Page 1

Operation/Reference Guide

ViewStat

Communicating Thermostat

Product Category

Last Revised: 5/16/2008

Page 2

AMX Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free of defects in material and workmanship under normal use for

three (3) years from the date of purchase from AMX Corporation, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, MX Series products, and KC Series products are

warranted for a period of one (1) year.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX Corporation or an Authorized AMX Dealer.

AMX Corporation is not liable for any damages caused by its products or for the failure of its products to perform. This includes any

lost profits, lost savings, incidental damages, or consequential damages. AMX Corporation is not liable for any claim made by a third

party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort claim (including

negligence and strict product liability), a contract claim, or any other claim. This limitation of

liability cannot be waived or amended by any person. This limitation of liability will be effective even if AMX

Corporation or an authorized representative of AMX Corporation has been advised of the possibility of any such damages. This limitation of liability, however, will not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of the Limited Warranty may not

apply. This Limited Warranty gives the owner specific legal rights. The owner may also have other rights that vary from state to state.

The owner is advised to consult applicable state laws for full

determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX CORPORATION MAKES NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. AMX CORPORATION

EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED WARRANTY. ANY

IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS

LIMITED WARRANTY.

Page 3

Table of Contents

V

Table of Contents

Product Information ...........................................................................................1

Introduction .............................................................................................................. 1

System Components ................................................................................................. 2

ViewStat Specifications............................................................................................. 2

Support Module Specifications ................................................................................ 3

Maximum Cable Distances ....................................................................................... 4

HVAC System Pre-Installation Check List .................................................................. 5

ViewStat Installation and Wiring ........................................................................7

Disconnecting Power to All HVAC Equipment.......................................................... 7

Selecting the Thermostat Location ........................................................................... 7

Stand-alone thermostat mounting criteria ...................................................................... 7

With remote temperature sensors .................................................................................. 7

Removing the Faceplate from the Base .................................................................... 8

Setting the DIP Switch .............................................................................................. 9

Reassembly ..................................................................................................................... 9

Attaching the MiniVerter to the ViewStat .............................................................. 10

Wiring the VST-TSTAT to a VST-DIST Distribution Panel ........................................ 11

Mounting the Base to a Wall .................................................................................. 12

Connecting the ViewStat to AMX Control Systems ................................................ 13

Connecting to an Axcess Control System (via AXC-232++, AXB-EM232,

or Axcent3/PRO) ........................................................................................................ 14

Connecting to an Axcess Master Controller via the RS232/422/485 (DB-9) Port.......... 15

Connecting to NetLinx Integrated Controllers via the RS232/422/485 (DB-9) Port...... 16

Connecting to a NetLinx Master controller via NXC-COM card.................................... 17

Connecting to a LandMark Control System................................................................... 18

Installing the Cat5 Suppression Ferrite ......................................................................... 18

Connecting to a NetLinx Control System...................................................................... 18

Connecting to a Landmark Control System................................................................... 19

Connecting the ViewStat to the HVAC System....................................................... 19

Installing the 24 VAC Suppression Ferrite..................................................................... 19

Wiring the Thermostat ........................................................................................... 20

Communication and Equipment terminal wiring definitions.......................................... 20

Connecting the ViewStat to the HVAC System............................................................. 21

Checking HVAC System Operation......................................................................... 23

Check Out Procedure.................................................................................................... 23

Optional HVAC Set-Up Features............................................................................. 24

To access these HVAC set-up features.......................................................................... 24

iewStat Communicating Thermostat

i

Page 4

Table of Contents

Address the Thermostats and Set Highest Address................................................ 24

Wiring Diagrams ..................................................................................................... 26

Single-stage furnace and AC configuration. .................................................................. 26

Two-stage furnace and two-stage AC configuration. .................................................... 27

Roof top unit (two-stage heat and two-stage cool) configuration................................. 28

Boiler with AC (two transformers) configuration........................................................... 29

Single-stage heat pump configuration .......................................................................... 30

Two-stage heat pump configuration. ............................................................................ 31

First- stage radiant floor heat, second-stage furnace one stage

of cooling configuration. ............................................................................................ 32

Support Module Installation and Wiring ...........................................................33

Installing the VST-TTM and VST-TRH Support Modules .......................................... 33

Choosing a mounting location....................................................................................... 33

Single Support Module Installation ............................................................................... 33

Multiple Support Module Installation............................................................................ 34

Setting the Support Module DIP Switches.............................................................. 35

DIP switches 1 and 2: Address (1-4) .............................................................................. 36

DIP switch 3: Temperature Sensor 1 ............................................................................. 36

Dip switch 4: Temperature Sensor 2 (VST-TTM support module only) .......................... 36

Dip switch 4: Humidity Sensor 2 (VST-TRH support module only)................................. 36

DIP switch 6: T1/T2 or Onboard Sensor ........................................................................ 36

Applications ............................................................................................................ 37

Heat Pump Applications................................................................................................ 37

Humidity Control (VST-TRH only) .................................................................................. 37

Troubleshooting Remote Sensors ........................................................................... 38

Set Up and Configuration .................................................................................39

Network Override Set-Up ....................................................................................... 40

Thermostat Button Lockout .................................................................................... 40

Security Set-Up ....................................................................................................... 41

Communications Set-Up.......................................................................................... 42

Temperature Set-Up ............................................................................................... 42

Backlighting Set-Up ................................................................................................ 42

Balance Point Set-Up .............................................................................................. 43

Display Set-Up ........................................................................................................ 43

Using the NetLinx Module to Program the ViewStat .......................................45

AMX_ViewStat NetLinx Module - Overview ........................................................... 45

The ViewStat Model ............................................................................................... 46

Command Interface - SEND_COMMANDs .............................................................. 47

String Feedback...................................................................................................... 52

ii

ViewStat Communicating Thermostat

Page 5

Table of Contents

V

Operating the Thermostat ................................................................................57

Front Panel Components ........................................................................................ 57

Message Display ........................................................................................................... 57

Scroll/Set-up buttons .................................................................................................... 57

Mode button................................................................................................................. 57

Adjust buttons............................................................................................................... 57

Fan button..................................................................................................................... 58

Enter button.................................................................................................................. 58

Main display .................................................................................................................. 58

Operating The Thermostat ..................................................................................... 59

Selecting the Mode....................................................................................................... 59

Setting temperatures .................................................................................................... 60

Fan operation................................................................................................................ 60

Backlight operation....................................................................................................... 60

Network override.......................................................................................................... 60

Clearing a temporary flashing message ........................................................................ 60

In Case Of Power Failure ........................................................................................ 60

Cleaning the Thermostat ........................................................................................ 60

iewStat Communicating Thermostat

iii

Page 6

Table of Contents

iv

ViewStat Communicating Thermostat

Page 7

Product Information

Introduction

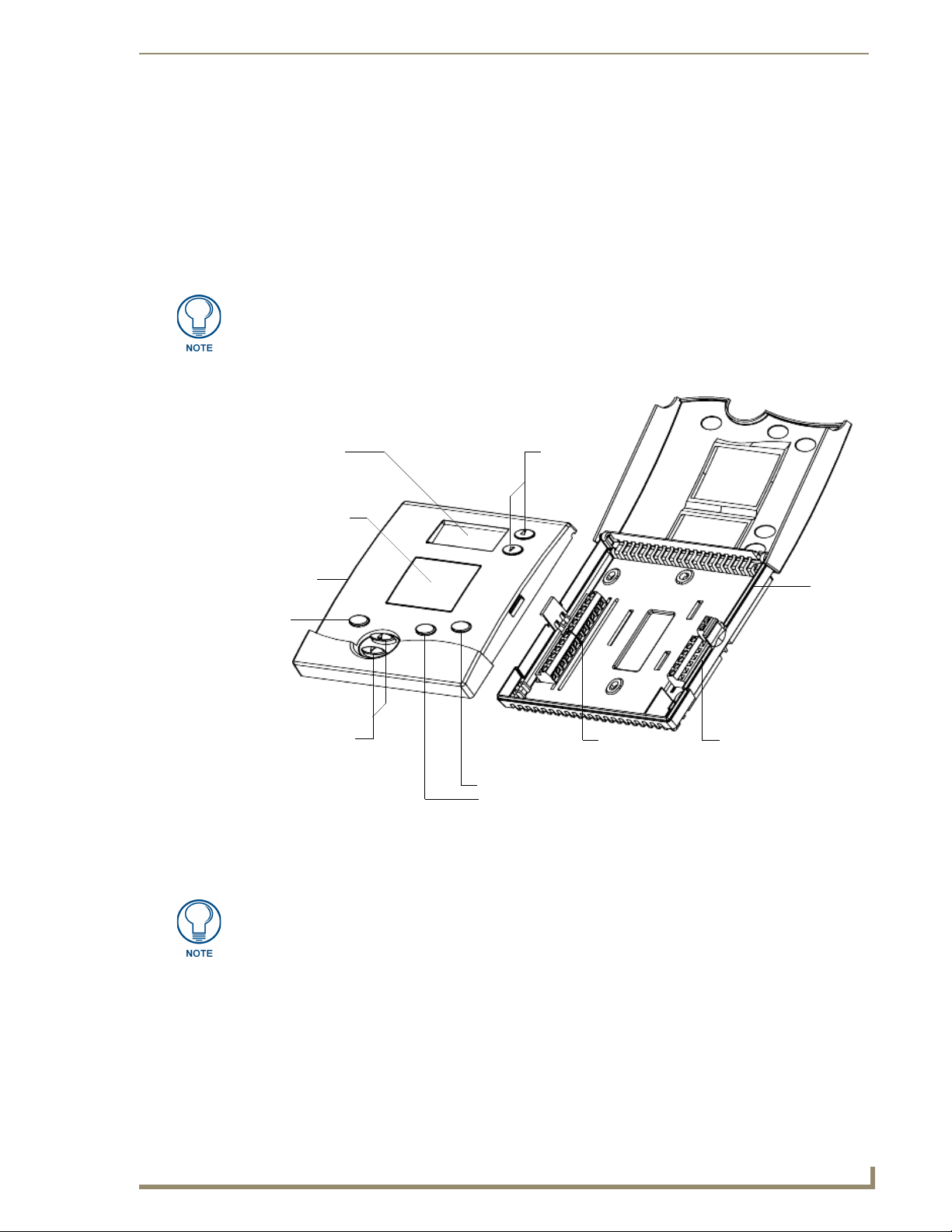

The ViewStat Communicating Thermostat (FIG. 1) operates similarly to a conventional thermostat but has the

unique capability of being controlled, either locally or remotely from a NetLinx or Landmark control system.

The ViewStat is compatible with any 24-volt controlled HVAC system. This manual describes how the

ViewStat connects to several different types (see theViewStat Installation and Wiring section on page 7).

If there are any specific wiring needs or unusual wiring configurations please contact

AMX Technical Support, and we will endeavor to find the answer, before your

installation.

If necessary, contact AMX Technical Support for help with additional specific control wiring scenarios.

Product Information

Message display

Main display

hinged

front panel

Mode

button

Adjust buttons

Mode button

FIG. 1 ViewStat Communicating Thermostat

Enter button

Fan button

Scroll/Setup

buttons

Communication

terminals

base

HVAC Equipment

terminals

The ViewStat is designed to work with VST-TTM (Temperature) and VST-TRH (Temperature and Humidity)

support modules, and remote sensors.

For information on using the VST-TSTAT with an (optional) VST-DIST Distribution

Panel for RS422 control, refer to the Wiring the VST-TSTAT to a VST-DIST

Distribution Panel section on page 11.

ViewStat Communicating Thermostat

1

Page 8

Product Information

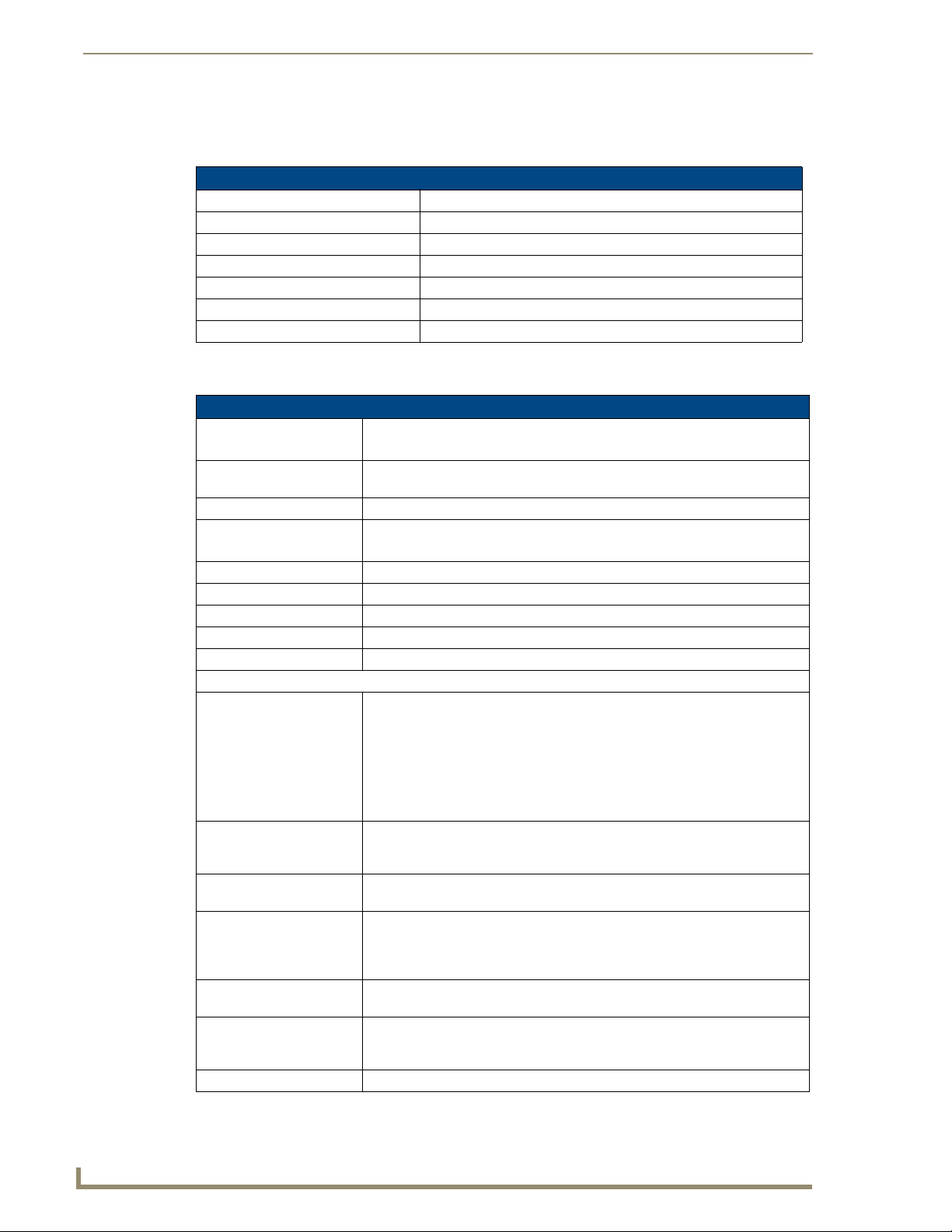

System Components

The components in a complete ViewStat system (including optional accessories) are listed below:

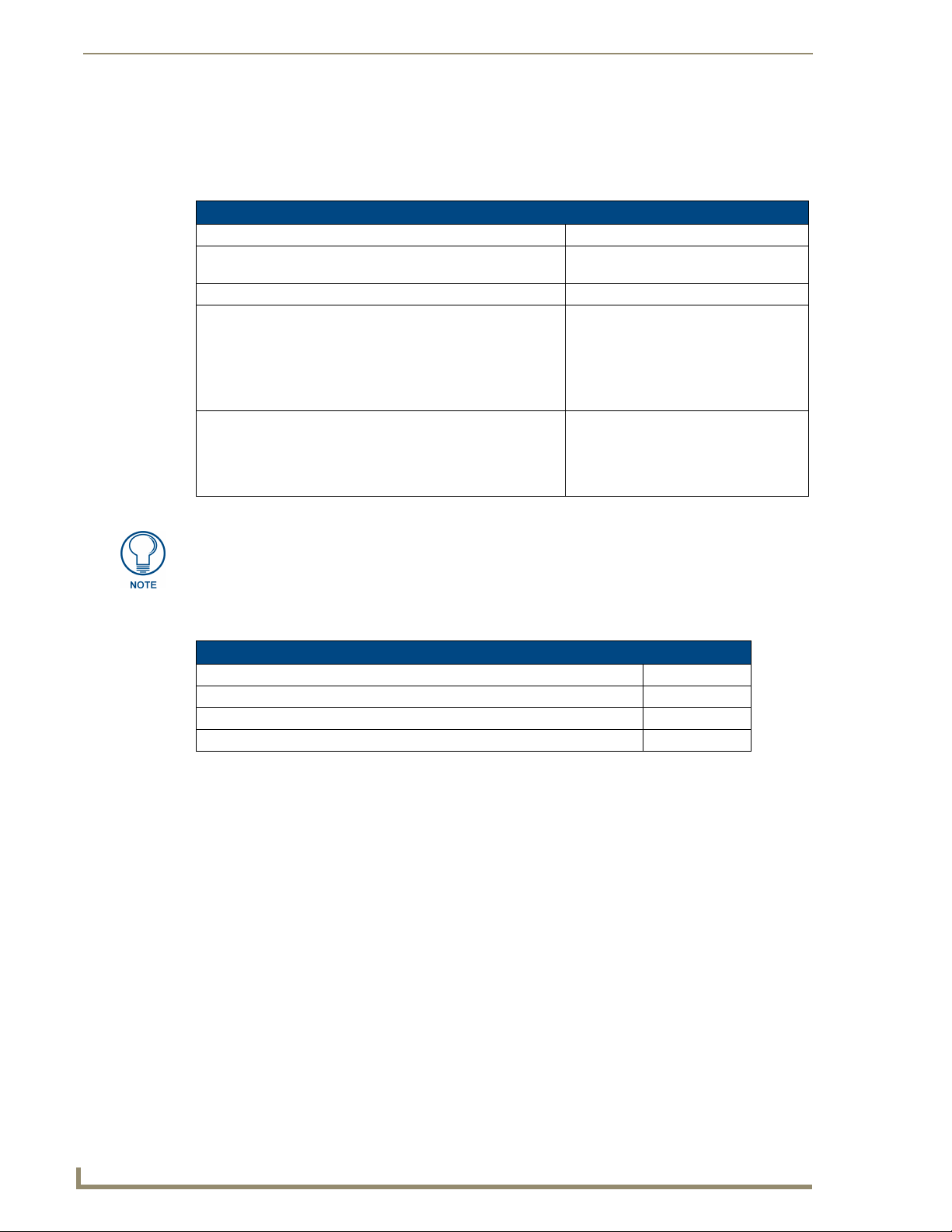

System Components

Component Name Description

ViewStat (VST) Communicating thermostat

VST-TTM Temperature support module (optional)

VST-TRH Temperature/Humidity support module (optional)

VST-TSF Flush-mount remote sensor Indoor flush-mount temperature/relative humidity sensor (optional)

VST-TSO Duct/Outdoor remote sensor Duct/Outdoor-mount temperature/relative humidity sensor (optional)

VST-DIST Distribution Panel

ViewStat Specifications

ViewStat Specifications

Control Ports • HVAC control

• ICSNet

Control Voltage 24 VAC ±20% or 24 VDC ±20% (delivered by an HVAC system or by an external

power supply)

Switched Voltage 18 – 30 VAC

Maximum Operating Current • 2 amps total at rated voltage, through all outputs.

• 1 amps through any one output.

Maximum Surge Current 2.0 A

Control Accuracy ±1.0° F (± 0.56° C)

Control Range 40° – 90° F (4.44° – 32.22° C)

Operating Range 32° – 99° F (0° – 37.22° C)

Baud Rate 9600

Front Panel Components:

Message display Two types of messages are displayed, Permanent and Temporary Messages.

• Permanent Messages are those that scroll continually during thermostat

operation.

• Temporary (flashing) Messages are intended to catch your eye and must be

reset to be removed from the display.

Thermostats are shipped with default (permanent) status messages (i.e. mode

status, fan status, equipment status).

Scroll/Set-up buttons The Scroll/Set-Up buttons function with the set-up features of the thermostat

(see theSet Up and Configuration section on page 39). These buttons are

located beneath the faceplate.

Main LCD display The MAIN DISPLAY (see FIG. 16 on page 23) provides the mode status, tem-

perature and system status information.

Mode button Five modes of operation are available: OFF, COOL, HEAT, AUTO, and EM.

HEAT (for heat pumps only). The mode of operation indicates how you want

your heating and cooling equipment to operate. This button is located beneath

the faceplate.

Fan button The fan can be operated continuously (FAN ON) or only when there is a need to

heat or cool. This button is located beneath the faceplate.

Enter button The Enter (or Network Override) button is used to override the home automation

system, to clear temporary flashing messages on the message display and with

the set-up features of the thermostat.

Adjust buttons The Adjust buttons adjust the heating and cooling temperature settings.

