Page 1

LC2MOS

a

FEATURES

Two-Channel, 8-Bit 2.5 ms ADC

Two 8-Bit, 2.5 ms DACs with Output Amplifiers

Span and Offset of ADC and DAC

Independently Adjustable

Low Power

APPLICATIONS

Winchester Disk Servo Controllers

Floppy Disk Microstepping

Closed Loop Servo Systems

GENERAL DESCRIPTION

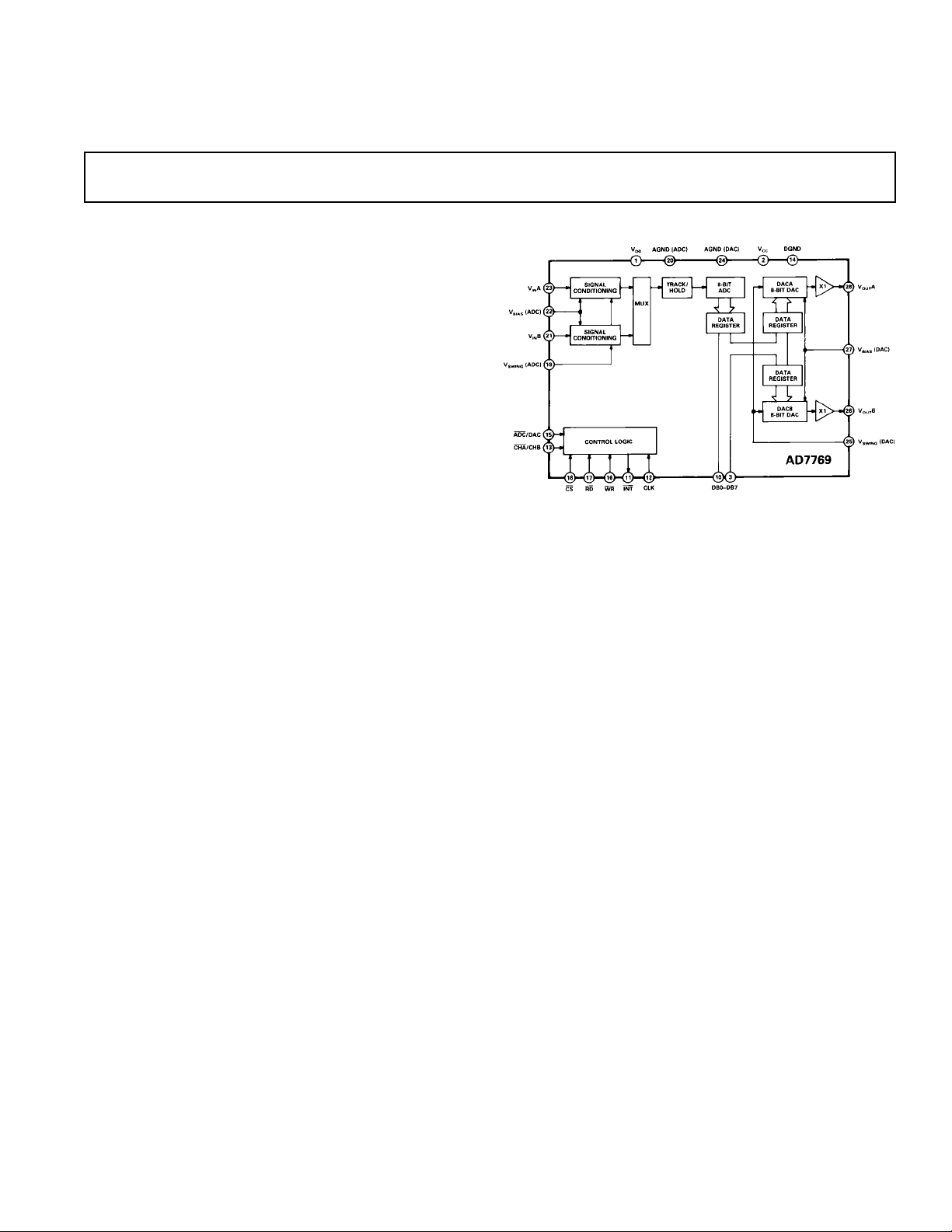

The AD7769 is a complete, two-channel, 8-bit, analog I/O port.

It has versatile input and output signal conditioning features

that make it ideal for use in head-positioning servos in Winchester disk systems. It is equally suitable for floppy disk microstepping head positioning, other closed loop digital servo systems

and general purpose 8-bit data acquisition.

The AD7769 contains a high speed successive approximation

ADC, preceded by a two-channel multiplexer and signal conditioning circuits. The input span of the ADC and the offset of

the zero point from ground can be independently set by applying ground referenced voltages. The AD7769 also contains two

independent, fast settling, 8-bit DACs with output amplifiers.

The output span and offset voltage of the DACs can be set independently of those of the ADC. This makes the AD7769 especially useful in disk drives, where only a positive supply rail is

available and the ranges of the ADC and DACs must be referenced to some positive voltage less than the supply.

The AD7769 is easily interfaced to a standard 8-bit mpu bus via

an 8-bit data port and standard microprocessor control lines.

The AD7769 is fabricated in Linear Compatible CMOS

2

(LC

MOS), an advanced, mixed technology process that combines precision bipolar circuits with low power CMOS logic.

The part is available in a 28-lead plastic DIP and 28-terminal

PLCC package.

Analog I/O Port

AD7769

FUNCTIONAL BLOCK DIAGRAM

PRODUCT HIGHLIGHTS

1. Two-Channel, 8-Bit Analog I/O port on a Single Chip.

The AD7769 contains a two-channel, high speed ADC with

input signal conditioning and two, fast settling 8-bit DACs

with output amplifiers, on a single chip.

2. Independent Control of Span and Offset.

The input voltage span of the ADC and the midpoint of the

transfer function, the output voltage swing of the two DACs

and the half-scale output voltage, can be set independently

by applying ground referenced control voltages.

3. Dynamic Specifications for DSP Users.

In addition to the traditional ADC and DAC specifications,

the AD7769 is specified with ac parameters including signalto-noise ratio, distortion and signal bandwidth.

4. Fast Microprocessor Interface.

The AD7769 has bus interface timing compatible with all

modern microprocessors, with bus access and relinquish

times less than 65 ns and a Write pulse width less than 90 ns.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106,U.S.A.

Tel: 617/329-4700 World Wide Web Site: http://www.analog.comFax:

617/326-8703 © Analog Devices, Inc., 1997

Page 2

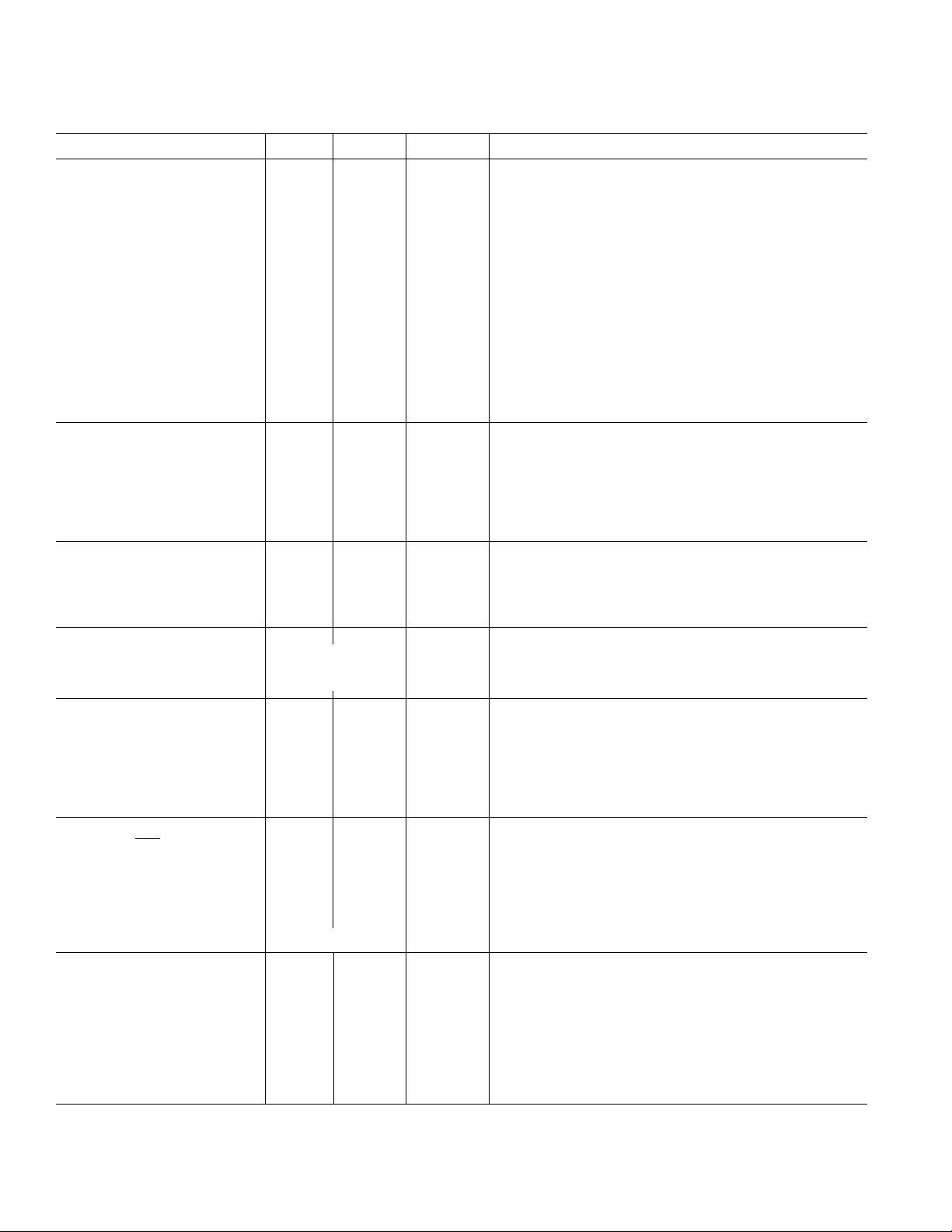

AD7769–SPECIFICA TIONS

(VDD = +12 V 6 10%; VCC = +5 V 6 5%; AGND [ADC] = AGND [DAC] = DGND = 0 V; V

ADC SPECIFICATIONS

V

[ADC] = +2.5 V; f

SWING

= 5 MHz external. All specifications T

CLK

MIN

Parameter J Version A Version Units Conditions/Comments

DC ACCURACY

Resolution 8 * Bits

Relative Accuracy ±1 * LSB max See Terminology

Differential Nonlinearity ±1 * LSB max No Missing Codes. See Terminology.

Bias Offset Error See Terminology

+25°C ±2.5 * LSB max

T

MIN

to T

MAX

±3.0 * LSB max

Bias Offset Match Channel A to Channel B

+25°C ±2.5 * LSB max

T

MIN

to T

MAX

±3.5 * LSB max

Plus or Minus Full-Scale Error See Terminology

+25°C ±2.0 * LSB max

T

MIN

to T

MAX

±2.5 * LSB max

Plus or Minus Full-Scale Match Channel A to Channel B

+25°C ±3.5 * LSB max

T

to T

MIN

MAX

ADC TO DAC MATCHING Channel A/B to V

Bias Offset Match V

±4 * LSB max

(DAC) = +5 V, V

BIAS

OUT

A/B

SWING

+25°C ±2.5 * LSB max

T

MIN

to T

MAX

±3.5 * LSB max

Plus or Minus Full-Scale Match

+25°C ±3.5 * LSB max

T

to T

MIN

MAX

DYNAMIC PERFORMANCE

±4.0 * LSB max

2

Signal-to-Noise Ratio (SNR) 44 * dB min VIN = 100 kHz Full-Scale Sine Wave with f

Total Harmonic Distortion (THD) 48 * dB max VIN = 100 kHz Full-Scale Sine Wave with f

Intermodulation Distortion (IMD) 60 * dB typ f

= 99 kHz, fb = 96.7 kHz with f

a

Frequency Response 0.1 * dB typ VIN = Full-Scale, dc to 200 kHz Sine Wave

ANALOG INPUTS

Input Voltage Ranges, V

A, VINBV

IN

V

BIAS

BIAS

– V

+ V

or 0 V min Whichever Is the Higher

SWING

or 9.8 V max Whichever Is the Lower

SWING

Input Currents, IINA, IINB ±0.4 * mA max

ADC REFERENCE INPUTS

Input Voltage Levels

V

(ADC) 2/6.8 * V min/max With Respect to AGND (ADC). For Specified Performance.

BIAS

V

(ADC) 2.0/3.0 * V min/max With Respect to AGND (ADC). For Specified Performance.

SWING

Input Currents

V

(ADC) Input ±800 * µA max

BIAS

V

(ADC) Input ±1* µA max

SWING

LOGIC OUTPUTS

DB0–DB7,

VOL, Output Low Voltage 0.4 * V max I

V

INT

, Output High Voltage 4.0 * V min I

OH

= 1.6 mA

SINK

SOURCE

= 200 µA

DB0–DB7

Floating State Leakage Current ±10 * µA max

Floating State Capacitance

2

10 * pF max

Output Coding Offset Binary

POWER REQUIREMENTS

V

Range 4.75/5.25 * V min/V max For Specified Performance. The Part Will Function with

CC

VCC =5 V ±10% with Degraded Performance.

V

Range 10.8/13.2 * V min/V max For Specified Performance

DD

I

@ +25°C 20 * mA max For ADC and DAC: V

DD

V

Am VINB = T

UB

MIN

to T

22 * mA max V

MAX

; DAC Code = FF (Hex); DACA and DACB Load = 5 kΩ

BIAS

BIAS

to AGND (DAC). Typically I

I

@ +25°C 5 * mA max Logic Inputs = 2.4 V, CLK Input = 0.8 V. Typically I

CC

T

to T

MIN

MAX

NOTES

1

Temperature range as follows: J Version: 0°C to +70°C; A Version: –40°C to +85°C.

2

Sample tested at +25°C to ensure compliance.

*Specification same as J Version.

Specifications subject to change without notice.

6 * mA max

1

to T

unless otherwise noted.)

MAX

(DAC) = +2.5 V.

SAMPLING

= 5.0 V; V

= 14 mA.

DD

BIAS

SAMPLING

SAMPLlNG

= 400 kHz

= 3.0 V; VINA,

SWING

[ADC] = +5 V;

= 400 kHz

= 400 kHz

= 1.5 mA.

