Precision, 500 ns Settling

a

FEATURES

AC PERFORMANCE

500 ns Settling to 0.01% for 10 V Step

1.5 s Settling to 0.0025% for 10 V Step

75 V/s Slew Rate

0.0003% Total Harmonic Distortion (THD)

13 MHz Gain Bandwidth – Internal Compensation

>200 MHz Gain Bandwidth (G = 1000)

External Decompensation

>1000 pF Capacitive Load Drive Capability with

10 V/s Slew Rate – External Compensation

DC PERFORMANCE

0.5 mV max Offset Voltage (AD744B)

10 V/ⴗC max Drift (AD744B)

250 V/mV min Open-Loop Gain (AD744B)

Available in Plastic Mini-DIP, Plastic SOIC, Hermetic

Cerdip, Hermetic Metal Can Packages and Chip Form

Surface Mount (SOIC) Package Available in Tape and

Reel in Accordance with EIA-481A Standard

APPLICATIONS

Output Buffers for 12-Bit, 14-Bit and 16-Bit DACs,

ADC Buffers, Cable Drivers, Wideband

Preamplifiers and Active Filters

BiFET Op Amp

AD744

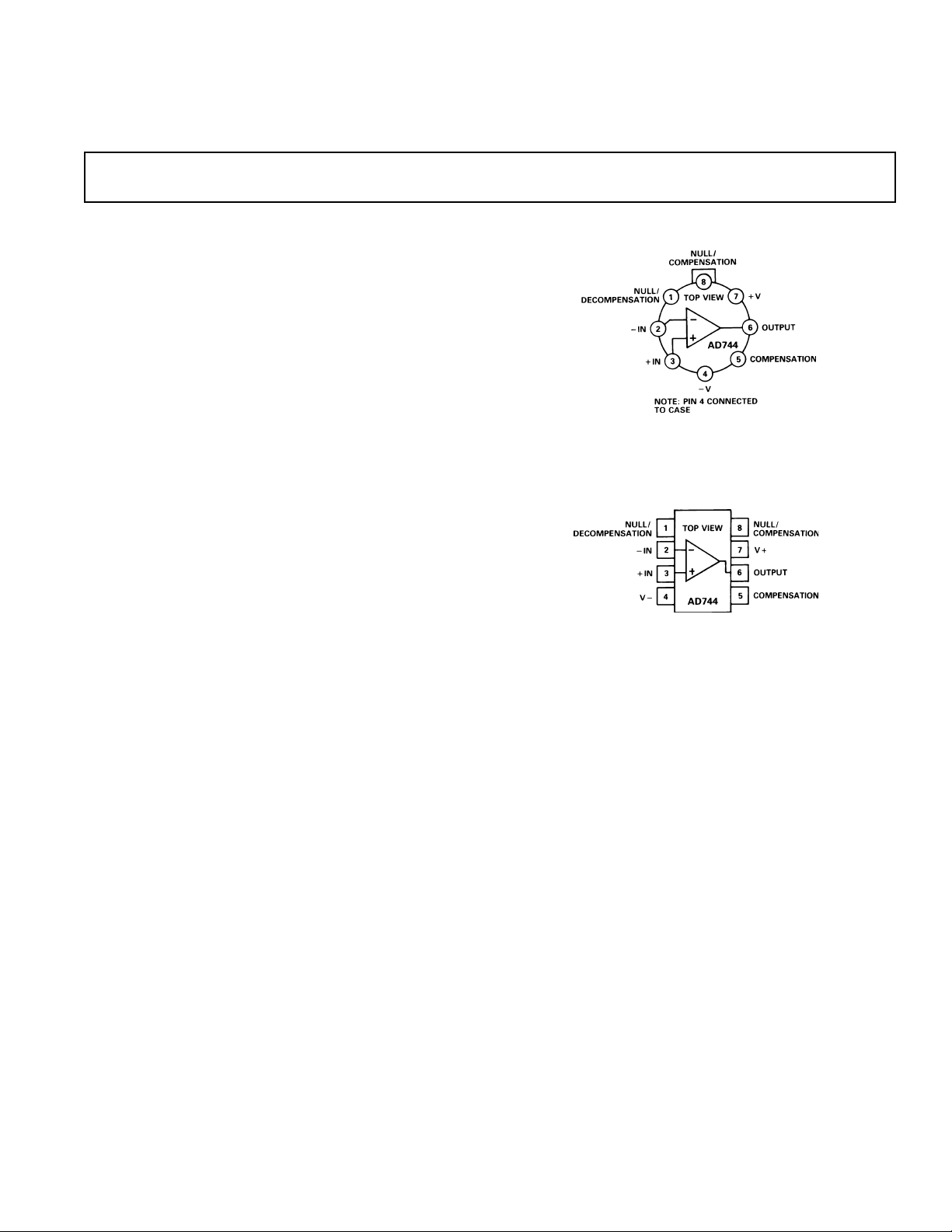

CONNECTION DIAGRAMS

TO-99 (H) Package

8-Lead Plastic Mini-DIP (N)

8-Lead SOIC (R) Package and

8-Lead Cerdip (Q) Packages

PRODUCT DESCRIPTION

The AD744 is a fast-settling, precision, FET input, monolithic

operational amplifier. It offers the excellent dc characteristics

of the AD711 BiFET family with enhanced settling, slew rate,

and bandwidth. The AD744 also offers the option of using

custom compensation to achieve exceptional capacitive load

drive capability.

