32-Channel, 14-Bit DAC with Full-Scale Output

Voltage Programmable from 50 V to 200 V

Preliminary Technical Data

FEATURES

High integration: 32-channel, 14-bit DAC with integrated,

high voltage output amplifier

Guaranteed monotonic

Housed in 15 × 15 mm CSP-BGA package

Full-scale output voltage programmable from 50 V to 200 V

via reference input

700 µA drive capability

Integrated silicon diode for temperature monitoring

DSP-/microcontroller-compatible serial interface

Channel update rate: 1.2 MHz

Asynchronous

Temperature range: –10°C to +85°C

APPLICATIONS

Optical micro-electromechanical systems (MEMS)

Optical cross-point switches

Micropositioning applications using Piezo Flextures

Level setting in automotive test and measurement

RESET

facility

DV

CC

AV

CC

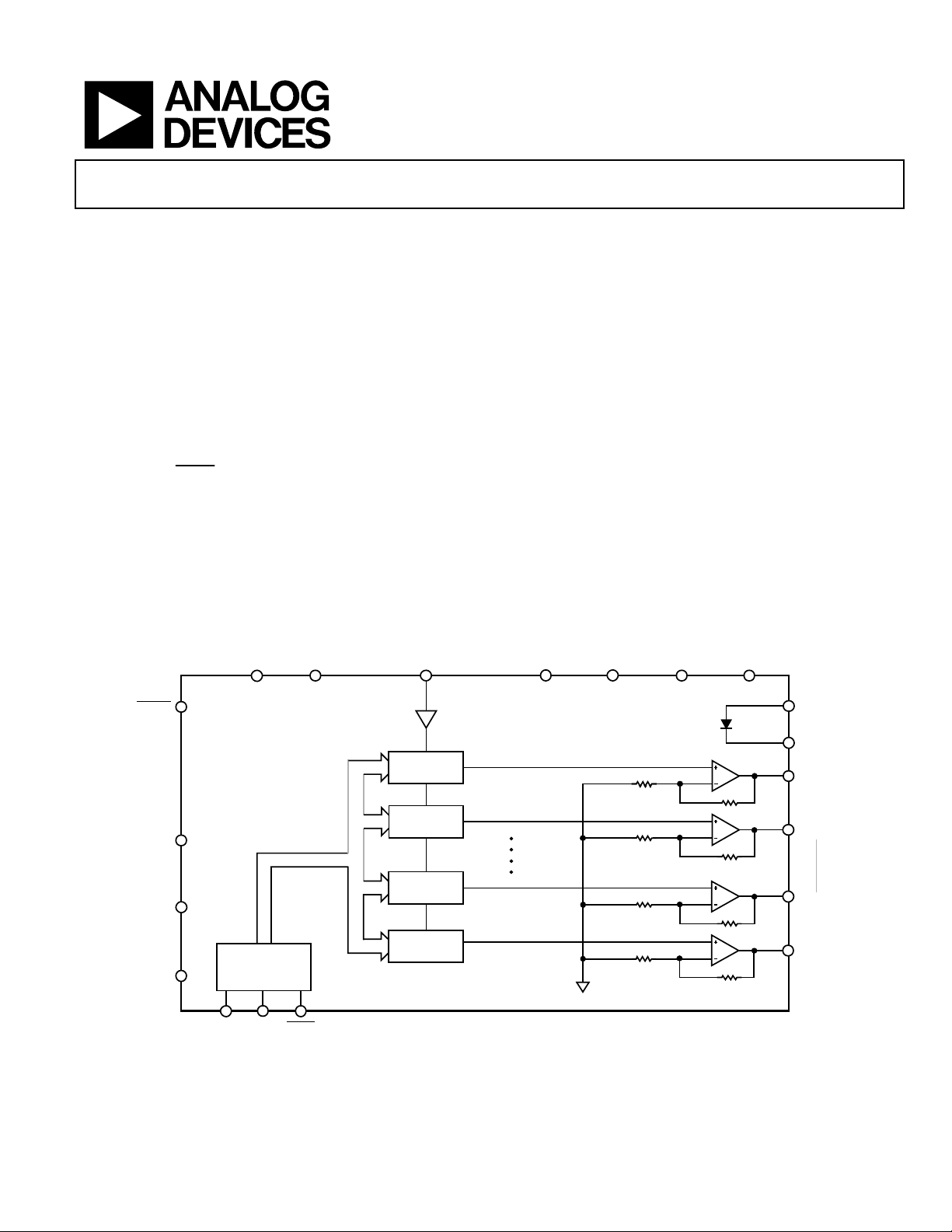

FUNCTIONAL BLOCK DIAGRAM

REF_IN

AD5535

GENERAL DESCRIPTION

The AD5535 is a 32-channel, 14-bit DAC with an on-chip high

voltage output amplifier. This device is targeted for optical

micro-electromechanical systems. The output voltage range is

programmable via the REFIN pin. Output range is 0 V to 50 V

with REFIN = 1 V and is 0 V to 200 V with REFIN = 4 V. Each

amplifier can source 700 µA, which is ideal for the deflection

and control of optical MEMS mirrors.

The selected DAC register is written to via the 3-wire interface.

The serial interface operates at clock rates of up to 30 MHz and

is compatible with DSP and microcontroller interface standards.

The device is operated with AV

to 5.25 V, V

= −4.75 V to −5.25 V, V+ = +4.75 V to +5.25 V, VPP

–

= 210 V. REF_IN is buffered internally on the AD5535 and

should be driven from a stable reference source.

V

PP

PGND

= 4.75 to 5.25 V, DVCC = 2.7 V

CC

V

–

V

+

RESET

DAC_GND

AGND

DGND

Rev. PrE

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

AD5535

INTERFACE

CONTROL

LOGIC

SCLK

D

IN

DAC

14-BIT BUS

DAC

DAC

DAC

SYNC

Figure 1.

