16-Channel, 12-Bit Voltage-Output DAC

a

FEATURES

High Integration:

16-Channel DAC in 12 mm ⴛ 12 mm

14-Bit Resolution via Increment/Decrement Mode

Guaranteed Monotonic

Low Power, SPI

TM

, QSPI

TM

, MICROWIRETM, and DSP-

Compatible

3-Wire Serial Interface

Output Impedance 0.5 ⍀

Output Voltage Range

ⴞ2.5 V (AD5516-1)

ⴞ5 V (AD5516-2)

ⴞ10 V (AD5516-3)

Asynchronous Reset-Facility (via RESET Pin)

Asynchronous Power-Down Facility (via PD Pin)

Daisy-Chain Mode

Temperature Range: –40ⴗC to +85ⴗC

APPLICATIONS

Level Setting

Instrumentation

Automatic Test Equipment

Optical Networks

Industrial Control Systems

Data Acquisition

Low Cost I/O

LFBGA

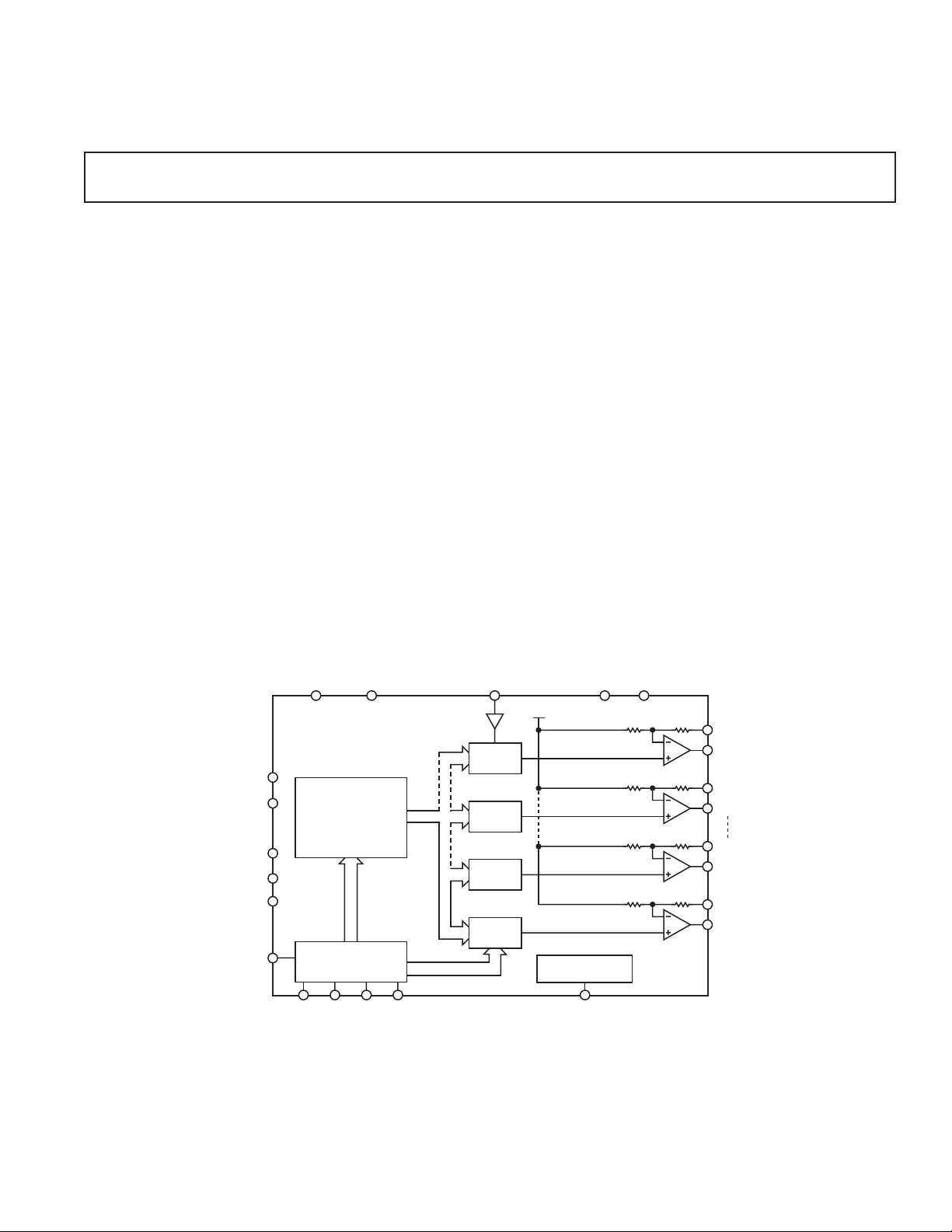

FUNCTIONAL BLOCK DIAGRAM

with 14-Bit Increment Mode

AD5516

GENERAL DESCRIPTION

The AD5516 is a 16-channel, 12-bit voltage-output DAC. The

selected DAC register is written to via the 3-wire serial interface.

DAC selection is accomplished via address bits A3–A0. 14-bit

resolution can be achieved by fine adjustment in Increment/

Decrement Mode (Mode 2). The serial interface operates at

clock rates up to 20 MHz and is compatible with standard SPI,

MICROWIRE, and DSP interface standards. The output voltage range is fixed at ±2.5 V (AD5516-1), ±5 V (AD5516-2),

and ± 10 V (AD5516-3). Access to the feedback resistor in each

channel is provided via R

The device is operated with AV

5.25 V, V

= –4.75 V to –12 V, and V

SS

and requires a stable 3 V reference on REF_IN.

PRODUCT HIGHLIGHTS

1. Sixteen 12-bit DACs in one package, guaranteed monotonic

2. Available in a 74-lead LFBGA package with a body size of

12 mm ⴛ 12 mm

0 to RFB15 pins.

FB

= 5 V ± 5%, DVCC = 2.7 V to

CC

= +4.75 V to +12 V

DD

*

DV

AV

CC

CC

AD5516

RESET

BUSY

DACGND

AGND

DGND

DCEN

ANALOG

CALIBRATION

LOOP

MODE1

INTERFACE

CONTROL

LOGIC

SCLK DIND

12-BIT BUS

SYNC

OUT

MODE2

7-BIT BUS

*Protected by U.S. Patent No. 5,969,657; other patents pending

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corporation.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

LOGIC

PD

V

DDVSS

R

OFFS

R

OFFS

R

OFFS

R

OFFS

R

FB

RFB0

V

0

OUT

R

FB

RFB1

1

V

OUT

R

FB

R

FB

14

R

FB

14

V

OUT

15

R

FB

V

15

OUT

REF_IN

V

BIAS

DAC

DAC

DAC

DAC

POWER-DOWN

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

(VDD = +4.75 V to +13.2 V, VSS = –4.75 V to –13.2 V; AVCC = 4.75 V to 5.25 V; DVCC =

AD5516

All specifications T

Parameter

–SPECIFICATIONS

to T

1

MIN

unless otherwise noted.)