The single-pole response of the AD744 provides fast settling:

500 ns to 0.01%. This feature, combined with its high dc precision, makes it suitable for use as a buffer amplifier for 12-bit,

14-bit or 16-bit DACs and ADCs. Furthermore, the AD744’s low

total harmonic distortion (THD) level of 0.0003% and gain bandwidth product of 13 MHz make it an ideal amplifier for demanding

audio applications. It is also an excellent choice for use in active

filters in 12-bit, 14-bit and 16-bit data acquisition systems.

The AD744 is internally compensated for stable operation as a

unity gain inverter or as a noninverting amplifier with a gain of

two or greater. External compensation may be applied to the

AD744 for stable operation as a unity gain follower. External

compensation also allows the AD744 to drive 1000 pF capacitive

loads, slewing at 10 V/µs with full stability.

Alternatively, external decompensation may be used to increase

the gain bandwidth of the AD744 to over 200 MHz at high

gains. This makes the AD744 ideal for use as ac preamps in

digital signal processing (DSP) front ends.

The AD744 is available in five performance grades. The AD744J

and AD744K are rated over the commercial temperature range

of 0°C to +70°C. The AD744A and AD744B are rated over

the industrial temperature range of –40°C to +85°C. The AD744T

is rated over the military temperature range of –55°C to +125°C

and is available processed to MIL-STD-883B, Rev. C.

The AD744 is available in an 8-lead plastic mini-DIP, 8-lead

small outline, 8-lead cerdip or TO-99 metal can.

PRODUCT HIGHLIGHTS

1. The AD744 is a high-speed BiFET op amp that offers excellent performance at competitive prices. It outperforms the

OPA602/OPA606, LF356 and LF400.

2. The AD744 offers exceptional dynamic response. It settles to

0.01% in 500 ns and has a 100% tested minimum slew rate

of 50 V/µs (AD744B).

3. The combination of Analog Devices’ advanced processing

technology, laser wafer drift trimming and well-matched

ionimplanted JFETs provide outstanding dc precision. Input

offset voltage, input bias current, and input offset current are

specified in the warmed-up condition; all are 100% tested.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

AD744–SPECIFICATIONS

(@ +25ⴗC and ⴞ15 V dc, unless otherwise noted)

Model Conditions Min Typ Max Min Typ Max Unit

AD744J/A/S AD744K/B/T

INPUT OFFSET VOLTAGE

1

Initial Offset 0.3 1.0 0.25 0.5 mV

Offset T

vs. Temp. 5 20 5 10 µV/°C

vs. Supply

2

vs. Supply T

Long-Term Stability 15 15 µV/month

INPUT BIAS CURRENT

3

MIN

MIN

to T

to T

MAX

MAX

2 1.0 mV

82 95 88 100 dB

82 88 dB

Either Input VCM = 0 V 30 100 30 100 pA

Either Input @ T

J, K 70°C 0.7 2.3 0.7 2.3 nA

=V

MAX

CM

= 0 V

A, B, C 85°C 1.9 6.4 1.9 6.4 nA

S, T 125°C 31 102 31 102 nA

Either Input VCM = +10 V 40 150 40 150 pA

Offset Current VCM = 0 V 20 50 10 50 pA

Offset Current @ T

J, K 70°C 0.4 1.1 0.2 1.1 nA

=V

MAX

CM

= 0 V

A, B, C 85°C 1.3 3.2 0.6 3.2 nA

S, T 125°C20521052nA

FREQUENCY RESPONSE

Gain BW, Small Signal G = –1 8 13 9 13 MHz

Full Power Response V

Slew Rate, Unity Gain G = –1 45 75 50 75 V/µs

Settling Time to 0.01%

4

= 20 V p-p 1.2 1.2 MHz

O

G = –1 0.5 0.75 0.5 0.75 µs

Total Harmonic f = 1 kHz

Distortion R1 ≥ 2 kΩ

VO = 3 V rms 0.0003 0.0003 %

INPUT IMPEDANCE

Differential 3 ⫻ 1012||5.5 3 ⫻ 1012||5.5 Ω||pF

Common Mode 3 ⫻ 1012||5.5 3 ⫻ 1012||5.5 Ω||pF

INPUT VOLTAGE RANGE

Differential

Common-Mode Voltage +14.5, –11.5 +14.5, –11.5 V

Over Max Operating Range

5

6

–11 +13 –11 +13 V

±20 ±20 V

Common-Mode

Rejection Ratio VCM = ±10 V 78 88 82 88 dB

T

to T

MIN

MIN

to T

MAX

MAX

VCM = ±11 V 72 84 78 84 dB

T

76 84 80 84 dB

70 80 74 80 dB

INPUT VOLTAGE NOISE 0.1 to 10 Hz 2 2 µV p-p

f = 10 Hz 45 45 nV/√Hz

f = 100 Hz 22 22 nV/√Hz

f = 1 kHz 18 18 nV/√Hz

f = 10 kHz 16 16 nV/√Hz

INPUT CURRENT NOISE f = 1 kHz 0.01 0.01 pA/√Hz

OPEN LOOP GAIN

7

VO = ±10 V

R

≥ 2 kΩ 200 400 250 400 V/mV

LOAD

T

MIN

to T

MAX

100 100 V/mV

OUTPUT CHARACTERISTICS

Voltage R

Current Short Circuit 25 25 mA

Capacitive Load

8

≥ 2 kΩ +13, –12.5 +13.9, –13.3 +13, –12.5 +13.9, –13.3 V

LOAD

T

MIN

to T

MAX

±12 +13.8, –13.1 ± 12 +13.8, –13.1 V

Gain = –1 1000 1000 pF

POWER SUPPLY

Rated Performance ±15 ±15 V

Operating Range ± 4.5 ± 18 ±4.5 ±18 V

Quiescent Current 3.5 5.0 3.5 4.0 mA

NOTES

1

Input offset voltage specifications are guaranteed after 5 minutes of operation at TA = +25°C.

