Precision

www.BDTIC.com/ADI

FEATURES

Low noise: 0.3 μV p-p at 0.1 Hz to 10 Hz

Low nonlinearity: 0.003% (G = 1)

High CMRR: 120 dB (G = 1000)

Low offset voltage: 50 μV

Low offset voltage drift: 0.5 μV/°C

Gain bandwidth product: 25 MHz

Pin programmable gains of 1, 10, 100, 1000

Input protection, power-on/power-off

No external components required

Internally compensated

MIL-STD-883B and chips available

16-lead ceramic DIP and SOIC packages and 20-terminal

leadless chip carrier available

Available in tape and reel in accordance with EIA-481A

standard

Standard military drawing also available

GENERAL DESCRIPTION

The AD524 is a precision monolithic instrumentation amplifier

designed for data acquisition applications requiring high accuracy under worst-case operating conditions. An outstanding

combination of high linearity, high common-mode rejection,

low offset voltage drift, and low noise makes the AD524 suitable

for use in many data acquisition systems.

The AD524 has an output offset voltage drift of less than

25 μV/°C, input offset voltage drift of less than 0.5 μV/°C, CMR

above 90 dB at unity gain (120 dB at G = 1000), and maximum

nonlinearity of 0.003% at G = 1. In addition to the outstanding

dc specifications, the AD524 also has a 25 kHz bandwidth

(G = 1000). To make it suitable for high speed data acquisition

systems, the AD524 has an output slew rate of 5 V/μs and settles

in 15 μs to 0.01% for gains of 1 to 100.

As a complete amplifier, the AD524 does not require any external components for fixed gains of 1, 10, 100 and 1000. For other

gain settings between 1 and 1000, only a single resistor is required.

The AD524 input is fully protected for both power-on and

power-off fault conditions.

The AD524 IC instrumentation amplifier is available in four

different versions of accuracy and operating temperature range.

The economical A grade, the low drift B grade, and lower drift,

Instrumentation Amplifier

AD524

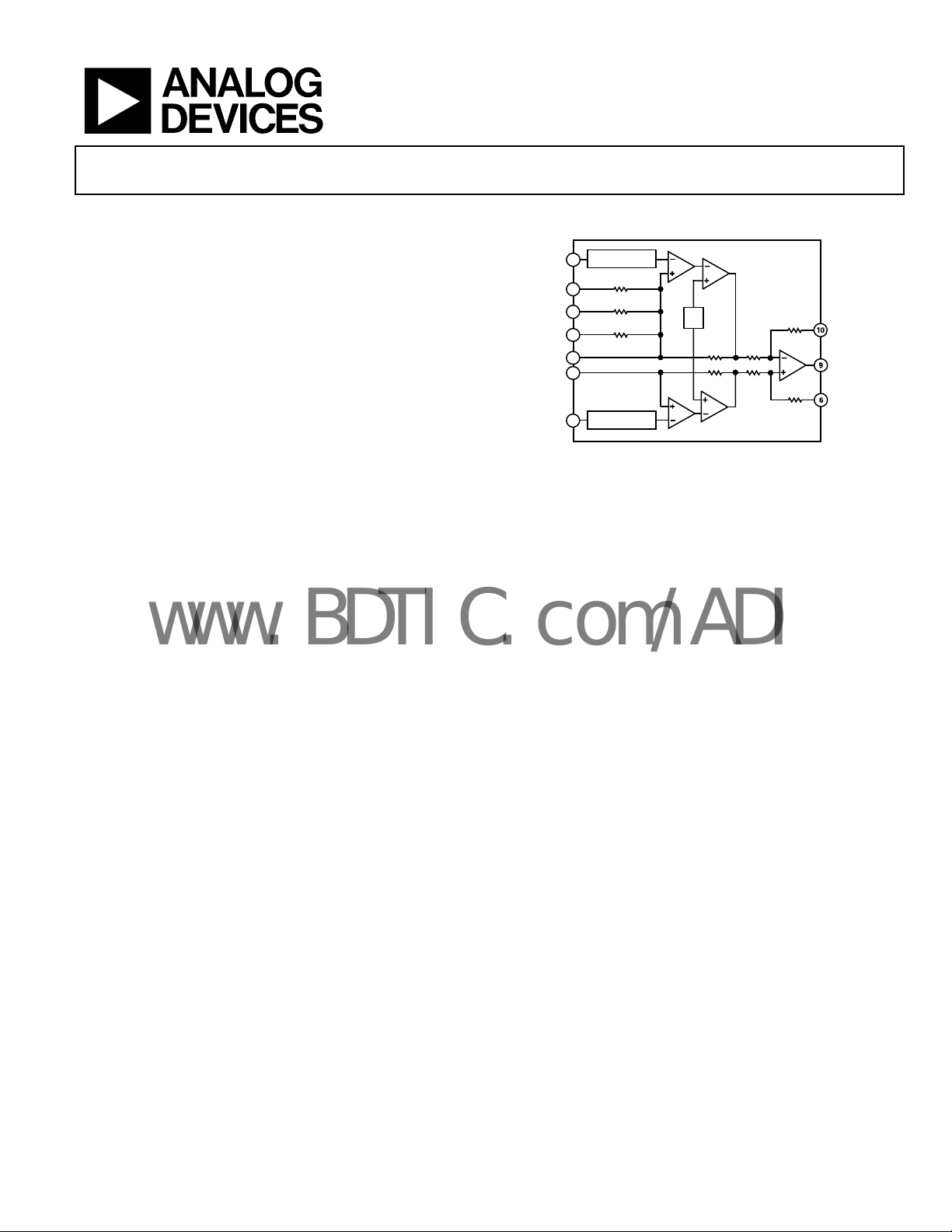

FUNCTIONAL BLOCK DIAGRAM

PROTECTION

1

– INPUT

G = 10

G = 100

G = 1000

RG

RG

+ INPUT

1

2

12

11

16

3

2

PROTECTION

404Ω

40Ω

V

b

20kΩ

20kΩ

Figure 1.

4.44kΩ

13

higher linearity C grade are specified from −25°C to +85°C.

The S grade guarantees performance to specification over the

extended temperature range −55°C to +125°C. The AD524 is

available in a 16-lead ceramic DIP, 16-lead SBDIP, 16-lead SOIC

wide packages, and 20-terminal leadless chip carrier.

PRODUCT HIGHLIGHTS

1. The AD524 has guaranteed low offset voltage, offset

voltage drift, and low noise for precision high gain

applications.

2. The AD524 is functionally complete with pin program-

mable gains of 1, 10, 100, and 1000, and single resistor

programmable for any gain.

3. Input and output offset nulling terminals are provided for

very high precision applications and to minimize offset

voltage changes in gain ranging applications.

4. The AD524 is input protected for both power-on and

power-off fault conditions.

5. The AD524 offers superior dynamic performance with a

gain bandwidth product of 25 MHz, full power response of

75 kHz and a settling time of 15 μs to 0.01% of a 20 V step

(G = 100).

20kΩ

20kΩ

AD524

20kΩ

20kΩ

SENSE

OUTPUT

REFERENCE

00500-001

Rev. F

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

AD524

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 8

Connection Diagrams .................................................................. 8

ESD Caution .................................................................................. 8

Typical Performance Characteristics ............................................. 9

Test Circuits ................................................................................. 14

Theory of Operation ...................................................................... 15

Input Protection .......................................................................... 15

REVISION HISTORY

11/07—Rev. E to Rev. F

Updated Format .................................................................. Universal

Changes to General Description .................................................... 1

Changes to Figure 1 .......................................................................... 1

Changes to Figure 3 and Figure 4 Captions .................................. 8

Changes to Error Budget Analysis Section ................................. 21

Changes to Ordering Guide .......................................................... 25

4/99—Rev. D to Rev. E

Input Offset and Output Offset ................................................ 15

Gain .............................................................................................. 16

Input Bias Currents .................................................................... 17

Common-Mode Rejection ........................................................ 17

Grounding ................................................................................... 18

Sense Terminal ............................................................................ 18

Reference Terminal .................................................................... 18

Programmable Gain ................................................................... 20

Autozero Circuits ....................................................................... 20

Error Budget Analysis ................................................................ 21

Outline Dimensions ....................................................................... 24

Ordering Guide .......................................................................... 25

