600 MHz, 32 × 16 Buffered

FEATURES

High channel count, 32 × 16 high speed, nonblocking

switch array

Differential or single-ended operation

Differential G = +1 (AD8104) or G = +2 (AD8105)

Pin compatible with

Flexible power supplies

Single +5 V supply, or dual ±2.5 V supplies

Serial or parallel programming of switch array

High impedance output disable allows connection of

multiple devices with minimal loading on output bus

Excellent video performance

>50 MHz 0.1 dB gain flatness

0.05% differential gain error (R

0.05° phase error (R

Excellent ac performance

Bandwidth: 600 MHz

Slew rate: 1800 V/μs

Settling time: 2.5 ns to 1%

Low power of 1.7 W

Low all hostile crosstalk

< −70 dB @ 5 MHz

< −40 dB @ 600 MHz

Reset pin allows disabling of all outputs (connected through

a capacitor to ground provides power-on reset capability)

304-ball BGA package (31 mm × 31 mm)

AD8117/AD8118, 32 × 32 switch arrays

= 150 Ω)

L

= 150 Ω)

L

SER/PAR

WE

CLK

DATA IN

UPDATE

RESET

32 INPUT PAIRS

Analog Crosspoint Switch

AD8104/AD8105

FUNCTIONAL BLOCK DIAGRAM

D0 D1 D2 D3 D4 D5 VDD DGND

AD8104/

AD8105

1

0

INPUT

RECEIVER

G = +1*

G = +2**

192-BIT SHIFT REGISTER

WITH 6-BIT

PARALLEL LOADING

96

PARALLEL LATCH

96

DECODE

16 × 6:32 DECODERS

512

OUTPUT

BUFFER

SWITCH

MATRIX

NO

CONNECT

16

G = +1

96

ENABLE/DISABLE

A0

A1

A2

A3

DATA

OUT

SET INDIVIDUAL, OR

RESET ALL OUTPUTS TO OFF

22

16 OUTPUT PAIRS

APPLICATIONS

Routing of high speed signals including

RGB and component video routing

KVM

Compressed video (MPEG, wavelet)

Data communications

GENERAL DESCRIPTION

The AD8104/AD8105 are high speed, 32 × 16 analog crosspoint

switch matrices. They offer 600 MHz bandwidth and slew rate of

1800 V/µs for high resolution computer graphics (RGB) signal

switching. With less than −70 dB of crosstalk and −90 dB isolation (@ 5 MHz), the AD8104/AD8105 are useful in many high

speed applications. The 0.1 dB flatness, which is greater than

50 MHz, makes the AD8104/AD8105 ideal for composite video

switching.

The AD8104/AD8105 include 16 independent output buffers

that can be placed into a high impedance state for paralleling

crosspoint outputs so that off-channels present minimal loading

to an output bus. The AD8104 has a differential gain of +1,

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

*AD8104 ONLY

**AD8105 ONLY

VPOS VNEG VOCM

Figure 1.

while the AD8105 has a differential gain of +2 for ease of use

in back-terminated load applications. They operate as fully

differential devices or can be configured for single-ended

operation. Either a single +5 V supply or dual ±2.5 V supplies

can be used, while consuming only 340 mA of idle current with

all outputs enabled. The channel switching is performed via a

double-buffered, serial digital control (which can accommodate

daisy-chaining of several devices), or via a parallel control,

allowing updating of an individual output without reprogramming the entire array.

The AD8104/AD8105 are packaged in a 304-ball BGA package

and are available over the extended industrial temperature

range of −40°C to +85°C.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

06612-001

AD8104/AD8105

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Timing Characteristics (Serial Mode) ....................................... 5

Timing Characteristics (Parallel Mode).................................... 6

Absolute Maximum Ratings............................................................ 7

Thermal Resistance ...................................................................... 7

Power Dissipation......................................................................... 7

REVISION HISTORY

6/07—Revision 0: Initial Version

ESD Caution...................................................................................7

Pin Configuration and Function Descriptions..............................8

Truth Table and Logic Diagram ............................................... 13

I/O Schematics................................................................................ 15

Typical Performance Characteristics........................................... 17

Theory of Operation ...................................................................... 25

Applications Information.............................................................. 26

Programming.............................................................................. 26

Operating Modes........................................................................ 27

Outline Dimensions....................................................................... 36

Ordering Guide .......................................................................... 36

Rev. 0 | Page 2 of 36

AD8104/AD8105

SPECIFICATIONS

VS = ±2.5 V at TA = 25°C, R

Table 1.

AD8104/AD8105

Parameter Conditions Min Typ Max Unit

DYNAMIC PERFORMANCE

−3 dB Bandwidth 200 mV p-p, typical channel

2 V p-p, typical channel 420/525 MHz

Gain Flatness 0.1 dB, 200 mV p-p 100/50 MHz

0.1 dB, 2 V p-p 70/50 MHz

Propagation Delay 2 V p-p 1.3 ns

Settling Time 1%, 2 V step 2.5 ns

Slew Rate 2 V step, peak 1800 V/µs

2 V step, 10% to 90% 1500 V/µs

NOISE/DISTORTION PERFORMANCE

Differential Gain Error NTSC or PAL, RL = 150 Ω 0.05 %

Differential Phase Error NTSC or PAL, RL = 150 Ω 0.05 Degrees

Crosstalk, All Hostile f = 5 MHz −80/−70 dB

f = 10 MHz −72/−68 dB

f = 100 MHz −48/−50 dB

f = 600 MHz −40/−50 dB

Off Isolation, Input-to-Output f = 10 MHz, one channel −90 dB

Input Voltage Noise 0.1 MHz to 50 MHz 45/53 nV/√Hz

DC PERFORMANCE

Voltage Gain Differential +1/+2 V/V

Gain Error ±1 %

No load ±1 ±3 %

Gain Matching Channel-to-channel ±1 %

Differential Offset ±5 ±25 mV

Common-Mode Offset ±25 ±90 mV

OUTPUT CHARACTERISTICS

Output Impedance DC, enabled 0.1 Ω

Disabled, differential 30 kΩ

Output Disable Capacitance Disabled 4 pF

Output Leakage Current Disabled 1 µA

Output Voltage Range No load 2.8 3.8 V p-p

V

Input Range V

OCM

V

Output Swing Limit Single-ended output −1.3 +1.3 V

Output Current Maximum operating signal 30 mA

INPUT CHARACTERISTICS

Input Voltage Range Common mode, V

Differential 2/1 V

Common-Mode Rejection Ratio f = 10 MHz 48 dB

Input Capacitance Any switch configuration 2 pF

Input Resistance Differential 5 kΩ

Input Offset Current 1 A

V

Input Bias Current 64 µA

OCM

V

Input Impedance 4 kΩ

OCM

= 200 Ω, V

L, diff

= 0 V, differential I/O mode, unless otherwise noted.

OCM

= 2 V p-p −0.5 +0.8 V

OUT, diff

= 2.8 V p-p −0.25 +0.6 V

OUT, diff

= 2 V p-p −2 +2 V

IN, diff

600 MHz

Rev. 0 | Page 3 of 36

AD8104/AD8105

AD8104/AD8105

Parameter Conditions Min Typ Max Unit

SWITCHING CHARACTERISTICS

Enable On Time 50% update to 1% settling 100 ns

Switching Time, 2 V Step 50% update to 1% settling 100 ns

Switching Transient (Glitch) Differential 40 mV p-p

POWER SUPPLIES

Supply Current VPOS, outputs enabled, no load 340 420 mA

VPOS, outputs disabled 210 240 mA

VNEG, outputs enabled, no load 340 420 mA

VNEG, outputs disabled 210 240 mA

VDD, outputs enabled, no load 1.2 mA

Supply Voltage Range 4.5 to 5.5 V

PSRR VNEG, VPOS, f = 1 MHz 85 dB

VOCM, f = 1 MHz 75 dB

OPERATING TEMPERATURE RANGE

Temperature Range Operating (still air) −40 to +85 °C

θJA Operating (still air) 14 °C/W

θJC Operating (still air) 1 °C/W

Rev. 0 | Page 4 of 36

AD8104/AD8105

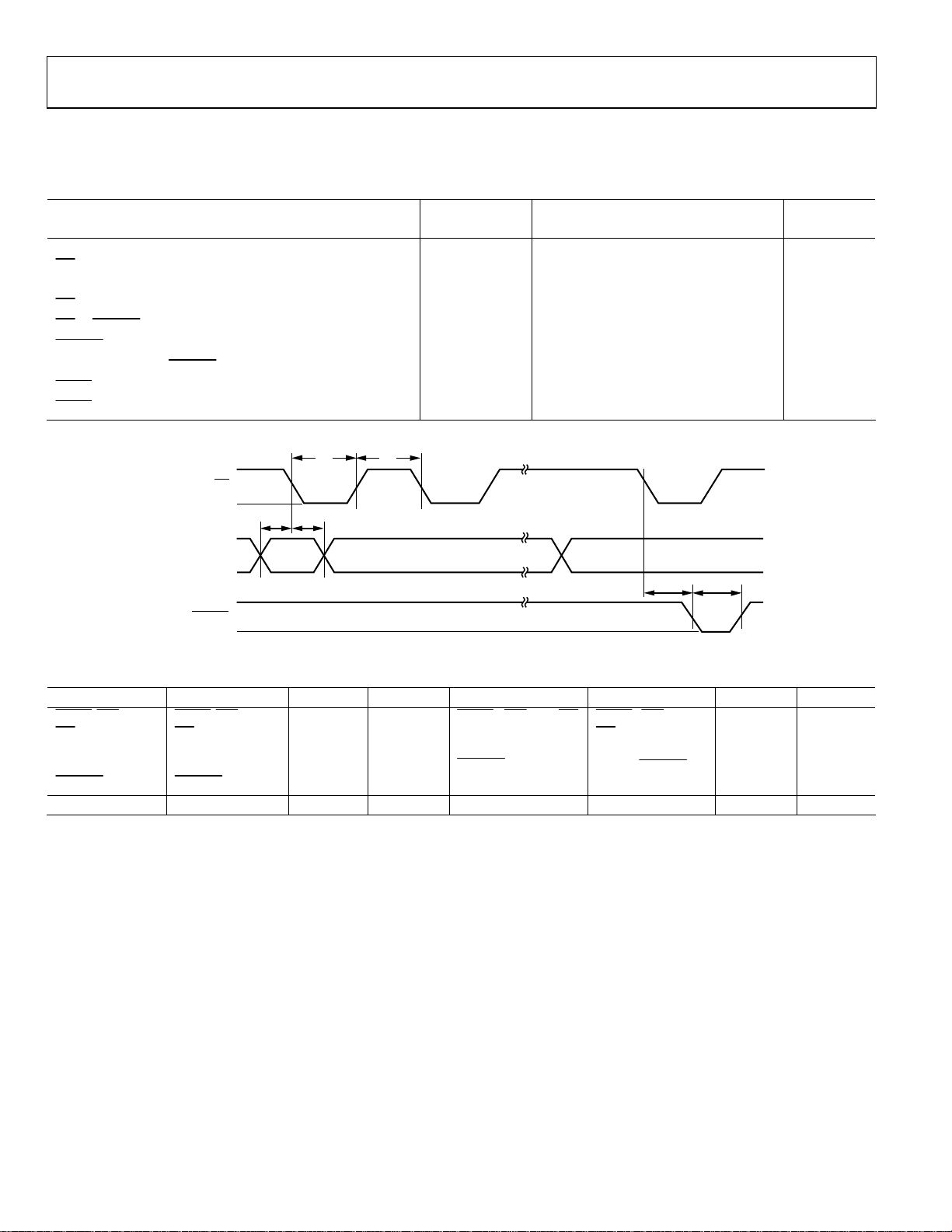

TIMING CHARACTERISTICS (SERIAL MODE)

Specifications subject to change without notice.

