Page 1

AMX Lighting

PROlink/AXlink Programming

instruction manual

Lighting Control

Page 2

AMX Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free of defects in material and workmanship under normal use for

three (3) years from the date of purchase from AMX Corporation, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch

overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, MX Series products, and KC Series products are

warranted for a period of one (1) year.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX Corporation or an Authorized AMX Dealer.

AMX Corporation is not liable for any damages caused by its products or for the failure of its products to perform.

This includes any lost profits, lost savings, incidental damages, or consequential damages. AMX Corporation is not

liable for any claim made by a third party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort

claim (including negligence and strict product liability), a contract claim, or any other claim. This limitation of

liability cannot be waived or amended by any person. This limitation of liability will be effective even if AMX

Corporation or an authorized representative of AMX Corporation has been advised of the possibility of any such

damages. This limitation of liability, however, will not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or

exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of

the Limited Warranty may not apply. This Limited Warranty gives the owner specific legal rights. The owner may

also have other rights that vary from state to state. The owner is advised to consult applicable state laws for full

determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX CORPORATION MAKES NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. AMX CORPORATION

EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED WARRANTY. ANY

IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS

LIMITED WARRANTY.

Page 3

Lighting Sales Information

AMX Lighting products are guaranteed to switch on and off any load that is properly connected to our lighting products, as long as the AMX Lighting products are under warranty. AMX Corporation does guarantee the control of dimmable loads that are properly connected to our lighting products. That includes loads correctly chosen, sized and

attached to our dimmers or switches under normal power conditions. Any load that cannot be verified by its manufacturer as rated for dimming is not guaranteed by AMX Corporation to dim properly. This includes various lamps, ballasts and transformers, as well as items no longer covered by warranty.

The dimming of low-voltage lighting requires the use of a dimmable transformer. Transformer manufacturers must

verify that the transformer is dimmable according to written or known specifications. Although AMX Corporation

will try to discern the dimming capability of a transformer by any manufacturer, it is still the responsibility of the

dealer to obtain this information. Therefore, an AMX Corporation dimmer designed for forward-phase dimming

should not be connected to a transformer that requires a reverse-phase dimmer.

The dimming of fluorescent lighting requires the use of a dimmable ballast and a dimmable lamp. Ballast manufactures must verify that the ballast is dimmable according to written or known specifications. Although AMX Corporation will try to discern the dimming capability of a ballast from the manufacturer, it is still the responsibility of the

dealer to obtain this information. Each dimmable ballast must be connected to the proper AMX Corporation Lighting

dimmer and a lamp specified for dimmable operation. We guarantee fluorescent dimming capability when the proper

AMX Fluorescent dimmer module is connected to the proper dimming ballast and a verified dimmable lamp.

Lamps must be verified as dimmable to ensure proper dimming. Lamps with integrated ballasts and transformers, as

well as other passive or electronic devices attached to the lamps must have written verification from the manufacturer

of dimming capability. Fluorescent lamps used for dimming should be operated in a full on condition for approximately four days before the dimming performance stabilizes.

The dimming performance or quality cannot be guaranteed due to the random combinations of a dimmer, a lamp and

a ballast or transformer. How well a device dims depends on many factors that cannot be controlled by AMX Lighting. AMX dimmers regulate the voltage to a lamp, ballast or transformer. AMX Corporation does not regulate lumen

output performance for a device manufactured by another company.

Page 4

Page 5

Table of Contents

Table of Contents

Introduction ...............................................................................................................1

PROlink ............................................................................................................................. 1

PROlink wall panels ................................................................................................................. 2

Lighting Systems ............................................................................................................... 2

Axcess Statements............................................................................................................ 3

Programming Commands ................................................................................................. 4

Setup commands ..................................................................................................................... 4

Recording commands .............................................................................................................. 4

Status commands .................................................................................................................... 4

Operation commands............................................................................................................... 4

Control Curves .................................................................................................................. 4

Pre-Installation Settings ..........................................................................................7

Dry Closures...................................................................................................................... 7

Configuring and connecting AXlink .......................................................................................... 7

Configuring and connecting PROlink ....................................................................................... 8

Connecting dry closures........................................................................................................... 9

Dry closure method to reset Default Settings.................................................................... 9

Default Settings and Parameters .................................................................................... 10

Wiring Considerations ..................................................................................................... 12

Preparing/connecting captive wires ....................................................................................... 12

Axcess Control - PC to Axcess Controller.............................................................................. 12

AXlink wiring between multiple devices ................................................................................. 13

PROlink wiring between multiple devices .............................................................................. 13

Power considerations ...................................................................................................... 13

Power connections................................................................................................................. 13

AXlink connections................................................................................................................. 13

Programming Strings .............................................................................................15

Strings ............................................................................................................................. 15

PROlink Programming Strings ........................................................................................ 15

AXlink Programming Strings ........................................................................................... 17

Levels..................................................................................................................................... 17

Buffers.................................................................................................................................... 18

Responses ............................................................................................................................. 18

Dry Closures .......................................................................................................................... 18

PROlink Command Structure ................................................................................19

Setup Commands............................................................................................................ 19

MX Lighting PROlink/AXlink Programming

i

Page 6

Table of Contents

Setting a Default Level Time .................................................................................................. 19

Setting a Default Ramp Time ................................................................................................. 19

Setting a Default Preset Time ................................................................................................ 20

Enabling a PROlink response ................................................................................................ 20

Disabling a PROlink response ............................................................................................... 20

Phase/zero-crossing detection and correction ....................................................................... 20

PROlink remote reboot........................................................................................................... 21

Setting a Curve ...................................................................................................................... 21

Setting a Low End voltage ..................................................................................................... 21

Recording Commands .................................................................................................... 21

Recording Presets.................................................................................................................. 22

Recording Dry Closure Presets.............................................................................................. 22

Status Commands........................................................................................................... 22

Obtaining a Dimmer status..................................................................................................... 22

Obtaining a Pack Curve status............................................................................................... 23

Obtaining All the Pack Curve status....................................................................................... 23

Obtaining a Pack Level status................................................................................................ 23

Obtaining All Pack Level status.............................................................................................. 23

Obtaining a Pack Low End Setting status .............................................................................. 24

Obtaining firmware version in PROlink .................................................................................. 24

Operation Commands ..................................................................................................... 24

Recalling Presets ................................................................................................................... 24

Ramping Dimmers Up............................................................................................................ 24

Ramping Dimmers Down ....................................................................................................... 25

Stop Ramping Dimmers - Method 1....................................................................................... 25

Stop Ramping Dimmers - Method 2....................................................................................... 25

Stop Ramping for All Dimmers............................................................................................... 25

Ramping a Preset Up............................................................................................................. 25

Ramping a Preset Down ........................................................................................................ 26

Stop Ramping Presets - Method 1 ......................................................................................... 26

Stop Ramping Presets - Method 2 ......................................................................................... 26

Setting Dimmer Levels ........................................................................................................... 26

Setting Group Dimmer Levels ................................................................................................ 27

Setting Dimmer Levels as Undefined..................................................................................... 27

Setting All Dimmer Levels as Undefined................................................................................ 27

Closing or Pushing a Dry Closure .......................................................................................... 27

Opening or Releasing a Dry Closure ..................................................................................... 28

AXlink Command Structure ...................................................................................29

AMX Lighting Channel Commands................................................................................. 29

Setup Commands ........................................................................................................... 29

ii

AMX Lighting PROlink/AXlink Programming

Page 7

Table of Contents

Setting a Default Level Time .................................................................................................. 29

Setting a Default Ramp Time ................................................................................................. 30

Setting a Default Preset Time ................................................................................................ 30

Enabling AXlink Levels/Responses........................................................................................ 30

Disabling AXlink Levels/Responses ....................................................................................... 30

Recording Commands..................................................................................................... 31

Recording Presets.................................................................................................................. 31

Status Commands........................................................................................................... 31

Retrieving the Current Preset status (feedback) .................................................................... 31

Retrieving a Dry Closure PUSH/RELEASE status................................................................. 31

Operation Commands ..................................................................................................... 32

Recalling Presets ................................................................................................................... 32

Ramping Dimmers Up............................................................................................................ 32

Ramping Dimmers Down ....................................................................................................... 32

Ramping All Dimmers Up....................................................................................................... 32

Ramping All Dimmers Down .................................................................................................. 33

Turning All Channels On ........................................................................................................ 33

Turning All Channels Off ........................................................................................................ 33

Ramping Presets Up .............................................................................................................. 33

Ramping Presets Down ......................................................................................................... 34

Setting Dimmer Levels ........................................................................................................... 34

Setting a Dimmer Level as Undefined.................................................................................... 34

Setting all Dimmer Levels to Undefined ................................................................................. 34

AXlink Buffer Commands ................................................................................................ 35

AXlink Level Commands ................................................................................................. 35

Appendix A: PROlink vs. AXlink Commands .......................................................37

Appendix B: AMX Lighting Curves .......................................................................39

Appendix C: Troubleshooting ...............................................................................55

Software Issues............................................................................................................... 55

Using PASS mode ................................................................................................................. 55

Testing AMX Lighting features ............................................................................................... 55

Hardware Issues ............................................................................................................. 56

Troubleshooting hardware ..................................................................................................... 56

MX Lighting PROlink/AXlink Programming

iii

Page 8

Table of Contents

iv

AMX Lighting PROlink/AXlink Programming

Page 9

Introduction

The AMX Lighting Control System employs a dual-platform programming system using the

Axcess and PROlink software programs to control the dimming of electronic ballasts, incandescent

lamps, low voltage track lighting, and a host of new transformers. This manual describes

connecting and programming a AMX Lighting system.

This section explains PROlink wall panels, programming commands, and lighting curves.

This manual refers to AMX Lighting firmware version 2.0 and higher.

PROlink

An AMX Lighting Central Controller has a computer processor attached to a six-channel digital

dimming engine. This dimming engine gets its commands from a buffered region called PROlink.

The dimming processes generated in the dimming engine can also send both commands and status

back to the PROlink buffer. The PROlink buffer in Pack #1 acts as housekeeper for the rest of the

PROlink system.

Introduction

The PROlink buffer allows a maximum of 24 characters. The PROlink programming and

operational commands are sent as strings to this buffer before going to the dimming engine.

PROlink allows ten 6-channel packs to be connected for a combined system of 60 dimmers. Any

preset sent to Pack #1 will be sent to all packs connected on the PROlink bus. There is a DIP switch

located on each controller that sets the PROlink Pack number from one to ten, or dimmers 1

through 60. An entire PROlink system consists of 60 channels of dimming or switching. PROlink

dimmer numbers are from 1-60; AXlink dimmer numbers are from 1-6.

Refer to the Programming Strings section for more information about these strings.

