20-Bit, Pin-Programmable,

A

http://www.BDTIC.com/ADI

FEATURES

Pin-programmable filter response

Update rate: 10 Hz or 16.7 Hz

Pin-programmable in-amp gain

Pin-programmable power-down and reset

Status function

Internal clock oscillator

Internal bridge power-down switch

Current

115 μA typical (gain = 1)

330 μA typical (gain = 128)

Simultaneous 50 Hz/60 Hz rejection

Power supply: 2.7 V to 5.25 V

−40°C to +105°C temperature range

Independent interface power supply

Packages

14-lead, narrow body SOIC

16-lead TSSOP

2-wire serial interface (read-only device)

SPI compatible

Schmitt trigger on SCLK

APPLICATIONS

Weigh scales

Pressure measurement

Industrial process control

Portable instrumentation

Low Power Sigma-Delta ADC

AD7781

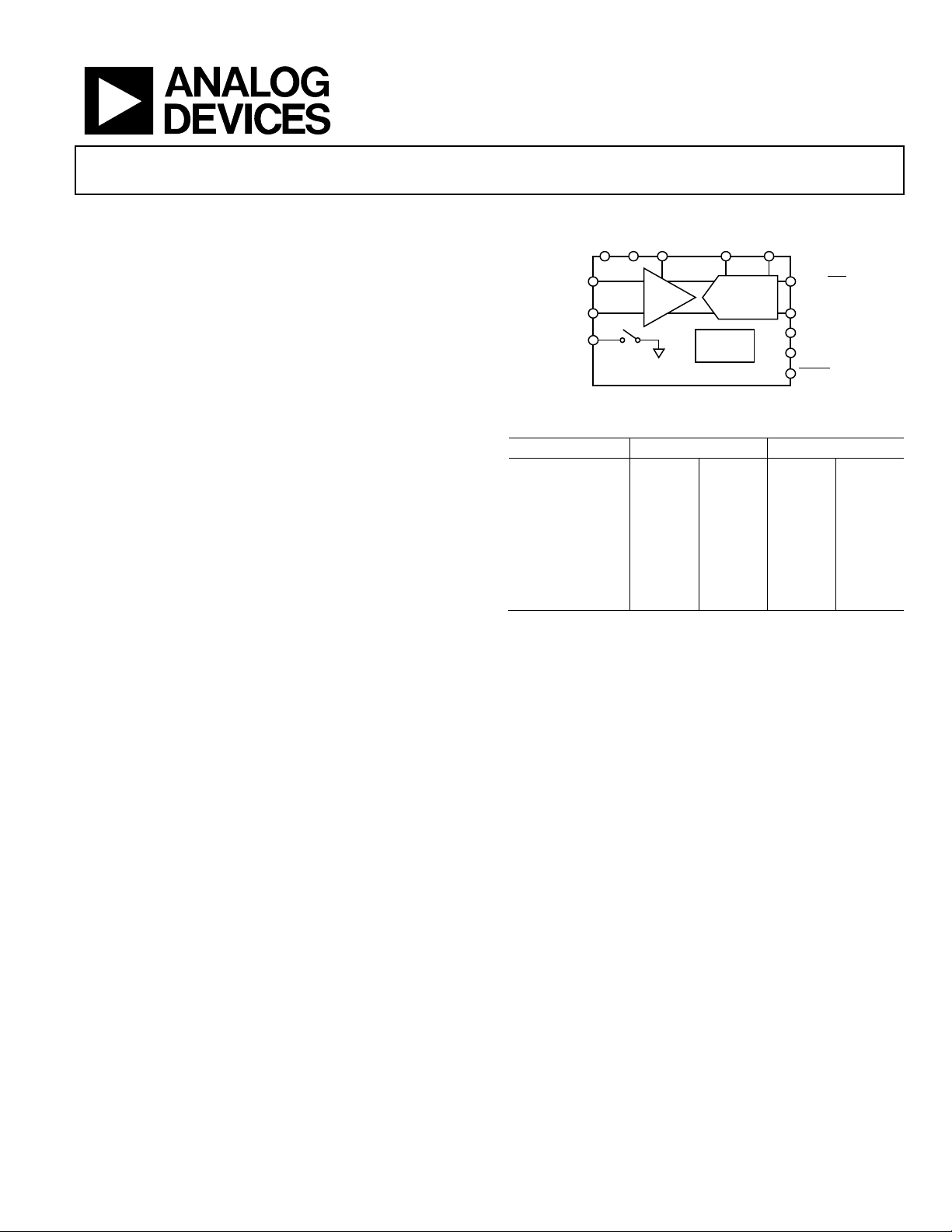

FUNCTIONAL BLOCK DIAGRAM

V

GND

DD

AIN(+)

AIN(–) SCLK

BPDSW

AD7781

G = 1

OR 128

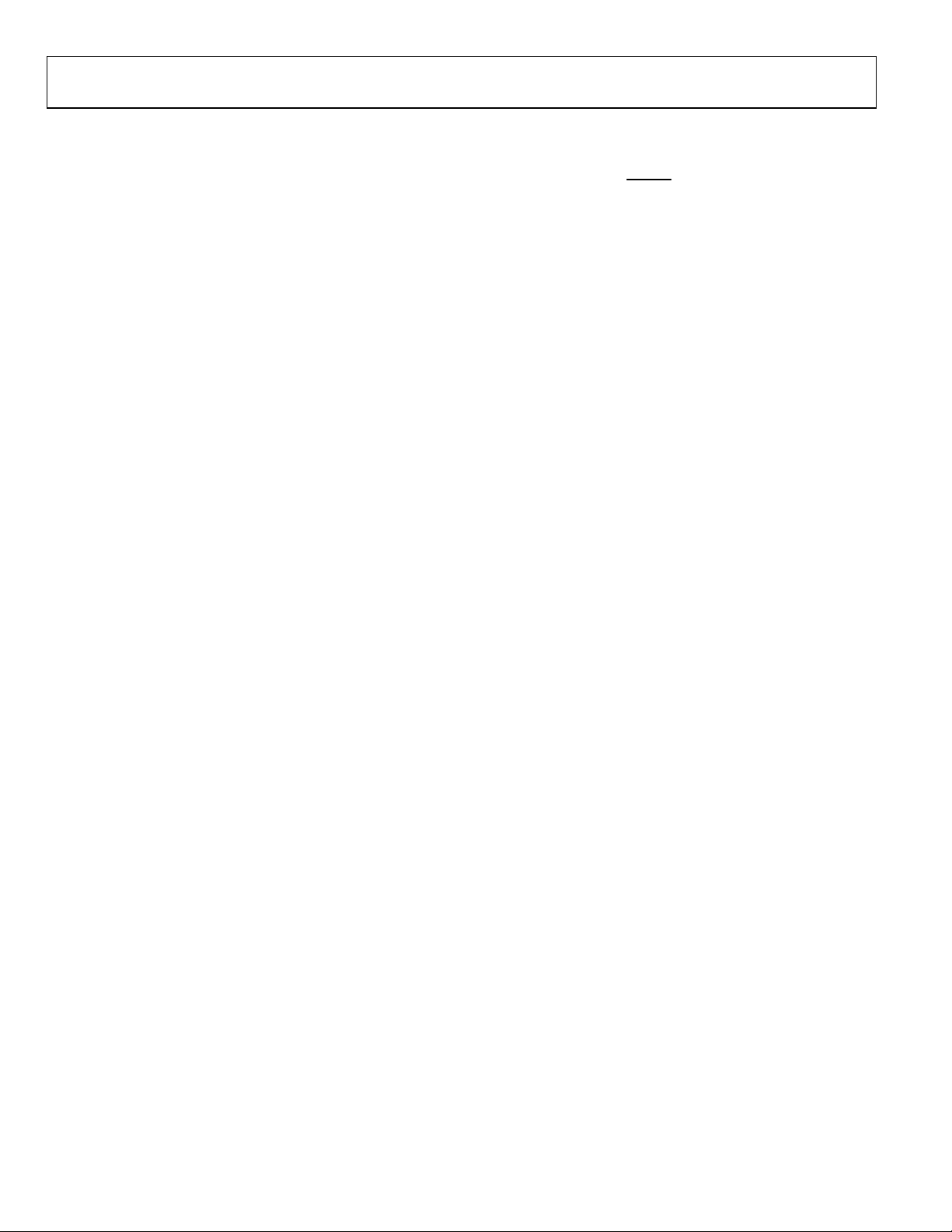

Table 1.

