12-Bit Monitor and Control System with Multichannel

ADC, DACs, Temperature Sensor, and Current Sense

FEATURES

12-bit SAR ADC with 3 μs conversion time

4 uncommitted analog inputs

Differential/single-ended

V

, 2 × V

REF

2 high-side current sense inputs

5 V to 59.4 V operating range

0.5% max gain error

±200 mV input range

2 external diode temperature sensor inputs

−55°C to +150°C measurement range

±2°C accuracy

Series resistance cancellation

1 internal temperature sensor

±2°C accuracy

Built-in monitoring features

Minimum/maximum recorder for each channel

Programmable alert thresholds

Programmable hysteresis

Four 12-bit monotonic 15 V DACs

5 V span, 0 V to 10 V offset

8 μs settling time

10 mA sink and source capability

Power-on resets (POR) to 0 V

Internal 2.5 V reference

2-wire fast mode I

Temperature range: −40°C to +105°C

Package type: 64-lead TQFP

input ranges

REF

2

C interface

AD7294

APPLICATIONS

Cellular base stations

GSM, EDGE, UMTS, CDMA, TD-SCDMA, W-CDMA, WiMAX

Point-to-multipoint and other RF transmission systems

12 V, 24 V, 48 V automotive applications

Industrial controls

GENERAL DESCRIPTION

The AD7294 contains all the functions required for generalpurpose monitoring and control of current, voltage, and

temperature integrated into a single-chip solution. The part

includes low voltage (±200 mV) analog input sense amplifiers

for current monitoring across shunt resistors, temperature sense

inputs, and four uncommitted analog input channels multiplexed

into a SAR analog-to-digital converter (ADC) with a 3 s conversion time. A high accuracy internal reference is provided to drive

both the digital-to-analog converter (DAC) and ADC. Four 12-bit

DACs provide the outputs for voltage control. The AD7294 also

includes limit registers for alarm functions. The part is designed

on Analog Devices, Inc., high voltage DMOS process for high

voltage compliance, 59.4 V on the current sense inputs, and up

to a 15 V DAC output voltage.

The AD7294 is a highly integrated solution that offers all the

functionality necessary for precise control of the power amplifier

in cellular base station applications. In these types of applications,

the DACs provide 12-bit resolution to control the bias currents

of the power transistors. Thermal diode-based temperature sensors

are incorporated to compensate for temperature effects. The ADC

monitors the high-side current and temperature. All this functionality is provided in a 64-lead TQFP operating over a

temperature range of −40°C to +105°C.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

AD7294

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Functional Block Diagram .............................................................. 3

Specifications ..................................................................................... 4

DAC Specifications....................................................................... 4

ADC Specifications ...................................................................... 5

General Specifications ................................................................. 7

Timing Characteristics ................................................................ 8

Absolute Maximum Ratings ............................................................ 9

Thermal Resistance ...................................................................... 9

ESD Caution .................................................................................. 9

Pin Configuration and Function Descriptions ........................... 10

Typical Performance Characteristics ........................................... 12

Terminology .................................................................................... 17

DAC Terminology ...................................................................... 17

ADC Terminology ...................................................................... 17

Theory of Operation ...................................................................... 18

ADC Overview ........................................................................... 18

ADC Transfer Functions ........................................................... 18

Analog Inputs .............................................................................. 18

Current Sensor ............................................................................ 20

Analog Comparator Loop ......................................................... 21

Temperature Sensor ................................................................... 22

DAC Operation ........................................................................... 23

ADC and DAC Reference .......................................................... 24

V

Feature .............................................................................. 24

DRIVE

Register Setting ............................................................................... 25

Address Pointer Register ........................................................... 25

Command Register (0x00) ........................................................ 26

Result Register (0x01) ................................................................ 26

T

1, T

2 Result Registers (0x02 and 0x03) ....................... 27

SENSE

INT Result Register (0x04).............................................. 27

T

SENSE

SENSE

DACA, DACB, DACC, DACD, Register (0x01 to 0x04) .............. 28

Alert Status Register A (0x05), Register B (0x06), and

Register C (0x07) ........................................................................ 28

Channel Sequence Register (0x08) .......................................... 28

Configuration Register (0x09) .................................................. 29

Power-Down Register (0x0A) ................................................... 30

DATA

(V

/DATA

HIGH

1); 0x11, 0x12 (VIN2); 0x14, 0x15 (VIN3) .............................. 30

IN

Registers: 0x0B, 0x0C (VIN0); 0x0E, 0x0F

LOW

Hysteresis Registers: 0x0D (VIN0), 0x10 (VIN1), 0x13 (VIN2),

0x16 (V

T

SENSE

3) .................................................................................. 30

IN

Offset Registers (0x26 and 0x27) ................................... 31

I2C Interface .................................................................................... 32

General I2C Timing .................................................................... 32

Serial Bus Address Byte ............................................................. 33

Interface Protocol ....................................................................... 33

Modes of Operation ....................................................................... 37

Command Mode ........................................................................ 37

Autocycle Mode .......................................................................... 38

Alerts and Limits Theory .............................................................. 39

Alert_Flag Bit .............................................................................. 39

Alert Status Registers ................................................................. 39

Data

and Data

HIGH

Monitoring Features ............................ 39

LOW

Hysteresis ..................................................................................... 40

Applications Information .............................................................. 41

Base Station Power Amplifier Monitor and Control ............. 41

Gain Control of Power Amplifier............................................. 42

Layout and Configuration ............................................................. 43

Power Supply Bypassing and Grounding ................................ 43

Outline Dimensions ....................................................................... 44

Ordering Guide .......................................................................... 44

REVISION HISTORY

1/08—Revision 0: Initial Version

Rev. 0 | Page 2 of 44

AD7294

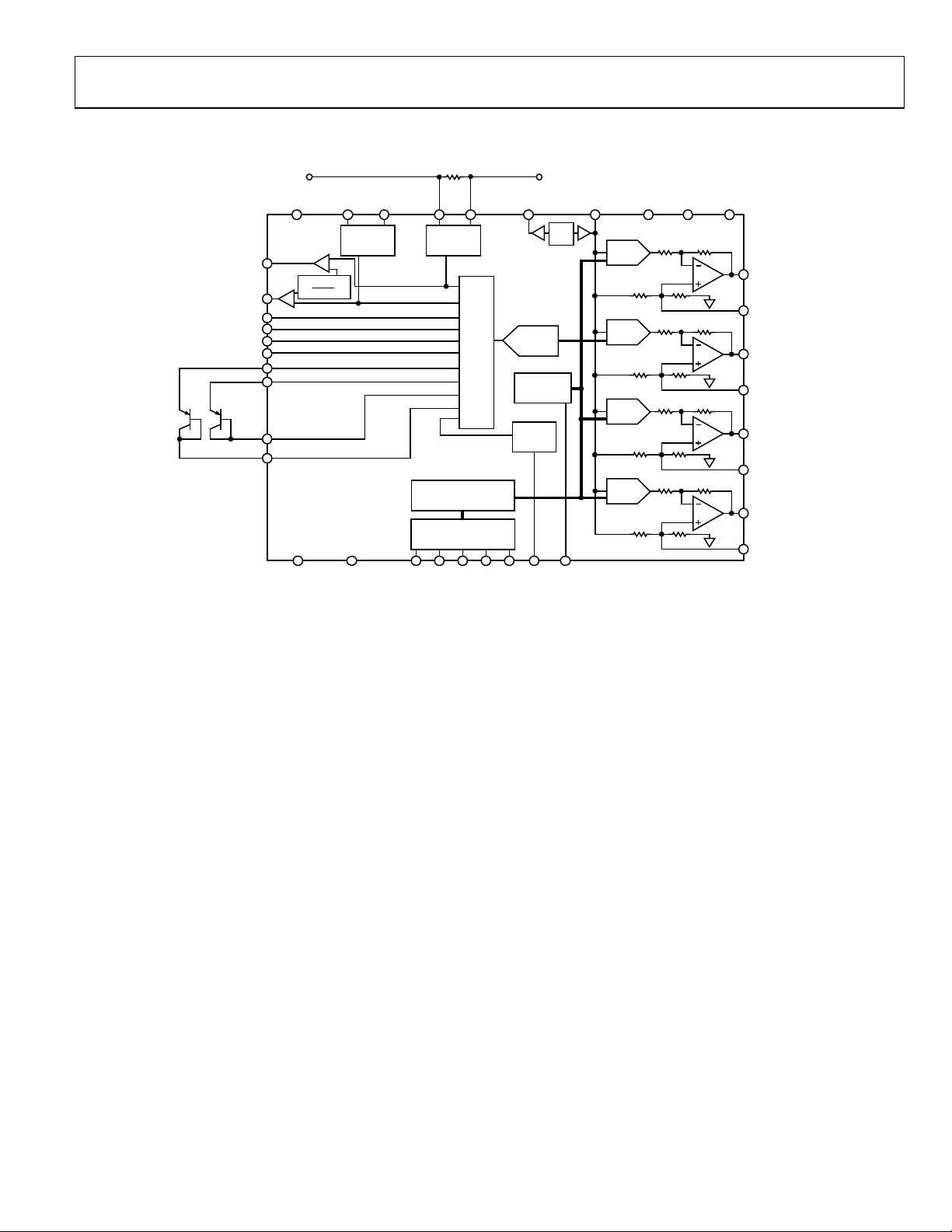

FUNCTIONAL BLOCK DIAGRAM

R

SENSE

OVERRANGE

OVERRANGE

T1 T2

I

SENSE

I

SENSE

VIN0

V

IN

V

IN

V

IN

D1+

D2+

D2–

D1–

1

2

3

VPP(1 TO 2)

2

1

AD7294

DV

V

10.41

DD

RS1(+) RS2(+) RS2(–)RS1(–)

HIGH SIDE

CURRENT

SENSE

REF

DGND

(1 TO 2)

HIGH SIDE

CURRENT

SENSE

CONTROL L OGIC

I2C INTERFACE

PROTOCOL

SDA

MUX

AS1AS2SCL

Figure 1.

REF

REF

IN

12-BIT

ADC

REGIS TERS

TEMP

SENSOR

DCAP

AS0

TO LOAD

OUT

ADC

LIMIT

/

2.5V

REF

ALERT/

BUSY

REF

REF

IN

OUT

DAC

AV

/

DD

(1 TO 6)

12-BIT

DAC

100kΩ 200kΩ

12-BIT

DAC

100kΩ 200kΩ

12-BIT

DAC

100kΩ 200kΩ

12-BIT

DAC

100kΩ 200kΩ

AGND

(1 TO 7)

