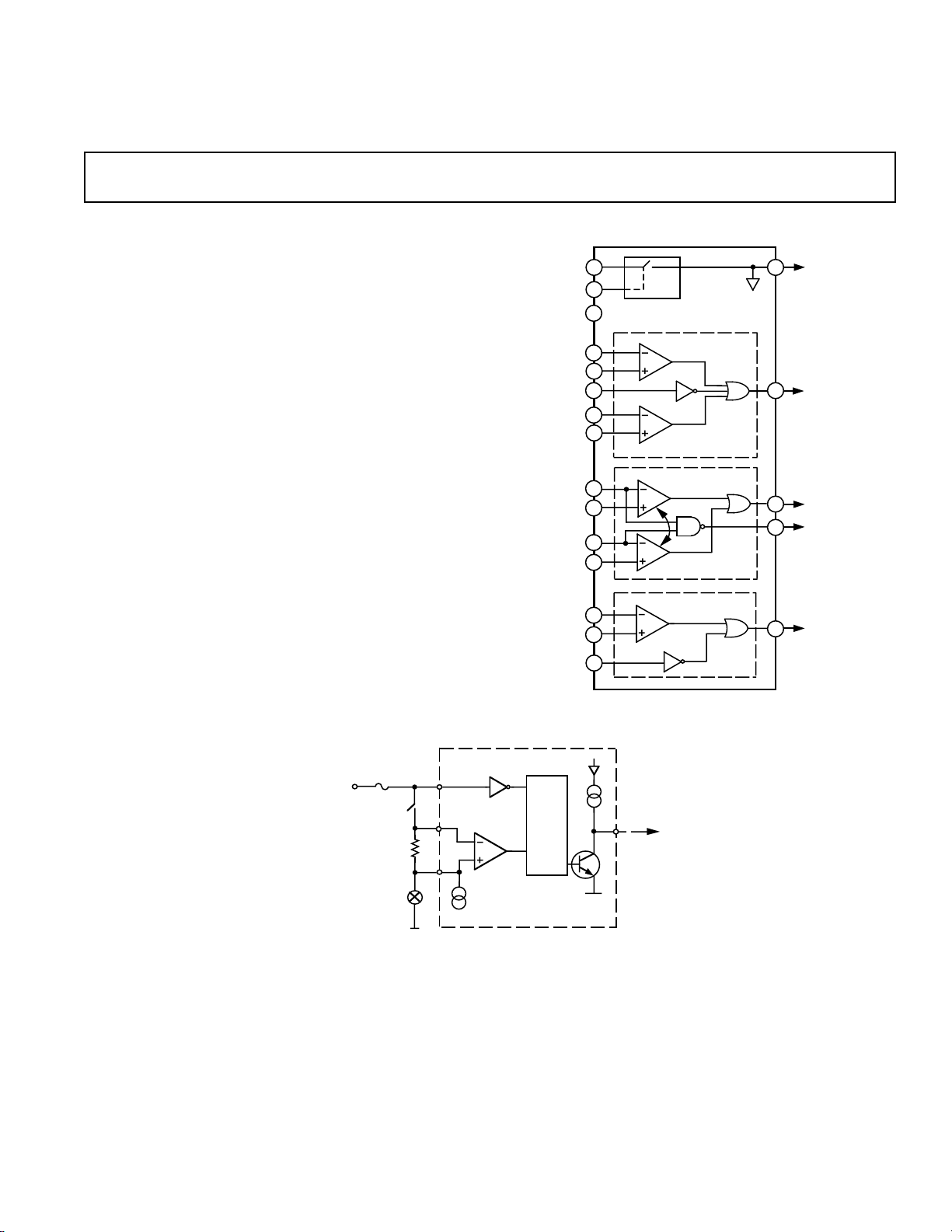

SWITCH &

LIMITER

4

5

6

9

8

CHANNEL 1

CHANNEL 2

CHANNEL 3

2

1

20

3

7

11

10

13

12

CHANNEL 4

CHANNEL 5

14

15

16

17

19

18

CHIP

ENABLE

GND

+IN1

–IN1

–IN2

+IN2

–IN3

+IN3

–IN4

+IN4

–IN5

+IN5

POWER

OUT

OUT 1 & 2

OUT 3 & 4

OUT (3 × 4)

