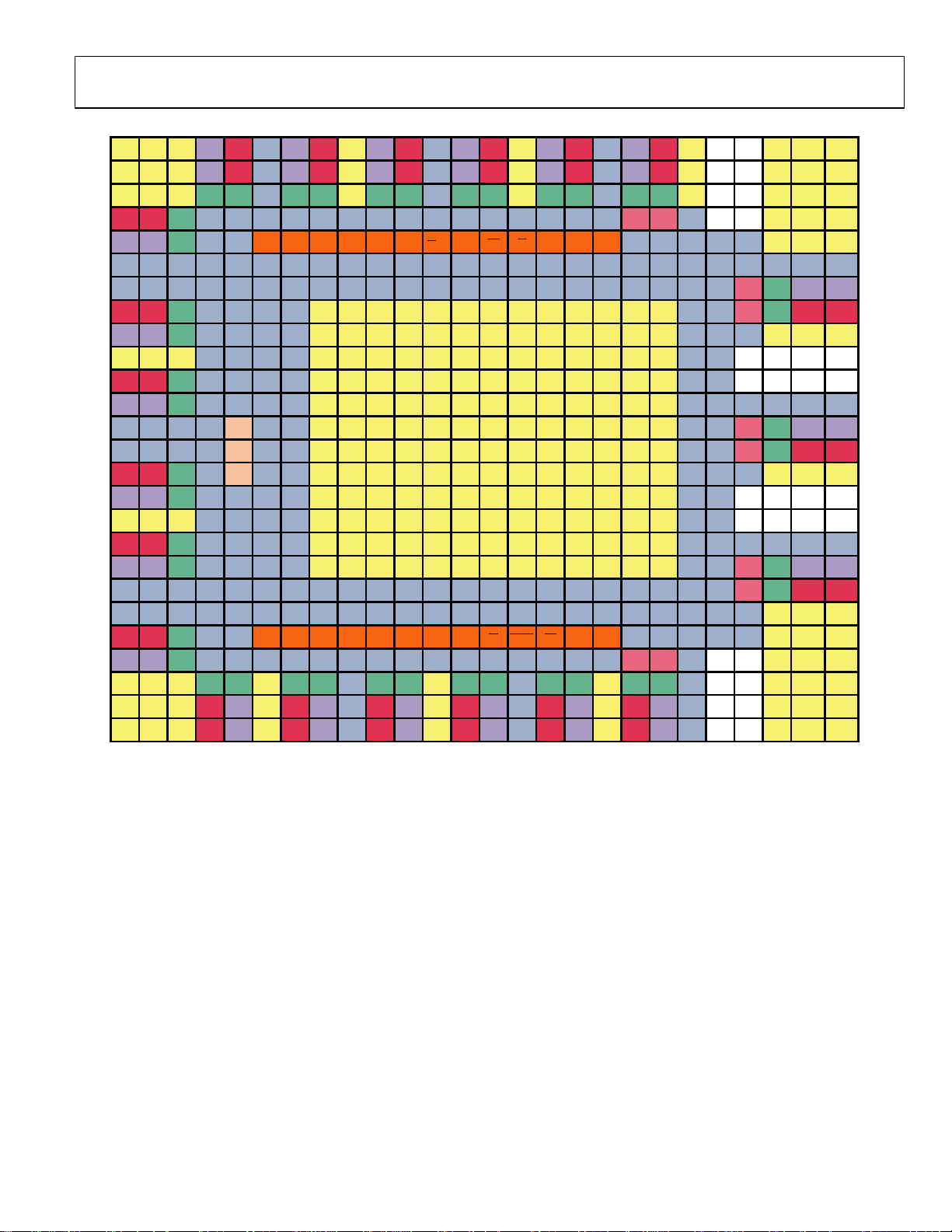

AD8178

1 2 3 4 5 6 7 8 9 101112131415161718192021222324 25 26

A

VNEG VNEG VNEG INB12 IPR12 VPOS INB11 IPR11 VNEG INB10 IPR10 VPOS INB9 IPR9 VNEG INB8 IPR8

B

VNEG VNEG VNEG IPB12 INR12 VPOS IPB11 INR11 VNEG IPB10 INR10 VPOS IPB9 INR9 VNEG IPB8 INR8 VPOS OPB4 ONR4 VNEG NC NC VNEG VNEG VNEG

C

VNEG VNEG VNEG ING12 IPG12 VPOS ING11 IPG11 VNEG ING10 IPG10 VPOS ING9 IPG9 VNEG ING8 IPG8 VPOS ONG4 OPG4 VNEG NC NC VNEG VNEG VNEG

D

IPR13 INR13 IPG13 VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS V4 H4 VPOS NC NC VNEG VNEG VNEG

CS

E

INB13 IPB13 ING13 VPOS VPOS DGND VDD CLR A0 A1 A2

F

VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS

G

VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS V3 ONG3 OPB3 ONB3

H

IPR14 INR14 IPG14 VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS H3 OPG3

J

INB14 IPB14 ING14 VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VNEG VNEG VNEG

K

VNEG VNEG VNEG VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS NC NC NC NC

L

IPR15 INR15 IPG15 VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS NC NC NC NC

M

INB15 IPB15 ING15 VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS VPOS VPOS

N

VPOS VPOS VPOS VPOS

P

VPOS VPOS VPOS VPOS VBLK VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS H2 OPG2 ONR2 OPR2

R

IPR7 INR7 IPG7 VPOS

T

INB7 IPB7 ING7 VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS NC NC NC NC

U

VNEG VNEG VNEG VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS NC NC NC NC

V

IPR6 INR6 IPG6 VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VPOS VPOS VPOS

W

INB6 IPB6 ING6 VPOS VPOS VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS V1 ONG1 OPB1 ONB1

Y

VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS H1 OPG1 ONR1 OPR1

AA

VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VNEG VNEG VNEG

AB

IPR5 INR5 IPG5 VPOS VPOS DGND VDD D0 D1 D2 D3 D4 CMENC VDD DGND VPOS VPOS VPOS VPOS VPOS VNEG VNEG VNEG

AC

INB5 IPB5 ING5 VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS VPOS H0 V0 VPOS NC NC VNEG VNEG VNEG

AD

VNEG V NEG V NEG IPG4 IN G4 V NEG IP G3 IN G3 V POS IP G2 IN G2 VNE G IPG1 IN G1 VP OS IPG0 IN G0 V NEG OP G0 ON G0 VP OS NC NC VN EG VNEG VNEG

AE

VNEG VNEG VNEG INR4 IPB4 VNEG INR3 IPB3 VPOS INR2 IPB2 VNEG INR1 IPB1 VPOS INR0 IPB0 VNEG ONR0 OPB0 VPOS NC NC VNEG VNEG VNEG

AF

VNEG VNEG VNEG IPR4 INB4 VNEG IPR3 INB3 VPOS IPR2 INB2 VNEG IPR1 INB1 VPOS IPR0 INB0 VNEG OPR0 ONB0 VPOS NC NC VNEG VNEG VNEG

VOCM_

VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS V2 ONG2 OPB2 ONB2

CMENCON

VOCM_

VPOS VPOS VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VNEG VPOS VPOS VPOS VNEG VNEG VNEG

CMENCOFF

SER/PAR

SERIN

CLK

UPDATE

SEROUT

RSTWE

1 2 3 4 5 6 7 8 9 101112131415161718192021222324 25 26

Figure 6. Pin Configuration, Package Top View

VPOS ONB4 OPR4 VNEG NC NC VNEG VNEG VNEG

VDD DGND VPOS VPOS VPOS VPOS VPOS VNEG VNEG VNEG

ONR3 OPR3

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

AD

AE

AF

6608-056

Rev. 0 | Page 9 of 40

AD8178

Table 14. Ball Grid Description

Ball No. Mnemonic Description

A1 VNEG Negative Analog Power Supply.

