LC2MOS

V

V

VCCVDDVSSV

A

V

A

FEATURES

Four 14-bit DACs in one package

AD7834—serial loading

AD7835—parallel 8-bit/14-bit loading

Voltage outputs

Power-on reset function

Maximum/minimum output voltage range of ±8.192 V

Maximum output voltage span of 14 V

Common voltage reference inputs

User-assigned device addressing

Clear function to user-defined voltage

Surface-mount packages

AD7834—28-lead SOIC and PDIP

AD7835—44-lead MQFP and PLCC

APPLICATIONS

Process control

Automatic test equipment

General-purpose instrumentation

GENERAL DESCRIPTION

The AD7834 and AD7835 contain four 14-bit DACs on one

monolithic chip. The AD7834 and AD7835 have output

voltages in the range ±8.192 V with a maximum span of 14 V.

The AD7834 is a serial input device. Data is loaded in 16-bit

format from the external serial bus, MSB first after two leading 0s,

Quad 14-Bit DACs

AD7834/AD7835

into one via DIN, SCLK, and

dedicated package address pins, PA0 to PA4, that can be wired

to AGND or V

to permit up to 32 AD7834s to be individually

CC

addressed in a multipackage application.

The AD7835 can accept either 14-bit parallel loading or doublebyte loading, where right-justified data is loaded in one 8-bit

byte and one 6-bit byte. Data is loaded from the external bus

into one of the input latches under the control of the

BYSHF

, and DAC channel address pins, A0 to A2.

With each device, the

DAC outputs simultaneously, or individually, on reception of

new data. In addition, for each device, the asynchronous

input can be used to set all signal outputs, V

the user-defined voltage level on the device sense ground pin,

DSG. On power-on, before the power supplies have stabilized,

internal circuitry holds the DAC output voltage levels to within

±2 V of the DSG potential. As the supplies stabilize, the DAC

output levels move to the exact DSG potential (assuming

exercised).

The AD7834 is available in a 28-lead 0.3" SOIC package and a

28-lead 0.6" PDIP package, and the AD7835 is available in a

44-lead MQFP package and a 44-lead PLCC package.

FSYNC

. The AD7834 has five

LDAC

signal is used to update all four

OUT

1 to V

WR

OUT

, CS,

CLR

4, to

CLR

is

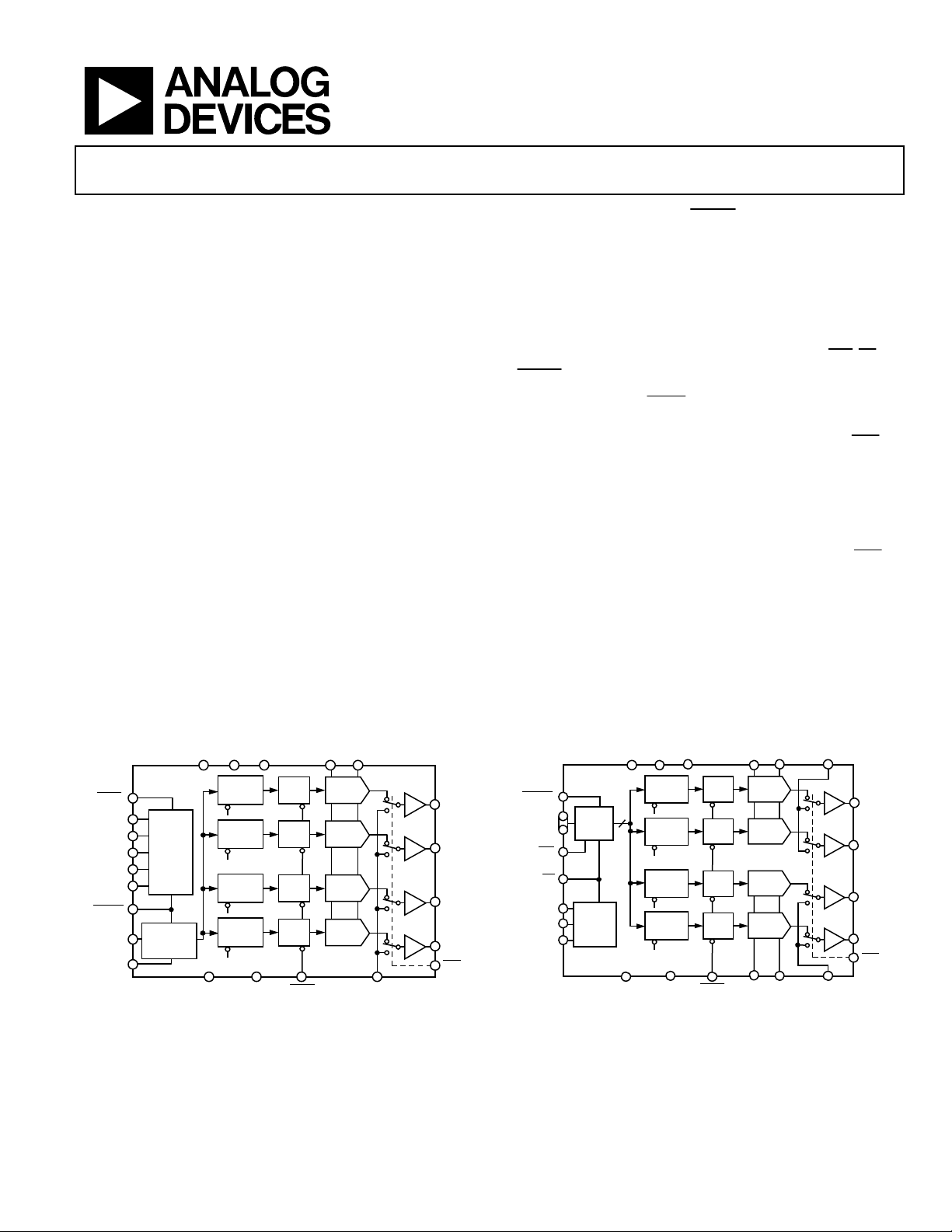

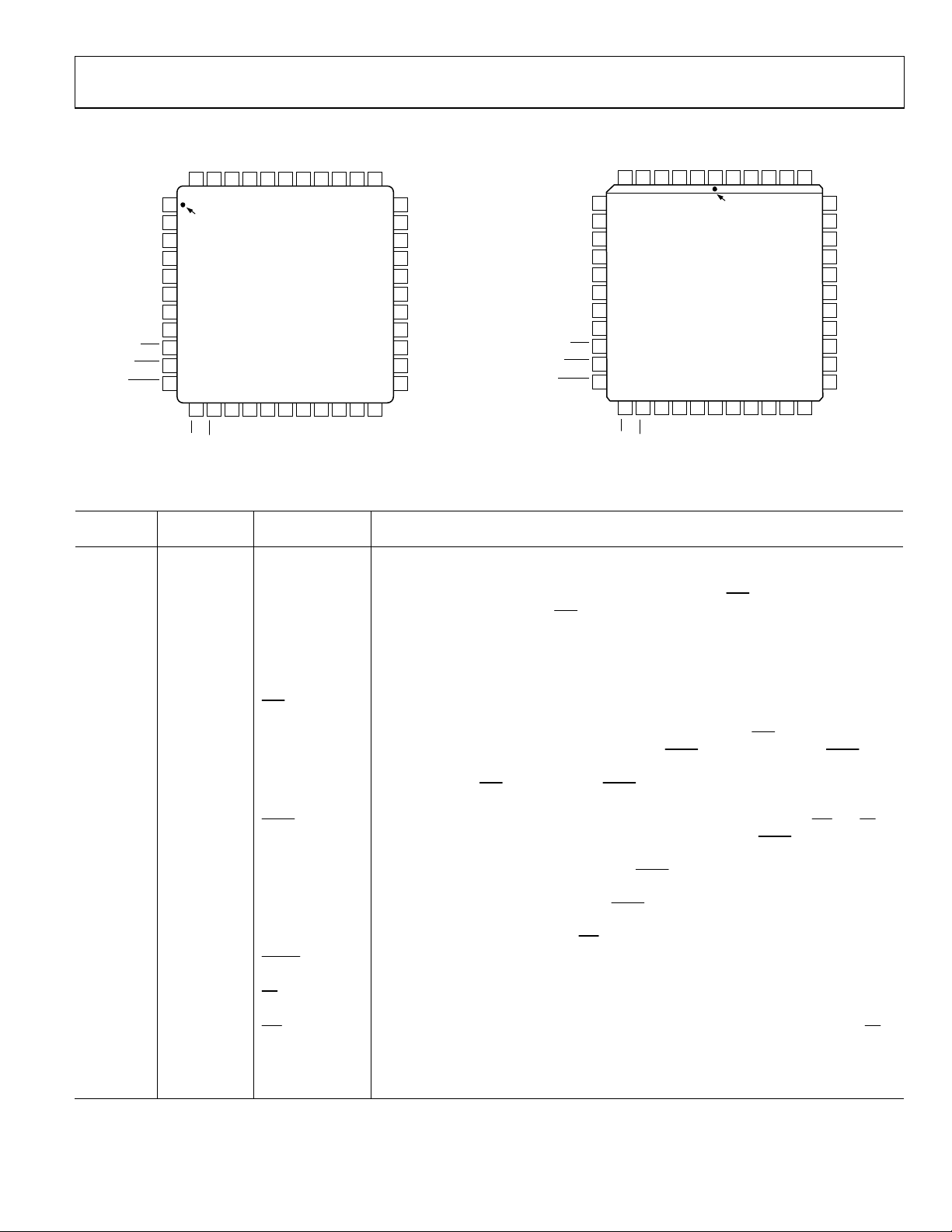

FUNCTIONAL BLOCK DIAGRAMS

(–)

VDDV

PAE N

PA0

PA1

PA2

PA3

PA4

FSYNC

DIN

SCLK

AD7834

CONTROL

LOGIC

AND

ADDRESS

DECODE

SERIAL-TO-

PARALLEL

CONVERTER

CC

AGND DGND DSG

INPUT

REGI STER

1

INPUT

REGISTER

2

INPUT

REGISTER

3

INPUT

REGISTER

4

SS

DAC 1

LATCH

DAC 2

LATCH

DAC 3

LATCH

DAC 4

LATCH

LDAC

Figure 1. AD7834 Figure 2. AD7835

Rev. D

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

REF

DAC 1

DAC 2

DAC 3

DAC 4

V

(+)

REF

×1

V

OUT

×1

V

OUT

V

×1

OUT

×1

V

OUT

CLR

(–)

REF

AD7835

1

2

3

4

BYSHF

DB13

01006-001

DB0

WR

CS

INPUT

BUFFER

A0

ADDRESS

A1

DECODE

A2

INPUT

REGISTER

1

14

INPUT

REGISTER

2

INPUT

REGISTER

3

INPUT

REGISTER

4

AGND DGND

DAC 1

LATCH

DAC 2

LATCH

DAC 3

LATCH

DAC 4

LATCH

LDAC

V

REF

DAC 3

(–)B

DAC 1

DAC 2

DAC 4

(+)

DSGA

REF

×1

V

1

OUT

×1

V

2

OUT

×1

V

3

OUT

×1

DSGB

(+)B

V

REF

V

OUT

CLR

4

01006-002

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.461.3113 ©2003–2007 Analog Devices, Inc. All rights reserved.

www.analog.com

AD7834/AD7835

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagrams............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

AC Performance Characteristics ................................................ 5

Timing Specifications .................................................................. 6

Absolute Maximum Ratings............................................................ 7

Thermal Resistance ...................................................................... 7

ESD Caution.................................................................................. 7

Pin Configurations and Function Descriptions ........................... 8

Typical Performance Characteristics ........................................... 11

Terminology .................................................................................... 13

Theory of Operation ...................................................................... 14

DAC Architecture....................................................................... 14