2

ViewStat Communicating Thermostat

Page 9

Product Information

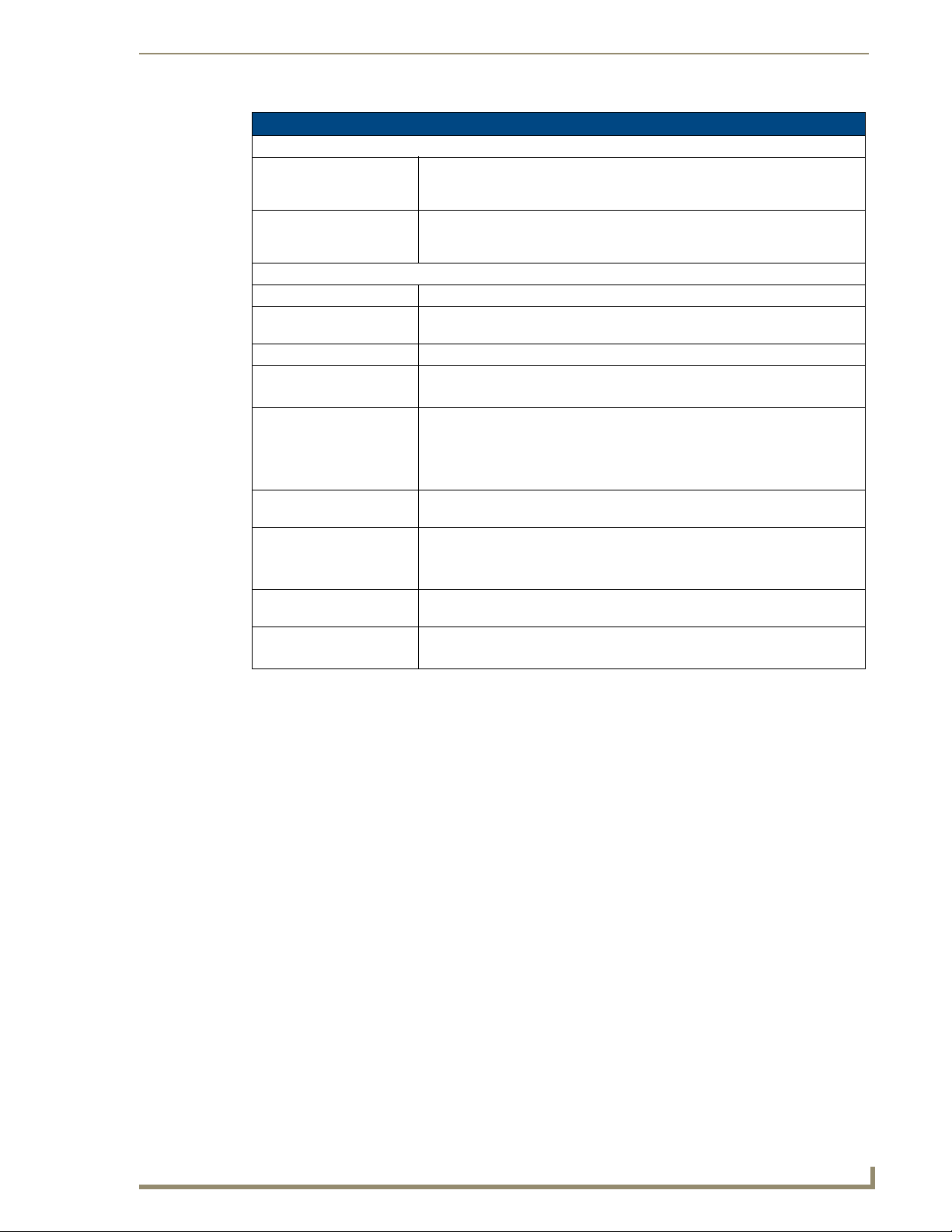

ViewStat Specifications (Cont.)

Circuit Board Components:

Communication and HVAC

Equipment connectors

DIP Switch 4-position DIP switch that configures the thermostat for various application types

Enclosure:

Material White plastic with hinged faceplate and removable front panel.

ViewStat Dimensions

(HWD)

Weight 5.29 oz. (150 grams)

Included Accessories • Cat5 Suppression Ferrite

Optional Accessories • VST-TTM Remote Temperature support module (FG944-10)

Remote Temperature

Sensors:

VST-TSF Dimensions: • Cable length: 9.00"(228 mm)

VST-TSO Dimensions

(HWD):

Weight: • VST-TSF: 0.5 lb (0.23 kg)

Terminals with captive-wire connectors that connects the Thermostat, HVAC

equipment, control system, remote sensors and power supply. Refer to the Wir-

ing the Thermostat section on page 20 for details.

(Servant/Master, Electric/Fossil, Single/Multi, Heat Pump/Heat-Cool). Refer to

the Setting the DIP Switch section on page 9 for details.

5.01" x 5.52" x 1.15"

(12.72 cm x 14.02 cm x 2.92 cm)

• 24 VAC Suppression Ferrite

• VST-TRH Remote Temperature/Humidity support module (FG944-20)

• VST-TSF Flush-mount indoor remote sensor (FG944-30)

• VST-TSO Duct/outdoor remote sensor (FG944-40)

• Sensor depth: 0.85" (22 mm)

• Sensor diameter: Ø1.50 (Ø38 mm)

• 2.75" x 1.44" x 1.75

(70 mm x 37 mm x 44 mm)

• VST-TSO: 0.75 lb (0.34 kg)

Support Module Specifications

There are two types of support modules available for the ViewStat:

VS T- TTM Te m per a t ure M o d ul e : The VST-TTM support module offers versatility in climate

control. A set of onboard dip switches on the VST-TTM circuit board allow you to determine

whether you want the two remote temperature sensor inputs to control, monitor or do a

combination of both. This temperature data is sent back to the ViewStat Thermostat, allowing you

to accurately control and monitor temperature in a given area or multiple areas.

VS T- TRH Te m p er a t ure a n d Hu m i dit y M odu l e : The VST-TRH support module brings further

versatility to the HVAC system. A set of onboard dip switches on the VST-TRH circuit board allow

you to determine whether you want the two remote temperature sensor inputs to control, monitor,

or both. The temperature/humidity data is sent back to the ViewStat, allowing you to accurately

control and monitor temperature/humidity in a given area or multiple areas.

ViewStat Communicating Thermostat

3

Page 10

Product Information

The ViewStat supports up to four Support Modules, and can display any one of the following:

The remote temperature on support module address 1 if its mode is set to "Control".

The average temperatures of all support modules set to "Control" mode.

The humidity of the VST-TRH (Temperature and Humidity Module) set to "Control" mode.

VST-TTM and VST-TRH Remote Sensor Specifications

Power supply 18 to 30 VAC or DC (24 V Nominal)

Support Module Dimensions (HWD) 2.50" x 3.50" x 0.88"

(63 mm x 89 mm x 22 mm)

Max. relative humidity 90% (non-condensing)

Temperature:

• Accuracy: Comfort Range: (60°F - 80°F): ± 1°F

Control Range: (40°F - 100°F): ± 2°F

Operating Range: (-40°F - 185°F): ± 3°F

• Maximum Display Range: -40°F - 185°F

Humidity (VST-TRH only):

• Accuracy: Comfort Range: (10% - 45%): ± 3%

Control Range: (10% - 90%): ± 5%

• Maximum Display Range: 0% - 90%

Refer to theSupport Module Installation and Wiring section on page 33 for

information on configuring, installing and wiring the support modules and remote

temperature sensors.

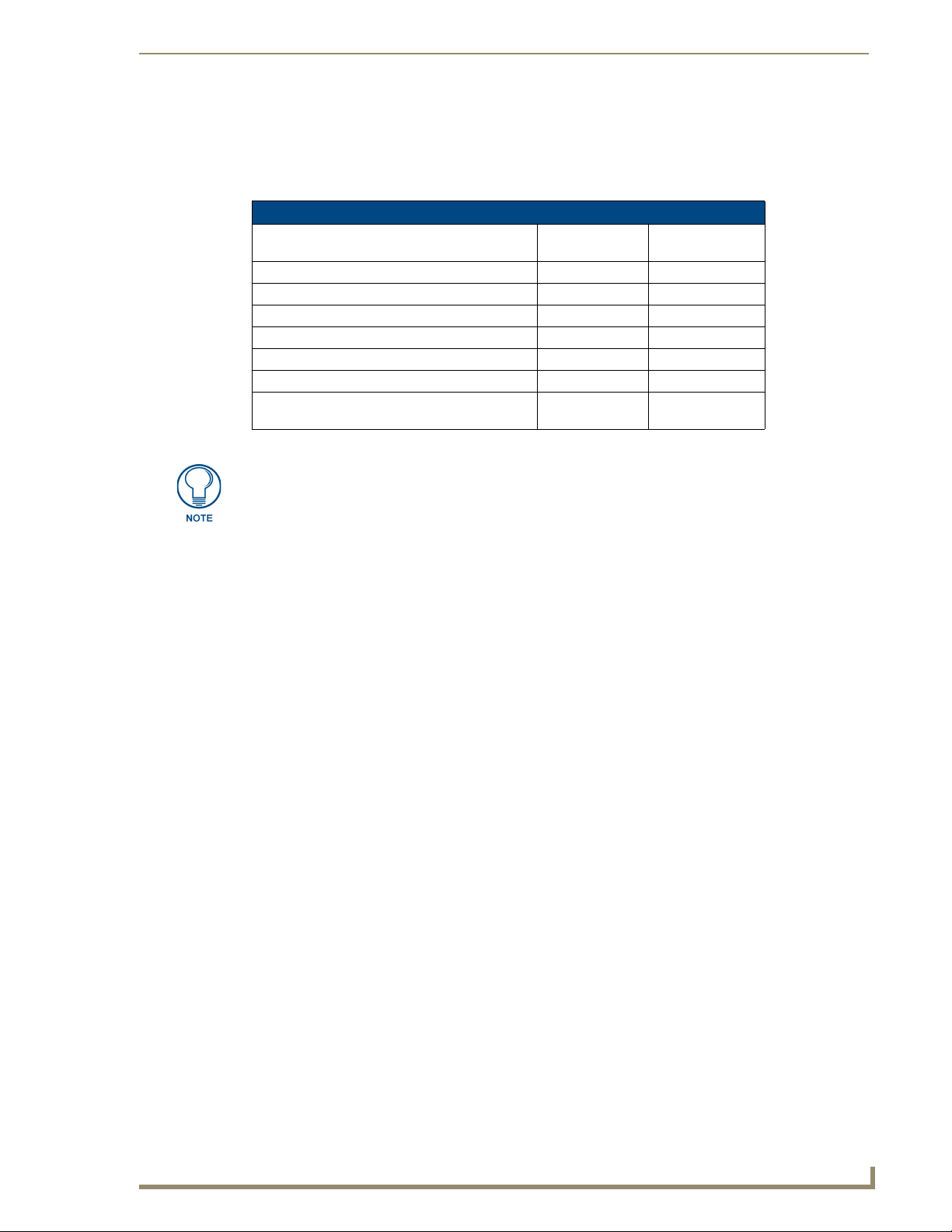

Maximum Cable Distances

Maximum Cable Distances

Between the VST and NetLinx or LandMark Controller: 1000’ (304.8m)

Between support module and VST: 1000’ (304.8m)

•Max. cumulative cable length between multiple support modules and VST: 1000’ (304.8m)

Between support module and remote sensor: 300’ (91.44m)

4

ViewStat Communicating Thermostat

Page 11

Product Information

HVAC System Pre-Installation Check List

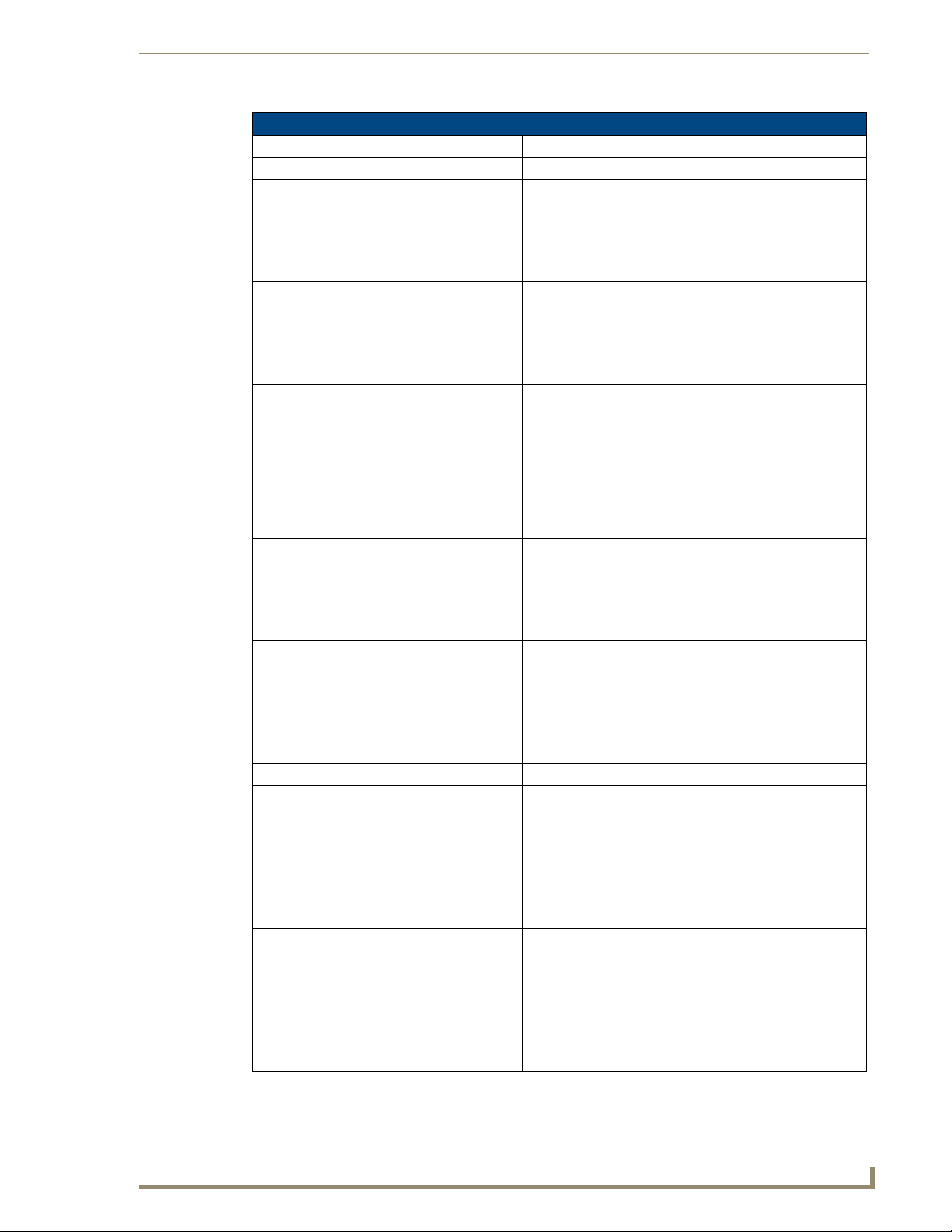

Before getting started, determine what type of heating system is/will be installed in the house. Then use the

following table to determine if the proper numbers of wires are available, depending on the HVAC System

type.

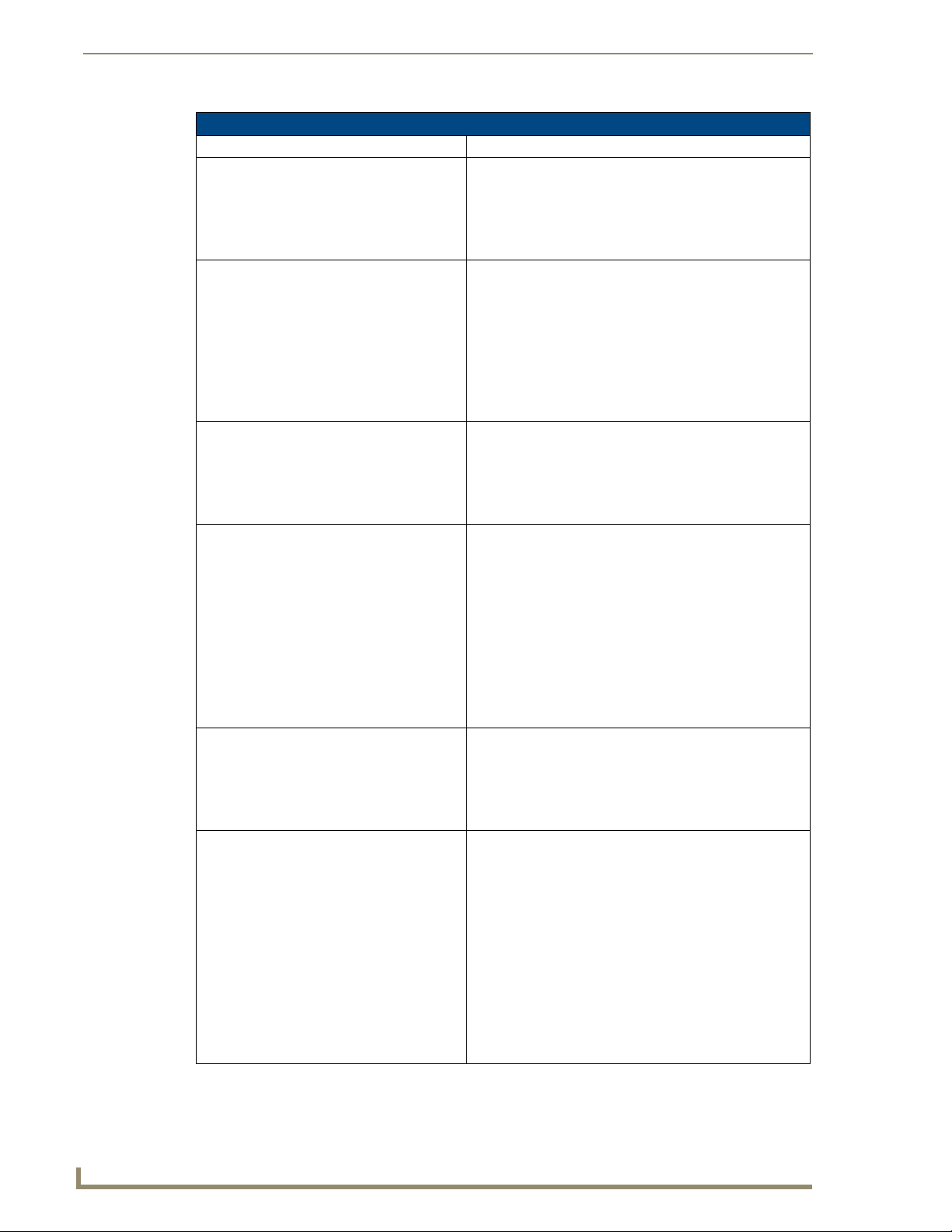

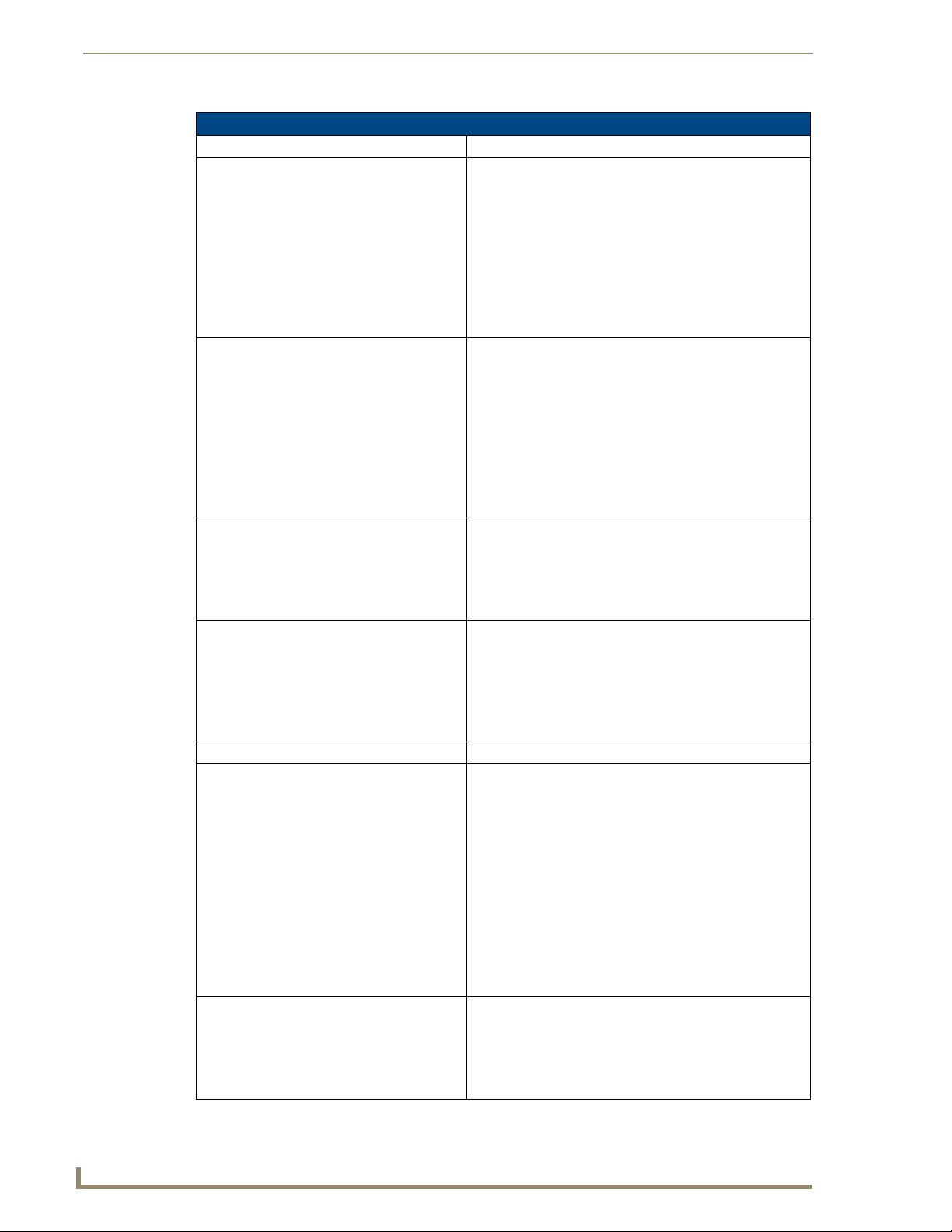

HVAC System Pre-installation Check List

Application # of HVAC

Wires

Single Stage Furnace & AC 5 FIG. 18 on page 26

Two Stage Furnace & Two Stage AC 7 FIG. 19 on page 27

Roof Top Unit (Two Stage Heat & Two Stage Cool) 7 FIG. 20 on page 28

Boiler with AC (Two Transformers) 5 FIG. 21 on page 29

Single Stage Heat Pump 7 FIG. 22 on page 30

Two Stage Heat Pump 9 FIG. 23 on page 31

First Stage Radiant Floor Heat

Second Stage Furnace One Stage of Cooling 6 FIG. 24 on page 32

In addition to the wires necessary to support the HVAC system control, an RJ45terminated Cat5 cable is necessary to support NetLinx or Landmark communications

(see theViewStat Installation and Wiring section on page 7 for details).

