Page 1

Installation Guide

ViewStat Communicating Thermostat (VST)

ATTENTION: READ THIS FIRST!

Additional Documentation

For additional installation, configuration, programming and operating instruction, refer

to the ViewStat Communicating Thermostat Instruction Manual and ViewStat Protocol

Reference Guide documents, available on-line, at www.amx.com.

The ViewStat Communicating Thermostat (FIG. 1) operates similarly to a conventional

thermostat but has the unique capability of being controlled, either locally or remotely

from a NetLinx or Landmark control system. The ViewStat is compatible with any 24volt controlled HVAC system, as well as millivolt systems. This manual describes how

the ViewStat connects to several different types. See the ViewStat Communicating

Thermostat Instruction Manual (available online at www.amx.com) for details.

If necessary, contact AMX Technical Support for help with additional specific control

wiring scenarios

Message display

Main display

hinged

front panel

Mode

button

Adjust buttons

.

Scroll/Setup

buttons

base

Enter button

Fan button

Communication

terminals

HVAC Equipment

terminals

FIG. 1 ViewStat Communicating Thermostat

The ViewStat is designed to work with VST-TTM (Temperature) and VST-TRH

(Temperature and Humidity) support modules, and remote sensors.

Connecting the ViewStat to AMX Control Systems

The Viewstat (VST) has a single RJ-45 jack on the rear panel, and uses ICSNet

cabling to connect to NetLinx or Landmark control systems.

Note: The terms "PhastLink" and ICSNet" are essentially interchangeable within the

context of cabling/connectors. They both use a standard 10BaseT type connection (i.e.

Category 5 wire and RJ-45 connectors), and they share the same pinout information

for the RJ-45 jacks. Generally the term "PhastLink" is used when dealing with

Landmark, and "ICSNet" is used when describing NetLinx control systems.

PHASTLink cables follow the EIA/TIA 568A color code, and NetLinx cables follow the

EIA/TIA 568B color code. The wires should be connected in the standard manner

described in the following table.

If standard EIA/TIA 568A/B color coding is followed, wiring problems will be minimized.