100kΩ 200kΩ

100kΩ 200kΩ

100kΩ 200kΩ

100kΩ 200kΩ

DAC OUT

V+ AB/CD

V

A

OUT

OFFSET IN A

V

B

OUT

OFFSET IN B

V

C

OUT

OFFSET IN C

V

D

OUT

OFFSET IN D

5747-001

Rev. 0 | Page 3 of 44

AD7294

SPECIFICATIONS

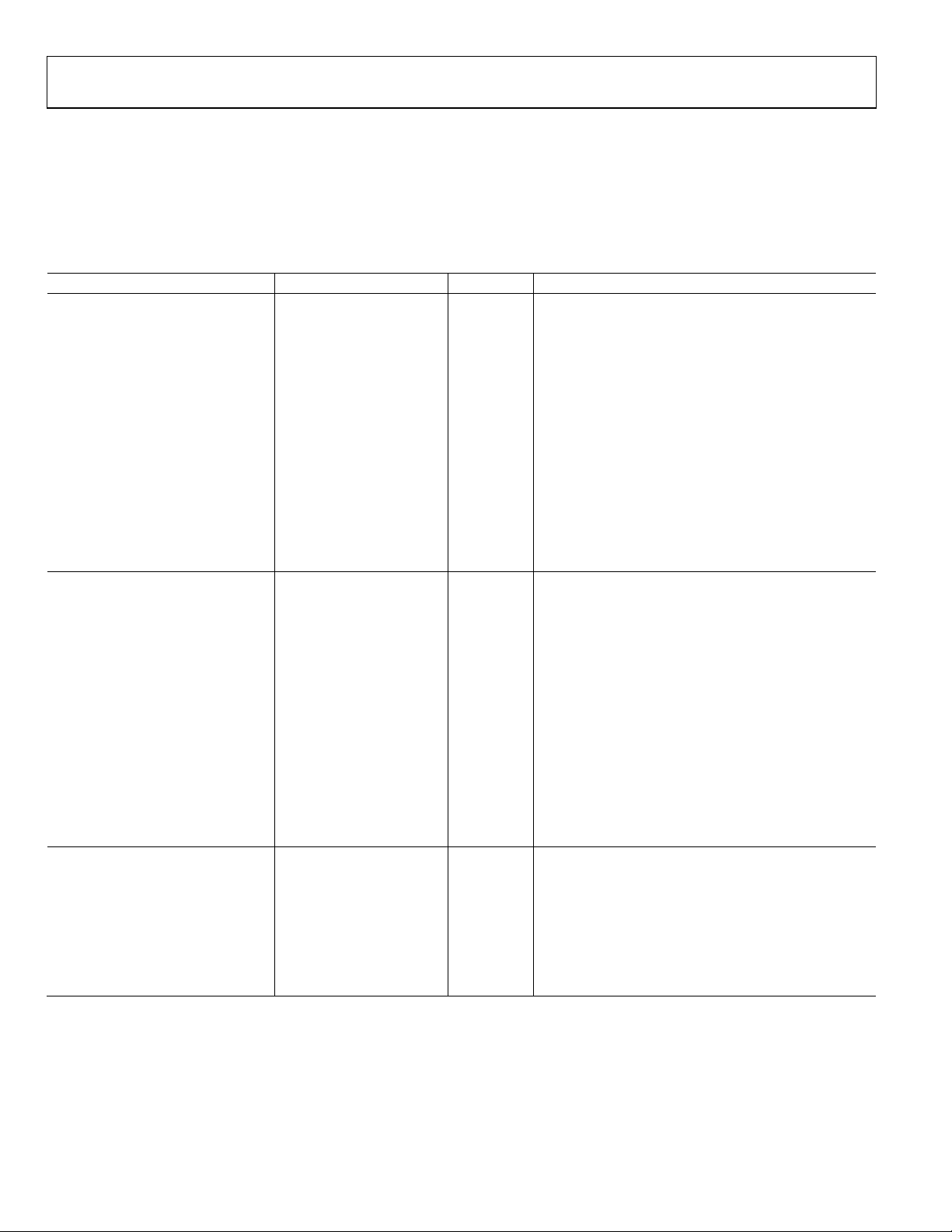

DAC SPECIFICATIONS

AVDD = DVDD = 4.5 V to 5.5 V, AGND = DGND = 0 V, internal 2.5 V reference; V

otherwise noted. DAC OUTV+ AB and DAC OUTV+ CD = 4.5 V to 16.5 V, OFFSET IN x is floating, therefore, the DAC output

span = 0 V to 5 V.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

ACCURACY

Resolution 12 Bits

Relative Accuracy (INL) ±1 ±3 LSB

Differential Nonlinearity (DNL) ±0.3 ±1 LSB Guaranteed monotonic

Zero-Scale Error 2.5 8 mV

1

Full-Scale Error of DAC and

15.5

mV DAC OUTV+ = 5.0 V

Output Amplifier

Full-Scale Error of DAC 2 mV DAC OUTV+ = 15.0 V

Offset Error ±8.575 mV Measured in the linear region, TA = −40°C to +105°C

±2 mV Measured in the linear region, TA = 25°C

Offset Error Temperature

±5 ppm/°C

Coefficient

Gain Error ±0.025 ±0.155 % FSR

Gain Temperature Coefficient ±5 ppm/°C

DAC OUTPUT CHARACTERISTICS

Output Voltage Span 0 2 × V

V 0 V to 5 V for a 2.5 V reference

REF

Output Voltage Offset 0 10 V

Offset Input pin range 0 5 V

1.667 5 V

DC Input Impedance

Output Voltage Settling Time

Slew Rate

2

1.1 V/µs

Short-Circuit Current

Load Current

Capacitive Load Stability

DC Output Impedance

2

75 kΩ 100 kΩ to V

2

8 µs

2

2

40 mA Full-scale current shorted to ground

±10 mA Source and/or sink within 200 mV of supply

2

10 nF R

2

1 Ω

REFERENCE

Reference Output Voltage 2.49 2.5 2.51 V ±0.4% maximum @ 25°C, AVDD = DVDD = 4.5 V to 5.5 V

Reference Input Voltage Range 0 AVDD − 2 V

Input Current 100 125 µA V

Input Capacitance

V

Output Impedance

REF

Reference Temperature

2

20 pF

2

25 Ω

10 25 ppm/°C

Coefficient

1

This value indicates that the DAC output amplifiers can output voltages 15.5 mV below the DAC OUTV+ supply. If higher DAC OUTV+ supply voltages are used, the

full-scale error of the DAC is typically 2 mV with no load.

2

Samples are tested during initial release to ensure compliance; they are not subject to production testing.

= 2.7 V to 5.5 V; TA =−40°C to +105°C, unless

DRIVE

The output voltage span can be positioned in the 0 V to

15 V range; if the OFFSET IN x is left floating, the offset

pin = 2/3 × V

= 3 V

OUT

= OFFSET IN x, DAC HIGH-Z = V

OUT

, giving an output of 0 V to 2 × V

REF

− 2 × V

OFFSET

, and 200 kΩ to AGND, see Figure 47

REF

REF

+ V

, DAC HIGH-Z = 0 V

DAC

DRIVE

REF

1/4 to 3/4 change within 1/2 LSB, measured from last

SCL edge

= ∞

L

= 2.5 V

REF

Rev. 0 | Page 4 of 44

AD7294

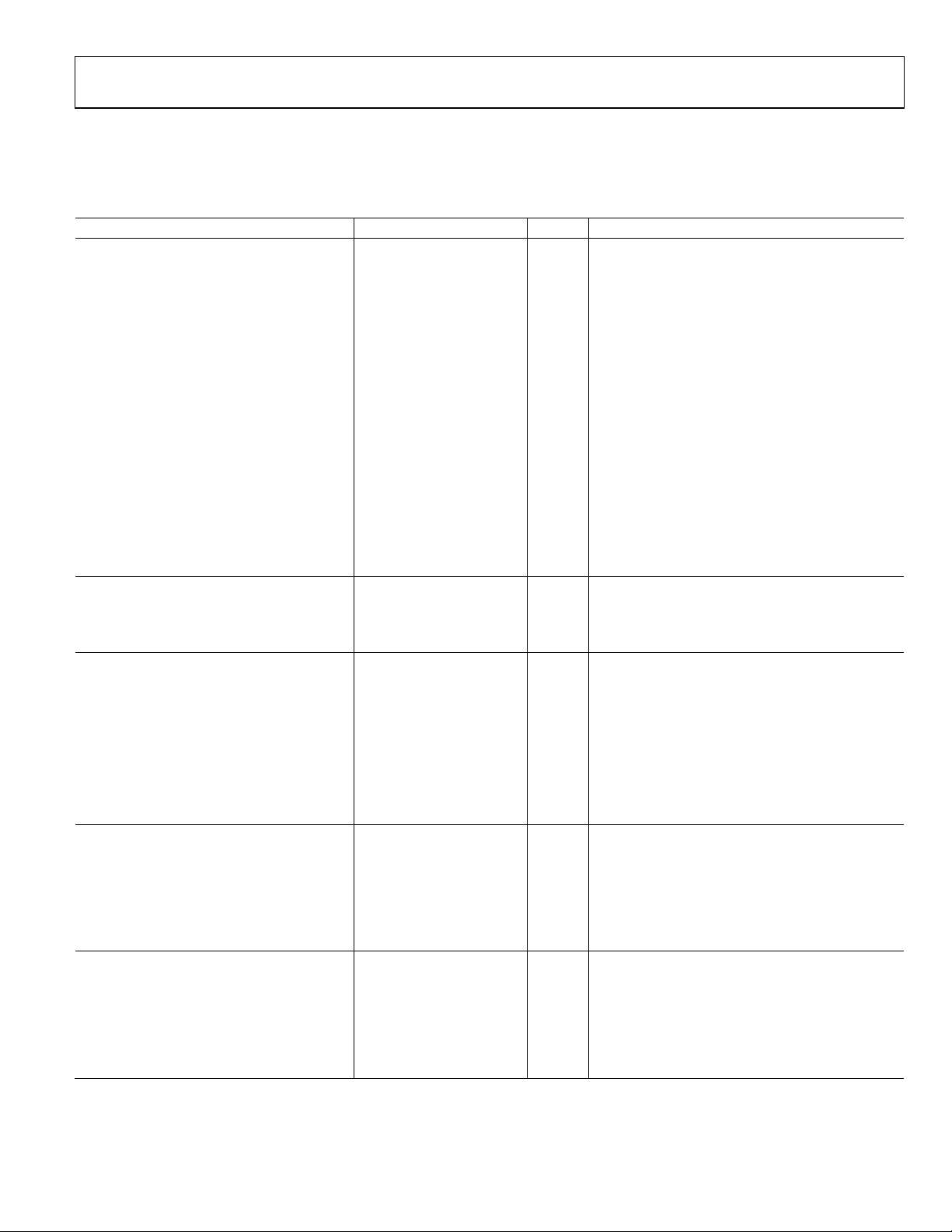

ADC SPECIFICATIONS

AVDD = DVDD = 4.5 V to 5.5 V, AGND = DGND = 0 V, V

T

= −40°C to +105°C, unless otherwise noted.

A

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

DC ACCURACY

Resolution 12 Bits

Integral Nonlinearity (INL)

1

±0.5 ±1 LSB Differential mode

±0.5 ±1.5 LSB Single-ended or pseudo differential mode

Differential Nonlinearity (DNL)1 ±0.5 ±0.99 LSB

Single-Ended Mode

Offset Error ±1 ±7 LSB

Offset Error Match ±0.4 LSB

Gain Error ±0.5 ±2.5 LSB

Gain Error Match ±0.4 LSB

Differential Mode

Positive Gain Error ±3 LSB

Positive Gain Error Match ±0.5 LSB

Zero Code Error ±3 ±10 LSB

Zero Code Error Match ±0.5 LSB

Negative Gain Error ±3 LSB

Negative Gain Error Match ±0.5 LSB

CONVERSION RATE

Conversion Time

Autocycle Update Rate

2

3 s

2

50 s

Throughput Rate 22.22 kSPS f

ANALOG INPUT

Single-Ended Input Range 0

3

0 2 × V

Pseudo Differential Input Range: V

4

− V

IN−

0

IN+

0 2 × V

Fully Differential Input Range: V

IN+

− V

−V

IN−

REF

−2 × V

Input Capacitance

2

30 pF

DC Input Leakage Current ±1 µA

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio (SNR)

1

72.5 73 dB f

71 72 dB

Signal-to-Noise + Distortion (SINAD) Ratio

1

69 71.5 dB f

71 72.5 dB

Total Harmonic Distortion (THD)

1

−81 –74 dB f

−79 –72 dB

Spurious-Free Dynamic Range (SFDR)

1

−91 −84.5 dB f

−93 −85.5

Channel-to-Channel Isolation

2

−90 dB f

= 2.5 V internal or external; V

REF

V

V

+V

+2 × V

REF

REF

V 0 V to 2 × V

REF

REF

0 V to 2 × V

REF

0 V to V

REF

0 V to 2 × V

REF

DRIVE

Differential, single-ended, and pseudo differential

modes

= 400 kHz

SCL

V 0 V to V

0 V to V

= 10 kHz sine wave; differential mode

IN

= 10 kHz sine wave; single-ended and pseudo

f

IN

differential modes

= 10 kHz sine wave; differential mode

IN

= 10 kHz sine wave; single-ended and pseudo

f

IN

differential modes

= 10 kHz sine wave; differential mode

IN

= 10 kHz sine wave; single-ended and pseudo

f

IN

differential modes

= 10 kHz sine wave; differential mode

IN

= 10 kHz sine wave; single-ended and pseudo

f

IN

differential modes

= 10 kHz to 40 kHz

IN

= 2.7 V to 5.5 V; VPP = AVDD to 59.4 V;

mode

REF

mode

REF

mode

REF

mode

REF

mode

REF

mode

REF

Rev. 0 | Page 5 of 44

AD7294

Parameter Min Typ Max Unit Test Conditions/Comments

TEMPERATURE SENSOR—INTERNAL

Operating Range −40 +105 °C

Accuracy ±2 °C Internal temperature sensor, TA = −30°C to +90°C

±2.5 °C Internal temperature sensor, TA = −40°C to +105°C

Resolution 0.25 °C LSB size

Update Rate 5 ms

TEMPERATURE SENSOR—EXTERNAL External transistor is 2N3906

Operating Range −55 +150 °C Limited by external diode

Accuracy ±2 °C TA = T

Resolution 0.25 °C LSB size

Low Level Output Current Source

Medium Level Output Current Source

High Level Output Current Source

Maximum Series Resistance (RS) for

External Diode

Maximum Parallel Capacitance (CP) for

External Diode

2

2

2

8 µA

2

32 µA

2

128 µA

100 Ω For < ±0.5°C additional error, C

1 nF RS = 0, see Figure 29

CURRENT SENSE VPP = AVDD to 59.4 V

VPP Supply Range AVDD 59.4 V

Gain 12.4375 12.5 12.5625

Gain of 12.5 gives a gain error = 0.5% maximum;

delivers ±200 mV range with +2.5 V reference

RS(+)/RS(−) Input Bias Current 25 32 µA

CMRR/PSRR

2

80 dB Inputs shorted to V

Offset Error ±50 ±340 µV

Offset Drift 1 µV/°C

Amplifier Peak-To-Peak Noise

2

400 µV Referred to input

VPP Supply Current 0.18 0.22 mA VPP = 59.4 V

REFERENCE

Reference Output Voltage 2.49 2.51 V ±0.2% maximum at 25°C only

Reference Input Voltage Range 0.1 4.1 V For four uncommitted ADCs

1 AVDD − 2 For current sense

DC Leakage Current ±2 A

V

Output Impedance

REF

Input Capacitance

2

25 Ω

2

20 pF

Reference Temperature Coefficient 10 25 ppm/°C

1

See the section for more details. Terminolo gy

2

Sampled during initial release to ensure compliance, not subject to production testing.

