Page 1

www.BDTIC.com/ADI

12-Bit, 400 MSPS A/D Converter

FEATURES

Up to 400 MSPS sample rate

SNR of 63 dBFS @128 MHz

SFDR of 70 dBFS @128 MHz

VSWR of 1:1.5

High or low gain grades

Wideband ac-coupled input signal conditioning

Enhanced spurious-free dynamic range

Single-ended or differential ENCODE signal

LVDS output levels

Twos complement output data

APPLICATIONS

Communications test equipment

Radar and satellite subsystems

Phased array antennas, digital beams

Multichannel, multimode receivers

Secure communications

Wireless and wired broadband communications

Wideband carrier frequency systems

GENERAL DESCRIPTION

The AD12401 is a 12-bit analog-to-digital converter (ADC)

with a transformer-coupled analog input and digital postprocessing for enhanced SFDR. The product operates at up to

400 MSPS conversion rate with outstanding dynamic performance

in wideband carrier systems.

The AD12401 requires a 3.7 V analog supply and 3.3 V and

1.5 V dig

that can be differential or single ended. No external reference is

required.

The AD12401 package style is an enclosed 2.9" × 2.6" × 0.6"

m

temperature range.

ital supplies, and provides a flexible ENCODE signal

odule. Performance is rated over a 0°C to 60°C case

AD12401

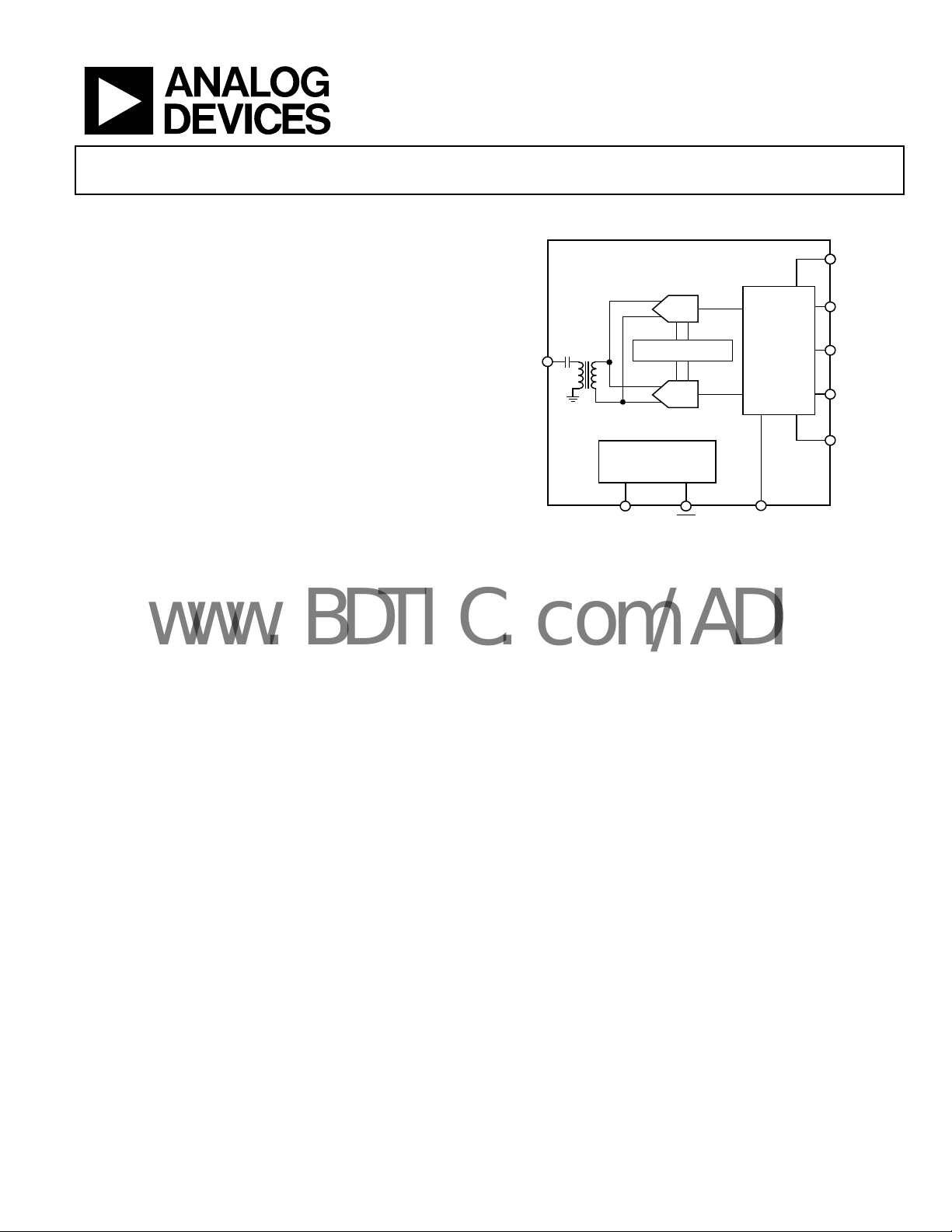

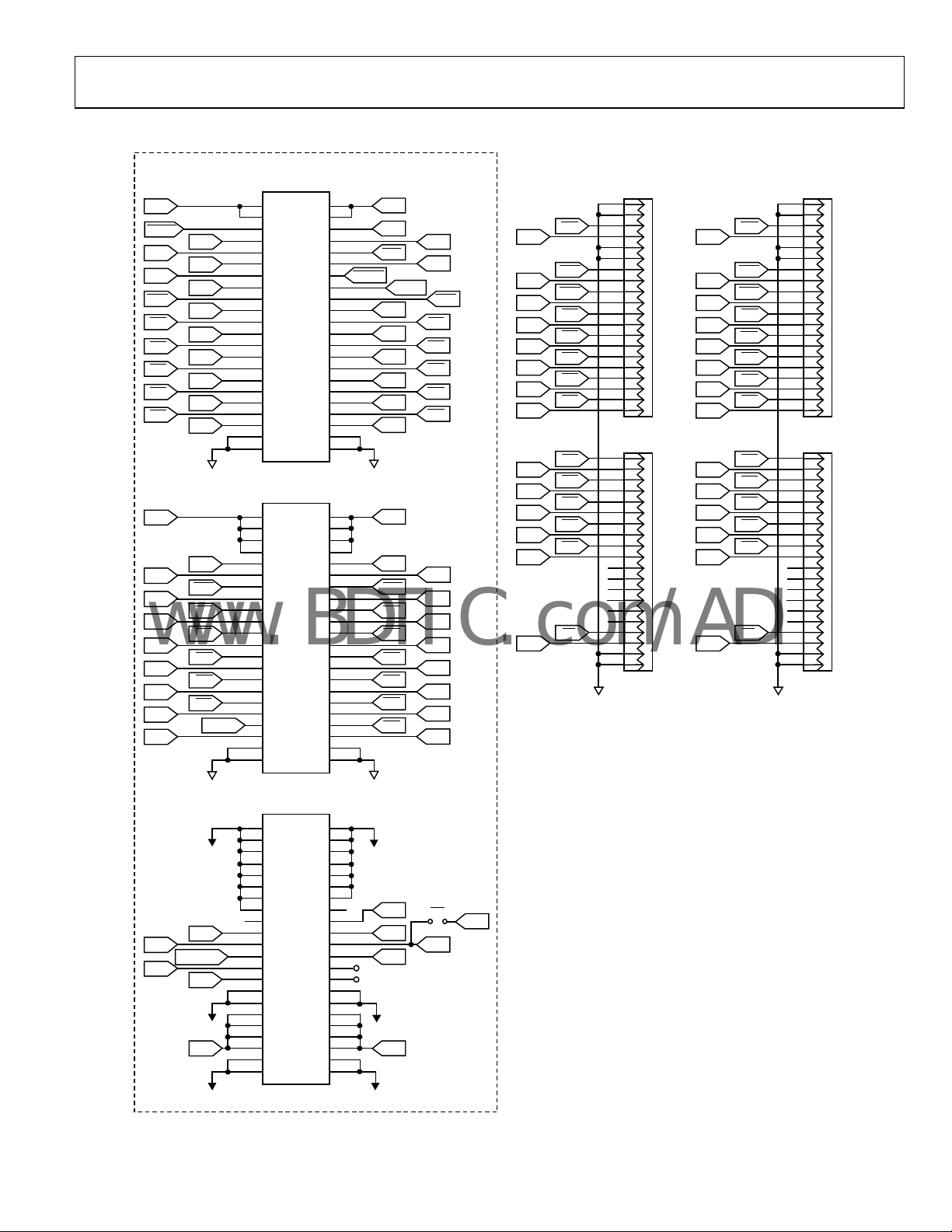

FUNCTIONAL BLOCK DIAGRAM

AD12401

ADC

A

POST-

A

IN

CLK DISTRIBUTION

ADC

B

CLOCK DISTRIBUTION

DIVIDE BY 2

ENC ENC

Figure 1.

PRODUCT HIGHLIGHTS

1. Guaranteed sample rate up to 400 MSPS.

2. I

nput signal conditioning with optimized dynamic

performance to 175 MHz.

3. H

igh and low gain grades available.

4. A

dditional performance options available (sample rates

>400 MSPS or second Nyquist zone operation); contact

sales.

5. Propr

ietary Advanced Filter Bank (AFB™) digital post-

processing from V Corp Technologies, Inc.

PROCESSING

OROUT

DATA

READY

A

DA0–DA11

DB0–DB11

DR_EN

DATA

READY

B

005649-001

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2006 Analog Devices, Inc. All rights reserved.

Page 2

AD12401

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Time-Interleaving ADCs........................................................... 18

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description......................................................................... 1

Product Highlights........................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

DC Specifications ......................................................................... 3

AC Specifications—ENCODE = 400 MSPS.............................. 4

AC Specifications—ENCODE = 360 MSPS.............................. 5

AC Specifications—ENCODE = 326 MSPS.............................. 6

Absolute Maximum Ratings............................................................ 8

Explanation of Test Levels........................................................... 8

ESD Caution.................................................................................. 8

Pin Configuration and Function Descriptions........................... 10

Te r mi n ol o g y .................................................................................... 13

Analog Input............................................................................... 18

Clock Input.................................................................................. 18

Digital Outputs........................................................................... 19

Power Supplies ............................................................................ 19

Start-Up and

DR_EN......................................................................................... 19

Overrange.................................................................................... 19

Gain Select................................................................................... 20

Thermal Considerations............................................................ 20

Package Integrity/Mounting Guidelines ................................. 20

AD12401 Evaluation Kit ........................................................... 21

Data Outputs............................................................................... 21

Layout Guidelines........................................................................... 26

PCB Interface.............................................................................. 26

Outline Dimensions ....................................................................... 28

RESET

.................................................................. 19

Typical Performance Characteristics........................................... 15

Theory of Operation ...................................................................... 18

REVISION HISTORY

4/06—Rev. 0 to Rev. A

Changes to Features and Product Highlights ............................... 1

Changes to Table 1............................................................................ 3

Changes to Table 2............................................................................ 4

Changes to Table 4............................................................................ 6

Changes to Table 7............................................................................ 9

Changes to Figure 5........................................................................ 10

Changes to Table 9.......................................................................... 11

Added Gain Select Section ............................................................ 20

Added H/L_GAIN Section............................................................ 21

Changes to Figure 25...................................................................... 23

Changes to the Ordering Guide.................................................... 28

7/05—Revision 0: Initial Version

Ordering Guide .......................................................................... 28

