Page 1

instruction manual

ViewStat

Programming Protocol Reference Guide

HVAC Controls

Page 2

AMX Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free of defects in material and workmanship under normal use for

three (3) years from the date of purchase from AMX Corporation, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch

overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, MX Series products, and KC Series products are

warranted for a period of one (1) year.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX Corporation or an Authorized AMX Dealer.

AMX Corporation is not liable for any damages caused by its products or for the failure of its products to perform.

This includes any lost profits, lost savings, incidental damages, or consequential damages. AMX Corporation is not

liable for any claim made by a third party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort

claim (including negligence and strict product liability), a contract claim, or any other claim. This limitation of

liability cannot be waived or amended by any person. This limitation of liability will be effective even if AMX

Corporation or an authorized representative of AMX Corporation has been advised of the possibility of any such

damages. This limitation of liability, however, will not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or

exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of

the Limited Warranty may not apply. This Limited Warranty gives the owner specific legal rights. The owner may

also have other rights that vary from state to state. The owner is advised to consult applicable state laws for full

determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX CORPORATION MAKES NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. AMX CORPORATION

EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED WARRANTY. ANY

IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS

LIMITED WARRANTY.

Page 3

Table of Contents

Table of Contents

ViewStat Programming Protocol .............................................................................1

Network Communication ................................................................................................... 1

Explicit Address Commands .................................................................................................... 1

Global Address Commands ..................................................................................................... 2

Unsolicited Responses............................................................................................................. 2

Multiple Commands ................................................................................................................. 3

Network Override or Hold.................................................................................................. 4

How to Detect When a Thermostat Has Gone Off-line ............................................................ 4

Command Set Syntax ....................................................................................................... 5

Command Response Syntax............................................................................................. 5

Programming Quick Reference ......................................................................................... 6

Communication Control Commands ............................................................................... 10

Thermostat Sensing Commands.................................................................................... 15

Thermostat HVAC Operational Commands .................................................................... 18

Text Messaging Commands............................................................................................ 25

Text Messaging Support Characters...................................................................................... 25

Keypad Lockout Commands ........................................................................................... 30

Auxiliary Information Commands .................................................................................... 33

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

i

Page 4

Table of Contents

ii

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 5

ViewStat Programming Protocol

You can program the Viewstat to perform a wide variety of operations using SEND_STRING

commands. The Viewstat is designed to automatically echo each command you send to the

thermostat. For example, if you send a

system automatically echoes

SN9=SCALE?. Then, the system will generate a reply when the

operation is complete that shows the current temperature scale. This section contains timing and

command descriptions, and lists communication control and thermostat commands.

To communicate with the control system, set the baud to 9,600, data bits to 8, parity

to none, and stop bits to 1.

For most applications, the NetLinx module for the ViewStat can be used, eliminating the need to

manually generate any code at all for the ViewStat. For detailed information on using the module,

refer to the ViewStat Communicating Thermostat Instruction Manual ("Using the NetLinx Module"

section), available on the AMX.COM web site.

SEND_STRING HVAC "'SN9 SCALE?',13" command, the

ViewStat Programming Protocol

Network Communication

Network communication is non-isolated, full duplex RS-422 using 4 + 1 wires. The 'A' terminals

are the transmit pair while the 'B' terminals are the receive pair. This nomenclature uses the host

computer as the reference, so transmit refers the lines on which the host transmits data to the

thermostat while receive refers to the lines on which the host receives data from the thermostat.

ASCII-based firmware, which is fully compatible with the StatNet command set, is defined below.

Up to 64 uniquely addressed devices are allowed on the network.

There are three response mechanisms depending on the nature of the command request:

! Explicit Address Commands

! Global Address Commands

! Unsolicited Responses

Explicit Address Commands

Explicit Address Commands are those commands that specify a single, particular address in the

command header (i.e.

each device connected will receive it into their buffer. The command will begin to be interpreted by

each device. Once the address is scanned, the entire command will be discarded if it is not that

unit's address. The unit that was explicitly addressed will complete the interpretation of the

command, act on it, and respond back to the host. Responses from an explicitly addressed

command can begin as quickly as 20 milliseconds after the command was sent, and not later than

330 milliseconds.

SN13 MODE=OFF). As this command is transmitted down the RS-422 bus,

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

1

Page 6

ViewStat Programming Protocol

Global Address Commands

Global Address commands are those commands that do not specify any address in the command

header (i.e.

command is transmitted, each device connected will receive it into their buffer. Since there is no

address, the units will recognize this as a global command. Each unit will complete the

interpretation of the command, act on it, and respond back to the host. However, unlike the Explicit

commands where only one unit will be responding, global commands imply that each unit will be

responding. Therefore the responses from global commands must be scheduled to prevent

collisions over the communications channel. Each device waits for its turn to issue its response.

The order of the response coincides with the unit address. Therefore the thermostat with address #1

will respond first, then #2, #3, on up to #64.

Responses from a global command can begin as quickly as 20 milliseconds after the command was

sent. The actual time lapse for the first response is dependent on the lowest addressed device on the

thermostat network. If there was no address #1 on the channel, then the first response opportunity

will be idle; simply passing time until the next response opportunity. Of course, if there is no

address #2 either, then there will be a delay as this opportunity passes. If no response begins within

265 * (Lowest Address) milliseconds, then one or more of the units did not understand the

command, the unit is in

unit with the highest address on the channel. Since the highest allowed address is 64, the longest

delay time for the start of the last response is approximately 17 seconds.

SN T?). As with the Explicitly Addressed Commands described above, as this

QUIET or SILENT mode, or is off-line. The last unit to respond will be the

Do not skip addresses unless absolutely necessary to avoid unwanted delays in

responses.

Unsolicited Responses

Change-Of-State (

the

COS commands, when the COS has been turned "ON". There are twelve COS commands

described in detail in the Communication Control Commands section on page 10.

COS) responses are sent whenever a COS is detected for a condition specified in

COS responses

are sent so that a host computer connected to the thermostat network need not poll in order to see if

any thermostat variable change has taken place.

In unsolicited responses, no actual command has been sent down to solicit the response (once the

COS commands are sent, the unit will automatically respond on a change of state). Unsolicited

responses are scheduled according to address, in a similar manner to global responses. Each device

waits for its opportunity to come up, and issues its response at that time.

Unsolicited responses can begin as quickly as 20 milliseconds after the

global responses, unsolicited responses are issued only during the unit’s assigned opportunity.

COS was detected. As with

COS

responses will be received from a specific device no faster than X*265 milliseconds (X is defined

as the number of thermostats on the network, which is configurable in Thermostat Setup), since the

unit will only respond in its unique opportunity.

Since the signal used to synchronize every device is the <CR> terminator of a

command, the host must issue a <CR> every 12 hours. Note that any command

send down the communications link from the host qualifies as a synchronizing

transmission.

2

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 7

ViewStat Programming Protocol

Multiple Commands

Explicit commands, to one particular thermostat, can be issued and acted upon with no more than

20 milliseconds between each command. Responses must be received before moving to the next

thermostat to issue commands. Global commands can also be issued with no more than 20

milliseconds between commands if the Command Response (

or Silent (

SN CR=S). Responses, stationed in a buffer awaiting the opportunity to be sent, can

CR) has been set to Quiet (SN CR=Q)

create a backlog and cause incoming commands to be disregarded. If global commands are to be

sent with the Command Response set to Normal (

SN CR=N), then the amount of time between any

set of two commands (the two commands must be separated by 20 milliseconds) must be 265

milliseconds times the "Number of Thermostats on the Network".

TIP: If responses are desired to a large number of commands, set the Command Response to Quiet,

send the commands (either globally or explicitly), then query individual thermostats (explicitly).

Return the command response to Normal when done. As an example consider a 64 thermostat

system. Now suppose the mode, fan, heat setting, cool setting and hold status were to be changed

on each thermostat. Further suppose that verification that all of these changes had been made were

required, and in addition the current temperature and remote temperature values were to be queried.