OUT 5

AD22001

IN

FUSE

1 & 2

IN

FUSE

5

+V

S

5-Channel Monolithic Comparator

FUSE

+V BATT

SWITCH

COPPER

SHUNT

RESISTOR

LAMP

SIGNAL CONDITIONING

AND SIGNAL PROCESSING

OUTPUT

a

FEATURES

Continuous Status Checks of Five Bulbs

Lamp Status Check in “ON” and “OFF” States

Status Checks of Two In-Line Fuses

Very Low Voltage Drop at Sensor Shunt Resistor

(Comparator Threshold 1.75 mV at 228C)

Temperature and Supply Voltage Compensated

Powered Directly from Car Battery: Protection

Included for Transient, Reverse Supply, Load Dump

Operating Temperature Range: –408C to +1258C

15 V CMOS Compatible Digital Output Signals

Voltage Limited Power Supply Output for 15 V CMOS

Logic ICs

GENERAL DESCRIPTION

The AD22001 is a monolithic, five-channel comparator circuit

for monitoring the functionality of lamps in automotive

applications.

The IC tests the series circuit leading to the lamp to determine

if the circuit is intact and a functional lamp is in the socket. The

AD22001 continuously checks the functionality of up to five

bulbs in either their “on” or “off” state, and also tests for the

presence of an in-line fuse in two of the series circuits.

Digital outputs indicate the status of each channel. Additionally,

the AD22001 provides a voltage limited power supply output to

supply 15 V CMOS circuits that may interface to the AD22001.