A2 VNEG Negative Analog Power Supply.

A3 VNEG Negative Analog Power Supply.

A4 INB12 Input Number 12, Negative Phase.

A5 IPR12 Input Number 12, Positive Phase.

A6 VPOS Positive Analog Power Supply.

A7 INB11 Input Number 11, Negative Phase.

A8 IPR11 Input Number 11, Positive Phase.

A9 VNEG Negative Analog Power Supply.

A10 INB10 Input Number 10, Negative Phase.

A11 IPR10 Input Number 10, Positive Phase.

A12 VPOS Positive Analog Power Supply.

A13 INB9 Input Number 9, Negative Phase.

A14 IPR9 Input Number 9, Positive Phase.

A15 VNEG Negative Analog Power Supply.

A16 INB8 Input Number 8, Negative Phase.

A17 IPR8 Input Number 8, Positive Phase.

A18 VPOS Positive Analog Power Supply.

A19 ONB4 Output Number 4, Negative Phase.

A20 OPR4 Output Number 4, Positive Phase.

A21 VNEG Negative Analog Power Supply.

A22 NC No Connect.

A23 NC No Connect.

A24 VNEG Negative Analog Power Supply.

A25 VNEG Negative Analog Power Supply.

A26 VNEG Negative Analog Power Supply.

B1 VNEG Negative Analog Power Supply.

B2 VNEG Negative Analog Power Supply.

B3 VNEG Negative Analog Power Supply.

B4 IPB12 Input Number 12, Positive Phase.

B5 INR12 Input Number 12, Negative Phase.

B6 VPOS Positive Analog Power Supply.

B7 IPB11 Input Number 11, Positive Phase.

B8 INR11 Input Number 11, Negative Phase.

B9 VNEG Negative Analog Power Supply.

B10 IPB10 Input Number 10, Positive Phase.

B11 INR10 Input Number 10, Negative Phase.

B12 VPOS Positive Analog Power Supply.

B13 IPB9 Input Number 9, Positive Phase.

B14 INR9 Input Number 9, Negative Phase.

B15 VNEG Negative Analog Power Supply.

B16 IPB8 Input Number 8, Positive Phase.

B17 INR8 Input Number 8, Negative Phase.

B18 VPOS Positive Analog Power Supply.

B19 OPB4 Output Number 4, Positive Phase.

B20 ONR4 Output Number 4, Negative Phase.

B21 VNEG Negative Analog Power Supply.

B22 NC No Connect.

B23 NC No Connect.

B24 VNEG Negative Analog Power Supply.

B25 VNEG Negative Analog Power Supply.

Ball No. Mnemonic Description

B26 VNEG Negative Analog Power Supply.

C1 VNEG Negative Analog Power Supply.

C2 VNEG Negative Analog Power Supply.

C3 VNEG Negative Analog Power Supply.

C4 ING12 Input Number 12, Negative Phase.

C5 IPG12 Input Number 12, Positive Phase.

C6 VPOS Positive Analog Power Supply.

C7 ING11 Input Number 11, Negative Phase.

C8 IPG11 Input Number 11, Positive Phase.

C9 VNEG Negative Analog Power Supply.

C10 ING10 Input Number 10, Negative Phase.

C11 IPG10 Input Number 10, Positive Phase.

C12 VPOS Positive Analog Power Supply.

C13 ING9 Input Number 9, Negative Phase.

C14 IPG9 Input Number 9, Positive Phase.

C15 VNEG Negative Analog Power Supply.

C16 ING8 Input Number 8, Negative Phase.

C17 IPG8 Input Number 8, Positive Phase.

C18 VPOS Positive Analog Power Supply.

C19 ONG4 Output Number 4, Negative Phase.

C20 OPG4 Output Number 4, Positive Phase.

C21 VNEG Negative Analog Power Supply.

C22 NC No Connect.

C23 NC No Connect.

C24 VNEG Negative Analog Power Supply.

C25 VNEG Negative Analog Power Supply.

C26 VNEG Negative Analog Power Supply.

D1 IPR13 Input Number 13, Positive Phase.

D2 INR13 Input Number 13, Negative Phase.

D3 IPG13 Input Number 13, Positive Phase.

D4 VPOS Positive Analog Power Supply.

D5 VPOS Positive Analog Power Supply.

D6 VPOS Positive Analog Power Supply.

D7 VPOS Positive Analog Power Supply.

D8 VPOS Positive Analog Power Supply.

D9 VPOS Positive Analog Power Supply.

D10 VPOS Positive Analog Power Supply.

D11 VPOS Positive Analog Power Supply.

D12 VPOS Positive Analog Power Supply.

D13 VPOS Positive Analog Power Supply.

D14 VPOS Positive Analog Power Supply.

D15 VPOS Positive Analog Power Supply.

D16 VPOS Positive Analog Power Supply.

D17 VPOS Positive Analog Power Supply.

D18 VPOS Positive Analog Power Supply.

D19 V4 Output Number 4, V Sync.

D20 H4 Output Number 4, H Sync.

D21 VPOS Positive Analog Power Supply.

D22 NC No Connect.

D23 NC No Connect.

D24 VNEG Negative Analog Power Supply.

Rev. 0 | Page 10 of 40

AD8178

Ball No. Mnemonic Description

D25 VNEG Negative Analog Power Supply.

D26 VNEG Negative Analog Power Supply.

E1 INB13 Input Number 13, Negative Phase.

E2 IPB13 Input Number 13, Positive Phase.

E3 ING13 Input Number 13, Negative Phase.

E4 VPOS Positive Analog Power Supply.

E5 VPOS Positive Analog Power Supply.

E6 DGND Digital Power Supply.

E7 VDD Digital Power Supply.

E8 CLR Internal Register Clearing

E9 A0 Control Pin 0, Output Address Bit 0.

E10 A1 Control Pin 1, Output Address Bit 1.

E11 A2 Control Pin 2, Output Address Bit 2.

E12

E13 SERIN Control Pin: Serial Data In.

E14

E15

E16 SEROUT Control Pin: Serial Data Out.

E17 VDD Digital Power Supply.

E18 DGND Digital Power Supply.

E19 VPOS Positive Analog Power Supply.

E20 VPOS Positive Analog Power Supply.

E21 VPOS Positive Analog Power Supply.

E22 VPOS Positive Analog Power Supply.

E23 VPOS Positive Analog Power Supply.

E24 VNEG Negative Analog Power Supply.

E25 VNEG Negative Analog Power Supply.

E26 VNEG Negative Analog Power Supply.

F1 VPOS Positive Analog Power Supply.

F2 VPOS Positive Analog Power Supply.

F3 VPOS Positive Analog Power Supply.

F4 VPOS Positive Analog Power Supply.

F5 VPOS Positive Analog Power Supply.

F6 VPOS Positive Analog Power Supply.

F7 VPOS Positive Analog Power Supply.

F8 VPOS Positive Analog Power Supply.

F9 VPOS Positive Analog Power Supply.

F10 VPOS Positive Analog Power Supply.

F11 VPOS Positive Analog Power Supply.

F12 VPOS Positive Analog Power Supply.

F13 VPOS Positive Analog Power Supply.

F14 VPOS Positive Analog Power Supply.

F15 VPOS Positive Analog Power Supply.

F16 VPOS Positive Analog Power Supply.

F17 VPOS Positive Analog Power Supply.

F18 VPOS Positive Analog Power Supply.

F19 VPOS Positive Analog Power Supply.

F20 VPOS Positive Analog Power Supply.

F21 VPOS Positive Analog Power Supply.

F22 VPOS Positive Analog Power Supply.

F23 VPOS Positive Analog Power Supply.

F24 VPOS Positive Analog Power Supply.

SER/PAR

CLK

CS

Control Pin: Serial Parallel Select Mode.

Control Pin: Serial Data Clock.

Control Pin: Chip Select.

Ball No. Mnemonic Description

F25 VPOS Positive Analog Power Supply.