Table 2.

Limit

Parameter Symbol Min Typ Max Unit

Serial Data Setup Time t1 40 ns

t

CLK Pulse Width

Serial Data Hold Time t3 50 ns

CLK Pulse Separation

CLK to UPDATE Delay

UPDATE Pulse Width

CLK to DATA OUT Valid

Propagation Delay, UPDATE to Switch On or Off

RESET Pulse Width

RESET Time

1

WE

CLK

DATA IN

1 = LATCHED

UPDATE

0 = TRANSPARENT

DATA OUT

0

1

0

t1t

1

OUT15 (D5)

0

1

0

t

2

3

t

7

t

4

Figure 2. Timing Diagram, Serial Mode

50 ns

2

t

150 ns

4

t

10 ns

5

t

90 ns

6

t

120 ns

7

100 ns

60 ns

200 ns

LOAD DATA INT O

SERIAL REGISTER

ON FALLING EDGE

OUT15 (D4) OUT0 (D0)

t

5

TRANSFER DATA FROM SERIAL

REGISTE R TO PARAL LEL

LATCHES DURING LOW L EV E L

t

6

06612-002

Table 3. Logic Levels

VIH VIL V

RESET,

/PAR, CLK,

SER

DATA IN,

UPDATE

,

RESET

/PAR, CLK,

SER

DATA IN,

UPDATE

2.0 V min 0.6 V max

1

See Figure 15.

V

OH

DATA OUT DATA OUT

VDD − 0.3 V

min

DGND +

0.5 V max

I

OL

I

IH

1

RESET

/PAR, CLK,

SER

DATA IN, UPDATE

1 μA max –1 μA min −1 mA max 1 mA min

Rev. 0 | Page 5 of 36

I

IL

1

,

RESET

SER

DATA IN, UPDATE

,

/PAR, CLK,

I

OH

DATA OUT DATA OUT

OL

AD8104/AD8105

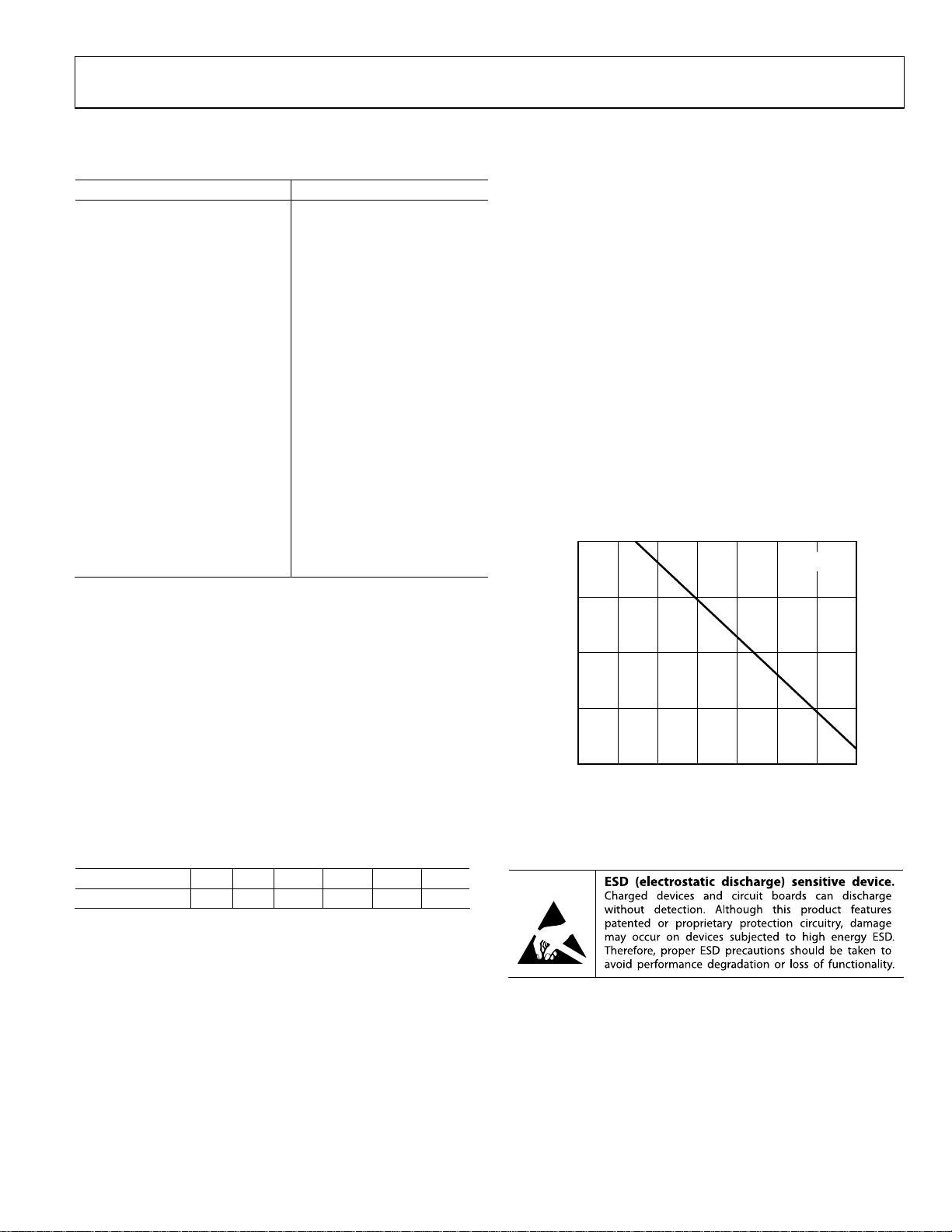

TIMING CHARACTERISTICS (PARALLEL MODE)

Specifications subject to change without notice.

Table 4.

Limit

Parameter Symbol Min Typ Max Unit

Parallel Data Setup Time t1 80 ns

t

WE Pulse Width

Parallel Data Hold Time t3 150 ns

WE Pulse Separation

WE to UPDATE Delay

UPDATE Pulse Width

Propagation Delay, UPDATE to Switch On or Off

RESET Pulse Width

RESET Time

WE

D0 TO D5

A0 TO A3

1 = LATCHED

0 = TRANSPARENT

UPDATE

t

1

0

t1t

1

0

2

3

t

4

Figure 3. Timing Diagram, Parallel Mode

110 ns

2

t

90 ns

4

t

10 ns

5

t

90 ns

6

100 ns

60 ns

200 ns

t

t

5

6

06612-003

Table 5. Logic Levels

VIH VIL V

RESET, SER/PAR,

WE, D0, D1, D2,

D3, D4, D5, A0,

A1, A2, A3,

UPDATE

RESET, SER/PAR,

WE, D0, D1, D2,

D3, D4, D5, A0,

A1, A2, A3,

UPDATE

V

OH

I

OL

DATA OUT DATA OUT

I

IH

RESET1, SER/PAR, WE,

D0, D1, D2, D3, D4,

D5, A0, A1, A2, A3,

UPDATE

I

IL

RESET1, SER/PAR,

WE, D0, D1, D2,

D3, D4, D5, A0, A1,

A2, A3,

UPDATE

I

OH

OL

DATA OUT DATA OUT

2.0 V min 0.6 V max Disabled Disabled 1 µA max –1 µA min Disabled Disabled

1

See Figure 15.

Rev. 0 | Page 6 of 36

AD8104/AD8105

ABSOLUTE MAXIMUM RATINGS

Table 6.

Parameter Rating

Analog Supply Voltage

6 V

(VPOS – VNEG)

Digital Supply Voltage

6 V

(VDD – DGND)

Ground Potential Difference

+0.5 V to −2.5 V

(VNEG – DGND)

Maximum Potential Difference

8 V

(VDD – VNEG)

Common-Mode Analog Input

VNEG to VPOS

Voltage

Differential Analog Input Voltage ±2 V

Digital Input Voltage VDD

Output Voltage

(VPOS − 1 V) to (VNEG + 1 V)

(Disabled Analog Output)

Output Short-Circuit Duration Momentary

Output Short-Circuit Current 80 mA

Storage Temperature Range −65°C to +125°C

Operating Temperature Range −40°C to +85°C

Lead Temperature

300°C

(Soldering, 10 sec)

