FREQUENCY – MHz

–30

–40

–110

1 10010

DISTORTION – dBc

–70

–80

–90

–100

–50

–60

2ND

3RD

G = +2

R

L

= 150⍀

V

S

= 5V

V

OUT

= 2V p-p

查询AD8007AKS-REEL供应商

Ultralow Distortion

a

FEATURES

Extremely Low Distortion

Second Harmonic

–88 dBc @ 5 MHz

–83 dBc @ 20 MHz (AD8007)

–77 dBc @ 20 MHz (AD8008)

Third Harmonic

–101 dBc @ 5 MHz

–92 dBc @ 20 MHz (AD8007)

–98 dBc @ 20 MHz (AD8008)

High Speed

650 MHz, –3 dB Bandwidth (G = +1)

1000 V/s Slew Rate

Low Noise

2.7 nV/

22.5 pA/

Low Power

9 mA/Amplifier Typ Supply Current

Wide Supply Voltage Range

5 V to 12 V

0.5 mV Typical Input Offset Voltage

Small Packaging

SOIC-8, MSOP, and SC70 Packages Available

Hz Input Voltage Noise

√

Hz Input Inverting Current Noise

√

High Speed Amplifiers

AD8007/AD8008

CONNECTION DIAGRAMS

SOIC (RN-8) SC70 (KS-5)

AD8007

1

NC

(Top View)

2

–IN

3

+IN

–V

4

S

NC = NO CONNECT

8

NC

7

+V

6

V

5

NC

SOIC (RN) and MSOP (RM)

1

V

OUT1

–IN1

27

36

+IN1

–V

45

S

S

OUT

AD8008

(Top View)

V

1

OUT

–V

2

S

3

+IN

8

+V

V

–IN2

+IN2

AD8007

(Top View)

S

OUT2

5

+V

S

4

–IN

APPLICATIONS

Instrumentation

IF and Baseband Amplifiers

Filters

A/D Drivers

DAC Buffers

GENERAL DESCRIPTION

The AD8007 (single) and AD8008 (dual) are high performance current feedback amplifiers with ultralow distortion

and noise. Unlike other high performance amplifiers, the low

price and low quiescent current allow these amplifiers to be

used in a wide range of applications. ADI’s proprietary second

generation eXtra-Fast Complementary Bipolar (XFCB)

process enables such high performance amplifiers with low

power consumption.

The AD8007/AD8008 have 650 MHz bandwidth, 2.7 nV/√Hz

voltage noise, –83 dB SFDR @ 20 MHz (AD8007), and –77 dBc

SFDR @ 20 MHz (AD8008).

With the wide supply voltage range (5 V to 12 V) and wide bandwidth, the AD8007/AD8008 are designed to work in a variety of

applications. The AD8007/AD8008 amplifiers have a low power

supply current of 9 mA/amplifier.

The AD8007 is available in a tiny SC70 package as well as a

standard 8-lead SOIC. The dual AD8008 is available in both

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

8-lead SOIC and 8-lead MSOP packages. These amplifiers are

rated to work over the industrial temperature range of –40°C

to +85°C.

Figure 1. AD8007 Second and Third Harmonic

Distortion vs. Frequency

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

AD8007/AD8008–SPECIFICATIONS

VS = ⴞ5 V

(@ TA = 25ⴗC, RS = 200 ⍀, RL = 150 ⍀, RF = 499 ⍀, Gain = +2, unless otherwise noted.)

AD8007/AD8008

Parameter Conditions Min Typ Max Unit

DYNAMIC PERFORMANCE

–3 dB Bandwidth G = +1, V

G = +1, V

G = +2, V

G = +1, V

Bandwidth for 0.1 dB Flatness V

= 0.2 V p-p, G = +2, RL = 150 Ω 50 90 MHz

O

Overdrive Recovery Time ±2.5 V Input Step, G = +2, R

Slew Rate G = +1, V

Settling Time to 0.1% G = +2, V

= 0.2 V p-p, RL = 1 kΩ 540 650 MHz

O

= 0.2 V p-p, RL = 150 Ω 250 500 MHz

O

= 0.2 V p-p, RL = 150 Ω 180 230 MHz

O

= 2 V p-p, RL = 1 kΩ 200 235 MHz

O

= 1 kΩ 30 ns

= 2 V Step 900 1000 V/µs

O

= 2 V Step 18 ns

O

L

Settling Time to 0.01% G = +2, VO = 2 V Step 35 ns

NOISE/HARMONIC PERFORMANCE

Second Harmonic fC = 5 MHz, VO = 2 V p-p –88 dBc

= 20 MHz, VO = 2 V p-p –83/–77 dBc

f

Third Harmonic f

IMD f

Third Order Intercept f

C

= 5 MHz, VO = 2 V p-p –101 dBc

C

f

= 20 MHz, VO = 2 V p-p –92/–98 dBc

C

= 19.5 MHz to 20.5 MHz, RL = 1 kΩ,

C

V

= 2 V p-p –77 dBc

O

= 5 MHz, RL = 1 kΩ 43.0/42.5 dBm

C

= 20 MHz, RL = 1 kΩ 42.5 dBm

f

C

Crosstalk (AD8008) f = 5 MHz, G = +2 –68 dB

Input Voltage Noise f = 100 kHz 2.7 nV/√Hz

Input Current Noise –Input, f = 100 kHz 22.5 pA/√Hz

+Input, f = 100 kHz 2 pA/√Hz

Differential Gain Error NTSC, G = +2, R

= 150 Ω 0.015 %

L

Differential Phase Error NTSC, G = +2, RL = 150 Ω 0.010 Degree

DC PERFORMANCE

Input Offset Voltage 0.5 4 mV

Input Offset Voltage Drift 3 µV/°C

Input Bias Current +Input 4 8 µA

–Input 0.4 6 µA

Input Bias Current Drift +Input 16 nA/°C

–Input 9 nA/°C

Transimpedance V

= ±2.5 V, RL = 1 kΩ 1.0 1.5 MΩ

O

RL = 150 Ω 0.4 0.8 MΩ

INPUT CHARACTERISTICS

Input Resistance +Input 4 MΩ

Input Capacitance +Input 1 pF

Input Common-Mode Voltage Range –3.9 to +3.9 V

Common-Mode Rejection Ratio VCM = ±2.5 V 56 59 dB

OUTPUT CHARACTERISTICS

Output Saturation Voltage VCC – VOH, VOL – VEE, RL = 1 kΩ 1.1 1.2 V

Short Circuit Current, Source 130 mA

Short Circuit Current, Sink 90 mA

Capacitive Load Drive 30% Overshoot 8 pF

POWER SUPPLY

Operating Range 5 12 V

Quiescent Current per Amplifier 9 10.2 mA

Power Supply Rejection Ratio

+PSRR 59 64 dB

–PSRR 59 65 dB

REV. C–2–

AD8007/AD8008

VS = +5 V

(@ TA = 25ⴗC, RS = 200 ⍀, RL = 150 ⍀, RF = 499 ⍀, Gain = +2, unless otherwise noted.)