Rev. A | Page 2 of 28

Page 3

AD12401

www.BDTIC.com/ADI

SPECIFICATIONS

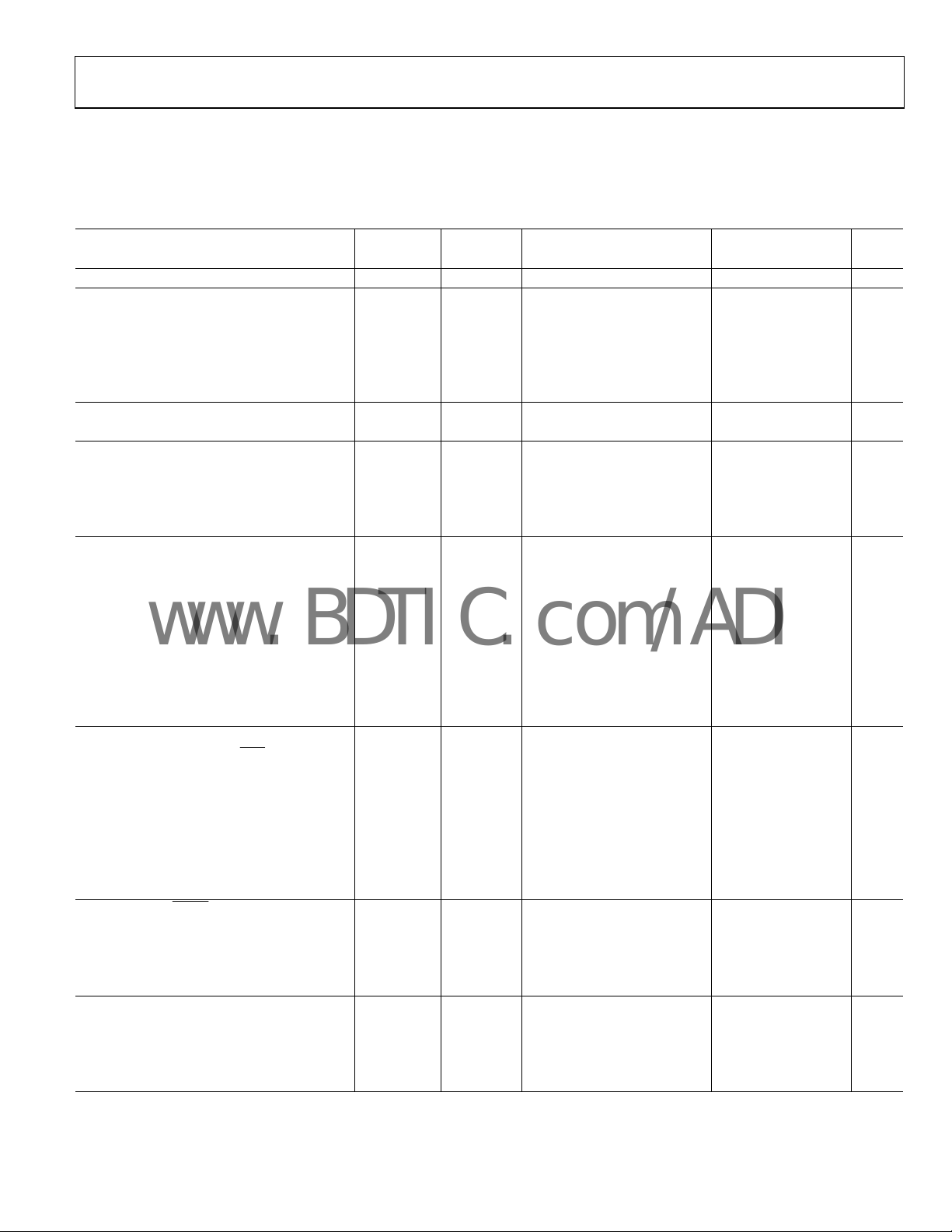

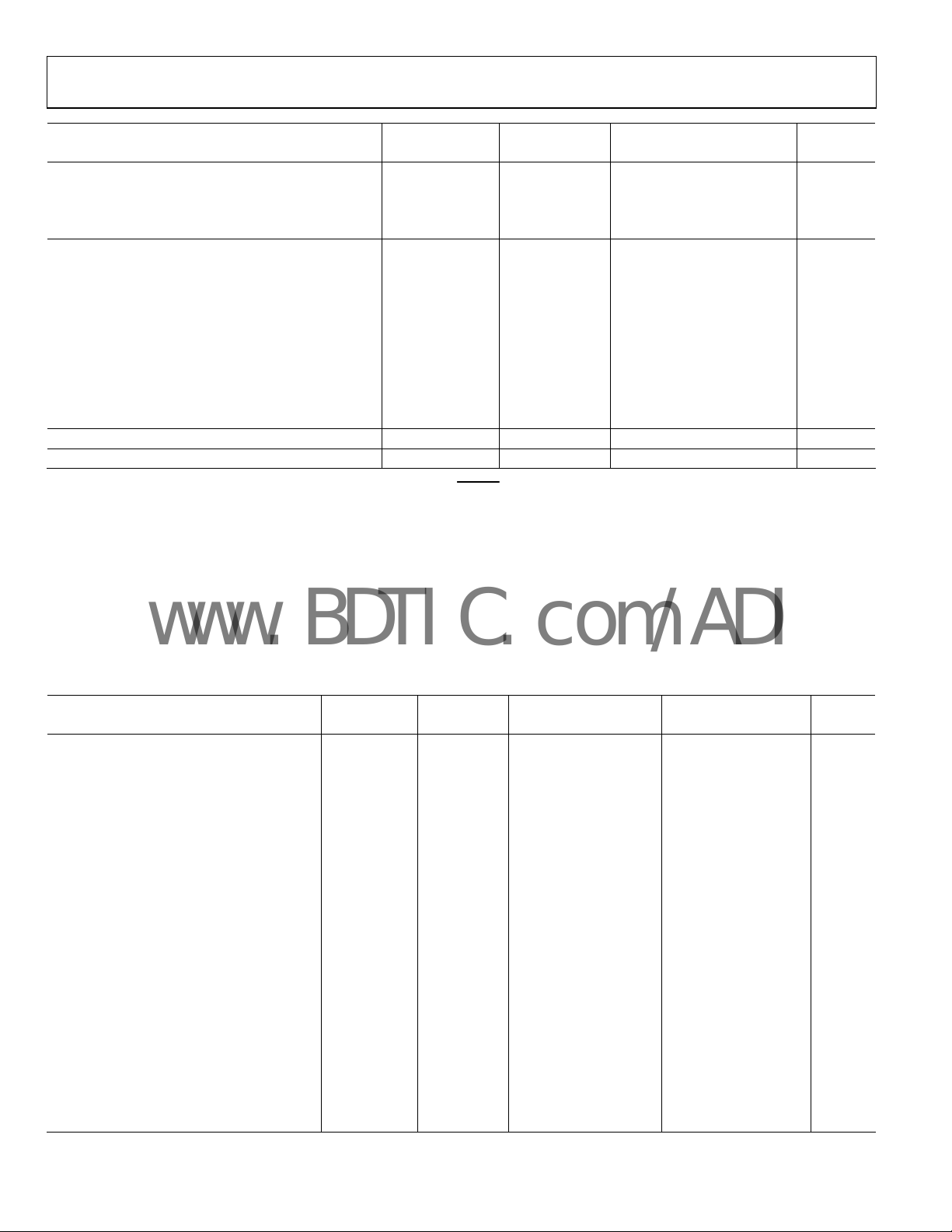

DC SPECIFICATIONS

VA = 3.7 V, VC = 3.3 V, VD = 1.5 V, 0°C ≤ T

Table 1.

AD12401-xxxKWS AD12401-xxxJWS

Parameter Case Temp Test Level Min Typ Max Min Typ Max Unit

RESOLUTION 12 Bits

ACCURACY

No Missing Codes Full IV Guaranteed

Offset Error Full I −12 +12 −12 +12 LSB

Gain Error @ 10 MHz Full I −10 +10 −10 +10 %FS

Differential Nonlinearity (DNL) 60°C V ±0.3 ±0.3 LSB

Integral Nonlinearity (INL) 60°C V ±0.5 ±0.5 LSB

TEMPERATURE DRIFT

Gain Error 60°C V 0.02 0.02 %/°C

ANALOG INPUT (AIN)

Full-Scale Input Voltage Range 60°C V 3.2 1.6 V p-p

Flatness (10 MHz to 175 MHz) Full IV 0.5 1 0.5 1 dB

Input VSWR, 50 Ω (300 kHz to 175 MHz) 60°C V 1.5 1.5

Analog Input Bandwidth 60°C V 480 480 MHz

POWER SUPPLY

Supply Voltage

VA Full IV 3.6 3.8 3.6 3.8 V

VC Full IV 3.2 3.4 3.2 3.4 V

VD Full IV 1.45 1.55 1.45 1.55 V

Supply Current

IVA (VA = 3.7 V) Full I 0.95 1.2 0.95 1.2 A

IVC (VC = 3.3 V) Full I 400 500 400 500 mA

IVD (VD = 1.5 V) Full I 0.8 1.2 0.8 1.2 A

Total Power Dissipation Full I 5.7 6.8 5.7 6.8 W

ENCODE INPUTS

Differential Inputs (ENC, ENC)

Input Voltage Full IV 0.4 0.4 V

Input Resistance 60°C V 100 100 Ω

Input Capacitance 60°C V 35 35 pF

Common-Mode Voltage 60°C V ±3 ±3 V

Single-Ended Inputs (ENC)

Input Voltage Full IV 0.4 2 0.4 2 V p-p

Input Resistance 60°C V 50 50 Ω

LOGIC INPUTS (RESET)

Logic 1 Voltage Full IV 2.0 2.0 V

Logic 0 Voltage Full IV 0.8 0.8 V

Source I

Sink I

LOGIC INPUTS (DR_EN)

Logic 1 Voltage Full IV 1.7 1.7 V

Logic 0 Voltage Full IV 0.7 0.7 V

Source I

Sink I

1

2

IH

IL

IH

IL

≤ 60°C, unless otherwise noted.

