V

1.6 V, Micropower 12-Bit ADC

Known Good Die

FEATURES

Specified for V

Low power

0.62 mW typical at 100 kSPS with 3 V supplies

0.48 mW typical at 50 kSPS with 3.6 V supplies

0.12 mW typical at 100 kSPS with 1.6 V supplies

Fast throughput rate: 200 kSPS

Wide input bandwidth: 71 dB SNR at 30 kHz input frequency

Flexible power/serial clock speed management

No pipeline delays

High speed serial interface

SPI/QSPI™/MICROWIRE™/DSP compatible

Automatic power-down

Power-down mode: 8 nA typical

APPLICATIONS

Battery-powered systems

Medical instruments

Remote data acquisition

Isolated data acquisition

of 1.6 V to 3.6 V

DD

AD7466-KGD

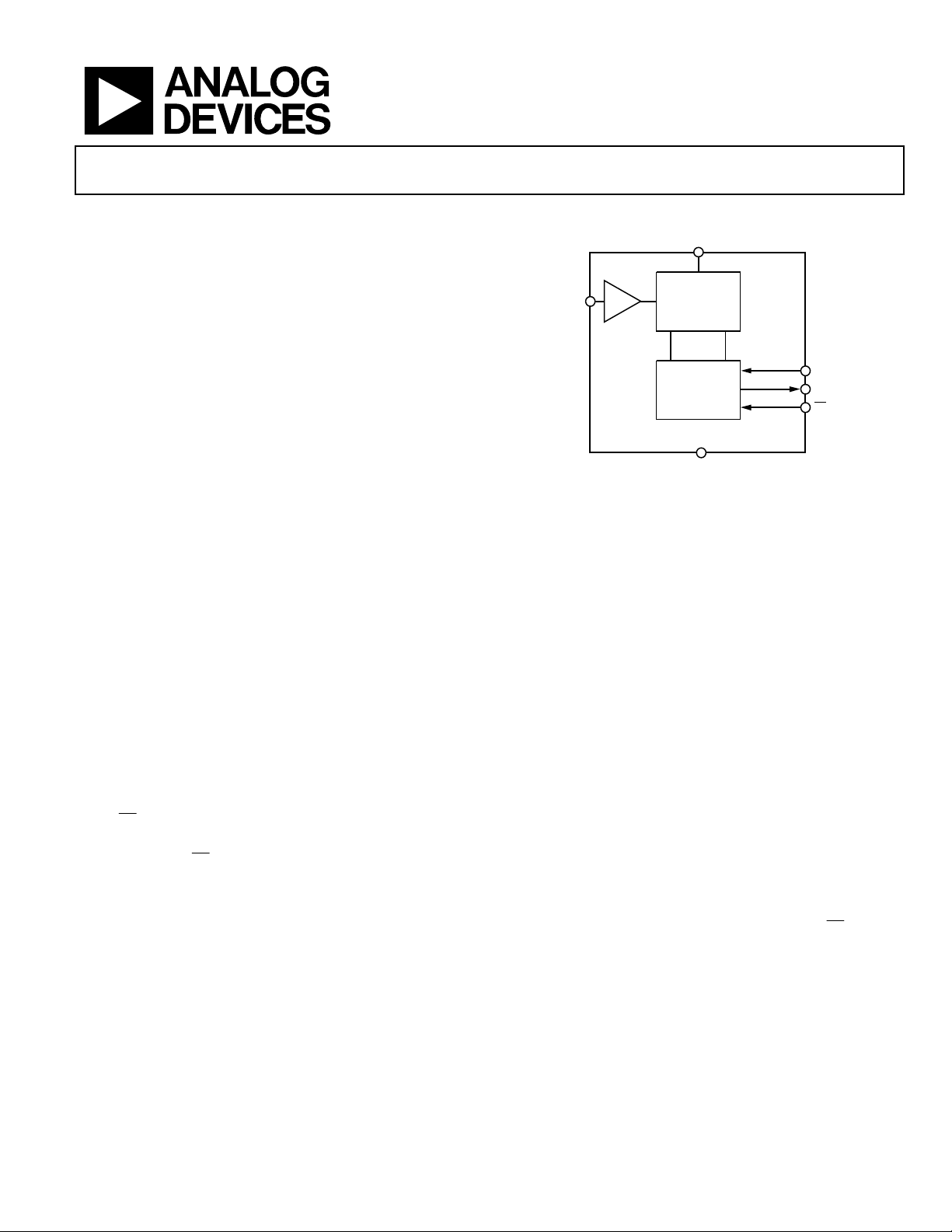

FUNCTIONAL BLOCK DIAGRAM

DD

12-BIT

T/H

V

IN

SUCCESSIVE

APPROXIMATION

ADC

CONTROL

LOGIC

AD7466-KGD

GND

Figure 1.