Junction Temperature 150°C

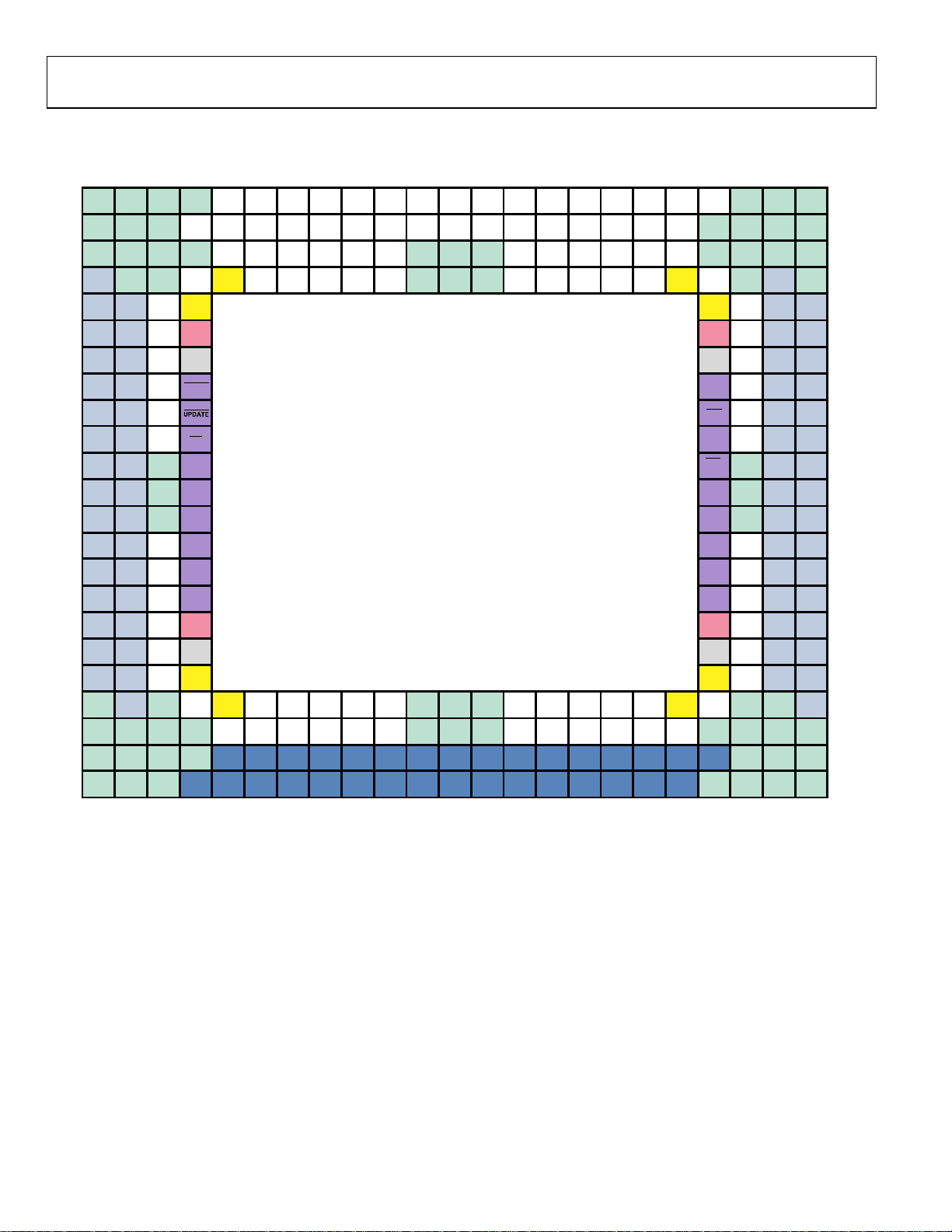

POWER DISSIPATION

The AD8104/AD8105 are operated with ±2.5 V or +5 V

supplies and can drive loads down to 100 , resulting in a large

range of possible power dissipations. For this reason, extra care

must be taken derating the operating conditions based on

ambient temperature.

Packaged in a 304-ball BGA, the AD8104/AD8105 junction-toambient thermal impedance (θ

reliability, the maximum allowed junction temperature of the

die should not exceed 150°C. Temporarily exceeding this limit

may cause a shift in parametric performance due to a change in

stresses exerted on the die by the package. Exceeding a junction

temperature of 175°C for an extended period can result in

device failure. The following curve shows the range of allowed

internal die power dissipations that meet these conditions over

the −40°C to +85°C ambient temperature range. When using

Tabl e 6 , do not include external load power in the maximum

power calculation, but do include load current dropped on the

die output transistors.

8

) is 14°C/W. For long-term

JA

TJ = 150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 7. Thermal Resistance

Package Type θJA θJC θJB ψJT ψJB Unit

304-Ball BGA 14 1 6.5 0.6 5.7 °C/W

7

6

MAXIMUM POWER (W)

5

4

25 35 45 55 65 75

15 85

Figure 4. Maximum Die Power Dissipation vs. Ambient Temperature

AMBIENT TEMPERATURE (°C)

ESD CAUTION

06612-004

Rev. 0 | Page 7 of 36

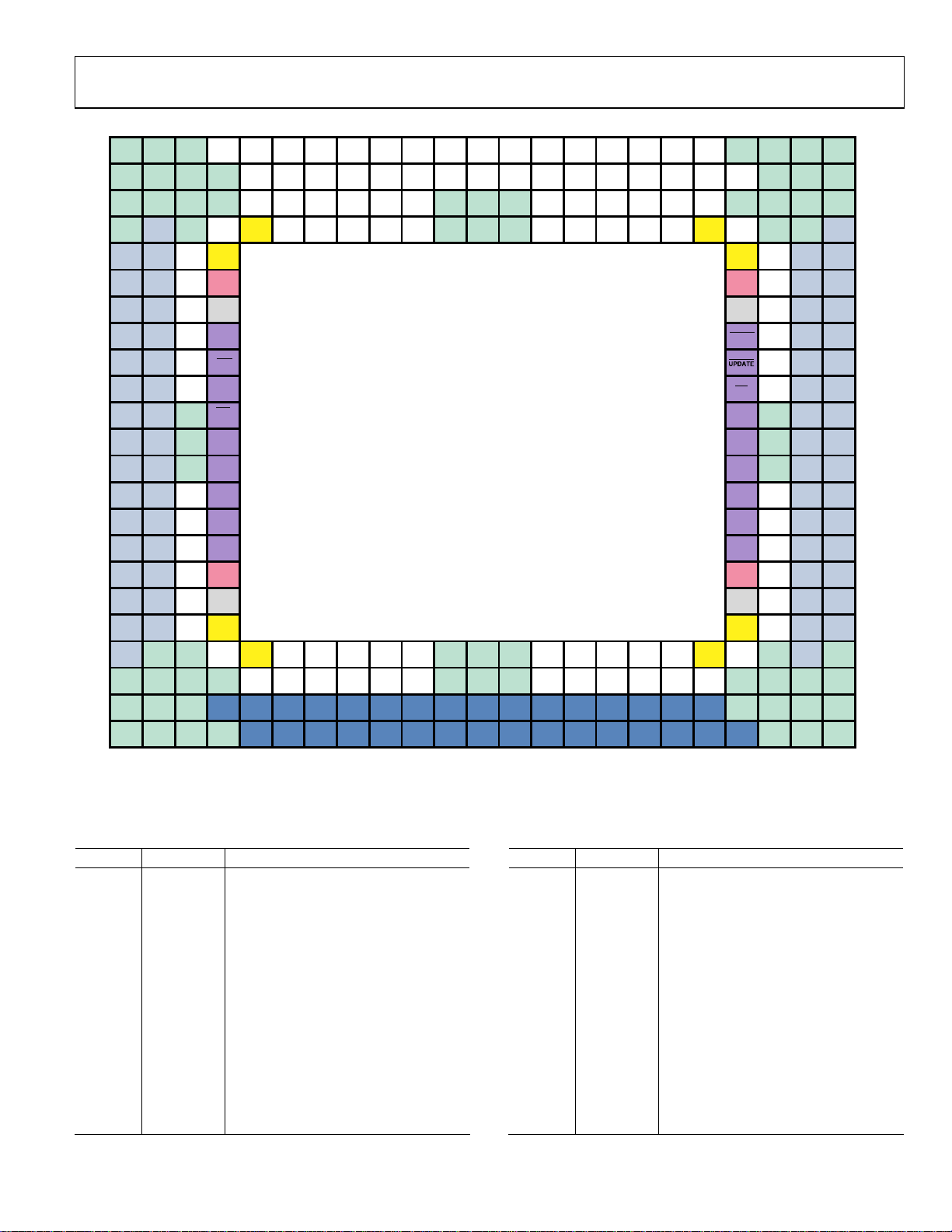

AD8104/AD8105

AA

A

A

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

A

VPOS

VPOS

VPOS

B

VPOS

VPOS

VPOS

C

VPOS

VPOS

IN16

D

VNEG

IN17

IP16

E

VNEG

IP17

IN18

F

VNEG

IN19

IP18

G

VNEG

IP19

IN20

H

VNEG

IN21

IP20

J

VNEG

IP21

IN22

K

VPOS

IN23

IP22

L

VPOS

IP23

IN24

M

VPOS

IN25

IP24

N

VNEG

IP25

IN26

P

VNEG

IN27

IP26

R

VNEG

IP27

IN28

T

VNEG

IN29

IP28

U

VNEG

IP29

IN30

V

VNEG

IN31

IP30

W

VPOS

IP31

VPOS

Y

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

B

VPOS

VPOS

VPOS

C

NC

VPOS

VNEG

VOCM

VDD

DGND

RESET

WE

D5

D4

D3

D2

D1

D0

VDD

DGND

VOCM

VNEG

VPOS

VPOS

ON15

NC

NC

VNEG

VOCM

VOCM

VNEG

ON14

OP15

NC

NC

VNEG

VNEG

VNEG

VNEG

OP14

ON13

NC

NC

VNEG

VNEG

VNEG

VNEG

ON12

OP13

NC

NC

NC

VNEG

VNEG

NC NC NC NC NC N C NC NC NC

NC

NC NC NC NC NC N C NC NC NC

VNEG

VNEG VPO S VPOS VPOS VNEG VNEG VNEG VNEG VNEG

VNEG

VNEG VPO S VPOS VPOS VNEG VNEG VNEG VNEG VNEG

AD8104/AD8105

BOTTOM VIEW

(Not to Scale)

VNEG

VNEG

VNEG

OP12

ON11

VNEG VPO S VPOS VPOS VNEG VNEG VNEG VNEG VNEG

VNEG

VNEG VPO S VPOS VPOS VNEG VNEG VNEG VNEG VNEG

ON10

OP10 O N8 OP8 ON6 OP6 ON4 OP4 ON2 O P2

OP11 ON9 OP9 ON7 OP7 ON5 OP5 ON3 OP3 ON1

NC

NC

VNEG

VOCM

VOCM

VNEG

ON0

OP1

NC

VPOS

VPOS

VNEG

VOCM

VDD

DGND

DATA

OUT

CLK

DATA

IN

SER/

PAR

DGND

A3

A2

A1

A0

VDD

DGND

VOCM

VNEG

VPOS

OP0

VPOS

VPOS

VPOS

VPOS

VPOS

VNEG

VNEG

VNEG

VNEG

VNEG

VNEG

VPOS

VPOS

VPOS

VNEG

VNEG

VNEG

VNEG

VNEG

VNEG

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

IP0

IN0

IP2

IN2

IP4

IN4

IP6

IN6

IP8

IN8

IP10

IN10

IP12

IN12

IP14

IN14

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

IP1

IN1

IP3

IN3

IP5

IN5

IP7

IN7

IP9

IN9

IP11

IN11

IP13

IN13

IP15

IN15

VPOS

VPOS

VPOS

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

Figure 5. Package Bottom View

Rev. 0 | Page 8 of 36

6612-005

AD8104/AD8105

VPOS

VPOS

VPOS

NC

AA

AB

AC

VPOS

VPOS

VNEG

VOCM

VDD

DGND

DATA

OUT

CLK

DATA

IN

SER/

PAR

DGND

A3

A2

A1

A0

VDD

DGND

VOCM

VNEG

VPOS

OP0

VPOS

NC

NC

VNEG

VOCM

VOCM

VNEG

ON0

OP1

AD8104/AD8105

TOP VIEW

(Not to Scale)