Wiring Diagram

ViewStat Communicating Thermostat

5

Page 12

Product Information

6

ViewStat Communicating Thermostat

Page 13

ViewStat Installation and Wiring

This section covers the installation, wiring and checkout of a ViewStat Communicating Thermostat System.

1. 120 volts may cause serious injury from electrical shock. Disconnect electrical power to the

HVAC system before starting installation. This system is a low-voltage system.

2. Improper installation may cause serious injury from electrical shock. This system must be

installed by a qualified contractor in accordance with NEC Standards and applicable local and state

codes.

Disconnecting Power to All HVAC Equipment

Since the ViewStats are wired directly to the HVAC equipment, the power must be shut off at the equipment.

This can generally be accomplished by turning off the disconnect switch located near the equipment. If an

obvious disconnect switch is unavailable, you will need to remove the circuit breaker or shut down the fuse

serving the equipment.

Failure to disconnect power could result in damage to the HVAC equipment or thermostats. Leave

power disconnected until all other electrical connections have been made and checked for

accuracy.

ViewStat Installation and Wiring

Selecting the Thermostat Location

Determine if the thermostat will be operating alone, or with remote temperature sensors. If the unit is standalone there are certain measures that must be taken to ensure accurate temperature control.

Stand-alone thermostat mounting criteria

One ViewStat per HVAC system.

Mount on an interior wall.

In a room frequently occupied.

At least 18 inches (45.72 cm) from any outside wall.

Approximately 5 feet (1.52 m) above the floor. Check with local building codes for height

requirements in commercial applications.

DO NOT locate the thermostat:

Behind doors, in corners or other dead air spaces.

In direct sunlight or near lamps, appliances or other sources of radiant heat.

On an outside wall or wall exposed to an unconditioned space (i.e. garage, etc.).

In the flow path of a supply register, in stairways or near outside doors.

On a wall where concealed pipes and/or duct work will affect the thermostat.

Near sources of electrical interference such as arcing relay contacts.

With remote temperature sensors

Follow the guidelines for placement of the sensors and locate the thermostat indoors where operating range

(see specs) will not be violated (i.e. do not install in a cold garage or hot equipment room). See the Support

Module Installation and Wiring section on page 33 for details.

ViewStat Communicating Thermostat

7

Page 14

ViewStat Installation and Wiring

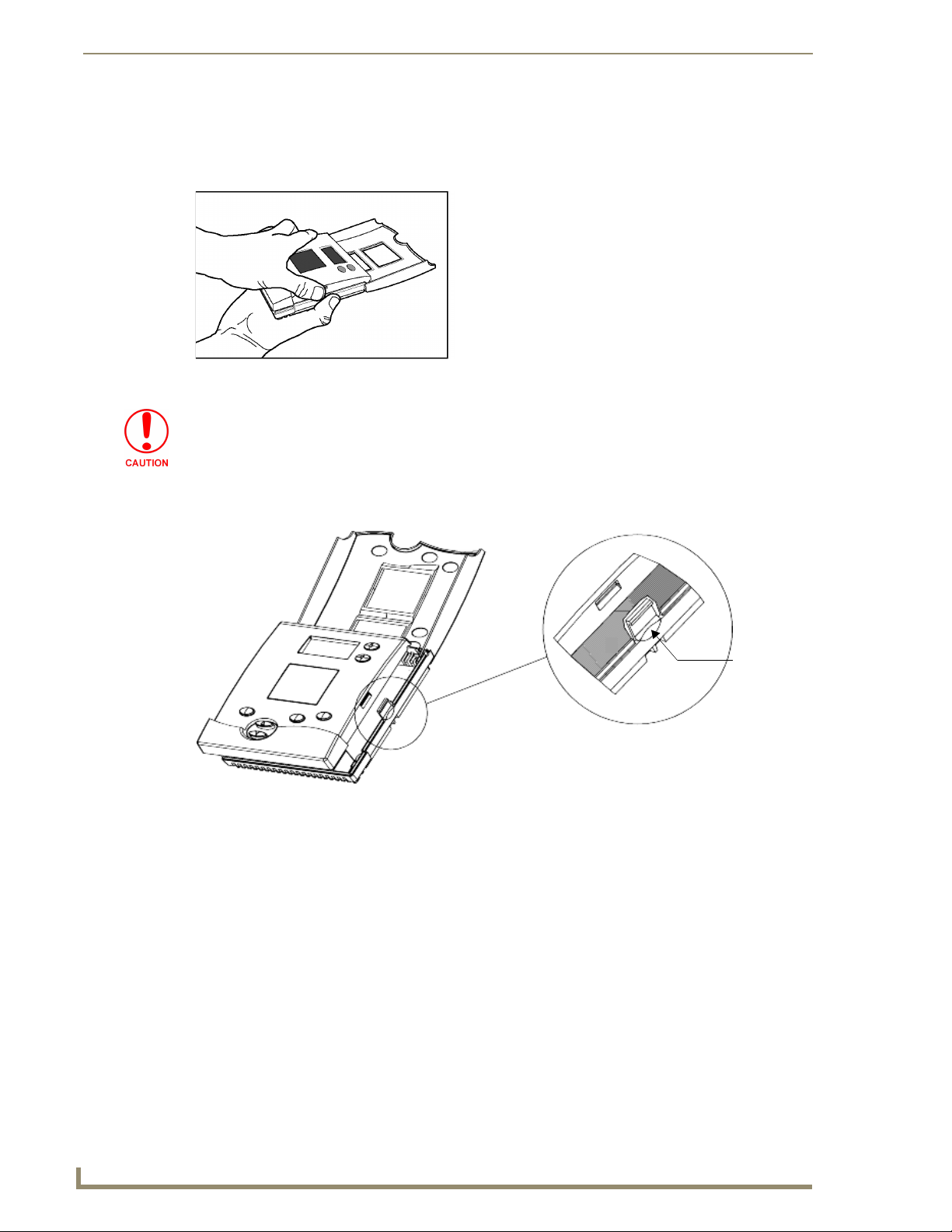

Removing the Faceplate from the Base

No tools are required to disassemble the thermostat – just use your hands to pull the front panel off of the base

(FIG. 2).

FIG. 2 Pulling the front panel off of the base

Loss of internal programs may result from static discharge to thermostat circuit board.

Touch a grounded metal object to discharge any static charge before handling the

circuit board.

While holding the base of the thermostat, apply pressure to the base of the latch with your thumb (FIG. 3).

Both sides have a latch, but it is easiest to unlatch one side at a time.

FIG. 3 Location of latch on base (one latch on each side)

Press base

here

8

ViewStat Communicating Thermostat

Page 15

ViewStat Installation and Wiring

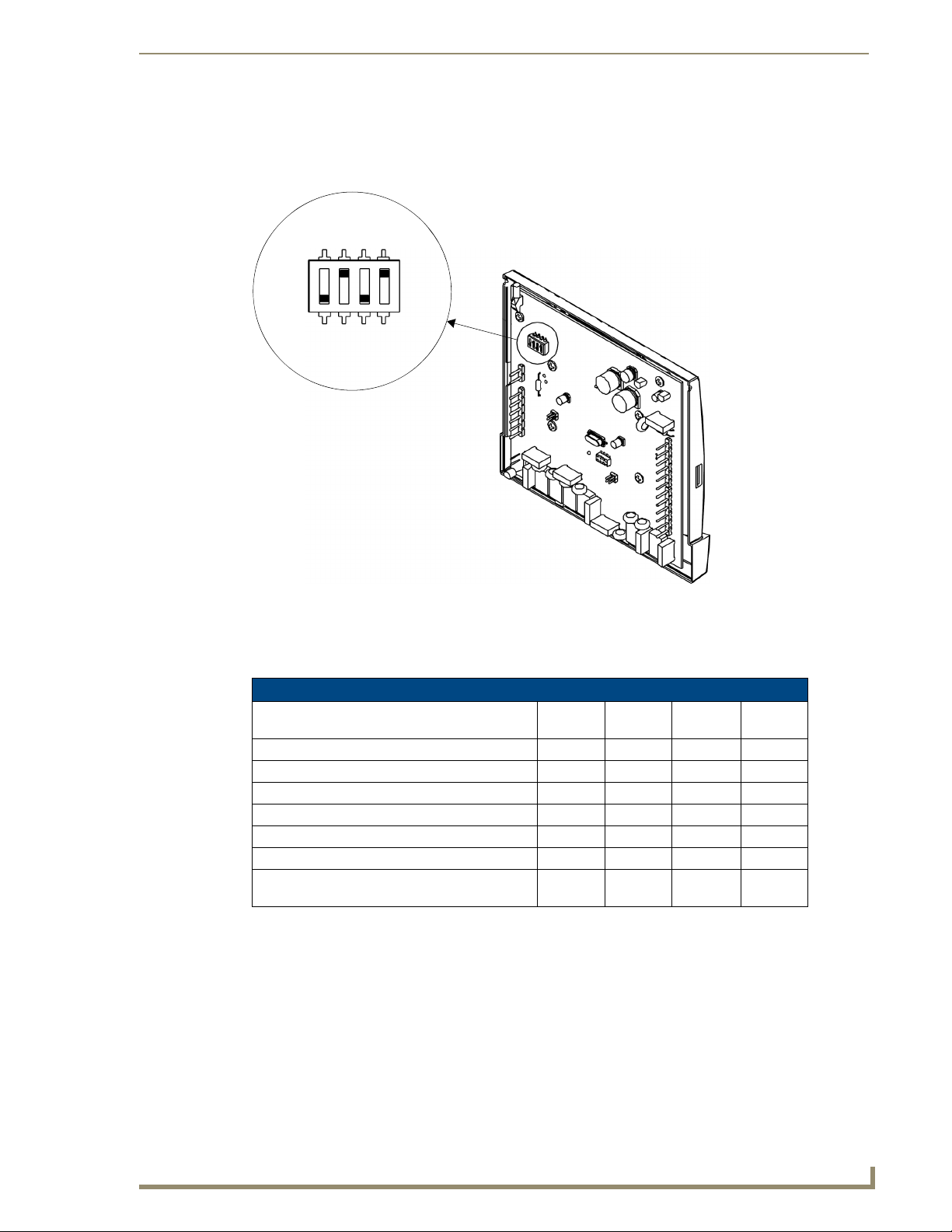

Setting the DIP Switch

Set the DIP switch located on the thermostat circuit board (FIG. 4) according to the application needs (see the

DIP Switch Settings table below for details).

FOSSIL

MULTI

MASTER

ON

OFF

SERVANT

H/C

SINGLE

HT.PUMP

ELECTRIC

FIG. 4 Setting the DIP Switch

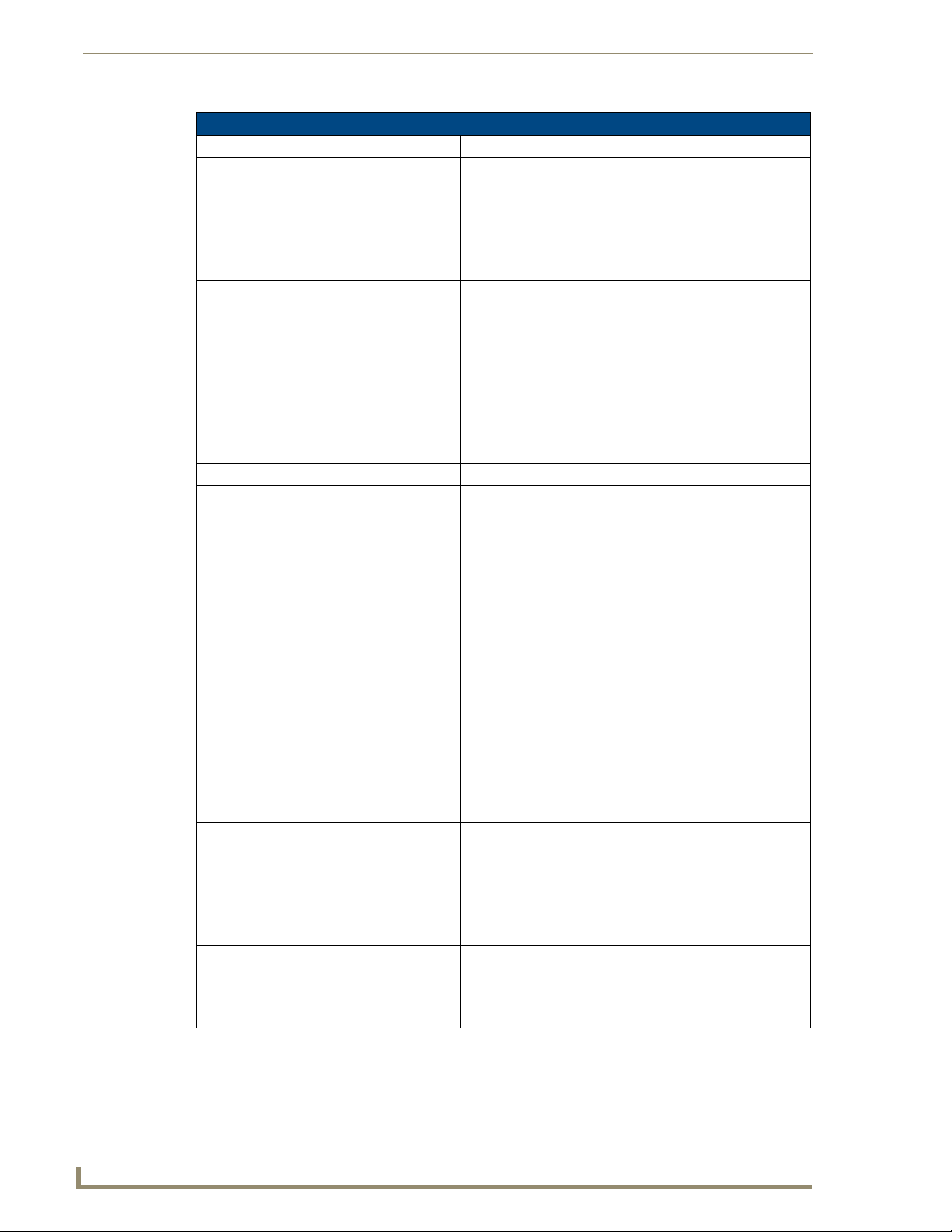

The following table shows what each switch corresponds to depending on position. Switch one should be set in

the “OFF Servant” position unless you plan to broadcast readings from remote temperature sensors to other

thermostats in the system when there is no control system in place.

DIP Switch Settings

Application Switch #1Switch #2Switch #3Switch

Single Stage Furnace & AC Servant Fossil Single H/C

Two Stage Furnace & Two Stage AC Servant Fossil Multi H/C

Roof Top Unit (Two Stage Heat & Two Stage Cool) Servant Fossil Multi H/C

Boiler with AC (Two Transformers) Servant Fossil Single H/C

Single Stage Heat Pump Servant Electric Single HT. Pump

Two Multi-stage Heat Pump Servant Electric Multi HT. Pump

First Stage Radiant Floor Heat,

Second Stage Furnace One Stage of Cooling

Servant Fossil Multi H/C

#4

Reassembly

No tools required – line up pins on circuit board with the corresponding terminal blocks. Use your hands to

push the front panel securely to the mounted base.

ViewStat Communicating Thermostat

9

Page 16

ViewStat Installation and Wiring

C

(black)

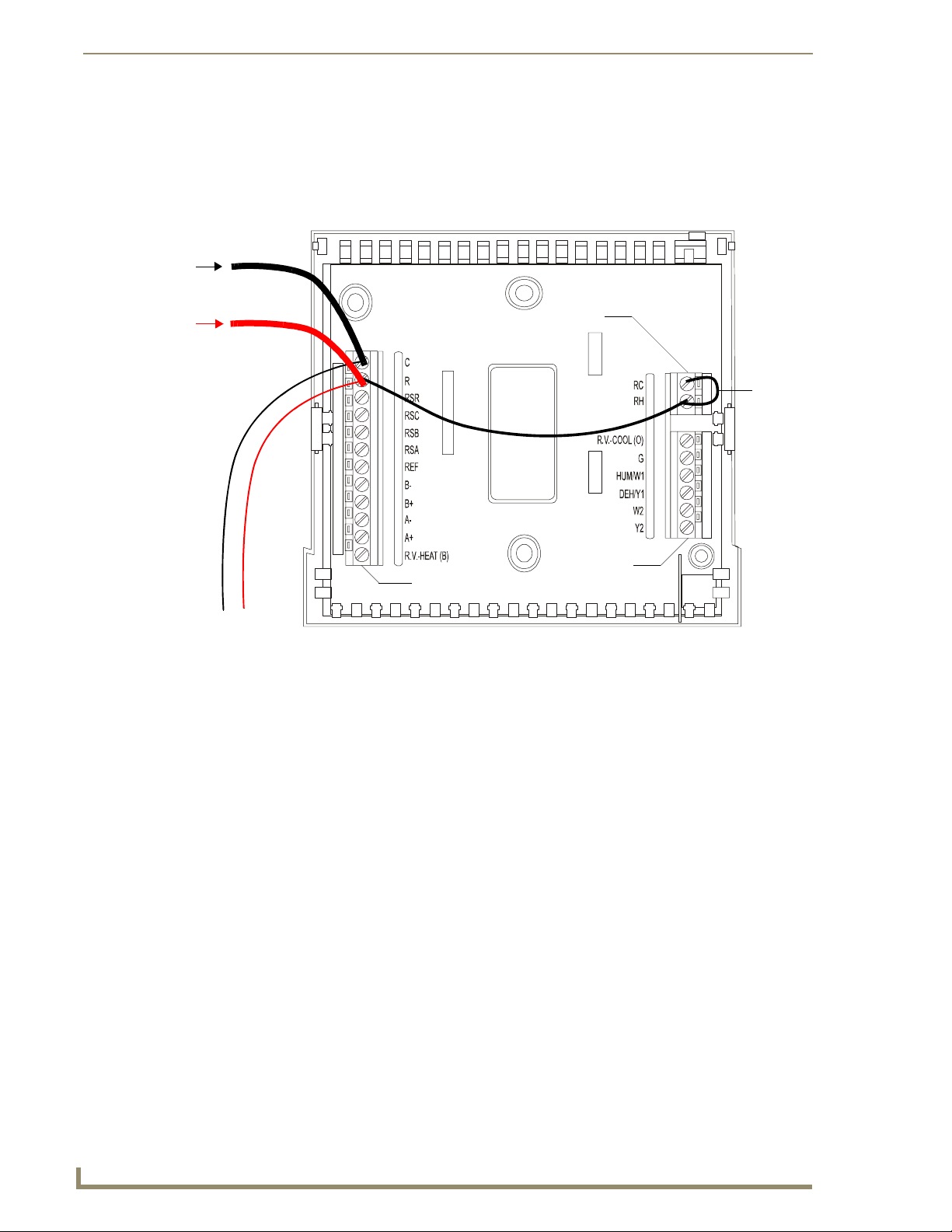

Attaching the MiniVerter to the ViewStat

Before attaching the MiniVerter to the rear of the ViewStat, connect the wiring, as described below:

1. Detach the faceplate from the base of the ViewStat.

2. Pull the stripped/tinned wires through the cutout in the center of the base (FIG. 5).

ommon

from 24 VAC

HVAC System

Power (red)

from 24 VAC

HVAC System

Power

Te r mi n al

cutout

jumper

from RC

to RH

Equipment

Communication

Terminal

from Miniverter

FIG. 5 ViewStat base with Communication, Power and Equipment terminals

terminal

Before mounting the ViewStat, you must attach the MiniVerter to the rear panel of the ViewStat, as described

below:

1. Detach the faceplate from the base of the ViewStat.

2. Pull the stripped/tinned wires through the cutout in the center of the base (FIG. 5)

3. Connect the communications wiring:

a. Blue to B-

b. Orange to B+

c. Red/White to A-

d. Black/White to A+

4. Connect the power wiring:

a. Black to C

b. Red to R

5. Install a jumper from RH to RC.

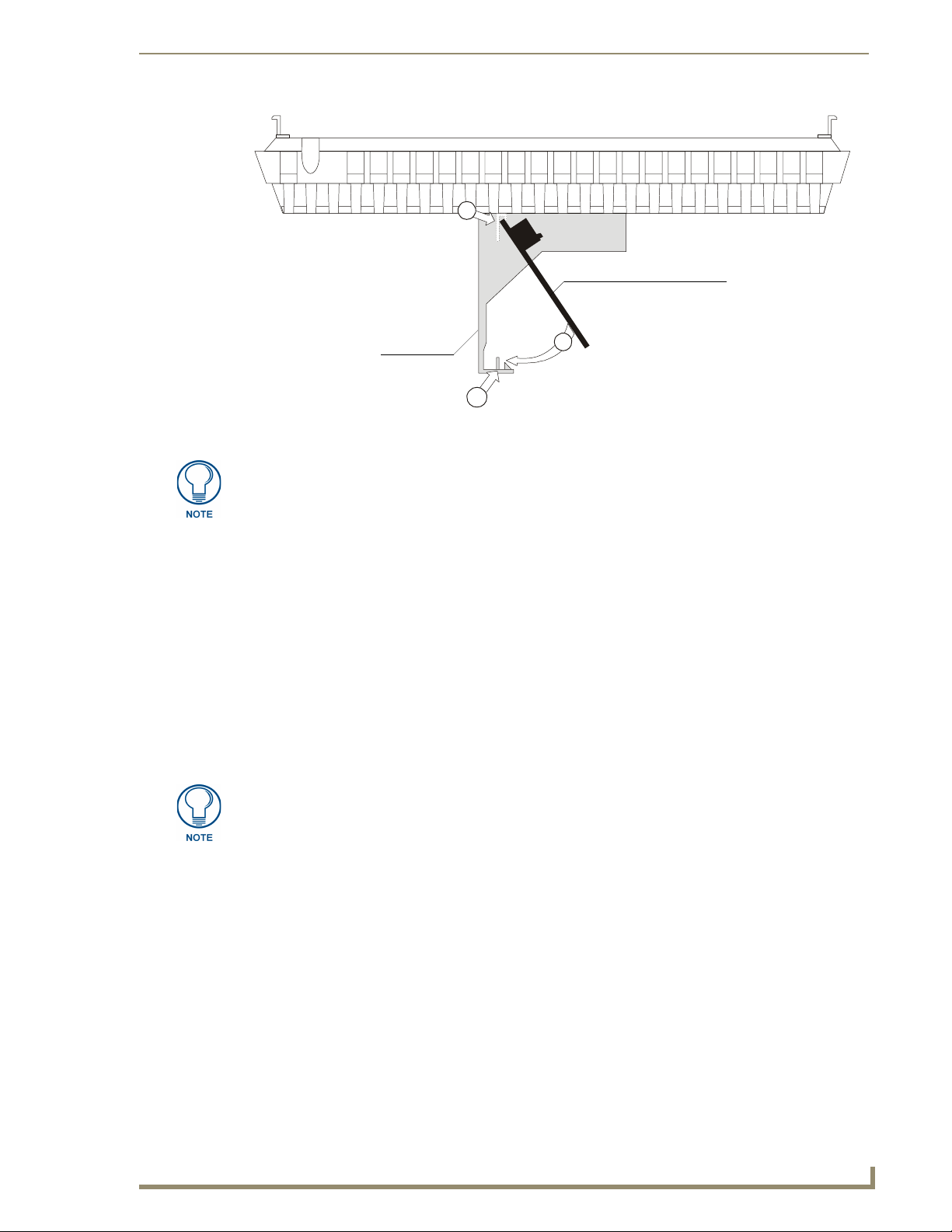

6. Insert the MiniVerter (connector-side first) into the guide-slots located on the bottom of the MiniVerter

mounting bracket (FIG. 6).

7. Slide the MiniVerter back into its locking position in the mounting bracket.

8. With the connector-side of the MiniVerter seated in the guide-slots, gently press the opposite side of the

MiniVerter in and down, to snap it into its locked position on the mounting bracket.

10

ViewStat Communicating Thermostat

Page 17

ViewStat Installation and Wiring

ViewStat base (top view)

1

Insert the MiniVerter

(connector-side down)

inside the mounting bracket.

mounting bracket

FIG. 6 Inserting the MiniVerter into the mounting bracket (top view).

into the guide slots

MiniVerter

Snap into place

3

Slide the MiniVerter into

2

locking position in

the bracket.

MiniVerter card

Repeated installation and removal of the MiniVerter bracket may result in damage to

the bracket.

9. Connect the Cat-5 RJ-45 connector on the MiniVerter to the Control System (Master or ICSNet Hub).

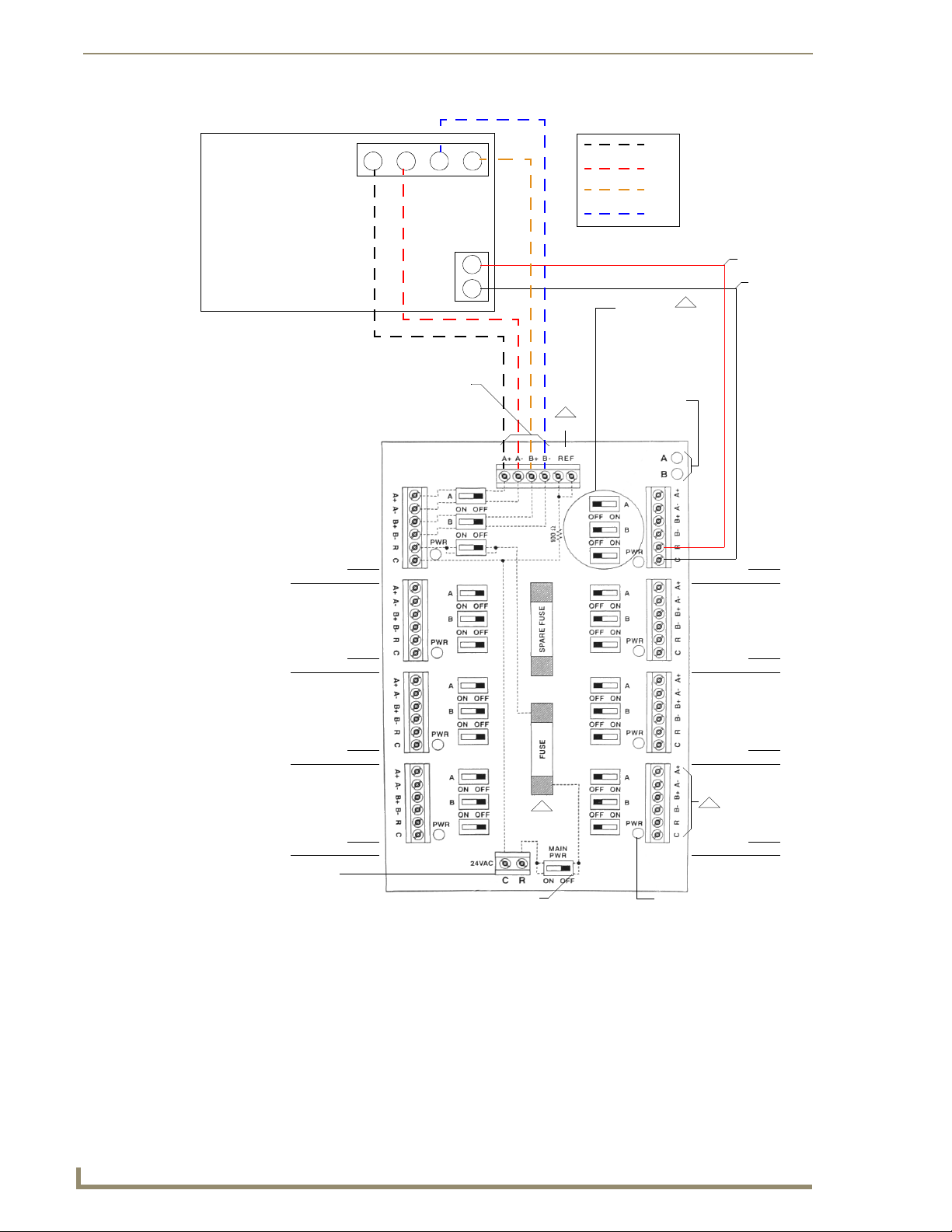

Wiring the VST-TSTAT to a VST-DIST Distribution Panel

The optional VST-DIST Distribution Panel (not included) connects to up to eight VST-TSTAT thermostats,

providing a convenient and effective method of wiring multiple thermostats to the control system's RS422

serial interface port.

The VST-DIST provides one RS422 interface to the control system and eight RS422 interfaces for the

thermostats.

Since the VST-DIST provides an RS422 interface to the control system, a MiniVerter (VST-MVRT)

is not required for communication.

The VST-DIST is intended for use with the VST-TSTAT, and is not intended for use with the VST,

which includes a MiniVerter.

The VST-DIST includes an Instruction Manual from the manufacturer with detailed

installation instructions, and a decal on the inside of the front cover (reproduced in

FIG. 7) gives wiring information for the panel.

ViewStat Communicating Thermostat

11

Page 18

ViewStat Installation and Wiring

Communications

Wire to Protocol Adapter,

other Distribution Panels or

directly to Automation System

A: Transmit B: Receive

REF

2

Rx+

Rx-

Tx+

Tx-

Switches

A - Allows Transmit

Communications

B - Allows Received

Communications

PWR - Turns power to

thermostat on/off

LEDs light when

communications are

transmitted (A)

or received (B)

24VAC

GND

3

ADDRESS #

ADDRESS #

ADDRESS #

ADDRESS #

Tra ns fo rm er

24 V, 40 VA minimum

up to 8 thermostats

C - 24 V (common) (-) if DC

R - 24 V (hot) (+ ) if DC

Main Power Switch

Turns main power to

Distribution Panel on/off

1

ADDRESS #

ADDRESS #

ADDRESS #

4

ADDRESS #

LED will light up when

power to thermostat is switched on

FIG. 7 Wiring the VST-TSTAT to a VST-DIST Distribution Panel

Mounting the Base to a Wall

There are four screw holes located on the base of the thermostat; two are for a junction box mounting, along

with two for alternate mounting spacing. Use one of the holes on the top and one on the bottom.

1. Place the base over the wire hole opening in the wall; level the base and mark the screw hole mounting

locations (leveling required for appearance only).

2. If using supplied wall anchors, drill 3/16" hole in the center of the marked locations and tap in the wall

anchors. If using the supplied screws only, drill a 3/32" hole in the center of the marked locations.

12

ViewStat Communicating Thermostat

Page 19

ViewStat Installation and Wiring

Minimize wire entry hole size and seal – drafts from inside the wall could affect

temperature readings.

3. Fasten the base to the wall with the supplied screws.

4. Seal wire entry using caulk, drywall putty or insulation.

Loss of internal programs may result from static discharge to thermostat circuit board.

Installer must touch a grounded metal object before handling the circuit board.

Connecting the ViewStat to AMX Control Systems

When a Mini Verter is used the Viewstat has a single RJ-45 jack on the rear panel, and uses ICSNet cabling to

connect to NetLinx or Landmark control systems.

The terms "PhastLink" and ICSNet" are essentially interchangeable within the

context of cabling/connectors. They both use a standard 10BaseT type connection

(i.e. Category 5 wire and RJ-45 connectors), and they share the same pinout

information for the RJ-45 jacks. Generally the term "PhastLink" is used when dealing

with Landmark, and "ICSNet" is used when describing NetLinx control systems.

The wires should be connected in the standard manner described in the following table. If standard EIA/TIA

568A/B color coding is followed, wiring problems will be minimized.

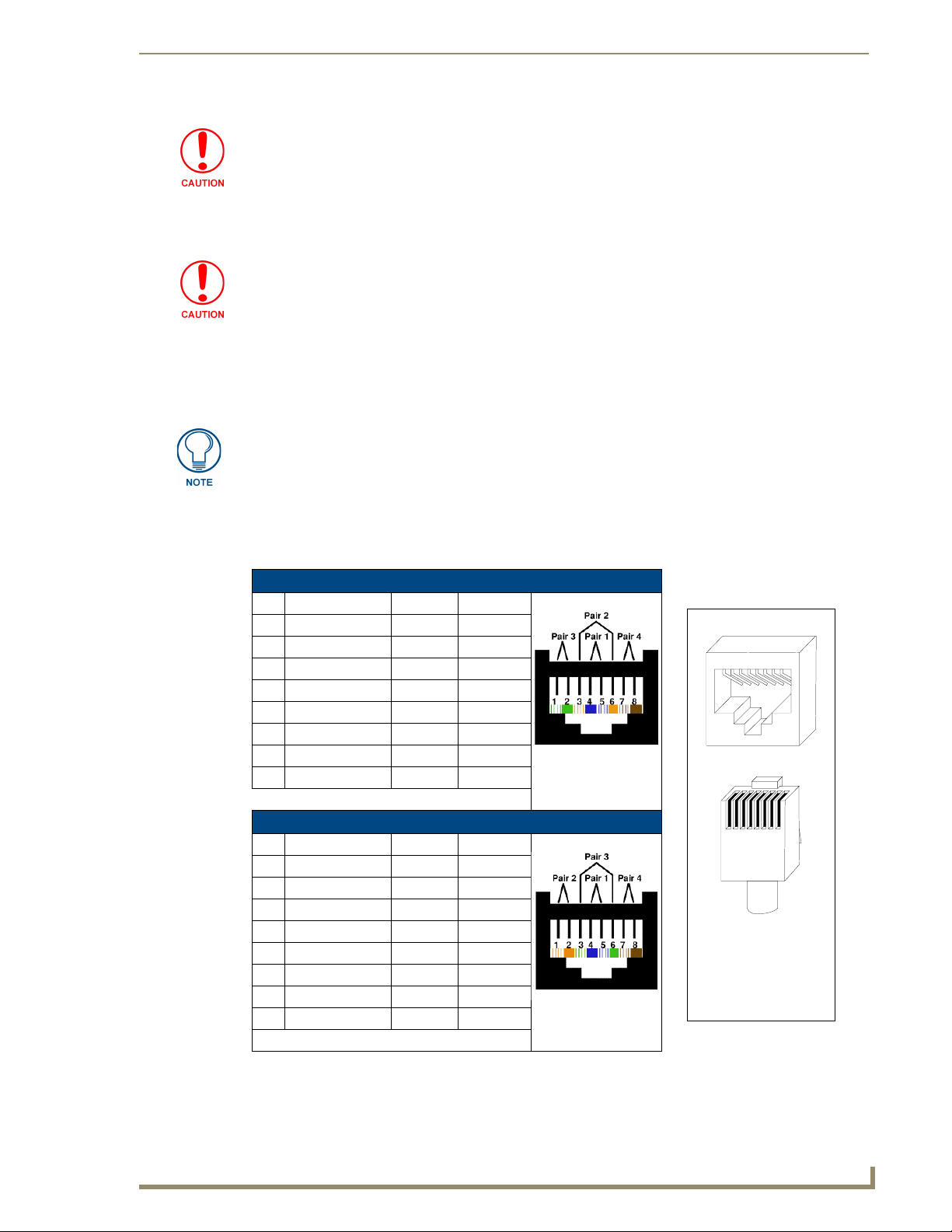

PHASTLink RJ-45 Pinout Information (EIA/TIA 568 A)

Pin W ire Color Polarity Function

1 White/Green + Transmit

2 Green - Transmit

3 White/Orange - Mic

4 Blue - Ground

5 White/Blue + 12 VDC

6 Orange + Mic

7 White/Brown + Receive

8Brown - Receive

TIA 568A

NetLinx RJ-45 Pinout Information (EIA/TIA 568 B)

Pin W ire Color Polarity Function

1 Orange/White + Transmit

2 Orange - Transmit

3 Green/White - Mic

4 Blue - Ground

5 White/Blue + 12 VDC

6 Green + Mic

7 White/Brown + Receive

8Brown - Receive

TIA 568B

1 2 3 4 5 6 7 8

(female)

1 2 3 4 5 6 7 8

RJ-45 connector pin configurations

(male)

ViewStat Communicating Thermostat

13

Page 20

ViewStat Installation and Wiring

It is important that the correct pairing is observed. Transmit, Receive, and Mic

need to be on twisted pairs. Splitting pairs (e.g., using a white/green wire with a blue/

white wire for transmit) will result in increased crosstalk, and may result in bus failure

or noise on the intercom.

Connecting to an Axcess Control System (via AXC-232++, AXB-EM232, or Axcent3/PRO)

To connect the ViewStat to an Axcess control system via an Axcess Cardframe (cardframe must be equipped

with an AXC-232 232/422/485 Control Card), AXB-EM232 Enhanced Master, or Axcent3(PRO) Controller,

refer to the card-edge pinout information below:

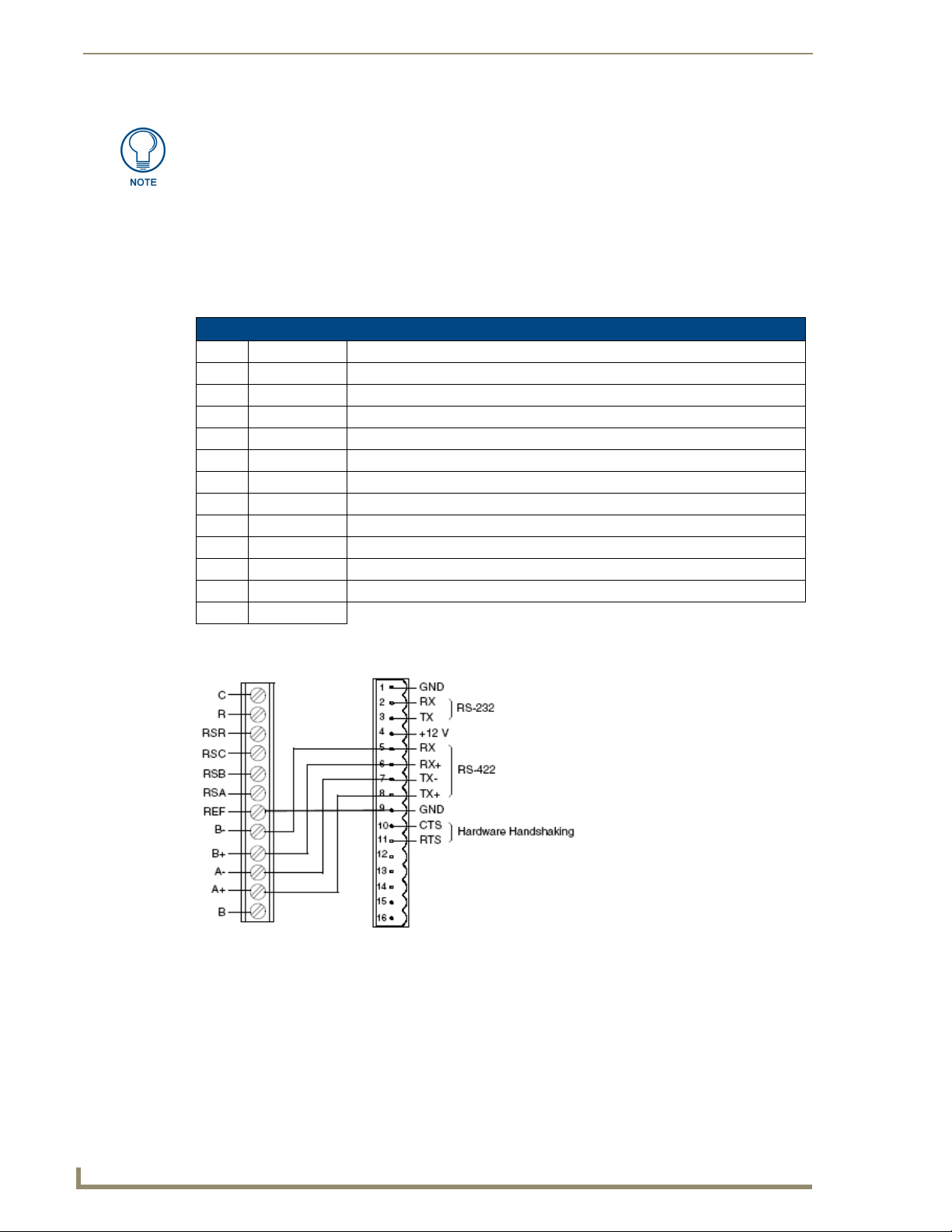

Axcess System Card Edge Pinouts

Pin Signal Function

1 GND Ground (RS-232)

2 RX Receive data (RS-232)

3 TX Transmit data (RS-232)

4 +12V Power

5 RX - Receive data (RS-422)

6 RX + Receive data (RS-422)

7 TX - Transmit data (RS-422)

8 TX + Transmit data (RS-422)

9 GND Ground

10 CTS Clear-to-send (hardware handshaking)

11 RTS Ready-to-send (hardware handshaking)

12-16 not used

FIG. 8 shows the wiring configuration for Axcess systems:

ViewStat

(Communication

terminal)

FIG. 8

Connecting the ViewStat to an Axcess Control System

Axcess

Control

System

AXC-232(++)

or

AXB-232(++)