Using global commands, with the Command Response set to Normal, 17 seconds would be

required between each command. Five commands and two queries would be required (7 total

commands) requiring a total time of approximately two minutes.

Global Command Sequence: Explicit Command Sequence

SN M=A SN CR=Q

SN F=A SN M=A

SN SH=70 SN F=A

SN SC=75 SN SH=70

SN HOLD=OFF SN SC=75

SN T? SN HOLD=OFF

SN OT? SN1 M?

SN1 F?

SN1 SH?

SN1 SC?

SN1 HOLD?

SN1 T?

SN1 OT?

SN2 M?

:

SN64 OT?

SN CR=N

Sending five commands and seven queries to each thermostat explicitly would require

approximately 37 seconds.

To maximize communication speed consider the following:

1. Communicate at 19200 baud

2. Do not skip addresses on the thermostat network unless absolutely necessary.

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

3

Page 8

ViewStat Programming Protocol

3. Set the "Number of Thermostats on the Network" to the highest addressed thermostat. If you

have only six thermostats address them 1 through 6 and set the highest address to six.

4. Only turn on the necessary change of state variables (COS - refer to the command

descriptions).

5. Send commands explicitly when possible.

6. When sending a large number of commands, set the Command Response to Quiet. If

responses are needed, explicitly query each thermostat on the network.

Network Override or Hold

Invoking Network Override causes the thermostat to disregard all received commands except

requests for data. This means that no response will be forthcoming. Network Override can be

invoked at the thermostat (by using the Enter button) or through the command set (

Unsolicited data transmission is unaffected. Should the thermostat be receiving communication

when Network Override is invoked, the reaction will be carried out following the reaction caused

by the communication signal.

If receiving no response to a command will cause disruption to your program, then there are two

options: disable this feature or begin every command transmission by "

the feature, ensure that Hold is "

Alternatively it could be disabled through the Thermostat Set Up menu.

SN HOLD=ON).

SN HOLD=OFF". To disable

OFF" at each thermostat and send the command "SN NETLK=1".

How to Detect When a Thermostat Has Gone Off-line

When a thermostat goes off-line (re-initializes) the Change of State (

default values -

OFF. The consequence of this occurring is that unsolicited responses will not be

COS) variables return to

sent by the thermostat (i.e. the automation system will not know when something has been changed

at the thermostat). There are two reasons that a thermostat will have gone off-line: the power had

been removed and reinstated or the Thermostat Set Up menu has been entered. When this occurs

the

COS variables must be reset. It is good practice to periodically check (once every 15 minutes is

a good start) that all thermostats are still responding. Simply query one of the

have turned on to verify it is still on. For example periodically send the command "

should receive the response "

SNx C2=ON"; where x is the address of each thermostat on the

COS variables you

SN C2?". You

network.

4

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 9

ViewStat Programming Protocol

Command Set Syntax

SN#[COMMAND][? OR =][VALUE] <CR>

Upper or lower case letters may be used for all commands. Invalid characters will immediately

invalidate a command, so the use of delete is not allowed (applies mainly when interacting with the

thermostat using HyperTerminal).

All Viewstat commands will begin with the characters

any intervening spaces (blanks), will be the address (

SN. Immediately following the SN, without

#) from 1 to 64 of the Viewstat with which you

are communicating. Single digit addresses may be sent as a two digit address with a leading zero.

Omitting the address, or using a 0 (zero) in place of a space makes the command global, and all

connected thermostats will respond. Following this initial command sequence, spaces may be

inserted at this point only, for clarity between commands. The next portion is the command or

variable

[? Or =] is the action to be performed: ? corresponds to "state your value", = corresponds to "set

[Command]. The table below describes the available commands. The next portion

your value". Spaces are allowed between the command and the action. The final portion,

[Value], is used only if a command or variable is to be set.

The value must follow the action with no intervening spaces. A carriage-return

used as the terminator for the command string. Line feeds (

LF) should not be sent with commands

<CR> (Enter) is

as this is a recognized ASCII character and invalidates any command received between the line

feed and the next carriage return.

EXCEPTIONS: The command SN? or SN0? will respond with all connected thermostats returning

their address. The command

BLTON performs its intended action without the need for a value.

Command Response Syntax

The ViewStat responds by supplying the information requested or by confirming the completion of

an action command. The response syntax is generally the same as that used for commands, but no

spaces separate command, action or value. Responses are sent in upper case ASCII format. Details

of the response can be found in the detailed description section for each command. Should a

command not be recognized, no response will be forthcoming - there is no

ERROR message.

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

5

Page 10

ViewStat Programming Protocol

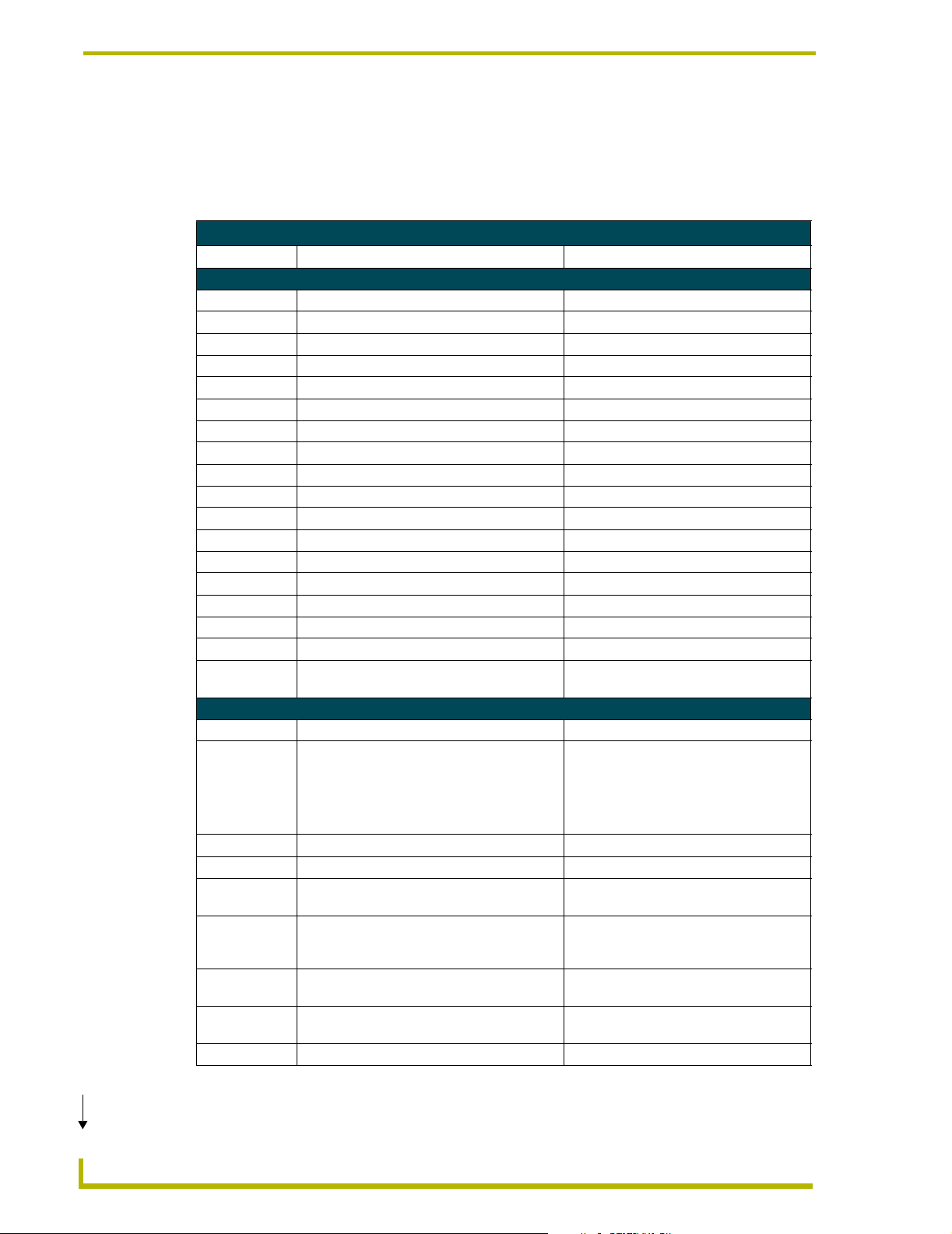

Programming Quick Reference

All of the commands are summarized in the following list. A detailed description of each

command follows the table. Unless otherwise noted as "Read Only" or "Write Only", all

commands are "Read and Write".