CC

–2–

REV. A

Page 3

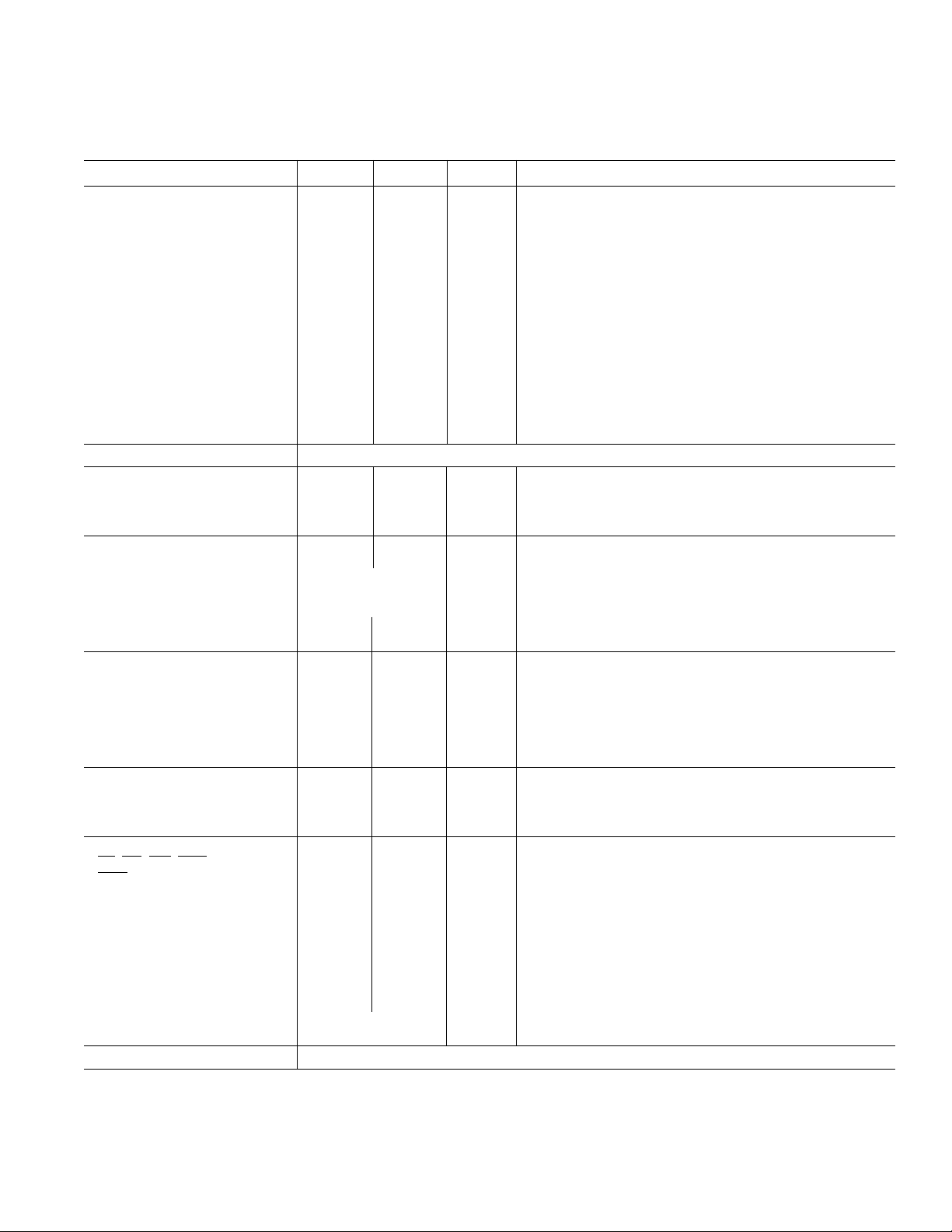

AD7769

(VDD = +12 V 6 10%; VCC = +5 V 6 5%; AGND [DAC] = AGND [ADC] = DGND = 0 V;

V

[DAC] = +5 V; V

BIAS

DACA, DACB SPECIFICATIONS

CL = 100 pF. All specifications T

Parameter J Version A Version Units Conditions/Comments

STATIC PERFORMANCE

Resolution 8 * Bits

Relative Accuracy ±1 * LSB max See Terminology

Differential Nonlinearity ±1 * LSB max Guaranteed Monotonic. See Terminology.

Bias Offset Error See Terminology

+25°C ±2.0 * LSB max

to T

T

MIN

MAX

±2.5 * LSB max

Bias Offset Match V

+25°C ±2.5 * LSB max

to T

T

MIN

MAX

±3.5 * LSB max

Plus or Minus Full-Scale Error See Terminology

+25°C ±1.5 * LSB max

to T

T

MIN

MAX

±2.0 * LSB max

Plus or Minus Full-Scale Match V

+25°C ±3.5 * LSB max

T

MIN

to T

MAX

±4.0 * LSB max

ADC to DAC MATCHING As Per ADC Specifications

DYNAMIC PERFORMANCE

2

Signal-to-Noise Ratio (SNR) 44 * dB min V

Total Harmonic Distortion (THD) 48 * dB max V

Intermodulation Distortion (IMD) 55 * dB typ fa = 18.4 kHz, fb = 14.5 kHz with f

ANALOG OUTPUTS

Output Voltage Ranges

A, V

V

OUT

BV

OUT

DC Output Impedance 0.5 *

– V

BIAS

+ V

V

BIAS

–2.0 V max Whichever Is the Lower

V

DD

or 0.5 V min Whichever Is the Higher

SWING

or

SWING

Ω

typ

Short-Circuit Current 20 * mA typ

DAC REFERENCE INPUTS

Input Voltage Levels

(DAC) 3/6.8 * V min/max With Respect to AGND (DAC). For Specified Performance.

V

BIAS

(DAC) 2.0/3.0 * V min/max With Respect to AGND (DAC). For Specified Performance.

V

SWING

Input Currents

(DAC) Input ±2* µA max

V

BIAS

V

(DAC) Input ±1* µA max

SWING

AC CHARACTERISTICS

2

Voltage Output Settling Time 4 * µs max Settling Time to Within ±1/2 LSB of Final Value. Typically 2.5 µs.

Digital-to-Analog Glitch Impulse 30 * nV sec typ See Terminology

Digital Feedthrough 1 * nV sec typ See Terminology

LOGIC INPUTS

CS, RD, WR, ADC/DAC,

CHA/CHB, DB0–DB7

Input Low Voltage, V

Input High Voltage, V

INL

INH

0.8 * V max

2.4 * V min

Input Leakage Current ±10 * µA max

Input Capacitance 10 * pF max

CLK

Input Low Voltage 0.8 * V max External Clock. For Internal Clock Operation Connect

Input High Voltage 2.4 * V min the CLK Pin to V

Input Leakage Current ±10 * µA max

DB0–DB7

Input Coding Offset Binary

POWER REQUIREMENTS As per ADC Specifications

NOTES

1

Temperature range as follows: J Version: 0°C to +70°C; A Version: –40 °C to +85 °C.

2

Sample tested at +25°C to ensure compliance.

*Specifications same as J Version.

Specifications subject to change without notice.

[DAC] = +2.5 V; V

SWING

MIN

A to V

OUT

A to V

OUT

= 20 kHz Full-Scale Sine Wave With f

OUT

= 20 kHz Full-Scale Sine Wave With f

OUT

A, V

OUT

OUT

1

to T

unless otherwise noted.)

MAX

B

OUT

B

OUT

.