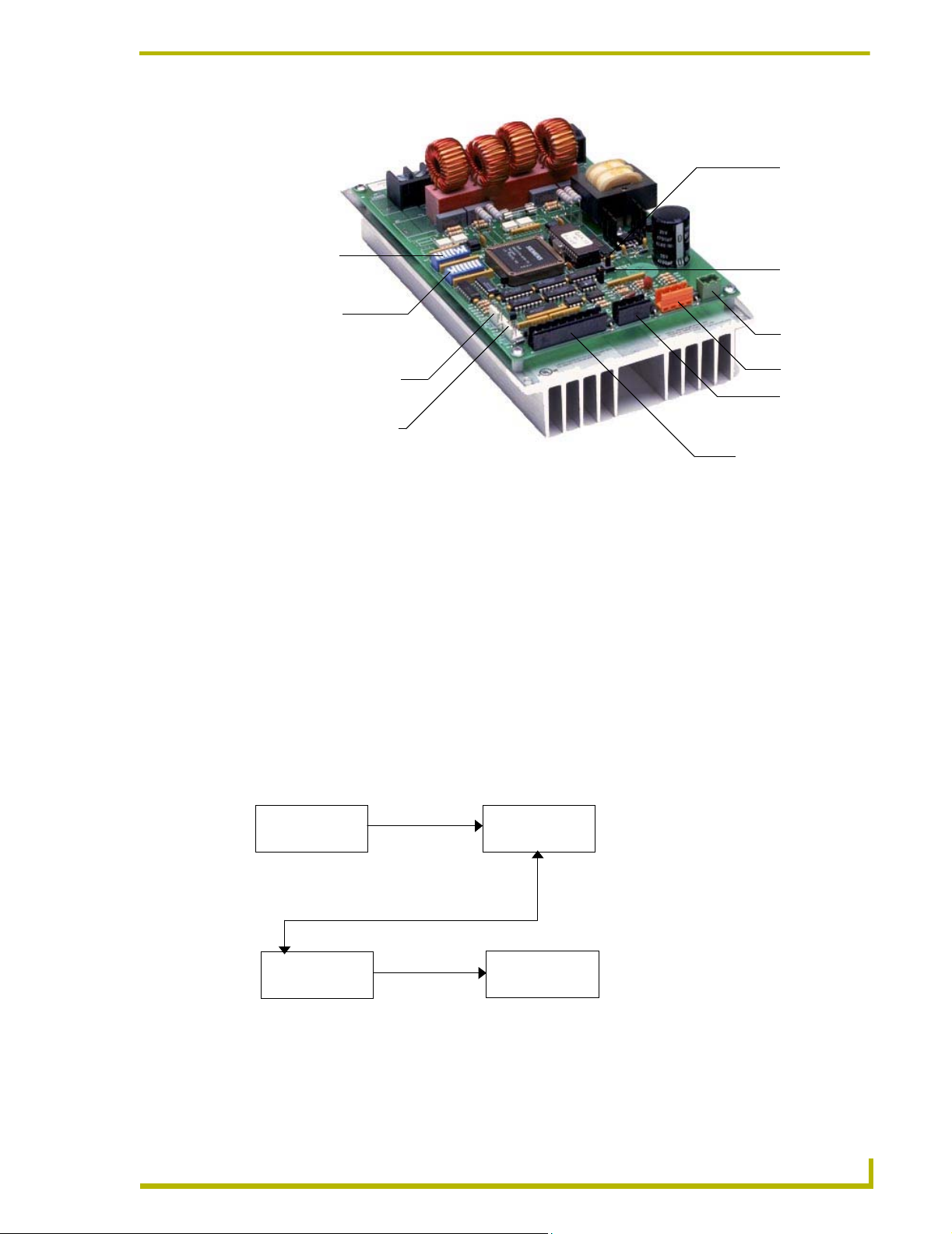

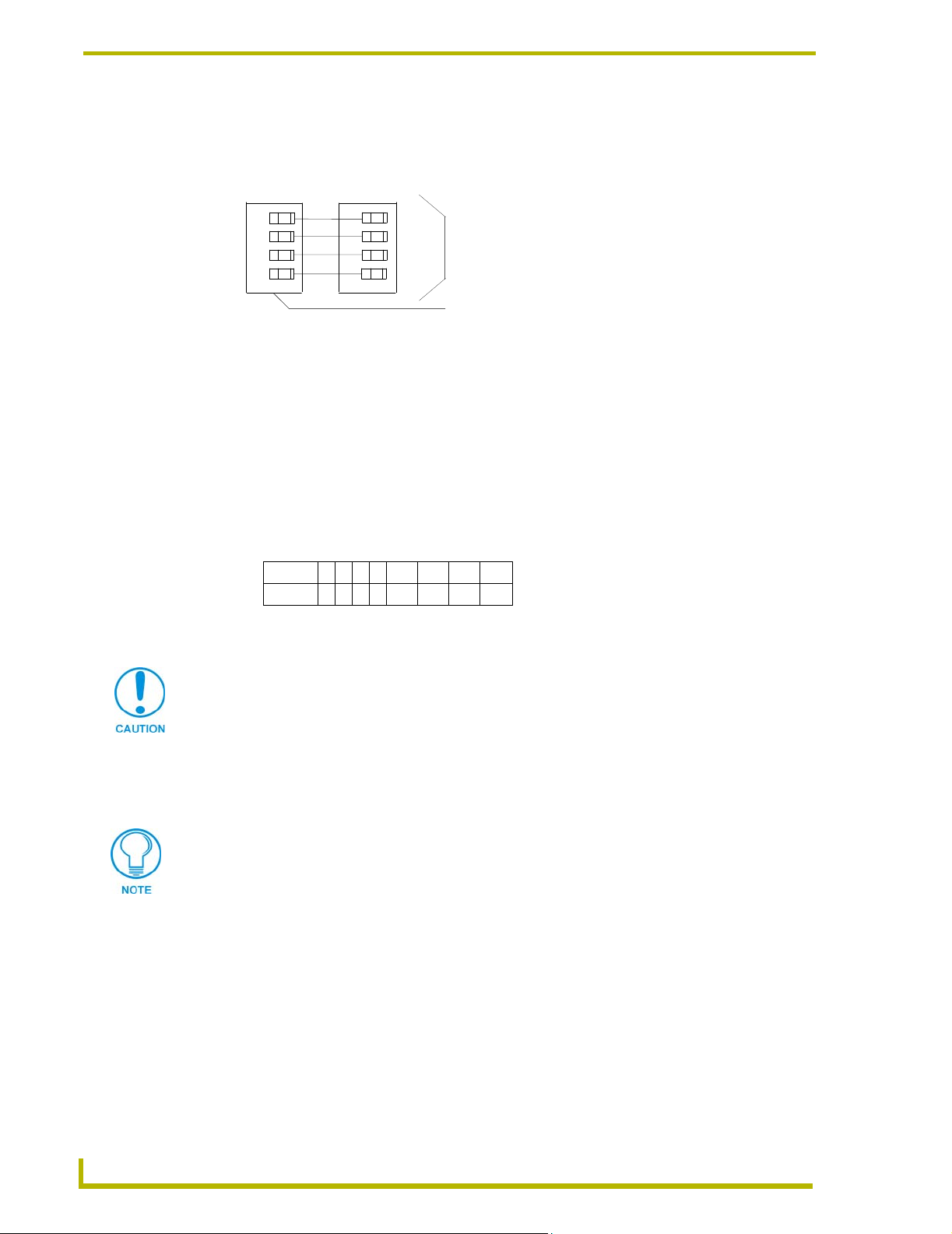

FIG. 1 shows a sample AMX Lighting system using the PROlink mode.

MX Lighting PROlink/AXlink Programming

1

Page 10

Introduction

RS-232

AXB-EM232

AXlink

AMX Lighting

Pack 1 Pack 2

Controllers

AXlink

Touch panel

FIG. 1 Sample AMX Lighting Control System

Wall panel

PROlink

PROlinkPROlink

Wall panel

PROlink wall panels

PROlink wall panels are available for direct connection to the AMX Lighting system. PROlink

panels do not rely on an AXlink connection. PROlink panels have an internal fixed program that is

powered from the PROlink connector on the AMX Lighting controller. These panels get power

from the power supply available to the controller where the panel is connected. These panels reflect

changes made to the AMX Lighting system by the Axcess system when the AMX Lighting

Controllers are also connected on AXlink.

Lighting Systems

AMX Lighting systems are based on a modular construction. There are three basic components to

the modular structure: Controller, Enclosure, and Dimmer/Switch Modules. All AMX Lighting

controllers have six channels of control. Seven channels of control will always require the use of

two controllers.

In order to have the controllers address different dimmers ranges, they have a DIP switch installed

to address each pack/group of six channels to a specific range. Changing the PROlink DIP switch

address (value) is a means of differentiating the various dimmers. All AXlink devices also have an

address DIP switch to set a unique ID from 1 to 255. FIG. 2 shows a sample AMX Lighting

controller and its internal components.

2

AMX Lighting PROlink/AXlink Programming

Page 11

AXlink device

number DIP

switch (SW1)

PROlink device

number DIP

switch (SW2)

Introduction

Reset

Memory

Protect

Powe r

CH5 connector for

optional satellite module

CH6 connector for

optional satellite module

FIG. 2 RDD-DM low-voltage connections and DIP switches

PROlink

AXlink

Dry Closure

The first of a ten pack PROlink system can have one of the 255 AXlink addresses. That means that

a single AXlink address can control 60 channels of dimming or an entire PROlink system. Refer to

the DIP switch configuration subsection for more detailed information about both the PROlink and

AXlink pack numbers.

Axcess Statements

Axcess Send_Command statements are received in the AXlink buffer, processed and sent to the

PROlink buffer where they are translated to the dimming engine. The same is true in reverse, such

that the dimming engine updates the PROlink buffer that sends data to the AXlink buffer and then

to the AXlink Central Controller.

FIG. 3 shows the pathway of the Axcess commands to the dimming engine.

AXCESS

Send_Commands

Statements

received

AXlink

buffer

PROlink

buffer

Commands are

translated then

FIG. 3 Flowchart for Axcess Send_Commands to dimming engine

MX Lighting PROlink/AXlink Programming

Commands

processed and

transmitted

Dimming

engine

transmitted

3

Page 12

Introduction

All this communication takes milliseconds of time. The AXlink buffer sends data to the PROlink

buffer, receives commands from the PROlink buffer, receives data from the Axcess Central

Controller, and connects AXlink levels to an Axcess Central Controller. Each Central Controller

can control over 250 devices on the AXlink control bus. There is a DIP switch on each AXlink

device to set the address from 1 to 255. Each AXlink Central Controller can receive 8 levels from a

device. AMX Lighting pack #1 can send all six of its levels directly to the AXlink bus. Only Pack

#1 can send AXlink levels; Pack 2-10 cannot return direct levels to the Axcess Central Controller.

Programming Commands

There are four main types of programming commands used in the AMX Lighting system: Setup,

Recording, Status, and Operation commands. The following descriptions apply to both the PROlink

and AXlink Command Structure.

Setup commands

These types of commands are global commands sent to Pack #1 that affect the entire PROlink

network. These commands are used to set the default values and parameters that are typically

entered at the startup of the system and not changed. If certain commands are issued with a time

value associated then the AMX Lighting system will use an available default value determined at

setup. The commands for recording and recalling presets use these defaults, as do ramping

operations. Curve settings are setup commands done on a individual channel basis and are not

global. Curves are set in the beginning and do not need to be changed unless the loads also change.

Recording commands

These commands send preset data to the AMX Lighting memory chip. All recording and setup

commands are stored in non-volatile memory. These commands are also used to store presets,

assign presets for dry closure recall, and erase stored presets.