2

PSRR test conditions: +VS = 15 V, –VS = –12 V to –18 V and +VS = +12 V to +18 V, –VS = –15 V.

3

Bias Current Specifications are guaranteed maximum at either input after 5 minutes of operation at TA = +25°C. For higher temperature, the current doubles every 10°C.

4

Gain = –1, RL = 2 k, CL = 10 pF, refer to Figure 25.

5

Defined as voltage between inputs, such that neither exceeds ±10 V from ground.

6

Typically exceeding –14.1 V negative common-mode voltage on either input results in an output phase reversal.

7

Open-Loop Gain is specified with VOS both nulled and unnulled.

8

Capacitive load drive specified for C

Refer to Table II for optimum compensation while driving a capacitive load.

Specifications subject to change without notice. All min and max specifications are guaranteed.

= 20 pF with the device connected as shown in Figure 32. Under these conditions, slew rate = 14 V/µs and 0.01% settling time = 1.5 µs typical.

COMP

–2–

REV.C

AD744

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Internal Power Dissipation

Input Voltage

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

2

. . . . . . . . . . . . . . . . . . . . 500 mW

1

Output Short Circuit Duration . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . . . +V

and –V

S

S

Storage Temperature Range (Q, H) . . . . . . –65°C to +150°C

Storage Temperature Range (N, R) . . . . . . . –65°C to +125°C

Operating Temperature Range

AD744J/K . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

AD744A/B . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

AD744S/T . . . . . . . . . . . . . . . . . . . . . . . . –55°C to +125°C

Lead Temperature Range (Soldering 60 seconds) . . . . . 300°C

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Thermal Characteristics

8-Lead Plastic Package: θJA = 100°C/Watt, θJC = 33°C/Watt

8-Lead Cerdip Package: θJA = 110°C/Watt, θJC = 22°C/Watt

8-Lead Metal Can Package: θJA = 150°C/Watt, θJC = 65°C/Watt

8-Lead SOIC Package: θJA = 160°C/Watt, θJC = 42°C/Watt

3

For supply voltages less than ± 18 V, the absolute maximum input voltage is equal

to the supply voltage.

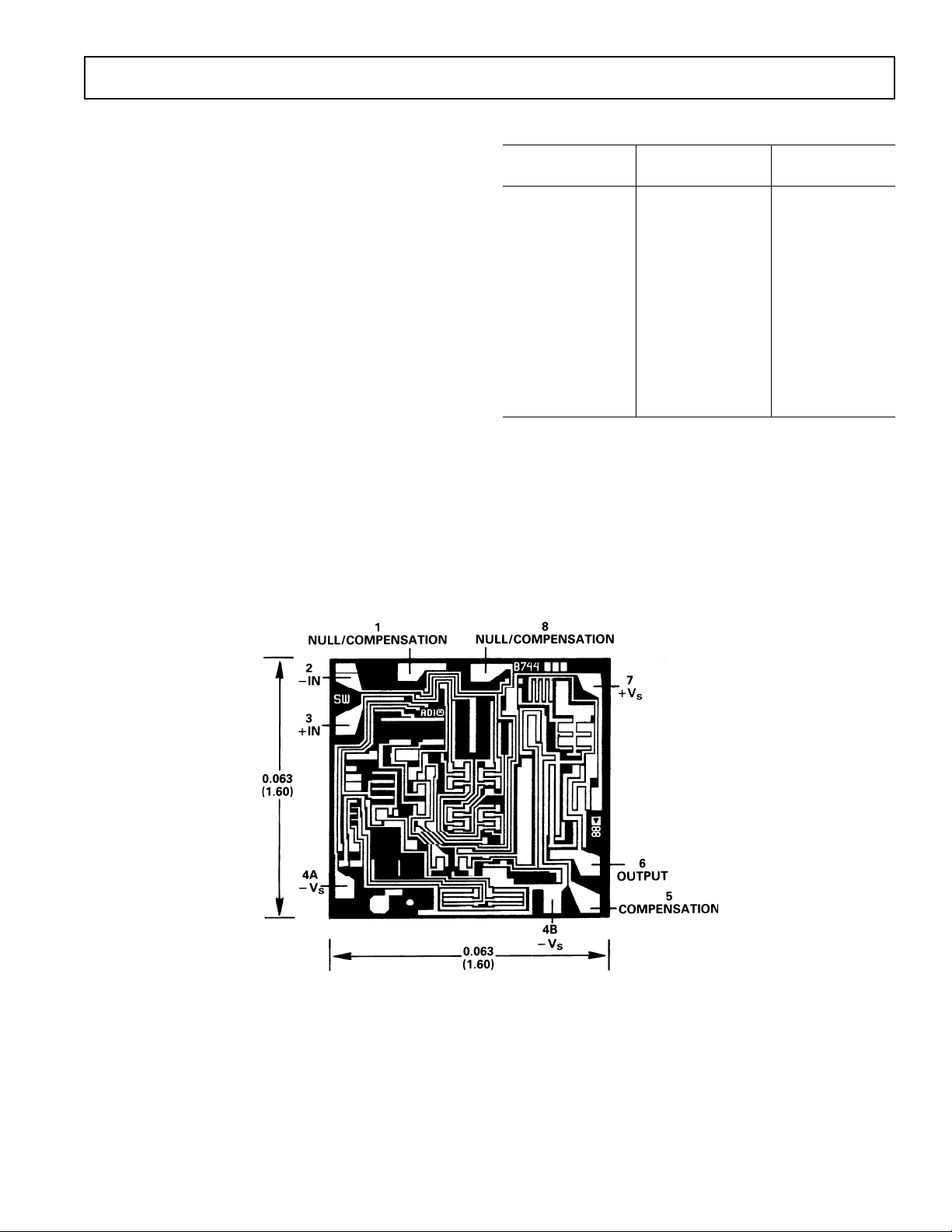

METALIZATION PHOTOGRAPH

Contact factory for latest dimensions.

