REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

Low Level,

True RMS-to-DC Converter

AD636

PRODUCT DESCRIPTION

The AD636 is a low power monolithic IC which performs true

rms-to-dc conversion on low level signals. It offers performance

which is comparable or superior to that of hybrid and modular

converters costing much more. The AD636 is specified for a

signal range of 0 mV to 200 mV rms. Crest factors up to 6 can

be accommodated with less than 0.5% additional error, allowing

accurate measurement of complex input waveforms.

The low power supply current requirement of the AD636, typi-

cally 800 µA, allows it to be used in battery-powered portable

instruments. A wide range of power supplies can be used, from

±2.5 V to ±16.5 V or a single +5 V to +24 V supply. The input

and output terminals are fully protected; the input signal can

exceed the power supply with no damage to the device (allowing

the presence of input signals in the absence of supply voltage)

and the output buffer amplifier is short-circuit protected.

The AD636 includes an auxiliary dB output. This signal is

derived from an internal circuit point which represents the logarithm of the rms output. The 0 dB reference level is set by an

externally supplied current and can be selected by the user

to correspond to any input level from 0 dBm (774.6 mV) to

–20 dBm (77.46 mV). Frequency response ranges from 1.2 MHz

at a 0 dBm level to over 10 kHz at –50 dBm.

The AD636 is designed for ease of use. The device is factorytrimmed at the wafer level for input and output offset, positive

and negative waveform symmetry (dc reversal error), and fullscale accuracy at 200 mV rms. Thus no external trims are required to achieve full-rated accuracy.

AD636 is available in two accuracy grades; the AD636J total

error of ±0.5 mV ±0.06% of reading, and the AD636K

FEATURES

True RMS-to-DC Conversion

200 mV Full Scale

Laser-Trimmed to High Accuracy

0.5% Max Error (AD636K)

1.0% Max Error (AD636J)

Wide Response Capability:

Computes RMS of AC and DC Signals

1 MHz –3 dB Bandwidth: V RMS >100 mV

Signal Crest Factor of 6 for 0.5% Error

dB Output with 50 dB Range

Low Power: 800 A Quiescent Current

Single or Dual Supply Operation

Monolithic Integrated Circuit

Low Cost

Available in Chip Form

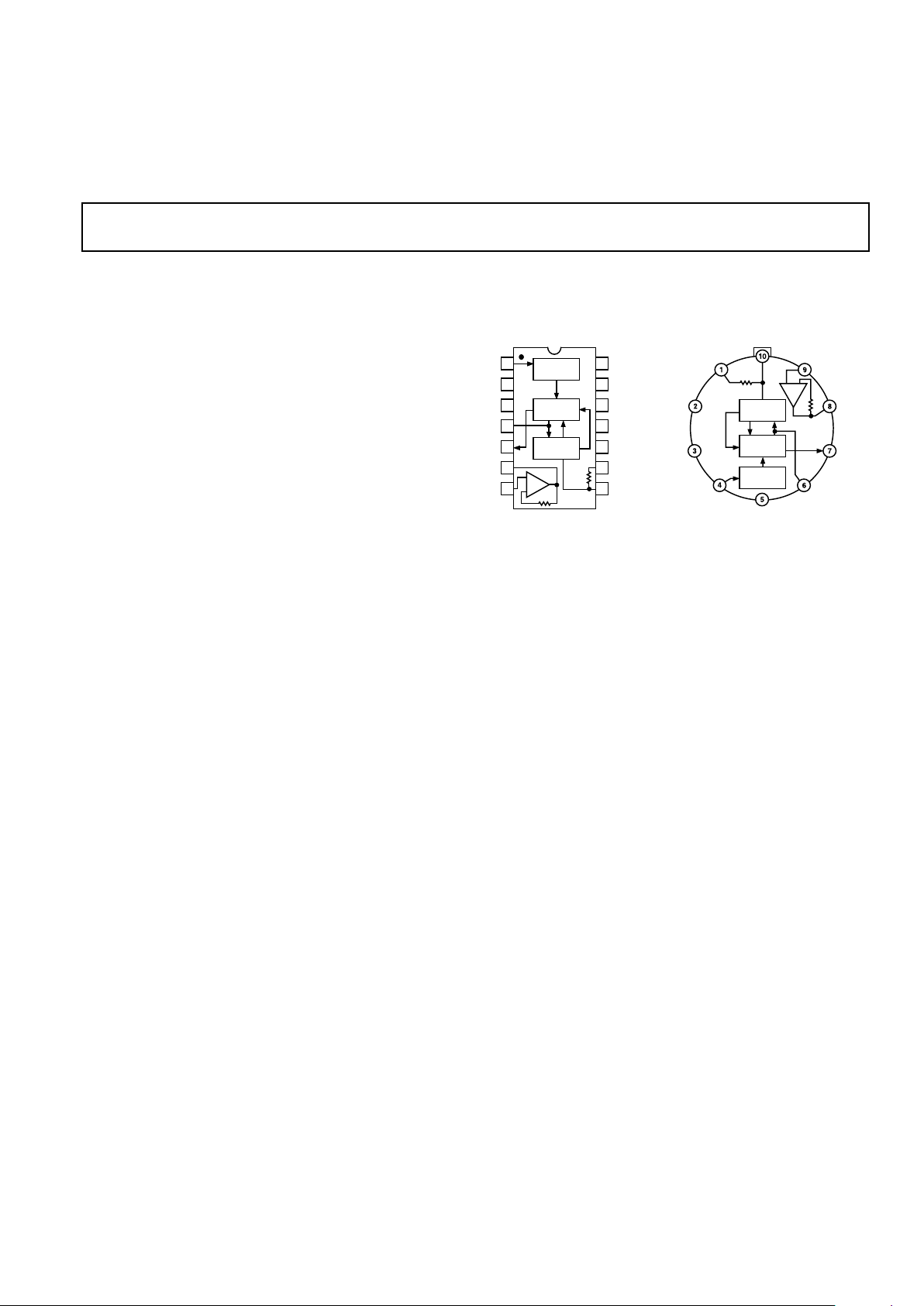

PIN CONNECTIONS &

FUNCTIONAL BLOCK DIAGRAM

is accurate within ±0.2 mV to ±0.3% of reading. Both versions

are specified for the 0°C to +70°C temperature range, and are

offered in either a hermetically sealed 14-pin DIP or a 10-lead

TO-100 metal can. Chips are also available.