ANODE

CATHODE

R1

RF

R1

RF

R1

RF

R1

RF

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

V

0

OUT

V

1

OUT

V

30

OUT

31

V

OUT

05068-001

AD5535 Preliminary Technical Data

TABLE OF CONTENTS

Specifications..................................................................................... 3

Timing Characteristics ................................................................ 5

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Te r m in o l o g y ...................................................................................... 9

Typical Performance Characteristics........................................... 10

Functional Description ..................................................................11

Digital-to-Analog Section......................................................... 11

Reset Function ............................................................................11

Serial Interface............................................................................ 11

REVISION HISTORY

10/04—Revision PrE: Preliminary Version

Microprocessor Interfacing....................................................... 11

Applications Information.............................................................. 13

MEMS Mirror Control Application......................................... 13

AD5535 Board Layout to Ensure Compliance with IPC-221

Specification

Power Supply Sequencing and Decoupling Recommendations

....................................................................................................... 14

Guidelines for Printed Circuit Board Layout......................... 14

Outline Dimensions....................................................................... 15

Ordering Guide .......................................................................... 15

................................................................................ 13

Rev. PrE | Page 2 of 16

Preliminary Technical Data AD5535

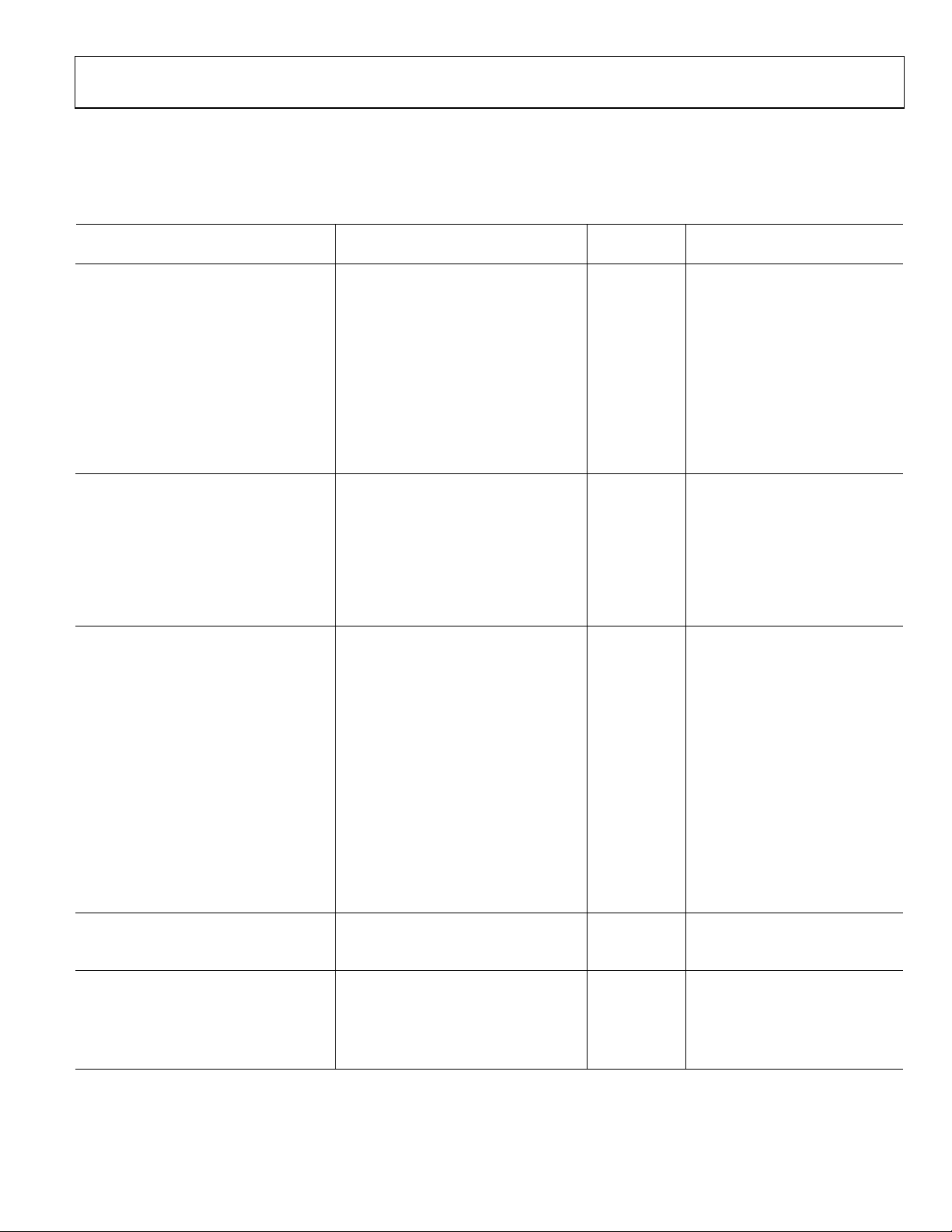

SPECIFICATIONS

VPP = 210 V, V− = −5 V, V+ = +5 V; AVCC = 5.25 V; DVCC = 2.7 V to 5.25 V; AGND = DGND = DAC_GND = 0 V; REF_IN = 4.096 V;

all outputs unloaded. All specifications T

MIN

to T

Table 1.

Parameter

1

DC PERFORMANCE

Resolution

Integral Nonlinearity (INL)

Differential Nonlinearity (DNL)

Zero Code Voltage

Offset Error –45

Offset Drift

Voltage Gain 47.5 50 52.5 V/V

Gain Temperature Coefficient

Channel-to-Channel Gain Match

Full-Scale Voltage Drift

OUTPUT CHARACTERISTICS

Output Voltage Range

3

Output Impedance

Resistive Load

Capacitive Load

4, 5

4

Short-Circuit Current

DC Crosstalk

DC Power Supply Rejection (PSRR), V

4

PP

AC CHARACTERISTICS

Settling Time

1/4 to 3/4 Scale Step

1 LSB Step

Slew Rate

–3 dB Bandwidth 5

Output Noise Spectral Density

0.1 Hz to 10 Hz Output Noise Voltage

Digital-to-Analog Glitch Impulse

Digital Crosstalk

Analog Crosstalk

Digital Feedthrough

VOLTAGE REFERENCE, REF_IN

Input Voltage Range

6

4

1

Input Current

TEMPERATURE MEASUREMENT DIODE

4

Peak Inverse Voltage, PIV

Forward Diode Drop, VF

Forward Diode Current, IF

VF Temperature Coefficient, T

C

, unless otherwise noted.

