Two-Terminal IC

K

FEATURES

Linear current output: 1 µA/K

Wide temperature range: −55°C to +150°C

Probe compatible ceramic sensor package

2-terminal device: voltage in/current out

Laser trimmed to ±0.5°C calibration accuracy (AD590M)

Excellent linearity: ±0.3°C over full range (AD590M)

Wide power supply range: 4 V to 30 V

Sensor isolation from case

Low cost

GENERAL DESCRIPTION

The AD590 is a 2-terminal integrated circuit temperature

transducer that produces an output current proportional to

absolute temperature. For supply voltages between 4 V and 30 V

the device acts as a high-impedance, constant current regulator

passing 1 µA/K. Laser trimming of the chip’s thin-film resistors

is used to calibrate the device to 298.2 µA output at 298.2 K

(25°C).

The AD590 should be used in any temperature-sensing

application below 150°C in which conventional electrical

temperature sensors are currently employed. The inherent low

cost of a monolithic integrated circuit combined with the

elimination of support circuitry makes the AD590 an attractive

alternative for many temperature measurement situations.

Linearization circuitry, precision voltage amplifiers, resistance

measuring circuitry, and cold junction compensation are not

needed in applying the AD590.

In addition to temperature measurement, applications include

temperature compensation or correction of discrete

components, biasing proportional to absolute temperature, flow

rate measurement, level detection of fluids and anemometry.

The AD590 is available in chip form, making it suitable for

hybrid circuits and fast temperature measurements in protected

environments.

Temperature Transducer

AD590

FLATPAC

+–

receiving circuitry. The output characteristics also make the

AD590 easy to multiplex: the current can be switched by a

CMOS multiplexer or the supply voltage can be switched by a

logic gate output.

PRODUCT HIGHLIGHTS

1. The AD590 is a calibrated, 2-terminal temperature sensor

requiring only a dc voltage supply (4 V to 30 V). Costly

transmitters, filters, lead wire compensation, and

linearization circuits are all unnecessary in applying the

device.

2. State-of-the-art laser trimming at the wafer level in

conjunction with extensive final testing ensures that

AD590 units are easily interchangeable.

3. Superior interface rejection occurs, because the output is a

current rather than a voltage. In addition, power

requirements are low (1.5 mWs @ 5 V @ 25°C). These

features make the AD590 easy to apply as a remote sensor.

4. The high output impedance (>10 MΩ) provides excellent

rejection of supply voltage drift and ripple. For instance,

changing the power supply from 5 V to 10 V results in only

a 1 µA maximum current change, or 1°C equivalent error.

TO-52 SOIC-8

–

+

Figure 1. Pin Designations

NC

NC

1

V+

2

TOP VIEW

(Not to Scale)

3

V–

4

NC = NO CONNECT

NC

8

NC

7

6

NC

5

NC

00533-C-001

The AD590 is particularly useful in remote sensing applications.

The device is insensitive to voltage drops over long lines due to

its high impedance current output. Any well-insulated twisted

pair is sufficient for operation at hundreds of feet from the

Rev. C

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

5. The AD590 is electrically durable: it withstands a forward

voltage of up to 44 V and a reverse voltage of 20 V.

Therefore, supply irregularities or pin reversal does not

damage the device.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2003 Analog Devices, Inc. All rights reserved.

www.analog.com

AD590

TABLE OF CONTENTS

Specifications..................................................................................... 3

AD590J and AD590K Specifications .........................................3

AD590L and AD590M Specifications........................................ 4

Absolute Maximum Ratings............................................................ 5

ESD Caution.................................................................................. 5

Product Description ......................................................................... 6

Circuit Description....................................................................... 6

Explanation of Temperature Sensor Specifications ................. 6

Calibration Error.......................................................................... 7

REVISION HISTORY

Revision C

Error Versus Temperature: with Calibration Error Trimmed

...................................................................................................7

Out

Error Versus Temperature: No User Trims ................................7

Nonlinearity ...................................................................................7

Voltage and Thermal Environment Effects ...............................8

General Applications...................................................................... 10

Outline Dimensions....................................................................... 13

Ordering Guide .......................................................................... 14

9/03—Data Sheet Changed from REV. B to REV. C.