PRODUCT HIGHLIGHTS

1. The AD636 computes the true root-mean-square of a complex ac (or ac plus dc) input signal and gives an equivalent dc

output level. The true rms value of a waveform is a more

useful quantity than the average rectified value since it is a

measure of the power in the signal. The rms value of an

ac-coupled signal is also its standard deviation.

2. The 200 millivolt full-scale range of the AD636 is compatible

with many popular display-oriented analog-to-digital converters. The low power supply current requirement permits

use in battery powered hand-held instruments.

3. The only external component required to perform measurements to the fully specified accuracy is the averaging capacitor. The value of this capacitor can be selected for the desired

trade-off of low frequency accuracy, ripple, and settling time.

4. The on-chip buffer amplifier can be used to buffer either the

input or the output. Used as an input buffer, it provides

accurate performance from standard 10 MΩ input attenua-

tors. As an output buffer, it can supply up to 5 milliamps of

output current.

5. The AD636 will operate over a wide range of power supply

voltages, including single +5 V to +24 V or split ±2.5 V to

±16.5 V sources. A standard 9 V battery will provide several

hundred hours of continuous operation.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

V

IN

NC

–V

S

C

AV

dB

BUF OUT

BUF IN

+V

S

NC

NC

NC

COMMON

R

L

I

OUT

AD636

14

13

12

11

10

9

8

1

2

3

4

5

6

7

ABSOLUTE

VALUE

SQUARER

DIVIDER

BUF

SQUARER

DIVIDER

ABSOLUTE

VALUE

AD636

BUF OUT

dB

C

AV

BUF IN

R

L

COMMON

+V

S

V

IN

–V

S

I

OUT

CURRENT

MIRROR

+–

+

–

CURRENT

MIRROR

BUF

10kV

10kV

10kV

10kV

NC = NO CONNECT

AD636–SPECIFICATIONS

(@ +25ⴗC, and +VS = +3 V, –VS = –5 V, unless otherwise noted)

REV. B–2–

M

odel AD636J AD636K

Min Typ Max Min Typ Max Units

TRANSFER FUNCTION

V

OUT

= avg. ( V

IN

)

2

V

OUT

= avg. ( V

IN

)

2

CONVERSION ACCURACY

Total Error, Internal Trim

1, 2

ⴞ0.5 ⴞ1.0 ⴞ0.2 ⴞ0.5 mV ±% of Reading

vs. Temperature, 0°C to +70°C ±0.1 ±0.01 ±0.1 ±0.005 mV ±% of Reading/°C

vs. Supply Voltage ±0.1 ±0.01 ±0.1 ±0.01 mV ±% of Reading/V

dc Reversal Error at 200 mV ±0.2 ±0.1 % of Reading

Total Error, External Trim

1

±0.3 ±0.3 ±0.1 ±0.2 mV ±% of Reading

ERROR VS. CREST FACTOR

3

Crest Factor 1 to 2 Specified Accuracy Specified Accuracy

Crest Factor = 3 –0.2 –0.2 % of Reading

Crest Factor = 6 –0.5 –0.5 % of Reading

AVERAGING TIME CONSTANT 25 25 ms/µF CAV

INPUT CHARACTERISTICS

Signal Range, All Supplies

Continuous rms Level 0 to 200 0 to 200 mV rms

Peak Transient Inputs

+3 V, –5 V Supply ±2.8 ±2.8 V pk

±2.5 V Supply ±2.0 ±2.0 V pk

±5 V Supply ±5.0 ±5.0 V pk

Maximum Continuous Nondestructive

Input Level (All Supply Voltages) ±12 ±12 V pk

Input Resistance 5.33 6.67 8 5.33 6.67 8 kΩ

Input Offset Voltage ±0.5 ±0.2 mV

FREQUENCY RESPONSE

2, 4

Bandwidth for 1% Additional Error (0.09 dB)

