Low Cost

DEMODIN

CLKOUT

DEMOD OUT

ERROR

AMP

LOS

LATCHES

FREQUENCY

SHAPING

VCO

PHASE

SENSITIVE

DEMODULATOR

C1

C2

R2

VEL

UP-DOWN

COUNTER

REFERENCE

(PRIMARY

EXCITATION)

DIFFERENTIAL

(SECONDARY

VOLTAGE)

REF

A

B

LOS

GAIN

V

DD

OVR

UNR

NULL

CS

DATA

SCLK

ACERROR

AC RATIO

BRIDGE

DIFF

DECODE

LOGIC

C3

AD2S93

INTIN

R4

R3

SERIAL

INTERFACE

DIR

R5

R1

C4

R6

R7

VCO GAIN

a

FEATURES

Full Function Monolithic LVDT-to-Digital Converter

Absolute Serial Data Output

Uncommitted Differential Input

Repeatability

Remote Diagnostics

14-Bit Resolution

Industrial Temperature Range

28-Pin PLCC

Low Power

APPLICATIONS

Industrial Gauging

Industrial Process Control

Linear Positioning Systems

Linear Actuator Control

Automotive Motion Sensing and Control

Torque Sensing Conditioner

AC Strain Gages Conditioning

Avionics

LVDT-to-Digital Converter

AD2S93

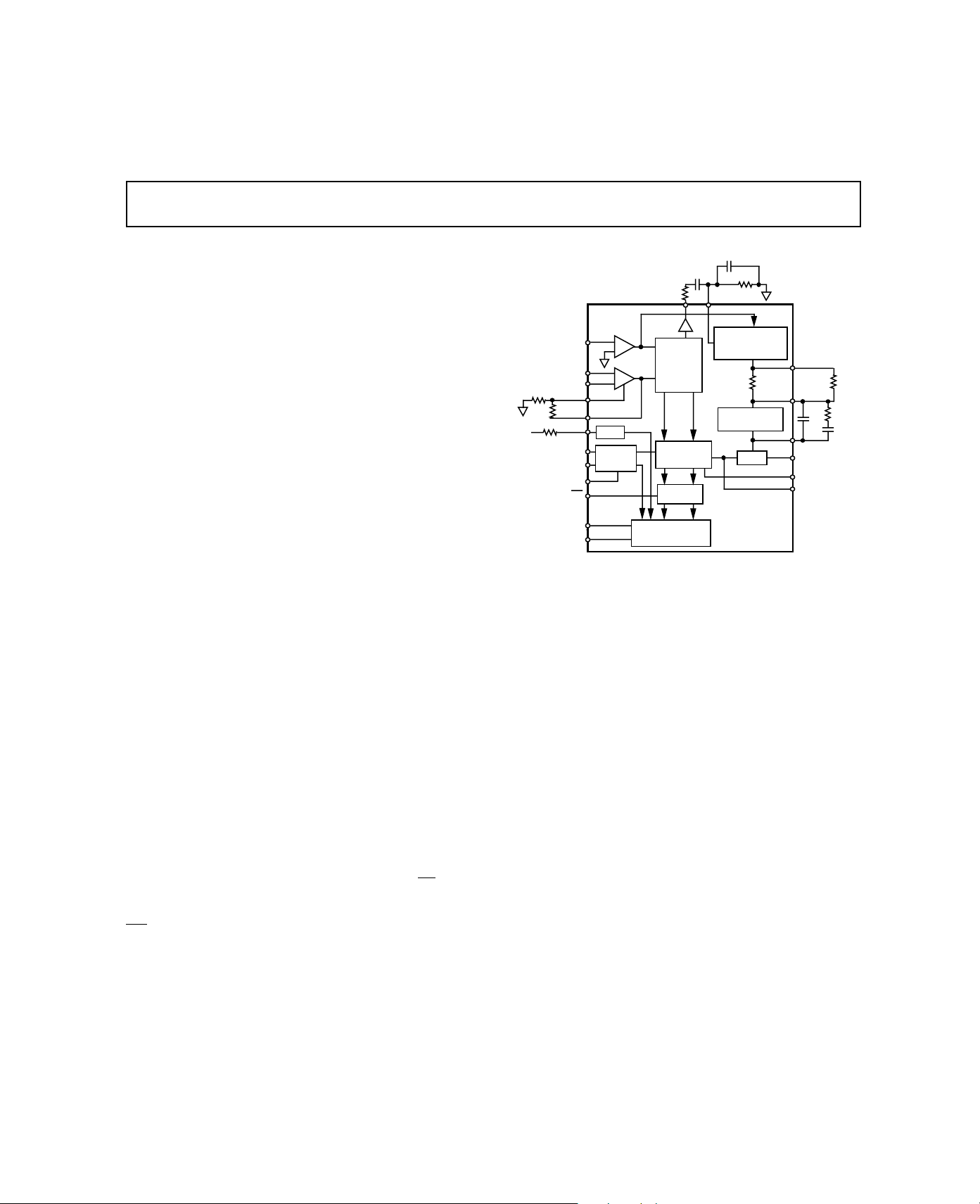

FUNCTIONAL BLOCK DIAGRAM

GENERAL DESCRIPTION

The AD2S93 is a complete 14-bit resolution tracking LVDT-todigital converter. A Type II tracking loop is employed to track

the A–B input and produce a digital output equal to (A–B)/

(REF/2), where REF is a fixed amplitude ac reference phase coherent with the A–B input. This allows the measurement of any

2-, 3-, 4- and 5-wire LVDT or linear amplitude modulated input. The operating frequency range is from 360 Hz to 10 kHz

with user definable bandwidth set externally within a range of

45 Hz to 1250 Hz.

The AD2S93 has a 16-bit serial output. The MSB (LOS), read

first, indicates a loss of the signal A, B, or reference inputs to the

converter or transducer. The second and third MSBs are flags

indicating whether [–REF/2 (UNR) ≤ A–B ≤ +REF/2 (OVR]) is

outside the linear operating range of the converter. The displacement data is presented as 13-bit offset binary giving a ±12bit operating range. LOS, OVR and UNR are pinned out on

the device, in addition a NULL flag is available which is set

when (A–B) = 0.

