LC2MOS 8-Channel, 12-Bit

A

V

www.BDTIC.com/ADI

FEATURES

Fast 12-bit ADC with 5.9 μs conversion time

Eight single-ended analog input channels

Selection of input ranges:

±10 V for AD7890-10

0 V to 4.096 V for AD7890-4

0 V to 2.5 V for AD7890-2

Allows separate access to multiplexer and ADC

On-chip track/hold amplifier

On-chip reference

High-speed, flexible, serial interface

Single supply, low-power operation (50 mW maximum)

Power-down mode (75 μW typ)

GENERAL DESCRIPTION

The AD7890 is an 8-channel 12-bit data acquisition system. The

part contains an input multiplexer, an on-chip track/hold

amplifier, a high speed 12-bit ADC, a 2.5 V reference, and a

high speed, serial interface. The part operates from a single 5 V

supply and accepts an analog input range of ±10 V (AD7890-10),

0 V to 4.096 V (AD7890-4), and 0 V to 2.5 V (AD7890-2).

Serial Data Acquisition System

AD7890

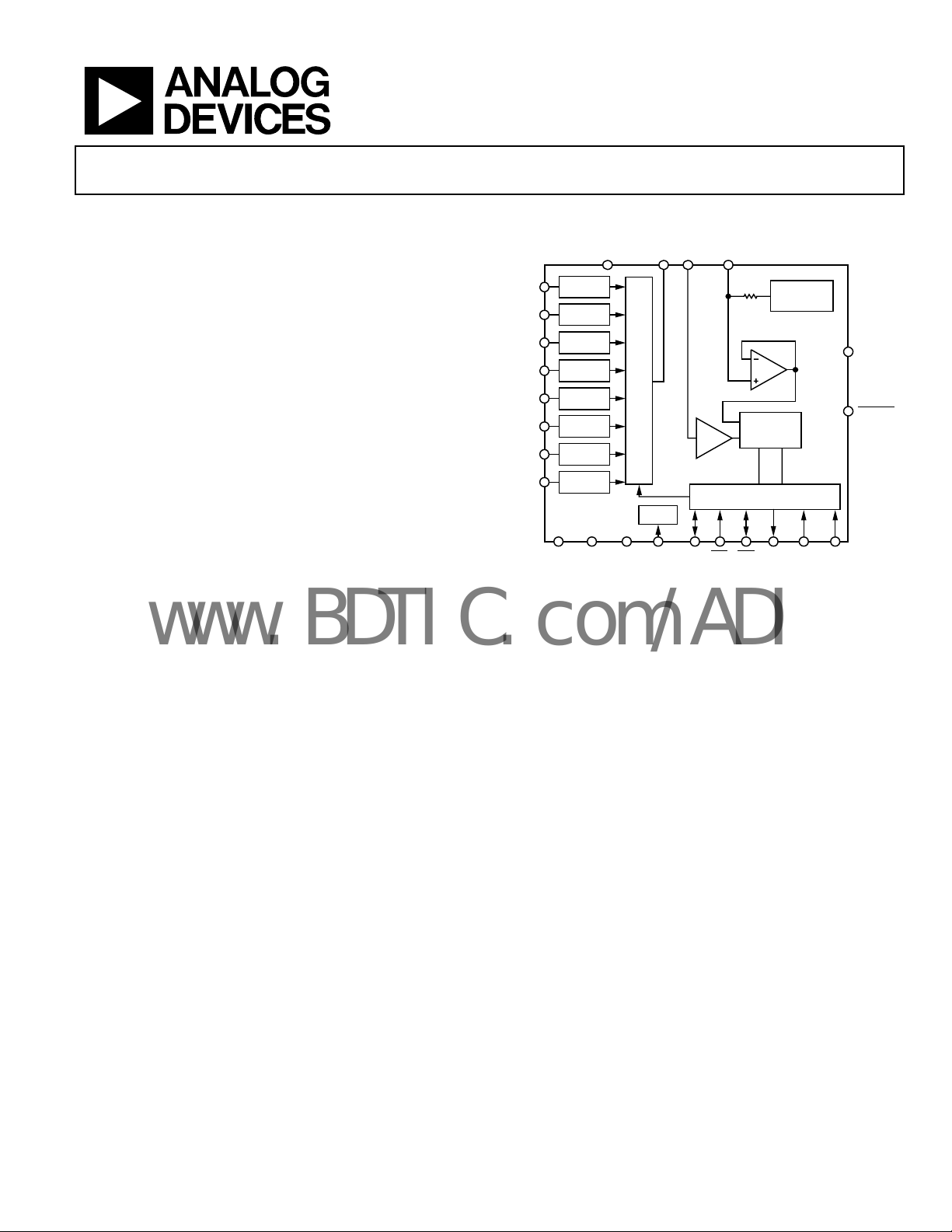

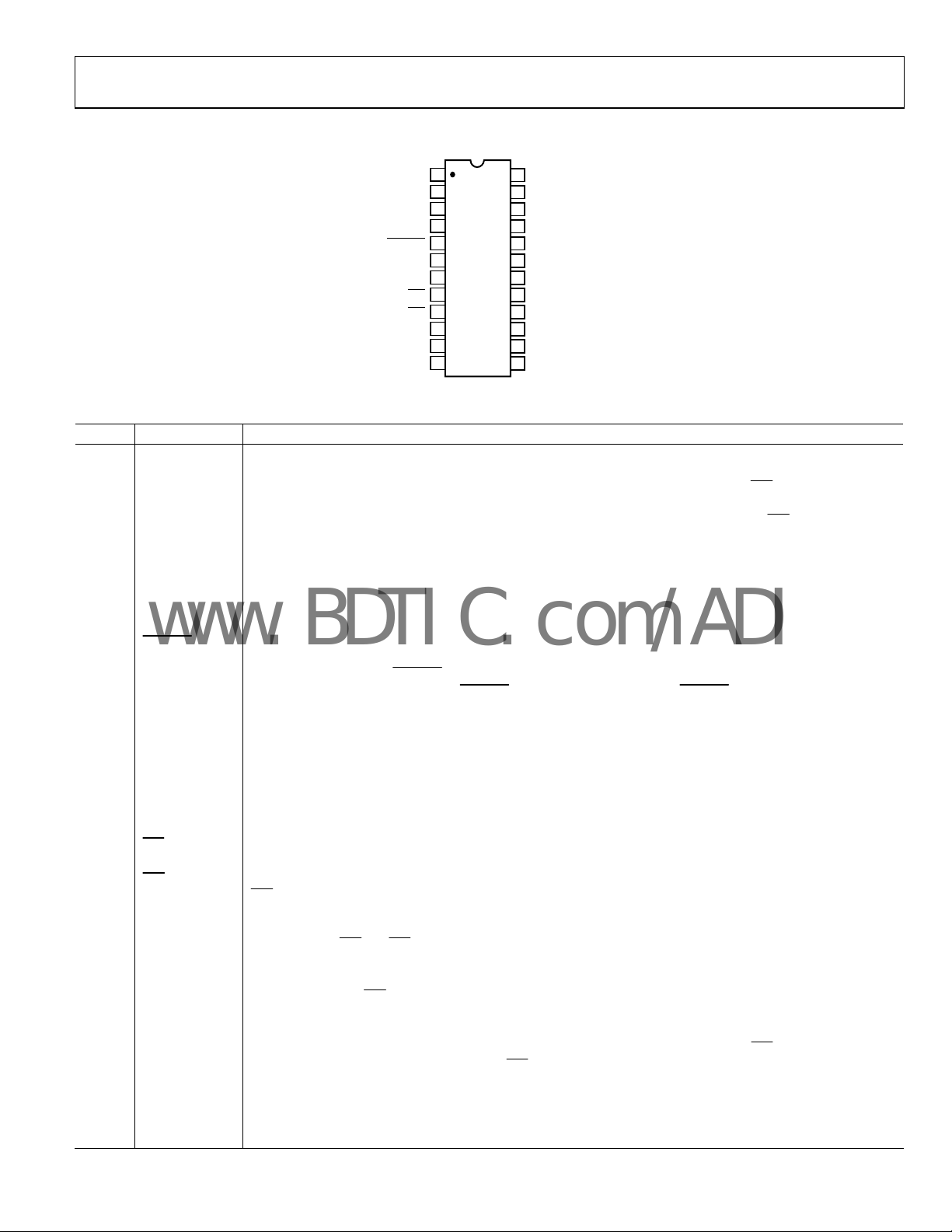

FUNCTIONAL BLOCK DIAGRAM

MUX

SH

DD

V

V

V

V

V

V

V

V

SIGNAL

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

AGND AGND DGND SCLK TFS RFS DATA

SCALING

SIGNAL

SCALING

SIGNAL

SCALING

SIGNAL

SCALING

SIGNAL

SCALING

SIGNAL

SCALING

SIGNAL

SCALING

SIGNAL

SCALING

AD7890

1

1

1

1

1

1

1

1

MUX

CLOCK

OUT

TRACK/HOL D

CLK

IN

REF OUT/

IN

REF IN

2kΩ

OUTPUT/CONTROL REGISTER

1

NO SCALING ON AD7890-2

Figure 1.

REFERENCE

12-BIT

ADC

OUT

2.5V

DATAINSMODE

C

EXT

CONVST

01357-001

The multiplexer on the part is independently accessible. This

al

lows the user to insert an antialiasing filter or signal

conditioning, if required, between the multiplexer and the

ADC. This means that one antialiasing filter can be used for all

eight channels. Connection of an external capacitor allows the

user to adjust the time given to the multiplexer settling to

include any external delays in the filter or signal conditioning

circuitry.

Output data from the AD7890 is provided via a high speed

b

idirectional serial interface port. The part contains an on-chip

control register, allowing control of channel selection,

conversion start, and power-down via the serial port. Versatile,

high speed logic ensures easy interfacing to serial ports on

microcontrollers and digital signal processors.

In addition to the traditional dc accuracy specifications such as

linea

rity, full-scale, and offset errors, the AD7890 is also

specified for dynamic performance parameters including

harmonic distortion and signal-to-noise ratio.