MAX

DAC DC PERFORMANCE

Resolution 12 Bits

Integral Nonlinearity (INL) ± 2 LSB max Mode 1

Differential Nonlinearity (DNL) –1/+1.3 LSB max ±0.5 LSB typ, Monotonic; Mode 1

Increment/Decrement Step-Size ± 0.25 LSB typ Monotonic; Mode 2 Only

Bipolar Zero Error ± 7 LSB max

Positive Full-Scale Error ± 10 LSB max

Negative Full-Scale Error ± 10 LSB max

VOLTAGE REFERENCE

REF_IN

Nominal Input Voltage 3 V

Input Voltage Range

3

Input Current ± 1 µA max < 1 nA typ

ANALOG OUTPUTS (V

Output Temperature Coefficient

DC Output Impedance

Output Range

5

OUT

3

0–15)

3, 4

AD5516-1 ± 2.5 V typ

AD5516-2 ± 5 V typ

AD5516-3 ± 10 V typ

Resistive Load

Capacitive Load

Short-Circuit Current

DC Power-Supply Rejection Ratio

DC Crosstalk

DIGITAL INPUTS

3, 6

3, 6

3

3

3

3

Input Current ± 10 µA max ±5 µA typ

Input Low Voltage 0.8 V max DV

Input High Voltage 2.4 V min DVCC = 5 V ± 5%

Input Hysteresis (SCLK and SYNC) 150 mV typ

Input Capacitance 10 pF max 5 pF typ

3

DIGITAL OUTPUTS (BUSY, D

OUT

)

Output Low Voltage, DVCC = 5 V 0.4 V max Sinking 200 µA

Output High Voltage, DVCC = 5 V 4 V min Sourcing 200 µA

Output Low Voltage, DVCC = 3 V 0.4 V max Sinking 200 µA

Output High Voltage, DVCC = 3 V 2.4 V min Sourcing 200 µA

High Impedance Leakage Current (D

High Impedance Output Capacitance (D

only) ± 1 µA max DCEN = 0

OUT

only) 5 pF typ DCEN = 0

OUT

POWER REQUIREMENTS

Power Supply Voltages

V

DD

V

SS

AV

CC

DV

CC

Power Supply Currents

I

DD

I

SS

AI

CC

DI

CC

Power-Down Currents

I

DD

I

SS

AI

CC

DI

CC

Power Dissipation

NOTES

1

See Terminology section.

2

A Version: Industrial temperature range –40°C to +85°C; typical at +25°C.

3

Guaranteed by design and characterization; not production tested.

4

AD780 as reference for the AD5516.

5

Output range is restricted from V

6

Ensure that you do not exceed T

7

Outputs unloaded.

Specifications subject to change without notice.

7

7

7

+ 2 V to V

SS

. See Absolute Maximum Ratings section.

J (MAX)

– 2 V. Output span varies with reference voltage and is functional down to 2 V.

DD

2.7 V to 5.25 V; AGND = DGND = DACGND = 0 V; REF_IN = 3 V; All outputs unloaded.

A Version

2.875/3.125 V min/max

10 ppm/°C typ of FSR

0.5 Ω typ

5kΩ min

200 pF

7 mA typ

–85 dB typ VDD = +12 V ± 5%, VSS = –12 V ± 5%

120 µV max

0.4 V max DVCC = 3 V ± 10%

2 V min DVCC = 3 V ± 10%

+4.75/+15.75 V min/max

–4.75/–15.75 V min/max

4.75/5.25 V min/max

2.7/5.25 V min/max

5 mA max 3.5 mA typ. All Channels Full-Scale

5 mA max 3.5 mA typ. All Channels Full-Scale

17 mA max 13 mA typ

1.5 mA max 1 mA typ

2 µA max 200 nA typ

3 µA max 200 nA typ

2 µA max 200 nA typ

2 µA max 200 nA typ

105 mW typ VDD= +5 V, VSS= –5 V

2

Unit Conditions/Comments

= 5 V ± 5%

CC

–2–

REV. 0

AD5516

(VDD = +4.75 V to +13.2 V, VSS = –4.75 V to –13.2 V; AVCC = 4.75 V to 5.25 V; DVCC = 2.7 V to 5.25 V; AGND = DGND

AC CHARACTERISTICS

Parameter

Output Voltage Settling Time (Mode 1)

Output Voltage Settling Time (Mode 2)

1, 2

= DACGND = 0 V; REF_IN = 3 V; All outputs unloaded. All specifications T

A Version

4

4

32 s max 100 pF, 5 kΩ Load Full-Scale Change

2.5 s max 100 pF, 5 kΩ Load, 1 Code Increment

3

Unit Conditions/Comments

Slew Rate 0.85 V/s typ

Digital-to-Analog Glitch Impulse 1 nV-s typ 1 LSB Change around Major Carry

Digital Crosstalk 5 nV-s typ

Analog Crosstalk AD5516-1 10 nV-s typ

Digital Feedthrough 1 nV-s typ

Output Noise Spectral Density @ 1 kHz 150 nV/(Hz)

NOTES

1

See Terminology section.

2

Guaranteed by design and characterization; not production tested.

3

A version: Industrial temperature range –40°C to +85°C.

4

Timed from the end of a write sequence.

Specifications subject to change without notice.

1/2

typ AD5516-1

(VDD = +4.75 V to +13.2 V, VSS = – 4.75 V to –13.2 V; AVCC = 4.75 V to 5.25 V; DVCC = 2.7 V to 5.25 V;

