Analog Devices AD7663CB, AD7662CB, AD7660CB, AD7650CB, AD7677CB Datasheet

...

PRELIMINAR Y TECHNICAL DATA

=

Preliminary Technical Data

FEATURES

Versatile Analog Signal Conditioning Circuitry

On-Board Reference, Crystal Oscillator and Buffers

16-Bit Parallel Buffered Outputs

Ideal For DSP and Data Acquisition Card Interfaces

Analog and Digital Prototyping Area

EVAL-CONTROL BOARD Compatibility

PC Software for Control and Data Analysis

GENERAL DESCRIPTION

The EVAL-AD766XCB/AD767XCB is an evaluation board

for the AD766X/AD767X 16-bit A/D converter family. The

AD766X/AD767X family ( see ordering guide for product list )

is a high speed, successive approximation based architecture

with very high performance, low power family of 16-Bit ADCs

which operate from a single +5V supply with a 100kSPS to

1MSPS throughput rate range, and a flexible parallel or serial

interface. The AD766X/AD767X evaluation board is designed

to demonstrate the ADC's performance and to provide an easy

to understand interface for a variety of system applications. A

full description of the AD766X/AD767X is available in the

Analog Devices AD766X/AD767X data sheets and should be

consulted when utilizing this evaluation board.

Evaluation Board AD766X/AD767X

EV AL-AD766XCB/AD767XCB

The EVAL-AD766XCB/AD767XCB is ideal for use with

either the Analog Devices EVAL-CONTROL BOARD, or as a

stand-alone evaluation board. The design offers the flexibility

of applying external control signals and is capable of generating

16-bit conversion results on a parallel buffered outputs.

On-board components include an AD780, a +2.5V ultrahigh

precision bandgap reference, a signal conditioning circuit

with two op-amps and digital logic. The board interfaces with

a 96-way connector for the EVAL-CONTROL BOARD, a

20-pin IDC connector for serial output interface, and a 40pin IDC connector for parallel output data. SMB connectors

are provided for the low noise analog signal source, an external master clock and an external start/convert input.