Parameter Gain = 128 Gain = 1

Output Data Rate 10 Hz 16.7 Hz 10 Hz 16.7 Hz

RMS Noise

C Grade 44 nV 65 nV 2.4 V 2.7 V

B Grade 55 nV 90 nV 2.4 V 2.7 V

P-P Resolution

C Grade 17.6 17.1 18.8 18.7

B Grade 17.3 16.6 18.8 18.7

Settling Time 300 ms 120 ms 300 ms 120 ms

REFIN(+)GAIN REFIN(–)

20-BIT Σ-Δ

INTERNAL

CLOCK

Figure 1.

ADC

DOUT/RDY

DV

DD

FILTER

PDRST

08162-001

GENERAL DESCRIPTION

The AD7781 is a complete, low power front-end solution for

bridge sensor products, including weigh scales, strain gages,

and pressure sensors. It contains a precision, low power, 20-bit

sigma-delta (Σ-) ADC, an on-chip, low noise programmable

gain amplifier (PGA), and an on-chip oscillator.

Consuming only 330 µA, the AD7781 is particularly suitable for

portable or battery-operated products where very low power is

required. The AD7781 also has a power-down mode that allows

the user to switch off the power to the bridge sensor and power

down the AD7781 when not converting, thus increasing the

battery life of the product.

For ease of use, all the features of the AD7781 are controlled by

dedicated pins. Each time that a data read occurs, eight status bits

are appended to the 20-bit conversion. These status bits contain a

pattern sequence that can be used to confirm the validity of the

serial transfer.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

The on-chip PGA has a gain of 1 or 128, supporting a full-scale

differential input of ±5 V or ±39 mV. The device has two filter

response options. The filter response at the 16.7 Hz update rate

provides superior dynamic performance. The settling time is

120 ms at this update rate. At the 10 Hz update rate, the filter

response provides better than −45 dB of stop-band attenuation.

In load cell applications, this stop-band rejection is useful to

reject low frequency mechanical vibrations of the load cell. The

settling time is 300 ms at this update rate. Simultaneous 50 Hz/

60 Hz rejection occurs at both the 10 Hz and 16.7 Hz update rates.

The AD7781 operates with a power supply from 2.7 V to 5.25 V.

It is available in a narrow body, 14-lead SOIC package and in a

16-lead TSSOP package.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

AD7781

http://www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Characteristics ................................................................ 5

Absolute Maximum Ratings ............................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution .................................................................................. 6

Pin Configurations and Function Descriptions ........................... 7

Typical Performance Characteristics ............................................. 8

Output Noise and Resolution........................................................ 10

Theory of Operation ...................................................................... 11

Filter, Data Rate, and Settling Time ......................................... 11

Gain .............................................................................................. 11

Power-Down/Reset (

Analog Input Channel ............................................................... 12

Bipolar Configuration ................................................................ 12

Data Output Coding .................................................................. 12

Reference ..................................................................................... 12

Bridge Power-Down Switch ...................................................... 12

Digital Interface .......................................................................... 13

Applications Information .............................................................. 14

Weigh Scales ................................................................................ 14

AD7781 Performance in a Weigh Scale System ......................... 14

EMI Recommendations ............................................................. 14

Grounding and Layout .............................................................. 15

Outline Dimensions ....................................................................... 16

Ordering Guide .......................................................................... 16