Added SOIC-8 package…………………………Universal

Change to Figure 1…………………………………….…1

Updated OUTLINE DIMENSIONS…………...……….13

Added ORDERING GUIDE………………...………….14

Rev. C | Page 2 of 16

AD590

SPECIFICATIONS

AD590J AND AD590K SPECIFICATIONS

Table 1. @ 25°C and VS = 5 V unless otherwise noted

AD590J AD590K

Parameter Min Typ Max Min Typ Max Unit

POWER SUPPLY

Operating Voltage Range

4

OUTPUT

Nominal Current Output @ 25°C (298.2K) 298.2 298.2 µA

Nominal Temperature Coefficient 1 1 µA/K

Calibration Error @ 25°C

Absolute Error (over rated performance temperature range)

Without External Calibration Adjustment

With 25°C Calibration Error Set to Zero

Nonlinearity

For TO-52 and Flatpack packages

For 8-Lead SOIC package

Repeatability

Long-Term Drift

1

2

±0.1 ±0.1 °C

±0.1 ±0.1 °C

Current Noise 40 40

Power Supply Rejection

4 V ≤ VS ≤ 5 V

5 V ≤ VS ≤ 15 V

15 V ≤ VS ≤ 30 V

0.5 0.5 µA/V

0.2 0.2 µV/V

0.1 0.1 µA/V

Case Isolation to Either Lead 10

Effective Shunt Capacitance 100 100 pF

Electrical Turn-On Time 20 20 µs

Reverse Bias Leakage Current

3

(Reverse Voltage = 10 V) 10 10 pA

30

±5.0

±10

±3.0

±1.5

±1.5

10

1010

4

30 Volts

±2.5

±5.5

±2.0

±0.8

±1.0

°C

°C

°C

°C

°C

pA/√Hz

Ω

1

Maximum deviation between +25°C readings after temperature cycling between –55°C and +150°C; guaranteed, not tested.

2

Conditions: constant 5 V, constant 125°C; guaranteed, not tested.

3

Leakage current doubles every 10°C.

Specifications shown in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min

and max specifications are guaranteed, although only those shown in boldface are tested on all production units.

Rev. C | Page 3 of 16

AD590

(

AD590L AND AD590M SPECIFICATIONS

Table 2. @ 25°C and VS = 5 V unless otherwise noted

AD590L AD590M

Parameter Min Typ Max Min Typ Max Unit

POWER SUPPLY

Operating Voltage Range

OUTPUT

Nominal Current Output @ 25°C (298.2K) 298.2

Nominal Temperature Coefficient 1

Calibration Error @ +25°C

Absolute Error (over rated performance temperature range)

Without External Calibration Adjustment

With ± 25°C Calibration Error Set to Zero

Nonlinearity

Repeatability

Long-Term Drift

1

2

Current Noise 40

Power Supply Rejection

4 V ≤ VS ≤ 5 V

5 V ≤ VS ≤ 15 V

15 V ≤ VS ≤ 30 V

Case Isolation to Either Lead 10

Effective Shunt Capacitance 100

Electrical Turn-On Time 20

Reverse Bias Leakage Current

3

(Reverse Voltage = 10 V) 10

4

30

±0.1

±0.1

±1.0

±3.0

±1.6

±0.4

0.5

0.2

0.1

10

4

298.2

1

40

0.5

0.2

0.1

10

100

20

10

30 Volts

±0.5

±1.7

±1.0

±0.3

±0.1 °C

±0.1 °C

10

1

Maximum deviation between +25°C readings after temperature cycling between –55°C and +150°C; guaranteed, not tested.

2

Conditions: constant 5 V, constant 125°C; guaranteed, not tested.

3

Leakage current doubles every 10°C.

Specifications shown in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min

and max specifications are guaranteed, although only those shown in boldface are tested on all production units.