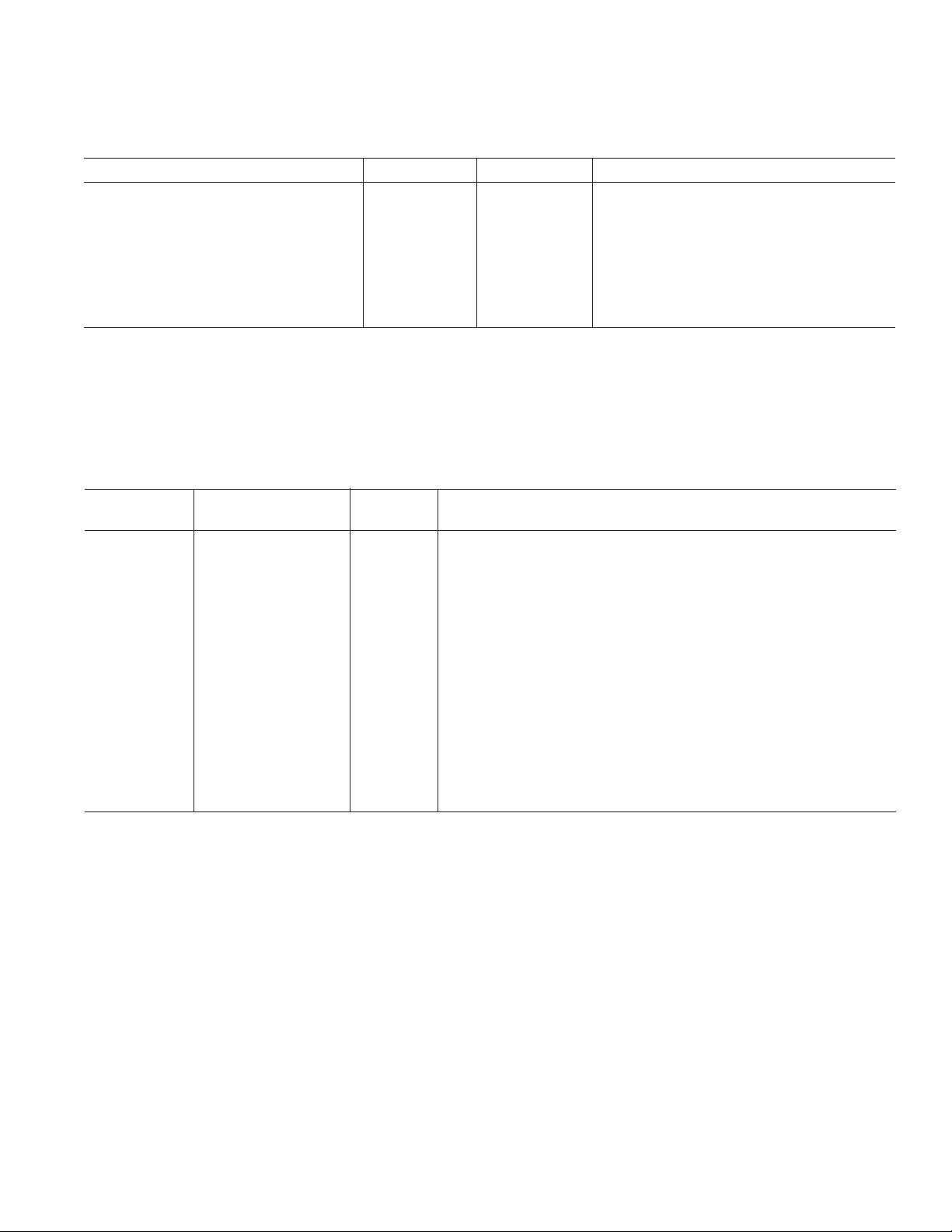

TIMING CHARACTERISTICS

Parameter

f

UPDATE1

f

UPDATE2

f

CLKIN

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

7MODE2

t

8MODE1

t

9MODE2

t

10

4

t

11

t

12

NOTES

1

See Timing Diagrams in Figures 1 and 2.

2

Guaranteed by design and characterization; not production tested.

3

All input signals are specified with tr = tf = 5 ns (10% to 90% of DVCC) and timed from a voltage level of (VIL + VIH)/2.

4

This is measured with the load circuit of Figure 3.

Specifications subject to change without notice.

1, 2, 3

Limit at T

(A Version) Unit Conditions/Comments

32 kHz max DAC Update Rate (Mode 1)

750 kHz max DAC Update Rate (Mode 2)

20 MHz max SCLK Frequency

20 ns min SCLK High Pulsewidth

20 ns min SCLK Low Pulsewidth

15 ns min SYNC Falling Edge to SCLK Falling Edge Setup Time

5 ns min DIN Setup Time

5 ns min DIN Hold Time

0 ns min SCLK Falling Edge to SYNC Rising Edge

10 ns min Minimum SYNC High Time (Standalone Mode)

400 ns min Minimum SYNC High Time (Daisy-Chain Mode)

10 ns min BUSY Rising Edge to SYNC Falling Edge

200 ns min 18th SCLK Falling Edge to SYNC Falling Edge (Standalone Mode)

10 ns min SYNC Rising Edge to SCLK Rising Edge (Daisy-Chain Mode)

20 ns max SCLK Rising Edge to D

20 ns min RESET Pulsewidth

MIN

, T

AGND = DGND = DACGND = 0 V. All specifications T

MAX

to T

MIN

MAX

Valid (Daisy-Chain Mode)

OUT

to T

MIN

unless otherwise noted.)

MAX

unless otherwise noted.)

–3–

AD5516

SERIAL INTERFACE TIMING DIAGRAMS

SCLK

SYNC

DIN

BUSY

RESET

SCLK

SYNC

D

1 2 17 18

t

MODE1

8

t

t

7

3

t

4

BIT 17 BIT 0

t

2

t

5

t

1

t

6

t

MODE2

LSBMSB

9

t

12

Figure 1. Serial Interface Timing Diagram

t

t

MODE2

7

IN

3

t

4

BIT 17 BIT 0 BIT 17 BIT 0

t

2

t

5

t

1

LSBMSB

t

10

t

6

D

OUT

BUSY

t

MODE1

8

INPUT WORD FOR DEVICE N

t

11

BIT 17 BIT 0

UNDEFINED INPUT WORD FOR DEVICE N

Figure 2. Daisy-Chaining Timing Diagram

200A

TO OUTPUT

PIN

C

L

50pF

200A

Figure 3. Load Circuit for D

I

OL

I

OH

Timing Specifications

OUT

INPUT WORD FOR DEVICE N+1

1.6V

–4–

REV. 0

AD5516

ABSOLUTE MAXIMUM RATINGS

(TA = 25°C unless otherwise noted.)

VDD to AGND . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +17 V

to AGND . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V to –17 V

V

SS

AV

to AGND, DACGND . . . . . . . . . . . . . . –0.3 V to +7 V

CC

DV

to DGND . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

CC

Digital Inputs to DGND . . . . . . . . . . –0.3 V to DV

Digital Outputs to DGND . . . . . . . . . –0.3 V to DV

REF_IN to AGND, DACGND . . . . . –0.3 V to AV

0–15 to AGND . . . . . . . . . . . . V

V

OUT

AGND to DGND . . . . . . . . . . . . . . . . . . . . –0.3 V to +0.3 V

R

0–15 to AGND . . . . . . . . . . . . V

FB

1, 2

CC

CC

– 0.3 V to V

SS

– 0.3 V to VDD+ 0.3 V

SS

CC

DD

+ 0.3 V

+ 0.3 V

+ 0.3 V

+ 0.3 V

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Junction Temperature (T

74-Lead LFBGA Package,

) . . . . . . . . . . . . . . . . . . . 150°C

J MAX

Thermal Impedance . . 41°C/W

JA

Reflow Soldering

Peak Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

Time at Peak Temperature . . . . . . . . . . . . .10 sec to 40 sec

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent

damage to the device. This is a stress rating only; functional operation of the device

at these or any other conditions above those listed in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

2

Transient currents of up to 100 mA will not cause SCR latch-up.