MAX

A Grade

Min Typ Max

0

1

2

Unit Conditions/Comments

14

±0.1

Bits

% of FSR

±0.5 ±1 LSB Guaranteed monotonic

2 V

0.09

TBD

5

8

50

+45 mV

VPP – 10 V

200 pF

0.7

3 LSB

70

30

100

10

10

10

3

TBD

TBD

TBD

TBD

13

TBD

LSB/°C

ppm/°C

%

ppm/°C

Ω

MΩ

mA

dB

µs No load

µs 200 pF load

µs No load

µs 200 pF load

V/µs No load

V/µs 200 pF load

kHz

nV/√Hz

µV p-p

nV–s typ 1 LSB change around major carry

nV–s typ

µV–s typ

nV–s typ

Measured at 1 kHz

AVCC must exceed REFIN by 1.25 V min

4.096 V

1 µA

5 V Cathode to anode

0.8 V IF = 2 mA, anode to cathode

2 mA Anode to cathode

–1.44

mV/°C IF = 250 µA

Rev. PrE | Page 3 of 16

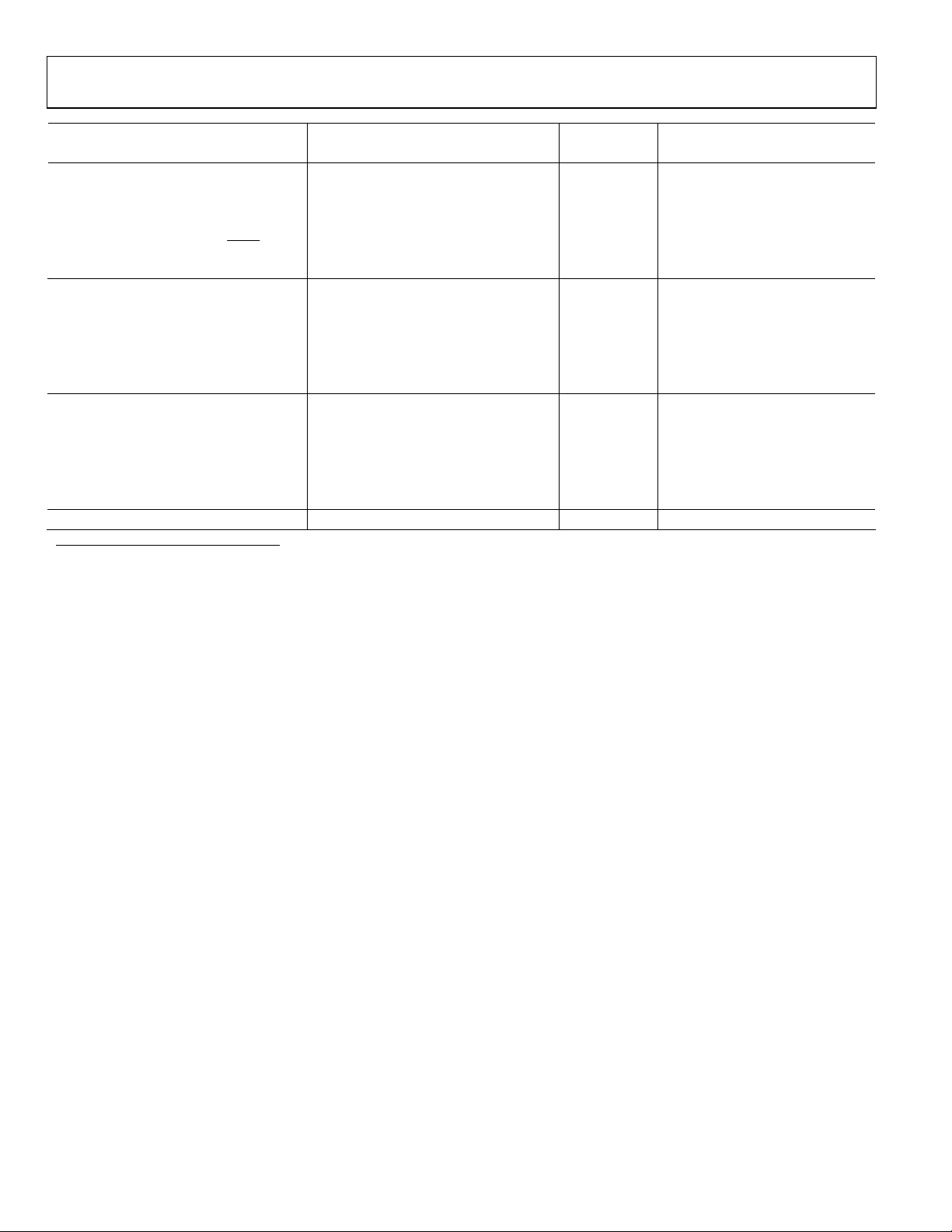

AD5535 Preliminary Technical Data

2

Unit Conditions/Comments

±5 ±10 µA

0.8 V DVCC = 3 V to 5 V

200

V DVCC = 3 V to 5 V

mV

10 pF

Parameter

DIGITAL INPUTS

1

4

Input Current

Input Low Voltage

Input High Voltage 2.0

Input Hysteresis (SCLK and

SYNC

only)

Input Capacitance

A Grade

Min Typ Max

POWER-SUPPLY VOLTAGES

VPP (50 × REF_IN) +10 210 225 V

V

–

–5.25 –4.75 V

V+ 4.75 5.25 V

AVCC 4.75 5.25 V

DVCC 2.7 5.25 V

POWER-SUPPLY CURRENTS

7

IPP 75 110 µA/channel

I

−

2.5 3.5 mA

I+ 2.5 3.5 mA

AICC 16 20 mA

DICC 0.1 0.5 mA

POWER DISSIPATION7 609 mW

1

See Terminology.

2

A Grade temperature range: −10°C to +85°C; typically +25°C.

3

Linear output voltage range: +7 V to VPP − 10 V.

4

Guaranteed by design and characterization, not production tested.

5

Ensure that TJ max is not exceeded. See the section. Absolute Maximum Ratings

6

Reference input determines output voltage range. Using a 4.096 V reference (REF 198) gives an output voltage range of 0 V to 200 V. Output range is programmable

via the reference input. The full-scale output range is programmable from 50 V to 200 V. The linear output voltage range is restricted from 7 V to V

7

Outputs unloaded.

− 10 V.