V

IN

= 10 mV 14 14 kHz

V

IN

= 100 mV 90 90 kHz

V

IN

= 200 mV 130 130 kHz

±3 dB Bandwidth

V

IN

= 10 mV 100 100 kHz

V

IN

= 100 mV 900 900 kHz

VIN = 200 mV 1.5 1.5 MHz

OUTPUT CHARACTERISTICS

2

Offset Voltage, VIN = COM ⴞ0.5 ⴞ0.2 mV

vs. Temperature ±10 ±10 µV/°C

vs. Supply ±0.1 ±0.1 mV/ V

Voltage Swing

+3 V, –5 V Supply 0.3 0 to +1.0 0.3 0 to +1.0 V

±5 V to ±16.5 V Supply 0.3 0 to +1.0 0.3 0 to +1.0 V

Output Impedance 8 10 12 8 10 12 kΩ

dB OUTPUT

Error, V

IN

= 7 mV to 300 mV rms ±0.3 ⴞ0.5 ±0.1 ⴞ0.2 dB

Scale Factor –3.0 –3.0 mV/dB

Scale Factor Temperature Coefficient +0.33 +0.33 % of Reading/°C

–0.033 –0.033 dB/°C

I

REF

for 0 dB = 0.1 V rms 248 2 4 8 µA

I

REF

Range 1 50 1 50 µA

I

OUT

TERMINAL

I

OUT

Scale Factor 100 100 µA/V rms

I

OUT

Scale Factor Tolerance –20 ±10 +20 –20 ±10 +20 %

Output Resistance 8 10 12 8 10 12 kΩ

Voltage Compliance –V

S

to (+V

S

–VS to (+V

S

–2 V) –2 V) V

BUFFER AMPLIFIER

Input and Output Voltage Range –V

S

to (+V

S

–VS to (+V

S

–2 V) –2 V) V

Input Offset Voltage, R

S

= 10k ±0.8 ⴞ2 ±0.5 ⴞ1 mV

Input Bias Current 100 300 100 300 nA

Input Resistance 10

8

10

8

Ω

Output Current (+5 mA, (+5 mA,

–130 µA) –130 µA)

Short Circuit Current 20 20 mA

Small Signal Bandwidth l l MHz

Slew Rate

5

55V/µs

POWER SUPPLY

Voltage, Rated Performance +3, –5 +3, –5 V

Dual Supply +2, –2.5 ±16.5 +2, –2.5 ±16.5 V

Single Supply +5 +24 +5 +24 V

Quiescent Current

6

0.80 1.00 0.80 1.00 mA

ORDERING GUIDE

Temperature Package Package

Model Range Descriptions Options

AD636JD 0°C to +70°C Side Brazed Ceramic DIP D-14

AD636KD 0°C to +70°C Side Brazed Ceramic DIP D-14

AD636JH 0°C to +70°C Header H-10A

AD636KH 0°C to +70°C Header H-10A

AD636J Chip 0°C to +70°C Chip

AD636JD/+ 0°C to +70°C Side Brazed Ceramic DIP D-14

AD636

M

odel AD636J AD636K

Min Typ Max Min Typ Max Units

TEMPERATURE RANGE

Rated Performance 0 +70 0 +70 °C

Storage –55 +150 –55 +150 °C

TRANSISTOR COUNT 62 62

NOTES

1

Accuracy specified for 0 mV to 200 mV rms, dc or 1 kHz sine wave input. Accuracy is degraded at higher rms signal levels.

2

Measured at Pin 8 of DIP (I

OUT

), with Pin 9 tied to common.

3

Error vs. crest factor is specified as additional error for a 200 mV rms rectangular pulse trim, pulse width = 200 µs.

4

Input voltages are expressed in volts rms.

5

With 10 kΩ pull down resistor from Pin 6 (BUF OUT) to –V

S

.

6

With BUF input tied to Common.

Specifications subject to change without notice.

All min and max specifications are guaranteed. Specifications shown in boldface are tested on all production units at final electrical test and are used to calculate outgoing

quality levels.

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage

Dual Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±16.5 V

Single Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +24 V

Internal Power Dissipation

2

. . . . . . . . . . . . . . . . . . . .500 mW

Maximum Input Voltage . . . . . . . . . . . . . . . . . . . . ±12 V Peak

Storage Temperature Range N, R . . . . . . . . . –55°C to +150°C

Operating Temperature Range

AD636J/K . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . +300°C

ESD Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000 V

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

10-Lead Header: θJA = 150°C/Watt.

14-Lead Side Brazed Ceramic DIP: θJA = 95°C/Watt.