Rev. F | Page 2 of 28

AD524

www.BDTIC.com/ADI

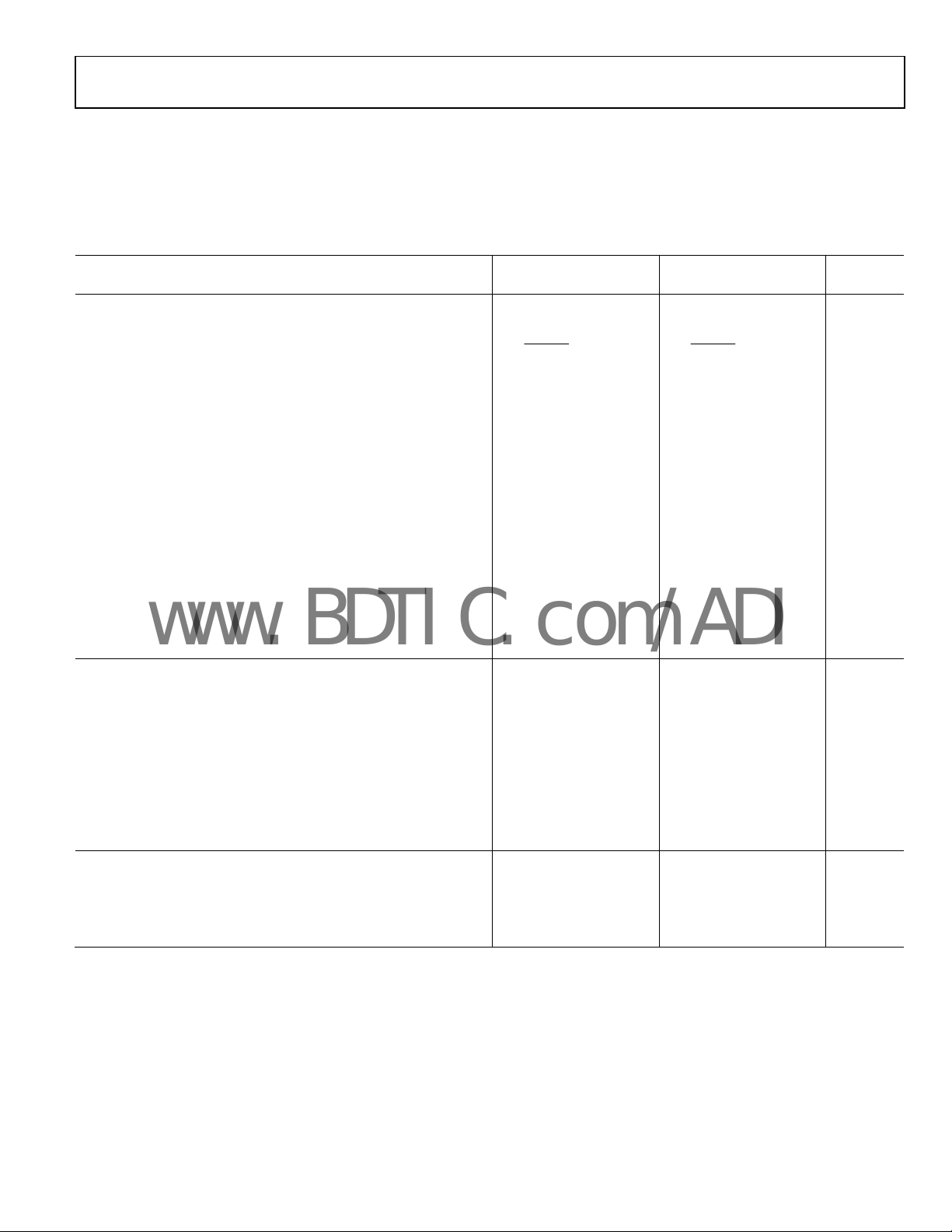

SPECIFICATIONS

@ VS = ±15 V, RL = 2 kΩ and TA = +25°C, unless otherwise noted.

All min and max specifications are guaranteed. Specifications shown in boldface are tested on all production units at the final electrical

test. Results from those tests are used to calculate outgoing quality levels.

Table 1.

AD524A AD524B

Parameter Min Typ Max Min Typ Max Unit

GAIN

Gain Equation (External Resistor Gain Programming)

Gain Range (Pin Programmable) 1 to 1000 1 to 1000

Gain Error

Nonlinearity

Gain vs. Temperature

VOLTAGE OFFSET (May be Nulled)

Input Offset Voltage

Output Offset Voltage 5

Offset Referred to the Input vs. Supply

INPUT CURRENT

Input Bias Current

Input Offset Current

1

G = 1

G = 10

G = 100

G = 1000

G = 1 ±0.01 ±0.005 %

G = 10, G = 100 ±0.01 ±0.005 %

G = 1000 ±0.01 ±0.01 %

G = 1 5 5 ppm/°C

G = 10 15 10 ppm/°C

G = 100 35 25 ppm/°C

G = 1000 100 50 ppm/°C

vs. Temperature 2

vs. Temperature 100

G = 1

G = 10

G = 100

G = 1000

vs. Temperature ±100 ±100 pA/°C

vs. Temperature ±100 ±100 pA/°C

70

85

95

100

⎡

⎢

R

⎣

⎤

000,40

+

G

±

⎥

⎦

%201

±0.05

±0.25

±0.5

±2.0

250

±50

±35

⎡

⎢

⎣

75

95

105

110

⎤

000,40

+

R

⎥

G

⎦

dB

dB

dB

dB

±

±0.03

±0.15

±0.35

±1.0

100

0.75

3

50

±25

±15

%201

%

%

%

%

μV

μV/°C

mV

μV

nA

nA

Rev. F | Page 3 of 28

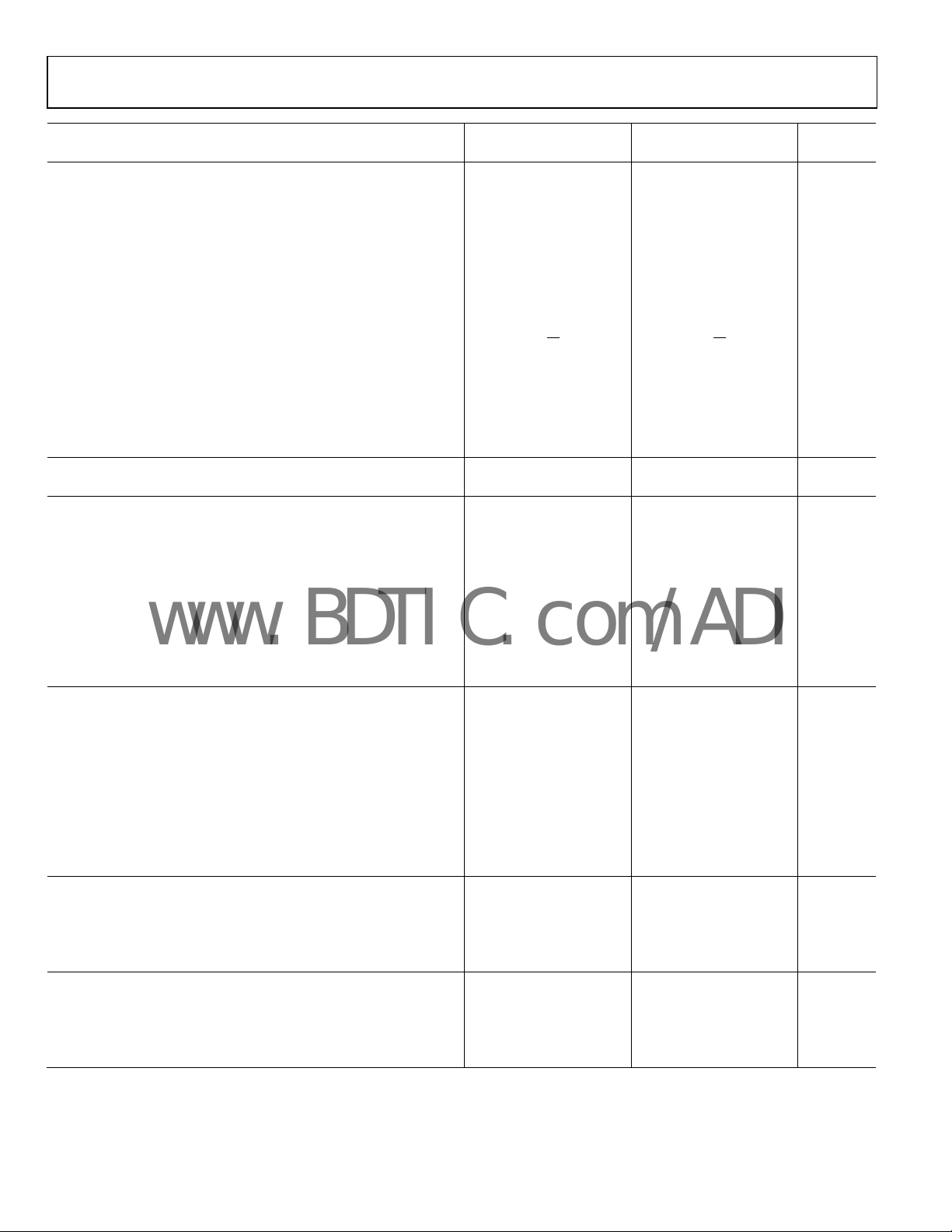

AD524

www.BDTIC.com/ADI

AD524A AD524B

Parameter Min Typ Max Min Typ Max Unit

INPUT

Input Impedance

Differential Resistance 109 109 Ω

Differential Capacitance 10 10 pF

Common-Mode Resistance 109 109 Ω

Common-Mode Capacitance 10 10 pF

Input Voltage Range

Maximum Differential Input Linear (VDL)

Maximum Common-Mode Linear (VCM)