PP

Rev. PrE | Page 4 of 16

Preliminary Technical Data AD5535

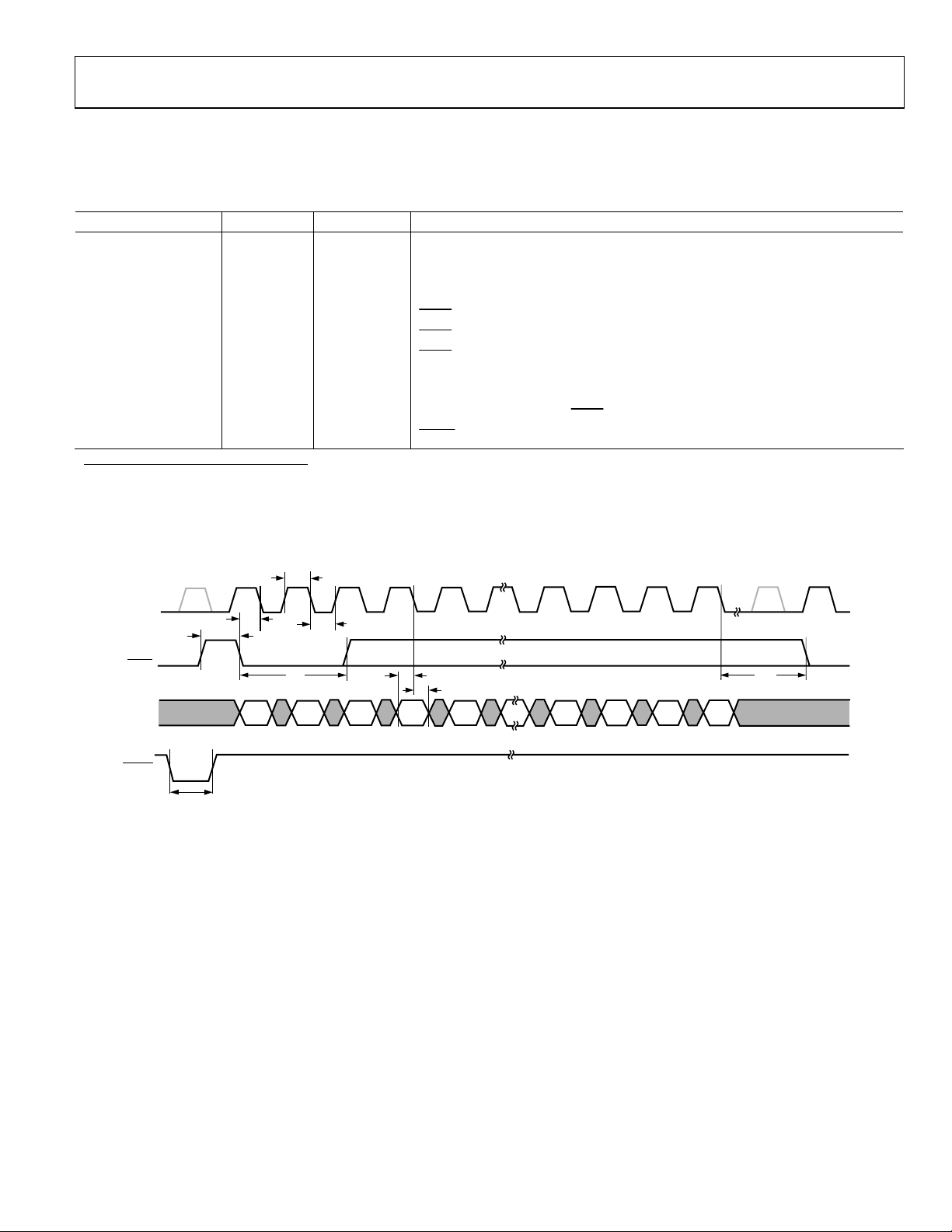

TIMING CHARACTERISTICS

VPP = 210 V, V− = –5 V, V+ = +5 V; AVCC = 5.25 V; DVCC = 2.7 V to 5.25 V; AGND = DGND = DAC_GND = 0 V; REF_IN = 4.096 V.

All specifications T

MIN

to T

Table 2.

Parameter1, 2,

f

UPDATE

f

CLKIN

t

13 ns min SCLK High Pulse Width

1

t

2

t

3

t

50 ns min

4

t

5

t

10 ns min DIN Setup Time

6

t

5 ns min DIN Hold Time

7

t

8

t

20 ns min

9

3

1

See timing diagrams in Figure 2.

2

Guaranteed by design and characterization, not production tested.

3

All input signals are specified with tr = tf = 5 ns (10% to 90% of DVCC) and timed from a voltage level of (VIL + VIH)/2.

SCLK

, unless otherwise noted.

MAX

A Grade Unit Conditions/Comments

1.2 MHz max Channel Update Rate

30 MHz max SCLK Frequency

13 ns min SCLK Low Pulse Width

15 ns min

10 ns min

200 ns min

t

1

1

t

t

5

2

3

34

t

2

SYNC

Falling Edge to SCLK Falling Edge Setup Time

SYNC

Low Time

SYNC

High Time

19th SCLK Falling Edge to

RESET

Pulse Width

5

SYNC

16 17 18 19

Falling Edge for Next Write

1

SYNC

D

RESET

IN

t

9

MSB

t

4

t

6

t

7

LSB

t

8

05068-002

Figure 2. Serial Interface Timing Diagram

Rev. PrE | Page 5 of 16

AD5535 Preliminary Technical Data

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

VPP to AGND

V− to AGND

V+ to AGND −0.3 V to +7 V

AVCC to AGND, DAC_GND −0.3 V to +7 V

DVCC to DGND −0.3 V to +7 V

Digital Inputs to DGND −0.3 V to DVCC + 0.3 V

REF_IN to AGND, DAC_GND −0.3 V to AVCC + 0.3 V

V

0–31 to AGND V– to V

OUT

Anode/Cathode to AGND, DAC_GND −0.3 V to +7 V

AGND to DGND −0.3 V to +0.3 V

Operating Temperature Range

Industrial −10°C to +85°C

Storage Temperature Range −65°C to +150°C

Junction Temperature (TJ max) 150°C

124-Lead CSP-BGA Package,

Thermal Impedance

θ

JA

Reflow Soldering

Peak Temperature 220°C

Time at Peak Temperature 10 s to 40 s

0.3 V to 225 V

+0.3 V to −6 V

PP

40°C/W

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Transient currents up to 100 mA do not cause SCR latch-up.