F26 VPOS Positive Analog Power Supply.

G1 VPOS Positive Analog Power Supply.

G2 VPOS Positive Analog Power Supply.

G3 VPOS Positive Analog Power Supply.

G4 VPOS Positive Analog Power Supply.

G5 VPOS Positive Analog Power Supply.

G6 VPOS Positive Analog Power Supply.

G7 VPOS Positive Analog Power Supply.

G8 VPOS Positive Analog Power Supply.

G9 VPOS Positive Analog Power Supply.

G10 VPOS Positive Analog Power Supply.

G11 VPOS Positive Analog Power Supply.

G12 VPOS Positive Analog Power Supply.

G13 VPOS Positive Analog Power Supply.

G14 VPOS Positive Analog Power Supply.

G15 VPOS Positive Analog Power Supply.

G16 VPOS Positive Analog Power Supply.

G17 VPOS Positive Analog Power Supply.

G18 VPOS Positive Analog Power Supply.

G19 VPOS Positive Analog Power Supply.

G20 VPOS Positive Analog Power Supply.

G21 VPOS Positive Analog Power Supply.

G22 VPOS Positive Analog Power Supply.

G23 V3 Output Number 3, V Sync.

G24 ONG3 Output Number 3, Negative Phase.

G25 OPB3 Output Number 3, Positive Phase.

G26 ONB3 Output Number 3, Negative Phase.

H1 IPR14 Input Number 14, Positive Phase.

H2 INR14 Input Number 14, Negative Phase.

H3 IPG14 Input Number 14, Positive Phase.

H4 VPOS Positive Analog Power Supply.

H5 VPOS Positive Analog Power Supply.

H6 VPOS Positive Analog Power Supply.

H7 VPOS Positive Analog Power Supply.

H8 VNEG Negative Analog Power Supply.

H9 VNEG Negative Analog Power Supply.

H10 VNEG Negative Analog Power Supply.

H11 VNEG Negative Analog Power Supply.

H12 VNEG Negative Analog Power Supply.

H13 VNEG Negative Analog Power Supply.

H14 VNEG Negative Analog Power Supply.

H15 VNEG Negative Analog Power Supply.

H16 VNEG Negative Analog Power Supply.

H17 VNEG Negative Analog Power Supply.

H18 VNEG Negative Analog Power Supply.

H19 VNEG Negative Analog Power Supply.

H20 VNEG Negative Analog Power Supply.

H21 VPOS Positive Analog Power Supply.

H22 VPOS Positive Analog Power Supply.

H23 H3 Output Number 3, H Sync.

H24 OPG3 Output Number 3, Positive Phase.

Rev. 0 | Page 11 of 40

AD8178

Ball No. Mnemonic Description

H25 ONR3 Output Number 3, Negative Phase.

H26 OPR3 Output Number 3, Positive Phase.

J1 INB14 Input Number 14, Negative Phase.

J2 IPB14 Input Number 14, Positive Phase.

J3 ING14 Input Number 14, Negative Phase.

J4 VPOS Positive Analog Power Supply.

J5 VPOS Positive Analog Power Supply.

J6 VPOS Positive Analog Power Supply.

J7 VPOS Positive Analog Power Supply.

J8 VNEG Negative Analog Power Supply.

J9 VNEG Negative Analog Power Supply.

J10 VNEG Negative Analog Power Supply.

J11 VNEG Negative Analog Power Supply.

J12 VNEG Negative Analog Power Supply.

J13 VNEG Negative Analog Power Supply.

J14 VNEG Negative Analog Power Supply.

J15 VNEG Negative Analog Power Supply.

J16 VNEG Negative Analog Power Supply.

J17 VNEG Negative Analog Power Supply.

J18 VNEG Negative Analog Power Supply.

J19 VNEG Negative Analog Power Supply.

J20 VNEG Negative Analog Power Supply.

J21 VPOS Positive Analog Power Supply.

J22 VPOS Positive Analog Power Supply.

J23 VPOS Positive Analog Power Supply.

J24 VNEG Negative Analog Power Supply.

J25 VNEG Negative Analog Power Supply.

J26 VNEG Negative Analog Power Supply.

K1 VNEG Negative Analog Power Supply.

K2 VNEG Negative Analog Power Supply.

K3 VNEG Negative Analog Power Supply.

K4 VPOS Positive Analog Power Supply.

K5 VPOS Positive Analog Power Supply.

K6 VPOS Positive Analog Power Supply.

K7 VPOS Positive Analog Power Supply.

K8 VNEG Negative Analog Power Supply.

K9 VNEG Negative Analog Power Supply.

K10 VNEG Negative Analog Power Supply.

K11 VNEG Negative Analog Power Supply.

K12 VNEG Negative Analog Power Supply.

K13 VNEG Negative Analog Power Supply.

K14 VNEG Negative Analog Power Supply.

K15 VNEG Negative Analog Power Supply.

K16 VNEG Negative Analog Power Supply.

K17 VNEG Negative Analog Power Supply.

K18 VNEG Negative Analog Power Supply.

K19 VNEG Negative Analog Power Supply.

K20 VNEG Negative Analog Power Supply.

K21 VPOS Positive Analog Power Supply.

K22 VPOS Positive Analog Power Supply.

K23 NC No Connect.

K24 NC No Connect.

Ball No. Mnemonic Description

K25 NC No Connect.

K26 NC No Connect.

L1 IPR15 Input Number 15, Positive Phase.

L2 INR15 Input Number 15, Negative Phase.

L3 IPG15 Input Number 15, Positive Phase.

L4 VPOS Positive Analog Power Supply.

L5 VPOS Positive Analog Power Supply.

L6 VPOS Positive Analog Power Supply.

L7 VPOS Positive Analog Power Supply.

L8 VNEG Negative Analog Power Supply.

L9 VNEG Negative Analog Power Supply.

L10 VNEG Negative Analog Power Supply.

L11 VNEG Negative Analog Power Supply.

L12 VNEG Negative Analog Power Supply.

L13 VNEG Negative Analog Power Supply.

L14 VNEG Negative Analog Power Supply.

L15 VNEG Negative Analog Power Supply.

L16 VNEG Negative Analog Power Supply.

L17 VNEG Negative Analog Power Supply.

L18 VNEG Negative Analog Power Supply.

L19 VNEG Negative Analog Power Supply.

L20 VNEG Negative Analog Power Supply.

L21 VPOS Positive Analog Power Supply.

L22 VPOS Positive Analog Power Supply.

L23 NC No Connect.

L24 NC No Connect.

L25 NC No Connect.

L26 NC No Connect.

M1 INB15 Input Number 15, Negative Phase.

M2 IPB15 Input Number 15, Positive Phase.

M3 ING15 Input Number 15, Negative Phase.

M4 VPOS Positive Analog Power Supply.

M5 VPOS Positive Analog Power Supply.

M6 VPOS Positive Analog Power Supply.

M7 VPOS Positive Analog Power Supply.

M8 VNEG Negative Analog Power Supply.

M9 VNEG Negative Analog Power Supply.

M10 VNEG Negative Analog Power Supply.

M11 VNEG Negative Analog Power Supply.

M12 VNEG Negative Analog Power Supply.

M13 VNEG Negative Analog Power Supply.

M14 VNEG Negative Analog Power Supply.

M15 VNEG Negative Analog Power Supply.

M16 VNEG Negative Analog Power Supply.

M17 VNEG Negative Analog Power Supply.

M18 VNEG Negative Analog Power Supply.

M19 VNEG Negative Analog Power Supply.

M20 VNEG Negative Analog Power Supply.

M21 VPOS Positive Analog Power Supply.

M22 VPOS Positive Analog Power Supply.

M23 VPOS Positive Analog Power Supply.

M24 VPOS Positive Analog Power Supply.

Rev. 0 | Page 12 of 40

AD8178

Ball No. Mnemonic Description

M25 VPOS Positive Analog Power Supply.