Common-Mode Rejection DC to 60 Hz with 1 kΩ Source Imbalance V

G = 1

G = 10

G = 100

G = 1000

OUTPUT RATING

V

, RL = 2 kΩ ±10 ±10 V

OUT

DYNAMIC RESPONSE

Small Signal – 3 dB

G = 1 1 1 MHz

G = 10 400 400 kHz

G = 100 150 150 kHz

G = 1000 25 25 kHz

Slew Rate 5.0 5.0 V/μs

Settling Time to 0.01%, 20 V Step

G = 1 to 100 15 15 μs

G = 1000 75 75 μs

NOISE

Voltage Noise, 1 kHz

RTI 7 7 nV/√Hz

RTO 90 90 nV√Hz

RTI, 0.1 Hz to 10 Hz

G = 1 15 15 μV p-p

G = 10 2 2 μV p-p

G = 100, 1000 0.3 0.3 μV p-p

Current Noise

0.1 Hz to 10 Hz 60 60 pA p-p

SENSE INPUT

RIN 20 20 kΩ ± 20%

IIN 15 15 μA

Voltage Range ±10 ±10 V

Gain to Output 1 1 %

REFERENCE INPUT

RIN 40 40 kΩ ± 20%

IIN 15 15 μA

Voltage Range ±10 ±10 V

Gain to Output 1 1 %

2

±10 ±10 V

2

70

90

100

110

G

⎛

V12

⎜

⎝

⎞

×−

V

⎟

D

2

⎠

G

75

95

105

115

⎛

V12

⎜

⎝

dB

dB

dB

dB

⎞

×−

V

⎟

D

2

⎠

V

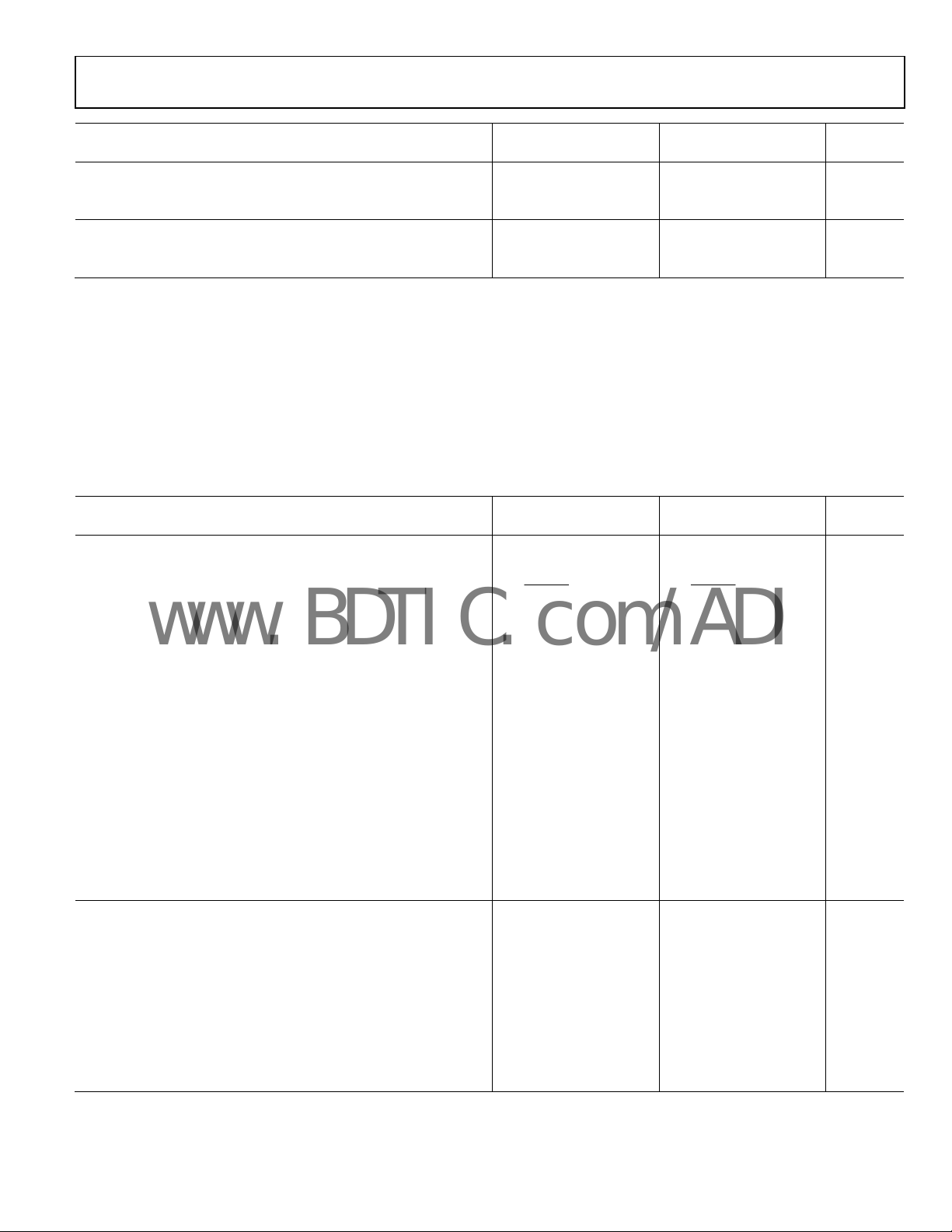

Rev. F | Page 4 of 28

AD524

www.BDTIC.com/ADI

AD524A AD524B

Parameter Min Typ Max Min Typ Max Unit

TEMPERATURE RANGE

Specified Performance –25 +85 –25 +85 °C

Storage –65 +150 –65 +150 °C

POWER SUPPLY

Power Supply Range

Quiescent Current 3.5

1

Does not include effects of external resistor, RG.

2

VOL is the maximum differential input voltage at G = 1 for specified nonlinearity.

VDL at the maximum = 10 V/G.

VD = actual differential input voltage.

Example: G = 10, V

V

= 12 V − (10/2 × 0.50 V) = 9.5 V.

CM

= 0.50.

D

±6

@ V

= ±15 V, RL = 2 kΩ and TA = +25°C, unless otherwise noted.

S

All min and max specifications are guaranteed. Specifications shown in boldface are tested on all production units at the final electrical

test. Results from those tests are used to calculate outgoing quality levels.

Table 2.

AD524C AD524S

Parameter Min Typ Max Min Typ Max Unit

GAIN

Gain Equation (External Resistor Gain Programming)

Gain Range (Pin Programmable) 1 to 1000 1 to 1000

Gain Error

Nonlinearity

Gain vs. Temperature

VOLTAGE OFFSET (May be Nulled)

Input Offset Voltage

Output Offset Voltage

Offset Referred to the Input vs. Supply

1

G = 1

G = 10

G = 100

G = 1000

G = 1 ±0.003 ±0.01 %

G = 10, G = 100 ±0.003 ±0.01 %

G = 1000 ±0.01 ±0.01 %

G = 1 5 5 ppm/°C

G = 10 10 10 ppm/°C

G = 100 25 25 ppm/°C

G = 1000 50 50 ppm/°C

vs. Temperature

vs. Temperature

G = 1

G = 10

G = 100

G = 1000

80

100

110

115

±15

⎡

000,40

⎢

⎣

+

R

G

±18 ±6

5.0

⎤

±

⎥

3.5

%201

⎦

±0.02

±0.1

±0.25

±0.5

50

0.5

2.0

25

75

95

105

110

±15

⎡

000,40

⎢

R

G

⎣

dB

dB

dB

dB

±18

5.0

⎤

+

⎥

%201

±

⎦

±0.05

±0.25

±0.5

±2.0

100

2.0

3.0

50

V

mA

%

%

%

%

μV

μV/°C

mV

μV

Rev. F | Page 5 of 28

AD524

www.BDTIC.com/ADI

AD524C AD524S

Parameter Min Typ Max Min Typ Max Unit

INPUT CURRENT

Input Bias Current

vs. Temperature ±100 ±100 pA/°C

Input Offset Current

vs. Temperature ±100 ±100 pA/°C

INPUT

Input Impedance

Differential Resistance 109 109 Ω

Differential Capacitance 10 10 pF

Common-Mode Resistance 109 109 Ω

Common-Mode Capacitance 10 10 pF

Input Voltage Range

Maximum Differential Input Linear (VDL)

Maximum Common-Mode Linear (VCM)

2

±10 ±10 V

2

V12

Common-Mode Rejection DC to 60 Hz with 1 kΩ Source Imbalance V

G = 1

G = 10

G = 100

G = 1000

OUTPUT RATING

V

, RL = 2 kΩ ±10 ±10 V

OUT

DYNAMIC RESPONSE

Small Signal – 3 dB

G = 1 1 1 MHz

G = 10 400 400 kHz

G = 100 150 150 kHz

G = 1000 25 25 kHz

Slew Rate 5.0 5.0 V/μs

Settling Time to 0.01%, 20 V Step

G = 1 to 100 15 15 μs

G = 1000 75 75 μs

NOISE

Voltage Noise, 1 kHz

RTI 7 7 nV/√Hz

RTO 90 90 nV√Hz

RTI, 0.1 Hz to 10 Hz

G = 1 15 15 μV p-p

G = 10 2 2 μV p-p

G = 100, 1000 0.3 0.3 μV p-p

Current Noise

0.1 Hz to 10 Hz 60 60 pA p-p

SENSE INPUT

RIN 20 20 kΩ ± 20%

IIN 15 15 μA

Voltage Range ±10 ±10 V

Gain to Output 1 1 %

80

100

110

120

±15

±10

G

⎛

⎜

⎝

⎞

V

×−

⎟

D

2

⎠

70

90

100

110

±50

±35

G

⎛

V12

⎜

⎝

dB

dB

dB

dB

⎞

V

×−

⎟

D

2

⎠

nA

nA

V

Rev. F | Page 6 of 28

AD524

www.BDTIC.com/ADI

AD524C AD524S

Parameter Min Typ Max Min Typ Max Unit

REFERENCE INPUT

RIN 40 40 kΩ ± 20%

IIN 15 15 μA

Voltage Range 10 10 V

Gain to Output 1 1 %

TEMPERATURE RANGE

Specified Performance –25 +85 –55 +85 °C

Storage –65 +150 –65 +150 °C

POWER SUPPLY

Power Supply Range

Quiescent Current 3.5

1

Does not include effects of external resistor RG.

2

VOL is the maximum differential input voltage at G = 1 for specified nonlinearity.

V

at the maximum = 10 V/G.

DL

VD = actual differential input voltage.

Example: G = 10, VD = 0.50.

VCM = 12 V − (10/2 × 0.50 V) = 9.5 V.