Status commands

Status commands allow a user or a program to get data from the lighting system and act on that

information. This feature gives a computer the ability to perform interactive processes with the

AMX Lighting system. AXlink status data and Axcess Levels have unique differences from

PROlink status data. The combination of AXlink and PROlink status commands provides the

greatest flexibility.

Operation commands

This is the largest category of commands. The operational commands are used for real-time

lighting control and setup of scenes prior to programming presets. Operational commands recall,

ramp, and set levels for dimmers. They can also be used for remote operation of the dry closure

contact.

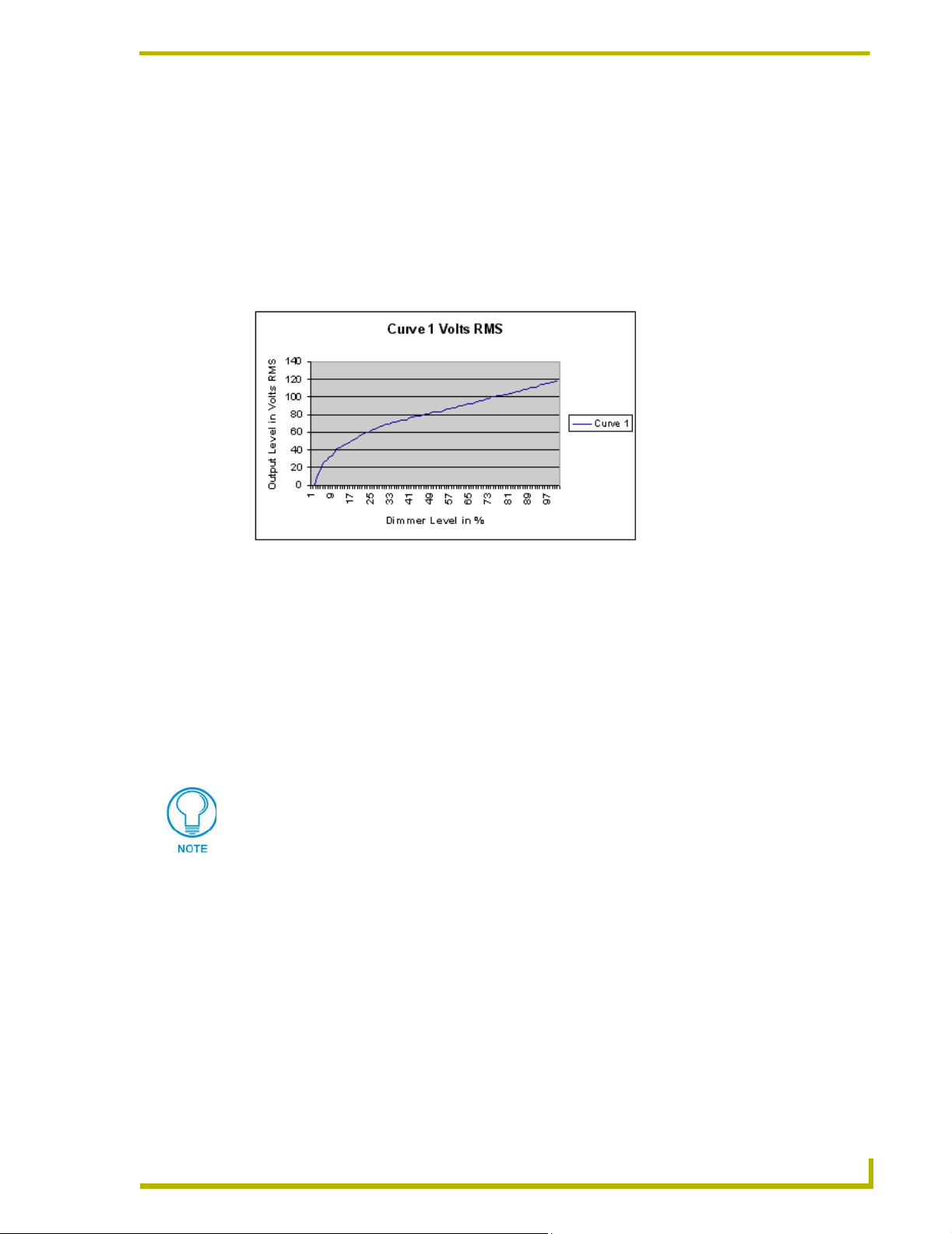

Control Curves

There is a great influx of new lamps and ballast on the market. Each one has properties and

dimming characteristics that present a new challenge for the dimmer manufacturer to provide an

appropriate dimmer. What was designed as a standard incandescent dimmer must now be able to

control electronic ballast, incandescent lamps, low voltage track lighting, and a host of new

transformers.

4

AMX Lighting PROlink/AXlink Programming

Page 13

Introduction

One way to solve many of these problems is to apply different control curves to each dimmer and to

provide a variable low-end cutoff point.

A dimming curve is a graphical or electronic representation of the amount of control that must be

applied to a dimmer in relation to the dimmer output. It is like a directional map that the controller

follows. The amount of control is typically measured in percent; from an Off-state of level 0 to an

On-state at level 100. Dimmer output is measured in volts. A graphical representation of a dimming

curve is usually the percentage of dimming in relation to the output voltage (RMS) of the dimmer

connected to a standard load. FIG. 4 shows a sample dimming curve.

FIG. 4 Sample dimming curve

Sometimes a fixture or lamp has a problem dimming down to a low range. When this happens the

lights can flicker and cause unwanted dimming performance. To correct for anomalies in the

dimming performance of various devices, the AMX Lighting controller has provisions to

individually set a low-end trim for each of the six dimming channels. The AMX Lighting dimming

system employs a low-end cutoff that allows the dimmer to turn on to a specified level or to dim

down to a specific level. The level at which the dimmer turns on is called the Low End Setting. Low

End commands prevent the dimmer from going below a set threshold. They also force the dimmers

on to the preset threshold. That is useful for some transformer loads and track lights.

Refer to Appendix C: AMX Lighting Curves for more information.

MX Lighting PROlink/AXlink Programming

5

Page 14

Introduction

6

AMX Lighting PROlink/AXlink Programming

Page 15

Pre-Installation Settings

8

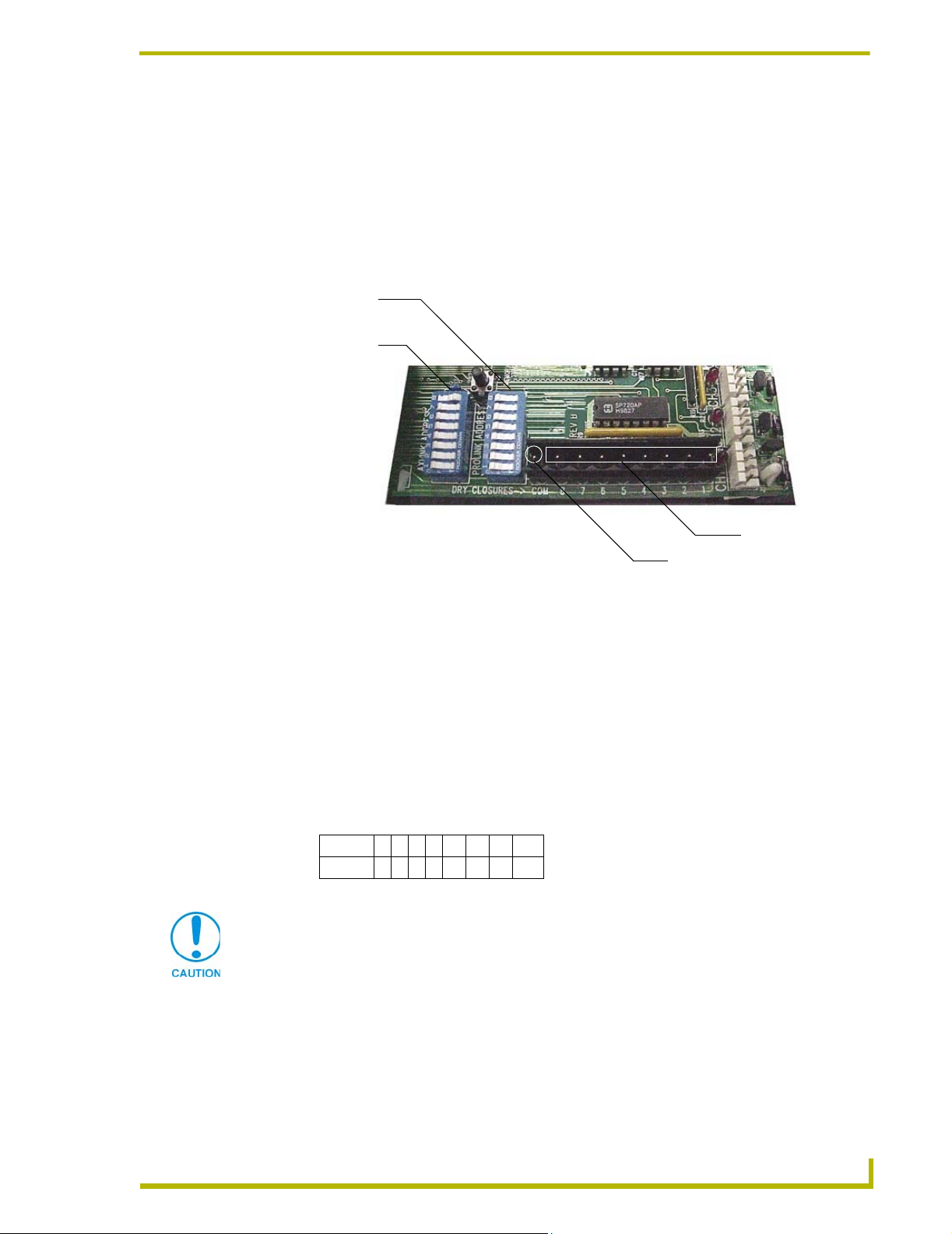

Dry Closures

Each AMX Lighting controller has a 9-pin captive screw connector for use as a dry closure input.

One connection is for a common ground and the rest are for the eight dry closure inputs.

