A

G

16-Bit, 80 MSPS A/D Converter

FEATURES

80 MSPS sample rate

80 dBFS signal-to-noise ratio

Transformer-coupled analog input

Single PECL clock source

Digital outputs

True binary format

3.3 V and 5 V CMOS-compatible

APPLICATIONS

Low signature radar

Medical imaging

Communications instrumentation

Instrumentation

Antenna array processing

GENERAL DESCRIPTION

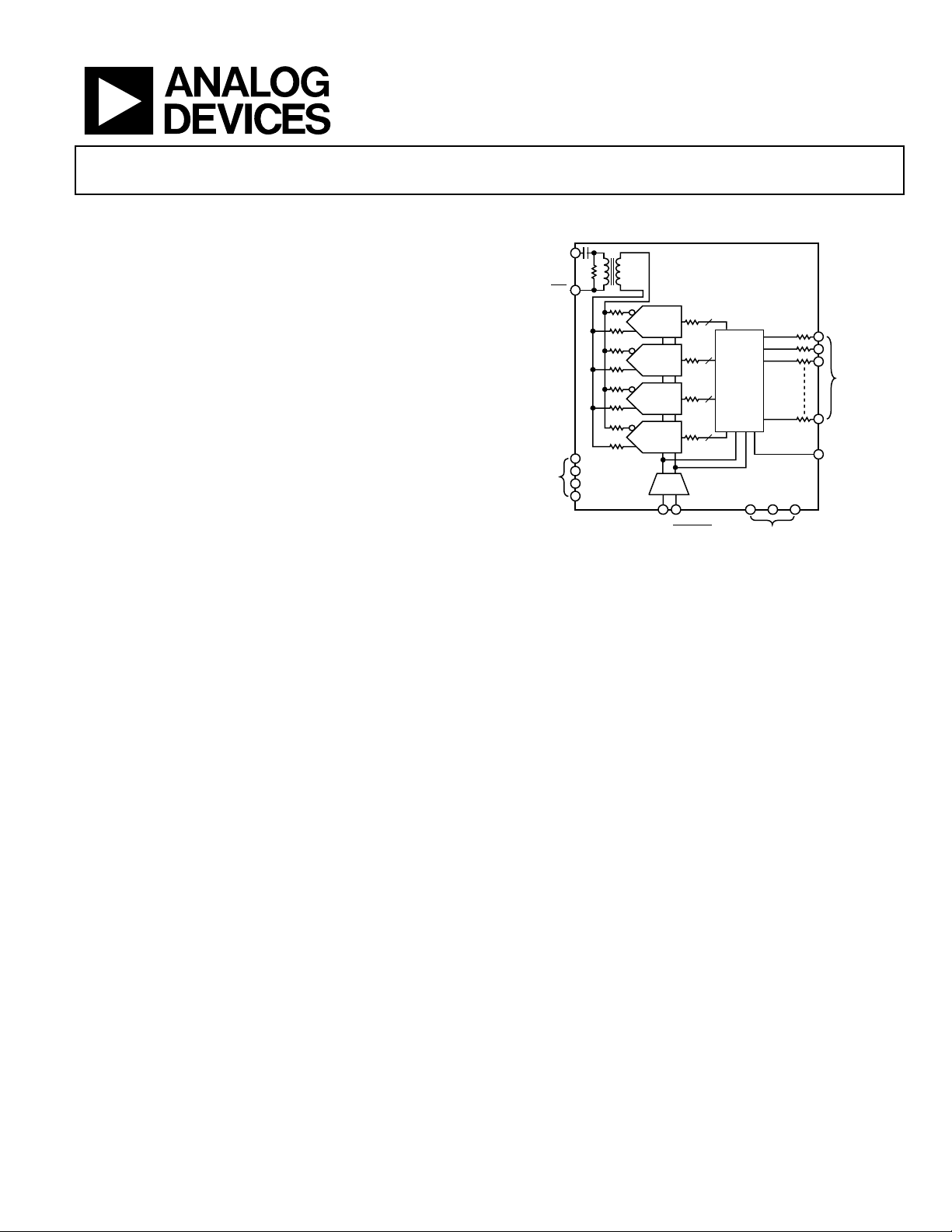

The AD10678 is a 16-bit, high performance, analog-to-digital

converter (ADC) for applications that demand increased SNR

levels. Exceptional noise performance and a typical signal-tonoise ratio of 80 dBFS are obtained by digitally postprocessing

the outputs of four ADCs. A single analog input and PECL

sampling clock and 3.3 V and 5 V power supplies are required.

The AD10678 is assembled using a 0.062" thick laminate board

with three sets of connector interface pads to accommodate

analog and digital isolation. Analog Devices recommends using

the FSI-110-03-G-D-AD-K-TR connector from Samtec. The

overall board fits a 2.2" × 2.8" PCB specified from 0°C to 70°C.

AD10678

FUNCTIONAL BLOCK DIAGRAM

AIN

AIN

ADC

ADC

ADC

ADC

AGND

NALO

POWER

5VA

3.3VE

AGND

CLOCK DISTRIBUTION

CIRCUIT

Figure 1.

PRODUCT HIGHLIGHTS

1. Guaranteed sample rate of 80 MSPS.

2. Input signal conditioning with optimized noise

performance.

3. Fully tested and guaranteed performance.

AD10678

14

14

DIGITAL

POST-

PROCES-

14

SING

14

DGND DGND

DIGITAL POWERENCODE ENCODE

D

D

3.3V

OUT

OUT

0

15

OUTPUT

DATA

BITS

DRY

03376-A-001

Rev. B

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.461.3113 © 2005 Analog Devices, Inc. All rights reserved.

www.analog.com

AD10678

TABLE OF CONTENTS

Specifications..................................................................................... 3

DC Specifications ......................................................................... 3

Digital Specifications ................................................................... 3

AC Specifications.......................................................................... 4

Switching Specifications.............................................................. 5

Absolute Maximum Ratings............................................................ 6

Explanation of Test Levels........................................................... 6

Operating Range........................................................................... 6

ESD Caution.................................................................................. 6

Test Circuits....................................................................................... 7

Pin Configurations and Function Descriptions ........................... 8

Typical Performance Characteristics ...........................................10

REVISION HISTORY

3/05—Rev. A to Rev. B

Changes to Figure 1.......................................................................... 1

Changes to Figure 2 and Figure 3................................................... 7

Added Figure 7 to Figure 9.............................................................. 8

Reformatted Table 7 ......................................................................... 8

Changes to Figure 10........................................................................ 9

Reformatted Theory of Operation Section ................................. 13

Changes to Figure 22...................................................................... 15