A

VPOS

VPOS

VPOS

IP0

IN0

IP2

IN2

IP4

IN4

IP6

IN6

IP8

IN8

IP10

IN10

IP12

IN12

IP14

IN14

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

VNEG

VNEG

VNEG

VNEG

VNEG

VNEG

VPOS

VPOS

VPOS

VNEG

VNEG

VNEG

VNEG

VNEG

VNEG

VPOS

VPOS

VPOS

VPOS

B

VPOS

C

VPOS

D

IP1

E

IN1

F

IP3

G

IN3

H

IP5

J

IN5

K

IP7

L

IN7

M

IP9

N

IN9

P

IP11

R

IN11

T

IP13

U

IN13

V

IP15

W

IN15

Y

VPOS

VPOS

VPOS

NC

NC

NC

NC

NC

VNEG

VNEG

VNEG

VNEG

OP14

ON13

NC

NC

VNEG

VOCM

VOCM

VNEG

ON14

OP15

NCNCNCNCNCNCNCNCNC

NC

NC

VNEG

VNEG

VNEG

VNEG

OP12

ON11

NC

VNEG

VNEG

VNEG

VNEG

ON12

OP13

NCNCNCNCNCNCNCNCNC

VNEG

VNEGVPOSVPOSVPO SVNEGVNEGVNEGVNEGVNEG

VNEG

VNEGVPOSVPOSVPO SVNEGVNEGVNEGVNEGVNEG

VNEG

VNEGVPOSVPOSVPOSVNEGVNEGVNEGVNEGVNEG

VNEG

VNEGVPOSVPOSVPOSVNEGVNEGVNEGVNEGVNEG

ON10

OP10ON8OP8ON6OP6ON4OP4ON2OP2

OP11ON9OP9ON7OP7ON5OP5ON3OP3ON1

VPOS

NC

VPOS

VNEG

VOCM

VDD

DGND

RESET

WE

D5

D4

D3

D2

D1

D0

VDD

DGND

VOCM

VNEG

VPOS

VPOS

ON15

21 22 232019181716151413121110987654321

VPOS

VPOS

VPOS

VPOS

VNEG

VNEG

VNEG

VNEG

VNEG

VNEG

VPOS

VPOS

VPOS

VNEG

VNEG

VNEG

VNEG

VNEG

VNEG

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

IN17

IP17

IN19

IP19

IN21

IP21

IN23

IP23

IN25

IP25

IN27

IP27

IN29

IP29

IN31

IP31

VPOS

VPOS

VPOS

VPOS

VPOS

VPOS

IN16

IP16

IN18

IP18

IN20

IP20

IN22

IP22

IN24

IP24

IN26

IP26

IN28

IP28

IN30

IP30

VPOS

VPOS

VPOS

VPOS

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

Table 8. Ball Grid Description

Ball No. Mnemonic Description

A1 VPOS Analog Positive Power Supply.

A2 VPOS Analog Positive Power Supply.

A3 VPOS Analog Positive Power Supply.

A4 NC No Connect.

A5 NC No Connect.

A6 NC No Connect.

A7 NC No Connect.

A8 NC No Connect.

A9 NC No Connect.

A10 NC No Connect.

A11 NC No Connect.

A12 NC No Connect.

A13 NC No Connect.

A14 NC No Connect.

Figure 6. Package Top View

Ball No. Mnemonic Description

A15 NC No Connect.

A16 NC No Connect.

A17 NC No Connect.

A18 NC No Connect.

A19 NC No Connect.

A20 VPOS Analog Positive Power Supply.

A21 VPOS Analog Positive Power Supply.

A22 VPOS Analog Positive Power Supply.

A23 VPOS Analog Positive Power Supply.

B1 VPOS Analog Positive Power Supply.

B2 VPOS Analog Positive Power Supply.

B3 VPOS Analog Positive Power Supply.

B4 VPOS Analog Positive Power Supply.

B5 NC No Connect.

Rev. 0 | Page 9 of 36

2322212019181716151413121110987654321

6612-006

AD8104/AD8105

Ball No. Mnemonic Description

B6 NC No Connect.

B7 NC No Connect.

B8 NC No Connect.

B9 NC No Connect.

B10 NC No Connect.

B11 NC No Connect.

B12 NC No Connect.

B13 NC No Connect.

B14 NC No Connect.

B15 NC No Connect.

B16 NC No Connect.

B17 NC No Connect.

B18 NC No Connect.

B19 NC No Connect.

B20 NC No Connect.

B21 VPOS Analog Positive Power Supply.

B22 VPOS Analog Positive Power Supply.

B23 VPOS Analog Positive Power Supply.

C1 VPOS Analog Positive Power Supply.

C2 VPOS Analog Positive Power Supply.

C3 VPOS Analog Positive Power Supply.

C4 VPOS Analog Positive Power Supply.

C5 VNEG Analog Negative Power Supply.

C6 VNEG Analog Negative Power Supply.

C7 VNEG Analog Negative Power Supply.

C8 VNEG Analog Negative Power Supply.

C9 VNEG Analog Negative Power Supply.

C10 VNEG Analog Negative Power Supply.

C11 VPOS Analog Positive Power Supply.

C12 VPOS Analog Positive Power Supply.

C13 VPOS Analog Positive Power Supply.

C14 VNEG Analog Negative Power Supply.

C15 VNEG Analog Negative Power Supply.

C16 VNEG Analog Negative Power Supply.

C17 VNEG Analog Negative Power Supply.

C18 VNEG Analog Negative Power Supply.

C19 VNEG Analog Negative Power Supply.

C20 VPOS Analog Positive Power Supply.

C21 VPOS Analog Positive Power Supply.

C22 VPOS Analog Positive Power Supply.

C23 VPOS Analog Positive Power Supply.

D1 VPOS Analog Positive Power Supply.

D2 IP0 Input Number 0, Positive Phase.

D3 VPOS Analog Positive Power Supply.

D4 VNEG Analog Negative Power Supply.

D5 VOCM

D6 VNEG Analog Negative Power Supply.

D7 VNEG Analog Negative Power Supply.

D8 VNEG Analog Negative Power Supply.

D9 VNEG Analog Negative Power Supply.

D10 VNEG Analog Negative Power Supply.

D11 VPOS Analog Positive Power Supply.

Output Common-Mode Reference

Supply.

Ball No. Mnemonic Description

D12 VPOS Analog Positive Power Supply.

D13 VPOS Analog Positive Power Supply.

D14 VNEG Analog Negative Power Supply.

D15 VNEG Analog Negative Power Supply.

D16 VNEG Analog Negative Power Supply.

D17 VNEG Analog Negative Power Supply.

D18 VNEG Analog Negative Power Supply.

D19 VOCM

D20 VNEG Analog Negative Power Supply.

D21 VPOS Analog Positive Power Supply.

D22 VPOS Analog Positive Power Supply.

D23 IN16 Input Number 16, Negative Phase.

E1 IP1 Input Number 1, Positive Phase.

E2 IN0 Input Number 0, Negative Phase.

E3 VNEG Analog Negative Power Supply.

E4 VOCM

E20 VOCM

E21 VNEG Analog Negative Power Supply.

E22 IN17 Input Number 17, Negative Phase.

E23 IP16 Input Number 16, Positive Phase.

F1 IN1 Input Number 1, Negative Phase.

F2 IP2 Input Number 2, Positive Phase.

F3 VNEG Analog Negative Power Supply.

F4 VDD Logic Positive Power Supply.

F20 VDD Logic Positive Power Supply.

F21 VNEG Analog Negative Power Supply.

F22 IP17 Input Number 17, Positive Phase.

F23 IN18 Input Number 18, Negative Phase.

G1 IP3 Input Number 3, Positive Phase.

G2 IN2 Input Number 2, Negative Phase.

G3 VNEG Analog Negative Power Supply.

G4 DGND Logic Negative Power Supply.

G20 DGND Logic Negative Power Supply.

G21 VNEG Analog Negative Power Supply.

G22 IN19 Input Number 19, Negative Phase.

G23 IP18 Input Number 18, Positive Phase.

H1 IN3 Input Number 3, Negative Phase.

H2 IP4 Input Number 4, Positive Phase.

H3 VNEG Analog Negative Power Supply.

H4 DATA OUT Control Pin: Serial Data Out.

H20

H21 VNEG Analog Negative Power Supply.

H22 IP19 Input Number 19, Positive Phase.

H23 IN20 Input Number 20, Negative Phase.

J1 IP5 Input Number 5, Positive Phase.

J2 IN4 Input Number 4, Negative Phase.

J3 VNEG Analog Negative Power Supply.

J4

J20

RESET

CLK

UPDATE

Output Common-Mode Reference

Supply.

Output Common-Mode Reference

Supply.

Output Common-Mode Reference

Supply.

Control Pin: Second Rank Data Reset.

Control Pin: Serial Data Clock.

Control Pin: Second Rank Write Strobe.

Rev. 0 | Page 10 of 36

AD8104/AD8105

Ball No. Mnemonic Description

J21 VNEG Analog Negative Power Supply.

J22 IN21 Input Number 21, Negative Phase.

J23 IP20 Input Number 20, Positive Phase.

K1 IN5 Input Number 5, Negative Phase.

K2 IP6 Input Number 6, Positive Phase.

K3 VNEG Analog Negative Power Supply.

K4 DATA IN Control Pin: Serial Data In.

K20

K21 VNEG Analog Negative Power Supply.

K22 IP21 Input Number 21, Positive Phase.

K23 IN22 Input Number 22, Negative Phase.

L1 IP7 Input Number 7, Positive Phase.

L2 IN6 Input Number 6, Negative Phase.

L3 VPOS Analog Positive Power Supply.

L4

L20 D5 Control Pin: Input Address Bit 5.

L21 VPOS Analog Positive Power Supply.

L22 IN23 Input Number 23, Negative Phase.

L23 IP22 Input Number 22, Positive Phase.

M1 IN7 Input Number 7, Negative Phase.

M2 IP8 Input Number 8, Positive Phase.

M3 VPOS Analog Positive Power Supply.

M4 DGND Logic Negative Power Supply

M20 D4 Control Pin: Input Address Bit 4.

M21 VPOS Analog Positive Power Supply.

M22 IP23 Input Number 23, Positive Phase.

M23 IN24 Input Number 24, Negative Phase.

N1 IP9 Input Number 9, Positive Phase.

N2 IN8 Input Number 8, Negative Phase.

N3 VPOS Analog Positive Power Supply.

N4 A3 Control Pin: Output Address Bit 3.

N20 D3 Control Pin: Input Address Bit 3.

N21 VPOS Analog Positive Power Supply.

N22 IN25 Input Number 25, Negative Phase.

N23 IP24 Input Number 24, Positive Phase.