Power dissipation in normal mode is low at 30 mW typical and the

part can be placed in a standby (power-down) mode if it is not

required to perform conversions. The AD7890 is fabricated in

Analog Devices, Inc.’s Linear Compatible CMOS (LC

2

MOS)

process, a mixed technology process that combines precision

bipolar circuits with low power CMOS logic. The part is available

in a 24-lead, 0.3" wide, plastic or ceramic dual-in-line package or in

a 24-lead small outline package (SOIC_W).

PRODUCT HIGHLIGHTS

1. Complete 12-Bit Data Acquisition System-on-a-Chip.

The AD7890 is a complete monolithic ADC combining an

8-channel multiplexer, 12-bit ADC, 2.5 V reference, and a

track/hold amplifier on a single chip.

eparate Access to Multiplexer and ADC.

2. S

The AD7890 provides access to the output of the

multiplexer allowing one antialiasing filter for 8 channels—

a considerable savings over the 8 antialiasing filters required if

the multiplexer is internally connected to the ADC.

gh Speed Serial Interface.

3. Hi

The part provides a high speed serial interface for easy

connection to serial ports of microcontrollers and DSP

processors.

Rev. C

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

AD7890

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features.............................................................................................. 1

Serial Interface ................................................................................ 17

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Timing Specifications .................................................................. 5

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Terminology ...................................................................................... 9

Control Register.............................................................................. 10

Theory of Operation ...................................................................... 11

Converter Details........................................................................ 11

Circuit Description..................................................................... 11

Track/Hold Amplifier ................................................................ 12

Self-Clocking Mode ................................................................... 17

External Clocking Mode ........................................................... 18

Simplifying the Interface........................................................... 19

Microprocessor/Microcontroller Interface................................. 20

AD7890 to 8051 Interface ......................................................... 20

AD7890 to 68HC11 Interface................................................... 20

AD7890 to ADSP-2101 Interface ............................................. 21

AD7890 to DSP56000 Interface ............................................... 21

AD7890 to TMS320C25/30 Interface...................................... 21

Antialiasing Filter....................................................................... 22

Performance.................................................................................... 23

Linearity....................................................................................... 23

Noise ............................................................................................ 23

Dynamic Performance............................................................... 24

Effective Number of Bits ........................................................... 24

Reference ..................................................................................... 13

Timing and Control ................................................................... 13

C

Functioning......................................................................... 16

EXT

REVISION HISTORY

9/06—Rev. B to Rev. C

Updated Format..................................................................Universal

Changes to Table 1............................................................................ 3

Updated Outline Dimensions....................................................... 25

Changes to Ordering Guide.......................................................... 27

2/01—Rev. A to Rev. B

Outline Dimensions....................................................................... 25

Ordering Guide .......................................................................... 27

Rev. C | Page 2 of 28

AD7890

www.BDTIC.com/ADI

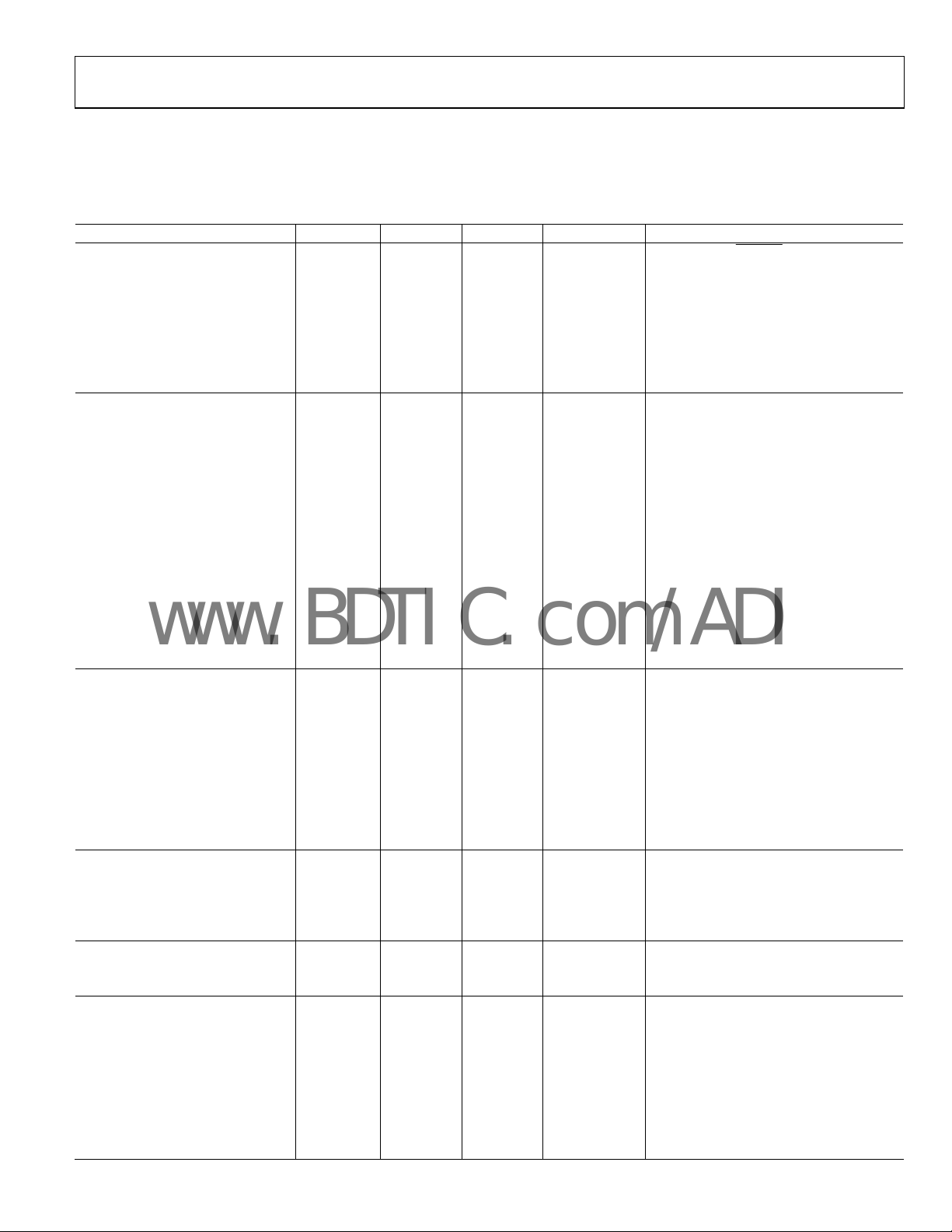

SPECIFICATIONS

VDD = 5 V, AGND = DGND = 0 V, REF IN = 2.5 V, f

T

, unless otherwise noted.

MAX

Table 1.

Parameter A Versions1B Versions S Version Unit Test Conditions/Comments

DYNAMIC PERFORMANCE

Signal to (Noise + Distortion) Ratio270 70 70 dB min fIN = 10 kHz sine wave, f

Total Harmonic Distortion (THD)2

Peak Harmonic or Spurious Noise2

Intermodulation Distortion

2nd Order Terms −80 −80 −80 dB typ

3rd Order Terms −80 −80 −80 dB typ

Channel-to-Channel Isolation2

DC ACCURACY

Resolution 12 12 12 Bits

Min. Resolution for Which No

Missing Codes Are Guaranteed

Relative Accuracy2

Differential Nonlinearity2

Positive Full-Scale Error2

Full-Scale Error Match

AD7890-2, AD7890-4

Unipolar Offset Error2

Unipolar Offset Error Match 2 2 2 LSB max

AD7890-10 Only

Negative Full-Scale Error2

Bipolar Zero Error2

Bipolar Zero Error Match 2 2 2 LSB max

ANALOG INPUTS

AD7890-10

Input Voltage Range ±10 ±10 ±10 Volts

Input Resistance 20 20 20 kΩ min

AD7890-4

Input Voltage Range 0 to 4.096 0 to 4.096 0 to 4.096 Volts

Input Resistance 11 11 11 kΩ min

AD7890-2

Input Voltage Range 0 to 2.5 0 to 2.5 0 to 2.5 Volts

Input Current 50 50 200 nA max

MUX OUT OUTPUT

Output Voltage Range 0 to 2.5 0 to 2.5 0 to 2.5 Volts

Output Resistance

AD7890-10, AD7890-4 3/5 3/5 3/5 kΩ min/kΩ max

AD7890-2 2 2 2 kΩ max Assuming VIN is driven from low impedance

SHA IN INPUT

Input Voltage Range 0 to 2.5 0 to 2.5 0 to 2.5 Volts

Input Current ±50 ±50 ±50 nA max

REFERENCE OUTPUT/INPUT

REF IN Input Voltage Range 2.375/2.625 2.375/2.625 2.375/2.625 V min/V max 2.5 V ± 5%