Terminology .................................................................................... 12

Theory of Operation ...................................................................... 13

Thermal Considerations............................................................ 13

Input Stage................................................................................... 13

Encoding the AD10678 ............................................................. 13

Output Loading .......................................................................... 13

Analog and Digital Power Supplies.......................................... 13

Analog and Digital Grounding................................................. 14

Other Notes................................................................................. 14

Evaluation Board........................................................................ 14

Outline Dimensions....................................................................... 19

Ordering Guide .......................................................................... 19

12/03—Rev. 0 to Rev. A

Updated format...................................................................Universal

Changes to AC Specifications table footnotes .............................. 4

Changes to Table 1............................................................................ 3

Changes to Table 3............................................................................ 6

Changes to Figure 11...................................................................... 10

Changes to Theory of Operation.................................................. 13

Changes to Ordering Guide.......................................................... 20

2/03—Revision 0: Initial Version

Rev. B | Page 2 of 20

AD10678

SPECIFICATIONS

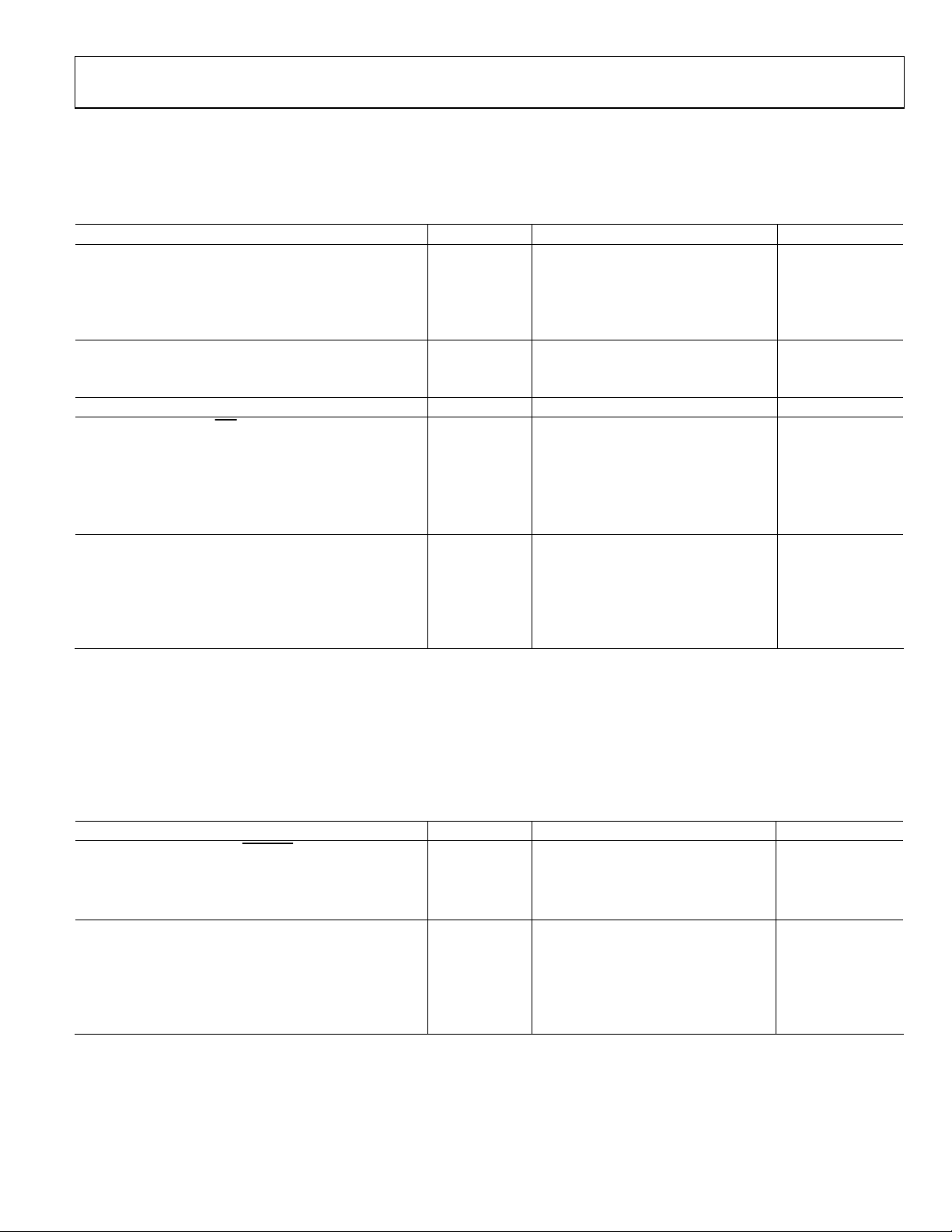

DC SPECIFICATIONS

AVCC = 5 V, EVCC = 3.3 V, VDD = 3.3 V, TA = 25°C, differential encode = 80 MSPS, C

Table 1.

Parameter Test Level Min Typ Max Unit

RESOLUTION 16 Bits

Offset Error I –0.30 +0.12 +0.30 %FS

Gain Error I –7 +7 %FS

Differential Nonlinearity (DNL) V ±0.7 LSB

Integral Nonlinearity (INL) V ±4 LSB

TEMPERATURE DRIFT

Offset Error V 13 ppm/°C

Gain Error V 200 ppm/°C

POWER SUPPLY REJECTION RATIO (PSRR) V 60 dB

ANALOG INPUTS (AIN, AIN)1

Differential Input Voltage Range V 2.15 V p-p

Differential Input Resistance V 50 Ω

Differential Input Capacitance V 2.5 nF

Input Bandwidth IV 0.40 220 MHz

VSWR2 V 1.04:1 Ratio

POWER SUPPLY3

Supply Current

IAVCC (AVCC = 5.0 V) I 0.95 1.1 A

IEVCC (EVCC = 3.3 V) I 0.15 0.2 A

IVDD (VDD = 3.3 V) I 0.49 0.625 A

Total Power Dissipation4 I 6.86 8.0 W

1

Measurement includes the recommended interface connector.

2

Input VSWR, see . Figure 18

3

Supply voltages should remain stable within ±5% for normal operation.

4

Power dissipation measured with encode at rated speed and –6 dBFS analog input at 10 MHz.

≤ 10 pF, unless otherwise noted.

LOAD

DIGITAL SPECIFICATIONS

AVCC = 5 V, EVCC = 3.3 V, VDD = 3.3 V, TA = 25°C, differential encode = 80 MSPS, C

Table 2.