14

ViewStat Communicating Thermostat

Page 21

ViewStat Installation and Wiring

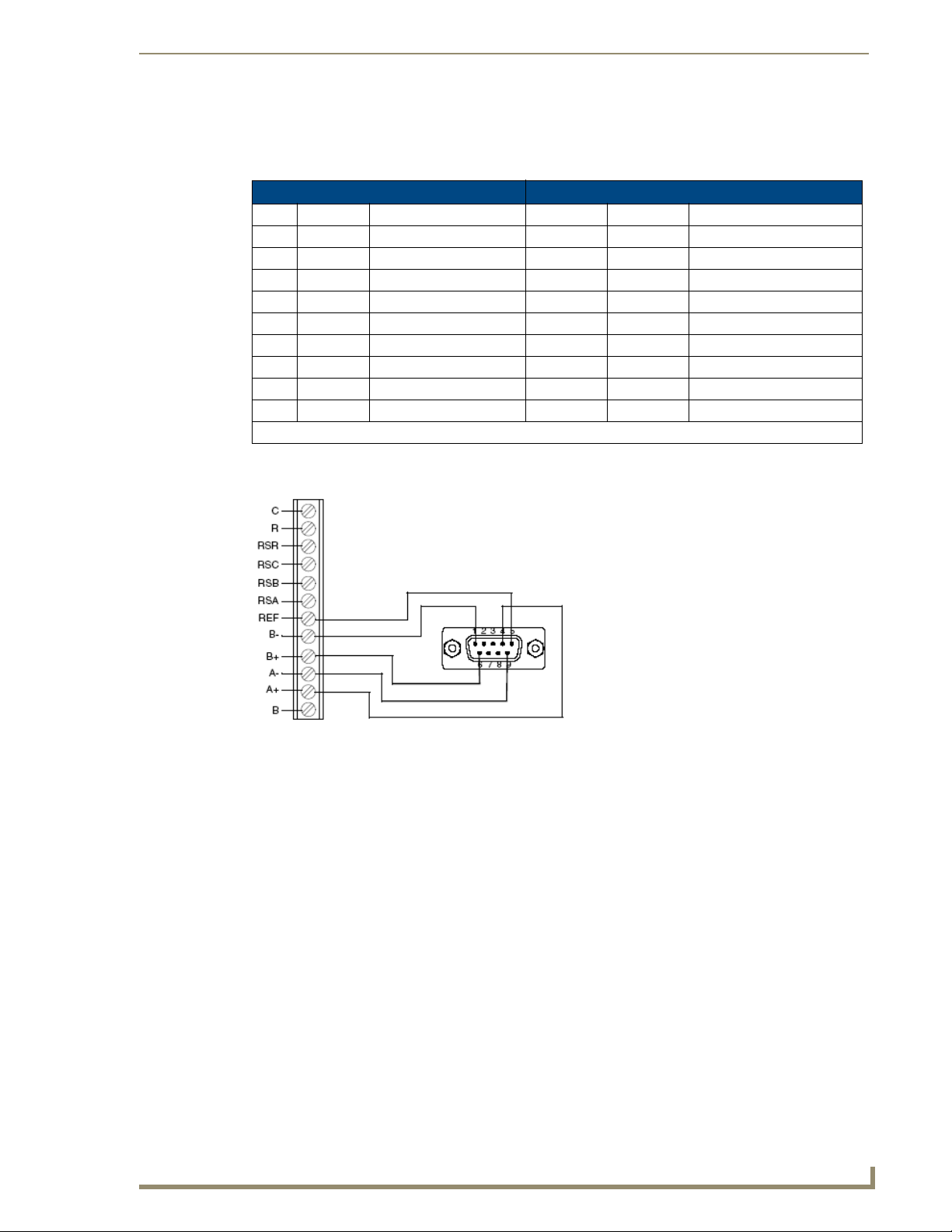

Connecting to an Axcess Master Controller via the RS232/422/485 (DB-9) Port

The table below lists the connector pins, signal types, and signal functions for RS-232/RS-422/RS- 485 DB-9

(male) connector on an Axcess Master Controller (i.e. Axcent3 or Axcent3/PRO).

DB-9 Pinouts Wiring and Baud Configurations

Pin Signal Function RS-232 RS-422 RS-485

1 RX- Receive data X X (strap to pin 9)

2 RXD Receive data X

3 TXD Transmit data X

4 TX+ Transmit data X X (strap to pin 6)

5 GND Signal ground X X

6 RX+ Receive data X X (strap to pin 4)

7 RTS Request to send X

8 CTS Clear to send X

9 TX- Transmit data X X (strap to pin 1)

The X’s show where to terminate the wires on the DB-9 connector.

FIG. 9 shows the wiring configuration for Axcess systems (using the DB-9 PROGRAM port).

ViewStat

(Communication

terminal)

FIG. 9

Connecting the ViewStat to an Axcess Control System via the RS232/422/485 (DB-9) port

ViewStat Communicating Thermostat

RS232/422/485

Por t

15

Page 22

ViewStat Installation and Wiring

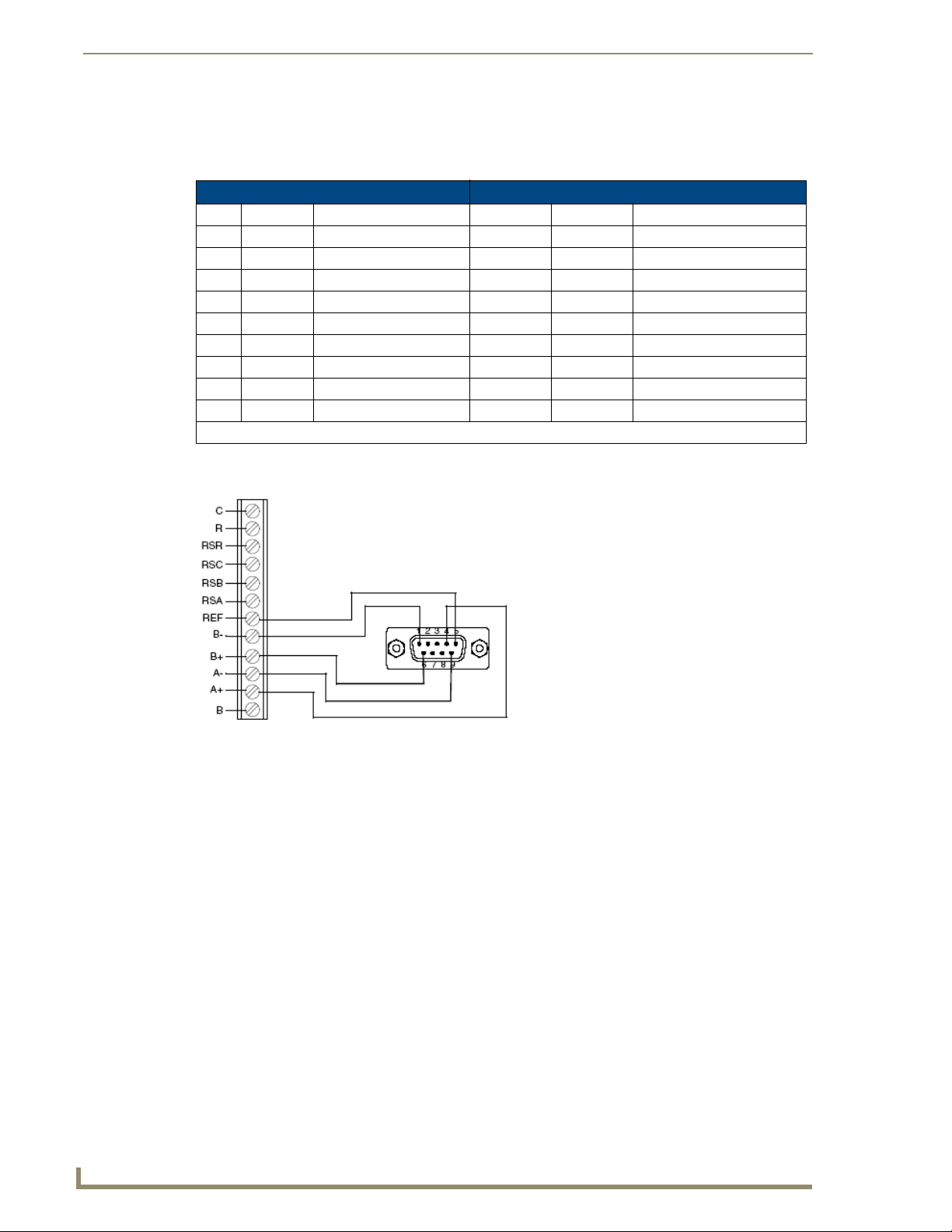

Connecting to NetLinx Integrated Controllers via the RS232/422/485 (DB-9) Port

The table below lists the connector pins, signal types, and signal functions for RS-232/RS-422/RS- 485 DB-9

(male) connector on an NetLinx Integrated Controllers (i.e. NI-2000/3000/4000).

DB-9 Pinouts Wiring and Baud Configurations

Pin Signal Function RS-232 RS-422 RS-485

1 RX- Receive data X X (strap to pin 9)

2 RXD Receive data X

3 TXD Transmit data X

4 TX+ Transmit data X X (strap to pin 6)

5 GND Signal ground X X

6 RX+ Receive data X X (strap to pin 4)

7 RTS Request to send X

8 CTS Clear to send X

9 TX- Transmit data X X (strap to pin 1)

FIG. 9 shows the wiring configuration for NetLinx systems (using the DB-9 PROGRAM port).

The X’s show where to terminate the wires on the DB-9 connector.

16

ViewStat

(Communication

terminal)

FIG. 10

RS232/422/485

Por t

Connecting the ViewStat to an NetLinx Integrated Control System via the RS232/422/485 (DB-9) port

ViewStat Communicating Thermostat

Page 23

ViewStat Installation and Wiring

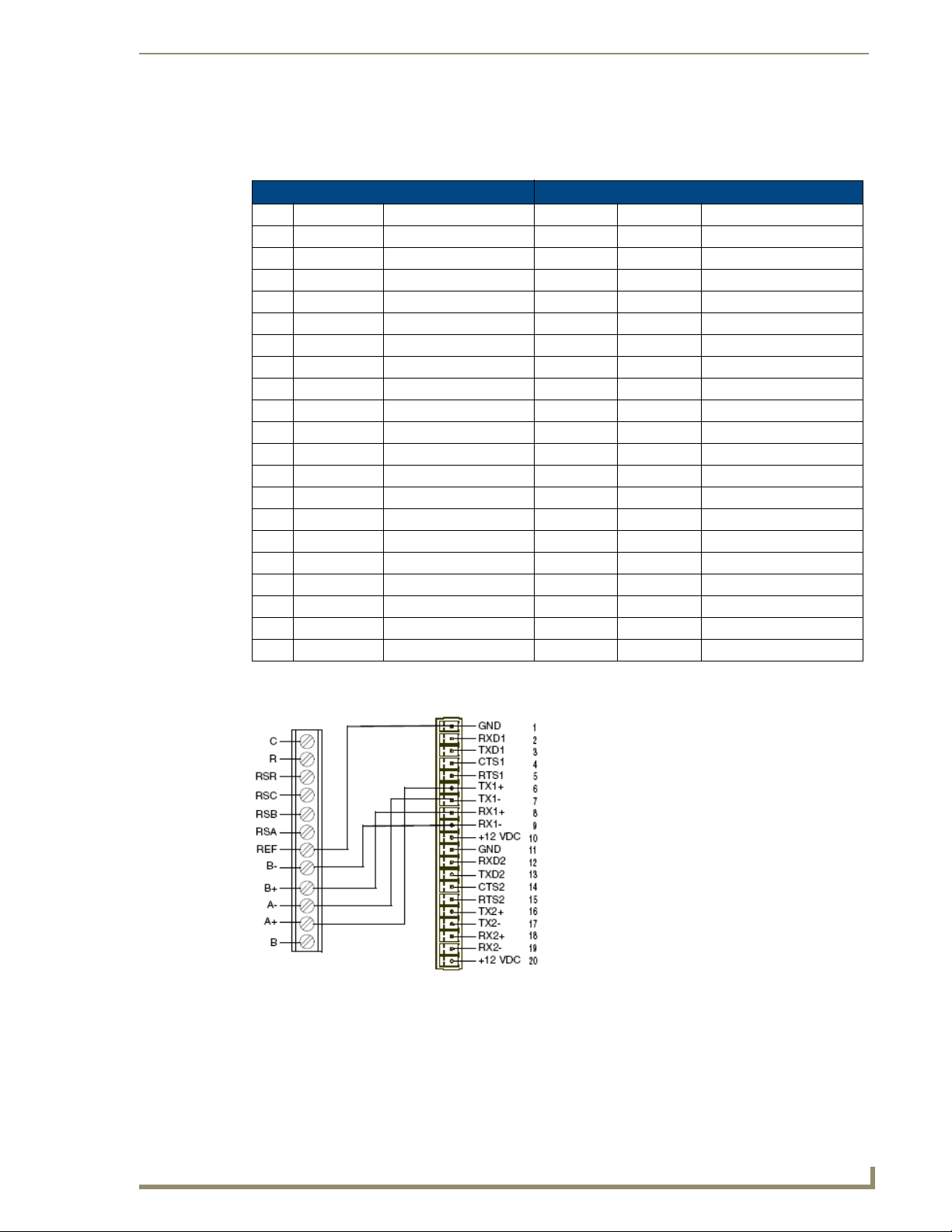

Connecting to a NetLinx Master controller via NXC-COM card

The Viewstat can connect to a NetLinx NXF Cardframe or NXI equipped with a NXC-COM Dual COM Port

Control Card. The following table shows the card edge pinout information for the NXC-COM card.

NXC-COM2 Pinouts NXC-COM2 Wiring Configuration

Pin Signal Function RS-232 RS-422 RS-485

1 GND Signal ground X X

2 RXD1 Receive data X

3 TXD1 Transmit data X

4 CTS1 Clear to send X

5 RTS1 Request to send X

6 TX1+ Transmit data X X (strap to pin 8)

7 TX1- Transmit data X X (strap to pin 9)

8 RX1+ Receive data X X (strap to pin 6)

9 RX1- Receive data X X (strap to pin 7)

10 +12 VDC Power Optional Optional

11 GND Signal ground X X

12 RXD2 Receive data X

13 TXD2 Transmit data X

14 CTS2 Clear to send X

15 RTS2 Request to send X

16 TX2+ Transmit data X X (strap to pin 18)

17 TX2- Transmit data X X (strap to pin 19)

18 RX2+ Receive data X X (strap to pin 16)

19 RX2- Receive data X X (strap to pin 17)

20 +12 VDC Power Optional Optional

FIG. 11 shows the wiring configuration for NetLinx systems.

ViewStat

(Communication

terminal)

FIG. 11

Connecting the ViewStat to a NetLinx Control System

ViewStat Communicating Thermostat

17

Page 24

ViewStat Installation and Wiring

Connecting to a LandMark Control System

PhastLink cables are used to connect all PhastLink-compatible devices, including keypads, dimmers, J-box IR

devices, amplifiers, audio switches, etc. The table below lists the RJ-45 pinout information.

RJ-45 Pinout Information

PinWire Color PolarityFunctio

1 White/Green + Transmit

2 Green - Transmit

3 White/Orange - Mic

4 Blue - Ground

5 White/Blue + 12 VDC

6 Orange + Mic

7 White/Brown + Receive

8 Brown - Receive

PhastLink uses a standard 10Base-T connection (i.e. Category 5 wire and RJ-45 connectors). The wire should

be connected in the standard manner. If a consistent color code is used, wiring problems will be minimized.

It is important that the correct pairing is observed. Transmit, Receive, and Mic need to be on twisted pairs.

Splitting pairs (e.g., using a white/green wire with a blue/white wire for transmit) will result in increased

crosswalk, and may result in bus failure or noise on the intercom.

n

Installing the Cat5 Suppression Ferrite

Before connecting the ICSNet cable, install the Cat5 Suppression Ferrite (provided), as described below (no

tools required):

Release the latch to

open the plastic

enclosure.

FIG. 12

Installing the Cat5 Suppression Ferrite

Insert the Cat5

cable and close

the enclosure.

Installation complete.

1. The Cat5 suppression ferrite is housed in a plastic enclosure, with a latch release on one side. Pull to

release the latch and open the enclosure.

2. Insert the Cat5 cable.

3. Snap the enclosure shut with the cable inside, and you’re done.

Connecting to a NetLinx Control System

To connect a single ViewStat to a NetLinx control system, use ICSNet cabling to connect the

RJ-45 jack on the ViewStat to any available ICSNet jack on the NetLinx Master. The maximum cabling

distance between the ViewStat and Master is 1,000 ft (304.8 m).

To connect multiple ViewStats to a NetLinx system, use a NetLinx Hub (NXC-NH) to add additional ICSNet

ports to the system, connect the RJ-45 jack on the ViewStat to an available ICSNet jack on the Hub.

18

ViewStat Communicating Thermostat

Page 25

ViewStat Installation and Wiring

Connecting to a Landmark Control System

To connect a single ViewStat to a Landmark control system, use PhastLink cabling to connect the RJ-45 jack

on the ViewStat to any available PhastLink jack on the Landmark Master (MCU). The maximum cabling

distance between the ViewStat and MCU is 1,000 ft (304.8 m).

To connect multiple ViewStats to a Landmark system, use a Landmark Hub (PLH-RPT) to add additional

PhastLink ports to the system, connect the RJ-45 jack on the ViewStat to an available PhastLink jack on the

Hub.

Connecting the ViewStat to the HVAC System

Before connecting the ViewStat to the

HVAC system, install the 24 VAC

Suppression Ferrite, to eliminate any

potential noise problems.

Installing the 24 VAC Suppression Ferrite

Before connecting the 24 VAC power supply cable to the HVAC system, install the 24 VAC Suppression

Ferrite (provided), as described below (no tools required):

Pass the 24VAC power cord

through the ferrite bead.

FIG. 13 Installing the 24 VAC Suppression Ferrite

Loop the cable around

and pass it through

the ferrite bead again.

Gently pull the cable

to eliminate excess

slack - installation

complete.

1. Pass the 24 VAC power cable through the ferrite bead once.

2. Loop the cord around, and pass it through the ferrite bead once more.

3. Gently remove any excess slack in the cable, and you’re done.

ViewStat Communicating Thermostat

19

Page 26

ViewStat Installation and Wiring

Wiring the Thermostat

1. Strip 1/4" (0.63 cm) of insulation from each wire to be used.

2. Secure wires into the terminals on the base according to the appropriate wiring diagram, as described in

the following table. Refer to the Wiring Diagrams section on page 26. Use color-coding practices (i.e.

white wire to W terminal) whenever possible.

3. Check each wire to ensure it is securely fastened, not broken, and exposed wires are not touching.

Communication and Equipment terminal wiring definitions

The following table describes the Communication and Equipment terminal wiring definitions (see FIG. 5 on

page 10).

• Single Stage Furnace & AC Refer to FIG. 18 on page 26

• Two Stage Furnace & Two Stage AC Refer to FIG. 19 on page 27

• Roof Top Unit (Two Stage Heat & Two Stage Cool) Refer to FIG. 20 on page 28

• Boiler with AC (Two Transformers) Refer to FIG. 21 on page 29

• Single Stage Heat Pump Refer to FIG. 22 on page 30

• Two Stage Heat Pump Refer to FIG. 23 on page 31

• First Stage Radiant Floor Heat

Second Stage Furnace One Stage of Cooling

Refer to FIG. 24 on page 32

Communication and Equipment Terminal Wiring Definitions

Communication Terminal

C Thermostat Voltage (common)

R Thermostat Voltage (hot)

RSR (support module) Thermostat Voltage (hot)

RSC (support module) Thermostat Voltage (common)

RSB/RSA (support module) Support module communication (half-duplex)

REF Ground Reference

B-/B+ Receive

A-/A+ Transmit

Equipment Terminal

RC Switched Voltage (cool)

RH Switched Voltage (heat)

RV COOL (O) Reversing Valve - Cool (energized in Cool mode)

RV HEAT (B) Reversing Valve - Heat (energized in other modes)

GFan

HUM/W1 1st stage Heat (non-heat pump)

-or3rd stage Heat AND 1st Stage Emergency Heat (heat pump)

-orHumidification (with humidity control sensor)

20

ViewStat Communicating Thermostat

Page 27

ViewStat Installation and Wiring

Communication and Equipment Terminal Wiring Definitions (Cont.)

Equipment Terminal (Cont.)

DEH/Y1 1st stage Cooling (non-heat pump)

-or1st stage Compressor (heat pump)

-orDehumidification (with humidity control sensor)

W2 2nd stage Heat (non-heat pump)

-or2nd stage Emergency Heat (heat pump)

Y2 2nd stage Cooling (non-heat pump)

-or2nd stage Compressor (heat pump)

Connecting the ViewStat to the HVAC System

A qualified HVAC technician should perform these steps step to ensure proper

termination.

1.

Make sure the HVAC system power is off.