P1 IN9 Input Number 9, Negative Phase.

P2 IP10 Input Number 10, Positive Phase.

P3 VNEG Analog Negative Power Supply.

P4 A2 Control Pin: Output Address Bit 2.

P20 D2 Control Pin: Input Address Bit 2.

P21 VNEG Analog Negative Power Supply.

P22 IP25 Input Number 25, Positive Phase.

P23 IN26 Input Number 26, Negative Phase.

R1 IP11 Input Number 11, Positive Phase.

R2 IN10 Input Number 10, Negative Phase.

R3 VNEG Analog Negative Power Supply.

R4 A1 Control Pin: Output Address Bit 1.

R20 D1 Control Pin: Input Address Bit 1.

R21 VNEG Analog Negative Power Supply.

R22 IN27 Input Number 27, Negative Phase.

R23 IP26 Input Number 26, Positive Phase.

T1 IN11 Input Number 11, Negative Phase.

WE

SER/PAR

Control Pin: First Rank Write Strobe.

Control Pin: Serial/Parallel Mode Select.

Ball No. Mnemonic Description

T2 IP12 Input Number 12, Positive Phase.

T3 VNEG Analog Negative Power Supply.

T4 A0 Control Pin: Output Address Bit 0.

T20 D0 Control Pin: Input Address Bit 0.

T21 VNEG Analog Negative Power Supply.

T22 IP27 Input Number 27, Positive Phase.

T23 IN28 Input Number 28, Negative Phase.

U1 IP13 Input Number 13, Positive Phase.

U2 IN12 Input Number 12, Negative Phase.

U3 VNEG Analog Negative Power Supply.

U4 VDD Logic Positive Power Supply.

U20 VDD Logic Positive Power Supply.

U21 VNEG Analog Negative Power Supply.

U22 IN29 Input Number 29, Negative Phase.

U23 IP28 Input Number 28, Positive Phase.

V1 IN13 Input Number 13, Negative Phase.

V2 IP14 Input Number 14, Positive Phase.

V3 VNEG Analog Negative Power Supply.

V4 DGND Logic Negative Power Supply.

V20 DGND Logic Negative Power Supply.

V21 VNEG Analog Negative Power Supply.

V22 IP29 Input Number 29, Positive Phase.

V23 IN30 Input Number 30, Negative Phase.

W1 IP15 Input Number 15, Positive Phase.

W2 IN14 Input Number 14, Negative Phase.

W3 VNEG Analog Negative Power Supply.

W4 VOCM

W20 VOCM

W21 VNEG Analog Negative Power Supply.

W22 IN31 Input Number 31, Negative Phase.

W23 IP30 Input Number 30, Positive Phase.

Y1 IN15 Input Number 15, Negative Phase.

Y2 VPOS Analog Positive Power Supply.

Y3 VPOS Analog Positive Power Supply.

Y4 VNEG Analog Negative Power Supply.

Y5 VOCM

Y6 VNEG Analog Negative Power Supply.

Y7 VNEG Analog Negative Power Supply.

Y8 VNEG Analog Negative Power Supply.

Y9 VNEG Analog Negative Power Supply.

Y10 VNEG Analog Negative Power Supply.

Y11 VPOS Analog Positive Power Supply.

Y12 VPOS Analog Positive Power Supply.

Y13 VPOS Analog Positive Power Supply.

Y14 VNEG Analog Negative Power Supply.

Y15 VNEG Analog Negative Power Supply.

Y16 VNEG Analog Negative Power Supply.

Y17 VNEG Analog Negative Power Supply.

Y18 VNEG Analog Negative Power Supply.

Output Common-Mode Reference

Supply.

Output Common-Mode Reference

Supply.

Output Common-Mode Reference

Supply.

Rev. 0 | Page 11 of 36

AD8104/AD8105

Ball No. Mnemonic Description

Y19 VOCM

Y20 VNEG Analog Negative Power Supply.

Y21 VPOS Analog Positive Power Supply.

Y22 IP31 Input Number 31, Positive Phase.

Y23 VPOS Analog Positive Power Supply.

AA1 VPOS Analog Positive Power Supply.

AA2 VPOS Analog Positive Power Supply.

AA3 VPOS Analog Positive Power Supply.

AA4 VPOS Analog Positive Power Supply.

AA5 VNEG Analog Negative Power Supply.

AA6 VNEG Analog Negative Power Supply.

AA7 VNEG Analog Negative Power Supply.

AA8 VNEG Analog Negative Power Supply.

AA9 VNEG Analog Negative Power Supply.

AA10 VNEG Analog Negative Power Supply.

AA11 VPOS Analog Positive Power Supply.

AA12 VPOS Analog Positive Power Supply.

AA13 VPOS Analog Positive Power Supply.

AA14 VNEG Analog Negative Power Supply.

AA15 VNEG Analog Negative Power Supply.

AA16 VNEG Analog Negative Power Supply.

AA17 VNEG Analog Negative Power Supply.

AA18 VNEG Analog Negative Power Supply.

AA19 VNEG Analog Negative Power Supply.

AA20 VPOS Analog Positive Power Supply.

AA21 VPOS Analog Positive Power Supply.

AA22 VPOS Analog Positive Power Supply.

AA23 VPOS Analog Positive Power Supply.

AB1 VPOS Analog Positive Power Supply.

AB2 VPOS Analog Positive Power Supply.

AB3 VPOS Analog Positive Power Supply.

AB4 OP0 Output Number 0, Positive Phase.

AB5 ON0 Output Number 0, Negative Phase.

AB6 OP2 Output Number 2, Positive Phase.

AB7 ON2 Output Number 2, Negative Phase.

AB8 OP4 Output Number 4, Positive Phase.

AB9 ON4 Output Number 4, Negative Phase.

Output Common-Mode Reference

Supply.

Ball No. Mnemonic Description

AB10 OP6 Output Number 6, Positive Phase.

AB11 ON6 Output Number 6, Negative Phase.

AB12 OP8 Output Number 8, Positive Phase.

AB13 ON8 Output Number 8, Negative Phase.

AB14 OP10 Output Number 10, Positive Phase.

AB15 ON10 Output Number 10, Negative Phase.

AB16 OP12 Output Number 12, Positive Phase.

AB17 ON12 Output Number 12, Negative Phase.

AB18 OP14 Output Number 14, Positive Phase.

AB19 ON14 Output Number 14, Negative Phase.

AB20 VPOS Analog Positive Power Supply.

AB21 VPOS Analog Positive Power Supply.

AB22 VPOS Analog Positive Power Supply.

AB23 VPOS Analog Positive Power Supply.

AC1 VPOS Analog Positive Power Supply.

AC2 VPOS Analog Positive Power Supply.

AC3 VPOS Analog Positive Power Supply.

AC4 VPOS Analog Positive Power Supply.

AC5 OP1 Output Number 1, Positive Phase.

AC6 ON1 Output Number 1, Negative Phase.

AC7 OP3 Output Number 3, Positive Phase.

AC8 ON3 Output Number 3, Negative Phase.

AC9 OP5 Output Number 5, Positive Phase.

AC10 ON5 Output Number 5, Negative Phase.

AC11 OP7 Output Number 7, Positive Phase.

AC12 ON7 Output Number 7, Negative Phase.

AC13 OP9 Output Number 9, Positive Phase.

AC14 ON9 Output Number 9, Negative Phase.

AC15 OP11 Output Number 11, Positive Phase.

AC16 ON11 Output Number 11, Negative Phase.

AC17 OP13 Output Number 13, Positive Phase.

AC18 ON13 Output Number 13, Negative Phase.

AC19 OP15 Output Number 15, Positive Phase.

AC20 ON15 Output Number 15, Negative Phase.

AC21 VPOS Analog Positive Power Supply.

AC22 VPOS Analog Positive Power Supply.

AC23 VPOS Analog Positive Power Supply.

Rev. 0 | Page 12 of 36

AD8104/AD8105

TRUTH TABLE AND LOGIC DIAGRAM

Table 9. Operation Truth Table

WE UPDATE CLK

INPUT

X X X X X 0 X

DATA

1 X

0 X X

1

Data

i

D0…D5

A0…A3

1 0 X X

1 X X X X 1 1 No change in logic.

1

Datai: serial data.

2

D0…D5: data bits.

3

A0…A3: address bits.

2

3

DATA

OUTPUT

Data

i-192

N/A in

RESET

1 0

1 1

parallel

mode

N/A in

1 X

parallel

mode

SER

/PAR

Operation/Comment

Asynchronous reset. All outputs are

disabled. Remainder of logic in 192-bit shift

register is unchanged.

Serial mode. The data on the serial DATA IN

line is loaded into the serial register. The first

bit clocked into the serial register appears

at DATA OUT 192 clock cycles later.

Parallel mode. The data on parallel lines D0

to D5 are loaded into the shift register

location addressed by A0 to A3.

Switch matrix update. Data in the 192-bit

shift register transfers into the parallel

latches that control the switch array.

Rev. 0 | Page 13 of 36

AD8104/AD8105

0

DATA OUT

(SERIAL)

Q

D

CLK

Q

0

S

D1

D

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

DQ

Q

S

D1

D0

Q

EN

OUT15

CLR

ENA

Q

B4

OUT15

CLR

ENA D

Q

B3

OUT15

CLR

ENA D

Q

B2

OUT15

CLR

ENA D

Q

B1

OUT15

CLR

ENA D

Q

B0

OUT15

CLR

ENA D

Q

EN

OUT14

CLR

ENA D

Q

B0

OUT1

CLR

ENA D

6612-007

OUTPUT ENABLE

DECODE

D0D1D2D3D4

Q

EN

DQ

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

Q

D

CLK CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

Q

D

CLK

Q

S

D1

D0

DQ

CLK

Q

S

D1

D0

D5

OUT0

CLR

ENA D

Q

B4

OUT0

CLR

ENA D

Q

B3

OUT0

CLR

ENA D

Q

B2

OUT0

CLR

ENA D

Q

B1

OUT0

CLR

ENA D

D

Q

B0

OUT0

CLR

ENA D

UPDATE

512 16

SWITCH MATRIX

RESET

WE

SER/PAR

PARALLEL DATA

(OUTPUT E NABLE)

DATA IN

CLK

(SERIAL)

OUT0 EN

OUT1 EN

OUT2 EN

OUT3 EN

OUT4 EN

Figure 7. Logic Diagram

OUT5 EN

OUT6 EN

OUT7 EN

OUT8 EN

OUT9 EN

OUT10 EN

OUT11 EN

OUT12 EN

OUT13 EN

4 TO 16 DECODER

ADDRESS

OUTPUT

A3A2A1

A0

OUT14 EN

OUT15 EN

Rev. 0 | Page 14 of 36

AD8104/AD8105

Ω

n

n

V

V

I/O SCHEMATICS

OPn, ONn

06612-008

Figure 8. AD8104/AD8105 Enabled Output

(see also ESD Protection Map,

0.4pF 30kΩ

Figure 18)