Data Loading—AD7834 Serial Input Device ......................... 14

Data Loading—AD7835 Parallel Loading Device .................14

Unipolar Configuration............................................................. 15

Bipolar Configuration................................................................ 16

Controlled Power-On of the Output Stage.................................. 17

Power-On with

Power-On with

Loading the DAC and Using the

DSG Voltage Range .................................................................... 18

Power-On of the AD7834/AD7835.............................................. 19

Microprocessor Interfacing........................................................... 20

AD7834 to 80C51 Interface ...................................................... 20

AD7834 to 68HC11 Interface................................................... 20

AD7834 to ADSP-2101 Interface ............................................. 20

AD7834 to DSP56000/DSP56001 Interface............................ 21

AD7834 to TMS32020/TMS320C25 Interface....................... 21

Interfacing the AD7835—16-Bit Interface.............................. 21

Interfacing the AD7835—8-Bit Interface................................ 22

Applications Information.............................................................. 23

Serial Interface to Multiple AD7834s ...................................... 23

Opto-Isolated Interface ............................................................. 23

Automated Test Equipment ...................................................... 23

Power Supply Bypassing and Grounding................................ 24

Outline Dimensions....................................................................... 25

Ordering Guide .......................................................................... 27

CLR

LDAC

Low,

Low,

LDAC

High................................... 17

CLR

High................................... 17

CLR

Input .......................... 17

REVISION HISTORY

7/07—Rev. C to Rev. D

Changes to Table 5 ........................................................................... 7

Added Table 6.................................................................................... 7

Changes to Table 8............................................................................ 9

Updated Outline Dimensions....................................................... 25

Changes to Ordering Guide.......................................................... 27

7/05—Rev. B to Rev. C

Updated Format..................................................................Universal

Changes to Figure 40...................................................................... 25

Changes to Ordering Guide.......................................................... 27

7/03—Rev. A to Rev. B

Revision 0: Initial Version

Rev. D | Page 2 of 28

AD7834/AD7835

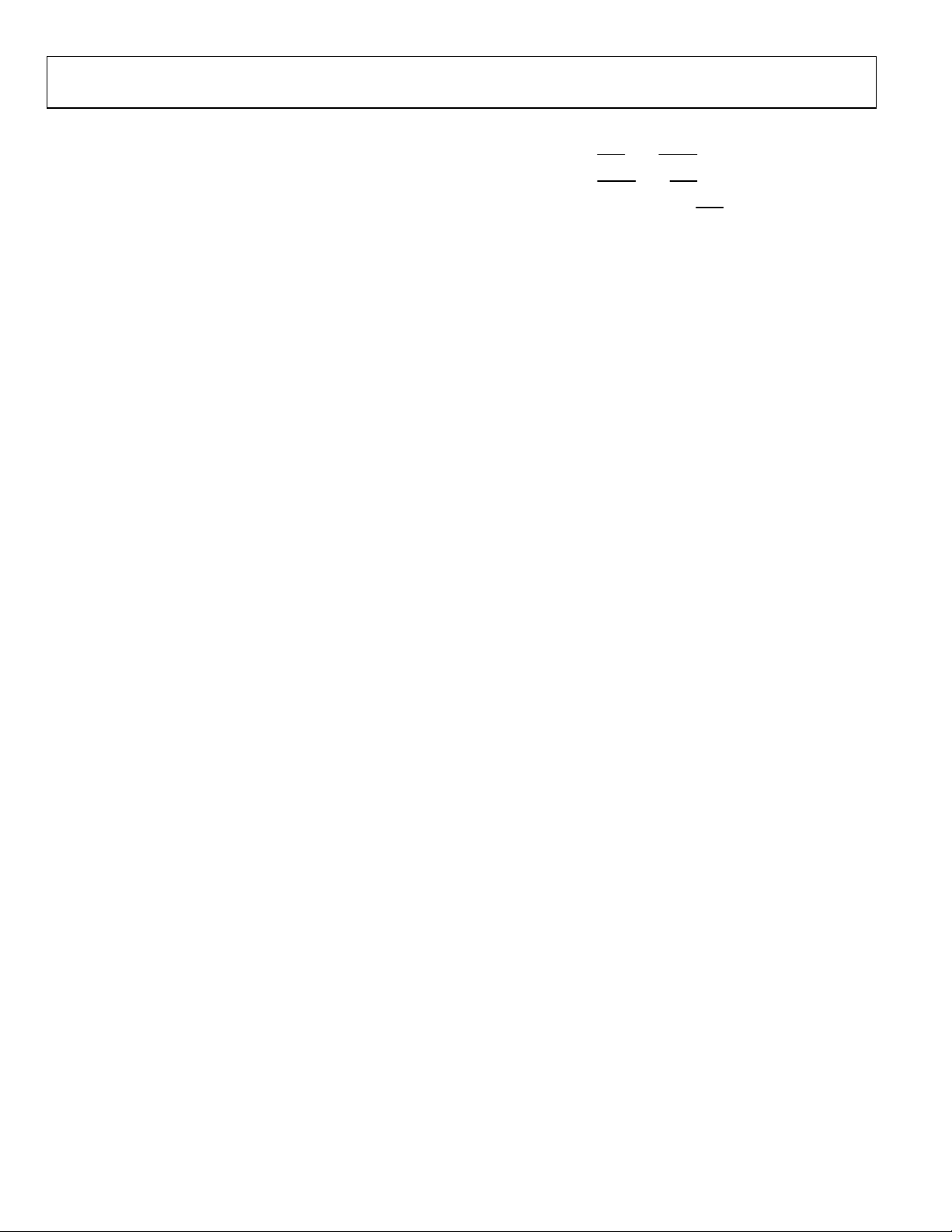

SPECIFICATIONS

1

= T

VCC = 5 V ± 5%; VDD = 15 V ± 5%; VSS = −15 V ± 5%; AGND = DGND = 0 V; T

A

MIN

to T

Table 1.

Parameter

A B S Unit Test Conditions/Comments

ACCURACY

Resolution 14 14 14 Bits

Relative Accuracy ±2 ±1 ±2 LSB max

Differential Nonlinearity ±0.9 ±0.9 ±0.9 LSB max Guaranteed monotonic over temperature.

Full-Scale Error V

T

to T

MIN

±5 ±5 ±8 mV max

MAX

Zero-Scale Error ±4 ±4 ±5 mV max V

Gain Error ±0.5 ±0.5 ±0.5 mV typ V

Gain Temperature

Coefficient

2

4 4 4 ppm FSR/°C typ

20 20 20 ppm FSR/°C max

DC Crosstalk2 50 50 50 μV max See the Terminology section. RL = 10 kΩ.

REFERENCE INPUTS

DC Input Resistance 30 30 30 MΩ typ

Input Current ±1 ±1 ±1 μA max Per input.

V

(+) Range 0/8.192 0/8.192 0/8.192 V min/max

REF

V

(−) Range −8.192/0 −8.192/0 −8.192/0 V min/max

REF

V

REF

(+) − V

(−) 5/14 7/14 5/14 V min/max

REF

DEVICE SENSE GROUND INPUTS

Input Current ±2 ±2 ±2 μA max Per input. V

DIGITAL INPUTS

V

, Input High Voltage 2.4 2.4 2.4 V min

INH

V

, Input Low Voltage 0.8 0.8 0.8 V max

INL

I

, Input Current ±10 ±10 ±10 μA max

INH

CIN, Input Capacitance 10 10 10 pF max

POWER REQUIREMENTS

VCC 5.0 5.0 5.0 V nom ±5% for specified performance.

VDD 15.0 15.0 15.0 V nom ±5% for specified performance.

VSS −15.0 −15.0 −15.0 V nom ±5% for specified performance.

Power Supply Sensitivity

ΔFull Scale/ΔVDD 110 110 110 dB typ

ΔFull Scale/ΔVSS 100 100 100 dB typ

ICC 0.2 0.2 0.5 mA max V

3 3 3 mA max AD7834: V

6 6 6 mA max AD7835: V

IDD 13 13 15 mA max AD7834: outputs unloaded.

15 15 15 mA max AD7835: outputs unloaded.

ISS 13 13 15 mA max Outputs unloaded.

1

Temperature range for A, B, and C versions is −40°C to +85°C.

2

Guaranteed by design.

, unless otherwise noted.

MAX

(+) = +7 V, V

REF

(+) = +7 V, V

REF

(+) = +7 V, V

REF

(−) = −7 V.

REF

(−) = −7 V.

REF

(−) = −7 V.

REF

For specified performance. Can go as low as

0 V, but performance is not guaranteed.

= −2 V to +2 V.

DSG

= VCC, V

INH

= DGND.

INL

= 2.4 V min, V

INH

= 2.4 V min, V

INH

= 0.8 V max.

INL

= 0.8 V max.

INL

Rev. D | Page 3 of 28

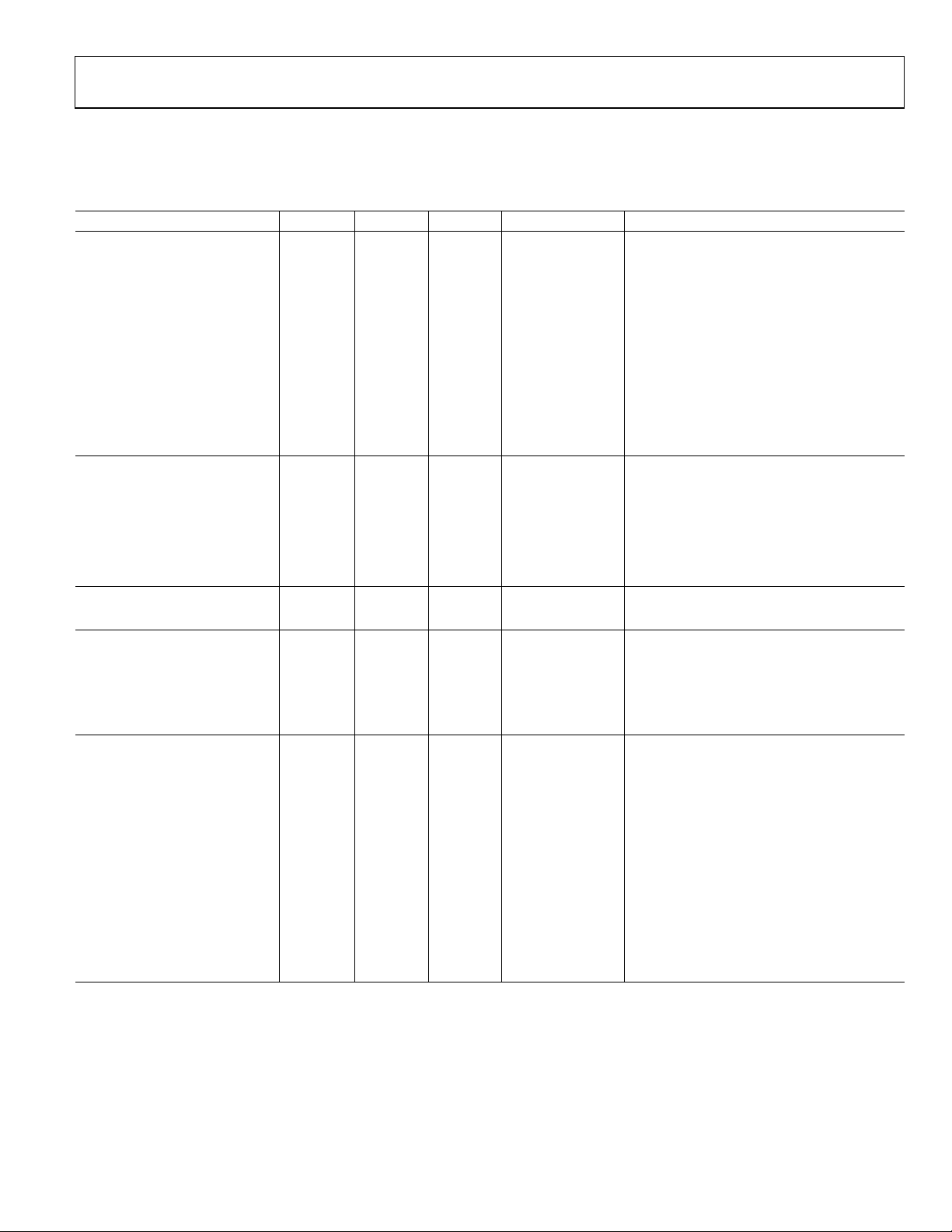

AD7834/AD7835

VCC = 5 V ± 5%; VDD = 12 V ± 5%; VSS = −12 V ± 5%; AGND = DGND = 0 V; T

1

= T

to T

MIN

A

, unless otherwise noted.