ORDERING GUIDE

Evaluation board Model Product

EVAL-AD7650CB AD7650AST

EVAL-AD7660CB AD7660AST

EVAL-AD7662CB AD7662YST

EVAL-AD7663CB AD7663AST

EVAL-AD7664CB AD7664AST

EVAL-AD7665CB AD7665AST

EVAL-AD7668CB AD7668YST

EVAL-AD7671CB AD7671AST

EVAL-AD7675CB AD7675AST

EVAL-AD7676CB AD7676AST

EVAL-AD7677CB AD7677AST

EVAL-CONTROL BRD2 Controller Board

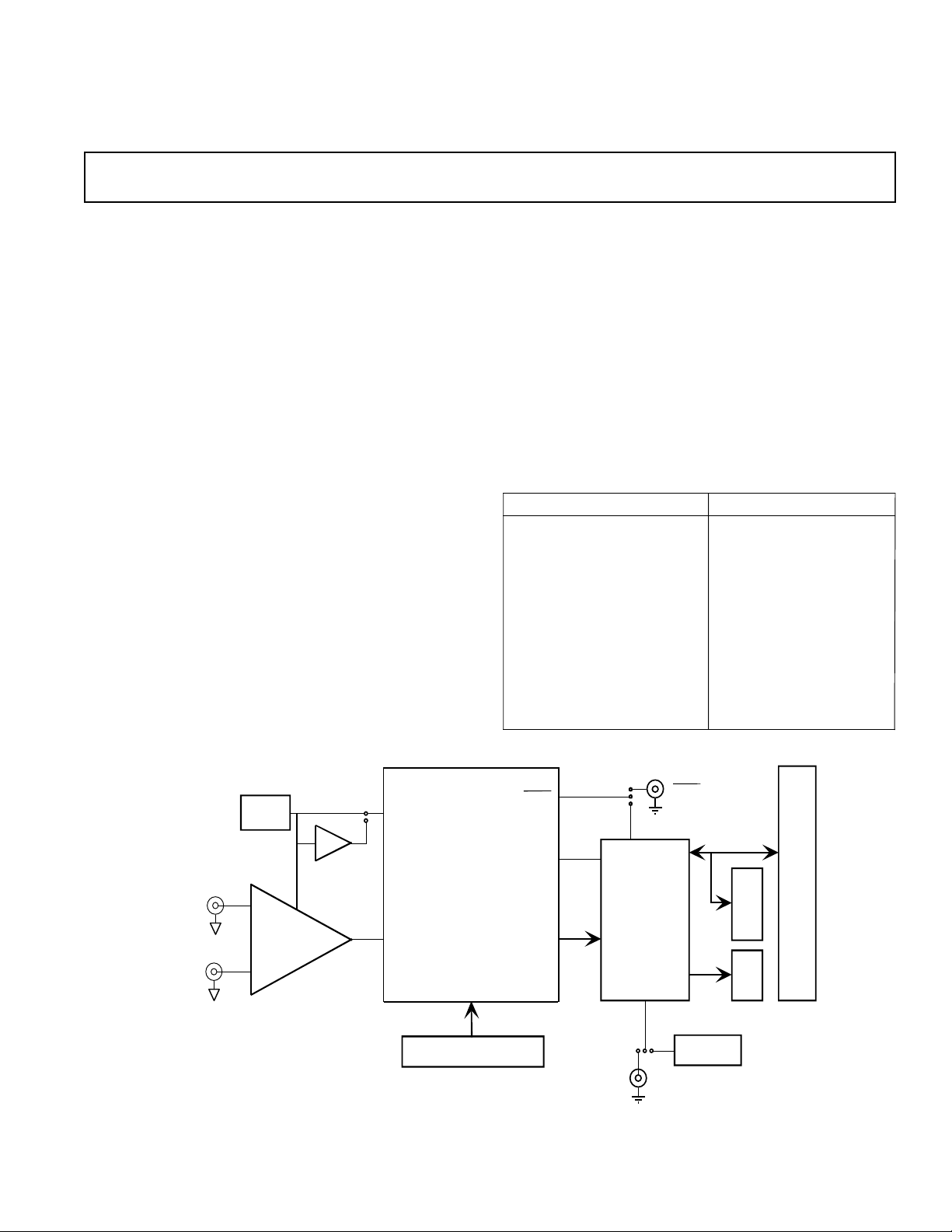

FUNCTIONAL BLOCK DIAGRAM

REF 2.5V

AD780

REF

AD766x

or

AUX_IN

SIGNAL

CONDITIONING

IN

REV. PrK

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

AD767x

IN

Configuration switches

+/-5 V

+/-12 V

+5 V

V

L

96

PIN

CONN

MCLK

CNVST

Clock

40

PIN

CONN

20

PIN

CONN

CNVST

BUSY

DIGITAL LOGIC

DATA

MCLK

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

PRELIMINARY TECHNICAL DATA

EVAL-AD766XCB/AD767XCB

OPERATING THE EVAL-AD766XCB/AD767XCB

The EVAL-AD766XCB/AD767XCB is a four-layer board

carefully laid out and tested to demonstrate the specific high

accuracy performance of the AD766X/AD767X. Figure 1

shows the schematics of the evaluation board. The layouts of

the board are given in :

Top side silk-screen - Figure 2

Top side layer - Figure 3

Ground layer - Figure 4

Shield layer - Figure 5

Bottom side layer - Figure 6

Bottom side silk-screen - Figure 7.

The EVAL-AD766XCB/AD767XCB is a flexible design that

enables the user to choose among many different board configurations. A description of each selectable jumper/switch is

listed in Table II and the available test points are listed in

Table III. Note that the button of a switch in position A ( U3

side ) defines a low level.

The EVAL-AD766XCB/AD767XCB is configured in factory

with 0 to 2.5 V ADC input range for the AD7660, AD7664,

and AD7675/7676/7677 and +/-5V for the AD7663/7665/

7671; front-end amplifiers U6 and U7 set with a gain of +1,

powered through the EVAL-CONTROL BOARD, and the

on-board CNVST generation used.