Programming Quick Reference

Command Description Value

CR Command Response Control Silent / Quiet / Normal

C1 Change of State (COS) - HVAC relays ON/OFF

C2 COS - Temperature ON/OFF

C3 COS - Remote Temperature ON/OFF

C4 COS - Contact Closures ON/OFF

C5 COS - Set Points ON/OFF

C6 COS - Network Override ON/OFF

C7 COS - Mode ON/OFF

C8 COS - Fan ON/OFF

C9 COS - Scroll Up activation ON/OFF

C10 COS - Scroll Down activation ON/OFF

C11 COS - Enter Button activation ON/OFF

C12 COS - Backlight Ready ON/OFF

CP Command Configuration Pattern 1 / 2

HOLD User Hold Status ON / OFF

NAME Location Name <String>

ID Report Model No. and software rev. Read Only

BAUD Specifies thermostat communication baud

SCALE Command Temperature Scale F / C (Fahrenheit/Celsius)

CT Controller Type; Temperature or Humidity. Set

TEMP, T Report Thermostat Room Temperature Read Only

HUM Report Thermostat Room Humidity Read Only

RSM Identify all remote sensors connected to a ther-

RxSy

(x = 1-4;

y = 1,2)

OT Report Thermostat Remote (outdoor) Temper-

R Report Thermostat Remote (outdoor) Temper-

OH Report Thermostat Remote Humidity Read Only

Communication Control Commands

rate.

Thermostat Sensing Commands

to Humidity only when auxiliary humidity control sensor is detected.

• 0 = Temperature controller

• 1 = Humidity controller

mostat's local communication network

Report value of any sensor on thermostat's

local communication network

ature

ature

9600, 19200

Read Only

Read Only

Read Only

Read Only

(Cont.)

6

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 11

ViewStat Programming Protocol

Programming Quick Reference (Cont.)

Command Description Value

Thermostat HVAC Operational Commands

SH Heat Mode Set Point Two digit integer: 40 - 88 for °F;

4 - 31 for °C

SH++ Increment heat set point Integer value which when added to the cur-

rent heat set point does not fall outside the

SH limits

SH-- Decrement heat set point Integer value which when deducted from

SC Cool Mode Set Point Two or three digit integer: 42 - 90 for °F;

SC++ Increment cool set point Integer value which when added to the cur-

SC-- Decrement cool set point Integer value which when deducted from

S Current Mode Set Point Two or three digit integer (see next two

SP++ Increment current mode set point Integer value which when added to the cur-

SP-- Decrement active set point Integer value which when deducted from

DIF1 Temperature control differential for 1st stage

heat/cool.

DIF2 Temperature control differential for 2nd stage

heat/cool.

OFFSET Amount to offset the display temperature from

the sensed temperature.

SHUM Humidify Mode set point Two digit integer: 10-90

SHUM++ Increment humidify set point Integer value which when added to the cur-

SHUM-- Decrement humidify set point Integer value which when deducted from

SDEH Dehumidify Mode set point Two digit integer: 10-90

SDEH++ Increment dehumidify set point Integer value which when added to the cur-

SDEH-- Decrement dehumidify set point Integer value which when deducted from

MODE,M Thermostat Mode of Operation A / C / H / E / OFF

FAN, F Fan Switch Setting A / ON (Auto/On)

HVAC, H Report HVAC Relay States Read Only

the current heat set point does not fall outside the SH limits

6 - 33 for °C

rent cool set point does not fall outside the

SC limits

the current cool set point does not fall outside the SC limits

commands)

rent mode set point does not fall outside

the SH and SC limits

the current mode set point does not fall outside the SH and SC limits

0.5° - 2° in 0.5° increments

0.5° - 2° in 0.5° increments

±3°, 1° increments

rent humidify set point does not fall outside

the SHUM limits

the current humidify set point does not fall

outside the SHUM limits

rent dehumidify set point does not fall outside the SDEH limits

the current dehumidify set point does not

fall outside the SDEH limits

(Auto/Cool/Heat/EMHT/Off)

Humid/Dehum when operating as a humidity controller.

(Cont.)

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

7

Page 12

ViewStat Programming Protocol

Programming Quick Reference (Cont.)

Command Description Value

HIBP Temperature value above which W1 terminal

LOBP Temperature value below which compressor

DATE Thermostat date value MMDDYY

TIME Thermostat time value HHMM

PMES1 1st message in the permanent message

PMES2 2nd message in the permanent message

PMES3 3rd message in the permanent message

PMES4 4th message in the permanent message

TMPMES Temporary message 32 character text string

MENU Operates the text messaging display in a User-

MSG User-Interactive message 32 character text string

FANLK Determines the degree to which the user is

MODELK Determines the degree to which the user is

NETLK Determines the degree to which the user is

UPDNLK Determines the degree to which the user is

LKTIME Time value (minutes) that an input change is

LKLIMIT Number limit that the increment/decrement is

CC Digital Input States All of these commands will simply return a

CO Digital Output States

Ln

(n = 1 to 4)

Thermostat HVAC Operational Commands (Cont.)

is locked out (heat pump equipment configuration only).

terminals are locked out (heat pump equipment configuration only).

Text Messaging Commands

sequence

sequence

sequence

sequence

Interactive mode. MSG is used to display messages when MENU is on.

Keypad Lockout Commands

locked out of fan control.

locked out of mode control.

locked out of network override control.

locked out of increment/decrement control.

allowed until it reverts back to the pre-change

value.

allowed to change when locked.

Monitoring Module Commands

Comm. Card LED Light 1,2,3 or 4

40° - 80°, 5° increments

0° - 40°, 5° increments

32 character text string

32 character text string

32 character text string

32 character text string

ON/OFF

0=no lockout,

1=time limited change,

2=total lockout

0=no lockout,

1=time limited change,

2=total lockout

0=no lockout,

1=total lockout

0=no lockout,

1=time limited change,

2=time and value limited change,

3=total lockout

Integer value between 0 and 255

Integer value between 0 and 20

response - no action at the thermostat

occurs. If inquired all will respond as

though all inputs/outputs/led's are OFF.

(Cont.)

8

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 13

ViewStat Programming Protocol

Programming Quick Reference (Cont.)

Command Description Value

Auxiliary Information Commands

EQUIPCONFIG Reports the setting of the thermostat configu-

ration DIP switches

BLREADY Reports ready state of photosensor 0 = Backlight in ready state,

BLTRIG Sets relative room light intensity level required

to put backlight in ready state

BLTON Turns on backlighting, regardless of ready

state, for 10 seconds.

ENTR Enter button status 1 = State change from inactive to active,

SCUP Scroll Up button status 1 = State change from inactive to active,

SCDN Scroll Down button status 1 = State change from inactive to active,

Read Only

1 = Backlight not in ready state.

0 = darker,

1=lighter

No value required for this command

0 = State change from active to inactive

0 = State change from active to inactive

0 = State change from active to inactive

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

9

Page 14

ViewStat Programming Protocol

Communication Control Commands

The following commands control how the ViewStat will communicate.