This device is a voltage-integrated circuit with an ESD rating of

<2 kV and it is ESD sensitive. Proper precautions should be

taken for handling and assembly.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. PrE | Page 6 of 16

Preliminary Technical Data AD5535

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

3

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Table 4. 124-Lead CSP-BGA Ball Configuration

CSP-BGA

Number

Ball Name

A1 N/C

A2 V

A4 V

A6 V

A8 V

A10 V

A12 V

OUT

OUT

OUT

OUT

OUT

OUT

A14 N/C

B1 V

B3 V

B5 V

B7 V

B9 V

B11 V

B13 V

C2 V

C12 V

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

OUT

1

7

11

16

20

25

0

4

9

13

17

21

26

3

22

CSP-BGA

Number

C14 V

D1 V

D13 V

E2 V

E4 V

E6 V

E8 V

E10 V

E12 V

E14 V

F3 V

F5 V

F7 V

F9 V

F13 V

G14 V

H1 VPP

1

2

1

6

3

5

4

5

2

4

Figure 3. Pin Configuration

Ball Name

29

OUT

2

OUT

23

OUT

5

OUT

8

OUT

12

OUT

15

OUT

19

OUT

24

OUT

31

OUT

6

OUT

10

OUT

14

OUT

18

OUT

30

OUT

28

OUT

7

11 12 13

9

10

8

9

10

876

11 12 13

14

A

B

C

D

E

F

G

H

J

K

L

M

N

P

14

CSP-BGA

Number

H2 VPP

H13 V

J3–J12 AGND

K1 V+

K2 V+

K3–K14 AGND

L1 V

L2 V

L3–L13 AGND

L14 DAC_GND

M1 AGND

M2 AGND

M3–12 AGND

M13 AVCC

M14 AVCC

N1 PGND

N2 PGND

05068-003

Ball Name

27

OUT

–

–

CSP-BGA

Number

Ball Name

N3 CATHODE

N4 ANODE

N5–N14 AGND

P1 N/C

P2 REF_IN

P3 DAC_GND

P4

RESET

P5 DVCC

P6 DGND

P7 TEST

P8 D

IN

P9 SCLK

P10

SYNC

P11–P13 AGND

P14 N/C

Rev. PrE | Page 7 of 16

AD5535 Preliminary Technical Data

Table 5. Pin Function Descriptions

Pin Function

AGND Analog GND Pins.

AV

CC

V

PP

V

V

+

V

–

PGND Output Amplifier Ground Reference Pins.

DGND Digital GND Pins.

DV

Digital Supply Pins. Voltage range from 2.7 V to 5.25 V.

CC

DAC_GND Reference GND Supply for All the DACs.

REF_IN

V

(0–31) Analog Output Voltages from the 32 Channels.

OUT

ANODE Anode of Internal Diode for Diode Temperature Measurement.

CATHODE Cathode of Internal Diode for Diode Temperature Measurement.

SYNC

1

SCLK

1

D

Serial Data Input. Data must be valid on the falling edge of SCLK.

IN

TEST

1

RESET

1

Internal pull-up device on this logic input. Therefore, it can be left floating and defaults to a logic high condition.

Analog Supply Pins. Voltage range from 4.75 V to 5.25 V.

Output Amplifier High Voltage Supply. Voltage range from (REF_IN × 50) + 10 V to 225 V.

Amplifier Supply Pins. Voltage range from 4.75 V to 5.25 V.

+

V– Amplifier Supply Pins. Voltage range from −4.75 V to −5.25 V.

Reference Voltage for Channels 0–31. Reference input range is 1 V to 4 V and can be used to program the full-scale

output voltage from 50 V to 200 V.

Active Low Input. This is the frame synchronization signal for the serial interface. While

on the falling edge of SCLK.

SYNC

is low, data is transferred in

Serial Clock Input. Data is clocked into the shift register on the falling edge of SCLK. This operates at clock speeds of up to

30 MHz.

Allows the same data to be simultaneously loaded to all channels of the AD5535. This pin is used for calibration purposes

when loading zero scale and full scale to all channels. To invoke this feature, take the TEST pin high. In normal operation,

TEST should be tied low.

Active Low Input. This pin can also be used to reset the complete device to its power-on reset conditions. Zero code is

loaded to the DACs.

Rev. PrE | Page 8 of 16

Preliminary Technical Data AD5535

TERMINOLOGY

Integral Nonlinearity (INL)

A measure of the maximum deviation from a straight line

passing through the endpoints of the DAC transfer function. It

is expressed as a percentage of full-scale range.

Differential Nonlinearity (DNL)

The difference between the measured change and the ideal

1 LSB change between any two adjacent codes. A specified DNL

of ±1 LSB maximum ensures monotonicity.

Zero-Code Voltage

A measure of the output voltage present at the device output

with all 0s loaded to the DAC. It includes the offset of the DAC

and the output amplifier. It is expressed in V.

Offset Error

Calculated by taking two points in the linear region of the

transfer function, drawing a line through these points, and

extrapolating back to the Y axis. It is expressed in mV.

Volt ag e Ga i n

Calculated from the change in output voltage for a change in

code multiplied by 16,384 and divided by the REF_IN voltage.

This is calculated between two points in the linear section of the

transfer function.

Gain Error

A measure of the output error with all 1s loaded to the DAC,

and is the difference between the ideal and actual analog output

range. Ideally, the output should be 50 × REF_IN. It is expressed

as a percentage of full-scale range.

DC Power-Supply Rejection Ratio (PSRR)

A measure of the change in analog output for a change in V

supply voltage. It is expressed in dB. V

is varied ±5%.

PP

PP

DC Crosstalk

The dc change in the output level of one DAC at midscale in

response to a full-scale code change (all 0s to all 1s and vice

versa) and the output change of all other DACs. It is expressed

in LSB.

Output Temperature Coefficient

A measure of the change in analog output with changes in

temperature. It is expressed in ppm/°C.

Output Voltage Settling Time

The time taken from when the last data bit is clocked into the

DAC until the output has settled to within ±0.5 LSB of its final

value.

Digital-to-Analog Glitch Impulse

The area of the glitch injected into the analog output when the

code in the DAC register changes state. It is specified as the area

of the glitch in nV–s, when the digital code is changed by 1 LSB

at the major carry transition (011 . . . 11 to 100 . . . 00 or 100 . . .

00 to 011 . . . 11).

Digital Crosstalk

The glitch impulse transferred to the output of one DAC at

midscale while a full-scale code change (all 1s to all 0s and

vice versa) is being written to another DAC. It is expressed

in nV–s.

Analog Crosstalk

The area of the glitch transferred to the output (V

DAC due to a full-scale change in the output (V

) of one

OUT

) of another

OUT

DAC. The area of the glitch is expressed in nV–s.