±6

±15

±18 ±6

5.0

3.5

±15

±18

5.0

V

mA

Rev. F | Page 7 of 28

AD524

O

O

www.BDTIC.com/ADI

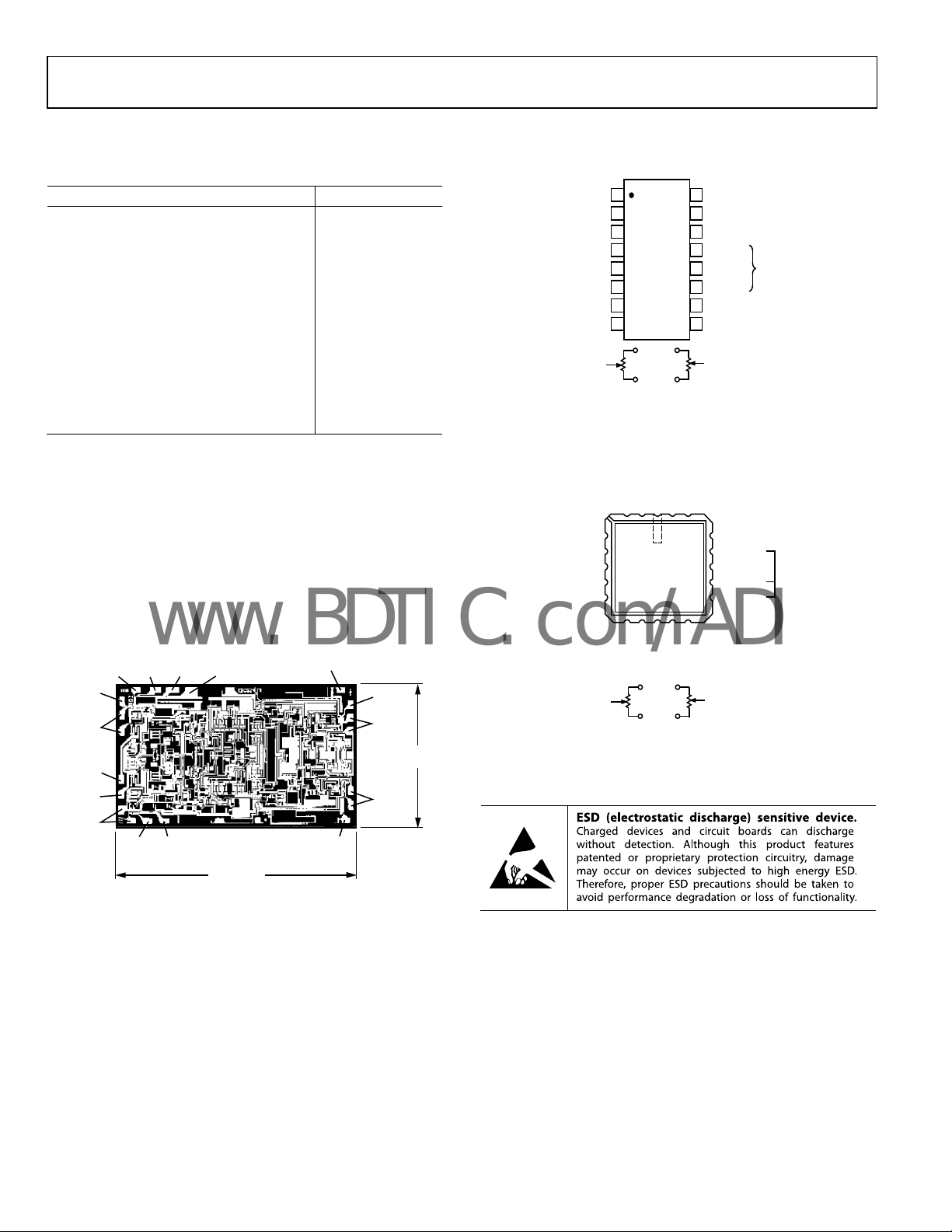

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Supply Voltage ±18 V

Internal Power Dissipation 450 mW

Input Voltage1

(Either Input Simultaneously) |VIN| + |VS| <36 V

Output Short-Circuit Duration Indefinite

Storage Temperature Range

(R) –65°C to +125°C

(D, E) –65°C to +150°C

Operating Temperature Range

AD524A/AD524B/AD524C –25°C to +85°C

AD524S –55°C to +125°C

Lead Temperature (Soldering, 60 sec) +300°C

1

Maximum input voltage specification refers to maximum voltage to which

either input terminal may be raised with or without device power applied.

For example, with ±18 volt supplies maximum, VIN is ±18 V; with zero supply

voltage maximum, VIN is ±36 V.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

OUTPUT

UTPUT

NULL

RG116

–INPUT

+INPUT

RG

G = 10

NULL

15

1

2

2

3

13

14

4

INPUT

NULL

PAD NUMBERS CORRESPOND TO PIN NUMBERS FOR

THE D-16 AND RW-16 16-L EAD CERAMIC PACKAGES.

G = 100

12

5

INPUT

NULL

G = 1000

11

0.170 (4.33)

SENSE

10

REFERENCE

Figure 2. Metallization Photograph

Contact factory for latest dimensions;

Dimensions shown in inches and (mm)

9

OUTPUT

8 +V

S

0.103

(2.61)

7 –V

S

6

00500-002

NC = NO CONNECT

ESD CAUTION

CONNECTION DIAGRAMS

1

– INPUT

2

+ INPUT

RG

3

2

AD524

INPUT NULL

INPUT NULL

REFERENCE

OFFSET NULL

INPUT NULL

INPUT NULL

REFERENCE

OFFSET NULL

4

TOP VIEW

5

(Not to Scale)

6

–V

7

S

+V

8

S

+V

INPUT

415

S

514

Figure 3. Ceramic (D) and

SOIC (RW-16 and D-16) Packages

1

RG

–INPUT3+INPUT

20

1NC2

4

RG

2

5

AD524

6

NC

7

8

+V

INPUT

S

TOP VIEW

(Not to Scal e)

11NC10

9

S

S

–V

+V

719

518

12

OUTPUT

Figure 4. Leadless Chip Carrier (E)

16

RG

1

15

OUTPUT NULL

14

OUTPUT NULL

13

G = 10

12

G = 100

11

G = 1000

10

SENSE

9

OUTPUT

–V

S

OUTPUT

OFFSET NULL

OUTPUT

NULL

19

18

OUTPUT NULL

17

G = 10

16

NC

15

G = 100

14

G = 1000

13

SENSE

–V

S

OUTPUT

OFFSET NULL

SHORT TO

RG

FOR

2

DESIRED

GAIN

SHORT T

RG2 FOR

DESIRED

GAIN

0500-003

00500-004

Rev. F | Page 8 of 28

AD524

www.BDTIC.com/ADI

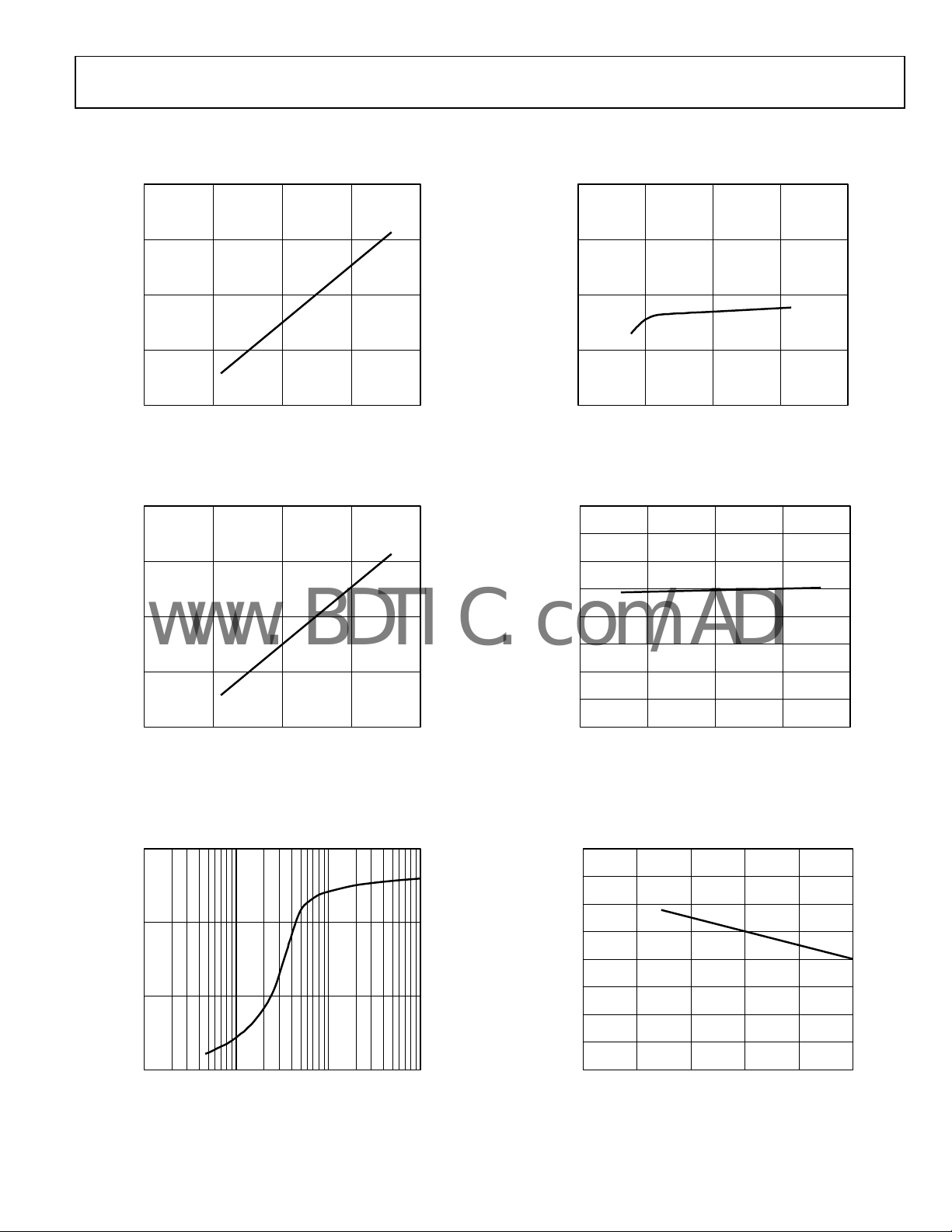

TYPICAL PERFORMANCE CHARACTERISTICS

20

15

10

+25°C

INPUT VOLTAGE (±V)

5

0

0 5 10 15 20

SUPPLY VOLTAGE (±V)

Figure 5. Input Voltage Range vs. Supply Voltage, G = 1

20

15

10

8

6

4

2

QUIESCE NT CURRENT (mA)

00500-005

0

0 5 10 15 20

SUPPLY VOLTAGE (±V)

00500-008

Figure 8. Quiescent Current vs. Supply Voltage

16

14

12

10

8

5

OUTPUT VOLTAGE SWING (±V)

0

0 5 10 15 20

SUPPLY VOLTAGE (±V)

Figure 6. Output Voltage Swing vs. Supply Voltage

30

20

10

OUTPUT VOLTAGE SWING (V p-p)

0

10 100 1k 10k

LOAD RESI STANCE (Ω)

Figure 7. Output Voltage Swing vs. Load Resistance

6

4

INPUT BI AS CURRENT (±n A)

2

00500-006

0

0 5 10 15 20

SUPPLY VOLTAG E (±V)

00500-009

Figure 9. Input Bias Current vs. Supply Voltage

40

30

20

10

0

–10

–20

INPUT BIAS CURRENT (n A)

–30

00500-007

–40

–75 –25 25 75 125

TEMPERATURE (°C)

00500-010

Figure 10. Input Bias Current vs. Temperature

Rev. F | Page 9 of 28

AD524

–

www.BDTIC.com/ADI

16

14

12

10

8

6

4

INPUT BIA S CURRENT (±n A)