for Lamp Monitoring

AD22001*

FUNCTIONAL BLOCK DIAGRAM

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

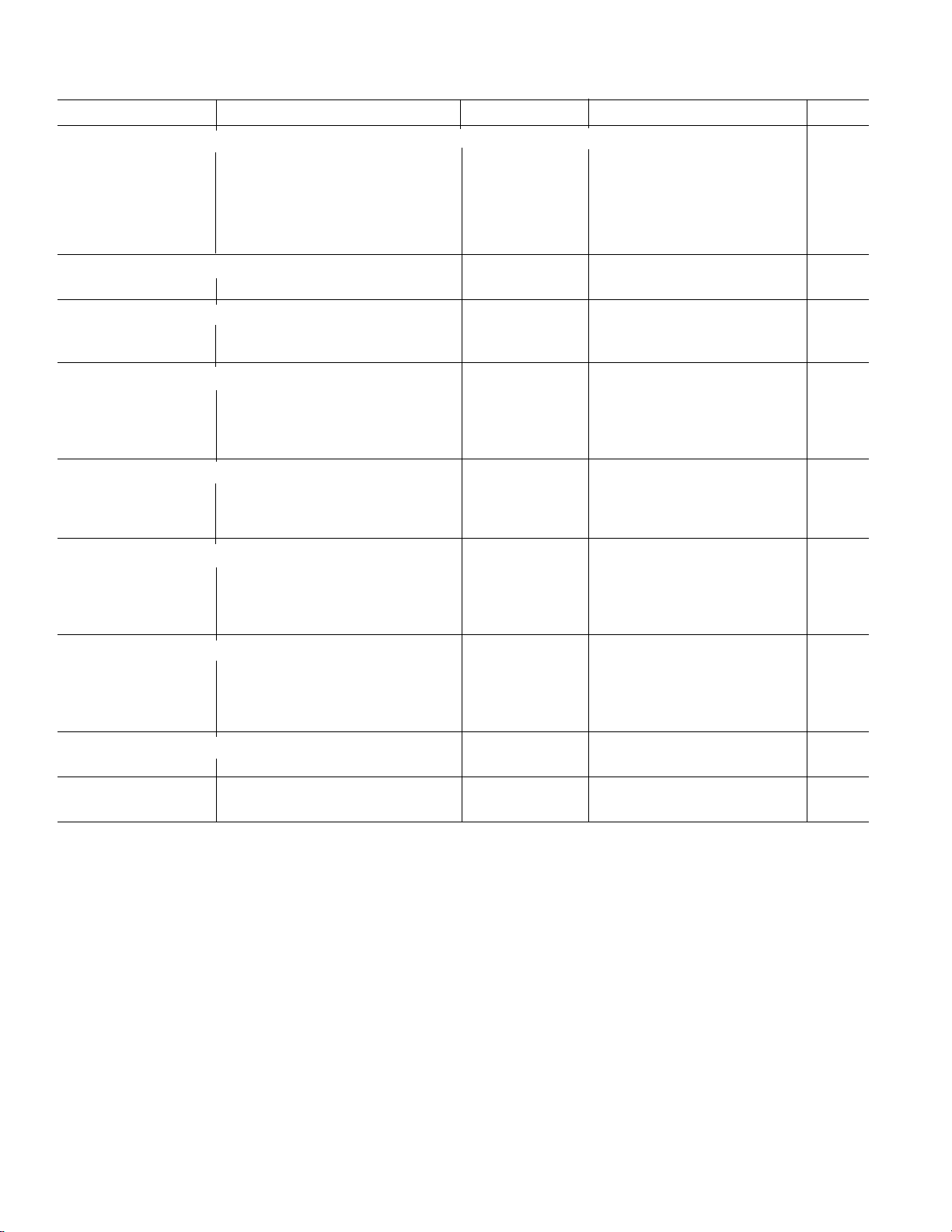

Figure 1. Typical Application Circuit for a Single Channel Lamp Monitor

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

AD22001–SPECIFICA TIONS

(TA = +228C, VS = +13.5 V unless otherwise noted)

Parameter Test Conditions Min Typ Max Units

DIFFERENTIAL INPUTS (Voltage Drop from Shunt Resistor: Pins 4 & 5, 8 & 9, 10 & 11, 14 & 15, 16 & 17)

V

INDIFF

V

INCM

Comparator Threshold Voltage

Common-Mode Threshold Voltage

Power Supply Sensitivity of V

Temperature Compensation of V

I

I

INB

INC

Input Bias Current 10 µA

Constant Current Source

SINGLE-ENDED INPUTS (Fuse Monitoring: Pins 6, 19)

V

INF

Fuse Input Threshold Voltage

1

1

2

INDIFF

INDIFF

4

5

9 V ≤ VS ≤ 16 V 50 %

3

1.5 1.75 2.0 mV

5 V

3770 ppm/°C

30 60 µA

CHIP ENABLE CONTROL INPUT (Pin 1)

V

V

INCE

INCD

Chip Enable, Input High 9 V

Chip Disable (Stop Operation)

6

OUTPUTS (Pins 7, 12, 13, 18)

V

OUTL

Output Voltage, Low Load = 500 µA 0.6 V

Indicates No Fault in Lamp Circuit

V

OUTH

Output Voltage, High 9 V ≤ VS ≤ V

SSDH

V

–2.5 V

OUTPS

Indicates Fault in Lamp Circuit Load = 50 µA

POWER SUPPLY (Pin 2: +V

V

S

I

S

, Pin 20: GND)

S

Supply Voltage 930V

Quiescent Supply Current Pin 1 High 1 3 5 mA

V

: No Load Pin 1 Low 100 µA

OUTH

POWER SUPPLY OUTPUT (Pin 3)

V

OUTPS

I

OUTPS

Power Supply Output Voltage 10 V < VS < 14.5 V VS–0.5 VS–0.3 V

≤ 1 mA

I

Max Output Voltage 16 18 V

Power Supply Output Current

7

OUTPS

2mA

OPERATING SHUTDOWN (Safety Features)

V

V

SSDH

SSDL

Operation Shutdown at High 30 33 36 V

Power Supply Voltages

Operation Shutdown at Low 79V

Power Supply Voltage

8

9

4 V

6 V

OUTPS

S

V

V

TEMPERATURE RANGE

T

A

Operating Temperature Range –40 +125 °C

PACKAGE

Plastic DIP (N-20) AD22001N

NOTES

1

In the presence of a common-mode voltage greater than 5 V, if the shunt voltage applied to the comparator does not exceed the threshold (i.e., the bulb is switched

on but does not draw current), then the device will indicate a failure.

2

At VS = 13.5 V, the differential input threshold voltage is typically 1.75 mV. With an increase of VS, the threshold voltage, V

Power supply sensitivity of 50% means that when the power supply voltage VS increases by 10%, the threshold voltage V

centage value: 5%.

3

This is the temperature coefficient to compensate for any temperature influence on the external copper PCB track shunt resistors. 3770 ppm/°C is equal to 6.6 µV/°C.

4

This current source is used to test the lamp when it is switched off (cold lamp test).

5

If the voltage at the input from the fuse (Pin 6 or 19) does not exceed the threshold voltage, then the output will indicate a failure.