Parameter Test Level Min Typ Max Unit

ENCODE INPUTS (ENCODE, ENCODE)

Differential Input Voltage Range IV 0.4 V p-p

Differential Input Resistance V 100 Ω

Differential Input Capacitance V 160 pF

LOGIC OUTPUTS (D15 to D0)

Logic Compatibility CMOS

Logic 1 Voltage I

Logic 0 Voltage I

≤100 mA IV 0.9 × VDD V

LOAD

≤100 mA IV 0.4 V

LOAD

Output Coding True binary

Series Output Resistance per Bit 120 Ω

Rev. B | Page 3 of 20

≤ 10 pF, unless otherwise noted.

LOAD

AD10678

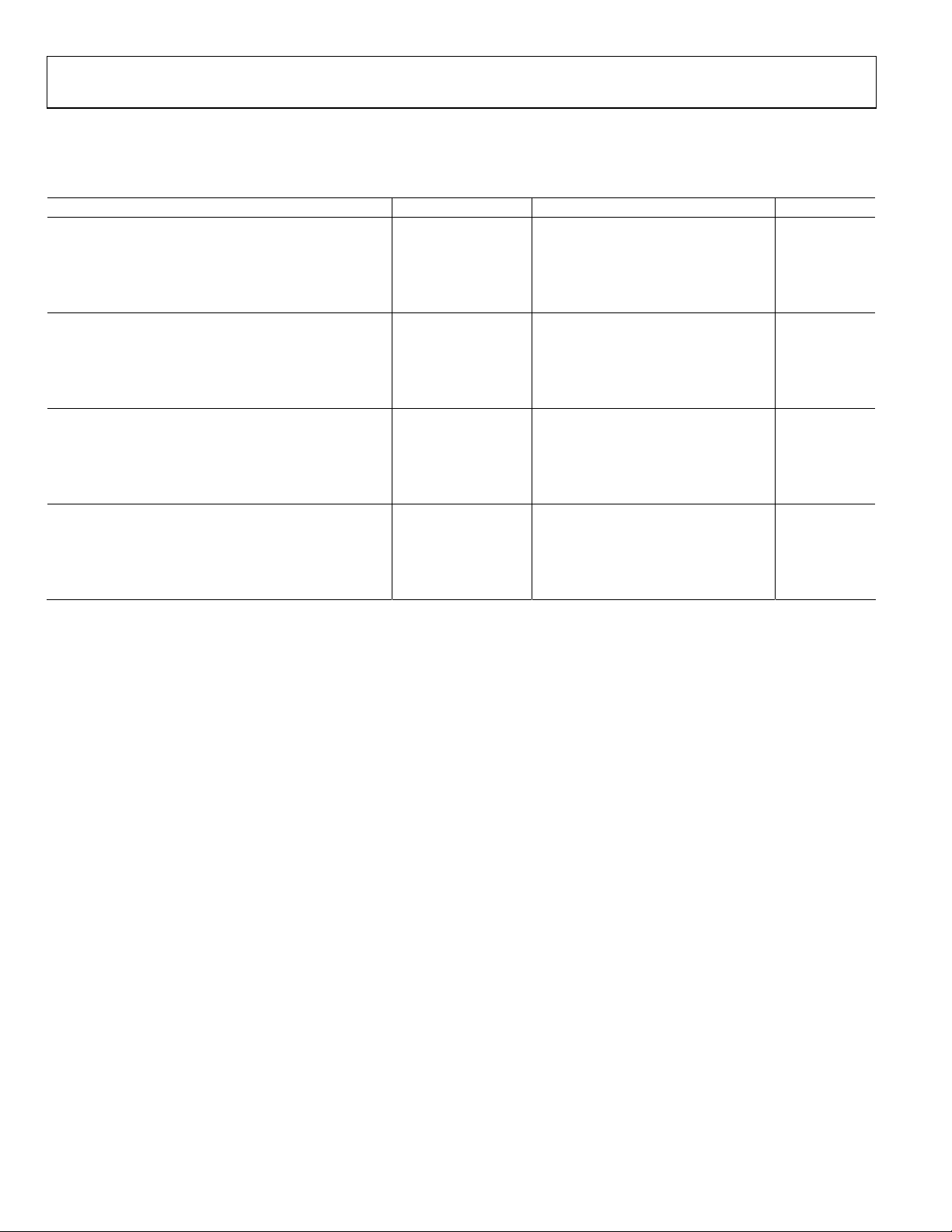

AC SPECIFICATIONS

AVCC = 5 V, EVCC = 3.3 V, VDD = 3.3 V, TA = 25°C, differential encode = 80 MSPS, C

Table 3.

Parameter Test Level Min Typ Max Unit

SNR1

Analog Input 2.5 MHz I 77.5 80.5 dBFS

@ −6 dBFS 10 MHz I 77.5 80.5 dBFS

30 MHz I 77 80.2 dBFS

70 MHz I 76 78 dBFS

SINAD2

Analog Input 2.5 MHz I 77.2 80.3 dBFS

@ −6 dBFS 10 MHz I 77.2 80.3 dBFS

30 MHz I 76.6 79.7 dBFS

70 MHz I 74.7 77.4 dBFS

SFDR3

Analog Input 2.5 MHz I 88 97.2 dBFS

@ −6 dBFS 10 MHz I 88 97.2 dBFS

30 MHz I 84 94.2 dBFS

70 MHz I 81 91.7 dBFS

TWO-TONE4

Analog Input

@ −7 dBFS IMD

f1 = 10 MHz, f2 = 12 MHz V 96 dBFS

f1 = 70 MHz, f2 = 72 MHz V 84 dBFS

1

Analog input signal power at −6 dBFS; signal-to-noise (SNR) is the ratio of signal level to total noise (first five harmonics removed). Encode = 80 MSPS. SNR is reported

in dBFS, related back to converter full scale.

2

Analog input signal power at −6 dBFS; signal-to-noise and distortion (SINAD) is the ratio of signal level to total noise + harmonics. Encode = 80 MSPS. SINAD is

reported in dBFS, related back to converter full scale.

3

Analog input signal equals −6 dBFS; SFDR is the ratio of converter full scale to worst spur.

4

Both input tones at −7 dBFS; two-tone intermodulation distortion (IMD) rejection is the ratio of either tone to the worst third-order intermodulation product.

≤ 10 pF, unless otherwise noted.

LOAD

Rev. B | Page 4 of 20

AD10678

SWITCHING SPECIFICATIONS

AVCC = 5 V, EVCC = 3.3 V, VDD = 3.3 V, TA = 25°C, differential encode = 80 MSPS, C

Table 4.