Dimensions shown in inches and (mm).

ORDERING GUIDE

Temperature Package

Model Range Option*

AD744JN 0°C to +70°C N-8

AD744KN 0°C to +70°C N-8

AD744JR 0°C to +70°C SO-8

AD744KR 0°C to +70°C SO-8

AD744AQ –40°C to +85°C Q-8

AD744BQ –40°C to +85°C Q-8

AD744AH –40°C to +85°C H-08A

AD744JCHIPS 0°C to +70°CDie

AD744JR-REEL 0°C to +70°C Tape/Reel 13"

AD744JR-REEL 7 0°C to +70°C Tape/Reel 7"

AD744KR-REEL 0°C to +70°C Tape/Reel 13"

AD744KR-REEL 7 0°C to +70°C Tape/Reel 7"

AD744TA/883B –55°C to +125°C H-08

*N = Plastic DIP; SO = Small Outline IC; Q = Cerdip; H = TO-99 Metal Can.

REV. C

–3–

AD744

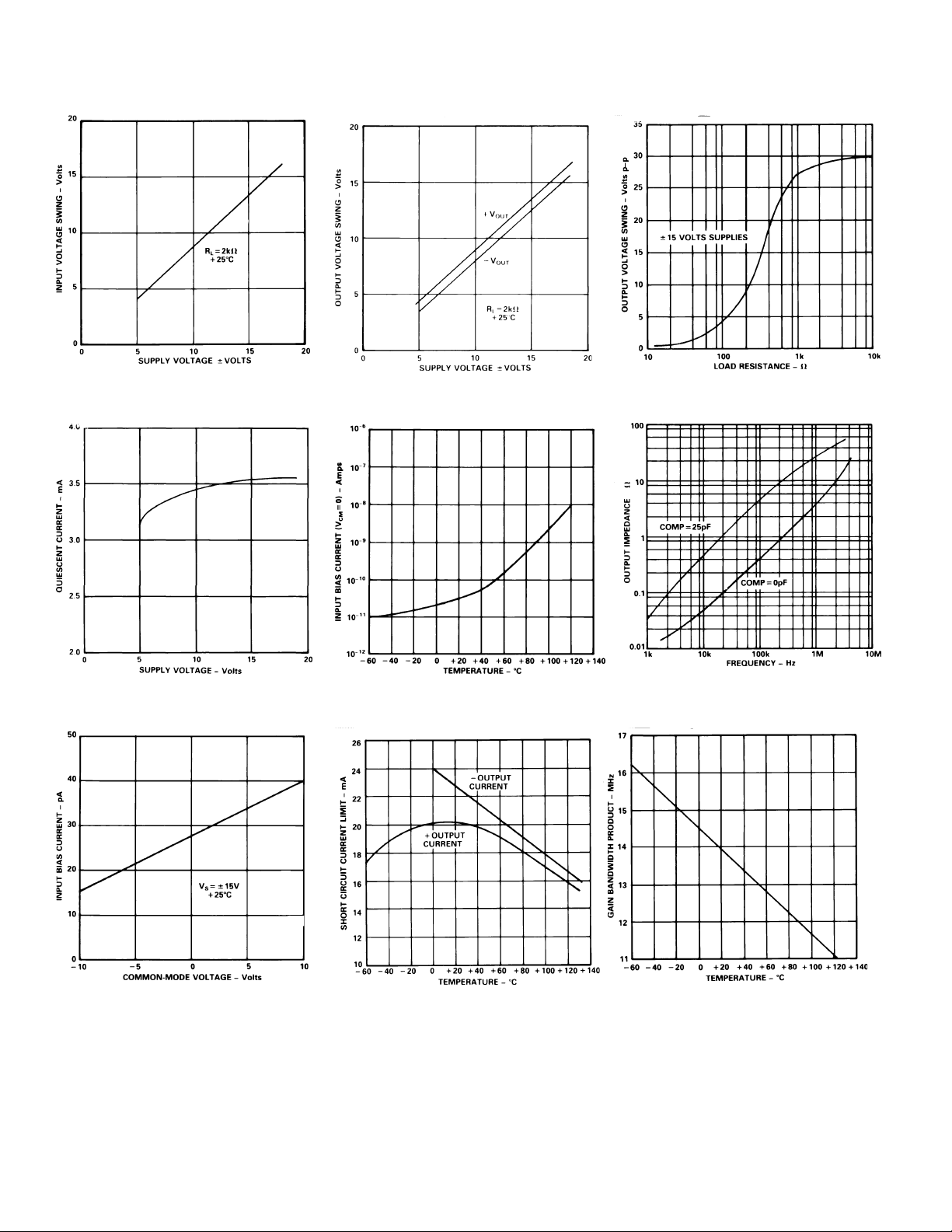

–Typical Characteristics

Figure 1. Input Voltage Swing

vs. Supply Voltage

Figure 4. Quiescent Current vs.

Supply Voltage

Figure 2. Output Voltage Swing

vs. Supply Voltage

Figure 5. Input Bias Current vs.