6

When the Chip Enable is open-circuited, the chip is disabled.

7

Shorting V

8

At this voltage, or above, the internal power supply and the power output V

9

Below the minimum voltage, the circuit will shut down. Above the maximum, the circuit will be on if enabled.

All min and max specifications are guaranteed, although only those marked in boldface are tested on all production units at final test.

Specifications subject to change without notice.

to ground will cause the device to stop operating for that period. However, the device will not suffer any damage.

OUTPS

will be shut off.

OUTPS

–2–

, will change as well.

INDIFF

will be increased by half of this per-

INDIFF

REV. A

SWITCH &

VOLTAGE LIMITER

INTERNAL

POWER SUPPLY

POWER

SUPPLY

OUTPUT

SIGNAL

OUT

GND

2

1

CAR

BATTERY

FUSE

SWITCH

COPPER

SHUNT

LIGHT

BULB

CE

–IN

+IN

NOTES

1. TEMPERATURE COMPENSATION FOR COPPER SHUNT RESISTOR

AND SUPPLY VOLTAGE COMPENSATION.

2. CURRENT SOURCE FOR COLD BULB CHECKING

(AVAILABLE IN CHANNELS 1, 2, 3 AND 4).

+V

S

V

INCE

V

INF

I

INB

V

INDIFF

I

INB

IN

FUSE

I

INC

ABSOLUTE MAXIMUM RATINGS*

Forward Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . .+36 V

Reversed Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . –34 V

Forward Transient (40 ms) . . . . . . . . . . . . . . . . . . . . . . +60 V

Reverse Transient (40 ms) . . . . . . . . . . . . . . . . . . . . . . . –40 V

Voltage on Any Input Pin Relative to GND . . .–34 V to +36 V

Power Dissipation (V

= 13.5 V) . . . . . . . . . . . . . . . . 300 mW

S

Operating Temperature (Ambient) . . . . . . . –40°C to +125°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only, the functional

operation of the device at these or any other conditions above those indicated in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