DD

B load to AGND [DAC], RL = 5 kV,

= 400 kHz

= 400 kHz

SAMPLING

SAMPLING

SAMPLING

= 400 kHz

REV. A

–3–

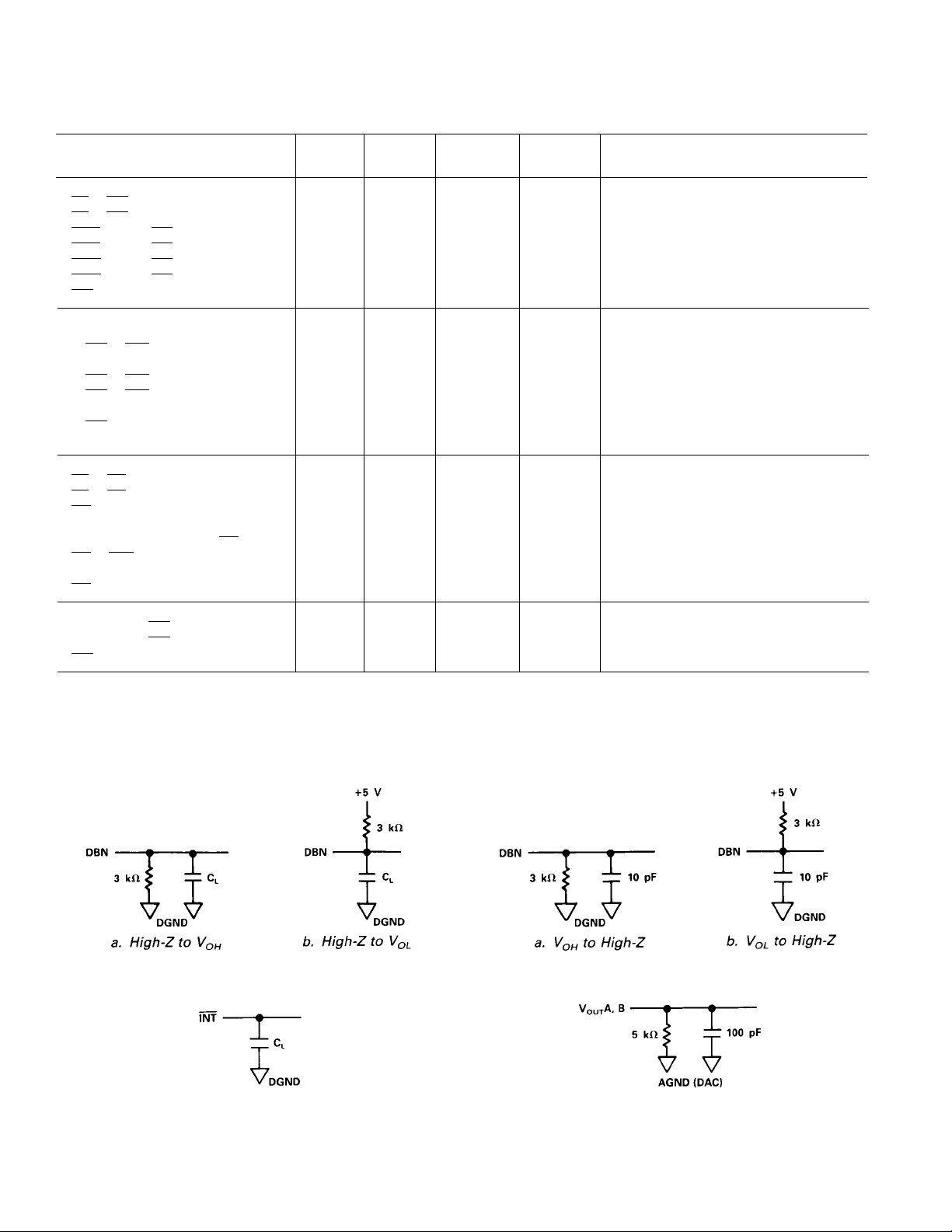

Page 4

AD7769

(VCC = +5 V 6 5%; VDD = +12 V 6 10%; AGND [ADC] = AGND [DAC] = DGND = 0 V.

TIMING CHARACTERISTICS

Parameter Label +258CT

ADC /DAC CONTROL TIMING

CS to WR Setup Time t

CS to WR Hold Time t

ADC/DAC to WR Setup Time t

ADC/DAC to WR Hold Time t

CHA/CHB to WR Setup Time t

CHA/CHB to WR Hold Time t

WR Pulse Width t

ADC CONVERSION TIMING

Using External Clock Load Circuit of Figure 3, CL = 20 pF

WR to INT Low Delay t

Using Internal Clock Load Circuit of Figure 3, C

WR to INT Low Delay t

WR to INT High Delay t

WR to Data Valid Delay

ADC READ TIMING

CS to RD Setup Time t

CS to RD Hold Mode t

RD to Data Valid Delay

Bus Relinquish Time after

RD to INT High Delay t

RD Pulse Width t

DAC WRITE TIMING

Data Valid to

Data Valid to

WR Setup Time t

WR Hold Time t

WR to DAC Output Settling Time t

NOTES

1

See Figures 11, 12 and 13.

2

Sample tested at +25°C to ensure compliance. All input signals are specified with tr = tf = 5 ns (10% to 90% of 5 V) and timed from a voltage level of 1.6 V.

3

t10 and t13 are measured with the load circuits of Figure 1 and defined as the time required for an output to cross 0.8 V or 2.4 V.

4

t14 is defined as the time required for the data lines to change 0.5 V when loaded with the circuits of Figure 2.

Specifications subject to change without notice.

3

3

RD High

1, 2

For ADC and DAC, V

Limit at Limit at

1

2

3

4

5

6

7

8

8

9

t

9

t

10

t

10

11

12

t

13

t

4

13

t

14

15

t

15

16

17

18

19

0 0 ns min

0 0 ns min

00 ns

0 0 ns min

0 0 ns min

0 0 ns min

80 80 ns min

2.6 2.6 µs max

1.9/3.0 1.9/3.0 µs min/max Typically 2.5 µs

85 85 ns max Load Circuit of Figure 3, CL = 20 pF

120 120 ns max Load Circuit of Figure 3, CL = 100 pF

t8+70 t8+70 ns max Load Circuit of Figure 1, CL = 20 pF

t8+110 t8+110 ns max Load Circuit of Figure 1, CL = 100 pF

0 0 ns min

0 0 ns min

15/65 15/65 ns min/max Load Circuit of Figure 1, CL = 20 pF

30/100 30/100 ns min/max Load Circuit of Figure 1, CL = 100 pF

15/65 15/65 ns min/max Load Circuit of Figure 2

80 80 ns max Load Circuit of Figure 3, CL = 20 pF

110 110 ns max Load Circuit of Figure 3, CL = 100 pF

t

13

65 65 ns nıin

15 20 ns min

44 µs max Load Circuit of Figure 4

= +5 V, V

BIAS

MIN

t

13

, T

= +2.5 V.)

SWING

Units Test Conditions/Comments

MAX

ns min Determined by t

13

= 20 pF

L

Figure 1. Load Circuits for Data Access Time Test

Figure 3. Load Circuit for

RD

and WR to

INT

Delay Test

–4–

Figure 2. Load Circuits for Bus Relinquish Time Test

Figure 4. Load Circuit for DAC Settling Time Test

REV. A

Page 5

AD7769

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

VDD to AGND or DGND . . . . . . . . . . . . . . . . .–0.3 V, +15 V

V

to DGND . . . . . . . . . . . . . . . . –0.3 V, VDD +0.3 V or 7 V

CC

(Whichever is Lower)

AGND to DGND . . . . . . . . . . . . . . . . . . –0.3 V, V

+0.3 V

DD

Power Dissipation (Any Package)

to +75°C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 mW

Derates Above +75°C by . . . . . . . . . . . . . . . . . . . 6 mW/°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering 10 secs) . . . . . . . . . . . .+300°C

Digital Inputs to DGND

(Pins 12, 13, 15–18) . . . . . . . . . . . . . . –0.3 V, V

Digital Outputs to DGND

(Pins 3–10, 11) . . . . . . . . . . . . . . . . . . .–0.3 V, V

Analog Inputs to AGND . . . . . . . . . . . . . –0.3 V, V

Analog Outputs to AGND . . . . . . . . . . . . –0.3 V, V

+0.3 V

DD

+0.3 V

CC

+0.3 V

DD

+0.3 V

DD

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability. Only one Absolute

Maximum Rating may be applied at any one time.

Operating Temperature Range

Commercial (J Version) . . . . . . . . . . . . . . . . . 0°C to +70°C

Industrial (A Version) . . . . . . . . . . . . . . . . –40°C to +85°C

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD7769 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

ORDERING GUIDE

Temperature Package

Model Range Option*

NOTE

Do not allow V

to exceed VDD by more than 0.3 V. In cases

CC

where this can happen the diode protection scheme shown

below is recommended.

AD7769JN 0°C to +70°C N-28

AD7769JP 0 °C to +70°C P-28A

AD7769AN –40°C to +85°C N-28

AD7769AP –40°C to +85°C P-28A

*N = Plastic DIP; P = Plastic Leaded Chip Carrier.

PIN CONFIGURATIONS

DIP PLCC

REV. A

–5–

Page 6

AD7769

PIN FUNCTION DESCRIPTION

Pin Mnemonic Description

1V

2V

DD

CC

+12 V Power Supply. This powers the analog circuitry.

+5 V Power Supply. This powers the logic circuitry.

3–10 DB7–DB0 Input/Output Data Bus. A bidirectional data port from which ADC output data may be read

and to which DAC input data may be written. DB7 is the Most Significant Bit.

11

INT Interrupt Output (active low). INT is set high on the falling edge of RD or WR to the ADC

and goes low at the end of a conversion.

12 CLK Clock input. A clock is required for the ADC. An external TTL-compatible clock may be applied to

this input pin. Alternatively, tying this pin to V

enables the internal clock oscillator. With an

DD

external clock, the mark-space ratio can vary from 30/70 to 70/30.

13 CHA/CHB Channel A/Channel B Select Input. Selects Channel A or Channel B of the DAC or ADC.

Used in conjunction with

WR, RD, CS and ADC/DAC for read or write operations.