On-board or external CNVST could be used. When an external CNVST signal is applied, this signal should have very low

jitter and sharp edges to get the best noise performance of the

part. Meanwhile, it is recommended to use the on-board

CNVST generation which is done by dividing MCLK signal

(20MHZ) by the numbers shown in Table I, which are entered in the software. Activity on BUSY pin of the ADC

turns on the LED.

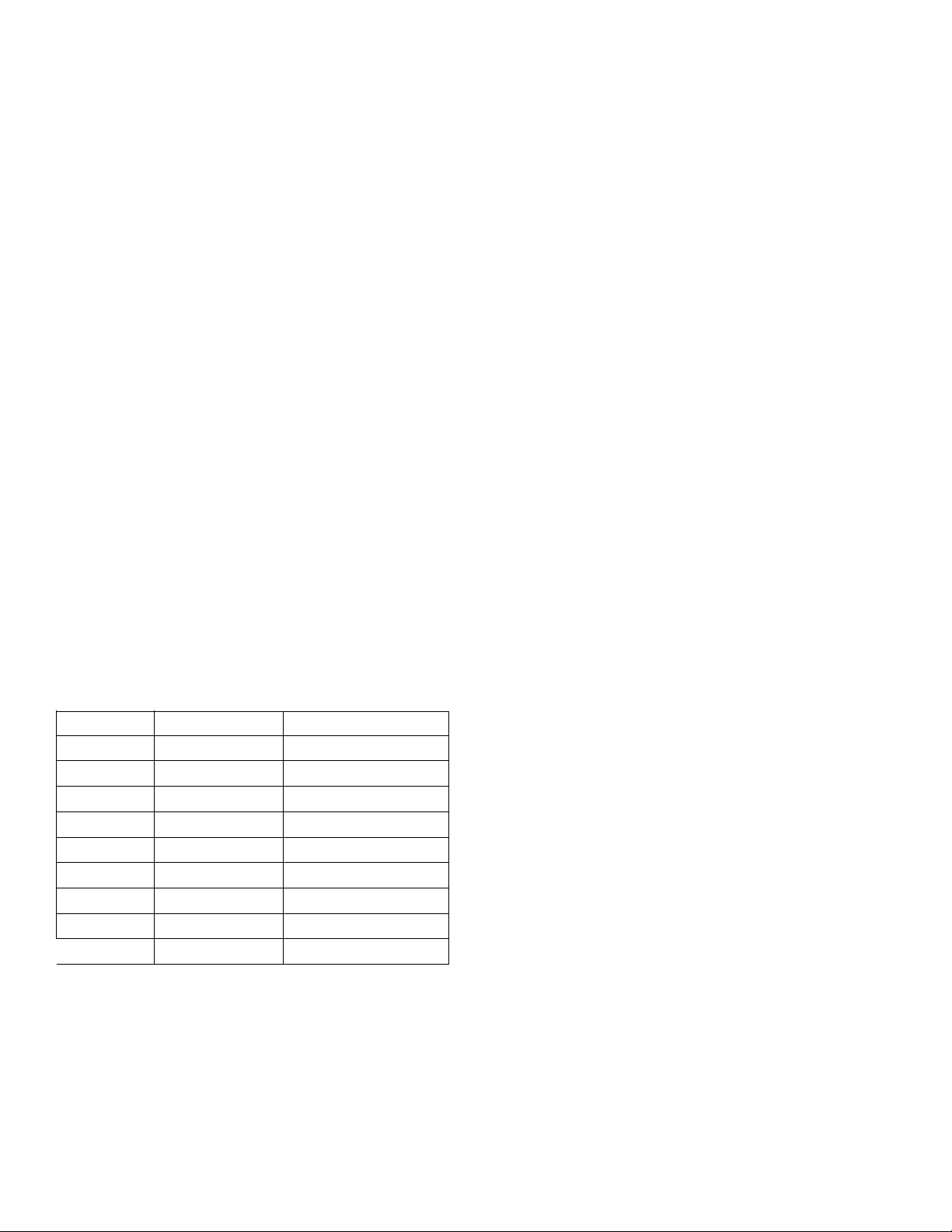

Table I. CNVST GENERATION

Part Division Factor Throughput Rate

AD7660 200 100KSPS

AD7662/68 40 500KSPS

AD7663 80 250KSPS

AD7664/50 35 571KSPS

AD7665 35 571KSPS

AD7671 20 1MSPS

AD7675 200 100KSPS

AD7676 35 571KSPS

AD7677 20 1MSPS

Conversion data is available at the output bus BD on U3, on

the 40-pin connector P2, and on the 96-pin connector P3.