MAX

Table 2.

Parameter

A B S Unit Test Conditions/Comments

ACCURACY

Resolution 14 14 14 Bits

Relative Accuracy ±2 ±1 ±2 LSB max

Differential Nonlinearity ±0.9 ±0.9 ±0.9 LSB max Guaranteed monotonic over temperature.

Full-Scale Error V

T

to T

MIN

±5 ±5 ±8 mV max

MAX

Zero-Scale Error ±4 ±4 ±5 mV max V

Gain Error ±0.5 ±0.5 ±0.5 mV typ V

(+) = +5 V, V

REF

(+) = +5 V, V

REF

(+) = +5 V, V

REF

(−) = –5 V.

REF

(−) = −5 V.

REF

(−) = −5 V.

REF

Gain Temperature Coefficient2 4 4 4 ppm FSR/°C typ

20 20 20 ppm FSR/°C max

DC Crosstalk2 50 50 50 μV max See the Terminology section. RL = 10 kΩ.

REFERENCE INPUTS

DC Input Resistance 30 30 30 MΩ typ

Input Current ±1 ±1 ±1 μA max Per input.

V

(+) Range 0/8.192 0/8.192 0/8.192 V min/max

REF

V

(−) Range −5/0 −5/0 −5/0 V min/max

REF

V

REF

(+) − V

(−) 5/13.192 7/13.192 5/13.192 V min/max

REF

For specified performance. Can go as low as

0 V, but performance is not guaranteed.

DEVICE SENSE GROUND INPUTS

Input Current ±2 ±2 ±2 μA max Per input. V

= −2 V to +2 V.

DSG

DIGITAL INPUTS

V

, Input High Voltage 2.4 2.4 2.4 V min

INH

V

, Input Low Voltage 0.8 0.8 0.8 V max

INL

I

, Input Current ±10 ±10 ±10 μA max

INH

CIN, Input Capacitance 10 10 10 pF max

POWER REQUIREMENTS

VCC 5.0 5.0 5.0 V nom ±5% for specified performance.

VDD 15.0 15.0 15.0 V nom ±5% for specified performance.

VSS −15.0 −15.0 −15.0 V nom ±5% for specified performance.

Power Supply Sensitivity

ΔFull Scale/ΔVDD 110 110 110 dB typ

ΔFull Scale/ΔVSS 100 100 100 dB typ

ICC 0.2 0.2 0.5 mA max V

3 3 3 mA max AD7834: V

6 6 6 mA max AD7835: V

= VCC, V

INH

= DGND.

INL

= 2.4 V min, V

INH

= 2.4 V min, V

INH

= 0.8 V max.

INL

= 0.8 V max.

INL

IDD 13 13 15 mA max AD7834: outputs unloaded.

15 15 15 mA max AD7835: outputs unloaded.

ISS 13 13 15 mA max Outputs unloaded.

1

Temperature range for A, B, and C versions is −40°C to +85°C.

2

Guaranteed by design.

Rev. D | Page 4 of 28

AD7834/AD7835

AC PERFORMANCE CHARACTERISTICS

These characteristics are included for design guidance and are not subject to production testing.

Table 3.

Parameter

DYNAMIC PERFORMANCE

Output Voltage Settling Time 10 10 10 μs

Digital-to-Analog Glitch Impulse 120 120 120 nV-s

DC Output Impedance 0.5 0.5 0.5 Ω See the Terminology section.

Channel-to-Channel Isolation 100 100 100 dB See the Terminology section; applies to the AD7835 only.

DAC-to-DAC Crosstalk 25 25 25 nV-s See the Terminology section.

Digital Crosstalk 3 3 3 nV-s

Digital Feedthrough—AD7834 0.2 0.2 0.2 nV-s Effect of input bus activity on DAC output under test.

Digital Feedthrough—AD7835 1.0 1.0 1.0 nV-s

Output Noise Spectral Density at 1 kHz 40 40 40 nV/√Hz All 1s loaded to DAC. V

A B S Unit (typ) Test Conditions/Comments

Full-scale change to ±1/2 LSB. DAC latch contents

alternately loaded with all 0s and all 1s.

Measured with V

(+) = V

REF

REF

alternately loaded with all 0s and all 1s.

Feedthrough to DAC output under test due to change in

digital input code to another converter.

(+) = V

REF

(−) = 0 V. DAC latch

(−) = 0 V.

REF

Rev. D | Page 5 of 28

AD7834/AD7835

)

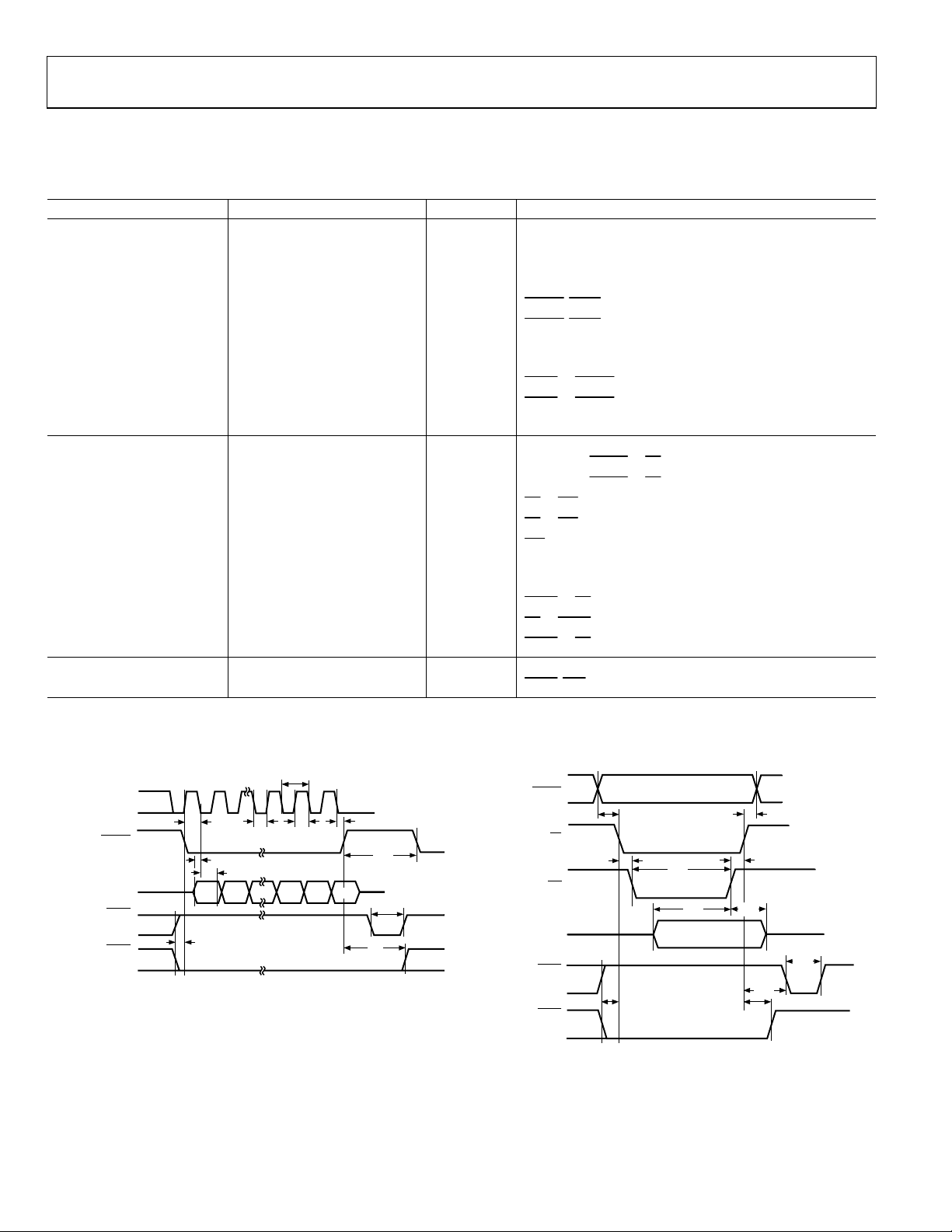

TIMING SPECIFICATIONS

VCC = 5 V ± 5%; VDD = 11.4 V to 15.75 V; VSS = −11.4 V to −15.75 V; AGND = DGND = 0 V1.

Table 4.

Parameter Limit at T

MIN

AD7834-SPECIFIC

2

t

1

2

t

2

2

t

30 ns min SCLK high time

3

30 ns min

t4

100 ns min SCLK cycle time

50 ns min SCLK low

t5 40 ns min

t6 30 ns min Data setup time

10 ns min Data hold time

t7

0 ns min

t8

t9 40 ns min

t21 20 ns min Delay between write operations

AD7835-SPECIFIC

t11 15 ns min

t12 15 ns min

t13 0 ns min

t14 0 ns min

t15 40 ns min

t16 40 ns min Data setup time

10 ns min Data hold time

t17

0 ns min

t18

t19 0 ns min

t20 0 ns min

GENERAL

t10 40 ns min

1

All input signals are specified with tr = tf = 5 ns (10% to 90% of 5 V) and time from a voltage level of 1.6 V.

2

Rise and fall times should be no longer than 50 ns.

1ST

SCLK

FSYNC

DIN

(SIMULTANEOUS

LDAC

UPDATE)

LDAC

(PER-CHANNE L

UPDATE

2ND

CLK

CLK

t

4

t

6

t

MSB LSB

7

D23 D2 2

t

8

Figure 3. AD7834 Timing Diagram Figure 4. AD7835 Timing Diagram

t

1

t

2

Unit Description

, T

MAX

24TH

CLK

t

3

t

5

t

21

D0

D1

t

10

t

9

01006-003

(SIMULTANEOUS

(PER-CHANNEL

, PAEN setup time

FSYNC

, PAEN hold time

FSYNC

LDAC

to FSYNC setup time

to FSYNC hold time

LDAC

A0, A1, A2, BYSHF

A0, A1, A2, BYSHF

CS

to WR setup time

CS

to WR hold time

WR

pulse width

LDAC

to CS setup time

CS

to LDAC setup time

to CS hold time

LDAC

LDAC

, CLR pulse width

A0 A1 A2

BYSHF

CS

WR

DB0 TO DB13

LDAC

UPDATE)