PDRST

) ................................................... 12

REVISION HISTORY

5/09—Revision 0: Initial Version

Rev. 0 | Page 2 of 16

AD7781

http://www.BDTIC.com/ADI

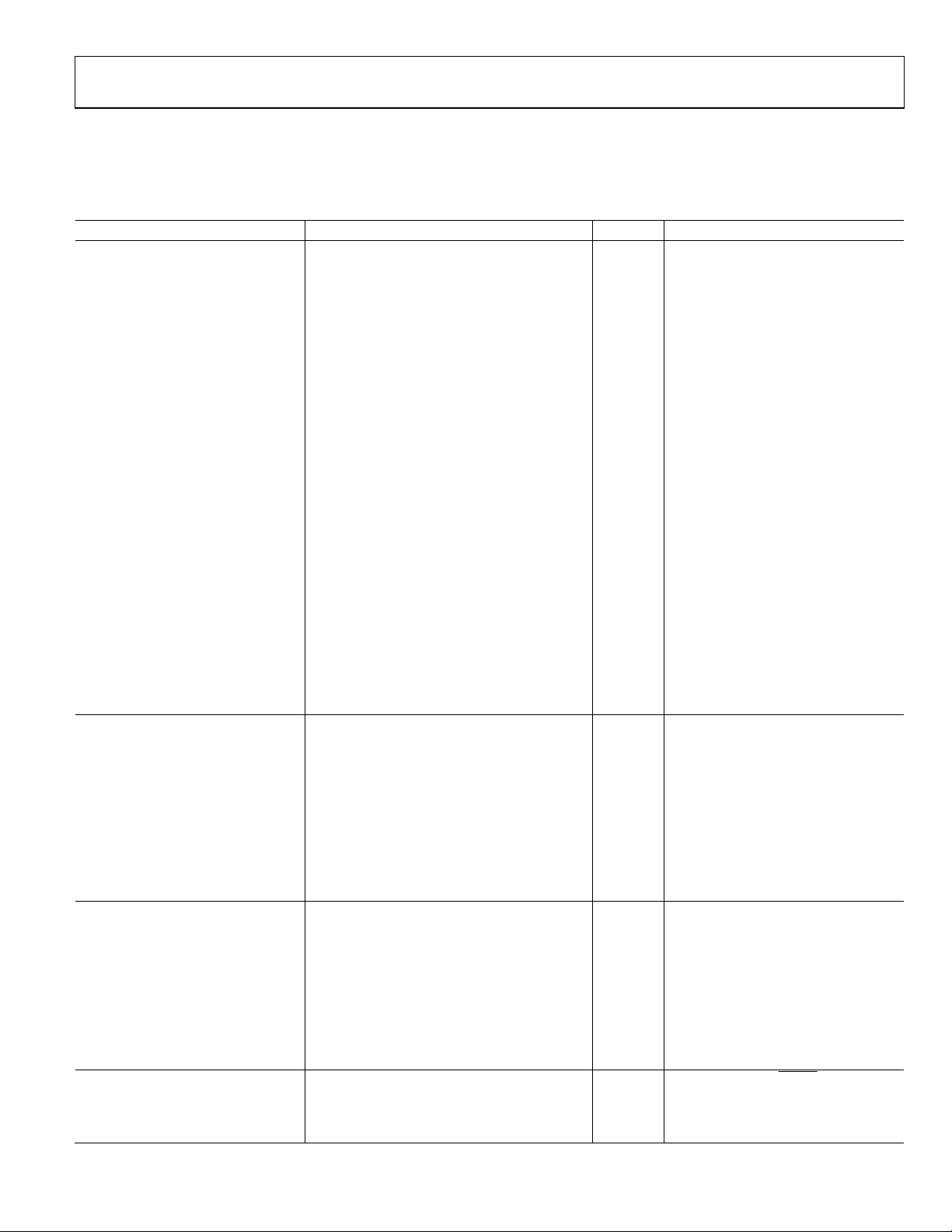

SPECIFICATIONS

AVDD = 2.7 V to 5.25 V, V

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

ADC CHANNEL

Output Update Rate (f

16.7 Hz FILTER = 0, settling time = 2/f

No Missing Codes

Resolution, Peak-to-Peak See Table 7 and Table 8

RMS Noise See Tab le 7 and Tabl e 8

Integral Nonlinearity ±6 ppm FSR

Offset Error ±6 µV Gain = 128 with FILTER = 1

±200 µV Gain = 1 with FILTER = 1

±1 µV Gain = 128 with FILTER = 0

±10 µV Gain = 1 with FILTER = 0

Offset Error Drift vs. Temperature ±10 nV/°C Gain = 128

±150 nV/°C Gain = 1 with FILTER = 1

±10 nV/°C Gain = 1 with FILTER = 0

Full-Scale Error ±0.25 % of FS

Gain Drift vs. Temperature ±2 ppm/°C

Power Supply Rejection 100 dB Gain = 128, FILTER = 1, AIN = 7.81 mV

120 dB Gain = 128, FILTER = 0, AIN = 7.81 mV

Normal Mode Rejection

50 Hz, 60 Hz 63 75 dB 50 Hz ± 1 Hz, 60 Hz ± 1 Hz, f

72 90 dB 50 Hz ± 1 Hz, 60 Hz ± 1 Hz, f

Common-Mode Rejection

DC 90 dB Gain = 1, AIN = 1 V

90 dB Gain = 128, AIN = 7.81 mV

50 Hz, 60 Hz 110 dB 50 Hz ± 1 Hz, 60 Hz ± 1 Hz

ANALOG INPUTS

Differential Input Voltage Range ±V

Absolute AIN Voltage Limits

GND + 450 mV AVDD − 1.1 V Gain = 128, FILTER = 0

GND + 1.1 AVDD − 1.1 V Gain = 128, FILTER = 1, AVDD ≤ 3.6 V

GND + 1.5 AVDD − 1.5 V Gain = 128, FILTER = 1, AVDD > 3.6 V

Average Input Current ±1 nA Gain = 1

±250 pA Gain = 128

Average Input Current Drift ±3 pA/°C

REFERENCE

External REFIN Voltage AVDD V REFIN = REFIN(+) − REFIN(−)

Reference Voltage Range

Absolute REFIN Voltage Limits

Average Reference Input Current 400 nA/V

Average Reference Input Current

Drift

Normal Mode Rejection Same as for analog inputs

Common-Mode Rejection 110 dB

BRIDGE POWER-DOWN SWITCH

(BPDSW)

RON 9 Ω

Allowable Current

= AVDD, DVDD = 2.7 V to 5.25 V, GND = 0 V, all specifications T

REF

) 10 Hz FILTER = 1, settling time = 3/f

ADC

2

2

20 Bits

/gain V

REF

MIN

to T

, unless otherwise noted.1

MAX

= REFIN(+) − REFIN(−),

V

REF

ADC

ADC

= 16.7 Hz

ADC

= 10 Hz

ADC

gain = 1 or 128

2

GND + 100 mV AV

2

0.5 AV

2

GND − 30 mV AV

− 100 mV V Gain = 1

DD

V

DD

+ 30 mV V

DD

±0.15 nA/V/°C

2

30 mA Continuous current

Controlled via the PDRST

pin

Rev. 0 | Page 3 of 16

AD7781

http://www.BDTIC.com/ADI

Parameter Min Typ Max Unit Test Conditions/Comments

INTERNAL CLOCK

Frequency 64 − 3% 64 + 3% kHz

Duty Cycle 50:50 %

LOGIC INPUTS

SCLK, FILTER, GAIN, PDRST

Input Low Voltage, V

0.8 V DVDD = 5 V

Input High Voltage, V

2.4 V DVDD = 5 V

SCLK (Schmitt-Triggered Input)

Hysteresis

2

100 mV DV

140 mV DVDD = 5 V

Input Currents ±2 µA VIN = DVDD or GND

Input Capacitance 10 pF All digital inputs

LOGIC OUTPUT (DOUT/RDY)

Output High Voltage, V

4 V DVDD = 5 V, I

Output Low Voltage, V

0.4 V DVDD = 5 V, I

Floating-State Leakage Current ±2 µA

Floating-State Output Capacitance 10 pF

Data Output Coding Offset binary

POWER REQUIREMENTS

Power Supply Voltage

AVDD to GND 2.7 5.25 V

DVDD to GND 2.7 5.25 V

Power Supply Currents

IDD Current

Gain = 1 115 µA AVDD = 3 V

130 160 µA AVDD = 5 V

Gain = 128 (B Grade) 300 µA AVDD = 3 V

350 400 µA AVDD = 5 V

Gain = 128 (C Grade) 330 µA AVDD = 3 V

420 500 µA AVDD = 5 V

IDD (Power-Down/Reset Mode) 10 µA

1

Temperature range is −40°C to +105°C.

2

This specification is not production tested but is supported by characterization data at initial product release.

3

Digital inputs are equal to DVDD or GND.

