1 MSPS, 12-Bit, Simultaneous Sampling

V

A

SAR ADC with PGA and Four Comparators

FEATURES

Dual simultaneous sampling 12-bit, 2-channel ADC

True differential analog inputs

Programmable gain stage: ×1, ×2, ×3, ×4, ×6, ×8, ×12, ×16,

×24, ×32, ×48, ×64, ×96, ×128

Throughput rate per ADC

1 MSPS for AD7262

500 kSPS for AD7262-5

Analog input impedance: >1 GΩ

Wide input bandwidth

−3 dB bandwidth: 1.7 MHz at gain = 2

4 on-chip comparators

SNR: 73 dB typical at gain = 2, 66 dB typical at gain = 32

Device offset calibration, system gain calibration

On-chip reference: 2.5 V

–40°C to +105°C operation

High speed serial interface

SPI/QSPI™/MICROWIRE™/DSP compatible

48-lead LFCSP and LQFP packages

GENERAL DESCRIPTION

The AD7262/AD7262-5 are dual, 12-bit, high speed, low power,

successive approximation ADCs that operate from a single 5 V

power supply. The AD7262 features throughput rates of up to

1 MSPS per on-chip ADC. The AD7262-5 features throughput

rates of up to 500 kSPS. Two complete ADC functions allow

simultaneous sampling and conversion of two channels. Each

ADC is preceded by a true differential analog input with a PGA.

There are 14 gain settings available: ×1, ×2, ×3, ×4, ×6, ×8, ×12,

×16, ×24, ×32, ×48, ×64, ×96, and ×128.

The AD7262/AD7262-5 contain four comparators. Comparator A

and Comparator B are optimized for low power, while Comparator C and Comparator D have fast propagation delays. The

AD7262/AD7262-5 feature a calibration function to remove any

device offset error and programmable gain adjust registers to

allow for input path (for example, sensor) offset and gain

compensation. The AD7262/AD7262-5 have an on-chip 2.5 V

reference that can be disabled if an external reference is preferred.

The AD7262/AD7262-5 are ideally suited for monitoring small

amplitude signals from a variety of sensors. They include all the

functionality needed for monitoring the position feedback

signals from a variety of analog encoders used in motor control

systems.

AD7262

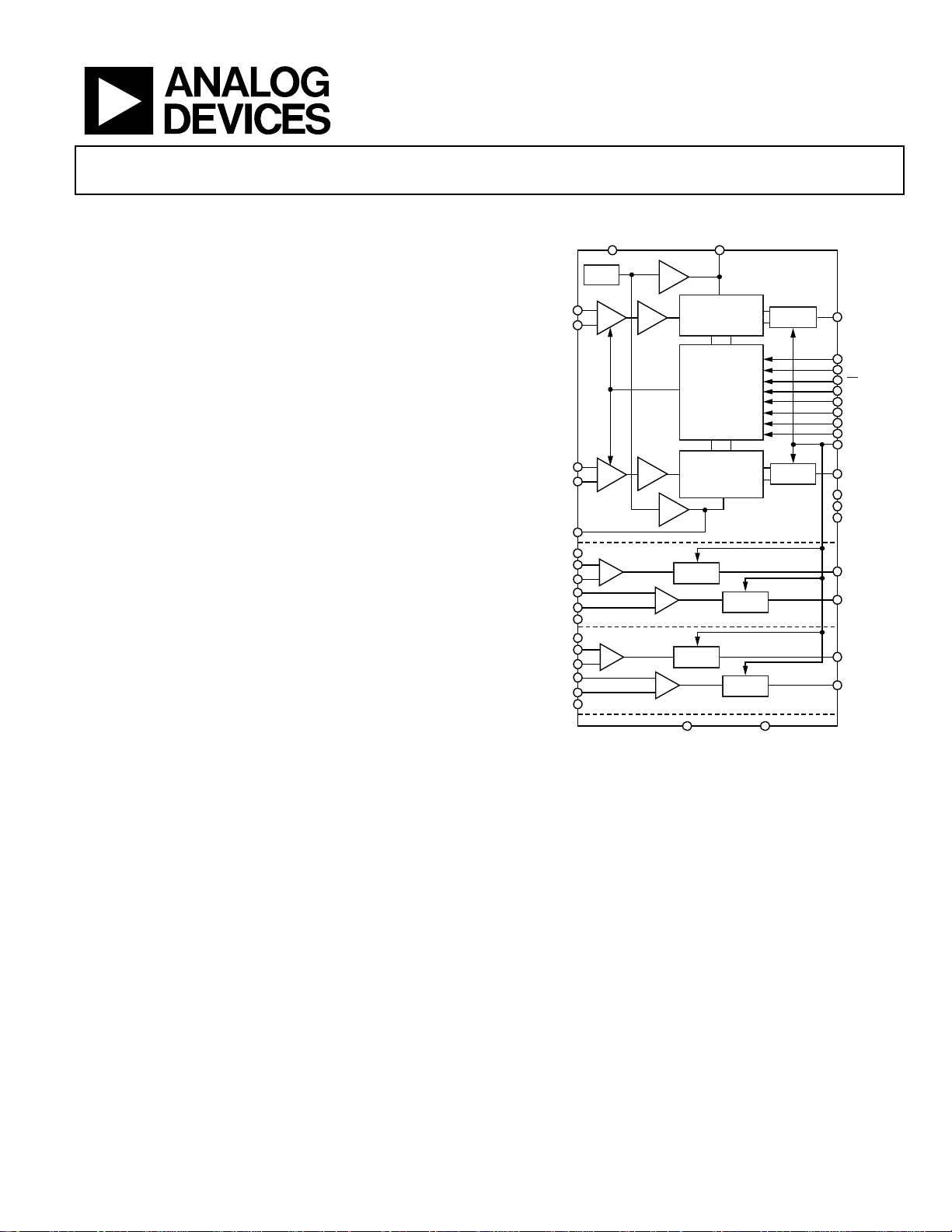

FUNCTIONAL BLOCK DIAGRAM

V

CC

VA+

V

V

V

V

REF

C

A_CBVCC

C

C

C

C

CA_CB_GND

C

C_CDVCC

C

C

C

C

CC_CD_GND

A

B

B

B

A

A

B

B

C

C

D

D

–

+

–

+

–

+

–

+

–

+

–

REF

PGA T/H

PGA

COMP

COMP

BUF

T/H

BUF

OUTPUT

DRIVERS

COMP

OUTPUT

DRIVERS

COMP

AGND DGND

PRODUCT HIGHLIGHTS

1. Integrated PGA with a variety of flexible gain settings to

allow detection and conversion of low level analog signals.

2. Each PGA is followed by a dual simultaneous sampling

ADC, featuring throughput rates of 1 MSPS per ADC for

the AD7262. The conversion results of both ADCs are

simultaneously available on separate data lines or in succession on one data line if only one serial port is available.

3. Four integrated comparators that can be used to count

signals from pole sensors in motor control applications.

4. Internal 2.5 V reference.

A

REF

12-BIT

SUCCESSIVE

APPROXIMATION

ADC

CONTRO L

LOGIC

12-BIT

SUCCESSIVE

APPROXIMATION

ADC

OUTPUT

DRIVERS

OUTPUT

DRIVERS

Figure 1.

AD7262

OUTPUT

DRIVERS

OUTPUT

DRIVERS

D

OUT

SCLK

CAL

CS

REFSEL

G0

G1

G2

G3

V

DRIVE

D

OUT

PD0/D

PD1

PD2

C

OUT

C

OUT

C

OUT

C

OUT

A

B

IN

A

B

C

D

07606-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

AD7262

TABLE OF CONTENTS

Features .............................................................................................. 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 6

Timing Diagram ........................................................................... 6

Absolute Maximum Ratings ............................................................ 7

ESD Caution .................................................................................. 7

Pin Configurations and Function Descriptions ........................... 8

Typical Performance Characteristics ........................................... 10

Terminology .................................................................................... 14

Theory of Operation ...................................................................... 15

Circuit Information .................................................................... 15

Comparators ................................................................................ 15

Operation ..................................................................................... 15

Analog Inputs .............................................................................. 15

V

............................................................................................ 16

DRIVE

Reference ..................................................................................... 17

Typical Connection Diagrams .................................................. 17

Application Details ..................................................................... 20

Modes of Operation ....................................................................... 22

Pin-Driven Mode ....................................................................... 22

Gain Selection ............................................................................. 22

Power-Down Modes .................................................................. 22

Control Register ......................................................................... 23

On-Chip Registers ...................................................................... 24

Serial Interface ................................................................................ 25

Calibration ....................................................................................... 27

Internal Offset Calibration ........................................................ 27

Adjusting the Offset Calibration Registers ................................. 28

System Gain Calibration............................................................ 28

Microprocessor Interfacing ........................................................... 29

AD7262/AD7262-5 to ADSP-BF53x ....................................... 29

Application Hints ........................................................................... 30

Grounding and Layout .............................................................. 30

PCB Design Guidelines for LFCSP .......................................... 30

Outline Dimensions ....................................................................... 31

Ordering Guide .......................................................................... 31

REVISION HISTORY

7/08—Revision 0: Initial Version

Rev. 0 | Page 2 of 32

AD7262

SPECIFICATIONS

AVCC = 4.75 V to 5.25 V, CA_CBVCC = CC_CDVCC = 2.7 V to 5.25 V, V

for AD7262, f

= 500 kSPS and f

SAMPLE

= 20 MHz for AD7262-5, V

SCLK

otherwise noted.