LDAC

UPDATE)

to CS setup time

to CS hold time

t

11

t

13

t

18

t

15

t

16

t

12

t

14

t

17

t

10

t

19

t

20

01006-004

Rev. D | Page 6 of 28

AD7834/AD7835

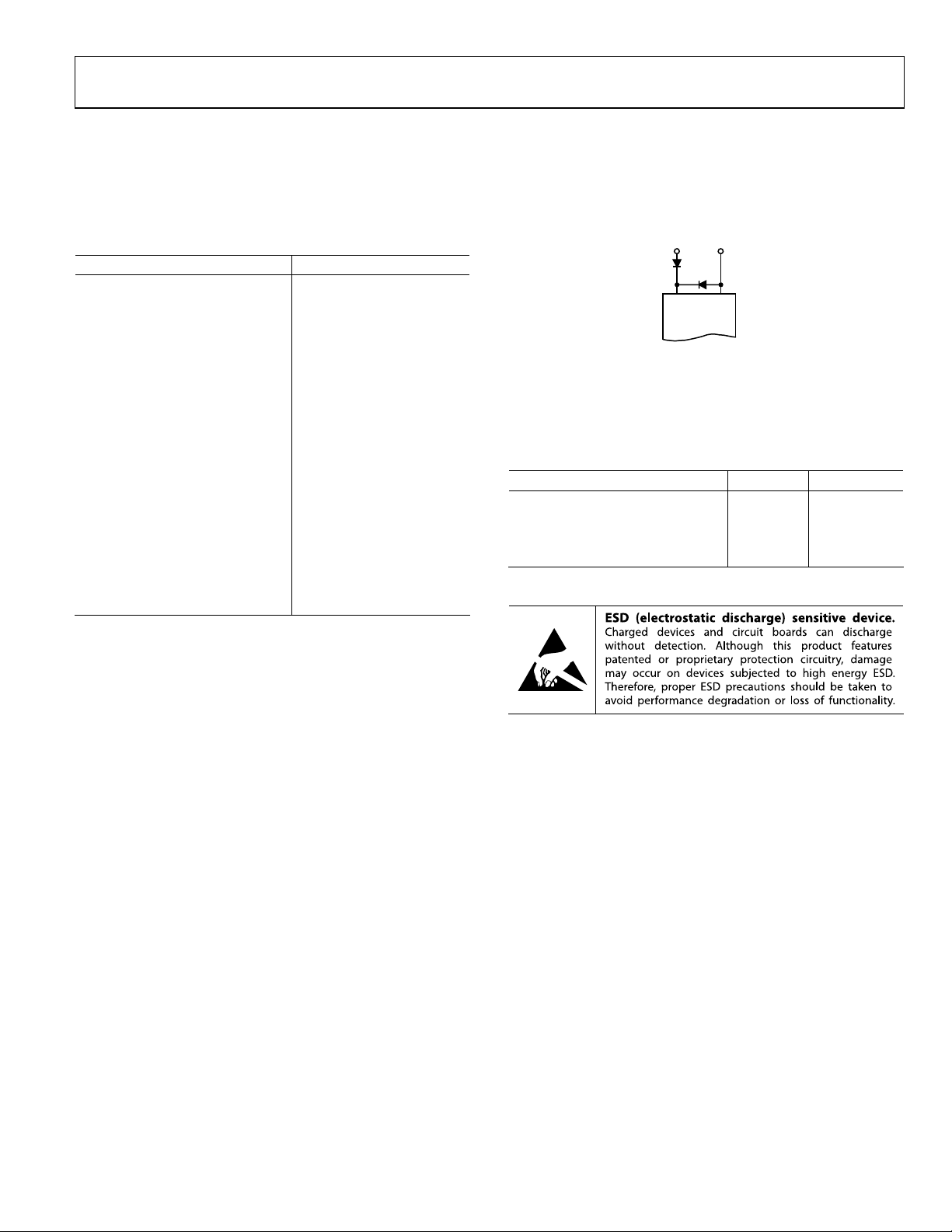

ABSOLUTE MAXIMUM RATINGS

TA = 25°C unless otherwise noted. Transient currents of up to 100 mA do not cause SCR latch-up. VCC must not exceed VDD by more than

0.3 V. If it is possible for this to happen during power supply sequencing, the diode protection scheme shown in

provide protection.

V

Table 5.

Parameter Rating

VCC to DGND −0.3 V to +7 V, or VDD + 0.3 V

(whichever is lower)

VDD to AGND −0.3 V to +17 V

DD

IN4148

SD103C

V

DD

AD7834/

AD7835

VSS to AGND +0.3 V to –17 V

AGND to DGND −0.3 V to +0.3 V

Figure 5. Diode Protection

−0.3 V to VCC + 0.3 V Digital Inputs to DGND

V

(+) to V

REF

V

(+) to AGND VSS – 0.3 V to VDD + 0.3 V

REF

V

(–) to AGND VSS – 0.3 V to VDD + 0.3 V

REF

(–) −0.3 V to +18 V

REF

VSS – 0.3 V to VDD + 0.3 V DSG to AGND

V

(1–4) to AGND VSS – 0.3 V to VDD + 0.3 V

OUT

Operating Temperature Range, T

A

−40°C to +85°C Industrial (A Version)

−65°C to +150°C Storage Temperature Range

150°C Junction Temperature, TJ (max)

Power Dissipation, PD (max) (TJ − TA)/θJA

Lead Temperature JEDEC Industry Standard

Soldering J-STD-020

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 6. Thermal Resistance

Package Type θJA Unit

PDIP 75 °C/W

SOIC 75

MQFP 95

PLCC 55 °C/W

ESD CAUTION

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Figure 5 can be used to

V

CC

V

CC

01006-005

°C/W

°C/W

Rev. D | Page 7 of 28

AD7834/AD7835

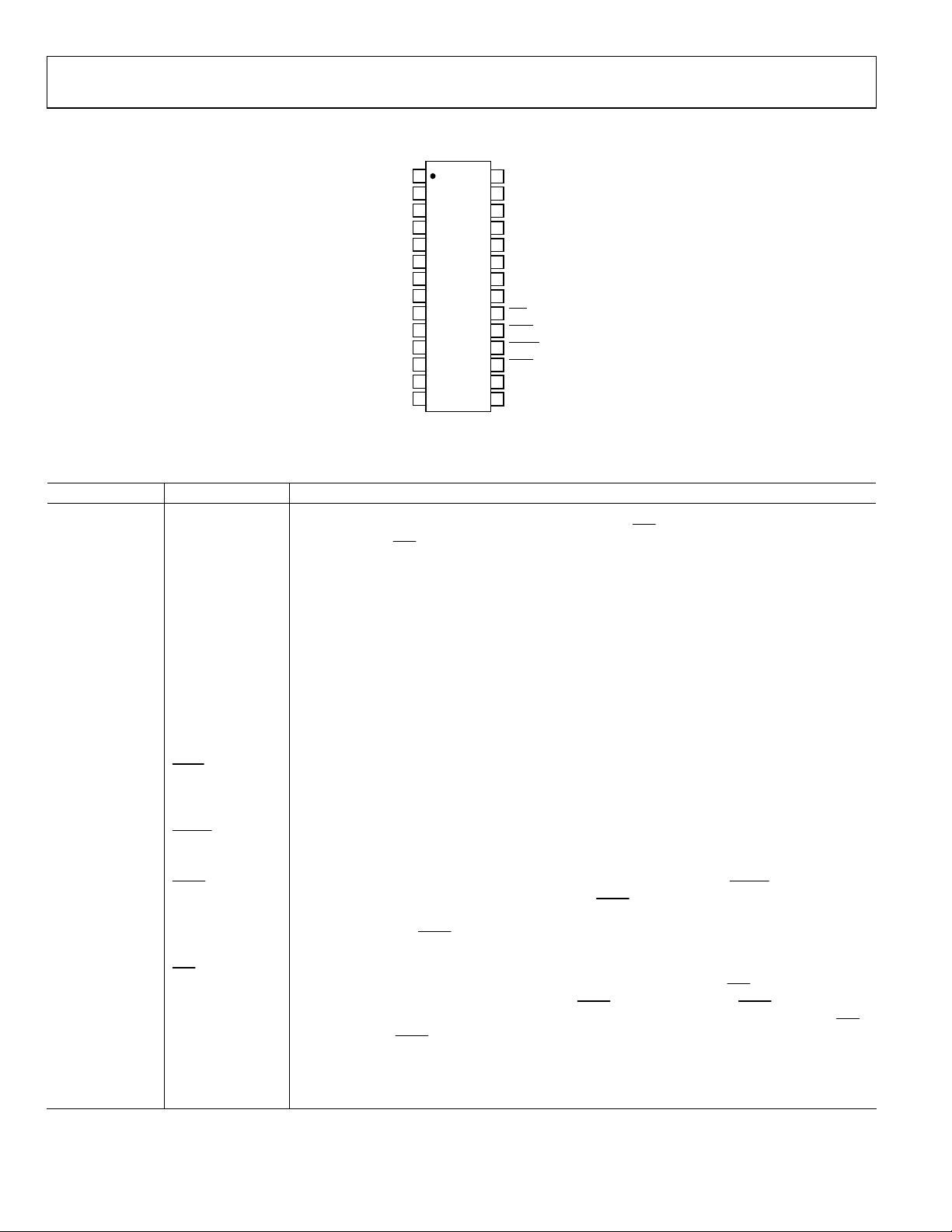

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AGND

NC

NC

NC

NC

V

DD

V

OUT

V

OUT

CLR

LDAC

FSYNC

PAEN

PA4

PA3

1

3

01006-006

V

REF

V

REF

V

V

DGND

SCLK

V

DSG

OUT

OUT

V

DIN

PA0

PA1

PA2

SS

(–)

(+)

NC

2

4

CC

1

2

3

4

5

AD7834

6

TOP VIEW

(Not to Scale)

7

8

9

10

11

12

13

14

NC = NO CONNECT

Figure 6. AD7834 PDIP and SOIC Pin Configuration

Table 7. AD7834 Pin Function Descriptions

Pin No. Pin Mnemonic Description

1 VSS Negative Analog Power Supply: −15 V ± 5% or −12 V ± 5%.

2 DSG

3 V

4 V

(−) Negative Reference Input. The negative reference voltage is referred to AGND.

REF

Positive Reference Input. The positive reference voltage is referred to AGND.

(+)

REF

5, 24, 25, 26, 27 NC

V

OUT

1 to V

OUT

4

8 DGND

9 VCC

Logic Power Supply: 5 V ± 5%.

10 SCLK

Device Sense Ground Input. Used in conjunction with the CLR

the DACs. When CLR

is low, the DAC outputs are forced to the potential on the DSG pin.

No Connect.

22, 6, 21, 7 DAC Outputs.

Digital Ground.

Clock Input. Used for writing data to the device; data is clocked into the input register on the

falling edge of SCLK.

11 DIN

12,13,14,15,16 PA0 to PA4

Serial Data Input.

Package Address Inputs. These inputs are hardwired high (VCC) or low (DGND) to assign dedicated

package addresses in a multipackage environment.

17

PAEN

Package Address Enable Input. When low, this input allows normal operation of the device. When

high, the device ignores the package address, but not the channel address, in the serial data

stream and loads the serial data into the input registers. This feature is useful in a multipackage

application where it can be used to load the same data into the same channel in each package.

18

Frame Sync Input. Active low logic input used, in conjunction with DIN and SCLK, to write data to

FSYNC

the device with serial data expected after the falling edge of this signal. The contents of the 24-bit

serial-to-parallel input register are transferred on the rising edge of this signal.

19

Load DAC Input (Level Sensitive). This input signal, in conjunction with the FSYNC input signal,

LDAC

LDAC

determines how the analog outputs are updated. If

is maintained high while new data is

being loaded into the device’s input registers, no change occurs on the analog outputs.

Subsequently, when

LDAC

is brought low, the contents of all four input registers are transferred

into their respective DAC latches, updating all of the analog outputs simultaneously.