Input Impedance 1.6 1.6 1.6 kΩ min Resistor connected to internal reference node

Input Capacitance

REF OUT Output Voltage 2.5 2.5 2.5 V nom

REF OUT Error @ 25°C ±10 ±10 ±10 mV max

T

to T

MIN

MAX

REF OUT Temperature Coefficient 25 25 25 ppm/°C typ

REF OUT Output Impedance 2 2 2 kΩ nom

4

5

±20 ±20 ±25 mV max

−77 −77 −77 dB max

−78 −78 −78 dB max

−80 −80 −80 dB max f

12 12 12 Bits

±1 ±0.5 ±1 LSB max

±1 ±1 ±1 LSB max

±2.5 ±2.5 ±2.5 LSB max

2 2 2 LSB max

±2 ±2 ±2 LSB max

±2 ±2 ±2 LSB max

±5 ±5 ±5 LSB max

10 10 10 pF max

= 2.5 MHz external, MUX OUT connect to SHA IN. All specifications T

CLK IN

CONVST

Rev. C | Page 3 of 28

Using external

fIN = 10 kHz sine wave, f

fIN = 10 kHz sine wave, f

fa = 9 kHz, fb = 9.5 kHz, f

= 1 kHz sine wave

IN

, any channel

= 100 kHz

SAMPLE

= 100 kHz3

SAMPLE

= 100 kHz3

SAMPLE

= 100 kHz3

SAMPLE

MIN

to

3

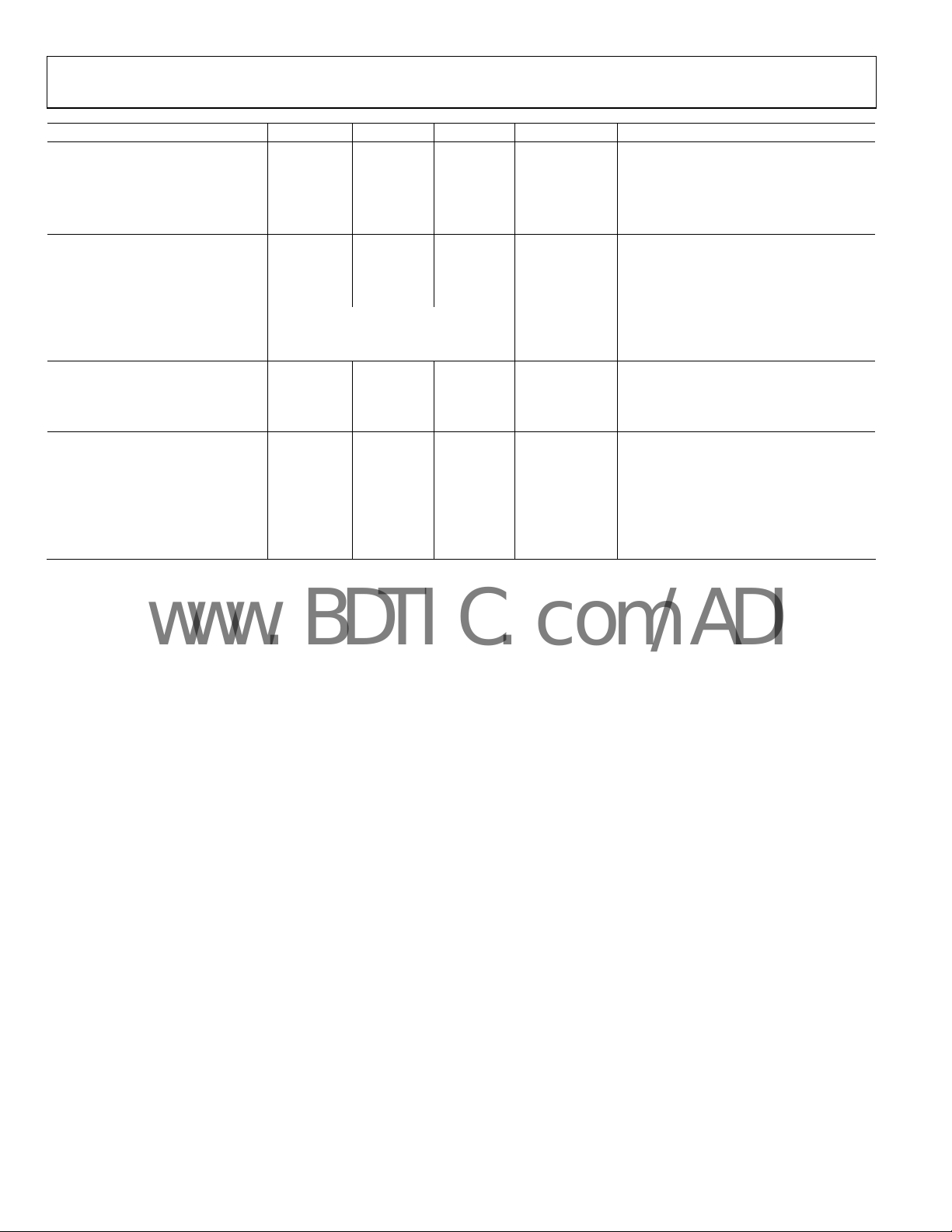

AD7890

www.BDTIC.com/ADI

Parameter A Versions1B Versions S Version Unit Test Conditions/Comments

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, IIN ±10 ±10 ±10 μA max VIN = 0 V to VDD

Input Capacitance, C

LOGIC OUTPUTS

Output High Voltage, VOH 4.0 4.0 4.0 V min I

Output Low Voltage, VOL 0.4 0.4 0.4 V max I

Serial Data Output Coding

AD7890-10 Twos Complement

AD7890-4 Straight (Natural) Binary

AD7890-2 Straight (Natural) Binary

CONVERSION RATE

Conversion Time 5.9 5.9 5.9 μs max f

Track/Hold Acquisition Time2, 5

POWER REQUIREMENTS

VDD 5 5 5 V nom ± 5% for specified performance

IDD (Normal Mode) 10 10 10 mA max Logic inputs = 0 V or VDD

IDD (Standby Mode)6 @ 25°C 15 15 15 μA typ Logic inputs = 0 V or VDD

Power Dissipation

Normal Mode 50 50 50 mW max Typically 30 mW

Standby Mode @ 25°C 75 75 75 μW typ

1

Temperature ranges are as follows: A, B Versions: −40°C to +85°C; S Version: −55°C to +125°C.

2

See the Terminology section.

3

This sample rate is only achievable when using the part in external clocking mode.

4

Full-scale error match applies to positive full scale for the AD7890-2 and AD7890-4. It applies to both positive and negative full scale for the AD7890-10.

5

Sample tested @ 25°C to ensure compliance.

6

Analog inputs on AD7890-10 must be at 0 V to achieve correct power-down current.

2.4 2.4 2.4 V min VDD = 5 V ± 5%

INH

0.8 0.8 0.8 V max VDD = 5 V ± 5%

INL

5

IN

10 10 10 pF max

= 200 μA

SOURCE

= 1.6 mA

SINK

= 2.5 MHz, MUX OUT, connected to

CLK IN

SHA IN

2 2 2 μs max

Rev. C | Page 4 of 28

AD7890

www.BDTIC.com/ADI

TIMING SPECIFICATIONS

VDD = 5 V ± 5%, AGND = DGND = 0 V, REF IN = 2.5 V, f

Parameter1,

3

f

CLKIN

2.5 MHz max

t

CLKIN IN LO

t

CLK IN HI

4

tr

tf4

t

CONVERT

t

100 ns min

CST

Self-Clocking Mode

t1 t

5

t

25 ns max

2

t3 t

t4 t

5

t

5

t6 40 ns max

6

t

7

t8 0 ns min

t

t9 0 ns min

t10 20 ns min Data Valid to SCLK Falling Edge Setup Time.

t11 10 ns min Data Valid to SCLK Falling Edge Hold Time.

t12 20 ns min

External Clocking Mode

t13 20 ns min

5

t

14

t15 50 ns min SCLK High Pulse Width.

t16 50 ns min SCLK Low Pulse Width.

5

t

17

t18 20 ns min

6

t

19

6

t

19A

t20 20 ns min

t21 10 ns min Data Valid to SCLK Falling Edge Setup Time.

t22 15 ns min Data Valid to SCLK Falling Edge Hold Time.

t23 40 ns min

1

Sample tested at −25°C to ensure compliance. All input signals are specified with tr = tf = 5 ns (10% to 90% of 5 V) and timed from a voltage level of 1.6 V.

2

See Figure 10 to Figure 13.

3

The AD7890 is production tested with f

4

Specified using 10% and 90% points on waveform of interest.

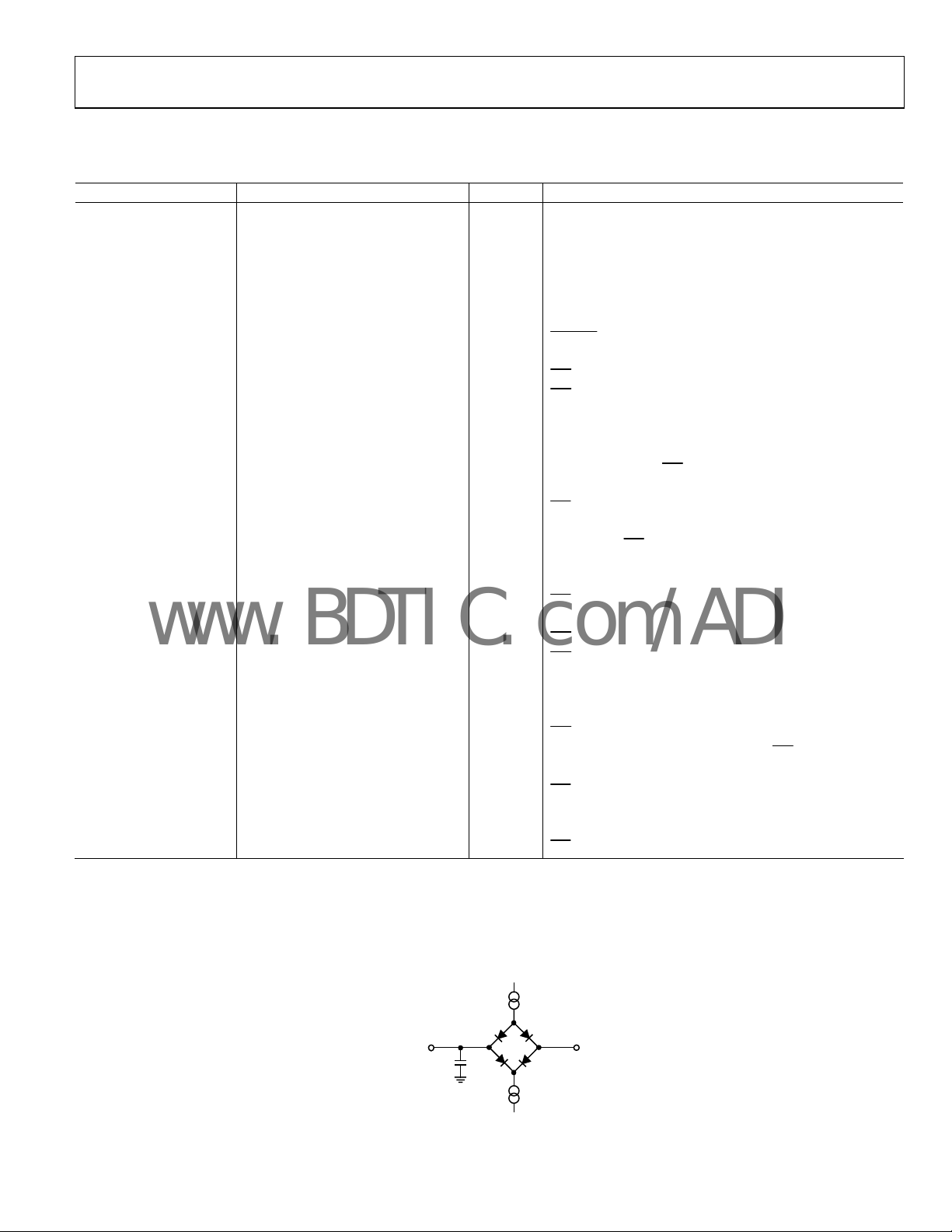

5

These numbers are measured with the load circuit of Figure 2 and defined as the time required for the output to cross 0.8 V or 2.4 V.