SCLK

SDATA

CS

10315-001

GENERAL DESCRIPTION

The AD7466-KGD1 are 12-bit, high speed, low power,

successive approximation analog-to-digital converter (ADC).

The part operates from a single 1.6 V to 3.6 V power supply and

features throughput rates up to 200 kSPS with low power

dissipation. The part contains a low noise, wide bandwidth

track-and-hold amplifier, which can handle input frequencies in

excess of 3 MHz.

The conversion process and data acquisition are controlled

CS

using

with microprocessors or DSPs. The input signal is sampled on

the falling edge of

point. There are no pipeline delays associated with the part.

The reference for the part is taken internally from V

allows the widest dynamic input range to the ADC. Thus, the

analog input range for the part is 0 V to V

rate is determined by the SCLK.

1

Protected by U.S. Patent No. 6,681,332.

and the serial clock, allowing the device to interface

CS

, and the conversion is also initiated at this

. This

DD

. The conversion

DD

PRODUCT HIGHLIGHTS

1. Specified for supply voltages of 1.6 V to 3.6 V.

2. High throughput rate with low power consumption.

Power consumption in normal mode of operation at

100 kSPS and 3 V is 0.9 mW maximum.

3. Flexible power/serial clock speed management.

The conversion rate is determined by the serial clock,

allowing the conversion time to be reduced through

increases in the serial clock speed. Automatic power-down

after conversion allows the average power consumption to

be reduced when in power-down. Current consumption is

0.1 μA maximum and 8 nA typically when in power-down.

4. Reference derived from the power supply.

5. No pipeline delay.

6. The part features a standard successive approximation

ADC with accurate control of conversions via a

CS

input.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

AD7466-KGD Known Good Die

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Timing Specifications .................................................................. 5

REVISION HISTORY

11/11—Revision 0: Initial Version

Timing Examples...........................................................................6

Absolute Maximum Ratings ............................................................7

ESD Caution...................................................................................7

Pad Configuration and Function Descriptions.............................8

Outline Dimensions..........................................................................9

Die Specifications and Assembly Recommendations ..............9

Ordering Guide .............................................................................9

Rev. 0 | Page 2 of 12

Known Good Die AD7466-KGD

SPECIFICATIONS

VDD = 1.6 V to 3.6 V, f

The temperature range for the AD7466-KGD version is −40°C to +85°C.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