20

CLR

Asynchronous Clear Input (Level Sensitive, Active Low). When this input is brought low, all analog

outputs are switched to the externally set potential on the DSG pin. When CLR

signal outputs remain at the DSG potential until LDAC

is brought low. When LDAC is brought low,

the analog outputs are switched back to reflect their individual DAC output levels. As long as CLR

LDAC

remains low, the

potential on the DSG pin.

signals are ignored, and the signal outputs remain switched to the

23 VDD Positive Analog Power Supply: 15 V ± 5% or 12 V ± 5%.

28 AGND Analog Ground.

input for power-on protection of

is brought high, the

Rev. D | Page 8 of 28

AD7834/AD7835

AGND

DB2

NC

DB3

(+)B

V

DB4

NC

1

DSGA

2

1

V

3

OUT

2

V

4

OUT

NC

5

A2

6

A1

7

8

A0

CLR

9

LDAC

10

11

BYSHF

NC = NO CONNECT

(+)A

(–)A

REF

NC

V

PIN 1

IDENTIFIER

REF

V

DD

SS

V

V

NC

40 39 3841424344 36 35 3437

AD7835

TOP VIEW

(Not to Scale)

12 13 14 15 16 17 18 192021 22

CC

CS

WR

V

DB0

DGND

DB1

Figure 7. AD7835 MQFP Pin Configuration Figure 8. AD7835 PLCC Pin Configuration

Table 8. AD7835 Pin Function Descriptions

Pin No.

MQFP

1, 5, 33, 34,

37, 41, 44

Pin No. PLCC Pin Mnemonic Description

3, 6, 7, 11, 39,

NC No Connect.

40, 43

(–)A

(–)B

REF

REF

V

NC

NC

DSGA

V

OUT

V

OUT

CLR

LDAC

BYSHF

NC

A0

7

8

1

9

10

2

11

A2

12

13

A1

14

15

16

17

DB5

DB6

NC

33

32

DSGB

3

V

31

OUT

4

30

V

OUT

DB13

29

DB12

28

27

DB11

DB10

26

25

DB9

24

DB8

23

DB7

01006-007

NC = NO CONNECT

(+)A

REF

NC

V

SS

DD

V

AGND

V

244345642414043

1

PIN 1

IDENTIFIER

NC

REF

V

AD7835

TOP VIEW

(Not to Scale)

181920 21 22 23 24 252627 28

CC

CS

WR

V

DGND

DB0

DB1

DB2

NC

DB3

(+)B

REF

V

DB4

(–)B

REF

V

DB5

NC

DB6

NC

39

38

DSGB

3

V

37

OUT

36

4

V

OUT

DB13

35

34

DB12

33

DB11

DB10

32

31

DB9

DB8

30

29

DB7

01006-008

2 8 DSGA

Device Sense Ground A Input. Used in conjunction with the CLR

protection of the DACs. When

V

1 to V

OUT

8, 7, 6 14, 13, 12 A0, A1, A2

potential on the DSGA pin.

4 3, 4, 31, 30 9, 10, 37, 36 DAC Outputs.

OUT

Address Inputs. A0 and A1 are decoded to select one of the four input latches for a data

transfer. A2 is used to select all four DACs simultaneously.

9 15

CLR

Asynchronous Clear Input (Level Sensitive, Active Low). When this input is brought low,

all analog outputs are switched to the externally set potentials on the DSG pins (V

and V

2 follow DSGA, and V

OUT

signal outputs remain at the DSG potentials until LDAC

brought low, the analog outputs are switched back to reflect their individual DAC output

levels. As long as

remains low, the LDAC signals are ignored, and the signal outputs

CLR

remain switched to the potential on the DSG pins.

10 16

Load DAC Input (Level Sensitive). This input signal, in conjunction with the WR and CS

LDAC

input signals, determines how the analog outputs are updated. If

high while new data is being loaded into the device’s input registers, no change occurs

on the analog outputs. Subsequently, when

input registers are transferred into their respective DAC latches, updating the analog

outputs simultaneously. Alternatively, if

entered, the addressed DAC latch and corresponding analog output are updated

immediately on the rising edge of

11 17

Byte Shift Input. When low, it shifts the data on DB0 to DB7 into the DB8 to DB13 half of

BYSHF

the input register.

12 18

CS

Level-Triggered Chip Select Input (Active Low). The device is selected when this input is

low.

13 19

Level-Triggered Write Input (Active Low). When active, it is used in conjunction with CS

WR

to write data over the input databus.

14 20 VCC Logic Power Supply: 5 V ± 5%.

15 21 DGND Digital Ground.

CLR

is low, DAC outputs V

OUT

3 and V

4 follow DSGB). When CLR

OUT

LDAC

LDAC

.

WR

input for power-on

1 and V

OUT

2 are forced to the

OUT

OUT

is brought high, the

is brought low. When LDAC is

LDAC

is maintained

is brought low, the contents of all four

is brought low while new data is being

1

Rev. D | Page 9 of 28

AD7834/AD7835

Pin No.

MQFP

16 to 29 22 to 35 DB0 to DB13

32 38 DSGB

36, 35 42, 41 V

38 44 AGND Analog Ground.

39 1 VDD Positive Analog Power Supply: 15 V ± 5% or 12 V ± 5%.

40 2 VSS Negative Analog Power Supply: −15 V ± 5% or −12 V ± 5%.

42, 43 4, 5 V

Pin No. PLCC Pin Mnemonic Description

Parallel Data Inputs. The AD7835 can accept a straight 14-bit parallel word on DB0 to

DB13, where DB13 is the MSB and the

Alternatively for byte loading, the bottom eight data inputs, DB0 to DB7, are used for

data loading, and the top six data inputs, DB8 to DB13, should be hardwired to a logic

low. The

BYSHF

into the device.

Device Sense Ground B Input. Used in conjunction with the CLR

protection of the DACs. When

potential on the DSGB pin.

REF

REF

(+)B, V

(+)A, V

(−)B Reference Inputs for DACs 3 and 4. These reference voltages are referred to AGND.

REF

(−)A Reference Inputs for DAC 1 and DAC 2. These reference voltages are referred to AGND.

REF

input is hardwired to a logic high.

BYSHF

control input selects whether 8 LSBs or 6 MSBs of data are being loaded

CLR

is low, DAC outputs V

OUT

input for power-on

3 and V

4 are forced to the

OUT

Rev. D | Page 10 of 28

AD7834/AD7835

TYPICAL PERFORMANCE CHARACTERISTICS

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

01

4 8 10 12 14

62

CODE/1000

01006-009

6

Figure 9. Typical INL Plot

0.50

0.45

0.40

INL (LSB)

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

DAC 3

DAC 2

TEMP = 25°C

ALL DACs FROM 1 DEVICE

Figure 12. Typical INL vs. V

DAC 1

DAC 4

01006-012

V

(+) (V)

REF

(+), V

(+) – V

REF

REF

(−) = 5 V

REF

8.00 2.5 5.0

0.5

0.4

0.3

0.2

0.1

0

DNL (LSB)

–0.1

–0.2

–0.3

–0.4

–0.5

01

CODE/1000

64 8 10 12 1462

01006-010

Figure 10. Typical DNL Plot

0.9

0.8

0.7

0.6

0.5

0.4

INL (LSB)

0.3

0.2

0.1

0

173

Figure 11. Typical INL vs. V

V

(+) (V)

REF

(+), V

REF

(−) = −6 V

REF

802456

01006-011

0.8

ALL DACs FROM ONE DEVI CE

0.7

0.6

DAC 3

0.5

0.4

INL (LSB)

0.3

0.2

0.1

0

–40 25

Figure 13. Typical INL vs. Temperature

1.0

0.8

0.6

0.4

0.2

0

DAC (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

014 8 10 12 1462

Figure 14. Typical DAC-to-DAC Matching

TEMPERATURE (°C)

CODE/1000

DAC 1

DAC 4

DAC 2

01006-013

85

01006-014

6

Rev. D | Page 11 of 28

AD7834/AD7835

–

VOLTS

–0.1

–0.2

8

6

4

2

VOLTS

0

0.7

0.6

0.5

0.4

0.3

0.2

0.1

VERT = 100mV/DIV

HORIZ = 1μs/DIV

0

Figure 15. Typical Digital/Analog Glitch Impulse

VERT = 2V/DIV

HORIZ = 1.2μs/DIV

(+) = +7V

V

REF

(–) = –3V

V

REF

7.250

7.225

7.200

7.175

7.150

01006-015

VOLTS

8

6

4

V

(+) = +7V

2

VOLTS

0

–2

–4

REF

V

(–) = –3V

REF

VERT = 2V/DIV

HORIZ = 1µs/DI V

VERT = 10mV/DIV

HORIZ = 1µs/DIV

2.985

–3.005

–3.025

–3.045

–3.065

–3.085

–3.105

VOLTS

01006-017

Figure 17. Settling Time(−)

–2

–4

VERT = 25mV/DIV

HORIZ = 2.5μs/DIV

7.125

7.100

01006-016

Figure 16. Settling Time(+)

Rev. D | Page 12 of 28

AD7834/AD7835

TERMINOLOGY

Relative Accuracy

Relative accuracy or endpoint linearity is a measure of the

maximum deviation from a straight line passing through the

endpoints of the DAC transfer function. It is measured after

adjusting for zero error and full-scale error. It is normally

expressed in LSBs or as a percentage of full-scale reading.

Differential Nonlinearity

Differential nonlinearity is the difference between the measured

change and the ideal 1 LSB change between any two adjacent

codes. A specified differential nonlinearity of 1 LSB maximum

ensures monotonicity.

DC Crosstalk

Although the common input reference (IR) voltage signals are

internally buffered, small IR drops in individual DAC reference

inputs across the die mean that an update to one channel

produces a dc output change in one or more channel outputs.

The four DAC outputs are buffered by op amps sharing

common V

and VSS power supplies. If the dc load current

DD

changes in one channel due to an update, a further dc change

occurs in one or more of the channel outputs. This effect is

most obvious at high load currents and is reduced as the load

currents are reduced. With high impedance loads, the effect is

virtually unmeasurable.

Output Voltage Settling Time

This is the amount of time it takes for the output to settle to a

specified level for a full-scale input change.

Digital-to-Analog Glitch Impulse

This is the amount of charge injected into the analog output

when the inputs change state. It is specified as the area of the

glitch in nV-secs. It is measured with the reference inputs

connected to 0 V and the digital inputs toggled between all

1s and all 0s.

Channel-to-Channel Isolation

Channel-to-channel isolation refers to the proportion of input

signal from the reference input of one DAC that appears at the

output of the other DAC. It is expressed in decibels (dB). The

AD7834 has no specification for channel-to-channel isolation

because it has one reference for all DACs. Channel-to-channel

isolation is specified for the AD7835.

DAC-to-DAC C rosst a l k

DAC-to-DAC crosstalk is defined as the glitch impulse that

appears at the output of one converter due to both the digital

change and the subsequent analog output (O/P) change at

another converter. It is specified in nV-secs.

Digital Crosstalk

The glitch impulse transferred to the output of one converter

due to a change in digital input code to the other converter is

defined as the digital crosstalk and is specified in nV-secs.

Digital Feedthrough

When the device is not selected, high frequency logic activity

on its digital inputs can be capacitively coupled both across and

through the device to show up as noise on the V

pins. This

OUT

noise is digital feedthrough.

DC Output Impedance

DC output impedance is the effective output source resistance.

It is dominated by package lead resistance.

Full-Scale Error

Full-scale error is the error in DAC output voltage when all 1s

are loaded into the DAC latch. Ideally, the output voltage, with

all 1s loaded into the DAC latch, should be V

(+) – 1 LSB.

REF

Full-scale error does not include zero-scale error.

Zero-Scale Error

Zero-scale error is the error in the DAC output voltage when

all 0s are loaded into the DAC latch. Ideally, the output voltage,

with all 0s in the DAC latch, is equal to V

(−). Zero-scale

REF

error is due mainly to offsets in the output amplifier.

Gain Error

Gain error is defined as (full-scale error) − (zero-scale error).