2

0

0 5 10 15 20

INPUT VOLTAGE (±V)

Figure 11. Input Bias Current vs. Input Voltage

0

1

2

3

4

FROM FINAL VALUE (µV)

OS

5

ΔV

6

02461357

WARM-UP TIME (Minutes)

Figure 12. Offset Voltage, RTI, Turn-On Drift

00500-011

00500-012

8

140

G = 1000

G = 100

–120

G = 10

–100

G = 1

–80

–60

CMRR (dB)

–40

–20

0

0 100 10k 1M10 1k 100k 10M

FREQUENCY (Hz)

Figure 14. CMRR vs. Frequency, RTI, Zero to 1000 Source Imbalance

30

G = 1, 10, 100

20

10

FULL POWER RESPONSE (V p-p )

0

1k 10k 100k 1M

G = 1000 G = 100 G = 10

BANDWIDTH L IMIT ED

FREQUENCY ( Hz)

Figure 15. Large Signal Frequency Response

00500-014

00500-015

10

8

1000

100

10

GAIN (V/V)

1

0 100 10k 1M10 1k 100k 10M

FREQUENCY (Hz)

Figure 13. Gain vs. Frequency

00500-013

6

4

SLEW RATE (V/µs)

2

0

1 10 100 1000

Figure 16. Slew Rate vs. Gain

Rev. F | Page 10 of 28

G = 1000

00500-016

GAIN (V/V)

AD524

www.BDTIC.com/ADI

160

140

120

100

80

60

40

20

POWER SUPPLY REJECTI ON RATIO (dB)

0

100 10k10 1k 100k

FREQUENCY (Hz)

+VS = 15V DC +

1V p-p SINEWAVE

G

=

1

0

0

0

G

=

1

0

0

G

=

1

0

G

=

1

00500-017

Figure 17. Positive PSRR vs. Frequency

160

140

120

100

80

60

40

–VS = –15V DC +

1V p-p SINEWAVE

G

=

1

0

0

0

G

=

1

0

0

G

=

1

0

G

=

1

100k

10k

1k

100

CURRENT NOISE SPECTRAL DENSITY (fA/ Hz)

0 10k

1 10 100 1k

FREQUENCY (Hz)

Figure 20. Input Current Noise vs. Frequency

0.1Hz TO 10Hz

5mV 1s

00500-020

20

POWER SUPPLY REJECTI ON RATIO (dB)

0

100 10k10 1k 100k

FREQUENCY (Hz)

Figure 18. Negative PSRR vs. Frequency

1000

100

10

VOLT NSD (nV/ Hz)

1

0.1

1 100k

10 100 1k 10k

G = 1

G = 10

G = 100, 1000

FREQUENCY (Hz)

Figure 19. RTI Noise Spectral Density vs. Gain

G = 1000

00500-018

VERTICAL SCALE; 1 DI VISIO N = 5µV

00500-021

Figure 21. Low Frequency Noise, G = 1 (System Gain = 1000)

0.1Hz TO 10Hz

10mV 1s

00500-019

VERTICAL SCALE; 1 DIVISION = 0.1µV

00500-022

Figure 22. Low Frequency Noise, G = 1000 (System Gain = 100,000)

Rev. F | Page 11 of 28

AD524

–

www.BDTIC.com/ADI

–12 TO +12

–8 TO +8

–4 TO +4

OUTPUT

STEP (V)

+4 TO –4

1% 0.1% 0. 01%

1mV 10V 10µs

+8 TO –8

1% 0.1% 0.01%

+12 TO –12

0 5 10 15 20

SETTLING TIME (µs)

Figure 23. Settling Time, Gain = 1

10V 10µs1mV

Figure 24. Large Signal Pulse Response and Settling Time, Gain =1

00500-023

0500-026

Figure 26. Large Signal Pulse Response and Settling Time, Gain = 10

12 TO +12

–8 TO +8

–4 TO +4

OUTPUT

STEP (V)

+4 TO –4

+8 TO –8

+12 TO –12

0 5 10 15 20

00500-024

0.1%

1%

1%

0.1%

SETTLING TIME (µs)

0.01%

0.01%

00500-027

Figure 27. Settling Time, Gain = 100

–12 TO +12

–8 TO +8

–4 TO +4

OUTPUT

STEP (V)

+4 TO –4

+8 TO –8

+12 TO –12

1%

1% 0.1%

0 5 10 15 20

0.1%

SETTLING TIME (µs)

Figure 25. Settling Time, Gain = 10

0.01%

1mV 10V 10µs

0.01%

00500-025

Figure 28. Large Signal Pulse Response and Settling Time, Gain = 100

Rev. F | Page 12 of 28

0500-028

AD524

www.BDTIC.com/ADI

–12 TO +12

–8 TO +8

–4 TO +4

OUTPUT

STEP (V)

+4 TO –4

+8 TO –8

+12 TO –12

1% 0.01%

1% 0.01%

0 102030405060708

SETTLING TIME (µs)

Figure 29. Settling Time, Gain = 1000

0.1%

0.1%

00500-029

0

5mV 10V 20µs

0500-030

Figure 30. Large Signal Pulse Response and Settling Time, Gain = 1000

Rev. F | Page 13 of 28

AD524

www.BDTIC.com/ADI

TEST CIRCUITS

10kΩ

1kΩ

0.01%

INPUT

20V p-p

11kΩ

0.1%

100kΩ

0.1%

1kΩ

0.1%

100Ω

0.1%

RG

G = 10

G = 100

G = 1000

RG

1

2

+V

1

–

8

16

13

12

AD524

11

3

7

2

+

–V

Figure 31. Settling Time Test Circuit

+V

S

10kΩ

10T

0.1%

V

S

10

6

S

OUT

9

00500-031

V

B

R56

20kΩ

S

50µA

C4C3

RG

G = 100

G = 1000

I

2

Q2, Q4

2

I

4

50µA

–IN

CH

CH

CH2,

3

1

, CH

I

1

50µA

A1 A2

++

R57

20kΩ

4

Q1, Q3

4.44kΩ

RG

1

404Ω

I

50µA

3

40Ω

–V

Figure 32. Simplified Circuit of Amplifier; Gain Is Defined as

((R56 + R57)/(R

)) +1; For a Gain of 1, RG Is an Open Circuit

G

R53

20kΩ

R54

20kΩ

CH

, CH3,

2

CH

R52

20kΩ

SENSE

A3

V

O

R55

20kΩ

REFERENCE

4

CH

+IN

1

00500-032

Rev. F | Page 14 of 28

AD524

V

www.BDTIC.com/ADI

THEORY OF OPERATION

The AD524 is a monolithic instrumentation amplifier based

on the classic 3-op amp circuit. The advantage of monolithic

construction is the closely matched components that enhance

the performance of the input preamplifier. The preamplifier

section develops the programmed gain by the use of feedback

concepts. The programmed gain is developed by varying the

value of R

(smaller values increase the gain) while the feedback

G

forces the collector currents (Q1, Q2, Q3, and Q4) to be constant,

which impresses the input voltage across R

is reduced to increase the programmed gain, the

As R

G

.

G

transconductance of the input preamplifier increases to the

transconductance of the input transistors. This has three

important advantages. First, this approach allows the circuit

to achieve a very high open-loop gain of 3 × 10

8

at a programmed

gain of 1000, thus reducing gain-related errors to a negligible

30 ppm. Second, the gain bandwidth product, which is determined by C3 or C4 and the input transconductance, reaches

25 MHz. Third, the input voltage noise reduces to a value

determined by the collector current of the input transistors

for an RTI noise of 7 nV/√Hz at G = 1000.

INPUT PROTECTION

As interface amplifiers for data acquisition systems, instrumentation amplifiers are often subjected to input overloads,

that is, voltage levels in excess of the full scale for the selected

gain range. At low gains (10 or less), the gain resistor acts as a

current limiting element in series with the inputs. At high gains,

the lower value of R

does not adequately protect the inputs

G

+

–

AD524

+

S

8

10

9

6

7

–V

S

G = 1000

100

1000

RG

1

16

10

13

12

11

2

3

2

16.2kΩ

1µF

G = 1, 10, 100

100Ω

from excessive currents. Standard practice is to place series

limiting resistors in each input, but to limit input current to

below 5 mA with a full differential overload (36 V) requires

over 7k of resistance, which adds 10 nV√Hz of noise. To

provide both input protection and low noise, a special series

protection FET is used.

A unique FET design was used to provide a bidirectional

current limit, thereby protecting against both positive and

negative overloads. Under nonoverload conditions, three

channels (CH

, CH3, CH4) act as a resistance (≈1 kΩ) in series

2

with the input as before. During an overload in the positive

direction, a fourth channel, CH

, acts as a small resistance

1

(≈3 kΩ) in series with the gate, which draws only the leakage

current, and the FET limits I

. When the FET enhances under

DSS

a negative overload, the gate current must go through the small

FET formed by CH

and when this FET goes into saturation,

1

the gate current is limited and the main FET goes into controlled

enhancement. The bidirectional limiting holds the maximum

input current to 3 mA over the 36 V range.

INPUT OFFSET AND OUTPUT OFFSET

Voltage offset specifications are often considered a figure of

merit for instrumentation amplifiers. While initial offset may

be adjusted to zero, shifts in offset voltage due to temperature

variations causes errors. Intelligent systems can often correct

this factor with an autozero cycle, but there are many smallsignal high-gain applications that do not have this capability.

AD712

+V

s

3

+

8

1/2

–

2

1µF

1

9.09kΩ

1kΩ

5

6

1.62MΩ

+

1/2

–

7

4

1µF

–V

S

16.2kΩ

1.82kΩ

Figure 33. Noise Test Circuit

Rev. F | Page 15 of 28

0500-033

AD524

–

Ω

V

V

www.BDTIC.com/ADI

Voltage offset and drift comprise two components each; input

and output offset and offset drift. Input offset is the component

of offset that is directly proportional to gain, that is, input offset

as measured at the output at G = 100 is 100 times greater than at

G = 1. Output offset is independent of gain. At low gains, output

offset drift is dominant, at high gains, input offset drift dominates.

