Linear Output

NC

R1

GND

R3

R2

V

CC

AD22151

NC = NO CONNECT

OUTPUT

0.1F

NC

R1

GND

R3

R2

V

CC

AD22151

NC = NO CONNECT

OUTPUT

0.1F

R4

a

FEATURES

Adjustable Offset to Unipolar or Bipolar Operation

Low Offset Drift Over Temperature Range

Gain Adjustable Over Wide Range

Low Gain Drift Over Temperature Range

Adjustable First Order Temperature Compensation

Ratiometric to V

APPLICATIONS

Automotive

Throttle Position Sensing

Pedal Position Sensing

Suspension Position Sensing

Valve Position Sensing

Industrial

Absolute Position Sensing

Proximity Sensing

GENERAL DESCRIPTION

The AD22151 is a linear magnetic field transducer. The sensor

output is a voltage proportional to a magnetic field applied

perpendicularly to the package top surface.

The sensor combines integrated bulk Hall cell technology and

instrumentation circuitry to minimize temperature related drifts

associated with silicon Hall cell characteristics. The architecture

maximizes the advantages of a monolithic implementation while

allowing sufficient versatility to meet varied application requirements with a minimum number of components.

Principle features include dynamic offset drift cancellation and a

built-in temperature sensor. Designed for single +5 volt supply

operation, the AD22151 achieves low drift offset and gain operation over –40°C to +150°C. Temperature compensation can

accommodate a number of magnetic materials commonly utilized in economic position sensor assemblies.

The transducer may be configured for specific signal gains dependent upon application requirements. Output voltage can be

adjusted from fully bipolar (reversible) field operation to fully

unipolar field sensing.

The voltage output achieves near rail-to-rail dynamic range,

capable of supplying 1 mA into large capacitive loads. The signal is ratiometric to the positive supply rail in all configurations.