Rev. D | Page 13 of 28

AD7834/AD7835

THEORY OF OPERATION

DAC ARCHITECTURE

Each channel consists of a segmented 14-bit R-2R voltage-mode

DAC. The full-scale output voltage range is equal to the entire

reference span of V

binary; all 0s produce an output of V

output of V

REF

The analog output voltage of each DAC channel reflects the

contents of its own DAC latch. Data is transferred from the

external bus to the input register of each DAC latch on a per

channel basis. The AD7835 has a feature whereby the A2 pin

data can be transferred from the input databus to all four input

registers simultaneously.

Bringing the

to V

OUT

CLR

4, to the voltage level on the DSG pin. The signal

outputs are held at this level after the removal of the

and do not switch back to the DAC outputs until the

signal is exercised.

DATA LOADING—AD7834 SERIAL INPUT DEVICE

A write operation transfers 24 bits of data to the AD7834. The

first 8 bits are control data and the remaining 16 bits are DAC

data (see

nel to be updated with new data and which of 32 possible

packages the DAC resides in. In any communication with the

device, the first 8 bits must always be control data.

The DAC output voltages, V

reflect new data in the DAC input registers in one of two ways.

The first method normally keeps

LDAC

eously with the contents of their respective input registers. The

second method ties

a per channel basis after new data has been clocked into the

AD7834. With

the new data directly into the DAC latch, updating the analog

output voltage.

Data being shifted into the AD7834 enters a 24-bit long shift

register. If more than 24 bits are clocked in before

high, the last 24 bits transmitted are used as the control data

and DAC data.

Individual bit functions are shown in Figure 18.

D23

D23 determines whether the following 23 bits of address and

data should be used or ignored. This is effectively a software

chip select bit. D23 is the first bit to be transmitted in the 24-bit

long word.

Figure 18). The control data identifies the DAC chan-

low momentarily to update all DAC latches simultan-

(+) – V

REF

(−). The DAC coding is straight

REF

(−); all 1s produce an

REF

(+) − 1 LSB.

line low switches all the signal outputs, V

OUT

LDAC

low and channel updating occurs on

LDAC

low, the rising edge of

1 to V

4, can be updated to

OUT

LDAC

high and only pulses

FSYNC

FSYNC

OUT

CLR

signal

LDAC

transfers

goes

Table 9. D23 Control

D23 Control Function

0 Ignore the following 23 bits of information.

1 Use the following 23 bits of address and data as normal.

D22 and D21

D22 and D21 are decoded to select one of the four DAC channels within a device, as shown in

Tabl e 10 .

Table 10. D22, D21 Control

D22 D21 Control Function

0 0 Select Channel 1

0 1 Select Channel 2

1

1 0 Select Channel 3

1 1 Select Channel 4

D20 to D16

D20 and D16 determine the package address. The five address

bits allow up to 32 separate packages to be individually decoded.

Successful decoding is accomplished when these five bits match

up with the five hardwired pins on the physical package.

D15 to D0

D15 and D0 provide DAC data to be loaded into the identified

DAC input register. This data must have two leading 0s followed

by 14 bits of data, MSB first. The MSB is in location D13 of the

24-bit data stream.

DATA LOADING—AD7835 PARALLEL LOADING DEVICE

Data is loaded into the AD7835 in either straight 14-bit wide

words or in two 8-bit bytes.

BYSHF

In systems that transfer 14-bit wide data, the

should be hardwired to V

. This sets up the AD7835 as a

CC

straight 14-bit parallel-loading DAC.

In 8-bit bus systems where it is required to transfer data in two

bytes, it is necessary to have the

BYSHF

input under logic control.

In such a system, the top six pins of the device databus, DB8 to

DB13, must be hardwired to DGND. New low byte data is

loaded into the lower eight places of the selected input register

by carrying out a write operation while holding

A second write operation is subsequently executed with

low and the 6 MSBs on the DB0 to DB5 inputs (DB5 = MSB).

input

BYSHF

high.

BYSHF

Rev. D | Page 14 of 28

AD7834/AD7835

CONTROL BIT TO USE/IGNORE

FOLLOWING 23 BITS OF INFORMATION

CHANNEL ADDRESS MSB, D1

CHANNEL ADDRESS LSB, D2

PACKAGE ADDRESS MSB, PA4

PACKAGE ADDRESS, PA3

PACKAGE ADDRESS, PA2

PACKAGE ADDRESS, PA1

PACKAGE ADDRESS LSB, PA0

NOTE: D23IS THE FIRST BIT TRANSMITTED IN THE SERIAL WORD.

D23 D22 D21

D18 D17 D16 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

D20 D19

Figure 18. Bit Assignments for 24-Bit Data Stream of AD7834

When 14-bit transfers are being used, the DAC output voltages,

1 to V

V

OUT

4, can be updated to reflect new data in the DAC

OUT

input registers in one of two ways. The first method normally

keeps

LDAC

high and only pulses

LDAC

low momentarily to

update all DAC latches simultaneously with the contents of

their respective input registers. The second method ties

LDAC

low, and channel updating occurs on a per channel basis after

new data is loaded to an input register.

To avoid the DAC output going to an intermediate value during

a 2-byte transfer,

LDAC

should not be tied low permanently but

should be held high until the two bytes are written to the input

register. When the selected input register has been loaded with

the two bytes,

LDAC

should then be pulsed low to update the

DAC latch and, consequently, perform the digital-to-analog

conversion.

In many applications, it may be acceptable to allow the DAC

output to go to an intermediate value during a 2-byte transfer.

In such applications,

LDAC

can be tied low, thus using one less

control line.

The actual DAC input register that is being written to is determined by the logic levels present on the device address lines, as

shown in Tab l e 1 1 .

Table 11. AD7835—Address Line Truth Table

A2 A1 A0 DAC Selected

0 0 0 DAC 1

0 0 1 DAC 2

0 1 0 DAC 3

0 1 1 DAC 4

1 X X All DACs selected

UNIPOLAR CONFIGURATION

Figure 19 shows the AD7834/AD7835 in the unipolar binary

circuit configuration. The V

the

AD586, a 5 V reference. V

(+) input of the DAC is driven by

REF

(−) is tied to ground. Tab l e 1 2

REF

SECOND LEADING ZERO

FIRST LEADING ZERO

LSB, DB0

SECOND LSB, DB1

THIRD LSB, DB2

DB3

DB4

DB5

DB6

DB7

DB8

DB9

DB10

THIRD MSB, DB11

SECOND MSB,DB12

MSB, DB13

01006-018

gives the code table for unipolar operation of the AD7834/

AD7835.

+15V +5V

2

AD586

4

SIGNAL

GND

6

5

8

C1

1nF

1

ADDITIONAL PINS OMITTED FOR CLARITY

R1

10kΩ

V

REF

V

V

DD

(+)

AD7834/

AD7835

(–)

REF

V

–15V

SS

V

CC

V

1

AGND

DGND

OUT

V

(0V TO 5V)

SIGNAL

GND

OUT

Figure 19. Unipolar 5 V Operation

Offset and gain can be adjusted in Figure 19 as follows:

• To adjust offset, disconnect the V

load the DAC with all 0s, and adjust the V

until V

OUT

= 0 V.

(−) input from 0 V,

REF

(−) voltage

REF

• To adjust gain, load the AD7834/AD7835 with all 1s and

adjust R1 until V

= 5 V(16383/16384) = 4.999695 V.

OUT

Many circuits do not require these offset and gain adjustments.

In these circuits, R1 can be omitted. Pin 5 of the

left open circuit, and Pin 2 (V

(−)) of the AD7834/AD7835 is

REF

AD586 can be

tied to 0 V.

Table 12. Code Table for Unipolar Operation

1, 2

Binary Number in DAC Latch

MSB

00 0000 0000 0001 V

LSB Analog Output (V

V

(16383/16384) V

REF

V

(8192/16384) V 10 0000 0000 0000

REF

V

(8191/16384) V 01 1111 1111 1111

REF

(1/16384) V

REF

00 0000 0000 0000 0 V

1

V

= V

(+); VREF(−) = 0 V for unipolar operation.

REF

REF

2

For V

(+) = 5 V, 1 LSB = 5 V/214 = 5 V/16384 = 305 μV.

REF

01006-019

OUT

11 1111 1111 1111

)

Rev. D | Page 15 of 28

AD7834/AD7835

BIPOLAR CONFIGURATION

+15V

+5V

R1

39kΩ

6

4

7

C1

1μF

9

AD588

R2

100kΩ

100kΩ

1

ADDITIONAL PINS OMITTED FOR CLARITY

5

10

11

12 8

R3

2

3

V

1

14

15

16

13

REF

V

REF

Figure 20. Bipolar ±5 V Operation

Figure 20 shows the AD7834/AD7835 setup for ±5 V operation.

The

AD588 provides precision ±5 V tracking outputs that are

fed to the V

(+) and V

REF

(−) inputs of the AD7834/AD7835.

REF

The code table for bipolar operation of the AD7834/AD7835 is

shown in

Tabl e 1 3 .

Table 13. Code Table for Bipolar Operation

Binary Number in DAC Latch

MSB LSB Analog Output (V

11 1111 1111 1111

10 0000 0000 0001

10 0000 0000 0000

01 1111 1111 1111

00 0000 0000 0001

00 0000 0000 0000

1

V

= V

(+) – V

2

For V

REF

REF

(+) = +5 V and V

REF

(−).

REF

(−) = –5 V, 1 LSB = 10 V/214 = 10 V/16384 = 610 μV.

REF

V

REF

V

REF

V

REF

V

REF

V

REF

V

REF

V

DD

(+)

AD7834/

AD7835

(–)

–15V

(−) + V

(−) + V

(−) + V

(−) + V

(−) + V

(−) V

V

CC

V

OUT

1

AGND

DGND

V

SS

SIGNAL

1, 2

OUT

(16383/16384) V

REF

(8193/16384) V

REF

(8192/16384) V

REF

(8191/16384) V

REF

(1/16384) V

REF

V

OUT

(–5V TO +5V)

GND

)

01006-020

In Figure 20, full-scale and bipolar zero adjustments are

provided by varying the gain and balance on the

AD588. R2

varies the gain on the AD588 while R3 adjusts the offset of both

the +5 V and –5 V outputs together with respect to ground.

For bipolar-zero adjustment, the DAC is loaded with

1000 . . . 0000 and R3 is adjusted until V

= 0 V. Full scale

OUT

is adjusted by loading the DAC with all 1s and adjusting R2

until V

= 5(8191/8192) V = 4.99939 V.

OUT

When bipolar zero and full-scale adjustment are not needed, R2

and R3 are omitted. Pin 12 on the

AD588 should be connected to

Pin 11, and Pin 5 should be left floating.

Rev. D | Page 16 of 28

AD7834/AD7835

CONTROLLED POWER-ON OF THE OUTPUT STAGE

G

A block diagram of the output stage of the AD7834/AD7835 is

shown in

parallel with 200 pF. G

control the power-on voltage present at V

used in conjunction with the

Figure 21. It is capable of driving a load of 10 kΩ in

to G6 are transmission gates used to

1

. G1 and G2 are also

OUT

CLR

input to set V

to the user-

OUT

defined voltage present at the DSG pin.

G

DAC

1

G

3

G

2

DSG

G

5

G

6

G

4

R

V

OUT

01006-021

Figure 21. Block Diagram of AD7834/AD7835 Output Stage

POWER-ON WITH CLR

LOW, LDAC HIGH

The output stage of the AD7834/AD7835 is designed to allow

CLR

output stability during power-on. If

power-on, and power is applied to the part, G

open while G

, G3, and G5 are closed (see Figure 22).