Operating Temperature Range, Industrial . . . . . –40°C to +85°C

ORDERING GUIDE

Model Function Output Voltage Span Package Option

AD5516ABC-1 16 DACs ± 2.5 V 74-Lead LFBGA

AD5516ABC-2 16 DACs ± 5 V 74-Lead LFBGA

AD5516ABC-3 16 DACs ± 10 V 74-Lead LFBGA

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD5516 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

REV. 0

–5–

AD5516

PIN CONFIGURATION

1110987654321

A

B

C

D

E

F

G

H

J

K

LL

TOP VIEW

A

B

C

D

E

F

G

H

J

K

1110987654321

74-LEAD LFBGA BALL CONFIGURATION

LFBGA Ball LFBGA Ball LFBGA Ball LFBGA Ball LFBGA Ball

Number Name Number Name Number Name Number Name Number Name

A1 NC

A2 NC

A3 RESET

A4 BUSY

A5 DGND

A6 DV

A7 D

A8 D

CC

OUT

IN

A9 SYNC

A10 NC

A11 NC

B1 NC

B2 NC

B3 NC

B4 DCEN

NC = Not Internally Connected

B5 DGND

B6 DGND

B7 NC

B8 NC

B9 SCLK

B10 NC

B11 REF_IN

C1 V

OUT

0

C2 DACGND

C6 NC

C10 AV

CC

1

C11 NC

D1 R

FB

0

D2 DACGND

D10 AVCC2

D11 NC

E1 V

OUT

1

E2 NC

E10 AGND1

E11 PD

F1 V

F2 R

OUT

FB

2

1

F10 AGND2

F11 R

G1 R

G2 R

G10 V

G11 R

H1 V

H2 V

FB

FB

FB

OUT

FB

OUT

OUT

14

2

15

14

13

3

15

H10 V

H11 V

J1 R

J2 V

OUT

OUT

FB

OUT

J6 NC

J10 R

J11 R

K1 R

K2 V

K3 R

FB

FB

FB

OUT

FB

K4 NC

K5 V

K6 V

K7 V

K8 V

SS

SS

OUT

OUT

3

12

11

4

5

2

1

13

12

14

5

10

9

K9 RFB10

K10 R

K11 V

FB

OUT

9

L1 NC

L2 V

L3 R

L4 V

OUT

FB

OUT

6

L5 NC

L6 VDD2

L7 V

L8 R

L9 V

L10 R

DD

FB

OUT

FB

1

7

8

L11 NC

11

6

7

8

PIN FUNCTION DESCRIPTIONS

Mnemonic Function

AGND (1–2) Analog GND pins

AV

(1–2) Analog supply pins. Voltage range from +4.75 V to +5.25 V.

CC

V

(1–2) VDD supply pins. Voltage range from +4.75 V to +15.75 V.

DD

V

(1–2) VSS supply pins. Voltage range from –4.75 V to –15.75 V.

SS

DGND Digital GND pins

DV

CC

Digital supply pin. Voltage range from 2.7 V to 5.25 V.

DACGND Reference GND supply for all 16 DACs.

REF_IN Reference input voltage for all 16 DACs. The recommended value of REF_IN is 3 V.

V

(0–15) Analog output voltages from the 16 DAC channels.

OUT

R

(0–15) Feedback resistors. For nominal output voltage range connect each RFB to its corresponding V

FB

OUT

.

SYNC Active low input. This is the frame synchronization signal for the serial interface. While SYNC is low, data is

transferred in on the falling edge of SCLK.

SCLK Serial clock input. Data is clocked into the shift register on the falling edge of SCLK. This operates at clock

speeds up to 20 MHz.

D

IN

Serial data input. Data must be valid on the falling edge of SCLK.

–6–

REV. 0

Mnemonic Function

AD5516

PIN FUNCTION DESCRIPTIONS (continued)

D

OUT

Serial data output. D

data in the shift register for diagnostic purposes. Data is clocked out on D

can be used for daisy-chaining a number of devices together or for reading back the

OUT

OUT

on the rising edge of SCLK and is

valid on the falling edge of SCLK.

1

DCEN

RESET

1

PD

2

Active high control input. This pin is tied high to enable daisy-chain mode.

Active low control input. This resets all DAC registers to power-on value.

Active high control input. All DACs go into power-down mode when this pin is high. The DAC outputs go into

a high-impedance state.

BUSY Active low output. This signal tells the user that the analog calibration loop is active. It goes low during

conversion. The duration of the pulse on BUSY determines the maximum DAC update rate, f

UPDATE

. Further

writes to the AD5516 are ignored while BUSY is active.

NOTES

1

Internal pull-down device on this logic input. Therefore it can be left floating and will default to a logic low condition.

2

Internal pull-up device on this logic input. Therefore it can be left floating and will default to a logic high condition.

TERMINOLOGY

Integral Nonlinearity (INL)

This is a measure of the maximum deviation from a straight line

passing through the endpoints of the DAC transfer function. It is

expressed in LSBs.

Differential Nonlinearity (DNL)

Differential nonlinearity (DNL) is the difference between the

measured change and the ideal 1 LSB change between any two

adjacent codes. A specified DNL of –1 LSB maximum ensures

monotonicity.

Bipolar Zero Error

Bipolar zero error is the deviation of the DAC output from the ideal

midscale of 0 V. It is measured with 10...00 loaded to the DAC.

It is expressed in LSBs.

Positive Full-Scale Error

This is the error in the DAC output voltage with all 1s loaded to

the DAC. Ideally the DAC output voltage, with all 1s loaded to the

DAC registers, should be 2.5 V – 1 LSB (AD5516-1), 5 V – 1 LSB

(AD5516-2), and 10 V – 1 LSB (AD5516-3). It is expressed in LSBs.

Negative Full-Scale Error

This is the error in the DAC output voltage with all 0s loaded to the

DAC. Ideally the DAC output voltage, with all 0s loaded to the

DAC registers, should be –2.5 V (AD5516-1), –5 V (AD5516-2),

and –10 V (AD5516-3). It is expressed in LSBs.

Output Temperature Coefficient

This is a measure of the change in analog output with changes in

temperature. It is expressed in ppm/°C of FSR.

DC Power Supply Rejection Ratio

DC power supply rejection ratio (PSRR) is a measure of the change

in analog output for a change in supply voltage (V

It is expressed in dBs. V

and VSS are varied ± 5%.

DD

and VSS).

DD

DC Crosstalk

This is the dc change in the output level of one DAC at midscale

in response to a full-scale code change (all 0s to all 1s and vice

versa) and output change of another DAC. It is expressed in mV.