Additionally, BD data is updated on the falling/rising edge of

DBUSY and BBUSY on P3, low when BD data is valid are

delayed from the BD data by about 20 ns to ease the interface. When either parallel or serial reading mode of the ADC

is used, the data is available on this parallel bus. When serial

reading mode of the ADC is used, the serial interface signals

of the ADC are buffered and available on the 20-pin connec-

tor P1. When slave serial reading mode of the

AD766X/AD767X is used, the external serial clock SCLK

applied to the ADC is at half the MCLK frequency.

Power Supplies and Grounding

The evaluation board ground plane is separated into two

sections: a plane for the digital interface circuitry and an analog plane for the analog input and external reference

circuitry. To attain high resolution performance, the board

was designed to ensure that all digital ground return paths do

not cross the analog ground return paths.

The EVAL-AD766XCB/AD767XCB has three power supply

blocks: a single 5V supply VA

and the reference voltage circuitry, a digital 5V supply VL

for the digital interface circuitry and the digital section of the

ADC, and a selectable +/-12V (with a possibility of +/-15V

with control Brd2) or +/-5V supply for the analog signal conditioning circuitry (SJ3). All supplies are decoupled to ground

with 10 F tantalum and 0.1 F ceramic capacitors.

Analog Input Ranges

The analog front-end amplifier circuitry U6 and U7 allows

flexible configuration changes such as positive or negative

gain, input range scaling, filtering, addition of a DC component, use of different op-amp and supplies.

Figure 1 shows the front end op-amp configuration used with

the AD7660/7663/7664/7665/7671/7675/7676/7677.