The following command descriptions describe the use of the command when setting a particular

variable. Inquiries can be made with all commands (with the exception of the

and

ENTR commands) to determine the existing value of a variable. Inquiry is done using the

following syntax:

SN [address number, or <blank> or 0 (zero) for global] "COMMAND" ?

where COMMAND is the variable whose value is desired.

Communication Control Commands

Command Description

CR

Command Response Control

SCUP, SCDN, BLTON

The ViewStat normally responds to all commands. All responses begin with the

string SNx where x is the ViewStat network address number (address range =

1-64). All responses are concluded with a carriage return. The Command

Response Control command allows you to change the response actions.

Syntax:

"'SN<address> CR=<mode>'"

Var iables:

• <address> = 0 (all thermostats), or 1 through 64 (thermostat-specific

address)

• <mode> = S, N, Q

S (SILENT) - Viewstat will not reply to any command. Action commands

(telling ViewStat to change a setting) will be acted upon, but no response will

be returned indicating that the action was performed. All inquiry commands

(asking ViewStat for information) will be ignored. COS commands will be

received by ViewStat, but ViewStat will not act upon those commands while in

the silent mode.

N (NORMAL) - sets the ViewStat to the default mode where a response is

always given.

Q (QUIET) - Viewstat will not reply to action commands. Inquiry commands

will be responded to. This suppresses the feedback response on action

commands. COS commands will be heard and carried out.

Example 1 - Silent mode

• Command Format:

SN[address] CR=S or SILENT

• Reply Format: No response will be received.

Example 2 - Normal mode

• Command Format:

SN[address] CR= N or NORMAL

• Reply Format:

SN[address number] CR=NORMAL

Example 3 - Quiet mode

• Command Format:

SN[address] CR= Q or QUIET

• Reply Format: No response will be received.

(Cont.)

10

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 15

ViewStat Programming Protocol

Communication Control Commands (Cont.)

Command Description

(C1 - C12) Change-Of-State (COS) notify commands:

The ViewStat can be configured to send out a message upon a Change-Of-State (COS) for any of the variables

below. Simply turn on the COS flag for any of the variables for which the automation system needs to be kept

informed. In this way, a computer connected to Eclipse need not poll in order to see if anything has occurred it can simply ignore the ViewStat until it hears from it. The computer will only be notified if some event takes

place at the thermostat unit. If all COS flags are set to OFF, the Eclipse will not report anything automatically,

and the computer unit must send inquiries to the ViewStat to determine any new conditions. (This equates to a

'polling' mode, whereas with any COS flag ON equates to an interrupt mode.) There are twelve COS

indicators, which by default, are set OFF on power-up or reset.

The command format for COS notify commands is:

SN[address number or <blank> for global] C1 through C12=ON or OFF

The reply format:

SN[address number] C1 through C12=ON or OFF

Each of the COS notify commands and their responses are described in the following cells.

C1

COS - HVAC Control Circuits

C2

COS - Temperature or

Humidity

C3

COS - Remote Temperature

or Humidity

C4

COS - Contact Closures

C5

COS - Thermostat Set Points

C6

COS - Network Override

(Hold) Function

C7

COS - Thermostat Mode

C8

COS - Thermostat Fan State

When any thermostat output goes from an energized state to a de-energized

state or vice versa.

Example of response:

SN1 HVAC = G+Y1+W1-Y2-W2-B-O+

When the thermostat room temperature (or humidity) reading changes.

Examples of response:

SN3 T = 72F

SN6 HUM = 36%

When the thermostat remote temperature (or humidity) reading changes.

Examples of response:

SN15 OT = 86F

SN4 OH = 57%

Applies to Monitoring Module output status.

When the thermostat Heat, Cool, Humidify or Dehumidify temperature setting is

changed by use of the up and down buttons on the thermostat.

Examples of response:

SN1 SH = 68F

SN5 SC = 78F

SN13 SHUM = 32%

SN4 SDEH = 65%

When thermostat network control has been overridden or returned at the thermostat.

Example of response:

SN1 HOLD = ON

When the mode of operation (i.e. Heat, Cool, Auto, Off or Emergency Heat) has

been changed by use of the thermostat Mode button.

Syntax:

SN<address> C7=<value>

Example of response:

When the fan is changed to On or Auto by use of the thermostat Fan button.

Example of response:

SN3 M = AUTO

SN2 F = AUTO

(Cont.)

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

11

Page 16

ViewStat Programming Protocol

Communication Control Commands (Cont.)

Command Description

C9

COS - Scroll Up (thermostat

button)

C10

COS - Scroll Down (thermostat button)

C11

COS - Enter Button activation

C12

COS - Backlight Ready

When the scroll-up button (top button next to the text messaging display) is

pressed or released.

Example of response:

SN4 SCUP = ON

SN4 SCUP = OFF

When the scroll-down button (bottom button next to the text messaging display)

is pressed or released.

Example of response:

SN5 SCDN = ON

SN5 SCDN = OFF

When the ENTER button is pressed or released.

Example of response:

SN3 ENTR = ON

SN3 ENTR = OFF

When the thermostat backlight enters the ready state (i.e. room illuminance

less than that set at the thermostat).

Example of response: SN1 BLREADY = ON

(Cont.)

12

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 17

(Cont.)

Communication Control Commands (Cont.)

Command Description

CP

Command Configuration Pattern

HOLD

Network Override

Set the default (CP=1) or custom (CP=2) control system configuration pattern.

The ViewStat can retain two independent sets of communication configuration

settings. Each set contains the state of all Change-Of-State (COS) settings

and the Command Response (CR) setting. Default values for CP #1 and CP #2

are shown below.

IMPORTANT: Once a configuration pattern has been selected, any changes

you make to the communications control commands are assigned to the active

configuration pattern.

By default, CP #1 is active upon startup. The benefit of this command is to

facilitate having a standard configuration for normal operation and a second

configuration for special functions. CP #2 is convenient for those who wish to

integrate the text messaging display into their automation system. You may

alternate between these two configurations by simply sending the Configuration

Pattern command.

Syntax:

SN[address] CP=<pattern>

Parameters:

• <address> = 0 (global), or 1 through 64 (thermostat-specific address)

• <pattern> = 1 or 2

Reply Format:

SN[address number] CP=1 or 2 No response sent when set to CP=1

(i.e. no response to SN1 CP=1)

Default Settings for

Configuration Pattern 1:

CR = Normal

C1 = Off

C2 = Off

C3 = Off

C4 = Off

C5 = Off

C6 = Off

C7 = Off

C8 = Off

C9 = Off

C10 = Off

C11 = Off

C12 = Off

Syntax:

SN[address] HOLD=ON or OFF

Parameters:

• <address> = 0 (all thermostats), or 1 through 64 (thermostat-specific

address)

The ViewStat incorporates an ENTER button. This button has three functions:

• Thermostat Set-up - During Thermostat Set-Up the user interacts with the text

messaging display to select various operational parameters and this button is

used to enter those selections.

• User Reset Message Resetting - When the thermostat receives a User Reset

Message command this button is used clear the message from the text

messaging display.

• Network Override - During all other times, this button is used to override

network control of the thermostat: temperature changes, mode changes and

fan state changes are controlled only by the buttons on the thermostat.

This command can be used to change the Network Override status or HOLD

status regardless of what the text messaging display is doing. When activated

(HOLD = ON), "NETWORK OVERRIDE" shows on the ViewStat display. The

NETLK command enables or disables this feature.

ViewStat Programming Protocol

Default Settings for

Configuration Pattern 2:

CR = Normal

C1 = Off

C2 = Off

C3 = Off

C4 = Off

C5 = Off

C6 = Off

C7 = Off

C8 = Off

C9 = On

C10 = On

C11 = On

C12 = Off

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

13

Page 18

ViewStat Programming Protocol

Communication Control Commands (Cont.)

Command Description

NAME

Location Name

You can have the ViewStat append an identifier name to its address when it

transmits a message. The identifier string must be 16 characters or less with

no spaces.