3

V

or V

must remain within GND/VDD.

IN+

IN−

4

V

= 0 V for specified performance. For full input range on V

IN−

, see . Figure 39

IN−

= −40°C to +105°C

DIODE

= 0, see Figure 30

P

PP

Rev. 0 | Page 6 of 44

AD7294

GENERAL SPECIFICATIONS

AVDD = DVDD = 4.5 V to 5.5 V, AGND = DGND = 0 V, V

DAC OUTV+ AB and DAC OUTV+ CD = 4.5 V to 16.5 V; OFFSET IN x is floating, therefore, DAC output span = 0 V to 5 V; T

−40°C to +105°C, unless otherwise noted.

Table 3.

Parameter Min Typ Max Unit Test Conditions/Comments

LOGIC INPUTS

Input High Voltage, VIH 0.7 V

DRIVE

Input Low Voltage, VIL 0.3 V

Input Leakage Current, IIN ±1 µA

Input Hysteresis, V

0.05 V

HYST

Input Capacitance, CIN 8 pF

Glitch Rejection 50 ns

I2C® Address Pins Maximum External

30 pF Tristate input

Capacitance if Floating

DAC HIGH-Z Pin Leakage 10 µA Input with pull-down resistor, VIN = 5.5 V

1 µA Input with pull-down resistor, VIN = 0 V

LOGIC OUTPUTS

SDA, ALERT SDA and ALERT/BUSY are open-drain outputs

Output Low Voltage, VOL 0.4 V I

0.6 V I

Floating-State Leakage Current ±1 µA

Floating-State Output Capacitance 8 pF

I

OVERRANGE I

SENSE

Output High Voltage, VOH V

Output Low Voltage, VOL 0.2 V I

Overrange Setpoint VFS V

POWER REQUIREMENTS

VPP AVDD 59.4 V

AVDD 4.5 5.5 V

V(+) 4.5 16.5 V

DVDD 4.5 5.5 V Tie DVDD to AVDD

V

2.7 5.5 V

DRIVE

IDD Dynamic 5.3 6.5 mA AVDD + DVDD + V

DAC OUTV+ x, IDD 0.6 0.9 mA

Power Dissipation 70 92 mW

Power-Down

IDD 0.5 1 µA For each AVDD and V

DIDD 1 16.5 µA

DAC OUTV+ x, IDD 35 60 µA

Power Dissipation 2.5 mW

= 2.5 V internal or external; V

REF

= 2.7 V to 5.5 V; VPP = AVDD to 59.4 V;

DRIVE

V SDA, SCL only

V SDA, SCL only

DRIVE

V

DRIVE

Input filtering suppresses noise spikes of less

than 50 ns

= 3 mA

SINK

= 6 mA

SINK

OVERRANGE is a push-pull output

SENSE

− 0.2 V I

DRIVE

× 1.2 mV VFS = ±V

FS

= 200 µA for push-pull outputs

SOURCE

= 200 µA for push-pull outputs

SINK

@ midscale output voltage, DAC outputs

unloaded

ADC/12.5

REF

, DAC outputs unloaded

DRIVE

DRIVE

=

A

Rev. 0 | Page 7 of 44

AD7294

T

TIMING CHARACTERISTICS

I2C Serial Interface

AVDD = DVDD = 4.5 V to 5.5 V, AGND = DGND = 0 V, V

DAC OUTV+ AB and DAC OUTV+ CD = 4.5 V to 16.5 V; OFFSET IN x is floating, therefore, DAC output span = 0 V to 5 V; T

−40°C to +105°C, unless otherwise noted.

= 2.5 V internal or external; V

REF

= 2.7 V to 5.5 V; VPP = AVDD to 59.4 V;

DRIVE

=

A

Table 4.

1

Parameter

f

400 kHz max SCL clock frequency

SCL

Limit at T

, T

Unit Description

MIN

MAX

t1 2.5 µs min SCL cycle time

t2 0.6 µs min t

t3 1.3 µs min t

t4 0.6 µs min t

t5 100 ns min t

2

t

0.9 µs max t

6

0 µs min t

t7 0.6 µs min t

t8 0.6 µs min t

t9 1.3 µs min t

, SCL high time

HIGH

, SCL low time

LOW

, start/repeated start condition hold time

HD,STA

, data setup time

SU,DAT

, data hold time

HD,DAT

, data hold time

HD,DAT

, setup time for repeated start

SU,STA

, stop condition setup time

SU,STO

, bus free time between a stop and a start condition

BUF

t10 300 ns max tR, rise time of SCL and SDA when receiving

0 ns min tR, rise time of SCL and SDA when receiving (CMOS compatible)

t11 300 ns max tF, fall time of SDA when transmitting

0 ns min tF, fall time of SDA when receiving (CMOS compatible)

300 ns max tF, fall time of SCL and SDA when receiving

20 + 0.1C

3

ns min t

b

, fall time of SCL and SDA when transmitting

F

Cb 400 pF max Capacitive load for each bus line

1

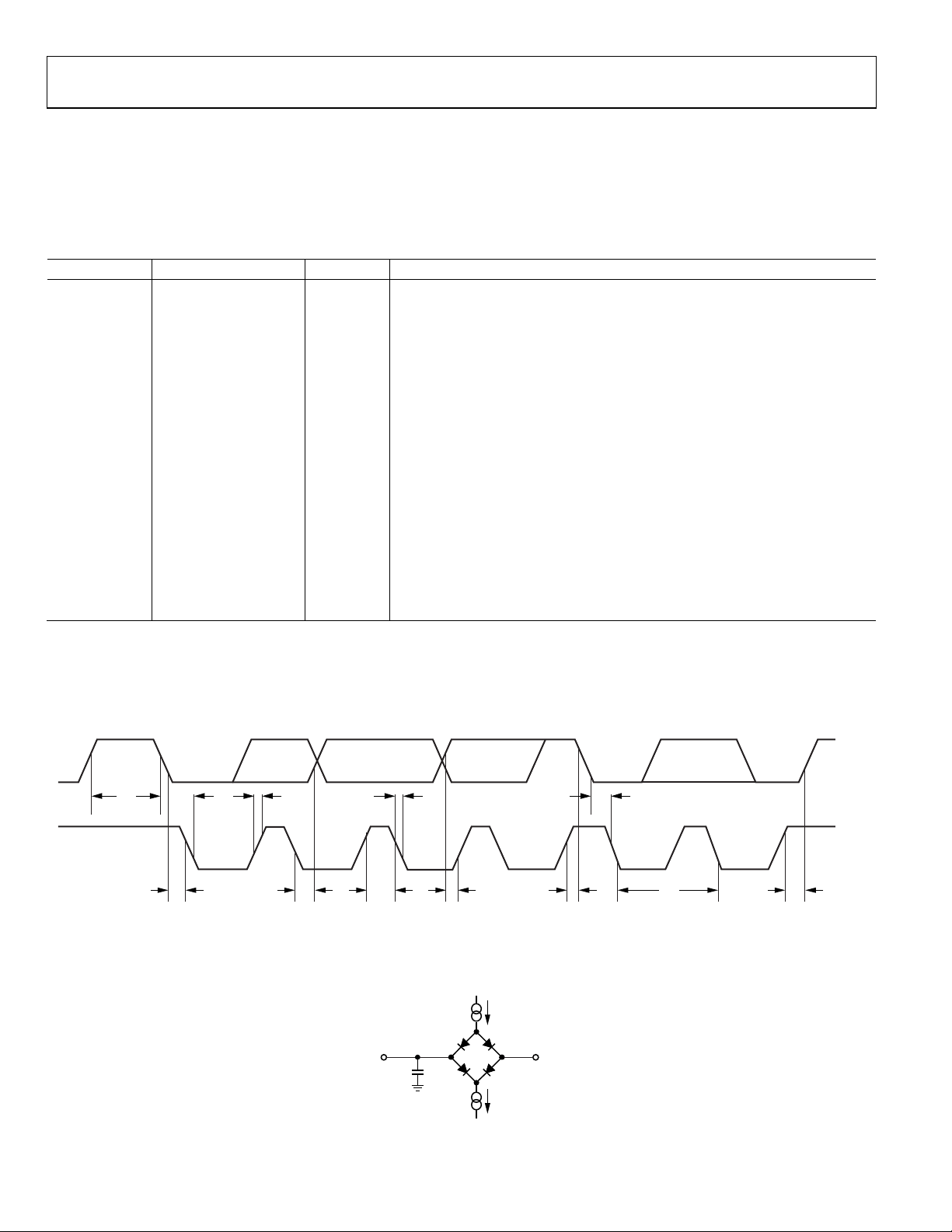

See Figure 2.

2

A master device must provide a hold time of at least 300 ns for the SDA signal (referred to the V

edge of SCL.

3

Cb is the total capacitance in pF of one bus line. tR and tF are measured between 0.3 DVDD and 0.7 DVDD.

minimum of the SCL signal) to bridge the undefined region of the falling

IH

Timing and Circuit Diagrams

SDA

SCL

t

9

t

4

START

CONDITION

t

3

t

10

t

6

O OUTPUT PIN

Figure 2. I

t

2

C-Compatible Serial Interface Timing Diagram

t

11

2

t

C

L

50pF

5

200µA

200µA

I

OL

I

OH

REPEATED

CONDITION

V

OH

V

OL

t

7

START

(MIN) OR

(MAX)

t

4

t

1

05747-003

t

8

STOP

CONDITIO N

05747-002

Figure 3. Load Circuit for Digital Output

Rev. 0 | Page 8 of 44

AD7294

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.1

Table 5.

Parameter Rating

VPPx to AGND −0.3 V to +70 V

AVDDx to AGND −0.3 V to +7 V

DAC OUTV+ AB to AGND −0.3 V to +17 V

DAC OUTV+ CD to AGND −0.3 V to +17 V

DVDD to DGND −0.3 V to +7 V

V

to OPGND −0.3 V to +7 V

DRIVE

Digital Inputs to OPGND −0.3 V to V

DRIVE

+ 0.3 V

SDA/SCL to OPGND −0.3 V to +7 V

Digital Outputs to OPGND −0.3 V to V

DRIVE

+ 0.3 V

RS(+)/RS(−) to VPPx VPP − 0.3 V to VPP + 0.3 V

REF

/REFIN ADC to AGND −0.3 V to AVDD + 0.3 V

OUT

REF

/REFIN DAC to AGND −0.3 V to AVDD + 0.3 V

OUT

OPGND to AGND −0.3 V to +0.3 V

OPGND to DGND −0.3 V to +0.3 V

AGND to DGND −0.3 V to +0.3 V

V

x to AGND −0.3 V to DAC OUTV(+) + 0.3 V

OUT

Analog Inputs to AGND −0.3 V to AVDD + 0.3 V

Operating Temperature Range

B Version −40°C to +105°C

Storage Temperature Range −65°C to +150°C

Junction Temperature (TJ Max) 150°C

ESD Human Body Model 1 kV

Reflow Soldering Peak

230°C

Temperature

1

Transient currents of up to 100 mA do not cause SCR latch-up.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

To conform with IPC 2221 industrial standards, it is advisable

to use conformal coating on the high voltage pins.