Output Settling Time

This is the time taken from when the last data bit is clocked into

the DAC until the output has settled to within ±0.5 LSB of its

final value (see TPC 7).

Digital-to-Analog Glitch Impulse

This is the area of the glitch injected into the analog output when

the code in the DAC register changes state. It is specified as the

area of the glitch in nV-secs when the digital code is changed by

1 LSB at the major carry transition (011...11 to 100...00 or

100...00 to 011...11).

Digital Crosstalk

This is the glitch impulse transferred to the output of one DAC at

midscale while a full-scale code change (all 1s to all 0s and vice

versa) is being written to another DAC. It is expressed in nV-secs.

Analog Crosstalk

This is the area of the glitch transferred to the output (V

one DAC due to a full-scale change in the output (V

OUT

OUT

) of

another DAC. The area of the glitch is expressed in nV-secs.

Digital Feedthrough

This is a measure of the impulse injected into the analog outputs

from the digital control inputs when the part is not being written

to, i.e., SYNC is high. It is specified in nV-secs and measured

with a worst-case change on the digital input pins, e.g., from all

0s to all 1s and vice versa.

Output Noise Spectral Density

This is a measure of internally generated random noise. Random

noise is characterized as a spectral density (voltage per root Hertz).

It is measured in nV/(Hz)

1/2

.

) of

REV. 0

–7–

CURRENT – mA

V

OUT

– V

–6

0.002

–4 –202 64

MIDSCALE

REF_IN = 3V

T

A

= 25ⴗC

0.0

–0.002

–0.004

–0.006

–0.008

–0.01

0.004

0.006

0.008

0.01

8–8

–Typical Performance CharacteristicsAD5516

1.0

REF_IN = 3V

= 25ⴗC

T

0.8

A

0.6

0.4

0.2

0

–0.2

DNL ERROR – LSB

–0.4

–0.6

–0.8

–1.0

1000 2000 3000 40000

TPC 1. Typical DNL Plot

3

REF_IN = 3V

2

1

BIPOLAR ZERO ERROR

0

ERROR – LSB

–1

–2

–3

–40

NEGATIVE FS ERROR

POSITIVE FS ERROR

–20 0 20 40 80

TEMPERATURE – ⴗC

DAC CODE

–0.2

INL ERROR – LSB

–0.4

–0.6

–0.8

–1.0

1.0

REF_IN = 3V

= 25ⴗC

T

0.8

A

0.6

0.4

0.2

0

0

1000 2000 3000 4000

DAC CODE

TPC 2. Typical INL Plot

2.0

REF_IN = 3V

1.5

–0.5

ERROR – LSB

–1.0

–1.5

–2.0

1.0

0.5

0

–20 0 20 40 80

–40

TEMPERATURE – ⴗC

INL

+VE

DNL

–VE

DNL

60

TPC 3. Typical INL Error and DNL

Error vs. Temperature

0.003

AV

= +12V

DD

= –12V

AV

SS

0.002

0.001

– V

0

OUT

V

–0.001

–0.002

60

–0.003

–40

= 3V

REF_IN

MIDSCALE LOADED

–20 0 20 40 80

TEMPERATURE – ⴗC

60

TPC 4. Bipolar Zero Error and

Full-Scale Error vs. Temperature

3.0

TA = 25ⴗC

REF_IN = 3V

2.0

1.0

– V

0

OUT

V

–1.0

–2.0

–3.0

TIME BASE = 2.5s/DIV

TPC 7. Full-Scale Settling Time

TPC 5. V

vs. Temperature

OUT

TPC 6. V

Source and Sink

OUT

Capability

= 25ⴗC

T

A

REF_IN = 3V

PD

V

OUT

5V/DIV

2V/DIV

2s/DIV

TPC 8. Exiting Power-Down to

Full Scale

–8–

–0.029

TA = 25ⴗC

REF_IN = 3V

–0.030

–0.031

–0.032

–0.033

OLD

VA LU E

CALIBRATION TIME

2.5s/DIV

5V

0V

TPC 9. Major Code Transition

Glitch Impulse

NEW

VA LU E

BUSY

REV. 0

AD5516

450

400

350

300

250

200

FREQUENCY

150

100

50

0

TPC 10. V

V

– V

OUT

Repeatability; Program-

OUT

2.48992.48962.4893

ming the Same Code Multiple Times

30

REF_IN = 3V

= 25ⴗC

T

A

20

40

REF_IN = 3V

= 25ⴗC

T

A

20

FREQUENCY – %

0

–10 0 10

LSBs

TPC 11. Bipolar Error Distribution

2.5

2.0

1.5

REF_IN = 3V

= 25ⴗC

T

A

40

REF_IN = 3V

TA = 25ⴗC

20

FREQUENCY – %

0

–10 0 10

LSBs

TPC 12. Positive Full-Scale

Error Distribution

10

FREQUENCY – %

0

–10 0 10

LSBs

TPC 13. Negative Full-Scale Error Distribution

1.0

ERROR – LSB

0.5

0

0 20 40 60 80 100 120

STEP SIZE

130

TPC 14. Increment Step vs. Accuracy

REV. 0

–9–

AD5516

FUNCTIONAL DESCRIPTION

The AD5516 consists of sixteen 12-bit DACs in a single package.

A single reference input pin (REF_IN) is used to provide a 3 V

reference for all 16 DACs. To update a DAC’s output voltage

the required DAC is addressed via the 3-wire serial interface.

Once the serial write is complete, the selected DAC converts the

code into an output voltage. The output amplifiers translate the

DAC output range to give the appropriate voltage range (±2.5 V,

± 5 V, or ± 10 V) at output pins V

OUT

0 to V

OUT

15.

The AD5516 uses a self-calibrating architecture to achieve

12-bit performance. The calibration routine servos to select the

appropriate voltage level on an internal 14-bit resolution DAC.

Noise during the calibration (

BUSY

low period) can result in

the selection of a voltage within a ±0.25 LSB band around the

normal selected voltage. See TPC 10.

It is essential to minimize noise on REFIN for optimal performance. The AD780’s specified decoupling makes it the ideal

reference to drive the AD5516.

On power-on, all DACs power up to a reset value (see RESET

section).

DIGITAL-TO-ANALOG SECTION

The architecture of each DAC channel consists of a resistorstring DAC followed by an output buffer amplifier. The voltage

at the REF_IN Pin provides the reference voltage for the corresponding DAC. The input coding to the DAC is offset binary;

this results in ideal DAC output voltages as follows:

AD5516-1

AD5516-2

AD5516-3

×××××225

V

DAC

V

DAC

V

DAC

REF IN

=

=

=

32

VDV

×××

REF IN

32

VDV

×××

REF IN

32

.

__

N

.

__

N

×

.