Parameter Test Level Min Typ Max Unit

MAXIMUM CONVERSION RATE I 80 MSPS

MINIMUM CONVERSION RATE IV 30 MSPS

DUTY CYCLE IV 40 60 %

ENCODE INPUTS PARAMETERS

Encode Period @ 80 MSPS, t

Encode Pulse Width High @ 80 MSPS, t

Encode Pulse Width Low @ 80 MSPS, t

V 12.5 ns

ENC

V 6.25 ns

ENCH

V 6.25 ns

ENCL

ENCODE/DATA (D15:D0)

Propagation Delay, t

Valid Time, t

7.3 ns

PDL

6.7 ns

PDH

ENCODE/DATA READY1

Encode Rising to Data Ready Falling, t

Encode Rising to Data Ready Rising, t

12.6 ns

DR_F

6.4 ns

DR_R

DATA READY/DATA1

Data Ready to Data (Hold Time) t

Data Ready to Data (Setup Time) t

10 ns

H_DR

1 ns

S_DR

APERTURE DELAY, tA V 480 ps

APERTURE UNCERTAINTY (JITTER), tJ V 500 fs rms

PIPELINE DELAYS V 10 Cycles

1

Duty cycle = 50%.

≤ 10 pF, unless otherwise noted.

LOAD

Rev. B | Page 5 of 20

AD10678

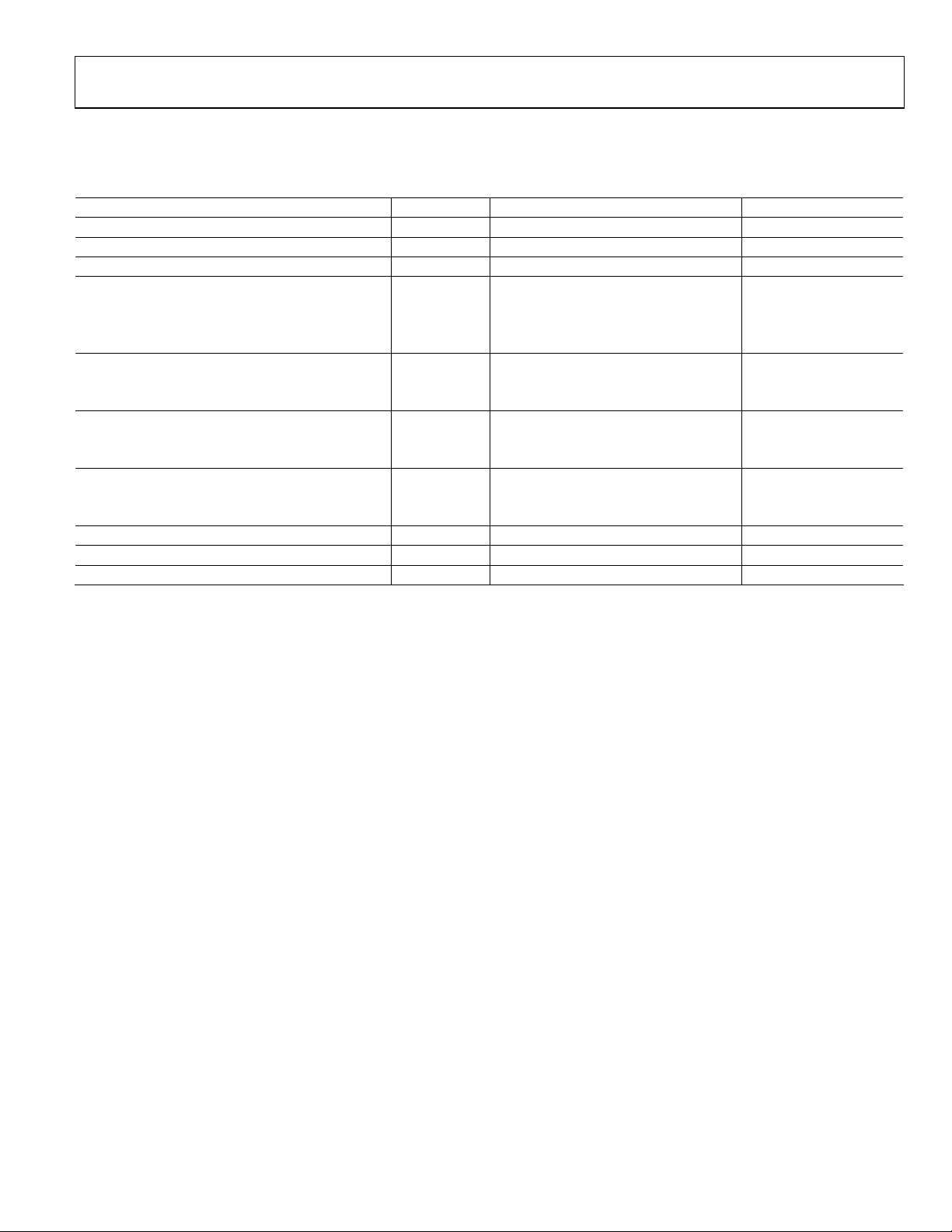

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter Rating

AVCC to AGND 0 V to 7 V

EVCC to AGND 0 V to 6 V

V

to DGND –0.5 V to +3.8 V

DD

Analog Input Voltage 0 V to AVCC

Analog Input Current 25 mA

Encode Input Voltage 0 V to 5 V

Digital Output Voltage –0.5 V to VDD

Maximum Junction Temperature 150°C

Storage Temperature Range Ambient –65°C to +150°C

Maximum Operating Temperature Ambient 92°C

Table 6. Output Coding (True Binary)

Code AIN (V) Digital Output

65535 +1.1 1111 1111 1111 1111

. . .

. . .

. . .

32768 0 1000 0000 0000 0000

32767 –0.000034 0111 1111 1111 1111

. . .

. . .

. . .

0 –1.1 0000 0000 0000 0000

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

EXPLANATION OF TEST LEVELS

I. 100% production tested.

II. 100% production tested at 25°C and sample tested at

specified temperatures.

III. Sample tested only.

IV. Parameter is guaranteed by design and characterization

testing.

V. Parameter is a typical value only.

100% production tested at 25°C; guaranteed by design and

characterization testing for industrial temperature range; 100%

production tested at temperature extremes for military devices.