DYNAMIC PERFORMANCE fIN = 30 kHz sine wave

Signal-to-Noise and Distortion (SINAD) 69 dB 1.8 V ≤ VDD ≤ 2 V

70 dB 2.5 V ≤ VDD ≤ 3.6 V

70 dB VDD = 1.6 V

Signal-to-Noise Ratio (SNR) 70 dB 1.8 V ≤ VDD ≤ 2 V

71 dB 1.8 V ≤ VDD ≤ 2 V

71 dB 2.5 V ≤ VDD ≤ 3.6 V

70.5 dB VDD = 1.6 V

Total Harmonic Distortion (THD) −83 dB

Peak Harmonic or Spurious Noise (SFDR) −85 dB

Intermodulation Distortion (IMD) fa = 29.1 kHz, fb = 29.9 kHz

Second-Order Terms −84 dB

Third-Order Terms −86 dB

Aperture Delay 10 ns

Aperture Jitter 40 ps

Full Power Bandwidth 3.2 MHz At 3 dB, 2.5 V ≤ VDD ≤ 3.6 V

1.9 MHz At 3 dB, 1.6 V ≤ VDD ≤ 2.2 V

750 kHz At 0.1 dB, 2.5 V ≤ VDD ≤ 3.6 V

450 kHz At 0.1 dB, 1.6 V ≤ VDD ≤ 2.2 V

DC ACCURACY

Resolution 12 Bits

Integral Nonlinearity ±1.5 LSB

Differential Nonlinearity −0.9/+1.5 LSB Guaranteed no missed codes to 12 bits

Offset Error ±1 LSB

Gain Error ±1 LSB

Total Unadjusted Error (TUE) ±2 LSB

ANALOG INPUT

Input Voltage Range 0 VDD V

DC Leakage Current ±1 μA

Input Capacitance 20 pF

LOGIC INPUTS

Input High Voltage, V

2 V 2.7 V ≤ VDD ≤ 3.6 V

Input Low Voltage, V

0.3 × VDD V 1.8 V ≤ VDD < 2.7 V

0.8 V 2.7 V ≤ VDD ≤ 3.6 V

Input Current, IIN, SCLK Pin ±1 μA Typically 20 nA, VIN = 0 V or VDD

Input Current, IIN, CS Pin

Input Capacitance, CIN 10 pF Sample tested at 25°C to ensure compliance

LOGIC OUTPUTS

Output High Voltage, VOH V

Output Low Voltage, VOL 0.2 V I

Floating-State Leakage Current ±1 μA

Floating-State Output Capacitance 10 pF

Output Coding Straight (natural) binary

= 3.4 MHz, f

SCLK

= 100 kSPS, unless otherwise noted. TA = T

SAMPLE

MIN

to T

MAX

Maximum specifications apply as typical figures

when VDD = 1.6 V

0.7 × VDD V 1.6 V ≤ VDD < 2.7 V

INH

0.2 × VDD V 1.6 V ≤ VDD < 1.8 V

INL

±1 μA

− 0.2 V I

DD

= 200 μA, VDD = 1.6 V to 3.6 V

SOURCE

= 200 μA

SINK

, unless otherwise noted.

Rev. 0 | Page 3 of 12

AD7466-KGD Known Good Die

Parameter Min Typ Max Unit Test Conditions/Comments

CONVERSION RATE

Conversion Time 4.70 μs 16 SCLK cycles with SCLK at 3.4 MHz

Throughput Rate 200 kSPS

POWER REQUIREMENTS

VDD 1.6 3.6 V

IDD Digital inputs = 0 V or VDD

Normal Mode (Operational) 300 μA VDD = 3 V, f

110 μA VDD = 3 V, f

20 μA VDD = 3 V, f

240 μA VDD = 2.5 V, f

80 μA VDD = 2.5 V, f

16 μA VDD = 2.5 V, f

165 μA VDD = 1.8 V, f

50 μA VDD = 1.8 V, f

10 μA VDD = 1.8 V, f

Power-Down Mode 0.1 μA SCLK on or off, typically 8 nA

Power Dissipation

Normal Mode (Operational) 0.9 mW VDD = 3 V, f

0.6 mW VDD = 2.5 V, f

0.3 mW VDD = 1.8 V, f

Power-Down Mode 0.3 μW VDD = 3 V

= 100 kSPS

SAMPLE

= 50 kSPS

SAMPLE

= 10 kSPS

SAMPLE

SAMPLE

SAMPLE

SAMPLE

SAMPLE

SAMPLE

SAMPLE

= 100 kSPS

SAMPLE

SAMPLE

SAMPLE

= 100 kSPS

= 50 kSPS

= 10 kSPS

= 100 kSPS

= 50 kSPS

= 10 kSPS

= 100 kSPS

= 100 kSPS

Rev. 0 | Page 4 of 12

Known Good Die AD7466-KGD

TIMING SPECIFICATIONS

For all devices, VDD = 1.6 V to 3.6 V; TA = T

signals are specified with tr = tf = 5 ns (10% to 90% of V

Table 2.

Parameter Limit at T

f

3.4 MHz max Mark/space ratio for the SCLK input is 40/60 to 60/40.

SCLK

MIN

, T

Unit Description

MAX

10 kHz min 1.6 V ≤ VDD ≤ 3 V; minimum f

20 kHz min VDD = 3.3 V; minimum f

150 kHz min VDD = 3.6 V; minimum f

t

16 × t

CONVER T

SCLK

Acquisition Time

780 ns max VDD = 1.6 V.

640 ns max 1.8 V ≤ VDD ≤ 3.6 V.

t

10 ns min

QUIET

t1 10 ns min

t2 55 ns min

t3 55 ns max

t4 140 ns max

t5 0.4 t

t6 0.4 t

ns min SCLK low pulse width.