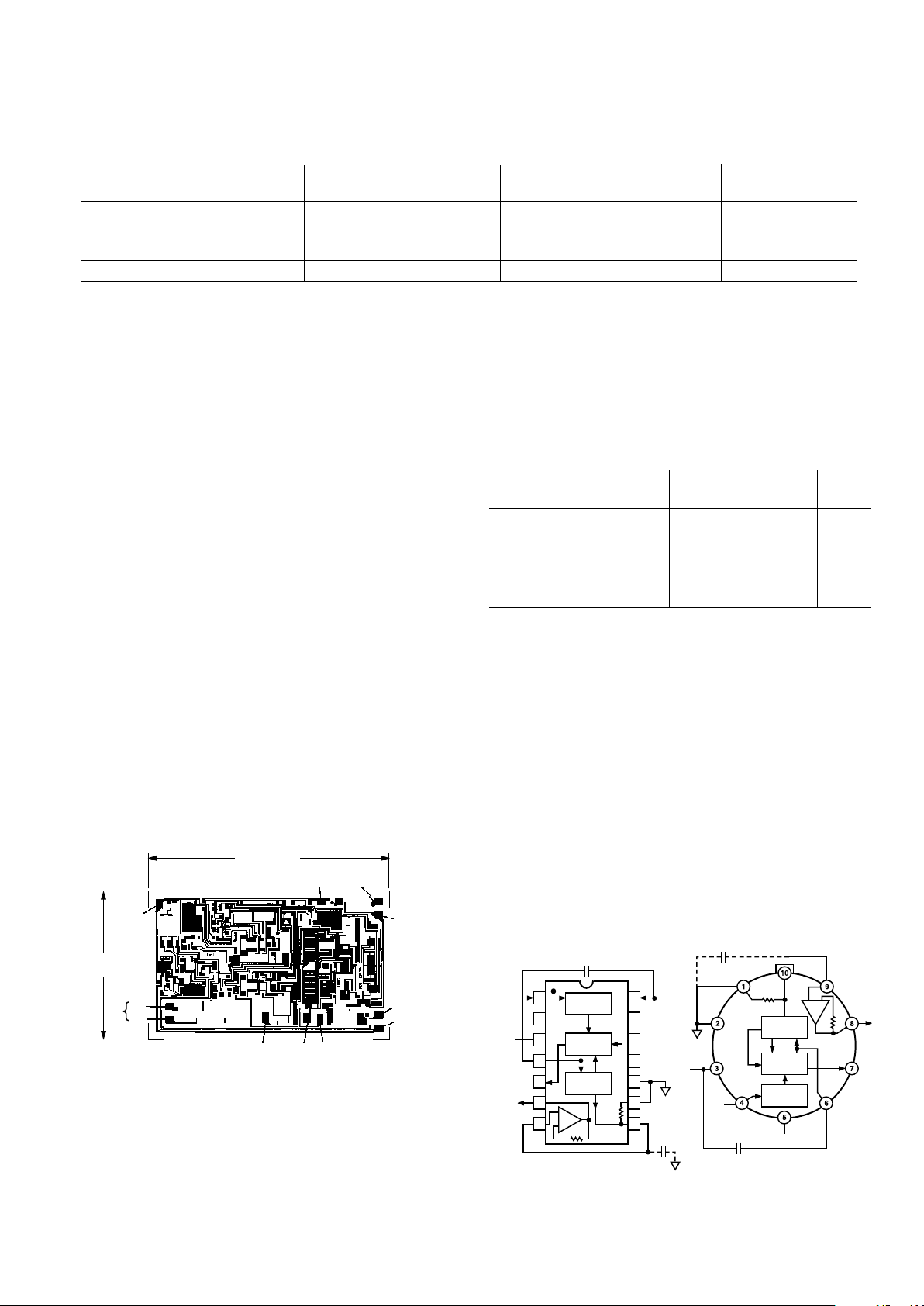

METALIZATION PHOTOGRAPH

Contact factory for latest dimensions.

Dimensions shown in inches and (mm).

COM

10

R

L

9

+V

S

14

1a*

1b*

V

IN

3

–V

S

4

C

AV

5

dB

7 BUF IN

6 BUF OUT

8 I

OUT

0.1315 (3.340)

0.0807

(2.050)

PAD NUMBERS CORRESPOND TO PIN NUMBERS

FOR THE TO-116 14-PIN CERAMIC DIP PACKAGE.

NOTE

*BOTH PADS SHOWN MUST BE CONNECTED TO V

IN

.

STANDARD CONNECTION

The AD636 is simple to connect for the majority of high accuracy rms measurements, requiring only an external capacitor to

set the averaging time constant. The standard connection is

shown in Figure 1. In this configuration, the AD636 will measure the rms of the ac and dc level present at the input, but will

show an error for low frequency inputs as a function of the filter

capacitor, C

AV

, as shown in Figure 5. Thus, if a 4 µF capacitor

is used, the additional average error at 10 Hz will be 0.1%, at

3 Hz it will be 1%. The accuracy at higher frequencies will be

according to specification. If it is desired to reject the dc input, a

capacitor is added in series with the input, as shown in Figure 3; the capacitor must be nonpolar. If the AD636 is driven

with power supplies with a considerable amount of high frequency

ripple, it is advisable to bypass both supplies to ground with

0.1 µF ceramic discs as near the device as possible. C

F

is an

optional output ripple filter, as discussed elsewhere in this data

sheet.

AD636

14

13

12

11

10

9

8

1

2

3

4

5

6

7

ABSOLUTE

VALUE

SQUARER

DIVIDER

BUF

+

–

CURRENT

MIRROR

10kV

10kV

V

IN

–V

S

+V

S

V

OUT

C

F

(OPTIONAL)

+–

C

AV

SQUARER

DIVIDER

ABSOLUTE

VALUE

AD636

CURRENT

MIRROR

+–

BUF

10kV

10kV

+V

S

V

IN

–V

S

+–

C

AV

V

OUT

C

F

(OPTIONAL)

Figure 1. Standard RMS Connection

REV. B –3–

AD636

REV. B–4–

flows into Pin 10 (Pin 2 on the “H” package). Alternately, the

COM pin of some CMOS ADCs provides a suitable artificial

ground for the AD636. AC input coupling requires only capacitor C2 as shown; a dc return is not necessary as it is provided

internally. C2 is selected for the proper low frequency break

point with the input resistance of 6.7 kΩ; for a cut-off at 10 Hz,

C2 should be 3.3 µF. The signal ranges in this connection are

slightly more restricted than in the dual supply connection. The

load resistor, R

L

, is necessary to provide current sinking capability.

1

2

3

4

5

6

7

AD636

14

13

12

11

10

9

8

ABSOLUTE

VALUE

SQUARER

DIVIDER

10kV

10kV

CURRENT

MIRROR

V

IN

V

OUT

+V

S

–+

C

AV

20kV

C2

3.3mF

NONPOLARIZED

R

L

10kV to 1kV

39kV

0.1mF

0.1mF

+

–

BUF

Figure 3. Single Supply Connection

CHOOSING THE AVERAGING TIME CONSTANT

The AD636 will compute the rms of both ac and dc signals. If

the input is a slowly-varying dc voltage, the output of the AD636

will track the input exactly. At higher frequencies, the average

output of the AD636 will approach the rms value of the input

signal. The actual output of the AD636 will differ from the ideal

output by a dc (or average) error and some amount of ripple, as

demonstrated in Figure 4.

DOUBLE-FREQUENCY

RIPPLE

E

O

IDEAL

E

O

AVERAGE EO = E

O

DC ERROR = EO – EO (IDEAL)

TIME

Figure 4. Typical Output Waveform for Sinusoidal Input

The dc error is dependent on the input signal frequency and the

value of C

AV

. Figure 5 can be used to determine the minimum

value of C

AV

which will yield a given % dc error above a given

frequency using the standard rms connection.