Absolute displacement information is accessed when

CS is taken

LO followed by the application of an external clock (SCLK)

with a maximum rate of 2 MHz. Data is read MSB first. When

CS is high the DATA output is high impedance; this allows

daisy chaining of more than one converter onto a common bus.

The A, B differential input allows the user to scale the A, B inputs between 1 and 10. This enables the user to accurately set

up the inputs matching the REF input to the DIFF output. The

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

DIFF output is the resultant A–B. The AD2S93 operates using

±5 V ± 5% power supplies and is fabricated on Analog Devices’

linear compatible CMOS process (LC

2

MOS). The (LC2MOS)

is a mixed technology process that combines precision bipolar

circuits with low power logic.

PRODUCT HIGHLIGHTS

Complete LVDT-to-Digital Interface. The AD2S93 pro-

vides the complete solution for digitizing LVDT signals to 14bit resolution.

Serial 16-Bit Output Data. One 16-bit read from the

AD2S93 determines input signal continuity (LOS), over and

underrange detection and 13 bits of offset binary displacement

information.

High Accuracy Grade in Low Cost Package. 0.05% and

0.1% integral linearity over the full –40°C to +85°C operating

temperature range.

Uncommitted Differential Input. Allows configuration of 2-,

3-, 4- and 5-wire LVDTs.

Multiple Converter Interfacing. High impedance data output and a simple three-wire interface reduces cabling and eliminates bus contention.

Low Power. 70 mW power consumption (typ).

One Technology Way, P.O. Box 9106, Norwood. MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

(VDD = +5 V ± 5%; VSS = –5 V ± 5%, AGND = DGND = 0 V, TA = –40°C to +85°C

AD2S93–SPECIFICATIONS

Parameter Test Conditions Min Typ Max Units

unless otherwise noted)

SIGNAL INPUTS

Frequency 0.36 1.0 10 kHz

Max Voltage Level

Nominal Full Scale

1

2

0.8 1.0 1.2 V rms

1.0 V rms

Input Bias Current @ +25°C 1.1 µA

Input Impedance 1.0 MΩ

CMRR 57 dB

Maximum Sensitivity

3

V

= 1 V rms, G = 1 342 µV pk/LSB

A–B

REFERENCE INPUT

Frequency 0.36 10 kHz

Voltage Level 1.8 2.0 2.2 V rms

Input Bias Current @ 0 V +25°C1µA

Input Impedance 1.0 MΩ

Permissible Phase Shift

4

Signal to Reference –10 +10 Degrees

CONVERTER DYNAMICS

Bandwidth Set by User

VCO Mode = 1 VCO Gain Connected to

VCO I/P 500 1250 Hz

VCO Mode = 2 VCO Gain No Connect 45 500 Hz

Maximum Slew Rate

Mode = 1 2400 3000 LSB/ms

Mode = 2 800 1000 LSB/ms

ACCURACY

Integral Linearity AP 0.1 % FSD

BP 0.05 % FSD

Differential Linearity AP <2 LSB

BP <1 LSB

Repeatability ±1 LSB

Zero Position Offset AP @ +25°C –3 3 LSB

BP @ +25°C –1 1 LSB

AP @ –40°C to +85°C –4 4 LSB

BP @ –40°C to +85°C –2 2 LSB

Gain Error ±0.7 % FS

VELOCITY OUTPUT

Max Output Voltage Denotes Max Input Speed ±4.0 V dc

Load Drive Capability ±250 µA

INL

INH

CS

3.5 V dc

1.5 V dc

500 nA

LOGIC INPUTS SCLK,

Input High Voltage V

Input Low Voltage V

Input Current I

IN

Input Capacitance 10 pF

LOGIC OUTPUTS

OVR, UNR, NULL, DATA, A, B CLKOUT DIR

Output High Voltage @ 1 mA 4.0 V dc

Output Low Voltage @ 1 mA 1.0 V dc

LOS OUTPUT Open Drain Output

Pull-Up to +V

via 12 kΩ 400 µA

DD

Drive Capability

Signal Threshold (A-B) 0.1 0.2 V rms

REF Threshold 0.22 V rms

Timeout Threshold 50 ms

–2–

REV. A

AD2S93

Parameter Test Conditions Min Typ Max Units

SERIAL CLOCK (SCLK)

SCK Input Rate 2 MHz

Maximum Read Rate (16 Bits) Continuous 9.2 µs

POWER SUPPLY

I

DD

I

SS

NOTES

1

The signal input voltage maximum should always be set at 10% less than the reference input.

2

Nominal + FS = V

3

With G = 10; Sensitivity 34.2 µV pk/LSB

4

Phase shift cause gain errors. “See Phase Shift and Quadrative Effects.”

A–B

= V

/2, FS = –V

REF

A–B

= V

REF

/2

Specifications subject to change without notice.