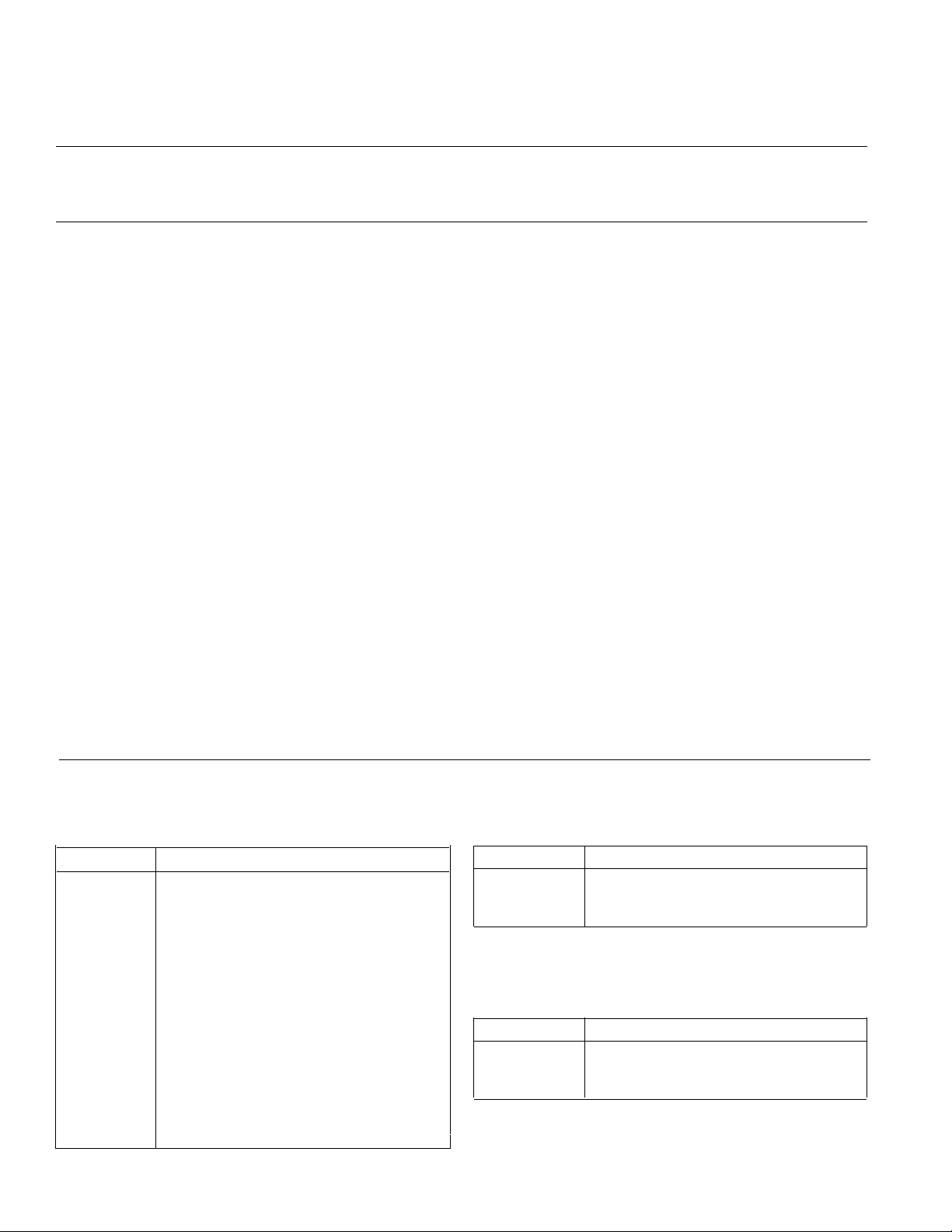

In some applications, it is desired to use a bipolar or wider

analog input range like, for instance, ± 10V, ± 5V, ± 2.5V, or

0 to +5V. For the AD76XX parts which do not have directly

those input ranges like the AD7660/7664/7675/7676/7677,

by simple modifications of the input driver circuitry of the

EVAL-AD766XCB/AD767XCB, bipolar and wider input

ranges can be used without any performance degradation.

Components values required and resulting full-scale ranges

are shown in table IV and table V.

In factory, the analog input of U6 is set at mid-scale

(R6=R7=590⍀) for the AD7660/7664/7675/7676/7677. For

AD7663/7665/7671, R7 is not connected to maintain the

input at 0V (mid-scale). This allows a transition noise test

without any other equipment. An FFT test can be done by

applying a very low distortion AC source.

EVAL-CONTROL BOARD INTERFACE

The EVAL-AD766XCB/AD767XCB interfaces to the EVALCONTROL BRD2 through the 96-way connector.

RUNNING THE EVAL-AD766X/AD767XCB SOFTWARE

Software Description

The EVAL-AD766XCB/AD767XCB comes with software for

analyzing the AD766X/AD767X. Through the EVAL-CONTROL BRD2 one can perform a histogram to determine code

transition noise, and Fast Fourier Transforms (FFT's) to

determine the Signal-to-Noise Ratio (SNR), Signal-to-Noiseplus-Distortion (SNRD) and Total-Harmonic-Distortion

(THD). The front-end PC software has four screens as

shown in Figure 8,9,10 and 11. Figure 8 is the Setup Screen

where input voltage range, sample rate, number of samples

are selected. Figure 9 is the Histogram Screen, which allows

the code distribution for DC input and computes the mean

and standard deviation.

–2–

(SJ1) for the AD766X/AD767X

REV. PrK

(SJ2)

PRELIMINARY TECHNICAL DATA

EVAL-AD766XCB/AD767XCB

Figure 10 is the FFT Screen, which performs an FFT on the

captured data, computes the Signal-to-Noise Ratio (SNR),

Signal-to-Noise-plus-Distortion (SINAD) and total-Harmonic-Distortion (THD). Figure 11 is the time domain

representation of the output. When the on-board CNVST

generation is used, a synchronous FFT could be achieved by

synchronizing the external AC generator with the Fsync signal

(TP11) which is an exact division by 2 of MCLK.

TABLE II. JUMPER DESCRIPTION

Jumper Default position Function

Designation with the control

board ( Factory

settings)

JP1 A Selection of the positive supply of the front-end amplifier U6. When JP1 is in posi-

tion A, the +12V supply from the control board is applied to JP3 otherwise VS+ on

SJ3 is used.