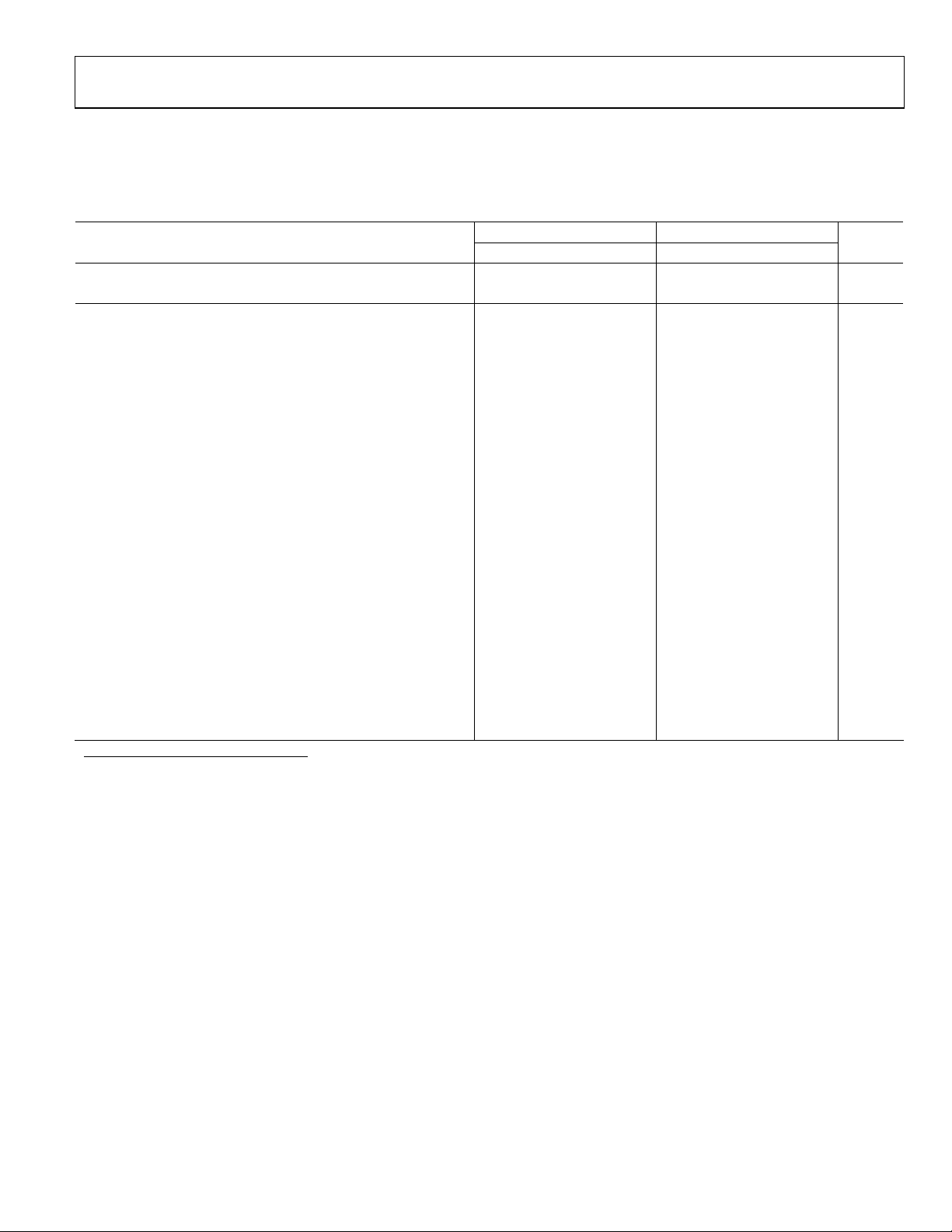

+223°

°K

°C

–50°

+273°0°+298°

+25°

+323°

+50°

+373°

+100°

+423°

+150°

µA

µA/K

°C

°C

°C

°C

°C

pA/√Hz

µA/V

µA/V

µA/V

Ω

pF

µs

pA

–100° 0° +100° +200° +300°

°F

Figure 2. Temperature Scale Conversion Equations

+32° +70° +212°

5

9

9

()

5

ooo

)

+=−=

CKFC

oooo

+=+=

FRCF

00533-C-002

15.27332

7.45932

Rev. C | Page 4 of 16

AD590

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Forward Voltage ( E+ or E–) 44 V

Reverse Voltage (E+ to E–) −20 V

Breakdown Voltage (Case E+ or E–) ±200 V

Rated Performance Temperature Range

Storage Temperature Range

Lead Temperature (Soldering, 10 sec) 300°C

1

The AD590 has been used at –100°C and +200°C for short periods of

measurement with no physical damage to the device. However, the absolute

errors specified apply to only the rated performance temperature range.

1

1

−55°C to +150°C

−65°C to +155°C

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at these or

any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Rev. C | Page 5 of 16

AD590

PRODUCT DESCRIPTION

The AD590H has 60 µ inches of gold plating on its Kovar leads

and Kovar header. A resistance welder is used to seal the nickel

cap to the header. The AD590 chip is eutectically mounted to

the header and ultrasonically bonded to with 1 mil aluminum

wire. Kovar composition: 53% iron nominal; 29% ±1% nickel;

17% ±1% cobalt; 0.65% manganese max; 0.20% silicon max;

0.10% aluminum max; 0.10% magnesium max; 0.10%

zirconium max; 0.10% titanium max; 0.06% carbon max.

The AD590F is a ceramic package with gold plating on its Kovar

leads, Kovar lid, and chip cavity. Solder of 80/20 Au/Sn

composition is used for the 1.5 mil thick solder ring under the

lid. The chip cavity has a nickel underlay between the

metallization and the gold plating. The AD590 chip is

eutectically mounted in the chip cavity at 410°C and

ultrasonically bonded to with 1 mil aluminum wire. Note that

the chip is in direct contact with the ceramic base, not the metal

lid. When using the AD590 in die form, the chip substrate must

be kept electrically isolated (floating) for correct circuit

operation.