Syntax:

SN[address] NAME={text string}

Parameters:

• <address> = 0 (all thermostats), or 1 through 64 (thermostat-specific

address)

• <text string> = text string used as an identifier for the specified thermostat.

String must be 16 characters or less - no spaces allowed.

Reply Format:

SN[address number]{NAME}

Example:

• Set a name to the thermostat with address #1:

SN1 NAME=MASTER BEDROOM<CR>

Response:

SN1MASTER BEDROOM (ViewStat confirms that a new name is assigned).

• Inquire temperature at thermostat #1:

SN1 T?<CR>

Response:

SN1MASTER BEDROOM T=72F (ViewStat responds with the temperature at

thermostat #1, now called Master Bedroom).

• Clear the name of the thermostat with address #1:

SN1 NAME=<CR>

Response:

SN1 (ViewStat confirms that the name has been removed).

ID

Report Thermostat Model

Number and Software Revision Number

Eclipse will respond with the model number followed by the current software

revision.

Syntax:

SN[address] ID?

Reply Format:

SN[address] MODEL# 8870 REV: x.x RPC 2001;

Parameters:

• <address> = 0 (all thermostats), or 1 through 64 (thermostat-specific

address)

• x.x = the current firmware revision level.

14

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 19

ViewStat Programming Protocol

Thermostat Sensing Commands

These commands are used to inquire and set scale for the various temperature or humidity values

read by the thermostat

The following command descriptions describe the use of the command when setting a particular

variable. Inquiries can be made with all commands (with the exception of the

and

ENTR commands) to determine the existing value of a variable. Inquiry is done using the

following syntax:

SN [address number, or <blank> or 0 (zero) for global] "COMMAND" ?

where COMMAND is the variable whose value is desired.

Thermostat Sensing Commands

Command Description

SCALE

Set Temperature Scale

CT

Controller Type

TEMP

Thermostat Temperature

Thermostat temperature readings can be displayed and communicated in either Celsius (Centigrade) or Fahrenheit as dictated by this command. The setting at initial

power up will default to °F. Subsequent start-ups (i.e. loss of power or resets) will

default to the scale that was last set. Scale setting applies to the room temperature,

the remote temperature and all temperature settings. When a temperature setting is

to be communicated to the thermostat, and no scale is designated, the temperature

will be read using the scale that has been set for the thermostat.

Syntax:

SN[address] SCALE=F or C

Reply Format:

SN[address] SCALE=F or C

Connecting an optional support module, configured for humidity control, to the ViewStat changes it from a temperature controller to a humidity controller. Controller type

is a read-only command. This command is used to determine which ViewStat thermostats connected to the network are currently acting as temperature controllers or

humidity controllers.

The response designations are CT=0, for temperature controller or CT=1, for humidity

controller.

Syntax:

SN[address] CT?

Reply Format:

SN[address] CT=0 (temperature controller) or 1 (humidity

controller)

Thermostat temperature is that shown on the display of the thermostat and against

which the temperature settings are compared for control purposes. This temperature

can be from the thermostat's on-board temperature sensing element or from attached

support module(s) configured for temperature control. ViewStat responds with the

temperature in the scale set by the SCALE command. It appends a C or F to the value

for clarity.

Syntax:

SN[address] TEMP?

Reply Format:

SN[address] T={value}F or {value}C

SCUP, SCDN, BLTON

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

15

Page 20

ViewStat Programming Protocol

Thermostat Sensing Commands (Cont.)

Command Description

HUM

Thermostat Humidity

RSM

Remote Sensor Modules

Connecting an optional support module, configured for humidity control, to the ViewStat changes it from a temperature controller to a humidity controller. Thermostat

humidity is that shown on the display of the thermostat and against which the humidity

settings are compared for control purposes. This humidity reading is that measured

attached support module(s) configured for humidity control. ViewStat responds with

the humidity reading appended by a "%" for clarity.

Syntax:

SN[address] HUM?

Reply Format:

SN[address number] H={value}%

Up to four addressable support-modules can be connected to a thermostat's local

communication network (LCN). Two sensors can be connected to each support module, each can be a temperature sensor or a humidity sensors depending on the support module model. Each sensor can be individually configured as control sensors or

remote sensors (for display only). This command returns the number of support modules connected to a thermostat, what type of sensors are attached to them and how

those sensors are configured.

Syntax:

SN[address] RSM?

Reply Format:

SN[address] RSM= M1:S1,S2 M2: S1,S2 M3: S1,S2 M4: S1,S

The response is made up of the number of modules (Mx) and the type of each of the

two sensors connected to that module (RT, CT, RH, CH or XX). The first sensor listed is

considered sensor #1 for that module and the second listed is considered sensor #2.

If there is no support module at a module address then it will not be shown. S1,S2

show what type of sensor is connected as sensor #1 and Sensor #2 respectively.

Sensor (S1, S2) options include:

• RT: Remote temperature sensor (i.e. for display only)

• CT: Control temperature sensor (i.e. replaces control value of thermostat)

• RH: Remote humidity sensor

• CH: Control humidity sensor

• XX: No sensor attached at this position

Following is an example that illustrates the response (commands are bold responses

are shown in italics):

SN1 RSM?

(Request information about sensors connected to thermostat with address #1.)

SN1 RSM= M1:RT,RT M2:CT,CT M3:RH,CT

(ViewStat responds that there are three support modules attached to thermostat 1,

that there are two remote temperature sensors on the module with address #1, two

control temperature sensors on the module with address #2 and that the module

with address #3 has a remote humidity sensor as sensor #1 and a control

temperature sensor as sensor #2).

16

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 21

Thermostat Sensing Commands (Cont.)

Command Description

RxSy

Remote Sensor Value

(x=1-4, y=1,2)

OT

Thermostat Remote

"Outdoor" Temperature

OH

Thermostat Remote

"Outdoor" Humidity

Up to four addressable support-modules can be connected to a thermostat's local

communication network (LCN). Two sensors can be connected to each support module. This value is used to retrieve the value of the sensor in the appropriate units of

measure. The 'RSM' command is used to determine what sensors of what type are

available on the thermostat LCN.

Syntax:

SN[address] RxSy?

Para meters:

•x = the support module address (1 - 4)

•y is the sensor number (1 or 2)

Reply Format:

SN[address] RxSy={value}F, C or %

Para meters:

•x = the support module address (1 - 4)

•y is the sensor number (1 or 2)

Up to four addressable support-modules can be connected to a thermostat's local

communication network (LCN). Two sensors can be connected to each support module, each can be a temperature sensor or a humidity sensors depending on the support module model. Each sensor can be individually configured as control sensors or

remote sensors (for display only).

Sensor #2, configured to be "remote", of the support module with address #1 is the

source for remote outdoor temperature.

ViewStat responds with the temperature in the scale defined by the SCALE command

and appends a C or F to the value for clarity. Should no sensor be attached the value

will show "- -". This is the temperature value shown on the lower left of the thermostat

display and is the value used for high and low balance point control (for heat pump

use only).

The alternate command and reply formats have been implemented to maintain backward compatibility with earlier thermostat versions.

Syntax:

SN[address] OT?

Reply Format:

SN[address] OT={value}F or C

Alternate Syntax:

SN[address] R?

Alternate Reply Format:

SN[address] R={value}F or C

Up to four addressable support-modules can be connected to a thermostat's local

communication network (LCN). Two sensors can be connected to each support module; each can be a temperature sensor or a humidity sensor depending on the support module model. Each sensor can be individually configured as control sensors or

remote sensors (for display only). The humidity sensor configured to be "remote" of

the support module with address #1 is the source of remote humidity. ViewStat

responds with the humidity value appended by a "%" for clarity. Should no sensor be

attached the value will show "- -". This is the humidity value shown on the lower left of

the thermostat display.

Syntax:

SN[address] OH?