__

N

×

REF IN

–

225

–

425

–

3

REF IN

3

REF IN

3

25

.

×425

×825

.

.

VDV

Where:

D = decimal equivalent of the binary code that is loaded to

the DAC register, i.e., 0–4096

N = DAC resolution = 12

Table I illustrates ideal analog output versus DAC code.

Table I. DAC Register Contents AD5516-1

MSB LSB Analog Output, V

1111 1111 1111 V

× 2.5/3 – 1 LSB

REF_IN

OUT

1000 0000 0000 0 V

0000 0000 0000 –V

REF_IN

× 2.5/3

MODES OF OPERATION

The AD5516 has two modes of operation.

Mode 1 (MODE bits = 00): The user programs a 12-bit data

word to one of 16 channels via the serial interface. This word is

loaded into the addressed DAC register and is then converted

into an analog output voltage. During conversion the BUSY

output is low and all SCLK pulses are ignored. At the end of a

conversion BUSY goes high indicating that the update of the

addressed DAC is complete. It is recommended that SCLK is

not pulsed while BUSY is low. Mode 1 conversion takes 25 µs typ.

Mode 2 (MODE bits = 01 or 10): Mode 2 operation allows the

user to increment or decrement the DAC output in 0.25 LSB steps,

resulting in a 14-bit monotonic DAC. The amount by which the

DAC output is incremented or decremented is determined by

Mode 2 bits DB6–DB0, e.g., for a 0.25 LSB increment/decrement

DB6...DB0 = 0000001, while for a 2.5 LSB increment/decrement,

DB6...DB0 = 0001010. The MODE bits determine whether the

DAC data is incremented (01) or decremented (10). The maximum

amount that the user is allowed to increment or decrement the DAC

output is 127 steps of 0.25 LSB, i.e., DB6...DB0 = 1111111.

Mode 2 update takes approximately 1 µs. The Mode 2 feature

allows increased resolution but overall increment/decrement accuracy varies with increment/decrement step as shown in TPC 14.

Mode 2 is useful in applications where greater resolution is

required, for example, in servo applications requiring fine-tune

to 14-bit resolution.

MSB LSB

0 0 A3 A2 A1 A0 DB11 DB10 DB9 DB8 DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

MODE

BITS

ADDRESS

BITS

DATA

BITS

Figure 4. Mode 1 Data Format

MSB LSB

0 1 A3 A2 A1 A0 0 0 0 0 0 DB6 DB5 DB4 DB3 DB2 DB1 DB0

MODE

BITS

MSB LSB

1 0 A3 A2 A1 A0 0 0 0 0 0 DB6 DB5 DB4 DB3 DB2 DB1 DB0

MODE

BITS

ADDRESS

BITS

ADDRESS

BITS

7 INCREMENT

BITS

7 DECREMENT

BITS

Figure 5. Mode 2 Data Format

–10–

REV. 0

AD5516

The user must allow 200 ns (min) between two consecutive

Mode 2 writes in standalone mode and 400 ns (min) between

two consecutive Mode 2 writes in daisy-chain mode.

See Figures 4 and 5 for Mode 1 and Mode 2 data formats.

When MODE bits = 11, the device is in No Operation mode.

This may be useful in daisy-chain applications where the user

does not wish to change the settings of the DACs. Simply write

11 to the MODE bits and the following address and data bits

will be ignored.

SERIAL INTERFACE

The AD5516 has a 3-wire interface that is compatible with SPI/

QSPI/MICROWIRE and DSP interface standards. Data is written

to the device in 18-bit words. This 18-bit word consists of two

mode bits, four address bits, and 12 data bits as shown in Figure 4.

The serial interface works with both a continuous and burst

clock. The first falling edge of SYNC resets a counter that counts

the number of serial clocks to ensure the correct number of bits

are shifted in and out of the serial shift registers. Any further

edges on SYNC are ignored until the correct number of bits are

shifted in or out. In order for another serial transfer to take

place, the counter must be reset by the falling edge of SYNC.

A3–A0

Four address bits (A3 = MSB Address, A0 = LSB). These are

used to address one of 16 DACs.

Table II. Selected DAC

A3 A2 A1 A0 Selected DAC

0 0 0 0 DAC 0

0 0 0 1 DAC 1

::::

1 1 1 1 DAC 15

DB11–DB0

These are used to write a 12-bit word into the addressed DAC

register. Figures 1 and 2 show the timing diagram for a write

cycle to the AD5516.

SYNC FUNCTION

In both standalone and daisy-chain modes, SYNC is an edgetriggered input that acts as a frame synchronization signal and

chip enable. Data can only be transferred into the device while

SYNC is low. To start the serial data transfer, SYNC should be

taken low observing the minimum SYNC falling to SCLK falling

edge setup time, t

Standalone Mode (DCEN = 0)

.

3

After SYNC goes low, serial data will be shifted into the device’s

input shift register on the falling edges of SCLK for 18 clock

pulses. After the falling edge of the 18th SCLK pulse, data will

automatically be transferred from the input shift register to the

addressed DAC.

SYNC must be taken high and low again for further serial data

transfer. SYNC may be taken high after the falling edge of the

18th SCLK pulse, observing the minimum SCLK falling edge

to SYNC rising edge time, t

. If SYNC is taken high before the

6

18th falling edge of SCLK, the data transfer will be aborted and

the addressed DAC will not be updated. See the timing diagram

in Figure 1.

Daisy-Chain Mode (DCEN = 1)

n daisy-chain mode, the internal gating on SCLK is disabled.

I

The SCLK is continuously applied to the input shift register

when SYNC is low. If more than 18 clock pulses are applied,

the data ripples out of the shift register and appears on the D

OUT

line. This data is clocked out on the rising edge of SCLK and is

valid on the falling edge. By connecting this line to the D

IN

input on the next device in the chain, a multidevice interface is

constructed. Eighteen clock pulses are required for each device

in the system. Therefore, the total number of clock cycles must

equal 18N where N is the total number of devices in the chain.

See the timing diagram in Figure 2.

When the serial transfer to all devices is complete, SYNC should

be taken high. This prevents any further data being clocked into the

input shift register. A burst clock containing the exact number of

clock cycles may be used and SYNC taken high some time later.

After the rising edge of SYNC, data is automatically transferred

from each device’s input shift register to the addressed DAC.

RESET Function

The RESET function on the AD5516 can be used to reset all

nodes on this device to their power-on reset condition. This is

implemented by applying a low-going pulse of minimum 20 ns

to the RESET Pin on the device.

Table III. Typical Power-ON Values

Device Output Voltage

AD5516-1 –0.073 V

AD5516-2 –0.183 V

AD5516-3 –0.391 V

BUSY Output

During conversion, the BUSY output is low and all SCLK

pulses are ignored. At the end of a conversion, BUSY goes high

indicating that the update of the addressed DAC is complete. It

is recommended that SCLK is not pulsed while BUSY is low.