2

0.4 V DVDD = 3 V

INL

1.8 V DVDD = 3 V

INH

2

DV

OH

2

0.4 V DV

OL

3

− 0.6 V DVDD = 3 V, I

DD

= 3 V

DD

= 3 V, I

DD

SOURCE

SOURCE

= 100 µA

SINK

= 1.6 mA

SINK

= 100 µA

= 200 µA

Rev. 0 | Page 4 of 16

AD7781

http://www.BDTIC.com/ADI

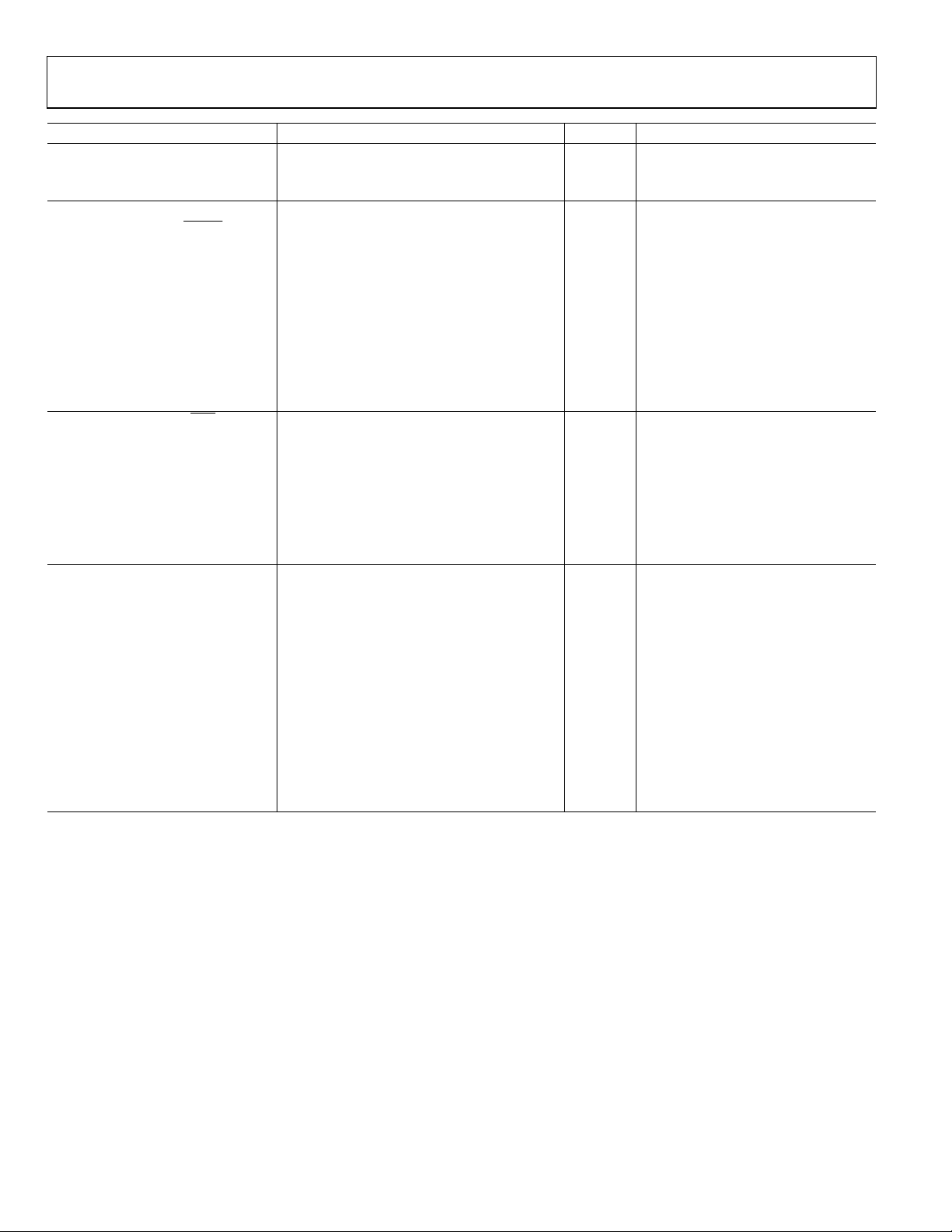

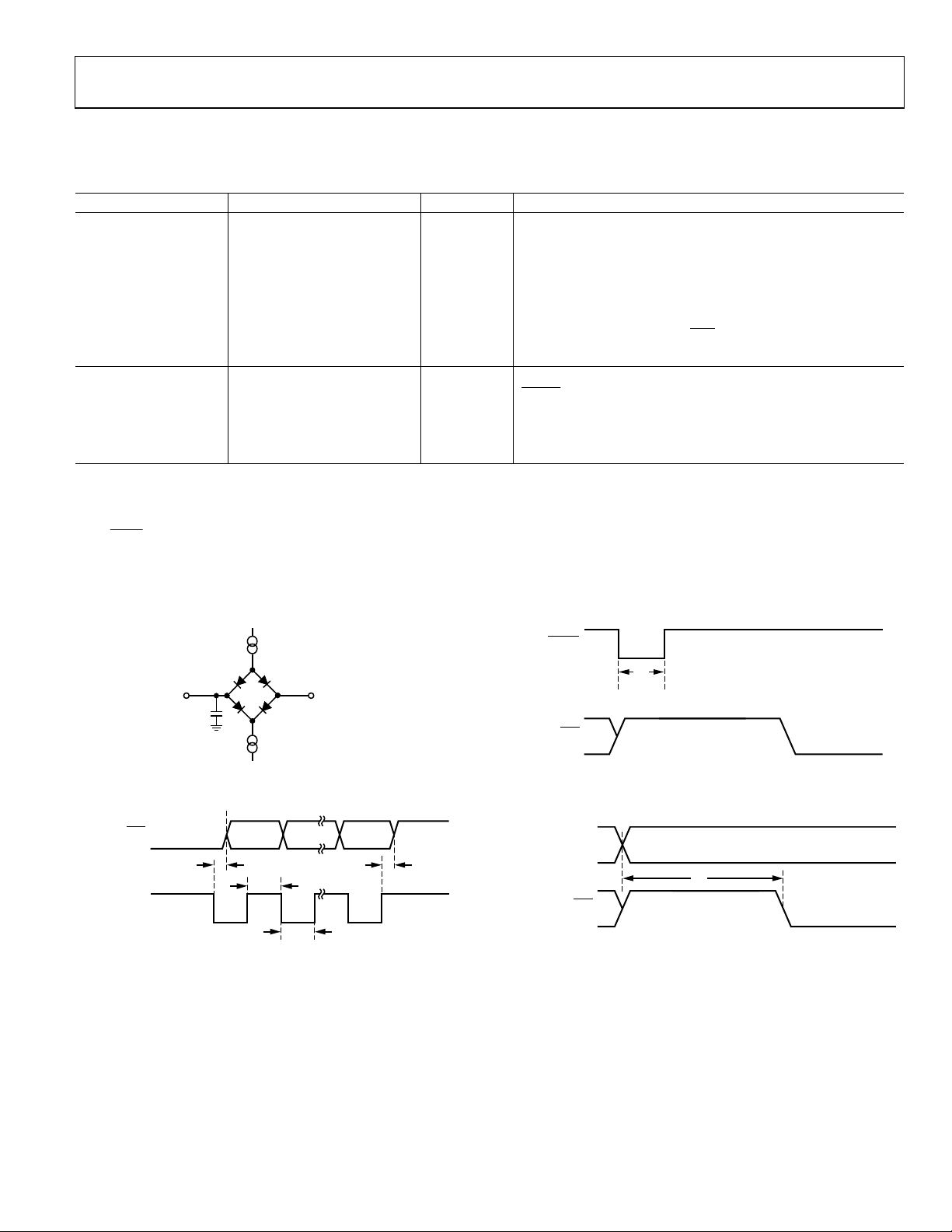

TIMING CHARACTERISTICS

AVDD = 2.7 V to 5.25 V, DVDD = 2.7 V to 5.25 V, GND = 0 V, Input Logic 0 = 0 V, Input Logic 1 = DVDD, unless otherwise noted.

Table 3.

Parameter

Read

1

2

Limit at T

MIN

, T

Unit Test Conditions/Comments

MAX

t1 100 ns min SCLK high pulse width

t2 100 ns min SCLK low pulse width

3

t

3

0 ns min SCLK active edge to data valid delay

4

60 ns max DVDD = 4.75 V to 5.25 V

80 ns max DVDD = 2.7 V to 3.6 V

t4 10 ns min

SCLK inactive edge to DOUT/RDY

high

130 ns max

Reset

t5 100 ns min

5

t

6

FILTER/GAIN change to data valid delay

low pulse width

PDRST

120 ms typ Update rate = 16.7 Hz

300 ms typ Update rate = 10 Hz

1

Sample tested during initial release to ensure compliance. All input signals are specified with tR = tF = 5 ns (10% to 90% of DVDD) and timed from a voltage level of 1.6 V.

2

See Figure 3.

3

The values of t3 are measured using the load circuit of Figure 2 and are defined as the time required for the output to cross the VOL or VOH limits.

4

SCLK active edge is falling edge of SCLK.

5

PDRST

The

high to data valid delay is typically 1 ms longer than t6 because the internal oscillator requires time to power up and settle.

Circuit and Timing Diagrams

DOUT/RDY

(OUTPUT)

SCLK

(INPUT)

I

(1.6mA WITH DVDD = 5V,

TO

OUTPUT

PIN

50pF

SINK

100µA WIT H DV

I

SOURCE

100µA WIT H DV

= 3V)

DD

1.6V

(200µA WIT H DVDD = 5V,

= 3V)

DD

Figure 2. Load Circuit for Timing Characterization

MSB LSB

t

3

t

1

t

2

t

Figure 3. Read Cycle Timing Diagram

PDRST

(INPUT)

t

5

DOUT/RDY

08162-002

(OUTPUT)

08162-004

Figure 4. Resetting the AD7781

GAIN OR FILTER

(INPUT)

4

DOUT/RDY

(OUTPUT)

08162-003

t

6

08162-005

Figure 5. Changing Gain or Filter Option

Rev. 0 | Page 5 of 16

AD7781

http://www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 4.