CC

Magnetic Field Sensor

AD22151

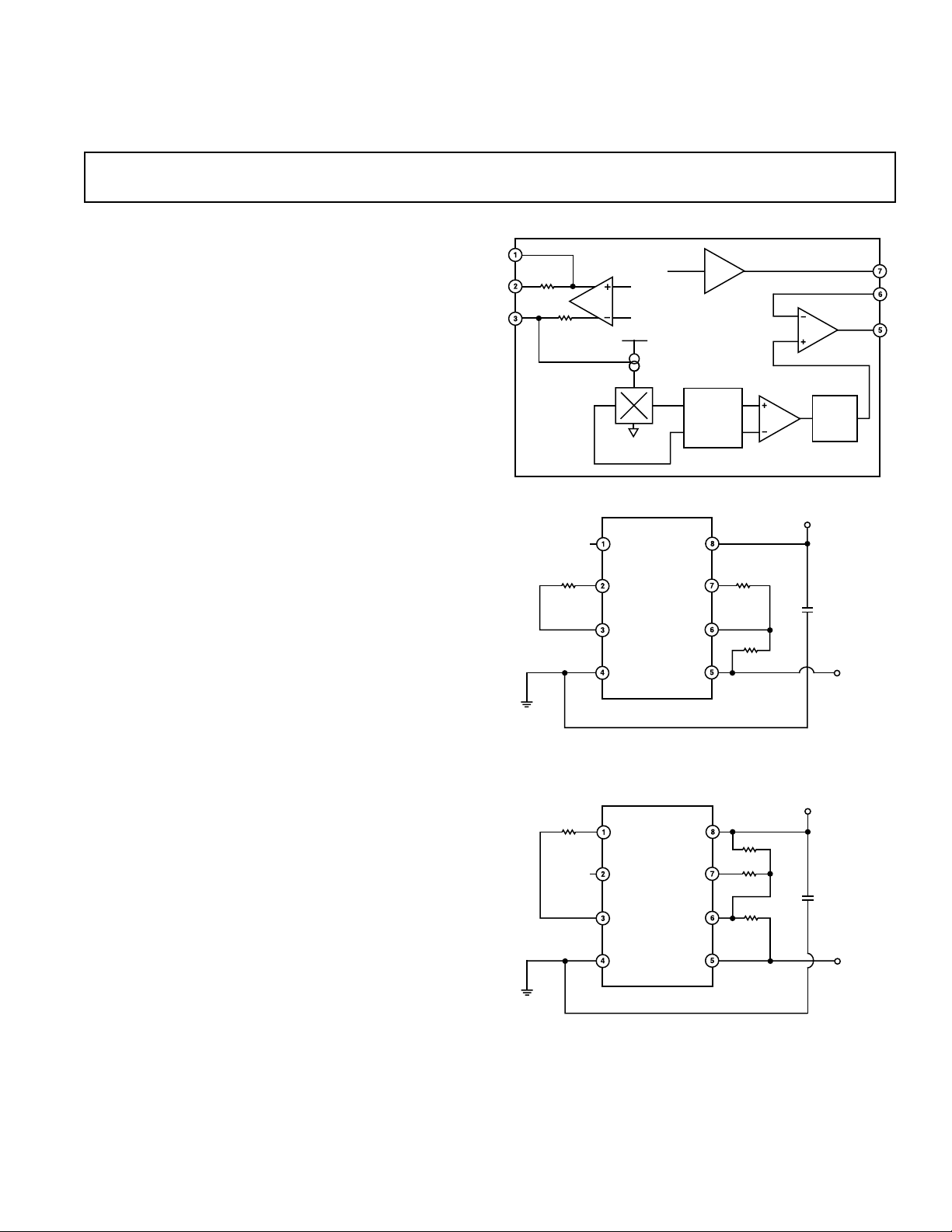

FUNCTIONAL BLOCK DIAGRAM

V

/2

CC

TEMP REF

AD22151

I

SOURCE

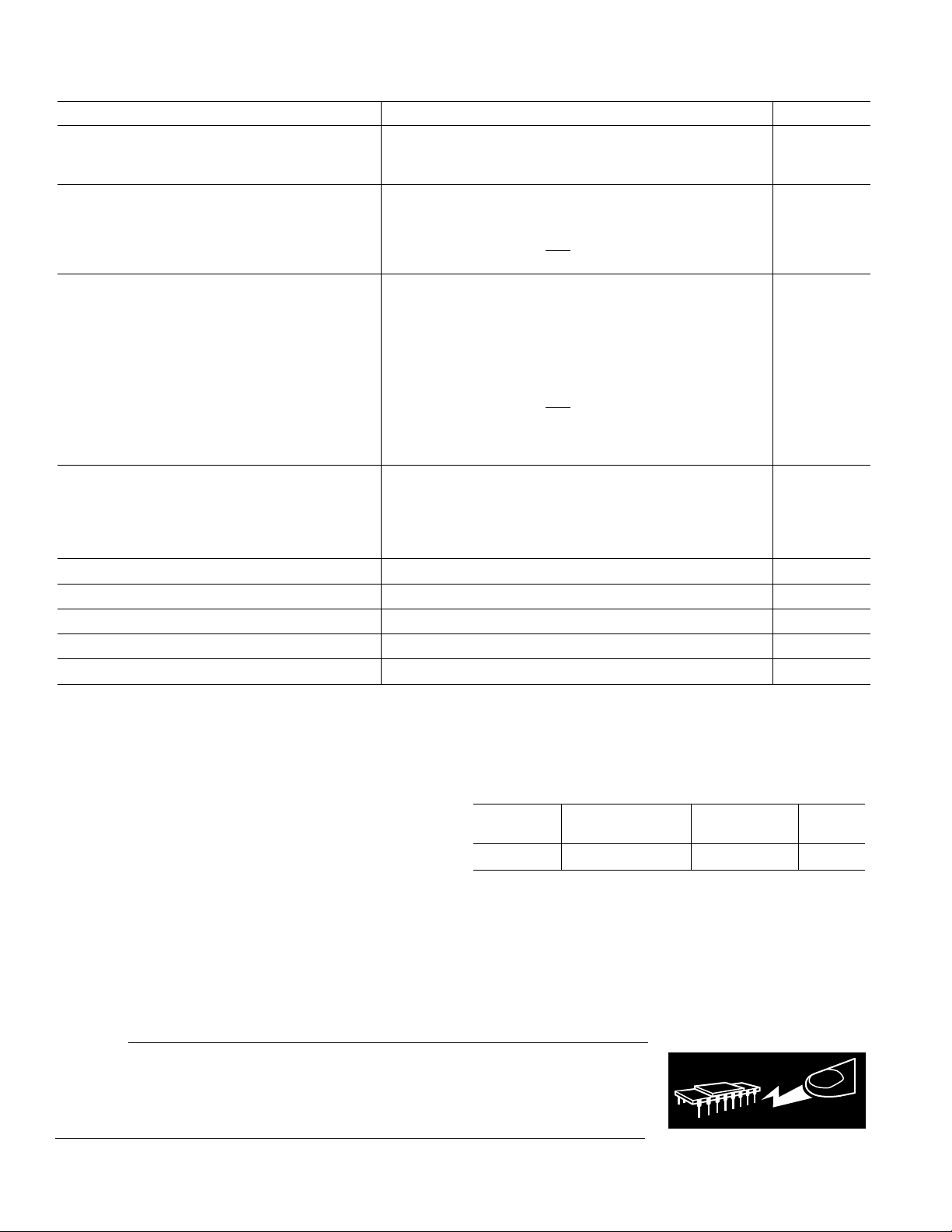

Figure 1. Typical Bipolar Configuration with Low

(< –500 ppm) Compensation

OUT AMP

DEMODSWITCHES

REF

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

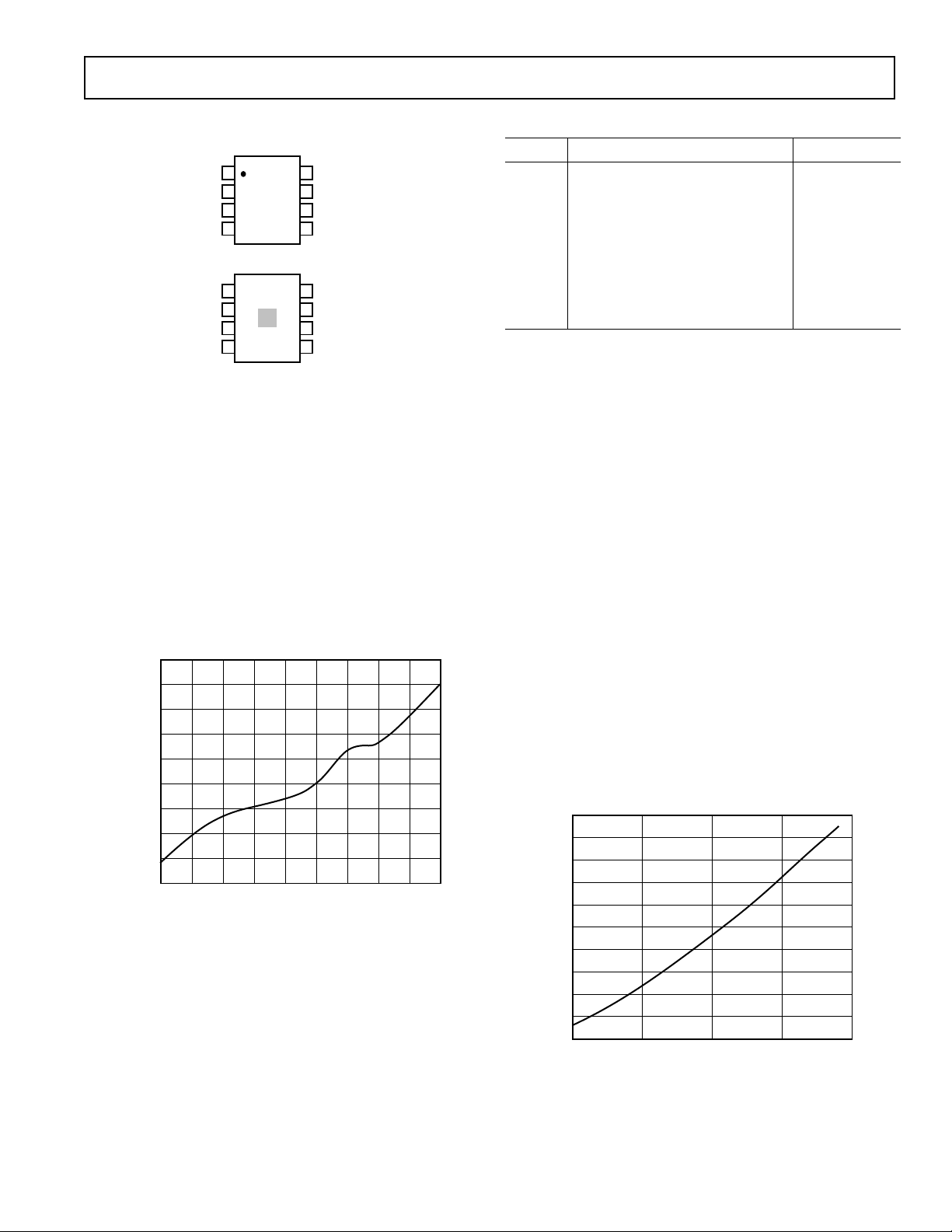

Figure 2. Typical Unipolar Configuration with High

(≈

–2000 ppm) Compensation

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1997

AD22151–SPECIFICATIONS

WARNING!

ESD SENSITIVE DEVICE

(TA = +25ⴗC and V+ = +5 V unless otherwise noted)

Parameters Min Typ Max Units

OPERATION

Operating 4.5 5.0 6.0 V

V

CC

ICC Operating 6.0 10 mA

INPUT

TC3 (Pin 3) Sensitivity/Volt 160 µV/G/V

V

Input Range

OUTPUT

1

2

CC

± 0.5 V

2

Sensitivity (External Adjustment, Gain = 1) 0.4 mV/G

Linear Output Range 10 90 % of V

Output Min 5 % of V

Output Max (Clamp) 93 % of V

CC

CC

CC

Drive Capability 1.0 mA

V

Offset @ 0 Gauss

Offset Adjust Range 5 95 % of V

CC

2

V

CC

Output Short Circuit Current 5.0 mA

ACCURACIES

Nonlinearity (10% to 90% Range) 0.1 % FS