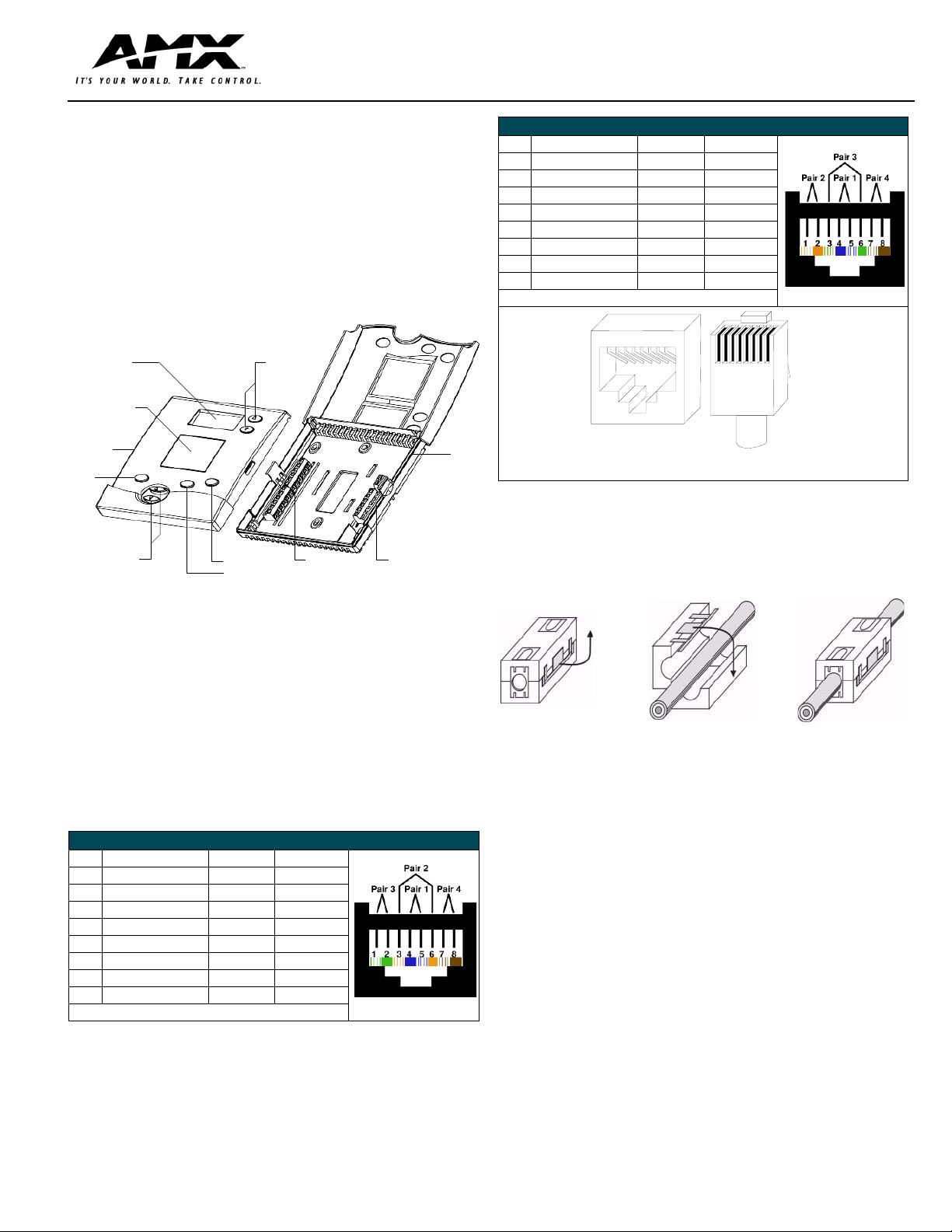

PHASTLink RJ-45 Pinout Information (EIA/TIA 568 A)

Pin Wire Color Polarity Function

1 White/Green + Transmit

2 Green - Transmit

3 White/Orange - Mic

4 Blue - Ground

5 White/Blue + 12 VDC

6Orange + Mic

7 White/Brown + Receive

8 Brown - Receive

TIA 568A

NetLinx RJ-45 Pinout Information (EIA/TIA 568 B)

Pin Wire Color Polarity Function

1 Orange/White + Transmit

2 Orange - Transmit

3 Green/White - Mic

4 Blue - Ground

5 White/Blue + 12 VDC

6 Green + Mic

7 White/Brown + Receive

8 Brown - Receive

TIA 568B

1 2 3 4 5 6 7 8

(female) (male)

RJ-45 connector - pin configurations

Note: It is important that the correct pairing is observed. Transmit, Receive, and

Mic need to be on twisted pairs. Splitting pairs (e.g., using a white/green wire with a

blue/white wire for transmit) will result in increased crosstalk, and may result in bus

failure or noise on the intercom.

1 2 3 4 5 6 7 8

Installing the Cat5 Suppression Ferrite

Before connecting the ICSNet cable, install the CAT5 Suppression Ferrite (provided),

as described below (no tools required):

1. Release the latch to open

the plastic enclosure.

2. Insert the Cat5 cable

and close the enclosure.

3. Installation

complete.

FIG. 2 Installing the CAT5 Suppression Ferrite

Connecting to a NetLinx Control System

To connect a single VST to a NetLinx control system, use ICSNet cabling to connect

the RJ-45 jack on the VST to any available ICSNet jack on the NetLinx Master. The

maximum cabling distance between the VST and Master is 1,000 ft. (304.8 m).

To connect multiple ViewStats to a NetLinx system, use a NetLinx Hub (NXC-NH) to

add additional ICSNet ports to the system. Connect the RJ-45 jack on the VST to an

available ICSNet jack.

Connecting to a Landmark Control System

To connect a single VST to a Landmark control system, use PhastLink cabling to

connect the RJ-45 jack on the VST to any available PhastLink jack on the Landmark

Master. The maximum cabling distance between the VST and Controller is 1,000 ft.

(304.8 m).

To connect multiple ViewStats to a Landmark system, use a Landmark Hub (PLHRPT) to add additional PhastLink ports to the system. Connect the RJ-45 jack on the

VST to an available PhastLink jack.

Connecting the ViewStat to the HVAC System

Before connecting the VST to the HVAC system, install the 24 VAC Suppression

Ferrite, to eliminate any potential noise problems.

Installing the 24 VAC Suppression Ferrite

Before connecting the 24 VAC power supply cable to the HVAC system, install the 24

VAC Suppression Ferrite (provided), as described below (no tools required - see

FIG. 3):

Page 2

1. Pass the 24VAC power

cord through the ferrite

bead.