The ac component of the output signal is the ripple. There are

two ways to reduce the ripple. The first method involves using

a large value of C

AV

. Since the ripple is inversely proportional

to C

AV

, a tenfold increase in this capacitance will effect a tenfold

reduction in ripple. When measuring waveforms with high crest

factors, (such as low duty cycle pulse trains), the averaging time

constant should be at least ten times the signal period. For

example, a 100 Hz pulse rate requires a 100 ms time constant,

which corresponds to a 4 µF capacitor (time constant = 25 ms

per µF).

APPLYING THE AD636

The input and output signal ranges are a function of the supply

voltages as detailed in the specifications. The AD636 can also

be used in an unbuffered voltage output mode by disconnecting

the input to the buffer. The output then appears unbuffered

across the 10 kΩ resistor. The buffer amplifier can then be used

for other purposes. Further, the AD636 can be used in a current

output mode by disconnecting the 10 kΩ resistor from the

ground. The output current is available at Pin 8 (Pin 10 on the

“H” package) with a nominal scale of 100 µA per volt rms input,

positive out.

OPTIONAL TRIMS FOR HIGH ACCURACY

If it is desired to improve the accuracy of the AD636, the external trims shown in Figure 2 can be added. R4 is used to trim the

offset. The scale factor is trimmed by using R1 as shown. The

insertion of R2 allows R1 to either increase or decrease the scale

factor by ±1.5%.

The trimming procedure is as follows:

1. Ground the input signal, V

IN

, and adjust R4 to give zero

volts output from Pin 6. Alternatively, R4 can be adjusted to

give the correct output with the lowest expected value of V

IN.

2. Connect the desired full-scale input level to VIN, either dc or

a calibrated ac signal (1 kHz is the optimum frequency);

then trim R1 to give the correct output from Pin 6, i.e.,

200 mV dc input should give 200 mV dc output. Of course,

a ±200 mV peak-to-peak sine wave should give a 141.4 mV

dc output. The remaining errors, as given in the specifications, are due to the nonlinearity.

1

2

3

4

5

6

7

AD636

14

13

12

11

10

9

8

ABSOLUTE

VALUE

SQUARER

DIVIDER

10kV

10kV

CURRENT

MIRROR

V

IN

V

OUT

+V

S

–V

S

SCALE

FACTOR

ADJUST

R1

200V

61.5%

–+

C

AV

+V

S

–V

S

R4

500kV

OFFSET

ADJUST

R3

470kV

R2

154V

+

–

BUF

Figure 2. Optional External Gain and Output Offset Trims

SINGLE SUPPLY CONNECTION

The applications in Figures 1 and 2 assume the use of dual

power supplies. The AD636 can also be used with only a single

positive supply down to +5 volts, as shown in Figure 3. Figure 3

is optimized for use with a 9 volt battery. The major limitation

of this connection is that only ac signals can be measured since

the input stage must be biased off ground for proper operation.

This biasing is done at Pin 10; thus it is critical that no extraneous signals be coupled into this point. Biasing can be accomplished by using a resistive divider between +V

S

and ground.

The values of the resistors can be increased in the interest of

lowered power consumption, since only 1 microamp of current

AD636

REV. B –5–

INPUT FREQUENCY – Hz

100

0.01

1 100k

REQUIRED C

AV

– mF

1.0

10 100 1k 10k

10

0.1

1.0

10

100

0.1

0.01

FOR 1% SETTLING TIME IN SECONDS

MULTIPLY READING BY 0.115

0.01% ERROR

0.1% ERROR

VALUES FOR CAV AND

1% SETTLING TIME FOR

STATED % OF READING

AVERAGING ERROR*

ACCURACY 620% DUE TO

COMPONENT TOLERANCE

10% ERROR

*% dc ERROR + % RIPPLE (PEAK)

1% ERROR

Figure 5. Error/Settling Time Graph for Use with the

Standard rms Connection

The primary disadvantage in using a large CAV to remove ripple

is that the settling time for a step change in input level is increased proportionately. Figure 5 shows the relationship between C

AV

and 1% settling time is 115 milliseconds for each

microfarad of C

AV

. The settling time is twice as great for decreasing signals as for increasing signals (the values in Figure 5

are for decreasing signals). Settling time also increases for low

signal levels, as shown in Figure 6.

rms INPUT LEVEL

10.0

7.5

0

1mV 1V10mV

SETTLING TIME RELATIVE TO

SETTLING TIME @ 200mV rms

100mV

1.0

5.0

2.5

Figure 6. Settling Time vs. Input Level

A better method for reducing output ripple is the use of a

“post-filter.” Figure 7 shows a suggested circuit. If a single pole

filter is used (C3 removed, R

X

shorted), and C2 is approxi-

mately 5 times the value of C

AV

, the ripple is reduced as shown

in Figure 8, and settling time is increased. For example, with

C

AV

= 1 µF and C2 = 4.7 µF, the ripple for a 60 Hz input is re-

duced from 10% of reading to approximately 0.3% of reading.

The settling time, however, is increased by approximately a

factor of 3. The values of C

AV

and C2 can therefore be reduced

to permit faster settling times while still providing substantial

ripple reduction.

The two-pole post-filter uses an active filter stage to provide

even greater ripple reduction without substantially increasing

the settling times over a circuit with a one-pole filter. The values

of C

AV

, C2, and C3 can then be reduced to allow extremely fast

settling times for a constant amount of ripple. Caution should

be exercised in choosing the value of C

AV

, since the dc error is

dependent upon this value and is independent of the post filter.