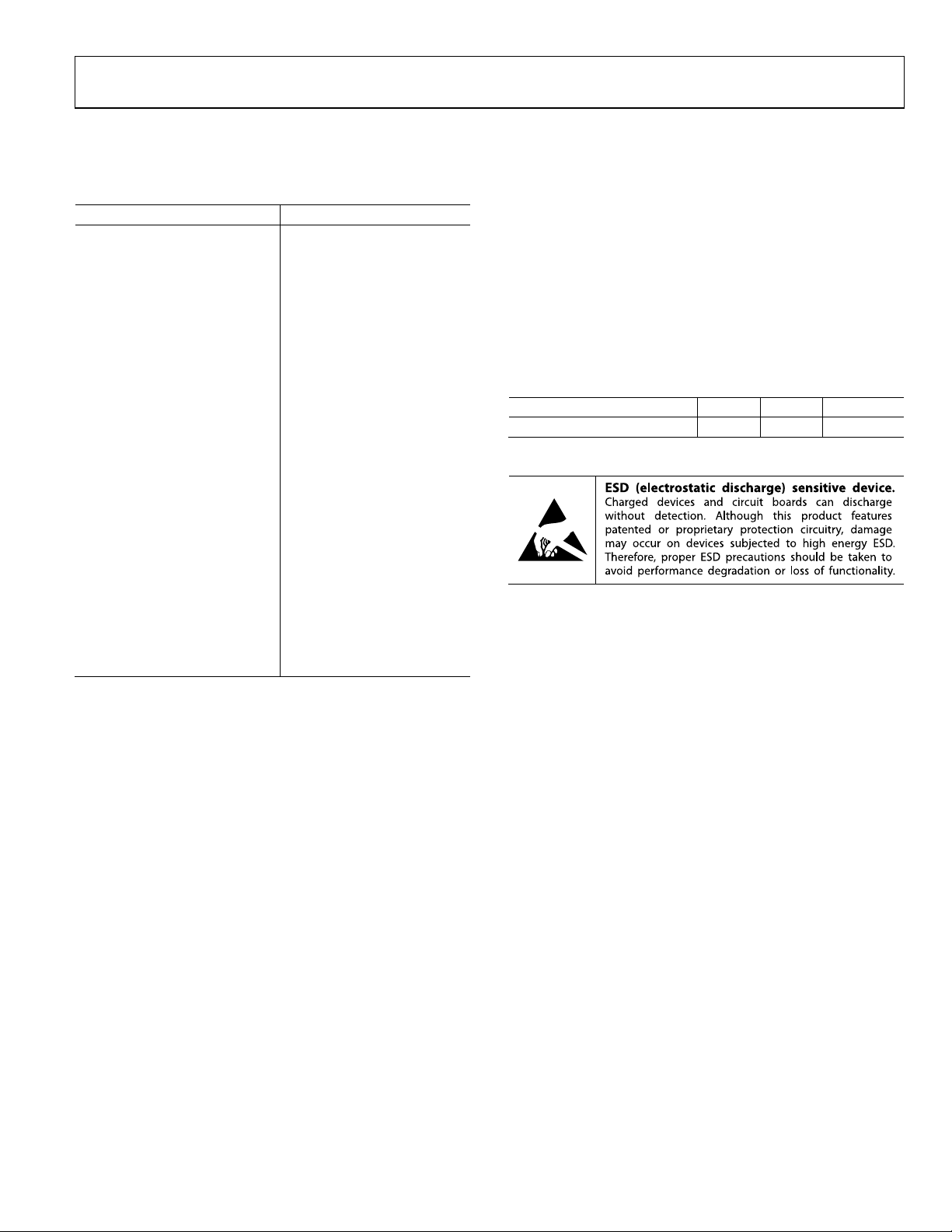

THERMAL RESISTANCE

Table 6. Thermal Resistance

Package Type θJA θ

Unit

JC

64-Lead TQFP 54 16 °C/W

ESD CAUTION

Rev. 0 | Page 9 of 44

AD7294

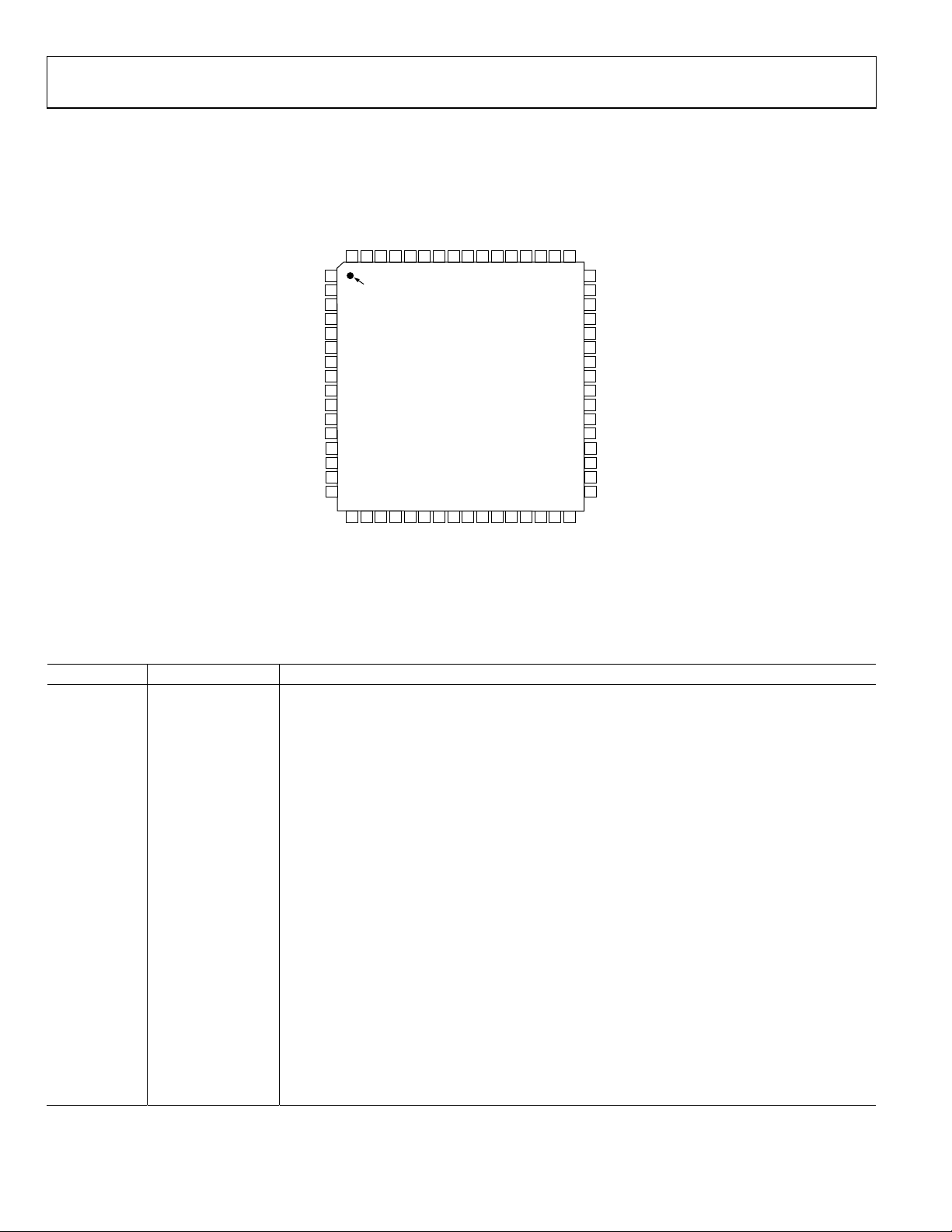

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

C

D

A

N

I

F

E

R

/

T

6

7

)

RS2(–)

RS2(+)

AV

AGND1

AGND2

AV

AGND3

/REFIN DAC

OUT

AV

REF

NC = NO CONNECT

)

–

(

2

1

1

P

P

C

S

P

P

N

V

R

V

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

NC

NC

DD

DD

D2–

D2+

D1+

D1–

DD

NC

1

2

3

PIN 1

2

INDICATO R

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

A

A

C

B

N

T

A

N

I

U

D

O

T

N

V

E

G

S

F

T

F

U

O

O

C

A

D

+

D

(

N

1

G

S

C

A

R

N

AD7294

TQFP

TOP VIEW

(Not to Scale)

B

B

B

A

T

N

I

U

+

O

T

V

V

E

T

S

U

F

O

F

C

O

A

D

6

D

D

V

A

4

D

N

G

A

Figure 4. Pin Configuration

U

5

D

P

O

D

D

V

A

4

D

D

V

A

0

N

A

F

N

G

C

E

I

A

V

D

R

C

D

D

C

C

T

C

N

U

I

+

D

O

T

V

N

V

E

T

G

S

U

F

T

O

F

U

C

O

O

A

C

D

A

D

1

2

3

N

N

N

I

I

I

V

V

V

48

DAC HIGH-Z

47

DGND

1 OVERRANGE

I

46

SENSE

2 OVERRANGE

I

45

SENSE

44

DV

DD

43

DGND

42

V

DRIVE

41

OPGND

40

SCL

39

SDA

38

AS0

37

AS1

36

AS2

35

ALERT/BUSY

34

AGND5

33

NC

D

C

D

N

T

N

I

U

O

T

V

E

S

F

F

O

05747-005

Table 7. Pin Function Descriptions

Pin No. Mnemonic Description

2, 61 RS2(−), RS1(−) Connection for External Shunt Resistor.

3, 60 RS2(+), RS1(+) Connection for External Shunt Resistor.

1, 4, 16, 17,

NC No Connection. Do not connect these pins.

32, 33, 59, 64

1 to AVDD6

5, 8, 14, 25,

56, 57

AV

DD

Analog Supply Pins. The operating range is 4.5 V to 5.5 V. These pins provide the supply voltage for

all the analog circuitry on the AD7294. Connect the AV

supply pins are at the same potential. This supply should be decoupled to AGND with one 10 µF

tantalum capacitor and a 0.1 µF ceramic capacitor for each AVDD pin.

6, 7, 13, 24,

34, 55, 58

AGND1 to AGND7

Analog Ground. Ground reference point for all analog circuitry on the AD7294. Refer all analog

input signals and any external reference signal to this AGND voltage. Connect all seven of these

AGND pins to the AGND plane of the system. Note that AGND5 is a DAC ground reference point and

should be used as a star ground for circuitry being driven by the DAC outputs. Ideally, the AGND

and DGND voltages should be at the same potential and must not be more than 0.3 V apart, even

on a transient basis.

9, 12 D2(−), D1(−)

Temperature Sensor Analog Input. These pins are connected to the external temperature sensing

transistor. See Figure 45 and Figure 46.

10, 11 D2(+), D1(+)

Temperature Sensor Analog Input. These pins are connected to the external temperature sensing

transistor. See Figure 45 and Figure 46.

15 REF

/REFIN DAC

OUT

DAC Reference Output/Input Pin. The REF

power-up, the default configuration of this pin is external reference (REF

reference by writing to the power-down register; see Tab le 27. Decoupling capacitors (220 nF

recommended) are connected to this pin to decouple the reference buffer. Provided the output is

buffered, the on-chip reference can be taken from this pin and applied externally to the rest of a

system. A maximum external reference voltage of AV

of the REF

/REFIN DAC pin.

OUT

and DVDD pins together to ensure that all

DD

/REFIN DAC pin is common to all four DAC channels. On

OUT

− 2 V can be supplied to the REF

DD

). Enable the internal

IN

portion

OUT

Rev. 0 | Page 10 of 44

AD7294

Pin No. Mnemonic Description

18, 23, 26, 31

19, 22, 27, 30 V

20, 29

21, 28

35 ALERT/BUSY

When configured as a busy output, this pin becomes active when a conversion is in progress.

38, 37, 36 AS0, AS1, AS2

39 SDA

40 SCL

41 OPGND Dedicated Ground Pin for I2C Interface.

42 V

43, 47 DGND Digital Ground. This pin is the ground for all digital circuitry.