6

These numbers are derived from the measured time taken by the data output to change 0.5 V when loaded with the circuit of Figure 2. The measured number is then

extrapolated back to remove effects of charging or discharging the 50 pF capacitor. This means that the times quoted in the timing characteristics are the true bus

relinquish times of the part and as such are independent of external bus loading capacitances.

2

Limit at T

, T

(A, B, S Versions) Unit Conditions/Comments

MIN

MAX

100 kHz min Master Clock Frequency. For specified performance.

0.3 × t

0 3 × t

ns min Master Clock Input Low Time.

CLK IN

ns min Master Clock Input High Time.

CLK IN

25 ns max Digital Output Rise Time. Typically 10 ns.

25 ns max Digital Output Fa

5.9 μs max Conversion Time.

+ 50 ns max

CLK IN HI

ns nom SCLK High Pulse Width.

CLK IN HI

ns nom SCLK Low Pulse Width.

CLK IN LO

20 ns max SCLK Rising Edge to Data Valid De

50 ns max Bus Relinquish Time after Rising Edge of SCLK.

+ 50 ns max

CLK IN

40 ns max

35 ns max SCLK Rising Edge to Data Valid De

50 ns max

90 ns max Bus Relinquish Time after Rising Edge of SCLK.

at 2.5 MHz. It is guaranteed by characterization to operate at 100 kHz.

CLK IN

= 2.5 MHz external, MUX OUT connected to SHA IN.

CLK IN

ll Time. Typically 10 ns.

CONVST

Pulse Width.

RFS

Low to SCLK Falling Edge.

RFS

Low to Data Valid Delay.

SCLK Rising Edge to

TFS

Low to SCLK Falling Edge.

Data Valid to

TFS

to SCLK Falling Edge Hold Time.

RFS

Low to SCLK Falling Edge Setup Time.

RFS

Low to Data Valid Delay.

RFS

to SCLK Falling Edge Hold Time.

RFS

Delay.

TFS

Falling Edge Setup Time (A2 Address Bit).

Bus Relinquish Time after Rising Edge of

TFS

Low to SCLK Falling Edge Setup Time.

TFS

to SCLK Falling Edge Hold Time.

lay.

lay.

RFS

.

1.6mA

TO OUTPUT

PIN

50pF

200µA

2.1V

01357-002

Figure 2. Load Circuit for Access Time and Bus Relinquish Time

Rev. C | Page 5 of 28

AD7890

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Parameter Rating

VDD to AGND −0.3 V to +7 V

VDD to DGND −0.3 V to +7 V

Analog Input Voltage to AGND

AD7890-10, AD7890-4 ±17 V

AD7890-2 −5 V, +10 V

Reference Input Voltage to AGND −0.3 V to VDD + 0.3 V

Digital Input Voltage to DGND −0.3 V to VDD + 0.3 V

Digital Output Voltage to DGND −0.3 V to VDD + 0.3 V

Operating Temperature Range

Commercial (A, B Versions) −40°C to +85°C

Extended (S Version) −55°C to +125°C

Storage Temperature Range −65°C to +150°C

Junction Temperature

PDIP Package, Power Dissipation 450 mW

θJA Thermal Impedance

Lead Temperature (Soldering, 10 sec)

CERDIP Package, Power Dissipation 450 mW

θJA Thermal Impedance 70°C/W

Lead Temperature (Soldering, 10 sec)

SOIC_W Package, Power Dissipation 450 mW

θJA Thermal Impedance 75°C/W

Lead Temperature, Soldering

Vapor Phase (60 sec)

Infrared (15 sec)

150°C

105°C/W

260°C

300°C

215°C

220°C

Stresses above those listed under Absolute Maximum Ratings

ma

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

y cause permanent damage to the device. This is a stress

Rev. C | Page 6 of 28

AD7890

N

www.BDTIC.com/ADI

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

AGND

SMODE

DGND

C

EXT

CONVST

CLK IN

SCLK

TFS

RFS

DATA OUT

DATA IN

V

DD

1

2

3

4

AD7890

5

TOP VIEW

(Not to Scale)

6

7

8

9

10

11

12

24

REF OUT/RE F I

V

23

IN8

V

22

IN7

V

21

IN6

V

20

IN5

V

19

IN4

V

18

IN3

V

17

IN2

V

16

IN1

AGND

15

SHA IN

14

MUX OUT

13

01357-003

Figure 3. Pin Configuration

Table 2. Pin Function Descriptions

Pin No. Mnemonic Description

1 AGND Analog Ground. Ground reference for track/hold, comparator, and DAC.

2 SMODE

Control Input. Determines whether the part operates in its external clocking (slave) or self-clocking (master)

serial mode. With SMODE at a logic low, the part is in its self-clocking serial mode with RFS

outputs. This self-clocking mode is useful for connection to shift registers or to serial ports of DSP processors.

With SMODE at a logic high, the part is in its external clocking serial mode with SCLK and RFS

external clocking mode is useful for connection to the serial port of microcontrollers, such as the 8xC51 and

the 68HCxx, and for connection to the serial ports of DSP processors.

3 DGND

4 C

EXT

Digital Ground. Ground reference for digital circuitry.

External Capacitor. An external capacitor is connected to this pin to determine the length of the internal pulse

(see the Control Register section). Larger capacitances on this pin extend the pulse to allow for settling time

delays through an external antialiasing filter or signal conditioning circuitry.

5

CONVST

Convert Start. Edge-triggered logic input. A low-to-high transition on this input puts the track/hold into hold

and initiates conversion if the internal pulse has timed out (see the Control Register section). If the internal

pulse is active when the CONVST

goes high, the track/hold does not proceed to hold until the pulse times out.

If the internal pulse times out when CONVST goes high, the rising edge of CONVST drives the track/hold into

hold and initiates conversion.

6 CLK IN

Clock Input. An external TTL-compatible clock is applied to this input pin to provide the clock source for the

conversion sequence. In the self-clocking serial mode, the SCLK output is derived from this CLK IN pin.

7 SCLK

Serial Clock Input. In the external clocking (slave) mode (see the Serial Interface section), this is an externally

applied serial clock used to load serial data to the control register and to access data from the output register.

In the self-clocking (master) mode, the internal serial clock, which is derived from the clock input (CLK IN),

appears on this pin. Once again, it is used to load serial data to the control register and to access data from the

output register.

8

Transmit Frame Synchronization Pulse. Active low logic input with serial data expected after the falling edge of

TFS

this signal.

9

Receive Frame Synchronization Pulse. In the external clocking mode, this pin is an active low logic input with

RFS

RFS

provided externally as a strobe or framing pulse to access serial data from the output register. In the selfclocking mode, it is an active low output, which is internally generated and provides a strobe or framing pulse

for serial data from the output register. For applications which require that data be transmitted and received at

10 DATA OUT

the same time,

Serial Data Output. Sixteen bits of serial data are provided with one leading zero, preceding the three address

RFS and TFS should be connected together.

bits of the control register and the 12 bits of conversion data. Serial data is valid on the falling edge of SCLK for

sixteen edges after RFS

goes low. Output coding from the ADC is twos complement for the AD7890-10 and

straight binary for the AD7890-4 and AD7890-2.

11 DATA IN

Serial Data Input. Serial data to be loaded to the control register is provided at this input. The first five bits of

serial data are loaded to the control register on the first five falling edges of SCLK after TFS

12 V

Positive Supply Voltage, 5 V ± 5%.

DD

13 MUX OUT

on subsequent SCLK edges is ignored while TFS

Multiplexer Output. The output of the multiplexer appears a

remains low.

t this pin. The output voltage range from this

output is 0 V to 2.5 V for the nominal analog input range to the selected channel. The output impedance of this

output is nominally 3.5 kΩ. If no external antialiasing filter is required, MUX OUT should be connected to SHA IN.

and SCLK as

as inputs. This

goes low. Serial data

Rev. C | Page 7 of 28

AD7890

www.BDTIC.com/ADI

Pin No. Mnemonic Description

14 SHA IN

15 AGND Analog Ground. Ground reference for track/hold, comparator, and DAC.

16 V

17 V

18 V

19 V

20 V

21 V

22 V

23 V

24 REF OUT/REF IN

IN1

IN2

IN3

IN4

IN5

IN6

IN7

IN8

Track/Hold Input. The input to the on-chip track/hold is applied t

input voltage range is 0 V to 2.5 V.

Analog Input Channel 1. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4), and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Analog Input Channel 2. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4), and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Analog Input Channel 3. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4), and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Analog Input Channel 4. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4), and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Analog Input Channel 5. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4), and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Analog Input Channel 6. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4), and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Analog Input Channel 7. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4), and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Analog Input Channel 8. Single-ended analog input. The analog input range on is ±10 V (AD7890-10), 0 V to

V (AD7890-4) and 0 V to 2.5 V (AD7890-2). The channel to be converted is selected using the A0, A1, and

4.096

A2 bits in the control register. The multiplexer has guaranteed break-before-make operation.

Voltage Reference Output/Input. The part can be used with either its own internal reference or with an external

ference source. The on-chip 2.5 V reference voltage is provided at this pin. When using this internal reference

re

as the reference source for the part, REF OUT should decoupled to AGND with a 0.1 μF disc ceramic capacitor.

The output impedance of this reference source is typically 2 kΩ. When using an external reference source as

the reference voltage for the part, the reference source should be connected to this pin. This overdrives the

internal reference and provides the reference source for the part. The REF IN input is buffered on-chip. The

nominal reference voltage for correct operation of the AD7890 is 2.5 V.

o this pin. It is a high impedance input and the

Rev. C | Page 8 of 28

AD7890

www.BDTIC.com/ADI

TERMINOLOGY

Signal to (Noise + Distortion) Ratio

This is the measured ratio of signal to (noise + distortion) at the

utput of the A/D converter. The signal is the rms amplitude of

o

the fundamental. Noise is the rms sum of all nonfundamental

signals up to half the sampling frequency (f

/2), excluding dc.