Reply Format:

SN[address number] OH={value}%

ViewStat Programming Protocol

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

17

Page 22

ViewStat Programming Protocol

Thermostat HVAC Operational Commands

These commands are used for temperature control and other thermostat operational parameters.

The following command descriptions describe the use of the command when setting a particular

variable. Inquiries can be made with all commands (with the exception of the

and

ENTR commands) to determine the existing value of a variable. Inquiry is done using the

following syntax:

SN [address number, or <blank> or 0 (zero) for global] "COMMAND" ?

where COMMAND is the variable whose value is desired.

Thermostat Action Commands

Command Description

SH

Temperature Setting - Heat

SH++/SH --

Increment Or Decrement

Temperature Setting - Heat

SC

Temperature Setting - Cool

SCUP, SCDN, BLTON

The heat setting is the temperature setting against which the current room

temperature is compared to control the heating outputs of the thermostat.

The value is assumed to be in the temperature scale set using the SCALE

command. If the integer value is outside the allowable range for the set

temperature scale the command will be ignored.

Syntax:

SN[address] SH={value}

Para meters:

• {value}: Integer value between 40 and 88 if SCALE is set to °F or

between 4 and 31 if SCALE is set to °C.

Reply Format:

SN[address number] SH={value}F or C depending on set

temperature scale

These commands are used to raise (SH++) or lower the (SH--) the heat

temperature setting by a specified value. The value is assumed to be in

the temperature scale (F or C) set using the SCALE command and the

response will include a scale designator. Should the resultant change be

outside the allowable range for the set temperature scale, the command

will be ignored.

SN[address] SH++={value} or SH--={value}

Var iable :

• {value}: Integer value (°F or °C designation not required).

Reply Format:

SN[address] SH++=Integer value F or C

or SH--=Integer value F or C

The cool setting is the temperature setting against which the current room

temperature is compared to control the cooling outputs of the thermostat.

The value is assumed to be in the temperature scale set using the SCALE

command.

Syntax:

SN[address] SC={value}

Para meters:

• {value}: Integer value between 42 and 90 if SCALE is set to °F or

between 6 and 33 if SCALE is set to °C.

Reply Format:

SN[address] SC={value}F or C depending on set

temperature scale

18

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 23

Thermostat Action Commands (Cont.)

Command Description

SC++/SC --

Increment Or Decrement

Temperature Setting - Cool

S

Current Mode Temperature Setting

SP++/SP --

Increment Or Decrement Current

Mode Temperature Setting

These commands are used to raise (SC++) or lower the (SC--) the cool

temperature setting by a specified value. The value is assumed to be in

the temperature scale set using the SCALE command and the response

will include a scale designator. Should the resultant change be outside the

allowable range for the set temperature scale, the command will be

ignored.

Syntax:

SN[address] SC++={value}F or C or SC--={value}F or C

Reply Format:

SN[address] SC++=Integer value F or C

or SC--=Integer value F or C

The ViewStat holds two temperature settings in memory: a heat setting

and a cool setting. In the Heat mode of operation, the heat setting is used

as the control point and in the Cool mode of operation the cool setting is

the control point. In the Auto mode of operation the thermostat will control

the temperature using either the heat setting or the cool setting depending

on which the current room temperature is closest. The Setpoint (S) command is used to change the active temperature setting, so knowledge of

the current mode of operation is not required. If the thermostat is currently

in the Heat mode, the heat setting will be changed. If the thermostat is in

the Cool mode the cool setting will be changed. If the thermostat is in the

Auto mode, the temperature setting corresponding to the last HVAC equipment call (i.e. current active reversing valve output). The thermostat will

automatically maintain a two degree (2°) difference between the heating

and cooling settings regardless of which mode of operation is currently

active, by raising or lowering the value not being adjusted if the two degree

separation rule is violated by this command.

Syntax:

SN[address] S={value}

Var iable :

• {value}: Integer value F or C - see Heat (SH) and Cool (SC) Setting

commands for allowable range.

Reply Format:

SN[address] SH={value} or SC={value}; depending on which

value was changed.

These commands are used to raise (SP++) or lower the (SP--) the current

mode temperature setting by a specified value. The value is assumed to

be in the temperature scale set using the SCALE command and the

response will include a scale designator. Should the resultant change be

outside the allowable range for the set temperature scale, the command

will be ignored.

Syntax:

SN[address] SP++=Integer value F

or C or SP--=Integer value F or C

Reply Format:

SN[address] SP++=Integer value F or C

or SP--=Integer value F or C

ViewStat Programming Protocol

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

19

Page 24

ViewStat Programming Protocol

Thermostat Action Commands (Cont.)

Command Description

DIF1, DIF2, & OFFSET

Temperature Control Configuration Settings

SHUM

Humidify Control Setting

Three temperature control variables can be accessed through the ViewStat command set; they are first stage differential (DIF1), second stage

differential (DIF2) and display temperature offset or bias (OFFSET).

The ViewStat is an on/off type temperature controller. This means that at

some temperature below or above the temperature setting the equipment

is turned on, generating or extracting heat at 100% capacity, and at some

temperature the equipment is turned off. Differential refers to the deviation

from setting that the temperature is allowed to be before the control outputs are turned on or off.

The default differential setting is 0.5° F or C for both DIF1 and DIF2. Differential settings for each stage can be increased in increments of 0.5°F or

C up to 2°F or C. The SN1 DIF1 command is used to add to the default

differential of 0.5° in increments of 0.5°. For example, SN1 DIF1=1 sets

the first stage differential at 1°F or C (= 0.5° + 1*0.5°), while SN1 DIF1=3

sets the first stage differential at 2° F or C (= 0.5° + 3*0.5°) and SN1

DIF1=0 returns the differential to 0.5° F or C. Second stage differential

setting is the value above or below the first stage differential setting that

the temperature is allowed to deviate before turning on the second stage of

either heating or cooling. For example, setting SN1 DIF1=0 and SN1

DIF2=2 will result in first stage operation at temperatures above or below

0.5° while second stage will be activated at 0.5° + 1.5° = 2° above or below

the setting.

Thermostats are factory set to be accurate to within 1° between 60°F and

80°F. Temperature comfort however can be a relative condition, so the

ViewStat allows the temperature displayed on the thermostat to be artificially offset. OFFSET is used to offset the display temperature. For

example setting SN1 OFFSET=-3 will change a displayed temperature

reading of 72°F to be 69°F.

Syntax:

SN[address] DIF1=Integer between 0 and 3 inclusive

Reply Format:

SN[address] DIF1=Integer between 0 and 3 inclusive

Syntax:

SN[address] DIF2 =Integer between 0 and 3 inclusive

Reply Format:

SN[address] DIF2 =Integer between 0 and 3 inclusive

Syntax:

SN[address] OFFSET=Integer between -3 through +3

Reply Format:

SN[address] OFFSET=Integer between -3 through +3

Connecting an optional support module configured for humidity control to

the ViewStat changes it from a temperature controller to a humidity controller. The corresponding modes of operation are Humidify, Dehumidify,

Humidify or Dehumidify and Off. SHUM is used to set the "Humidify" control

setting. The humidify setting is that against which the current room humidity is compared to control the humidify output of the thermostat.

Syntax:

SN[address] SHUM={value}%

• Variable:

{value}: Integer value between 10 and 90

Reply Format:

SN[address] SHUM={value}%

20

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 25

Thermostat Action Commands (Cont.)

Command Description

SHUM++/SHUM - -

Increment Or Decrement

Humidify Setting

SDEH

Dehumidify Control Setting

SDEH++/SDEH - -

Increment Or Decrement

Humidify Setting

These commands are used to raise (SHUM++) or lower the (SHUM--) the

humidify setting by a specified value. Should the resultant change be out

of the allowable humidify setting limits, the command will be ignored.