Temperature

Figure 3. Output Voltage Swing vs.

Load Resistance

Figure 6. Output Impedance vs.

Frequency

Figure 7. Input Bias Current vs.

Common-Mode Voltage

Figure 8. Short Circuit Current

Limit vs. Temperature

–4–

Figure 9. Gain Bandwidth

Product vs. Temperature

REV. C

AD744

Figure 10. Open-Loop Gain and

Phase Margin vs. Frequency

= 0 pF

C

COMP

Figure 13. Common-Mode and

Power Supply Rejection vs.

Frequency

Figure 11. Open Loop Gain and

Phase Margin vs. Frequency

C

= 25 pF

COMP

Figure 14. Large Signal Frequency

Response

Figure 12. Open-Loop Gain vs.

Supply Voltage

Figure 15. Output Swing and Error

vs. Settling Time

Figure 16. Total Harmonic Distortion

vs. Frequency, Circuit of Figure 20

(G = 10)

REV. C

Figure 17. Input Noise Voltage

Spectral Density

–5–

Figure 18. Slew Rate vs. Input

Error Signal

AD744

–Typical Characteristics

Figure 19. Settling Time vs. Closed

Loop Voltage Gain

Figure 22a. Unity-Gain Follower

Figure 20. THD Test Circuit

Figure 22b. Unity-Gain Follower

Large Signal Pulse Response,

C

= 5 pF

COMP

Figure 21. Offset Null Configuration

Figure 22c. Unity-Gain Follower

Small Signal Pulse Response,

C

= 5 pF

COMP

Figure 23a. Unity-Gain Inverter

Figure 23b. Unity-Gain Inverter Large

Signal Pulse Response, C

COMP

= 5 pF

–6–

Figure 23c. Unity-Gain Inverter Small

Signal Pulse Response, C

COMP

= 0 pF

REV. C

AD744

POWER SUPPLY BYPASSING

The power supply connections to the AD744 must maintain a

low impedance to ground over a bandwidth of 10 MHz or more.

This is especially important when driving a significant resistive

or capacitive load, since all current delivered to the load comes

from the power supplies. Multiple high quality bypass capacitors

are recommended for each power supply line in any critical

application. A 0.1 µF ceramic and a 1 µF electrolytic capacitor

as shown in Figure 24 placed as close as possible to the amplifier (with short lead lengths to power supply common) will

assure adequate high frequency bypassing, in most applications. A minimum bypass capacitance of 0.1 µF should be used

for any application.

+V

S

1F

0.1F

AD744

1F

–V

S

0.1F

Figure 24. Recommended Power Supply Bypassing

MEASURING AD744 SETTLING TIME

The photos of Figures 26 and 27 show the dynamic response of

the AD744 while operating in the settling time test circuit of

Figure 25. The input of the settling time fixture is driven by a

flat-top pulse generator. The error signal output from the false

summing node of A1, the AD744 under test, is clamped, amplified by op amp A2 and then clamped again.

The error signal is thus clamped twice: once to prevent overloading

amplifier A2 and then a second time to avoid overloading the

oscilloscope preamp. A Tektronix oscilloscope preamp type

7A26 was carefully chosen because it recovers from the

approximately 0.4 V overload quickly enough to allow accurate

measurement of the AD744’s 500 ns settling time. Amplifier A2

is a very high-speed FET-input op amp; it provides a voltage

gain of 10, amplifying the error signal output of the AD744

under test.

Figure 26. Settling Characteristics 0 to +10 V Step

Upper Trace: Output of AD744 Under Test (5 V/div.)

Lower Trace: Amplified Error Voltage (0.01%/div.)

+15V

COM

–15V

2X

HP2835

FLAT-TOP

PULSE

GENERATOR

DATA

DYNAMICS

5109

OR

EQUIVALENT

TO

+V

S

–V

S

A2

AD3554

0.47F

1.1k⍀

–V

S

4.99k⍀

V

10k⍀

IN

1F

0.1F

NOTE: USE CIRCUIT BOARD WITH GROUND PLANE

TEKTRONIX

7A26

OSCILLOSCOPE

PREAMP

INPUT SECTION

5pF

(VIA LESS THAN 1 FT 50⍀

COAXIAL CABLE)

0.47F

+V

S

10k⍀

0.2pF – 0.8pF

NULL

200⍀

5pF – 18pF

AD744

A1

+V

–V

S

206⍀

4.99k⍀

10k⍀

S

5k⍀

1F

1M⍀ 20pF

V

ERROR

2X

HP2835

0.1F

Figure 25. Settling Time Test Circuit

ⴛ 10

Figure 27. Settling Characteristics 0 to –10 V Step

Upper Trace: Output of AD744 Under Test (5 V/div.)

Lower Trace: Amplified Error Voltage (0.01%/div.)

10pF

REV. C

–7–

AD744

EXTERNAL FREQUENCY COMPENSATION

Even though the AD744 is useable without compensation in

most applications, it may be externally compensated for even

more flexibility. This is accomplished by connecting a capacitor

between Pins 5 and 8. Figure 28, a simplified schematic of the

AD744, shows where this capacitor is connected. This feature is

useful because it allows the AD744 to be used as a unity gain

voltage follower. It also enables the amplifier to drive capacitive

loads up to 2000 pF and greater.