MICROPROCESSOR INTERFACING

The AD5516 is controlled via a versatile 3-wire serial interface

that is compatible with a number of microprocessors and DSPs.

AD5516 to ADSP-2106x SHARC DSP Interface

The ADSP-2106x SHARC DSPs are easily interfaced to the

AD5516 without the need for extra logic.

The AD5516 expects a t

(SYNC falling edge to SCLK falling

3

edge setup time) of 15 ns min. Consult the ADSP-2106x User

Manual for information on clock and frame sync frequencies for

the SPORT register and contents of the TDIV, RDIV registers.

REV. 0

–11–

AD5516

A data transfer is initiated by writing a word to the TX register

after the SPORT has been enabled. In write sequences data is

clocked out on each rising edge of the DSP’s serial clock and

clocked into the AD5516 on the falling edge of its SCLK. The

SPORT transmit control register should be set up as follows:

DTYPE = 00, Right Justify Data

ICLK = 1, Internal Serial Clock

TFSR = 1, Frame Every Word

INTF = 1, Internal Frame Sync

LTFS = 1, Active Low Frame Sync Signal

LAFS = 0, Early Frame Sync

SENDN = 0, Data Transmitted MSB First

SLEN = 10011, 18-Bit Data Words (SLEN = Serial Word)

Figure 6 shows the connection diagram.

AD5516*

SYNC

D

IN

SCLK

*ADDITIONAL PINS OMITTED FOR CLARITY

ADSP-2106x*

TFS

DT

SCLK

Figure 6. AD5516 to ADSP-2106x Interface

AD5516 to MC68HC11

The serial peripheral interface (SPI) on the MC68HC11 is

configured for master mode (MSTR = 1), clock polarity bit

(CPOL) = 0, and the clock phase bit (CPHA) = 1. The SPI is

configured by writing to the SPI control register (SPCR)—see

the 68HC11 User Manual. SCK of the 68HC11 drives the SCLK

of the AD5516, the MOSI output drives the serial data line

) of the AD5516. The SYNC signal is derived from a port

(D

IN

line (PC7). When data is being transmitted to the AD5516, the

SYNC line is taken low (PC7). Data appearing on the MOSI

output is valid on the falling edge of SCK. Serial data from the

68HC11 is transmitted in 8-bit bytes with only eight falling

clock edges occurring in the transmit cycle. Data is transmitted

MSB first. In order to transmit 18 data bits, it is important to

left justify the data in the SPDR register. PC7 must be pulled

low to start a transfer and taken high and low again before any

further read/write cycles can take place. A connection diagram is

shown in Figure 7.

AD5516*

SYNC

SCLK

D

IN

*ADDITIONAL PINS OMITTED FOR CLARITY

MC68HC11*

PC7

SCK

MOSI

Figure 7. AD5516 to MC68HC11 Interface

AD5516 to PIC16C6x/7x

The PIC16C6x/7x synchronous serial port (SSP) is configured

as an SPI master with the clock polarity bit (CKP) = 0. This is

done by writing to the synchronous serial port control register

(SSPCON). See user PIC16/17 Microcontroller User Manual.

In this example, I/O port RA1 is being used to provide a SYNC

signal and enable the serial port of the AD5516. This microcontroller transfers only eight bits of data during each serial transfer

operation; therefore, three consecutive write operations are

required. Figure 8 shows the connection diagram.

AD5516*

SCLK

D

IN

SYNC

*ADDITIONAL PINS OMITTED FOR CLARITY

PIC16C6x/7x*

SCK/RC3

SDI/RC4

RA1

Figure 8. AD5516 to PIC16C6x/7x Interface

AD5516 to 8051

A serial interface between the AD5516 and the 80C51/80L51

microcontroller is shown in Figure 9. The AD5516 requires a

clock synchronized to the serial data. The 8051 serial interface

must therefore be operated in Mode 0. TxD of the microcontroller drives the SCLK of the AD5516, while RxD drives the

serial data line. P3.3 is a bit programmable pin on the serial port

that is used to drive SYNC. The 80C51/80L51 provides the

LSB first, while the AD5516 expects MSB of the 18-bit word

first. Care should be taken to ensure the transmit routine takes

this into account.

AD5516*

SCLK

D

IN

SYNC

*ADDITIONAL PINS OMITTED FOR CLARITY

8051*

TxD

RxD

P1.1

Figure 9. AD5516 to 8051 Interface

When data is to be transmitted to the DAC, P3.3 is taken

low. Data on RxD is valid on the falling edge of TxD, so the

clock must be inverted as the AD5516 clocks data into the

input shift register on the rising edge of the serial clock. The

80C51/80L51 transmits its data in 8-bit bytes with only eight

falling clock edges occurring in the transmit cycle. As the DAC

requires an 18-bit word, P3.3 must be left low after the first eight

bits are transferred, and brought high after the complete 18 bits

have been transferred. DOUT may be tied to RxD for data verification purposes when the device is in daisy-chain mode.

–12–

REV. 0

AD5516

APPLICATION CIRCUITS

The AD5516 is suited for use in many applications, such as level

setting, optical, industrial systems, and automatic test applications. In level setting and servo applications where a fine-tune

adjust is required, the Mode 2 function increases resolution.

The following figures show the AD5516 used in some potential

applications.

AD5516 in a Typical ATE System

The AD5516 is ideally suited for the level setting function in

automatic test equipment. A number of DACs are required to

control pin drivers, comparators, active loads, parametric measurement units, and signal timing. Figure 10 shows the AD5516

in such a system.