66MILS

V+

42MILS

PTAT current. Figure 4 is the schematic diagram of the AD590.

In this figure, Q8 and Q11 are the transistors that produce the

PTAT voltage. R5 and R6 convert the voltage to current. Q10,

whose collector current tracks the collector currents in Q9 and

Q11, supplies all the bias and substrate leakage current for the

rest of the circuit, forcing the total current to be PTAT. R5 and

R6 are laser-trimmed on the wafer to calibrate the device at

25°C.

Figure 5 shows the typical V–I characteristic of the circuit at

25°C and the temperature extremes.

+

R

R

2

1

1040Ω

260Ω

Q

Q

1

2

Q

Q

7

CHIP

SUBSTRATE

Q

9

R

6

820Ω

–

6

Q

R

146Ω

Figure 4. Schem atic Diag ram

12

R

5kΩ

5

Q

Q

5

3

Q

4

C

1

26pF

Q

8

R

4

11kΩ

3

Q

10

Q

11

118

00533-C-004

V–

THE AD590 IS AVAILABLE IN LASER-TRIMMED CHIP FORM;

CONSULT THE CHIP CATALOG FOR DETAILS

Figure 3. Metalization Diagram

CIRCUIT DESCRIPTION

1

The AD590 uses a fundamental property of the silicon

transistors from which it is made to realize its temperature

proportional characteristic: if two identical transistors are

operated at a constant ratio of collector current densities, r, then

the difference in their base-emitter voltage will be (kT/q)(In r).

Since both k (Boltzman’s constant) and q (the charge of an

electron) are constant, the resulting voltage is directly

proportional to absolute temperature (PTAT).

In the AD590, this PTAT voltage is converted to a PTAT current

by low temperature coefficient thin-film resistors. The total

current of the device is then forced to be a multiple of this

1

For a more detailed description, see M.P. Timko, “A Two-Terminal IC

Temperature Transducer,” IEEE J. Solid State Circuits, Vol. SC-11, p. 784-788,

Dec. 1976. Understanding the Specifications–AD590.

423

00533-C-003

298

(µA)

OUT

I

218

012

34

SUPPLY VOLTAGE (V)

+150°C

+25°C

–55°C

56 30

00533-C-005

Figure 5. V-1 Plot

EXPLANATION OF TEMPERATURE SENSOR SPECIFICATIONS

The way in which the AD590 is specified makes it easy to apply

in a wide variety of applications. It is important to understand

the meaning of the various specifications and the effects of

supply voltage and thermal environment on accuracy.

Rev. C | Page 6 of 16

AD590

The AD590 is basically a PTAT (proportional to absolute

temperature)

1

current regulator. That is, the output current is

equal to a scale factor times the temperature of the sensor in

degrees Kelvin. This scale factor is trimmed to 1 µA/K at the

factory, by adjusting the indicated temperature (that is, the

output current) to agree with the actual temperature. This is

done with 5 V across the device at a temperature within a few

degrees of 25°C (298.2K). The device is then packaged and

tested for accuracy over temperature.

CALIBRATION ERROR

At final factory test, the difference between the indicated

temperature and the actual temperature is called the calibration

error. Since this is a scale factory error, its contribution to the

total error of the device is PTAT. For example, the effect of the

1°C specified maximum error of the AD590L varies from

0.73°C at –55°C to 1.42°C at 150°C. Figure 6 shows how an

exaggerated calibration error would vary from the ideal over

temperature.

ACTUAL

TRANSFER

FUNCTION

I

(µA)

I

OUT

ACTUAL

298.2

CALIBRATION

ERROR

IDEAL

TRANSFER

FUNCTION

+

5V

–

100Ω

950Ω

R

+

AD590

–

= 1mV/K

V

T

+

00533-C-007

–

Figure 7. One Temperature Trim

ERROR VERSUS TEMPERATURE: WITH CALIBRATION ERROR TRIMMED OUT

Each AD590 is tested for error over the temperature range with

the calibration error trimmed out. This specification could also

be called the “variance from PTAT,” because it is the maximum

difference between the actual current over temperature and a

PTAT multiplication of the actual current at 25°C. This error

consists of a slope error and some curvature, mostly at the

temperature extremes. Figure 8 shows a typical AD590K

temperature curve before and after calibration error trimming.