Gain Error (Over Temperature Range) ±1%

Offset Error (Over Temperature Range) ±6.0 G

Uncompensated Gain TC (G

RATIOMETRICITY ERROR 1 %V/V

) 950 ppm

TCU

CC

3 dB ROLL-OFF (5 mV/G) 5.7 kHz

OUTPUT NOISE FIGURE (6 kHz BW) 2.4 mV/rms

PACKAGE 8-Lead SOIC

OPERATING TEMPERATURE RANGE –40 +150 °C

NOTES

1

–40°C to +150°C.

2

RL = 4.7 kΩ.

Specifications subject to change without notice.

ABSOLUTE MAXIMUM RATING*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 V

Package Power Dissipation . . . . . . . . . . . . . . . . . . . . . 25 mW

Storage Temperature . . . . . . . . . . . . . . . . . . –50°C to +160°C

Output Sink Current, I

. . . . . . . . . . . . . . . . . . . . . . . 15 mA

O

Model Range Description Option

AD22151YR –40°C to +150°C 8-Lead SOIC SO-8

Temperature Package Package

Magnetic Flux Density . . . . . . . . . . . . . . . . . . . . . . Unlimited

Lead Temperature (Soldering 10 sec) . . . . . . . . . . . . .+300°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; the functional operation of

the device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to the absolute maximum