2. Loop the cable around

and pass it through the

ferrite bead again.

3. Gently pull the cable

to eliminate excess

slack.

FIG. 3 Installing the 24 VAC Suppression Ferrite

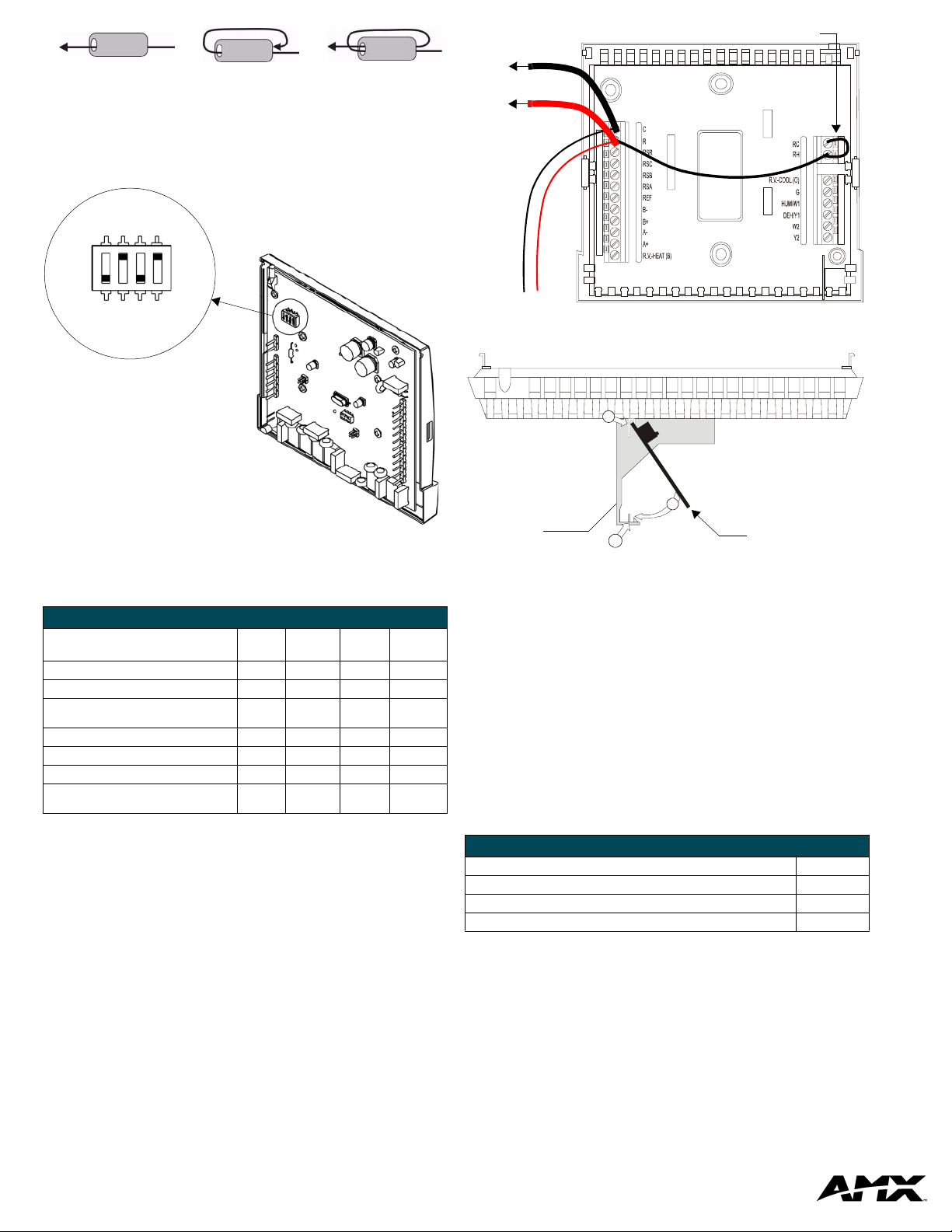

Setting the DIP Switch

Set the DIP switch located on the thermostat circuit board (FIG. 4) according to the

application needs (see the DIP Switch Settings table below for details).

FOSSIL

MULTI

MASTER

ON

H/C

Common (black) from

24 VAC HVAC System

Power (red)

from 24 VAC

HVAC System

jumper from RC to RH

cutout

OFF

SINGLE

SERVANT

ELECTRIC

HT.PUMP

FIG. 4 Setting the DIP Switch

The following table shows what each switch corresponds to depending on position.