OPERATING RANGE

Operating ambient temperature range: 0°C to 70°C. See the

Thermal Considerations section.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on the

human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. B | Page 6 of 20

AD10678

TEST CIRCUITS

t

ANALOG INPUT

A

N N+1

t

ENC

t

ENCL

N+2 N+3

t

ENCH

N+4

N+5

N+6

ENCODE, ENCODE

DATA BITS, D[15:0]

DATA-READY

OUTPUT

ENC

ENC

Figure 4. Equivalent Encode Input

100Ω

N

N

N+1

N–10 N–9 N–8 N–7 N–6 N–5

N+1

N+2

t

PDH

N+2

t

S_DR

N+3

t

PDL

t

H_DR

N+3

N+4

t

DR_R

N+4

N+5

t

N+6

DR_F

N+5

N+6

03376-A-002

Figure 2. Timing Diagram

V

AV

CH

CC

AIN

AIN

1:1

200Ω 500Ω

25Ω

25Ω

BUF

AV

500Ω

CC

500Ω

BUF

V

CL

V

CH

×4

V

CL

BUF

T/H

T/H

V

REF

03376-A-003

Figure 3. Analog Input Stage

EV

CC

37.5kΩ

PECL

DRIVER

V

DD

MACROCELL

LOGIC

03376-A-004

V

DD

P

120Ω

D0–D

15

N

03376-A-005

Figure 5. Digital Output Stage

V

DD

MACROCELL

LOGIC

V

DD

P

DRY

1kΩ

N

03376-A-023

Figure 6. Data-Ready Output

Rev. B | Page 7 of 20

AD10678

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

DGND

1

D

15

3

OUT

5

D

14

OUT

7

D

13

OUT

D

OUT

D

OUT

D

OUT

D

D

DGND

OUT

OUT

AD10678

12

9

TOP VIEW

11

11

(Not to Scale)

10

13

9

15

17

8

19

NC = NO CONNECT

Figure 7. Pin Configuration P1

(See Figure 22)

DGND

2

NC

4

6

DGND

8

NC

DGND

10

NC

12

DGND

14

NC

16

18

DGND

20

DRY

03376-A-026

DGND

+3.3VD

+3.3VD

+3.3VD

DGND

DGND

DGND

DGND

+3.3VD

+3.3VD

1

3

5

7

AD10678

9

TOP VIEW

11

(Not to Scale)

13

15

17

19

10

12

14

16

18

20

2

4

6

8

DGND

D

OUT

D

OUT

D

OUT

D

OUT

D

OUT

D

OUT

D

OUT

D

OUT

DGND

0

1

2

3

4

5

6

7

03376-A-027

Figure 8. Pin Configuration P2

(See Figure 22)

+3.3VE

1

+3.3VE

3

5

AGND

7

AGND

AGND

AGND

AGND

ENCODE

ENCODE

AGND

AD10678

9

TOP VIEW

11

(Not to Scale)

13

15

17

19

Figure 9. Pin Configuration P3

(See Figure 22)

2

4

6

8

10

12

14

16

18

20

+5.0VA

+5.0VA

+5.0VA

+5.0VA

AGND

AIN

AIN

AGND

AGND

AGND

Table 7. Pin Function Descriptions

P11 Pin No. P22 Pin No. P33 Pin No. Mnemonic Description

1, 2, 6, 10, 14, 18, 19 1, 2, 9, 11, 13, 15, 20 N/A DGND Digital Ground.

3, 5, 7, 9, 11, 13, 15, 17 4, 6, 8, 10, 12, 14, 16, 18 N/A D

x Data Bit Output.

OUT

N/A 3, 5, 7, 17, 19 N/A +3.3VD Digital Voltage (VDD).

4, 8, 12, 16 N/A N/A NC No Connection.

20 N/A N/A DRY Data Ready Output.

N/A N/A 1, 3 +3.3VE Encode Voltage (EVCC).

N/A N/A 2, 4, 6, 8 +5.0VA Analog Voltage (AVCC).

N/A N/A 5, 7, 9 to11, 13, 16, 18 to 20 AGND Analog Ground.

N/A N/A 12 AIN Analog Input.

N/A N/A 14 AIN

Analog Input

(Complement).

N/A N/A 15 ENCODE Encode Input.

N/A N/A 17 ENCODE

1

Equivalent pin configuration in is J12. Figure 22

2

Equivalent pin configuration in is J11.

3

Equivalent pin configuration in is J13.

Figure 22

Figure 22

Encode Input

(Complement).

03376-A-028

Rev. B | Page 8 of 20

AD10678

0.466

20 2

P1

MH4

19 1

0.960

0.888

P3

19

20

MH2

2.148

1.223

1.693

1

INTERFACE NOTES:

SUGGESTED INTERFACE MANUFACTURER: SAMTEC

HOLES 1–4 ACCOMMODATE 2-56 THREADED HARDWARE. USE FOUR 2-56 NUTS FOR SECURING

2

0.925

MH1

INTERFACE PART NUMBERS FOR P1-P3: FSI-110-03-G-D-AD-K-TR (20-PIN)

THE PART TO INTERFACE PCB.

MANUFACTURER: BUILDING FASTENERS

PART NUMBER: HNSS256

DIGIKEY #: H723-ND

0.433

0.900

0.526

0.7570.955

TOLERANCES: 0.xxx = ±5mils

MH3

0.805

20 2

19 1

P2

03376-A-006

Figure 10. Interface PCB Assembly, Top View

(Dimensions Shown in Inches)

Rev. B | Page 9 of 20

AD10678

TYPICAL PERFORMANCE CHARACTERISTICS

0

–10

–20

–30

–40

–50

–60

–70

dBFS

–80

–90

–100

–110

–120

–130

0

–10

–20

–30

–40

–50

–60

–70

dBFS

–80

–90

–100

–110

–120

–130

0

ENCODE = 80MSPS

–10

AIN = 32MHz

SNR = 80.18dBFS

–20

SFDR = 91.8dBFS

–30

–40

–50

–60

–70

dBFS

–80

–90

–100

–110

–120

–130

FREQUENCY (MHz)

Figure. 11. Single-Tone at 2.5 MHz

FREQUENCY (MHz)

Figure 12. Single-Tone at 10 MHz

FREQUENCY (MHz)

Figure 13. Single-Tone at 32 MHz

ENCODE = 80MSPS

AIN = 2.5MHz

SNR = 80.79dBFS

SFDR = 97.22dBFS

ENCODE = 80MSPS

AIN = 10MHz

SNR = 80.76dBFS

SFDR = 94.81dBFS

40015305203510 25

03376-A-007

40015305203510 25

03376-A-008

40015305203510 25

03376-A-009

dBFS

–100

–110

–120

–130

dBFS

–100

–110

–120

–130

dBFS

–100

–110

–120

–130

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

FREQUENCY (MHz)

Figure 14. Single-Tone at 70 MHz

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

FREQUENCY (MHz)

ENCODE = 80MSPS

AIN = 10.1MHz AND 12.1MHz

IMD = 98.25dBFS

Figure 15. Two-Tone at 10.1 MHz and 12.1 MHz

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

FREQUENCY (MHz)