CASE

60°C IV 3.4 6 3.4 6 mA

60°C IV 0.9 1 0.9 1 mA

60°C IV 20 50 20 50 μA

60°C IV 30 160 30 160 μA

Rev. A | Page 3 of 28

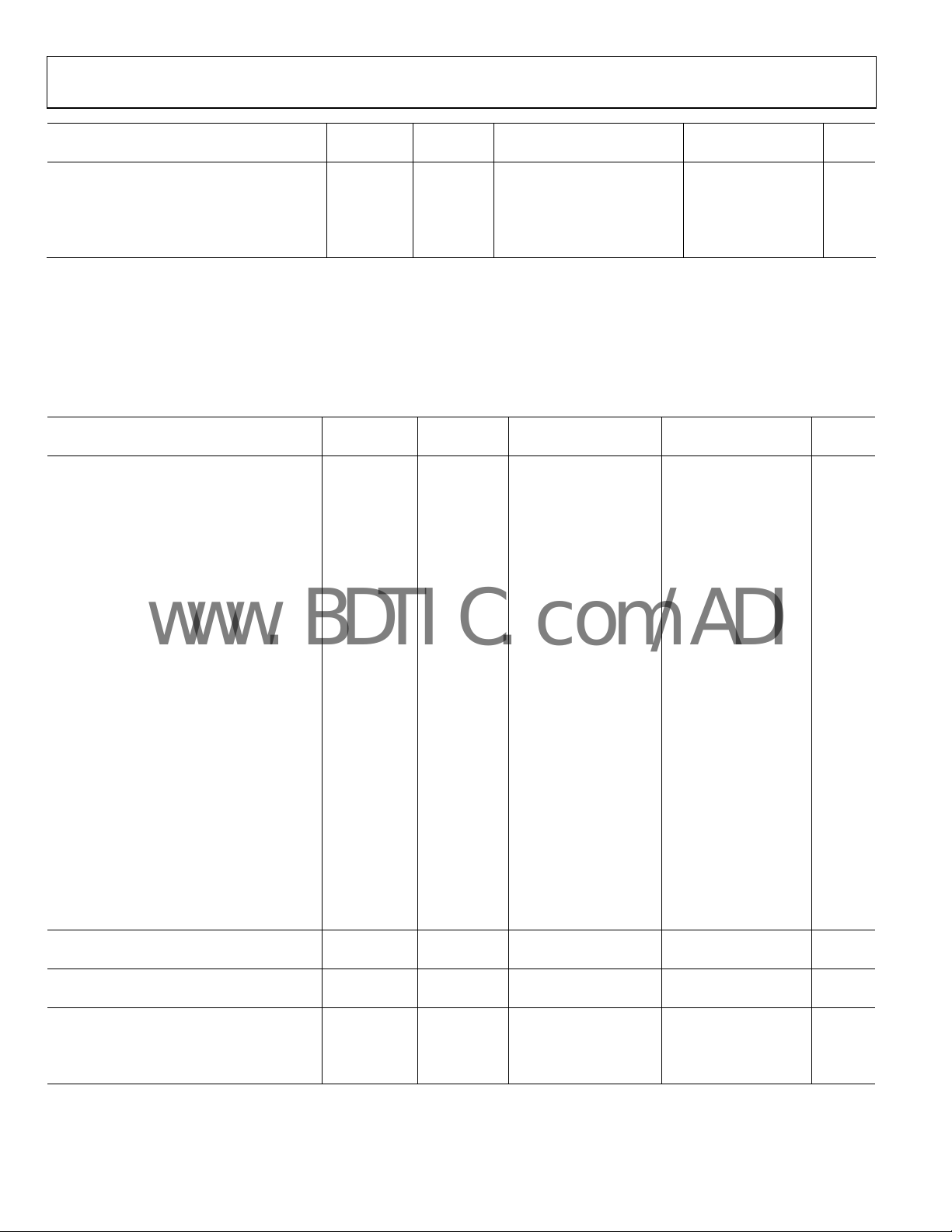

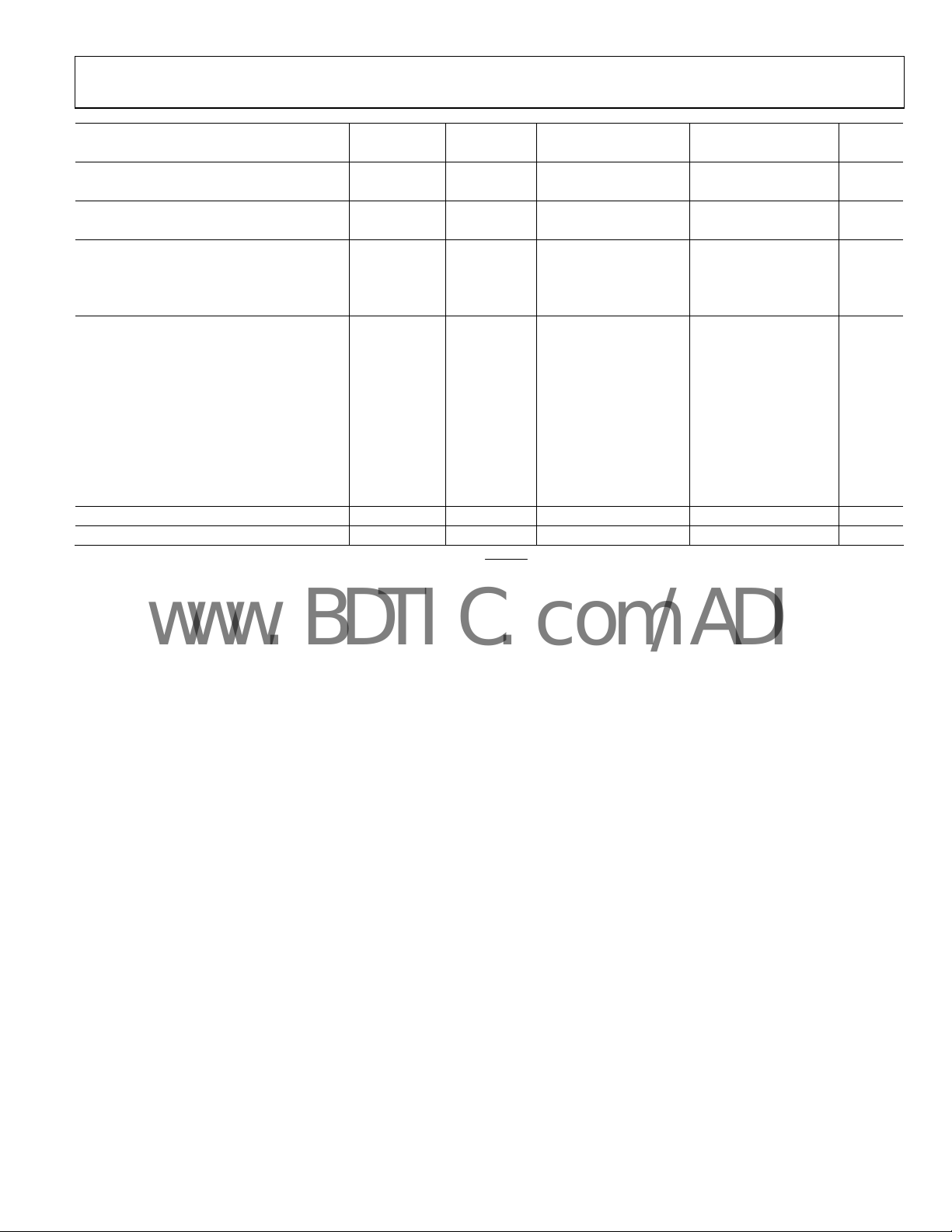

Page 4

AD12401

www.BDTIC.com/ADI

AD12401-xxxKWS AD12401-xxxJWS

Parameter Case Temp Test Level Min Typ Max Min Typ Max Unit

LOGIC OUTPUTS (DRA, DRB, OUTPUT BITS)

Differential Output Voltage Full IV 247 350 454 247 350 454 mV

Output Common-Mode Voltage Full IV 1.125 1.25 1.375 1.125 1.25 1.375 V

Output High Voltage 60°C IV 1.602 1.602 V

Output Low Voltage 60°C IV 0.898 0.898 V

1

Tested using input frequency of 70 MHz (see Figure 17).

2

Refer to Table 8 for logic convention on all logic inputs.

3

Digital output logic levels: VC = 3.3 V, C

LOAD

AC SPECIFICATIONS1—ENCODE = 400 MSPS

VA = 3.7 V, VC = 3.3 V, VD = 1.5 V, ENCODE = 400 MSPS, 0°C ≤ T

Table 2.

AD12401-400KWS AD12401-400JWS

Parameter Case Temp Test Level Min Typ Max Min Typ Max Unit

DYNAMIC PERFORMANCE

SNR

Analog Input 10 MHz Full I 62 64 60 62 dBFS

@ −1.0 dBFS 70 MHz Full I 61.5 63.5 59.5 61.5 dBFS

128 MHz Full I 60 63 58 61 dBFS

2

SINAD

Analog Input 10 MHz Full I 59 63.5 57 61.5 dBFS

@ −1.0 dBFS 70 MHz Full I 58.5 63 56.5 61 dBFS

Spurious-Free Dynamic Range

Analog Input 10 MHz Full I 69 85 69 85 dBFS

@ −1.0 dBFS 70 MHz Full I 69 80 69 80 dBFS

Image Spur

Analog Input 10 MHz Full I 60 75 60 75 dBFS

@ −1.0 dBFS 70 MHz Full I 60 72 60 72 dBFS

Offset Spur

Analog Input @ −1.0 dBFS 60°C V 65 65 dBFS

Two-Tone IMD

F1, F2 @ −6 dBFS 60°C V −75 −75 dBc

ANALOG INPUT

Frequency Range Full IV 10 175 10 175 MHz

DIGITAL INPUT (DR_EN)

Minimum Time (Low) Full IV 5.0 5.0 ns

SWITCHING SPECIFICATIONS

Conversion Rate

Encode Pulse Width High (tEH)

Encode Pulse Width Low (tEL)

175 MHz Full I 60 62.5 57.5 60.5 dBFS

128 MHz Full I 57.5 61.5 55.5 59.5 dBFS

175 MHz Full I 55 60 53 58 dBFS

3

128 MHz Full I 66 72 66 72 dBFS

175 MHz Full I 62 68 62 68 dBFS

4

128 MHz Full I 60 66 60 66 dBFS

175 MHz Full I 57 63 57 63 dBFS

4

5

6

1

1

3

= 8 pF, 2.5 V LVDS, RT = 100 Ω.

Full IV 396 400 404 396 400 404 MSPS

60°C V 1.25 1.25 ns

60°C V 1.25 1.25 ns

≤ 60°C, unless otherwise noted.

CASE

Rev. A | Page 4 of 28

Page 5

AD12401

www.BDTIC.com/ADI

AD12401-400KWS AD12401-400JWS

Parameter Case Temp Test Level Min Typ Max Min Typ Max Unit

DIGITAL OUTPUT PARAMETERS

Valid Time (tV) Full IV 3.9 3.9 ns

Propagation Delay (tPD) 60°C V 8.7 8.7 ns

Rise Time, tR (20% to 80%) 60°C V 0.3 0.3 ns

Fall Time, tF (20% to 80%) 60°C V 0.3 0.3 ns

DR Propagation Delay (t

Data to DR Skew (t

Pipeline Latency

7

Start-Up Time Full IV 29 44 87 29 44 87 ms

Postprocessing Configuration Time Full IV 2.8 2.8 sec

APERTURE DELAY (tA) 60°C V 2.3 2.3 ns

APERTURE UNCERTAINTY (Jitter, tJ) 60°C V 0.4 0.4 ps rms

1

All ac specifications tested with a single-ended, 2.0 V p-p encode on ENCODE and

2

The image spur is included in the SINAD measurement.

3

The image spur is not included in the SFDR specification.

4

The image spur is at fS/2 – AIN; the offset spur is at fS/2.

5

F1 = 70 MHz, F2 = 73 MHz.

6

Parts are tested with 400 MSPS encode. Device can be clocked at lower encode rates, but specifications are not guaranteed. Specifications are guaranteed by design

for encode 400 MSPS ± 1%.

7

Pipeline latency is exactly 74 cycles with an additional tPD required for data to emerge.

) 60°C V 11.2 11.2 ns

EDR

− tPD) 60°C V 2.5 2.5 ns

EDR

Full IV 74 74 Cycles

ENCODE

floating.

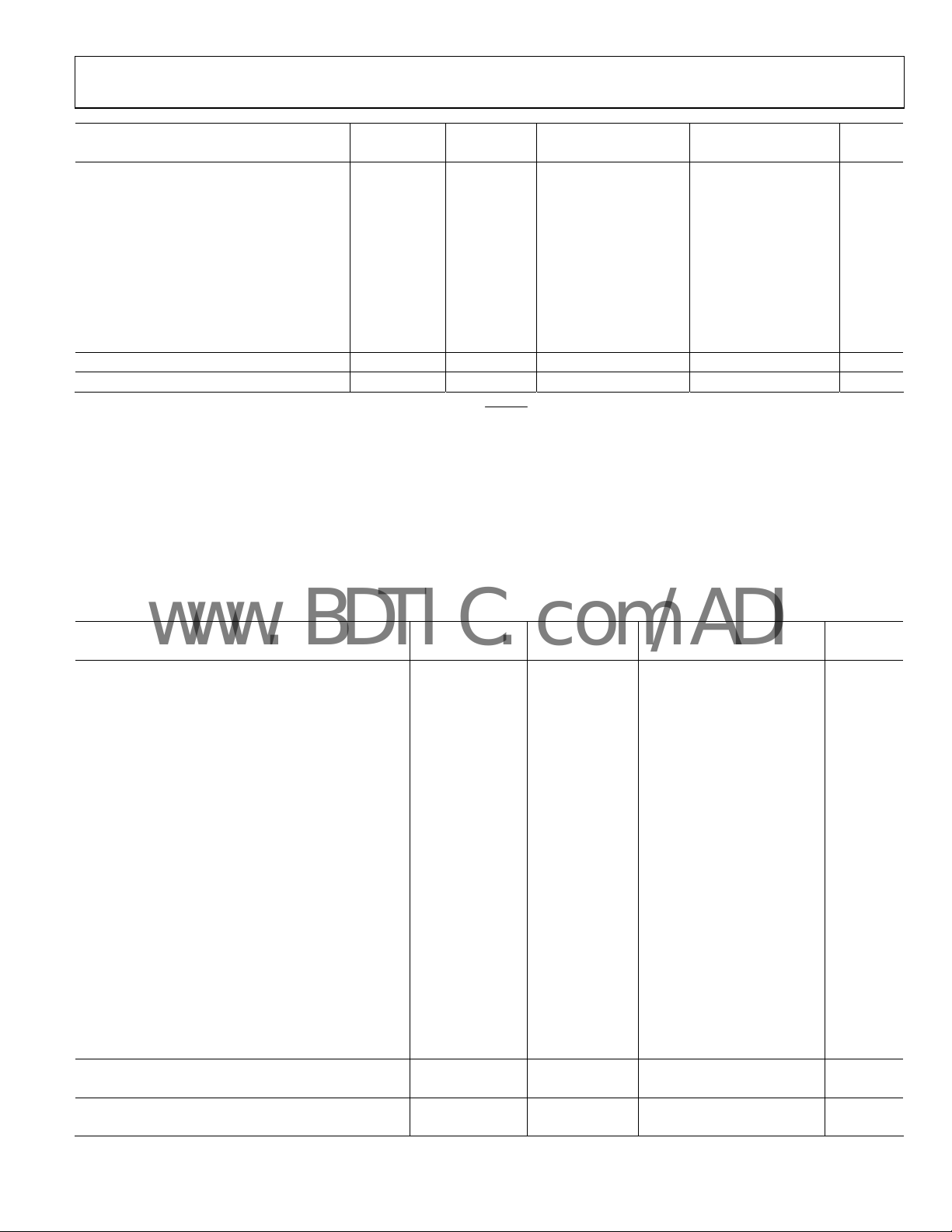

AC SPECIFICATIONS1—ENCODE = 360 MSPS

VA = 3.7 V, VC = 3.3 V, VD = 1.5 V, encode = 360 MSPS, 0°C ≤ T

Table 3.