Syntax:

SN[address] SHUM++={value}%

or SHUM--={value}%

Reply Format:

SN[address] SHUM++={value}% or SHUM--={value}%

Connecting an optional support module, configured for humidity control, to

the ViewStat changes it from a temperature controller to a humidity controller. The corresponding modes of operation are Humidify, Dehumidify,

Humidify or Dehumidify and Off. SHUM is used to set the "Humidify" control

setting. The dehumidify setting is that against which the current room

humidity is compared to control the dehumidify output of the thermostat.

Syntax:

SN[address] SDEH={value}%

Var iable :

• {value}: Integer value between 10 and 90

Reply Format:

SN[address] SDEH={value}%

These commands are used to raise (SDEH++) or lower the (SDEH--) the

dehumidify setting by a specified value. Should the resultant change be

out of the allowable dehumidify setting limits, the command will be ignored.

Syntax:

SN[address] SDEH++={value}% or SDEH--={value}%

Reply Format:

SN[address] SDEH++={value}% or SDEH--={value}%

ViewStat Programming Protocol

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

21

Page 26

ViewStat Programming Protocol

Thermostat Action Commands (Cont.)

Command Description

MODE

Thermostat Mode Of Operation

FAN

Hvac Fan Operation

This command dictates what equipment the thermostat will turn on/off to

control temperature. In the HEAT mode, only the heating equipment will

be used, in the COOL mode, only the cooling equipment will be used.

When the thermostat has been configured to operate a heat pump (this is

a DIP switch configuration on the thermostat), Emergency Heat (EMHT)

mode is available. In the Emergency Heat mode, only the back-up heat

source is used.

When a humidity control sensor (optional accessory) is wired to the thermostat it becomes a humidity controller instead of a temperature controller. Operating as a humidity controller, HUMID mode will operate the

humidifier only, DEHUM mode operates the dehumidification equipment

only.

In the AUTO mode, either the heating or cooling equipment will be used, or

if acting as a humidity controller, either the humidification or dehumidification equipment will be used. Care must be exercised in the selection of

AUTO mode. The AUTO mode should not be set during extremely high or

extremely low outdoor temperature conditions. Operating the cooling

equipment when the outdoor temperature is low (i.e. below 50°F) can be

damaging to the equipment as can operating the heating equipment when

the outdoor temperature is too high. Consult with HVAC installers for safe

operating conditions.

The OFF mode effects equipment operation only. When OFF, the thermostat does not control temperature or humidity. OFF mode should not be set

when it is possible to encounter freezing outdoor temperatures to avoid

water pipe freezing.

Syntax:

SN[address] MODE=HEAT, COOL, EMHT, HUMID, DEHUM, AUTO

or OFF

• (Alternatively H may be used for Heat, C for Cool, A for Auto or E for

EMHT)

Reply Format:

SN[address] M=HEAT, COOL, E, HUMID, DEHUM, AUTO or OFF

HVAC system blowers run automatically when the heating or cooling system is operating. They can also be turned on to run continuously to provide air movement and/or air filtration. The Fan button on the thermostat is

used to run the system blower continuously or to run automatically. This

command performs the same function as the thermostat Fan button.

Syntax:

SN[address] FAN=ON or AUTO

• (Alternatively A can be used for Auto)

Reply Format:

SN[address] F=ON or AUTO

22

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 27

Thermostat Action Commands (Cont.)

Command Description

HVAC

Report HVAC Relay States

Thermostats control HVAC units by energizing various relays within the

thermostat completing a circuit to the HVAC controls. This command

reports the on or off state of each relay within the thermostat.

Syntax:

SN[address] HVAC?

Reply Format:

SN[address] HVAC=G±Y1±W1±Y2±W2±B±O± (see example below)

The relay names used are consistent with HVAC terminology. Note that the

compressor is active during cooling operation and during heating operation with heat pump systems:

• G: Fan

• Y1: First stage compressor or Dehumidifier

• W1: First stage heat (or auxiliary heat with heat pump systems) or

Humidifier

• W2: Second stage heat (or 2nd stage auxiliary heat during Emergency

Heat operation with heat pump systems)

• Y2: Second stage compressor

• O: Reversing valve cooling mode (heat pump)

• B: Reversing valve heating mode (heat pump)

On (or energized) is indicated by a plus sign "+" following the relay name.

Off is indicated by a minus sign "-" following the relay name. An example

of this command sequence is as follows:

Command:

SN1 HVAC?

(Request to the thermostat with network address 1 as to the state of the

HVAC control relays)

Response:

SN1 HVAC=G+Y1+W1-W2-Y2-O+B-

ViewStat responds that the fan and first stage compressor relays are

currently energized.

ViewStat Programming Protocol

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

23

Page 28

ViewStat Programming Protocol

Thermostat Action Commands (Cont.)

Command Description

HIBP & LOBP

High And Low Balance Point

(Applicable Only For Heat Pumps)

Heat pumps, when operating in the heating mode, extract heat from the

outdoor air and transfers it to the indoor air. An auxiliary source of heat is

usually present on heat pump systems to meet the heating demand when

the heat pump can not meet the capacity needs. At a particular outdoor

temperature it is more economical to operate the auxiliary heat source

than it is to operate the heat pump, this is called the Low Balance Point

(LOBP).

Conversely, it is so much less economical to operate the auxiliary heat at

higher outdoor temperatures that some municipalities require that the auxiliary heat be locked out above a particular temperature, this is called the

High Balance Point (HIBP). This command is used to set these temperatures. Integer values must be within the range specified for the current

scale.

ViewStat will accept this command only if the thermostat has been configured for heat pump operation and if a support module is attached to the

network that has been configured for remote temperature sensing.

Syntax:

SN[address number] HIBP={value}F or C

Para meter:

• {value}: Integer value between 40 and 80 for °F and between 4 and 27

for °C

Reply Format:

SN[address number] HIBP={value}F or C

Syntax:

SN[address number] LOBP={value}F or C

Para meter:

• {value}: Integer value between 0 and 40 for °F and between -18 and 4

for °C

Reply Format:

SN[address number] LOBP={value}F or C

24

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 29

ViewStat Programming Protocol

Text Messaging Commands

ViewStat incorporates two displays, a segmented display and a two-line, 16-character per line text

messaging display. These commands are used to control the text messaging display.

Text Messaging Support Characters

FIG. 1 shows the correspondence between character codes and character patterns.

Higher 4-bit (D4 to D7) of character code (hexadecimal)

0 12 3 4 5 789AB C D E F6

CG

RAM

0

(1)

CG

RAM

1

(2)

CG

RAM

2

(3)

CG

RAM

3

(4)

CG

4

RAM

(5)

CG

RAM

5

(6)

CG

6

RAM

(7)

CG

RAM

7

(8)

CG

RAM

8

(1)

CG

RAM

9

(2)

CG

RAM

A

(3)

CG

RAM

B

Lower 4-bit (D0 to D3) of character code (hexadecimal)

(4)

CG

RAM

C

(5)

CG

RAM

D

(6)

CG

RAM

E

(7)

CG

RAM

F

(8)

FIG. 1 Text Messaging Support Characters

The following command descriptions describe the use of the command when setting a particular

variable. Inquiries can be made with all commands (with the exception of the

and

ENTR commands) to determine the existing value of a variable. Inquiry is done using the

following syntax:

SN [address number, or <blank> or 0 (zero) for global] "COMMAND" ?

where COMMAND is the variable whose value is desired..

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

SCUP, SCDN, BLTON

25

Page 30

ViewStat Programming Protocol

Text Messaging Commands

Command Description

DATE

Text Messaging Display - Date

ViewStat has a counter and can maintain a clock, once set, with reasonable accuracy over a 24-hour period. Therefore it is necessary to send

ViewStat the current Date and Time from the automation system at least

once per day. Each variable, Date and Time, has its own command.

Date is sent in 6-digit form and will be displayed on the text messaging display as the same six digits, with each set of two separated by a "-". Date

values with less than 6 digits, or with any of the three numbers higher than

the allowable limit, will be seen as an error and the command will not be

carried out. For example the command SN1 DATE = 122304 will result in

the display reading "12-23-04". The thermostat does recognize that there

are not more than 31 days in a month, and that there are no more than 12

months, but does not recognize months with less than 31 days.