5710 mA

5710 mA

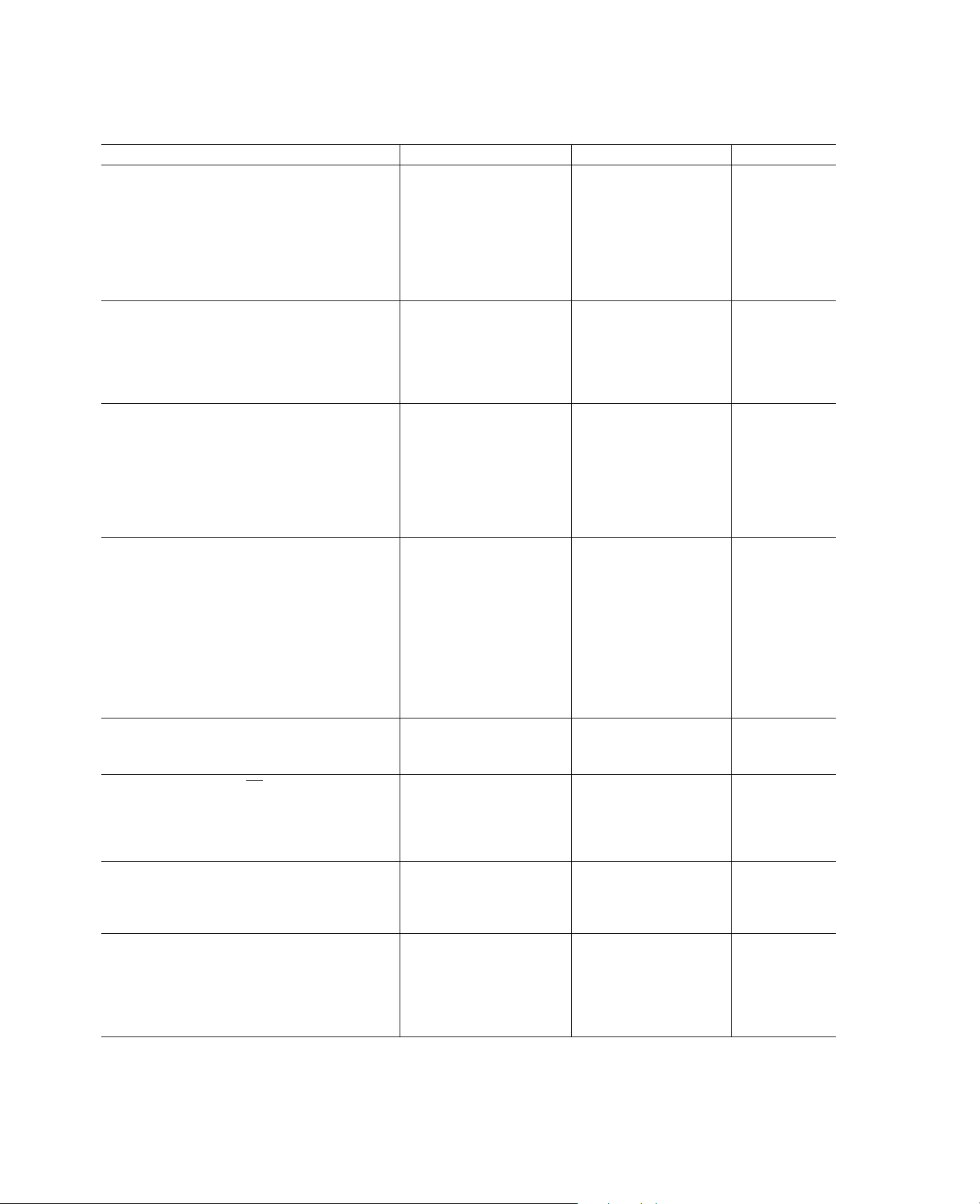

TIMING CHARACTERISTICS

(VDD = +5 V ± 5%, AGND = DGND = 0 V, TA = –40°C to +85°C unless otherwise noted)

Parameter AD2S93 Units Test Conditions

1

t

1

t

2

t

3

t

4

t

5

t

6

t

7

NOTE

1

SCLK can only be applied after t2 has elapsed.

150 ns max CS to DATA Enable

600 ns min CS to 1st SCLK Positive Edge

250 ns min SCLK High Pulse

250 ns min SCLK Low Pulse

100 ns max SCLK Positive Edge to DATA Valid

600 ns min CS High Pulse Width

150 ns max CS High to DATA High Z (Bus Relinquish)

t

6

*

t

LSBMSB

CS

SCLK

DATA

t

2

t

3

t

4

t

1

t

5

t

7

REV. A

t * = THE MINIMUM ACCESS TIME: USER DEPENDENT

TOTAL MAX READ TIME =

TOTAL MAX READ TIME = 600 +16 (250 + 250) + 150 ns

TOTAL MAX READ TIME = 600 + 8000 + 150 ns

TOTAL MAX READ TIME = 8.750 µs (SINGLE READ ONLY)