AD8007/AD8008

Parameter Conditions Min Typ Max Unit

DYNAMIC PERFORMANCE

–3 dB Bandwidth G = +1, V

G = +1, V

G = +2, V

G = +1, V

Bandwidth for 0.1 dB Flatness Vo = 0.2 V p-p, G = +2, R

Overdrive Recovery Time 2.5 V Input Step, G = +2, R

Slew Rate G = +1, V

Settling Time to 0.1% G = +2, V

= 0.2 V p-p, RL = 1 kΩ 520 580 MHz

O

= 0.2 V p-p, RL = 150 Ω 350 490 MHz

O

= 0.2 V p-p, RL = 150 Ω 190 260 MHz

O

= 1 V p-p, RL = 1 kΩ 270 320 MHz

O

= 2 V Step 665 740 V/µs

O

= 2 V Step 18 ns

O

= 150 Ω 72 120 MHz

L

= 1 kΩ 30 ns

L

Settling Time to 0.01% G = +2, VO = 2 V Step 35 ns

NOISE/HARMONIC PERFORMANCE

Second Harmonic fC = 5 MHz, VO = 1 V p-p –96/–95 dBc

= 20 MHz, VO = 1 V p-p –83/–80 dBc

f

Third Harmonic f

IMD f

Third Order Intercept f

C

= 5 MHz, VO = 1 V p-p –100 dBc

C

f

= 20 MHz, VO = 1 V p-p –85/–88 dBc

C

= 19.5 MHz to 20.5 MHz, RL = 1 kΩ, –89/–87 dBc

C

V

= 1 V p-p

O

= 5 MHz, RL = 1 kΩ 43.0 dBm

C

= 20 MHz, RL = 1 kΩ 42.5/41.5 dBm

f

C

Crosstalk (AD8008) Output to Output f = 5 MHz, G = +2 –68 dB

Input Voltage Noise f = 100 kHz 2.7 nV/√Hz

Input Current Noise –Input, f = 100 kHz 22.5 pA/√Hz

+Input, f = 100 kHz 2 pA/√Hz

DC PERFORMANCE

Input Offset Voltage 0.5 4 mV

Input Offset Voltage Drift 3 µV/°C

Input Bias Current +Input 4 8 µA

–Input 0.7 6 µA

Input Bias Current Drift +Input 15 nA/°C

–Input 8 nA/°C

Transimpedance V

= 1.5 V to 3.5 V, RL = 1 kΩ 0.5 1.3 MΩ

O

RL = 150 Ω 0.4 0.6 MΩ

INPUT CHARACTERISTICS

Input Resistance +Input 4 MΩ

Input Capacitance +Input 1 pF

Input Common-Mode Voltage Range 1.1 to 3.9 V

Common-Mode Rejection Ratio VCM = 1.75 V to 3.25 V 54 56 dB

OUTPUT CHARACTERISTICS

Output Saturation Voltage VCC – VOH, VOL – VEE, RL = 1 kΩ 1.05 1.15 V

Short Circuit Current, Source 70 mA

Short Circuit Current, Sink 50 mA

Capacitive Load Drive 30% Overshoot 8 pF

POWER SUPPLY

Operating Range 5 12 V

Quiescent Current per Amplifier 8.1 9 mA

Power Supply Rejection Ratio

+PSRR 59 62 dB

–PSRR 59 63 dB

REV. C

–3–

AD8007/AD8008

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.6 V

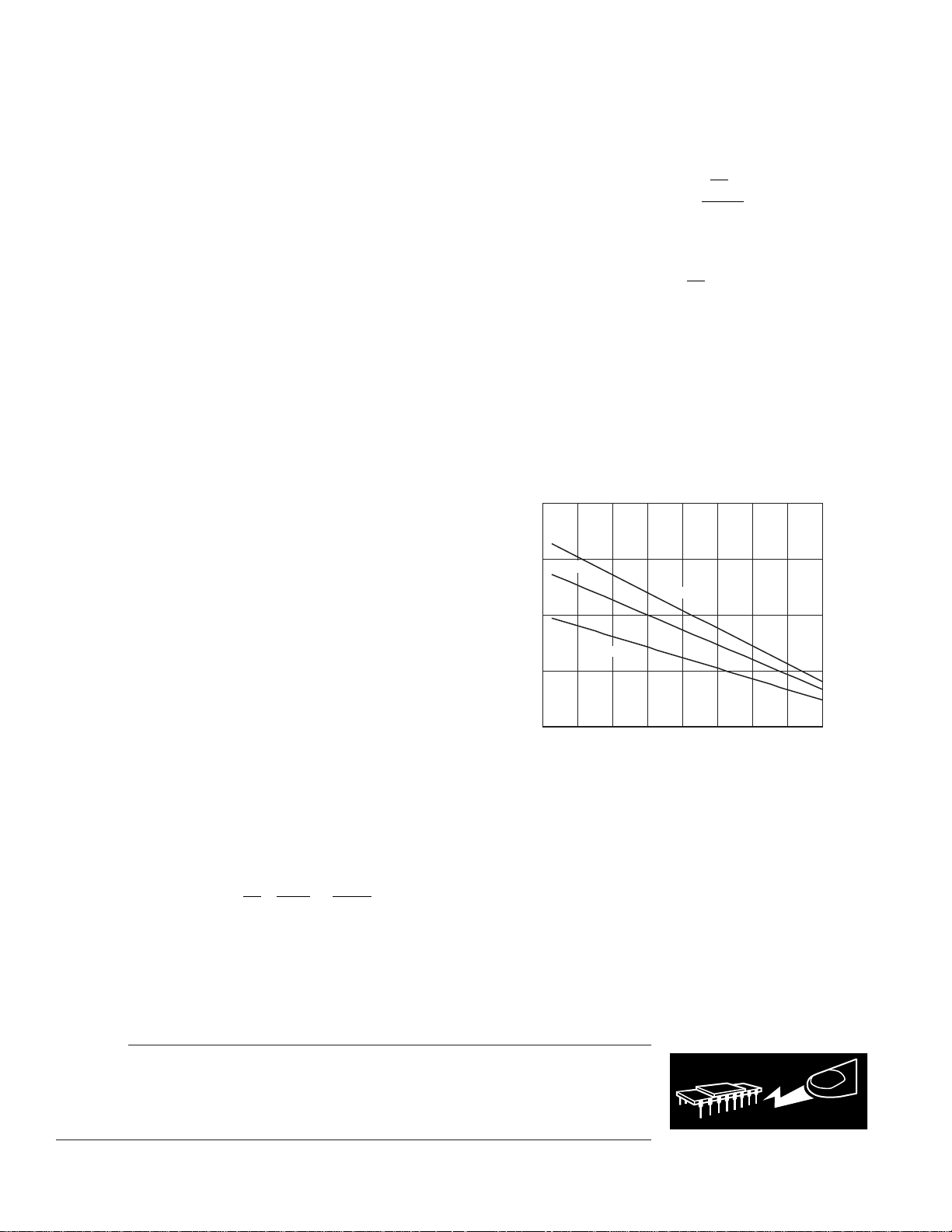

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . See Figure 2

Common-Mode Input Voltage . . . . . . . . . . . . . . . . . . . . . ±V

S

Differential Input Voltage . . . . . . . . . . . . . . . . . . . . . . ± 1.0 V

Output Short Circuit Duration . . . . . . . . . . . . . . See Figure 2

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +125°C

Operating Temperature Range . . . . . . . . . . . –40°C to +85°C

Lead Temperature Range (soldering 10 sec) . . . . . . . . . 300°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

MAXIMUM POWER DISSIPATION

The maximum safe power dissipation in the AD8007/AD8008

packages is limited by the associated rise in junction temperature

) on the die. The plastic encapsulating the die will locally reach

(T

J