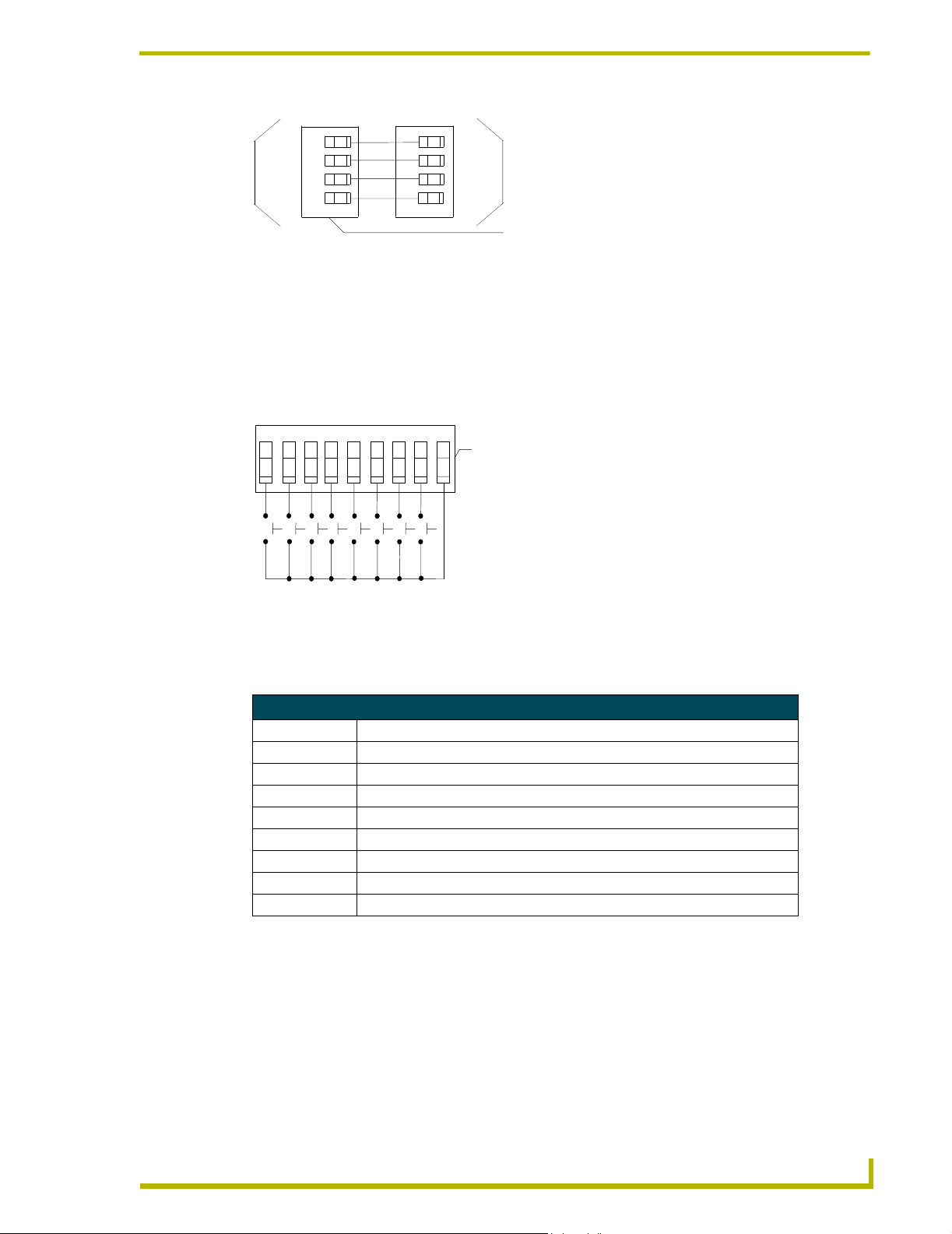

AXlink device number

DIP switch (SW1)

PROlink pack number

DIP switch (SW1)

Pre-Installation Settings

Dry closure inputs 1-

Common Ground (COM)

FIG. 5 Sample dry closure connector

The inputs are an open collector pulled up to 5 VDC. The status is normally open, channel Off,

closure released. When an input is pulled low to ground and falls below 3 VDC, the AMX Lighting

system sees the action as an input closure and the AXlink channel is turned On and a push sent to

the Axcess Central Controller.

Configuring and connecting AXlink

The DIP switch SW1 sets the AXlink device number. The device number is determined by the

value of all the switch position settings. The following table shows the SW1 DIP switch positions

and their values. The device number assignment range is 1 through 255.

Position12345678

Value 1 2 4 8 16 32 64 128

Power Off the unit before setting the DIP switch

To set DIP switch SW1 and connect AXlink:

1. Power Off the unit at the circuit breaker.

2. Locate the SW1 DIP switch (marked AXLINK ADDRESS) and set the device number using

the values shown above.

MX Lighting PROlink/AXlink Programming

7

Page 16

Pre-Installation Settings

r

3. Connect the four-pin AXlink male connector onto the four-pin female AXlink connector in the

AMX Lighting Controller. FIG. 6 shows how to wire the AXlink connector to a Central

Controller.

PWR +

AXP/TX

AXM/RX

GND -

FIG. 6 AXlink wiring diagram

PWR +

AXP

AXM

GND -

Central Controlle

AXlink connector

4. Power up the AMX Lighting Controller at the circuit breaker panel or push the Reset Button.

Configuring and connecting PROlink

DIP switch SW2 sets the PROlink pack number. The pack number is determined by the value of all

the switch position settings. The following table shows the SW2 DIP switch positions and their

values. The pack number assignment range is 1 through 10. The lighting system will not work if

you assign pack numbers outside of the range. DIP switch #8 is a test switch. It will turn all the

lights to full in the On position. It must be in the Off position for normal operation.

Position12345 6 7 8

Value 1 2 4 8 N/A N/A N/A Test

To set DIP switch SW2 and connect PROlink:

Power Off the unit before setting the DIP switch

1. Power Off the unit at the circuit breaker.

2. Locate the SW2 DIP switch and set the pack number using the values shown above. The pack

number must be 1 to 10.

Assign pack #1 for all communications, diagnostics, and response (feedback).

3. Connect the four-pin PROlink male connector into the four-pin female PROlink connector in

the AMX Lighting Controller. FIG. 7 shows how to wire the PROlink connector to a PROlink

wall panel.

8

AMX Lighting PROlink/AXlink Programming

Page 17

Pre-Installation Settings

+12V

PR+

PR-

GND

FIG. 7 PROlink wiring diagram

+12V

PR+

PR-

GND

PRO-SP8 wall panel

Panja Lighting PROlink connector

Connecting dry closures

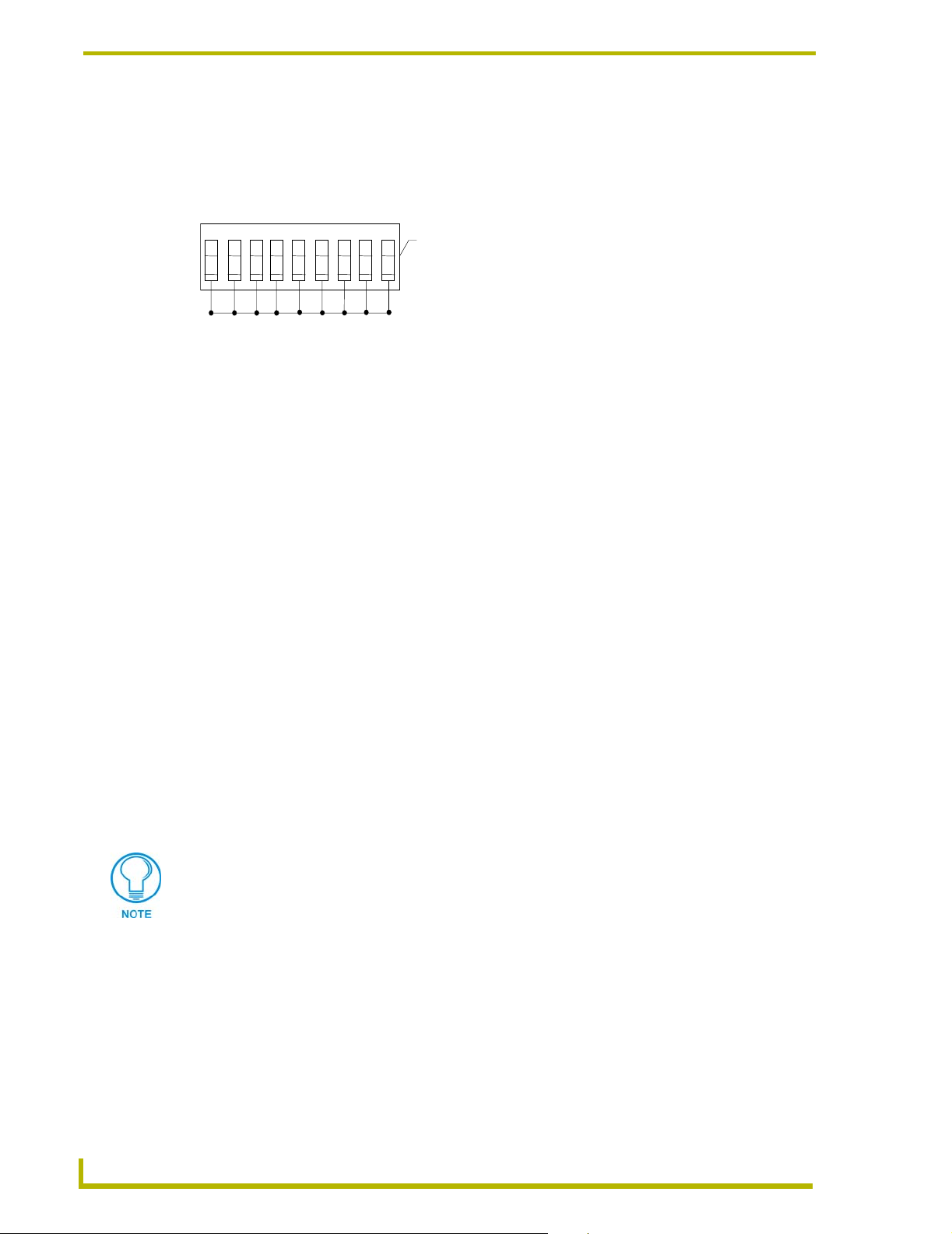

Eight connections are available for dry contact closures and one common reference point. FIG. 8

shows the standard wiring configuration for the 9-pin dry closure connector.

C

O

1

2 3 4 5 6 7 8

M

9-pin dry closure

connector

FIG. 8 9-pin dry closure connector (standard configuration)

Each contact closure connection (1 through 8) is pre-programmed with a default preset. The

following table shows the default presets for each contact closure.

Default Dry-Closure Presets

Contact closure Default presets & functions

1 Preset 1, Channel 1 at 100% in 1 second*

2 Preset 2, Channel 2 at 100% in 1 second*

3 Preset 3, Channel 3 at 100% in 1 second*

4 Preset 4, Channel 4 at 100% in 1 second*

5 Preset 5, Channel 5 at 100% in 1 second*

6 Preset 6, Channel 6 at 100% in 1 second*

7 Preset 7, Channel 1 - 6 at 100% in 1 second*

8 Preset 8, Channel 1 - 6 at 0% in 1 second*

Dry closure method to reset Default Settings

The default settings can be restored using the Dry Closure Input connection. By wiring all nine pins

(input pins 1-8, and the COM pin) together and plugging it into the Dry Closure port on a control

card for one minute will reset all default settings and parameters to the factory default settings as

listed previously.

To reset a AMX Lighting controller to default mode:

1. Power Off the AMX Lighting controller at the circuit breaker panel.

MX Lighting PROlink/AXlink Programming

9

Page 18

Pre-Installation Settings

2. Disconnect all AXlink and PROlink cables from the controller module.

3. Connect a jumper to the dry contact closures 1 through 8 and to ground as shown in FIG. 9.

1

2 3 4 5 6 7 8

FIG. 9 9-pin dry closure connector set to default mode

C

O

M

9-pin dry closure connector

4. Power up the controller and wait for the controller's green status LED to go off after about one

minute.