S

The ratio is dependent upon the number of quantization levels

in the digitization process; the more levels, the smaller the

quantization noise. The theoretical signal to (noise + distortion)

ratio for an ideal N-bit converter with a sine wave input is given by:

Signal to (Noise + Distortion) = (6.02

N + 1.76) dB

Thus, for a 12-bit converter, this is 74 dB.

Total Harmonic Distortion

Total harmonic distortion (THD) is the ratio of the rms sum of

rmonics to the fundamental. For the AD7890, it is defined as

ha

2

2

2

2

THD

2

2

log20)dB(

=

4

3

V

1

VVVVV

++++

5

6

where:

is the rms amplitude of the fundamental and

V

1

V

, V3, V4, V5, and V6 are the rms amplitudes of the second

2

through the sixth harmonics.

Peak Harmonic or Spurious Noise

Peak harmonic or spurious noise is defined as the ratio of the

ms value of the next largest component in the ADC output

r

spectrum (up to f

/2 and excluding dc) to the rms value of the

S

fundamental. Normally, the value of this specification is

determined by the largest harmonic in the spectrum, but for

parts where the harmonics are buried in the noise floor, it is

determined by a noise peak.

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, fa and

fb

, any active device with nonlinearities creates distortion

products at sum and difference frequencies of mfa ± nfb where

m, n = 0, 1, 2, 3, and so on. Intermodulation terms are those for

which neither m nor n are equal to zero. For example, the

second-order terms include (fa + fb) and (fa − fb), while the

third-order terms include (2fa + fb), (2fa − fb), (fa + 2fb), and

(fa − 2fb).

The AD7890 is tested using the CCIF standard where two input

f

requencies near the top end of the input bandwidth are used.

In this case, the second and third order terms are of different

significance. The second-order terms are usually distanced in

frequency from the original sine waves while the third-order

terms are usually at a frequency close to the input frequencies.

As a result, the second- and third-order terms are specified

separately. The calculation of the intermodulation distortion is

as per the THD specification where it is the ratio of the rms

sum of the individual distortion products to the rms amplitude

of the fundamental expressed in dBs.

Rev. C | Page 9 of 28

Channel-to-Channel Isolation

Channel-to-channel isolation is a measure of the level of crosstalk

etween channels. It is measured by applying a full-scale 1 kHz

b

signal to any one of the other seven inputs and determining how

much that signal is attenuated in the channel of interest. The figure

given is the worst case across all eight channels.

Relative Accuracy

Relative accuracy or endpoint nonlinearity is the maximum

de

viation from a straight line passing through the endpoints of

the ADC transfer function.

Differential Nonlinearity

This is the difference between the measured and the ideal 1 LSB

ch

ange between any two adjacent codes in the ADC.

Positive Full-Scale Error (AD7890-10)

This is the deviation of the last code transition (01 . . . 110 to

01 . . . 111) f

rom the ideal (4 × REF IN − 1 LSB) after the

bipolar zero error has been adjusted out.

Positive Full-Scale Error (AD7890-4)

This is the deviation of the last code transition (11 . . . 110 to

11 . . . 111) f

rom the ideal (1.638 × REF IN − 1 LSB) after the

unipolar offset error has been adjusted out.

Positive Full-Scale Error (AD7890-2)

This is the deviation of the last code transition (11 . . . 110 to

11 . . . 111) f

rom the ideal (REF IN − 1 LSB) after the unipolar

offset error has been adjusted out.

Bipolar Zero Error (AD7890-10)

This is the deviation of the midscale transition (all 0s to all 1s)

f

rom the ideal 0 V (AGND).

Unipolar Offset Error (AD7890-2, AD7890-4)

This is the deviation of the first code transition (00 . . . 000 to

00 . . . 001) f

rom the ideal 0 V (AGND).

Negative Full-Scale Error (AD7890-10)

This is the deviation of the first code transition (10 . . . 000 to

10 . . . 001) f

rom the ideal (−4 × REF IN + 1 LSB) after bipolar

zero error has been adjusted out.

Trac k / Hold Ac q u isiti o n Ti me

Track/hold acquisition time is the time required for the output

o

f the track/hold amplifier to reach its final value, within

±1/2 LSB, after the end of conversion (the point at which the

track/hold returns to track mode). It also applies to situations

where a change in the selected input channel takes place or

where there is a step input change on the input voltage applied

to the selected V

input of the AD7890. It means that the user

IN

must wait for the duration of the track/hold acquisition time

after the end of conversion or after a channel change/step input

change to V

before starting another conversion, to ensure that

IN

the part operates to specification.

AD7890

www.BDTIC.com/ADI

CONTROL REGISTER

The control register for the AD7890 contains 5 bits of information.

Six serial clock pulses must be provided to the part in order to

write data to the control register (seven if the write is required

to put the part in standby mode). If

serial clock cycles, then no data transfer takes place to the

control register and the write cycle has to be restarted to write

the data to the control register.

MSB LSB

A2 A1 A0 CONV STBY

Table 3.

Bit Name Description

A2 Address Input. This input is the most significant address input for multiplexer channel selection.

A1 Address Input. This is the 2nd most significant address input for multiplexer channel selection.

A0

CONV

STBY

Address Input. Least significant address input for multiplexer channel selection. When the address is written to the control

egister, an internal pulse is initiated, the pulse width of which is determined by the value of capacitance on the C

r

this pulse is active, it ensures the conversion process cannot be activated. This allows for the multiplexer settling time,

track/hold acquisition time before the track/hold goes into hold, and the conversion is initiated. In applications where there is

an antialiasing filter between the MUX OUT pin and the SHA IN pin , the filter settling time can be taken into account before the

input on the SHA IN pin is sampled. When the internal pulse times out, the track/hold goes into hold and conversion is initiated.

Conversion Start. Writing a 1 to this bit initiates a conversion in a similar manner to the CONVST

starts do not take place when there is a 1 in this location. The internal pulse and the conversion process are initiated after the

sixth serial clock cycle of the write operation if a 1 is written to this bit. With a 1 in this bit, the hardware conversion start (the

CONVST input) is disabled. Writing a 0 to this bit enables the hardware CONVST input.

Standby Mode Input. Writing a 1 to this bit places the devic

the device in its normal operating mode. The part does not enter its standby mode until the seventh falling edge of SCLK in a

write operation. Therefore, the part requires seven serial clock pulses in its serial write operation if it is required to put the part

into standby.

TFS

returns high before six

If, however, the CONV bit of the register is set to a Logic 1, then

a co

nversion is initiated whenever a control register write takes

place regardless of how many serial clock cycles the

remains low for. The default (power-on) condition of all bits in

the control register is 0.

input. Continuous conversion

e in its standby, or power-down, mode. Writing a 0 to this bit places

TFS

pin. When

EXT

Rev. C | Page 10 of 28

AD7890

www.BDTIC.com/ADI

THEORY OF OPERATION

CONVERTER DETAILS

The AD7890 is an 8-channel, 12-bit, single supply, serial data

acquisition system. It provides the user with signal scaling,

multiplexer, track/hold, reference, ADC, and versatile serial

logic functions on a single chip. The signal scaling allows the

part to handle ±10 V input signals (AD7890-10) and 0 V to

4.096 V input signals (AD7890-4) while operating from a single

5 V supply. The AD7890-2 contains no signal scaling and

accepts an analog input range of 0 V to 2.5 V. The part operates

from a 2.5 V reference, which can be provided from the part’s

own internal reference or from an external reference source.

Unlike other single chip data acquisition solutions, the AD7890

p

rovides the user with separate access to the multiplexer and

the ADC. This means that the flexibility of separate multiplexer

and ADC solutions is not sacrificed with the one-chip solution.

With access to the multiplexer output, the user can implement

external signal conditioning between the multiplexer and the

track/hold. It means that one antialiasing filter can be used on

the output of the multiplexer to provide the antialiasing

function for all eight channels.

Conversion is initiated on the AD7890 either by pulsing the

CONVST

control register. When using the hardware

the rising edge of the

goes from track to hold mode and the conversion sequence is

started, provided the internal pulse has timed out. This internal

pulse (which appears at the C

multiplexer address is loaded to the AD7890 control register.

This pulse goes from high to low when a serial write to the part

is initiated. It starts to discharge on the sixth falling clock edge

of SCLK in a serial write operation to the part. The track/hold

cannot go into hold and conversion cannot be initiated until the

C

EXT

time of the voltage on C

connected to the C

The fact that the pulse is initiated every time a write to the

control register takes place means that the software conversion

start and track/hold signal is always delayed by the internal pulse.

The conversion clock for the part is generated from the clock

sig

for the AD7890 is 5.9 μs from the rising edge of the hardware

CONVST

obtain optimum performance from the part, the data read

operation or control register write operation should not occur

during the conversion or during 500 ns prior to the next

conversion.

input or by writing a Logic 1 to the CONV bit of the

CONVST

CONVST

signal, the on-chip track/hold

pin) is initiated whenever the

EXT

input, on

pin has crossed its trigger point of 2.5 V. The discharge

depends upon the value of capacitor

EXT

pin (see the C

EXT

Functioning section).

EXT

nal applied to the CLK IN pin of the part. Conversion time

signal and the track/hold acquisition time is 2 μs. To

This allows the part to operate at throughput rates up to

117 kH

z in the external clocking mode and achieve data sheet

specifications. The part can operate at slightly higher

throughput rates (up to 127 kHz), again in external clocking

mode with degraded performance (see the Timing and Control

section). The throughput rate for self-clocking mode is limited

by the serial clock rate to 78 kHz.

All unused inputs should be connected to a voltage within the

inal analog input range to avoid noise pickup. On the

nom

AD7890-10, if any one of the input channels which are not

being converted goes more negative than −12 V, it can interfere

with the conversion on the selected channel.

CIRCUIT DESCRIPTION

The AD7890 is offered as three part types: the AD7890-10

handles a ±10 V input voltage range, the AD7890-4 handles a

0 V to 4.096 V input range, while the AD7890-2 handles a 0 V

to 2.5 V input voltage range.