the junction temperature. At approximately 150°C, which is the

glass transition temperature, the plastic will change its properties. Even temporarily exceeding this temperature limit may

change the stresses that the package exerts on the die, permanently shifting the parametric performance of the AD8007/

AD8008. Exceeding a junction temperature of 175°C for an

extended period of time can result in changes in the silicon

devices, potentially causing failure.

The still-air thermal properties of the package and PCB (θ

ambient temperature (T

package (P

) determine the junction temperature of the die.

D

), and the total power dissipated in the

A

),

JA

The junction temperature can be calculated as follows:

TT P

=+ ×

ADA

JJ

θ

()

The power dissipated in the package (PD) is the sum of the quiescent power dissipation and the power dissipated in the package

due to the load drive for all outputs. The quiescent power is the

voltage between the supply pins (V

(I

). Assuming the load (RL) is referenced to midsupply, the

S

total drive power is V

/2 ⫻ I

S

package and some in the load (V

) times the quiescent current

S

, some of which is dissipated in the

OUT

OUT

⫻ I

). The difference

OUT

between the total drive power and the load power is the drive

power dissipated in the package.

P

= quiescent power + (total drive power – load power):

D

PVI

=×

()

DSS

+×

VVRV

S OUT

2

L

2

OUT

−

R

L

RMS output voltages should be considered. If RL is referenced

to V

, as in single-supply operation, then the total drive power

S

is V

⫻ I

OUT

.

S

If the rms signal levels are indeterminate, then consider the

worst case, when V

= VS/4 for RL to midsupply:

OUT

V

S

4

PVI

=×

()

DSS

+

R

L

2

In single-supply operation, with RL referenced to VS, worst case is:

V

V

OUT

S

=

2

Airflow will increase heat dissipation, effectively reducing θJA.

Also, more metal directly in contact with the package leads from

metal traces, through holes, ground, and power planes will

reduce the θ

. Care must be taken to minimize parasitic capaci-

JA

tances at the input leads of high speed op amps as discussed in

the board layout section.

Figure 2 shows the maximum safe power dissipation in the package versus the ambient temperature for the SOIC-8 (125°C/

W),

MSOP (150°C/W), and SC70 (210°C/W) packages on a

JEDEC standard 4-layer board. θ

2.0

1.5

MSOP-8

1.0

SC70-5

0.5

MAXIMUM POWER DISSIPATION – W

0

–60 100–40

–20 0 20 406080

AMBIENT TEMPERATURE – ⴗC

values are approximations.

JA

SOIC-8

Figure 2. Maximum Power Dissipation vs.

Temperature for a 4-Layer Board

OUTPUT SHORT CIRCUIT

Shorting the output to ground or drawing excessive current for

the AD8007/AD8008 will likely cause catastrophic failure.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate

on the human body and test equipment and can discharge without detection. Although the AD8007/