rating conditions for extended periods may affect device reliability.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD22151 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–2–

ORDERING GUIDE

REV. 0

AD22151

TEMPERATURE – ⴗC

14

–4

–40

% GAIN

10 60 110 160

12

4

2

0

–2

10

6

8

–6

PIN CONFIGURATION

1

TC1

2

AD22151

TC2

TOP VIEW

3

TC3

(Not to Scale)

4

GND

AREA OF SENSITIVITY*

1

2

3

(Not to Scale)

4

* SHADED AREA REPRESENTS

MAGNETIC FIELD AREA OF

SENSITIVITY (20MILS ⴛ 20MILS)

•

POSITIVE B FIELD INTO TOP OF

PACKAGE RESULTS IN A POSITIVE

VOLTAGE RESPONSE

8

V

7

REF

6

GAIN

5

OUTPUT

8

7

6

5

CC

CIRCUIT OPERATION

The AD22151 consists of epi Hall plate structures located at

the center of the die. The Hall plates are orthogonally sampled

by commutation switches via a differential amplifier. The two

amplified Hall signals are synchronously demodulated to provide a resultant offset cancellation (see Figure 3). The demodulated signal passes through a noninverting amplifier to provide

final gain and drive capability. The frequency at which the

output signal is refreshed is 50 kHz.