For a more detailed explanation of these topics refer to the

RMS-to-DC Conversion Application Guide, 2nd Edition, available

from Analog Devices.

1

2

3

4

5

6

7

AD636

14

13

12

11

10

9

8

ABSOLUTE

VALUE

SQUARER

DIVIDER

+

–

BUF

10kV

10kV

CURRENT

MIRROR

V

rms

OUT

+V

S

V

IN

–V

S

C

AV

+

–

+

–

+

–

C2

C3

(FOR SINGLE POLE, SHORT Rx,

REMOVE C3)

Rx

10kV

Figure 7. 2 Pole ‘’Post’’ Filter

FREQUENCY – Hz

10

0.1

10 10k

DC ERROR OR RIPPLE – % of Reading

1

1k100

p-p RIPPLE

CAV = 1mF (FIG 1)

p-p RIPPLE

(ONE POLE)

CAV = 1mF

C2 = 4.7mF

DC ERROR

CAV = 1mF

(ALL FILTERS)

p-p RIPPLE

(TWO POLE)

CAV = 1mF, C2 = C3 = 4.7mF

Figure 8. Performance Features of Various Filter Types

RMS MEASUREMENTS

AD636 PRINCIPLE OF OPERATION

The AD636 embodies an implicit solution of the rms equation

that overcomes the dynamic range as well as other limitations

inherent in a straightforward computation of rms. The actual

computation performed by the AD636 follows the equation:

V rms = Avg .

V

IN

2

V rms

Figure 9 is a simplified schematic of the AD636; it is subdivided

into four major sections: absolute value circuit (active rectifier),

squarer/divider, current mirror, and buffer amplifier. The input

voltage, V

IN

, which can be ac or dc, is converted to a unipolar

current I

1

, by the active rectifier A1, A2. I1 drives one input of

the squarer/divider, which has the transfer function:

I

4

=

I

1

2

I

3

The output current, I4, of the squarer/divider drives the current

mirror through a low-pass filter formed by R1 and the externally

connected capacitor, C

AV

. If the R1, CAV time constant is much

greater than the longest period of the input signal, then I

4

is

effectively averaged. The current mirror returns a current I

3

,

which equals Avg. [I

4

], back to the squarer/divider to complete

the implicit rms computation. Thus:

I

4

= Avg .

I

1

2

I

4

= I

1

rms

AD636

REV. B–6–

Addition of an external resistor in parallel with RE alters this

voltage divider such that increased negative swing is possible.

Figure 11 shows the value of R

EXTERNAL

for a particular ratio of

V

PEAK

to –VS for several values of R

LOAD.

Addition, of R

EXTERNAL

increases the quiescent current of the buffer amplifier by an

amount equal to R

EXT

/–VS. Nominal buffer quiescent current

with no R

EXTERNAL

is 30 µA at –V

S

= –5 V.

R

EXTERNAL

– V

1.0

0.5

0

01M1k

RATIO OF V

PEAK

/V

SUPPLY

10k 100k

RL = 6.7kV

RL = 16.7kV

RL = 50kV

Figure 11. Ratio of Peak Negative Swing to –VS vs.

R

EXTERNAL

for Several/Load Resistances

FREQUENCY RESPONSE

The AD636 utilizes a logarithmic circuit in performing the

implicit rms computation. As with any log circuit, bandwidth is

proportional to signal level. The solid lines in the graph below

represent the frequency response of the AD636 at input levels

from 1 millivolt to 1 volt rms. The dashed lines indicate the

upper frequency limits for 1%, 10%, and ±3 dB of reading

additional error. For example, note that a 1 volt rms signal will

produce less than 1% of reading additional error up to 220 kHz.

A 10 millivolt signal can be measured with 1% of reading addi-

tional error (100 µV) up to 14 kHz.

FREQUENCY – Hz

1

V

OUT

– Volts

200m

100m

10m

1m

30m

1k 10k 100k 1M

100m

1 VOLT rms INPUT

200mV rms INPUT

100mV rms INPUT

30mV rms INPUT

10mV rms

INPUT

1mV rms INPUT

10% 63dB

10M

1%

Figure 12. AD636 Frequency Response

AC MEASUREMENT ACCURACY AND CREST FACTOR

Crest factor is often overlooked in determining the accuracy of

an ac measurement. Crest factor is defined as the ratio of the

peak signal amplitude to the rms value of the signal (C.F. = V

P

/

V rms) Most common waveforms, such as sine and triangle

waves, have relatively low crest factors (<2). Waveforms that

The current mirror also produces the output current, I

OUT

,

which equals 2I

4

. I

OUT

can be used directly or converted to a

voltage with R2 and buffered by A

4

to provide a low impedance

voltage output. The transfer function of the AD636 thus results:

V

OUT

= 2 R2 I rms =V

IN

rms

The dB output is derived from the emitter of Q3, since the voltage at this point is proportional to –log V

IN

. Emitter follower,

Q

5

, buffers and level shifts this voltage, so that the dB output

voltage is zero when the externally supplied emitter current

(I

REF

) to Q5 approximates I3.

A4 6

7

5

3

984

10

14

A1

A2

A3

1

+V

S

COM

R

L

dB

OUT

BUF

OUT

BUFFER

BUF

IN

10k

V

Q5

Q4Q2

Q1

Q3

ONE-QUADRANT

SQUARER/

DIVIDER

C

AVIOUT

ABSOLUTE VALUE/

VOLTAGE–CURRENT

CONVERTER

V

IN

R3

10kV

8kV

8kV

+

R4

20kV

|VIN|

R4

I

1

10mA

FS

I

3

20mA

FS

R1

25kV

I

4

R2

10kV

I

REF

–V

S

CURRENT MIRROR

Figure 9. Simplified Schematic

THE AD636 BUFFER AMPLIFIER

The buffer amplifier included in the AD636 offers the user

additional application flexibility. It is important to understand

some of the characteristics of this amplifier to obtain optimum

performance. Figure 10 shows a simplified schematic of the buffer.