AD8008 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. C–4–

AD8007/AD8008

ORDERING GUIDE

Model Temperature Range

AD8007AR +85ºC 8-Lead SOIC RN-8

AD8007AR-REEL +85ºC 8-Lead SOIC RN-8

AD8007AR-REEL7 +85ºC 8-Lead SOIC RN-8

AD8007AKS-REEL +85ºC 5-Lead SC70 KS-5 HTA

AD8007AKS-REEL7 –40ºC to +85ºC 5-Lead SC70 KS-5 HTA

AD8008AR –40ºC to +85ºC 8-Lead SOIC RN-8

AD8008AR-REEL7 –40ºC to +85ºC 8-Lead SOIC RN-8

AD8008AR-REEL –40ºC to +85ºC 8-Lead SOIC RN-8

AD8008ARM-REEL +85ºC 8-Lead MSOP RM-8 H2B

AD8008ARM-REEL7 +85ºC 8-Lead MSOP RM-8 H2B

–40ºC to

–40ºC to

–40ºC to

–40ºC to

–40ºC to

–40ºC to

Package

Description

Package Outline

Branding

Information

REV. C

–5–

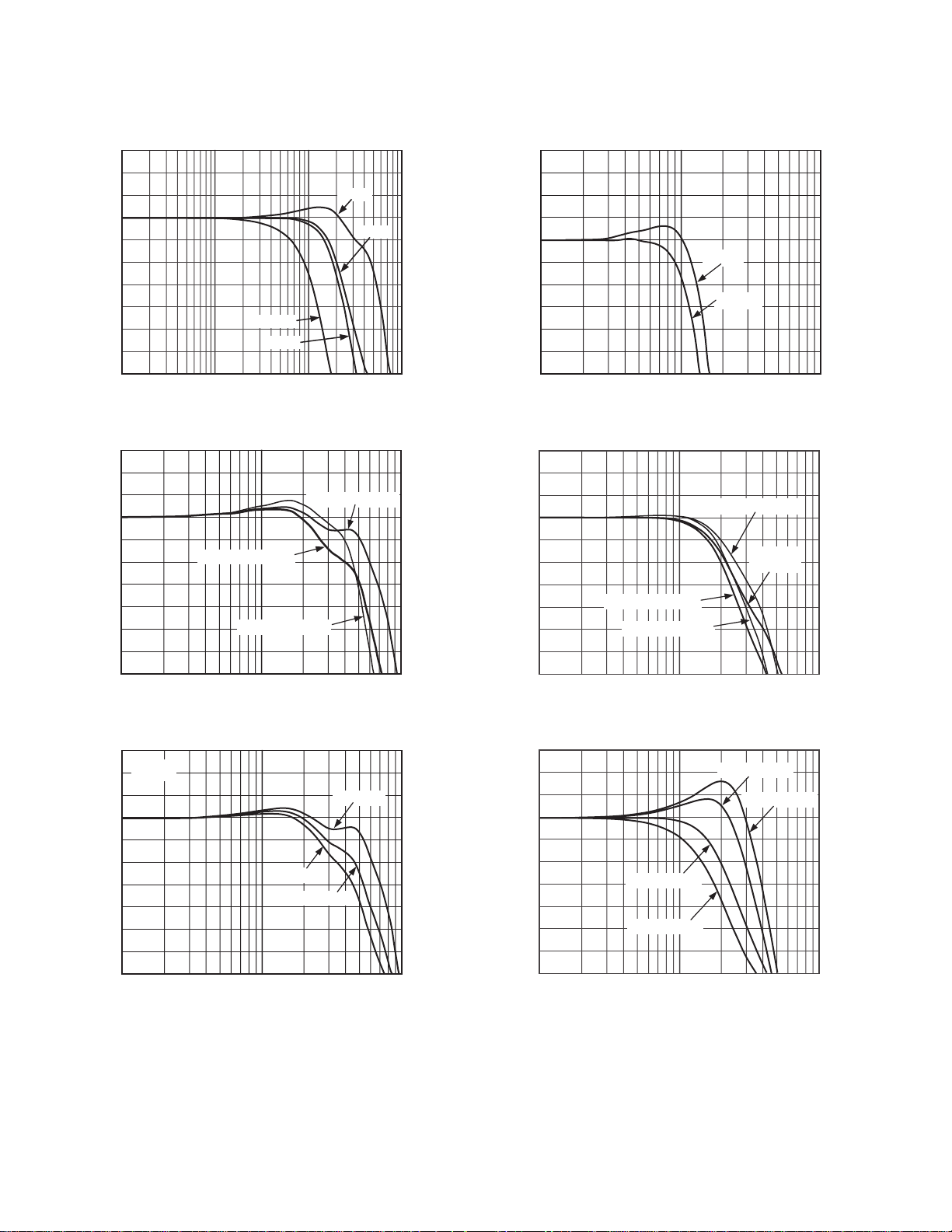

AD8007/AD8008–Typical Performance Characteristics

(VS = ⴞ5 V, RL = 150 ⍀, RS = 200 ⍀, RF = 499 ⍀, unless otherwise noted.)