Digital Feedthrough

A measure of the impulse injected into the analog outputs from

the digital control inputs when the part is not being written to

SYNC

(

is high). It is specified in nV–s and is measured with a

worst-case change on the digital input pins, for example, from

all 0s to all 1s and vice versa.

Output Noise Spectral Density

A measure of internally generated random noise. Random noise

is characterized as a spectral density (voltage per √Hz). It is

measured by loading all DACs to midscale and measuring noise

1/2

at the output. It is measured in nV/(Hz)

.

Rev. PrE | Page 9 of 16

AD5535 Preliminary Technical Data

TYPICAL PERFORMANCE CHARACTERISTICS

16

V

= 50V

OUT

12

1.00

0.75

V

= 200V

OUT

8

4

0

–4

INL ERROR (LSB)

–8

–12

–16

0 2048 4096 6144 8192 10240 12288 14336 16384

Figure 4. Integral Linearity with VPP = 60 V, V

1.00

V

= 50V

OUT

0.75

0.50

0.25

0

–0.25

DNL ERROR (LSB)

–0.50

CODE

Full Scale = 50 V

OUT

05068-004

0.50

0.25

0

–0.25

DNL ERROR (LSB)

–0.50

–0.75

–1.00

0 2048 4096 6144 8192 10240 12288 14336 16384

Figure 7. DNL with VPP = 210 V, V

1.00

0.75

0.50

0.25

0

–0.25

DNL ERROR (LSB)

–0.50

T

INPUT CODE

OUT

Full Scale = 200 V

05068-007

–0.75

–1.00

0 2048 4096 6144 8192 10240 12288 14336 16384

INPUT CODE

Figure 5.DNL with VPP = 60 V, V

16

V

= 200V

OUT

12

8

4

0

–4

INL ERROR (LSB)

–8

–12

–16

0 2048 4096 6144 8192 10240 12288 14336 16384

INPUT CODE

Figure 6. Integral Linearity with VPP = 210 V, V

OUT

Full Sca le = 50 V

Full Scale = 200 V

OUT

05068-005

05068-006

–0.75

–1.00

CH1 5V CH2 5V M 500ns CH1 21.6V

0 2048 4096 6144 8192 10240 12288 14336 16384

INPUT CODE

Figure 8. Short-Circuit Current Limit Timing

1.00

0.75

0.50

0.25

2

0

–0.25

DNL ERROR (LSB)

–0.50

1

–0.75

–1.00

CH1 50V CH2 200mV M 10µs CH1 83V

0 2048 4096 6144 8192 10240 12288 14336 16384

T

T

INPUT CODE

Figure 9. Worst-Case Adjacent Channel Crosstalk

05068-008

05068-009

Rev. PrE | Page 10 of 16

Preliminary Technical Data AD5535

V

FUNCTIONAL DESCRIPTION

The AD5535 consists of 32 14-bit DACs with 200 V high voltage

amplifiers in a single 15 mm × 15 mm CSP-BGA package. The

output voltage range is programmable via the REFIN pin.

Output range is 0 V to 50 V with REFIN = 1 V, and 0 V to 200 V

with REFIN = 4 V. Communication to the device is through a

serial interface operating at clock rates of up to 30 MHz and is

compatible with DSP and microcontroller interface standards. A

5-bit address and a 14-bit data-word are loaded into the

AD5535 input register via the serial interface. The channel

address is decoded, and the data-word is converted into an

analog output voltage for this channel.

At power-on, all the DAC registers are loaded with 0s.

DIGITAL-TO-ANALOG SECTION

The architecture of each DAC channel consists of a resistor

string DAC followed by an output buffer amplifier operating

with a nominal gain of 50. The voltage at the REF_IN pin

provides the reference voltage for the corresponding DAC. The

input coding to the DAC is straight binary and the ideal DAC

output voltage is given by

V

50 D

=

OUT

××

_

INREF

14

2

where D is the decimal equivalent of the binary code, which is

loaded to the DAC register (0 to 16,383).

The output buffer amplifier is specified to drive a load of 1 MΩ

and 200 pF. The linear output voltage range for the output

amplifier is from 7 V to V

− 10V. The amplifier output band-

PP

width is typically 5 kHz, and is capable of sourcing 700 µA and

sinking 2.8mA. Settling time for a full-scale step is typically

30 µs with no load and 110 µs with a 200 pF load.

RESET FUNCTION

The reset function on the AD5535 can be used to reset all nodes

on the device to their power-on reset condition. All the DACs

are loaded with 0s and all registers are cleared. The reset

function is implemented by taking the

RESET

pin low.

SERIAL INTERFACE

The serial interface is controlled by three pins:

SYNC

•

• SCLK is the serial clock input. This pin operates at clock

• D

To update a single DAC channel, a 19-bit data-word is written

to the AD5535 input register.

is the frame synchronization pin for the serial

interface.

speeds of up to 30 MHz.

is the serial data input. Data must be valid on the falling

IN

edge of SCLK.

A4 to A0 Bits

These bits can address any one of the 32 channels. A4 is the

MSB of the address; A0 is the LSB.

DB13 to DB0 Bits

These bits are used to write a 14-bit word into the addressed

DAC register.

Figure 2 is the timing diagram for a serial write to the AD5535.

The serial interface works with both a continuous and a discon-

SYNC

tinuous serial clock. The first falling edge of

resets a

counter that counts the number of serial clocks to ensure that

the correct number of bits are shifted into the serial shift

register. Any further edges on

SYNC

are ignored until the

correct number of bits are shifted in. Once 19 bits have been

shifted in, the SCLK is ignored. For another serial transfer to

take place, the counter must be reset by the falling edge of

SYNC

. The user must allow 200 ns (minimum) between

successive writes.

MSB

A4 A3 A2 A1 A0 DB13–DB0

Figure 10. Serial Data Format

LSB

05068-010

MICROPROCESSOR INTERFACING

AD5535 to ADSP-21xx Interface

The ADSP-21xx family of DSPs is easily interfaced to the

AD5535 without the need for extra logic. A data transfer is

initiated by writing a word to the TX register after the SPORT

has been enabled. In a write sequence, data is clocked out on

each rising edge of the DSP’s serial clock and clocked into the

AD5535 on the falling edge of its SCLK. The easiest way to

provide the 19-bit data-word required by the AD5535, is to

transmit two 10-bit data-words from the ADSP-21xx. Ensure

that the data is positioned correctly in the TX register so that

the first 19 bits transmitted contain valid data.