AD12401-360KWS

Parameter Case Temp Test Level Min Typ Max Unit

DYNAMIC PERFORMANCE

SNR

Analog Input 10 MHz Full I 62 64 dBFS

@ −1.0 dBFS 70 MHz Full I 61.5 63.5 dBFS

128 MHz Full I 60 63 dBFS

2

SINAD

Analog Input 10 MHz Full I 59 63.5 dBFS

@ −1.0 dBFS 70 MHz Full I 58.5 63 dBFS

128 MHz Full I 57.5 61.5 dBFS

Spurious-Free Dynamic Range

3

Analog Input 10 MHz Full I 69 85 dBFS

@ −1.0 dBFS 70 MHz Full I 69 80 dBFS

128 MHz Full I 66 72 dBFS

Image Spur

4

Analog Input 10 MHz Full I 60 75 dBFS

@ −1.0 dBFS 70 MHz Full I 60 72 dBFS

128 MHz Full I 60 66 dBFS

Offset Spur

4

Analog Input @ −1.0 dBFS 60°C V 65 dBFS

Two-Tone IMD

5

F1, F2 @ −6 dBFS 60°C V −75 dBc

ANALOG INPUT

Frequency Range Full IV 10 160 MHz

DIGITAL INPUT (DR_EN)

Minimum Time (Low) Full IV 5.6 ns

≤ 60°C, unless otherwise noted.

CASE

Rev. A | Page 5 of 28

Page 6

AD12401

www.BDTIC.com/ADI

AD12401-360KWS

Parameter Case Temp Test Level Min Typ Max Unit

SWITCHING SPECIFICATIONS

Conversion Rate

Encode Pulse Width High (tEH)

Encode Pulse Width Low (tEL)

DIGITAL OUTPUT PARAMETERS

Valid Time (tV) Full IV 4.5 ns

Propagation Delay (tPD) 60°C V 8.7 ns

Rise Time, tR (20% to 80%) 60°C V 0.3 ns

Fall Time, tF (20% to 80%) 60°C V 0.3 ns

DR Propagation Delay (t

Data to DR Skew (t

Pipeline Latency

Start-Up Time Full IV 29 44 87 ms

Postprocessing Configuration Time Full IV 3.1 sec

APERTURE DELAY (tA) 60°C V 2.3 ns

APERTURE UNCERTAINTY (Jitter, tJ) 60°C V 0.4 ps rms

1

All ac specifications tested with a single-ended, 2.0 V p-p encode on ENCODE and

2

The image spur is included in the SINAD specification.

3

The image spur is not included in the SFDR specification.

4

The image spur is at fS/2 – AIN; the offset spur is at fS/2.

5

F1 = 70 MHz, F2 = 73 MHz.

6

Parts are tested with 360 MSPS encode. Device can be clocked at lower encode rates, but specifications are not guaranteed. Specifications are guaranteed by design

for encode 360 MSPS ± 1%.

7

Pipeline latency is exactly 74 cycles with an additional tPD required for data to emerge.

6

1

1

) 60°C V 11.5 ns

EDR

− tPD) 60°C V 2.8 ns

EDR

7

Full IV 356 360 364 MSPS

60°C V 1.38 ns

60°C V 1.38 ns

Full IV 74 Cycles

ENCODE

floating.

AC SPECIFICATIONS1—ENCODE = 326 MSPS

VA = 3.7 V, VC = 3.3 V, VD = 1.5 V, ENCODE = 326 MSPS, 0°C ≤ T

Table 4.

AD12401-326KWS AD12401-326JWS

Parameter Case Temp Test Level Min Typ Max Min Typ Max Unit

DYNAMIC PERFORMANCE

SNR

Analog Input 10 MHz Full I 62 64 60 62 dBFS

@ −1.0 dBFS 70 MHz Full I 61.5 63.5 59.5 61.5 dBFS

128 MHz Full I 60 63 58 61 dBFS

2

SINAD

Analog Input 10 MHz Full I 59 63.5 57 61.5 dBFS

@ −1.0 dBFS 70 MHz Full I 58.5 63 56.5 61 dBFS

128 MHz Full I 57.5 61.5 55.5 59.5 dBFS

Spurious-Free Dynamic Range

3

Analog Input 10 MHz Full I 69 85 69 85 dBFS

@ −1.0 dBFS 70 MHz Full I 69 80 69 80 dBFS

128 MHz Full I 66 72 66 72 dBFS

Image Spur

4

Analog Input 10 MHz Full I 60 75 60 75 dBFS

@ −1.0 dBFS 70 MHz Full I 60 72 60 72 dBFS

128 MHz Full I 60 66 60 66 dBFS

Offset Spur

5

Analog Input @ −1.0 dBFS 60°C V 65 65 dBFS

Two-Tone IMD

5

F1, F2 @ −6 dBFS 60°C V −75 −75 dBc

≤ 60°C, unless otherwise noted.

CASE

Rev. A | Page 6 of 28

Page 7

AD12401

www.BDTIC.com/ADI

AD12401-326KWS AD12401-326JWS

Parameter Case Temp Test Level Min Typ Max Min Typ Max Unit

ANALOG INPUT

Frequency Range Full IV 10 140 10 140 MHz

DIGITAL INPUT (DR_EN)

Minimum Time (Low) Full IV 6.2 6.2 ns

SWITCHING SPECIFICATIONS

Conversion Rate

Encode Pulse Width High (tEH)

Encode Pulse Width Low (tEL)

DIGITAL OUTPUT PARAMETERS

Valid Time (tV) Full IV 5.0 5.0 ns

Propagation Delay (tPD) 60°C V 8.7 8.7 ns

Rise Time, tR (20% to 80%) 60°C V 0.3 0.3 ns

Fall Time, tF (20% to 80%) 60°C V 0.3 0.3 ns

DR Propagation Delay (t

Data to DR Skew (t

Pipeline Latency

Start-Up Time Full IV 29 44 87 29 44 87 ms

Postprocessing Configuration Time Full IV 3.4 3.4 sec

APERTURE DELAY (tA) 60°C V 2.3 2.3 ns

APERTURE UNCERTAINTY (Jitter, tJ) 60°C V 0.4 0.4 ps rms

1

All ac specifications tested with a single-ended, 2.0 V p-p encode on ENCODE and

2

The image spur is included in the SINAD measurement.

3

The image spur is not included in the SFDR specification.

4

The image spur is at fS/2 − AIN; the offset spur is at fS/2.

5

F1 = 70 MHz, F2 = 73 MHz.

6

Parts are tested with 326 MSPS encode. Device can be clocked at lower encode rates, but specifications are not guaranteed. Specifications are guaranteed by design

for encode 326 MSPS ±1%.

7

Pipeline latency is exactly 74 cycles with an additional tPD required for data to emerge.

6

1

1

) 60°C V 11.8 11.8 ns

EDR

− tPD) 60°C V 3.1 3.1 ns

EDR

7

Full IV 323 326 329 323 326 329 MSPS

60°C V 1.53 1.53 ns

60°C V 1.53 1.53 ns

Full IV 74 74 Cycles

ENCODE

floating.

Rev. A | Page 7 of 28

Page 8

AD12401

www.BDTIC.com/ADI

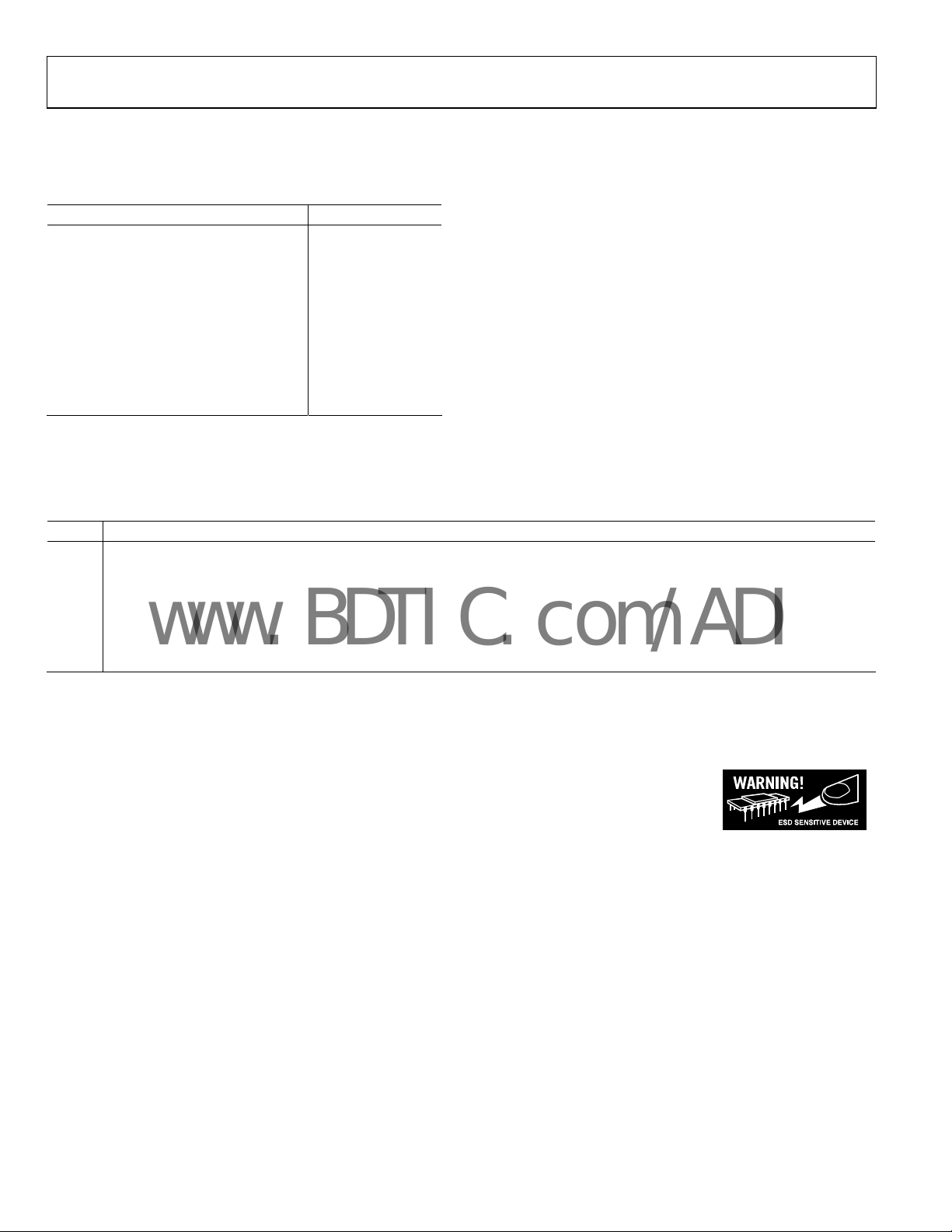

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter Value

VA to AGND 5 V

VC to DGND 4 V

VD to DGND 1.6 V max

Analog Input Voltage 6 V (dc)

Analog Input Power 18 dBm (ac)

ENCODE Input Voltage 6 V (dc)

ENCODE Input Power 12 dBm (ac)

Logic Inputs −0.3 V to +4 V

Storage Temperature Range, Ambient −65°C to +150°C

Operating Temperature Range 0°C to 60°C

EXPLANATION OF TEST LEVELS

Table 6.

Level Description

I 100% production tested.

II 100% production tested at 25°C and sample tested at specified temperatures.

III Sample tested only.

IV Parameter is guaranteed by design and characterization testing.

V Parameter is a typical value only.

VI

100% production tested at 25°C; guaranteed by design and charac

production tested at temperature extremes for military devices.

Stresses above those listed under Absolute Maximum Ratings

y cause permanent damage to the device. This is a stress

ma

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

terization testing for industrial temperature range; 100%

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. A | Page 8 of 28

Page 9

AD12401

www.BDTIC.com/ADI

Table 7. Output Coding (Twos Complement)

A

(V)

IN

Code KWS JWS Digital Output

4095 +1.6 +0.8 0111 1111 1111

. . . .

. . . .

. . . .

2048 0 0 0000 0000 0000

2047 −0.000781 to +0.0003905 1111 1111 1111

. . . .

. . . .