2

0

ABSOLUTE ERROR (°C)

BEFORE

CALIBRATION

TRIM

CALIBRATION

ERROR

AFTER

CALIBRATION

TRIM

298.2

TEMPERATURE (°K)

00533-C-006

Figure 6. Calibration Error vs. Temperature

The calibration error is a primary contributor to maximum

total error in all AD590 grades. However, since it is a scale factor

error, it is particularly easy to trim. Figure 7 shows the most

elementary way of accomplishing this. To trim this circuit, the

temperature of the AD590 is measured by a reference

temperature sensor and R is trimmed so that V

= 1 mV/K at

T

that temperature. Note that when this error is trimmed out at

one temperature, its effect is zero over the entire temperature

range. In most applications there is a current-to-voltage

conversion resistor (or, as with a current input ADC, a

reference) that can be trimmed for scale factor adjustment.

1

T(°C) = T(K) –273.2. Zero on the Kelvin scale is “absolute zero”; there is no

lower temperature.

–2

–55 150

TEMPERATURE (°C)

00533-C-008

Figure 8. Effect to Scale Factor Trim on Accuracy

ERROR VERSUS TEMPERATURE: NO USER TRIMS

Using the AD590 by simply measuring the current, the total

error is the variance from PTAT, described above, plus the effect

of the calibration error over temperature. For example, the

AD590L maximum total error varies from 2.33°C at –55°C to

3.02°C at 150°C. For simplicity, only the large figure is shown on

the specification page.

NONLINEARITY

Nonlinearity as it applies to the AD590 is the maximum

deviation of current over temperature from a best-fit straight

line. The nonlinearity of the AD590 over the −55°C to +150°C

range is superior to all conventional electrical temperature

sensors such as thermocouples, RTDs, and thermistors. Figure 9

shows the nonlinearity of the typical AD590K from Figure 8.

Rev. C | Page 7 of 16

AD590

A

(

)

=

−

1.6

0.8

0.8°C MAX

0

= 100mV/°C

T

0.8°C

MAX

00533-C-009

00533-C-010

0.8°C

MAX

ABSOLUTE ERROR (°C)

–0.8

–1.6

–55 150

TEMPERATURE (°C)

Figure 9. Nonlinearity

Figure 10 shows a circuit in which the nonlinearity is the major

contributor to error over temperature. The circuit is trimmed by

adjusting R1 for a 0 V output with the AD590 at 0°C. R2 is then

adjusted for 10 V out with the sensor at 100°C. Other pairs of

temperatures may be used with this procedure as long as they

are measured accurately by a reference sensor. Note that for

15 V output (150°C) the V+ of the op amp must be greater than

17 V. Also note that V− should be at least −4 V; if V− is ground,

there is no voltage applied across the device.

15V

D581

R

1

2kΩ

35.7kΩ

27kΩ

V–

Figure 10. 2-Temperature Trim

2

97.6kΩ

AD590

R

2

5kΩ

30pF

AD707A

100mV/°C

V

VOLTAGE AND THERMAL ENVIRONMENT EFFECTS

The power supply rejection specifications show the maximum

expected change in output current versus input voltage changes.

The insensitivity of the output to input voltage allows the use of

unregulated supplies. It also means that hundreds of ohms of

resistance (such as a CMOS multiplexer) can be tolerated in

series with the device.

It is important to note that using a supply voltage other than 5 V

does not change the PTAT nature of the AD590. In other words,

this change is equivalent to a calibration error and can be

removed by the scale factor trim (see Figure 8).

The AD590 specifications are guaranteed for use in a low

thermal resistance environment with 5 V across the sensor.

Large changes in the thermal resistance of the sensor’s

environment change the amount of self-heating and result in

changes in the output, which are predictable but not necessarily

desirable.

The thermal environment in which the AD590 is used

determines two important characteristics: the effect of selfheating and the response of the sensor with time. Figure 12 is a

model of the AD590 that demonstrates these characteristics.

θ

T

JC

J

P

C

CH

Figure 12. Thermal Circuit Model

As an example, for the TO-52 package, θJC is the thermal

resistance between the chip and the case, about 26°C/W. θ

the thermal resistance between the case and the surroundings

and is determined by the characteristics of the thermal

connection. Power source P represents the power dissipated on

the chip. The rise of the junction temperature, T

ambient temperature T

is

A

J

Equation 1.

PTT θ+θ

θ

T

CA

C

+

T

CAJCA

A

–

, above the

J

00533-C-012

is

CA

C

C

Tabl e 4 gives the sum of θJC and θCA for several common

0

TEMPERATURE (°C)

thermal media for both the H and F packages. The heat sink

used was a common clip-on. Using Equation 1, the temperature

rise of an AD590 H package in a stirred bath at 25°C, when

driven with a 5 V supply, is 0.06°C. However, for the same

conditions in still air, the temperature rise is 0.72°C. For a given

–2

–55 0 150100

TEMPERATURE (°C)

Figure 11. Typical 2-Trim Accuracy

00533-C-011

supply voltage, the temperature rise varies with the current and

is PTAT. Therefore, if an application circuit is trimmed with the

sensor in the same thermal environment in which it will be

used, the scale factor trim compensates for this effect over the

entire temperature range.