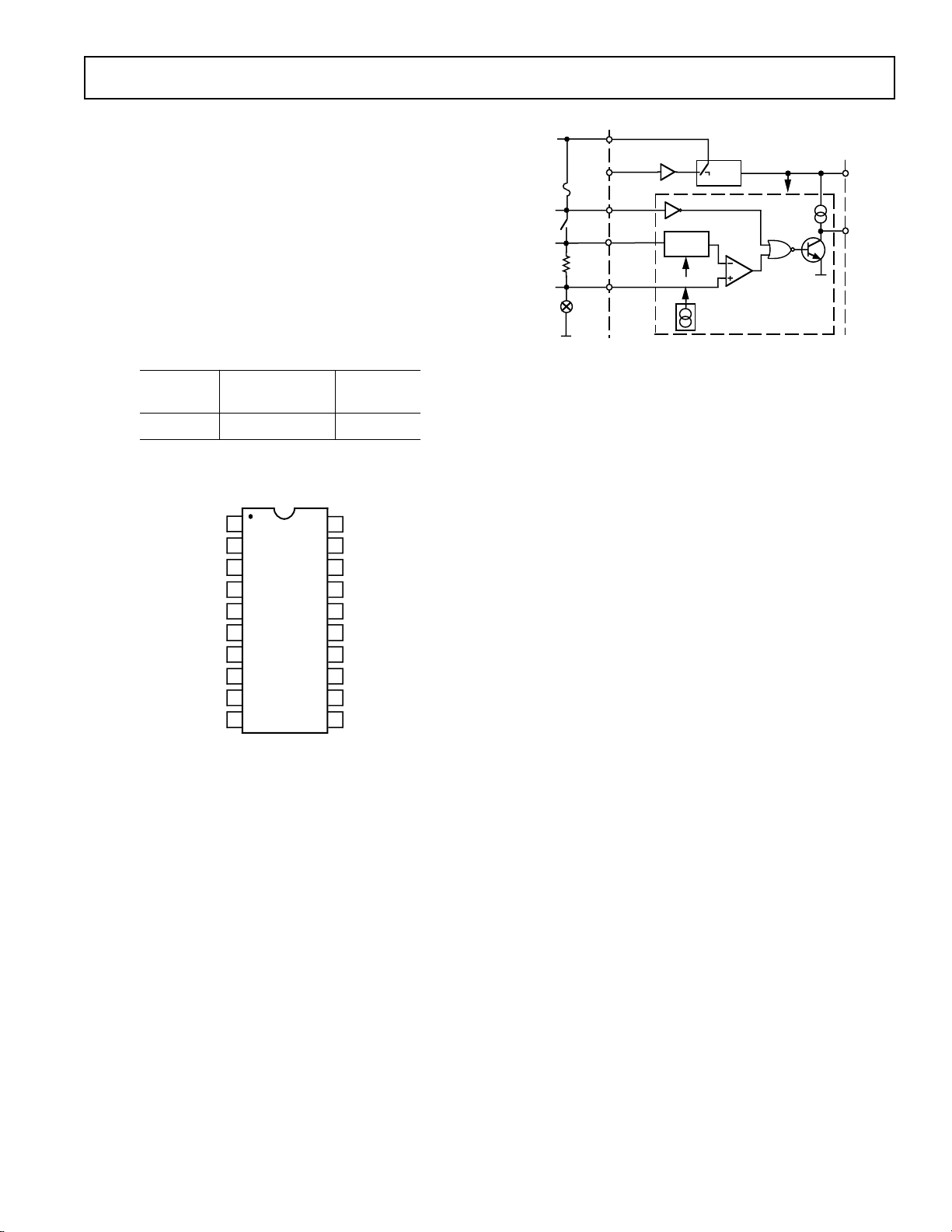

ORDERING INFORMATION

Temperature Package

Model Range Option*

AD22001N –40°C to +125°C N-20

*N = Plastic DIP Package.

CONNECTION DIAGRAM

+V

POWER OUT

–IN 1

+IN 1

FUSE 1 + 2

OUT 1 + 2

+IN 2

–IN 2

+IN 3

CE

S

1

2

3

4

5

6

7

8

9

10

AD22001N

TOP VIEW

(Not to Scale)

20

GND

19

FUSE 5

18

OUT 5

17

+IN 5

16

–IN 5

15

+IN 4

14

–IN 4

13

OUT 3 + 4

12

OUT (3 × 4)

11

–IN 3

PRODUCT DESCRIPTION

The AD22001’s five comparators each monitor the voltage

across a current sensing shunt resistor which is part of a lamp

circuit. Each comparator has a small threshold voltage, nominally 1.75 mV. The output of the comparator will change state

as the voltage developed across the shunt (by the lamp current)

crosses the threshold level. Because the threshold voltage is very

small, copper tracks on the PC board can be used as shunt resistors with low power dissipation.

AD22001

Figure 2. Typical Block Diagram of One Channel and

Power Supply Control

The AD22001 has internal linear signal processing that compensates the comparator threshold voltage as the resistance of the

copper shunt resistor changes with varying temperature. The

comparator thresholds are also adjusted to compensate for

changes in lamp current due to power supply variations.

The AD22001 was designed for a common automotive lamp

monitoring application. The connection diagram (Figure 3) and

the application suggestion (Figure 4) show the different combinations of functions that are performed for each channel.

FUNCTIONAL DESCRIPTION

The AD22001 consists of fine sensitive comparators with

built-in offset plus biasing and support for comprehensive lamp

circuit monitoring. The comparators are arrayed as a single and

two groups of two (as shown in Figure 3) arranged to meet a

variety of requirements. Two or more AD22001s can be

combined. The comparators are basically similar with additional

features according to their place in the array.

Hot Lamp Test

Each comparator has a differential input with built-in threshold

of 1.75 mV, under nominal operating conditions. The comparators are intended to monitor the voltage developed across a low

resistance shunt by a lamp current. The comparators are active

whenever they are connected to the battery circuit. They indicate normal or okay (the series circuit to the lamp is intact)

when the threshold voltage of 1.75 mV is exceeded. This occurs

when the +input is driven negative with respect to the –input by

a voltage greater than the threshold. They also indicate normal

if they are not activated by common-mode battery voltage,

whether the threshold voltage is exceeded or not. They indicate

a fault if the common-mode is applied but the threshold is not

exceeded.