Software Installation

- Double-Click on Setup.exe from the CD-ROM and follow the

installation instructions.

NOTE: The software runs under Windows 95/98 only.

JP2 A Selection of the negative supply of the front-end amplifier U6. When JP2 is in posi-

tion A, the -12V supply from the control board is applied to JP4 otherwise VS- on

SJ3 is used.

JP3 A Selection of the positive supply of the front-end amplifier U6. When JP3 is in posi-

tion A, the +5V supply from the control board is used otherwise JP1 output is used.

JP4 A Selection of the negative supply of the front-end amplifier U6. When JP4 is in posi-

tion A, the -5V supply from the control board is used otherwise JP2 output is used.

JP5 not A Selection of the master clock MCLK signal. When JP5 is in position A, the signal on

J4 is used otherwise the on-board 20 MHz clock is used as a MCLK signal. MCLK

signal is used to generate the on-board CNVST signal and the external serial clock

SCLK.

JP6 A, U3 side Selection of RDC ( Read during convert ). When the button of the switch is close to

J4 connector ( not A position ) and when the serial reading mode is selected, the data

are read during conversion otherwise the data are read after conversion. JP6 has no

use in parallel reading mode.

JP7 A, U3 side Selection of PD ( Powerdown ). When the button of the switch is close to J4 connec-

tor ( not A position ), the ADC is in power-down mode.

JP8 A, U3 side Spare switch.

JP9 A, U3 side Selection of RESET. When the button of the switch is close to J4 connector ( not A

position ), the ADC is reset.

JP10 A, U3 side Selection of SER/PAR ( serial/parallel reading mode ). When the button of the switch

is close to J4 connector ( not A position ), the data are read in serial mode otherwise

the data are read in parallel mode.

JP11 not A, SJ4 side Selection of OC/2C ( coding ). When the button of the switch is close to J4 connector

( not A position ), the ADC uses a straight binary coding otherwise the twos complement coding is used.

JP12 A, U3 side Selection of WARP. When the button of the switch is close to J4 connector ( not A

position ), the ADC uses the WARP mode which is the fastest one. With the AD7660,

JP12 is a spare switch.

REV PrK

–3–

PRELIMINARY TECHNICAL DATA

EVAL-AD766XCB/AD767XCB

TABLE II. JUMPER DESCRIPTION

Jumper Default position Function

Designation with the control

board ( Factory

settings)

JP13 A, U3 side Selection of IMPULSE. When the button of the switch is close to J4 connector

( not A position ), the ADC uses the IMPULSE mode which is the mode with the

lowest power dissipation. With the AD7660, JP13 is a spare switch.

JP14 A, U3 side TEST1. For factory use only and it is pull down.

JP15 A, U3 side TEST0. For factory use only and it is pull down.

JP16 A, U3 side Selection of EXT/INT ( use of external or internal serial clock ). When the button of

the switch is close to J4 connector ( not A position ) and when the serial reading

mode is selected, the data are read with an external serial clock SCLK generated from

the master clock MCLK otherwise the data are read with the ADC serial clock. When

external serial clock reading mode is selected, MCLK has to be fast enough to be able

the read the data properly as explained in the AD766X data sheet. JP16 has no use in

parallel reading mode.

JP17 A, U3 side Selection of INVSYNC ( SYNC active level ). When the button of the switch is close

to J4 connector ( not A position ) and when the master serial reading mode is se

lected, the SYNC signal is active Low. JP17 has no use in parallel reading mode or

slave serial reading mode.

JP18 A, U3 side Selection of INVSCLK ( SCLK active edge ). When the button of the switch is close

to J4 connector ( not A position ) and when the serial reading mode is selected,

INVSCLK is high. JP18 has no use in parallel reading mode.

JP19 not A Selection of CNVST signal. When JP19 is in position A, the signal on J3 is used

otherwise the on-board CNVST generation is used. MCLK signal is used to generate

the on-board CNVST signal.

JP20 not A Selection of REF signal. When JP20 is in position A, the REF is buffered. When

JP20 is not in position A, the REF is not buffered.