0 −1.6 to +0.8 1000 0000 0000

N

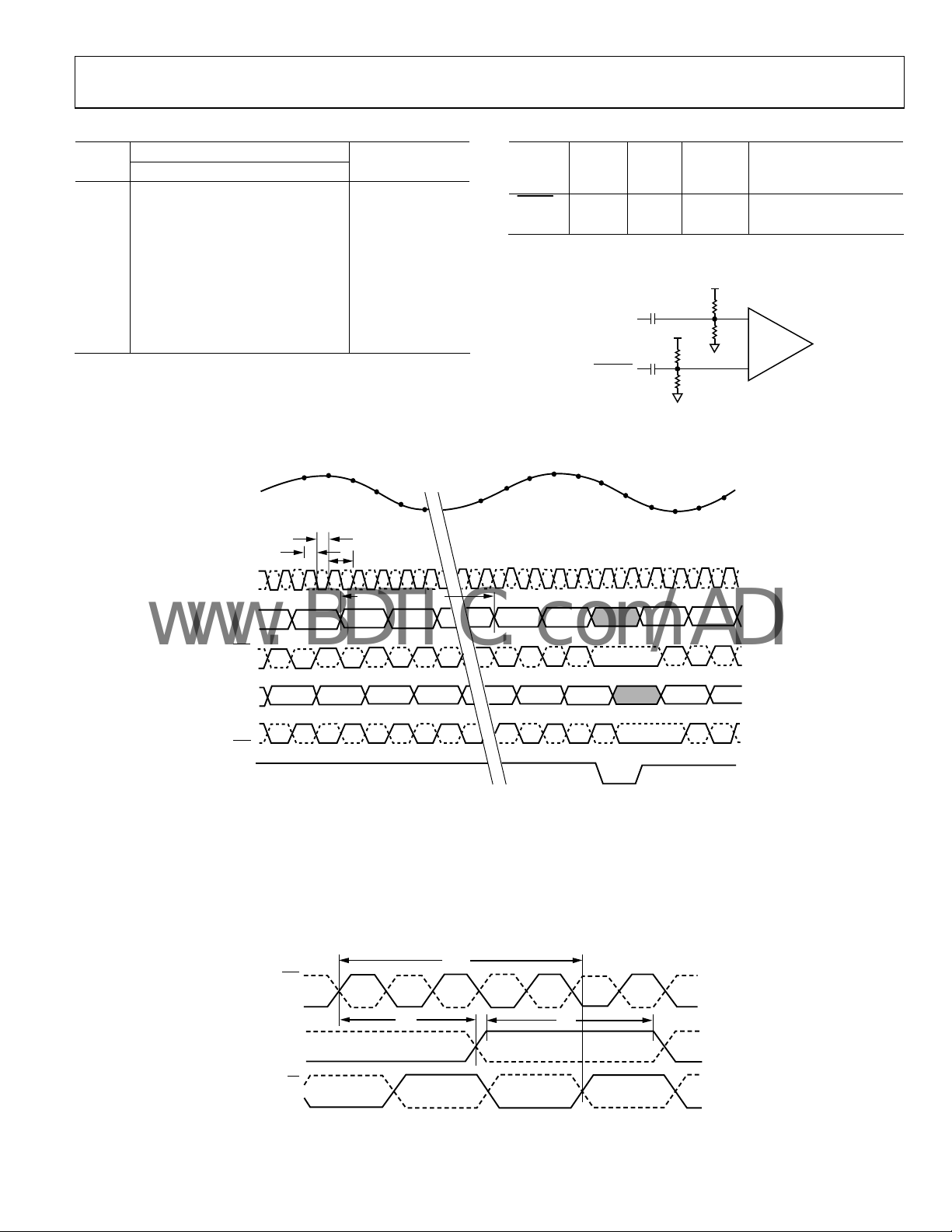

ENC

400MHZ

DATA OUT A

N– 1

t

EL

t

EH

N + 1

N + 2

N + 3

1/f

S

74 CLOCK CYCLES

N – 74

N – 73

Table 8. Option Pin List with Necessary Associated Circuitry

Logic

Pin

Name

RESET

Active

High

Lev

Typ e

el

Default

Lev

Associated Circuitry

el

Within Part

Low LVTTL High 3.74 kΩ Pull-Up

DR_EN High LVTTL High Weak Pull-Up (>16 kΩ)

3.3V

100Ω

100Ω

100Ω

100Ω

PECL

DRIVER

05649-002

ENCODE

ENCODE

3.3V

Figure 2. ENCODE Equivalent Circuit

N

N + 2

1

N + 4 N + 6 N + 8

DRA

DRA

DATA OUT B

DRB

DRB

DR_EN

NOTES

1. DATA LOST DUE TO ASSERTION OF DR_EN. LATENCY OF 74 ENCODE CLOCK CYCLES BEFORE DATA VALID.

2. IF A SINGLE-ENDED SINE WAVE IS USED FOR ENCODE, USE THE ZERO CROSSING POINT (AC-COUPLED) AS

THE 50% POINT AND APPLY THE SAME TIMING INFORMATION.

3. THE DR_EN PIN IS USED TO SYNCHRONIZE THE COLLECTION OF DATA INTO EXTERNAL BUFFER MEMORIES.

THE DR_EN PIN CAN BE APPLIED SYNCHRONOUSLY OR ASYNCHRONOUSLY TO THE AD12401. IF APPLIED

ASYNCHRONOUSLY, DR_EN MUST BE HELD LOW FOR A MINIMUM OF 5ns TO ENSURE CORRECT OPERATION.

THE FUNCTION SHUTS OFF DRA AND DRB UNTIL THE DR_EN PIN IS SET HIGH AGAIN. DRA AND DRB RESUME

ON THE NEXT VALID DRA AFTER DR_EN IS RETURNED HIGH. IF THIS FEATURE IS NOT REQUIRED, TIE THIS

PIN TO 3.3V THROUGH A 3.74kΩ RESISTOR OR LEAVE IT FLOATING.

N + 1

N + 3 N + 5 N + 7

1

Figure 3. Timing Diagram

t

EDR

ENC

ENC

DATA OUT

DR

DR

t

PD

t

VD

Figure 4. Highlighted Timing Diagram

05649-004

05649-003

Rev. A | Page 9 of 28

Page 10

AD12401

www.BDTIC.com/ADI

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

AIN

ENC

ENC

TOP VIEW

JOHNSON SMA-50 Ω CONNECT NO. 142-0711-821

2-56 STUDS 4⋅

END VIEW

SAMTEC CONNECT OR

QTE-060-01-L-D-A-K-TR

ENC

ENC

AIN

BOTTOM VIEW

NOTE:

1. FOR MATING CONNECT OR, USE SAMTEC, INC.

PART NO. QSE-60-01-L - D-A-K.

INTEGRAL GROUND PLANE CO NNE CTIONS.

SECTIO N A = DGND, PINS 121–12 4.

SECTIO N B = DGND, PINS 125–12 8.

SECTIO N C = AGND, PINS 129–13 2.

PIN 1

LEFT SIDE VIEW

Figure 5. Pin Configuration

BOARD

PIN 119

PIN 79

PIN 39

PIN 1

VA

VA

VA

VA

AGND

AGND

DNC

DNC

H/L_GAIN

DNC

DNC

DNC

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

DNC

DR_EN

DA1

DA1

DA3

DA3

DA5

DA5

DA7

DA7

DA9

DA9

DA11

DA11

DNC

DNC

VD

VD

VD

VD

DB1

DB1

DB3

DB3

DB5

DB5

DB7

DB7

DB9

DB9

DB11

DB11

DNC

DNC

DNC

DNC

DNC

RESET

VC

VC

1

VA

VA

VA

VA

AGND

AGND

DNC

DNC

DNC

DNC

DNC

DNC

DNC

AGND

AGND

AGND

AGND

AGND

AGND

AGND

1

DRA

DRA

DA0

DA0

DA2

DA2

DA4

DA4

DA6

DA6

DA8

DA8

DA10

DA10

DNC

DNC

VD

VD

VD

VD

1

DB0

DB0

DB2

DB2

DB4

DB4

DB6

DB6

DB8

DB8

DB10

DB10

OROUT

OROUT

DRB

DRB

DNC

DNC

VC

VC

PIN 120

C

PIN 80

B

PIN 40

A

PIN 2

05649-005

Rev. A | Page 10 of 28

Page 11

AD12401

www.BDTIC.com/ADI

Table 9. Pin Function Descriptions

Pin No. Mnemonic Description

1 to 4 VC Digital Supply, 3.3 V.

5

6 to 9, 11, 13 ,15,

49 to 52, 79, 96 to

102, 104 to108

10

12 DRB Channel B Data Ready. True output.

14

16 OROUT Overrange. True Output 1 = overranged, 0 = normal operation.

17

18

19 DB11 Channel B Data Bit 11. True output bit.

20 DB10 Channel B Data Bit 10. True output bit.

21

22

23 DB9 Channel B Data Bit 9. True output bit.

24 DB8 Channel B Data Bit 8. True output bit.

25

26

27 DB7 Channel B Data Bit 7. True output bit.

28 DB6 Channel B Data Bit 6. True output bit.

29

30

31 DB5 Channel B Data Bit 5. True output bit.

32 DB4 Channel B Data Bit 4. True output bit.

33

34

35 DB3 Channel B Data Bit 3. True output bit.

36 DB2 Channel B Data Bit 2. True output bit.

37

38

39 DB1 Channel B Data Bit 1. True output bit.

40 DB0 Channel B Data Bit 0. True output bit. DB0 is LSB.

41 to 48 VD Digital Supply, 1.5 V.

53

54

55 DA11 Channel A Data Bit 11. True output bit.

56 DA10 Channel A Data Bit 10. True output bit.

57

58

59 DA9 Channel A Data Bit 9. True output bit.

60 DA8 Channel A Data Bit 8. True output bit.

61

62

63 DA7 Channel A Data Bit 7. True output bit.

64 DA6 Channel A Data Bit 6. True output bit.

65

66

67 DA5 Channel A Data Bit 5. True output bit.

68 DA4 Channel A Data Bit 4. True output bit.

RESET

DNC Do Not Connect.

DRB

OROUT

DB11

DB10

DB9

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

DA11

DA10

DA9

DA8

DA7

DA6

DA5

DA4

LVTTL. 0 = device reset. Minimum width = 200 ns. Device resumes operation after 600 ms maximum.

Channel B Data Ready. Complement output.

Overrange. Complement output.

Channel B Data Bit 11. Complement output bit.

Channel B Data Bit 10. Complement output bit.

Channel B Data Bit 9. Complement output bit.

Channel B Data Bit 8. Complement output bit.

Channel B Data Bit 7. Complement output bit.

Channel B Data Bit 6. Complement output bit.

Channel B Data Bit 5. Complement output bit.

Channel B Data Bit 4. Complement output bit.

Channel B Data Bit 3. Complement output bit.

Channel B Data Bit 2. Complement output bit.

Channel B Data Bit 1. Complement output bit.

Channel B Data Bit 0. Complement output bit. DB0 is LSB.

Channel A Data Bit 11. Complement output bit.

Channel A Data Bit 10. Complement output bit.

Channel A Data Bit 9. Complement output bit.

Channel A Data Bit 8. Complement output bit.

Channel A Data Bit 7. Complement output bit.

Channel A Data Bit 6. Complement output bit.

Channel A Data Bit 5. Complement output bit.

Channel A Data Bit 4. Complement output bit.

Rev. A | Page 11 of 28

Page 12

AD12401

www.BDTIC.com/ADI

Pin No. Mnemonic Description

69

70

71 DA3 Channel A Data Bit 3. True output bit.

72 DA2 Channel A Data Bit 2. True output bit.

73

74

75 DA1 Channel A Data Bit 1. True output bit.

76 DA0 Channel A Data Bit 0. True output bit. DA0 is LSB.

77 DR_EN Data Ready Enable, Typically DNC. See the DR_EN section.

78

80 DRA Channel A Data Ready. True output.

103 H/L GAIN Gain Select Pin. Ground for low gain mode (KWS); pull up to 3.3 V for high gain mode (JWS).

81 to 95, 109 to 112,

129 to 132

113 to 120 VA Analog Supply, 3.7 V.

121 to 128

1

Internal ground plane connections: Section A = DGND, Pin 121 to Pin 124; Section B = DGND, Pin 125 to Pin 128; Section C = AGND, Pin 129 to Pin 132.

1

1

DA3

DA2

DA1

DA0

DRA

AGND Analog Ground.

DGND Digital Ground.

Channel A Data Bit 3. Complement output bit.

Channel A Data Bit 2. Complement output bit.