REV. A

–3–

AD22001

INPUTS AND SUPPLY OUTPUTS

POWER SUPPLY

+V

2

S

CHIP

GND

1 & 2

–IN2

+IN2

–IN3

+IN3

–IN4

+IN4

+IN5

FUSE

–IN1

+IN1

–IN5

1

20

4

5

6

9

8

11

10

14

15

16

17

19

5

ENABLE

R

S

IN

FUSE

R

S

R

S

R

S

R

S

IN

SWITCH &

LIMITER

CHANNEL 1

CHANNEL 2

CHANNEL 3

CHANNEL 4

CHANNEL 5

OUTPUT

3

V

SIGNAL OUTPUTS

OUT 1 & 2

7

13

OUT 3 & 4

12

OUT (3 × 4)

18

OUT 5

OUTPS

Figure 3. AD22001 Connection Diagram

Thus, in the absence of voltage applied to light the lamp, the

lamp resistance holds the common-mode voltage low, and no

fault is indicated. When the lamp circuit is powered, voltage on

the comparator inputs activates the comparator which indicates

a fault if the lamp current does not cause the shunt voltage to

exceed the threshold.

Cold Lamp Test

In addition to the standard hot lamp test, four of the comparators have a cold lamp test current of about 60 µA applied. If the

lamp circuit is not switched on but the lamp circuit is incomplete (failed lamp or connection), the small test current will

raise the common-mode voltage of the comparator at its input

and cause it to indicate a fault. Individual comparator inputs

draw about 10 µA each.

Description of Channel 5

The single comparator in Channel 5 is intended for brake-light

testing. Comparator 5 does not have the cold test feature, since

this lamp is normally tested in conjunction with the brake-light

switch. The comparator is combined with a fuse test circuit

which checks for battery voltage at its input. This input

normally connects between the fuse and brake-light switch.

The outputs of the hot lamp test and the fuse test are combined

at OUT 5 which indicates zero or low as the normal or okay

state and one or high if either test fails. The output will indicate

a fault if battery voltage is lost from the fuse test line, or if the

lamp circuit is powered, but the circuit fails to draw current.

Description of Channels 3 and 4

Comparators 3 and 4 are linked to test pairs of lamp circuits. In

addition to the hot lamp test, Channels 3 and 4 each have a cold

lamp test current. A fault for either test at input 3 or 4 will

cause their common output, OUT 3 & 4, to indicate failure

(registered as a one or high).

These comparators are intended for lamp circuits which are

switched simultaneously, but are fused independently. A special

linkage between the comparators causes them to indicate a fault

if common-mode voltage is applied to only one of the pair. This

functions as a test of both fuses.

One additional output is provided which tests when both lamps

are switched on (whether the lamp circuit draws current or not).

This circuit signals a zero or low level at OUT (3 3 4) whenever

both lamp circuits are powered (implying fuses are present) and

a one or high level otherwise.

Description of Channels 1 and 2

Comparators 1 and 2 are also linked and share a common output. A fault at either input will register as a one or high at OUT

1 & 2. Otherwise this output will be low. Each of these comparators also has a cold lamp test current. These comparators

are intended for two lamp circuits which have a common fuse,

and a fuse test line, similar to the brake-light test, is brought

out.

A summary of the tests performed by each channel is given in

Table I.

Signal Outputs

The signal outputs, OUT 1 & 2, OUT 3 & 4, OUT (3 3 4),

and OUT 5, are NPN collectors with pull-up currents provided

by the power control section. These currents are about 75 µA

each, and are intended to be sufficient to drive high level CMOS

inputs.

Table I. Summary of Recommended Applications and

Tests Performed for Each Channel

In a common automotive application, the AD22001 can be used

to monitor the following lamps:

Recommended Tests

Channel Applications Performed

1, 2 Fog Light Front I, II, III

Fog Light Rear

Number Plate Light

3, 4 Low Beam Headlight I, II, IV

Parking/Position

Taillight

5 Brake Light I, III

The following tests are performed and status indicated with the

AD22001:

Test Description

I Hot Lamp Test: Lamp is functional.

Test performed while lamp is switched on.

II Cold Lamp Test: Lamp is functional.

Test performed while lamp is switched off.

III Fuse is in place and functional.

IV The two monitored light bulbs are powered simulta-

neously. This can be used as an implicit fuse test.

–4–

REV. A

AD22001

Threshold Biasing

The comparators are all activated by a common bias connection

which controls their threshold voltage. The threshold is

compensated for variations in temperature and operating

voltage. The temperature compensation is approximately +3770

ppm/°C. This causes the threshold to track the voltage across a

copper shunt operated at constant current and varying

temperature. The comparators are intended for use with small

value shunts made using normal copper tracks on PC cards.