44 DV

46, 45

48 DAC HIGH-Z

49, 50, 51, 52 VIN3 to VIN0

53 REF

54 DCAP

62, 63 VPP1, VPP2

OFFSET IN A to

OFFSET IN D

OUT

A to V

OUT

D

DAC OUT GND AB,

DAC OUT GND CD

DAC OUTV+ AB,

DAC OUTV+ CD

DRIVE

DD

1 OVERRANGE,

I

SENSE

2 OVERRANGE

I

SENSE

/REFIN ADC

OUT

DAC Analog Offset Input Pins. These pins set the desired output range for each DAC channel. The

DACs have an output voltage span of 5 V, which can be shifted from 0 V to 5 V to a maximum output

voltage of 10 V to 15 V by supplying an offset voltage to these pins. These pins can be left floating,

in which case decouple them to AGND with a 100 nF capacitor.

Buffered Analog DAC Outputs for Channel A to Channel D. Each DAC analog output is driven from

an output amplifier that can be offset using the OFFSET IN x pin. The DAC has a maximum output

voltage span of 5 V that can be level shifted to a maximum output voltage level of 15 V. Each output

is capable of sourcing and sinking 10 mA and driving a 10 nF load.

Analog Ground. Analog ground pins for the DAC output amplifiers on V

and V

D, respectively.

OUT

Analog Supply. Analog supply pins for the DAC output amplifiers on V

V

D, respectively. The operating range is 4.5 V to 16.5 V.

OUT

OUT

OUT

A and V

A and V

OUT

B, and V

OUT

B, and V

OUT

C

OUT

C and

Digital Output. Selectable as an alert or busy output function in the configuration register. This is an

open-drain output. An external pull-up resistor is required.

When configured as an alert, this pin acts as an out-of-range indicator and becomes active when

the conversion result violates the DATA

HIGH

or DATA

register values. See the Alert Status Registers

LOW

section.

2

Digital Logic Input. Together, the logic state of these inputs selects a unique I

C address for the

AD7294. See Tab le 34 for details.

Digital Input/Output. Serial bus bidirectional data. This open-drain output requires a pull-up

resistor.

2

C Bus Clock. The data transfer rate in I2C mode is compatible with both 100 kHz and 400 kHz

Serial I

operating modes. This open-drain output requires pull-up resistors.

Logic Power Supply. The voltage supplied at this pin determines at what voltage the interface

operates. Decouple this pin to DGND. The voltage range on this pin is 2.7 V to 5.5 V and may be

different to the voltage level at AV

and DVDD, but should never exceed either by more than 0.3 V.

DD

To set the input and output thresholds, connect this pin to the supply to which the I2C bus is pulled.

Logic Power Supply. The operating range is 4.5 V to 5.5 V. These pins provide the supply voltage for

all the digital circuitry on the AD7294. Connect the AV

and DVDD pins together to ensure that all

DD

supply pins are at the same potential. Decouple this supply to DGND with a10 µF tantalum

capacitor and a 0.1 µF ceramic capacitor.

Fault Comparator Outputs. These pins connect to the high-side current sense amplifiers.

High Impedance Control on DAC Outputs. When this pin is set to a high logic level, it sets the DAC

outputs to the voltage level on the OFFSET IN x pins. This pin has an internal 1 MΩ pull-down

resistor.

Uncommitted ADC Analog Inputs. These pins are programmable as four single-ended channels or

two true differential analog input channel pairs. See Table 1 and Table 13 for more details.

ADC Reference Input/Output Pin. The REF

ADC. Upon power-up, the default configuration of this pin is external reference (REF

/REFIN ADC pin provides the reference source for the

OUT

). Enable the

IN

internal reference by writing to the power-down register; see Table 27. Connect decoupling

capacitors (220 nF recommended) to this pin to decouple the reference buffer. Provided the output

is buffered, the on-chip reference can be taken from this pin and applied externally to the rest of a

system. A maximum external reference voltage of 2.5 V can be supplied to the REF

REF

/REFIN ADC pin.

OUT

portion of the

OUT

External Decoupling Capacitor Input for Internal Temperature Sensor. Decouple this pin to AGND

using a 0.1 F capacitor. In normal operation, the voltage is typically 3.7 V.

Current Sensor Supply Pins. Power supply pins for the high-side current sense amplifiers. Operating

range is from AV

to 59.4 V. Decouple this supply to AGND. See the Current Sense Filtering section.

DD

Rev. 0 | Page 11 of 44

AD7294

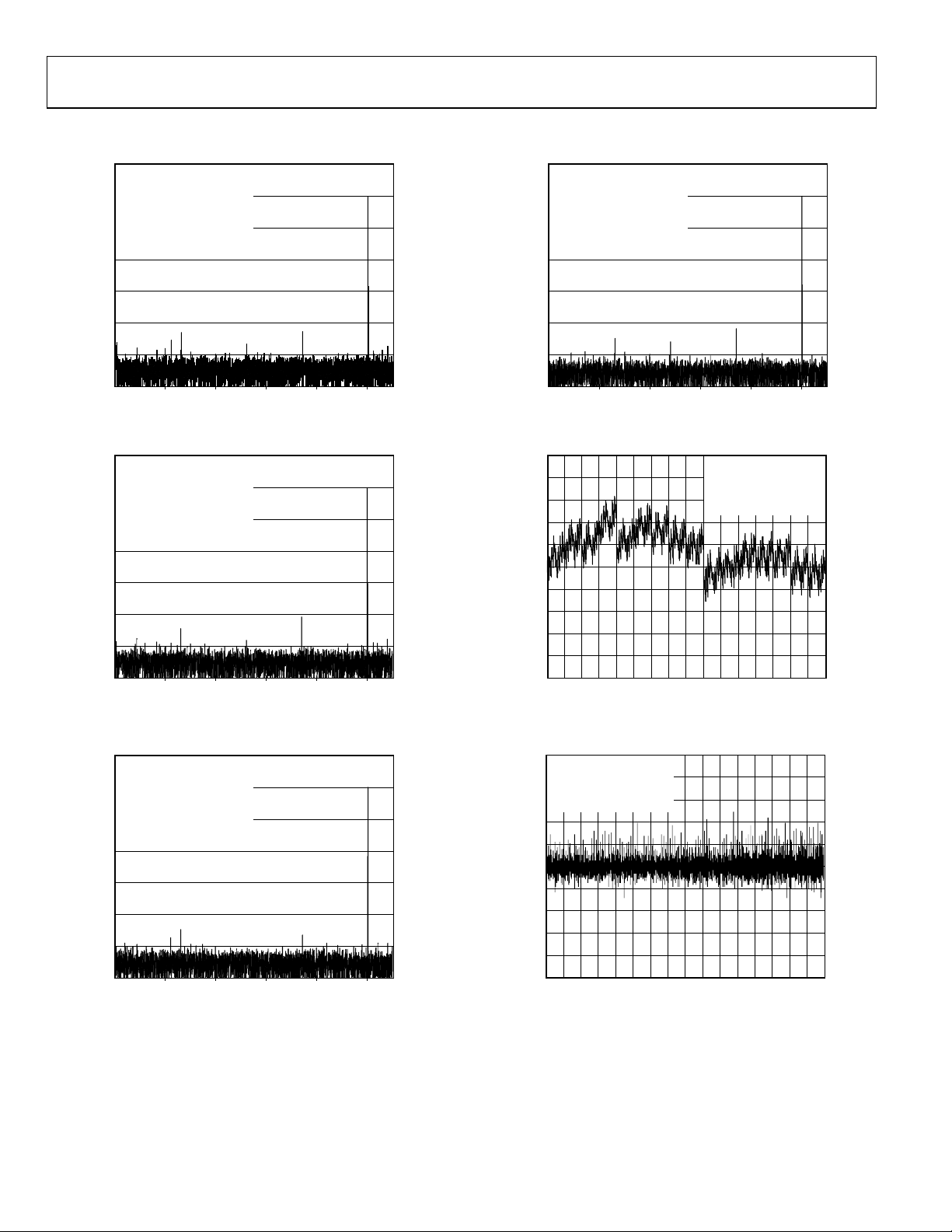

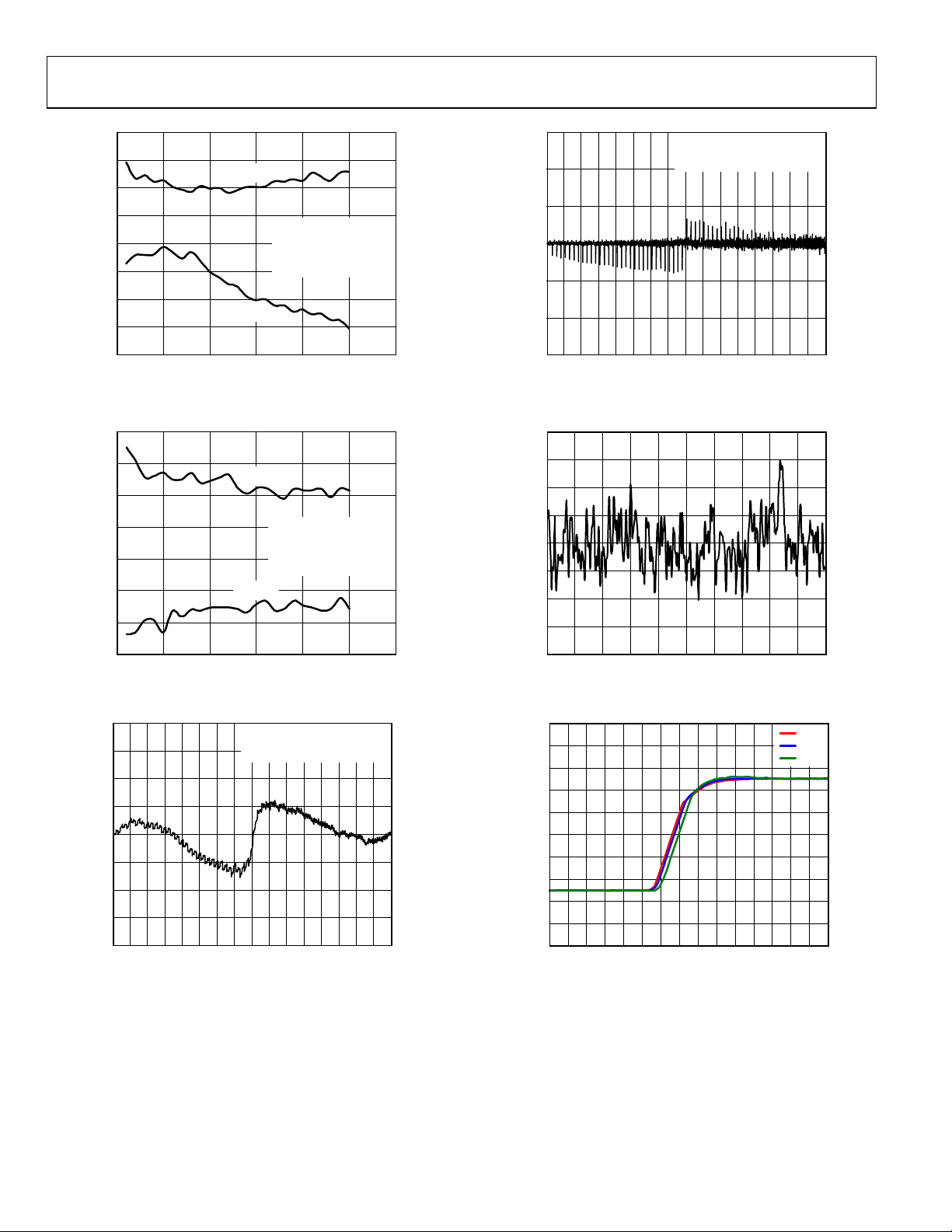

TYPICAL PERFORMANCE CHARACTERISTICS

20

8192 POINT FFT

AV

= DVDD = 5V

DD

V

0

= 5V, V

DRIVE

F

SAMPLE

F

= 10kHz, F

IN

–20

SINGLE ENDED

SNR = 71dB, THD = –82dB

–40

RANGE

REF

= 22.22kSPS

SCLK

= 400kHz

20

8192 POINT FFT

AV

= DVDD = 5V

DD

V

0

= 5V, 2V

DRIVE

F

= 22.22kSPS

SAMPLE

F

= 10kHz, F

IN

–20

DIFFERENTIAL

SNR = 73dB, T HD = –82dB

–40

REF

SCLK

RANGE

= 400kHz

–60

AMPLITUDE ( dB)

–80

–100

–120

0 100008000600040002000

FREQUENCY (kHz)

Figure 5. Signal-to-Noise Ratio Single-Ended, V

20

8192 POINT FFT

AV

= DVDD = 5V

DD

V

0

DRIVE

F

SAMPLE

F

= 10kHz, F

IN

–20

SINGLE ENDED

SNR = 72dB, THD = –80dB

–40

–60

AMPLITUDE ( dB)