Rev. C | Page 8 of 16

AD590

Table 4. Thermal Resistance

θ

+ θCA (°C/Watt) τ (sec)

JC

1

Medium H F H F

Aluminum Block 30 10 0.6 0.1

Stirred Oil

Moving Air

2

3

42 60 1.4 0.6

With Heat Sink 45 – 5.0 –

Without Heat Sink 115 190 13.5 10.0

Still Air

With Heat Sink 191 – 108 –

Without Heat Sink 480 650 60 30

1

τ is dependent upon velocity of oil; average of several velocities listed above.

2

Air velocity @ 9 ft/sec.

3

The time constant is defined as the time required to reach 63.2% of an

instantaneous temperature change.

The time response of the AD590 to a step change in

temperature is determined by the thermal resistances and the

thermal capacities of the chip, C

about 0.04 Ws/°C for the AD590. C

, and the case, CC. CCH is

CH

varies with the measured

C

medium, because it includes anything that is in direct thermal

contact with the case. The single time constant exponential

curve of Figure 13 is usually sufficient to describe the time

response, T (t).

several media.

T

FINAL

SENSED TEMPERATURE

T

INITIAL

τ 4τ

Tabl e 4 shows the effective time constant, τ, for

+ (T

T(t) = T

INITIAL

FINAL

TIME

– T

INITIAL

Figure 13. Time Response Curve

) × (1 – e

–t/τ

)

00533-C-013

Rev. C | Page 9 of 16

AD590

A

(

GENERAL APPLICATIONS

Figure 14 demonstrates the use of a low cost digital panel meter

for the display of temperature on either the Kelvin, Celsius, or

Fahrenheit scales. For Kelvin temperature, Pins 9, 4, and 2 are

grounded; for Fahrenheit temperature, Pins 4 and 2 are left

open.

5V

8

AD2040

3

GND

D590

6

+

–

5

Figure 14. Variable Scale Display

The above configuration yields a 3-digit display with 1°C or 1°F

resolution, in addition to an absolute accuracy of ±2.0°C over

the −55°C to +125°C temperature range, if a one-temperature

calibration is performed on an AD590K, AD590L, or AD590M.

Connecting several AD590 units in series as shown in Figure 15

allows the minimum of all the sensed temperatures to be

indicated. In contrast, using the sensors in parallel yields the

average of the sensed temperatures.

15V

+

10kΩ

0.1%)

AD590

–

+

AD590

–

+

AD590

–

+

MIN

V

T

–

+

–

333.3Ω

(0.1%)

5V

Figure 15. Series and Parallel Connection

The circuit in Figure 16 demonstrates one method by which

differential temperature measurements can be made. R1 and R2

can be used to trim the output of the op amp to indicate a

desired temperature difference. For example, the inherent offset

between the two devices can be trimmed in. If V+ and V− are

radically different, then the difference in internal dissipation

causes a differential internal temperature rise. This effect can be

used to measure the ambient thermal resistance seen by the

sensors in applications such as fluid-level detectors or

anemometry.

9

4

2

+

–

OFFSET

CALIBRATION

GAIN

SCALING

OFFSET

SCALING

+

AD590

–

+

AVG

V

T

–

00533-C-014

00533-C-015

V+

V–

R

1

5MΩ

R

10kΩ

3

10kΩ

–

AD707A

(T1 – T2) × (10mV/°C)

+

R

4

00533-C-016

+

AD590L

–

+

AD590L

–

#2

#1

R

2

50kΩ

Figure 16. Differential Measurements

Figure 17 is an example of a cold junction compensation circuit

for a Type J thermocouple using the AD590 to monitor the

reference junction temperature. This circuit replaces an ice-bath

as the thermocouple reference for ambient temperatures

between 15°C and 35°C. The circuit is calibrated by adjusting R

for a proper meter reading with the measuring junction at a

known reference temperature and the circuit near 25°C. Using

components with the TCs as specified in Figure 17,

compensation accuracy is within ±0.5°C for circuit

temperatures between 15°C and 35°C. Other thermocouple

types can be accommodated with different resistor values. Note

that the TCs of the voltage reference and the resistors are the

primary contributors to error.