Figure 16. Two-Tone at 70 MHz and 72 MHz

ENCODE = 80MSPS

AIN = 70MHz

SNR = 78.31dBFS

SFDR = 87.64dBFS

ENCODE = 80MSPS

AIN = 70MHz AND 72MHz

IMD = 87.5dBFS

40015305203510 25

03376-A-010

40015305203510 25

03376-A-011

40015305203510 25

03376-A-012

Rev. B | Page 10 of 20

AD10678

100

90

dBc

80

70

60

SFDR 70MHz

50

40

30

20

10

0

SFDR 30MHz

SFDR 10MHz

FUNDAMENTAL LEVEL (dBFS)

SFDR 2.5MHz

Figure 19. SFDR and SNR vs. Analog Input Level

100

dBc

94

88

82

76

ANALOG INPUT FREQUENCY (MHz)

SFDR

SNR

Figure 20. SFDR and SNR vs. Analog Input Frequency

SNR 2.5MHz

SNR 10MHz

SNR 70MHz

SNR 30MHz

700 102030405060

0–80 –70 –60 –50 –40 –30 –20 –10

03376-A-015

03376-A-024

–0.30

–0.60

–0.90

–1.20

–1.50

dBFS

–1.80

–2.10

–2.40

–2.70

–3.00

VSWR

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0

AIN = –1dB

FREQUENCY (MHz)

150.01.0 15.9 30.8 45.7 60.6 75.5 90.4 105.3 120.2 135.1

03376-A-013

Figure 17. Gain Flatness

VSWR

FREQUENCY (MHz)

1k0.1 1 10 100

03376-A-014

Figure 18. Analog Input VSWR

Rev. B | Page 11 of 20

AD10678

TERMINOLOGY

Analog Bandwidth

The analog input frequency at which the spectral power of the

fundamental frequency (as determined by the FFT analysis) is

reduced by 3 dB.

Output Propagation Delay

The delay between the 50% point of the rising edge of the

ENCODE command and the time when all output data bits

are within valid logic levels.

Aperture Delay

The delay between the 50% point on the rising edge of the

ENCODE command and the instant at which the analog input

is sampled.

Aperture Uncertainty (Jitter)

The sample-to-sample variation in aperture delay.

Differential Nonlinearity (DNL)

The deviation of any code from an ideal 1 LSB step.

Encode Pulse Width/Duty Cycle

Pulse width high is the minimum amount of time that the

ENCODE pulse should be left in Logic 1 state to achieve rated

performance; pulse width low is the minimum time that the

ENCODE pulse should be left in low state. At a given clock rate,

these specifications define an acceptable encode duty cycle.

Integral Nonlinearity (INL)

The deviation of the transfer function from a reference line

measured in fractions of 1 LSB using a best straight line

determined by a least square curve fit.

Harmonic Distortion

The ratio of the rms signal amplitude to the rms value of the worst

harmonic component.

Maximum Conversion Rate

The encode rate at which parametric testing is performed.

Minimum Conversion Rate

The encode rate at which the SNR of the lowest analog signal

frequency drops by no more than 3 dB below the guaranteed limit.

Power Supply Rejection Ratio (PSRR)

The ratio of a change in output offset voltage to a change in

power supply voltage.

Signal-to-Noise-and-Distortion (SINAD)

The ratio of the rms signal amplitude (set at 1 dB below full

scale) to the rms value of the sum of all other spectral

components, including the first five harmonics and dc. May be

reported in dBc (that is, degrades as signal level is lowered) or

in dBFS (always related back to converter full scale).

Signal-to-Noise Ratio (SNR)

The ratio of the rms signal amplitude (set at 1 dB below full

scale) to the rms value of the sum of all other spectral components, excluding the first five harmonics and dc. May be

reported in dBc (that is, degrades as signal level is lowered) or

in dBFS (always related back to converter full scale).

Spurious-Free Dynamic Range (SFDR)

The ratio of the rms signal amplitude to the rms value of the

peak spurious spectral component. The peak spurious component may or may not be an harmonic. May be reported in dBc

(such as, degrades as signal level is lowered) or in dBFS (always

related back to converter full scale).

Two-Tone Intermodulation Distortion Rejection (IMD)

Ratio of the rms value of either input tone to the rms value of

the worst third-order intermodulation product; reported in dBc.

Voltage Standing-Wave Ratio (VSWR)

The ratio of the amplitude of the elective field at a voltage

maximum to that at an adjacent voltage minimum.

Rev. B | Page 12 of 20

AD10678

THEORY OF OPERATION

The AD10678 uses four parallel, high speed ADCs in a correlation

technique to improve the dynamic range of the ADCs. The

technique consists of summing the parallel outputs of the four

converters to reduce the uncorrelated noise introduced by the

individual converters. Signals processed through the high speed

adder are correlated and summed coherently. Noise is not

correlated and sums on an rms basis.

The four high speed ADCs use a three-stage subrange architecture. The AD10678 provides complementary analog input pins,

AIN

AIN and

should swing ±0.55 V around the reference. Since AIN and

. Each analog input is centered around 2.4 V and

AIN

are 180 degrees out of phase, the differential analog input signal is

2.15 V p-p.

The analog input is designed for a 50 Ω input impedance for easy

interface to commercially available cables, filters, drivers, and so on.

The AD10678 encode inputs are ac-coupled to a PECL differential

receiver/driver. The output of the receiver/driver provides a clock

source for a 1:5 PECL clock driver and a PECL-to-TTL translator.

The 1:5 PECL clock driver provides the differential encode signal

for each of the four high speed ADCs. The PECL-to-TTL

translator provides a clock source for the complex programmable

logic device (CPLD).

The digital outputs from the four ADCs drive 120 Ω series output

terminators and are applied to the CPLD for postprocessing. The

digital outputs are added together in the complex programmable

logic device through a ripple-carry adder, which provides the

16-bit data output. The AD10678 provides valid data following

10 pipeline delays. The result is a 16-bit parallel digital CMOScompatible word coded as true binary.

THERMAL CONSIDERATIONS

Due to the high power nature of the part, it is critical that the

following thermal conditions be met for the part to perform to

data sheet specifications. This also ensures that the maximum

junction temperature (150°C) is not exceeded.

• Operation temperature (T

• All mounting standoffs should be fastened to the interface

PCB assembly with 2-56 nuts. This ensures good thermal

paths as well as excellent ground points.

• The unit rises to ~72°C (T

(0 linear feet per minute (LFM)). The minimum recommended air flow is 100 linear feet per minute (LFM) in either

direction across the heat sink (see Figure 21).