t

+ 16. (

2

t

+

t

) +

t

3

4

7

Timing Diagram

–3–

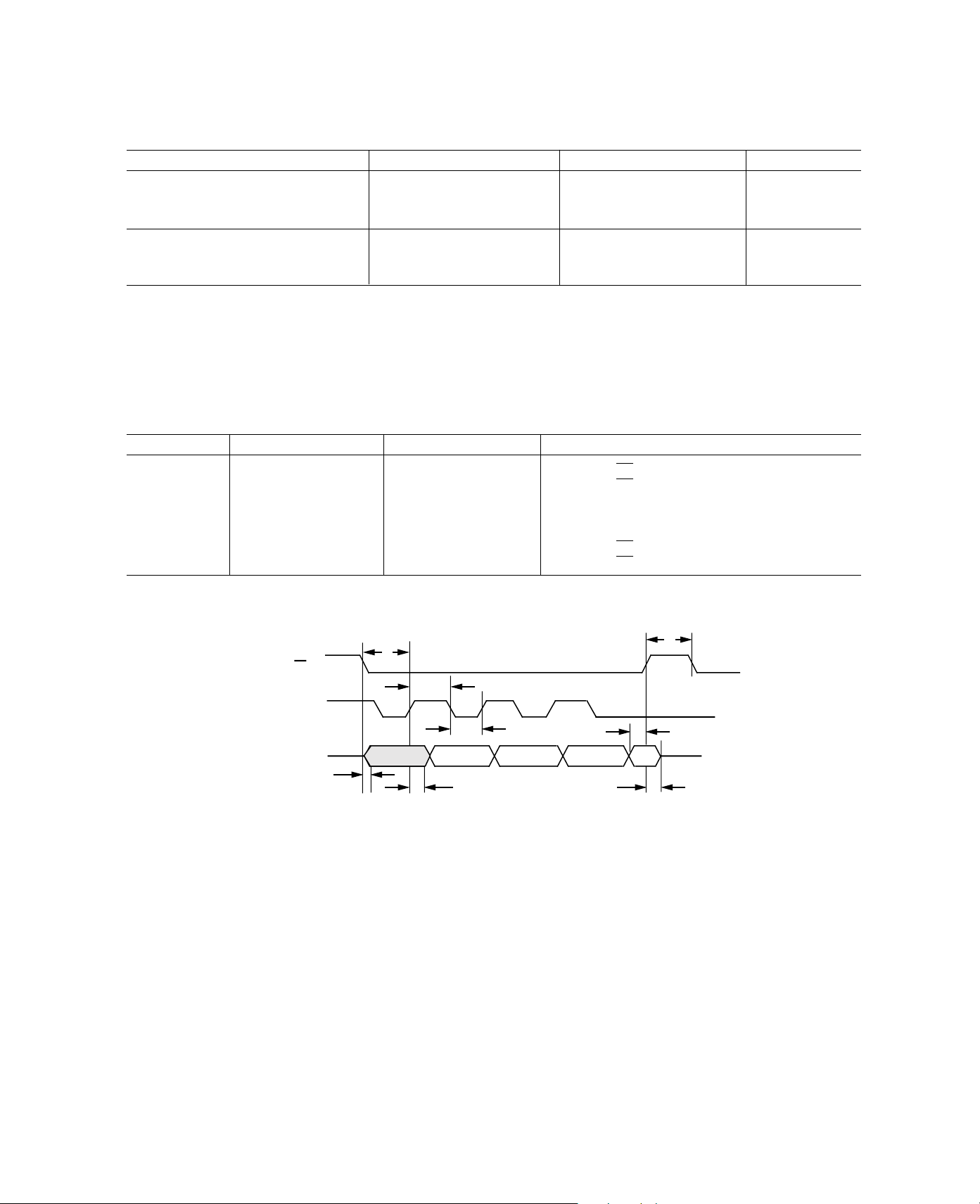

AD2S93

WARNING!

ESD SENSITIVE DEVICE

RECOMMENDED OPERATING CONDITIONS

Power Supply Voltage (VDD–V

) . . . . . . . . . . . ±5 V dc ± 5%

SS

Analog Input Voltage (A, B) . . . . . . . . . . . . . . 1 V rms ± 10%

Analog Reference Input (REF) . . . . . . . . . . . . 2 V rms ± 10%

Signal and Reference Harmonic Distortion . . . . . . . . . . . <10%

Operating Temperature Range

Industrial (AP, BP) . . . . . . . . . . . . . . . . . . .–40°C to +85°C

ABSOLUTE MAXIMUM RATINGS*

VDD to AGND . . . . . . . . . . . . . . . . . . .–0.3 V dc to + 7.0 V dc

to AGND . . . . . . . . . . . . . . . . . . . +0.3 V dc to – 7.0 V dc

V

SS

AGND to DGND . . . . . . . . . . . . –0.3 V dc to V

Analog Inputs to AGND REF . . . . V

A, B . . . . . . . . . . . . . . . . . . . . . . . . . V

– 0.3 V to VDD + 0.3 V

SS

– 0.3 V to VDD + 0.3 V

SS

Analog Output to AGND VEL . . . . . . . . . . . . . . . . V

+ 0.3 V dc

DD

to V

SS

DD

Digital Inputs to DGND

CS, SCLK . . . . . . . . . . . . . . . . . . . . . –0.3 V to V

+ 0.3 V

DD

Digital Outputs to DGND

NULL, DIR, CLKOUT, DATA . . . . –0.3 V to V

+ 0.3 V

DD

Operating Temperature Range

Industrial (A, B) . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Lead Temperature (Soldering 10 sec) . . . . . . . . . . . . . +300°C

Power Dissipation to +75°C . . . . . . . . . . . . . . . . . . +100 mW

Derates above +75°C by . . . . . . . . . . . . . . . . . . . . . 10 mW/°C

*

Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

DIFF

AGND

DATA

SCLK

CS

NC

UNR

CLKOUT

NC

GAIN

LOS

423

5

6

7

8

9

10

11

OVR

NULL

NC = NO CONNECT

AD2S93

TOP VIEW

(Not to Scale)

DIR

B

A

28

27

1

15 18

16121413

17

SS

DD

V

V

DGND

NC

26

25

24

23

22

21

20

19

DEMODOUT

NC

REF

VEL

INTIN

VCOGAIN

ACERROR

DEMODIN

ORDERING GUIDE

Temperature Package

Model Range Linearity Option

AD2S93AP –40°C to +85°C 0.1% P-28A

AD2S93BP –40°C to +85°C 0.05% P-28A

PIN DESIGNATIONS

Pin

No. Mnemonic Description

1 AGND Analog Ground.

2 DIFF Output of Signal Input Preamplifier.

3 GAIN Connect GAIN Pin to DIFF for

nominal × 1. Gains greater than

1 can be resistively scaled.

Do not leave unconnected.

4 LOS Denotes A or B lines loss of

connection and/or loss of reference

to transducer or converter.

5 DATA 16-bit serial data output 13 bits of

absolute position information plus

overrange and underrange plus LOS.

6 SCLK Serial Clock. Maximum rate = 2 MHz.

CS Chip Select. Loads serial interface

7

with current positional information

and enable output.

9, 12 UNR, OVR Two pins that denote whether the

input signals are underrange or

overrange.

10 CLKOUT Updates every LSB.

13 NULL Denotes Null Position.

14 DIR Indicates direction. DIR is HI for

positive displacement and LO for

negative displacement.

15 DGND Digital Ground.

16 V

SS

Negative Power Supply –5.0 V dc

± 5%.

17 V

DD

Positive Power Supply +5.0 V dc

± 5%.

18 DEMODOUT Output of the Phase Sensitive

Demodulator.

19 DEMODIN Input to Phase Sensitive

Demodulator.

20 ACERROR AC Error Output.

21 VCO GAIN Sets the VCO gain internally.

Connect to VEL for 2400 LSB/s.

Disconnect for 800 LSB/s.

22 INTIN Determines system dynamics connect

C and RC (serial) parallel

combination across INTIN and

VEL to determine loop dynamics.

23 VEL Analog Velocity Output.

24 REF Single ended input for fixed

amplitude reference.

27, 28 B, A Uncommitted differential inputs

for the A, B signal inputs.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD2S93 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–4–

REV. A

AD2S93

GLOSSARY OF TERMS

INTEGRAL LINEARITY

Integral linearity deviation as a percent of full scale. A 0.1% deviation is equivalent to 8-LSB change on the output.

Gain

The converter gain is the maximum variation in the ratio of

A–B/REF/2 to the maximum digital input.

Output Offset

The output offset is the digital output code when the analog input signal A–B = 0.

Overrange (OVR)

OVR goes high when A–B is in phase with REF and larger than

REF/2.

Underrange (UNR)

UNR goes high when A–B is out of phase with REF and larger

than REF/2.

PRINCIPLE OF OPERATION

The AD2S93 is based on a Type 2 tracking closed-loop principle. The output tracks the position of the LVDT without the

need for external convert and wait states. As the transducer

moves through a position equivalent to the least significant bit

weighting, the output is updated by one LSB. On the AD2S93,

CLKOUT updates corresponding to one LSB increment. Figure 1 illustrates the principle of operation.