Parameter Rating

AVDD to GND −0.3 V to +7 V

DVDD to GND −0.3 V to +7 V

Analog Input Voltage to GND −0.3 V to AVDD + 0.3 V

Reference Input Voltage to GND −0.3 V to AVDD + 0.3 V

Digital Input Voltage to GND −0.3 V to DVDD + 0.3 V

Digital Output Voltage to GND −0.3 V to DVDD + 0.3 V

AIN/Digital Input Current 10 mA

Operating Temperature Range −40°C to +105°C

Storage Temperature Range −65°C to +150°C

Maximum Junction Temperature 150°C

Lead Temperature, Soldering Reflow 260°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 5.

Package Type θJA θ

14-Lead SOIC 104.5 42.9 °C/W

16-Lead TSSOP 150.4 27.6 °C/W

Unit

JC

ESD CAUTION

Rev. 0 | Page 6 of 16

AD7781

http://www.BDTIC.com/ADI

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

16

15

14

13

12

11

10

9

NC

FILTER

PDRST

DV

DD

AV

DD

GND

BPDSW

REFIN(–)

08162-007

1

SCLK

DOUT/RDY 2

NC 3

AD7781

TOP VIEW

4

GAIN

AIN(+) 5 GND10

AIN(–) 6 BPDSW9

REFIN(+)

(Not to Scale)

7

NC = NO CONNECT

14

12

11

8

FILTER

PDRST13

DV

DD

AV

DD

REFIN(–)

1

NC

2

SCLK

NC

GAIN

AIN(+)

AIN(–)

3

AD7781

4

TOP VIEW

(Not to Scale)

5

6

7

8

NC = NO CO NNECT

DOUT/RDY

8162-006

REFIN(+)

Figure 6. SOIC Pin Configuration Figure 7. TSSOP Pin Configuration

Table 6. Pin Function Descriptions

Pin No.

SOIC TSSOP Mnemonic Description

1 2 SCLK

Serial Clock Input. This serial clock input is for data transfers from the ADC. The SCLK pin has a Schmitttriggered input. The serial clock can be active only when transferring data from the AD7781. The data

from the AD7781 can be read as a continuous 32-bit word. Alternatively, SCLK can be noncontinuous

during the data transfer, with the information being transmitted from the ADC in smaller data batches.

2 3

DOUT/RDY

Serial Data Output/Data Ready Output. DOUT/RDY serves a dual purpose: as a data ready pin, going low

to indicate the completion of a conversion, and as a serial data output pin to access the data register of

the ADC. Eight status bits accompany each data read (see ). The DOUT/Figure 22 RDY falling edge can be

used as an interrupt to a processor, indicating that new data is available. If the data is not read after the

conversion, the pin goes high before the next update occurs. The serial interface is reset each time that a

conversion is available. Therefore, the user must ensure that any conversions being transmitted are

completed before the next conversion is available.

3 1, 4, 16 NC No Connect. This pin can be left floating.

4 5 GAIN Gain Select Pin. When GAIN is low, the gain is set to 128. When GAIN is high, the gain is set to 1.

5 6 AIN(+) Analog Input. AIN(+) is the positive terminal of the differential analog input pair, AIN(+)/AIN(−).

6 7 AIN(−) Analog Input. AIN(−) is the negative terminal of the differential analog input pair, AIN(+)/AIN(−).

7 8 REFIN(+)

Positive Reference Input. An external reference can be applied between REFIN(+) and REFIN(−). The nomi-

nal reference voltage (REFIN(+) − REFIN(−)) is 5 V, but the part can function with a reference of 0.5 V to AVDD.

8 9 REFIN(−) Negative Reference Input.

9 10 BPDSW

Bridge Power-Down Switch to GND. When PDRST

When PDRST

is low, the switch is opened.

is high, the bridge power-down switch is closed.

10 11 GND Ground Reference Point.

11 12 AVDD Supply Voltage, 2.7 V to 5.25 V.

12 13 DVDD

13 14

PDRST

Digital Interface Supply Voltage. The logic levels for the serial interface pins and the digital control pins

are related to this supply, which is between 2.7 V and 5.25 V. The DV

voltage on AV

Power-Down/Reset. When this pin is low, the ADC is placed in power-down mode, and the low-side power

; therefore, AVDD can equal 5 V with DVDD at 3 V or vice versa.

DD

switch is opened. All the logic on the chip is reset, and the DOUT/RDY

voltage is independent of the

DD

pin is tristated. When PDRST is high,

the ADC is taken out of power-down mode. The on-chip clock powers up and settles, and the ADC continuously converts. In addition, the low-side power switch is closed. The internal clock requires approximately

1 ms to power up.

14 15 FILTER

Filter Select Pin. When FILTER is low, the fast settling filter is selected. The update rate is set to 16.7 Hz,

which gives a filter settling time of 120 ms. When FILTER is high, the high rejection filter is selected. The

update rate is set to 10 Hz, which gives a filter settling time of 300 ms. With this filter, the stop-band

(higher than f

) attenuation is better than −45 dB.

ADC

Rev. 0 | Page 7 of 16

AD7781

http://www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

524,294

524,293

524,292

524,291

524,290

CODE

524,289

524,288

524,287

600

400

OCCURRENCE

200

524,286

0 200 400 600 800 1000

Figure 8. C Grade Noise (V

500

400

300

200

OCCURRENCE

100

0

524,286 524, 288 524,290 524,292 524,294

SAMPLE

= AVDD, Update Rate = 16.7 Hz, Gain = 128)

REF

CODE

Figure 9. C Grade Noise Distribution Histogram

= AVDD, Update Rate = 16.7 Hz, Gain = 128)

(V

REF

524,281

0

524,275 524,277 524, 279 MORE

08162-008

CODE

08162-011

Figure 11. C Grade Noise Distribution Histogram

= AVDD, Update Rate = 10 Hz, Gain = 128)

(V

REF

524,289

524,288

CODE

524,287

524,286

0 200 400 600 800 1000

08162-009

Figure 12. Noise (V

505

REF

SAMPLE

= AVDD, Update Rate = 16.7 Hz, Gain = 1)

08162-012

524,280

524,279

524,278

CODE

524,277

524,276

524,275

524,274

0 200 400 600 800 1000

Figure 10. C Grade Noise (V

SAMPLE

= AVDD, Update Rate = 10 Hz, Gain = 128)

REF

08162-010

Rev. 0 | Page 8 of 16

500

OCCURRENCE

495

524,287 524,288

CODE

Figure 13. Noise Distribution Histogram

= AVDD, Update Rate = 16.7 Hz, Gain = 1)

(V

REF

162-01308

AD7781

http://www.BDTIC.com/ADI

524,276

524,275

2.0

1.5

1.0

0.5

CODE

524,274

524,273

0 200 400 600 800 1000

Figure 14. Noise (V

800

600

400

OCCURRENCE

200

0

REF

524,274 524,275

SAMPLE

= AVDD, Update Rate = 10 Hz, Gain = 1)

CODE

Figure 15. Noise Distribution Histogram

= AVDD, Update Rate = 10 Hz, Gain = 1)

(V

REF

0

INL (ppm FS)

–0.5

–1.0

–1.5

–2.0

–6 –4 –2 0 2 4 6

08162-014

Figure 17. Integral Nonlinearity (V

10

8

6

4

2

0

–2

OFFSET (µV)