Channel A Data Bit 1. Complement output bit.

Channel A Data Bit 0. Complement output bit. DA0 is LSB.

Channel A Data Ready. Complement output.

Rev. A | Page 12 of 28

Page 13

AD12401

www.BDTIC.com/ADI

TERMINOLOGY

Analog Bandwidth

The analog input frequency at which the spectral power of the

undamental frequency (as determined by the FFT analysis) is

f

reduced by 3 dB.

Aperture Delay

The delay between the 50% point on the rising edge of the

EN

CODE command and the instant at which the analog input

is sampled.

Analog Input VSWR (50 Ω)

VSWR is a ratio of the transmitted and reflected signals. The

V

SWR can be related to input impedance.

− ZS)/(ZL + ZS)

Γ = (Z

L

where:

Z

= actual load impedance.

L

Z

= reference impedance.

S

VSWR = (1 − |Γ

Aperture Uncertainty (Jitter)

The sample-to-sample variation in aperture delay.

Differential Nonlinearity

The deviation of any code width from an ideal 1 LSB step.

Distortion, Image Spur

The ratio of the rms signal amplitude to the rms signal amplit

ude of the image spur, reported in dBFS. The image spur, a

result of gain and phase errors between two time-interleaved

conversion channels, is located at f

Distortion, Offset Spur

The ratio of the rms signal amplitude to the rms signal ampli-

de of the offset spur, reported in dBFS. The offset spur, a

tu

result of offset errors between two time-interleaved conversion

channels, is located at f

|)/(1 +|Γ|)

/2.

S

/2 − f

S

AIN

.

Full-Scale Input Power

Expressed in dBm. Computed using the equation

POWER

Full-Scale Input Voltage Range

The maximum peak-to-peak input signal magnitude that results

in a full-scale response, 0 dBFS on a single-tone input signal

case. Any magnitude increase from this value results in an

overrange condition.

Gain Error

The difference between the measured and ideal full-scale input

voltage range of the ADC.

Harmonic Distortion, Second

The ratio of the rms signal amplitude to the rms value of the

second harmonic component, reported in dBFS.

Harmonic Distortion, Third

The ratio of the rms signal amplitude to the rms value of the

third harmonic component, reported in dBFS.

Integral Nonlinearity

The deviation of the transfer function from a reference line

measured in fractions of 1 LSB using a best straight line

determined by a least square curve fit.

Maximum Conversion Rate

The maximum ENCODE rate at which the image spur calibration

degrades no more than 1 dB (when the image spur is 70 dB).

Minimum Conversion Rate

The minimum ENCODE rate at which the image spur calibration

degrades no more than 1 dB (when the image spur is 70 dB).

Offset Error

The dc offset imposed on the input signal by the ADC, reported

in LSB (codes).

= 10 log ((V2Full-Scale

Full-Scale

rms

)/(|Z

| × 0.001))

INPUT

Effective Number of Bits (ENOB)

Calculated from the measured SNR based on the equation

dB761..SNR

ENOB

ENCODE Pulse Width/Duty Cycle

Pulse width high is the minimum amount of time the ENCODE

pulse should be left in Logic 1 state to achieve rated performance; pulse width low is the minimum time the ENCODE pulse

should be left in low state.

MEASURED

=

−

026

Rev. A | Page 13 of 28

Output Propagation Delay

The delay between a differential crossing of ENCODE and

ENCODE

Pipeline Latency

The number of clock cycles the output data lags the corresponding clock cycle.

Power Supply Rejection Ratio (PSRR)

The ratio of power supply voltage change to the resulting ADC

output voltage change.

(or zero crossing of a single-ended ENCODE).

Page 14

AD12401

www.BDTIC.com/ADI

Signal-to-Noise-and-Distortion (SINAD)

The ratio of the rms signal amplitude (set 1 dB below full scale)

to the rms value of the sum of all other spectral components,

including harmonics, but excluding dc and image spur.

Signal-to-Noise Ratio (SNR)

The ratio of the rms signal amplitude (set at 1 dB below full

scale) to the rms value of the sum of all other spectral components, excluding the first five harmonics and dc.

Spurious-Free Dynamic Range (SFDR)

The ratio of the rms signal amplitude to the rms value of the

peak spurious spectral component, except the image spur. The

peak spurious component may or may not be a harmonic. It can

be reported in dBc (that is, degrades as signal level is lowered)

or dBFS (always related back to converter full-scale).

Tot a l N ois e

Calculated as

SignalSNRFS

−−

dBcdBm

dBFS

NOISE

where:

Z is the input impedance.

FS is t

he full scale of the device for the frequency in question.

SNR is t

Signal is

full scale. This value includes both thermal and quantization noise.

Two-Tone Intermodulation Distortion Rejection

The ratio of the rms value of either input tone to the rms value

of the worst third-order intermodulation product; reported in dBc.

Two -Tone SFDR

The ratio of the rms value of either input tone to the rms value

of the peak spurious component. The peak spurious component

may or may not be an IMD product. It can be reported in dBc

(that is, degrades as signal level is lowered) or in dBFS (always

related back to converter full-scale).

ZV

he value of the particular input level.

the signal level within the ADC reported in dB below

××=

10001.0

10

)(

Rev. A | Page 14 of 28

Page 15

AD12401

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

0

1

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

–110

Figure 6. FFT: f

3

5

2

0 20 40 60 80 100 120 140 160 180 200

6

4

FREQUENCY (MHz)

= 400 MSPS, AIN = 10.123 MHz @ –1.0 dBFS;

S

SNR = 63.26dB

SFDR = 76.77dBc

SINAD = 62.97dB

IMAGE SPUR = –76.69dBc

X = Image Spur, N = Interleaved Offset Spur

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

–110

6

0 20 40 60 80 100 120 140 160 180 200

Figure 7. FFT: f

1

5

FREQUENCY (MHz)

= 400 MSPS, AIN = 70.123 MHz @ –1.0 dBFS;

S

SNR = 62.61dB

SFDR = 78.03dBc

SINAD = 62.41dB

IMAGE SPUR = –86.28dBc

2

X

4

X = Image Spur, N = Interleaved Offset Spur

0

SNR = 61.54dB

–10

SFDR = 74.03dBc

SINAD = 60.92dB

–20

IMAGE SPUR = –75.09dBc

–30

–40

–50

dB

–60

–70

3

–80

–90

–100

–110

6

0 20 40 60 80 100 120 140 160 180 200

Figure 8. FFT: f

X

FREQUENCY (MHz)

= 400 MSPS, AIN = 128.123 MHz @ –1.0 dBFS;

S

1

2

4

5

X = Image Spur, N = Interleaved Offset Spur

X

N

05649-006

N

3

05649-007

N

05649-008

0

SNR = 60.74dB

–10

SFDR = 71.57dBc

SINAD = 60.29dB

–20

IMAGE SPUR = –82.52dBc

–30

–40

–50

dB

–60

–70

–80

–90

–100

–110

0 20 40 60 80 100 120 140 160 180 200

Figure 9. FFT: f

2

X

S

5

FREQUENCY (MHz)

= 400 MSPS, AIN = 175.123 MHz @ –1.0 dBFS;

3

4

6

X = Image Spur, N = Interleaved Offset Spur

0

2

1

2F2 – F1

2F1 – F2

F2 – F1

0 20 40 60 80 100 120 140 160 180 200

2F1 + F2

F2 + F1

2F2 + F1

FREQUENCY (MHz)

dB

–100

–110

–10

–20

–30

–40

–50

–60

–70

–80

–90

Figure 10. Two-Tone Intermodulation Distortion

(25.

1 MHz and 28.1 MHz; f

= 400 MSPS);

S

X = Image Spur, N = Interleaved Offset Spur

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

F2 + F1

–90

–100

–110

0 20 40 60 80 100 120 140 160 180 200

1

2

2F1 – F2

2F2 – F1

FREQUENCY (MHz)

F2 + F1

Figure 11. Two-Tone Intermodulation Distortion

(70.

1 MHz and 73.1 MHz; f

= 400 MSPS);

S

X = Image Spur, N = Interleaved Offset Spur

1

N

05649-009

05649-010

2F1 + F2

2F2 + F1

05649-011

Rev. A | Page 15 of 28

Page 16

AD12401

www.BDTIC.com/ADI

0

–10

–20

–30

–40

–50

dB

–60

–70

F2 – F1

–80

–90

–100

–110

0 20 40 60 80 100 120 140 160 180 200

F2 + F1

FREQUENCY (MHz)

2F1 + F2

2F2 + F1

Figure 12. Two-Tone Intermodulation Distortion

(17

2.1 MHz and 175.1 MHz; f

= 400 MSPS), SFDR = 70 dBc;

S

X = Image Spur, N = Interleaved Offset Spur

1

2F1 – F2

2

2F2 – F1

05649-012

95

90

85

80

75

SECOND HARMONIC

HARMONICS (dBc)

70

65

60

0 20 40 60 80 100 120 140 160 180

THIRD HARMONIC

ANALOG INPUT FREQUENCY (MHz)

IMAGE SPUR

Figure 15. Harmonics vs. Analog Input Frequency

05649-042

0.5

0.4

0.3

0.2

0.1

0

GAIN (dB)

–0.1

–0.2

–0.3

–0.4

–0.5

10.7 35.0 59.3 83.6 108 132 157 181 205 229

FREQUENCY (MHz)

05649-040

Figure 13. Interleaved Gain Flatness

100

95

90

85

80

IMAGE SPUR

75

DISTORTION (dBFS)

70

65

60

05040302010 70

ANALOG INPUT LEVEL (dB)

THIRD HARMONIC

SECOND HARMONIC

60

05649-041

Figure 14. Second/Third Harmonics and Image Spur vs. Analog Input Level;

= 400 MSPS, A

f

S

= 70 MHz

IN

64.5

64.0

63.5

63.0

62.5

62.0

SNR (dBFS)

61.5

61.0

60.5

60.0

59.5

1.0

0.9

0.8

0.7

0.6

0.5

VD SUPPLY CURRENT (A)

0.4

0.3

ANALOG INPUT FREQUENCY (MHz)

Figure 16. SNR vs. Analog Input Frequency

806040200

INPUT FREQUENCY (MHz)

Figure 17. VD Supply Current vs. A

Frequency

IN

200150100500

180160140120100 200

05649-016

05649-017

Rev. A | Page 16 of 28

Page 17

AD12401

www.BDTIC.com/ADI

–1.00

–1.42

–1.84

–2.26

–2.68

–3.10

–3.52

–3.94

ANALOG INPUT LEVEL

–4.36

–4.78

–5.20

0.100 0.530 0.960 1.390 1.820 2.250 2.680 3.110 3.540 3.970

ANALOG INPUT FREQUENCY

Figure 18. Low Frequency Gain Flatness

4.400

05649-043

Rev. A | Page 17 of 28

Page 18

AD12401

www.BDTIC.com/ADI

THEORY OF OPERATION

The AD12401 uses two high speed, 12-bit ADCs in a timeinterleaved configuration to double the sample rate, while

maintaining a high level of dynamic range performance. The

digital output of each ADC channel is calibrated using a

proprietary digital postprocessing technique, Advanced Filter

Bank (AFB). AFB is implemented using a state-of-the-art field

programmable gate array (FPGA) and provides a wide

bandwidth and wide temperature match for any gain, phase,

and clock timing errors between each ADC channel.

TIME-INTERLEAVING ADCS

When two ADCs are time-interleaved, gain and/or phase

mismatches between each channel produce an image spur at

/2 − f

f

S

mismatches can be the result of any combination of device

tolerance, temperature, and frequency deviations.

Figure 20 shows the performance of a similar converter with

on-board AFB postprocessing implemented. The –44 dBFS

image spur has been reduced to –77 dBFS and, as a result, the

dynamic range of this time-interleaved ADC is no longer

limited by the channel matching.

and an offset spur, as shown in Figure 19. These

AIN

0

–10

–20

–30

–40

–50

–60

dB

–70

–80

–90

–100

–110

–120

0 20 40 60 80 100 120 140 160 180 200

Figure 19. Image Spur due to Mismatches Between Two Interleaved ADCs

0

–10

–20

–30

–40

–50

–60

dB

–70

–80

–90

–100

–110

–120

0 20 40 60 80 100 120 140 160 180 200

Figure 20. AD12401 with AFB Digital Postprocessing

IMAGE SPUR

X

2

5

FREQUENCY (MHz)

AFB Digital Postprocessing)

(No

IMAGE SPUR

X

2

5

FREQUENCY (MHz)

OFFSET SPUR

3

4

OFFSET SPUR

3

1

N

6

05649-018

1

N

6

4

05649-019

The relationship between image spur and channel mismatches

is captured in Tab l e 10 for specific conditions.