5. At the breaker panel, remove power from the controller again.

6. Remove the 9-pin connector from the Dry Closure connector.

7. Reconnect AXlink and PROlink.

8. Reapply power to the AMX Lighting controller.

Default Settings and Parameters

There are several default settings involved with the AMX Lighting controller. There are default

values for recalling a preset, going to a specified level, ramping up or down a dimmer or preset,

which presets are stored for dry closure recall, and enabling PROlink response and feedback

strings. Once a default parameter is set it does not have to be changed for the life of the system.

These settings are stored in non-volatile memory in a separate memory chip. The first 8 presets are

defined in the default startup, and these presets are also attached to the default dry closures. The

eight dry closures will recall the first 8 presets. All default values and the clearance of all other

presets can be accomplished using a special function of the dry closure connector. All channels are

cleared of any low-end trim during a factory reset of the processor. The pack will report,

CP01:000,000,000,000,000,000 designating all channels be cleared of low-end settings. By

connecting a jumper to dry contacts 1-8 and to the common ground, the factory default mode erases

all existing presets stored in memory.

10

The symbol C is obtained by pressing ALT+ 012, entering the Hexadecimal value $0C, or by

entering the decimal number 12.

AMX Lighting PROlink/AXlink Programming

Page 19

Pre-Installation Settings

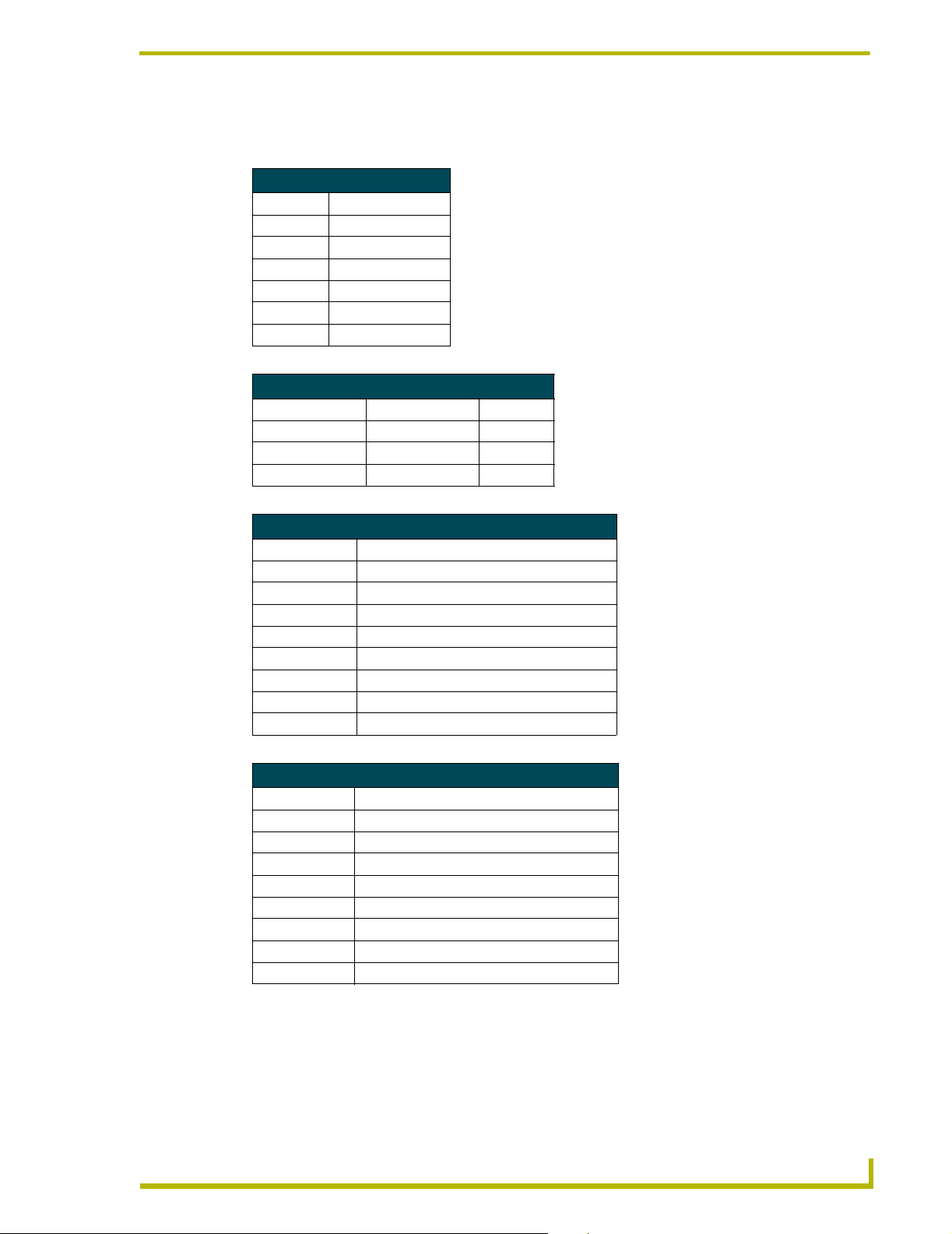

The following tables shows the default low-end settings, default preset time values, default dryclosure presets and factory presets for AMX Lighting:

Default Low-End Settings

Function Low-end setting

Channel 1 LE=0

Channel 2 LE=0

Channel 3 LE=0

Channel 4 LE=0

Channel 5 LE=0

Channel 6 LE=0

Default preset time values

Firmware version Function Time Value

2.0 or greater Default ramp time 6

Default level time 1

Default preset time 3

Default dry-closure presets

Contact closure Default presets & functions

1 Preset 1, Channel 1 at 100% in 1 second*

2 Preset 2, Channel 2 at 100% in 1 second*

3 Preset 3, Channel 3 at 100% in 1 second*

4 Preset 4, Channel 4 at 100% in 1 second*

5 Preset 5, Channel 5 at 100% in 1 second*

6 Preset 6, Channel 6 at 100% in 1 second*

7 Preset 7, Channel 1 - 6 at 100% in 1 second*

8 Preset 8, Channel 1 - 6 at 0% in 1 second*

Factory presets

Preset number Description

1 Channel 1, Channel 1 at 100% in 1 second*

2 Channel 2, Channel 2 at 100% in 1 second*

3 Channel 3, Channel 3 at 100% in 1 second*

4 Channel 4, Channel 4 at 100% in 1 second*

5 Channel 5, Channel 5 at 100% in 1 second*

6 Channel 6, Channel 6 at 100% in 1 second*

7 Channel 1 - 6 at 100% in 1 second*

8 Channel 1 - 6 at 0% in 1 second*

MX Lighting PROlink/AXlink Programming

11

Page 20

Pre-Installation Settings

Wiring Considerations

The following information relates to wiring considerations for a AMX Lighting system.

Do not connect power to the device until the wiring is complete.

Preparing/connecting captive wires

1. Strip 0.25 inch of wire insulation off all wires.

2. Insert each wire into the appropriate opening on the connector according to the wiring

Axcess Control - PC to Axcess Controller

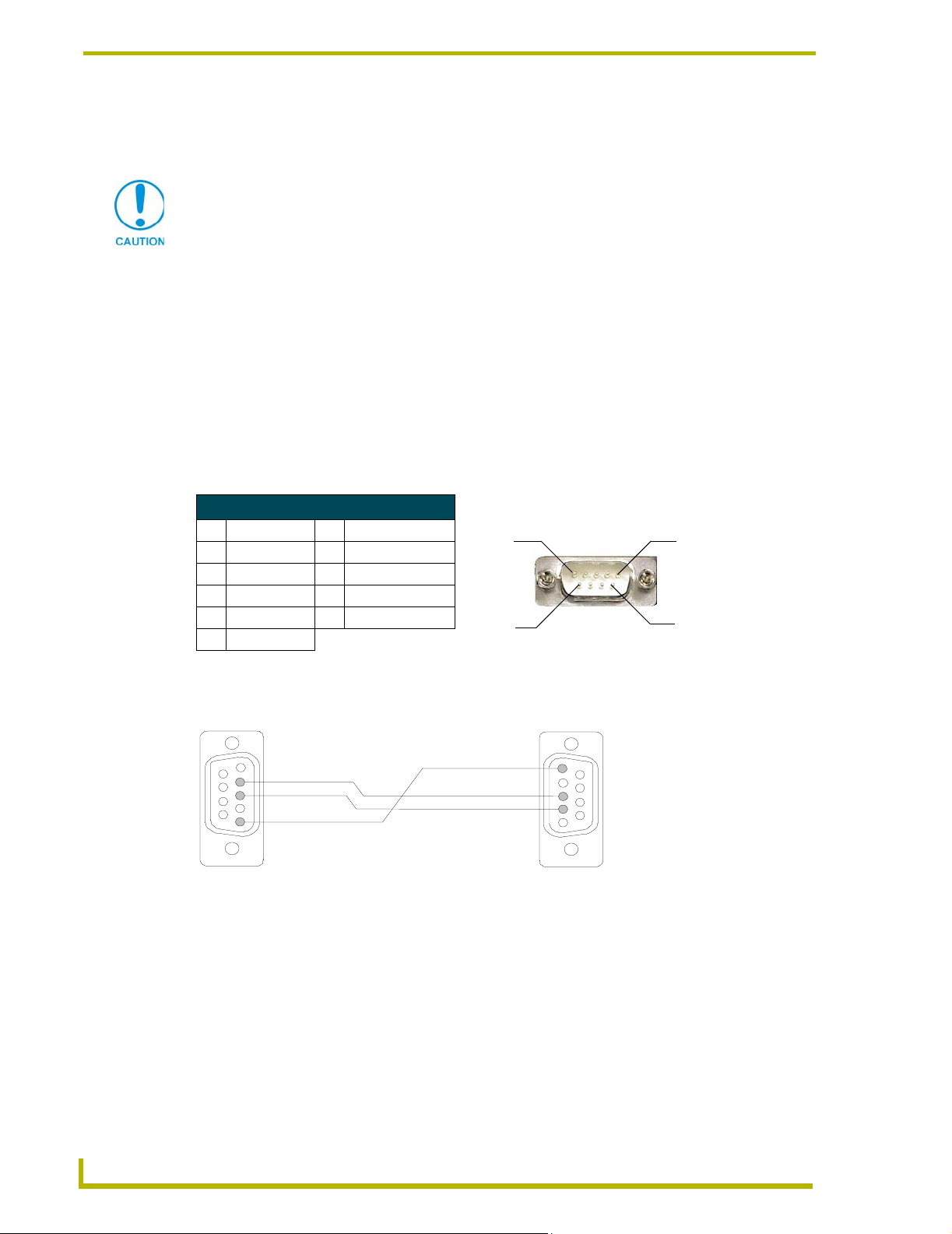

The following table lists the pinout information for the DB-9 connector.

DB-9 Connector Pinouts

Pin Signal Pin Signal

1 N/A 6 N/A

2RXD 7RTS

3TXD 8CTS

4 N/A 9 N/A

5GND

diagrams and connector types described in this section.

! Do not tighten the screws excessively; doing so may strip the threads and damage the

connector.

Pin 1

Pin 6

Pin 5

Pin 9

FIG. 10 shows a DB9 pinout relation from the computer to the Axcess Central Controller.