0.005

0.004

0.003

0.002

0.001

0

OFFSET – Volts

–0.001

–0.002

–0.003

–0.004

140 –40120

100 80 60 40 20 0 –20

TEMPERATURE – ⴗC

Figure 3. Relative Quiescent Offset vs. Temperature

PIN FUNCTION DESCRIPTIONS

Pin No. Description Connection

1 Temperature Compensation 1 Output

2 Temperature Compensation 2 Output

3 Temperature Compensation 3 Input/Output

4 Ground

5 Output Output

6 Gain Input

7 Reference Output

8 Positive Power Supply

“valleys” of the silicon crystal. Mechanical force on the sensor

is attributable to package-induced stress. The package material

acts to distort the encapsulated silicon altering the Hall cell gain

by ±2% and G

Figure 4 shows the typical G

by ±200 ppm.

TCU

characteristic of the AD22151.

TCU

This is the observable alteration of gain with respect to temperature with Pin 3 (TC3) held at a constant 2.5 V (uncompensated).

If a permanent magnet source used in conjunction with the

sensor also displays an intrinsic TC (B

), it will require factor-

TC

ing into the total temperature compensation of the sensor

assembly.

Figures 5 and 6 represent typical overall temperature/gain performance for a sensor and field combination (B

= –200 ppm).

TC

Figure 5 is the total drift in volts over a –40°C to +150°C temperature range with respect to applied field. Figure 6 represents

typical percentage gain variation from +25°C. Figures 7 and 8

show similar data for a B

= –2000 ppm.

TC

TEMPERATURE DEPENDENCIES

The uncompensated gain temperature coefficient (G

TCU

) of the

AD22151 is the result of fundamental physical properties associated with silicon bulk Hall plate structures. Low doped Hall

plates operated in current bias mode exhibit a temperature

relationship determined by the action of scattering mechanisms

and doping concentration.

The relative value of sensitivity to magnetic field can be altered

by the application of mechanical force upon silicon. The mechanism is principally the redistribution of electrons throughout the

–3–REV. 0

Figure 4. Uncompensated Gain Variation (from +25°C) vs.

Temperature

AD22151

0.025

0.020

0.015

0.010

DELTA SIGNAL – Volts

0.005

0

–600 –400 –200 0 200 400 600

Figure 5. Signal Drift Over Temperature (–40°C to +150°C)

vs. Field (–200 ppm); +5 V Supply

FIELD – Gauss

2.0

1.8

1.6

1.4

1.2

1.0

0.8

% GAIN

0.6

0.4

0.2

0

–0.2

–40 10 60 110 160

TEMPERATURE – ⴗC

Figure 8. Gain Variation (from +25°C) vs. Temperature

Ω

(–2000 ppm Field; R1 = 12 k

)

0.25

0.20

0.15

0.10

% GAIN

0.05

0

–0.05

–40 10 60 110 160

TEMPERATURE – ⴗC

Figure 6. Gain Variation from +25°C vs. Temperature

(–200 ppm) Field; R1 –15 k

0.045

0.040

0.035

0.030

0.025

0.020

0.015

DELTA SIGNAL – Volts

0.010

0.005

0

–600 800

–800 –400 –200 0 200 400 600

Ω

FIELD – Gauss

Figure 7. Signal Drift Over Temperature (–40°C to +150°C)

vs. Field (–2000 ppm); +5 V Supply

TEMPERATURE COMPENSATION

The AD22151 incorporates a “thermistor” transducer that

detects relative chip temperature within the package. This

function provides a compensation mechanism for the various

temperature dependencies of the Hall cell and magnet combinations. The temperature information is accessible at Pins 1 and 2

(≈ +2900 ppm /°C) and Pin 3 (≈ –2900 ppm/°C) as represented

by Figure 9. The compensation voltages are trimmed to converge at V

/2 at +25°C. Pin 3 is internally connected to the

CC

negative TC voltage via an internal resistor (see Functional

Block Diagram). An external resistor connected between Pin 3

and Pins 1 or 2 will produce a potential division of the two complementary TC voltages to provide optimal compensation. The

aforementioned Pin 3 internal resistor provides a secondary TC

designed to reduce second order Hall cell temperature sensitivity.