REFERENCE

(PRIMARY

EXCITATION)

DIFFERENTIAL

(SECONDARY

VOLTAGE)

R4

R3

V

DD

NULL

REF

GAIN

DIFF

LOS

OVR

UNR

CS

A

B

LOS

DECODE

LOGIC

ACERROR

ERROR

AMP

AC RATIO

BRIDGE

UP-DOWN

COUNTER

LATCHES

C3

R6

R5

C4

DEMODIN

PHASE

SENSITIVE

DEMODULATOR

R1

FREQUENCY

SHAPING

VCO

DEMOD OUT

R7

INTIN

R2

C1

VEL

VCO GAIN

DIR

CLKOUT

C2

Because the conversion depends on the ratio of the input signals

(ratiometric ac bridge), the AD2S93 is remarkably tolerant of

input amplitude and frequency. This, combined with the definable Type 2 tracking closed-loop guarantees the AD2S93's repeatability for a given input. A phase sensitive detector,

integrator and voltage controlled oscillator (VCO) form a closed

loop system which seeks to null the output of the ACERROR.

When this is accomplished the word state of the up/down

counter equals within the rated accuracy of the converter, the

LVDT position output.

For more information on the operation of the converter, see

“Circuit Dynamics” section.

DATA FORMAT

OPERATING RANGE

The AD2S93 operating range is defined in Figure 2. The linearity and specified operating range of the converter is the central two 12-bit quadrants through zero. The corresponding

input relationship is –REF/2 ≤ A–B ≤ +REF/2, (± is used to denote phase coherency). The sign bit is low for inputs with A–B

in phase with REF. The two remaining 12-bit quadrants are

used to denote over (OVR) and underrange (UNR). OVR goes

high when A–B is in phase with REF and larger than REF/2.

UNR goes high when A–B is out of phase with REF and larger

than REF/2. LOS is an open drain output which pulls high

when A and/or B are removed or REF is removed (see “Inbuilt

Diagnostics”), or A + B is less than 100 mV.

SCALING THE INPUTS

In order to match the LVDT output to the AD2S93 output, the

inputs to the AD2S93 need to be scaled. The operating range is

illustrated in Figure 2. The AD2S93 operates across ±12-bit

range where the remaining 12-bit quadrants are used to denote

overrange and underrange. The output position word is a function of the ratio between A–B and V

±FSR =

(see Figure 2) where:

REF

( A − B)

V

/2

REF

REV. A

DATA

SCLK

SERIAL

INTERFACE

AD2S93

Figure 1. Functional Block Diagram

–5–

AD2S93

AGND

R4

R3

GAIN

DIFF

A

B

OUTPUT CODES

MAGNITUDE

0100 0000 0000 0000

0100 1111 1111 1111

0100 0000 0000 0000

0000 0000 0000 0001

0000 1111 1111 1111

0001 0000 0000 0000

0001 0000 0000 0001

0001 1111 1111 1110

0001 1111 1111 1111

0011 0000 0000 0000

0011 0000 0000 0001

LOS

OVR

UNR

SIGN

0011 1111 1111 1111

Figure 2. Output Code Format

If the maximum operating stroke of an LVDT yielded a 1 V rms

A–B output, the weighting of the LVDT to AD2S93 digital output would be:

+VE POSITION

FULL SCALE

POSITION

–VE POSITION

FULL SCALE

NULL

A – B = – REF/2

UNDER-

RANGE

–1 0 ≠ 1

RATIO OF A- B/REF/2

A – B = 0

RANGE

A – B = + REF/2

RANGE

OVER-

Input Signal Full Scale

Full-Scale Operating Range (±2

12

)

1×22

13

2

Input Scaling = 345 µV/LSB

This can be equated directly to the LVDT sensitivity specification in mm/v/v.

Note: The overrange and underrange quadrants can be utilized

by decoding the overrange and underrange MSBs and decoding

the 12 magnitude bits. This will increase the operating range of

the AD2S93 accordingly. However, if the input A–B > V

REF

then the converter will lose track of the input and will only regain track when the input signal returns to within the operating

range of the converter.

INPUT GAIN

Since the transformation ratio of an LVDT or RVDT from excitation voltage to signal voltage can be 1:0.15, provision for gain

scaling has been provided. The gain can, therefore, be selected

to ensure that the full-scale output of converter represents the

maximum stroke position of the transducer.

The gain setting is accomplished by connecting Pin 2, (DIFF)

and Pin 3 (GAIN) together (unity gain) or connecting two resistors as shown in Figure 3.

The gain of the input stage is calculated using the following

equation:

DIFF( A – B)

( A – B) IN

=1 +

R

3

R

4

e.g., For a gain of 5, R3 = 12 kΩ, R4 = 3 kΩ

For a gain of 10, R3 = 18 kΩ, R4 = 2 kΩ

Figure 3. Pre-Amp Gain Block

SETTING THE CONVERTER BANDWIDTH

The AD2S93 bandwidth is set by placing three external components, C1, C2, and R2, around the integrator as illustrated by

the figure below.

C1

R2

C

C2

TH

R1

I

TH

O

R

V

V

VCOINT

62.5

Figure 4. Integrator and VCO

Before the bandwidth can be set, the corresponding VCO gain

setting must be determined. The VCO gain is directly related to

the slew rate of the converter. This is set internally to two different rates defined internally by R

.

V

Typical converter slew rates are defined below,

G (1) = 2400 LSB/ms–Mode 1

G (2) = 800 LSB/ms–Mode 2

–6–

REV. A

AD2S93

Calculation of the component values for the bandwidth is detailed below. For more detailed information on component

value selection for the AD2S93, please consult the “Passive

Component Selection and Dynamic Modeling Software for the

AD2S93 LVDT-to-Digital Converter.”

VCO Gain G (1) Mode 1

The available bandwidth with this option is from 0.5 kHz to

1.25 kHz.

F

> 8 × Fo

REF

C1 = 1/(800 × Fo

2

)

C2 = 8 × C1

R2 = 45 × Fo

Where F

is the reference frequency, Fo is the closed-loop

REF

3 dB point.

VCO Gain G (2) Mode 2

The available bandwidth with this option is from 45 Hz

to 500 Hz.