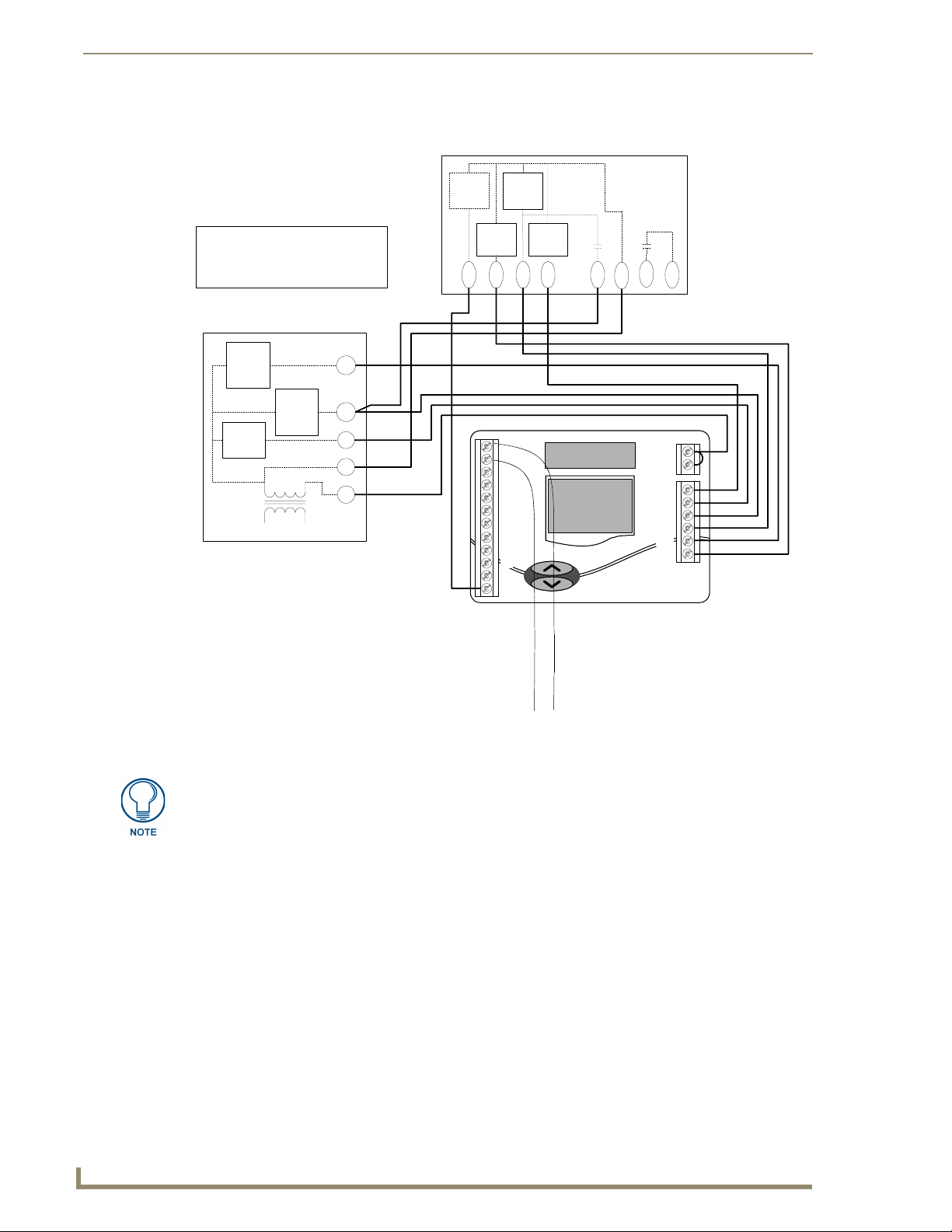

2. The following figures (FIG. 14, FIG. 15) show wiring diagrams for several different HVAC equipment

types. Use these diagrams as a reference only. Use color coding where possible.

a. FIG. 14 shows a typical heat/cool wiring schematic:

MULTI-STAGE FURNACE

2ND

STAGE

HEAT

FAN

RELAY

2ND STAGE

1ST STAGE

1ST

STAGE

HEAT

24

VAC

L2

120

VAC

COOL

COOL

L1

Y2

W2

Y1

W1

G

C

R

MULTI-STAGE A/C

2ND

1ST

STG

COOL

STG

COOL

Y2

Y1

C

CAUTION!

ENSURE HVAC SYSTEM POWER

IS OFF BEFORE WIRING

(common)

(from MiniVerter)

FIG. 14 Typical heat/cool wiring schematic

USE 18-20 GA. THERMOSTAT CABLE. NUMBER OF CONDUCTORS

REQUIRED DEPENDS ON THE HVAC SYSTEM BEING CONTROLLED

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

B

REFER TO THE THERMOSTAT INSTALLATION SHEET FOR

INTERNAL SCHEMATIC, THERMOSTAT CHECK-OUT

PROCEDURES AND OTHER HVAC WIRING DETAILS

Black

Red

(power)

RC

RH

O

G

W1

Y1

W2

Y2

ViewStat Communicating Thermostat

21

Page 28

ViewStat Installation and Wiring

b. FIG. 15 shows a typical heat/cool wiring schematic:

OUTDOOR HEAT PUMP UNIT

USE 18-20 GA. THERMOSTAT CABLE. NUMBER

OF CONDUCTORS REQUIRED DEPENDS ON THE

HVAC SYSTEM BEING CONTROLLED

CAUTION!

ENSURE HVAC SYSTEM POWER

IS OFF BEFORE WIRING

INDOOR BLOWER/HEAT

REFER TO THE THERMOSTAT INSTALLATION

SHEET FOR INTERNAL SCHEMATIC, THERMOSTAT

CHECK-OUT PROCEDURES AND OTHER HVAC

WIRING DETAILS

2ND

STAGE

AUX.

HEAT

FAN

RELAY

UNIT

W2

1ST

STAGE

AUX.

HEAT

24

VAC

L2

120

VAC

W1

G

C

R

L1

REV

VALVE

HEAT

COMP.

B

2ND

STG

Y2

C

R

RSR

RSC

RSB

RSA

REF

BB+

AA+

B

1ST

STG

COMP.

Y1

REV

VALVE

COOL

DEFROST

O

W1

SERVICE

L

C

R

RC

RH

O

G

W1

Y1

W2

Y2

Red

(power)

Black

(common)

(from MiniVerter)

FIG. 15 Typical heat pump wiring schematic

For additional HVAC system wiring diagrams (for Single-Stage Furnace and AC,

Two-Stage Furnace and Two-Stage AC, Roof-Top Unit (Two-Stage Heat and TwoStage Cool), Boiler With AC (Two Transformers), and Single Stage Heat Pump

Configurations, refer to the Wiring Diagrams section on page 26.

22

ViewStat Communicating Thermostat

Page 29

ViewStat Installation and Wiring

Checking HVAC System Operation

Use the thermostat buttons to verify that the thermostat is controlling the equipment operation. A checkout

procedure is supplied in the installation instructions supplied with thermostat. This procedure will verify only

that the thermostat operates the equipment.

The HVAC installer may need to connect 24VAC to the R and C terminals to check HVAC operation. If the

automation system is to be installed after the HVAC installation, leave the R and C terminals connected to

ensure the HVAC system operates. If the automation system is installed before either the placement of HVAC

wiring or an external power supply is used, then do not connect HVAC wires to R and C.

When the thermostat is first turned on all of the graphics of the main LCD are momentarily displayed; this will

look like FIG. 16.

Message display

Scroll/Set-Up buttons

Main (LCD) display

Adjust buttons

FIG. 16 Front panel (with all graphics on Main LCD displayed)

Check Out Procedure

The following check-out procedure will turn the heating and cooling equipment on

and off. Do not operate in cooling at low outdoor temperatures. Do not operate in

heating at high outdoor temperatures. Refer to the HVAC equipment manufacturer

specifications for safe operating temperatures.

Use the Check Out procedure (below) to determine if the thermostat is controlling the HVAC equipment.

1. Press the Mode button, and look for the OFF message on the Main display.

2. Press the Fan button. The system blower should start and the message FAN ON appears on the Main

display. Press Fan again to stop.

3. Press the Mode button until the COOL message appears, along with the current cool setting on the Main

display.

4. Use the down arrow button to lower the set point 3°F below room temperature. In 5 to 10 seconds the

first stage of cooling begins, and the COOL message icon begins to flash. If there is a second stage it will

begin in four minutes.

5. Press the Mode button until OFF appears n the Main display. During Check-out, change the mode to

override the Minimum On time delays.

6. Press the Mode button until the HEAT message appears, along with the current heat setting in the Main

display.

ViewStat Communicating Thermostat

23

Page 30

ViewStat Installation and Wiring

7. Use the up arrow button to raise the set point 3°F above room temperature. In 5-10 seconds, the first stage

of heating begins and the HEAT message icon begins to flash. If there is a second stage it will begin in 4

minutes.

Heat Pump Only: The message HEAT -AUX is displayed when the auxiliary heat terminal (W1) is

energized. The LED on top of the thermostat will illuminate.

8. Press the Mode button until OFF appears in the Main display. During Check-out, change the mode to

override the minimum On time delays.

9. Press the Mode button until EM.HEAT appears on the Main display. Repeat step 7 to verify Emergency

Heat operation.

Optional HVAC Set-Up Features

There are a number of HVAC features that can be configured for the particular application. These include

temperature control options, display options and high/low balance points (heat pumps only).

Temperature control options

Balance points

Display options

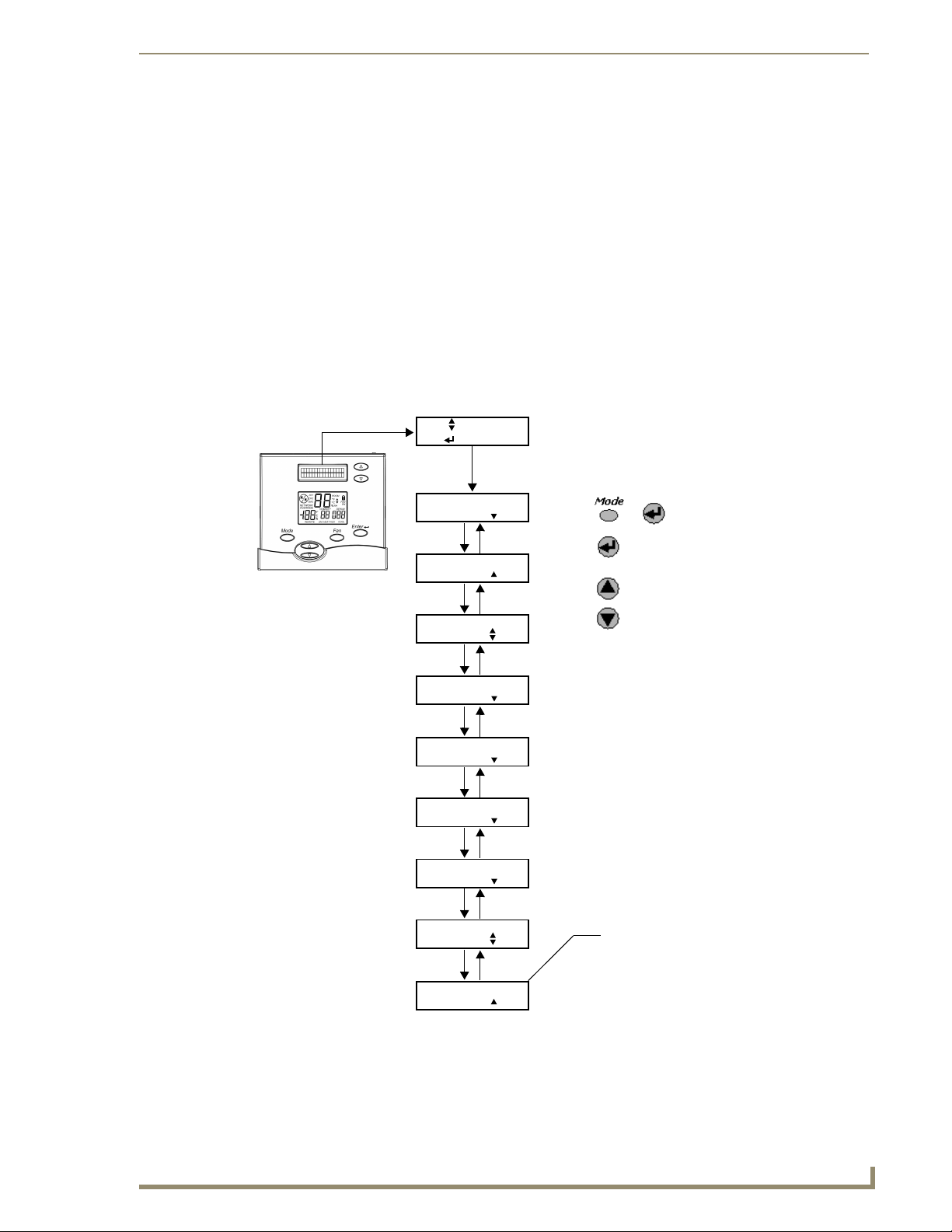

To access these HVAC set-up features

When first powered up, the message display will scroll through the current mode status, fan status, and

heating/cooling output status. This is referred to as Passive Display because you do not interact with it. To get

into the Set-Up Menu, press the Enter and Mode buttons at the same time. This is referred to as User

Interactive Display, as the user navigates through various menu and sub-menu selections to change variables.

Set-Up is menu driven but only one menu item is visible at a time. FIG. 32 on page 39 shows the entire Main

Menu. Selecting any one of the Main Menu items (by pressing the Enter button) will enter a corresponding

Sub-Menu. The Scroll Up and Scroll Down buttons are used to move between menu items or change values.

The Enter button is used to select a menu item or enter a value. When in Thermostat Set-Up, if none of the

three navigation buttons are pressed in 5 minutes, the display will return to Passive Display.

For detailed information on accessing and using the various Set-Up menus, refer to the Set Up and

Configuration section on page 39.

Address the Thermostats and Set Highest Address

These steps must be done at each thermostat for communication to work properly.

1. Press the Mode and Enter buttons simultaneously at the thermostat. It may take a couple of tries to get

them pressed together.

This will enter the Thermostat Set Up Menu. The first menu item that will appear on the text messaging

display is an informational item that indicates that only the Scroll Up, Scroll Down (two buttons located

immediately to the right of the text display) and the Enter buttons are used in thermostat set up. This will

remain on the display for approximately 5 seconds or until any of the three aforementioned buttons are

pressed. Thermostat Set Up is a series of sub-menu's that allow you to customize the ViewStat in various

ways. The Set Up and Configuration section on page 39 outlines the set up features. The following steps

will guide you only through Communications Set Up sub-menu (FIG. 17).

2. Press the Scroll Down button until the "Communications Set Up" menu shows on the display.

3. Press the Enter button to select this menu.

4. The first sub-menu item is "Set Thermostat ADDRESS". Press the Enter button to select this item.

5. Set the address between 1 and 64 using the Scroll Up and Scroll Down buttons.

Each thermostat must have a unique address (i.e. no two thermostats can have the same address)

Start with address 1 and increment by 1 for each new address - do not skip an address. This will

optimize communications speed.

24

ViewStat Communicating Thermostat

Page 31

ViewStat Installation and Wiring

Communica tions

Set Up More

FIG. 17 Setting the thermostat address

Set Thermostat

Address

Set Baud

Rate More

EXIT

Next

Network Address

1 to 64

No.of T-stats On

the Network

Select

Back

Write down the address for each thermostat.

9600

6. After the address has been selected, press the Enter button to store the address.

7. Use the Scroll Up and Scroll Down buttons to set the "Number of Stats on the Network" to the highest

address that will be on the thermostat network. This will be equal to the total number of thermostats on

the network (unless one or more addresses are skipped - see step 5).

This number must be set the same at each thermostat.

8. Press Enter to set the baud rate. The ViewStat must be set for 9600 baud to communicate with the

miniverter. This is the default setting, and you shouldn’t ever change this setting.

9. Press Enter to "Exit" the Communications Set Up sub-menu. This will return you to the main menu.

10. Press the Scroll Down button until "Exit" is displayed. Press the Enter button. The thermostat will then

reset and return to normal operation.

ViewStat Communicating Thermostat

25

Page 32

ViewStat Installation and Wiring

Wiring Diagrams

Single-stage furnace and AC configuration.

ViewStat

FIG. 18 Single-stage furnace and AC configuration

Red

(power)

(from MiniVerter)

Black

(common)

26

ViewStat Communicating Thermostat

Page 33

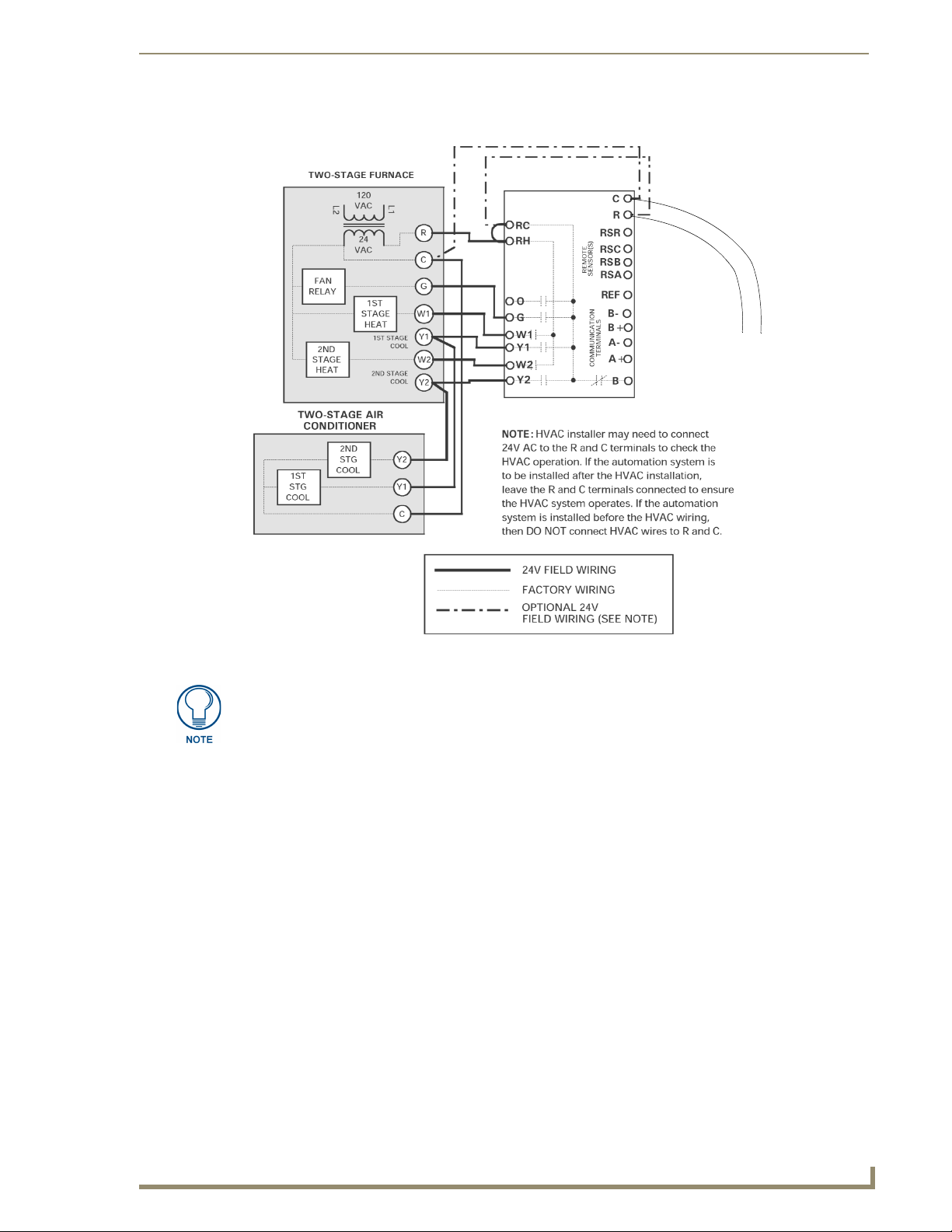

Two-stage furnace and two-stage AC configuration.

ViewStat

ViewStat Installation and Wiring

Red

(power)

(from MiniVerter)

FIG. 19 Two-stage furnace and two-stage AC configuration

IMPORTANT! The B terminal is for reversing valve-heat. DO NOT connect the B

terminal to the common side of the transformer.

Black

(common)

ViewStat Communicating Thermostat

27

Page 34

ViewStat Installation and Wiring

Roof top unit (two-stage heat and two-stage cool) configuration.

ViewStat

Red

(power)

(from MiniVerter)

FIG. 20 Roof top unit (two-stage heat and two-stage cool) configuration

Black

(common)

IMPORTANT! The B terminal is for reversing valve-heat. DO NOT connect the B

terminal to the common side of the transformer.