It is important to update the date value at least once per day as date

values do not automatically increment.

Should the Date value not be updated, the thermostat could read "02-3102".

If a Date value has been sent to the thermostat, it will be displayed in addition to the four Rotating Message Display messages (see PMES1-PMES4)

as a fifth message. It will be shown as the top line of the two line text messaging display. Should there not be a Date value, only the four Rotating

Message Display messages will be displayed.

Syntax:

SN[address] DATE=MMDDYY

Var iable s:

• MM = 01-12

• DD = 01-31

• YY = 00-99

Reply Format:

SN[address] DATE=MMDDYY

26

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 31

Text Messaging Commands (Cont.)

Command Description

TIME

Text Messaging Display - Time

The ViewStat has a counter and can maintain a clock, once set, with reasonable accuracy over a 24 hour period. Therefore it is necessary to send

ViewStat the current Date and Time from the automation system at least

once per day. Each variable, Time and Date, has its own command.

Time is sent as a four digit integer with 0000 corresponding to midnight,

and 2359 corresponding to 11:59 p.m. (i.e. Military time). Noon is "1200".

Time values with less than four digits or higher in value than 2359 will be

seen as an error and the command will not be carried out. For example

the command SN1 TIME = 0631 will result in the display reading "6:31

am". The counter will maintain the clock to within one minute over a 24hour period.

It is important to update the time value at least once per day.

If a Time value has been sent to the thermostat, it will be displayed in addition to the four Rotating Message Display messages (see PMES1-PMES4)

as a fifth message. It will be shown as the bottom line of the two-line text

messaging display. Should there not be a Time value, only the four Rotating Message Display messages will be displayed.

Syntax:

SN[address] TIME=HHMM

Var iable s:

• HH = 01-23

• MM = 00-59

Reply Format:

SN[address number] TIME=HHMM

ViewStat Programming Protocol

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

27

Page 32

ViewStat Programming Protocol

Text Messaging Commands (Cont.)

Command Description

PMES1 - PMES4

Text Messaging Rotating Message Display

ViewStat can store and display up to four messages on a rotating basis.

The text messaging display is a two-line, 16-character display. The first

character in the top line of the display is filled with the first character in the

text string of the command. The remainder of the character spaces are

filled across the top line and then down and across the bottom line. Blanks

(spaces) count as characters, and if there are not 32 characters in the

message, blank spaces will be appended to the end of the message. Each

message is displayed for 5 seconds, after which the next is displayed. If

the message is filled with nothing but blank characters (spaces), then the

message is skipped in the sequence. If only one message is available, it

will be permanently displayed, and if no messages (including date and

time) are available none will be displayed. The characters in the text string

are limited to alphanumeric characters either upper or lower case. Leaving

any one of the messages blank (i.e. no characters including spaces)

results in the default message being displayed.

Syntax:

SN[address] PMES1 through PMES4={32 char text string}

Reply Format:

SN[address] PMES1 through PMES4={Up to 32 char text

string}

The default messages are:

• PMES1: This message default is blank and is skipped in the default

rotation.

• PMES2:

CURRENT S TA TUS

MO DE

MODE is the current mode of operation.

• PMES3:

CURRENT S TA TUS

FAN ST ATUS

FAN STATUS is the current fan status (ON or Auto).

• PMES4:

CURRENT S TA TUS

EQU I PMENT

EQUIPMENT STATUS is the current state of the equipment heating,

cooling, humidifier or dehumidifier outputs.

ST ATUS

28

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

Page 33

Text Messaging Commands (Cont.)

Command Description

TMPMES

Text Messaging User Reset Message

MENU

Text Messaging User Interactive Mode

MSG

Text Messaging User Interface Message

With this command messages can be shown on the text messaging display that must be acknowledged by the user at the thermostat to reset.

Examples of this type of message might be that it is time to change a filter

or call for service. The text messaging display is a two-line, 16-character

display. The first character in the top line of the display is filled with the first

character in the text string of the command. The remainder of the character spaces are filled across the top line and then down and across the bottom line. Blanks count as characters, and if there are not 32 characters in

the message, blank spaces will be appended to the end of the message.

When the thermostat receives the command, the permanent message

sequence will be interrupted by the User Reset Message. The backlight

for the text messaging display will flash on for five seconds and off for two

seconds ten times. The message will also flash at a rate of 5 seconds on,

2 seconds off. This continues until the ENTER/HOLD button on the thermostat is pressed or until a second User Reset Message is sent with no

characters in the text string. The characters in the text string are limited to

alphanumeric characters either upper or lower case.

Syntax:

SN[address] TMPMES={32 char text string}

Reply Format:

SN[address] TMPMES={Up to 32 char text string}

Normally the thermostat will display the permanent messages and user

reset message as described above - this is the passive display mode. The

user may want to use the text messaging display as an interactive device

and this command is used for this purpose. When ON, the permanent text

message sequence is stopped and User Reset messages are ignored.

The display will show the characters designated with the MSG command.

The thermostat continues to control HVAC functions during the user interaction with the text messaging display, and as such only the Enter, Scroll

Up and Scroll Down buttons may be used for interaction.

Syntax:

SN[address] MENU=ON or OFF

Reply Format:

SN[address number] MENU=ON or OFF

This command is ignored unless the text messaging display has been put

in the MENU mode of operation. When done, this command is used to

enter characters to the text messaging display. Messages are displayed

continually until a new message has been received or until the thermostat

is no longer in the MENU mode of operation. The text messaging display

is a two-line, 16-character display. The first character in the top line of the

display is filled with the first character in the text string of the command.

The remainder of the character spaces are filled across the top line and

then down and across the bottom line. Blanks count as characters, and if

there are not 32 characters in the message, blank spaces will be

appended to the end of the message. The characters in the text string are

limited to alphanumeric characters either upper or lower case.

Syntax:

SN[address] MSG={32 char text string}

Reply Format:

SN[address] MSG={Up to 32 char text string}

ViewStat Programming Protocol

ViewStat Communicating Thermostat - Programming Protocol Reference Guide

29

Page 34

ViewStat Programming Protocol

Keypad Lockout Commands

Use of the buttons on the thermostat can be locked out to varying degrees using the following

commands.

The following command descriptions describe the use of the command when setting a particular

variable. Inquiries can be made with all commands (with the exception of the

and

ENTR commands) to determine the existing value of a variable. Inquiry is done using the

following syntax:

SN [address number, or <blank> or 0 (zero) for global] "COMMAND" ?

where COMMAND is the variable whose value is desired.

Keypad Lockout Commands

Command Description

FANLK

HVAC Fan State Change Lockout

MODELK

Mode State Change Lockout

SCUP, SCDN, BLTON

There are three levels of user lockout associated with the FAN button on

the thermostat.

• The first, FANLK=0 represents no lockout at all. This is the default

setting.

• The second, FANLK=1 allows the user to change the fan state (on or

auto) for an amount of time determined by the LKTIME value (see

LKTIME command). At the end of the time limit, the fan state will return

to that which was set when the FANLK command was received.

Subsequent changes to the fan state made at the thermostat will follow

the same sequence.

• Finally, FANLK=2 represents a total lockout. The fan will remain in its

current state until the FANLK setting is changed. Pressing the FAN

button on the thermostat will cause the "lock" icon on the thermostat's

segmented display to light. Releasing the button removes the icon. This

setting is stored in non-volatile memory, so on power loss the current fan

lock setting will be retained.

Syntax:

SN[address] FANLK=0, 1 or 2

Reply Format:

SN[address number] FANLK=0, 1 or 2

There are three levels of user lockout associated with the MODE button on

the thermostat.

• The first, MODELK=0 represents no lockout at all. This is the default