) must be within 0°C to 70°C.

A

) on the heat sink in still air

C

75

70

65

60

55

50

45

40

TEMPERATURE (CASE) (°C)

35

30

AIR FLOW (AMBIENT) (LFM)

Figure 21. Temperature (Case) vs. Air Flow (Ambient)

3000 100 15050 200 250

03376-A-025

INPUT STAGE

The user is provided with a single-to-differential transformercoupled input. The input impedance is 50 Ω and requires a

2.15 V p-p input level to achieve full scale.

ENCODING THE AD10678

The AD10678 encode signal must be a high quality, low phase

noise source to prevent performance degradation. The clock

input must be treated as an analog input signal because aperture

jitter may affect dynamic performance. For optimum performance, the AD10678 must be clocked differentially.

OUTPUT LOADING

Take care when designing the data receivers for the AD10678.

The complex programmable logic device 16-bit outputs drive

120 Ω series resistors to limit the amount of current that can

flow into the output stage. To minimize capacitive loading, there

should be only one gate on each of the output pins. A typical

CMOS gate combined with the PCB trace has a load of approximately 10 pF. Note that extra capacitive loading increases output

timing and invalidates timing specifications. Digital output

timing is guaranteed with a 10 pF load.

ANALOG AND DIGITAL POWER SUPPLIES

Care must be taken when selecting a power source. Linear

supplies are recommended. Switching supplies tend to have

radiated components that may be coupled into the ADCs. The

AD10678 features separate analog and digital supply and

ground currents, helping to minimize digital corruption of

sensitive analog signals.

Rev. B | Page 13 of 20

AD10678

The +3.3VE supply provides power to the clock distribution

circuit. The +3.3VD supply provides power to the digital output

section of the ADCs, the PECL-to-TTL translator, and the CPLD.

Separate +3.3VE and +3.3VD supplies are used to prevent

modulation of the clock signal with digital noise.

The +5.0VA supply provides power to the analog sections of the

ADCs. Decoupling capacitors are strategically placed throughout

the circuit to provide low impedance noise shunts to ground. The

+5.0VA supply (analog power) should be decoupled to analog

ground (AGND), and +3.3VD (digital power) should be

decoupled to digital ground (DGND). The +3.3VE supply (analog

power) should be decoupled to AGND. The evaluation board

schematic and layout data provide a typical PCB implementation

of the AD10678. Table 8 shows the PCB Bill of Material.

ANALOG AND DIGITAL GROUNDING

Although the AD10678 provides separate analog and digital

ground pins, the device should be treated as an analog component.

Proper grounding is essential in high speed, high resolution

systems. Multilayer printed circuit boards are recommended to

provide optimal grounding and power distribution. The use of

power and ground planes provides distinct advantages. Power and

ground planes minimize the loop area encompassed by a signal

and its return path, minimize the impedance associated with

power and ground paths, and provide a distributed capacitor

formed by the power plane, printed circuit board material, and

ground plane. The AD10678 unit has four metal standoffs (see

Figure 10). MH2 is located in the center of the unit and MH1 is

located directly below analog header P3. Both of these standoffs

are tied to analog ground and should be connected accordingly on

the next level assembly for optimum performance. The two

standoffs located near P1 and P2 (MH3 and MH4) are tied to

digital ground and should be connected accordingly on the nextlevel assembly.

Table 8. PCB Bill of Material

Item Quantity Reference Designator Description

1 1 J1 Connector, 40-position header, male straight

2 1 U1 IC, LV 16-bit D-type flip-flop with 5 V tolerant I/O

3 3 L1 to L3 Common-mode surface-mount ferrite bead 20 Ω

4 3 J11 to J13 Connector, 1 mm single-element interface

5 6 P1, P2, P8 to P10, P12 Uninsulated banana jack, all metal

6 2 U5, U6 IC, 3.3 V/5 V ECL differential receiver/driver

7 1 U7 IC, 3.3 V dual differential LVPECL to LVTTL translator

8 1 R24 RES 0.0 Ω 1/10 W 5% 0805 SMD

9 19 R0 to R16, R20, R23 RES 51.1 Ω 1/10 W 1% 0805 SMD

10 1 R17 RES 18.2 kΩ 1/10 W 1% 0805 SMD

11 4 R18, R19, R21, R22 RES 100 Ω 1/10 W 1% 0805 SMD

12 17 C1, C10 to C13, C16 to C18, C23 to C26, C29 to C32 CAP 0.1 µF 16 V ceramic X7R 0805

13 6 C8, C9, C4, C15, C27, C33 CAP 10 µF 10 V ceramic Y5V 1206

14 4 J2, J3, J5, J6 Connector, SMA jack 200 Mil STR gold

15 1 A1 Assembly, AD10678BWS

16 1 AD106xx Evaluation Board GS04483 (PCB)

OTHER NOTES

The circuit is configured on a 2.2" × 2.8" laminate board with

three sets of connector interface pads. The pads are configured

to provide easy keying for the user. The pads are made for low

profile applications and have a total height of 0.12" after mating.

The part numbers for the header mates are provided in Figure 10.

All pins of the analog and digital sections are described in the

Pin Configurations and Function Descriptions section.

EVALUATION BOARD

The AD10678 evaluation board provides an easy way to test the

16-bit 80 MSPS ADC. The board requires a clock source, an

analog input signal, two 3.3 V power supplies, and a 5 V power

supply. The clock source is buffered on the board to provide a

latch, a data ready signal, and the clock for the AD10678. To use

the AD10678 data ready output to clock the buffer memory,

remove R24 (0.0 Ω) and install a 0.0 Ω resistor at R31 (DNI).

The ADC digital outputs are latched on board by a

74LCX16374. The digital outputs and output clock are available

on a 40-pin connector, J1. Power is supplied to the board via

uninsulated metal banana jacks.

The analog input is connected via an SMA connector, AIN. The

analog input section provides a single-ended input option or a

differential input option. The board is shipped in a single-ended

analog input option. Removing a ground tie at E17 converts the

circuit to a differential analog input configuration.