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

VOLTS – Reference

–0.6

–0.8

–1.0

150 112 74 –2 –40

TC1, TC2 VOLTS

TC3 VOLTS

36

TEMPERATURE – ⴗC

Figure 9. TC1, TC2 and TC3 with Respect to Reference vs.

Temperature

The voltages present at Pins 1, 2 and 3 are proportional to the

supply voltage. The presence of the Pin 2 internal resistor

distinguishes the effective compensation ranges of Pins 1 and 2

(see temperature configuration in Figures 1 and 2, and typical

resistor values in Figures 10 and 11).

Variation occurs in the operation of the gain temperature

compensation for two reasons. First, the die temperature within

–4–

REV. 0

the package is somewhat higher than the ambient temperature

R1 – k⍀

800

DRIFT – ppm

600

–200

400

0

200

0 5 10 20 25

–400

–600

15 30 35 40 45 50

due to self-heating as a function of power dissipation. Second,

package stress effect alters the specific operating parameters of

the gain compensation, particularly the specific cross over

temperature of TC1, TC3 ( ≈ ±10°C).

CONFIGURATION AND COMPONENT SELECTION

There are three areas of sensor operation that require external

component selection. Temperature compensation (R1), signal

gain (R2

Temperature

If the internal gain compensation is used, an external resistor is

required to complete the gain TC circuit at Pin 3. A number of

factors contribute to the value of this resistor.

a. The intrinsic Hall cell sensitivity TC ≈ 950 ppm.

b. Package induced stress variation in a. ≈ ±150 ppm.

c. Specific field TC ≈ –200 ppm (Alnico), –2000 ppm

(Ferrite), 0 ppm (electromagnet) etc.

d. R1, TC.

The final value of target compensation also dictates the use of

either Pin 1 or Pin 2. Pin 1 is provided to allow for large negative field TC such as ferrite magnets, thus R1 would be connected to Pins 1 and 3.

Pin 2 uses an internal resistive TC to optimize smaller field

coefficients such as Alnico, down to 0 ppm coefficients when

only the sensor gain TC itself is dominant. The TC of R1 itself

will also effect the compensation and as such a low TC resistor

(±50 ppm) is recommended.

Figures 10 and 11 indicate R1 resistor values and their associated effectiveness for Pins 1 and 2 respectively. Note that the

indicated drift response in both cases incorporates the intrinsic

Hall sensitivity TC (B

For example, the AD22151 sensor is to be used in conjunction

with an Alnico material permanent magnet. The TC of such

magnets is ≈ –200 ppm (see Figures 5 and 6). Figure 11 indicates that a compensating drift of +200 ppm at Pin 3 requires a

nominal value of R1 = 18 kΩ (assuming negligible drift of R1

itself).

3000

1500

DRIFT – ppm

Figure 10. Typical Resistor Value R1 vs. (Pins 1 and 3)

Drift Compensation

and R3), and offset (R4).

).

TCU

3500

2500

2000

1000

500

0

0 5 10 20 25

15 30

R1 – k⍀

AD22151

Figure 11. Typical Resistor Value R1 (Pins 2 and 3) vs.

Drift Compensation

GAIN AND OFFSET

The operation of the AD22151 can be bipolar (i.e., 0 Gauss =

/2) or a ratiometric offset can be implemented to Position

V

CC

Zero Gauss point at some other potential (i.e., 0.25 V).

The gain of the sensor can be set by the appropriate R2 and R3

resistor values (see Figure 1) such that:

Gain =1+

However, if an offset is required to position the quiescent output at some other voltage then the gain relationship is modified

to:

Gain =1+

The offset that R4

Offset =

For example:

At V

= 5 V at room temperature, the internal gain of the

CC

sensor is approximately 0.4 mV/Gauss. If a sensitivity of 6 mV/

Gauss is required with a quiescent output voltage of 1 V, the

following calculations apply (see Figure 2 ).