3

2

1

0

–1

–2

–3

–4

NORMALIZED GAIN – dB

–5

–6

–7

1 10010

G = +10

G = –1

FREQUENCY – MHz

G = +1

G = +2

1000

TPC 1. Small Signal Frequency Response for Various Gains

3

G = +1

2

1

0

–1

–2

GAIN – dB

–3

–4

–5

–6

–7

RL = 150⍀, VS = ⴞ5V

RL = 150⍀, VS = +5V

10010

FREQUENCY – MHz

RL = 1k⍀, VS = ⴞ5V

1000

6.4

G = +2

6.3

6.2

6.1

6.0

5.9

GAIN – dB

5.8

5.7

5.6

5.5

5.4

FREQUENCY – MHz

VS = +5V

VS = ⴞ5V

10010

TPC 4. 0.1 dB Gain Flatness; VS = +5, ±5 V

9

G = +2

8

7

6

5

4

GAIN – dB

3

2

1

0

–1

RL = 150⍀, VS = ⴞ5V

RL = 1k⍀, VS = ⴞ5V

FREQUENCY – MHz

10010

RL = 1k⍀, VS = +5V

RL = 150⍀

= +5V

V

S

1000

1000

TPC 2. Small Signal Frequency Response for VS and R

3

G = +1

2

RL = 1k⍀

1

0

–1

–2

GAIN – dB

–3

–4

–5

–6

–7

RS = 301⍀

10010

FREQUENCY – MHz

RS = 200⍀

RS = 249⍀

1000

TPC 3. Small Signal Frequency Response for

Various R

Values

S

LOAD

TPC 5. Small Signal Frequency Response for VS and R

9

G = +2

8

7

6

5

4

GAIN – dB

3

2

1

0

–1

RF = RG = 499⍀

RF = RG = 649⍀

10010

FREQUENCY – MHz

RF = RG = 324⍀

RF = RG = 249⍀

1000

TPC 6. Small Signal Frequency Response for Various

Feedback Resistors, R

F=RG

LOAD

–6–

REV. C

10

FREQUENCY – Hz

10M

1M

10k 1M100k

TRANSIMPEDANCE – ⍀

1k

100

10

1

100k

10k

10M

100M 1G

0

–30

–90

–150

–210

–270

–330

PHASE – Degrees

2G

TRANSIMPEDANCE

PHASE

30

90

–180

FREQUENCY – MHz

9

8

1

10010

GAIN – dB

5

4

3

2

7

6

0

–1

1000

G = +2

VS = +5V, +85ⴗC

VS = ⴞ5V, –40ⴗC

VS = +5V, –40ⴗC

VS = ⴞ5V, +85ⴗC

FREQUENCY – MHz

9

8

1

10010

GAIN – dB

5

4

3

2

7

6

0

–1

1000

RL = 150⍀, VS = ⴞ5V, VO = 2V p-p

RL = 1k⍀, VS = ⴞ5V, VO = 2V p-p

RL = 150⍀, VS = +5V, VO = 1V p-p

RL = 1k⍀, VS = +5V, VO = 1V p-p

G = +2

G = +2

9

8

7

6

5

GAIN – dB

4

3

2

1

0

499⍀

200⍀

49.9⍀

1 10010

499⍀

R

SNUB

C

LOAD

FREQUENCY – MHz

20pF

20pF AND

20⍀ SNUB

0pF

20pF AND

10⍀ SNUB

AD8007/AD8008

1000

TPC 7. Small Signal Frequency Response for Capacitive

Load and Snub Resistor

TPC 9. Large Signal Frequency Response for Various Gains

REV. C

3

2

1

0

–1

–2

GAIN – dB

–3

–4

–5

–6

–7

G = +1

VS = +5V, –40ⴗC

VS = ⴞ5V, –40ⴗC

10010

FREQUENCY – MHz

VS = +5V, +85ⴗC

VS = ⴞ5V, +85ⴗC

TPC 8. Small Signal Frequency Response over

Temperature, V

3

V

= 2V p-p

OUT

2

1

0

–1

–2

–3

–4

NORMALIZED GAIN – dB

–5

–6

–7

1 10010

= +5 V, ±5 V

S

G = +10

FREQUENCY – MHz

G = –1

G = +1

G = +2

1000

1000

TPC 10. Transimpedance and Phase vs. Frequency

TPC 11. Small Signal Frequency Response over

Temperature, V

= +5 V, ±5 V

S

TPC 12. Large Signal Frequency Response for VS and R

–7–

LOAD

AD8007/AD8008

(VS = ⴞ5 V, RL = 150 ⍀, RS = 200 ⍀, RF = 499 ⍀, unless otherwise noted.)

–40

G = ⴙ1

V

–50

V

–60

–70

–80

DISTORTION – dBc

–90

–100

–110

= 5V

S

= 1V p-p

O

HD2, RL = 1k⍀

HD3, RL = 1k⍀

FREQUENCY – MHz

HD3, RL = 150⍀

101

HD2, RL = 150⍀

100

TPC 13. AD8007 Second and Third Harmonic Distortion

vs. Frequency and R

–40

G = ⴙ1

= ⴞ5V

V

S

–50

= 2V p-p

V

O

–60

–70

HD2, RL = 1k⍀

–80

DISTORTION – dBc

–90

–100

L

HD2, RL = 150⍀

HD3, RL = 150⍀

HD3, RL = 1k⍀

–40

G = ⴙ2

V

= 5V

S

–50

= 1V p-p

V

O

–60

–70

–80

DISTORTION – dBc

–90

–100

–110

HD3, RL = 1k⍀

FREQUENCY – MHz

HD2, RL = 1k⍀

HD2, RL = 150⍀

HD3, RL = 150⍀

101

100

TPC 16. AD8007 Second and Third Harmonic Distortion

vs. Frequency and R

–40

G = ⴙ2

= ⴞ5V

V

S

–50

= 2V p-p

V

O

–60

–70

–80

DISTORTION – dBc

–90

–100

L

HD2, RL = 1k⍀

HD2, RL = 150⍀

HD3, RL = 150⍀

HD3, RL = 1k⍀

–110

101

FREQUENCY – MHz

100

TPC 14. AD8007 Second and Third Harmonic Distortion

vs. Frequency and R

–30

VS = ⴞ5V

= 2V p-p

V

O

–40

= 150⍀

R

L

–50

–60

–70

–80

DISTORTION – dBc

–90

–100

–110

L

HD3, G = ⴙ10

FREQUENCY – MHz

HD2, G = ⴙ10

HD2, G = ⴙ1

101

HD3, G = ⴙ1

100

TPC 15. AD8007 Second and Third Harmonic Distortion

vs. Frequency and Gain

–110

101

FREQUENCY – MHz

100

TPC 17. AD8007 Second and Third Harmonic Distortion

vs. Frequency and R

–30

G = +2

= 5V

V

S

–40

= 150⍀

R

L

–50

–60

–70

–80

DISTORTION – dBc

–90

–100

–110

L

HD2, VO = 4V p-p

HD2, VO = 2V p-p

FREQUENCY – MHz

HD3, VO = 4V p-p

HD3, VO = 2V p-p

101

100

TPC 18. AD8007 Second and Third Harmonic Distortion

vs. Frequency and V

OUT

REV. C–8–

FREQUENCY – MHz

10010

HD2, RL = 1k⍀

HD2, RL = 150⍀

HD3, RL = 1k⍀

HD3, R

L

= 150⍀

G = 2

V

S

= 5V

V

O

= 1V p-p

–40

1

DISTORTION – dBc

–110

–100

–90

–80

–70

–60

–50

FREQUENCY – MHz

10010

HD2, RL = 150⍀

HD3, R

L

= 1k⍀

HD3, RL = 150⍀

G = 2

VS = 5V

V

O

= 2V p-p

–40

1

DISTORTION – dBc

–110

–100

–90

–80

–70

–60

–50

HD2, RL = 1k⍀

(VS = ⴞ5 V, RS = 200 ⍀, RF = 499 ⍀, RL = 150 ⍀, @25ⴗC, unless otherwise noted.)

–40

G = 1

= 5V

V

S

–50

= 1V p-p

V

O

–60

–70

–80

DISTORTION – dBc

–90

–100

–110

HD2, RL = 1k⍀

1

TPC 19. AD8008 Second and Third Harmonic

Distortion vs. Frequency and R

–40

G = 1

VS = 5V

–50

= 1V p-p

V

O

HD2, RL = 150⍀

HD3, RL = 150⍀

FREQUENCY – MHz

HD3, RL = 1k⍀

L

10010

TPC 22. AD8008 Second and Third Harmonic

Distortion vs. Frequency and R

AD8007/AD8008

L

REV. C

–60

–70

HD2, RL = 150⍀

–80

HD2, RL = 1k⍀

DISTORTION – dBc

–90

–100

HD3, RL = 1k⍀

–110

1 10010

FREQUENCY – MHz

HD3, RL = 150⍀

TPC 20. AD8008 Second and Third Harmonic

Distortion vs. Frequency and R

–30

VS = 5V

= 2V p-p

V

–40

O

= 150 ⍀

R

L

–50

–60

–70

–80

DISTORTION – dBc

HD2, G = 1

–90

–100

–110

1

TPC 21. AD8008 Second and Third Harmonic

HD3, G = 10

HD2, G = 10

FREQUENCY – MHz

L

HD3, G = 1

Distortion vs. Frequency and Gain

TPC 23. AD8008 Second and Third Harmonic

Distortion vs. Frequency and R

–30

G = 2

= 150 ⍀

R

L

–40

= 5

V

S

–50

–60

HD2, VO = 4V p-p

–70

–80

DISTORTION – dBc

–90

–100

10010

–110

1

HD2, VO = 2V p-p

HD3, VO = 4V p-p

FREQUENCY – MHz

L

HD3, V

= 2V p-p

O

10010

TPC 24. AD8008 Second and Third Harmonic

Distortion vs. Frequency and V

OUT

–9–

AD8007/AD8008

(VS = ⴞ5 V, RS = 200 ⍀, RF = 499 ⍀, RL = 150 ⍀, @25ⴗC unless otherwise noted.)