M26 VPOS Positive Analog Power Supply.

N1 VPOS Positive Analog Power Supply.

N2 VPOS Positive Analog Power Supply.

N3 VPOS Positive Analog Power Supply.

N4 VPOS Positive Analog Power Supply.

N5

N6 VPOS Positive Analog Power Supply.

N7 VPOS Positive Analog Power Supply.

N8 VNEG Negative Analog Power Supply.

N9 VNEG Negative Analog Power Supply.

N10 VNEG Negative Analog Power Supply.

N11 VNEG Negative Analog Power Supply.

N12 VNEG Negative Analog Power Supply.

N13 VNEG Negative Analog Power Supply.

N14 VNEG Negative Analog Power Supply.

N15 VNEG Negative Analog Power Supply.

N16 VNEG Negative Analog Power Supply.

N17 VNEG Negative Analog Power Supply.

N18 VNEG Negative Analog Power Supply.

N19 VNEG Negative Analog Power Supply.

N20 VNEG Negative Analog Power Supply.

N21 VPOS Positive Analog Power Supply.

N22 VPOS Positive Analog Power Supply.

N23 V2 Output Number 2, V Sync.

N24 ONG2 Output Number 2, Negative Phase.

N25 OPB2 Output Number 2, Positive Phase.

N26 ONB2 Output Number 2, Negative Phase.

P1 VPOS Positive Analog Power Supply.

P2 VPOS Positive Analog Power Supply.

P3 VPOS Positive Analog Power Supply.

P4 VPOS Positive Analog Power Supply.

P5 VBLK Output Blank Level.

P6 VPOS Positive Analog Power Supply.

P7 VPOS Positive Analog Power Supply.

P8 VNEG Negative Analog Power Supply.

P9 VNEG Negative Analog Power Supply.

P10 VNEG Negative Analog Power Supply.

P11 VNEG Negative Analog Power Supply.

P12 VNEG Negative Analog Power Supply.

P13 VNEG Negative Analog Power Supply.

P14 VNEG Negative Analog Power Supply.

P15 VNEG Negative Analog Power Supply.

P16 VNEG Negative Analog Power Supply.

P17 VNEG Negative Analog Power Supply.

P18 VNEG Negative Analog Power Supply.

P19 VNEG Negative Analog Power Supply.

P20 VNEG Negative Analog Power Supply.

P21 VPOS Positive Analog Power Supply.

P22 VPOS Positive Analog Power Supply.

P23 H2 Output Number 2, H Sync.

P24 OPG2 Output Number 2, Positive Phase.

VOCM_

CMENCON

Output CM Reference with CM

Encoding On.

Ball No. Mnemonic Description

P25 ONR2 Output Number 2, Negative Phase.

P26 OPR2 Output Number 2, Positive Phase.

R1 IPR7 Input Number 7, Positive Phase.

R2 INR7 Input Number 7, Negative Phase.

R3 IPG7 Input Number 7, Positive Phase.

R4 VPOS Positive Analog Power Supply.

R5

R6 VPOS Positive Analog Power Supply.

R7 VPOS Positive Analog Power Supply.

R8 VNEG Negative Analog Power Supply.

R9 VNEG Negative Analog Power Supply.

R10 VNEG Negative Analog Power Supply.

R11 VNEG Negative Analog Power Supply.

R12 VNEG Negative Analog Power Supply.

R13 VNEG Negative Analog Power Supply.

R14 VNEG Negative Analog Power Supply.

R15 VNEG Negative Analog Power Supply.

R16 VNEG Negative Analog Power Supply.

R17 VNEG Negative Analog Power Supply.

R18 VNEG Negative Analog Power Supply.

R19 VNEG Negative Analog Power Supply.

R20 VNEG Negative Analog Power Supply.

R21 VPOS Positive Analog Power Supply.

R22 VPOS Positive Analog Power Supply.

R23 VPOS Positive Analog Power Supply.

R24 VNEG Negative Analog Power Supply.

R25 VNEG Negative Analog Power Supply.

R26 VNEG Negative Analog Power Supply.

T1 INB7 Input Number 7, Negative Phase.

T2 IPB7 Input Number 7, Positive Phase.

T3 ING7 Input Number 7, Negative Phase.

T4 VPOS Positive Analog Power Supply.

T5 VPOS Positive Analog Power Supply.

T6 VPOS Positive Analog Power Supply.

T7 VPOS Positive Analog Power Supply.

T8 VNEG Negative Analog Power Supply.

T9 VNEG Negative Analog Power Supply.

T10 VNEG Negative Analog Power Supply.

T11 VNEG Negative Analog Power Supply.

T12 VNEG Negative Analog Power Supply.

T13 VNEG Negative Analog Power Supply.

T14 VNEG Negative Analog Power Supply.

T15 VNEG Negative Analog Power Supply.

T16 VNEG Negative Analog Power Supply.

T17 VNEG Negative Analog Power Supply.

T18 VNEG Negative Analog Power Supply.

T19 VNEG Negative Analog Power Supply.

T20 VNEG Negative Analog Power Supply.

T21 VPOS Positive Analog Power Supply.

T22 VPOS Positive Analog Power Supply.

T23 NC No Connect.

T24 NC No Connect.

VOCM_

CMENCOFF

Output Reference with CM

Encoding Off.

Rev. 0 | Page 13 of 40

AD8178

Ball No. Mnemonic Description

T25 NC No Connect.

T26 NC No Connect.

U1 VNEG Negative Analog Power Supply.

U2 VNEG Negative Analog Power Supply.

U3 VNEG Negative Analog Power Supply.

U4 VPOS Positive Analog Power Supply.

U5 VPOS Positive Analog Power Supply.

U6 VPOS Positive Analog Power Supply.

U7 VPOS Positive Analog Power Supply.

U8 VNEG Negative Analog Power Supply.

U9 VNEG Negative Analog Power Supply.

U10 VNEG Negative Analog Power Supply.

U11 VNEG Negative Analog Power Supply.

U12 VNEG Negative Analog Power Supply.

U13 VNEG Negative Analog Power Supply.

U14 VNEG Negative Analog Power Supply.

U15 VNEG Negative Analog Power Supply.

U16 VNEG Negative Analog Power Supply.

U17 VNEG Negative Analog Power Supply.

U18 VNEG Negative Analog Power Supply.

U19 VNEG Negative Analog Power Supply.

U20 VNEG Negative Analog Power Supply.

U21 VPOS Positive Analog Power Supply.

U22 VPOS Positive Analog Power Supply.

U23 NC No Connect.

U24 NC No Connect.

U25 NC No Connect.

U26 NC No Connect.

V1 IPR6 Input Number 6, Positive Phase.

V2 INR6 Input Number 6, Negative Phase.

V3 IPG6 Input Number 6, Positive Phase.

V4 VPOS Positive Analog Power Supply.

V5 VPOS Positive Analog Power Supply.

V6 VPOS Positive Analog Power Supply.

V7 VPOS Positive Analog Power Supply.

V8 VNEG Negative Analog Power Supply.

V9 VNEG Negative Analog Power Supply.

V10 VNEG Negative Analog Power Supply.

V11 VNEG Negative Analog Power Supply.

V12 VNEG Negative Analog Power Supply.

V13 VNEG Negative Analog Power Supply.

V14 VNEG Negative Analog Power Supply.

V15 VNEG Negative Analog Power Supply.

V16 VNEG Negative Analog Power Supply.

V17 VNEG Negative Analog Power Supply.

V18 VNEG Negative Analog Power Supply.

V19 VNEG Negative Analog Power Supply.

V20 VNEG Negative Analog Power Supply.

V21 VPOS Positive Analog Power Supply.

V22 VPOS Positive Analog Power Supply.

V23 VPOS Positive Analog Power Supply.

V24 VPOS Positive Analog Power Supply.