Therefore, the output offset voltage drift is normally specified as

drift at G = 1 (where input effects are insignificant), whereas

input offset voltage drift is given by drift specification at a high

gain (where output offset effects are negligible). All input

related numbers are referred to the input (RTI) that is the effect

on the output is G times larger. Voltage offset vs. power supply

is also specified at one or more gain settings and is also RTI.

By separating these errors, one can evaluate the total error

independent of the gain setting used. In a given gain configuration, both errors can be combined to give a total error referred

to the input (RTI) or output (RTO) by the following formulas:

Total error RTI = input error + (output error/gain)

Total error RTO = (gain × input error) + output error

As an illustration, a typical AD524 might have a +250 µV

output offset and a −50 µV input offset. In a unity gain

configuration, the total output offset would be 200 µV or

the sum of the two. At a gain of 100, the output offset would

be −4.75 mV or: +250 µV + 100(−50 µV) = −4.75 mV.

The AD524 provides for both input and output offset adjustment.

This simplifies very high precision applications and minimizes

offset voltage changes in switched gain applications. In such

applications, the input offset is adjusted first at the highest

programmed gain, then the output offset is adjusted at G = 1.

GAIN

The AD524 has internal high accuracy pretrimmed resistors

for pin programmable gains of 1, 10, 100, and 1000. One of the

preset gains can be selected by pin strapping the appropriate

gain terminal and RG

INPUT

G = 100

G = 1000

RG

+INPUT

Figure 34. Operating Connections for G = 100

together (for G = 1, RG2 is not connected).

2

10kΩ

4

AD524

7

–V

S

INPUT

OFFSET

NULL

5

10

9

6

RG

G = 10

2

+V

S

8

1

16

1

13

12

11

3

2

V

OUT

OUTPUT

SIGNAL

COMMON

00500-034

The AD524 can be configured for gains other than those that

are internally preset; there are two methods to do this. The first

method uses just an external resistor connected between

Pin 3 and Pin 16 (see Figure 35), which programs the gain

according to the following formula:

k40

=

R

G

For best results, R

temperature coefficient. An external R

1

−=

G

should be a precision resistor with a low

G

affects both gain

G

accuracy and gain drift due to the mismatch between it and

the internal thin-film resistors. Gain accuracy is determined

by the tolerance of the external R

and the absolute accuracy

G

of the internal resistors (±20%). Gain drift is determined by the

mismatch of the temperature coefficient of R

and the tempera-

G

ture coefficient of the internal resistors (−50 ppm/°C typical).

+

S

–INPUT

1.5kΩ

1kΩ

+INPUT

RG

2.105kΩ

RG

1

16

1

13

12

11

2

2

3

8

AD524

7

–V

10

9

6

40,000

G = + 1 = 20 ±20%

S

2.105

V

OUT

REFERENCE

Figure 35. Operating Connections for G = 20

The second method uses the internal resistors in parallel with

an external resistor (see Figure 36). This technique minimizes

the gain adjustment range and reduces the effects of temperature coefficient sensitivity.

+

S

–INPUT

RG

1

G = 10

4kΩ

RG

+INPUT

2

*R|

= 4444.44Ω

G = 10

*R|

= 404.04Ω

G = 100

*R|

= 40.04Ω

G = 1000

*NOMINAL (±20%)

Figure 36. Operating Connections for G = 20, Low Gain

1

3

2

8

AD524

7

–V

S

10

6

G =

4000||4444.44

9

40,000

16

13

12

11

Temperature Coefficient Technique

V

OUT

REFERENCE

+ 1 = 20 ±17%

00500-035

00500-036

Rev. F | Page 16 of 28

AD524

T

V

V

www.BDTIC.com/ADI

The AD524 can also be configured to provide gain in the output

stage. Figure 37 shows an H pad attenuator connected

to the reference and sense lines of the AD524. R1, R2, and R3

should be made as low as possible to minimize the gain variation

and reduction of CMRR. Varying R2 precisely sets the gain

without affecting CMRR. CMRR is determined by the match

of R1 and R3.

+V

–INPUT

+INPUT

(R2||40kΩ) + R1 + R3

G =

(R2||40kΩ)

G = 10

G = 100

G = 1000

RG

RG

1

16

1

13

12

11

3

2

2

8

AD524

7

–V

S

10

6

S

(R1 + R2 + R3)||RL ≥ 2kΩ

R1

2.26kΩ

R2

5kΩ

9

R3

2.26kΩ

V

OU

R

L

00500-037

Figure 37. Gain of 2000

Table 4. Output Gain Resistor Values

Output Gain R2 R1, R3 Nominal Gain

2 5 kΩ 2.26 kΩ 2.02

5 1.05 kΩ 2.05 kΩ 5.01

10 1 kΩ 4.42 kΩ 10.1

INPUT BIAS CURRENTS

Input bias currents are those currents necessary to bias the

input transistors of a dc amplifier. Bias currents are an

additional source of input error and must be considered in

a total error budget. The bias currents, when multiplied by

the source resistance, appear as an offset voltage. What is of

concern in calculating bias current errors is the change in bias

current with respect to signal voltage and temperature. Input

offset current is the difference between the two input bias

currents. The effect of offset current is an input offset voltage

whose magnitude is the offset current times the source

impedance imbalance.

+V

S

2

+

8

3

11

12

AD524

13

16

1

–

Figure 38. Indirect Ground Returns for Bias Currents—Transformer Coupled

2

+

3

11

AD524

12

13

16

1

–

Figure 39. Indirect Ground Returns for Bias Currents—Thermocouple

10

9

6

7

–V

S

+V

S

8

7

–V

S

LOAD

TO POWER

SUPPLY

GROUND

10

9

6

LOAD

TO POWER

SUPPLY

GROUND

00500-038

00500-039

Rev. F | Page 17 of 28

+

S

2

+

8

3

11

12

13

16

1

AD524

–

10

9

6

7

–V

S

LOAD

TO POWER

SUPPLY

GROUND

00500-040

Figure 40. Indirect Ground Returns for Bias Currents–AC-Coupled

Although instrumentation amplifiers have differential inputs,

there must be a return path for the bias currents. If this is not

provided, those currents charge stray capacitances, causing the

output to drift uncontrollably or to saturate. Therefore, when

amplifying floating input sources such as transformers and

thermocouples, as well as ac-coupled sources, there must still

be a dc path from each input to ground.

COMMON-MODE REJECTION

Common-mode rejection is a measure of the change in output

voltage when both inputs are changed equal amounts. These

specifications are usually given for a full-range input voltage

change and a specified source imbalance. Common-mode

rejection ratio (CMRR) is a ratio expression whereas commonmode rejection (CMR) is the logarithm of that ratio. For

example, a CMRR of 10,000 corresponds to a CMR of 80 dB.

In an instrumentation amplifier, ac common-mode rejection is

only as good as the differential phase shift. Degradation of ac

common-mode rejection is caused by unequal drops across

differing track resistances and a differential phase shift due

to varied stray capacitances or cable capacitances. In many

applications, shielded cables are used to minimize noise. This

technique can create common-mode rejection errors unless the

shield is properly driven. Figure 41 and Figure 42 show active

data guards that are configured to improve ac common-mode

rejection by bootstrapping the capacitances of the input cabling,

thus minimizing differential phase shift.

+

–

+

1

1

16

12

3

2

2

8

AD524

7

–V

–

AD524

+

S

10

9

V

10

6

OUT

REFERENCE

9

V

OUT

REFERENCE

6

S

+V

S

8

7

–V

S

100Ω

100Ω

100Ω

–INPUT

1

G = 100

12

RG

2

AD711

+INPUT

3

2

Figure 41. Shield Driver, G ≥ 100

–INPUT

–V

S

+INPUT

RG

RG

AD712

Figure 42. Differential Shield Driver

00500-041

00500-042

AD524

V

www.BDTIC.com/ADI

GROUNDING

Many data acquisition components have two or more ground

pins that are not connected together within the device. These

grounds must be tied together at one point, usually at the system

power-supply ground. Ideally, a single solid ground would be

desirable. However, because current flows through the ground

wires and etch stripes of the circuit cards, and because these

paths have resistance and inductance, hundreds of millivolts can

be generated between the system ground point and the data

acquisition components. Separate ground returns should be

provided to minimize the current flow in the path from the

sensitive points to the system ground point. In this way, supply

currents and logic-gate return currents are not summed into the

same return path as analog signals where they would cause

measurement errors.

Because the output voltage is developed with respect to the

potential on the reference terminal, an instrumentation

amplifier can solve many grounding problems.

DIG

COM

DIGITAL P.S.

+5V

C–15V

7 9 11 15

AD574A

SIGNAL

GROUND

1µF1µF 1µF

1

DIGITAL

DATA

OUTPUT

2

AD524

1

OUTPUT

REFERENCE

ANALOG P.S.

C+15V

0.1

9

ANALOG

GROUND*

0.1

µF

µF

AD583

SAMPLE

AND HOLD

0.1

0.1

µF

µF

8

7

10

6

*IF INDE PENDENT; OTHERW ISE, RE TURN AMPL IFIE R REFERENCE

TO MECCA AT ANALOG P.S. COMMON.

Figure 43. Basic Grounding Practice

00500-043

SENSE TERMINAL

The sense terminal is the feedback point for the instrument

amplifier’s output amplifier. Normally, it is connected to the

instrument amplifier output. If heavy load currents are to be

drawn through long leads, voltage drops due to current flowing

through lead resistance can cause errors. The sense terminal can

be wired to the instrument amplifier at the load, thus putting

the IxR drops inside the loop and virtually eliminating this

error source.

+

(SENSE)

OUTPUT

(REF)

9

CURRENT

BOOSTE R

X1

R

L

00500-044

VIN+

V

8

2

3

12

–

1

IN

AD524

7

V–

10

6

Figure 44. AD524 Instrumentation Amplifier with Output Current Booster

Typically, IC instrumentation amplifiers are rated for a full

±10 volt output swing into 2 kΩ. In some applications, however,

the need exists to drive more current into heavier loads.