F

> 8 × Fo

REF

C1 = 1/(2400 × Fo

2

)

C2 = 8 C1

R2 = 45 × Fo

Where F

is the reference frequency, Fo is the closed-loop

REF

3 dB point.

INTERFACING TO THE AD2S93 (SEE “TIMING

CHARACTERISTICS”)

The absolute position information is extracted via a three-wire

interface, DATA,

a high impedance state when

Upon the application of logic low to the

CS and SCLK. The DATA output is held in

CS is high.

CS pin, the DATA is

enabled and the current position information is transferred from

the counters to the serial interface. Data is retrieved by applying

an external clock to the SCLK pin. The maximum data rate of

the SCLK is 2 MHz. To ensure secure data retrieval, it is

important to note that SCLK should not be applied until a

minimum period of 600 ns after the application of logic low to

CS. Data is then clocked out on successive positive edges of

SCLK: 16 clock edges are required to extract the entire data

word. Subsequent positive edges greater than the defined resolution of the converter will clock zeros from the data output if

CS remains in a low state. The format of the data read is shown

in Table I.

Table I.

DB0 DB1 DB2 DB3 DATA DB4–D15

MSB LSB

Function LOS OVR UNR SIGN MAGNITUDE

If less than the full 16-bit word is required, then the data read

can be terminated by releasing

CS after the required number of

bits have been read.

CS can be released a minimum of 100 ns after the last positive

edge. If the user is reading data continuously,

CS can be reapplied after a minimum of 600 ns after it is released. The minimum repetitive read time of the same converter is given by (16

bits read @ 2 MHz). Min RD Time = [600 + (16 × 500) +

600] = 9.2 µs.

IN-BUILT DIAGNOSTICS

The first three bits read from the serial interface preceding the

sign and magnitude data can be used to determine whether the

data is valid or not. Over and underrange (OVR, UNR) denote

the two extremes of the LVDT stroke where linearity of the

LVDT may degrade. Loss of signal LOS is an open drain output which pulls high (12 kΩ pull up) when one of the following

conditions is satisfied:

1. A and/or B is disconnected.

2. REF is disconnected.

Note: LOS has a response time of 50 ms max to the conditions

stated above, see “Specifications.”

CONNECTING THE CONVERTER

Positive power supply V

nected to Pin 17 and negative power supply V

= +5 V dc ± 5% should be con-

DD

= –5 V dc ± 5%

SS

to Pin 16. Reversal of these power supplies will destroy this device.

For LVDT connections to the converter please refer to Figures

5 through 7. On all connections, the maximum input reference

signal V

= 2.0 V rms ± 10%. To operate within the standard

REF

operating range, A–B should not exceed 1.0 V rms ± 10%. The

AD2S93 AGND point is the point at which all analog signal

grounds should be connected. Ground returns from the LVDT

should be connected to AGND. The AD2S93 DGND pin

should be connected to the AD2S93 AGND pin. Ancillary Digital circuitry must be connected to the Star Point and not to the

AD2S93 AGND pin.

In all cases, the AD2S93 has been configured with the following

dynamics.

Reference Frequency 5 kHz

3 dB Bandwidth 625 Hz

Vco Gain is set in MODE 1 where VCO GAIN is connected to

VEL.

Using the procedure described in “setting the converter bandwidth” the following preferred values (E12 series) were calculated:

C1 = 3.3 nF

C2 = 27 nF

R2 = 27 k

CALCULATING HF FILTER (C3, C4, R5, R6)

Ω

15 kΩ ≤ R5 = R6 ≤ 56 kΩ

C3=C4=

1

2πR5F

REF

So, C3 = 1 nF, R5 = R6 = 33 kΩ, C4 = 1 nF and in all cases

R7 = 15 kΩ.

Half-Bridge Type LVDT Connection

In this method of connection, it is necessary to add two additional bridge completion resistors R

C

and R

in order to derive

C,

a reference for the AD2S93. In selecting the bridge completion

resistor, it is important to remember that mismatch between R

and R

will cause nonzero errors at null. If two LVDTs are be-

C2

C1

ing used for differential measurements, the resistors can be replaced by the second LVDT.

REV. A

–7–

AD2S93

Three- or Four-Wire LVDT Connection

In this method of connection, shown in Figure 6, the converters

digital output is proportional to the ratio:

( A − B)

( A + B)/2

where A and B are the individual LVDT secondary output voltages. Inspection of Figure 6 should demonstrate why this relationship is true. (A–B) is simply the voltage across the series

connected secondaries of the LVDT and is applied to the A, B

input to the converter. (A + B)/2 is effectively the average of

the two secondary voltages as computed by the balanced bridge

completion resistors and the grounding of the secondary

center-tap.

Note: This method of connection is appropriate only for where

(A + B) is a constant, independent of LVDT position. Any lack

of constancy in (A + B) will be reflected as an additional non-

REF

26

NC

27

B

28

PISTON

R

C1

GND

R

C2

A

B

R4

12kΩ

V

DD

AGND

R3

GAIN

A

DIFF

LOS

linearity in the output. It is up to the user to determine if (A +

B) is sufficiently constant over the particular stroke length employed.

This method will usually restrict the usable LVDT range to half

of its full range. The restriction can be eliminated, however, by

attenuating DIFF by a factor of 2 or increasing V

by a factor

REF

of 2. This connection method has the tremendous advantage of

being insensitive to temperature related phase shifts and excitation oscillator instability effects usually associated with more

conventional LVDT conversion systems.

As in the case of the half-bridge type LVDT connection, R

and R

are the bridge completion resistors and are matched to

C2

C1

a degree sufficient to ensure that the digital output representing

the null position does not vary from the LVDT’s natural null

position. If null adjustment is required, a potentiometer can be

used in place of the common connection between the two

resistors.