Rev. B | Page 14 of 20

AD10678

DNI

R25

+3.3VD

BUFMEM

U1

16V

C31

0.1µF

10V

C33

10µF

+3.3VD

DGND

DGND

LATCH

1

1

3

3

5

5

7

7

9

9

11

11

13

13

15

15

17

17

19

19

J11

MH3

MH1–MH4 = DUT MOUNTING HOLES

MH1

AD10678 PART OUTLINE

40383634323028262422201816141210864

403836343230282624222018161412

J1

393735333129272523211917151311

39373533312927252321191715

R1 51.1Ω

R2 51.1Ω

R3 51.1Ω

R4 51.1Ω

R5 51.1Ω

R6 51.1Ω

R7 51.1Ω

O9

O10

I10I9I8

R8 51.1Ω

13

O8

CP1

OE1

48

1

R0 51.1Ω

71823222019171614

42

31

O15

VCC

VCC

VCC

VCC

CP2

I15

OE2

25

27293032333536

24

26

DNI

R30

DGND

FSI-110-03-G-D-AD-TR

2

2

4

4

6

6

8

8

10

10

12

12

14

14

16

16

18

18

20

20

O11

O14

O13

O12

I14

I13

I12

I11

DGND

E15

MH2

J2

INPUT

ANALOG

DGND

AGND

+5VA

AGND

C14

C30

10V

10µF

AGND

16V

0.1µF

24681012141618

246

8

1012141618

J13

911131517

135

7

1

3

579

11

2

2

864

10

97531

97531

11

13

R9 51.1Ω

R10 51.1Ω

R11 51.1Ω

1211986532211510

O7O6O5O4O3O2O1

I7I6I5I4I3I2I1

3840414344464728343945

37

+3.3VD

R12 51.1Ω

R13 51.1Ω

R14 51.1Ω

R15 51.1Ω

O0

GND

GND

I0

GND

GND

AGND

J3

AGND

DNI

E17

R27

20

20

19

131517

19

AGND

FSI-110-03-G-D-AD-TR

40-PIN

GND

GND

DGND

AGND

AGND

HMS

E7 E8

4

GND

GND

1

1

3

3

5

5

7

7

9

9

11

11

13

13

15

15

17

17

19

19

INPUT OPTION

DIFFERENTIAL

INPUT OPTION

SINGLE-ENDED

16V

C24

0.1µF

C1

16V

0.1µF

+3.3VD

2

10V

C27

10µF

DGND

4

L3

1

3

74LCX16374MTD

DGND DGND DGND DGND

P12

+3.3VD

DGND

AGND

P8

SI-110-03-G-D-AD-TR

2

2

4

4

6

6

8

J12

MH4

8

10

10

12

12

14

14

16

16

18

18

20

20

DGND

DRY

DGND

+3.3VD+3.3VD

14

12

10

8

6

4

2

C17

0.1µF

LATCH

DGND

R23

51.1Ω

DNI

R29

876

CC

V

U7

D0D1D1

1

234

R24

Q0

D0

J8

16V

Q1

0.0Ω

BUFMEM

5

GND

13

11

9

7

5

3

1

DRY

R28

MC100ELT23D

HEADER 732mm

DGND

DNI

R31

DNI

DGND

BYPASS CAPACITORSPOWER CONNECTIONS POWER CONNECTIONS

DGND

+3.3VE

+3.3VD

C28

C23

C29

C18

C16

16V

0.1µF

AGND

16V

0.1µF

E19 E21 E4 E3 E20 E22 E13 E1 E5 E9 E11

16V

0.1µF

DGND

16V

0.1µF

16V

0.1µF

E2 E6 E10 E12 E18

OPTIONAL EVALUATION BOARD GROUND TIES

AGND AGND AGND AGND AGND AGND AGND AGND DGND DGND DGND DGND DGND DGND DGND DGND

+3.3VE

C15

C32

DNI

U6

R17

876

123

18.2kΩ

R30

Q

CC

V

NCDD

2

1

+5VA

16V

C25

0.1µF

C8

10V

10µF

AGND

4

3

P2

AGND

AGND

03376-A-016

10V

C26

+3.3VE

2

L1

1

P10

C9

4

3

+3.3VE

0.1µF

+5VA

10V

10µF

AGND

L2

P1

AGND

P9

AGND

R22

100Ω

R21

100Ω

5

Q

VEE

VBB

4

AGND AGND AGND

MC10EL16D

AGND

10V

10µF

C11

16V

0.1µF

16V

0.1µF

+3.3VE

C10

16V

C12

0.1µF

R19

100Ω

AGND

R20

AGND

+3.3VE

51.1Ω

R18

876

5

Q

Q

CC

V

VEE

U5

NCDD

VBB

123

4

16V

0.1µF

R16

J6

ENCODE

100Ω

AGND

MC10EL16D

16V

C13

0.1µF

51.1Ω

J5

ENCODE

Figure 22. Evaluation Board Schematic

Rev. B | Page 15 of 20

AD10678

AD10678/PCP

EVALUATION BOARD

Figure 23. Evaluation Board Mechanical Layout, Top View

03376-A-017

Figure 24. Evaluation Board Mechanical Layout, Bottom View

Rev. B | Page 16 of 20

03376-A-018

AD10678

Figure 25. Evaluation Board Top Layer Copper

03376-A-019

Figure 26. Evaluation Board Second Layer Copper

Rev. B | Page 17 of 20

03376-A-020

AD10678

Figure 27. Evaluation Board Third Layer Copper

03376-A-021

Figure 28. Evaluation Board Bottom Layer Copper

Rev. B | Page 18 of 20

03376-A-022

AD10678

OUTLINE DIMENSIONS

2.220

2.170

2.120

MP3

R10

2.795

2.745

2.695

C15

U2

C50

C54

R15

C53

R41

R17

C1

C14 C52 C51

R16

C21

P3

C22C2R1

C5

C6

R11

U8

C9

C7

R4

U7

C20

R25

C23

C56

C55

C11

R9

R37

C63

R8

R38

C18

R3

C19

C65

C13

C25

R33

R30

C39

C17

C49

C58

C57

R12

R14

C67

C59

R13

T1

MP4

C43

R19

C41

R5

C62

R7

C26

R18

C34

C45

C66

C64

C12

C44

U1

C28

R32R31

C24

MP5

R27

C40

U3

R40

C47

C38

C48

R6

C46

C10

R39

C42

U4

C35

C60

U6

C61

C3

C27

C4

C29

R26

U5

a

C37

C30

AD10678BWS

LOT NUMBER

DATA CODE

C36

USA

R28

R21

R29

R2

MP6

C8

P2

R35

C33

R34

C31

C32

P1

0.370

0.320

0.270

0.170

0.120

0.070

0.314

0.264

0.214

Top View

Figure 29. AD10678 Outline Dimensions

Dimensions shown in inches

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD10678BWS 0°C to 70°C Non-Herm Hybrid Surface Mount (2.2" × 2.8") WS-120

AD10678/PCB Evaluation Board

Rev. B | Page 19 of 20

AD10678

NOTES

© 2005 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

C03376–0–3/05(B)

Rev. B | Page 20 of 20

Loading...

Loading...