SCLK

ns min SCLK high pulse width.

SCLK

t7 10 ns min

t8 60 ns max

7 ns min SCLK falling edge to SDATA three-state.

MIN

to T

, unless otherwise noted. Sample tested at 25°C to ensure compliance. All input

MAX

) and timed from a voltage level of 1.4 V.

DD

at which specifications are guaranteed.

SCLK

at which specifications are guaranteed.

SCLK

at which specifications are guaranteed.

SCLK

Acquisition time/power-up time from power-down. The acquisition time is the

time required for the part to acquire a full-scale step input value within ±1 LSB or a

30 kHz ac input value within ±0.5 LSB.

Minimum quiet time required between bus relinquish and the start of the next

conversion.

Minimum CS

to SCLK setup time. If VDD = 1.6 V and f

CS

pulse width.

= 3.4 MHz, t2 has to be 192 ns

SCLK

minimum in order to meet the maximum figure for the acquisition time.

Delay from CS

in and defined as the time required for the output to cross the VIH or VIL

Figure 2

until SDATA is three-state disabled. Measured with the load circuit

voltage.

Data access time after SCLK falling edge. Measured with the load circuit in Figure 2

and defined as the time required for the output to cross the VIH or VIL voltage.

SCLK to data valid hold time. Measured with the load circuit in Figure 2 and

defined as the time required for the output to cross the V

SCLK falling edge to SDATA three-state. t

is derived from the measured time taken

8

or VIL voltage.

IH

by the data outputs to change 0.5 V when loaded with the circuit in Figure 2. The

measured number is then extrapolated back to remove the effects of charging or

discharging the 50 pF capacitor. This means that the time, t

, quoted in the timing

8

characteristics, is the true bus relinquish time of the part, and is independent of

the bus loading.

200µA I

TO OUTPUT

PIN

C

L

50pF

200µA I

Figure 2. Load Circuit for Digital Output Timing Specifications

Rev. 0 | Page 5 of 12

OL

1.4V

OH

10315-002

AD7466-KGD Known Good Die

TIMING EXAMPLES

Figure 3 shows some of the timing parameters from Tab l e 2 in

the Timing Specifications section.

Timing Example 1

As shown in Figure 3, f

100 kSPS gives a cycle time of t

Assuming V

= 1.8 V, t

DD

4.41 μs = 4.46 μs, and t

which satisfies the requirement of 10 ns for t

fully powered up and the signal is fully acquired at Point A.

This means that the acquisition/power-up time is t

= 55 ns + 588 ns = 643 ns, satisfying the maximum requirement

of 640 ns for the power-up time.

CS

SCLK

= 3.4 MHz and a throughput of

SCLK

+ t8 + t

CONVERT

= t2 + 15(1/f

CONVERT

= 60 ns maximum, then t

8

t

2

1

ACQUISIT ION TI M E

TRACK-AND-HOLD

IN TRACK

B A

23

QUIET

) = 55 ns +

SCLK

QUIET

= 10 μs.

= 5.48 μs,

QUIET

. The part is

+ 2(1/f

2

t

CONVERT

5

4

SCLK

)

TRACK-AND-HOL D IN HOLD

Timing Example 2

The AD7466-KGD can also operate with slower clock frequencies.

As shown in Figure 3, assuming V

throughput of 50 kSPS gives a cycle time of t

20 μs. With t

and t

= 60 ns maximum, this leaves t

8

CONVERT

= t2 + 15(1/f

satisfies the requirement of 10 ns for t

= 1.8 V, f

DD

) = 55 ns + 7.5 μs = 7.55 μs,

SCLK

QUIET

QUIET

= 2 MHz, and a

SCLK

+ t8 + t

CONVERT

to be 12.39 μs, which

. The part is fully

QUIET

powered up and the signal is fully acquired at Point A, which

means the acquisition/power-up time is t

+ 2(1/f

2

) = 55 ns +

SCLK

1 μs = 1.05 μs, satisfying the maximum requirement of 640 ns

for the power-up time. In this example and with other slower

clock values, the part is fully powered up and the signal already

acquired before the third SCLK falling edge; however, the trackand-hold does not go into hold mode until that point. In this

example, the part can be powered up and the signal can be fully

acquired at approximately Point B in Figure 3.