Ball No. Mnemonic Description

V25 VPOS Positive Analog Power Supply.

V26 VPOS Positive Analog Power Supply.

W1 INB6 Input Number 6, Negative Phase.

W2 IPB6 Input Number 6, Positive Phase.

W3 ING6 Input Number 6, Negative Phase.

W4 VPOS Positive Analog Power Supply.

W5 VPOS Positive Analog Power Supply.

W6 VPOS Positive Analog Power Supply.

W7 VPOS Positive Analog Power Supply.

W8 VNEG Negative Analog Power Supply.

W9 VNEG Negative Analog Power Supply.

W10 VNEG Negative Analog Power Supply.

W11 VNEG Negative Analog Power Supply.

W12 VNEG Negative Analog Power Supply.

W13 VNEG Negative Analog Power Supply.

W14 VNEG Negative Analog Power Supply.

W15 VNEG Negative Analog Power Supply.

W16 VNEG Negative Analog Power Supply.

W17 VNEG Negative Analog Power Supply.

W18 VNEG Negative Analog Power Supply.

W19 VNEG Negative Analog Power Supply.

W20 VNEG Negative Analog Power Supply.

W21 VPOS Positive Analog Power Supply.

W22 VPOS Positive Analog Power Supply.

W23 V1 Output Number 1, V Sync.

W24 ONG1 Output Number 1, Negative Phase.

W25 OPB1 Output Number 1, Positive Phase.

W26 ONB1 Output Number 1, Negative Phase.

Y1 VPOS Positive Analog Power Supply.

Y2 VPOS Positive Analog Power Supply.

Y3 VPOS Positive Analog Power Supply.

Y4 VPOS Positive Analog Power Supply.

Y5 VPOS Positive Analog Power Supply.

Y6 VPOS Positive Analog Power Supply.

Y7 VPOS Positive Analog Power Supply.

Y8 VPOS Positive Analog Power Supply.

Y9 VPOS Positive Analog Power Supply.

Y10 VPOS Positive Analog Power Supply.

Y11 VPOS Positive Analog Power Supply.

Y12 VPOS Positive Analog Power Supply.

Y13 VPOS Positive Analog Power Supply.

Y14 VPOS Positive Analog Power Supply.

Y15 VPOS Positive Analog Power Supply.

Y16 VPOS Positive Analog Power Supply.

Y17 VPOS Positive Analog Power Supply.

Y18 VPOS Positive Analog Power Supply.

Y19 VPOS Positive Analog Power Supply.

Y20 VPOS Positive Analog Power Supply.

Y21 VPOS Positive Analog Power Supply.

Y22 VPOS Positive Analog Power Supply.

Y23 H1 Output Number 1, H Sync.

Y24 OPG1 Output Number 1, Positive Phase.

Rev. 0 | Page 14 of 40

AD8178

Ball No. Mnemonic Description

Y25 ONR1 Output Number 1, Negative Phase.

Y26 OPR1 Output Number 1, Positive Phase.

AA1 VPOS Positive Analog Power Supply.

AA2 VPOS Positive Analog Power Supply.

AA3 VPOS Positive Analog Power Supply.

AA4 VPOS Positive Analog Power Supply.

AA5 VPOS Positive Analog Power Supply.

AA6 VPOS Positive Analog Power Supply.

AA7 VPOS Positive Analog Power Supply.

AA8 VPOS Positive Analog Power Supply.

AA9 VPOS Positive Analog Power Supply.

AA10 VPOS Positive Analog Power Supply.

AA11 VPOS Positive Analog Power Supply.

AA12 VPOS Positive Analog Power Supply.

AA13 VPOS Positive Analog Power Supply.

AA14 VPOS Positive Analog Power Supply.

AA15 VPOS Positive Analog Power Supply.

AA16 VPOS Positive Analog Power Supply.

AA17 VPOS Positive Analog Power Supply.

AA18 VPOS Positive Analog Power Supply.

AA19 VPOS Positive Analog Power Supply.

AA20 VPOS Positive Analog Power Supply.

AA21 VPOS Positive Analog Power Supply.

AA22 VPOS Positive Analog Power Supply.

AA23 VPOS Positive Analog Power Supply.

AA24 VNEG Negative Analog Power Supply.

AA25 VNEG Negative Analog Power Supply.

AA26 VNEG Negative Analog Power Supply.

AB1 IPR5 Input Number 5, Positive Phase.

AB2 INR5 Input Number 5, Negative Phase.

AB3 IPG5 Input Number 5, Positive Phase.

AB4 VPOS Positive Analog Power Supply.

AB5 VPOS Positive Analog Power Supply.

AB6 DGND Digital Power Supply.

AB7 VDD Digital Power Supply.

AB8 D0 Control Pin, Input Address Bit 0.

AB9 D1 Control Pin, Input Address Bit 1.

AB10 D2 Control Pin, Input Address Bit 2.

AB11 D3 Control Pin, Input Address Bit 3.

AB12 D4 Control Pin, Input Address Bit 4.

AB13 CMENC Control Pin, Pass/Stop CM Encoding.

AB14

AB15

AB16

AB17 VDD Digital Power Supply.

AB18 DGND Digital Power Supply.

AB19 VPOS Positive Analog Power Supply.

AB20 VPOS Positive Analog Power Supply.

AB21 VPOS Positive Analog Power Supply.

AB22 VPOS Positive Analog Power Supply.

AB23 VPOS Positive Analog Power Supply.

AB24 VNEG Negative Analog Power Supply.

WE

UPDATE

RST

Control Pin, 1st Rank Write Strobe.

Control Pin, 2nd Rank Write Strobe.

Control Pin, 2nd Rank Data Reset.

Ball No. Mnemonic Description

AB25 VNEG Negative Analog Power Supply.

AB26 VNEG Negative Analog Power Supply.

AC1 INB5 Input Number 5, Negative Phase.

AC2 IPB5 Input Number 5, Positive Phase.

AC3 ING5 Input Number 5, Negative Phase.

AC4 VPOS Positive Analog Power Supply.

AC5 VPOS Positive Analog Power Supply.

AC6 VPOS Positive Analog Power Supply.

AC7 VPOS Positive Analog Power Supply.

AC8 VPOS Positive Analog Power Supply.

AC9 VPOS Positive Analog Power Supply.

AC10 VPOS Positive Analog Power Supply.

AC11 VPOS Positive Analog Power Supply.

AC12 VPOS Positive Analog Power Supply.

AC13 VPOS Positive Analog Power Supply.

AC14 VPOS Positive Analog Power Supply.

AC15 VPOS Positive Analog Power Supply.

AC16 VPOS Positive Analog Power Supply.

AC17 VPOS Positive Analog Power Supply.

AC18 VPOS Positive Analog Power Supply.

AC19 H0 Output Number 0, H Sync.

AC20 V0 Output Number 0, V Sync.

AC21 VPOS Positive Analog Power Supply.

AC22 NC No Connect.

AC23 NC No Connect.

AC24 VNEG Negative Analog Power Supply.

AC25 VNEG Negative Analog Power Supply.

AC26 VNEG Negative Analog Power Supply.

AD1 VNEG Negative Analog Power Supply.

AD2 VNEG Negative Analog Power Supply.

AD3 VNEG Negative Analog Power Supply.

AD4 IPG4 Input Number 4, Positive Phase.

AD5 ING4 Input Number 4, Negative Phase.

AD6 VNEG Negative Analog Power Supply.

AD7 IPG3 Input Number 3, Positive Phase.

AD8 ING3 Input Number 3, Negative Phase.

AD9 VPOS Positive Analog Power Supply.

AD10 IPG2 Input Number 2, Positive Phase.

AD11 ING2 Input Number 2, Negative Phase.

AD12 VNEG Negative Analog Power Supply.

AD13 IPG1 Input Number 1, Positive Phase.

AD14 ING1 Input Number 1, Negative Phase.