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

DYNAMIC PERFORMANCE

Signal-to-Noise Ratio (SNR)

Signal-to-(Noise + Distortion) Ratio

(SINAD)

2

Total Harmonic Distortion (THD)

Spurious-Free Dynamic Range (SFDR)

Common-Mode Rejection Ratio (CMRR)

ADC-to-ADC Isolation

Bandwidth

3

1.2 MHz @ −3 dB; PGA gain setting = 128

1

2

f

70 73 dB PGA gain setting = 2

70 72 dB

2

−85 −77 dB

2

−97 dB

3

−76 dB

3

−90 dB

1.7 MHz @ −3 dB; PGA gain setting = 2

DC ACCURACY

Resolution 12 Bits

Integral Nonlinearity

Differential Nonlinearity

Positive Full-Scale Error

2

±0.5 ±1 LSB

2

±0.5 ±0.99 LSB Guaranteed no missed codes to 12 bits

2

±0.122 ±0.305 % FSR Pregain calibration

±0.018 % FSR Postgain calibration

Positive Full-Scale Error Match ±0.061 % FSR

Zero Code Error

2

±0.092 ±0.244 % FSR Preoffset and pregain calibration

±0.012 % FSR Postoffset and postgain calibration

Zero Code Error Match ±0.061 % FSR

Negative Full-Scale Error

2

±0.122 ±0.305 % FSR Pregain calibration

±0.018 % FSR Postgain calibration

Negative Full-Scale Error Match ±0.061 % FSR

Zero Code Error Drift 2.5 µV/°C

ANALOG INPUT

Input Voltage Range, VIN+ and VIN−

V

±

CM

Common-Mode Voltage Range, VCM V

− 100 mV VCM + 100 mV V

CM

(VCC/2) − 0.4 (VCC/2) + 0.2 V VCM = AVCC/2; PGA gain setting = 2

(VCC/2) − 0.4 (VCC/2) + 0.4 V VCM = AVCC/2; 3 ≤ PGA gain setting ≤ 32

(VCC/2) − 0.6 (VCC/2) + 0.8 V VCM = AVCC/2; PGA gain setting ≥ 48

DC Leakage Current ±0.001 ±1 µA

Input Capacitance

Input Impedance

3

5 pF

3

1 GΩ

REFERENCE INPUT/OUTPUT

Reference Output Voltage

5

2.495 2.5 2.505 V 2.5 V ± 5 mV max @ 25°C

Reference Input Voltage Range 2.5 V

DC Leakage Current ±0.3 ±1 µA

Input Capacitance

V

A, V

REF

B Output Impedance

REF

3

20 pF

3

4 Ω

Reference Temperature Coefficient 20 ppm/°C

V

REF

3

Noise

20 µV rms

= 2.7 V to 5.25 V, f

DRIVE

= 2.5 V internal/external; TA = −40°C to +105°C, unless

REF

= 1 MSPS and f

SAMPLE

IN

= 40 MHz

SCLK

= 100 kHz sine wave

For PGA gain setting = 2, ripple

frequency of 50 Hz/60 Hz; see Figure 17

and Figure 18

V

REF

Gain2

×

V VCM = AVCC/2; PGA gain setting ≥ 2

= 2; PGA gain setting = 1;

V

CM

see Figure 19

4

External reference applied to

Pin V

A/Pin V

REF

REF

B

Rev. 0 | Page 3 of 32

AD7262

Parameter Min Typ Max Unit Test Conditions/Comments

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input Current, IIN ±1 µA VIN = 0 V or V

Input Capacitance, C

LOGIC OUTPUTS

Output High Voltage, VOH V

Output Low Voltage, VOL 0.4 V

Floating State Leakage Current ±1 µA

Floating State Output Capacitance

Output Coding Twos complement

CONVERSION RATE

Conversion Time 19 × t

Track-and-Hold Acquisition Time 400 ns

Throughput Rate 1 MSPS AD7262

500 kSPS AD7262-5

COMPARATORS

Input Offset

Comparator A and Comparator B ±2 ±4 mV TA = 25°C to 105°C only

Comparator C and Comparator D ±2 ±4 mV

Offset Voltage Drift 0.5 V/°C All comparators

Input Common-Mode Range

0 to 1.7 V CA_CBVCC = 2.7 V

Input Capacitance

Input Impedance

IDD Normal Mode (Static)

Comparator A and Comparator B 3 µA CA_CBVCC = 3.3 V

6 8.5 µA CA_CBVCC = 5.25 V

Comparator C and Comparator D 60 µA CC_CDVCC = 3.3 V

120 170 µA CC_CDVCC = 5.25 V

Propagation Delay Time

High to Low, t

Comparator A and Comparator B 1.4 3.5 µs CA_CBVCC = 2.7 V

0.95 µs CA_CBVCC = 5 V

Comparator C and Comparator D 0.20 0.32 µs CC_CDVCC = 2.7 V

0.13 µs CC_CDVCC = 5 V

Low to High, t

Comparator A and Comparator B 2 4 µs CA_CBVCC = 2.7 V

0.93 µs CA_CBVCC = 5 V

Comparator C and Comparator D 0.18 0.28 µs CC_CDVCC = 2.7 V

0.12 µs CC_CDVCC = 5 V

Delay Matching

Comparator A and Comparator B ±250 ns

Comparator C and Comparator D ±10 ns

0.7 × V

INH

0.8 V

INL

3

IN

3

3

0 to 4 V C

3

4 pF

3

1 GΩ

6

4 pF

DRIVE

5 pF

V

DRIVE

− 0.2 V

ns

SCLK

= 5 V

A_CBVCC

25 pF load, C

V

V

= 200 mV differential

OVERDRIVE

= AVCC/2, V

CM

DRIVE

x = 0 V, VCM = AVCC/2,

OUT

OVERDRIVE

differential

PHL

PLH

= AVCC 2, V

V

CM

OVERDRIVE

differential

= 200 mV

= 200 mV

Rev. 0 | Page 4 of 32

AD7262

Parameter Min Typ Max Unit Test Conditions/Comments

POWER REQUIREMENTS Digital inputs = 0 V or V

AVCC 4.75 5.25 V

CA_CBVCC, CC_CDVCC 2.7 5.25 V

V

2.7 5.25 V

DRIVE

IDD

ADC Normal Mode (Static) 20 31.5 mA AVCC = 5.25 V

ADC Normal Mode (Dynamic) 23 33.3 mA AVCC = 5.25 V

Shutdown Mode 0.5 1 A

= 5.25 V, ADCs and comparators

AV

CC

powered down

Power Dissipation

ADC Normal Mode (Static) 105 165 mW

ADC Normal Mode (Dynamic) 120 175 mW

Shutdown Mode 2.625 5.25 µW

1

These specifications were determined without the use of the gain calibration feature.

2

See the Terminology section.

3

Samples tested during initial release to ensure compliance; they are not subject to production testing.

4

For PGA gain = 1; to use the full analog input range (VCM ± V

5

Refers to Pin V

6

This specification includes the IDD for both comparators. The IDD per comparator is the specified value divided by two.

A or Pin V

REF

B.

REF

/2) of the AD7262, the VCM voltage should be dropped to lie within a range from 1.95 V to 2.05 V.

REF

DRIVE

Rev. 0 | Page 5 of 32

AD7262

TIMING SPECIFICATIONS

AVCC = 4.75 V to 5.25 V, CA_CBVCC = CC_CDVCC = 2.7 V to 5.25 V, V

Table 2.

Limit at T

Parameter 2.7 V ≤ V

f

200 200 kHz min

SCLK

t

CONVER T

t

13 13 ns min

QUIET

t

2

3

t

3

t

29 23 ns max Data access time after SCLK falling edge

4

t

5

t

6

40 40 MHz max AD7262

32 32 MHz typ AD7262

20 20 MHz max AD7262-5

19 × t

475 475 ns max AD7262

950 950 ns max AD7262-5

10 10 ns min

15 15 ns max

15 13 ns min SCLK to data valid hold time

0.4 × t

t7 0.4 × t

≤ 3.6 V 4.75 V ≤ V

DRIVE

19 × t

SCLK

0.4 × t

SCLK

SCLK

, T

MIN

0.4 × t

MAX

≤ 5.25 V Unit Description

DRIVE

ns max t

SCLK

ns min SCLK high pulse width

SCLK

SCLK

t8 13 13 ns min

t

9

t

10

13 13 ns max

5 5 ns min SCLK falling edge to D

35 35 ns max SCLK falling edge to D

t11 2 2 s min Minimum CAL pin high time

t12 2 2 s min

t13 3 3 ns min DIN setup time prior to SCLK falling edge

t14 3 3 ns min DIN hold time after SCLK falling edge

t

240 240 s max Internal reference, with a 1 F decoupling capacitor

POWER-UP

15 15 s max With an external reference, 10 s typical

1

Sample tested during initial release to ensure compliance. All input signals are specified with tR = tF = 5 ns (10% to 90% of AVCC) and timed from a voltage level of 1.6 V.

All timing specifications given are with a 25 pF load capacitance. With a load capacitance greater than this value, a digital buffer or latch must be used. See the

Terminology section.

2

See the Serial Interface section.

3

The time required for the output to cross 0.4 V or 2.4 V.