–4

–6

–8

–10

162-015

08

–60 –40 –20 0 20 40 60 80 100 120

V

(V)

IN

REF

TEMPERATURE (° C)

= AVDD, Gain = 1)

08162-017

08162-018

Figure 18. Offset vs. Temperature (Gain = 128)

3.0

2.5

2.0

1.5

1.0

0.5

0

INL (ppm FS)

–0.5

–1.0

–1.5

–2.0

–2.5

–0.04 –0.03 –0.02 –0.01 0 0.01 0.02 0. 03 0.04

Figure 16. Integral Nonlinearity (V

(V)

V

IN

REF

= AVDD, Gain = 128)

08162-016

Rev. 0 | Page 9 of 16

150

100

50

0

–50

GAIN ERROR (ppm)

–100

–150

–200

–60 –40 –20 0 2 0 40 60 80 100 120

TEMPERATURE (°C)

Figure 19. Gain Error vs. Temperature (Gain = 128)

08162-019

AD7781

http://www.BDTIC.com/ADI

OUTPUT NOISE AND RESOLUTION

Tabl e 7 and Tab l e 8 show the rms noise of the AD7781 for the two output data rates and gain settings when using a 3 V and a 5 V reference.

These numbers are typical and are generated with a differential input voltage of 0 V. The peak-to-peak (p-p) resolution is also listed. The

p-p resolution represents the resolution for which there is no code flicker. These numbers are typical.

Table 7. RMS Noise and Peak-to-Peak Resolution When AV

Parameter Gain = 128 Gain = 1

Update Rate 10 Hz 16.7 Hz 10 Hz 16.7 Hz

RMS Noise

C Grade 44 nV 65 nV 2.4 V 2.7 V

B Grade 55 nV 90 nV 2.4 V 2.7 V

P-P Resolution

C Grade 17.6 17.1 18.8 18.7

B Grade 17.3 16.6 18.8 18.7

= 3 V and V

DD

REF

= 3 V

Table 8. RMS Noise and Peak-to-Peak Resolution When AV

Parameter Gain = 128 Gain = 1

Update Rate 10 Hz 16.7 Hz 10 Hz 16.7 Hz

RMS Noise

C Grade 49 nV 69 nV 3.0 V 2.7 V

B Grade 60 nV 90 nV 3.0 V 2.7 V

P-P Resolution

C Grade 18.2 17.7 19.3 19.4

B Grade 17.9 17.3 19.3 19.4

= 5 V and V

DD

REF

= 5 V

Rev. 0 | Page 10 of 16

AD7781

http://www.BDTIC.com/ADI

THEORY OF OPERATION

The AD7781 is a low power ADC that incorporates a precision,

20-bit, Σ-∆ modulator; a PGA; and an on-chip digital filter

intended for measuring wide dynamic range, low frequency

signals. The part provides a complete front-end solution for

bridge sensor applications such as weigh scales and pressure

sensors.

The device has an internal clock and one buffered differential

input. It offers a choice of two update rates (10 Hz or 16.7 Hz)

and two gain settings (1 or 128). These functions are controlled

using dedicated pins, which makes the interface easy to configure.

A 2-wire interface simplifies data retrieval from the AD7781.

FILTER, DATA RATE, AND SETTLING TIME

The AD7781 has two filter options. When the FILTER pin is

low, the 16.7 Hz filter is selected; when the FILTER pin is high,

the 10 Hz filter is selected. When the polarity of the FILTER pin

is changed, the AD7781 modulator and filter are reset immediately. DOUT/

using the selected filter response. The first conversion requires

the total settling time of the filter. Subsequent conversions

occur at the selected update rate. The settling time of the 10 Hz

filter is 300 ms (three conversion cycles), and the settling time

of the 16.7 Hz filter is 120 ms (two conversion cycles).

When a step change occurs on the analog input, the AD7781

requires several conversion cycles to generate a valid conversion.

If the step change occurs synchronous to the conversion period, the

settling time of the AD7781 must be allowed to generate a valid

conversion. If the step change occurs asynchronous to the end

of a conversion, an extra conversion must be allowed to generate

a valid conversion. The data register is updated with all the conversions, but, for an accurate result, the user must allow for the

required time.

Figure 20 and Figure 21 show the filter response for each filter.

The 10 Hz filter provides more than −45 dB of rejection in the

stop band. The only external filtering required on the analog

inputs is a simple R-C filter to provide rejection at multiples of

the master clock. A 1 k resistor in series with each analog input,

a 0.01 F capacitor from each input to GND, and a 0.1 F

capacitor from AIN(+) to AIN(−) are recommended.

When the filter is changed, DOUT/

high until the appropriate settling time for that filter elapses

(see ). Therefore, the user should complete any read

Figure 5

operations before changing the filter. Otherwise, 1s are read

back from the AD7781 because the DOUT/

following the filter change.

RDY

is set high, and the ADC begins conversions

RDY

goes high and remains

RDY

pin is set high

0

–20

–40

–60

FILTER GAIN (dB)

–80

–100

–120

012010080604020

Figure 20. Filter Profile with Update Rate = 16.7 Hz (FILTER = 0)

INPUT SIGNAL FREQUENCY (Hz)

08162-020

0

–20

–40

–60

FILTER GAIN (dB)

–80

–100

–120

0 12010080604020

Figure 21. Filter Profile with Update Rate = 10 Hz (FILTER = 1)

INPUT SIG NAL FREQUENCY ( Hz)

08162-021

GAIN

The AD7781 has two gain options: gain = 1 and gain = 128.

When the GAIN pin is low, the gain is set to 128; when the

GAIN pin is high, the gain is set to 1. The acceptable analog

input range is ±V

is ±5 V when GAIN is high and ±39 mV when GAIN is low.

When the polarity of the GAIN pin is changed, the AD7781 modulator and filter are reset immediately. DOUT/

the ADC begins conversions. DOUT/

the appropriate settling time for the filter elapses (see ).

Therefore, the user should complete any read operations before

changing the gain. Otherwise, 1s are read back from the AD7781

because the DOUT/

The total settling time of the selected filter is required to generate

the first conversion after the gain change; subsequent conversions

occur at the selected update rate.

/gain. Thus, with V

REF

= 5 V, the input range

REF

RDY

RDY

remains high until

RDY

pin is set high following the gain change.

is set high, and

Figure 5

Rev. 0 | Page 11 of 16

AD7781

http://www.BDTIC.com/ADI

POWER-DOWN/RESET (PDRST)

PDRST

The

When

pin functions as a power-down pin and a reset pin.

PDRST

is taken low, the AD7781 is powered down. The

entire ADC is powered down (including the on-chip clock), the

low-side power switch is opened, and the DOUT/

RDY

pin is

tristated. The circuitry and serial interface are also reset, which

resets the logic, the digital filter, and the analog modulator.

PDRST

must be held low for 100 ns minimum to initiate the

reset function (see ). Figure 4

PDRST

When

is taken high, the AD7781 is taken out of powerdown mode. When the on-chip clock has powered up (1 ms,

typically), the modulator begins sampling the analog input.

The low-side power switch is closed, and the DOUT/

RDY

pin

becomes active.

A reset is automatically performed on power-up.

ANALOG INPUT CHANNEL

The AD7781 has one differential analog input channel. The

input channel feeds into a high impedance input stage of the

amplifier. Therefore, the input can tolerate significant source

impedances and is tailored for direct connection to external

resistive-type sensors such as strain gages.

The absolute input voltage range is restricted to a range between

GND + 450 mV and AV

− 1.1 V. Care must be taken in setting

DD

up the common-mode voltage to avoid exceeding these limits.

Otherwise, there is degradation in linearity and noise performance.