AD15 VPOS Positive Analog Power Supply.

AD16 IPG0 Input Number 0, Positive Phase.

AD17 ING0 Input Number 0, Negative Phase.

AD18 VNEG Negative Analog Power Supply.

AD19 OPG0 Output Number 0, Positive Phase.

AD20 ONG0 Output Number 0, Negative Phase.

AD21 VPOS Positive Analog Power Supply.

AD22 NC No Connect.

AD23 NC No Connect.

AD24 VNEG Negative Analog Power Supply.

Rev. 0 | Page 15 of 40

AD8178

Ball No. Mnemonic Description

AD25 VNEG Negative Analog Power Supply.

AD26 VNEG Negative Analog Power Supply.

AE1 VNEG Negative Analog Power Supply.

AE2 VNEG Negative Analog Power Supply.

AE3 VNEG Negative Analog Power Supply.

AE4 INR4 Input Number 4, Negative Phase.

AE5 IPB4 Input Number 4, Positive Phase.

AE6 VNEG Negative Analog Power Supply.

AE7 INR3 Input Number 3, Negative Phase.

AE8 IPB3 Input Number 3, Positive Phase.

AE9 VPOS Positive Analog Power Supply.

AE10 INR2 Input Number 2, Negative Phase.

AE11 IPB2 Input Number 2, Positive Phase.

AE12 VNEG Negative Analog Power Supply.

AE13 INR1 Input Number 1, Negative Phase.

AE14 IPB1 Input Number 1, Positive Phase.

AE15 VPOS Positive Analog Power Supply.

AE16 INR0 Input Number 0, Negative Phase.

AE17 IPB0 Input Number 0, Positive Phase.

AE18 VNEG Negative Analog Power Supply.

AE19 ONR0 Output Number 0, Negative Phase.

AE20 OPB0 Output Number 0, Positive Phase.

AE21 VPOS Positive Analog Power Supply.

AE22 NC No Connect.

AE23 NC No Connect.

AE24 VNEG Negative Analog Power Supply.

AE25 VNEG Negative Analog Power Supply.

Ball No. Mnemonic Description

AE26 VNEG Negative Analog Power Supply.

AF1 VNEG Negative Analog Power Supply.

AF2 VNEG Negative Analog Power Supply.

AF3 VNEG Negative Analog Power Supply.

AF4 IPR4 Input Number 4, Positive Phase.

AF5 INB4 Input Number 4, Negative Phase.

AF6 VNEG Negative Analog Power Supply.

AF7 IPR3 Input Number 3, Positive Phase.

AF8 INB3 Input Number 3, Negative Phase.

AF9 VPOS Positive Analog Power Supply.

AF10 IPR2 Input Number 2, Positive Phase.

AF11 INB2 Input Number 2, Negative Phase.

AF12 VNEG Negative Analog Power Supply.

AF13 IPR1 Input Number 1, Positive Phase.

AF14 INB1 Input Number 1, Negative Phase.

AF15 VPOS Positive Analog Power Supply.

AF16 IPR0 Input Number 0, Positive Phase.

AF17 INB0 Input Number 0, Negative Phase.

AF18 VNEG Negative Analog Power Supply.

AF19 OPR0 Output Number 0, Positive Phase.

AF20 ONB0 Output Number 0, Negative Phase.

AF21 VPOS Positive Analog Power Supply.

AF22 NC No Connect.

AF23 NC No Connect.

AF24 VNEG Negative Analog Power Supply.

AF25 VNEG Negative Analog Power Supply.

AF26 VNEG Negative Analog Power Supply.

Rev. 0 | Page 16 of 40

AD8178

TRUTH TABLE AND LOGIC DIAGRAM

Table 15. Operation Truth Table

/PAR

WE UPDATE CLK

1

X

X X X X 0 X X X

1 1

SERIN SEROUT

SERIN

SERIN

i

RST

1 0 0 X

i-45

0 1 1 X X 1 1 0 X

1 0 1 X X 1 X 0 X

1 X X X X 1 1 0 X No change in logic.

1

X = don’t care.

SER

CS

CMENC Operation/Comment

Asynchronous reset. All outputs

are disabled. Contents of the

45-bit shift register are

unchanged.

Serial mode. The data on the

SERIN line is loaded into the

45-bit shift register. The first bit

clocked into the shift register

appears at SEROUT 45 clock

cycles later. Data is not applied

to the switch array.

Parallel mode. The data on

parallel lines D0 through D4 is

loaded into the shift register

location addressed by A0

through A2. Data is not applied

to the switch array.

Switch array update. Data in

the 45-bit shift register is transferred to the parallel latches

and applied to the switch array.

Rev. 0 | Page 17 of 40

AD8178

SEROUT

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

CLK

Q

S

D1

D0

CLK

DQ

Q

S

D1

D0

D

ENA

D

ENA

D

ENA

D

ENA

D

ENA

D

ENA

D

ENA

Q

EN

OUT4

CLR

Q

B3

OUT4

CLR

Q

B2

OUT4

CLR

Q

B1

OUT4

CLR

Q

B0

OUT4

CLR

Q

EN

OUT4

CLR

Q

B0

OUT1

CLR

06608-028

5

OUTPUT ENABLE

DECODE

D0D1D2D3D4

D

Q

EN

DQ DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

ENA

D

ENA

D

ENA

D

ENA

D

ENA

OUT0

CLR

Q

B3

OUT0

CLR

Q

B2

OUT0

CLR

Q

B1

OUT0

CLR

Q

B0

OUT0

CLR

UPDATE

80

SWITCH MATRIX

CS

RST

OUT0 EN

CS

WE

SER/PAR

PARALLEL DATA

(OUTPUT ENABLE)

SERIN

CLK

OUT1 EN

OUT2 EN

3 TO 5 DECODER

ADDRESS

OUTPUT

A2A1A0

OUT3 EN

OUT4 EN

Figure 7. Logic Diagram

Rev. 0 | Page 18 of 40

AD8178

V

n

Ω

Ω

n

n

V

V

V

V

V

V

EQUIVALENT CIRCUITS

POS

OPn, ONn

1kΩ

1kΩ

(VPOS – VNEG)

2

Figure 8. Enabled Output (see also ESD Protection Map,

3.4pF

0.4pF 3.1kΩ

3.4pF

Figure 9. Disabled Output (see also ESD Protection Map,

IPn

IN

1.3pF

0.3pF

1.3pF

2500

10kΩ

2500Ω 5050Ω

POS

VNEG

VPOS

VNEG

5050

20kΩ

20kΩ

20kΩ

20kΩ

06608-008

Figure 19)

Figure 19)

Figure 10. Receiver Differential (see also ESD Protection Map,

OPn

ONn

06608-009

06608-010

Figure 19)

VNEG

10kΩ

06608-013

BLK,

OCM_CMENCOFF

0.1pF

0.1pF 10kΩ

Figure 13. VBLK and VOCM_CMENCOFF Inputs

POS

VNEG

Figure 19)

3.33kΩ

06608-014

(see also ESD Protection Map,

0.3pF

OCM_CMENCON

0.3pF 3.33kΩ

Figure 14. VOCM_CMENCON Input (see also ESD Protection Map, Figure 19)

DD

25kΩ

1kΩ

DGND

06608-015

Figure 15.

RST

RST

Input (see also ESD Protection Map, Figure 19)

IP

INn

Figure 11. Receiver Simplified Equivalent Circuit When Driving Differentially

Figure 12. Receiver Simplified Equivalent Circuit When Driving Single-Ended

0.3pF

IP

INn

1.3pF

1.3pF

1.6pF

10kΩ

2.5kΩ

2500Ω

2500Ω

06608-012

CLK, SER/PAR, WE,

UPDATE, SERIN

A[2:0], D[4:0] ,

06608-011

CMENC

Figure 16. Logic Input (see also ESD Protection Map,

CS

25kΩ

CS

Figure 17.