A value for R3 would be selected that complied with the various

considerations of current and power dissipation, trim ranges (if

applicable), etc. For the purpose of example assume a value of

85 kΩ.

To achieve a quiescent offset of 1 V requires a value for R4 as:

V

CC

2

V

CC

Thus:

R4 =

The gain required would be 6/0.4 (mV/Gauss) = 15

–5–REV. 0

R3

R2

(R2R4)

(R3+ R4)

–1

= 0.375

–1

85 kΩ

0.375

× 0.4 mV /G

R3

×0. 4 mV /G

introduces is:

R3

× VCC–V

()

– 85 kΩ=141.666 kΩ

OUT

(1)

(2)

(3)

(4)

(5)

AD22151

(

)

Knowing the values of R3 and R4 from above, and noting Equation 2, the parallel combination of R2 and R4 required is:

85 kΩ

= 6. 071 kΩ

15 –1

()

Thus:

= 6.342 kΩ

R2 =

6.071 kΩ

1

1

–

141.666 kΩ

1

NOISE

The principle noise component in the sensor is thermal noise

from the Hall cell. Clock feedthrough into the output signal is

largely suppressed with application of a supply bypass capacitor.

Figure 12 shows the power spectral density (PSD) of the output

signal for a gain of 5 mV/Gauss. The effective bandwidth of the

sensor is approximately 5.7 kHz. This is shown by Figure 13

small signal bandwidth vs. gain. The PSD indicates an rms

noise voltage of 2.8 mV within the 3 dB bandwidth of the sensor. A wideband measurement of 250 MHz indicates 3.2 mV

rms (see Figure 14a).

In many position sensing applications bandwidth requirements

can be as low as 100 Hz. Passing the output signal through an

LP filter, for example 100 Hz, would reduce the rms noise voltage to ≈1 mV. A dominant pole may be introduced into the

output amplifier response by connection of a capacitor across

feedback resistor R3, as a simple means of reducing noise at the

expense of bandwidth. Figure 14b indicates the output signal of

a 5 mV/G sensor bandwidth limited to 180 Hz with a 0.01 µF

feedback capacitor.

Note: Measurements taken with 0.1 µF decoupling capacitor

between V

and GND at +25°C.

CC

7

6

5

4

3

FREQUENCY– kHz

2

1

0

123

3dB FREQ. (kHz)

456

GAIN – mV/GAUSS

Figure 13. Small-Signal Gain Bandwidth

TEK STOP: 25.0 kS/s

2

CH2 10.0mV

3ACQS

[

B

W

T

T

M2.00ms

[

CH2 PK-PK

19.2mV

Figure 14a. Peak-to-Peak Full Bandwidth (10 mV/Division)

TEK STOP: 25.0 kS/s

7ACQS

[

T

[

B MARKER X 64Hz

100

H

LOGMAG

5 dB

/div

1

H

START: 64 Hz

NOISE: PSD

8 mV/GAUSS

STOP: 25.6 kHz

RMS: 64

Figure 12. Power Spectral Density (5 mV/G)

Y: 3.351 H

–6–

CH2 PK-PK

4.4mV

2

CH2 10.0mV

B

W

T

M2.00ms

Figure 14b. Peak-to-Peak 180 Hz Bandwidth

(10 mV/Division)

REV. 0

TEMPERATURE – ⴗC

2.496

VOLTS

2.494

2.492

2.488

2.490

140 120 100 80 60 40 20

2.486

2.484

0 –40–20

GAIN = 3.78mV/G

0.06

0.05

0.04

0.03

0.02

0.01

0

% ERROR

–0.01

–0.02

–0.03

–0.04

–0.05

–600 –400 –200 0 200 400 600

FIELD – Gauss

AD22151

Figure 15. Integral Nonlinearity vs. Field

Figure 16. Absolute Offset Volts vs. Temperature

–7–REV. 0

AD22151

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead SOIC

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

85

0.0500 (1.27)

PLANE

0.2440 (6.20)

0.2284 (5.80)

41

BSC

0.0192 (0.49)

0.0138 (0.35)

0.0688 (1.75)

0.0532 (1.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8ⴗ

0.0500 (1.27)

0ⴗ

0.0160 (0.41)

C3213–8–10/97

ⴛ 45ⴗ

–8–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...