C1

C2

R2

24

23

25

22

21 20

R6

19

AD2S93

1

2

3

4

TOP VIEW

(Not to Scale)

69

7

5

DATA

SCLK

8

CS

NC

UNR

10

CLKOUT

11

C4

C3

R5

R7

DEMODOUT

18

V

DD

17

16

V

SS

15

DGND

14

DIR

13

NULL

OVR

12

NC = NO CONNECT

NC

+5V

0V

–5V

PISTON

Figure 5. Half-Bridge Type LVDT Connection

C1

C2

R2

REF

25

24

26

NC

B

27

28

A

1

R

C1

R

C2

AGND

2

DIFF

R3

R4

12kΩ

V

DD

GAIN

LOS

3

4

6

5

SCLK

DATA

21 20

22

23

AD2S93

TOP VIEW

(Not to Scale)

7

9

8

CS

NC

UNR

R6

10

CLKOUT

C3

19

11

NC

Figure 6. Three- or Four-Wire LVDT Connection

–8–

C4

R5

R7

DEMODOUT

18

V

17

DD

V

16

SS

15

DGND

DIR

14

13

NULL

OVR

12

NC = NO CONNECT

+5V

0V

–5V

REV. A

AD2S93

2-4 DECODING

(74HC139)

LVDT

LVDT

LVDT

LVDT

AD2S93

1

AD2S93

2

AD2S93

3

AD2S93

4

OSC

BUFFER

4

4

4

4

2

2

0V

V

SS

A0

A1

CS

4

V

DD

CS

3CS2CS1

DATA

SCLK

Two-Wire LVDT Connection

This method should be used in cases where the sum of the

LVDT secondary output voltages (A + B) is not constant with

LVDT displacement over the desired stroke length. This method

of connection, shown in Figure 7, still maintains the ratiometric

operation and the insensitivity to variations in reference amplitude and frequency. However, the phase shift between V

REF

and V1 should be minimized to maintain accuracy (see Section

“PHASE SHIFT AND QUADRATURE EFFECTS”). Suggested phase compensation circuits are shown in Figure 7.

PHASE SHIFT AND QUADRATURE EFFECTS

Reference to signal phase shift can be high in LVDTs, sometimes in the order of 70 degrees. If the converter is connected

as in Figures 5 and 6, any effects due to this phase shift are

minimized. This connection method, therefore, provides outstanding benefits.

The additional gain error caused by reference to signal phase

shifts is given by:

(1 – cos θ) × 100% of FSR

where

θ = phase shift between V

When the phase shift between V

and DIFF.

REF

and V1 is zero, additional

REF

quadrature on the signal will have no effect on the converter.

This is another benefit of the conversion method. For example,

when a REF lags (A–B) by approximately 10°, the gain error is

approximately 1%. When (A–B) lags REF by approximately

10°, the gain error is approximately 2%.

REMOTE MULTIPLE SENSOR INTERFACING

The DATA output of the AD2S93 is held in a high impedance

state until

CS is taken LO. This allows a user to operate the

AD2S93 in an application with more than one converter connected on the same line. Figure 8 shows four LVDTs interfaced

to four AD2S93s. Excitation for the LVDT is provided locally

by an oscillator.

SCLK, DATA and two address lines are fed down low loss

cables suitable for communication links. The two address lines

are decoded locally into

CS for the individual converters. Data

is received and transmitted using transmitters and receivers.

Figure 8. Remote Sensor Interface

REV. A

OSC

PHASE LEAD = ARCTAN

PHASE

PHASE

SHIFT

SHIFT

CCT

CCT

PISTON

C

R

1

2π fRC

C1

C2

R2

NC

B

A

AGND

DIFF

R3

R4

GAIN

12kΩ

LOS

V

DD

PHASE LAG = ARCTAN 2 π fRC

R

C

REF

26

27

28

1

1

2

2

3

3

4

4

23

23

25 24

25 24 21 20 19

5

5

DATA

22

22

AD2S93

AD2S93

TOP VIEW

TOP VIEW

(Not to Scale)

(Not to Scale)

69

7

69

7

CS

SCLK

Figure 7. Two-Wire LVDT Connection

–9–

C4

C3

R6

21

20 19

11

10

10

8

8

NC

UNR

CLKOUT

R5

R7

18

V

17

DD

16

V

SS

DGND

15

DIR

14

13

NULL

OVR

12

NC

NC = NO CONNECT

DEMODOUT

+5V

0V

–5V

AD2S93

CIRCUIT DYNAMICS/ERROR SOURCES TRANSFER FUNCTION

The AD2S93 operates as a Type 2 tracking servo loop. An integrator and VCO/counter perform the two integrations inherent

in a Type 2 loop.

The overall system response of the AD2S93 is that of a unity

gain second order low-pass filter, with the position of the LVDT

as the input and the digital position data as the output. Figure 9

illustrates the AD2S93 system diagram.

VEL OUT

IN

+

G1 (s) G2 (s)

OUT

Figure 9. AD2S93 Transfer Function

Note: The AD2S93 has been configured with the following dynamics.

Reference Frequency 10 kHz

3 dB Bandwidth 1250 Hz

VCO Gain is set in MODE 1 where VCOGAIN is connected to

VEL.

Using the procedure described in “SETTING THE CONVERTER BANDWIDTH,” the following preferred values (E12

series) were calculated:

C1 = 820 pF

C2 = 6.8 nF

R2 = 56 kΩ

C3 = C4 = 470 pF, R7 = 15 kΩ, R5 = R6 = 33 kΩ, C4 =

470 pF

The open-loop transfer function is given by:

G1( s ) =

1

s

G2( s) =

1+st

1

2

K

2

s

1 + st

K

where:

t2= R

2

t1 = R2 C

C1×C

C1+C

2

2

2

and:

−3

Note A

4 ×10

K1=

25 ×10

K

=

2

R

has two values depending on which mode is being used

2

4

V×CV

K

2 (MODE1)

K2

(MODE2)

3

=160 ×10−9×

= 640 × 10

= 160 × 10

C

3

3

1

1+C2

= 21

The AD2S93 acceleration constant is given by:

= K1 × K

K

a

2

Therefore in the example given,

K

= K1 × K2 = 21 × 640 × 103 = 13.44 × 106 s

a

–2

The AD2S93’s design has been optimized with a critically

damped response. The closed-loop transfer function is given

by:

θ

OUT

θ

IN

=

1+st1+

1+st

s

K1K

1

2

+

2

s

3t2

K1K

θ

OUT

=

θ

IN

2

K

1K2

2

s

(1+ st

1+st

)