The low noise in-amp means that signals of small amplitude can

be amplified within the AD7781, which still maintains excellent

noise performance. The amplifier can be configured to have a gain

of 128 or 1, using the GAIN pin. The analog input range is equal

to ±V

/gain. The common-mode voltage (AIN(+) + AIN(−))/2

REF

must be ≥0.5 V.

BIPOLAR CONFIGURATION

The AD7781 accepts a bipolar input range. A bipolar input range

does not imply that the part can tolerate negative voltages with

respect to system GND. Signals on the AIN(+) input are referenced to the voltage on the AIN(−) input. For example, if AIN(−)

is 2.5 V, the analog input range on the AIN(+) input is 2.46 V to

2.54 V for a gain of 128.

DATA OUTPUT CODING

The AD7781 uses offset binary coding. Thus, a negative fullscale voltage results in a code of 000...000, a zero differential

input voltage results in a code of 100...000, and a positive fullscale input voltage results in a code of 111...111.

The output code for any analog input voltage can be represented as

Code = 2

N − 1

× [(AIN × Gain/V

REF

) + 1]

where:

AIN is the analog input voltage.

Gain is 1 or 128.

N = 20.

REFERENCE

The AD7781 has a fully differential input capability for the channel.

The common-mode range for these differential inputs is GND to

. The reference input is unbuffered; therefore, excessive R-C

AV

DD

source impedances introduce gain errors. The reference voltage of

REFIN (REFIN(+) − REFIN(−)) is AV

is functional with reference voltages of 0.5 V to AV

nominal, but the AD7781

DD

. In applica-

DD

tions where the excitation (voltage or current) for the transducer

on the analog input also drives the reference voltage for the part,

the effect of the low frequency noise in the excitation source is

removed because the application is ratiometric. If the AD7781

is used in a nonratiometric application, a low noise reference

should be used.

Recommended 2.5 V reference voltage sources for the AD7781

include the ADR381 and ADR391, which are low noise, low power

references. These references have low output impedances and

are, therefore, tolerant to decoupling capacitors on REFIN(+)

without introducing gain errors in the system. Deriving the

reference input voltage across an external resistor means that

the reference input sees a significant external source impedance.

External decoupling on the REFIN pins is not recommended in

this type of circuit configuration.

BRIDGE POWER-DOWN SWITCH

The bridge power-down switch (BPDSW) is useful in batterypowered applications where the optimization of system power

consumption is essential. A 350 load cell typically consumes

15 mA when excited with a 5 V power supply. To minimize

current consumption, the load cell is disconnected when it is

not being used. The bridge power-down switch can be included

in series with the load cell. When

down switch is closed, and the load cell measures the strain. When

is low, the bridge power-down switch is opened so no

PDRST

current flows through the load cell. Therefore, the current

consumption of the system is minimized. The bridge powerdown switch has an on resistance of 9 maximum. The switch

is capable of withstanding 30 mA of continuous current.

is high, the bridge power-

PDRST

Rev. 0 | Page 12 of 16

AD7781

http://www.BDTIC.com/ADI

DIGITAL INTERFACE

The serial interface of the AD7781 consists of two signals: SCLK

and DOUT/

and data transfers occur with respect to the SCLK signal. The

DOUT/

pin and as a data output pin. DOUT/

data-word is available in the output register. A 32-bit word is

placed on the DOUT/

applied. This word consists of a 20-bit conversion result followed

by four 0s to generate a 24-bit word. Following this, status bits

are output. shows the status bits, and describes

the status bits and their functions.

DOUT/

If the conversion is not read, DOUT/

data register update to indicate when not to read from the device.

This ensures that a read operation is not attempted while the register is being updated. Each conversion can be read only once. The

data register is updated for every conversion.

RDY

. SCLK is the serial clock input for the device,

RDY

pin is dual purpose: it functions as a data ready

RDY

goes low when a new

RDY

pin when sufficient SCLK pulses are

Figure 22 Tabl e 9

FILTER ERRRDY ID1 ID0 GAIN PAT1 PAT0

Figure 22. Status Bits

RDY

is reset high when the conversion has been read.

RDY

goes high prior to the

08162-022

When a conversion is complete, the serial interface is reset, and

the new conversion is placed in the data register. Therefore, the

user must ensure that the complete word is read before the next

conversion is complete.

PDRST

When

PDRST

is low, the DOUT/

is taken high, the internal clock requires approximately

RDY

pin is tristated. When

1 ms to power up. Following power-up, the ADC continuously

converts. The first conversion requires the total settling time

(see ). DOUT/Figure 4

RDY

goes high when

PDRST

is taken

high and returns low only when a conversion is available. The

ADC then converts continuously, and subsequent conversions

are available at the selected update rate. shows the

Figure 3

timing for a read operation from the AD7781.

When the filter response is changed (using the FILTER pin) or

the gain is changed (using the GAIN pin), the modulator and

filter are reset immediately (see Figure 5). DOUT/

RDY

is set

high. The ADC then begins conversions using the selected filter

response/gain setting. DOUT/

RDY

remains high until the appropriate settling time for that filter has elapsed. Therefore, the user

should complete any read operations before changing the gain or

update rate. Otherwise, 1s are read back from the AD7781 because

the DOUT/

RDY

pin is set high following the gain/filter change.

Table 9. Status Bit Functions

Bit Name Description

RDY

0: a conversion is available.

FILTER Filter bit.

1: 10 Hz filter is selected.

0: 16.7 Hz filter is selected.

ERR Error bit.

1: an error occurred during conversion. (An error occurs when the analog input is out of range.)

ID1, ID0 ID bits.

0 0 Indicates the ID number for the AD7781.

GAIN Gain bit.

1: gain = 1.

0: gain = 128.

PAT1, PAT0 Status pattern bits. When the user reads data from the AD7781, a pattern check can be performed.

0 1 Indicates that the serial transfer from the ADC was performed correctly (default).

0 0 Indicates that the serial transfer from the ADC was not performed correctly.

1 x Indicates that the serial transfer from the ADC was not performed correctly.

Ready bit.

ID1 ID0 Function

PAT1 PAT0 Func tion

Rev. 0 | Page 13 of 16

AD7781

V

http://www.BDTIC.com/ADI

APPLICATIONS INFORMATION

The AD7781 provides a low cost, high resolution analog-todigital function. Because the analog-to-digital function is

provided by a Σ- architecture, the part is more immune to

noisy environments, making it ideal for use in sensor measurement and industrial and process control applications.

(the conversion result from the ADC when the maximum load

is applied to the load cell) must be determined. Subsequent

conversions from the AD7781 are then corrected, using the

offset and gain coefficients that were calculated from these

calibrations.

WEIGH SCALES

Figure 23 shows the AD7781 being used in a weigh scale

application. The load cell is arranged in a bridge network and

gives a differential output voltage between its OUT+ and OUT−

terminals. Assuming a 5 V excitation voltage, the full-scale

output range from the transducer is 10 mV when the sensitivity

is 2 mV/V. The excitation voltage for the bridge can be used to

directly provide the reference for the ADC because the reference input range includes the supply voltage.

A second advantage of using the AD7781 in transducer-based

applications is that the bridge power-down switch (BPDSW)

can be fully utilized in low power applications. The bridge powerdown switch is connected in series with the low side of the bridge.

In normal operation, the switch is closed and measurements

can be taken. In applications where power is of concern, the

AD7781 can be placed in power-down mode, significantly

reducing the power consumed in the application. In addition,

the bridge power-down switch is opened while in power-down

mode, thus avoiding unnecessary power consumption by the

front-end transducer. When the part is taken out of power-down

mode and the bridge power-down switch is closed, the user should

ensure that the front-end circuitry is fully settled before attempting

to read from the AD7781.