14 DGND Digital Ground.

15

16

ADC/DAC ADC or DAC Select Input. Selects either the ADC or the DAC for read or write operations in

conjunction with

WR, RD, CS and CHA/CHB.

WR Write Input (edge triggered). This is used in conjunction with the ADC/DAC, CHA/CHB and CS

control inputs to start an ADC conversion or write data to the DAC. An ADC conversion starts on the

17

18

19 V

rising edge of

RD Read Input (active low). This input must be low to access data from the ADC.

CS Chip Select Input (active low). The device is selected when this input is low.

(ADC) ADC Reference Input. The voltage applied to this pin with respect to AGND (ADC) sets the

SWING

in put voltage Full-Scale Range (FSR) of the ADC. V

WR.

(FSR) = 2 V

IN

SWING

(ADC).

20 AGND (ADC) ADC Analog Ground.

21 V

22 V

B Analog Input for Channel B. See VINA description.

IN

(ADC) ADC Reference Input. The voltage applied to this pin with respect to AGND (ADC) sets the

BIAS

midpoint of the ADC transfer function.

23 V

A Analog Input for Channel A. The input voltage range of both ADC channels is given by:

IN

V

A/B = V

IN

(ADC) ±V

BIAS

SWING

(ADC).

24 AGND (DAC) DAC Analog Ground.

25 V

26 V

27 V

(DAC) DAC Reference Input. The voltage applied to this pin with respect to AGND (DAC) sets the

SWING

B Analog Output Voltage from DAC B. See V

OUT

(DAC) DAC Reference Input. The voltage applied to this pin with respect to AGND (DAC) sets the

BIAS

output voltage Full-Scale Range (FSR) of the DACs. V

OUT

OUT

A description.

(FSR) = 2 V

SWING

(DAC).

midpoint output voltage of the DACs.

28 V

A Analog Output Voltage from DAC A. The output voltage range of both DACs is given by:

OUT

V

OUT

A/B = V

(DAC) ± V

BIAS

SWING

(DAC).

TERMINOLOGY

Relative Accuracy

For an ADC, Relative Accuracy or endpoint nonlinearity is the

maximum deviation, in LSBs, of the ADC’s actual code transition points from a straight line drawn between the endpoints of

the ADC transfer function, i.e., the 00 to 01 and FE to FF Hex

(01111111 to 11111111 Binary) code transitions.

For a DAC, Relative Accuracy or endpoint nonlinearity is a

measure of the maximum deviation, in LSBs, from a straight

line passing through the endpoints of the DAC transfer function, i.e., those voltages which correspond to codes 00 and FF

Hex.

For the specified input and output ranges, 1 LSB = 19.5 mV,

but will vary with V

1 LSB = 2 V

SWING

. For both DACs and ADC,

SWING

/256 = FSR/256.

–6–

Differential Nonlinearity

Differential Nonlinearity is the difference between the measured

change and the ideal 1 LSB change between any two adjacent

codes. A specified differential nonlinearity of ± 1 LSB max ensures monotonicity (DAC) or no missed codes (ADC).

Bias Offset Error

For an ideal ADC, the output code for an input voltage equal to

V

(ADC), should be 80 Hex (10000000 binary). The ADC

BIAS

Bias Offset Error is the difference between the actual midpoint

voltage for code 80 Hex and V

(ADC), expressed in LSBs.

BIAS

For an ideal DAC, the output voltage for code 80 Hex should

be equal to V

difference between the actual output voltage and V

(DAC). The DAC Bias Offset Error is the

BIAS

BIAS

(DAC),

expressed in LSBs.

REV. A

Page 7

AD7769

Plus and Minus Full-Scale Error

The ADC and DACs in the AD7769 can be considered as devices with bipolar (plus and minus) input ranges, but referred to

V

instead of AGND. Plus Full-Scale Error for the ADC is the

BIAS

difference between the actual input voltage at the FE to FF code

transition and the ideal input voltage (V

BIAS

+ V

SWING

–1.5 LSB),

expressed in LSBs. Minus Full-Scale Error is similarly specified

for the 01 to 00 code transition, relative to the ideal input voltage

for this transition (V

BIAS

– V

+0.5 LSB). Plus Full-Scale

SWING

Error for the DACs is the difference, expressed in LSBs, between

the actual output voltage for input code FF and the ideal voltage

(V

+ V

BIAS

specified for code 00, relative to the ideal output voltage (V

V

). Note that Plus and Minus Full-Scale errors for the

SWING

– 1 LSB). Minus Full-Scale Error is similarly

SWING

BIAS

–

ADC and the DAC outputs are measured after their respective

Bias Offset errors have been adjusted out.

Digital-to-Analog Glitch Impulse

Digital-to-Analog Glitch Impulse is the impulse injected into the

analog outputs when the digital inputs change state with either

DAC selected. It is normally specified as the area of the glitch in

nV secs and is measured when the digital input code is changed

by 1 LSB at the major carry transition.

Digital Feedthrough

Digital Feedthrough is also a measure of the impulse injected

into the analog outputs from the digital inputs but is measured

when the DACs are not selected. This is essentially feedthrough

across the die and package. It is important in the AD7769 since

it is a measure of the glitch impulse transferred to the analog

outputs when data is read from the ADC register. It is specified

in nV secs and measured with

WR high and a digital code

change from all 0s to all 1s.

Signal-to-Noise Ratio (SNR)

SNR is the measured Signal-to-Noise Ratio at the output of the

converter. The signal is the rms magnitude of the fundamental.

Noise is the rms sum of all the nonfundamental signals up to

half the sampling frequency. SNR is dependent on the number

of quantization levels used in the digitization process; the more

levels, the smaller the quantization noise. The theoretical SNR

for a sine wave is given by

SNR = (6.02N + 1.76) dB

where N is the number of bits. Thus for an ideal 8-bit converter,

SNR = 49.92 dB.

Total Harmonic Distortion (THD)

THD is the ratio of the rms sum of harmonics to the fundamental. For the AD7769, Total Harmonic Distortion is defined as

1/2

2

2

+V

)

6

20 log

(V

2

+V

2

2

2

+V

3

+V

4

5

V

1

where V1 is the rms amplitude of the fundamental and V2,

V

, V4, V5 and V6 are the rms amplitudes of the individual

3

harmonics.

Intermodulation Distortion (IMD)

With inputs consisting of sine waves at two frequencies, fa and

f

, any active device with nonlinearities will create distortion

b

products, of order (m+n), at sum and difference frequencies of

mf

+nfb, where m, n = 0, 1, 2, 3 . . . Intermodulation terms are

a

those for which neither m nor n is equal to zero. For example,

the second order terms include (f

order terms include (2f

), (2fa–fb), (fa+2fb) and (fa–2fb).

a+fb

) and (fa–fb) and the third

a+fb

LOGIC TRUTH TABLE

ADC CHANNEL SELECT AND START CONVERSION

CS ADC/DAC CHA/CHB WR RD DB0–DB7 INT Comments

0 0 X Note 1 Note 1 1

0 0 0 Note 1 Note 1 1 Select ADC Channel A and Start Conversion.

0 0 1 Note 1 Note 1 1 Select ADC Channel B and Start Conversion.

READ ADC DATA

CS ADC/DAC CHA/CHB WR RD DB0–DB7 INT Comments

0 X X X ADC Data 1

0 X X X 0 ADC Data 1 ADC Data on Data Bus.

0 X X X High-Z 1 Data Outputs Impedance.

WRITE TO DACA OR DACB

CS ADC/DAC CHA/CHB WR RD DB0–DB7 INT Comments

01 0 1 µP Data N/C µP Writing Data to DACA.

01 1 1 µP Data N/C µP Writing Data to DACB.

0 1 0 0 ADC Data N/C Data from Last ADC Conversion Will Be Written to DACA.

0 1 1 0 ADC Data N/C Data from Last ADC Conversion Will Be Written to DACB.

1 X X X X High-Z N/C No Operation.

NOTES

1

If RD = 1, DB0–DB7 will remain high impedance. If RD = 0, DB0–DB7 will output previous ADC data. The RD input should not change during a conversion.

2

X = Don’t Care.

3

N/C = No Change.