Table III. EVAL-AD766XCB/AD767XCB Test Points

Test Point Available Signal

TP1 DGND Digital ground

TP2 DGND Digital ground

TP3 SIG+ ADC Analog input

TP4 AGND Analog ground close to SIG+

TP 5 REF ADC Reference input

TP6 BUSY ADC BUSY signal

TP7 RD ADC RD signal

TP8 CS ADC CS signal

TP9 AGND Analog ground close to REF

TP10 CNVST ADC CNVST signal

TP11 F

TP12 OVDD ADC digital output supply

TP13 DVDD ADC digital core supply

TP14 VANA1 ADC analog supply

TP15 AGND Analog ground close to SIGTP16 SI G- ADC Analog input

SYNC

MCLK divided by 2

Table IV. Component values Vs. Input ranges ( AD7660 )

Input range R1 R3 R6 R7

± 10V 8k⍀ 1k⍀ 8k⍀ 10k⍀

± 5V 8k⍀ 2k⍀ 6.67k⍀ 10k⍀

0 to -5V 8k⍀ 8k⍀ 0⍀ none

Table V. Component values Vs. Input ranges ( AD7664 )

Input range R1 R3 R6 R7

± 10V 2k⍀ 250⍀ 8k⍀ 10k⍀

± 5V 2k⍀ 500⍀ 6.67k⍀ 10k⍀

0 to -5V 1k⍀ 1k⍀ 0⍀ none

–4–

REV. PrK

PRELIMINARY TECHNICAL DATA

EVAL-AD766XCB/AD767XCB

TESTING METHODS

Histogram

To perform a histogram test, apply a DC signal to the input. It

is advised to filter the signal to make the DC Source noise compatible with that of the ADC. C26 provides this filtering.

AC Testing

To perform an AC test, apply a sinusoidal signal to the

evaluation board. Low distortion, better than 100dB, is required

to allow true evaluation of the part. One possibility is to filter the

input signal from the AC source. There is no suggested

bandpass filter but consideration should be taken in the choice.

Furthermore, when the full-scale input range is more than a few

Vpp, it is recommended that you use the on board amplifier to

amplify the signal, thus preventing the filter from distorting the

input signal.

Please refer to Figures 8,9,10 and 11 to see the screens of the

software.

Software Description

The AD16bit.exe is the software which allows you to analyze

different performance characteristics of the AD766X,

AD767X, AD97X and AD67X 16-bit ADC family. The software allows you to test the histogram as well as perform

different AC tests.

Setup Requirements

- Evaluation Control Board 2 (ADSP2189)

- Evaluation Board

- Power Supply (AC 15V/1A source could be bought from

ADI)

- Parallel Port Cable (provided with the evaluation control

board)

- AC Source (low distortion)

- DC Source (low noise)

- Bandpass Filter (value based on your signal frequency, low

distortion)

USE OF EVAL-AD766XCB/AD767XCB AS STANDALONE EVALUATION BOARD

You have the option of using the

EVAL-AD766XCB/AD767XCB as a stand-alone evaluation

board. This method does not require the control board, nor does

it require use of the accompanied software. The digital output

will now be available on P1 (20-pin connector, for use in serial

mode) or P2 (40-pin connector, for use in parallel mode). Certain modifications have to be made on the board to allow proper

operation of the evaluation board. Refer to Table II to obtain

the jumper positions for stand-alone operation. When in standalone, CNVST could be externally applied or is generated

internally according to Table I.

Please refer to Figure 1 to obtain the data output pins on the

connectors.

Data is updated on the falling edge of BUSY. BCS and BWR

are inputs to the FPGA and are connected to P1 and P2.

When BCS, CONTROL are low and BWR is high, which is

the default value defined by the on-board pull-up/pull-down

resistors, the data bus BD available on the P2 connector is

enabled.

SUPPLYING THE BOARD FOR STAND-ALONE USE

SJ1 is the analog supply. Connect VA+ to +5V and AGND to

GND. SJ2 is the digital supply. SJ2 requires the same values as

SJ1, and SJ2 may be connected to SJ1. SJ3 is the supply for the

front end amplifier (U6). Connect +12V to VS+, GND to

AGND, and -12V to VS-.

REV PrK

–5–

Loading...

Loading...