The load cell has an offset, or tare, associated with it. This tare is

the main component of the system offset (load cell + ADC) and

is similar in magnitude to the full-scale signal from the load cell.

For this reason, calibrating the offset and gain of the AD7781

alone is not sufficient for optimum accuracy; a system calibration

that calibrates the offset and gain of the ADC, plus the load cell,

is required. A microprocessor can be used to perform the calibrations. The offset error (the conversion result from the AD7781

when no load is applied to the load cell) and the full-scale error

DD

AD7781 PERFORMANCE IN A WEIGH SCALE SYSTEM

If the load cell has a sensitivity of 2 mV/V and a 5 V excitation

voltage is used, the full-scale signal from the load cell is 10 mV.

When the AD7781 (C grade) operates with a 10 Hz output data

rate and the gain is set to 128, the device has a p-p resolution of

18.2 bits when the reference is equal to 5 V. Postprocessing the

data from the AD7781 using a microprocessor increases the p-p

resolution. For example, an average by 4 in the microprocessor

increases the accuracy by 2 bits. The noise-free counts value is

equal to

Noise-Free Counts = (2

Effective Bits

) × (FSLC/FS

ADC

)

where:

Effective Bits = 18.2 bits (AD7781) + 2 bits (due to postprocessing

in the microprocessor).

FS

is the full-scale signal from the load cell (10 mV).

LC

FS

is the full-scale input range when gain = 128 and

ADC

V

= 5 V (78 mV).

REF

The noise-free counts is equal to

18.2 + 2

(2

) × (10 mV/78 mV) = 154,422

This example shows that with a 5 V supply, 154,422 noise-free

counts can be achieved with the AD7781.

EMI RECOMMENDATIONS

For simplicity, the EMI filters are not included in Figure 23.

However, an R-C antialiasing filter should be included on each

analog input. This filter is needed because the on-chip digital

filter does not provide any rejection around the master clock or

multiples of the master clock. Suitable values are a 1 kΩ resistor

in series with each analog input, a 0.1 F capacitor from AIN(+)

to AIN(−), and 0.01 F capacitors from AIN(+)/AIN(−) to GND.

IN+

OUT–

IN–

G = 1

OR 128

GND

REFIN(+)

AIN(+)

OUT+

AIN(–)

REFIN(–)

BPDSW

Figure 23. Weigh Scales Using the AD7781

Rev. 0 | Page 14 of 16

20-BIT Σ-Δ

INTERNAL

CLOCK

AD7781

AV

ADC

DD

DOUT/RDY

SCLK

DV

DD

FILTER

PDRST

GAIN

8162-023

AD7781

http://www.BDTIC.com/ADI

GROUNDING AND LAYOUT

Because the analog input and reference input of the ADC are

differential, most of the voltages in the analog modulator are

common-mode voltages. The excellent common-mode rejecttion of the part removes common-mode noise on these inputs.

The digital filter provides rejection of broadband noise on the

power supply, except at integer multiples of the modulator

sampling frequency. The digital filter also removes noise from

the analog and reference inputs, provided that these noise sources

do not saturate the analog modulator. As a result, the AD7781

is more immune to noise interference than conventional high

resolution converters. However, because the resolution of the

AD7781 is so high and the noise levels from the AD7781 are so

low, care must be taken with regard to grounding and layout.

The printed circuit board (PCB) that houses the AD7781 should

be designed so that the analog and digital sections are separated

and confined to certain areas of the board. A minimum etch

technique is generally best for ground planes because it gives

the best shielding.

It is recommended that the GND pin of the AD7781 be tied

to the AGND plane of the system. In any layout, pay attention

to the flow of currents in the system and ensure that the return

paths for all currents are as close as possible to the paths that the

currents took to reach their destinations. Avoid forcing digital

currents to flow through the AGND sections of the layout.

The ground plane of the AD7781 should be allowed to run under

the AD7781 to prevent noise coupling. The power supply lines

to the AD7781 should use as wide a trace as possible to provide

low impedance paths and reduce the effects of glitches on the

power supply line. Fast switching signals such as clocks should

be shielded with digital ground to avoid radiating noise to other

sections of the board, and clock signals should never be run near

the analog inputs. Avoid crossover of digital and analog signals.

Traces on opposite sides of the board should run at right angles

to each other. This reduces the effects of feedthrough through

the board. A microstrip technique is by far the best, but it is not

always possible with a double-sided board. In this technique,

the component side of the board is dedicated to ground planes,

and the signals are placed on the solder side.

Good decoupling is important when using high resolution ADCs.

AV

should be decoupled with 10 µF tantalum capacitors in

DD

parallel with 0.1 µF capacitors to GND. DV

with 10 µF tantalum capacitors in parallel with 0.1 µF capacitors to GND, with the system’s AGND to DGND connection

being close to the AD7781. To achieve the best results from

these decoupling components, place them as close as possible

to the device, ideally right up against the device. All logic chips

should be decoupled with 0.1 µF ceramic capacitors to DGND.

should be decoupled

DD

Rev. 0 | Page 15 of 16

AD7781

http://www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.25 (0.0098)

0.10 (0.0039)

COPLANARIT Y

8.75 (0.3445)

8.55 (0.3366)

4.00 (0.1575)

3.80 (0.1496)

0.10

14

1

1.27 (0.0500)

BSC

0.51 (0.0201)

0.31 (0.0122)

CONTROLL ING DIMENSIONS ARE IN MILLIMETERS; INCH DI MENSIONS

(IN PARENTHESES) ARE ROUNDED-O FF MIL LIMETE R EQUIVALENTS FOR

REFERENCE ON LY AND ARE NOT APPROPRI ATE FOR USE IN DESIGN.

COMPLIANT TO JEDEC STANDARDS MS-012-AB

8

6.20 (0.2441)

5.80 (0.2283)

7

1.75 (0.0689)

1.35 (0.0531)

SEATING

PLANE

8°

0°

0.25 (0.0098)

0.17 (0.0067)

Figure 24. 14-Lead Standard Small Outline Package [SOIC_N]

Narrow Body

(R-14)

Dimensions shown in millimeters and (inches)

5.10

5.00

4.90

0.15

0.05

4.50

4.40

4.30

PIN 1

16

0.65

BSC

COPLANARITY

COMPLIANT TO JEDEC STANDARDS MO-153-AB

0.10

0.30

0.19

9

BSC

81

1.20

MAX

SEATING

PLANE

6.40

0.20

0.09

8°

0°

Figure 25. 16-Lead Thin Shrink Small Outline Package [TSSOP]

(RU-16)

Dimensions shown in millimeters

0.50 (0.0197)

0.25 (0.0098)

1.27 (0.0500)

0.40 (0.0157)

0.75

0.60

0.45

45°

-A

060606

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD7781BRZ

AD7781BRZ-REEL

AD7781BRUZ

AD7781BRUZ-REEL

AD7781CRZ

AD7781CRZ-REEL

AD7781CRUZ

AD7781CRUZ-REEL

1

Z = RoHS Compliant Part.

©2009 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D08162-0-5/09(0)

1

1

1

1

1

1

1

1

−40°C to +105°C 14-Lead SOIC_N R-14

−40°C to +105°C 14-Lead SOIC_N R-14

−40°C to +105°C

−40°C to +105°C 16-Lead TSSOP RU-16

−40°C to +105°C 14-Lead SOIC_N R-14

−40°C to +105°C

−40°C to +105°C 16-Lead TSSOP RU-16

−40°C to +105°C 16-Lead TSSOP RU-16

16-Lead TSSOP RU-16

14-Lead SOIC_N R-14

Rev. 0 | Page 16 of 16

Loading...

Loading...