Connection view

5 (GND)

2 (RXD)

3 (TXD)

5 (GND)

Computer COM Port

DB9 (9-Pin Female)

FIG. 10 Computer to Axcess connection

3 (TXD)

2 (RXD)

AXCENT

DB-9 (9-Pin Female)

3

Pro Program Port

Use cable FG #10-727 to connect computer the COM port to Axcess or AXCENT Program Port.

12

AMX Lighting PROlink/AXlink Programming

Page 21

AXlink wiring between multiple devices

FIG. 11 shows AXlink wiring between AXlink devices.

Pre-Installation Settings

AXP

AXM

DEV.#3

PWR

P+

M-

GND

AXP

AXM

DEV.#1

PWR

P+

M-

GND

FIG. 11 Multiple AXlink wiring connections

DEV.#2

AXP

AXM

PWR

P+

M-

GND

Disconnect the main power to the AMX Lighting controller if rewiring the AXlink cables.

PROlink wiring between multiple devices

FIG. 12 shows PROlink wiring between PROlink panels and controllers.

PRO-SP8

+12

PR

PR-

GND

FIG. 12 Multiple PROlink wiring connections

Panja Lighting Controller 1

+

+12

PR+

PR-

GND

Panja Lighting Controller 2

+12

+

PR

PR-

GND

Disconnect the main power to the AMX Lighting controller if rewiring the PROlink cables.

Power considerations

The following information relates to wiring considerations for a AMX Lighting system.

Power connections

Power to a controller must be maintained to avoid losing communication with AXlink. Pack #1 will

survive a brownout or temporary loss of power and recover online to AXlink. Reset Pack #1 to

bring Packs #2 and above online. If Pack #1 loses power and power is then restored, all other packs

(2 - 10) will remain offline until Pack #1 is reset.

AXlink connections

In order to establish an AXlink connection for programming, the controller must be connected to a

power source and be powered on. The AMX Lighting system will allow programming after power

has been applied. Once power has been applied and the AMX Lighting controller has established an

AXlink connection, the 12VDC supply to the processor will allow program changes if the 120VAC

supply is cut off.

MX Lighting PROlink/AXlink Programming

13

Page 22

Pre-Installation Settings

14

AMX Lighting PROlink/AXlink Programming

Page 23

Programming Strings

Strings

A string is a set of values grouped together with single and/or double quotes. Character arrays

(strings) are enclosed between double quotes while ASCII strings are enclosed within single

quotes. All ASCII strings are character arrays. If an ASCII string needs to be sent with non-ASCII

characters, it must first be enclosed in double quotes and then the non-ASCII characters must be

delineated with commas. Axcess looks at:

• ASCII characters These characters are surrounded with single quotes.

• Hexadecimal characters These characters begin with a $. An example is $0D that acts as a

carriage return and enters the information.

• Decimal characters These characters are numerical and are not enclosed with any quotation but are separated from other types of characters by a comma.

PROlink Programming Strings

PROlink accepts ASCII commands from the AXlink connection. These commands take the form of

a Send_String command to the AXlink device. Most commands are terminated with a carriage

return. A carriage return is represented by the decimal value 13 or the hexadecimal form $0D.

Response (feedback) values for presets, time values, and dimmer levels are usually three characters.

The AMX Lighting controller is both an AXlink and PROlink device. You can send PROlink

commands through the AXlink COM port, but you cannot send AXlink commands to the PROlink

port.

Programming Strings

A sample command structure is shown below:

•Example:

•Example 2:

• PROlink response example:

SEND_STRING <device>,"'<command string>', <CR>"

Send_String LTS, "'RT5', 13"

CRAMPTIME SET AT 005

The 'RT5' are ASCII characters and the '13' are decimal characters. Everything within the double

quotes gets sent out when followed with a carriage return, <CR> like $0D.

The ASCII character C or $0C precedes all responses from the AMX Lighting controller. The

PROlink response will have a carriage return $0D and a line feed $0A at the end of each response.

For example purposes the <device> is always named 'LTS' and the <CR> will be substituted with

the Decimal numerals 13. Levels are expressed in percent from level 0 (zero) to 99 with full On or

100% expressed as two characters, FF.

In the command format, such as the one shown below, the <n> parameter refers to the individual

dimmer number or group of dimmers. The value <n> can be in the range from 1 to 60. It can be

expressed as a compound number using the - (dash) and & (ampersand). The letter A for ALL

('include all 60 dimmers') is also valid as a value for <n>. The string '1&3-6&9L99' is an example

of a compound group consisting of dimmers 1, 3, 4, 5, 6, and 9. The example string 'AL0T0' would

send all 60 dimmers to level 0 instantly. The following is a generalized PROlink command structure

example:

MX Lighting PROlink/AXlink Programming

15

Page 24

Programming Strings

PROlink commands should not be sent while the PROlink buffer is responding to the previous

command or a data collision could occur. In Axcess programs there should be at minimum a 3/10sec. wait (WAIT 3) between commands sent to the controller. Repetitive commands should have a

½ second wait (WAIT 5) between commands for greater accuracy. The dimmers all have the ability

to turn On or Off in 1/10 of a second.

A <CR> or '13' is sent before a command string will also clear the PROlink buffer allowing more

reliable data transfer.

A dimmer or group of dimmers can be excluded from a preset using the 'Undefined' command.

Undefined is a level command that allows a dimmer to be ignored during the recording of a preset;

it has no defined level. A preset can be created where dimmers 1 and 2 can be set to 50% while

dimmers 3 and 4 are set to undefined levels.

PROlink Command Structure

Sample format:

Variables: • <n>: This is the dimmer number from 1-60 (Any combination of dimmers

Example:

PROlink response example:

Send_String <device>, "'<n>L<m>T<t>', 13"

• <m>: This is the dimmer level percentage 0-100

• <t>: This is the time value, 0-255 in seconds

Send_String LTS, "'1L57T3', 13"

C001 LEVEL 57 IN 003

The following example shows a command line where any undefined dimmers wouldn't be included

in a preset:

•Example:

• PROlink response example:

Send_String LTS, "'3-4LU'"

CGROUP LEVEL UN IN 000

If all lights were on full before this preset was recalled, then only dimmers 1 and 2 would go to 50%

while dimmers 3 and 4 would stay at full. This is useful where one AMX Lighting enclosure must

service several rooms or when a preset is needed for only one light in the entire room. The 'All

Levels Undefined' command is often used before recording a preset to clear the scene to a 'neutral'

level. A preset stored with all levels undefined will have no affect on the dimmers when recalled.

AXlink cannot 'Undefine' a single channel.

The following example shows a command line where any undefined dimmers wouldn't be included

in a preset.

•Example:

• PROlink response example:

Send_String LTS, "'ALU', 13"

CALL LEVEL UN IN 000

16

Use this type of preset to initiate unique actions that do not change the lighting. All unique action

presets can be assigned to AXlink, PROlink, or dry closure panels. This allows any AMX Lighting

panel to do non-lighting functions. A non-lighting preset could be used to turn on music or set an

alarm. A preset using all levels undefined will still be counted as one of the available 128 presets

and there can be many presets that do nothing to the lights.

AMX Lighting PROlink/AXlink Programming

Page 25

Programming Strings

There are three special presets in AMX Lighting controllers that have a fixed, non-programmable

function. Special preset #255 ramps a preset down; preset #254 ramps a preset up; and preset #253

allows dry closures to record presets. All special presets can be stored and recalled just like the

other 128 standard presets. The addition of preset ramping as a preset was most useful for dry

closures, giving them the ability to raise or lower lighting levels using simple switches.

Preset ramping can raise or lower all the levels in a preset in a proportional manner. Preset ramping

gives you the ability to raise all the levels to 100% or lower all the levels to 0. The preset will retain

its proportional levels after it has been raised or lowered to an extreme level (0 or 100). If a preset is

raised to all levels equal 100%, then it can be lowered back to its original state with all levels in

proportion to the others. If a preset has channel 1 at 75% and channel 2 at 90%, then ramping the

preset up 10% will put channel 1 at 85% and channel 2 at 100%; then ramping down 20% will put

channel 1 at 65% and channel 2 at 80%. All presets can be recovered after ramping the preset to an

extreme level. This is useful for incremental changes to an entire scene.

All presets and startup features are stored in a separate non-volatile memory chip. The memory

protect jumper on each control card will physically prevent the memory chip from being updated,

or accidentally erased. If the Memory Protection jumper is installed the AMX Lighting controller

will still react like it has changed or stored the new preset without actually doing so. This can be a

potential source of confusion. There is no digital command to determine if the jumper is in place or

not.

AXlink Programming Strings

Earlier lighting products communicated via RS232 that required them to use Send_Strings. More

recent lighting products began to use AXlink cable to communicate on an AXlink bus.

Send_Commands, channel and level information was also added to the programming language.

PROlink uses Send_Strings such as "13, $0D, 'S'" where decimal, hexadecimal, and ASCII

characters are used respectively. AXlink uses Send_Commands such as SEND_COMMAND LTS.

The relation between the two is that the current Axcess language used in AMX Lighting integrates

the two. For example:

SEND_COMMAND <device>, '<Send_String>'

As Axcess processes a string expression, it evaluates each member of the expression from left to

right, and the result is a complete string.

Levels

The best way to get levels from the AMX Lighting controller is to use the AXlink level feature built

in to each AMX Lighting controller. Use the DEFINE_CONNECT_LEVEL feature for touch panel

and wall panel bargraphs. The CREATE_LEVEL command feature can be used to display the 8-bit

AMX Lighting level or to use the level on other AXlink 8-bit level devices like the AXB-VOL3

box, a text window, or the AXB-DMX512 controller.

Active bargraphs on touch panels tend to raise or lower lights in uneven steps. The size of the active

bargraph does not lend itself to smooth dimming, especially at the top or bottom of the slider. The

preferred way would be to use Up and Down arrows or commands, and to put bargraphs in display

mode only.

Polling the AMX Lighting controller for levels is the least effective way to get and display levels;

this is not recommended.

MX Lighting PROlink/AXlink Programming

17

Page 26

Programming Strings

To determine if a AMX Lighting level is in the 'UNDEFINED' state you must use the PROlink

string command for single dimmer status as described in PROlink - Status section under the

heading 'Dimmer status'. The AXlink layer could report a level as FF (all on), but at the same time

the PROlink layer has assigned that channel as 'UNDEFINED'; this will make a difference when

recording presets. Presets are stored using the PROlink layer, not the AXlink layer.

Levels are returned in AXlink as an 8-bit figure with 256 steps from 0 to 255. Use the formula

x = (x*100/255) [where x is the dimmer level] to express an 8-bit level in percent. This will give an

approximate percentage level, with a 1% accuracy.

Buffers

The recommended way to determine a AMX Lighting response to a buffer is to use this format:

There are a few constants that may help in PROlink string manipulation. Presets use the 'GOTO'

command, levels are preceded by the word 'LEVEL', and time values are preceded by the word 'IN'.

Refer to the Create_Buffer subsection on more information on creating a buffer.

LTS_RESPONSE = REMOVE_STRING (LTS_BUFFER,"13,10", 1) '

Responses

The responses from the AMX Lighting controller can be turned Off in order to quickly send

commands. Commands can be sent faster if there is no waiting for a response after each command

is sent. The default mode at startup is RXON, which will allow responses to be sent from the AMX

Lighting controller. It is recommended to send a command and wait for the response, then send

another command. Use the RXOFF mode to avoid data collisions. This will disable most of the

return responses from PROlink and speed up the data transfer rate. It will also stop all feedback.