+V

S

OUTPUT

COMPENSATION

–V

S

–IN

COMPENSATION

DECOMPENSATION

NULL /

NULL /

300⍀

300⍀

1k⍀1k⍀ 8k⍀

+IN

2mA400A

5pF

Figure 28. AD744 Simplified Schematic

The slew rate and gain bandwidth product of the AD744 are inversely proportional to the value of the compensation capacitor,

. Therefore, when trying to maximize the speed of the

C

COMP

amplifier, the value of C

should be minimized. C

COMP

COMP

can

also be used to slow the amplifier to a point where the slew rate

is perfectly symmetrical and well controlled. Figure 29 summarizes the effect of external compensation on slew rate and

bandwidth.

0.2

GAIN BANDWIDTH – MHz

20

2

100

10

1.0

SLEW RATE – V/s

The following section provides tables to show what C

COMP

values

will provide the necessary compensation for given circuit configurations

and capacitive loads. In each case, the recommended C

minimum value. A larger C

can always be used, but slew rate

COMP

COMP

is a

and bandwidth performance will be degraded.

Figure 30 shows the AD744 configured as a unity gain voltage

follower. In this case, a minimum compensation capacitor of

5 pF is necessary for stable operation. Larger compensation capacitors can be used for driving larger capacitive loads. Table I

outlines recommended minimum values for C

COMP

based on

the desired capacitive load. It also gives the slew rate and bandwidth that will be achieved for each case.

+V

S

1F 0.1F

AD744

V

IN

–V

S

C

COMP

1F 0.1F

5pF

V

OUT

Figure 30. AD744 Connected as a Unity Gain

Voltage Follower

Table I. Recommended Values of C

COMP

vs.

Various Capacitive Loads

Max –3 dB

C

LOAD

C

COMP

Slew Rate Bandwidth

Gain (pF) (pF) (V/s) (MHz)

1 50 5 37 6.5

1 150 10 25 4.3

1 2000 25 12.5 2.0

Figures 31 and 32 show the AD744 as a voltage follower

with gain and as an inverting amplifier. In these cases, external

compensation is not necessary for stable operation. However, compensation may be applied to drive capacitive loads

above 50 pF. Table II gives recommended C

values, along

COMP

with expected slew rates and bandwidths for a variety of load

conditions and gains for the circuits in Figures 31 and 32.

0.02

0

10 100 1000

C

– pF

COMP

Figure 29. Gain Bandwidth and Slew Rate vs. C

0.1

COMP

C

*

LEAD

R1*

R2*

+V

S

1F

0.1F

AD744

1F

C

COMP

OPTIONAL

0.1F

V

IN

*SEE TABLE II

–V

S

Figure 31. AD744 Connected as a Voltage Follower

Operating at Gains of 2 or Greater

–8–

V

OUT

REV. C

AD744

Table II. Recommended Values of C

vs. Various Load Conditions for the Circuits of

COMP

Figures 31 and 32.

Max Slew –3 dB

R1 R2 Gain Gain C

LOAD

(⍀)(⍀) Follower Inverter (pF) (pF) (pF) (V/s) (MHz)

4.99 k 4.99 k 2 1 50 0 7 75 2.5

4.99 k 4.99 k 2 1 150 5 7 37 2.3

4.99 k 4.99 k 2 1 1000 20 – 14 1.2

4.99 k 4.99 k 2 1 >2000 25 – 12.5

499 Ω 4.99 k 11 10 270 0 – 75 1.2

499 Ω 4.99 k 11 10 390 2 – 50 0.85

499 Ω 4.99 k 11 10 1000 5 – 37

NOTES

1

Bandwidth with C

2

Into large capacitive loads the AD744’s 25 mA output current limit sets the slew rate of the amplifier, in V/ µs, equal to 0.025

amps divided by the value of C

specified with a 50 pF. load.

C

LEAD

R1*

V

IN

AD744

*SEE TABLE II

–V

S

adjusted for minimum settling time.

LEAD

in µF. Slew rate is specified into rated max C

LOAD

*

R2*

+V

S

1F

C

1F

COMP

0.1F

OPTIONAL

0.1F

V

OUT

Figure 32. AD744 Connected as an Inverting Amplifier

Operating at Gains of 1 or Greater

Using Decompensation to Extend the Gain Bandwidth

Product

When the AD744 is used in applications where the closed-loop

gain is greater than 10, gain bandwidth product may be enhanced

by connecting a small capacitor between Pins 1 and 5 (Figure

33). At low frequencies, this capacitor cancels the effects of the

chip’s internal compensation capacitor, C

, effectively dec-

COMP

ompensating the amplifier.

C

COMPCLEAD

except for cases marked 2, which are

LOAD

Rate Bandwidth

1

1

2

2

1.0

0.60

Due to manufacturing variations in the value of the internal

, it is recommended that the amplifier’s response be

C

COMP

optimized for the desired gain by using a 2 to 10 pF trimmer

capacitor rather than using a fixed value.

R1*

AD744

V

IN

\

–V

S

R2*

+V

S

1F

2 – 10pF

1F

0.1F

NOT CONNECTED

*SEE TABLE III

0.1F

V

OUT

Figure 33. Using the Decompensation Connection to

Extend Gain Bandwidth

Table III. Performance Summary for the Circuit of Figure 33

R1 R2 Gain Gain –3 dB Gain/BW

(⍀)(⍀) Follower Inverter Bandwidth Product

1 k 10 k 11 10 2.5 MHz 25 MHz

100 10 k 101 100 760 kHz 76 MHz

100 100 k 1001 1000 225 kHz 225 MHz

REV. C

–9–

AD744

GAIN

ADJUST

100⍀

REF

REF

GND

BIPOLAR

OFFSET

0.1F

V

10V

20k⍀

CC

AD565A

REF

OUT

19.95k⍀

IN

100⍀

9.96k⍀

ADJUST

5k⍀

5k⍀

8k⍀

20V SPAN

10V SPAN

DAC OUT

C

10pF

LEAD

+15V

AD744

1F

1F

0.1F

POWER

GND

–V

EE

MSB

LSB

Figure 34.±10 V Voltage Output Bipolar DAC Using the AD744 as an Output Buffer

HIGH-SPEED OP AMP APPLICATIONS AND TECHNIQUES

DAC Buffers (I-to-V Converters)