Switch one should be set in the “OFF Servant” position unless you plan to broadcast

readings from remote temperature sensors to other thermostats in the system when

there is no control system in place.

DIP Switch Settings

Application

Single Stage Furnace & AC Servant Fossil Single H/C

Two Stage Furnace & Two Stage AC Servant Fossil Multi H/C

Roof Top Unit (Two Stage Heat & Two Stage

Cool)

Boiler with AC (Two Transformers) Servant Fossil Single H/C

Single Stage Heat Pump Servant Electric Single HT. Pump

Two Multi-stage Heat Pump Servant Electric Multi HT. Pump

First Stage Radiant Floor Heat, Second

Stage Furnace One Stage of Cooling

Switch #1Switch #2Switch #3Switch

Servant Fossil Multi H/C

Servant Fossil Multi H/C

#4

Attaching the MiniVerter

Before mounting the VST, you must attach the MiniVerter to the rear panel:

1. Detach the faceplate from the base of the VST (FIG. 1).

2. Pull the stripped/tinned wires through the cutout in the center of the base.

3. Connect the communications wiring:

a. Blue to B-

b. Orange to B+

c. Red/White to A-

d. Black/White to A+

4. Connect the power wiring (FIG. 5):

a. Connect Black (common) from the HVAC system to C on the VST

Communication terminal.

b. Connect Red (24 VAC power) from the HVAC system to R on the VST

5. Jumper RH to RC (FIG. 5):.

6. Insert the MiniVerter (connector-side first) into the guide-slots located on the

7. Slide the MiniVerter back into its locking position in the mounting bracket

Communication terminal.

bottom of the MiniVerter mounting bracket (FIG. 6).

(FIG. 6).

from

MiniVerter

FIG. 5 ViewStat base with Communication, Power and Equipment terminals

ViewStat base (top view)

1

Insert the MiniVerter

(connector-side down)

into the guide slots

inside the mounting

mounting

bracket

bracket.

Snap into place

3

Slide the MiniVerter into locking

position in the bracket.

2

MiniVerter

FIG. 6 Inserting the MiniVerter into the mounting bracket (top view).

8. With the connector-side of the MiniVerter seated in the guide-slots, gently

press the opposite side of the MiniVerter in and down, to snap it into its locked

position on the mounting bracket.

Connecting the ViewStat to the HVAC System

Warning!

• 120 volts may cause serious injury from electrical shock. Disconnect electrical

power to the HVAC system before starting installation. This system is a lowvoltage system.

• Improper installation may cause serious injury from electrical shock. This system must be installed by a qualified contractor in accordance with NEC Standards and applicable local and state codes.

For HVAC system wiring diagrams (for Single-Stage Furnace and AC, Two-Stage

Furnace and Two-Stage AC, Roof-Top Unit (Two-Stage Heat and Two-Stage Cool),

Boiler With AC (Two Transformers), and Single Stage Heat Pump Configurations,

refer to the Wiring Diagrams section in the ViewStat Communicating Thermostat

Installation Instructions document (included).

Maximum Cable Distances

Maximum Cable Distances

Between the VST and NetLinx or LandMark Controller: 1000’ (304.8m)

Between support module and VST: 1000’ (304.8m)

Max. cumulative cable length between multiple support modules and VST: 1000’ (304.8m)

Between support module and remote sensor: 300’ (91.44m)

Additional Information

Refer to the ViewStat Communicating Thermostat Instruction Manual (available

online at www.amx.com) for additional information and details on the VST and

related devices, including:

• Product Specifications for the VST and Support Modules

• Configuration, installation and wiring of the VST, Support Modules and Remote

Temperature Sensors.

• Programming and operation instructions.

• HVAC system wiring diagrams.

AMX Corporation reserves the right to alter specifications without notice at any time.

For full warranty information, refer to the AMX Instruction Manual(s) associated with your Product(s).

AMX Corporation. All rights reserved. The AMX logo is a trademark of AMX Corporation. AMX reserves the right to alter specifications without notice at any time.

3000 RESEARCH DRIVE, RICHARDSON, TX 75082 • 800.222.0913 • 469.624.7153 • fax 469.624.7153 • technical support 800.932.6993 • www.amx.com

062-004-2639 6/04 ©2004

93-0944

REV: C

Loading...

Loading...