–60

G = ⴙ2

V

S

F

O

–65

–70

–75

–80

DISTORTION – dBc

–85

–90

= 5V

= 20MHz

1.51

HD2, R

V

OUT

= 1k⍀

L

– V p-p

HD3, RL = 1k⍀

HD3, RL = 150⍀

HD2, R

2

= 150⍀

L

TPC 25. AD8007 Second and Third Harmonic

Distortion vs. V

44

43

42

41

40

39

38

37

THIRD ORDER INTERCEPT – dBm

36

35

5

10 15 20 25 30 35 40 45 50 55 60 65 70

and R

OUT

FREQUENCY – MHz

L

G = +2

VS = ⴞ5V

= 2V p-p

V

O

= 1k⍀

R

L

2.5

–65

G = ⴙ2

V

–70

F

–75

–80

–85

–90

–95

DISTORTION – dBc

–100

–105

–110

= ⴞ5V

S

= 20MHz

O

HD2, RL = 150⍀

21

HD3, RL = 1k⍀

HD3, RL = 150⍀

34

V

OUT

HD2, RL = 1k⍀

56

– V p-p

TPC 28. AD8007 Second and Third Harmonic

Distortion vs. V

44

43

42

41

40

39

38

37

THIRD ORDER INTERCEPT – dBm

36

35

and R

OUT

FREQUENCY – MHz

L

G = ⴙ2

= 5V

V

S

= 2V p-p

V

O

= 1k⍀

R

L

6560555045403530252015105

70

TPC 26. AD8007 Third Order Intercept vs. Frequency

–65

G = ⴙ2

= 5V

V

S

= 20MHz

–70

–75

–80

–85

–90

F

O

= 1k⍀

HD2, R

L

1.51

HD2, R

HD3, R

HD3, R

V

OUT

= 150⍀

L

= 150⍀

L

= 1k⍀

L

– V p-p

2

2.5

TPC 27. AD8008 Second and Third Harmonic

Distortion vs. V

OUT

and R

L

TPC 29. AD8008 Third Order Intercept vs. Frequency

–65

–70

–75

–80

–85

–90

–95

–100

–105

–110

HD2, RL = 150⍀

HD3, RL = 1k⍀

1

HD2, RL = 1k⍀

HD3, RL = 150⍀

G = ⴙ2

= 5V

V

S

= 20MHz

F

O

26

345

V

– V p-p

OUT

TPC 30. AD8008 Second and Third Harmonic

Distortion vs. V

OUT

and R

L

REV. C–10–

FREQUENCY – Hz

10 10k100

CURRENT NOISE – pA/ Hz

100

10

1

100k

1M

1000

10M1k

NONINVERTING CURRENT NOISE 2.0pA/ Hz

INVERTING CURRENT NOISE 22.5pA/ Hz

FREQUENCY – Hz

100k 1G

CROSSTALK – dB

–100

1M

10M 100M

–90

–80

–70

–60

–50

–40

–20

–30

G = ⴙ2

R = 150⍀

V

S

= ⴞ5V

V

M

= 1V p-p

SIDE B DRIVEN

SIDE A DRIVEN

FREQUENCY – Hz

20

10

10k 1M100k

PSRR – dB

–20

–30

–40

–50

0

–10

10M

100M 1G

–60

–70

–80

+PSRR

–PSRR

(VS = ±5 V, RL = 150 ⍀, RS = 200 ⍀, RF = 499 ⍀, unless otherwise noted.)

100

10

2.7nV/ Hz

VOLTA G E NOISE – nV/ Hz

AD8007/AD8008

1

10 1k100

FREQUENCY – Hz

10k

100k 1M

TPC 31. Input Voltage Noise vs. Frequency

1000

G = ⴙ2

100

10

1

OUTPUT IMPEDANCE – ⍀

0.1

0.01

100k 10M1M

FREQUENCY – Hz

100M

TPC 32. Output Impedance vs. Frequency

0

VS = ⴞ5V, ⴙ5V

–10

–20

TPC 34. Input Current Noise vs. Frequency

1G

TPC 35. AD8008 Crosstalk vs. Frequency (Output to Output)

–30

–40

CMRR – dB

–50

–60

REV. C

–70

100k

1M

FREQUENCY – Hz

TPC 33. CMRR vs. Frequency

10M

100M 1G

TPC 36. PSRR vs. Frequency

–11–

AD8007/AD8008

R

G = ⴙ1

= 150⍀, VS = ⴙ5V AND ⴞ5V

L

G = +2

R

= 150⍀, VS = +5V AND 5V

L

R

= 1k⍀, VS = ⴙ5V AND ⴞ5V

L

50mV/DIV

010

20 30 40 50

TIME – ns

TPC 37. Small Signal Transient Response for

= 150Ω, 1 kΩ and VS = +5 V, ±5 V

R

L

G = +1

1V/DIV

R

L

R

= 150⍀

= 1k⍀

L

RL = 1k⍀, VS = +5V AND 5V

50mV/DIV

01020304050

TIME – ns

TPC 40. Small Signal Transient Response for

R

= 150 Ω, 1 kΩ and VS = +5 V, ±5 V

L

G = –1

INPUT

OUTPUT

1V/DIV

01020304050

TIME – ns

TPC 38. Large Signal Transient Response for

R

= 150 Ω, 1 k

L

G = ⴙ2

010 20304050

1V/DIV

Ω

C

= 0pF

LOAD

C

= 10pF

LOAD

C

= 20pF

LOAD

TIME – ns

TPC 39. Large Signal Transient Response

for Capacitive Load = 0 pF, 10 pF, and 20 pF

010203040 50

TIME – ns

TPC 41. Large Signal Transient Response, G = –1,

R

= 150

L

Ω

499⍀

200⍀

49.9⍀

50mV/DIV

CL = 0pF

CL = 20pF

499⍀

–

+

C

LOAD

TIME – ns

CL = 20pF

= 10⍀

R

SNUB

R

SNUB

G = ⴙ2

010 20304050

TPC 42. Small Signal Transient Response: Effect of

Series Snub Resistor when Driving Capacitive Load

REV. C–12–

ⴙV

AD8007/AD8008

4

G = ⴙ2

S

RL = 1k⍀

3

2

G = +10

V

= 5V

S

= 0.75V

V

IN

RL = 150⍀

OUTPUT (2V/DIV)