7.5V

IRON

CONSTANTAN

+

–

MEASURING

–

JUNCTION

00533-C-017

+

–

AD580

V

OUT

AD590

52.3Ω

8.66kΩ

1kΩ

+

–

R

T

REFERENCE

JUNCTION

C

U

+

METER

RESISTORS ARE 1%, 50PPM/°C

Figure 17. Cold Junction Compensation Circuit for Type J Thermocouple

Figure 18 is an example of a current transmitter designed to be

used with 40 V, 1 kΩ systems; it uses its full current range of

4 mA to 20 mA for a narrow span of measured temperatures. In

this example, the 1 µA/K output of the AD590 is amplified to

1 mA/°C and offset so that 4 mA is equivalent to 17°C and

20 mA is equivalent to 33°C. R

is trimmed for proper reading

T

at an intermediate reference temperature. With a suitable choice

of resistors, any temperature range within the operating limits

of the AD590 may be chosen.

T

Rev. C | Page 10 of 16

AD590

V+

+

4mA = 17°C

12mA = 25°C

20mA = 33°C

AD590

0.01µF

AD581

V

OUT

–

+

–

10kΩ

35.7kΩ

5kΩ

12.7kΩ

10Ω

R

T

30pF

–

AD707A

+

5kΩ 500Ω

V–

00533-C-018

Figure 18. 4 mA to 20 mA Current Transmitter

Figure 19 is an example of a variable temperature control circuit

(thermostat) using the AD590. R

high and low limits for R

SET

and RL are selected to set the

H

. R

could be a simple pot, a

SET

calibrated multiturn pot, or a switched resistive divider.

Powering the AD590 from the 10 V reference isolates the

AD590 from supply variations while maintaining a reasonable

voltage (~7 V) across it. Capacitor C

extraneous noise from remote sensors. R

is often needed to filter

1

is determined by the

B

β of the power transistor and the current requirements of the

load.

V+

AD581

V+

OUT

V–

10V

R

H

AD590

R

SET

R

L

+

–

2

3

C

1

10kΩ

–

LM311

+

R

B

7

1

4

GND

HEATING

ELEMENTS

00533-C-019

Figure 19. Simple Temperature Control Circuit

Figure 20 shows that the AD590 can be configured with an 8-bit

DAC to produce a digitally controlled set point. This particular

circuit operates from 0°C (all inputs high) to 51.0°C (all inputs

low) in 0.2°C steps. The comparator is shown with 1.0°C

hysteresis, which is usually necessary to guard-band for

extraneous noise. Omitting the 5.1 MΩ resistor results in no

hysteresis.

20pF

1.25kΩ

REF

+5V

1.15kΩ

200Ω, 15T

+5V

+2.5V

200Ω

1kΩ

OUTPUT HIGH-

TEMPERATURE ABOVE SET POINT

7

OUTPUT LOWTEMPERATURE BELOW SET POINT

5.1MΩ

AD580

00533-C-020

–15V

DAC OUT

BIT 1 BIT 8

BIT 2 BIT 7

BIT 3 BIT 6

BIT 4 BIT 5

6.98kΩ

1kΩ, 15T

+

AD590

–

–15V

1408/1508

+5V +5V

3

LM311

2

–15V

6.8kΩ

MC

4

8

1

Figure 20. DAC Set Point

The voltage compliance and the reverse blocking characteristic

of the AD590 allows it to be powered directly from 5 V CMOS

logic. This permits easy multiplexing, switching, or pulsing for

minimum internal heat dissipation. In Figure 21, any AD590

connected to a logic high passes a signal current through the

current measuring circuitry, while those connected to a logic

zero pass insignificant current. The outputs used to drive the

AD590s may be employed for other purposes, but the additional

capacitance due to the AD590 should be taken into account.

5V

+

AD590

CMOS

GATES

+

–

+

–

Figure 21. AD590 Driven from CMOS Logic

–

+

–

1kΩ (0.1%)

00533-C-021

CMOS analog multiplexers can also be used to switch AD590

current. Due to the AD590’s current mode, the resistance of

such switches is unimportant as long as 4 V is maintained

across the transducer. Figure 22 shows a circuit that combines

the principle demonstrated in Figure 21 with an 8-channel

CMOS multiplexer. The resulting circuit can select 1–80 sensors

over only 18 wires with a 7-bit binary word.

Rev. C | Page 11 of 16

AD590

Ω

The inhibit input on the multiplexer turns all sensors off for

minimum dissipation while idling.

Figure 23 demonstrates a method of multiplexing the AD590 in

the two-trim mode (see Figure 10 and Figure 11). Additional

AD590s and their associated resistors can be added to multiplex

10V

0

3

1

14

2

2

+

–

ROW

SELECT

DECODER

11

12

13

10

16

4028

CMOS

BCD-TO-

DECIMAL

8

up to eight channels of ±0.5°C absolute accuracy over the

temperature range of −55°C to +125°C. The high temperature

restriction of 125°C is due to the output range of the op amps;

output to 150°C can be achieved by using a 20 V supply for the

op amp.