STORED

DATA AND

INHIBIT

PATTERN

PERIOD

GENERATION

AND

DELAY

TIMING

DACs

DAC

DAC

DAC

FORMATTER

COMPARE

REGISTER

SYSTEM BUS

ACTIVE

LOAD

DRIVER

PARAMETRIC

MEASUREMENT

UNIT

DAC

DAC

COMPARATOR

SYSTEM BUS

DUT

DAC

DAC

Figure 10. AD5516 in an ATE System

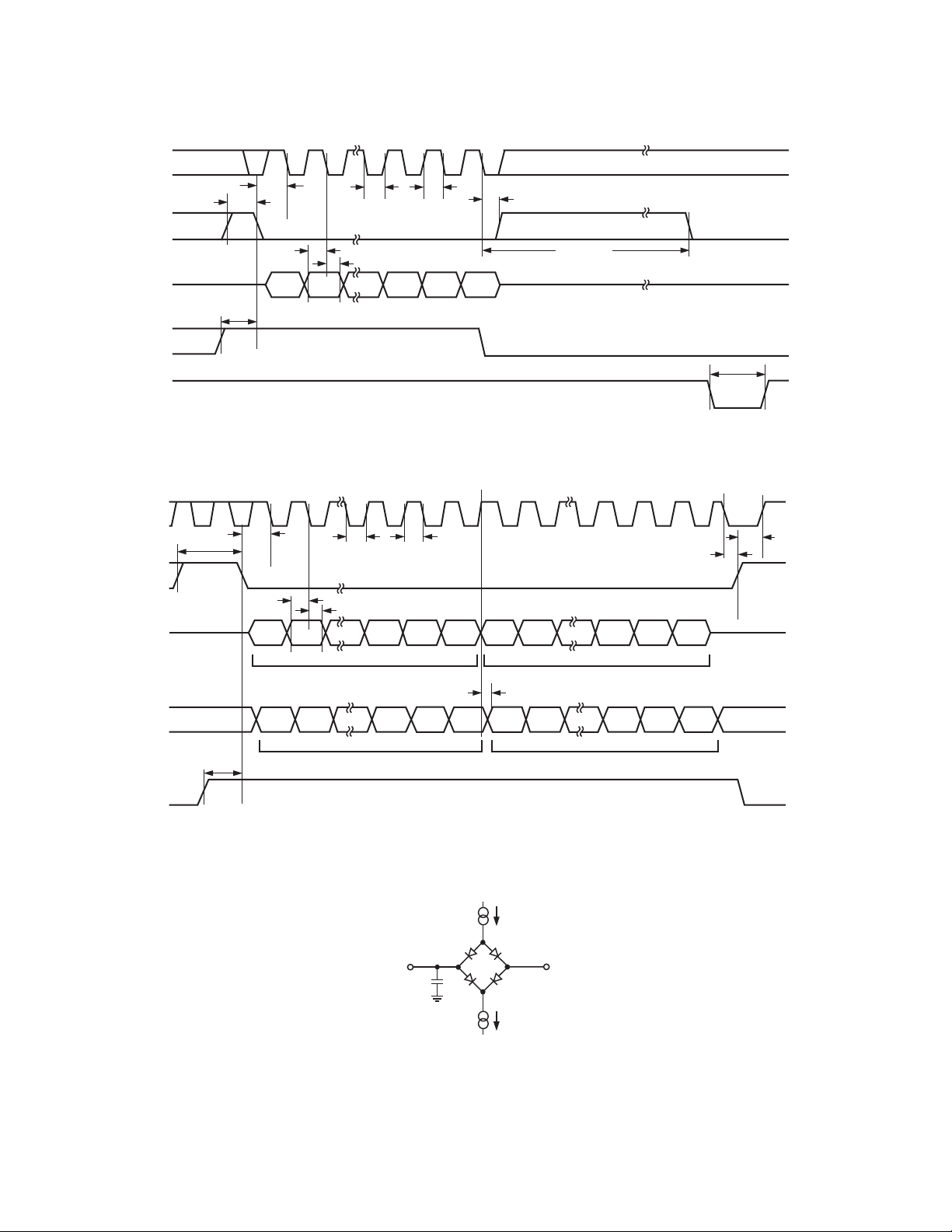

AD5516 in an Optical Network Control Loop

The AD5516 can be used in optical network control applications that require a large number of DACs to perform a control

and measurement function. In the example shown below, the

outputs of the AD5516 are fed into amplifiers and used to control

actuators that determine the position of MEMS mirrors in an

optical switch. The exact position of each mirror is measured and

the readings are multiplexed into an 8-channel, 14-bit ADC

(AD7865). The increment and decrement modes of the DACs are

useful in this application as it allows the user 14-bit resolution.

The control loop is driven by an ADSP-2106x, a 32-bit

SHARC DSP.

POWER SUPPLY DECOUPLING

In any circuit where accuracy is important, careful consideration

of the power supply and ground return layout helps to ensure the

rated performance. The printed circuit board on which the AD5516

is mounted should be designed so that the analog and digital

sections are separated and confined to certain areas of the board. If

the AD5516 is in a system where multiple devices require an

AGND-to-DGND connection, the connection should be made at

one point only. The star ground point should be established as

close as possible to the device. For supplies with multiple pins

1, AVCC2) it is recommended to tie those pins together. The

(AV

CC

AD5516 should have ample supply bypassing of 10 µF in parallel

with 0.1 µF on each supply located as closely to the package as

possible, ideally right up against the device. The 10 µF capacitors

are the tantalum bead type. The 0.1 µF capacitor should have low

effective series resistance (ESR) and effective series inductance

(ESI), like the common ceramic types that provide a low-impedance

path to ground at high frequencies, to handle transient currents

due to internal logic switching.

The power supply lines of the AD5516 should use as large a trace

as possible to provide low-impedance paths and reduce the effects

of glitches on the power supply line. Fast switching signals such

as clocks should be shielded with digital ground to avoid radiating

noise to other parts of the board, and should never be run near

the reference inputs. A ground line routed between the D

IN

and

SCLK lines will help reduce crosstalk between them (not required

on a multilayer board as there will be a separate ground plane, but

separating the lines will help). It is essential to minimize noise

on REFIN.

Avoid crossover of digital and analog signals. Traces on opposite

sides of the board should run at right angles to each other. This

reduces the effects of feedthrough through the board. A microstrip technique is by far the best, but not always possible with a

double-sided board. In this technique, the component side of

the board is dedicated to ground plane while signal traces are

placed on the solder side.

As is the case for all thin packages, care must be taken to avoid

flexing the package and to avoid a point load on the surface of

the package during the assembly process.

S

E

0

N

S

O

15

R

S

ADSP-2106x

ADG609

ⴛ 2

AD5516

0

15

MEMS

MIRROR

ARRAY

Figure 11. AD5516 in an Optical Control Loop

REV. 0

0

7

AD8644

ⴛ 2

AD7865

–13–

AD5516

OUTLINE DIMENSIONS

Dimensions shown in millimeters and (inches)

74-Lead LFBGA

(BC-74)

A1 CORNER

INDEX CORNER

1.70

(0.0669)

MAX

12.00 (0.4724) BSC

TOP VIEW

12.00

(0.4724)

BSC

DETAIL A

1.00

(0.0394)

BSC

10.00 (0.3937) BSC

11 10 9 8 7 6 5 4 3 2 1

BOTTOM

VIEW

1.00 (0.0394) BSC

DETAIL A

0.50

(0.0197)

MIN

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF MILLIMETER EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN

COMPLIANT TO JEDEC STANDARDS MO-192

0.63 (0.0248)

BSC

BALL DIAMETER

SEATING

PLANE

A1 CORNER

INDEX CORNER

A

B

C

D

10.00

E

(0.3937)

F

BSC

G

H

J

K

L

–14–

REV. 0

–15–

C02792–0–5/02(0)

–16–

PRINTED IN U.S.A.

Loading...

Loading...