ⴚV

S

0 100 200

INPUT (1V/DIV)

TIME – ns

300 400 500

TPC 43. Output Overdrive Recovery, RL = 1 kΩ,

Ω

, VIN = ±2.5 V

150

0.5

0.4

0.3

0.2

0.1

0

ⴚ0.1

ⴚ0.2

SETTLING TIME – %

ⴚ0.3

ⴚ0.4

ⴚ0.5

0

18ns

51015202530354045

TIME – ns

G = +2

1

– V

0

OUT

V

–1

–2

–3

–4

TPC 45. V

=±0.75 V

V

IN

2000

Swing vs. R

OUT

400 600

RL – ⍀

LOAD

800 1000

, VS=±5 V, G = +10,

TPC 44. 0.1% Settling Time, 2 V Step

REV. C

–13–

AD8007/AD8008

THEORY OF OPERATION

The AD8007 (single) and AD8008 (dual) are current feedback

amplifiers optimized for low distortion performance. A simplified

conceptual diagram of the AD8007 is shown in Figure 3. It closely

resembles a classic current feedback amplifier comprised of a

complementary emitter-follower input stage, a pair of signal mirrors, and a diamond output stage. However, in the case of the

AD8007/AD8008, several modifications have been made to greatly

improve the distortion performance over that of a classic current

feedback topology.

+V

Q5

Q6

OUT

S

–V

S

IN+

M1

I

–

I

–

1

CJ1

+V

D1

D2

I

–

2

Q1

IN–

I

DI

Q2

S

HiZ

–V

S

CJ2

M2

R

G

3

Q3

I

DO

Q4

–

I

4

R

F

Figure 3. Simplified Schematic of AD8007

The signal mirrors have been replaced with low distortion, high

precision mirrors. They are shown as “M1” and “M2” in Figure 3.

Their primary function from a distortion standpoint is to greatly

reduce the effect of highly nonlinear distortion caused by capacitances C

1 and CJ2. These capacitors represent the collector-to-base

J

capacitances of the mirrors’ output devices.

A voltage imbalance arises across the output stage, as measured

from the high impedance node “HiZ” to the output node “Out.”

This imbalance is a result of delivering high output currents and

is the primary cause of output distortion. Circuitry is included

to sense this output voltage imbalance and generate a compensating

current “I

.” When injected into the circuit, IDO reduces the

DO

distortion that would be generated at the output stage. Similarly,

the nonlinear voltage imbalance across the input stage (measured

from the noninverting to the inverting input) is sensed, and a current “I

” is injected to compensate for input-generated distortion.

DI

The design and layout are strictly top-to-bottom symmetric in

order to minimize the presence of even-order harmonics.

USING THE AD8007/AD8008

Supply Decoupling for Low Distortion

Decoupling for low distortion performance requires careful

consideration. The commonly adopted practice of returning the

high frequency supply decoupling capacitors to physically separate (and possibly distant) grounds can lead to degraded

even-order harmonic performance. This situation is shown in

Figure 4 using the AD8007 as an example. Note that for a sinusoidal input, each decoupling

quasi-rectified current carrying

R

G

499⍀

IN

capacitor returns to its ground a

high even-order harmonics.

R

F

499⍀

GND 1

AD8007

GND 2

10F

+

10F

+

OUT

+V

R

200⍀

–V

0.1F

S

S

S

0.1F

Figure 4. High Frequency Capacitors Returned

to Physically Separate Grounds (Not Recommended)

The decoupling scheme shown in Figure 5 is preferable. Here,

the two high frequency decoupling capacitors are first tied

together at a common node, and are then returned to the

ground plane through a single connection. By first adding the

two currents flowing through each high frequency decoupling

capacitor, one is ensuring that the current returned into the

ground plane is only at the fundamental frequency.

R

F

499⍀

10F

AD8007

10F

+

0.1F

OUT

0.1F

+

R

499⍀

IN

+V

S

G

R

S

200⍀

–V

S

Figure 5. High Frequency Capacitors Returned

to Ground at a Single Point (Recommended)

Whenever physical layout considerations prevent the decoupling

scheme shown in Figure 5, the user can connect one of the high

frequency decoupling capacitors directly across the supplies and

connect the other high frequency decoupling capacitor to ground.

This is shown in Figure 6.

REV. C–14–

R

F

499⍀

10F

+

+V

S

C1

0.1F

R

G

499⍀

R

S

AD8007

200⍀

IN

–V

S

10F

C2

0.1F

+

OUT

Figure 6. High Frequency Capacitors Connected

across the Supplies (Recommended)

Layout Considerations

The standard noninverting configuration with recommended power

supply bypassing is shown in Figure 6. This is also the bypassing

scheme used on the evaluation board shown in Figure 7. The

0.1 µF high frequency decoupling capacitors should be X7R or

NPO chip components. Connect C2 from the +VS pin to the –V

S

pin. Connect C1 from the +VS pin to signal ground.

The length of the high frequency bypass capacitor leads is critical.

Parasitic inductance due to long leads will work against the low

impedance created by the bypass capacitor. The ground for the

load impedance should be at the same physical location as the

bypass capacitor grounds. For the larger value capacitors, which

are intended to be effective at lower frequencies, the current

return path distance is less critical.

LAYOUT AND GROUNDING CONSIDERATIONS

Grounding

A ground plane layer is important in densely packed PC boards

to minimize parasitic inductances. However, an understanding of

where the current flows in a circuit is critical to implementing

effective high speed circuit design. The length of the current path

is directly proportional to the magnitude of parasitic inductances and thus the high frequency impedance of the path. High

speed currents in an inductive ground return will create an

unwanted voltage noise. Broad ground plane areas will reduce

the parasitic inductance.

Input Capacitance

Along with bypassing and ground, high speed amplifiers can be

sensitive to parasitic capacitance between the inputs and ground.