Digital-to-analog converters which use bipolar transistors to

switch currents into (or out of) their outputs can achieve very

fast settling times. The AD565A, for example, is specified to

settle to 12 bits in less than 250 ns, with a current output. However, in many applications, a voltage output is desirable, and it

would be useful – perhaps essential – that this I-to-V conversion

be accomplished without increasing the settling time or without

degrading the accuracy of the DAC.

Figure 34 is a schematic of an AD565A DAC using an AD744

output buffer. The 10 pF C

capacitor compensates for the

LEAD

DAC’s output capacitance, plus the 5.5 pF amplifier input

capacitance.

Figure 35 is an oscilloscope photo of the AD744’s output voltage with a +10 V to 0 V step applied; this corresponds to an all

“1s” to all “0s” code change on the DAC. Since the DAC is

–15V

A HIGH-SPEED, 3 OP AMP INSTRUMENTATION AMPLIFIER CIRCUIT

The instrumentation amplifier circuit shown in Figure 36 can

provide a range of gains from unity up to 1000 and higher. The

circuit bandwidth is 4 MHz at a gain of 1 and 750 kHz at a gain

of 10; settling time for the entire circuit is less than 2 µs

to within 0.01% for a 10 V step, (G = 10).

While the AD744 is not stable with 100% negative feedback (as

when connected as a standard voltage follower), phase margin

and therefore stability at unity gain may be increased to an acceptable level by placing the parallel combination of a resistor and a

small lead capacitor between each amplifier’s output and its

inverting input terminal.

The only penalty associated with this method is a small bandwidth reduction at low gains. The optimum value for C

LEAD

may be determined from the graph of Figure 41. This technique

can be used in the circuit of Figure 36 to achieve stable operation at gains from unity to over 1000.

20,000

R

G

*1.5pF – 20pF

(TRIM FOR BEST SETTLING TIME)

**10k⍀

**10k⍀

**10k⍀

5pF

A3

AD744

**10k⍀

SENSE

–IN

CIRCUIT GAIN = + 1

AD744

A1

7.5pF

7.5pF

R

G

10k⍀

10k⍀

Figure 35. Upper Trace: AD744 Output Voltage for

a +10 V to 0 V Step, Scale: 5 mV/div.

Lower Trace: Logic Input Signal, Scale: 5 V/div.

connected in the 20 V span mode, 1 LSB is equal to 4.88 mV.

Output settling time for the AD565/AD744 combination is less

than 500 ns to within a 2.44 mV, 1/2 LSB error band.

–10–

+IN

A2

AD744

*VOLTRONICS SP20 TRIMMER CAPACITOR OR EQUIVALENT

**RATIO MATCHED 1% METAL FILM RESISTORS

+15V

COMM

–15V

FOR OPTIONAL OFFSET ADJUSTMENT:

TRIM A1, A3 USING TRIM PROCEDURE SHOWN IN FIGURE 21.

1F

1F

+V

S

–V

S

1F

1F

0.1F

0.1F

Figure 36. A High Performance, 3 Op Amp

Instrumentation Amplifier Circuit

REFERENCE

PIN 7

EACH

AMPLIFIER

PIN 4

REV. C

AD744

Table IV. Performance Summary for the 3 Op Amp

Instrumentation Amplifier Circuit

Gain RG Bandwidth T Settle (0.01%)

1 NC 3.5 MHz 1.5 µs

2 20 kΩ 2.5 MHz 1.0 µs

10 2.22 kΩ 1 MHz 2 µs

100 202 Ω 290 kHz 5 µs

Figure 37. The Pulse Response of the 3 Op Amp

Instrumentation Amplifier. Gain = 1, l Horizontal Scale:

0.5 µV/div., Vertical Scale: 5 V/div. (Gain= 10)

Equation 1 would completely describe the output of the system

if not for the op amp’s finite slew rate and other nonlinear

effects. Even considering these effects, the fine scale settling to

<0.1% will be determined by the op amp’s small signal behavior. Equation 1.

V

O

=

I

RC

+ C

()

IN

L

2πF

O

–R

s2+

G

2πF

N

O

X

+ RC

s +1

L

Where FO = the op amp’s unity gain crossover frequency

GN= the “noise” gain of the circuit 1 +

R

R

O

This Equation May Then Be Solved for CL:

Equation 2.

CL=

2 − G

R 2πF

2 RC

N

+

O

2πFO+ 1− G

X

R 2πF

O

()

N

In these equations, capacitance CX is the total capacitance appearing at the inverting terminal of the op amp. When modeling an

I-to-V converter application, the Norton equivalent circuit of

Figure 39 can be used directly. Capacitance C

is the total capaci-

X

tance of the output of the current source plus the input capacitance

of the op amp, which includes any stray capacitance at the op

amp’s input.

Figure 38. Settling Time of the 3 Op Amp Instrumentation

Amplifier. Horizontal Scale: 500 ns/div., Vertical Scale,

Pulse Input: 5 V/div., Output Settling: 1 mV/div.