Set up the SPORT control register as follows:

TFSW = 1, Alternate Framing

INVTFS = 1, Active Low Frame Signal

DTYPE = 00, Right Justify Data

ISCLK = 1, Internal Serial Clock

TFSR = 1, Frame Every Word

ITFS = 1, Internal Framing Signal

SLEN = 1001, 10-Bit Data Word

Figure 11 shows the connection diagram.

Rev. PrE | Page 11 of 16

AD5535 Preliminary Technical Data

AD5535*

SCLK

D

IN

SYNC

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 11. AD5535 to ADSP-2101/ADSP-2103 Interface

ADSP-2101/

ADSP-2103*

SCLK

DT

TFS

AD5535 to MC68HC11

The serial peripheral interface (SPI) on the MC68HC11 is

configured for master mode (MSTR = 1), clock polarity bit

(CPOL) = 0, and clock phase bit (CPHA) = 1. The SPI is

configured by writing to the SPI control register (SPCR)—see

the 68HC11 User Manual. SCK of the 68HC11 drives the SCLK

of the AD5535 and the MOSI output drives the serial data line

SYNC

(DIN) of the AD5535. The

signal is derived from a port

line (PC7). When data is being transmitted to the AD5535, the

SYNC

line is taken low (PC7).

Data appearing on the MOSI output is valid on the falling edge

of SCK. The 68HC11 transfers only eight bits of data during

each serial transfer operation; therefore, three consecutive write

operations are necessary to transmit 19 bits of data. Data is

transmitted MSB first. It is important to left-justify the data in

the SPDR register so that the first 19 bits transmitted contain

valid data. PC7 must be pulled low to start a transfer. It is taken

high and pulled low again before any further write cycles can

take place. See Figure 12.

AD5535*

SCLK

D

IN

SYNC

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 12. AD5535 to MC68HC11 Interface

MC68HC11*

SCK

MOSI

PC7

05068-011

05068-012

AD5535 to PIC16C6X/7X

The PIC16C6x/7x synchronous serial port (SSP) is configured

as an SPI master with the clock polarity bit = 0. This is done by

writing to the synchronous serial port control register

(SSPCON). See the PIC16/17 Microcontroller User Manual. In

SYNC

this example, I/O port RA1 is being used to pulse

and

enable the serial port of the AD5535. This microcontroller

transfers only eight bits of data during each serial transfer

operation; therefore, three consecutive write operations are

necessary to transmit 19 bits of data. Data is transmitted MSB

first. It is important to left-justify the data in the SPDR register

so that the first 19 bits transmitted contain valid data. RA1 must

be pulled low to start a transfer. It is taken high and pulled low

again before any further write cycles can take place. Figure 13

shows the connection diagram.

AD5535*

SCLK

D

IN

SYNC

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 13. AD5535 to PIC16C6x/7x Interface

PIC16C6x/7x*

SCK/RC3

SDI/RC4

RA1

AD5535 to 8051

The AD5535 requires a clock synchronized to the serial data.

The 8051 serial interface must, therefore, be operated in

Mode 0. In this mode, serial data exits the 8051 through RxD,

and a shift clock is output on TxD. The

SYNC

signal is derived

from a port line (P1.1). Figure 14 shows how the 8051 is

connected to the AD5535. Because the AD5535 shifts data out

on the rising edge of the shift clock and latches data in on the

falling edge, the shift clock must be inverted. Note also that the

AD5535 requires its data with the MSB first. Because the 8051

outputs the LSB first, the transmit routine must take this into

account.

AD5535*

SCLK

D

SYNC

IN

8051*

TxD

RxD

P1.1

05068-013

*ADDITIONAL PINS OMITTED FOR CLARITY

Figure 14. AD5535 to 8051 Interface

05068-014

Rev. PrE | Page 12 of 16

Preliminary Technical Data AD5535

APPLICATIONS INFORMATION

MEMS MIRROR CONTROL APPLICATION

The AD5535 is targeted to all optical switching control systems

based on micro-electromechanical systems (MEMS)

technology. The AD5535 is a 32-channel, 14-bit DAC with

integrated high voltage amplifiers. The output amplifiers are

capable of generating an output range of 0 V to 200 V when

using a 4 V reference. The full-scale output voltage is

programmable from 50 V to 200 V using reference voltages

from 1 V to 4V. Each amplifier can output 700 µA and directly

drives the control actuators, which determine the position of

MEMS mirrors in optical switch applications.

The AD5535 is generally used in a closed-loop feedback system,

as shown in Figure 15, with a high resolution ADC and DSP.

The exact position of each mirror is measured using capacitive

sensors. The sensor outputs are multiplexed using an ADG739

to an 8-channel 14-bit ADC (AD7856). An alternative solution

is to multiplex using a 32-to-1 multiplexer (ADG732) into a

single-channel ADC (AD7671). The control loop is driven by an

ADSP-21065L, a 32-bit SHARC DSP with an SPI-compatible

SPORT interface. With its 14-bit monotonic behavior and 0 V to

200 V output range coupled with its fast serial interface, the

AD5535 is ideally suited for controlling a cluster of MEMSbased mirrors.

A1 BALL PAD CORNER

1

ORIGINAL

NO-CONNECTS

ADDITIONAL

NO-CONNECTS

1

3

5

2

4

7

1

6

11 12 13

9

10

8

14

A

B

C

D

E

F

G

H

J

K

L

M

N

P

11

Figure 16. Layout Guidelines to Comply with IPC-221

1.414mm

REF198

(4.096V)

REF_IN

14-BIT DAC

14-BIT DAC

AD5535

AD5535 BOARD LAYOUT TO ENSURE

COMPLIANCE WITH IPC-221 SPECIFICATION

The diagram in Figure 16 is a typical 2-layer printed circuit

board layout for the AD5535 complying with the specifications

outlined in IPC221. The four corner balls labeled as original noconnects must remain, because no connections and no signals

should be connected to these balls. Balls labeled as additional

no-connects should be connected to AGND.

The routing shown in Figure 16 shows the feasibility of

connecting to the high voltage balls while complying with the

spacing requirements of IPC-221. Figure 17 shows the physical

distances that are available.