AD7890-10 Analog Input

Figure 4 shows the analog input section for the AD7890-10. The

analog input range for each of the analog inputs is ±10 V into

an input resistance of typically 33 kΩ. This input is benign with

no dynamic charging currents with the resistor attenuator stage

followed by the multiplexer and, in cases where MUX OUT is

connected to SHA IN, this is followed by the high input

impedance stage of the track/hold amplifier. The designed code

transitions occur on successive integer LSB values (such as:

1 LSB, 2 LSBs, 3 LSBs...). Output coding is twos complement

binary with 1 LSB − FSR/4096 = 20 V/4096 = 4.88 mV. The

ideal input/output transfer function is shown in Table 4.

MUX OUT

2.5V

REFERENCE

REF OUT/

REF IN

AGND

2kΩ

TO ADC

REFERENCE

CIRCUIT RY

V

INX

30kΩ

1

EQUIVALENT ON-RESISTANCE OF MULTIPLEXER

Figure 4. AD7890-10 Analog Input Structure

7.5kΩ

10kΩ

200Ω

AD7890-10

1

01357-004

Rev. C | Page 11 of 28

AD7890

www.BDTIC.com/ADI

Table 4. Ideal Input/Output Code Table for the AD7890-10

Analog Input1 Digital Output Code Transition

+FSR/2 − 1 LSB2 (9.995117 V) 011 . . . 110 to 011 . . . 111

+FSR/2 − 2 LSBs (9.990234 V) 011 . . . 101 to 011 . . . 110

+FSR/2 − 3 LSBs (9.985352 V) 011 . . . 100 to 011 . . . 101

AGND + 1 LSB (0.004883 V) 000 . . . 000 to 000 . . . 001

AGND (0.000000 V) 111 . . . 111 to 000 . . . 000

AGND − 1 LSB (−0.004883 V) 111 . . . 110 to 111 . . . 111

−FSR/2 + 3 LSBs (−9.985352 V) 100 . . . 010 to 100 . . . 011

−FSR/2 + 2 LSBs (−9.990234 V) 100 . . . 001 to 100 . . . 010

−FSR/2 + 1 LSB (−9.995117 V) 100 . . . 000 to 100 . . . 001

1

FSR is full-scale range and is 20 V with REF IN = 2.5 V.

2

1 LSB = FSR/4096 = 4.883 mV with REF IN = 2.5 V.

AD7890-4 Analog Input

Figure 5 shows the analog input section for the AD7890-4. The

analog input range for each of the analog inputs is 0 to 4.096 V

into an input resistance of typically 15 kΩ. This input is benign

with no dynamic charging currents with the resistor attenuator

stage followed by the multiplexer and in cases where MUX OUT is

connected to SHA IN this is followed by the high input

impedance stage of the track/hold amplifier. The designed code

transitions occur on successive integer LSB values (such as:

1 LSB, 2 LSBs, 3 LSBs . . . ). Output coding is straight (natural)

binary with 1 LSB = FSR/4096 = 4.096 V/4096 = 1 mV. The

ideal input/output transfer function is shown in Table 5.

MUX OUT

2.5V

REFERENCE

REF OUT/

REF IN

V

AGND

Table 5. Ideal Input/Output Code Table for the AD7890-4

Analog Input1 Digital Output Code Transition

+FSR − 1 LSB2 (4.095 V) 111 . . . 110 to 111 . . . 111

+FSR − 2 LSBs (4.094 V) 111 . . . 101 to 111 . . . 110

+FSR − 3 LSBs (4.093 V) 111 . . . 100 to 111 . . . 101

AGND + 3 LSBs (0.003 V) 000 . . . 010 to 000 . . . 011

AGND + 2 LSBs (0.002 V) 000 . . . 001 to 000 . . . 010

AGND + 1 LSB (0.001 V) 000 . . . 000 to 000 . . . 001

1

FSR is full-scale range and is 4.096 V with REF IN = 2.5 V.

2

1 LSB = FSR/4096 = 1 mV with REF IN = 2.5 V.

AD7890-2 Analog Input

The analog input section for the AD7890-2 contains no biasing

resistors and the selected analog input connects to the multiplexer and, in cases where MUX OUT is connected to SHA IN,

2kΩ

TO ADC

REFERENCE

CIRCUIT RY

INX

6kΩ

9.38kΩ

1

EQUIVALENT ON-RESISTANCE OF MULTIPLEXER

Figure 5. AD7890-4 Analog Input Structure

200Ω

AD7890-4

1

01357-005

Rev. C | Page 12 of 28

this is followed by the high input impedance stage of the track/

hold amplifier. The analog input range is, therefore, 0 V to 2.5 V

into a high impedance stage with an input current of less than

50 nA. The designed code transitions occur on successive

integer LSB values (such as: l LSB, 2 LSBs, 3 LSBs . . . FS-1

LSBs). Output coding is straight (natural) binary with 1 LSB =

FSR/4096 = 2.5 V/4096 = 0.61 mV. The ideal input/output

transfer function is shown in Table 6.

Table 6. Ideal Input/Output Code Table for the AD7890-2

Analog Input1 Digital Output Code Transition

+FSR − 1 LSB2 (2.499390 V) 111 . . . 110 to 111 . . . 111

+FSR − 2 LSBs (2.498779 V) 111 . . . 101 to 111 . . . 110

+FSR − 3 LSBs (2.498169 V) 111 . . . 100 to 111 . . . 101

AGND + 3 LSBs (0.001831 V) 000 . . . 010 to 010 . . . 011

AGND + 2 LSBs (0.001221 V) 000 . . . 001 to 001 . . . 010

AGND + 1 LSB (0.000610 V) 000 . . . 000 to 000 . . . 001

1

FSR is full-scale range and is 2.5 V with REF IN = 2.5 V.

2

1 LSB = FSR/4096 = 0.61 mV with REF IN = 2.5 V.

TRACK/HOLD AMPLIFIER

The SHA IN input on the AD7890 connects directly to the input

stage of the track/hold amplifier. This is a high impedance input

with input leakage currents of less than 50 nA. Connecting the

MUX OUT pin directly to the SHA IN pin connects the

multiplexer output directly to the track/hold amplifier. The input

voltage range for this input is 0 V to 2.5 V. If external circuitry is

connected between MUX OUT and SHA IN, then the user must

ensure that the input voltage range to the SHA IN input is 0 V to

2.5 V to ensure that the full dynamic range of the converter is

utilized.

The track/hold amplifier on the AD7890 allows the ADC to

acc

urately convert an input sine wave of full-scale amplitude to

12-bit accuracy. The input bandwidth of the track/hold is

greater than the Nyquist rate of the ADC even when the ADC is

operated at its maximum throughput rate of 117 kHz (for example,

the track/hold can handle input frequencies in excess of 58 kHz).

The track/hold amplifier acquires an input signal to 12-bit

uracy in less than 2 μs. The operation of the track/hold is

acc

essentially transparent to the user. The track/hold amplifier

goes from its tracking mode to its hold mode at the start of

conversion. The start of conversion is the rising edge of

CONVST

hardware conversion starts and for software conversion starts is

the point where the internal pulse is timed out. The aperture

time for the track/hold (for example, the delay time between the

external

hold) is typically 15 ns. For software conversion starts, the time

depends on the internal pulse widths. Therefore, for software

conversion starts, the sampling instant is not very well defined.

For sampling systems which require well defined, equidistant

sampling, it may not be possible to achieve optimum performance

from the part using the software conversion start. At the end of

(assuming the internal pulse has timed out) for

CONVST

signal and the track/hold actually going into

AD7890

www.BDTIC.com/ADI

conversion, the part returns to its tracking mode. The acquisition

time of the track/ hold amplifier begins at this point.

REFERENCE

The AD7890 contains a single reference pin, labeled REF OUT/

REF IN, which either provides access to the part’s own 2.5 V

reference or to which an external 2.5 V reference can be connected

to provide the reference source for the part. The part is specified

with a 2.5 V reference voltage. Errors in the reference source results

in gain errors in the AD7890’s transfer function and adds to the

specified full-scale errors on the part. On the AD7893-10, it also

results in an offset error injected in the attenuator stage.

The AD7890 contains an on-chip 2.5 V reference. To use this

r

eference as the reference source for the AD7890, simply connect a

0.1 μF disc ceramic capacitor from the REF OUT/REF IN pin to

AGND. The voltage which appears at this pin is internally buffered

before being applied to the ADC. If this reference is required for

use external to the AD7890, it should be buffered as the source

impedance of this output is 2 kΩ nominal. The tolerance on the

internal reference is ±10 mV at 25°C with a typical temperature

coefficient of 25 ppm/°C and a maximum error over temperature

of ±25 mV.

If the application requires a reference with a tighter tolerance or

e AD7890 needs to be used with a system reference, then the

th

user has the option of connecting an external reference to this

REF OUT/REF IN pin. The external reference effectively

overdrives the internal reference and thus provides the reference

source for the ADC. The reference input is buffered, but has a

nominal 2 kΩ resistor connected to the AD7890’s internal

reference. Suitable reference sources for the AD7890 include the

AD680, AD780, and REF-43 precision 2.5 V references.

TIMING AND CONTROL

The AD7890 is capable of two interface modes, selected by the

SMODE input. The first of these is a self-clocking mode where

the part provides the frame sync, serial clock, and serial data at

the end of conversion. In this mode the serial clock rate is

determined by the master clock rate of the part (at the CLK IN

input). The second mode is an external clocking mode where

the user provides the frame sync and serial clock signals to obtain

th

e serial data from the part. In this second mode, the user has

control of the serial clock rate up to a maximum of 10 MHz. The

two modes are discussed in the Serial Interface section.

The part also provides hardware and software conversion start

atures. The former provides a well-defined sampling instant

fe

with the track/hold going into hold on the rising edge of the

CONVST

signal. For the software conversion start, a write to

the CONV bit to the control register initiates the conversion

sequence. However, for the software conversion start an internal

pulse has to time out before the input signal is sampled. This

pulse, plus the difficulty in maintaining exactly equal delays

between each software conversion start command, means that

the dynamic performance of the AD7890 may have difficulty

meeting specifications when used in software conversion start

mode. The AD7890 provides separate channel select and

conversion start control. This allows the user to optimize the

throughput rate of the system. Once the track/hold has gone into

hold mode, the input channel can be updated and the input voltage

can settle to the new value while the present conversion is in

progress.