Since the output of an rms-to-dc converter is always positive, it

is not necessary to use a traditional complementary Class AB

output stage. In the AD636 buffer, a Class A emitter follower is

used instead. In addition to excellent positive output voltage

swing, this configuration allows the output to swing fully down

to ground in single-supply applications without the problems

associated with most IC operational amplifiers.

CURRENT

MIRROR

BUFFER

INPUT

BUFFER

OUTPUT

+V

S

R

E

40kV

10kV

R

EXTERNAL

PTI

NAL EE TEXT

–V

S

R

LOAD

5mA5mA

Figure 10. AD636 Buffer Amplifier Simplified Schematic

When this amplifier is used in dual-supply applications as an

input buffer amplifier driving a load resistance referred to

ground, steps must be taken to insure an adequate negative

voltage swing. For negative outputs, current will flow from the

load resistor through the 40 kΩ emitter resistor, setting up a

voltage divider between –V

S

and ground. This reduced effective

–V

S

, will limit the available negative output swing of the buffer.

AD636

REV. B –7–

Circuit Description

The input voltage, VIN, is ac coupled by C4 while resistor R8,

together with diodes D1, and D2, provide high input voltage

protection.

The buffer’s output, Pin 6, is ac coupled to the rms converter’s

input (Pin 1) by capacitor C2. Resistor, R9, is connected between

the buffer’s output, a Class A output stage, and the negative output

swing. Resistor R1, is the amplifier’s “bootstrapping” resistor.

With this circuit, single supply operation is made possible by

setting “ground” at a point between the positive and negative

sides of the battery. This is accomplished by sending 250 µA

from the positive battery terminal through resistor R2, then

through the 1.2 volt AD589 bandgap reference, and finally back

to the negative side of the battery via resistor R10. This sets

ground at 1.2 volts +3.18 volts (250 µA × 12.7 kΩ) = 4.4 volts

below the positive battery terminal and 5.0 volts (250 µA × 20 kΩ)

above the negative battery terminal. Bypass capacitors C3 and

C5 keep both sides of the battery at a low ac impedance to

ground. The AD589 bandgap reference establishes the 1.2 volt

regulated reference voltage which together with resistor R3 and

trimming potentiometer R4 set the zero dB reference current I

REF

.

Performance Data

0 dB Reference Range = 0 dBm (770 mV) to –20 dBm

(77 mV) rms

0 dBm = 1 milliwatt in 600 Ω

Input Range (at I

REF

= 770 mV) = 50 dBm

Input Impedance = approximately 10

10

Ω

V

SUPPLY

Operating Range +5 V dc to +20 V dc

I

QUIESCENT

= 1. 8 mA typical

Accuracy with 1 kHz sine wave and 9 volt dc supply:

0 dB to –40 dBm ± 0.1 dBm

0 dBm to –50 dBm ± 0.15 dBm

+10 dBm to –50 dBm ± 0.5 dBm

Frequency Response ⴞ3 dBm

Input

0 dBm = 5 Hz to 380 kHz

–10 dBm = 5 Hz to 370 kHz

–20 dBm = 5 Hz to 240 kHz

–30 dBm = 5 Hz to 100 kHz

–40 dBm = 5 Hz to 45 kHz

–50 dBm = 5 Hz to 17 kHz

Calibration

1. First calibrate the zero dB reference level by applying a 1 kHz

sine wave from an audio oscillator at the desired zero dB

amplitude. This may be anywhere from zero dBm (770 mV

rms – 2.2 volts p-p) to –20 dBm (77 mV rms 220 mV – p-p).

Adjust the I

REF

cal trimmer for a zero indication on the analog

meter.

2. The final step is to calibrate the meter scale factor or gain.

Apply an input signal –40 dB below the set zero dB reference

and adjust the scale factor calibration trimmer for a 40 µA

reading on the analog meter.

The temperature compensation resistors for this circuit may be

purchased from: Tel Labs Inc., 154 Harvey Road, P.O. Box 375,

Londonderry, NH 03053, Part #Q332A 2 kΩ 1% +3500 ppm/°C

or from Precision Resistor Company, 109 U.S. Highway 22, Hill-

side, NJ 07205, Part #PT146 2 kΩ 1% +3500 ppm/°C.

resemble low duty cycle pulse trains, such as those occurring in

switching power supplies and SCR circuits, have high crest

factors. For example, a rectangular pulse train with a 1% duty

cycle has a crest factor of 10 (C.F. =

1 η

).

Figure 13 is a curve of reading error for the AD636 for a 200 mV

rms input signal with crest factors from 1 to 7. A rectangular

pulse train (pulse width 200 µs) was used for this test since it is

the worst-case waveform for rms measurement (all the energy is

contained in the peaks). The duty cycle and peak amplitude

were varied to produce crest factors from 1 to 7 while maintaining a constant 200 mV rms input amplitude.