0 INT Goes Low at End of Conversion.

INT Is Set on Falling Edge of WR.

INT Is Set High on Falling Edge of RD.

REV. A

–7–

Page 8

AD7769

CIRCUIT DESCRIPTION

Analog Inputs and Outputs

The AD7769 provides the analog-to-digital and digital-to-analog

conversion functions required between the microcontroller and

the servo power amplifier in digital servo systems. It is intended

primarily for closed loop head positioning in Winchester disk

drives, but may also be used for microstepping in drives with

stepper motor head positioning or other servo applications. The

AD7769 contains a high speed, 8-bit, sampling ADC with two

input channels and two 8-bit DACs with output buffer amplifiers. A unique feature of the AD7769 is the input and output signal conditioning circuitry that allows the analog input and

output voltages to be referred to a point other than analog

ground. The input range and offset of the ADC, the output

swing and offset of the DACs may be adjusted independently by

the application of ground-referenced, positive control voltages,

V

(ADC), V

BIAS

SWING

(ADC), V

(DAC) and V

BIAS

SWING

(DAC).

Thus, for example, the peak-to-peak output swing of the DACs

could be set to 3 V above and 3 V below a bias voltage of 5 V.

Figures 5 and 6 show the transfer functions of the ADC

and DACs and their relationship to V

BIAS

and V

SWING.

The

midpoint code of the ADC, 80 Hex (10000000 Binary), occurs

at an input voltage equal to V

equal to 2 V

, so that the Plus Full-Scale code transition

SWING

(FE to FF Hex) occurs at a voltage equal to V

. The input FSR of the ADC is

BIAS

+ V

BIAS

SWING

–1.5 LSBs and the Minus Full-Scale code transition (01 to 00

Hex) occurs at a voltage V

BIAS

– V

+0.5 LSBs. The

SWING

transfer function of the DACs bears a similar relationship to

V

and V

BIAS

(10000000 binary) is equal to V

binary) gives an output voltage of V

(Plus Full-Scale) and 00 Hex gives an output voltage of V

V

(Minus Full-Scale).

SWING

. The DAC output voltage for code 80 Hex

SWING

, while FF Hex (11111111

BIAS

BIAS

+ V

SWING

–1 LSB

BIAS

–

The ability to refer input and output signals to some voltage

other than ground is of particular importance in disk drive applications. Typically, only +5 V digital and +12 V analog supply

voltages are available, and the analog signals are often referred

to a voltage around half the analog supply.

Driving the Analog Inputs and Reference Inputs

The analog inputs, VINA and VINB, must be driven from low

output impedance sources, such as from op amps. In addition,

V

(ADC) must be driven from a similar type low impedance

BIAS

source (e.g., voltage reference).

Op amps are not required to drive the V

(DAC) and V

(DAC) inputs as these are high impedance

SWING

SWING

(ADC), V

BIAS

inputs (200 nA typical input current) that feed into on-chip

buffer amplifiers. The reference voltages for these inputs can be

derived using suitable resistor divider networks.

The analog reference available in the disk drive system can be

used to set the bias voltage of the AD7769, and could also be attenuated to provide the reference for the input and output swing

as shown in Figure 7. The same bias voltage would generally

(though not necessarily) be used for the ADC and the DACs,

though the input and output ranges might be different.

Figure 5. ADC Transfer Function

Figure 6. DAC Transfer Function

Figure 7. Typical Analog Connections to the AD7769

ADC Conversion Cycle

Figure 8 shows the operating waveforms for a conversion cycle.

On the rising edge of

acquisition and tracking of the selected ADC channel, V

V

B. The analog input voltage is held 50 ns (typically) after the

IN

WR, the conversion cycle starts with the

A or

IN

fourth falling edge of the input CLK following a conversion

start. If t

in Figure 8 is greater than 150 ns, then the falling

D

edge of the input CLK will be seen as the first falling clock edge.

If t

is less than 150 ns, the first falling clock edge to be recog-

D

nized will not occur until one cycle later.

–8–

REV. A

Page 9

Figure 8. Operating Waveforms Using External Clock

Following the “hold” on the analog input, the MSB decision is

made approximately 50 ns after the next falling edge of the input CLK. The succeeding bit decisions are made approximately 50 ns after a CLK edge until conversion is complete. At

the end of conversion, the

after the LSB decision and the SAR contents are transferred to

the output latch. The SAR is then reset in readiness for a new

conversion.

Track-and-Hold

The track-and-hold (T/H) amplifier on the analog input to the

ADC of the AD7769 allows the ADC to accurately convert an

input sine wave of 5 V peak-to-peak amplitude up to a frequency of 200 kHz, the Nyquist frequency of the ADC when

operated at its maximum throughput rate of 400 kHz. This

maximum rate of conversion includes conversion time and time

between conversions. Because the input bandwidth of the trackand-hold is much greater than 200 kHz, the input signal should

be band limited to avoid folding unwanted signals into the band

of interest.

DAC Outputs

The D/A converter outputs are buffered with on-board, high

speed op amps that are capable of driving 5 kΩ and 100 pF

loads to AGND (DAC). Each output amplifier settles to within

1/2 LSB of its final output value in typically less than 2.5 µs.

See Figures 9 and 10 for waveforms of the typical output settling time performance.

The output noise from the amplifiers with full scale on the

DACs is typically 200 µV peak-to-peak.

Figure 9. Positive-Going Settling Time

INT line goes low 100 ns (typically)

AD7769

Figure 10. Negative-Going Settling Time

Internal / External Clock Operation

The AD7769 can be operated on either its own internal clock or

with an externally applied clock signal. For internal clock operation the CLK input must be tied to V

nents are required. The internal clock typically runs at 5 MHz

giving a typical conversion time of 2.5 µs. For external clock op-

eration the CLK input must be driven with a TTL/ HCMOS

compatible input. The mark/space ratio of the clock signal can

vary from 30/70 to 70/30. For an input frequency of 5 MHz, the

conversion time is 2.5 µs.

Digital Inputs and Outputs

The AD7769 communicates over a standard, 8-bit microprocessor data bus and is controlled by standard mpu control lines,

CS, WR, RD, INT, plus two address lines, ADC/DAC and

CHA/CHB, which select the DAC or ADC function and Chan-

nel A or Channel B input/output channel. The Chip Select (

line selects the device, Write (

versions or to write data to the DAC, depending on the state of

ADC/DAC. INT is a status flag that indicates completion of a

conversion, while

8-bit data port (DB0–DB7) is a bidirectional port into which

data can be written to the two DAC registers, and from which

data can be read from the ADC register. ADC output data may

also be written directly into either of the DAC registers.

These logical operations are detailed in Table I and in the time

ing diagrams, Figures 11 to 13. Figures 12 and 13 show the

fairly straightforward operations of reading ADC data and writing data to the DACs, and need little explanation. Figure 11

shows the timing for ADC channel selection and conversion

start. This is more complicated as the state of the data outputs

during a conversion depends on

To initiate a conversion (or any other operation) the device

must be selected by taking

taking

WR low, then high again (conversion starts on rising edge

of

WR). There are three possibilities for the state of the data

outputs during the conversion.

1. If

RD is held high, the data outputs will be high impedance

throughout the conversion.

2. If

RD and CS are both held low until after INT goes low,

then DB0–DB7 will initially output data from the last conversion. After

appear on DB0–DB7.

RD is used to read ADC output data. The

INT goes low the new conversion data will

WR) is used to initiate ADC con-

CS low. A conversion is started by

. No external compo-

DD

CS and RD.

CS)

REV. A

–9–

Page 10

AD7769

3. If RD is held low but CS is taken high during the conversion,

the device will be de-selected and DB0–DB7 will revert to

their high impedance state. This will not affect completion of

the conversion, but the data cannot be read, or any other

operation performed, until

4. Note that the state of

CS is taken low again.

RD should not be changed during a

conversion.

Figure 11. Timing for ADC Channel Select and Conversion

Start

DIGITAL SIGNAL PROCESSING APPLICATIONS

In Digital Signal Processing (DSP) application areas like voice

recognition, echo cancellation and adaptive filtering, the dynamic characteristics (SNR, Harmonic Distortion, Intermodulation Distortion) of both the ADC and DACs are critical. The

AD7769 is specified dynamically as well as with standard dc

specifications. Because the track/hold amplifier has a wide bandwidth, an antialiasing filter should be placed on the V

V

B inputs to avoid aliasing of high frequency noise back into

IN

A and

IN

the bands of interest.