2

G

DAC

1

G

3

G

2

DSG

G

5

is kept low during

, G4, and G6 are

1

G

6

G

4

R

V

OUT

01006-022

Figure 22. Output Stage with VDD < 10 V

V

is kept within a few hundred millivolts of DSG via G5

OUT

and R. R is a thin-film resistor between DSG and V

output amplifier is connected as a unity gain buffer via G

the DSG voltage is applied to the buffer input via G

. The

OUT

. The

2

, and

3

amplifier output is thus at the same voltage as the DSG pin. The

output stage remains configured as in

voltage at V

and VSS reaches approximately ±10 V. At this

DD

Figure 22 until the

point, the output amplifier has enough headroom to handle

signals at its input and has also had time to settle. The internal

power-on circuitry opens G

and G5 and closes G4 and G6 (see

3

Figure 23). As a result, the output amplifier is connected in

unity gain mode via G

to the noninverting input via G

and G6. The DSG voltage is still applied

4

. This voltage appears at V

2

OUT

.

DAC

V

is disconnected from the DSG pin by the opening of G5

OUT

but tracks the voltage present at DSG via the unity gain buffer.

POWER-ON WITH LDAC

In many applications of the AD7834/AD7835,

continuously low, updating the DAC after each valid data

transfer. If

G

is open, connecting the output of the DAC to the input of the

2

output amplifier. G

connecting the amplifier as a unity gain buffer, as before. V

connected to DSG via G

DSG and V

Then, the internal power-on circuitry opens G

closes G

and G6. This is the situation shown in Figure 24. At

4

this point, V

DAC

LOADING THE DAC AND USING THE CLR

LDAC

When

The voltage at V

put of the DAC. The output stage remains connected in this

manner until a

(see

Figure 23). Once again, V

DSG until

the unity gain buffer.

1

G

3

G

2

DSG

G

5

Figure 23. Output Stage with V

G

6

G

4

R

> 10 V and

DD

CLR

V

Low

OUT

LOW, CLR HIGH

LDAC

is kept

LDAC

is low when power is applied, G1 is closed and

and G5 are closed and G4 and G6 are open,

3

and R (a thin-film resistance between

5

) until VDD and VSS reach approximately ±10 V.

OUT

and G5 and

3

is at the same voltage as the DAC output.

OUT

G

1

G

G

2

DSG

G

5

Figure 24. Output Stage with

G

6

3

G

4

R

LDAC

Low

V

OUT

INPUT

goes low, it closes G1 and opens G2 as in Figure 24.

now follows the voltage present at the out-

OUT

CLR

signal is applied. Then, the situation reverts

remains at the same voltage as

OUT

LDAC

goes low. This reconnects the DAC output to

01006-023

OUT

01006-024

is

Rev. D | Page 17 of 28

AD7834/AD7835

DSG VOLTAGE RANGE

During power-on, the V

connected to the relevant DSG pins via G

resistor, R. The DSG potential must obey the maximum ratings

at all times. Thus, the voltage at DSG must always be within the

range V

at the V

– 0.3 V to VDD + 0.3 V. However, to keep the voltages

SS

pins of the AD7834/AD7835 within ±2 V of the

OUT

relevant DSG potential during power-on, the voltage applied to

DSG should also be kept within the range AGND – 2 V to

AGND + 2 V.

pins of the AD7834/AD7835 are

OUT

and the thin-film

6

Once the AD7834/AD7835 have powered on and the on-chip

amplifiers have settled, the situation is as shown in

Figure 23.

Any voltage subsequently applied to the DSG pin is buffered by

the same amplifier that buffers the DAC output voltage in

normal operation. Thus, for specified operations, the maximum

voltage applied to the DSG pin increases to the maximum

allowable V

DSG is the minimum V

(+) voltage, and the minimum voltage applied to

REF

(−) voltage. After the AD7834 or

REF

AD7835 has fully powered on, the outputs can track any DSG

voltage within this minimum/maximum range.

Rev. D | Page 18 of 28

AD7834/AD7835

POWER-ON OF THE AD7834/AD7835

Power is normally applied to the AD7834/AD7835 in the

following sequence: first V

V

(+) and V

REF

(−). The V

REF

power is applied to the part. V

(−) − 0.3 V. V

V

REF

V

is not allowed to go below VCC − 0.3 V.

DD

(−) is not allowed to go below VSS − 0.3 V.

REF

and VSS, then VCC, and then

DD

pins are not allowed to float when

REF

(+) is not allowed to go below

REF

In some systems, it is necessary to introduce one or more

Schottky diodes between pins to prevent the above situations

arising at power-on. These diodes are shown in

Figure 25.

However, in most systems, with careful consideration given to

power supply sequencing, the above rules are adhered to, and

protection diodes are not necessary.

1

ADDITIONAL PINS OMITTED FOR CLARITY

V

(+)

REF

AD7834

V

REF

1

(–)

SD103C

1N5711

1N5712

Figure 25. Power-On Protection

01006-025

Rev. D | Page 19 of 28

AD7834/AD7835

MICROPROCESSOR INTERFACING

AD7834 TO 80C51 INTERFACE

A serial interface between the AD7834 and the 80C51 microcontroller is shown in

of the AD7834, while RXD drives the serial data line of the part.

The 80C51 provides the LSB of its SBUF register as the first bit

in the serial data stream. The AD7834 expects the MSB of the

24-bit write first. Therefore, the user has to ensure that data in

the SBUF register is arranged correctly so the data is received

MSB first by the AD7834/AD7835. When data is to be transmitted to the part, P3.3 is taken low. Data on RXD is valid on

the falling edge of TXD. The 80C51 transmits its data in 8-bit

bytes with only eight falling clock edges occurring in the transmit cycle. To load data to the AD7834, P3.3 is left low after the

first 8 bits are transferred. A second byte is then transferred,

with P3.3 still kept low. After the third byte has been transferred, the P3.3 line is taken high.

80C51

1

ADDITIONAL PINS OMITTED FOR CLARITY

and

CLR

LDAC

port outputs. The user can bring

bytes have been transmitted to update the DAC, which has been

programmed. Alternatively, it is possible to wait until all the

input registers have been loaded (12-byte transmits) and then

update the DAC outputs.

AD7834 TO 68HC11 INTERFACE

Figure 27 shows a serial interface between the AD7834 and the

68HC11 microcontroller. SCK of the 68HC11 drives SCLK of

the AD7834, while the MOSI output drives the serial data line,

DIN, of the AD7834. The

Line PC7.

For correct operation of this interface, the 68HC11 should be

configured so that its CPOL bit is 0 and its CPHA bit is 1. When

data is to be transferred to the part, PC7 is taken low. When the

68HC11 is configured like this, data on MOSI is valid on the

falling edge of SCK. The 68HC11 transmits its serial data in 8-bit

bytes, MSB first. The AD7834 also expects the MSB of the 24-bit

write first. Eight falling clock edges occur in the transmit cycle.

Figure 26. TXD of the 80C51 drives SCLK

1

P3.5

P3.4

P3.3

TXD

RXD

Figure 26. AD7834 to 80C51 Interface

CLR

LDAC

FSYNC

SCLK

DIN

AD7834

1

01006-026

on the AD7834 are also controlled by 80C51

LDAC

low after every three

FSYNC

signal is derived from Port

To load data to the AD7834, PC7 is left low after the first eight

bits are transferred. A second byte of data is then transmitted

serially to the AD7834. Then, a third byte is transmitted and,

when this transfer is complete, the PC7 line is taken high.

AD7834

1

01006-027

1

ADDITIONAL PINS OMITTED FOR CLARITY

In Figure 27,

1

68HC11

PC5

PC6

PC7

SCK

MOSI

Figure 27. AD7834 to 68HC11 Interface

and

CLR

are controlled by the PC6 and PC5

LDAC

CLR

LDAC

FSYNC

SCLK

DIN

port outputs, respectively. As with the 80C51, each DAC of the

AD7834 can be updated after each 3-byte transfer, or all DACs

can be simultaneously updated after 12 bytes are transferred.

AD7834 TO ADSP-2101 INTERFACE

An interface between the AD7834 and the

Figure 28. In the interface shown, SPORT0 is used to transfer

in

data to the part. SPORT1 is configured for alternate functions.

FO, the flag output on SPORT0, is connected to

used to load the DAC latches. In this way, data is transferred

from the

ADSP-2101 to all the input registers in the DAC, and

the DAC latches are updated simultaneously. In the application

shown, the

CLR

pin on the AD7834 is controlled by circuitry

that monitors the power in the system.

POWER

MONITOR

ADSP-2101

1

ADDITIONAL PINS OMITTED FOR CLARITY

1

FO

TFS

SCK

DT

Figure 28. AD7834 to ADSP-2101 Interface

The AD7834 requires 24 bits of serial data framed by a single

FSYNC

pulse. It is necessary that this

all the data is transferred. This can be provided by the

in one of two ways. Both require setting the serial word length of

the SPORT to 12 bits, with the following conditions: internal

SCLK, alternate framing mode, and active low framing signal.

ADSP-2101 is shown

LDAC

AD7834

CLR

LDAC

FSYNC

SCLK

DIN

FSYNC

pulse stay low until

and is

1

01006-028

ADSP-2101

Rev. D | Page 20 of 28

AD7834/AD7835

First, data can be transferred using the autobuffering feature of

the

ADSP-2101, sending two 12-bit words directly after each

other. This ensures a continuous transmit frame synchronization (TFS ) pulse. Second, the first data word is loaded to the

serial port, the subsequent generated interrupt is trapped, and

then the second data word is sent immediately after the first.

Again, this produces a continuous TFS pulse that frames the

24 data bits.

AD7834 TO DSP56000/DSP56001 INTERFACE

Figure 29 shows a serial interface between the AD7834 and the

DSP56000/DSP56001. The serial port is configured for a word

length of 24 bits, gated clock, and FSL0 and FSL1 control bits

each set to 0. Normal mode synchronous operation is selected,

which allows the use of SC0 and SC1 as outputs controlling

CLR

be inverted before being applied to

and

LDAC

, respectively. The framing signal on SC2 has to

FSYNC

. SCK is internally

generated on the DSP56000/DSP56001 and is applied to SCLK

on the AD7834. Data from the DSP56000/DSP56001 is valid on

the falling edge of SCK.

DSP56000/

1

DSP56001

SC0

SC1

SC2

SCK

STD

1

ADDITIONAL PINS OMITTED FOR CLARITY

CLR

LDAC

FSYNC

SCLK

DIN

Figure 29. AD7834 to DSP56000/DSP56001 Interface

AD7834

1

01006-029

AD7834 TO TMS32020/TMS320C25 INTERFACE

A serial interface between the AD7834 and the TMS32020/

TMS320C25 DSP processor is shown in

CLKX and FSX signals for the TMS32020/TMS32025 are

generated using an external clock/timer circuit. The CLKX and

FSX pins are configured as inputs. The TMS32020/ TMS320C25

are set up for an 8-bit serial data length. Data can then be written

to the AD7834 by writing three bytes to the serial port of the

TMS32020/TMS320C25. In the configuration shown in

30

, the CLR input on the AD7834 is controlled by the XF output

on the TMS32020/TMS320C25. The clock/timer circuit controls

LDAC

the

input on the AD7834. Alternatively,

tied to ground to allow automatic update of the DAC latches after

each transfer.

Figure 30. The

LDAC

can also be

Figure

TMS32020/

TMS320C25

1

ADDITIONAL PINS OMITTED FOR CLARITY

1

XF

FSX

CLKX

DX

Figure 30. AD7834 to TMS32020/TMS320C25 Interface

INTERFACING THE AD7835—16-BIT INTERFACE

The AD7835 can be interfaced to a variety of microcontrollers

or DSP processors, both 8-bit and 16-bit.

AD7835 interfaced to a generic 16-bit microcontroller/DSP

Tabl e 1 1 .