Table 10. Image Spur vs. Channel Mismatch

Gain Error (%) Aperture Delay Error (ps) Image Spur (dBc)

1 15 –40

0.25 2.7 –54

0.2 1.1

–62

0.025 0.5 –70

For a more detailed description of time-interleaving in ADCs and a

design example using the AD12401, see Advanced Digital Post-

P

rocessing Techniques Enhance Performance in Time-Interleaved

ADC Systems, which was published in the August, 2003 edition of

e Analog Dialogue (www.analog.com/analogDialogue).

th

ANALOG INPUT

The AD12401 analog input is ac-coupled using a proprietary

transformer front-end circuit that provides 1 dB of gain flatness

over the first Nyquist zone and a −3 dB bandwidth of 480 MHz.

This front-end circuit provides a VSWR of 1.5 (50 Ω) over the

first Nyquist zone, and the typical full-scale input is 3.2 V p-p.

The Mini-Circuits® HELA-10 amplifier module can be used to

drive the input at these power levels.

CLOCK INPUT

The AD12401 requires a 400 MSPS ENCODE that is divided by 2

and distributed to each ADC channel, 180° out of phase from

each other. Internal ac-coupling and bias networks provide the

framework for flexible clock input requirements that include

single-ended sine wave, single-ended PECL, and differential

PECL. While the AD12401 is tested and calibrated using a

single-ended sine wave, properly designed PECL circuits that

provide fast slew rates (>1 V/ns) and minimize ringing result in

comparable dynamic range performance.

Aperture jitter and harmonic content are two major factors to

c

onsider when designing the input clock circuit for the AD12401.

The relationship between aperture jitter and SNR can be

characterized using the following equation. The equation

assumes a full-scale, single-tone input signal.

SNR =

2

⎡

⎢

()

⎢

⎢

⎣

where:

f

= input frequency.

A

t

= aperture jitter.

JRMS

ADC resolution (bits).

N =

ε = ADCDNL (LSB).

V

= ADC input noise (LSB rms).

NOISErms

2

⎛

×

V

ε+

1

1

⎛

2

tf

020log20

JRMSA

×+××π−

⎜

N

2

5.1

⎝

22

⎞

⎜

+

⎟

⎜

⎠

⎝

NOISErms

N

2

⎤

⎞

⎥

⎟

⎟

⎥

⎠

⎥

⎦

Rev. A | Page 18 of 28

Page 19

AD12401

www.BDTIC.com/ADI

Figure 21 displays the application of this relationship to a fullscale, single-tone input signal on the AD12401, where the DNL

was assumed to be 0.4 LSB, and the input noise was assumed to

be 0.8 LSB rms. The vertical marker at 0.4 ps displays the SNR

at the jitter level present in the AD12401 evaluation system,

including the jitter associated with the AD12401 itself.

65

64

63

62

61

SNR (dB)

60

59

58

57

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

APERTURE JITTER (ps rms)

Figure 21. SNR vs. Aperture Jitter

= 180MHz

A

IN

AIN = 10MHz

A

= 65MHz

IN

A

= 128MHz

IN

05649-020

In addition to jitter, the harmonic content of the single-ended

sine wave clock sources must be controlled. The clock source

used in the test and calibration process has a harmonic performance that is better than 60 dBc. Additionally, when using

PECL or other square-wave clock sources, unstable behavior,

such as overshoot and ringing, can affect phase matching and

degrade the image spur performance.

DIGITAL OUTPUTS

The AD12401’s digital postprocessing circuit provides two

parallel, 12-bit, 200 MSPS data output buses. By providing two

output busses that operate at one half the conversion rate, the

AD12401 eliminates the need for large, expensive, high power

demultiplexing circuits. The output data format is twos complement, maintaining the standard set by other high speed

ADCs, such as the

pr

ovided for facilitating proper timing in the data capture circuit.

AD9430 and AD6645. Data-ready signals are

POWER SUPPLIES

The AD12401 requires three different supply voltages: a 1.5 V

supply for the digital postprocessing circuit, a 3.3 V supply to

facilitate digital I/O through the system, and a 3.8 V supply for

the analog conversion and clock distribution circuits. The

AD12401 incorporates two key features that result in solid

PSRR performance. First, on-board linear regulators are used to

provide an extra level of power supply rejection for the analog

circuits. The linear regulator used to supply the ADCs provides

an additional 60 dB of rejection at 100 kHz. Second, to address

higher frequency noise (where the linear regulators’ rejection

degrades), the AD12401 incorporates high quality ceramic

decoupling capacitors.

While this product was designed to provide good PSRR

p

erformance, system designers need to be aware of the risks

associated with switching power supplies and consider using

linear regulators in their high speed ADC systems. Switching

power supplies typically produces both conducted and radiated

energy that result in common-/differential-mode EMI currents.

Any system that requires 12-bit performance has very little

room for errors associated with power supply EMI. For example, a system goal of 74 dB dynamic range performance on the

AD12401 requires noise currents that are less than 4.5 μA and

noise voltages of less than 225 μV in the analog input path.

STARTUP AND RESET

The AD12401’s FPGA configuration is stored in the on-board

EPROM and loaded into the FPGA when power is applied to

the device. The

pin (active low) allows the user to reload

RESET

the FPGA in case of a low digital supply voltage condition or a

power supply glitch. Pulling the

pin low pulls the data-

RESET

ready and output bits high until the FPGA is reloaded. The

pin should remain low for a minimum of 200 ns. On the

RESET

rising edge of the reset pulse, the AD12401 starts loading the

configuration into the FPGA. The reload process requires a

maximum of 87 ms to complete. Valid signals on the data-ready

pins indicate the reset process is complete. In addition, system

designers must be aware of the thermal conditions of the

AD12401 at startup. If large thermal imbalances are present, the

AD12401 can require additional time to stabilize before providing

specified image spur performance.

DR_EN

The DR_EN pin is used to synchronize the collection of data

into external buffer memories. DR_EN must be held low for a

minimum amount of time (see Tabl e 2 through Ta b le 4 for each

CODE rate) to ensure correct operation. The function shuts

EN

off DRA and DRB until the DR_EN pin is set high again. DRA

and DRB resume on the next valid DRA after DR_EN is

released. If this feature is not required, tie this pin to 3.3 V

through a 3.74 kΩ.

OVERRANGE

The differential OROUT pins are used to determine if the

AD12401 input is overranged. OROUT timing is identical to the

Channel B data. If the OROUT pin is high, then the Channel B

data coincident with the overrange indication or the Channel A

data immediately preceding it resulted from an overrange input.

If the OROUT pin is low, the operation is normal.

Rev. A | Page 19 of 28

Page 20

AD12401

R

A

www.BDTIC.com/ADI

GAIN SELECT

The AD12401 is graded out for the gain mode and should be

ordered accordingly: the AD12401-xxxKWS is calibrated in the

low gain mode, and the AD12401-xxxJWS is calibrated in the

high gain mode. Performance is not guaranteed if either grade

is used in the wrong gain mode.

The high gain mode sets the analog input voltage to

pproximately 1.6 V p-p. The low gain mode sets the analog

a

input voltage to approximately 3.2 V p-p. For high gain mode,

the user should pull Pin 103 (H/L_GAIN) up to 3.3 V using

a 4.02 kΩ resistor. For low gain mode, the user should ground

Pin 103.

THERMAL CONSIDERATIONS

The module is rated to operate over a case temperature of 0°C

to 60°C. To maintain the tight channel matching and reliability

of the AD12401, care must be taken to ensure that proper

thermal and mechanical considerations have been made and

addressed to ensure case temperature is kept within this range.

Each application requires evaluation of the thermal management as applicable to the system design. This section provides

information that should be used in the evaluation of the

AD12401’s thermal management for each specific use.

In addition to the radiation of heat into its environment, the

AD12401

mounting studs and standoffs as they contact the motherboard.

As described in the

s

ection, the module should be secured to the motherboard

using 2-56 nuts (washer use is optional). The torque on the nuts

should not exceed 32-inch ounces. Using a thermal grease at the

standoffs results in better thermal coupling between the board

and module. Depending on the ambient conditions, airflow can

be necessary to ensure the components in the module do not

exceed their maximum operating temperature. For reliability,

the most sensitive component has a maximum junction

temperature rating of 125°C.

Figure 22 and Figure 23 provide a basic guideline for two key

hermal management decisions: the use of thermal interface

t

material between the module bottom cover/mother board and

airflow. Figure 21 characterizes the typical thermal profile of an

AD12401 tha

rovides the same information for a configuration that uses

p

gap-filling thermal interface material. In this case, Thermagon

T-flex 600 Series™, 0.040” thickness, was used. These profiles

show that the maximum die temperature is reduced by

approximately 2°C when thermal interface material is used.

Figure 22 and Figure 23 also provide a guideline for determining

he airflow requirements for given ambient conditions. For

t

example, a goal of 120°C die temperature in a 40°C ambient

environment without the use of thermal interface material

requires an airflow of 100 LFM.

module enables the flow of heat through the

Package Integrity/Mounting Guidelines

t is not using thermal interface material. Figure 22

From a channel-matching perspective, the most important

nsideration is external thermal influences. It is possible for

co

thermal imbalances in the end application to adversely affect

the dynamic performance. Due to the temperature dependence

of the image spur, substantial deviation from the factory calibration conditions can have a detrimental effect. Unbalanced

thermal influences can cause gradients across the module, and

performance degradation can result. Examples of unbalanced

thermal influences can include large heat dissipating elements

near one side of the AD12401, or obstructed airflow that does

not flow uniformly across the module. The thermal sensitivity

of the module can be affected by a change in thermal gradient

across the module of 2°C.

110

100

90

80

70

TURE (°C)

60

50

TEMPE

40

30

20

NO AIRFL OW 100 LFM 300 LFM

Figure 22. Typical Temperature vs. Airflow with No Module/Board

Interfa

ce Material (Normalized to 60°C Module Case Temperature)

110

100

90

80

70

60

50

TEMPERATURE (°C)

40

30

20

NO AIRFLOW 100 LFM 300 LFM

Figure 23. Typical Temperature vs. Airflow with T-flex Module/Board

Interfa

ce Material (Normalized to 60°C Module Case Temperature Ambient)

TYPICAL JUNCTION

CASE

AMBIENT

AIRFLOW CO NDITION

TYPICAL JUNCTION

CASE

AMBIENT

AIRFLOW CONDITION

05649-021

05649-022

PACKAGE INTEGRITY/MOUNTING GUIDELINES

The AD12401 is a printed circuit board (PCB)-based module

designed to provide mechanical stability and to support the

intricate channel-to-channel matching necessary to achieve high

dynamic range performance. The module should be secured to

the motherboard using 2-56 nuts (washer use is optional). The

torque on the nuts should not exceed 32-inch ounces.

Rev. A | Page 20 of 28

Page 21

AD12401

www.BDTIC.com/ADI

The SMA edge connectors (AIN and ENC/

mounted to the board to achieve minimum height of the

module. When attaching and routing the cables, one must

ensure they are stress-relieved and do not apply stress to the

SMA connector/board. The presence of stress on the cables can

degrade electrical performance and mechanical integrity of the

module. In addition to the routing precautions, the smallest

torque necessary to achieve consistent performance should be

used to secure the system cable to the AD12401’s SMA

connectors. The torque should never exceed 5-inch pounds.

Any disturbances to the AD12401 structure, including

moving the covers or mounting screws, invalidates the

re

calibration and results in degraded performance. See the

Outline Dimensions section for mounting stud dimensions, see

Figure 38 for PCB interface locations. Mounting stud length

typ

ically accommodates a PCB thickness of 0.093". Consult

sales if board thickness requirements exceed this dimension.

AD12401 EVALUATION KIT

The AD12401/KIT offers an easy way to evaluate the AD12401.

The AD12401/KIT includes the AD12401 mounted on an

adapter card, the AD12401 evaluation board, the power supply

cables, a 225 MHz buffer memory FIFO board, and the Dual

Analyzer software. The user must supply a clock source, an

analog input source, a 1.5 V power supply, a 3.3 V power supply,

a 5 V power supply, and a 3.8 V power supply. The clock source

and analog input source connect directly to the AD12401. The

power supply cables (included) and a parallel port cable (not

included) connect to the evaluation board. The AD12401

works on the same evaluation board as the AD12400 and the

AD12500: GS08054.

Power Connector

Power is supplied to the board via a detachable 12-lead power

strip (three 4-pin blocks).