OPn

3.4pF

3.4pF

ONn

Figure 9. AD8104/AD8105 Disabled Output

2500Ω

2500Ω

Figure 18)

2538Ω

2538Ω

(see also ESD Protection Map,

IPn

INn

1.3pF

0.3pF

1.3pF

IP

INn

0.3pF

1.3pF

1.3pF

2500Ω

2500Ω

6612-012

Figure 12. AD8104/AD8105 Receiver Simplified Equivalent Circuit When

Driving Differentially

IP

3.33kΩ AD8104 G = +1

1.6pF

3.76kΩ AD8105 G = +2

INn

06612-009

6612-013

Figure 13. AD8104/AD8105 Receiver Simplified Equivalent Circuit When

Driving Single-Ended

OCM

VNEG

6612-014

06612-010

Figure 10. AD8104 Receiver (see also ESD Protection Map,

IPn

INn

2500

1.3pF

0.3pF

1.3pF

2500Ω 5075Ω

5075Ω

Figure 11. AD8105 Receiver (see also ESD Protection Map,

6612-011

Figure 18)

Figure 18)

Rev. 0 | Page 15 of 36

Figure 14. VOCM Input (see also ESD Protection Map,

DD

25kΩ

RESET

1kΩ

DGND

6612-015

Figure 15. Reset Input (see also ESD Protection Map,

Figure 18)

Figure 18)

AD8104/AD8105

V

V

V

CLK, SER/PAR, WE,

UPDATE, DATA IN,

A[3:0], D[5:0]

1kΩ

Figure 16. Logic Input (see also ESD Protection Map,

DD

DATA OUT

DGND

Figure 17. Logic Output (see also ESD Protection Map,

DGND

6612-017

6612-016

Figure 18)

Figure 18)

IPn, INn,

OPn, ONn,

VOCM

POS

VNEG

Figure 18. ESD Protection Map

DD

DGND

CLK, RESET,

SER/PAR, WE,

UPDATE,

DATA IN,

DATA OUT,

A[3:0], D[5:0]

06612-018

Rev. 0 | Page 16 of 36

AD8104/AD8105

TYPICAL PERFORMANCE CHARACTERISTICS

VS = ±2.5 V at TA = 25°C, R

10

8

6

4

2

0

GAIN (dB)

–2

–4

–6

–8

–10

1

Figure 19. AD8104, AD8105 Small Signal Frequency Response, 200 mV p-p

= 200 Ω, V

L, diff

10

FREQUENCY (MHz)

= 0 V, differential I/O mode, unless otherwise noted.

OCM

200

COUNT

180

160

140

120

100

80

60

40

20

0

540

100

AD8105

AD8104

06612-019

1000

Figure 22. AD8104 −3 dB Bandwidth Histogram,

560 580 600 620 640 660 680 700 800

FREQUENCY (MHz)

One Device, All 512 Channels

06612-022

10

8

6

4

2

0

GAIN (dB)

–2

–4

–6

–8

–10

1

10

FREQUENCY (MHz )

100

AD8105

AD8104

06612-020

1000

Figure 20. AD8104, AD8105 Large Signal Frequency Response, 2 V p-p

10

8

6

4

2

0

–2

–4

NORMALIZE D GAIN (dB)

–6

–8

–10

0 1000

FREQUENCY (MHz)

10pF

5pF

2pF

0pF

10010

06612-021

Figure 21. AD8104 Small Signal Frequency Response with Capacitive Loads,

200 mV p-p

0

–0.5

–1.0

–1.5

NORMALIZE D BANDWIDTH ERROR ( %)

–2.0

NUMBER OF ENABLE D CHANNELS

1286402 11410

Figure 23. AD8104 Bandwidth Error vs. Enabled Channels

0

–10

–20

–30

–40

CMR (dB)

–50

–60

–70

300k 1M 10M 100M 1G 2G

FREQUENCY (Hz)

DIFFERENTIAL OUT

Figure 24. AD8104, AD8105 Common-Mode Rejection

06612-023

6

06612-024

Rev. 0 | Page 17 of 36

AD8104/AD8105

–

15

–25

–35

–45

–55

PSR (dB)

–65

–75

–85

–95

0.1 1000

VPOS AGGRESSOR

VNEG AGGRESSORDIFFERENTIAL OUT

VOCM AGGRESSOR

100101

FREQUENCY (MHz)

Figure 25. AD8104 Power Supply Rejection

10

SINGLE-E NDED OUT

5

0

–5

–10

–15

–20

VNEG AGGRESSOR

PSR (dB)

–25

–30

–35

–40

–45

–50

0.1 1000

VOCM AGGRESSOR

VPOS AGGRESSOR

100101

FREQUENCY (MHz)

Figure 26. AD8104 Power Supply Rejection, Single-Ended

06612-025

06612-026

0

–20

–40

–60

CROSSTALK (d B)

–80

–100

300k 1M 10M 100M 1G

FREQUENCY (Hz)

DIFFERENTIAL IN/O UT

Figure 28. AD8104 Crosstalk, One Adjacent Channel

0

–20

–40

–60

CROSSTALK (d B)

–80

–100

300k 1M 10M 100M 1G

FREQUENCY (Hz)

DIFFERENTIAL IN/OUT

Figure 29. AD8105 Crosstalk, One Adjacent Channel

06612-028

06612-029

180

160

140

120

100

80

60

40

NOISE SPECTRAL DENSITY (nV/ Hz)

20

0

1k 10k 100k 1M

AD8105

AD8104

FREQUENCY (Hz)

DIFFERENTIAL OUT

Figure 27. AD8104, AD8105 Noise Spectral Density, RTO

06612-027

0

–20

–40

–60

CROSSTALK (d B)

–80

–100

300k 1M 10M 100M 1G

FREQUENCY (Hz)

SINGLE-E NDED IN/OUT

Figure 30. AD8104 Crosstalk, One Adjacent Channel, Single-Ended

06612-030

Rev. 0 | Page 18 of 36

AD8104/AD8105

0

–20

–40

–60

CROSSTALK (dB)

–80

–100

300k 1M 10M 100M 1G

FREQUENCY (Hz)

SINGLE-ENDED IN/OUT

Figure 31. AD8105 Crosstalk, One Adjacent Channel, Single-Ended

0

DIFFERENTIAL IN/OUT

–20

–40

–60

CROSSTALK (d B)

–80

0

SINGLE-ENDED IN/OUT

–20

–40

–60

CROSSTALK (d B)

–80

–100

06612-031

–120

300k 1M 10M 100M 1G

FREQUENCY (Hz)

Figure 34. AD8104 Crosstalk, All Hostile, Single-Ended

0

–20

–40

–60

CROSSTALK (dB)

SINGLE-ENDED IN/OUT

06612-034

–100

–120

300k 1M 10M 100M 1G

Figure 32. AD8104 Crosstalk, All Hostile

0

–20

–40

–60

CROSSTALK (d B)

–80

–100

300k 1M 10M 100M 1G

Figure 33. AD8105 Crosstalk, All Hostile

FREQUENCY (Hz)

DIFFERENT IAL IN/O UT

FREQUENCY (Hz)

–80

06612-032

–100

300k 1M 10M 100M 1G

FREQUENCY (Hz)

Figure 35. AD8105 Crosstalk, All Hostile, Single-Ended

0

–20

–40

–60

FEEDTHROUG H (dB)

–80

06612-033

–100

300k 1M 10M 100M 1G 2G

FREQUENCY (Hz)

DIFFERENTIAL IN/O UT

06612-035

06612-036

Figure 36. AD8104 Crosstalk, Off Isolation

Rev. 0 | Page 19 of 36

AD8104/AD8105

0

–20

–40

–60

FEEDTHROUG H (dB)

–80

–100

300k 1M 10M 100M 1G 2G

FREQUENCY (Hz)

SINGLE-ENDED IN/OUT

Figure 37. AD8104 Crosstalk, Off Isolation, Single-Ended

6000

AD8105

5000

AD8104

4000

3000

DIFFERENTIAL IN

06612-037

30000

25000

20000

15000

10000

OUTPUT IMPEDANCE (Ω)

5000

0

100k 1M 10M 100M 1G

FREQUENCY (Hz)

DIFFERENTIAL OUT

Figure 40. AD8104, AD8105 Output Impedance, Disabled

1000

100

10

06612-040

2000

INPUT IMP EDANCE (Ω)

1000

0

300k 1M 10M 100M 1G

FREQUENCY (Hz)

Figure 38. AD8104, AD8105 Input Impedance

4500

4000

3500

3000

2500

2000

1500

INPUT IMPE DANCE (Ω)

1000

500

0

300k 1M 10M 100M 1G

AD8105

AD8104

FREQUENCY (Hz)

SINGLE-ENDED IN

Figure 39. AD8104, AD8105 Input Impedance, Single-Ended

OUTPUT IMPEDANCE (Ω)

1

06612-038

0.1

100k 1G

10M 100M1M

FREQUENCY (Hz)

06612-041

Figure 41. AD8104, AD8105 Output Impedance, Enabled

0.4

0.3

0.2

0.1

0

(V, DIFF)

OUT

–0.1

V

–0.2

–0.3

06612-039

–0.4

01

35791113

4 6 8 10 12 1412

TIME (ns)

06612-042

5

Figure 42. AD8104 Small Signal Pulse Response, 200 mV p-p

Rev. 0 | Page 20 of 36

AD8104/AD8105

0.20

0.15

0.10

N-CHANNEL

0.05

0

(V, SE)

OUT

V

–0.05

P-CHANNEL

–0.10

–0.15

–0.20

01

4 6 8 10 12 1412

35791113

TIME (ns)

5

Figure 43. AD8104 Small Signal Pulse Response, Single-Ended, 200 mV p-p

2.0

1.5

1.0

0.5

0

(V, DIFF)

OUT

–0.5

V

–1.0

–1.5

–2.0

01

4 6 8 10 12 1412

35791113

TIME (ns)

5

Figure 44. AD8104 Large Signal Pulse Response, 2 V p-p

1.5

UPDATE

1.0

0.5

0

(V, DIFF)

OUT

V

–0.5

V

OUT

–1.0

06612-043

–1.5

–40 120

TIME (ns)

100806040200–20

3

2

1

0

UPDATE (V)

–1

–2

–3

06612-046

Figure 46. AD8104 Switching Time

54321

5000

4000

3000

2000

1000

0

–1000

SLEW RATE (V/µs)

06612-047

2

1

0

V

OUT

–1

(V, DIFF)

OUT

V

–2

–3

SLEW RATE

06612-044

–4

0

TIME (ns)