CREST FACTOR

0.5

0

–1.0

172

INCREASE IN ERROR – % of Reading

3456

–0.5

T

V

P

0

200ms

E

O

h = DUTY CYCLE =

CF = 1/ h

E

IN

(rms) = 200mV

200ms

T

Figure 13. Error vs. Crest Factor

A COMPLETE AC DIGITAL VOLTMETER

Figure 14 shows a design for a complete low power ac digital

voltmeter circuit based on the AD636. The 10 MΩ input

attenuator allows full-scale ranges of 200 mV, 2 V, 20 V and

200 V rms. Signals are capacitively coupled to the AD636 buffer

amplifier, which is connected in an ac bootstrapped configura-

tion to minimize loading. The buffer then drives the 6.7 kΩ

input impedance of the AD636. The COM terminal of the ADC

chip provides the false ground required by the AD636 for single

supply operation. An AD589 1.2 volt reference diode is used to

provide a stable 100 millivolt reference for the ADC in the linear rms mode; in the dB mode, a 1N4148 diode is inserted in

series to provide correction for the temperature coefficient of the

dB scale factor. Calibration of the meter is done by first adjusting offset pot R17 for a proper zero reading, then adjusting the

R13 for an accurate readout at full scale.

Calibration of the dB range is accomplished by adjusting R9 for

the desired 0 dB reference point, then adjusting R14 for the

desired dB scale factor (a scale of 10 counts per dB is convenient).

Total power supply current for this circuit is typically 2.8 mA

using a 7106-type ADC.

A LOW POWER, HIGH INPUT IMPEDANCE dB METER

Introduction

The portable dB meter circuit featured here combines the functions of the AD636 rms converter, the AD589 voltage reference,

and a µA776 low power operational amplifier. This meter offers

excellent bandwidth and superior high and low level accuracy

while consuming minimal power from a standard 9 volt transistor radio battery.

In this circuit, the built-in buffer amplifier of the AD636 is used

as a “bootstrapped” input stage increasing the normal 6.7 kΩ

input Z to an input impedance of approximately 10

10

Ω.

AD636

REV. B–8–

C651d–0–8/99

PRINTED IN U.S.A.

1

2

3

4

5

6

7

AD636

14

13

12

11

10

9

8

ABSOLUTE

VALUE

SQUARER

DIVIDER

+

–

BUF

10kV

10kV

CURRENT

MIRROR

+

–

+

–

+

+V

S

3-1/2

DIGIT

LCD

DISPLAY

3-1/2 DIGIT

7106 TYPE

A/D

CONVERTER

+V

DD

REF HI

REF LO

COM

HI

LO

–V

SS

ANALOG

IN

+

–

+

+V

DD

ON

OFF

1mF

9V

BATTERY

–V

SS

LXD 7543

–V

S

C6

0.01mF

R15

1MV

LIN

dB

LIN

dB

LIN

SCALE

R13

500V

R12

1kV

R11

10kV

D2

1N4148

LIN

dB

R14

10kV

dB

SCALE

D3

1.2V

AD589

R10

20kV

R9

100kV

0dB SET

R8

2.49kV

C7

6.8mF

C4

2.2mF

D1

1N4148

R6

1MV

R5

47kV

1W

10%

C3

0.02mF

200mV

V

IN

R1

9MV

2V

R2

900kV

20V

R3

90kV

200V

R4

10kV

COM

6.8mF

R7

20kV

D4

1N4148

Figure 14. A Portable, High Z Input, RMS DPM and dB Meter Circuit

1

2

3

4

5

6

7

AD636

14

13

12

11

10

9

8

ABSOLUTE

VALUE

SQUARER

DIVIDER

BUF

+

–

10kV

10kV

CURRENT

MIRROR

+–

+

–

mA776

+–

+

+

+

+

ON/OFF

9 VOLT

SCALE FACTOR

ADJUST

R5

10kV

0–50mA

R11

820kV

5%

100mA

R4

500kV

I

REF

ADJUST

R3

5kV

+1.2 VOLTS

AD589J

250mA

+

R6

100V

*R7

2kV

C6

0.1mF

+4.4 VOLTS

R2

12.7kV

C3

10mF

C5

10mF

R10

20kV

+4.7 VOLTS

C1

3.3mF

C2

6.8mF

R1

1MV

D1

1N6263

SIGNAL

INPUT

C4

0.1mF

R8

47kV

1 WATT

D2

1N6263

R9

10kV

ALL RESISTORS 1/4 WATT 1% METAL FILM UNLESS OTHERWISE STATED EXCEPT

*WHICH IS 2kV +3500ppm 1% TC RESISTOR.

Figure 15. A Low Power, High Input Impedance dB Meter

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

D Package (TO-116) H Package (TO-100)

14

1

7

8

0.098 (2.49) MAX

0.310 (7.87)

0.220 (5.59)

0.005 (0.13) MIN

PIN 1

0.100

(2.54)

BSC

SEATING

PLANE

0.023 (0.58)

0.014 (0.36)

0.060 (1.52)

0.015 (0.38)

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.070 (1.78)

0.030 (0.76)

0.150

(3.81)

MAX

0.785 (19.94) MAX

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

0.250 (6. 35) MIN

0.750 (19.05)

0.500 (12.70)

0.185 (4.70)

0.165 (4.19)

REFERENCE PLANE

0.050 (1.27) MAX

0.019 (0.48)

0.016 (0.41)

0.021 (0.53)

0.016 (0.41)

0.045 (1.14)

0.010 (0.25)

0.040 (1.02) MAX

BASE & SEATING PLANE

0.335 (8.51)

0.305 (7.75)

0.370 (9.40)

0.335 (8.51)

1

0.034 (0.86)

0.027 (0.69)

0.045 (1.14)

0.027 (0.69)

0.160 (4.06)

0.110 (2.79)

6

2

8

7

5

4

3

0.115

(2.92)

BSC

9

10

0.230 (5.84)

BSC

36° BSC

Loading...

Loading...