Even 1 pF or 2 pF of capacitance will reduce the input impedance at high frequencies, in turn increasing the amplifier’s gain,

causing peaking of the frequency response or even oscillations

if severe enough. It is recommended that the external passive components that are connected to the input pins be placed as close as

possible to the inputs to avoid parasitic capacitance. The ground

and power planes must be kept at a distance of at least 0.05 mm

from the input pins on all layers of the board.

AD8007/AD8008

Output Capacitance

To a lesser extent, parasitic capacitances on the output can cause

peaking of the frequency response. There are two methods to

effectively minimize its effect:

1. Put a small value resistor in series with the output to isolate

the load capacitance from the amplifier’s output stage.

(See TPC 7.)

2. Increase the phase margin by (a) increasing the amplifier’s

gain or (b) adding a pole by placing a capacitor in parallel

with the feedback resistor.

Input-to-Output Coupling

To minimize capacitive coupling, the input and output signal

traces should not be parallel. This helps reduce unwanted positive feedback.

External Components and Stability

The AD8007 and AD8008 are current feedback amplifiers and,

to a first order, the feedback resistor determines the bandwidth

and stability. The gain, load impedance, supply voltage, and

input impedances also have an effect.

TPC 6 shows the effect of changing R

for a gain of +2. Increasing R

F

reduce the bandwidth. TPC 1 shows that for a given R

the gain will also reduce peaking and bandwidth. Table I shows

the recommended R

and RG values that optimize bandwidth with

F

minimal peaking.

Table I. Recommended Component Values

Gain RF(Ω)R

–1 499 499 200

+1 499 NA 200

+2 499 499 200

+5 499 124 200

+10 499 54.9 200

The load resistor will also affect bandwidth as shown in TPCs 2

and 5. A comparison between TPCs 2 and 5 also demonstrates

the effect of gain and supply voltage.

When driving loads with a capacitive component, stability is

improved by using a series snub resistor “R

The frequency and pulse responses for various capacitive loads

are illustrated in TPCs 7 and 42, respectively.

For noninverting configurations, a resistor in series with the input,

R

, is needed to optimize stability for Gain = +1, as illustrated

S

in TPC 3. For larger noninverting gains, the effect of a series

resistor is reduced.

on bandwidth and peaking

F

will reduce peaking but also

, increasing

F

(Ω)R

G

SNUB

” at the output.

S

REV. C

–15–

AD8007/AD8008

R

F

+V

S

C4

10F

+

C1

4

AD8007

3

0.1F

C2

0.1F

C3

10F

AGND

1

+

5

2

–V

S

R

GN

SMA

INPUT

R

T

AGND

R

GP

AGND

R

S

Figure 7. Schematic of AD8007 Evaluation Board

for the SC70 Package

RBT

OUTPUT

SMA

EVALUATION BOARD

The SC70 board schematic is shown in Figure 7. To use the

SC70 board in an inverting configuration, R

left open. The position of R

can be shifted so that it connects

S

Pin 3 to ground. When used as a noninverter, R

and R

is left open. In both configurations, RT allows for a 50 Ω

GN

is used and RGP is

GN

is populated

GP

termination resistor. Universal (inverting or noninverting) AD8007

SOIC, AD8008 SOIC, and AD8008 MSOP boards are also available. The SC70 and MSOP evaluation boards are shown in

Figures 8–15.

REV. C–16–

AD8007/AD8008

Figure 8. SC70 Evaluation Board Silkscreen (Top)

Figure 10. SC70 Evaluation Board, Amplifier Side (Top)

Figure 9. SC70 Evaluation Board Silkscreen (Bottom)

REV. C

Figure 11. SC70 Evaluation Board, Component

Side (Bottom)

–17–

AD8007/AD8008

Figure 12. MSOP Evaluation Board Silkscreen (Top)

Figure 13. MSOP Evaluation Board Silkscreen (Bottom)

Figure 14. MSOP Evaluation Board, Amplifier Side (Top)

Figure 15. MSOP Evaluation Board, Amplifier

Side (Bottom)

REV. C–18–

OUTLINE DIMENSIONS

8-Lead Standard Small Outline Package [SOIC]

Narrow Body

(RN-8)

Dimensions shown in millimeters and (inches)

5.00 (0.1968)

4.80 (0.1890)

4.00 (0.1574)

3.80 (0.1497)

85

6.20 (0.2440)

5.80 (0.2284)

41

AD8007/AD8008

1.27 (0.0500)

0.25 (0.0098)

0.10 (0.0040)

COPLANARITY

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

BSC

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012AA

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.33 (0.0130)

0.25 (0.0098)

0.19 (0.0075)

0.50 (0.0196)

0.25 (0.0099)

8ⴗ

0ⴗ

1.27 (0.0500)

0.41 (0.0160)

8-Lead MSOP Package [MSOP]

(RM-8)

Dimensions shown in millimeters

3.00

BSC

85

3.00

BSC

1

PIN 1

0.65 BSC

0.15

0.00

0.38

0.22

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-187AA

4

SEATING

PLANE

4.90

BSC

1.10 MAX

0.23

0.08

8ⴗ

0ⴗ

0.80

0.40

ⴛ 45ⴗ

REV. C

5-Lead Pastic Surface Mount Package [SC70]

(KS-5)

Dimensions shown in millimeters

2.00 BSC

0.30

0.15

4

3

0.65 BSC

2.10 BSC

1.10 MAX

SEATING

PLANE

0.22

0.08

2

1.25 BSC

PIN 1

1.00

0.90

0.70

0.10

0.00

5

1

COMPLIANT TO JEDEC STANDARDS MO-203AA

–19–

0.46

0.36

0.26

AD8007/AD8008

Revision History

Location Page

10/02—Data Sheet changed from REV. B to REV. C

CONNECTION DIAGRAMS captions updated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ORDERING GUIDE updated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 5 edited . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9/02—Data Sheet changed from REV. A to REV. B.

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8/02—Data Sheet changed from REV. 0 to REV. A.

Added AD8008 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Universal

Added SOIC-8 (RN) and MSOP-8 (RM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Changes to FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Changes to GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Changes to SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Edits to MAXIMUM POWER DISSIPATION SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

New Figure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Changes to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

New TPCs 19–24 and TPCs 27, 29, 30, and 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Changes to EVALUATION BOARD section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MSOP-8 (RM) added . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

C02866–0–10/02(C)

–20–

PRINTED IN U.S.A.

REV. C

Loading...

Loading...