Figure 47. AD8104 Large Signal Rising Edge and Slew Rate

1.0

0.8

0.6

0.4

N-CHANNEL

0.2

0

(V, SE)

OUT

–0.2

V

P-CHANNEL

–0.4

–0.6

–0.8

–1.0

01

35791113

4 6 8 10121412

TIME (ns)

06612-045

5

Figure 45. AD8104 Large Signal Pulse Response, Single-Ended, 2 V p-p

2

V

OUT

1

0

–1

(V, DIFF)

SLEW RATE

OUT

V

–2

–3

–4

0

Figure 48. AD8104 Large Signal Falling Edge and Slew Rate

Rev. 0 | Page 21 of 36

1ns/DIV

54321

3500

2500

1500

500

–500

–1500

–2500

SLEW RATE (V/µs)

06612-048

AD8104/AD8105

5

4

3

2

OFFSET (mV)

1

0

Figure 49. AD8104 V

50

40

30

20

(mV, DIFF)

10

OUT

V

0

–10

–20

–0.10 0.10

–40 100

TEMPERATURE (º C)

vs. Temperature with All Outputs Enabled

OS

TIME (µs)

9080706050403020100–10–20–30

0.080.060.040.020–0.02–0.04–0.06–0.08

Figure 50. AD8104 Switching Transient (Glitch)

0.014

0.012

0.010

0.008

0.006

0.004

0.002

0

DIFFERENTIAL PHASE ERRO R (%)

–0.002

06612-049

–0.004

–700 700–500 500300100–100–300

VIN, DIFF (mV)

06612-052

Figure 52. AD8104 Phase vs. DC Voltage, Carrier Frequency = 3.58 MHz,

Subcarrier Amplitude = 600 mV p-p, Differential

2.0

0pF

2pF

5pF

10pF

TIME (ns)

06612-053

161412108642

8

1.5

1.0

0.5

0

(V, DIFF)

OUT

–0.5

V

–1.0

–1.5

06612-050

–2.0

01

Figure 53. AD8104 Large Signal Pulse Response with Capacitive Loads

0.020

0.015

0.010

0.005

0

DIFFERENTIAL GAIN E RROR (%)

–0.005

–0.010

–700 700

–500 500300100–100– 300

VIN, DIFF (mV)

Figure 51. AD8104 Gain vs. DC Voltage, Carrier Frequency = 3.58 MHz,

Subcarrier Amplitude = 600 mV p-p, Differential

06612-051

Rev. 0 | Page 22 of 36

0.4

0.3

0.2

0.1

0

(V, DIFF)

OUT

–0.1

V

–0.2

–0.3

–0.4

01

0pF

2pF

5pF

10pF

TIME (ns)

06612-054

161412108642

8

Figure 54. AD8104 Small Signal Pulse Response with Capacitive Loads

AD8104/AD8105

1.4

UPDATE

1.2

1.0

0.8

0.6

(V, DIFF)

OUT

0.4

V

0.2

V

OUT

0

–0.2

–50 150

TIME (ns)

Figure 55. AD8104 Enable Time

1.4

UPDATE

1.2

1.0

V

OUT

0.8

0.6

(V, DIFF)

OUT

0.4

V

0.2

2.8

2.4

2.0

1.6

1.2

UPDATE (V)

0.8

0.4

0

–0.4

1301109070503010–10–30

06612-055

2.8

2.4

2.0

1.6

1.2

UPDATE (V)

0.8

0.4

600

IDD (SERIAL MODE)

500

400

CURRENT (mA)

NEG

300

AND I

POS

I

200

100

–35 95

I

AND I

POS

(ALL OUTPUTS DISABLED)

IDD (PARALLEL MODE)

I

POS

(ALL OUTPUTS ENABLED)

NEG

TEMPERATURE ( °C)

AND I

NEG

850

750

650

550

450

350

85756555453525155–5–15–25

Figure 58. AD8104, AD8105 Quiescent Supply Currents vs. Temperature

360

340

320

300

(mA)

NEG

280

AND I

260

POS

I

240

I

, I

POS

NEG

IDD SERIAL

IDD PARALLEL

1040

960

880

800

720

640

560

CURRENT (µ A)

DD

I

06612-058

(µA)

DD

I

0

–0.2

–50 150

TIME (ns)

Figure 56. AD8104 Disable Time

0

–0.01

–0.02

GAIN (dB)

–0.03

–0.04

–0.05

–50 100

–250 255075

TEMPERATURE (°C)

Figure 57. AD8104 DC Gain vs. Temperature

0

–0.4

1301109070503010–10–30

06612-056

220

200

11

23456789101112131415

CHANNELS

480

400

6

06612-059

Figure 59. AD8104, AD8105 Quiescent Supply Currents vs. Enabled Outputs

65

60

55

50

45

40

35

30

25

20

OUTPUT ERRO R (%)

15

10

5

06612-057

0

–5

07

(V

– VIN)/V

V

OUT

V

OUT

OUT

IN

453621

TIME (ns)

3.25

3.00

2.75

2.50

2.25

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.25

0

–0.25

(V, DIFF)

06612-060

Figure 60. AD8104 Settling Time

Rev. 0 | Page 23 of 36

AD8104/AD8105

–

5

4

3

2

1

0

–1

OUTPUT/I NPUT (%)

–2

–3

–4

–5

07

TIME (ns)

654321

06612-061

Figure 61. AD8104 Settling Time (Zoom)

2.5

V

2.0

1.5

1.0

0.5

0

(V, SE)

OUT

–0.5

V

–1.0

–1.5

–2.0

–2.5

07

INP

V

OUTP

V

V

INN

TIME (ns)

OUTN

06612-062

00

600500400300200100

Figure 62. AD8104 Overdrive Recovery, Single-Ended

2.0

1.5

1.0

0.5

0

(V, SE)

OUT

V

–0.5

–1.0

–1.5

–2.0

07

V

OUTP

V

INN

V

INP

TIME (ns)

V

OUTN

600500400300200100

06612-063

00

Figure 63. AD8105 Overdrive Recovery, Single-Ended

30

V

= 2V p-p, DIFF

OUT

–40

–50

THIRD

–60

–70

DISTO RTIO N (dBc)

–80

–90

–100

0.1

HARMONIC

1

FREQUENCY (MHz)

10

SECOND

HARMONIC

100

06612-064

1000

Figure 64. AD8104 Harmonic Distortion

Rev. 0 | Page 24 of 36

AD8104/AD8105

THEORY OF OPERATION

The AD8104/AD8105 are fully differential crosspoint arrays

with 16 outputs, each of which can be connected to any one

of 32 inputs. Organized by output row, 32 switchable input

transconductance stages are connected to each output buffer to

form 32-to-1 multiplexers. There are 16 of these multiplexers,

each with its inputs wired in parallel, for a total array of 512

transconductance stages forming a multicast-capable crosspoint

switch.

Decoding logic for each output selects one (or none) of the

transconductance stages to drive the output stage. The enabled

transconductance stage drives the output stage, and feedback

forms a closed-loop amplifier with a differential gain of +1 (the

difference between the output voltages is equal to the difference

between the input voltages). A second feedback loop controls

the common-mode output level, forcing the average of the

differential output voltages to match the voltage on the VOCM

reference pin. Although each output has an independent

common-mode control loop, the VOCM reference is common

for the entire chip, and as such needs to be driven with a low

impedance to avoid crosstalk.

Each differential input to the AD8104/AD8105 is buffered by a

receiver. The purpose of this receiver is to provide an extended

input common-mode range, and to remove this common mode

from the signal chain. Like the output multiplexers, the input

receiver has both a differential loop and a common-mode

control loop. A mask-programmable feedback network sets the

closed-loop differential gain. For the AD8104, this differential

gain is +1, and for the AD8105, this differential gain is +2. The

receiver has an input stage that does not respond to the

common mode of the signal. This architecture, along with the

attenuating feedback network, allows the user to apply input

voltages that extend from rail to rail. Excess differential loop

gain bandwidth product reduces the effect of the closed-loop

gain on the bandwidth of the device.

The output stage of the AD8104/AD8105 is designed for low

differential gain and phase error when driving composite video

signals. It also provides slew current for fast pulse response

when driving component video signals. Unlike many multiplexer designs, these requirements are balanced such that large

signal bandwidth is very similar to small signal bandwidth. The

design load is 150 , but provisions are made to drive loads

as low as 75 as long as on-chip power dissipation limits are

not exceeded.

The outputs of the AD8104/AD8105 can be disabled to

minimize on-chip power dissipation. When disabled, there is a

feedback network of 25 k between the differential outputs.

This high impedance allows multiple ICs to be bussed together

without additional buffering. Care must be taken to reduce

output capacitance, which results in more overshoot and

frequency domain peaking. A series of internal amplifiers drive

internal nodes such that a wideband high impedance is

presented at the disabled output, even while the output bus is

under large signal swings. When the outputs are disabled and

driven externally, the voltage applied to them should not exceed

the valid output swing range for the AD8104/AD8105 in order

to keep these internal amplifiers in their linear range of

operation. Applying excess differential voltages to the disabled

outputs can cause damage to the AD8104/AD8105 and should

be avoided (see the

guidelines).

The connection of the AD8104/AD8105 is controlled by a

flexible TTL-compatible logic interface. Either parallel or serial

loading into a first rank of latches preprograms each output. A

global update signal moves the programming data into the

second rank of latches, simultaneously updating all outputs. In

serial mode, a serial-out pin allows devices to be daisy-chained

together for single-pin programming of multiple ICs. A poweron reset pin is available to avoid bus conflicts by disabling all

outputs. This power-on reset clears the second rank of latches,

but does not clear the first rank of latches. In parallel mode, to

quickly clear the first rank, a broadcast parallel programming

feature is available. In serial mode, preprogramming individual

inputs is not possible and the entire shift register needs to

be flushed.

The AD8104/AD8105 can operate on a single +5 V supply,

powering both the signal path (with the VPOS/VNEG supply

pins), and the control logic interface (with the VDD/DGND

supply pins). However, to easily interface to ground-referenced

video signals, split supply operation is possible with ±2.5 V

supplies. In this case, a flexible logic interface allows the control

logic supplies (VDD/DGND) to be run off +2 V/0 V to

+5 V/0 V while the core remains on split supplies. Additional

flexibility in the analog output common-mode level facilitates

unequal split supplies. If +3 V/–2 V supplies to +2 V/–3 V

supplies are desired, the VOCM pin can still be set to 0 V for

ground-referenced video signals.

Absolute Maximum Ratings section for

Rev. 0 | Page 25 of 36

AD8104/AD8105

APPLICATIONS INFORMATION

PROGRAMMING

The AD8104/AD8105 have two options for changing the

programming of the crosspoint matrix. In the first option, a

serial word of 192 bits can be provided to update the entire

matrix each time. The second option allows for changing the

programming of a single output via a parallel interface. The

serial option requires fewer signals, but more time (clock cycles)

for changing the programming, while the parallel programming

technique requires more signals, but can change a single output

at a time and requires fewer clock cycles to complete programming.