Figure 44 shows how a high current booster may be connected

inside the loop of an instrumentation amplifier to provide the

required current boost without significantly degrading overall

performance. Nonlinearities and offset and gain inaccuracies of

the buffer are minimized by the loop gain of the AD524 output

amplifier. Offset drift of the buffer is similarly reduced.

REFERENCE TERMINAL

The reference terminal can be used to offset the output by up to

±10 V. This is useful when the load is floating or does not share

a ground with the rest of the system. It also provides a direct

means of injecting a precise offset. It must be remembered that

the total output swing is ±10 V to be shared between signal and

reference offset.

When the AD524 is of the 3-amplifier configuration it

is necessary that nearly zero impedance be presented to the

reference terminal.

Any significant resistance from the reference terminal to

ground increases the gain of the noninverting signal path,

thereby upsetting the common-mode rejection of the AD524.

In the AD524, a reference source resistance unbalances the CMR

trim by the ratio of 20 kΩ/R

source impedance is 1 Ω, CMR is reduced to 86 dB (20 kΩ/1 Ω

= 86 dB). An operational amplifier can be used to provide that

low impedance reference point, as shown in Figure 45. The

input offset voltage characteristics of that amplifier adds directly

to the output offset voltage performance of the instrumentation

amplifier.

. For example, if the reference

REF

Rev. F | Page 18 of 28

AD524

www.BDTIC.com/ADI

VIN+

V

–

IN

2

3

12

1

+V

8

AD524

7

–V

S

S

SENSE

10

6

REF

AD711

9

LOAD

V

OFFSET

0500-045

Figure 45. Use of Reference Terminal to Provide Output Offset

An instrumentation amplifier can be turned into a voltageto-current converter by taking advantage of the sense and

reference terminals, as shown in Figure 46.

–IN

+IN

–V

+V

ANALOG

COMMON

INPUT

OFFSET

TRIM

S

S

1µF

35V

C2

C1

GAIN TABLE

ABGAIN

0

0

1

0

0

1

1

1

1

2

3

4

R1

10kΩ

5

6

7

8

K1 – K3 =

THERMOSEN DM2C

4.5V COIL

D1 – D3 = IN4148

10

1000

100

1

PROTECTION

PROTECTION

20kΩ

20kΩ

20kΩ

+V

S

20kΩ

20kΩ

20kΩ

A1

AD524

INPUTS

GAIN

RANGE

Figure 47. Three-Decade Gain Programmable Amplifier

16

15

14

4.44kΩ

13

404Ω

12

40Ω

11

10

9

1

A

B

2

3

4

5

6

+5V

7

NC = NO CONNECT

+INPUT

–INPUT

2

3

13

1

+

AD524

–

10

6

SENSE

REF

R1

9

V

A2

I

L

X

AD711

I

L

VXV

R1

40,000

IN

(

1 +

===

R1

)

R

G

LOAD

Figure 46. Voltage-to-Current Converter

By establishing a reference at the low side of a current setting

resistor, an output current may be defined as a function of input

voltage, gain, and the value of that resistor. Because only a small

current is demanded at the input of the buffer amplifier (A2)

the forced current, I

, largely flows through the load. Offset and

L

drift specifications of A2 must be added to the output offset and

drift specifications of the AD524.

OUTPUT

OFFSET

TRIM

R2

10kΩ

OUT

74LS138

DECODER

RELAY

SHIELDS

16

Y0

15

Y1

14

Y2

13

G = 10

K1

NC

K1 K2 K3D1 D2 D3

G = 100

K2

1

2

3

4

5

6

7

G = 1000

7407N

BUFFER

DRIVER

K3

+5V

16

10µF

LOGIC

COMMON

00500-046

00500-047

Rev. F | Page 19 of 28

AD524

+

www.BDTIC.com/ADI

PROGRAMMABLE GAIN

Figure 47 shows the AD524 being used as a software programmable gain amplifier. Gain switching can be accomplished with

mechanical switches such as DIP switches or reed relays. It should

be noted that the on resistance of the switch in series with the

internal gain resistor becomes part of the gain equation and has

an effect on gain accuracy.

The AD524 can also be connected for gain in the output stage.

Figure 48 shows an AD711 used as an active attenuator in the

output amplifier’s feedback loop. The active attenuation presents

very low impedance to the feedback resistors, therefore

minimizing the common-mode rejection ratio degradation.

(+INPUT)

–IN

(–INPUT)

+IN

INPUT

OFFSET

NULL

–V

S

V

S

1µF

35V

10kΩ

AD711

1

PROTECTION

2

PROTECTION

3

4

20kΩ

5

20kΩ

6

7

AD524

8

10pF

+V

S

–

+

–V

S

20kΩ

+

+V

20kΩ

15

13

11

9

S

–

20kΩ

20kΩ

20kΩ

VSSV

DD

18

AD7590

34567

V

DD

Figure 48. Programmable Output Gain

4.44kΩ

404Ω

40Ω

GND

16

A4A3A2 WR

16

OUTPUT

OFFSET

15

NULL

TO –V

R2

14

10kΩ

13

12

11

10

9

2

39.2kΩ

14

28.7kΩ

12

316kΩ

10

V

OUT

1kΩ

1kΩ

1kΩ

00500-048

+INPUT

(–INPUT)

G = 10

G = 100

G = 1000

–INPUT

(+INPUT)

DAC A/ DAC B

RG

RG

1

13

12

11

16

1

3

2

2

DATA

INPUTS

PROTECTION

4.44kΩ

404Ω

40Ω

PROTECTION

CS

WR

AD524

V

b

20kΩ

20kΩ

+V

S

17 3

4

14

15

16

18

DAC A

DB0

7

DB7

AD7528

6

DAC B

5

20kΩ

20kΩ

20kΩ

10

9

6

20kΩ

1/2

1/2

AD712

AD712

256:1

2

1

19

20

V

OUT

Figure 49. Programmable Output Gain Using a DAC

Another method for developing the switching scheme is to

use a DAC. The AD7528 dual DAC, which acts essentially as

a pair of switched resistive attenuators having high analog

linearity and symmetrical bipolar transmission, is ideal in this

application. The multiplying DAC’s advantage is that it can

handle inputs of either polarity or zero without affecting the

programmed gain. The circuit shown uses an AD7528 to set

the gain (DAC A) and to perform a fine adjustment (DAC B).

AUTOZERO CIRCUITS

In many applications, it is necessary to provide very accurate

data in high gain configurations. At room temperature, the

offset effects can be nulled by the use of offset trim potentiometers. Over the operating temperature range, however,

offset nulling becomes a problem. The circuit of Figure 50

shows a CMOS DAC operating in bipolar mode and connected

to the reference terminal to provide software controllable offset

adjustments.

00500-049

Rev. F | Page 20 of 28

AD524

www.BDTIC.com/ADI

–V

DATA

INPUTS

CS

WR

S

39kΩ

AD589

MSB

LSB

+INPUT

RG

1

G = 10

G = 100

G = 1000

RG

2

–INPUT

V

REF

+V

S

16

14

15

4

11

AD7524

12

13

1

2

3

GND

2

16

13

12

11

3

1

C1

OUT1

OUT2

+

AD524

–

+V

–V

2

3

S

8

7

S

–

+

+V

S

8

1/2

AD712

10

9

6

R3

R5

20kΩ

20kΩ

6

5

AD712

–

+

–V

1/2

7

4

S

R4

10kΩ

1

R6

5kΩ

Figure 50. Software Controllable Offset

In many applications, complex software algorithms for autozero

applications are not available. For those applications, Figure 51

provides a hardware solution.

+V

S

+

2

15 16

RG

1

14

13

RG

2

16

13

12

11

3

1

8

AD524

7

–

–V

S

10

6

AD711

9

0.1µF LO W

LEAKAGE

–

+

1kΩ

1112

910

V

OUT

CH

+V

+10V

350Ω350Ω

350Ω350Ω

RG

G = 100

RG

2

S

8

+

–

10kΩ

4

AD524C

7

–V

S

5

10

6

14-BIT

ADC

9

0V TO 2V

F.S.

00500-052

2

16

1

13

12

11

3

1

Figure 52. Typical Bridge Application

ERROR BUDGET ANALYSIS

To illustrate how instrumentation amplifier specifications are

applied, review a typical case where an AD524 is required to

00500-050

amplify the output of an unbalanced transducer. Figure 52

shows a differential transducer, unbalanced by 100 Ω, supplying

a 0 mV to 20 mV signal to an AD524C. The output of the I

A

feeds a 14-bit ADC with a 0 V to 2 V input voltage range. The

operating temperature range is −25°C to +85°C. Therefore, the

largest change in temperature, ∆T, within the operating range is

from ambient to +85°C (85°C − 25°C = 60°C).

In many applications, differential linearity and resolution are of

prime importance in cases where the absolute value of a variable is

less important than changes in value. In these applications, only

the irreducible errors (45 ppm = 0.004%) are significant. Furthermore, if a system has an intelligent processor monitoring the

analog-to-digital output, the addition of an autogain/autozero

cycle removes all reducible errors and may eliminate the requirement for initial calibration. This also reduces errors to 0.004%.

V

DD

V

SS

GND

200µs

ZERO PULSE

8

1

2

A1 A2 A3 A4

Figure 51. Autozero Circuit

AD7510KD

00500-051

Rev. F | Page 21 of 28

AD524

www.BDTIC.com/ADI

Table 5. Error Budget Analysis

Effect on

Absolute

AD524C

Error Source

Gain Error ±0.25% ±0.25% = 2500 ppm 2500 ppm 2500 ppm –

Gain Instability 25 ppm (25 ppm/°C)(60°C) = 1500 ppm – 1500 ppm –

Gain Nonlinearity ±0.003% ±0.003% = 30 ppm – – 30 ppm

Input Offset Voltage ±50 μV, RTI ±50 μV/20 mV = ±2500 ppm 2500 ppm 2500 ppm –

Input Offset Voltage Drift

Output Offset Voltage

Output Offset Voltage Drift

Bias Current-Source

Imbalance Error

Bias Current-Source

Imbalance Drift

Offset Current-Source

Imbalance Error

Offset Current-Source

Imbalance Drift

Offset Current-Source

Resistance-Error

Offset Current-Source

Resistance-Drift

Common Mode Rejection 5 V DC 115 dB 115 dB = 1.8 ppm × 5 V = 8.8 μV

Noise, RTI (0.1 Hz to 10 Hz) 0.3 μV p-p 0.3 μV p-p/20 mV = 15 ppm – – 15 ppm

1

Output offset voltage and output offset voltage drift are given as RTI figures.