13

14

15

16

t

8

t

QUIET

AUTOMATIC

POWER-DOWN

=

1/THROUGHPUT

POINT A: THE PART I F FULLY POWERED UP WITH V

FULLY ACQUIRED.

IN

10315-003

Figure 3. AD7466-KGD Serial Interface Timing Diagram Example

Rev. 0 | Page 6 of 12

Known Good Die AD7466-KGD

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted. Transient currents of up to

100 mA do not cause SCR latch-up.

Table 3.

Parameter Rating

VDD to GND −0.3 V to +7 V

Analog Input Voltage to GND −0.3 V to VDD + 0.3 V

Digital Input Voltage to GND −0.3 V to +7 V

Digital Output Voltage to GND −0.3 V to VDD + 0.3 V

Input Current to any Pin Except Supplies ±10 mA

Operating Temperature Range −40°C to +85°C

Storage Temperature Range −65°C to +150°C

Junction Temperature 150°C

Lead Temperature, Soldering

Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

ESD 3.5 kV

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. 0 | Page 7 of 12

AD7466-KGD Known Good Die

PAD CONFIGURATION AND FUNCTION DESCRIPTIONS

6

1

2

5

4

3

Figure 4. Pad Configuration

Table 4. Pad Function Descriptions

Pad No. X-Axis (μm) Y-Axis (μm) Mnemonic Pad Type Description

1 −173 +634

2 −173 +494 SDATA Single

3 −187 −600 SCLK Single

4 +187 −600 VIN Single

5A +173 +447.6 GND Double

5B +173 +489.6 GND Double

6A +173 +637.6 VDD Double Power Supply Input. The VDD range for the devices is from 1.6 V to 3.6 V.

6B +173 +679.6 VDD Double Power Supply Input. The VDD range for the devices is from 1.6 V to 3.6 V.

CS

Single

Chip Select. Active low logic input. This input provides the dual function of

initiating conversions on the devices and frames the serial data transfer.

Data Out. Logic output. The conversion result from the AD7466-KGD is

provided on this output as a serial data stream. The bits are clocked out on

the falling edge of the SCLK input. The data stream from the AD7466-KGD

consists of four leading zeros followed by the 12 bits of conversion data,

provided MSB first.

Serial Clock. Logic input. SCLK provides the serial clock for accessing data

from the parts. This clock input is also used as the clock source for the

conversion process of the parts.

Analog Input. Single-ended analog input channel. The input range is 0 V

to V

DD

Analog Ground. Ground reference point for all circuitry on the devices.

All analog input signals should be referred to this GND voltage.

Analog Ground. Ground reference point for all circuitry on the devices.

All analog input signals should be referred to this GND voltage.

10315-004

.

Rev. 0 | Page 8 of 12

Known Good Die AD7466-KGD

OUTLINE DIMENSIONS

0.880

1

2

3

6

5

2.185

4

0.500

TOP VIEW

(CIRCUIT SI DE)

0.076 × 0.076

Figure 5. 6-Pad Bare Die [CHIP]

(C-6-4)

Dimensions shown in millimeters

SIDE VIEW

11-03-2011-A

DIE SPECIFICATIONS AND ASSEMBLY RECOMMENDATIONS

Table 5. Die Specifications

Parameter Value Unit

Chip Size 660 (x) × 2015 (y) μm

Scribe Line Width 120 (x) × 170 (y) μm

Die Size 880 (x) × 2185 (y) μm

Thickness 500 μm

Backside Silicon Not applicable

Passivation Nitride Not applicable

Bond Pads (Minimum Size) 76 × 76 μm

Bond Pad Composition 98.5% Al, 1% Si, 0.5% Cu %

ESD 3.5 kV

Table 6. Assembly Recommendations

Assembly Component Recommendation

Die Attach Epoxy adhesive

Bonding Method Gold ball or aluminum wedge

Bonding Sequence Five First

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD7466-KGD-DF −40°C to +85°C 6-Pad Bare Die [CHIP] C-6-4

Rev. 0 | Page 9 of 12

AD7466-KGD Known Good Die

NOTES

Rev. 0 | Page 10 of 12

Known Good Die AD7466-KGD

NOTES

Rev. 0 | Page 11 of 12

AD7466-KGD Known Good Die

NOTES

©2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D10315-0-11/11(0)

Rev. 0 | Page 12 of 12

Loading...

Loading...