+

+

–

22

+

–

02

12

–

+

+

–

21

+

–

01

11

–

+

+

AD590

–

00

–

10

20

COLUMN

SELECT

INHIBIT

9

10

11

6

10V

16

LOGIC

LEVEL

INTERFACE

78

BINARY TO 1-OF-8 DECODER

0131142

15

4051 CMOS ANALOG

MULTIPLEXER

10kΩ 10mV/°C

00533-C-022

Figure 22. Matrix Multiplexer

AD581

+15V

+

–

2kΩ

35.7kΩ

2kΩ

35.7kΩ

V

OUT

5k

97.6kΩ

5kΩ

97.6kΩ

V+

S1

S2

DECODER/

DRIVER

S8

AD707A

27kΩ

10mV/°C

–15V

AD7501

AD590L

+

–

–5V TO –15V

+15V

–15V

+

–

AD590L

TTL/DTL TO CMOS

INTERFACE

EN

BINARY

CHANNEL

SELECT

00533-C-023

Figure 23. 8-Channel Multiplexer

Rev. C | Page 12 of 16

AD590

Y

OUTLINE DIMENSIONS

0.230 (5.84)

0.195 (4.95)

0.178 (4.52)

0.030 (0.76)

MAX

0.209 (5.31)

0.050

(1.27)

MAX

0.150 (3.81)

0.115 (2.92)

0.019 (0.48)

0.017 (0.43)

0.015 (0.38)

0.055 (1.40)

0.050 (1.27)

0.045 (1.14)

POSITIVE LEAD

INDICATOR

0.500 (12.69)

MIN

0.0065 (0.17)

0.0050 (0.13)

0.0045 (0.12)

0.230 (5.84)

0.250 (6.35)

Figure 24. 2-Lead Ceramic Flat Package [CQFP]

(F-2)

Dimensions shown in inches and (millimeters)

4.00 (0.1574)

3.80 (0.1497)

0.093 (2.36)

0.081 (2.06)

0.050 (1.27)

0.041 (1.04)

5.00 (0.1968)

4.80 (0.1890)

85

6.20 (0.2440)

5.80 (0.2284)

41

0.019 (0.48)

0.016 (0.41)

3

1

0.250 (6.35)

45 T.P.

MIN

0.048 (1.22)

0.028 (0.71)

0.046 (1.17)

0.036 (0.91)

0.021 (0.53)

MAX

0.050 (1.27) T.P.

0.100

(2.54)

T.P.

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETERS DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

0.050

(1.27)

T.P.

2

0.500

(12.70)

MIN

Figure 25. 3-Pin Metal Header Package [TO-52]

(H-03)

Dimensions shown in inches and (millimeters)

1.27 (0.0500)

BSC

0.25 (0.0098)

0.10 (0.0040)

COPLANARIT

0.10

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

SEATING

PLANE

COMPLIANT TO JEDEC STANDARDS MS-012AA

1.75 (0.0688)

1.35 (0.0532)

0.51 (0.0201)

0.31 (0.0122)

0.25 (0.0098)

0.17 (0.0067)

0.50 (0.0196)

0.25 (0.0099)

8°

1.27 (0.0500)

0°

0.40 (0.0157)

Figure 26. 8-Lead Standard Small Outline Package [SOIC]

Narrow Body

(R-8)

Dimensions shown in millimeters and (inches)

Rev. C | Page 13 of 16

× 45°

AD590

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD590JH

AD590JF

AD590JR −55°C to +150°C 8-Lead SOIC SOIC-8

AD590KH

AD590KF

AD590KR −55°C to +150°C 8-Lead SOIC SOIC-8

AD590LH

AD590LF

AD590MH

AD590MF

AD590JR-REEL −55°C to +150°C 8-Lead SOIC SOIC-8

AD590KR-REEL −55°C to +150°C 8-Lead SOIC SOIC-8

AD590JCHIPS −55°C to +150°C TO-52 H-03A

1

Available in 883B; consult factory for data sheet.

1

1

1

1

1

1

1

1

−55°C to +150°C TO-52 H-03A

−55°C to +150°C Flatpack F-2A

−55°C to +150°C TO-52 H-03A

−55°C to +150°C Flatpack F-2A

−55°C to +150°C TO-52 H-03A

−55°C to +150°C Flatpack F-2A

−55°C to +150°C TO-52 H-03A

−55°C to +150°C Flatpack F-2A

Rev. C | Page 14 of 16

AD590

NOTES

Rev. C | Page 15 of 16

AD590

NOTES

© 2003 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

C00533–0–9/03(C)

Rev. C | Page 16 of 16

Loading...

Loading...