The dynamic performance of the ADC is evaluated by applying

a sine wave signal of very low distortion to the V

A or VINB

IN

input which is sampled at a 409.6 kHz sampling rate. A Fast

Fourier Transform (FFT) plot or Histogram plot is then generated from which SNR, harmonic distortion and dynamic differential nonlinearity data can be obtained. For the DACs, the

codes for an ideal sine wave are stored in PROM and loaded

down to the DAC. The output spectrum is analyzed, using a

spectrum analyzer to evaluate SNR and harmonic distortion

performance. Similarly, for intermodulation distortion, an input

(either to VIN or DAC code) consisting of pure sine waves at

two frequencies is applied to the AD7769.

Figure 14 shows a 2048 point FFT plot of the ADC with an input signal of 130 kHz. The SNR is 49.2 dB. It can be seen that

most of the harmonics are buried in the noise floor. It should be

noted that the harmonics are taken into account when calculating the SNR. The relationship between SNR and resolution (N)

is expressed by the following equation:

SNR = (6.02N + 1.76) dB

Figure 12. Timing for ADC Data Read

Figure 13. Timing for DAC Channel Select and Data Write

–10–

Figure 14. ADC FFT Plot

REV. A

Page 11

AD7769

This is for an ideal part with no differential or integral linearity

errors. These errors will cause a degradation in SNR. By working backwards from the above equation, it is possible to get a

measure of ADC performance expressed in effective number of

bits (N). The effective number of bits is plotted versus frequency in Figure 15. The effective number of bits typically falls

between 7.7 and 7.9, corresponding to SNR Figures 48.1 and

49.7 dB.

Figure 15. Effective Number of Bits vs. Frequency

Figure 16 shows a spectrum analyzer plot of the output spectrum from one of the DACs with an ideal sine wave table loaded

to the data inputs of the DAC. In this case, the SNR is 47 dB.

where A is the peak amplitude of the sine wave and p (V) the

probability of occurrence at a voltage V. The histogram plot of

Figure 17 corresponds very well with this shape.

Figure 17. ADC Histogram Plot

In digital signal processing applications, where the AD7769 is

used to sample ac signals, it is essential that the signal sampling

occurs at exactly equal intervals. This minimizes errors due to

sampling uncertainty or jitter. A precise timer or clock source,

to start the conversion process, is the best method of generating

equidistant sampling intervals.

Figure 16. DAC Output Spectrum

Histogram Plot

When a sine wave of specified frequency is applied to the VINA

or V

B input of the AD7769 and several thousand samples are

IN

taken, it is possible to plot a histogram showing the frequency of

occurrence of each of the 256 ADC codes. If a particular step is

wider than the ideal 1 LSB width, then the code associated with

that step will accumulate more counts than for the code for an

ideal step. Likewise, a step narrower than ideal width will have

fewer counts. Missing codes are easily seen because a missing

code means zero counts for a particular code. The absence of

large spikes in the plot indicates small differential nonlinearity.

Figure 17 shows a histogram plot for the ADC indicating very

small differential nonlinearity and no missing codes for an input

frequency of 204 kHz. For a sine wave input, a perfect ADC

would produce a probability density function described by the

equation:

p (V) =

π(A

1

2

–V2)

1/2

MICROPROCESSOR/MICROCOMPUTER INTERFACING

The AD7769 is designed for easy interfacing to microprocessors

and microcomputers as a memory mapped peripheral or an I/O

device. In addition, the AD7769 high speed bus timing allows

direct interfacing to many DSP processors such as the

TMS320C10 and ADSP-2101.

AD7769–TMS320C10 Interface

A typical interface to the TMS320C10 is shown in Figure 18.

The AD7769 is mapped at a port address, and the interface is

designed for the maximum TMS320C10 clock frequency of

20 MHz.

Figure 18. AD7769 to TMS320C10 Interface

REV. A

–11–

Page 12

AD7769

Conversion is initiated on the selected AD7769 ADC channel

using a single I/O instruction, <OUT ADC, A>. The processor

then polls

result using an <IN A, ADC> instruction. Writing data to the relevant AD7769 DAC consists of an <OUT DAC, A> instruction.

AD7769–ADSP-2101 Interface

Figure 19 shows a typical interface to the DSP microcomputer,

the ADSP-2101. The ADSP-2101 is optimized for high speed

numeric processing tasks.

INT until it goes low before reading the conversion

Figure 20. AD7769 to 8051 (Processor Bus) Interface

Figure 19. AD7769 to ADSP-2101 Interface

Because the instruction cycle of the ADSP-2101 is very fast

(80 ns cycle), the

suit the AD7769. This is easily achieved as the ADSP-2101

memory interface supports slower memories and memorymapped peripherals (i.e., AD7769) with a programmable wait

state generation capability. A number of wait states, from 0 to 7,

can be specified for each memory interface. One wait state is

sufficient for the interface to the AD7769.

AD7769–8051 Interface

A choice of two interface modes are available to the 8051

microcomputer.

Figure 20 shows a typical interface to the 8051 processor bus. It

is suitable for the maximum 8051 clock frequency of 12 MHz.

In this interface mode, Port 0 provides the multiplexed low order address and data bus and Port 2 provides the high order address bus (A

Figure 21 shows the AD7769 interfaced to the 8051 parallel I/O

ports. This interface circuit is simpler to implement than the

previous interface to the processor bus, but, in general, the

maximum data throughput rate is much slower (for the same

clock frequencies). In addition to its simplicity, the interface to

the parallel I/O ports versus the processor bus allows independent control of both the

For example, the 8051 can set both

same time. This permits data from the last ADC conversion to

be written directly from the ADC register into the selected DAC

register (see Logic Truth Table). This allows very fast transfer

of data from the ADC to the DAC and is a useful feature for

some applications such as a fast, programmable, infinite sampleand-hold function.

WR and RD pulses must be stretched out to

).

8–A15

WR and RD inputs to the AD7769.

WR and RD low at the

Figure 21. AD7769 to 8051 (Parallel l/O Ports) Interface

AD7769–MC68HC11 Interface

Figure 22 shows a typical interface between the AD7769 and the

MC68HC11 microcomputer. This interface is designed for the

maximum MC68HC11 clock speed of 8.4 MHz. The microcomputer is operated in the expanded multiplexed mode, with the

AD7769 as a memory mapped peripheral. The expansion bus is

made up of Ports B and C, and control signals AS and R/

Figure 22. AD7769 to MC68HC11 Interfaced

W.

–12–

REV. A

Page 13

APPLICATIONS

The AD7769 analog I/O port is used to convert servo related

signals between the analog and digital domains. The input

structure of the two-channel ADC makes it very easy to convert

the typical output signals provided by a servo demodulator.

In a magnetic disk drive employing a dedicated servo surface,

the servo demodulator produces two, positive-only, quadrature

signals, generally sinusoidal or triangular, from the all-bit patterns read from the servo surface. The quadrature signals have

the form of V

BIAS

± V

. The very fast conversion time of the

SWING

AD7769 ADC allows sequential conversion of these quadrature

signals without introducing significant phase delay errors. These

converted signals provide the servo microcontroller with position and track crossing information from which velocity information can be derived. In optical disk drives, analogous servo

signals can be derived from the quad photodiode detector to

provide position and focus information for the microcontroller.

The two DACs in the AD7769 accept servo data from the

microcontroller to position the head assembly. The DACs provide positive-only output signals of the form V

BIAS

± V

SWING

,

which are ideal for driving voice coil motors. In magnetic disk

drives, a single voice coil motor is used to position the head assembly and one DAC is usually sufficient to drive the motor in

both the seek and track modes. In the seek mode, the DAC can

be used to generate directly the desired analog velocity trajectory which the head must travel in order to achieve minimum

access times. Alternatively, the DAC can generate a servo error

value (computed by the microcontroller) between the actual

head velocity and the desired head velocity. In the track mode,

the DAC can be used to provide a position error signal to keep

the head over the track or to detent the head off track, for such

purposes as thermal compensation and soft error retries. The

second DAC in the AD7769 may be employed in this fine positioning loop. Alternatively, the second DAC can be used to control the speed of the spindle motor via a pulse width modulator.