= 2.5 V internal/external; TA = T

REF

2

2

SCLK

= 1/f

SCLK

Minimum time between end of serial read/bus relinquish

and next falling edge of CS

to SCLK setup time

CS

th

Delay from 19

SCLK falling edge until D

three-state disabled

ns min SCLK low pulse width

rising edge to falling edge pulse width

CS

rising edge to D

CS

OUT

relinquish

Minimum time between the CAL pin high and the CS

falling edge

to T

MIN

A, D

OUT

OUT

A, D

A, D

, unless otherwise noted.1

MAX

B, high impedance/bus

OUT

B, high impedance

OUT

B, high impedance

OUT

A and D

OUT

OUT

B are

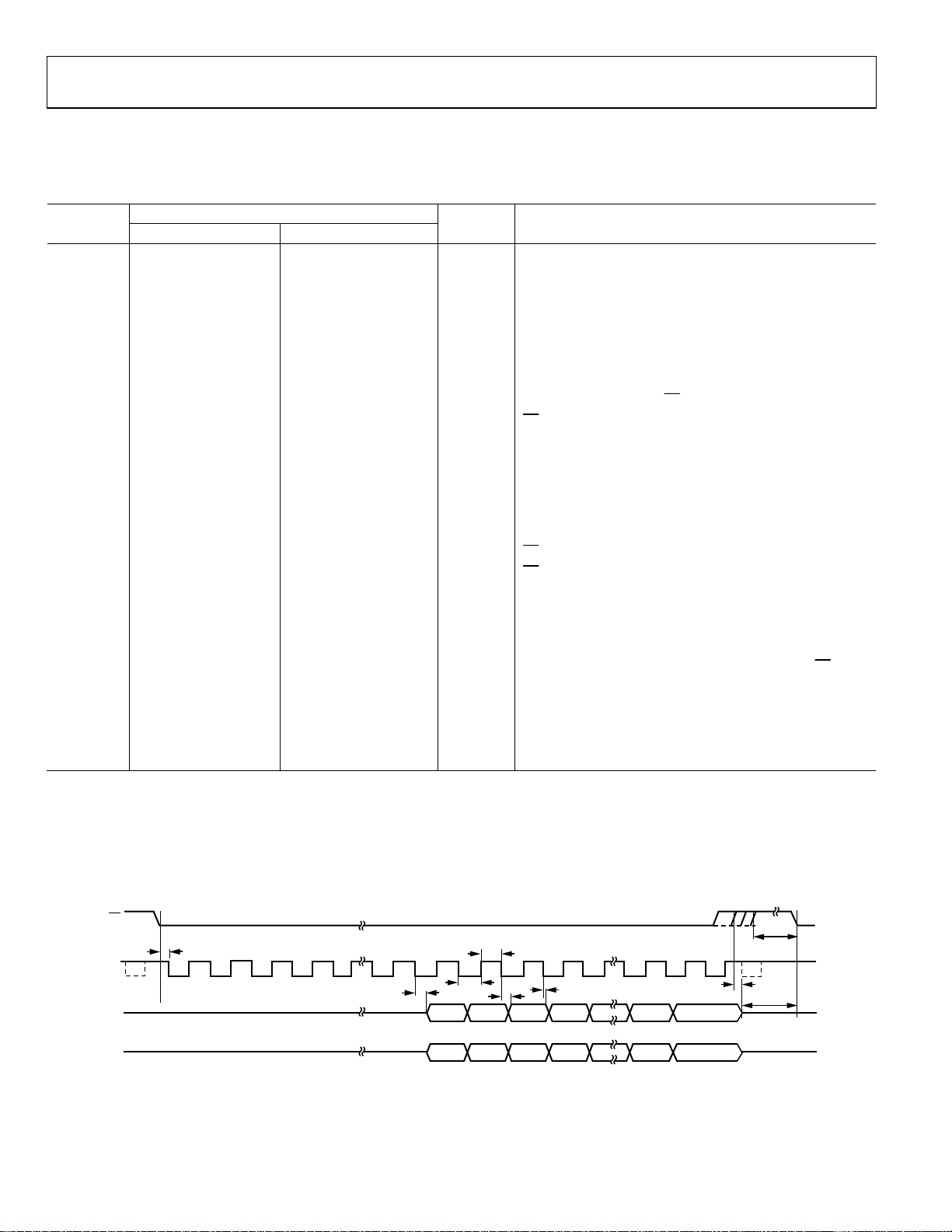

TIMING DIAGRAM

CS

SCLK

D

OUT

D

OUT

A

B

1519

t

2

234 20

THREE-STAT E

THREE-STAT E

18

t

3

Figure 2. Serial Interface Timing Diagram

Rev. 0 | Page 6 of 32

DB11

DB11

t

8

t

6

21 29 30 31

t

7

t

4

DB9

DB10

A

A

DB9

DB10

B

B

t

5

A

B

DB1

DB1

A

B

DB0

DB0

t

9

t

QUIET

A

THREESTATE

B

THREESTATE

07606-002

AD7262

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

V

to DGND −0.3 V to AVCC

DRIVE

V

to AGND −0.3 V to AVCC

DRIVE

AVCC to AGND/DGND −0.3 V to +7 V

CA_CBVCC to CA_CB_GND −0.3 V to +7 V

CC_CDVCC to CC_CD_GND −0.3 V to +7 V

AGND to DGND −0.3 V to +0.3 V

CA_CB_GND/CC_CD_GND to DGND −0.3 V to +0.3 V

Analog Input Voltage to AGND −0.3 V to AVCC + 0.3 V

Digital Input Voltage to DGND −0.3 V to +7 V

Digital Output Voltage to GND −0.3 V to V

V

A/V

REF

C

OUT

CA±/CB±/CC±/CD± to

B Input to AGND −0.3 V to AVCC + 0.3 V

REF

A/C

B/C

C/C

OUT

OUT

D to GND −0.3 V to V

OUT

−0.3 V to

_GND/CC_CD_GND

C

A_CB

CA_CBVCC/CC_CDVCC + 0.3 V

DRIVE

DRIVE

+ 0.3 V

+ 0.3 V

Operating Temperature Range −40°C to +105°C

Storage Temperature Range −65°C to +150°C

Junction Temperature 150°C

LFCSP Package

θJA Thermal Impedance 30°C/W

θJC Thermal Impedance 3°C/W

LQFP Package

θJA Thermal Impedance 55°C/W

θJC Thermal Impedance 16°C/W

Pb-Free Temperature, Soldering

Reflow 255°C

ESD 2 kV

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. 0 | Page 7 of 32

AD7262

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

_GND

B

A

CC

_C

A

REF

AV

AGND

C

V

42

434445

B

CC

REF

AV

_GND

AGND

V

D

_C

C

C

37G338G239G140G041

36

CAL

35

CS

34

SCLK

33

AV

CC

32

D

A

OUT

31

D

B

OUT

30

C

A

OUT

C

B

29

OUT

DGND

28

27

V

DRIVE

26

C

C

OUT

25

C

D

OUT

IN

PD2

PD1

PD0/D

REFSEL

7606-003

CA_CBV

CC_CDV

NOTES

1. THE EXPOSED METAL PADDLE ON THE BOTTOM OF THE L FCSP PACKAGE MUST

BE SOLDERED T O PCB GROUND F OR PROPER HEAT DISSIPATION AND ALSO FOR

NOISE AND MECHANICAL STRENGT H BENEFITS.

AV

VA–

V

AGND

AGND

AV

AGND

V

VB–

AV

1

CC

2

CC

3

+

4

A

5

6

7

CC

8

+

9

B

10

11

CC

12

CC

CA_CBV

AGND

AGND

AGND

CC_CDV

AV

AV

AV

–

+

–

+

B

B

A

A

C

C

C

C

46

47

48

1

VA–

V

V

VB–

CC

CC

+

A

CC

+

B

CC

CC

PIN 1

2

INDICATO R

3

4

5

6

7

8

9

10

11

12

13 15 16 17 18 19 20 21 22 23 24

14

+

C

C

–

C

C

AD7262

TOP VIEW

(Not to Scale)

–

+

D

D

C

C

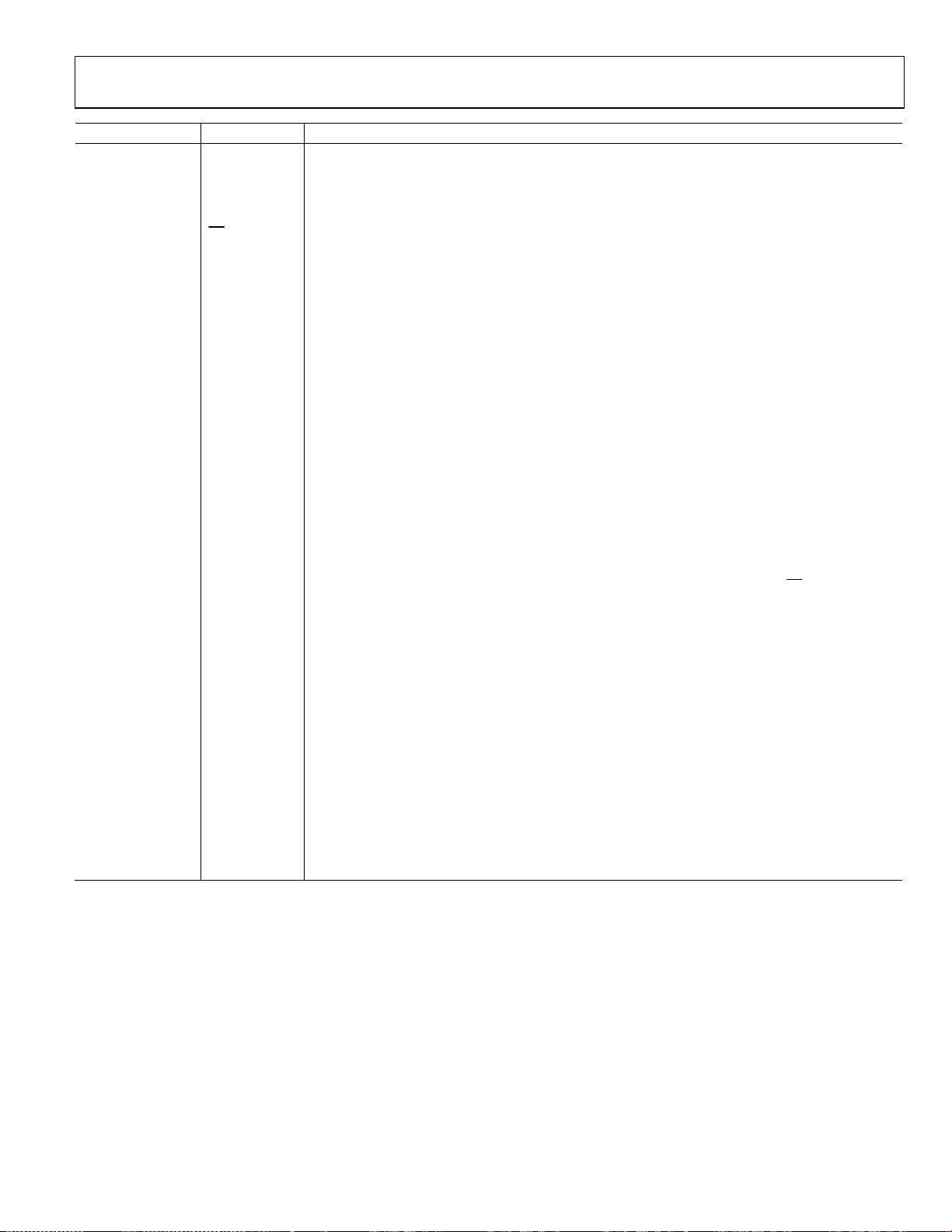

Figure 3. 48-Lead LQFP Pin Configuration Figure 4. 48-Lead LFCSP Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

2, 7, 11, 20, 33, 41 AVCC

Analog Supply Voltage, 4.75 V to 5.25 V. This is the supply voltage for the analog circuitry on the

AD7262/AD7262-5. All AV

pins can be tied together. This supply should be decoupled to AGND

CC

with a 100 nF ceramic capacitor per supply and a 10 F tantalum capacitor.

1 CA_CBVCC

Comparator Supply Voltage, 2.7 V to 5.25 V. This is the supply voltage for Comparator A and

Comparator B. This supply should be decoupled to C

tied together.

12 C

C_CDVCC

Comparator Supply Voltage, 2.7 V to 5.25 V. This is the supply voltage for Comparator C and

Comparator D. This supply should be decoupled to C

tied together.

4, 3 VA+, VA− Analog Inputs of ADC A. True differential input pair.

9, 10 V

43, 18 V

+, VB− Analog Inputs of ADC B. True differential input pair.