DSP

PROCESSOR

DATABUS

UPPER BITS OF

ADDRESS BUS

BYSHF

is tied to VCC in this interface. The lower

1

D13

D0

A2

A1

A0

R/W

Figure 31. AD7835 16-Bit Interface

processor.

address lines from the processor are connected to A0, A1, and

A2 on the AD7835 as shown. The upper address lines are

decoded to provide a chip select signal for the AD7835. They

are also decoded, in conjunction with the lower address lines if

need be, to provide an

driven by an external timing circuit or just tied low. The data

lines of the processor are connected to the data lines of the

AD7835. Selection options available for the DACs are provided

in

MICROCONTROLLER/

1

ADDITIONAL PI NS OMIT TED FOR CL ARITY

CLOCK/

TIMER

LDAC

signal. Alternatively,

ADDRESS

DECODE

1

AD7834

LDAC

CLR

FSYNC

SCLK

DIN

Figure 31 shows the

LDAC

V

CC

AD7835

BYSHF

D13

D0

CS

LDAC

A2

A1

A0

WR

01006-030

can be

1

01006-031

Rev. D | Page 21 of 28

AD7834/AD7835

INTERFACING THE AD7835—8-BIT INTERFACE

Figure 32 shows an 8-bit interface between the AD7835 and

a generic 8-bit microcontroller/DSP processor. Pin D13 to

Pin D8 of the AD7835 are tied to DGND. Pin D7 to Pin D0 of the

processor are connected to Pin D7 to Pin D0 of the AD7835.

BYSHF

is driven by the A0 line of the processor. This maps the

DAC upper bits and lower bits into adjacent bytes in the processor address space.

the DACs in the AD7835. For example, if the base address for the

DACs in the processor address space is decoded by the upper

address bits to location HC000, then the upper and lower bits of

the first DAC are at locations HC000 and HC001, respectively.

MICROCONTROLLER/

DSP

PROCESSOR

DATABUS

UPPER BITS O F

ADDRESS BUS

1

ADDITIONAL PINS OMIT TED FOR CL ARITY

Table 1 4 shows the truth table for addressing

D13

1

D7

D0

A3

A2

A1

A0

R/W

Figure 32. AD7835 8-Bit Interface

DGND

ADDRESS

DECODE

D8

AD7835

D7

D0

CS

LDAC

A2

A1

A0

BYSHF

WR

1

When writing to the DACs, the lower eight bits must be written

first, followed by the upper six bits. The upper six bits should be

output on data lines D0 to D5. Once again, the upper address

lines of the processor are decoded to provide a

CS

signal. They

are also decoded in conjunction with lines A3 to A0 to provide

an

LDAC

signal. Alternatively,

LDAC

can be driven by an external timing circuit or, if it is acceptable to allow the DAC output

to go to an intermediate value between 8-bit writes,

LDAC

can

be tied low.

Table 14. DAC Channel Decoding, 8-Bit Interface

Processor Address Lines

A3 A2 A1 A0 DAC Selected

x X X 0 Upper 6 bits of all DACs

1 X X 1 Lower 8 bits of all DACs

0 0 0 0

0 0 0 1

0 0 1 0

0 0 1 1

0 1 0 0

0 1 0 1

0 1 1 0

Upper 6 bits, DAC 1

Lower 8 bits, DAC 1

Upper 6 bits, DAC 2

Lower 8 bits, DAC 2

Upper 6 bits, DAC 3

Lower 8 bits, DAC 3

Upper 6 bits, DAC 4

0 1 1 1 Lower 8-bits, DAC 4

01006-032

Rev. D | Page 22 of 28

AD7834/AD7835

V

APPLICATIONS INFORMATION

SERIAL INTERFACE TO MULTIPLE AD7834S

Figure 33 shows how the package address pins of the AD7834

are used to address multiple AD7834s. This figure shows only

10 devices, but up to 32 AD7834s can each be assigned a unique

address by hardwiring each of the package address pins to V

or DGND. Normal operation of the device occurs when

PA EN

CC

is low. When serial data is being written to the AD7834s, only

the device with the same package address as the package address

contained in the serial data accepts data into the input registers.

Conversely, if

PA EN

is high, the package address is ignored, and

the data is loaded into the same channel on each package.

The primary limitation with multiple packages is the output

update rate. For example, if an output update rate of 10 kHz is

required, 100 μs are available to load all DACs. Assuming a

serial clock frequency of 10 MHz, it takes 2.5 μs to load data to

one DAC. Thus, 40 DACs or 10 packages can be updated in this

time. As the update rate requirement decreases, the number of

possible packages increases.

1

MICROCONTRO LLER

CONTROL OUT

CONTROL OUT

SYNC OUT

SERIAL CLOCK O UT

SERIAL DATA OUT

1

ADDITIONAL PINS OMIT TED FOR CL ARITY

Figure 33. Serial Interface to Multiple AD7834s

AD7834

DEVICE 0

PAE N

LDAC

FSYNC

SCLK

DIN

AD7834

DEVICE 1

PAE N

LDAC

FSYNC

SCLK

DIN

AD7834

DEVICE 9

PAE N

LDAC

FSYNC

SCLK

DIN

PA0

PA1

PA2

PA3

PA4

1

PA0

PA1

PA2

PA3

PA4

1

PA0

PA1

PA2

PA3

PA4

V

CC

V

CC

01006-033

OPTO-ISOLATED INTERFACE

In many process control applications, it is necessary to provide

an isolation barrier between the controller and the unit being

controlled. Opto-isolators can provide voltage isolation in

excess of 3 kV. The serial loading structure of the AD7834

makes it ideal for opto-isolated interfaces because the number

of interface lines is kept to a minimum.

Figure 34 shows a 5-channel isolated interface to the AD7834.

Multiple devices are connected to the outputs of the opto-coupler

and controlled as for serial interfacing. To reduce the number of

opto-isolators, the

is not used. If the

PA EN

line doesn’t need to be controlled if it

PA EN

line is not controlled by the microcontroller, it should be tied low at each device. If simultaneous updating of the DACs is not required, the

LDAC

pin on each part can

be tied permanently low and another opto-isolator is not needed.

MICROCONTROLLER

CONTROL OUT

CONTROL OUT

SYNC OUT

SERIAL CLOCK OUT

SERIAL DATA OUT

Figure 34. Opto-Isolated Interface

CC

OPTO-COUPLER

TO PAEN s

TO LDACs

TO FSYNCs

TO SCLKs

TO DINs

01006-034

AUTOMATED TEST EQUIPMENT

The AD7834/AD7835 are particularly suited for use in an

automated test environment.

providing the necessary voltages for the pin driver and the

window comparator in a typical ATE pin electronics configuration. Two

AD588s are used to provide reference voltages for

the AD7835. In the configuration shown, the

configured so that the voltage at Pin 1 is 5 V greater than the

voltage at Pin 9 and the voltage at Pin 15 is 5 V less than the

voltage at Pin 9.

AD588

One

is used as a reference for DAC 1 and DAC 2. These

DACs are used to provide high and low levels for the pin driver.

The pin driver can have an associated offset. This can be nulled

by applying an offset voltage to Pin 9 of the

code 1000 . . . 0000 is loaded into the DAC 1 latch, and the pin

driver output is set to the DAC 1 output. The V

adjusted until 0 V appears between the pin driver output and

DUT GND. This causes both V

set with respect to AGND by an amount equal to V

However, the output of the pin driver varies from −5 V to +5 V

with respect to DUT GND as the DAC input code varies from

000 . . . 000 to 111 . . . 111. The V

the DSGA pin. When a clear is performed on the AD7835, the

output of the pin driver is 0 V with respect to DUT GND.

Figure 35 shows the AD7835

AD588s are

AD588. First, the

voltage is

OFFSET

(+)A and V

REF

voltage is also applied to

OFFSET

(−)A to be off-

REF

OFFSET

.

Rev. D | Page 23 of 28

AD7834/AD7835

V

1µF

1

ADDITIONAL P INS OMIT TED FOR CLARITY

13

13

10

11

12

1µF

4

6

8

7

4

6

8

+15V

AD588

10 11 12

+15V

AD588

7

–15V

–15V

162

9

162

DUT

GND

OFFSET

3

1

15

14

9

3

1

15

14

0.1µF

V

REF

V

REF

DSG A

AD7835

V

REF

V

REF

(+)A

(–)A

(+)B

(–)B

AGND

V

OUT

V

OUT

1

DSG B

V

OUT

V

OUT

WINDOW

COMPARATOR

+15V

1

PIN

DRIVER

2

–15V

DUT

GND

V

DUT

DUT

GND

3

4

TO TESTER

Figure 35. ATE Application

The other AD588 provides a reference voltage for DAC 3 and

DAC 4. These provide the reference voltages for the window

comparator shown in

nected to DUT GND. This causes V

Figure 35. Pin 9 of this AD588 is con-

(+)B and V

REF

(−)B to be

REF

referenced to DUT GND. As DAC 3 and DAC 4 input codes vary

from 000 . . . 000 to 111 . . . 111, V

3 and V

OUT

4 vary from −5 V

OUT

to +5 V with respect to DUT GND. DUT GND is also connected

to DSGB. When the AD7835 is cleared, V

OUT

3 and V

OUT

4 are

cleared to 0 V with respect to DUT GND.

Care must be taken to ensure that the maximum and minimum

voltage specifications for the AD7835 reference voltages are

followed as shown in

Figure 35.

POWER SUPPLY BYPASSING AND GROUNDING

In any circuit where accuracy is important, careful consideration of the power supply and ground return layout helps to

ensure the rated performance. The printed circuit boards on

which the AD7834/AD7835 are mounted should be designed so

the analog and digital sections are separated and confined to

certain areas of the boards. This facilitates the use of ground

planes that can be easily separated. A minimum etch technique

is generally best for ground planes because it gives the best

shielding. Digital and analog ground planes should be joined at

only one place.

If the AD7834/AD7835 are the only devices requiring an AGND

to DGND connection, then the ground planes should be connected

at the AGND and DGND pins of the AD7834/ AD7835. If the

AD7834/AD7835 are in a system where multiple devices require

an AGND to DGND connection, the connection can still be made

at one point only, a star ground point, which can be established as

close as possible to the AD7834/AD7835.

Digital lines running under the device must be avoided because

they couple noise onto the die. The analog ground plane can run

under the AD7834/AD7835 to avoid noise coupling. The power

supply lines of the AD7834/AD7835 can use as large a trace as

possible to provide low impedance paths and reduce the effects of

glitches on the power supply line. Fast switching signals, such as

clocks, should be shielded with digital ground to avoid radiating

noise to other parts of the board. These signals should never be

run near the analog inputs. Avoid crossover of digital and analog

01006-035

signals. Traces on opposite sides of the board should run at right

angles to each other. This reduces the effects of feedthrough

through the board. A microstrip method is best but not always

possible with a double-sided board. With this method, the

component side of the board is dedicated to ground plane while

signal traces are placed on the solder side.

The AD7834/AD7835 must have ample supply bypassing located

as close as possible to the package, ideally right up against the

Figure 36 shows the recommended capacitor values of

device.

10 μF in parallel with 0.1 μF on each of the supplies. The 10 μF

capacitors are the tantalum bead type. The 0.1 μF capacitor can

have low effective series resistance (ESR) and effective series

inductance (ESI), such as the common ceramic types, which

provide a low impedance path to ground at high frequencies to

handle transient currents due to internal logic switching.

V

V

CC

DGND

10μF

0.1μF

1

ADDITIONAL PINS OMITTED FOR CLARITY

Figure 36. Power Supply Decoupling

AD7834/

AD7835

DD

1

V

SS

10μF0.1μF

AGND

10μF0.1μF

01006-036

Rev. D | Page 24 of 28

AD7834/AD7835

OUTLINE DIMENSIONS

18.10 (0.7126)

17.70 (0.6969)

15

7.60 (0.2992)

7.40 (0.2913)

14

10.65 (0.4193)

10.00 (0.3937)

2.65 (0.1043)

2.35 (0.0925)

SEATING

PLANE

8°

0°

0.33 (0.0130)

0.20 (0.0079)

0

0

.

7

.

2

5

(

0

5

(

0

9

5

)

.

0

2