1

±2.0 mV ±2.0 mV/20 mV = 1000 ppm 1000 ppm 1000 ppm –

1

±25 μV/°C (±25 μV/°C)(60°C)= 1500 μV

Specifications Calculation

±0.5 μV/°C

–

±15 nA (±15 nA)(100 Ω ) = 1.5 μV

±100 pA/°C (±100 pA/°C)(100 Ω )(60°C) = 0.6 μV

±10 nA (±10 nA)(100 Ω ) = 1 μV

±100 pA/°C (100 pA/°C)(100 Ω )(60°C) = 0.6 μV

±10 nA (10 nA)(175 Ω ) = 3.5 μV

±100 pA/°C (100 pA/°C)(175 Ω )(60°C) = 1 μV

(±0.5 μV/°C)(60°C) = 30 μV

30 μV/20 mV = 1500 ppm

1500 μV/20 mV = 750 ppm

1.5 μV/20 mV = 75 ppm

0.6 μV/20 mV = 30 ppm

1 μV/20 mV = 50 ppm

0.6 μV/20 mV = 30 ppm

3.5 μV/20 mV = 87.5 ppm

1 μV/20 mV = 50 ppm

8.8 μV/20 mV = 444 ppm

Total Error 6656.5 ppm 10516.5 ppm 45 ppm

Accuracy

at TA = 25°C

– 1500 ppm –

– 750 ppm –

75 ppm 75 ppm –

– 30 ppm –

50 ppm 50 ppm –

– 30 ppm –

87.5 ppm 87.5 ppm –

– 50 ppm –

444 ppm 444 ppm –

Effect on

Absolute

Accuracy

at TA = 85°C

Effect

on

Resolution

Rev. F | Page 22 of 28

AD524

www.BDTIC.com/ADI

Figure 53 shows a simple application in which the variation

of the cold-junction voltage of a Type J thermocouple-iron ±

constantan is compensated for by a voltage developed in series

by the temperature-sensitive output current of an AD590

semiconductor temperature sensor.

R

A

VALUE

52.3Ω

41.2Ω

61.4Ω

40.2Ω

5.76Ω

REFERENCE

JUNCTION

+15°C < T

IRON

V

CONSTANTAN

T

EO = VT – VA +

~

= V

T

< +35°C

A

V

A

T

A

52.3ΩI

1 +

+V

+ 2.5V

A

52.3Ω

R

S

I

A

AD590

2.5V

52.3Ω

CU

– 2.5V

NOMINAL VAL UE

7.5V

AD580

G = 100

+V

S

AD524

E

O

8.66kΩ

1kΩ

+

–

–V

S

OUTPUT

AMPLIFI ER

OR METER

R

A

R

T

9135Ω

TYPE

J

K

E

T

S, R

MEASURING

JUNCTION

NOMINAL

Figure 53. Cold-Junction Compensation

The circuit is calibrated by adjusting RT for proper output

voltage with the measuring junction at a known reference

temperature and the circuit near 25°C. If resistors with low

temperature coefficients are used, compensation accuracy is

to within ±0.5°C, for temperatures between +15°C and +35°C.

0500-053

Other thermocouple types may be accommodated with the

standard resistance values shown in Table 5. For other ranges

of ambient temperature, the equation in Figure 53 may be

solved for the optimum values of R

and RA.

T

The microprocessor controlled data acquisition system shown

in Figure 54 includes both autozero and autogain capability. By

dedicating two of the differential inputs, one to ground and one

to the A/D reference, the proper program calibration cycles can

eliminate both initial accuracy errors and accuracy errors over

temperature. The autozero cycle, in this application, converts a

number that appears to be ground and then writes that same

number (8-bit) to the AD7524, which eliminates the zero error.

Because its output has an inverted scale, the autogain cycle

converts the A/D reference and compares it with full scale. A

multiplicative correction factor is then computed and applied

to subsequent readings.

For a comprehensive study of instrumentation amplifier

design and applications, refer to the Designer’s Guide to

Instrumentation Amplifiers (3

rd

Edition), available free from

Analog Devices, Inc.

2

AD7507

A0, A2,

EN, A1

LATCH

RG

2

RG

1

20kΩ

1/2

AD712

16

13

12

11

3

1

–

+

+

AD524

–

10kΩ

AD712

5kΩ

ADDRESS BUS

1/2

AD583

10

9

6

–V

20kΩ

–

AD7524

+

REF

DECODE

V

IN

AGND

AD574A

CONTROL

V

REF

MICRO-

PROCESSOR

0500-054

Figure 54. Microprocessor Controlled Data Acquisition System

Rev. F | Page 23 of 28

AD524

C

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.005 (0.13) MIN

16

PIN 1

0.200 (5.08)

MAX

0.200 (5.08)

0.125 (3.18)

0.023 (0.58)

0.014 (0.36)

CONTROLLING DIMENSIONS ARE IN INCHES; MILLIMETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE ONLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

Figure 55. 16-Lead Side-Brazed Ceramic Dual In-Line [SBDIP]

Dimensions shown in inches and (millimeters)

0.100 (2.54)

0.064 (1.63)

0.358 (9.09)

0.342 (8.69)

SQ

0.358

(9.09)

MAX

0.088 (2.24)

0.054 (1.37)

SQ

0.080 (2.03) MAX

1

0.840 (21.34) MAX

0.100

0.070 (1.78)

(2.54)

0.030 (0.76)

BSC

(D-16)

0.075 (1.91)

REF

0.095 (2.41)

0.075 (1.90)

0.011 (0.28)

0.007 (0. 18)

R TYP

0.075 (1.91)

REF

0.055 (1.40)

0.045 (1.14)

9

8

0.310 (7.87)

0.220 (5.59)

0.060 (1.52)

0.015 (0.38)

0.150

(3.81)

MIN

SEATING

PLANE

19

20

18

1

BOTTOM

VIEW

14

13

0.150 (3.81)

0.320 (8.13)

0.290 (7.37)

0.015 (0.38)

0.008 (0.20)

0.200 (5.08)

REF

0.100 (2.54) REF

3

4

8

9

45° TYP

BSC

0.015 (0.38)

MIN

0.028 (0. 71)

0.022 (0. 56)

0.050 (1.27)

BSC

CONTROL LING DIMENSIO NS ARE IN INCHES; MI LLIM ETER DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-OFF INCH EQUIVALENTS FOR

REFERENCE O NLY AND ARE NOT APPROPRIATE FO R USE IN DES IGN.

022106-A

Figure 56. 20-Terminal Ceramic Leadless Chip Carrier [LCC]

(E-20)

Dimensions shown in inches and (millimeters)

10.50 (0.4134)

10.10 (0.3976)

BSC

9

7.60 (0.2992)

7.40 (0.2913)

8

10.65 (0.4193)

10.00 (0.3937)

2.65 (0.1043)

2.35 (0.0925)

SEATING

PLANE

Wide Body (RW-16)

8°

0°

0.33 (0.0130)

0.20 (0.0079)

0

0

.

7

.

2

5

(

0

5

(

0

.

0

2

9

5

)

9

8

)

.

0

0

1.27 (0.0500)

0.40 (0.0157)

45°

032707-B

0.30 (0.0118)

0.10 (0.0039)

OPLANARI TY

0.10

16

1

1.27 (0.0500)

0.51 (0.0201)

0.31 (0.0122)

CONTROLLING DIMENSIONS ARE IN MILLIMETERS; INCH DIMENSIONS

(IN PARENTHESES) ARE ROUNDED-O FF MILLIMETER EQUIVALENTS FOR

REFERENCE O NLY AND ARE NOT APPROPRIATE FOR USE IN DESIGN.

COMPLIANT TO JEDEC STANDARDS MS-013- AA

Figure 57. 16-Lead Standard Small Outline Package [SOIC_W]

Dimensions shown in millimeters and (inches)

Rev. F | Page 24 of 28

AD524

www.BDTIC.com/ADI

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD524AD −40°C to +85°C 16-Lead SBDIP D-16

AD524ADZ

AD524AE −40°C to +85°C 20-Terminal LCC E-20

AD524AR-16 −40°C to +85°C 16-Lead SOIC_W RW-16

AD524AR-16-REEL −40°C to +85°C 16-Lead SOIC_W, 13" Tape and Reel RW-16

AD524AR-16-REEL7 −40°C to +85°C 16-Lead SOIC_W, 7" Tape and Reel RW-16

AD524ARZ-16

AD524ARZ-16-REEL7

AD524BD −40°C to +85°C 16-Lead SBDIP D-16

AD524BDZ

AD524BE −40°C to +85°C 20-Terminal LCC E-20

AD524CD −40°C to +85°C 16-Lead SBDIP D-16

AD524CDZ

AD524SD −55°C to +125°C 16-Lead SBDIP D-16

AD524SD/883B −55°C to +125°C 16-Lead SBDIP D-16

5962-8853901EA2 −55°C to +125°C 16-Lead SBDIP D-16

AD524SE/883B −55°C to +125°C 20-Terminal LCC E-20

AD524SCHIPS −55°C to +125°C Die

1

Z = RoHS Compliant Part.

2

Refer to the official DESC drawing for tested specifications.

1

1

−40°C to +85°C 16-Lead SOIC_W RW-16

1

−40°C to +85°C 16-Lead SOIC_W, 7”Tape and Reel RW-16

1

−40°C to +85°C 16-Lead SBDIP D-16

1

−40°C to +85°C 16-Lead SBDIP D-16

−40°C to +85°C 16-Lead SBDIP D-16

Rev. F | Page 25 of 28

AD524

www.BDTIC.com/ADI

NOTES

Rev. F | Page 26 of 28

AD524

www.BDTIC.com/ADI

NOTES

Rev. F | Page 27 of 28

AD524

www.BDTIC.com/ADI

NOTES

©2007 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D00500-0-11/07(F)

Rev. F | Page 28 of 28

Loading...

Loading...