1

2

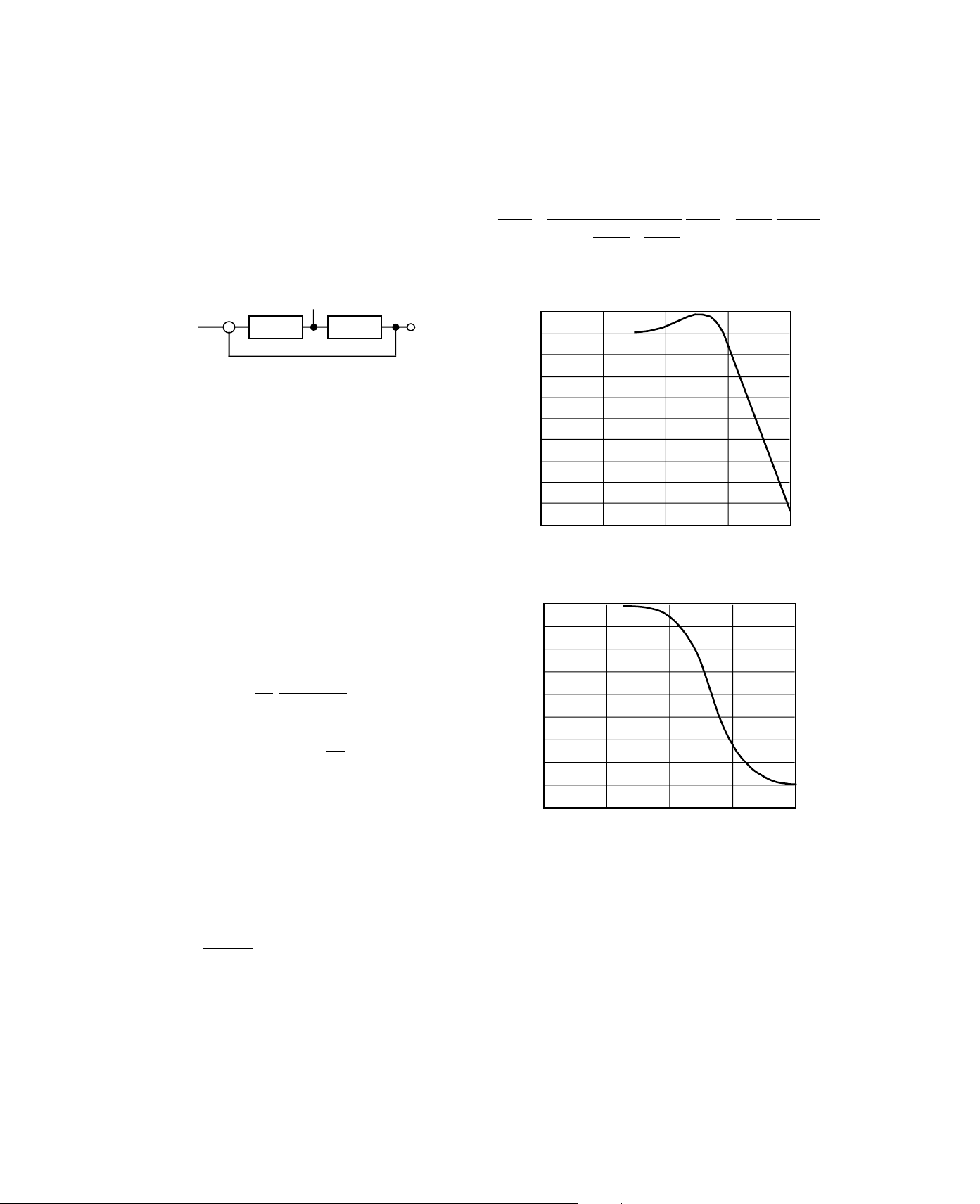

The normalized gain and phase diagrams are given in Figures 10

and 11 with a bandwidth of 1.25 kHz.

5

0

–5

–10

–15

–20

–25

–30

–35

–40

–45

1

10

100

FREQUENCY – Hz

1k

10k

Figure 10. AD2S93 Gain Plot

0

–20

–40

–60

–80

–100

–120

–140

–160

–180

1

100

FREQUENCY – Hz

1k

10k10

Figure 11. AD2S93 Phase Plot

–10–

REV. A

AD2S93

The small step response is given in Figure 12, and is the time

taken for the converter to settled to within 1 LSB.

ts = 7 ms (14-bit resolution)

The large step response (steps >5% of FSR) applies when the

error voltage will exceed the linear range of the converter. Typically it will take three times longer to reach the first peak FSR.

In response to a velocity step [VELOUT/(dθ/dt)] the velocity

output will exhibit the same response characteristics as outlined

above.

2%FS

POSITION

0

0

161284

20

Figure 12. Small Step Response

SOURCES OF ERROR

ACCELERATION ERROR

A tracking converter employing a Type 2 servo loop does not

suffer any velocity lag, however, there is an additional error due

to acceleration. This additional error can be defined using the

acceleration constant K

of the converter.

a

input acceleration

Ka=

position

The numerator and denominator’s units must be consistent.

does not define maximum input acceleration, only the error due

K

a

to its acceleration. The maximum acceleration allowable before

the converter loses track is dependent on the positional accuracy

requirement of the system.

Position Error × K

K

can be used to predict the output position error for a

a

given input acceleration. The AD2S93 in the example has

= 13.44 × 10

a K

a

14

100 × 2

LSB/sec2.

6

sec-2 if we apply an input accelerating at

input acceleration LSB/ sec

Error in LSBs =

100 × 2

=

13.44 ×10

a

K

14

= 0.12 LSBs

6

= LSB/sec

sec

[]

a

2

2

[]

-2

REV. A

–11–

0.048 (1.21)

0.042 (1.07)

0.050

(1.27)

BSC

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

P-28A

PIN 1

IDENTIFIER

TOP VIEW

0.056 (1.42)

0.042 (1.07)

26 4

25

19

18

SQ

SQ

0.020

(0.50)

0.048 (1.21)

0.042 (1.07)

5

11

12

R

0.456 (11.58)

0.450 (11.43)

0.495 (12.57)

0.485 (12.32)

0.180 (4.57)

0.165 (4.19)

0.110 (2.79)

0.085 (2.16)

0.025 (0.63)

0.015 (0.38)

0.021 (0.53)

0.013 (0.33)

0.430 (10.92)

0.390 (9.91)

0.032 (0.81)

0.026 (0.66)

0.040 (1.01)

0.025 (0.64)

C1881–28–1/94

–12–

PRINTED IN U.S.A.

Loading...

Loading...