28

ViewStat Communicating Thermostat

Page 35

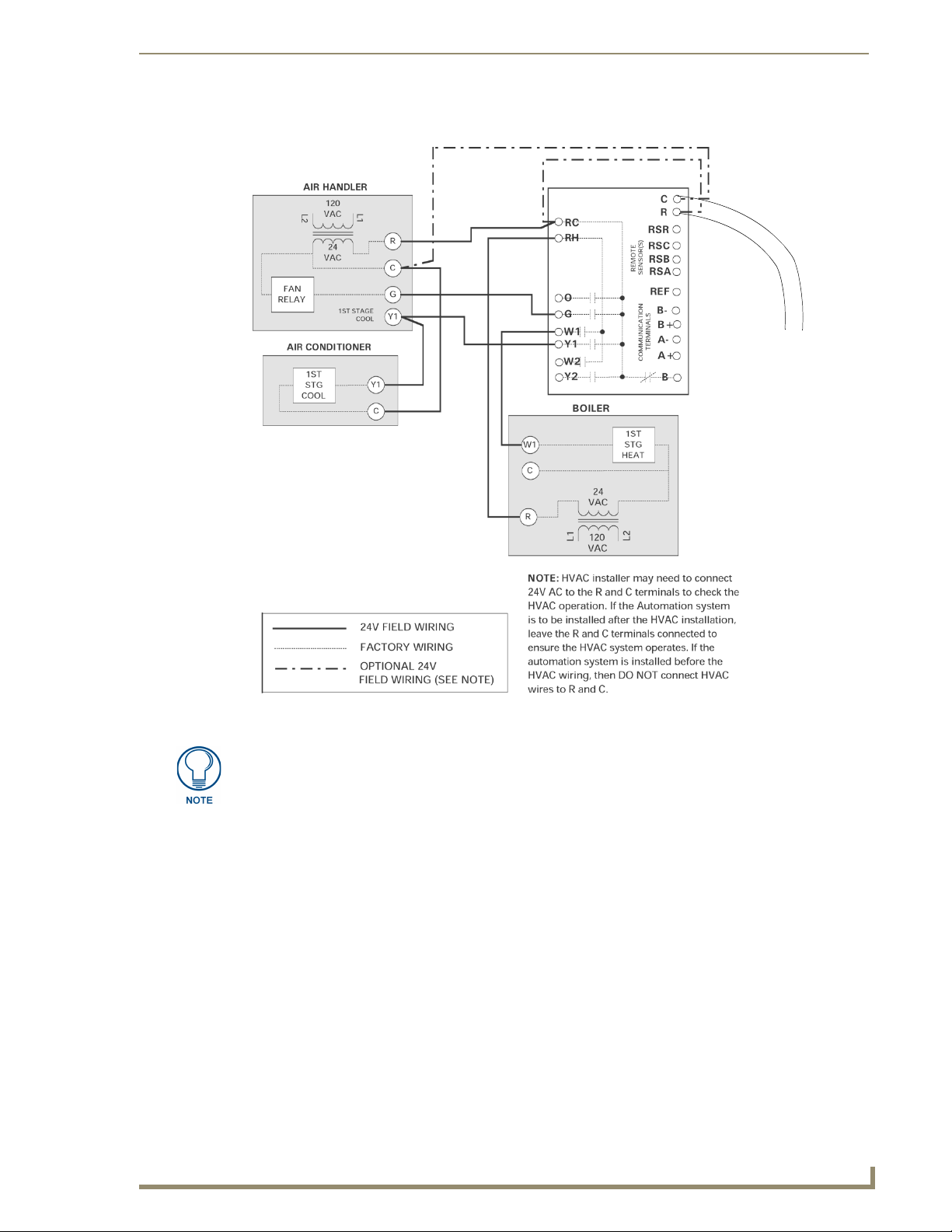

Boiler with AC (two transformers) configuration.

ViewStat Installation and Wiring

ViewStat

FIG. 21 Boiler with AC (two transformers) configuration

Red

(power)

(from MiniVerter)

Black

(common)

IMPORTANT! The B terminal is for reversing valve-heat. DO NOT connect the B

terminal to the common side of the transformer.

ViewStat Communicating Thermostat

29

Page 36

ViewStat Installation and Wiring

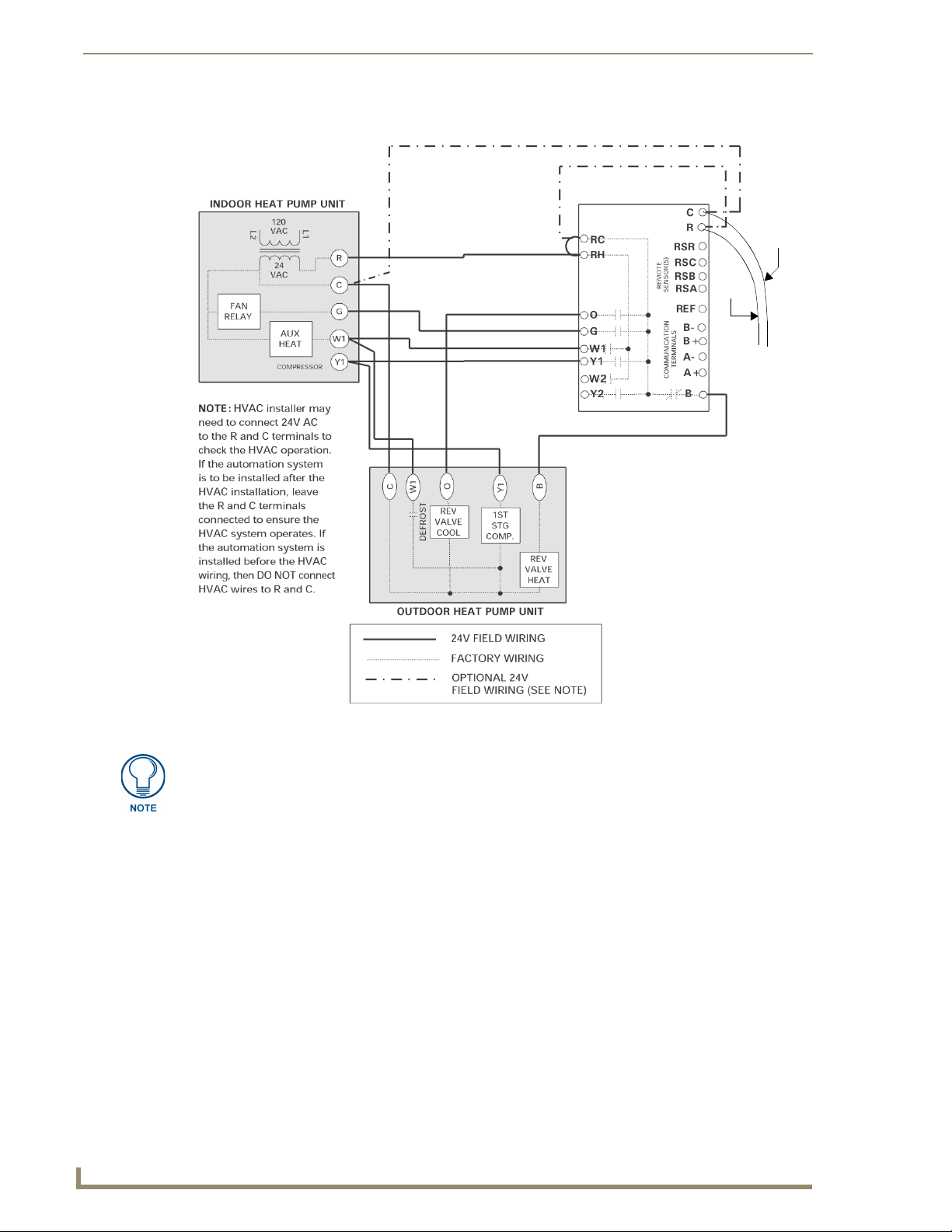

Single-stage heat pump configuration

ViewStat

Black

(common)

Red

(power)

(from MiniVerter)

FIG. 22 Single-stage heat pump configuration

IMPORTANT! The B terminal is for reversing valve-heat. DO NOT connect the B

terminal to the common side of the transformer.

30

ViewStat Communicating Thermostat

Page 37

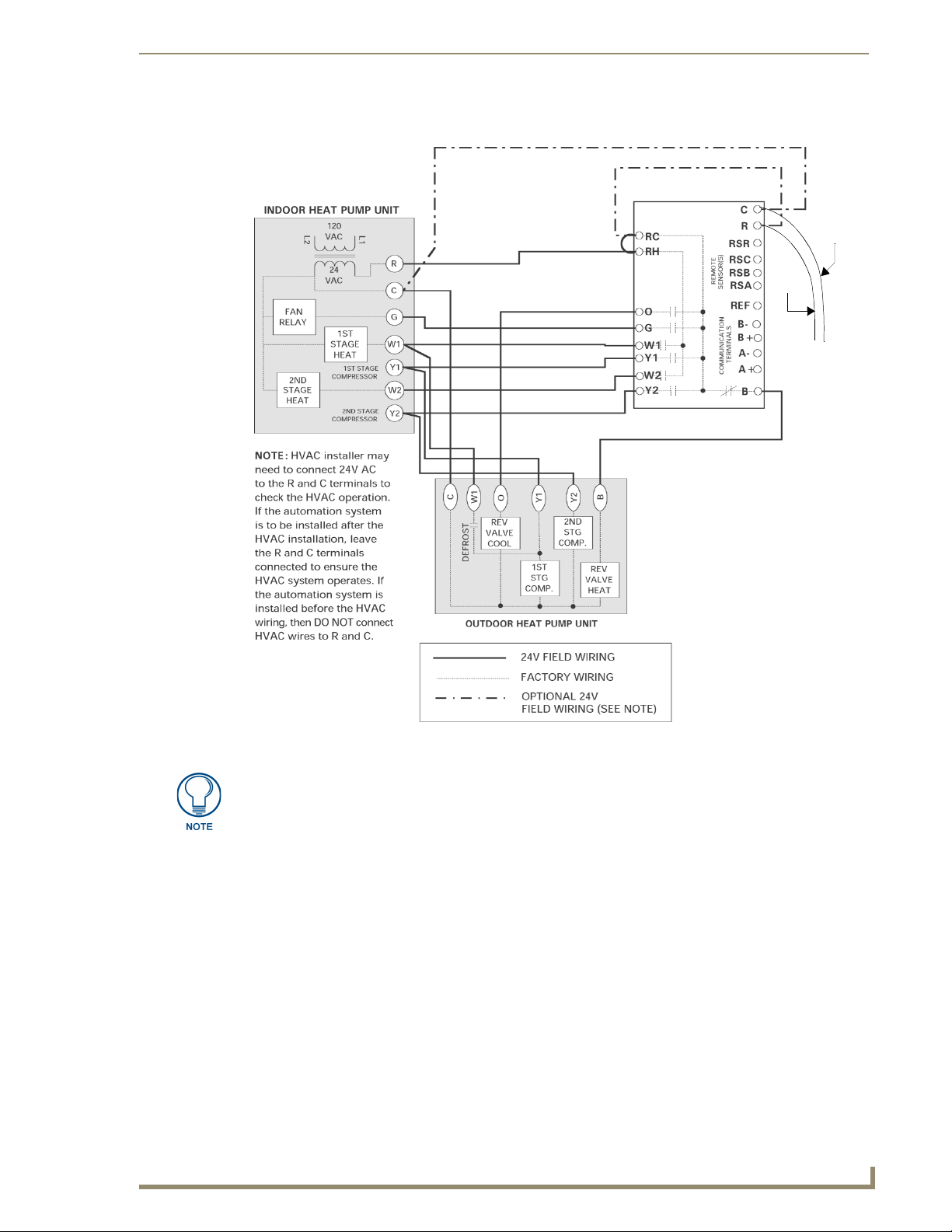

Two-stage heat pump configuration.

ViewStat Installation and Wiring

ViewStat

Black

(common)

Red

(power)

(from MiniVerter)

FIG. 23 Two-stage heat pump configuration

IMPORTANT! The B terminal is for reversing valve-heat. DO NOT connect the B

terminal to the common side of the transformer.

ViewStat Communicating Thermostat

31

Page 38

ViewStat Installation and Wiring

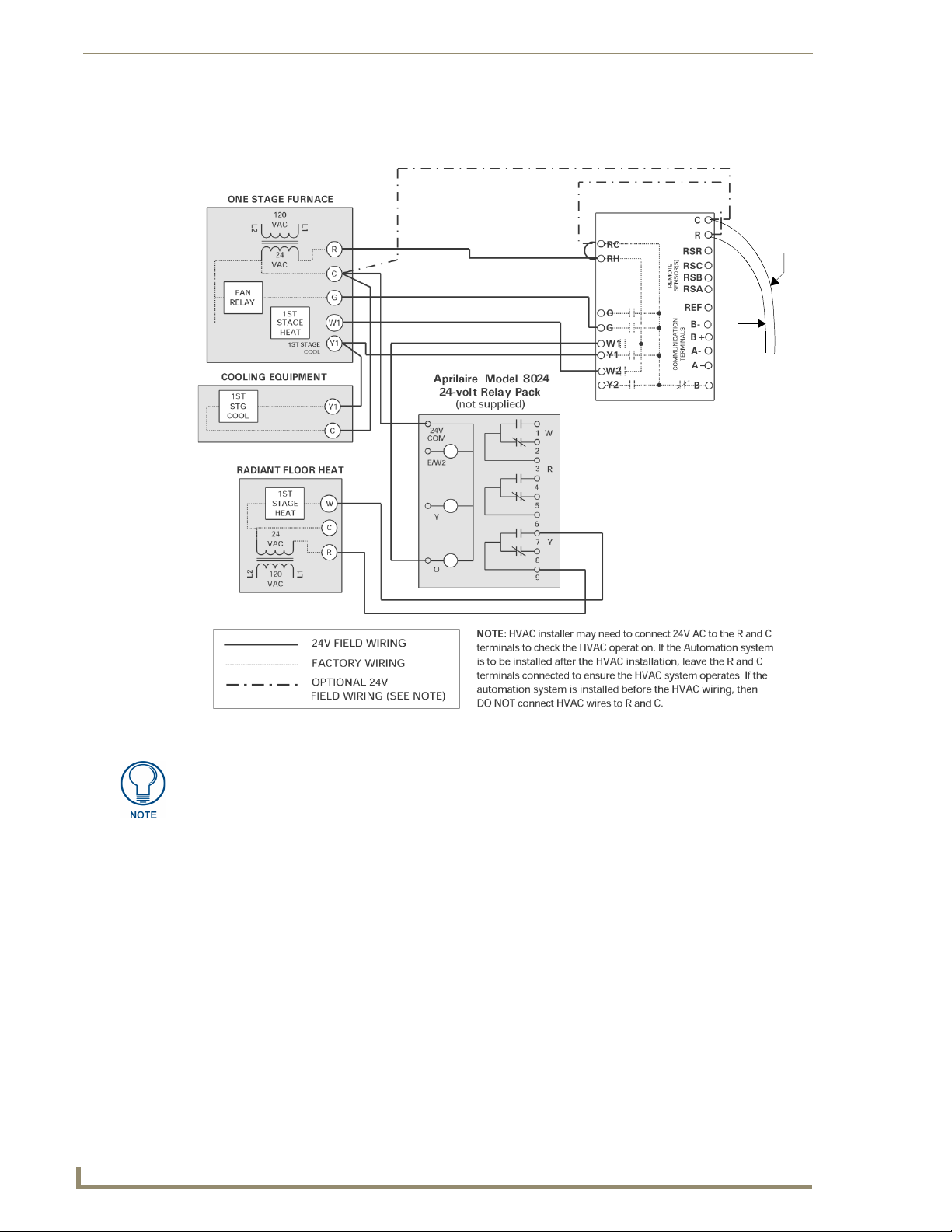

First- stage radiant floor heat, second-stage furnace one stage of cooling configuration.

ViewStat

Black

(common)

Red

(power)

(from MiniVerter)

32

FIG. 24 First-stage radiant floor heat, second-stage furnace one stage of cooling configuration

IMPORTANT! The B terminal is for reversing valve-heat. DO NOT connect the B

terminal to the common side of the transformer.

ViewStat Communicating Thermostat

Page 39

Support Module Installation and Wiring

Support Module Installation and Wiring

Follow the guidelines for placement of the support modules (as described below), and locate the ViewStat

indoors where the operating range of the ViewStat (32° - 99°F/0° - 37°C) will not be violated (i.e. do not

install in a cold garage or hot equipment room). Refer to the Support Module Specifications section on page 3

for more information on the modules.

The thermostat will display one of the following sets of information:

The remote temperature on the support module at address 1 if its mode is set to "control".

The average temperature of all support modules set to "control".

The humidity of the VST-TRH sensors set to the "control" mode.

Installing the VST-TTM and VST-TRH Support Modules

Choosing a mounting location

In choosing a mounting location for the support module(s), locate an interior wall surface in an area free from

drafts. The maximum distance from the thermostat is 1000 ft. (304.8 m).

Do not mount support module on an exterior wall.

Avoid routing wires near sources of noise such as computer monitors or fluorescent lights.

Single Support Module Installation

Install the Viewstat according to the instructions in the ViewStat Installation and Wiring section on

1.

page 7. Check to ensure that thermostat is operating (display shows correct temperature).

Remove the thermostat from its sub-base before wiring the support module to avoid

damage from live wire.

2. Choose the wall location where the VST-TTM or VST-TRH module will be mounted. Run CAT-5 wire

from the thermostat to the support module location

(max distance = 1000 ft./304.8 m).

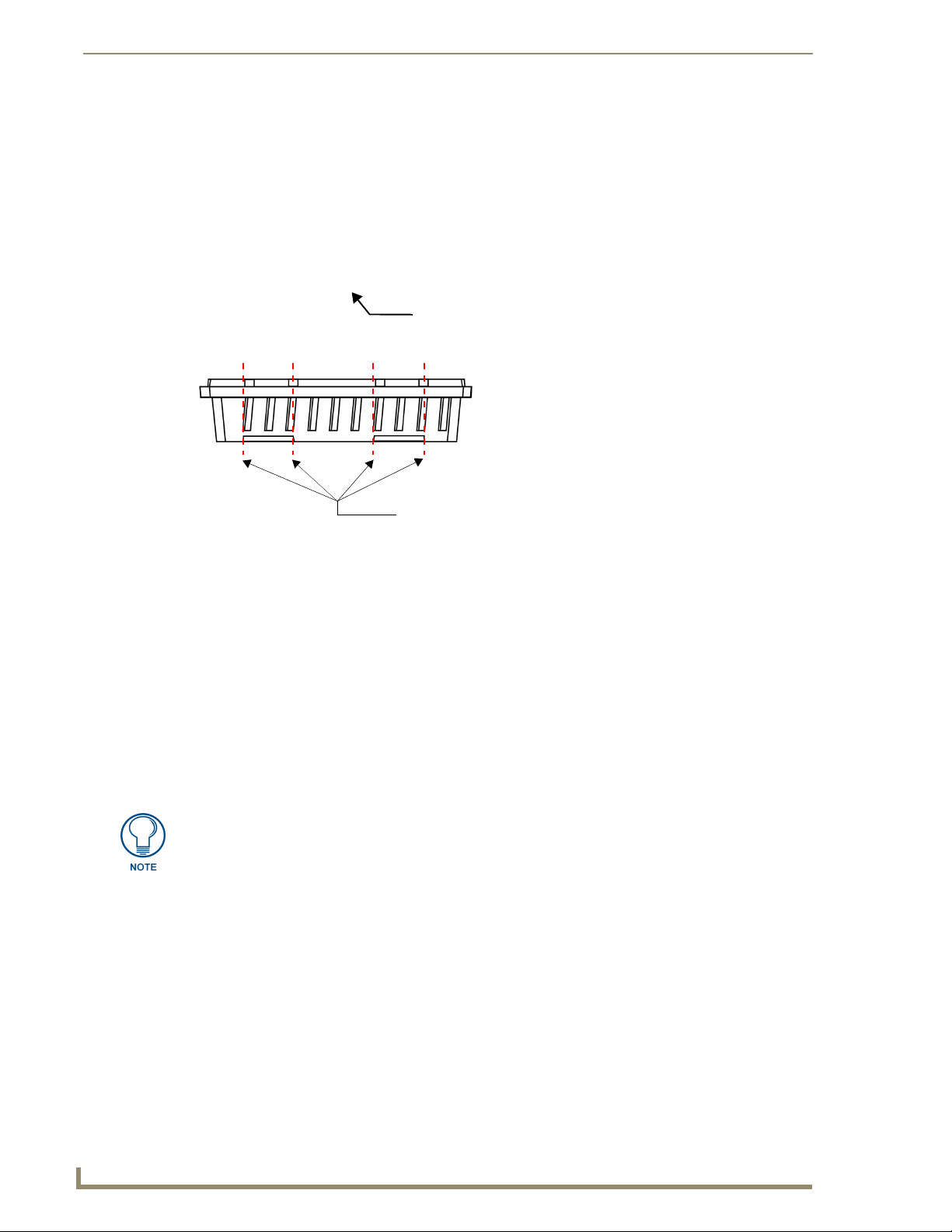

3. Open the support module case by pulling the cover straight forward, as shown in FIG. 25:

FIG. 25 Opening the support module case

4. Remove the circuit board from the base by pulling back the latch that holds it at the bottom center, as

shown in FIG. 26:

5. Use the sub-base as a template to mark the mounting hole locations on the wall. The word "TOP" is

written in the sub-base. Position the sub-base so that the wires can be pulled through the hole in the top

left-hand corner. Drill size for the wall anchors is 3/16 inch. Mount the

sub-base using the two #6 screws and anchors provided (larger screws will prevent the circuit board from

properly snapping into place).

If side access is preferred for wiring, clip out the side vents on the scored lines (FIG. 27).

ViewStat Communicating Thermostat

33

Page 40

Support Module Installation and Wiring

FIG. 26 Removing the circuit board

Pull down

Cut here for access

FIG. 27 For side access, cut out the side vents on the scored lines.

6. Snap the circuit board back into the sub-base by sliding the top of the board in first and then snapping

down on the bottom. Check to be sure that the latch holds the board properly.

7. Strip ¼ inch of insulation from the four wires at the support module. Install the wires in the terminals

labeled RSR, RSC, RSB and RSA. One twisted pair of wires should be used for the RSR and RSC

connection and another pair of twisted wires should be used for the RSB and RSA connection. Push the

extra wire back into the wall cavity. Seal the hole in the wall around the cable to eliminate any draft that

might affect the sensor.

8. Connect the wires on the thermostat sub-base to the terminals labeled RSR, RSC, RSB and RSA on the

ViewStat base (see FIG. 5 on page 10) and the Communication and Equipment Terminal Wiring

Definitions table on page 20). Make sure that each terminal on the support module is wired to the

terminal with the same label at the thermostat.