–80

–100

–120

0 100008000600040002000

= 5V, 2V

REF

= 22.22kSPS

SCLK

RANGE

= 400kHz

FREQUENCY (kHz)

Figure 6. Signal-to-Noise Ratio Single-Ended, 2 × V

20

8192 POINT FFT

AV

= DVDD = 5V

DD

V

0

DRIVE

F

SAMPLE

F

= 10kHz, F

IN

–20

DIFFERENTIAL

SNR = 72dB, THD = –86dB

–40

–60

AMPLITUDE ( dB)

–80

–100

–120

0 100008000600040002000

= 5V, V

RANGE

REF

= 22.22kSPS

SCLK

= 400kHz

FREQUENCY (kHz)

Figure 7. Signal-to-Noise Ratio Differential, V

REF

Range

REF

Range

Range

REF

–60

AMPLITUDE ( dB)

–80

–100

–120

5747-088

5747-089

5747-087

0 100008000600040002000

FREQUENCY (kHz)

Figure 8. Signal-to-Noise Ratio Differential, 2 × V

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

256

768

1280

5120

1024

1536

1792

2048

CODE

2304

TA = 25°C

V

DRIVE

V

REF

V

DD

SINGLE-E NDED

2560

Figure 9. ADC INL Single-Ended, V

1.0

TA = 25°C

V

DNL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

DRIVE

0.8

V

REF

V

DD

0.6

SINGLE-ENDED

0.4

0.2

0

256

= 5V, V

= 2.5V

= 5V

5120

768

1024

REF

RANGE

1280

1536

1792

2048

CODE

2304

2560

Figure 10. ADC DNL Single-Ended, V

= 5V, V

= 2.5V

= 5V

2816

2816

3072

Range

REF

3072

REF

REF

REF

3328

3328

Range

Range

RANGE

3840

3584

3840

3584

5747-086

4096

05747-077

4096

05747-072

Rev. 0 | Page 12 of 44

AD7294

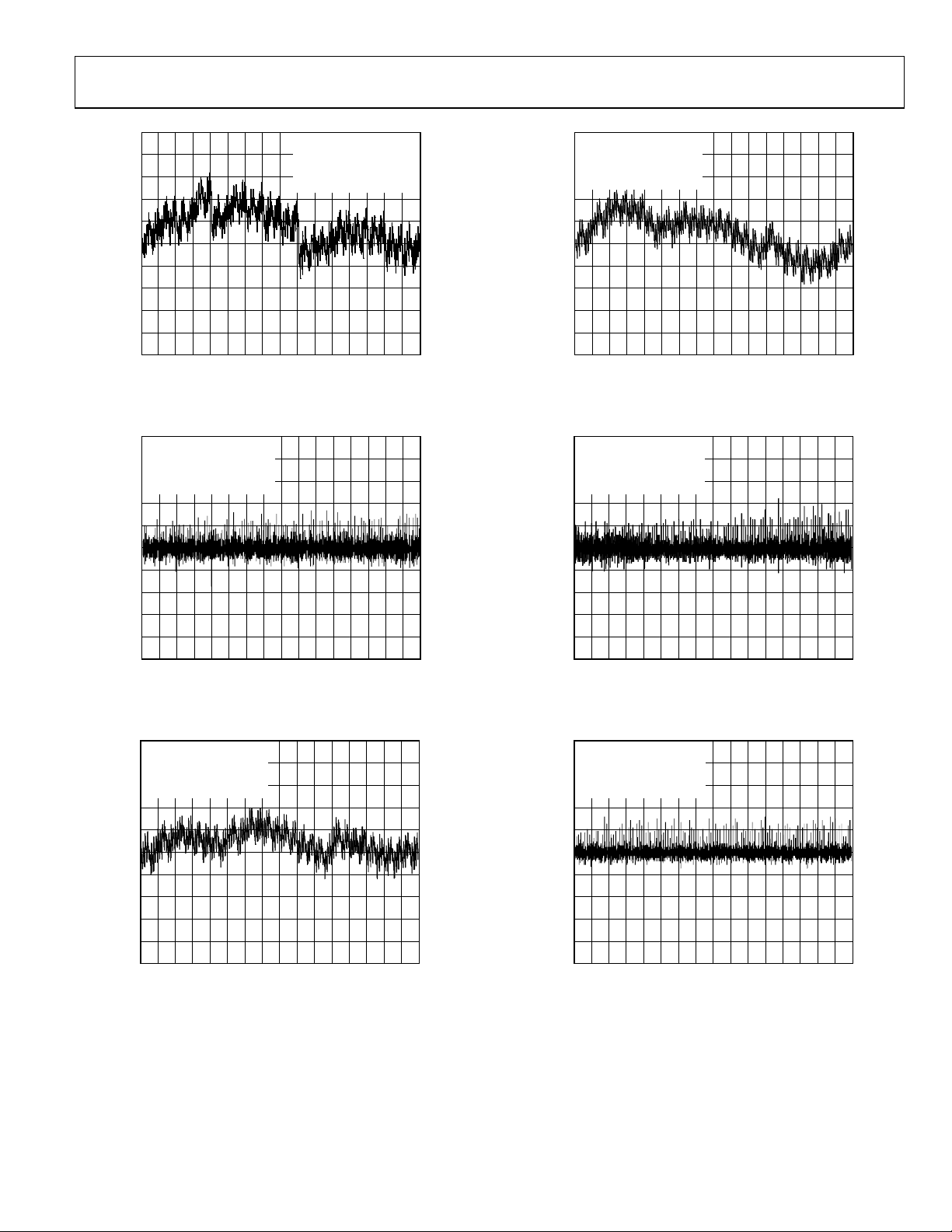

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

DNL (LSB)

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

1.0

0.8

0.6

0.4

0.2

0

256

768

1280

5120

1024

1536

1792

Figure 11. ADC INL Single-Ended, 2 × V

1.0

TA = 25°C

V

0.8

V

V

0.6

SINGLE-ENDED

DRIVE

REF

DD

= 5V

= 5V

= 5V, 2V

REF

RANGE

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1.0

256

768

1280

5120

1024

1536

1792

Figure 12. ADC DNL Single-Ended, 2 × V

1.0

TA = 25°C

V

0.8

V

V

0.6

DIFFERENTIAL

DRIVE

REF

DD

= 5V, V

= 2.5V

= 5V

REF

RANGE

0.4

0.2

0

256

768

1280

5120

1024

1536

1792

Figure 13. ADC INL Differential, V

2048

CODE

2048

CODE

2048

CODE

2304

2304

2304

TA = 25°C

V

= 5V, 2V

DRIVE

V

= 2.5V

REF

V

= 5V

DD

SINGLE-E NDED

2816

2560

3072

REF

2816

2560

3072

REF

2816

2560

3072

Range

REF

REF

3328

3584

Range

3328

3584

Range

3328

3584

RANGE

3840

3840

3840

4096

4096

4096

05747-078

05747-073

05747-075

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

DNL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

DNL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

1.0

TA = 25°C

V

0.8

V

V

0.6

DIFFERENTIAL

DRIVE

REF

DD

= 5V

= 5V

= 5V, V

REF

RANGE

0.4

0.2

0

256

768

1280

5120

1024

1536

1792

Figure 14. ADC INL Differential, V

1.0

TA = 25°C

TA = 25°C

V

V

0.8

V

V

V

DIFFERENTIAL

0.6

DIFFERENTIAL

DRIVE

REF

REF

= 5V

DD

DD

= 5V, 2V

= 2.5V

= 2.5V

= 5V

REF

RANGE

0.4

0.2

0

256

768

1280

5120

1024

1536

1792

Figure 15. ADC DNL Differential, 2 × V

1.0

TA = 25°C

V

0.8

V

V

0.6

DIFFERENTIAL

DRIVE

REF

DD

= 5V, 2V

= 5V

= 5V

REF

RANGE

0.4

0.2

0

256

768

1280

5120

1024

1536

1792

Figure 16. ADC DNL Differential, 2 × V

2048

CODE

2048

CODE

2048

CODE

2304

2304

2304

2560

2560

2560

2816

REF

2816

2816

3328

3072

Range

3328

3072

Range

REF

3328

3072

Range

REF

3584

3584

3584

3840

3840

3840

4096

4096

4096

05747-076

05747-070

05747-071

Rev. 0 | Page 13 of 44

AD7294

1.5

1.0

0.5

0

–0.5

INL (LSB)

–1.0

–1.5

–2.0

MAX INL

MIN INL

T

= 25°C

A

= 5V, V

V

DRIVE

= 5V

V

DD

SINGLE-ENDED

2

C MODE 400kHz

I

REF

RANGE

0.6

0.4

0.2

0

DNL (LSB)

–0.2

–0.4

AVDD = DVDD = 5V

= 5V, INTE RNAL REF,

V

DRIVE

OFFSET IN A/B/C/D = FLOATI NG

INL (LSB)

DNL (LS B)

–0.5

–1.0

–1.5

–2.0

–2.5

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

2.0

1.5

1.0

0.5

0

0654321

REFERENCE VOL TAGE (V)

Figure 17. ADC INL vs. Reference Voltage

MAX DNL

T

V

V

SINGLE-E NDED

2

I

MIN DNL

0654321

REFERENCE VOL TAGE (V)

Figure 18. ADC DNL vs. Reference Voltage

AVDD = DVDD = 5V

= 5V, INTE RNAL REF,

V

DRIVE

OFFSET IN A/B/C/D = FLOATI NG

256

768

1280

1792

5120

1024

1536

2048

CODE

2304

2560

Figure 19. DAC INL

= 25°C

A

= 5V, V

DRIVE

DD

C MODE 400kHz

= 5V

2816

3072

REF

3328

RANGE

3584

3840

4096

–0.6

256

768

1280

1792

2304

2816

3328

5120

1024

1536

2048

2560

5747-093

CODE

3072

3584

3840

4096

05747-080

Figure 20. DAC DNL

20

15

10

5

0

OUTPUT (µV)

–5

–10

–15

–20

5747-094

012345678910

TIME (s)

5747-097

Figure 21. 0.1 Hz to 10 Hz DAC Output Noise (Code 800)

5.0

4.5

4.0

3.5

3.0

2.5

2.0

DAC OUTPUT (V)

1.5

1.0

0.5

0

–5–4–3–2–1012345678910

05747-079

TIME (µs)

64pF

1nF

10nF

5747-084

Figure 22. Settling Time for a ¼ to ¾ Output Voltage Step

Rev. 0 | Page 14 of 44

AD7294

0.8

0.6

0.4

0.2

0

(%)

–0.2

–0.4

–0.6

–0.8

020

TIME (µs)

64pF

1nF

10nF

18161412108642

5747-085

Figure 23. Zoomed in Settling for a ¼ to ¾ Output Voltage Step

1.0

0.9

0.8

0.7

0.6

(V)

0.5

OUT

V

0.4

0.3

0.2

0.1

Figure 24. DAC Sinking Current at Input Code = x000, (V

–0.1

–0.2

–0.3

–0.4

–0.5

– (V+)

OUT

–0.6

V

–0.7

–0.8

–0.9

–1.0

Figure 25. DAC Sourcing Current at Input Code = x000, (V

DAC A

DAC B

DAC C

DAC D

0

043530252015105

0

AVDD = DVDD = 5V

OFFSET IN = FLOATING

DAC OUT V = 15V

V

= 5V, INTERNAL REF

DRIVE

043530252015105

AVDD = DVDD = 5V

OFFSET IN = FLOATING

DAC OUT V = 15V

V

= 5V, INTERNAL REF

DRIVE

SINK CURRENT (mA)

SOURCE CURRENT (mA)

0

5747-090

= 0 V)

OUT

DAC A

DAC B

DAC C

DAC D

0

5747-091

= 0 V)

OUT

100

80

60

40

20

–20

–40

–60

CHANGE IN OUTP UT VOLT AGE (mV)

–80

–100

0

–50 5020 4030100–10–20–30–40

DAC A

DAC B

DAC C

DAC D

AVDD = DVDD = 5V

OFFSET IN = FLOATING

DAC OUT V = 15V

V

DRIVE

LOAD CURRENT (mA)

= 5V, INTERNAL REF

5747-092

Figure 26. DAC Output Voltage vs. Load Current, Input Code = x800

55

50

45

40

35

30

TEMPERATURE READI NG (°C)

25

20

–5 0 5 10 15 20

TIME (S econds)