Input (see also ESD Protection Map, Figure 19)

1kΩ

1kΩ

DGND

DGND

06608-030

06608-016

Figure 19)

Rev. 0 | Page 19 of 40

AD8178

V

V

V

DD

SEROUT,

H, V

DGND

06608-017

Figure 18.SEROUT, H, V Logic Outputs

(see also ESD Protection Map,

Figure 19)

IPn, INn,

OPn, ONn, VBLK,

VOCM_CM ENCOF F

VOCM_CM ENCON

POS

VNEG DGND

DD

Figure 19. ESD Protection Map

CLK, RST,

SER/PAR,

WE,

UPDATE,

SERIN,

SEROUT,

A[2:0],

D[4:0],

CMENC,

CS

06608-018

Rev. 0 | Page 20 of 40

AD8178

TYPICAL PERFORMANCE CHARACTERISTICS

VS = ±2.5 V at TA = 25°C, G = +2, RL = 100 Ω (each output), VBLK = 0 V, output CM voltage = 0 V, differential I/O mode, unless

otherwise noted.

20

18

16

14

12

10

GAIN (dB)

8

6

4

2

0

1 10 100 1000

FREQUENCY (MHz)

Figure 20. Small Signal Frequency Response, 200 mV p-p

06608-019

0.15

0.10

0.05

0

, DIFF (V)

OUT

V

–0.05

–0.10

–0.15

0 2 4 6 8 101214161820

TIME (ns)

Figure 23. Small Signal Pulse Response, 200 mV p-p

6608-032

18

16

14

12

10

8

GAIN (dB)

6

4

2

0

–2

1 10 100 1000

FREQUENCY (MHz)

Figure 21. Large Signal Frequency Response, 2 V p-p

22

20

18

16

14

12

10

GAIN (dB)

8

6

4

2

0

1 10 100 1000

FREQUENCY (MHz)

10pF

5pF

2pF

0pF

Figure 22. Small Signal Frequency Response with Capacitive Loads

1.5

1.0

0.5

0

, DIFF (V)

OUT

V

–0.5

–1.0

–1.5

0 2 4 6 8 101214161820

6608-020

TIME (ns)

06608-033

Figure 24. Large Signal Pulse Response, 2 V p-p

15

V

OUT

10

V

IN

5

0

–5

–10

OUTPUT ERROR (%)

–15

–20

–25

012345678

06608-031

TIME (ns)

ERROR

1.2

0.9

0.6

0.3

0

–0.3

–0.6

–0.9

–1.2

, DIFF (V)

OUT

V

06608-034

Figure 25. Settling Time

Rev. 0 | Page 21 of 40

AD8178

5

4

3

2

1

0

–1

OUTPUT ERROR (%)

–2

–3

–4

–5

012345678

TIME (ns)

Figure 26. Settling Time, 1% Zoom

2

1

0

–1

, DIFF (V)

–2

OUT

V

–3

1650V/µs PEAK

6000

5000

4000

3000

2000

1000

6608-035

SLEW RATE (V/µs)

0

–10

–20

–30

–40

–50

–60

CROSSTALK (d B)

–70

–80

–90

–100

1 10 100 1000

FREQUENCY (MHz )

Figure 29. Crosstalk, All Hostile

0

–20

–40

–60

–80

FEEDTHROUG H (dB)

6608-038

–4

–5

012345678910

TIME (ns)

Figure 27. Large Signal Rising Edge Slew Rate

0

–10

–20

–30

–40

–50

CROSSTALK (d B)

–60

–70

–80

1 10 100 1000

FREQUENCY (MHz )

Figure 28. Crosstalk, All Hostile, Single-Ended

0

–1000

–100

–120

1 10 100 1000

06608-036

FREQUENCY (MHz)

06608-039

Figure 30. Crosstalk, Off Isolation

0

–10

–20

–30

–40

CMR (dB)

–50

–60

–70

1 10 100 1000

06608-037

CMENC HIGH

CMENC LOW

FREQUENCY (MHz )

06608-040

Figure 31. Common-Mode Rejection

Rev. 0 | Page 22 of 40

AD8178

600

|I

| AND |I

500

400

| (mA)

NEG

300

| AND |I

200

POS

|I

100

0

–50–40–30–20–100 102030405060708090100

POS

(BROADCAST)

|I

| AND |I

POS

(ALL OUTPUTS DISABLE D)

|

NEG

|

NEG

TEMPERATURE ( °C)

Figure 32. Quiescent Supply Currents vs. Temperature

3000

2500

2000

1500

6608-041

10000

1000

IMPEDANCE (Ω)

100

1 10 100 1000

FREQUENCY (MHz)

Figure 35. Input Impedance

10000

1000

6608-044

IMPEDANCE (Ω)

1000

500

0

1 10 100 1000

FREQUENCY (MHz)

Figure 33. Output Impedance, Disabled

100

90

80

70

60

50

40

IMPEDANCE (Ω)

30

20

10

0

1 10 100 1000

FREQUENCY (MHz)

Figure 34. Output Impedance, Enabled

IMPEDANCE (Ω)

100

1 10 100 1000

06608-042

FREQUENCY (MHz )

06608-045

Figure 36. Input Impedance, Single-Ended

0

–10

–20

–30

–40

–50

BALANCE ERROR (dB)

–60

–70

–80

1 10 100 1000

06608-043

FREQUENCY (MHz )

06608-046

Figure 37. Output Balance Error

Rev. 0 | Page 23 of 40

AD8178

1.0

20

1400

0.5

0

–0.5

, COMM ON MO DE (V)

OUT

V

–1.0

–1.5

0 100 200 300 400 500 600 700 800 900 1000

BLUE

HSYNC

TIME (ns)

RED

Figure 38. Common-Mode Pulse Response

0

–10

–20

–30

–40

–50

FEEDTHROUG H (dB)

–60

–70

–80

1 10 100 1000

FREQUENCY (MHz )

Figure 39. Common-Mode Isolation, CMENC Low

GREEN

VSYNC

15

10

(V)

OUT

V

5

0

–5

6608-047

06608-048

1200

1000

800

COUNT

600

400

200

0

–70 –60 –50 –40 –30 –20 –10 0 10 20 30 40 50 60 70

VOS (mV)

Figure 41. V

5

4

3

2

1

0

(mV)

OS

V

–1

–2

–3

–4

–5

–40 –20 0 20 40 60 80 100

Figure 42. V

Distribution

OS

58µV/°C

TEMPERATURE ( °C)

Drift, RTO

OS

06608-050

06608-051

200

160

120

80

40

NOISE SPECTRAL DENSITY (nV/√Hz)

0

0 102030405060708090100

FREQUENCY (MHz )

Figure 40. Noise Spectral Density

6608-049

Rev. 0 | Page 24 of 40

1.5

1.0

0.5

0

–0.5

COMMON MODE (mV)

OS

V

–1.0

–1.5

–40–200 20406080100

Figure 43. V

–16µV/°C

TEMPERATURE ( °C)

Drift, Common Mode, RTO

OS

06608-052

AD8178

5

4

UPDATE

3

2

UPDATE (V)

1

0

–1

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280

TIME (ns)

Figure 44. Enable Time

1.25

1.00

V

OUT

0.75

0.50

, SINGLE-ENDED (V)

0.25

OUT

V

0

–0.25

06608-053

0.020

0.015

0.010

0.005

0

–0.005

–0.010

NORMALIZE D DC GAIN (dB)

–0.015

–0.020

–40 –20 0 20 40 60 80 100

TEMPERATURE (° C)

32ppm/°C

06608-054

Figure 45. Normalized DC Gain vs. Temperature

Rev. 0 | Page 25 of 40

AD8178

THEORY OF OPERATION

The AD8178 is a nonblocking crosspoint with 16 RGB input

channels and 5 RGB output channels. Architecturally, the

AD8178 is a differential-in, differential-out crosspoint suited

for middle-of-Cat-5-run applications. Furthermore, its

differential-in, differential-out gain of +4 and its decoded H and

V sync outputs make it the ideal solution for driving a monitor

directly. The ability to set the output common-mode (CM) and

black level through external pins offers additional flexibility.