Serial Programming Description

The serial programming mode uses the

SER

and

SER

parallel clock

programming operation.

The

shifted into the serial port of the device. Although the data still

shifts in when

latches allow the shifting data to reach the matrix. This causes

the matrix to try to update to every intermediate state as

defined by the shifting data.

The data at DATA IN is clocked in at every falling edge of

A total of 192 bits must be shifted in to complete the programming. For each of the 16 outputs, there are five bits (D0 to D4)

that determine the source of its input followed by one bit (D5)

that determines the enabled state of the output. If D5 is low

(output disabled), the five associated bits (D0 to D4) do not

matter, because no input is switched to that output. These

comprise the first 96 bits of DATA IN. The remaining 96 bits

of DATA IN should be set to zero. If a string of 96 zeros is not

suffixed to the first 96 bits of DATA IN, a certain test mode is

employed that can cause the device to draw up to 40% more

supply current.

The most significant output address data, the enable bit (D5), is

shifted in first, followed by the input address (D4 to D0) entered

sequentially with D4 first and D0 last. Each remaining output is

programmed sequentially, until the least significant output

address data is shifted in. At this point,

low, which programs the device according to the data that was

just shifted in. The

when

If more than one AD8104/AD8105 device is to be serially

programmed in a system, the DATA OUT signal from one

device can be connected to the DATA IN of the next device to

form a serial chain. All of the

pins should be connected in parallel and operated as described

previously. The serial data is input to the DATA IN pin of the

first device of the chain, and it ripples through to the last.

/PAR device pins. The first step is to assert a low on

/PAR in order to enable the serial programming mode. The

WE

should be held high during the entire serial

UPDATE

UPDATE

signal should be high during the time that data is

UPDATE

is low, they are transparent.

is low, the transparent, asynchronous

UPDATE

latches are asynchronous and

CLK, UPDATE

CLK

, DATA IN,

UPDATE

, and

UPDATE

CLK

can be taken

SER

/PAR

,

.

Therefore, the data for the last device in the chain should come

at the beginning of the programming sequence. The length of

the programming sequence is 192 bits times the number of

devices in the chain.

Parallel Programming Description

When using the parallel programming mode, it is not necessary

to reprogram the entire device when making changes to the matrix.

In fact, parallel programming allows the modification of a

single output at a time. Because this takes only one

cycle, significant time savings can be realized by using parallel

programming.

One important consideration in using parallel programming is

that the

AD8105. When taken low, the

output to the disabled state. This is helpful during power-up to

ensure that two parallel outputs are not active at the same time.

After initial power-up, the internal registers in the device

generally have random data, even though the

been asserted. If parallel programming is used to program one

output, then that output will be properly programmed, but the

rest of the device will have a random program state depending

on the internal register content at power-up. Therefore, when

using parallel programming, it is essential that all outputs be

programmed to a desired state after power-up. This ensures that

the programming matrix is always in a known state. From then

on, parallel programming can be used to modify a single output

or more at a time.

In similar fashion, if

up, the random power-up data in the shift register will be

programmed into the matrix. Therefore, in order to prevent the

crosspoint from being programmed into an unknown state, do

not apply a low logic level to

applied. Programming the full shift register one time to a

desired state, by either serial or parallel programming after

initial power-up, eliminates the possibility of programming the

matrix to an unknown state.

To change the programming of an output via parallel programming,

programming clock,

programming. The parallel clock,

state. The 4-bit address of the output to be programmed should

be put on A0 to A3. The first five data bits (D0 to D4) should

contain the information that identifies the input that is programmed to the output that is addressed. The sixth data bit

(D5) determines the enabled state of the output. If D5 is low

(output disabled), then the data on D0 to D4 does not matter.

After the desired address and data signals have been established,

they can be latched into the shift register by a high to low

transition of the

RESET

SER

/PAR and

signal does not reset all registers in the AD8104/

RESET

signal only sets each

UPDATE

UPDATE

CLK

WE

signal. The matrix is not programmed,

is taken low after initial power-

UPDATE

, should be left high during parallel

after power is initially

should be taken high. The serial

WE

, should start in the high

WE/UPDATE

RESET

signal has

Rev. 0 | Page 26 of 36

AD8104/AD8105

=×=

however, until the

UPDATE

signal is taken low. It is thus possible

to latch in new data for several or all of the outputs first via

successive negative transitions of

WE

high, and then have all the new data take effect when

while

UPDATE

is held

UPDATE

goes low. This technique should be used when programming

the device for the first time after power-up when using parallel

programming.

Reset

When powering up the AD8104/AD8105, it is usually desirable

to have the outputs come up in the disabled state. The

RESET

pin, when taken low, causes all outputs to be in the disabled state.

However, the

UPDATE

signal does not reset all registers in the

AD8104/AD8105. This is important when operating in the

parallel programming mode. Refer to the

Description

section for information about programming internal

Parallel Programming

registers after power-up. Serial programming programs the entire

matrix each time; therefore, no special considerations apply.

Since the data in the shift register is random after power-up, it

should not be used to program the matrix, or the matrix can

enter unknown states. To prevent this, do not apply a logic low

signal to

should first be loaded with the desired data, and then

UPDATE

initially after power-up. The shift register

UPDATE

can be taken low to program the device.

RESET

The

pin has a 20 k pull-up resistor to VDD that can be

used to create a simple power-up reset circuit. A capacitor from

RESET

to ground holds

RESET

low for some time while the rest

of the device stabilizes. The low condition causes all the outputs

to be disabled. The capacitor then charges through the pull-up

resistor to the high state, thus allowing full programming

capability of the device.

Because the AD8104/AD8105 have random data in the internal

registers at power-up, the device may power up in a test state

where the supply current is larger than typical. Therefore, the

RESET

pin should be used to disable all outputs and bring the

device out of any test mode.

OPERATING MODES

The AD8104/AD8105 has fully differential inputs and outputs.

The inputs and outputs can also be operated in a single-ended

fashion. This presents several options for circuit configurations

that require different gains and treatment of terminations, if

they are used.

Differential Input

Each differential input to the AD8104/AD8105 is applied to a

differential receiver. These receivers allow the user to drive the

inputs with a differential signal with an uncertain commonmode voltage, such as from a remote source over twisted pair.

The receivers respond only to the difference in input voltages,

and will restore a common-mode voltage suitable for the

internal signal path. Noise or crosstalk that is present in both

inputs is rejected by the input stage, as specified by its common-

mode rejection ratio (CMRR). Differential operation offers a

great noise benefit for signals that are propagated over distance

in a noisy environment.

R

F

R

IN+

VOCM

IN–

G

RCVR

R

G

Figure 65. Input Receiver Equivalent Circuit

R

TO SWITCH MATRIX

F

OUT–

OUT+

06612-065

The circuit configuration used by the differential input receivers

is similar to that of several Analog Devices, Inc. general-purpose

differential amplifiers, such as the

AD8131. It is a voltage

feedback amplifier with internal gain setting resistors. The

arrangement of feedback makes the differential input impedance appear to be 5 k across the inputs.

k52

RR

dmIN

,

G

This impedance creates a small differential termination error if

the user does not account for the 5 k parallel element, although

this error is less than 1% in most cases. Additionally, the source

impedance driving the AD8104/AD8105 appears in parallel

with the internal gain-setting resistors, such that there may be a

gain error for some values of source resistance. The AD8104/

AD8105 are adjusted such that its gains are correct when driven

by a back-terminated 75 source impedance at each input

phase (37.5 effective impedance to ground at each input pin,

or 75 differential source impedance across pairs of input

pins). If a different source impedance is presented, the differential

gain of the AD8104/AD8105 can be calculated by

V

G

OUT,dm

dm

V

,

dmIN

R

F

==

RR

+

SG

where:

R

= 2.5 k.

G

is the user single-ended source resistance (such as 37.5 for

R

S

a back-terminated 75 source).

R

= 2.538 k for the AD8104 and 5.075 k for the AD8105.

F

In the case of the AD8104,

k538.2

=

G

dm

k5.2

R

+

S

In the case of the AD8105,

k075.5

=

G

dm

k5.2

R

+

S

Rev. 0 | Page 27 of 36

AD8104/AD8105

+

When operating with a differential input, care must be taken to

keep the common mode, or average, of the input voltages within

the linear operating range of the AD8104/AD8105 receiver. This

common-mode range can extend rail-to-rail, provided the

differential signal swing is small enough to avoid forward

biasing the ESD diodes (it is safest to keep the common mode

plus differential signal excursions within the supply voltages

of the part). See the

Specifications section for guaranteed

input range.

The differential output of the AD8104/AD8105 receiver is

linear for a peak of 1.4 V of output voltage difference (1.4 V

peak input difference for the AD8104, and 0.7 V peak input

difference for the AD8105). Taking the output differentially,

using the two output phases, this allows 2.8 V p-p of linear

output signal swing. Beyond this level, the signal path can

saturate and limits the signal swing. This is not a desired

operation, as the supply current increases and the signal path is

slow to recover from clipping. The absolute maximum allowed

differential input signal is limited by the long-term reliability of

the input stage. The limits in the

Absolute Maximum Ratings

section should be observed in order to avoid degrading device

performance permanently.

AD8104

IPn

RCVR

INn

50Ω 50Ω

Figure 66. Example of Input Driven Differentially

OPn

ONn

06612-066

Single-Ended Input

The AD8104/AD8105 input receivers can be driven singleendedly (unbalanced). From the standpoint of the receiver,

there is very little difference between signals applied positive

and negative in two phases to the input pair vs. a signal applied

to one input only with the other input held at a constant

potential. One small difference is that the common mode

between the input pins is changing if only one input is moving,

and there is a very small common-mode to differential

conversion gain in the receiver that adds an additional gain

error to the output (see the common-mode rejection ratio for

the input stage in the

Specifications section). For low

frequencies, this gain error is negligible. The common-mode

rejection ratio degrades with increasing frequency.

When operating the AD8104/AD8105 receivers single-endedly,

the observed input resistance at each input pin is lower than in

the differential input case, due to a fraction of the receiver

internal output voltage appearing as a common-mode signal on

its input terminals, bootstrapping the voltage on the input

resistance. This single-ended input resistance can be calculated

by the equation

RR

R

=

IN

1

−

SG

R

F

SG

)(2

RRR

++×

F

where:

R

= 2.5 k.

G

is the user single-ended source resistance (such as 37.5 for

R

S

a back-terminated 75 source).

R

= 2.538 k for the AD8104 and 5.075 k for the AD8105.

F

In most cases, a single-ended input signal is referred to midsupply, typically ground. In this case, the undriven differential input

can be connected to ground. For best dynamic performance and