05747-064

Figure 27. Response of the AD7294 to Thermal Shock Using 2N3906

(2N3906 Placed in a Stirred Oil Bath)

55

EXTERNAL

INTERNAL

AD7294 IN SOCKET ON

200mm × 100mm 2-LAYE R FR-4 PCB

TIME (Seconds)

05747-066

TEMPERATURE ( °C)

50

45

40

35

30

25

–5 0 60555045403530252015105

Figure 28. Response to Thermal Shock from Room Temperature into 50°C

Stirred Oil (Both the AD7294 and the 2N3906 are Placed in a Stirred Oil Bath)

Rev. 0 | Page 15 of 44

AD7294

–

–

0

–0.2

–0.4

–0.6

–0.8

–1.0

–1.2

ERROR (°C)

–1.4

–1.6

–1.8

–2.0

0 0.5 1.0 1.5 2.0 2.5

Figure 29. Temperature Error vs. Capacitor Between D+ and D−

15

CAPACITANCE FROM D+ TO D– (n F)

50

–55

–60

–65

–70

–75

PSRR (dB)

–80

–85

–90

–95

1k 10k 100k 1M 10M

05747-065

Figure 32. I

Without V

50

Power Supply Rejection Ratio vs. Supply Ripple Frequency

SENSE

Supply Decoupling Capacitors for a 500 mV Ripple

PP

FREQUENCY (Hz)

5747-102

10

5

0

–5

ERROR (°C)

–10

–15

–20

0 20 00 4000 6000 8000 10000 12000

SERIES RESI STANCE (Ω)

Figure 30. Temperature Error vs. Series Resistance for 15 Typical Parts

5

0

–5

–10

–15

–20

–25

–30

AMPLITUDE ( dB)

–35

–40

–45

–50

1k 10k 100k 1M 10M 100M

FREQUENCY (Hz)

Figure 31. Frequency Response of the High-Side Current Sensor

on the AD7294

–60

–70

–80

CMRR (dB)

–90

–100

–110

1 100M10M1M100k10k1k10010

05747-062

Figure 33. I

Common-Mode Rejection Ratio vs. Ripple Frequency for a

SENSE

RIPPLE FREQUENCY (Hz)

5747-103

400 mV Peak-To-Peak Ripple

5747-096

Rev. 0 | Page 16 of 44

AD7294

TERMINOLOGY

DAC TERMINOLOGY

Relative Accuracy

For the DAC, relative accuracy or integral nonlinearity (INL) is

a measure of the maximum deviation, in LSBs, from a straight

line passing through the endpoints of the DAC transfer function.

Differential Nonlinearity

Differential nonlinearity (DNL) is the difference between the

measured change and the ideal 1 LSB change between any two

adjacent codes. A specified differential nonlinearity of ±1 LSB

maximum ensures monotonicity. This DAC is guaranteed monotonic by design.

Zero Code Error

Zero code error is a measure of the output error when zero code

(0x0000) is loaded to the DAC register. Ideally, the output

should be 0 V. The zero code error is always positive in the

AD7294 because the output of the DAC cannot go below 0 V.

Zero code error is expressed in mV.

Full-Scale Error

Full-scale error is a measure of the output error when full-scale

code (0xFFFF) is loaded to the DAC register. Ideally, the output

should be V

− 1 LSB. Full-scale error is expressed in mV.

DD

Gain Error

Gain error is a measure of the span error of the DAC. It is the

deviation in slope of the DAC transfer characteristic from ideal,

expressed as a percent of the full-scale range.

Tot a l U n ad ju s te d E rr o r

Total unadjusted error (TUE) is a measure of the output error,

taking all of the various errors into account.

Zero Code Error Drift

Zero code error drift is a measure of the change in zero code

error with a change in temperature. It is expressed in µV/°C.

Gain Error Drift

Gain error drift is a measure of the change in gain error with

changes in temperature. It is expressed in (ppm of full-scale

range)/°C.

ADC TERMINOLOGY

Signal-to-Noise and Distortion Ratio (SINAD)

The measured ratio of signal-to-noise and distortion at the

output of the ADC. The signal is the rms amplitude of the

fundamental. Noise is the sum of all nonfundamental signals

up to half the sampling frequency (f

/2), excluding dc. The

S

ratio is dependent on the number of quantization levels in the

digitization process; the more levels, the smaller the quantization

noise. The theoretical signal-to-noise and distortion ratio for

an ideal N-bit converter with a sine wave input is given by

Signal-to-(Noise + Distortion) = (6.02 N + 1.76) dB

Thus, the SINAD is 74 dB for an ideal 12-bit converter.

Total Harmonic Distortion (THD)

The ratio of the rms sum of harmonics to the fundamental. For

the AD7294, it is defined as

2

2

THD

where V

V

1

, V5, and V6 are the rms amplitudes of the second through

4

log20)dB(

=

is the rms amplitude of the fundamental and V2, V3,

4

3

V

1

VVVVV

++++

6

5

2

2

2

2

sixth harmonics.

Peak Harmonic or Spurious Noise

The ratio of the rms value of the next largest component in the

ADC output spectrum (up to f

/2 and excluding dc) to the rms

S

value of the fundamental. Typically, the value of this specification

is determined by the largest harmonic in the spectrum, but for

ADCs where the harmonics are buried in the noise floor, it is a

noise peak.

Integral Nonlinearity

The maximum deviation from a straight line passing through

the endpoints of the ADC transfer function. The endpoints are

zero scale, a point 1 LSB below the first code transition, and full

scale, a point 1 LSB above the last code transition.

Differential Nonlinearity

The difference between the measured and the ideal 1 LSB

change between any two adjacent codes in the ADC.

Offset Error

The deviation of the first code transition (00…000) to

(00…001) from the ideal—that is, AGND + 1 LSB.

Offset Error Match

The difference in offset error between any two channels.

Gain Error

The deviation of the last code transition (111…110) to

(111…111) from the ideal (that is, REF

− 1 LSB) after the

IN

offset error has been adjusted out.

Gain Error Match

The difference in gain error between any two channels.

Rev. 0 | Page 17 of 44

AD7294

V

/

6

THEORY OF OPERATION

ADC OVERVIEW

The AD7294 provides the user with a 9-channel multiplexer, an

on-chip track-and-hold, and a successive approximation ADC

based around a capacitive DAC. The analog input range for the

part can be selected as a 0 V to V

configured with either single-ended or differential analog inputs.

The AD7294 has an on-chip 2.5 V reference that can be disabled

when an external reference is preferred. If the internal ADC

reference is to be used elsewhere in a system, the output must

first be buffered.

The various monitored and uncommitted input signals are multiplexed into the ADC. The AD7294 has four uncommitted

analog input channels, V

0 to VIN3. These four channels allow

IN

single-ended, differential, and pseudo differential mode

measurements of various system signals.

ADC TRANSFER FUNCTIONS

The designed code transitions occur at successive integer LSB

values (1 LSB, 2 LSB, and so on). In single-ended mode, the

LSB size is V

2 × V

REF

transfer characteristic for the ADC when outputting straight

binary coding is shown in Figure 34.

111. ..111

111.. .110

111. ..00 0

011. ..111

ADC CODE

000...010

000...001

000...000

NOTE

1. V

REF

In differential mode, the LSB size is 2 × V

to V

range is used, and 4 × V

REF

range is used. The ideal transfer characteristic for the ADC when

outputting twos complement coding is shown in Figure 35 (with

the 2 × V

/4096 when the 0 V to V

REF

/4096 when the 0 V to 2 × V

1LSB

0V

IS EITHER V

Figure 34. Single-Ended Transfer Characteristic

range).

REF

REF

OR 2 × V

input or a 2 × V

REF

range is used and

REF

range is used. The ideal

REF

1LSB = V

ANALOG INPUT

.

REF

/4096 when the 0 V to 2 × V

REF

/4096

REF

V

– 1LSB

REF

/4096 when the 0 V

REF

input,

REF

05747-016

REF

1LSB = 2 ×

011. ..111

011...110

000...001

000...000

111.. .111

ADC CODE

100...010

100...001

100...000

+ 1LSB V

REF

Figure 35. Differential Transfer Characteristic with V

REF

– 1LSB

REF

ANALOG INPUT

409

+V

– 1LSB–V

REF

REF

± V

REF

Input Range

5747-017

For VIN0 to VIN3 in single-ended mode, the output code is

straight binary, where

V

= 0 V, D

IN

= x000, VIN = V

OUT

− 1 LSB, and D

REF

OUT

= xFFF

In differential mode, the code is twos complement, where

V

− V

− V

− V

IN−

IN−

IN−

= 0 V, and D

= V

− 1 LSB, and D

REF

= −V

REF

IN+

V

IN+

V

IN+

OUT

, and D

= x00

= x800

OUT

= x7FF

OUT

Channel 5 and Channel 6 (current sensor inputs) are twos

complement, where

V

− V

− V

− V

IN−

IN−

IN−

= 0 mV, and D

= V

/12.5 − 1 LSB, D

REF

= −V

/12.5, D

REF

IN+

V

IN+

V

IN+

OUT

OUT

= x000

OUT

= x800

= x7FF

Channel 7 to Channel 9 (temperature sensor inputs) are twos

complement with the LSB equal to 0.25°C, where

= 0°C, and D

T

IN

T

= +255.75°C, and D

IN

= −256°C, and D

T

IN

OUT

= x000

OUT

= x800

OUT

= x7FF

ANALOG INPUTS

The AD7294 has a total of four analog inputs. Depending on

the configuration register setup, they can be configured as two

single-ended inputs, two pseudo differential channels, or two

fully differential channels. See the Register Setting section for

further details.

Single-Ended Mode

The AD7294 can have four single-ended analog input channels.

In applications where the signal source has high impedance, it is

recommended to buffer the analog input before applying it to the

ADC. The analog input range can be programmed to be either

0 V to V

or 0 V to 2 × V

REF

. In 2 × V

REF

mode, the input is

REF

effectively divided by 2 before the conversion takes place. Note

that the voltage with respect to GND on the ADC analog input

pins cannot exceed AV

DD

.

If the analog input signal to be sampled is bipolar, the internal

reference of the ADC can be used to externally bias up this

Rev. 0 | Page 18 of 44

AD7294

V

signal so that it is correctly formatted for the ADC. Figure 36

shows a typical connection diagram when operating the ADC

in single-ended mode.

+2.5

+1.25V

–1.25V

0V

V

IN

3R

1

ADDITIONAL PINS OMI TTED FO R CLARITY.

R

R

R

0V

OUT

ADC

0.47µF

1

05747-018

V

IN

VIN3

0

REF

AD7294

Figure 36. Single-Ended Mode Connection Diagram

Differential Mode

The AD7294 can have two differential analog input pairs.

Differential signals have some benefits over single-ended

signals, including noise immunity based on the commonmode rejection of the device and improvements in distortion

performance. Figure 37 defines the fully differential analog

input of the AD7294.

p-p

p-p

V

IN+

AD7294

V

IN–

1

05747-019

V

REF

COMMON-MO DE

VOLTAGE

1

ADDITIONAL PINS OMIT TED FOR CL ARITY.

V

REF

Figure 37. Differential Input Definition

The amplitude of the differential signal is the difference

between the signals applied to V

pair (V

IN+

− V

). The resulting converted data is stored in twos

IN−

IN+

and V

in each differential

IN−

complement format in the result register. Simultaneously drive

V

0 and VIN1 by two signals, each of amplitude V

IN

V

, depending on the range chosen), that are 180° out of

REF

phase. Assuming the 0 V to V

of the differential signal is, therefore, −V

peak (2 × V

), regardless of the common mode (VCM).

REF

range is selected, the amplitude

REF

to +V

REF

(or 2 ×

REF

peak-to-

REF

The common mode is the average of the two signals

(V

+ V

IN−

)/2

IN+

The common mode is, therefore, the voltage on which the two

inputs are centered.

This results in the span of each input being V

CM

± V

/2. This

REF

voltage has to be set up externally, and its range varies with the

reference value, V

. As the value of V

REF

increases, the common-

REF

mode range decreases. When driving the inputs with an amplifier,

the actual common-mode range is determined by the output

voltage swing of the amplifier.

The common mode must be in this range to guarantee the

functionality of the AD7294.

When a conversion takes place, the common mode is rejected,

resulting in a virtually noise-free signal of amplitude −V

+V

, corresponding to the digital output codes of −2048 to

REF

REF

to

+2047 in twos complement format.

If the 2 × V

from −2 ×V

V

= V

IN+

range is used, the input signal amplitude extends

REF

(V

REF

REF

= 0 V, V

IN+

).

IN−

= V

) to +2 × V

REF

REF

(V

IN−

= 0 V,

Driving Differential Inputs

The differential modes available on VIN0 to VIN3 in Tabl e 13

require that V

IN+

and V

be driven simultaneously with two

IN−

equal signals that are 180° out of phase. The common mode on

which the analog input is centered must be set up externally. The

common-mode range is determined by V

, the power supply,

REF

and the particular amplifier used to drive the analog inputs.

Differential modes of operation with either an ac or dc input

provide the best THD performance over a wide frequency

range. Because not all applications have a signal preconditioned

for differential operation, there is often a need to perform a singleended-to-differential conversion.

Using an Op Amp Pair

An op amp pair can be used to directly couple a differential signal

to one of the analog input pairs of the AD7294. The circuit configurations illustrated in Figure 38 show how a dual op amp can

be used to convert a single-ended bipolar signal into a differential

unipolar input signal.

The voltage applied to Point A sets up the common-mode voltage.

As shown in Figure 38, Point A connects to the reference, but any

value in the common-mode range can be the input at Point A to

set up the common mode. The AD8022 is a suitable dual op amp

that can be used in this configuration to provide differential

drive to the AD7294.

Care is required when choosing the op amp because the selection

depends on the required power supply and system performance

objectives. The driver circuits in Figure 38 are optimized for dc

coupling applications requiring best distortion performance.

The differential op amp driver circuit shown in Figure 38 is

configured to convert and level shift a single-ended, ground

referenced (bipolar) signal to a differential signal centered at the

V

level of the ADC.

REF

Rev. 0 | Page 19 of 44

AD7294

GND

2 × V

REF

p-p

440Ω

220kΩ

20kΩ

220Ω

V+

27Ω

V–

220Ω

220Ω

V+

27Ω

A

V–

10kΩ

1

ADDITIONAL PINS O MITTED FO R CLARITY.

3.75V

2.5V

1.25V

3.75V

2.5V

1.25V

AD7294

ADC

OUT

0.47µF

1

V

IN+

REF

V

IN–

Figure 38. Dual Op Amp Circuit to Convert a Single-Ended Bipolar Signal

into a Differential Unipolar Signal

Pseudo Differential Mode

The four uncommitted analog input channels can be configured

as two pseudo differential pairs. Uncommitted input, V

V

1, are a pseudo differential pair, as are VIN2 and VIN3. In this

IN

mode, V

maximum amplitude of V

is connected to the signal source, which can have a

IN+

(or 2 × V

REF

, depending on the

REF

0 and

IN

range chosen) to make use of the full dynamic range of the part.

A dc input is applied to V

provides an offset from ground or a pseudo ground for the V

input. Which channel is V

. The voltage applied to this input

IN−

is determined by the ADC channel

IN+

IN+

allocation. The differential mode must be selected to operate in the

pseudo differential mode. The resulting converted pseudo differential data is stored in twos complement format in the result register.

The governing equation for the pseudo differential mode, for

V

0 is

IN

V

where V

OUT

= 2(V

IN+

− V

IN+

IN−

) − V

REF_ADC

is the single-ended signal and V

is a dc voltage.

IN−

The benefit of pseudo differential inputs is that they separate

the analog input signal ground from the ADC ground, allowing

dc common-mode voltages to be cancelled. The typical voltage

range for V

while in pseudo differential mode is shown in

IN−

Figure 39; Figure 40 shows a connection diagram for pseudo

differential mode.

2.0

1.5

1.0

(V)

IN–

V

0.5

0

–0.5

054321

Figure 39. V

Input Range vs. V

IN−

V

(V)

REF

in Pseudo Differential Mode

REF

AVDD = DVDD = 5V

V

= 5V

DRIVE

6

05747-095

Rev. 0 | Page 20 of 44

V

REF

p-p

V

IN+

V

DC INPUT

VOLTAGE

1

ADDITIONAL PINS OMITTED FO R CLARITY.

REF

IN–

OUT

/REFIN ADC

AD7294

0.47µF

1

05747-026

Figure 40. Pseudo Differential Mode Connection Diagram

05747-023

CURRENT SENSOR

Two bidirectional high-side current sense amplifiers are

provided that can accurately amplify differential current shunt

voltages in the presence of high common-mode voltages from

AV

up to 59.4 V. Each amplifier can accept a ±200 mV

DD

differential input. Both current sense amplifiers have a fixed

gain of 12.5 and utilize an internal 2.5 V reference.

An analog comparator is also provided with each amplifier for

fault detection. The threshold is defined as

1.2 × Full-Scale Voltage Range

When this limit is reached, the output is latched onto a

dedicated pin. This output remains high until the latch is

cleared by writing to the appropriate register.

I

AVDD TO 54.5V

V

PP

AD7294

100kΩ

R

RS(+)

R1

40kΩ

Q1 Q2

R3

SENSE

A1

A1

RS(–)

R2

40kΩ

LOAD

R4

100kΩ

V

OUT

A2

TO MUX

05747-029

Figure 41. High-Side Current Sense

The AD7294 current sense comprises two main blocks: a

differential and an instrumentation amplifier. A load current

flowing through the external shunt resistor produces a voltage

at the input terminals of the AD7294. Resistors R1 and R2

connect the input terminals to the differential amplifier (A1).

A1 nulls the voltage appearing across its own input terminals

by adjusting the current through R1 and R2 with Transistor Q1

and Transistor Q2. Common-mode feedback maintains the sum

of these currents at approximately 50 A. When the input signal

to the AD7294 is zero, the currents in R1 and R2 are equal. When

the differential signal is nonzero, the current increases through

one of the resistors and decreases in the other. The current difference is proportional to the size and polarity of the input signal.

The differential currents through Q1 and Q2 are converted into

a differential voltage by R3 and R4. A2 is configured as an instrumentation amplifier, buffering this voltage and providing additional

AD7294

V

gain. Therefore, for an input voltage of ±200 mV at the pins, an

output span of ±2.5 V is generated.

The current sensors on the AD7294 are designed to remove any

flicker noise and offset present in the sensed signal. This is

achieved by implementing a chopping technique that is transparent to the user. The V

signal is first converted by the AD7294,

SENSE

the analog inputs to the amplifiers are then swapped, and the

differential voltage is once again converted by the AD7294. The

two conversion results enable the digital removal of any offset

or noise. Switches on the amplifier inputs enable this chopping

technique to be implemented. This process requires 6 s in total

to return a final result.

Choosing R

SENSE

The resistor values used in conjunction with the current sense

amplifiers on the AD7294 are determined by the specific application requirements in terms of voltage, current, and power.

Small resistors minimize power dissipation, have low inductance

to prevent any induced voltage spikes, and have good tolerance,

which reduce current variations. The final values chosen are a

compromise between low power dissipation and good accuracy.

Low value resistors have less power dissipated in them, but higher

value resistors may be required to utilize the full input range of

the ADC, thus achieving maximum SNR performance.

When the sense current is known, the voltage range of the

AD7294 current sensor (200 mV) is divided by the maximum

sense current to yield a suitable shunt value. If the power dissipation in the shunt resistor is too large, the shunt resistor can be

reduced, in which case, less of the ADC input range is used.

Using less of the ADC input range results in conversion results,

which are more susceptible to noise and offset errors because

offset errors are fixed and are thus more significant when

smaller input ranges are used.

R

must be able to dissipate the I2R losses. If the power dissi-

SENSE

pation rating of the resistor is exceeded, its value may drift or

the resistor may be damaged resulting in an open circuit. This

can result in a differential voltage across the terminals of the

AD7294 in excess of the absolute maximum ratings. Additional

protection is afforded to the current sensors on the AD7294 by

the recommended current limiting resistors, RF1 and RF2, as

illustrated in Figure 42. The AD7294 can handle a maximum

continuous current of 30 mA; thus, an RF2 of 1 kΩ provides

adequate protection for the AD7294.

If I

has a large high frequency component, take care to

SENSE

choose a resistor with low inductance. Low inductance metal

film resistors are best suited for these applications.

Current Sense Filtering

In some applications, it may be desirable to use external

filtering to reduce the input bandwidth of the amplifier (see

Figure 42). The −3 dB differential bandwidth of this filter is

equal to

BW

= 1/(4πRC)

DM

Note that the maximum series resistance on the RS(+) and

RS(−) inputs (as shown in Figure 41) is limited to a maximum

of 1 k due to back-to-back ESD protection diodes from RS(+)

and RS(−) to V

. Also, note that if RF1 and RF2 are in series

PP

with R1 and R2 (shown in Figure 41), it affects the gain of the

amplifier. Any mismatch between RF1 and RF2 can introduce

offset error.

PP

10nF

V

PP

AD7294

Figure 42. Current Sense Filtering (RS

R

RF1 RF2

Can Be Either RS1 or RS2)

X

SENSE

CF

I

LOAD

RSx(–)RSx(+)

5747-098

For certain RF applications, the optimum value for RF1 and

RF2 is 1 k whereas CF1 can range from 1 F to 10 F. CF2 is a

decoupling capacitor for the V

supply. Its value is application

PP

dependant, but for initial evaluation, values in the range of 1 nF

to 100 nF are recommended.

Kelvin Sense Resistor Connection

When using a low value sense resistor for high current

measurement, the problem of parasitic series resistance can

arise. The lead resistance can be a substantial fraction of the

rated resistance, making the total resistance a function of lead

length. Avoid this problem by using a Kelvin sense connection.

This type of connection separates the current path through the

resistor and the voltage drop across the resistor. Figure 43 shows

the correct way to connect the sense resistor between the RS(+)

and RS(−) pins of the AD7294.

SENSE RESISTOR

CURRENT

FLOW FROM

SUPPLY

KELVIN

SENSE

TRACES

RSX(+) RSX(–)

AD7294

Figure 43. Kelvin Sense Connections (RSX Can Be Either RS1 or RS2)

CURRENT

FLOW TO

LOAD

05747-031

ANALOG COMPARATOR LOOP

The AD7294 contains two setpoint comparators that are used

for independent analog control. This circuitry enables users

to quickly detect if the sensed voltage across the shunt has

Rev. 0 | Page 21 of 44

AD7294

V

2

2

increased about the preset (V

I

OVERRANGE pin is set to a high logic level enabling

SENSE

appropriate action to be taken to prevent any damage to the

external circuitry.

The setpoint threshold level is fixed internally in the AD7294,

and the current sense amplifier saturates above this level. The

comparator also triggers if a voltage of less than AV

to the R

or VPP pin.

SENSE

TEMPERATURE SENSOR

The AD7294 contains one local and two remote temperature

sensors. The temperature sensors continuously monitor the

three temperature inputs and new readings are automatically

available every 5 ms.

The on-chip, band gap temperature sensor measures the temperature of the system. Diodes are used in conjunction with the two

remote temperature sensors to monitor the temperature of other

critical board components.

4 × I

16 × I I I-BIAS

D2+

D1+

T1 T2

REMOTE

SENSING

TRANSISTORS

The temperature sensor module on the AD7294 is based on the

three current principle (see Figure 44), where three currents are

passed through a diode and the forward voltage drop is measured

at each diode, allowing the temperature to be calculated free of

errors caused by series resistance.

Each input integrates, in turn, over a period of several hundred

microseconds. This takes place continuously in the background,

leaving the user free to perform conversions on the other channels.

When integration is complete, a signal passes to the control logic

to initiate a conversion automatically. If the ADC is in command

mode, the temperature conversion is performed as soon as the

next conversion is completed. In autocycle mode, the conversion

is inserted into an appropriate place in the current sequence; see

the Register Setting section for further details. If the ADC is

idle, the conversion takes place immediately.

Three registers store the result of the last conversion on each

temperature channel; these can be read at any time. In addition,

in command mode, one or both of the two external channel

registers can be read out as part of the output sequence.

D1–

D2–

Figure 44. Internal and Remote Temperature Sensors

MUX

AD7294

× 1.2)/12.5. If this occurs, the

REF

is applied

DD

DD

TO ADC

LPF

MUX

LIMIT

REGISTERS

TEMP

SENSOR

CAP

f

= 65kHz

C

BIAS DIODE

ALERT

Remote Sensing Diode

The AD7294 is designed to work with discrete transistors,

2N3904 and 2N3906. If an alternative transistor is used, the

AD7294 operates as specified provided the following conditions

are adhered to.

Ideality Factor

The ideality factor, nf, of the transistor is a measure of the