Processing of CM voltage levels is achieved by placing the AD8178

in either of its two operation modes. In the first operation mode

(CMENC low), the input CM of each RGB differential pair

(possibly present in the form of either sync-on CM signaling or

noise) is removed through the switch, and the output CM is set

to a global reference voltage via the VOCM_CMENCOFF analog

input. In this mode, the AD8178 behaves as a traditional

differential-in, differential-out switch. If sync-on CM signaling

is present at the differential RGB inputs, then the H and V

outputs represent decoded syncs. In the second operation mode

(CMENC high), input sync-on CM signaling is propagated

through the switch with unity gain. In this mode, the overall

output CM is set to a global reference voltage via the

VOCM_CMENCON analog input. Note that in both operation

modes, the overall input CM is blocked through the switch.

Input Pin VBLK defines the black level of the positive output

phase. The combination of VBLK and VOCM_CMENCOFF

allows the user to position the positive and negative output

phases anywhere in the allowable output voltage range, thus

maximizing output headroom usage.

The switch is organized into five 16:1 RBG multiplexers, with

each being responsible for connecting an RGB input channel to

its respective RGB output channel. Decoding logic selects a single

input (or none) in each multiplexer and connects it to its respective

output. Feedback around each multiplexer realizes a closed-loop

differential-in, differential-out gain of +2 in the core.

Each differential RGB input channel is buffered by a differential

receiver that is capable of accepting input CM voltages extending

all the way to either supply rail. Excess closed-loop receiver

bandwidth reduces the effect of the receiver on the overall device

bandwidth. Feedback around each differential receiver realizes

a gain of +2 yielding an overall differential-in, differential-out

crosspoint gain of +4. A separate loop realizes a closed-loop

common-mode gain of +1.

The output stage is designed for fast slew rate and settling time,

while driving a series-terminated Cat-5 cable. Unlike competing

multiplexer designs, the small signal bandwidth closely approaches

the large signal bandwidth.

The outputs of the AD8178 can be disabled to minimize on-chip

power dissipation. When disabled, there is only a commonmode feedback network of 2.7 k between the differential outputs.

This high impedance allows multiple ICs to be bussed together

without additional buffering. Care must be taken to reduce

output capacitance, which can result in overshoot and frequencydomain peaking. A series of internal amplifiers drive internal

nodes such that wideband high impedance is presented at the

disabled output, even while the output bus experiences fast signal

swings. When the outputs are disabled and driven externally, the

voltage applied to them should not exceed the valid output swing

range for the AD8178 to keep these internal amplifiers in their

linear range of operation. Applying excessive differential voltages

to the disabled outputs can cause damage to the AD8178 and

should be avoided (see the

for guidelines).

The connectivity of the AD8178 is controlled by a flexible TTLcompatible logic interface. Either parallel or serial loading into

a first rank of latches preprograms each output. A global update

signal moves the programming data into the second rank of latches,

simultaneously updating all outputs. In serial mode, a serial-out

pin allows devices to be daisy-chained together for a single-pin

programming of multiple ICs. A power-on reset pin is available

to avoid bus conflicts by disabling all outputs. This power-on

reset clears the second rank of latches but does not clear the first

rank of latches. In serial mode, preprogramming individual inputs

is not possible and the entire shift register needs to be flushed. A

global chip-select pin gates the input clock and the global update

signal to the second rank of buffers.

The AD8178 can operate on a single 5 V supply, powering both

the signal path (with the VPOS/VNEG supply pins) and the control

logic interface (with the VDD/DGND supply pins). Split supply

operation is possible with ±2.5 V supplies that easily interface to

ground-referenced video signals. In this case, a flexible logic

interface allows the control logic supplies (VDD/DGND) to be

run off 5 V/0 V to 3.3 V/0 V while the analog core remains on

split supplies. Additional flexibility in the analog output commonmode level (VOCM_CMENCOFF) and output black level (VBLK)

facilitates operation with unequally split supplies. If +3 V/−2 V

supplies to +2 V/−3 V supplies are desired, the output CM can

still be set to 0 V for ground-referenced video signals.

Absolute Maximum Ratings section

Rev. 0 | Page 26 of 40

AD8178

APPLICATIONS INFORMATION

OPERATING MODES

Depending on the state of the CMENC logic input, the AD8178

can be set in either of two differential-in, differential-out operating modes. In addition, monitors can be driven directly by tapping

the outputs single-ended and making use of the decoded H and

V sync outputs.

Middle-of-Cat-5-Run Application, CM Encoding Turned Off

In this application, the AD8178 is placed somewhere in the middle

of a Cat-5 run. By tying CMENC low, the CM of each RGB differential pair is removed through the device (or turned off), and

the overall CM at the output is defined by the reference value

VOCM_CMENCOFF. In this mode of operation, CM noise is

removed, while the intended differential RGB signals are buffered

and passed to the outputs. The AD8178 is placed in this operation

mode when used in a sync-on color scheme.

the voltage levels and CM handling for a single input channel

connected to a single output channel in a middle-of-Cat-5-run

application with CM encoding turned off.

DIFF. R

CM

R

CM

G

Figure 46. AD8178 in a Middle-of-Cat-5-Run Application, CM Encoding Off

(Note that in this application, the H and V outputs, though asserted, are not used.)

CM

DIFF. G

B

DIFF. B

INPUT

OVERALL

CM

CMENC

AD8178

CM

VOCM_CMENCOFF

Input VBLK and Input VOCM_CMENCOFF allow the user

complete flexibility in defining the output CM level and the

amount of overlap between the positive and negative phases,

thus maximizing output headroom usage. Whenever VBLK

differs from VOCM_CMENCOFF by more than ±100 mV,

a differential voltage,

to the expression

, is added at the outputs according

diff

= 2 × (VBLK − VOCM_CMENCOFF.)

diff

Conversely, whenever the difference between VBLK and

VOCM_CMENCOFF is less than ±100 mV, no differential

voltage is added at the outputs.

Middle-of-Cat-5-Run Application, CM Encoding Turned On

In this application, the AD8178 is also placed somewhere in the

middle of a Cat-5 run, although the common-mode handling is

different. By tying CMENC high, the CM of each RGB input is

passed through the part with a gain of +1, while at the same time,

the overall output CM is stripped and set equal to the voltage

applied at the VOCM_CMENCON pin. The AD8178 is placed in

this operation mode when used with a sync-on CM scheme.

Although asserted, the H and V outputs are not used in this

application.

Figure 46 shows

DIFF. R

CM

R

G

DIFF. G

DIFF. B

CM

B

OUTPUT

OVERALL

CM

06608-021

Figure 47 shows the voltage levels and CM handling for a single

input channel connected to a single output channel in a middleof-Cat-5-run application with CM encoding turned on.

DIFF. R

CM

R

CM

G

Figure 47. AD8178 in Middle-of-Cat-5-Run Application, CM Encoding On

(Note that in this application, the H and V outputs, though asserted, are not used.)

In this operation mode, the difference

CM

B

DIFF. G

DIFF. B

INPUT

OVERALL

CM

CMENC

AD8178

DIFF. R

CM

R

CM

VOCM_CMENCON

= 2 × (VBLK −

diff

DIFF. B

CM

B

OUTPUT

OVERALL

CM

DIFF. G

G

VOCM_CMENCOFF) still adds an output differential voltage,

as described in the

Encoding Turned Off

Middle-of-Cat-5-Run Application, CM

section.

End-of-Cat-5-Run Application, CM Encoding Turned Off— Driving a Monitor Directly

In this application, the AD8178 is placed at the end of a Cat-5

run to drive a monitor directly: the differential outputs are