Table 11. Power Connector

Supply Description

VA 3.7 V Analog supply for the ADC (950 mA typ)

VC 3.3 V Digital supply for the ADC outputs (400 mA typ)

VD 1.5 V1Digital supply for the FPGA (1.25 A max, 0.7 A typ)

VB 5.0 V Digital supply for the buffer memory board (400 mA typ)

1

The power supply cable has an approximately 100 mV drop. The VD supply

current is dependent on the analog input frequency (see Figure 17).

Analog Input

The analog input source connects directly to an SMA on the

AD12401.

) are surface

ENC

ENCODE

The single-ended or differential ENCODE signal connects directly

to SMA connector(s) on the AD12401. A single-ended sine wave

at 10 dBm connected to the ENCODE SMA is recommended.

A low jitter clock source (<0.5 ps) is recommended to properly

eval

uate the AD12401.

DATA OUTPUTS

The AD12401xxxKWS digital outputs are available at the 80-pin

connector, P2, on the evaluation board. The AD12401/KIT

comes with a buffer memory FIFO board connected to P2,

which provides the interface to the parallel port of a PC. The

Dual Analyzer software is compatible with Windows® 95,

Windows 98, Windows 2000, and Windows NT®.

The buffer memory FIFO board can be removed, and an external

ic analyzer or other data acquisition module can be connected

log

to this connector, if required.

Adapter Card

The AD12401 is attached to an adapter card that interfaces to

the evaluation board through a 120-pin connector, P1, which is

on the top side of the evaluation board.

Digital Postprocessing Control

The evaluation board has a 2-pin jumper, labeled AFB, that

allows the user to enable/disable the digital postprocessing. The

digital postprocessing is active when the AFB jumper is applied.

When the jumper is removed, the FPGA is set to a passthrough

mode, which demonstrates to the user the performance of the

AD12401 without the digital postprocessing.

RESET

The AD12401’s FPGA configuration is stored in an EEPROM

and loaded into the FPGA when power is applied to the AD12401.

The

the FPGA in case of a low voltage condition or a power supply

glitch. Depressing the

output bits high. The

minimum of 200 ns. On the rising edge of the

AD12401 starts loading the configuration into the on-module

FPGA. The reload process requires a maximum of 600 ms to

complete. Valid signals on the data-ready pins indicate the reset

process is complete.

The AD12401 is not compatible with the HSC-ADC-EVAL-

DC

/SC hardware or software.

switch, SW1 (active low), allows the user to reload

RESET

switch pulls the data-ready and

RESET

switch should remain low for a

RESET

RESET

pulse, the

H/L_GAIN

The H/L_GAIN select jumper, Pin 103, should be on for low

gain mode (AD12401-xxxKWS). The H/L_GAIN select jumper

should be removed for high gain mode, AD12401-xxxJWS.

Rev. A | Page 21 of 28

Page 22

AD12401

www.BDTIC.com/ADI

Table 12. Evaluation Board Bill of Materials (BOM)

Item No. Qty. Ref-Des Device Package Value, Mfg

1 2 C3, C5 Capacitors 603 0.1 μF, 25 V

2 2 C4, C6 Capacitors 805 10 μF, 6.3 V

3 1 R9 Resistor 603

4 1 AFB 2-Pin Header/Jumper Pin Strip

5 1 P2 80-Pin Dual Connector Assembly Surface-Mount

6 1 SW1 Switch Push Button SPST 6 MM

7 3 J2, J3, J4 4-Pin Header Power Connecters Pin Strip

8 1 P1 60-Pin Dual-Socket Assembly Surface-Mount

9 1 PCB AD12401 Interface Board GS08054 PCB

R8

4.02kΩ

3.3VC

PASS

3.3VC

H/L_GAIN

3.3VC

NYQ

3.3VC

OTHER

R9

4.02kΩ

R10

4.02kΩ

R11

4.02kΩ

E12

E13

AFB

H/L_GAIN

NYQ

DITHER

JP2

JP3

SPARE1

SPARE2

SPARE1

SPARE2

E14

E18

4.02 kΩ, 1%

Molex/GC/Weldon

Post Header AMP

Panasonic

Wieland

Samtec

DGND

E17

SELECT D

E1

1

2

E22

JP4

EVQ-PAC85R

1.5V SENSE

3.3VD

4

3

DGND

05649-023

DGND

1.5VD

DGND

3.3VC

5V

DIGITAL

J4

1

2

3

4

DIGITAL

J3

1

2

3

4

3.8V

AGND

+VA

ANALOG

J2

1

2

3

4

5V 5V

C4

10μFC30.1μF

DGND DGND

3.3VC

C6

10μFC50.1μF

DGND DGND

Figure 24. Evaluation Board

SELECT D

RESET

3.3VD

Rev. A | Page 22 of 28

Page 23

AD12401

A

www.BDTIC.com/ADI

AD1240X

P1:A

21

3.3VC

RESET

DNC

DNC

DB11

DB9

DB7

DB5

DB3

DB1

1.5VD

DNC

DA11

DA9

DA7

DA5

DA3

DA1

DNC

DNC

DNC

3

5

DNC

DNC

DNC

DB11

DB11

DB9

DB7

DB5

DB3

DB1

DGND

DNC

DA11

DA9

DA7

DA5

DA3

DA1

DR_EN

DGND

AGND

DNC

H/L_GAIN

DNC

AGND AGND

+VA

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

121

123

QSE–60–01–L–D–A–K

43

45

47

49

51

53

55

57

59

61

63

65

67

69

71

73

75

77

79

125

127

QSE–60–01–L–D–A–K

83

85

87

89

91

93

95

97

99

101

103

105

107

109

111

113

115

117

119

129

131

QSE–60–01–L–D–A–K

GND

GND

GND

GND

GND

P1:B

P1:C

GND

GND

GND

GND

GND

GND

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

122

124

4241

44

46

48

50

52

54

56

58

60

62

64

66

68

70

72

74

76

78

80

126

128

8281

84

86

88

90

92

94

96

98

100

102

104

106

108

110

112

114

116

118

120

130

132

OROUT

DGND

DGND

AGND

E2

E19

AGNDAGND

3.3VC

DNC

DRB

DB10

DB8

DB6

DB4

DB2

DB0

1.5VD

PASS

DA10

DA8

DA6

DA4

DA2

DA0

DRA

DNC

DNC

DNC

+VA

OROUT

DNC

DRB

DB8

DB6

DB4

DB2

DB0

DNC

DA10

DA8

DA6

DA4

DA2

DA0

DRA

WP

DNC

DB10

3.3VC

DRA

DA11

DA10

DA9

DA8

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

OR

DRA

DA11

DA10

DA9

DA8

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

OR

Figure 25. Evaluation Board

AMP104655-9

DGND

P2:C

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

P2:D

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

AMP104655-9

DRB

DB11

DB10

DB9

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

OR

DRB

DB11

DB10

DB9

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

OR

DGND

P2:A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

AMP104655-9

P2:B

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

MP104655-9

05649-024

Rev. A | Page 23 of 28

Page 24

AD12401

www.BDTIC.com/ADI

Figure 26. Power Plane 1

Figure 27. Power Plane 2

05649-025

05649-026

Figure 29. Second Ground Plane

Figure 30. Top Side Copper

05649-028

05649-029

05649-027

Figure 28. First Ground Plane

Rev. A | Page 24 of 28

Figure 31. Bottom Side Copper

05649-030

Page 25

AD12401

www.BDTIC.com/ADI

05649-031

Figure 32. Top Mask

Figure 35. Evaluation Adapter Board, Top Silkscreen

05649-034

Figure 33. Top Silkscreen

Figure 34. Bottom Silkscreen

05649-032

05649-033

Figure 36. Evaluation Adapter Board, Analog and Digital Layers

Figure 37. Evaluation Adapter Board, Bottom Silkscreen

05649-035

05649-037

Rev. A | Page 25 of 28

Page 26

AD12401

www.BDTIC.com/ADI

LAYOUT GUIDELINES

The AD12401 requires a different approach from traditional

high speed ADC system layouts. While the AD12401’s internal

PCB isolates digital and analog grounds, these planes are tied

together through the product’s aluminum case structure.

Therefore, the decision to isolate the analog and digital grounds

on the system PCB has additional factors to consider.

For example, if the AD12401 is attached with conductive

hermal interface material to the system PCB, there is

t

essentially no benefit to keeping the analog and digital ground

planes separate. If neither thermal interface material nor

nonconductive interface material is used, system architects

must consider the ground loop that is created if analog and

digital planes are tied together directly under the AD12401.

This EMI-based decision must be considered on a case-by-case

basis and is largely dependent on the other sources of EMI in

the system. One critical consideration is that a 12-bit performance requirement (–74 dBc) requires keeping conducted EMI

currents (referenced to the input of the AD12401) below 4.5 μA.

All the characterization and testing of the AD12401 is performed

using a system that isolated these ground planes.

PCB INTERFACE

Figure 38 provides the mounting hole footprint for assembling

the AD12401 to the second-level assembly. The diagram is

referenced to the center of the mating QTE connector. Refer to

the QTE/QSE series connector documentation at www.samtec.com

for the SMT footprint of the mating connector.

The top view of the second-level assembly footprint provides a

gram of the second-level assembly locating tab locations for

dia

mating the Samtec QTE-060-01-L-A-K-TR terminal strip on

the AD12401 to a QSE-060-01-L-A-K-TR socket on the secondlevel assembly. The diagram is referenced to the center of the

QTE terminal strip on the AD12401 and the mounting holds

for the screws, which holds the AD12401 to the second-level

assembly board. The relationship of these locating tabs is based

on information provided by Samtec (connector supplier) and

should be verified with Samtec by the customer.

Mating and unmating forces—the knifing or peeling action of

a

pplying force to one end or one side—must be avoided to

prevent damage to the connector and guidepost.

If thermal interface material is used in the final system design,

e following layout factors need to be considered: open solder

th

mask on the area that contacts the interface material and the

thickness of the ground plane. While this should be analyzed in

each specific system design, the use of solder mask can negate

any advantage achieved by using the thermal interface material,

and its use should be carefully considered. The ground plane

thickness does not have a major impact on the thermal performance, but if design margin is slight, additional thickness

can yield incremental improvements.

Rev. A | Page 26 of 28

Page 27

AD12401

www.BDTIC.com/ADI

1.184 [30.0673]

1.025 [26.0164] 2×

0, 0 DATUM = CENTER OF CONNECTOR

R.0470[R1.19] 6×

0.000 [.0000]

2.159 [54.8258] 2×

Figure 38. Top View of Interface PCB Assembly

0.396 [10.0456] 2×

0.105 [2.6670] 2×

.000 [.0000]

1.025 [26.0164] 2×

1.184 [30.0673]

05649-038

Rev. A | Page 27 of 28

Page 28

AD12401

0

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

3.190 TYP

2.890 MAX

PIN 1

AIN

BOARD

.700 MAX

0.175 TYP

2.060

2.040

TOP VIEW

ENC

ENC

JOHNSON SMA-50 O HM CONNECT NO. 142-07 11-821

SIDE VIEW

2-56 STUDS 4⋅

BOTTOM VIEW

0.270 2⋅

2.590 MAX

0.200 TYP

2.060

2.040

0.267 TYP

0.600 MAX

SAMTEC CONNECTOR

QTE-060-01-L-D-A-K-TR

2.328 TYP

0.856 TYP

0.256 TYP

0.505 TYP 2⋅

1.773

1.753

Figure 39. Non-Hermetic Hybrid—Surface-Mounted Parts

(WS-Suffix)

Dimensions sh

own in inches

Tolerances: 0.xxx = ±5 mils

ORDERING GUIDE

Model Temperature Range Package Description

AD12401-326KWS 0°C to 60°C (Case) 2.9" × 2.6" × 0.6" Module

AD12401-326JWS 0°C to 60°C (Case) 2.9" × 2.6" × 0.6" Module

AD12401-360KWS 0°C to 60°C (Case)

AD12401-400KWS 0°C to 60°C (Case)

AD12401-400JWS 0°C to 60°C (Case)

AD12401/KIT

1

The encode rate and gain mode must be selected when ordering the AD12401/KIT. The standard AD12401/KIT is configured for low gain mode at 400 MSPS.

©2006 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D05649-0-4/06(A)

1

Evaluation Kit

Rev. A | Page 28 of 28

2.9" × 2.6" × 0.6" Module

2.9" × 2.6" × 0.6" Module

2.9" × 2.6" × 0.6" Module

040606-A

Loading...

Loading...