+V

BATT

AD22001

CHIP ENABLE

1

+V

S

2

POWER

FUSE

OUT

LAMP

OUT 1 & 2

LAMP

LAMP

NOTE

R

ARE COPPER-TRACK SHUNT RESISTORS ON THE

S

PRINTED CIRCUIT BOARD.

FUSE

CHECK

R

3

4

R

S

5

6

7

8

S

9

10

R

S

GND

20

FUSE CHECK

19

18

17

16

15

14

13

12

11

R

R

OUT 5

S

S

OUT

3 & 4

OUT

(3 × 4)

LAMP

LAMP

FUSE

FUSE

FUSE

Figure 4. Application Suggestion

The power supply voltage compensation alters the comparator

threshold with a 50% sensitivity around the nominal 13.5 V

powering voltage. That is, a 10% change in battery voltage

results in a 5% change in threshold voltage. This compensation

approximately tracks the current in a hot lamp which typically

varies nonlinearly with applied voltage, with approximately 50%

sensitivity.

ON-OFF and Power Control

The AD22001 is intended to be powered directly from the

battery voltage. In normal operation an internal switch connects

internal circuits and the Power Out pin to the battery voltage,

under control of the Chip Enable. When Chip Enable is high

(above 9 V) the switch is on, the AD22001 is active and the

Power Out pin will be close to battery potential. When Chip

Enable is low, or open circuit, the switch will open and the

AD22001 will be inactive and Power Out will go low.

In order to protect the external circuits connected to Power Out

from overvoltage, the power switch is “soft” and limits the

output voltage to typically 16 V. If the applied voltage exceeds

this value, both Power Out and the internal voltage (from which

the threshold is derived) will limit. The limited Power Out

voltage will be available for moderate overvoltage conditions

such as double battery. If the applied voltage goes above

typically 33 V, the internal switch will be turned off, the lamp

monitor circuits will be inactivated and Power Out will go low

for the duration of the overvoltage.

Copper Resistors

Low value resistors can be produced as part of the printed

circuit pattern on copper clad boards. These resistors will have a

large positive TC, but this effect is compensated by the

temperature sensitive threshold in the AD22001.

At a design temperature of 24°C the sheet resistance, ρ

, of 35 µm

S

copper cladding is about 0.5 milliOhms per square (mΩ/sq),

and 70 µm copper is about 0.25 mΩ/sq. That is, a resistor made

from 35 µm copper with an aspect ratio (length/width) of 1 will

have a resistance of 0.5 mΩ, while with an aspect ratio of 4 its

resistance would be 2 mΩ, etc. The resistor can be designed for

a given value R by noting R = ρ

The sheet resistance ρ

is based on the thickness of copper

S

cladding (with 1 ounce per square foot (oz./ft

0.0014" approx. equal to 35 µm, and 2 oz./ft

L/W, so that L = RW/ρS.

S

2

) copper at

2

copper at 0.0028"

approx. equal to 70 µm) and the temperature. Choosing the

resistance value to correspond to the desired current trip level

and AD22001 threshold at 22°C, the 24°C “round number” is

convenient allowing a 2°C gradient from the resistor to the IC.

Choose W, the track width, as the larger of two values to be

determined. First the conductor should be sized so that the

nominal operating current results in only a small temperature

rise. This can be determined from the table from MIL STD275C, 9 Jan. 1970 (Figure 8).

Second, the width must be great enough to survive the peak

currents which are allowed by the fuse which supplies the track.

This can be determined from recommendations by the laminate

manufacturer, or the MIL table.

Using the larger of the two values determined for W, the length

of the resistor can be calculated. The resistor is defined by

“Kelvin” connections to the ends which sense the voltage across

this section of the track, and apply it to the differential input of

the AD22001 comparator.

As an example, consider the case of a parking lamp which

nominally draws 325 mA, and is on a circuit fused for 10A.

Suppose the board uses 70 µm (2 oz.) copper cladding, then a

conductor width of a few mils will suffice for the nominal

current. However, the 10A fuse may allow as much as 13.5A

current before it opens. A conductor 0.1" in width will carry

13.5A with less than 50°C rise in temperature, according to the

table.

Selecting 1/2 the nominal current as the AD22001 trip level

gives:

R = 1.75 mV/(325 mA/2)

or R = 10.769 mΩ.