9. If necessary, change the Support Module DIP switch settings as described in Setting the Support Module

DIP Switches section on page 35.

DIP switches must be set prior to powering the support module (support module is

powered when thermostat is returned to its base). If switches need to be changed

after powering the support module, the thermostat must be removed from its base for

a minimum of 15 seconds to ensure proper reset of the support module.

10. Mount the thermostat on the sub-base and confirm that it is displaying the right temperature from the

support module or remote sensor.

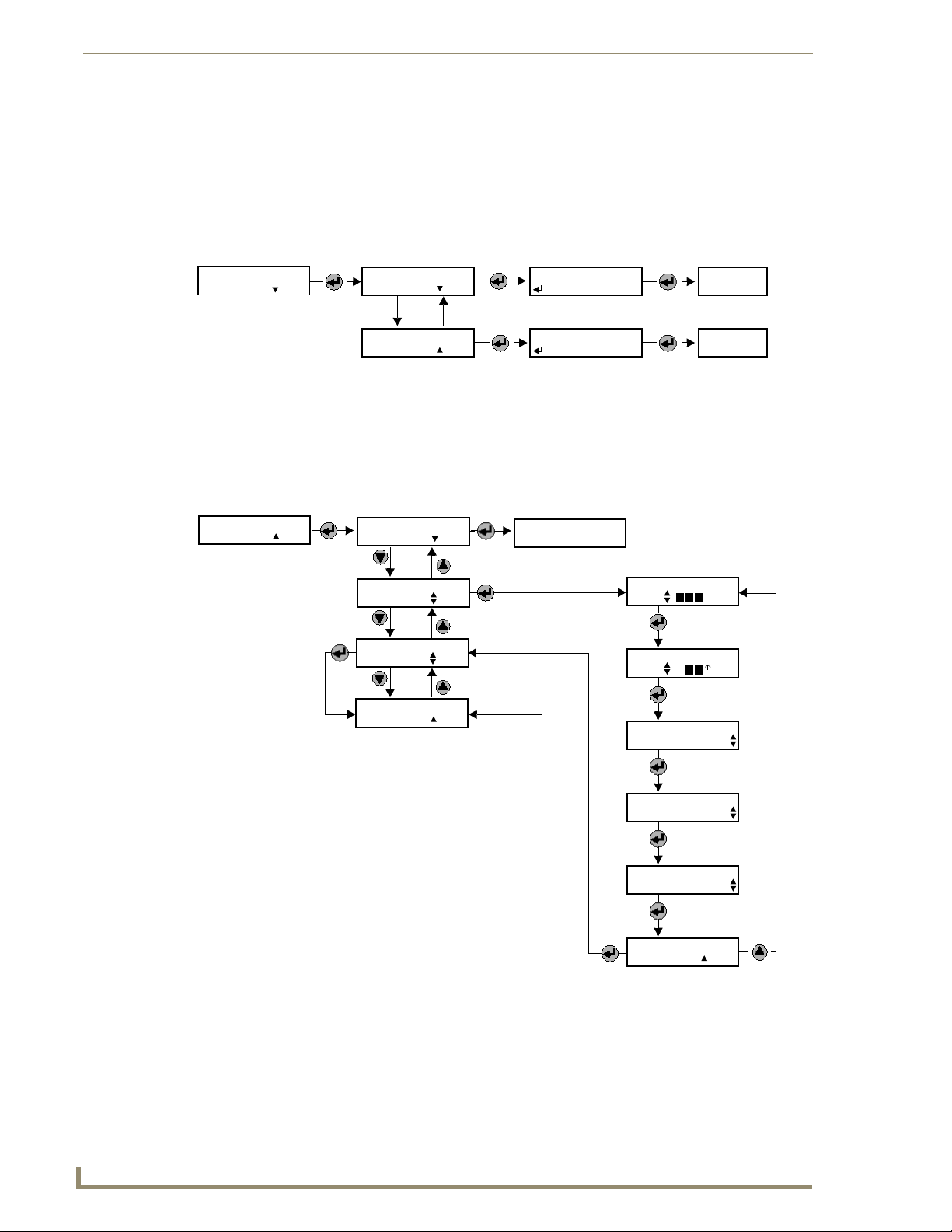

Multiple Support Module Installation

Up to 4 support modules can be connected to provide temperature or humidity averaging in a large area or for

several zones being controlled by the same system. The maximum cumulative distance of all the support

modules from the ViewStat is 1000 ft (304.8 m).

FIG. 28 shows daisy-chaining of the VST-TTM Remote Temperature and VST-TRH Remote Temperature/

Humidity Sensors.

34

ViewStat Communicating Thermostat

Page 41

Support Module Installation and Wiring

ViewStat (faceplate removed)

To other support modules

(maximum of 4 total)

VST-TTM or VST-TRH support modules

Flush-mount Indoor

VST-TSF

remote sensor

VST-TSO

Duct/Outdoor

remote sensor

FIG. 28 Daisy-chaining VST-TTM Remote Temperature and VST-TRH Remote Temperature/Humidity support modules

Always make sure that there is no power to the modules by removing the thermostat

from the sub-base.

1. Remove the thermostat from the sub-base.

2. Wire the first sensor using the single support module instructions. Daisy chain the remaining support

modules as shown below (FIG. 29).

Thermostat Module 1 Module 2 Module 3 Module 4

RSR

RSC

RSB

RSA

RSR RSR RSR

RSC RSC RSC

RSB RSB RSB

RSA RSA RSA

RSR

RSC

RSB

RSA

FIG. 29 Daisy-chaining support modules

3. Set the VST-TTM or VST-TRH Support Module DIP switches as described in the following Setting the

Support Module DIP Switches section.

4. Replace the thermostat on the sub-base. Check for proper operation of each sensor.

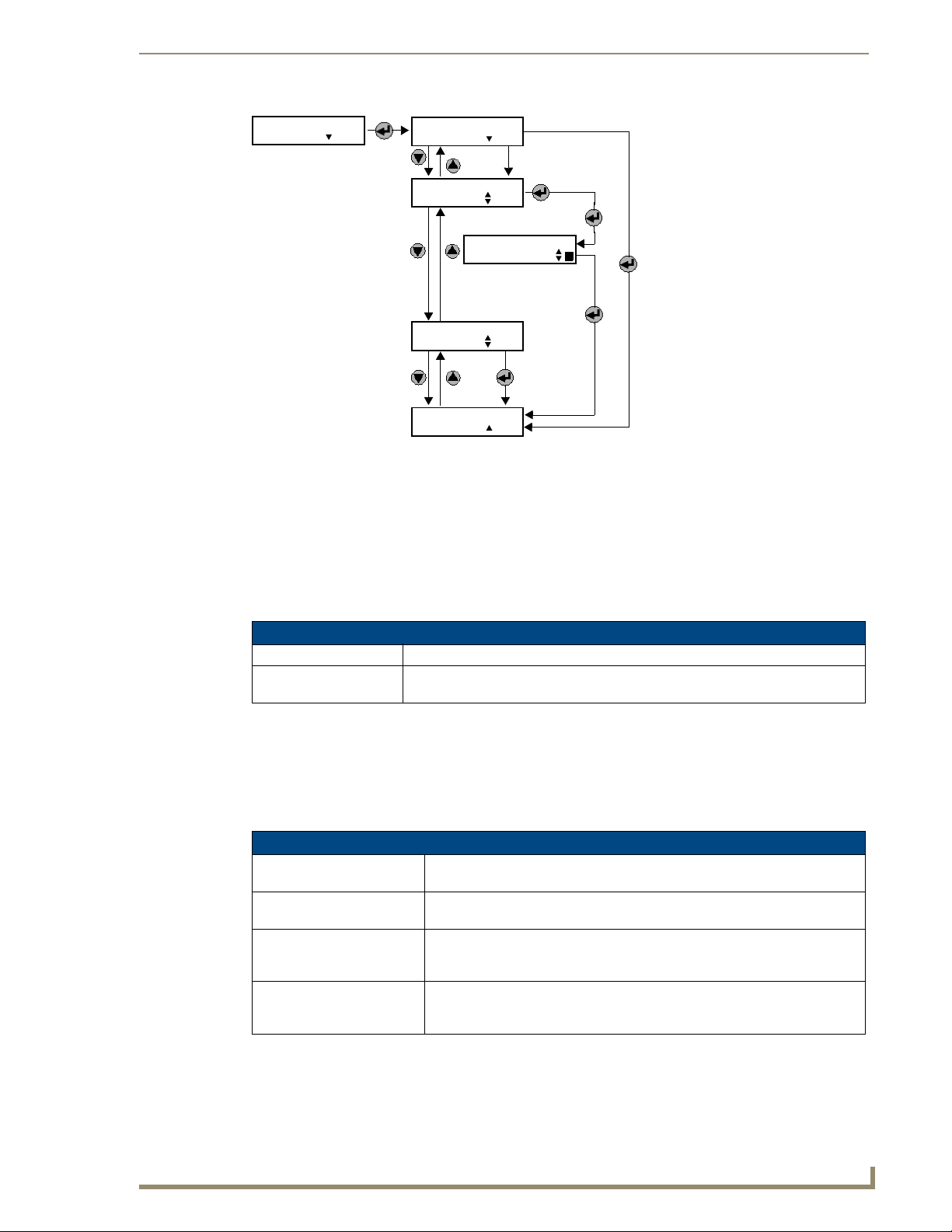

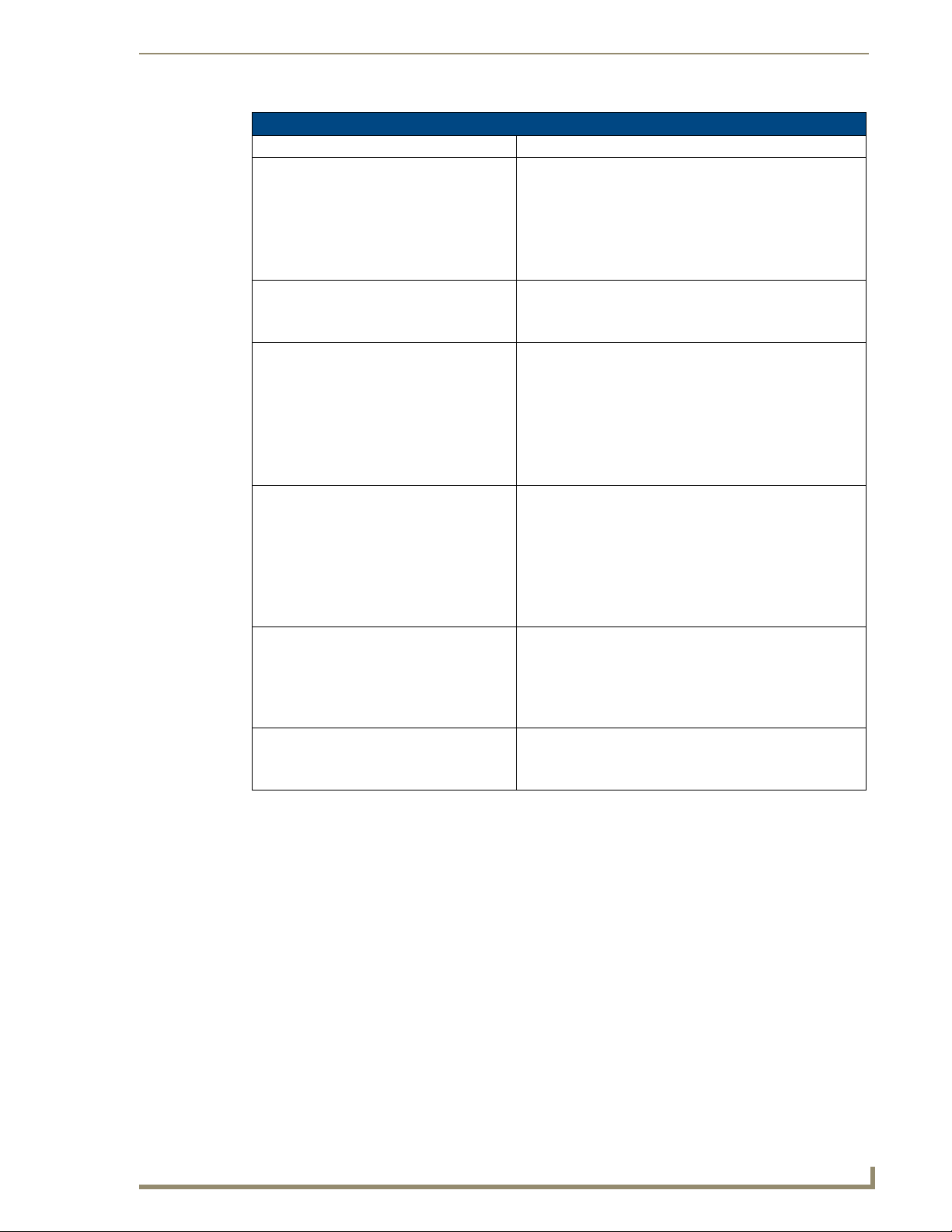

Setting the Support Module DIP Switches

Both the VST-TTM and VST-TRH support modules contain a 6-position DIP switch (FIG. 30) located on the

circuit board to set the support modules address, mode (monitor/control), and the temperature sensor source

(T1/T2 or Onboard Sensor). The ViewStat displays the temperature reading of whichever remote sensors are

connected to support modules in control mode. When multiple support modules are connected and in control

mode, the ViewStat displays an average of all incoming temperature readings. If all connected support

modules are set to monitor mode, then the ViewStat displays the temperature reading from the on-board

sensor, and the temperature from the remote sensor (or the average temperature if you’re using multiple

sensors) is displayed as the REMOTE temperature.

1

2

3

4

5

6

FIG. 30 VST-TTM or VST-TRH support module DIP switch

OFF ON

ADDRESS

ADDRESS

MONITOR (S1)

MONITOR (S2)

SPARE

T1/T2 (S1)

ADDRESS

ADDRESS

CONTROL (S1)

CONTROL (S2)

SPARE

ONBOARD SENSOR

ViewStat Communicating Thermostat

35

Page 42

Support Module Installation and Wiring

DIP switches 1 and 2: Address (1-4)

The following diagram shows how to set the top two address DIP switches. Each support module must have its

own address (1-4).

ADDRESS 1

ADDRESS 2

FIG. 31 Setting the top two address switches (switches 1 and 2)

ADDRESS 3

ADDRESS 4

DIP switch 3: Temperature Sensor 1

Each support module has two sensors: Sensor 1 and Sensor 2. Determine whether you want the Sensor 1 input

to monitor or control temperature. If DIP switch number 3 is in the "off " position, it will monitor the

temperature.

If the support module is set to Address 1 and the Sensor 1 input is set to "monitor",

then the monitored temperature will be displayed as the remote temperature in the

lower left hand corner of the thermostat. Otherwise, the monitored value will only be

available through the home automation system.

If DIP switch 3 is set to the "on" position, it will use the Sensor 1 temperature to control the thermostat. The

sensor control temperature will be displayed on the thermostat. If multiple sensors are daisy chained together,

all of the sensors set to control will be averaged and the average temperature will be displayed on the

thermostat.

Dip switch 4: Temperature Sensor 2 (VST-TTM support module only)

Sensor 2 is for an external flush-mount or outdoor/duct temperature sensor for the VST-TTM support module.

Determine whether you want the Sensor 2 input to monitor or control temperature. If DIP switch number 4 is

in the "off " position, it will monitor the temperature.

If DIP switch 4 is set to the "on" position, it will use the reported temperature to control the thermostat. The

sensor control temperature will be displayed on the thermostat. If multiple support modules are daisy chained

together, all of the sensors set to control will be averaged and the average temperature will be displayed on the

thermostat.

Dip switch 4: Humidity Sensor 2 (VST-TRH support module only)

Sensor 2 is for an onboard humidity sensor for the VST-TRH support module.

Determine whether you want the Sensor 2 input to monitor or control humidity. If DIP switch number 4 is in

the "off" position, it will monitor the humidity level (%).

If DIP switch 4 is set to the "on" position, it will control the humidity level and the value will be displayed on

the thermostat (with a % sign to indicate humidity). Up to 4 support modules can be daisy chained together.

All humidity sensors that are set to "Control" mode will be averaged and the average humidity will be

displayed on the thermostat.

If any of the remaining temperature sensors are also set to "control", the temperature

control averaging will override the humidity control averaging and humidity control

values will be ignored by the thermostat. To ensure that the thermostat recognizes

humidity control values, make sure that all temperature sensors (for this thermostat)

are set to the "Monitor" mode.

DIP switch 6: T1/T2 or Onboard Sensor

Determine whether you want the Sensor 1 input to use the temperature sensed by the onboard thermistor or to

use the input from a remote sensor (i.e. flush mount sensor or duct/outdoor sensor). If DIP switch number 6 is

in the "off" position it will use the remote sensor inputs (T1/T2). If the DIP switch is in the "on" position, it

will use the temperature input from the onboard thermistor. This option only exists for the Sensor 1 input and

can still be configured to monitor or control.

36

ViewStat Communicating Thermostat

Page 43

Support Module Installation and Wiring

The ViewStat will not display temperature or humidity (Sensor 1 or Sensor 2) values if

DIP switch 6 is set to T1/T2 without wiring a sensor to the T1/T2 terminal.

If a sensor is connected to the T1/T2 terminal; DIP switch 6 MUST be set to Off or an

invalid temperatures will be reported to the ViewStat.

Applications

Heat Pump Applications

If the support module is being used with a heat pump thermostat with auxiliary heat, the thermostat can be

configured to disable the use of auxiliary heat during warm weather and to lock out the compressor when the

outdoor temperature is too cold. This allows for the most efficient use of energy.

At warmer temperatures, a heat pump will operate much more efficiently than the auxiliary heat. It can save

energy to disable auxiliary heat in some cases, for example, when returning from a setback on a mild day. The

temperature above which auxiliary heat is disabled is the auxiliary lockout temperature or high balance point.

Refer to the thermostat user manual for a detailed explanation.

Air-to-air heat pumps become less efficient as the outdoor temperature drops. The temperature at which it

becomes more efficient to use auxiliary heat instead of the heat pump is the balance point or low balance point.

Configure the temperature sensor (T1/T2) that you are using to sense outdoor temperature to the "Monitor"

mode by setting the DIP switch 3 to the "off" position and the support module address to number 1. The high

and low balance points are set at the thermostat.

Humidity Control (VST-TRH only)

In order to set your thermostat up as a humidity controller, you will need at least one (up to four for averaging)

VST-TRH (temperature/humidity) support module(s) wired to the thermostat.

1. Locate the VST-TRH Support Module in the area that you want to control humidity.

2. Set the T3/T4 sensor (Humidity) Input to "Control" by moving the # 4 DIP switch to the "on" position.

Up to four T3/ T4 humidity sensors can be set to control and the reported values will be averaged and

displayed on the thermostat.

None of the temperature sensors connected to this ViewStat can be set to control

mode because a control temperature input to the ViewStat will override a control

humidity input. Make sure all temperature sensors connected to this ViewStat are set

to "Monitor".

3. Once the humidity control sensor(s) have been wired to the ViewStat, the thermostat display will change

to indicate % RH instead of °F/°C. The thermostat mode selections will also change to reflect humidity

control. The modes are "Humidify", "Dehumidify", "Humidify or Dehumidify" and "Off". Humidification/

Dehumidification set points are changed the same way that temperature control set points would be

changed.

Mode of Operation Set to "Humidify"

The B terminal is continually energized in the "Humidify" mode. When the thermostat calls for humidity, the

W1/HUM terminal will energize. If the minimum off time of 2 minutes has not elapsed since the previous call,

no terminals will energize until it has. All energized terminals will remain energized for the minimum on time

of 2 minutes.

Mode of Operation Set to "Dehumidify"

The O terminal is continually energized in the "Dehumidify" mode. When the thermostat calls for

dehumidification, the Y1/DEHUM terminal will energize. If the minimum off time of 4 minutes has not

elapsed since the previous call, no terminals will energize until it has. All energized terminals will remain

energized for the minimum on time of 4 minutes.

ViewStat Communicating Thermostat

37

Page 44

Support Module Installation and Wiring

Troubleshooting Remote Sensors

Thermostat has no display: Check 24 VAC supply. Check for incorrect wiring between the

thermostat and support module. Incorrect wiring can damage the thermostat and transformer or

blow a fuse in the equipment.

Also, verify that all support modules have a unique address.

Thermostat displays very high temperature or humidity: Ensure that DIP switch 6 is set

properly. If DIP switch 6 is set to T1/T2 and a sensor has not been wired to the T1/T2 terminal, no

temperature or humidity readings will be displayed. Also, if DIP switch 6 is set to onboard and a

remote sensor has been wired to the T1/T2 terminal, incorrect temperature readings will be

displayed. Check wires on remote sensors (flush mount or outdoor/duct) to ensure that they are not

touching. If they are, separate them.

Thermostat displays very low temperature: Remote sensor (flush mount or outdoor/duct) is not

connected to support module properly. Check wiring.

Thermostat doesn't display remote temperature/humidity: Make sure that the support module

is set to address 1. Reset support module after changing any DIP switches by turning off power for

approximately 15 seconds.

Thermostat displays RH instead of °F or °F instead of RH: Make sure that monitor/control DIP

switches are set correctly. Reset support module after changing any DIP switches by turning off

power for approximately 15 seconds.

38

ViewStat Communicating Thermostat

Page 45

Set Up and Configuration