Assuming the internal pulse has timed out before the

CONVST

pulse is exercised, the conversion consists of 14.5 master clock

cycles. In the self-clocking mode, the conversion time is defined

as the time from the rising edge of

RFS

of

(for example, when the device starts to transmit its

CONVST

to the falling edge

conversion result). This time includes the 14.5 master clock

cycles plus the updating of the output register and delay time in

outputting the

RFS

signal, resulting in a total conversion time of

5.9 μs maximum. Figure 6 shows the conversion timing for the

AD7890 when used in the self-clocking (master) mode with

hardware

internal pulse is not active when the

CONVST

. The timing diagram assumes that the

CONVST

signal goes high.

To ensure this, the channel address to be converted should be

selected by writing to the control register prior to the

CONVST

pulse. Sufficient setup time should be allowed between the

control register write and the

CONVST

to ensure that the internal

pulse has timed out. The duration of the internal pulse (and hence

the duration of setup time) depends on the value of C

EXT

.

CONVST (I)

RFS (O)

SCLK (O)

DATA OUT (O)

1

NOTES:

1. (I) SIGNIFIES AN INPUT.

2. (O) SIGNIFIES AN OUTPUT. PULL-UP RESISTOR ON SCLK.

TRACK/HOLD GO ES

INTO THE HOLD

t

CONVERT

THREE-S TATE

Figure 6. Self-Clocking (Master) Mode Conversion Sequence

Rev. C | Page 13 of 28

01357-006

AD7890

www.BDTIC.com/ADI

When using the device in the external-clocking mode, the

output register can be read at any time and the most up-to-date

conversion result is obtained. However, reading data from the

output register or writing data to the control register during

conversion or during the 500 ns prior to the next

results in reduced performance from the part. A read operation

to the output register has the most effect on performance with

the signal-to-noise ratio likely to degrade, especially when

higher serial clock rates are used while the code flicker from the

part also increases (see the Performance section).

Figure 7 shows the timing and control sequence required to

o

btain optimum performance from the part in the external

clocking mode. In the sequence shown, conversion is initiated

on the rising edge of

CONVST

and new data is available in the

output register of the AD7890 5.9 μs later. Once the read

operation has taken place, a further 500 ns should be allowed

CONVST

CONVST

before the next rising edge of

CONVST

to optimize the settling

of the track/hold before the next conversion is initiated.

The diagram shows the read operation and the write operation

t

aking place in parallel. On the sixth falling edge of SCLK in the

write sequence the internal pulse is initiated. Assuming MUX OUT

is connected to SHA IN, 2 μs are required between this sixth

falling edge of SCLK and the rising edge of

CONVST

to allow

for the full acquisition time of the track/hold amplifier. With

the serial clock rate at its maximum of 10 MHz, the achievable

throughput rate for the part is 5.9 μs (conversion time) plus 0.6

μs (six serial clock pulses before internal pulse is initiated) plus

2 μs (acquisition time). This results in a minimum throughput

time of 8.5 μs (equivalent to a throughput rate of 117 kHz). If

the part is operated with a slower serial clock, it affects the

achievable throughput rate for optimum performance.

SCLK

RFS

TFS

t

CONVERT

CONVERSION I S

INITIAT ED AND

TRACK/HOLD GOES

INTO HOLD

Figure 7. External Clocking (Slave) Mode Timing Sequence for Optimum Performance

CONVERSION

ENDS 5.9µs

LATER

SERIAL READ

AND WRITE

OPERATIO NS

READ AND WRITE

OPERATIONS SHOULD END

500ns PRIOR T O NEXT

RISING EDG E OF CONVST

500ns MIN

NEXT CONVERSI ON

START COMMAND

01357-007

Rev. C | Page 14 of 28

AD7890

www.BDTIC.com/ADI

In the self-clocking mode, the AD7890 indicates when

RFS

conversion is complete by bringing the

line low and

initiating a serial data transfer. In the external clocking mode,

there is no indication of when conversion is complete. In many

applications, this is not a problem as the data can be read from

the part during conversion or after conversion. However,

applications that seek to achieve optimum performance from

the AD7890 has to ensure that the data read does not occur

during conversion or during 500 ns prior to the rising edge

CONVST

of

.

This can be achieved in either of two ways. The first is to ensure

oftware that the read operation is not initiated until 5.9 μs

in s

after the rising edge of

software knows when the

second scheme would be to use the

CONVST

CONVST

. This is only possible if the

command is issued. The

CONVST

signal as both the

conversion start signal and an interrupt signal. The simplest

way to do this is to generate a square wave signal for

CONVST

with high and low times of 5.9 μs (see Figure 8). Conversion is

initiated on the rising edge of

CONVST

. The falling edge of

CONVST

low or falling edge-triggered interrupt signal to tell the

processor to read the data from the AD7890. Provided the read

operation is completed 500 ns before the rising edge of

CONVST

This scheme limits the throughput rate to 11.8 μs minimum.

owever, depending upon the response time of the

H

microprocessor to the interrupt signal and the time taken by the

processor to read the data, this may be the fastest which the

system could have operated. In any case, the

does not have to have a 50:50 duty cycle. This can be tailored to

optimize the throughput rate of the part for a given system.

Alternatively, the

narrow pulse width. The rising edge of

an active high or rising edge-triggered interrupt. A software

delay of 5.9 μs can then be implemented before data is read

from the part.

occurs 5.9 μs later and can be used as either an active

, the AD7890 operates to specification.

CONVST

CONVST

signal can be used as a normal

CONVST

signal

can be used as

CONVST

SCLK

RFS

TFS

500ns MIN

NEXT CONVST

RISING EDG E

01357-008

CONVERSION IS

INITIATED AND

TRACK/HOLD GOES

INTO HOLD

t

CONVERT

Figure 8.

CONVERSION

ENDS 5.9µs

LATER

CONVST

MICROPROCESSOR

INT SERVICE

OR POLLING

ROUTI NE

Used as Status Signal in External Clocking Mode

SERIAL READ

AND WRITE

OPERATIONS

READ AND WRITE

OPERATIONS SHOULD

END 500ns PRIO R

TO NEXT RISING

EDGE OF CONVST

Rev. C | Page 15 of 28

AD7890

www.BDTIC.com/ADI

C

FUNCTIONING

EXT

The C

how long after a new channel address is written to the part that

a conversion can take place. The reason behind this is two-fold.

First, when the input channel to the AD7890 is changed, the

input voltage on this new channel is likely to be very different

from the previous channel voltage. Therefore, the part’s track/

hold has to acquire the new voltage before an accurate

conversion can take place. An internal pulse delays any

conversion start command (as well as the signal to send the

track/hold into hold) until after this pulse has timed out.

The second reason is to allow the user to connect external

an

MUX OUT pin and the SHA IN pin. This external circuitry

introduces extra settling time into the system. The C

provides a means for the user to extend the internal pulse to

take this extra settling time into account. Effectively varying the

value of the capacitor on the C

internal pulse. Figure 9 shows the relationship between the

value of the C

input on the AD7890 provides a means of determining

EXT

tialiasing or signal conditioning circuitry between the

EXT

pin varies the duration of the

EXT

capacitor and the internal delay.

EXT

64

56

= +25°C

T

48

40

32

24

16

INTERNAL PUL SE WIDTH (µs)

8

0

0 250 500 750 1000 1250 1500 1750 2000

C

Figure 9. Internal Pulse Width vs. C

T

CAPACITANCE (pF)

EXT

= +85°C

A

A

T

= –40°C

A

EXT

pin

01357-009

The duration of the internal pulse can be seen on the C

The C

the part is initiated (on the falling edge of

pin goes from a low to a high when a serial write to

EXT

TFS

). It starts to

EXT

pin.

discharge on the sixth falling edge of SCLK in the serial write

operation. Once the C

pin has discharged to crossing its

EXT

nominal trigger point of 2.5 V, the internal pulse is timed out.

The internal pulse is initiated each time a write operation to the

ontrol register takes place. As a result, the pulse is initiated and

c

the conversion process delayed for all software conversion start

commands. For hardware conversion start, it is possible to

separate the conversion start command from the internal pulse.

If the multiplexer output (MUX OUT) is connected directly to

he track/hold input (SHA IN), then no external settling has to

t

be taken into account by the internal pulse width. In applications

where the multiplexer is switched and conversion is not

initiated until more than 2 μs after the channel is changed (as is

possible with a hardware conversion start), the user does not

have to worry about connecting any capacitance to the

C

pin. The 2 μs equates to the track/hold acquisition time of

EXT

the AD7890. In applications where the multiplexer is switched

and conversion is initiated at the same time (such as with a

software conversion start), a 120 pF capacitor should be

connected to C

to allow for the acquisition time of the

EXT

track/hold before conversion is initiated.

If external circuitry is connected between the MUX OUT pin

nd SHA IN pin, then the extra settling time introduced by this

a

circuitry must be taken into account. In the case where the

multiplexer change command and the conversion start

command are separated, they need to be separated by greater

than the acquisition time of the AD7890 plus the settling time

of the external circuitry if the user does not have to worry about

the C

capacitance. In applications where the multiplexer is

EXT

switched and conversion is initiated at the same time (such as

with a software conversion start), the capacitor on C

needs to

EXT

allow for the acquisition time of the track/hold and the settling

time of the external circuitry before conversion is initiated.

Rev. C | Page 16 of 28

AD7890

www.BDTIC.com/ADI

SERIAL INTERFACE

The AD7890’s serial communications port provides a flexible

arrangement to allow easy interfacing to industry-standard

microprocessors, microcontrollers, and digital signal processors.

A serial read to the AD7890 accesses data from the output

register via the DATA OUT line. A serial write to the AD7890

writes data to the control register via the DATA IN line.

Two different modes of operation are available, optimized for

dif

ferent types of interface where the AD7890 can act either as

master in the system (it provides the serial clock and data

framing signal) or acts as slave (an external serial clock and

framing signal can be provided to the AD7890). The former is

self-clocking mode while the latter is external clocking mode.

SELF-CLOCKING MODE

The AD7890 is configured for its self-clocking mode by tying

the SMODE pin of the device to a logic low. In this mode, the

AD7890 provides the serial clock signal and the serial data

RFS (O)

t

SCLK (O)

DATA OUT (O)

THREE-STAT E

t

2

1

LEADING

ZERO

t

3

framing signal used for the transfer of data from the AD7890.