Substituting these values in the expression for L,

L = 10.769 mΩ 3 0.1" /0.25 mΩ per sq

or L = 4.3".

A track of at least 0.1" in width should be used to convey this

current anywhere on the board. A section 4.3" long should be

sampled by Kelvin connections to the comparator differential

inputs.

This case, where the peak current available is large while the

sensed current is small, results in extremes of resistor length. In

such cases it may be convenient to bend or fold the shunt

REV. A

–5–

AD22001

resistance track. Bends in the track make the effective L/W more

difficult to calculate, however, certain common cases have been

evaluated.

To calculate the resistance of a track of width W with a 180°

bend at radius W/2 resulting in a spacing W, add a resistance

equivalent to 2.96 squares to account for the bend. Solving the

resistance equation for L/W,

L/W = R/ρ

= 10.769 mΩ/0.25 mΩ/sq,

S

or L/W = 43 squares.

Subtracting out the bend, the remainder is 40.04 squares.

Converting this to linear dimensions gives 4.004" at W = 0.1".

AD22001

(Not to Scale)

4

5

TO LAMP

2.002"

0.1"

0.05"0.1"

0.1"

2.002"

Figure 5. PCB Track Shunt Resistor with One 180° Bend

As shown in Figure 5, the contacts are made to the resistor

section of the track at 2.002" from the bend. The bend has a

uniform width of W, which is 0.1" in this case, and a radius of

W/2. As a result, the aspect ratio of the straight sections plus the

bend total 2.96 squares + (2.002" + 2.002")/0.1" or 43 squares.

The straight sections need not be of equal length, so long as

They have the proper total, and the shorter one is longer than

about 3W. A shorter resistor can be made by using more bends

and reducing the linear portion. For example, with three bends

the total length of four linear sections would be:

(43 squares – 3 3 2.96 squares/Bend)W

or (43 – 8.88) 3 0.1"= 3.412".

Assuming equal linear sections, the contacts and the bends

should be made at spacings of 3.412"/4 = 0.853", as shown in

Figure 6.

FROM SWITCH

TO LAMP

0.853"

0.05"0.1"

0.1"

0.1"

0.853"

AD22001

(Not to Scale)

4

5

Figure 6. PCB Track Shunt Resistor with Two 180° Bends

A 90° bend with an inside radius of W/2 and a smooth width of

W adds 0.341 squares to the aspect ratio as shown in Figure 7.

Note that the linear measurements are differently made at the

90° and the 180° bend.

Other styles of bend can be used with minor variation in total

resistance, however, we do not recommend the use of sharp

inside corners on high current conductors in general and shunt

resistors in particular. Sharp inside corners result in very high

local current density and poor resistance repeatability.

L1

W

W

2

W

L2

–6–

Figure 7. PCB Track Shunt Resistor with 90° Bend

REV. A

35.0

30.0

AD22001

100°C

25.0

20.0

15.0

12.0

10.0

8.0

7.0

CURRENT – Amperes

6.0

5.0

4.0

3.0

2.0

1.5

1.0

0.75

0.50

0.25

0.125

0

0

0.001

0.005

0.010

0.020

0.030

0.050

0.070

0.100

0.150

CONDUCTOR WIDTH – Inches

0.200

0.250

0.300

0.350

0.400

0 1 5 10 20 30 50 70 100 150 200 250 300 350 400 450 500 600 700

2

(1 oz/ft ) 0.0014"

2

(1/2 oz/ft ) 0.0007"

45°C

(2 oz/ft ) 0.0028"

CROSS SECTION – Mils

60°C

2

2

75°C

10°C

(3 oz/ft ) 0.0042"

30°C

20°C

2

Figure 8. Current-Carrying Capacities and Sizes of Etched Copper Conductors for Various Temperature Rises Above

Ambient (MIL-STD-275C, 9 January 1970)

REV. A

–7–

AD22001

0.210 (5.33)

MAX

0.200 (5.05)

0.125 (3.1)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Pin Plastic DIP (N) Package

1.060 (26.92)

0.925 (23.50)

20

110

PIN 1

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

11

0.070 (1.77)

0.045 (1.15)

0.280 (7.11)

0.240 (6.10)

0.015 (0.38)

MIN

0.150

(3.81)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

15°

0°

C1533–21–4/91

0.015 (0.381)

0.008 (0.203)

–8–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...