Minimizing Settling Time in Real-World Applications

An amplifier with a “single pole” or “ideal” integrator open-loop

frequency response will achieve the minimum possible settling

time for any given unity-gain bandwidth. However, when this

“ideal” amplifier is used in a practical circuit, the actual settling

time is increased above the minimum value because of added

time constants which are introduced due to additional capacitance

on the amplifier’s summing junction. The following discussion

will explain how to minimize this increase in settling time by the

selection of the proper value for feedback capacitor, C

.

L

If an op amp is modeled as an ideal integrator with a unity gain

crossover frequency, f

, Equation 1 will accurately describe the

O

small signal behavior of the circuit of Figure 39. This circuit

models an op amp connected as an I-to-V converter.

C

(OPTIONAL)

COMP

AD744

R

R

I

O

C

O

X

C

L

R

L

C

LOAD

V

OUT

Figure 39. A Simplified Model of the AD744 Used as a

Current-to-Voltage Converter

When RO and IO are replaced with their Thevenin VIN and R

IN

equivalents, the general purpose inverting amplifier model of

Figure 40 is created. Here capacitor C

represents the input

X

capacitance of the AD744 (5.5 pF) plus any stray capacitance

due to wiring and the type of IC package employed.

C

(OPTIONAL)

COMP

AD744

R

IN

V

IN

C

R

X

C

L

R

L

C

LOAD

V

OUT

Figure 40. A Simplified Model of the AD744 Used

as an Inverting Amplifier

REV. C

–11–

AD744

In either case, the capacitance CX causes the system to go from

a one-pole to a two-pole response; this additional pole increases

settling time by introducing peaking or ringing in the op amp’s

output. If the value of C

can be estimated with reasonable accu-

X

racy, Equation 2 can be used to choose the correct value for

a small capacitor, C

the value of C

As an aid to the designer, the optimum value of C

, which will optimize amplifier response. If

L

is not known, CL should be a variable capacitor.

X

for one spe-

L

cific amplifier connection can be determined from the graph of

Figure 41. This graph has been produced for the case where the

AD744 is connected as in Figures 39 and 40 with a practical

minimum value for C

The approximate value of C

of 2 pF and a total CX value of 7.5 pF.

STRAY

can be determined for almost any

L

application by solving Equation 2. For example, the AD565/

AD744 circuit of Figure 34 constrains all the variables of Equation 2 (G

Therefore, under these conditions, C

= 3.25, R = 10 kΩ, FO = 13 MHz, and CX = 32.5 pF)

N

= 10.5 pF.

L

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

TO-99 (H) Package

35

30

– pF

25

LEAD

20

15

10

IN THIS REGION

VALUE OF CAPACITOR C

C

5

GN = 1 TO

0

100

LEAD

= 0pF

GN = 1

GN = 1.5

GN = 2

GN = 3

1k 10k 100k

VALUE OF RESISTOR – ⍀

Figure 41. Practical Values of CL vs. Resistance of R

for Various Amplifier Noise Gains

Cerdip (Q) Package

C00833a-0-7/00 (rev. C)

0.370 (9.40)

0.335 (8.50)

0.335 (8.50)

0.305 (7.75)

0.165 ⴞ 0.01

(4.19 ⴞ 0.25)

0.125 (3.18)

0.185 (4.70)

0.165 (4.19)

0.04 (1.0) MAX

INSULATION

0.05 (1.27) MAX

0.39 (9.91)

8

0.31

(7.87)

14

PIN 1

0.10 (2.54)

MIN

0.018 ⴞ 0.003

(0.46 ⴞ 0.08)

REFERENCE PLANE

0.5 (12.70)

MIN

EQUALLY

SPACED

8 LEADS

0.019 (0.48)

0.016 (0.41)

SEATING PLANE

DIA

0.034 (0.86)

0.028 (0.71)

Mini-DIP (N) Package

MAX

5

0.25

(6.35)

TYP

0.033

(0.84)

NOM

0.035 ⴞ 0.01

(0.89 ⴞ 0.25)

0.18 ⴞ 0.03

(4.57 ⴞ 0.76)

SEATING

PLANE

0-15ⴗ

45°

0.30 (7.62)

0.2 (5.1) TYP

3

2

1

8

7

0.045 (1.1)

0.020 (0.51)

BOTTOM VIEW

REF

0.011 ⴞ 0.003

(0.28 ⴞ 0.08)

0.005 (0.13)

4

5

6

PIN 1

0.20 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.023 (0.58)

0.014 (0.36)

0.055 (1.35)

MIN

0.1 (2.54) BSC

0.405 (10.29) MAX

MAX

85

1

4

0.07 (1.78)

0.03 (0.76)

0.310 (7.87)

0.220 (5.59)

0.06 (1.52)

0.015 (0.38)

0.15

(3.81)

MIN

SEATING

PLANE

15°

0°

0.32 (8.13)

0.29 (7.37)

0.015 (0.38)

0.008 (0.20)

Small Outline (SO-8) Package

0.193 ⴞ 0.008

(4.90 ⴞ 0.10)

PIN 1

PLANE

85

0.050 (1.27)

41

BSC

0.017 ⴞ 0.003

(0.42 ⴞ 0.07)

0.236 ⴞ 0.012

(6.00 ⴞ 0.20)

0.098 ⴞ 0.006

(2.49 ⴞ 0.23)

0.011 ⴞ 0.002

(0.269 ⴞ 0.03)

0.033 ⴞ 0.017

(0.83 ⴞ 0.43)

PRINTED IN U.S.A.

0.154 ⴞ 0.004

(3.91 ⴞ 0.10)

0.008 ⴞ 0.004

(0.203 ⴞ 0.075)

SEATING

–12–

REV.C

Loading...

Loading...