2

5

0

S

P

1

A

0

0

µ

m

S

P

A

2

5

0

+210V+5V

OUTPUT RANGE

0V TO 200V

V

V

+

PP

SENSOR

4 TO 1 MUX

(ADG739)

32 TO 1 MUX

(ADG732)

–5V

V

–

VO1

V

32

O

ACTUATORS

FOR

MEMS

MIRROR

ARRAY

ADSP21065L

Figure 15. AD5535 in a MEMS-Based Optical Switch

µ

m

R

A

D

C

E

=

4

0

5

µ

m

C

E

=

4

µ

0

m

5

µ

R

m

A

D

DETAIL A

250µm RAD

SPACE = 433µm

SPACE = 433µm

SPACE = 433µm

250µm RAD

OR

100µm

100µm

8-CHANNEL

ADC (AD7856)

OR

SINGLE

CHANNEL

ADC (AD7671)

2mm

05068-016

05068-015

+

Rev. PrE | Page 13 of 16

AD5535 Preliminary Technical Data

POWER SUPPLY SEQUENCING AND DECOUPLING RECOMMENDATIONS

The diagram in Figure 17 shows the recommended decoupling,

and power supply protection for the AD5535. On the AD5535 it

is recommended that all grounds be tied together as close to the

device as possible. All supplies should be brought back

separately and a provision be made on the board via a link

option to drive the AV

and V+ from the same supply if

CC

required to reduce the number of supplies. All power supplies

should be adequately decoupled with 10 uF tantalum and 0.1 uF

ceramic capacitors. Note that the capacitors on the V

supply

PP

must be rated at greater than 210 V. To overcome issues

associated with power supply sequencing when using high

voltage supplies, the use of protection diodes as indicated in

Figure 17 is recommended.

V

= +5V

+

V

10µF

0.1µF

+

V

PP

= +210V

V

PP

AV

CC

DV

CC

HIGH VOLTAGE DIODE

MFTR: GS

10µF

10µF

0.1µF

10µF

AVCC = +5V

0.1µF

DV

0.1µF

CC

= +5V

V

= –5V

–

SCHOTTKY DIODE

MFTR: ITT

Figure 17. Recommended Power Supply Sequencing and Decoupling

10µF

0.1µF

SD103C RS1G

V

PGND

AGND

DACGND

DGND

–

AD5535

GUIDELINES FOR PRINTED CIRCUIT BOARD LAYOUT

Printed circuit boards should be designed such that the analog

and digital sections are separated and confined to designated

analog and digital sections of the board. This facilitates the use

of ground planes that can be separated easily. A minimum etch

technique is generally found to be the best for ground planes,

because this optimizes shielding of sensitive signal lines. Digital

and analog grounds planes should be joined only in one place,

at the AGND and DGND pins of the high resolution converter.

Data and address busses on the board should be buffered or

latched to isolate the high frequency bus of the processor from

the bus of the high-resolution converters. These act as a faraday

05068-017

shield and increase the signal-to-noise performance of the

converters by reducing the amount of high frequency digital

coupling. Avoid running digital lines under the device, becaus

they couple noise onto the die. The ground plane shou

e

ld be

allowed to run under the IC to avoid noise coupling.

As large a trace as possible should be used for the supply lin

es to

the device to provide low impedance paths and reduce the

effects of glitches on the power supply line. Fast switching

signals like clocks should be shielded with digital ground to

avoid radiating noise to other sections of the board, and clock

signals should never be run near analog inputs of devices. Avoid

crossovers of digital and analog signals. Traces for analog inpu

ts

should be kept as wide and as short as possible and should be

shielded with analog ground where possible. Traces on opp

osite

sides of a 2-layer printed circuit board should run at right

angles to each other

to reduce the effects of feedthrough

through the board.

A microstrip technique is by far the best, but not always possi

ble

with a double-sided board. In this technique the component

side of the board is dedicated to ground planes, and signals are

placed on the solder side. Multilayer printed circuit boards with

dedicated ground, power, and tracking layers offer the opti

solution in terms of obtaining an

alog performance but at

mum

increased manufacturing costs.

Good decoupling is vitally important when using high resolu-

tion converters. All analog supplies should be decoupled with

10 µF tantalum in parallel with 0.1 µF ceramic capacitors

to

analog ground. To achieve the best from the decoupling

components, these have to be placed as close to the device as

possible ideally right up against the IC or IC socket. The main

aim of a bypassing element is to maximize the charge s

tored in

the bypass loop while simultaneously minimizing the

inductance of this loop. Inductance in the loop acts as an

impedance to high frequency transients and results in power

supply spiking. By keeping the decoupling as close to the devi

ce

as possible, the loop area is kept as small as possible, thereby

reducing the possibility of power-supply spikes. Digital supplie

of high resolution converters should be decoupled with 10 µF

tantalum and 0.1 µF ceramic to the digital ground plane. VDD

and VSS supplies of amplifie

rs should be decoupled again with

10 µF and 0.1 µF to AGND.

All logic chips should be decoupled with 0.1µF to digital

ground to decoup

le high frequency effects associated with

digital circuitry.

s

Rev. PrE | Page 14 of 16

Preliminary Technical Data AD5535

OUTLINE DIMENSIONS

A1 CORNER

15.00

BSC SQ

TOP VIEW

DETAIL A

1.70 MAX

*

COMPLIANT WITH JEDEC STANDARDS

MO-192-AAE-1 EXCEPT FOR DIMENSIONS

INDICATED BY A "*" SYMBOL. NOMINAL BALL

SIZE IS REDUCED FROM 0.60mm TO 0.46mm.

*

0.41

0.36

0.31

11121314

1.00 BSC

*

0.46 NOM

BALL DIAMETER

10

BOTTOM VIEW

Figure 18. 124-Lead CSB-BGA Package [CSP-BGA]

(BC-124)

Dimensions shown in millimeters

876

9

DETAIL A

INDEX AREA

3

5

4

2

SEATING

PLANE

1

A

B

C

D

E

F

G

H

J

K

L

M

N

P

*

1.25 MAX

0.85 MIN

0.12 NOM

COPLANARITY

ORDERING GUIDE

Model Function Output Voltage Span Temperature Range Package Description Package Option

AD5535ABC 32 DACs 0 to 200 V maximum

−10°C to +85°C

124-Lead CSP-BGA BC-124

Rev. PrE | Page 15 of 16

AD5535 Preliminary Technical Data

NOTES

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

PR05068–0–10/04(PrE)

Rev. PrE | Page 16 of 16

Loading...

Loading...