Dry Closures

Dry closures are read in sequential order and are assigned to AXlink channels 147 - 154. If two

buttons are pressed simultaneously, only one channel will be active. Buttons on closures must be

pushed sequentially to have more than one channel active. Pushing dry closure #1, then #2, then #3

will activate all three channels (AXlink channels 147, 148, 149). All eight closures can be used at

once.

18

AMX Lighting PROlink/AXlink Programming

Page 27

PROlink Command Structure

Setup Commands

These commands are used to set the default values and parameters that are typically entered at the

startup of the system and not changed.

! For example purposes the <device> is always named 'LTS' and the <CR> will be

substituted with the ASCII numerals 13.

Setting a Default Level Time

PROlink Command Structure

LT

Level Time is the time it takes for a level to change from its present state to a

new level when using a Level command. If a level command is sent without the

time value specified (T), the dimmer will go to the specified level using the

Default Level Time.

The factory default for this value is 1 second

Send_String LTS, "'LT<t>', 13"

Var iabl es:

• <t>: Fade time, 0-255 in seconds

Example:

Send_String LTS, "'LT1', 13"

PROlink response:

CLEVEL TIME SET AT 001

Setting a Default Ramp Time

RT

Ramp Time is the time it takes to raise or lower the channel or preset from its

preset levels to either extreme of level zero or 100%. All ramp commands will

use the Default Ramp Time. Individual dimmers cannot have individual ramp

rates

Send_String LTS, "'RT<t>', 13"

Var iabl es:

• <t>: Fade time, 1-255 in seconds, zero is not valid

Example:

Send_String LTS, "'RT5', 13"

PROlink response:

CRAMPTIME SET AT 005

MX Lighting PROlink/AXlink Programming

19

Page 28

PROlink Command Structure

Setting a Default Preset Time

PT

Preset Time is the time it takes for a preset to be recalled. If a preset is stored

or recalled without the time value specified (T), it will be recalled or stored

using the Default Preset Time.

The factory default for this value is 3 seconds

Send_String LTS, "'PT<t>', 13"

Var iabl es:

• <t>: Fade time, 0-255 in seconds

Example:

Send_String LTS, "'PT3', 13"

PROlink response:

CPRESET TIME SET AT 003

Enabling a PROlink response

RN

Response On: PROlink acknowledges each command with a response. This

command will enable responses to the AXlink master, and it is the default startup condition.

Send_String LTS, "'RN', 13"

Example:

Send_String LTS, "'RN', 13"

PROlink response:

CRXON MODE

Disabling a PROlink response

RF

Response Off: PROlink acknowledges each command with a response. This

command will disable responses to the AXlink master and speed up communication.

Send_String LTS, "'RF', 13"

Example:

Send_String LTS, "'RF', 13"

Phase/zero-crossing detection and correction

P

Phase/zero-crossing detection and correction features at startup and reset.

In the presence of a phase/zero-crossing error:

• The green AXlink LED on the Radia will blink very fast.

• The Radia will add a "P<pack#> PHASE ERROR" to any command response.

The current state of the phase/zero-cross detection system can be queried on a pack by

pack basis.

Syntax:

<pack#>Y

Return:

P<pack#>PH: (OK or FAIL)

1(Y or N), 2A(Y or N), 2B(Y or N), 3(Y or N)

A correctly working system will dislplay OK,Y,Y,Y,Y. A failure would read: PH: FAIL and an

N following the <phase #> in question

20

AMX Lighting PROlink/AXlink Programming

Page 29

PROlink remote reboot

PROlink Command Structure

QQQ

The command triggers execution equivalent to start-up or activation of reset button.

Syntax:

<pack#>QQQ

Setting a Curve

A curve is used to match the channel level setting with the dimmer output. A curve can be used to

govern the amount of dimming control relative to the level setting allowing for uniform dimming

between different loads.

Format: Send_String LTS, "'<n>/<c>', 13"

Variables: • <n>: Dimmer number from 1-60, and All

• <c>: Curve selection from 1-9, A-F, N, O

Example 1:

PROlink response: C01 CURVE 1

Example 2: Send_String LTS, "'1&2/6', 13"

PROlink response: CGROUP CURVE 6

Send_String LTS, "'1/1', 13"

Setting a Low End voltage

The Low End setting allows a programmer to set the initial turn On voltage. The dimmer will ramp

up to the Low End threshold at Level 1 and stay there until the LE command releases the threshold

and allows normal dimming. This is also used to prevent certain loads from dimming below the

product's ability. They only ramp down to a set level and stay there until it reaches level 0.

Format: Send_String LTS, "'<n>LE<m>', 13"

Variables: • <n>: Dimmer number from 1-60, and All

• <m>: Dimmer level percentage (0-100)

Example 1:

PROlink response: CMINIMUM LEVEL IS: 007

Example 2: Send_String LTS, "'1-6LE3', 13"

PROlink response: CMINIMUM LEVEL IS: 003

Send_String LTS, "'1LE7', 13"

Recording Commands

These commands send preset data to the AMX Lighting controller memory chip. All recording and

setup commands are stored in non-volatile memory. These commands are also used to store presets,

assign presets for dry closure recall, and erase stored presets.

MX Lighting PROlink/AXlink Programming

21

Page 30

PROlink Command Structure

Recording Presets

If the value for <t> is not entered, the AMX Lighting controller will use the value specified by the

Default Preset Time. The <t> parameter is optional.

Format:

Variables: • <s>: This is the preset number

Example 1:

PROlink response:

Example 2:

PROlink response:

Send_String LTS, "'<s>R<t>', 13"

• <t>: This is the ramp rate, 0-255 in seconds

Send_String LTS, "'4R2', 13"

CRECORD 004 IN 002

Send_String LTS, "'4R', 13"

CRECORD 004 IN 003 (default time=3)

Recording Dry Closure Presets

Special presets #253, #254, and #255 are allowed for the <s> value. These presets allow preset

ramping and enable the record mode.

Format:

Variables: • <p>: This is the pack number 1-10 or A (all)

Special presets: All special presets can be stored and recalled just like the other 128 standard

Example:

PROlink response:

Send_String LTS, "'<p>E<cl>P<s>', 13"

• <cl>: This is the dry closure number 1-8

• <s>: This is the preset number 1-128, 253, 254, 255

presets.

• #253 allows dry closures to record presets

• #254 ramps a preset up

• #255 ramps a preset down

Send_String LTS, "'1E2P99', 13"

CPRST 099 ON PK 01 SW 2

22

Status Commands

Status commands allow a user or a program to get data from the lighting system and to act on that

information.

Obtaining a Dimmer status

This is the fastest way to get dimmers status. It is also the fastest way to see if a computer is

connected to the AMX Lighting controller using the terminal emulator mode in Axcess. Use this

command to determine any undefined channels.

Format:

Variables: • <n>: This is the dimmer number from 1-60 (Only one dimmer at a time)

Example:

PROlink response: CCHAN:01 CURV: 1 LEV: 25

Send_String LTS, "'<n>', 13"

Send_String LTS, "'1', 13"

AMX Lighting PROlink/AXlink Programming

Page 31

PROlink Command Structure

Obtaining a Pack Curve status

This is the fastest way to see the curves in a pack. The PROlink answer gives the pack number

followed by the dimmer curve status starting with dimmer one.

Format:

Variables: • <p>: This is the pack number 1-10 (Only one pack at a time)

Example:

PROlink response: CP01: 1, 1, 1, 6, N, N

Send_String LTS, "'<p>C', 13"

Send_String LTS, "'1C', 13"

Obtaining All the Pack Curve status

This is the fastest way to see the curves in a PROlink system. The PROlink answer gives the pack

curve status starting with pack one, a carriage return, and a line feed, and then the next pack. It does

not report packs that are not on line.

Format:

Example:

PROlink responses: CP01: 1, 1, 1, 6, N, N

Send_String LTS, "'AC', 13"

Send_String LTS, "'AC', 13"

CP02: 1, 1, 1, 6, N, N …

Obtaining a Pack Level status

This is the fastest way to see the levels in a pack. The PROlink answer gives the pack level status

starting with pack one. This command does not identify any undefined channels.

Format:

Variables: • <p>: This is the pack number 1-10 (Only one pack at a time)

Example:

PROlink response:

Send_String LTS, "'<p>Z', 13"

Send_String LTS, "'1Z', 13"

CP01: 25, 37, 00, 00, FF, 88

Obtaining All Pack Level status

This is the fastest way to see the levels in a PROlink system. The PROlink answer gives the pack

levels starting with pack one, a carriage return, and a line feed, and then the next pack. It does not

report packs that are not on line. This command does not identify any undefined channels.

Format:

Example:

PROlink responses:

MX Lighting PROlink/AXlink Programming

Send_String LTS, "'AZ', 13"

Send_String LTS, "'AZ', 13"

CP01: 25, 37, 00, 00, FF, 88

CP02: 00, 22, 99, FF, FF, FF …

23

Page 32

PROlink Command Structure

Obtaining a Pack Low End Setting status

This is the fastest way to see the Low End Settings in a pack. The PROlink answer gives the pack

Low End trim status from the selected pack starting with the pack number, followed by the six

dimmer channels beginning with dimmer one.

Format:

Variables: • <p>: This is the pack number 1-10 or A (all) (Only one pack at a time)

Example:

PROlink response:

Send_String LTS, "'<p>LE?', 13"

Send_String LTS, "'1LE?', 13"

CP01: 000, 005, 000, 000, 005, 000

Obtaining firmware version in PROlink

The PROlink version is useful if a specific Radia is to be queried for its Firmware version.

Format:

Example:

SEND_STRING RADIA," <pack#> `VER', 13"

String From [96:1:1]-[$0C<pack#> VERSION #3.01$0D$0A?] 11:53:29

Operation Commands

Operation commands are used for real-time lighting control and setup of scenes prior to

programming presets.

Recalling Presets

If the value for <t> is not entered, the AMX Lighting controller will use the value stored at the time

the preset was recorded. The <t> parameter is optional. This is the fastest way to have many lights

change levels.

Format:

Variables: • <s>: This is the preset number 1-128, 253, 254, 255

Example 1:

PROlink response:

Example 2:

PROlink response:

Send_String LTS, "'<s>B<t>', 13"

• <t>: This is the ramp rate, 0-255 in seconds (optional)

Send_String LTS, "'3B5', 13"

CGOTO 003 in 005

Send_String LTS, "'3B', 13"

CGOTO 003 in 003 (default time = 3)

Ramping Dimmers Up

The dimmer will continue ramping until the carriage return is sent or until the dimmer reaches level

zero or 100. Ramping is best done on the push, while stopping is done on the release of a button.

Format:

Variables: • <n>: This is the dimmer number from 1-60 or All (Any combination of dimmers)

Example:

PROlink response:

Send_String LTS, "'<n>U'" no<enter>

Send_String LTS, "'1U'"

C01 UP

24

AMX Lighting PROlink/AXlink Programming

Page 33

PROlink Command Structure

Ramping Dimmers Down

The dimmer will continue ramping until the carriage return is sent or until the dimmer reaches level

zero or 100. Ramping is best done on the push, while stopping is done on the release of a button.