B

A, V

REF

REF

B

Reference Input/Output. Decoupling capacitors are connected to these pins to decouple the

internal reference buffer for each respective ADC. Typically, 1 F capacitors are required to decouple

the reference. Provided the output is buffered, the on-chip reference can be taken from these pins

and applied externally to the rest of a system.

34 SCLK

Serial Clock. Logic input. A serial clock input provides the SCLK for accessing the data from the

AD7262/AD7262-5. This clock is also used as the clock source for the conversion process. A

minimum of 31 clocks is required to perform the conversion and access the 12-bit result.

36 CAL

21 PD2

Logic Input. Initiates an internal offset calibration.

Logic Input. Places the AD7262/AD7262-5 in selected shutdown mode in conjunction with the PD1

and PD0 pins (see Table 7).

22 PD1

Logic Input. Places the AD7262/AD7262-5 in selected shutdown mode in conjunction with the PD2

and PD0 pins (see Table 7).

_GND

B

A

–

+

–

+

A

C

4847464544434241403938

13141516171819

+

C

C

A_CB

C_CD

_C

B

B

A

A

REF

C

C

PIN 1

INDICAT OR

–

+

C

D

C

C

C

C

V

AD7262

TOP VIEW

(Not to Scale)

–

B

D

C

REF

_GND

AGND

V

D

_C

C

C

AVCCAGND

2021222324

CC

AV

G0

PD2

G1

PD1

G3

G2

37

CAL

36

CS

35

SCLK

34

AV

33

D

32

D

31

C

30

C

29

DGND

28

V

27

C

26

C

25

IN

PD0/D

REFSEL

_GND. AVCC, CC_CDVCC, and CA_CBVCC can be

_GND. AVCC, CC_CDVCC, and CA_CBVCC can be

CC

OUT

OUT

OUT

OUT

DRIVE

OUT

OUT

A

B

A

B

C

D

07606-004

Rev. 0 | Page 8 of 32

AD7262

Pin No. Mnemonic Description

23 PD0/DIN

35

48, 47, 46, 45

13, 14, 15, 16

CS

+, CA−,

C

A

+, CB−

C

B

+, CC−,

C

C

+, CD−

C

D

5, 6, 8, 19, 42 AGND

28 DGND

30, 29, 26, 25

32, 31 D

A, C

C

OUT

OUT

C, C

C

OUT

OUT

A, D

OUT

OUT

40, 39, 38, 37 G0, G1, G2, G3

27 V

44, 17

C

C

DRIVE

A_CB

C_CD

_GND,

_GND

24 REFSEL

Logic Input/Data Input. Places the AD7262/AD7262-5 in selected shutdown mode in conjunction

with the PD2 and PD1 pins (see Table 7). If all gain selection pins, G0 to G3, are tied low, this pin acts

as the data input pin, and all programming is via the control register (see Table 8). Data to be written

to the AD7262/AD7262-5 control register is provided on this input and is clocked into the register

on the falling edge of SCLK.

Chip Select. Active low logic input. This input initiates conversions on the AD7262/AD7262-5.

Comparator Inputs. These pins are the inverting and noninverting analog inputs for Comparator A

and Comparator B. These two comparators have very low power consumption.

Comparator Inputs. These pins are the inverting and noninverting analog inputs for Comparator C

and Comparator D. This pair of comparators offers very fast propagation delays.

Analog Ground. Ground reference point for all analog circuitry on the AD7262/AD7262-5. All

analog input signals and any external reference signal should be referred to this AGND voltage.

All AGND pins should connect to the AGND plane of a system. The AGND, DGND, C

C

_GND voltages ideally should be at the same potential and must not be more than 0.3 V apart,

C_CD

even on a transient basis. C

_GND and CC_CD_GND can be tied to AGND.

A_CB

A_CB

Digital Ground. This is the ground reference point for all digital circuitry on the AD7262/AD7262-5.

The DGND pin should be connected to the DGND plane of a system. The DGND and AGND voltages

should ideally be at the same potential and must not be more than 0.3 V apart, even on a transient

basis.

Comparator Outputs. These pins provide a CMOS (push-pull) output from each respective

B,

D

comparator. These are digital output pins with logic levels determined by the V

B

Serial Data Outputs. The data output from the AD7262/AD7262-5 is supplied to each pin as a serial

DRIVE

supply.

data stream in twos complement format. The bits are clocked out on the falling edge of the SCLK

input. A total of 31 SCLKs is required to perform the conversion and access the 12-bit data. During

the conversion process, the data output pins are in three-state and, when the conversion is

completed, the 19

th

SCLK edge clocks out the MSB. The data simultaneously appears on both pins

from the simultaneous conversions of both ADCs. The data is provided MSB first. If CS

an additional 12 SCLK cycles on either D

the other ADC follows on the D

pin. This allows data from a simultaneous conversion on both

OUT

ADCs to be gathered in serial format on either D

OUT

A or D

B following the initial 31 SCLKs, the data from

OUT

OUT

A or D

B using only one serial port.

OUT

Logic Inputs. These pins are used to program the gain setting of the front-end amplifiers. If all four

pins are tied low, the PD0 pin acts as a data input pin, DIN, and all programming is made via the

control register (see Table 6 ).

Logic Power Supply Input, 2.7 V to 5.25 V. The voltage supplied at this pin determines at what

voltage the interface operates, including the comparator outputs. This pin should be decoupled to

DGND.

Comparator Ground. This is the ground reference point for all comparator circuitry on the AD7262/

AD7262-5. Both the CA_CB_GND pin and the CC_CD_GND pin should connect to the GND plane of a

system and can be tied to AGND. The DGND, AGND, C

_GND, and CC_CD_GND voltages should

A_CB

ideally be at the same potential and must not be more than 0.3 V apart, even on a transient basis.

Internal/External Reference Selection. Logic input. If this pin is tied to a logic high voltage, the on-

chip 2.5 V reference is used as the reference source for both ADC A and ADC B. If the REFSEL pin is

tied to GND, an external reference can be supplied to the AD7262/AD7262-5 through the V

and/or V

REF

B pin.

_GND, and

is held low for

A

REF

Rev. 0 | Page 9 of 32

AD7262

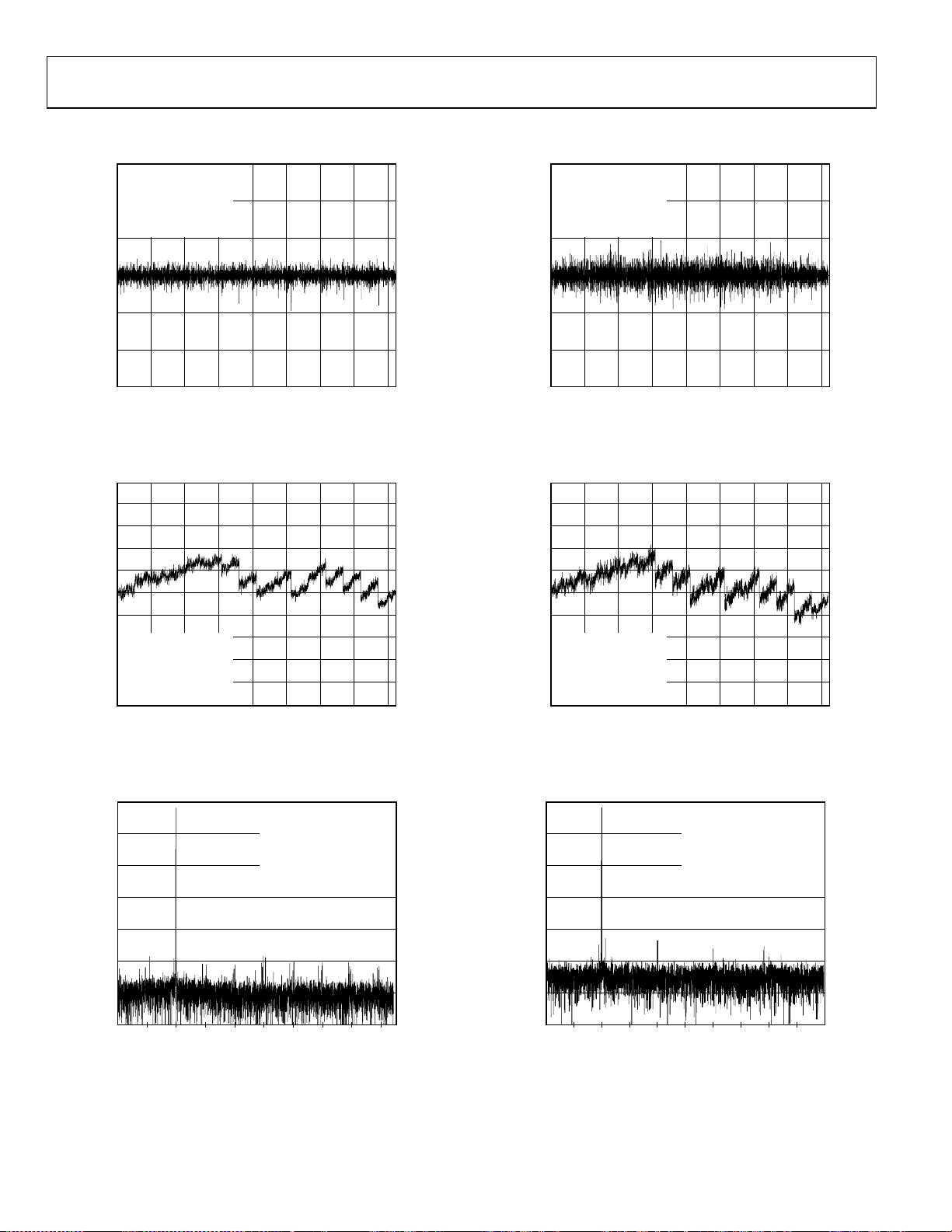

TYPICAL PERFORMANCE CHARACTERISTICS

0.6

AVCC = 5V

V

= 5V

DRIVE

f

= 1MSPS

S

0.4

T

= 25°C

A

INTERNAL REFERENCE

PGA GAIN = 2

0.2

0.6

AVCC = 5V

V

= 5V

DRIVE

f

= 1MSPS

S

0.4

T

= 25°C

A

INTERNAL REFERENCE

PGA GAIN = 32

0.2

0

–0.2

DNL ERRO R (LSB)

–0.4

–0.6

0400035003000250020001 5001000500

1.0

0.8

0.6

0.4

0.2

0

–0.2

INL ERROR (LS B)

–0.4

AVCC = 5V

V

DRIVE

–0.6

f

= 1MSPS

S

T

= 25°C

A

–0.8

INTERNAL REFERENCE

PGA GAIN = 2

–1.0

0400035003000250020001 5001000500

CODE

Figure 5. Typical DNL at Gain of 2

= 5V

CODE

Figure 6. Typical INL at Gain of 2

0

–0.2

DNL ERRO R (LSB)

–0.4

–0.6

0435003000250020001 5001000500

07606-005

CODE

000

07606-008

Figure 8. Typical DNL at Gain of 32

1.0

0.8

0.6

0.4

0.2

0

–0.2

INL ERROR (LS B)

–0.4

AVCC = 5V

V

= 5V

DRIVE

–0.6

f

= 1MSPS

S

T

= 25°C

A

–0.8

INTERNAL REFERENCE

PGA GAIN = 32

–1.0

0435003000250020001 5001000500

07606-006

CODE

000

07606-009

Figure 9. Typical INL at Gain of 32

0

–20

–40

–60

(dB)

–80

–100

–120

–140

0 400k 450k350k300k250k200k150k100k50k

FREQUENCY (Hz)

AVCC = 5V

V

= 2.7V

DRIVE

f

= 1MSPS

S

T

= 25°C

A

f

= 100kHz

IN

INTERNAL REFERENCE

SNR = 73dB, T HD = –82.5dB

PGA GAIN = 2

07606-007

Figure 7. 3 dB Typical FFT at Gain of 2

0

–20

–40

–60

(dB)

–80

–100

–120

–140

0 400k 450k 500k350k300k250k200k150k100k50k

AVCC = 5V

V

= 5V

DRIVE

f

= 1MSPS

S

T

= 25°C

A

f

= 100kHz

IN

INTERNAL REFERENCE

SNR = 68.38dB, THD = –82dB

PGA GAIN = 32

FREQUENCY (Hz)

07606-010

Figure 10. Typical FFT at Gain of 32

Rev. 0 | Page 10 of 32

AD7262

–

9000

8000

7000

6000

5000

4000

3000

NUMBER OF HITS

2000

1000

0

0

8839

828

333

2043 2044 2045

CODE

0

Figure 11. Histogram of Codes for 10k Samples at Gain of 2

07606-011

2.4968

2.4967

2.4966

2.4965

(V)

REF

2.4964

V

2.4963

AVCC = 5V

2.4962

V

= 3V

DRIVE

f

= 1MSPS

S

INTERNAL REFERENCE

2.4961

0 20 40 60 80 100 120 140 160 180 200

CURRENT LOAD ( µA)

Figure 14. V

vs. Reference Output Current Load

REF

07606-014

8000

7000

6000

5000

4000

3000

NUMBER OF HITS

2000

1000

0

1297

0

20452044 2046 2047 2048 2049

6967

CODE

1732

40

07606-012

Figure 12. Histogram of Codes for 10k Samples at Gain of 32

50

AV

= 5V

CC

V

= 5V

DRIVE

–55

f

= 1MSPS

S

INTERNAL REFERENCE

–60

–65

–70

THD (dB)

–75

–70

–85

–90

10 910810710610510410310210110

ANALOG INPUT FREQUENCY (kHz)

GAIN = 32

GAIN = 2

07606-013

Figure 13. THD vs. Analog Input Frequency up to 1 MHz at Gain of 2 and 32

1900

1800

1700

1600

1500

1400

1300

1200

1100

1000

3dB BANDWIDTH (kHz)

900

AVCC = 5V

800

700

600

= 5V

V

DRIVE

f

= 1MSPS

S

INTERNAL REFERENCE

2 3 4 6 8 12 16 24 32 48 64 96 128

1

GAIN

Figure 15. 3 dB Bandwidth vs. Gain

80

75

70

65

60

55

SNR (dB)

50

45

AVCC = 5V

40

35

30

= 5V

V

DRIVE

f

= 1MSPS

S

INTERNAL REFERENCE

= 100kHz

F

IN

1 2 3 4 6 8 12 16 24 32 48 64 96 128

PGA GAIN

Figure 16. SNR vs. PGA Gain for an Analog Input Tone of 100 kHz

07606-015

07606-016

Rev. 0 | Page 11 of 32

AD7262

–

–

–

–

90

–88

–86

–84

–82

–80

CMR (dB)

–78

–76

–74

–72

–70

1 2 3 4 6 8 12 16 24 32 48 64 96 128

AVCC = 5V

V

DRIVE

f

= 1MSPS

S

INTERNAL REFERENCE

f

RIPPLE

GAIN

Figure 17. Common-Mode Rejection vs. Gain

= 5V

= 50kHz

07606-017

10

9

8

7

6

5

4

3

PROPAG ATIO N DELAY (µs)

2

H TO L, C

A_CBVCC

H TO L, C

A_CBVCC

H TO L, C

A_CBVCC

H TO L, C

A_CBVCC

L TO H, C

A_CBVCC

L TO H, C

A_CBVCC

L TO H, CA_CBVCC = 4.5V

L TO H, C

A_CBVCC

AVCC = 5V

V

DRIVE

T

A

= 3.6V

= 4.5V

= 2.7V

= 5V

= 2.7V

= 3.6V

= 5V

= 3.3V

= 25°C

1

0

0 102030405060708090100

OVERDRIVE VOLTAGE (mV)

Figure 20. Propagation Delay for Comparator A and Comparator B vs.

Overdrive Voltage for Various Supply Voltages

07606-020

80

–79

–78

–77

–76

–75

CMR (dB)

–74

–73

–72

–71

–70

0 20 40 60 80 100 120 140 160 180 200

RIPPLE FREQUENCY (kHz)

AVCC = 5V

= 5V

V

DRIVE

f

= 1MSPS

S

= 700mV p-p

V

RIPPLE

GAIN = 2

INTERNAL REFERENCE

07606-018

Figure 18. Common-Mode Rejection vs. Common-Mode Ripple Frequency

10

AVCC = 5V

V

= 5V

DRIVE

–20

f

= 1MSPS

S

INTERNAL REFERENCE

–30

f

= 100kHz

IN

–40

–50

–60

THD (dB)

–70

–80

GAIN 8

GAIN 4

–90

GAIN 12

–100

1.3 1.5 1.7 1.9 2.1 2.3 2.5 2.7 2. 9 3.1 3.3 3 .5 3.7

GAIN 24

V

CM

GAIN ≥ 32

RANGE (V)

GAIN 1

GAIN 2

GAIN 3

GAIN 16

GAIN 6

07606-019

Figure 19. THD vs. Common-Mode Range for Various PGA Gain Settings

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

PROPAG ATIO N DELAY (µs)

0.4

L TO H, C

L TO H, C

L TO H, C

L TO H, C

H TO L, C

H TO L, C

H TO L, C

H TO L, CC_CDVCC = 4.5V

C_CDVCC

C_CDVCC

C_CDVCC

C_CDVCC

C_CDVCC

C_CDVCC

C_CDVCC

AVCC = 5V

V

= 3.3V

DRIVE

T

= 25°C

A

= 2.7V

= 3.6V

= 4.5V

= 5V

= 2.7V

= 3.6V

= 5V

0.2

0

0 102030405060708090100

OVERDRIVE VOLTAGE (mV)

Figure 21. Propagation Delay for Comparator C and Comparator D vs.

Overdrive Voltage for Various Supply Voltages

70

V

= 5V

DRIVE

GAIN = 2

–75

T

= 25°C

A

INTERNAL REFERENCE

–80

100mV p-p SINE WAVE ON AV

AVCC DECOUPLED WI TH

–85

10µF AND 100nF CAPACITORS

CC

–90

–95

PSRR (dB)

–100

–105

–110

–115

–120

0 200 400 600 800 1000

SUPPLY RIPPLE FREQUENCY (kHz)

Figure 22. Power Supply Rejection Ratio vs. Supply Ripple Frequency?

07606-021

07606-022

Rev. 0 | Page 12 of 32

AD7262

300

C

A/C

B SINK CURRENT

OUT

C/C

D SINK CURRENT

OUT

SINK CURRENT

SOURCE CURRENT

A/C

B SOURCE CURRENT

OUT

C/C

D SOURCE CURRENT

OUT

0.2

0.4

0.6

0.3

0.5

0.7

OUT

0.8

1.0

1.2

0.9

1.1

1.3

CURRENT (mA)

and C

Source and Sink Current

OUT

1.4

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.3

2.4

2.5

07606-023

(mV)

OUT

– V

DD

–100

(V) OR V

OUT

V

–200

–300

200

100

0

OUT

C

OUT

D

OUT

D

OUT

C

OUT

C

OUT

0

0.1

Figure 23. D

Rev. 0 | Page 13 of 32

AD7262

TERMINOLOGY

Differential Nonlinearity (DNL)

Differential nonlinearity is the difference between the measured

and the ideal 1 LSB change between any two adjacent codes in

the ADC.

Integral Nonlinearity (INL)

Integral nonlinearity is the maximum deviation from a straight

line passing through the endpoints of the ADC transfer function.

The endpoints of the transfer function are zero scale, a single

(1) LSB point below the first code transition and full scale, a single

(1) LSB point above the last code transition.

Zero Code Error

This is the deviation of the midscale transition (all 1s to all 0s)

from the ideal V

voltage, that is, V

IN

– ½ LSB.

CM

Positive Full-Scale Error

This is the deviation of the last code transition (011 … 110) to

(011 … 111) from the ideal, that is,

V

REF

×+Gain

⎞

LSB12−

⎟

⎠

⎛

V

⎜

CM

⎝

after the zero code error has been adjusted out.

Negative Full-Scale Error

This is the deviation of the first code transition (10 … 000) to

(10 … 001) from the ideal, that is,

V

REF

×−Gain

⎞

LSB12+

⎟

⎠

⎛

V

⎜

CM

⎝

after the zero code error has been adjusted out.

Zero Code Error Match

This is the difference in zero code error across both ADCs.

Positive Full-Scale Error Match

This is the difference in positive full-scale error across both ADCs.

Negative Full-Scale Error Match

This is the difference in negative full-scale error across both ADCs.

Track-and-Hold Acquisition Time

The track-and-hold amplifier returns to track mode at the end

of a conversion. Track-and-hold acquisition time is the time

required for the output of the track-and-hold amplifier to reach

its final value, within ±1/2 LSB, after the end of a conversion.

Signal-to-(Noise + Distortion) Ratio

This ratio is the measured ratio of signal-to-(noise + distortion)

at the output of the analog-to-digital converter. The signal is the

rms amplitude of the fundamental. Noise is the sum of all nonfundamental signals up to half the sampling frequency (f

/2),

S

excluding dc. The ratio is dependent on the number of quantization levels in the digitization process; the more levels, the

smaller the quantization noise. The theoretical signal-to-(noise +

distortion) ratio for an ideal N-bit converter with a sine wave

input is given by

Signal-to-(Noise + Distortion) = (6.02N + 1.76) dB

Thus for a 12-bit converter, this is 86 dB.

Rev. 0 | Page 14 of 32

Total Harmonic Distortion (THD)

Total harmonic distortion is the ratio of the rms sum of harmonics

to the fundamental. For the AD7262/AD7262-5, it is defined as

2

2

2

2

where

V

, V

4

2

THD

V

, and V

5

=

is the rms amplitude of the fundamental, and V2, V3,

1

are the rms amplitudes of the second through the

6

2

log20(dB)

4

3

V

1

++++

VVVVV

6

5

sixth harmonics.

Peak Harmonic or Spurious Noise

Peak harmonic, or spurious noise, is defined as the ratio of the

rms value of the next largest component in the ADC output

spectrum (up to f

/2, excluding dc) to the rms value of the fun-

S

damental. Normally, the value of this specification is determined

by the largest harmonic in the spectrum, but for ADCs where

the harmonics are buried in the noise floor, it is a noise peak.

ADC-to-ADC Isolation

ADC-to-ADC isolation is a measure of the level of crosstalk

between the ADC A and ADC B. It is measured by applying a

full-scale, 100 kHz sine wave signal to all unselected input channels

and determining how much that signal is attenuated in the

selected channel with a 40 kHz signal. The figure given is the

worst case.

PSRR (Power Supply Rejection)

Variations in power supply affect the full-scale transition but

not the linearity of the converter. Power supply rejection is the

maximum change in the full-scale transition point due to a

change in power supply voltage from the nominal value (see

Figure 22).

Propagation Delay Time, Low to High (t

PLH

)

Propagation delay time from low to high is defined as the time

taken from the 50% point on a low to high input signal until the

digital output signal reaches 50% of its final low value.

Propagation Delay Time, High to Low (t

PHL

)

Propagation delay time from high to low is defined as the time

taken from the 50% point on a high to low input signal until the

digital output signal reaches 50% of its final high value.

Comparator Offset

Comparator offset is the measure of the density of digital 1s

and 0s in the comparator output when the negative analog

terminal of the comparator input is held at a static potential

and the analog input to the positive terminal of the comparators

is varied proportionally about the static negative terminal voltage.

AD7262

THEORY OF OPERATION

CIRCUIT INFORMATION

The AD7262/AD7262-5 are fast, dual, simultaneous sampling,

differential, 12-bit, serial ADCs. The AD7262/ AD7262-5

contain two on-chip differential programmable gain amplifiers,

two track-and-hold amplifiers, and two successive approximation analog-to-digital converters with a serial interface with two

separate data output pins. The AD7262/ AD7262-5 also include

four on-chip comparators. They are housed in 48-lead LFCSP

and LQFP packages, offering the user considerable space-saving

advantages over alternative solutions. The AD7262/AD7262-5

require a low voltage 5 V ± 5% AV

supply the digital power, a 5.25 V to 2.7 V C

supply for the comparators, and a 2.7 V to 5.25 V V

to power the ADC core and

CC

A_CBVCC

, CC_CDVCC

supply

DRIVE

for interface power.

The on-board PGA allows the user to select from 14 programmable gain stages: ×1, ×2, ×3, ×4, ×6, ×8, ×12, ×16, ×24, ×32,

×48, ×64, ×96, and ×128. The PGA accepts fully differential

analog signals. The gain can be selected either by setting the

logic state of the G0 to G3 pins or by programming the control

register.

The serial clock input accesses data from the part while also

providing the clock source for each successive approximation

ADC. The AD7262/AD7262-5 have an on-chip 2.5 V reference

that can be disabled when an external reference is preferred. If

the internal reference is used elsewhere in a system, the output

from V

A and V

REF

B must first be buffered. If the internal

REF

reference is the preferred option, the user must tie the

REFSEL pin to a logic high voltage. Alternatively, if REFSEL

is tied to GND, an external reference can be supplied to both

ADCs through the V

A and V

REF

B pins (see the Reference

REF

section).

The AD7262/AD7262-5 also feature a range of power-down

options to allow the user great flexibility with the independent

circuit components while allowing for power savings between

conversions. The power-down feature is implemented via the

control register or the PD0 to PD2 pins, as described in the

Control Register section.

COMPARATORS

The AD7262/AD7262-5 have four on-chip comparators. Comparator A and Comparator B have ultralow power consumption,

with static power consumption typically less than 10 W with a

3.3 V supply. Comparator C and Comparator D feature ver y fast

propagation delays of 130 ns for a 200 mV differential overdrive.

These comparators have push-pull output stages that operate

from the V

minimum amount of power consumption.

supply. This feature allows operation with a

DRIVE

Each pair of comparators operates from its own independent

supply, C

A_CBVCC

for supply voltages from 2.7 V to 5.25 V. If desired, C

and C

C_CDVCC

rators on the AD7262/AD7262-5 are functional with C

C

C_CDVCC

and CC_CDVCC. The comparators are specified

A_CBVCC

can be tied to the AVCC supply. The four compa-

A_CBVCC

greater than or equal to 1.8 V. However, no specifications are guaranteed for comparator supplies less than 2.7 V.

The wide range of supply voltages ensures that the comparators

can be used in a variety of battery backup modes.

The four on-chip comparators on the AD7262/AD7262-5 are

ideally suited for monitoring signals from pole sensors in motor

control systems. The comparators can be used to monitor

signals from Hall effect sensors or the inner tracks from an

optical encoder. One of the comparators can be used to count

the index marker or z marker, which is used on startup to place

the motor in a known position.

OPERATION

The AD7262/AD7262-5 have two successive approximation

ADCs, each based around two capacitive DACs and two

programmable gate amplifiers.

The ADC itself comprises control logic, a SAR, and two capacitive

DACs. The control logic and the charge redistribution DACs are

used to add and subtract fixed amounts of charge from the sampling capacitor amplifiers to bring the comparator back into a

balanced condition. When the comparator is rebalanced, the

conversion is complete. The control logic generates the ADC

output code.

Each ADC is preceded by its own programmable gain stage. The

PGA features high analog input impedance, true differential analog

inputs that allow the output from any source or sensor to be

connected directly to the PGA inputs without any requirement for

additional external buffering. The variable gain settings ensure

that the device can be used for amplifying signals from a variety

of sources. The AD7262/AD7262-5 offer the flexibility to choose

the most appropriate gain setting to use the wide dynamic range

of the device.

ANALOG INPUTS

Each ADC in the AD7262/AD7262-5 has two high impedance

differential analog inputs. Figure 24 shows the equivalent circuit

of the analog input structure of the AD7262/AD7262-5. It consists

of a fully differential input amplifier that buffers the analog input

signal and provides the gain selected by using the gain pins or

the control register.

/

Rev. 0 | Page 15 of 32

AD7262

V

V

The two diodes provide ESD protection. Care must be taken to

ensure that the analog input signals never exceed the supply rails

by more than 300 mV. Exceeding 300 mV causes these diodes to

become forward-biased and to start conducting current into the

substrate. These diodes can conduct up to 10 mA without

causing irreversible damage to the part. The C1 capacitors in

Figure 24 are typically 5 pF and can primarily be attributed to

pin capacitance.

DD

+

IN

C1

V

DD

–

V

IN

C1

Figure 24. Analog Input Structure

AMP

AMP

+

V

OUT

–

V

OUT

07606-024

The AD7262/AD7262-5 can accept differential analog inputs from

V

REF

×−Gain

⎞

V

to

⎟

CM

⎠

⎛

V

⎜

CM

2

⎝

⎛

⎜

2

⎝

V

REF

×+Gain

⎞

⎟

⎠

Tabl e 5 details the analog input range for the AD7262/AD7262-5

for the various PGA gain settings. Here, V

2.5 V (AV

/2, with AVCC = 5 V).

CC

= 2.5 V and VCM =

REF

Table 5. Analog Input Range for Various PGA Gain Settings

PGA Gain Setting Analog Input Range for VIN+ and VIN−

1 0.75 V to 3.25 V1

2 1.875 V to 3.125 V

3 2.083 V to 2.916 V

4 2.187 V to 2.813 V

6 2.292 V to 2.708 V

8 2.344 V to 2.656 V

12 2.396 V to 2.604 V

16 2.422 V to 2.578 V

24 2.448 V to 2.552 V

32 2.461 V to 2.539 V

48 2.474 V to 2.526 V

64 2.480 V to 2.520 V

96 2.487 V to 2.513 V

128 2.490 V to 2.510 V

1

For VCM = 2 V. If VCM = AVCC /2, the analog input range for VIN+ and VIN− is 1.6 V

to 3.4 V.

When a full-scale step input is applied to either differential input

on the AD7262/AD7262-5 while the other analog input is held

at a constant voltage, 3 s of settling time is typically required

prior to capturing a stable digital output code.

Transfer Function

The AD7262/AD7262-5 output is twos complement, and the

ideal transfer characteristic is shown in Figure 25. The designed

code transitions occur at successive integer LSB values (that is,

1 LSB, 2 LSB, and so on). The LSB size is dependent on the analog

input range selected. The LSB size for the AD7262/AD7262-5 is

shown in the following equation:

⎛

⎛

⎜

V

⎜

⎜

⎝

×

2

⎜

⎜

⎜

⎝

CM

V

⎛

REF

+

⎜

×

Gain

⎝

⎛

⎞

⎞

V

⎜

⎟

⎟

⎠

⎝

⎠

4096

CM

V

⎛

−−

⎜

×

22

⎝

REF

Gain

⎞

⎞

⎞

⎟

⎟

⎟

⎠

⎟

⎠

⎟

⎟

⎟

⎠

011...111

011...110

000...001

000...000

111.. .111

ADC CODE

100...010

100...001

100...000

0V

NOTES

1. FULL-SCALE RANGE (FSR) = V

Figure 25. Twos Complement Transfer Function

V

DRIVE

The AD7262/AD7262-5 have a V

voltage at which the serial interface operates. V

(V

ANALOG INPUT

IN

CM

+ – VIN–.

feature to control the

DRIVE

+ (FSR/2)) – 1LSB(VCM – (FSR/2)) + 1LSB

07606-025

allows the

DRIVE

ADC and the comparators to easily interface to both 3 V and

5 V processors. For example, when the AD7262/AD7262-5 are

operated with AV

= 5 V, the V

CC

pin can be powered from

DRIVE

a 3 V supply, allowing a large analog input range with low voltage

digital processors.

Rev. 0 | Page 16 of 32

AD7262

REFERENCE

The AD7262/AD7262-5 can operate with either the internal

2.5 V on-chip reference or an externally applied reference. The

logic state of the REFSEL pin determines whether the internal

reference is used. The internal reference is selected for both ADCs

when the REFSEL pin is tied to logic high. If the REFSEL pin is

tied to AGND, an external reference can be supplied through

the V

A and/or V

REF

must be tied to either a low or high logic state for the part to

operate. Suitable reference sources for the AD7262/AD7262-5

include AD780, AD1582, ADR431, REF193, and ADR391.

The internal reference circuitry consists of a 2.5 V band gap

reference and a reference buffer. When the AD7262/AD7262-5

are operated in internal reference mode, the 2.5 V internal

reference is available at the V

be decoupled to AGND using a 1 F capacitor. It is recommended

that the internal reference be buffered before applying it elsewhere

in the system. The internal reference is capable of sourcing up

to 90 A of current when the converter is static. If the internal

reference operation is required for the ADC conversion, the

REFSEL pin must be tied to logic high on power-up. The reference buffer requires 240 µs to power up and charge the 1 F

decoupling capacitor during the power-up time.

B pins. On power-up, the REFSEL pin

REF

A and V

REF

B pins, which should

REF

TYPICAL CONNECTION DIAGRAMS

Figure 26 and Figure 27 are typical connection diagrams for the

AD7262/AD7262-5. In these configurations, the AGND pin is

connected to the analog ground plane of the system, and the

DGND pin is connected to the digital ground plane of the system.

The analog inputs on the AD7262/AD7262-5 are true differential and have an input impedance in excess of 1 G; thus, no

driving op amps are required. The AD7262/AD7262-5 can operate

with either an internal or an external reference. In Figure 26, the

AD7262/AD7262-5 are configured to operate in control register

mode; thus, G0 to G3, PD1, and PD2 can be connected to ground

(low logic state). Figure 27 has the gain pins configured for a gain

of 2 setup; thus, the device is in pin-driven mode. Both circuit

configurations illustrate the use of the internal 2.5 V reference

The C

A_CBVCC

a 3 V or a 5 V supply voltage. The AV

to a 5 V supply. All supplies should be decoupled with a 100 nF

capacitor at the device pin, and some supply sources may require a

10 F capacitor where the source is supplied to the circuit board.

The V

DRIVE

processor. The voltage applied to the V

voltage of the serial interface. V

and the CC_CDVCC pins can be connected to either

pin must be connected

CC

pin is connected to the supply voltage of the micro-

input controls the

DRIVE

can be set to 3 V or 5 V.

DRIVE

Rev. 0 | Page 17 of 32

AD7262

V

V

– AND VA+

A

CONNECT

DIRECTLY

TO SENSOR

OUTPUTS

THIS REFERENCE SIGNAL

MUST BE BUFFERED

BEFORE IT CAN BE

USED ELSEWHERE IN

VB– AND VB+

CONNECT

DIRECTLY

TO SENSOR

OUTPUTS

3.125V

2.500V

1.875V

3.125V

2.500V

1.875V

THE CIRCUIT

3.125V

2.500V

1.875V

3.125V

2.500V

1.875V

GAIN 2

GAIN 2

GAIN 2

GAIN 2

ANALOG

SUPPLY

43

1µF

18

1µF

10

+5

1

100nF

10µF

100nF

100nF

100nF

100nF

17 44 5 6 8 19 42 28 2 7 11 20 41 12 1 33

GND

GND

AGND

AGND

AGND

D–

B–

C

C

C–

A–

C

3

4

C

V

–

A

+

V

A

V

A

REF

AGND

AGND

DGND

CCAVCCAVCCAVCCAVCC

AV

AD7262

V

B

REF

9

V

+

B

VB–

+

–

+

C

C

–

C

D

D

C

C

C

13 14 15 16 45 46 47 48 25 26 29 30

–

+

–

+

B

B

A

A

C

C

C

C

D

OUT

C

CC

CC

V

V

D

B

C

C

C–

A–

C

C

V

DRIVE

SCLK

D

OUT

D

OUT

REFSEL

CAL

PD0/D

PD1

PD2

C

B

OUT

OUT

C

C

G0

G1

G2

G3

CS

1

100nF

10µF

COMPARATOR

SUPPLY 3V TO 5V

2

100nF

100nF

CC

AV

27

V

DRIVE

40

100nF

10µF

1

3V OR 5V

SUPPLY

39

38

37

SERIAL

INTERFACE

34

35

32

A

31

B

24

V

DRIVE

MICROPROCESSOR/

MICROCONTROLLER

36

23

IN

22

21

A

OUT

C

FAST PROPAG ATION DEL AY

COMPARATOR INPUTS

1

THESE CAPACITORS ARE PLACED AT THE SUPPLY SOURCE AND MAY NOT BE REQUIRED IN AL L SYSTEMS.

2

THIS SUPPL Y CAN BE CONNECTED T O THE ANALOG 5V SUPPL Y IF REQ UIRED.

LOW POWER

COMPARATOR I NPUTS

07606-026

Figure 26. Typical Connection Diagram for the AD7262/AD7262-5 in Control Register Mode (All Gain Pins Tied to Ground) Configured for a PGA Gain of 2

Rev. 0 | Page 18 of 32

AD7262

V

V

V

– AND VA+

A

CONNECT

DIRECTLY

TO SENSOR

OUTPUTS

THIS REFERENCE SIGNAL

MUST BE BUFFERED

BEFORE IT CAN BE

USED ELSEWHERE IN

– AND VB+

B

CONNECT

DIRECTLY

TO SENSOR

OUTPUTS

3.125V

2.500V

1.875V

3.125V

2.500V

1.875V

THE CIRCUIT

3.125V

2.500V

1.875V

3.125V

2.500V

1.875V

GAIN 2

GAIN 2

GAIN 2

GAIN 2

ANALOG

SUPPLY

43

1µF

18

1µF

10

+5

1

100nF

10µF

100nF

100nF

100nF

100nF

17 44 5 6 8 19 42 28 2 7 11 20 41 12 1 33

GND

GND

AGND

AGND

AGND

D–

B–

C

C

C–

A–

C

3

4

C

V

–

A

+

V

A

V

A

REF

AGND

AGND

DGND

CCAVCCAVCCAVCCAVCC

AV

AD7262

V

B

REF

9

V

+

B

VB–

+

–

+

–

C

C

D

D

C

C

C

C

13 14 15 16 45 46 47 48 25 26 29 30

–

+

–

B

C

+

B

A

A

C

C

C

D

OUT

C

CC

CC

V

V

D

B

C

C

C–

A–

C

C

V

DRIVE

SCLK

D

OUT

D

OUT

REFSEL

CAL

PD0/D

PD1

PD2

C

B

OUT

OUT

C

C

CS

G0

G1

G2

G3

1

100nF

10µF

COMPARATOR

SUPPLY 3V TO 5V

2

100nF

100nF

CC

AV

27

40

39

38

37

V

DRIVE

V

DRIVE

GAIN 2

SETUP

SERIAL

INTERFACE

100nF

10µF

1

3V OR 5V

SUPPLY

34

35

32

A

31

B

24

V

DRIVE

MICROPROCESSOR/

MICROCONTROLLER

36

23

V

IN

A

OUT

C

DRIVE

V

DRIVE

BOTH

COMPARAT ORS

AND ADCs

POWERED ON

22

21

FAST PROPAG ATION DEL AY

COMPARATOR INPUTS

1

THESE CAPACITORS ARE PLACED AT THE SUPPLY SOURCE AND MAY NOT BE REQUIRED IN AL L SYSTEMS.

2

THIS SUPPL Y CAN BE CONNECTED T O THE ANALOG 5V SUPPL Y IF REQ UIRED.

LOW POWER

COMPARATOR I NPUTS

07606-027

Figure 27. Typical Connection Diagram for the AD7262/AD7262-5 in Pin-Driven Mode with Gain of 2 and Both ADCs and Comparators Fully Powered On

Rev. 0 | Page 19 of 32

AD7262

Comparator Application Details

The comparators on the AD7262/AD7262-5 have been

designed with no internal hysteresis, allowing users the

flexibility to add external hysteretic if required for systems

operating in noisy environments. If the comparators on the

AD7262/AD7262-5 are used with external hysteresis, some

external resistors and capacitors are required, as shown in

Figure 28. The value of R

and RS, the external resistors, can be

F

determined using the following equation, depending on the

amount of hysteresis required in the application:

V _×

HYS

where C

x_CxVCC

S

=

RR

+

F

S

= CA_CBVCC or CC_CDVCC.

VCC

xx

CC

R

The amount of hysteresis chosen must be sufficient to eliminate

the effects of analog noise at the comparator inputs, which may

affect the stability of the comparator outputs. The level of

hysteresis required in any system depends on the noise in the

system; thus, the values of R

and RS need to be carefully selected

F

to eliminate any noise effects. To increase the level of hysteresis in

the system, increase the value of R

= 1 k give 330 V of hysteresis with a Cx_CxV

R

S

hysteresis is increased to 1 mV, R

or RF. For example, RF = 10 M,

S

of 3.3 V; if

CC

= 3.1 k. In certain applications,

S

a load capacitor (100 pF) may be required on the comparator

outputs to suppress high frequency transient glitches.

R

F

R

Cx–

S

C

SENSOR

Figure 28. Recommended Comparator Connection Diagram

R

C

S

+

x

OUT

x

7606-028

APPLICATION DETAILS

The AD7262/AD7262-5 have been specifically designed to meet

the requirements of any motor control shaft position feedback

loop. The devices can interface directly to multiple sensor types,

including optical encoders, magneto resistive sensors, and Hall

effect sensors. Flexible analog inputs that incorporate programmable gain ensure that identical board design can be used for a

variety of sensors, which results in reduced design cycles and costs.

The two simultaneous sampling ADCs are used to sample the

sine and cosine outputs from the sensor. No external buffering

is required between the sensor/transducer and the analog inputs

of the AD7262/AD7262-5. The on-chip comparators can be

used to monitor the pole sensors, which can be Hall effect sensors

or the inner tracks from an optical encoder.

Figure 29 shows how the AD7262/AD7262-5 can be used in a

typical application. An optical encoder is shown in Figure 29,

but other sensor types could as easily be used. Figure 29 indicates

a typical application configuration only, and there are several

other configurations that render equally effective results.

Rev. 0 | Page 20 of 32

AD7262

COMP

H.E.

COMP

A

VA+

V

–

A

AV

CC

REF

PGA T/H

BUF

B

+

V

B

V

–

B

PGA

T/H

BUF

B

V

REF

C

Z

U

V

W

A_CBVCC

C

C

CB+

C

CA_CB_GND

C

C_CDVCC

C

C

C

C

CC_CD_GND

+

A

–

A

–

B

+

C

–

C

+

D

–

D

COMP

COMP

V

REF

12-BIT

SUCCESSIVE

APPROXIMATION

ADC

CONTROL

LOGIC

12-BIT

SUCCESSIVE

APPROXIMATION

ADC

OUTPUT

DRIVERS

OUTPUT

OUTPUT

DRIVERS

DRIVERS

OUTPUT

DRIVERS

COMP

COMP

A

AD7262

OUTPUT

DRIVERS

OUTPUT

DRIVERS

D

A

OUT

SCLK

CAL

CS

REFSEL

G0

G1

G2

G3

V

DRIVE

D

B

OUT

PD0/D

PD1

PD2

A

C

OUT

C

B

OUT

C

C

OUT

D

C

OUT

IN

AGND DGND

07606-029

Figure 29. Typical System Connection Diagram with Optical Encoder

Rev. 0 | Page 21 of 32

AD7262

MODES OF OPERATION

The AD7262/AD7262-5 allow the user to choose between two

modes of operation, pin-driven mode and control register mode.

PIN-DRIVEN MODE

In pin-driven mode, the user can select the gain of the PGA, the

power-down mode, internal or external reference, and initiate

a calibration of the offset for both ADC A and ADC B. These

functions are implemented by setting the logic levels on the gain

pins (G3 to G0), the power-down pins (PD2 to PD0), the REFSEL

pin, and the CAL pin, respectively.

The logic state of Pin G3 to Pin G0 determines which mode of

operation is selected. Pin-driven mode is selected if at least one

of the gain pins is set to a logic high state. Alternatively, if all

four gain pins are connected to a logic low, the control register

mode of operation is selected.

GAIN SELECTION

The on-board PGA allows the user to select from 14 programmable gain stages: ×1, ×2, ×3, ×4, ×6, ×8, ×12, ×16, ×24, ×32,

×48, ×64, ×96, and ×128. The PGA accepts fully differential

analog signals and provides three key functions, which include

selecting gains for small amplitude input signals, driving the

ADCs switched capacitive load, and buffering the source from

the switching effects of the SAR ADCs. The AD7262/AD7262-5

offer the user great flexibility in user interface, providing gain

selection via the control register or by driving the gain pins to

the desired logic state. The AD7262/AD7262-5 have four gain

pins, G3, G2, G1 and G0, as shown in Figure 3. Each gain setting

is selected by setting up the appropriate logic state on each of

the four gain pins, as outlined in Tab l e 6 . If all four gain pins are

connected to a logic low level, the part is put in control register

mode and the gain settings are selected via the control register.

Table 6. Gain Selection

G3 G2 G1 G0 Gain

0 0 0 0

0 0 0 1 1

0 0 1 0 2

0 0 1 1 3

0 1 0 0 4

0 1 0 1 6

0 1 1 0 8

0 1 1 1 12

1 0 0 0 16

1 0 0 1 24

1 0 1 0 32

1 0 1 1 48

1 1 0 0 64

1 1 0 1 96

1 1 1 0 128

Software control

via control register

POWER-DOWN MODES

The AD7262/AD7262-5 offer the user a number of power-down

options to enable individual device components to be powered

down independently. These options can be chosen to optimize

the power dissipation for different application requirements.

The power-down modes can be selected by either programming

the device via the control register or by driving the PD pins to

the appropriate logic levels. By setting the PD pins to a logic low

level when in pin-driven mode, all four comparators and both

ADCs can be powered down. The PD2 and PD0 pins must be

set to logic high and the PD1 pin set to logic low to power up all

circuitry on the AD7262/AD7262-5. The PD pin configurations

for the various power-down options are outlined in Tab l e 7.

Table 7. Power-Down Modes

PD2 PD1 PD0

0 0 0 Off Off Off

0 0 1 Off Off On

0 1 0 Off On Off

0 1 1 On Off Off

1 0 0 On On Off

1 0 1 On On On

11 11 11 Off Off Off

1

PD2 = PD1 = PD0 = 1 resets the AD7262/AD7262-5 when in pin-driven mode

only.

The AVCC and V

Comparator A,

Comparator B

supplies must continue to be supplied to

DRIVE

the AD7262/AD7262-5 when the comparators are powered up

but the ADCs are powered-down. External diodes can be used

from the C

V

DRIVE

A_CBVCC

supplies to ensure they retain a supply at all instances.

and/or CC_CDVCC to both the AVCC and the

The AD7262/AD7262-5 can be reset in pin-driven mode only

by setting the PDx pins to a logic high state. When the device is

reset, all the registers are cleared and the four comparators and

the two ADCs are left powered down.

In normal mode of operation with the ADCs and comparators

powered on, the C

A_CBVCC/CC_CDVCC

supply can be at different voltage levels, as indicated in Table 1 .

When the comparators on the AD7262/AD7262-5 are in powerdown mode, and the C

A_CBVCC/CC_CDVCC

potential 0.3 V greater than or less than the AV

supplies consume more current than would be the case if both

sets of supplies were at the same potential. This configuration

does not damage the AD7262/AD7262-5 but results in additional

current flowing in any or all of the AD7262/AD7262-5 supply

pins. This is due to ESD protection diodes within the device. In

applications where power consumption in power-down mode is

critical, it is recommended that the C

and the AV

supply be held at the same potential.

CC

Comparator C,

Comparator D

supply and the AVCC

supplies are at a

supply, the

CC

A_CBVCC/CC_CDVCC

ADC A,

ADC B

supply

Rev. 0 | Page 22 of 32

AD7262

Power-Up Conditions

On power-up, the status of the gain pins determine which mode

of operation is selected, as outlined in the Gain Selection section.

All registers are set to 0 by default.

If the AD7262/AD7262-5 are powered up in pin-driven mode,

the gain pins and the PDx pins should be configured to the

appropriate logic states and a calibration initiated if required.

Alternatively, if the AD7262/AD7262-5 are powered up in

control register mode, the comparators and ADCs are powered

down and the default gain is 1. Thus, powering up in control

register mode requires a write to the device to power up the

comparators and the ADCs.

It takes 15 s to power up the AD7262/AD7262-5 when using

an external reference. When the internal reference is used, 240 s

are required to power up the AD7262/AD7262-5 with a 1 F

decoupling capacitor.

CONTROL REGISTER

The control register on the AD7262/AD7262-5 is a 12-bit read

and write register, which is used to control the device when not

in pin-driven mode. The PD0/D

pin for the AD7262/AD7262-5 when the gain pins are set to

D

IN

0 (that is, the part is not in pin-driven mode). The control

register can be used to select the gain of the PGAs, the powerdown modes, and the calibration of the offset for both ADC A

and ADC B. When operating in the control register mode, PD1

and PD2 should be connected to a low logic state.

pin serves as the serial

IN

These functions can also be implemented by setting the logic

levels on the gain pins, the power-down pins, and the CAL pin,

respectively. The control register can also be used to read the

offset and gain registers.

Data is loaded from the PD0/D

on the falling edge of SCLK when

pin of the AD7262/AD7262-5

IN

CS

is in a logic low state. The

control register is selected by first writing the appropriate four

WR bits, as outlined in . The 12 data bits must then be

clocked into the control register of the device. Thus, on the 16

Tabl e 10

th

falling SCLK edge, the LSB is clocked into the device. One more

SCLK cycle is then required to write to the internal device

registers. In total, 17 SCLK cycles are required to successfully

write to the AD7262/AD7262-5. The data is transferred on the

PD0/D

The data transferred on the D

line while the conversion result is being processed.

IN

line corresponds to the AD7262/

IN

AD7262-5 configuration for the next conversion.

Only the information provided on the 12 falling clock edges

CS

after the

loaded to the control register. The PD0/D

falling edge and the initial four write address bits is

pin should have a

IN

logic low state for the four bits RD3 to RD0 when using the

control register to select the power-down modes or gain setting

or when initializing a calibration. The RD bits should also be set

to a logic low level to access the ADC results from both D

OUT

B.

and D

OUT

A

The power-up status of all bits is 0 and the MSB denotes the first

bit in the data stream. The bit functions are outlined in Tab l e 8

and Tabl e 9.

Table 8. Control Register Bits

MSB LSB

Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

RD3 RD2 RD1 RD0 CAL PD2 PD1 PD0 G3 G2 G1 G0

Table 9. Control Register Bit Function Description

Bits Mnemonic Description

11 to 8 RD3 to RD0 Register address bits. These bits select which register the subsequent read is from. See Table 11.

7 CAL

Setting this bit high initiates an internal offset calibration. Once the calibration is completed, this pin can be reset low,

and the internal offset, which is stored in the on-chip offset registers, is automatically removed from the ADC results.

6 to 4 PD2 toPD0 Power-down bits. These bits select which power-down mode is programmed. See Table 7 .

3 to 0 G3 to G0 Gain selection bits. These bits select which gain setting is used on the front-end PGA. See Table 6.

Table 10. Write Address Bits

WR3 WR2 WR1 WR0 Read Register Addressed

0 0 0 1 Control register

SCLK

D

OUT

PD0/D

CS

t

2

A

IN

THREE-STATE

WR1 WR0 RD3 RD2 RD1 RD0 CAL PD2 PD1 PD0 G 3 G2 G 1 G0WR2WR3

t

13

Figure 30. Timing Diagram for a Write Operation to the Control Register

t

14

10 14 16

987654321

11 12 13 17

15

18

2019 30 31

DB10

DB11

THREE-STATE

DB0

t

QUIET

THREE-

STATE

t

8

07606-030

Rev. 0 | Page 23 of 32

AD7262

ON-CHIP REGISTERS

The AD7262/AD7262-5 contain a control register, two offset