This self-clocking mode can be used with processors that allow

an external device to clock their serial port, including most

digital signal processors.

Read Operation

Figure 10 shows a timing diagram for reading from the AD7890

in the self-clocking mode. At the end of conversion,

RFS

low and the serial clock (SCLK) and serial data (DATA OUT)

outputs become active. Sixteen bits of data are transmitted with

one leading zero, followed by the three address bits of the

control register, followed by the 12-bit conversion result starting

with the MSB. Serial data is clocked out of the device on the

rising edge of SCLK and is valid on the falling edge of SCLK.

RFS

The

cycles. On the 16

output remains low for the duration of the 16 clock

th

rising edge of SCLK, the

RFS

output is driven

high and DATA OUT is disabled.

t

6

t

4

t

5

DB0DB10DB11A2 A1 A0

t

7

THREE-STATE

goes

01357-010

TFS (I)

SCLK (O)

DATA IN (I)

NOTES:

1. (I) SIGNIFIES AN INPUT.

2. (O) SIGNIFIES AN OUTPUT. PULL-UP RESISTOR ON SCLK.

Figure 10. Self-Clocking (Master) Mode Output Register Read

t

8

t

9

A2 A1 A0 CONV STBY

NOTES:

1. (I) SIGNIFIES AN INPUT.

2. (O) SIGNIFIES AN OUTPUT. PULL-UP RESISTOR ON SCLK.

t

11

t

10

Figure 11. Self-Clocking (Master) Mode Control Register Write

t

3

t

12

t

4

DON’T

CARE

DON’T

CARE

DON’T

CARE

01357-011

Rev. C | Page 17 of 28

AD7890

www.BDTIC.com/ADI

Write Operation

Figure 11 shows a write operation to the control register of the

AD7890. The

a serial write is about to occur.

output and this is used to clock data out of the processors serial

port and into the control register of the AD7890. The AD7890

control register requires only five bits of data. These are loaded

on the first five clock cycles of the serial clock with data on all

subsequent clock cycles being ignored. However, the part

requires six serial clock cycles to load data to the control

register. Serial data to be written to the AD7890 must be valid

on the falling edge of SCLK.

EXTERNAL CLOCKING MODE

The AD7890 is configured for its external clocking mode by

tying the SMODE pin of the device to a logic high. In this

mode, SCLK and

This external-clocking mode is designed for direct interface to

systems, which provide a serial clock output which is

synchronized to the serial data output including

microcontrollers such as the 80C51, 87C51, 68HC11, and

68HC05, and most digital signal processors.

Read Operation

Figure 12 shows the timing diagram for reading from the

AD7890 in the external clocking mode.

data from the AD7890. The serial clock input does not have to be

continuous. The serial data can be accessed in a number of bytes.

TFS

input is taken low to indicate to the part that

TFS

going low initiates the SCLK

RFS

of the AD7890 are configured as inputs.

RFS

goes low to access

RFS

However,

must remain low for the duration of the data

transfer operation. Once again, 16th bits of data are transmitted

with one leading zero, followed by the three address bits in the

control register, followed by the 12-bit conversion result starting

with the MSB. If

the leading zero is clocked out from the falling edge of

per Figure 12). If

RFS

goes low during the high time of SCLK,

RFS

goes low during the low time of SCLK,

RFS

(as

the leading zero is clocked out on the next rising edge of SCLK.

This ensures that, regardless of whether

RFS

goes low during a

high time or low time of SCLK, the leading zero is valid on the

first falling edge of SCLK after

RFS

goes low, provided t14 and t17

are adhered to. Serial data is clocked out of the device on the

rising edge of SCLK and is valid on the falling edge of SCLK. At

the end of the read operation, the DATA OUT line is three-stated

by a rising edge on either the SCLK or

RFS

inputs, whichever

occurs first. If a serial read from the output register is in progress

when conversion is complete, the updating of the output register is

deferred until the serial data read is complete and

RFS

returns high.

Write Operation

Figure 13 shows a write operation to the control register of the

TFS

AD7890. As with self-clocking mode, the

input goes low to

indicate to the part that a serial write is about to occur. As before,

the AD7890 control register requires only five bits of data. These

are loaded on the first five clock cycles of the serial clock; data on all

subsequent clock cycles are ignored. However, the part requires six

serial clocks to load data to the control register. Serial data to be

written to the AD7890 must be valid on the falling edge of SCLK.

DATA OUT (O)

TFS (I)

SCLK (I)

DATA IN (I)

RFS (I)

SCLK (I)

t

13

t

14

LEADING

ZERO

NOTES:

1. (I) SIGNIFIES AN INPUT.

2. (O) SIGNIFIES AN OUTPUT.

Figure 12. External Clocking (Slave) Mode Output Register Read

t

20

t

22

t

21

A2 A1 A0 CONV STBY

NOTES:

1. (I) SIGNIFIES AN INPUT.

2. (O) SIGNIFIES AN OUTPUT. PULL-UP RESISTOR ON SCLK.

Figure 13. External Clocking (Slave) Mode Control Register Write

t

15

t

16

Rev. C | Page 18 of 28

t

17

DON’T

CARE

t

18

t

19

t

19A

DB10 DB0DB11A2 A1 A0

t

23

DON’T

CARE

THREE-STATE

DON’T

CARE

01357-012

01357-013

AD7890

www.BDTIC.com/ADI

SIMPLIFYING THE INTERFACE

To minimize the number of interconnect lines to the AD7890,

and

TFS

lines of the AD7890

TFS

line

the user can connect the

together and read and write from the part simultaneously. In

this case, new control register data should be provided on the

DATA IN line selecting the input channel and possibly

providing a conversion start command while the part provides

the result from the conversion just completed on the

DATA OUT line.

In the self-clocking mode, this means that the part provides all

t

he signals for the serial interface. It does require that the

microprocessor has the data to be written to the control register

available in its output register when the part brings the

low. In the external clocking mode, it means that the user only

has to supply a single frame synchronization signal to control

both the read and write operations.

RFS

Care must be taken with this scheme that the read operation is

co

mpleted before the next conversion starts, if the user wants to

obtain optimum performance from the part. In the case of the

software conversion start, the conversion command is written

to the control register on the sixth serial clock edge. However,

the read operation continues for another 10 serial clock cycles.

To avoid reading during the sampling instant or during

conversion, the user should ensure that the internal pulse width

is sufficiently long (by choosing C

is completed before the next conversion sequence begins.

Failure to do this results in significantly degraded performance

from the part, both in terms of signal-to-noise ratio and dc

parameters. In the case of a hardware conversion start, the user

should ensure that the delay between the sixth falling edge of

the serial clock in the write operation and the next rising edge

CONVST

of

is greater than the internal pulse width.

) so that the read operation

EXT

Rev. C | Page 19 of 28

AD7890

V

www.BDTIC.com/ADI

MICROPROCESSOR/MICROCONTROLLER INTERFACE

The AD7890’s flexible serial interface allows for easy

connection to the serial ports of DSP processors and

microcontrollers. Figure 14 through Figure 17 show the

AD7890 interfaced to a number of different microcontrollers

and DSP processors. In some of the interfaces shown, the

AD7890 is configured as the master in the system, providing

the serial clock and frame sync for the read operation while in

others it acts as a slave with these signals provided by the

microprocessor.

AD7890 TO 8051 INTERFACE

Figure 14 shows an interface between the AD7890 and the

8xC51 microcontroller. The AD7890 is configured for its

external clocking mode while the 8xC51 is configured for its

Mode 0 serial interface mode. The diagram shown in Figure 14

makes no provisions for monitoring when conversion is

complete on the AD7890 (assuming hardware conversion start

is used). To monitor the conversion time on the AD7890, a

scheme, such as the scheme outlined with

CONVST

in the

Simplifying the Interface section, can be used. This can be

implemented in two ways. One is to connect the

CONVST

line

to another parallel port bit, which is configured as an input.

This port bit can then be polled to determine when conversion is

complete. An alternative is to use an interrupt driven system where

CONVST

the

line is connected to the

INT1

input of the 8xC51.

Since the 8xC51 contains only one serial data line, the DATA

UT and DATA IN lines of the AD7890 must be connected

O

together. This means that the 8xC51 cannot communicate with

the output register and control register of the AD7890 at the

same time. The 8xC51 outputs the LSB first in a write operation

so care should be taken in arranging the data, which is to be

transmitted to the AD7890. Similarly, the AD7890 outputs the

MSB first during a read operation while the 8xC51 expects the

LSB first. Therefore, the data that is to be read into the serial

port needs to be rearranged before the correct data word from

the AD7890 is available in the microcontroller.

The serial clock rate from the 8xC51 is limited to significantly

les

s than the allowable input serial clock frequency with which

the AD7890 can operate. As a result, the time to read data from

the part is actually longer than the conversion time of the part.

This means that the AD7890 cannot run at its maximum

throughput rate when used with the 8xC51.

AD7890 TO 68HC11 INTERFACE

An interface circuit between the AD7890 and the 68HC11

microcontroller is shown in Figure 15. For the interface shown,

the AD7890 is configured for its external clocking mode while

the 68HC11’s SPI port is used and the 68HC11 is configured in

its single-chip mode. The 68HC11 is configured in the master

mode with its CPOL bit set to a Logic 0 and its CPHA bit set to

a Logic 1.

As with the previous interface, there are no provisions for

onitoring when conversion is complete on the AD7890. To

m

monitor the conversion time on the AD7890, a scheme, such as

the scheme outlined with

Interface section, can be used. This can be implemented in two

ways. One is to connect the

port bit, which is configured as an input. This port bit can then

be polled to determine when conversion is complete. An alternative

is to use an interrupt driven system in which case the

line should be connected to the

DD

P1.0

P1.1

8xC51

P3.0

P3.1

Figure 14. AD7890 to 8xC51 Interface

CONVST

CONVST

IRQ

DV

SS

PC0

PC1

68HC11

SCK

MISO

MOSI

Figure 15. AD7890 to 68HC11 Interface

DV

DD

SMODE

RFS

TFS

AD7890

DATA OUT

DATA IN

SCLK

in the Simplifying the

line to another parallel

CONVST

input of the 68HC11.