In optical disk drives two voice coil motors are used, requiring

both DACs of the AD7769–one for the focus servo loop and

one for the radial positioning servo loop.

A typical servo control loop using the AD7769 is shown in Figure 23. In this dedicated servo drive, the servo demodulator converts the servo information bit patterns from the disk into the

standard N and Q (normal and quadrature) servo signals. The

voice coil motor current, I

, is bidirectional and is supplied by the

L

power transconductance amplifier. One input to this amplifier is

held at V

output, V

stage are shown in Figure 24. The transconductance, G

(DAC), while the other input is driven from a DAC

BIAS

A/B. Typical input/output waveforms for this power

OUT

, of the

O

power stage is determined by external sense resistors.

AD7769

Figure 23. Typical Dedicated Servo Control Loop Using

the AD7769

Figure 24. Typical Relationship Between Input Voltage and

Output Current for Transconductance Amplifier

REV. A

–13–

Page 14

AD7769

Increased Resolution DAC Output

Since both V

(DAC) and V

BIAS

(DAC) are common to

SWING

both output channels, the full-scale output voltages of both

channels are nominally identical. However, by adding an external op amp and scaling resistors, it is possible to attenuate the

full-scale output voltage of one (or both) of the DAC outputs to

effectively increase the output voltage resolution. Figure 25

shows channel A being attenuated using a resistor scaling of

10:1. The attenuated output voltage, V

V

OUT

A' = V

BIAS

+ (V

SWING

A', is

OUT

/10)(2DA–1).

The output voltage of Channel B remains at

V

OUT

B = V

BIAS

+ V

SWING

(2DB–1).

DA and DB are fractional representations of the DAC input

codes, e.g., D

V

voltage level of 2 V, the Channel B output span is 4 V

SWING

= NA/256 and DB = NB/256. For example, with a

A

with an LSB size of 15.6 mV and (attenuated) Channel A output span is 400 mV with an LSB size of 1.56 mV. Changing the

resistor scaling in Figure 25 obviously changes the attenuated

full-scale output.

DAC A can be programmed to produce an interpolation function between the 8-bit steps of DAC B to allow, for example,

very smooth velocity profile waveforms to be generated.

Servo Offset Facility

Most dedicated servo disk drives offer an offset facility whereby

some small voltage is injected into the track-following loop. The

purpose of the offset is to move the head to the right or left of its

current on-track position to permit reading of off-track data.

The circuit is shown in Figure 27. With the 10:1 resistor scaling

used in the circuit the output voltage, V

V

= VPE + (V

OUT

SWING

, is

OUT

/10) (2DA–1).

Figure 25. Increasing the DAC Output Voltage Resolution

A single change to the circuit Figure 25 allows the two DAC

outputs to be combined to provide a single analog output with

resolution beyond the standard 8-bits. Figure 26 shows the rearranged circuit. The composite output, V

V

OUT

= V

OUT

B + (V

SWING

, is

OUT

/10)(2DA–1)

or

V

OUT

= V

BIAS

+ V

(2DB–1) + (V

SWING

/10) (2DA–1).

SWING

Figure 27. Servo Offset Facility

With no offset added, V

= VPE, where VPE is the position

OUT

error voltage which the servo loop normally drives to its zero

level, V

. When an offset voltage is supplied by DAC A, the

BIAS

action of the servo is to move the head away from its current

on-track position until the position error voltage is equal and

opposite to the offset voltage. The position of the head about

the track centre is thus programmable.

Programmable Full-Scale Range

The output voltage span of both DACs is determined by the

V

(DAC) voltage level. This is normally supplied from

SWING

some fixed voltage source. However, it is possible to use one of

the DAC channels to generate a programmable V

SWING

voltage

level. The remaining channel will thus have a full-scale range

and LSB size which is software programmable. This circuit is

shown in Figure 28 where V

loop to generate a programmable swing voltage, V

B is used in an implicit feedback

OUT

SWING

(DAC),

for the AD7769 from an external fixed input swing voltage,

V

. Using the 5:1 resistor scaling shown in Figure 28, the

SWING

expression for the AD7669 input swing voltage is

V

V

SWING

(DAC) =

SWING

2D

()

1–

.

–1

B

5

Figure 26. Combined V

OUT

A, V

B Circuit

OUT

–14–

REV. A

Page 15

AD7769

Figure 28. Generating a Software Programmable V

SWING

(DAC)

For example, with a fixed input swing voltage of 2.5 V, the programmable span via DAC B is as follows:

D

= 0: V

B

= 1/2: V

D

B

DB ≈ 1: V

The AD7769 is specified for a V

(DAC) = 2.08

SWING

(DAC) = 2.5 V = V

SWING

(DAC) = 3.125 V

SWING

SWING

(DAC) voltage range

SWING

from 2 V to 3 V, although in practice this range can be extended

while still maintaining monotonic operation.

Closed Loop Microstepping

Microstepping is a popular technique in low density disk drives

(both floppy and hard disk) that allows higher positional resolution of the disk drive head over that obtainable from a full-step

driven stepper motor. Typically, a two-phase stepper motor has

its phase currents driven with a sine-cosine relationship. These

cosinusoidal signals are generated by two DACs driven with the

appropriate data. The resolution of the DACs determines the

number of microsteps into which each full step can be divided.

For example, with a 1.8° full-step motor and a 4-bit DAC, a

microstep size of 0.11° (1.8°/2

n

) is obtainable.

The microstepping technique improves the positioning resolution possible in any control application. However, the positional

accuracy can be significantly worse than that offered by the original full-step accuracy specification due to load torque effects.

To ensure that the increased resolution is usable, it is therefore

necessary to use a closed-loop system where the position of the

disk drive head (or motor) is monitored. The closed-loop system

allows an error between the desired position and the actual position to be monitored and corrected. The correction is achieved

by adjusting the ratio of the phase currents in the motor windings until the required head position is reached.

The AD7769 is ideally suited for the closed-loop microstepping

technique with its dual DACs for positioning the disk drive

head and dual channel ADC for monitoring the position of the

head. A typical circuit for a closed-loop microstepping system is

shown in Figure 29. The DAC waveforms are shown in Figure

30 along with the direction information of clockwise rotation

supplied by the controller.

Figure 29. Typical Closed-Loop Microstepping Circuit

with the AD7769

Figure 30. Typical Control Waveforms for the Microstepping Circuit of Figure 29

A typical transducer would be a moire-fringe transducer which

consists of two gratings, one fixed and one moveable. The relative positions of these two gratings will modulate the amount of

light from a LED which can pass through. In order to derive

head direction information the stationary grating has two sets of

bars, with a 90° phase relationship, and two photo-transistors.

The quadrature sinusoidal output waveforms (N & Q) can be

converted directly by the AD7769.

REV. A

–15–

Page 16

AD7769

Multichannel Expansion

In some applications, more than two analog input channels are

required to be converted by the ADC. Figure 31 shows a circuit

configuration for such an application. The ADG528A is a

latched, B-channel analog multiplexer that is ideally suited for

this application since it is specified for single supply operation

(+12 V ±10%).

The

CS, ADC/DAC and WR inputs of the AD7769 are gated to

drive the

signal is selected on the falling edge of the

signal is latched on the rising edge. Also, on the rising edge of

WR, the AD7769 ADC starts conversion. Therefore, the output

signal of the multiplexer must have settled to within 8-bits over

the duration of the

tion for details). The t

ADG528A thus determines the width of the

WR input of the ADG528A. The multiplexer input

WR pulse while the

WR pulse (see ADC Conversion Cycle sec-

(WR) and settling time of the

ON

WR pulse.

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

28-Lead Plastic DIP

(N-28)

C1315a–0–6/97

Figure 31. Multichannel Inputs

28-Lead Plastic Leaded Chip Carrier

(P-28A)

–16–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...