Format:

Variables: • <n>: This is the dimmer number from 1-60 or All (Any combination of dimmers)

Example:

PROlink response:

Send_String LTS, "'<n>D'" no<enter>

Send_String LTS, "'1D'"

C01 DOWN

Stop Ramping Dimmers - Method 1

The dimmer will continue ramping until the carriage return or <enter> is sent or until the dimmer

reaches level zero or 100. Ramping is best done on the push, while stopping is done on the release

of a button.

Format:

Example:

PROlink response:

Send_String LTS, "13"

Send_String LTS, "13"

C01 STOP

Stop Ramping Dimmers - Method 2

This command will stop any amount of dimmers. It is useful in stopping individual dimmers during

a long fade.

Format:

Variables: • <n>: This is the dimmer number from 1-60 (Any combination of dimmers)

Example:

PROlink response:

Send_String LTS, "'<n>S', 13"

Send_String LTS, "'1-3&5S', 13"

CGROUP STOP

Stop Ramping for All Dimmers

This command will stop all dimmers. It is the most reliable way to stop the ramping of dimmers.

This command will also stop preset ramping.

Format:

Example:

PROlink response:

Send_String LTS, "'AS', 13"

Send_String LTS, "'AS', 13"

CALL STOP

Ramping a Preset Up

The preset will continue ramping until the carriage return is sent or until the new preset is reached.

Ramping is best done on the push, while stopping is done on the release of a button. This is the

same as AXlink channel command 145 and preset 254.

Format:

Example:

PROlink response:

Send_String LTS, "'PU'"

Send_String LTS, "'PU'"

CPRESET 001 RAMPING UP

MX Lighting PROlink/AXlink Programming

25

Page 34

PROlink Command Structure

Ramping a Preset Down

The preset will continue ramping until the carriage return is sent or until the new preset is reached.

Ramping is best done on the push, while stopping is done on the release of a button. This is the

same as AXlink channel command 146 and preset 255.

Format:

Example:

PROlink response:

Send_String LTS, "'PD'"

Send_String LTS, "'PD'"

CPRESET 001 RAMPING DOWN

Stop Ramping Presets - Method 1

The dimmer will continue ramping until the carriage return or <enter> is sent or until the dimmer

reaches level zero or 100. Ramping is best done on the push, while stopping is done on the release

of a button.

Format:

Example:

PROlink response:

Send_String LTS, "13"

Send_String LTS, "13"

CPRESET 001 RAMP STOPPED

Stop Ramping Presets - Method 2

The dimmer will continue ramping until this command is received.

Format:

Example:

PROlink response:

Send_String LTS, "'PS'"

Send_String LTS, "'PS'"

CPRESET 001 RAMP STOPPED

Setting Dimmer Levels

If the value for <t> is not entered, the AMX Lighting controller will use the value specified by the

Default Preset Time. The <t> parameter is optional. This is the fastest and most reliable way to send

multiple dimmers to the same level.

Format:

Optional Format:

Variables: • <n>: This is the dimmer number from 1-60 (Any combination of dimmers

Example:

PROlink response:

Send_String LTS, "'<n>L<m>T<t>', 13"

Send_String LTS, "'<n>L<m>', 13"

• <m>: This is the dimmer level percentage 0-100

• <t>: This is the ramp rate, 0-255 in seconds (optional)

Send_String LTS, "'1L57T3', 13"

C001 LEVEL 57 IN 003

26

AMX Lighting PROlink/AXlink Programming

Page 35

PROlink Command Structure

Setting Group Dimmer Levels

If the value for <t> is not entered, the AMX Lighting controller will use the value specified by the

Default Preset Time. The <t> parameter is optional. This is the fastest and most reliable way to send

multiple dimmers to the same level.

Format:

Optional Format:

Variables: • <n>: This is the dimmer number from 1-60 (Any combination of dimmers

Example:

PROlink response:

Send_String LTS, "'<n>L<m>T<t>', 13"

Send_String LTS, "'<n>L<m>', 13"

• <m>: This is the dimmer level percentage 0-100

• <t>: This is the ramp rate, 0-255 in seconds (optional)

Send_String LTS, "'1-3&6-8&12L63T5', 13"

CGROUP LEVEL 63 in 005

Setting Dimmer Levels as Undefined

Any undefined dimmers will not be included in a preset. A dimmer will stay in the undefined mode

until it is reassigned to a level from 0 to 100.

Format:

Variables: • <n>: This is the dimmer number from 1-60

Example:

PROlink response:

Send_String LTS, "'<n>LU', 13"

Send_String LTS, "'1LU', 13"

C001 LEVEL UN IN 000

Setting All Dimmer Levels as Undefined

Any undefined dimmers will not be included in a preset. A dimmer will stay in the undefined mode

until it is reassigned to a level from 0 to 100. This command duplicates the AXlink channel

command 155. This command is often used before recording a preset to clear the scene to a 'neutral'

level. A preset stored with all levels undefined will have no affect on the dimmers when recalled.

Use this type of preset to initiate unique actions that do not change the lighting.

Format:

Example:

PROlink response:

Send_String LTS, "'ALU', 13"

Send_String LTS, "ALU', 13'"

CALL LEVEL UN IN 000

Closing or Pushing a Dry Closure

The closure will remain closed until a release is sent. Closed closures respond on AXlink with

channels 147 to 154 going on. PROlink will display preset number recalled.

Format:

Variables: • <p>: This is the pack number 1-10 or A (all)

Example:

PROlink response:

MX Lighting PROlink/AXlink Programming

Send_String LTS, "'<p>XN<cl>', 13"

• <cl>: This is the dry closure number 1-8

Send_String LTS, "'1XN2', 13"

CGOTO 001 IN 000

27

Page 36

PROlink Command Structure

Opening or Releasing a Dry Closure

The closure will remain closed until a release is sent. Released closures respond on AXlink with

channels 147 to 154 going off.

Format:

Variables: • <p>: This is the pack number 1-10 or A (all)

Example:

PROlink response:

Send_String LTS, "'<p>XO<cl>', 13"

• <cl>: This is the dry closure number 1-8

Send_String LTS, "'1XO2', 13"

NO RESPONSE

28

AMX Lighting PROlink/AXlink Programming

Page 37

AXlink Command Structure

AMX Lighting Channel Commands

Channel commands are available for AMX Lighting firmware version 2.0 and greater. The

following table shows the AMX Lighting AXlink programming commands.

AMX Lighting Channel Commands

Channel number Function Channel number Function

1-128 Status of presets, indicates active preset 142 Ramp all 60 channels down

129 Ramp channel 1 up 143 Turn all 60 channel on

130 Ramp channel 2 up 144 Turn all 60 channels off

131 Ramp channel 3 up 145 Ramp active preset up

132 Ramp channel 4 up 146 Ramp active preset down

133 Ramp channel 5 up 147 Status of dry closure 1

134 Ramp channel 6 up 148 Status of dry closure 2

135 Ramp channel 1 down 149 Status of dry closure 3

136 Ramp channel 2 down 150 Status of dry closure 4

137 Ramp channel 3 down 151 Status of dry closure 5

138 Ramp channel 4 down 152 Status of dry closure 6

139 Ramp channel 5 down 153 Status of dry closure 7

140 Ramp channel 6 down 154 Status of dry closure 8

141 Ramp all 60 channels up 155 All levels 'Undefined'

AXlink Command Structure

Setup Commands

These commands are used to set the default values and parameters that are typically entered at the

startup of the system and not changed.

Setting a Default Level Time

Level Time is the time it takes for a level to change from its present state to a new level when using

a Level command. If a Level command is sent without the time value specified (T), the dimmer

goes to the specified level using the Default Level Time. The factory default for this value is 1

second.

Format:

Variables: • <t>: This is the ramp rate, 0-255 in seconds

Example:

PROlink response:

SEND_COMMAND LTS, 'LT<t>'

SEND_COMMAND LTS, 'LT1'

CLEVEL TIME SET AT 001

MX Lighting PROlink/AXlink Programming

29

Page 38

AXlink Command Structure

Setting a Default Ramp Time

Ramp Time is the time it takes to raise or lower the channel or preset from its preset levels to either

extreme of level zero or 100%. All ramp commands will use the Default Ramp Time. Individual

dimmers cannot have individual ramp rates. The factory default for this value is 6 seconds.

Format:

Variables: • <t>: This is the ramp rate, 1-255 in seconds; zero is not valid

Example:

PROlink response:

SEND_COMMAND LTS, 'RT<t>'

SEND_COMMAND LTS, 'RT5'

CRAMP TIME SET AT 005

Setting a Default Preset Time

Preset Time is the time it takes for a preset to be recalled. If a preset is stored or recalled without the

time value specified (T), it will be recalled or stored using the Default Preset Time. The factory

default for this value is 3 seconds.

Format:

Variables: • <t>: This is the ramp rate, 0-255 in seconds

Example:

PROlink response:

SEND_COMMAND LTS, 'PT<t>'

SEND_COMMAND LTS, 'PT3'

CPRESET TIME SET AT 003

Enabling AXlink Levels/Responses

PROlink acknowledges each command with a response. This command will enable responses to the

AXlink master, and it is the default start-up condition.

Format:

Example:

PROlink response:

SEND_COMMAND LTS, 'RXON'

SEND_COMMAND LTS, 'RXON'

CRXON MODE

30

Disabling AXlink Levels/Responses

PROlink acknowledges each command with a response. This command will disable responses to

the AXlink master, and it is the default start-up condition.

Format:

Example:

PROlink response:

SEND_COMMAND LTS, 'RXOFF'

SEND_COMMAND LTS, 'RXOFF'

NO RESPONSE

AMX Lighting PROlink/AXlink Programming

Page 39

AXlink Command Structure

Recording Commands

These commands send preset data to the AMX Lighting controller memory chip. All recording and

setup commands are stored in non-volatile memory. These commands are also used to store presets,

assign presets for dry closure recall, and erase stored presets.

Recording Presets

If the value for <t> is not entered, the AMX Lighting controller will use the value specified by the

Default Preset Time. The <t> parameter is optional.

Format:

Variables: • <s>: This is the preset number

Example:

PROlink response:

SEND_COMMAND LTS, 'SP<s>T<t>'

• <t>: This is the ramp rate, 0-255 in seconds

SEND_COMMAND LTS, 'SP1T3'

NO RESPONSE

Status Commands

Status commands allow a user or a program to get data from the lighting system and to act on that

information.

Retrieving the Current Preset status (feedback)

AXlink channels 1 through 128 are linked to the active status of the 128 presets. Presets are

mutually exclusive. If preset #1 is active, AXlink channel #1 is active.

Format:

Example:

PROlink response:

Retrieving a Dry Closure PUSH/RELEASE status

AXlink channels 147 through 154 are linked to the active status of the 8 dry closure inputs. Each

closure has an independent status. This input section of the AMX Lighting controller can act in a

similar manner to an Input8 card.

AXlink channel 1..channel 128

[PANEL, 100] = [LTS, 1]

CGOTO 001 IN 003

Format:

Feedback:

PUSH example:

PROlink response:

RELEASE example:

PROlink response:

Example 2: