Page 1

Hardware Reference Guide

NXI-x000 Series

NetLinx Integrated Controllers

(NI-2000, NI-3000, NI-4000)

NetLinx Integrated Controllers

Last Revised: 5/30/2008

Page 2

AMX Limited Warranty and Disclaimer

AMX warrants its products to be free of defects in material and workmanship under normal use for three (3) years from

the date of purchase from AMX, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch

overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, and MX Series products are warranted for a period of one

(1) year.

• AMX Lighting products are guaranteed to switch on and off any load that is properly connected to our lighting

products, as long as the AMX Lighting products are under warranty. AMX does guarantee the control of dimmable

loads that are properly connected to our lighting products. The dimming performance or quality cannot be

guaranteed due to the random combinations of dimmers, lamps and ballasts or transformers.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• AMX Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX or an Authorized AMX Dealer.

All products returned to AMX require a Return Material Authorization (RMA) number. The RMA number is obtained

from the AMX RMA Department. The RMA number must be clearly marked on the outside of each box. The RMA is

valid for a 30-day period. After the 30-day period the RMA will be cancelled. Any shipments received not consistent

with the RMA, or after the RMA is cancelled, will be refused. AMX is not responsible for products returned without a

valid RMA number.

AMX is not liable for any damages caused by its products or for the failure of its products to perform. This includes any

lost profits, lost savings, incidental damages, or consequential damages. AMX is not liable for any claim made by a

third party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort claim

(including negligence and strict product liability), a contract claim, or any other claim. This limitation of liability cannot

be waived or amended by any person. This limitation of liability will be effective even if AMX or an authorized

representative of AMX has been advised of the possibility of any such damages. This limitation of liability, however, will

not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or

exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of

the Limited Warranty may not apply. This Limited Warranty gives the owner specific legal rights. The owner may also

have other rights that vary from state to state. The owner is advised to consult applicable state laws for full

determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX MAKES NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. AMX EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED

WARRANTY. ANY IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF

THIS LIMITED WARRANTY.

Page 3

Table of Contents

Table of Contents

Introduction ........................................................................................................1

NI-2000 Specifications .............................................................................................. 2

NI-3000 Specifications .............................................................................................. 6

NI-4000 Specifications ............................................................................................ 10

Related Documents................................................................................................. 14

Installation and Upgrading ...............................................................................15

Installing NetLinx Control Cards (NI-4000 Only) ..................................................... 15

Setting the NetLinx Control Card Addresses (NI-4000 Only).................................. 16

Device:Port:System (D:P:S)............................................................................................ 16

Removing NetLinx Control Cards (NI-4000 Only) ................................................... 17

Compact Flash Upgrades........................................................................................ 17

Accessing The Internal Components On An Integrated Controller ............................... 17

Installation of Compact Flash Upgrades........................................................................ 18

Closing and Securing the Outer Housing ...................................................................... 19

Installing Into An Equipment Rack .......................................................................... 19

Connections and Wiring ...................................................................................21

Setting the Configuration DIP Switch (for the Program Port) ................................. 21

Baud Rate Settings........................................................................................................ 21

Program Run Disable (PRD) Mode................................................................................. 21

Working With the Configuration DIP Switch ................................................................. 22

Setting the CardFrame DIP Switch (NI-4000 Only) ................................................. 22

Program Port Connections and Wiring ................................................................... 22

Modes and Front Panel LED Blink Patterns ............................................................ 23

Port Assignments and Functionality........................................................................ 23

AXlink Port and LED ............................................................................................... 24

Wiring Guidelines ................................................................................................... 24

Wiring length guidelines ............................................................................................... 24

Preparing Captive Wires ............................................................................................... 25

Wiring a Power Connection........................................................................................... 25

Using the 4-Pin Mini-Phoenix Connector For Data and Power ...................................... 25

Using the 4-pin Mini-Phoenix Connector For Data With External Power ...................... 26

DB9 Device Port: Connections and Wiring ............................................................. 26

ICSNet Port: Connections and Wiring..................................................................... 27

ICSHub OUT Port: Connections and Wiring ............................................................ 28

Relay Port: Connections and Wiring ....................................................................... 28

Relay Connections ......................................................................................................... 28

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

i

Page 4

Table of Contents

Input/Output (I/O) Port: Connections and Wiring ................................................... 29

IR/Serial Port: Connections and Wiring................................................................... 30

NetLinx Control Card Slot Connector (NI-4000 only).............................................. 30

Ethernet/RJ-45 Port: Connections and Wiring ........................................................ 31

Ethernet LEDs .............................................................................................................. 31

Ethernet Ports Used By the Integrated Controller ........................................................ 32

ii

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 5

Introduction

NetLinx Integrated Master Controllers can be programmed to control RS-232/422/485, Relay,

IR/Serial, and Input/Output devices through the use of both the NetLinx programming language and the

NetLinx Studio application (version 2.4 or higher). Another key feature of this products is the ability to

easily access the configuration switches without having to remove a

cover plate.

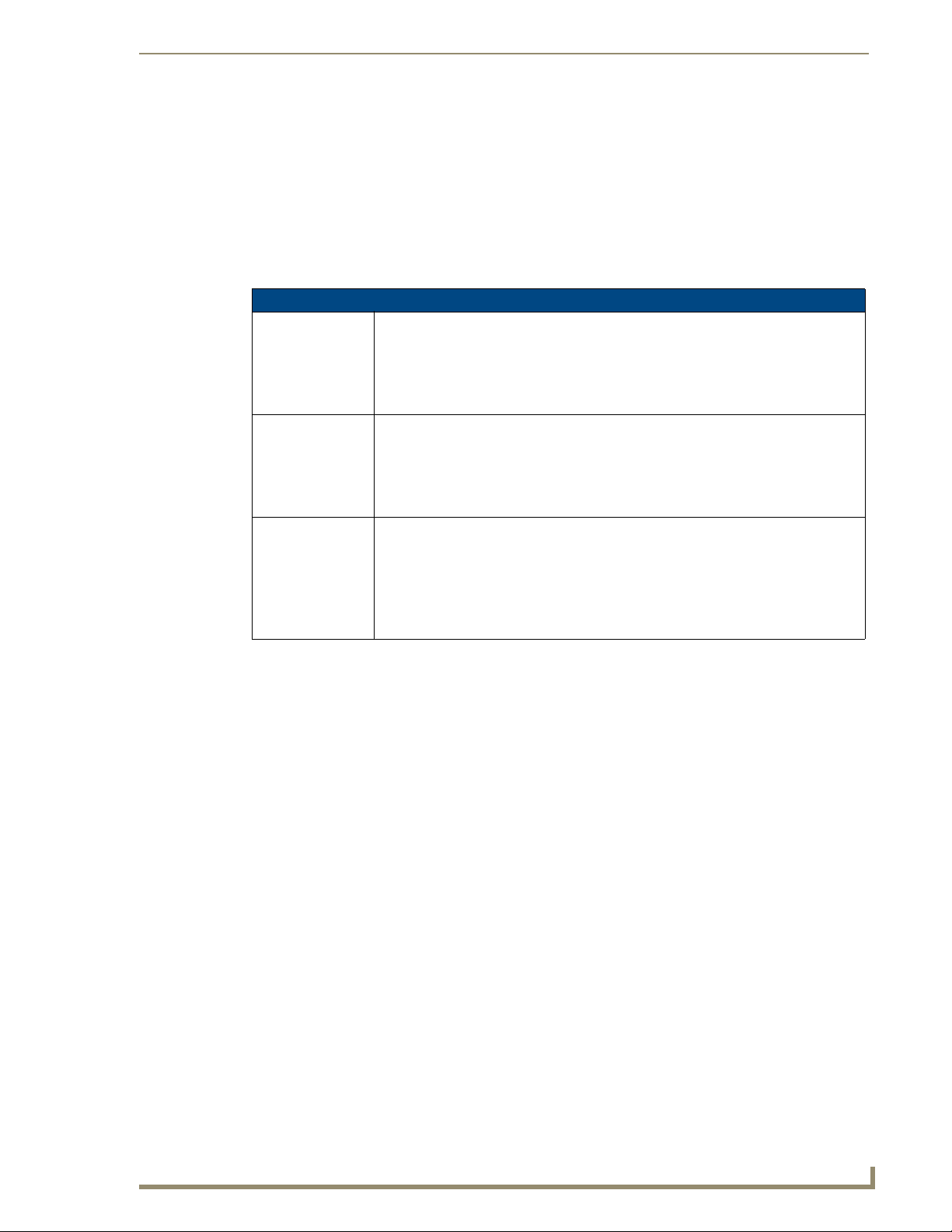

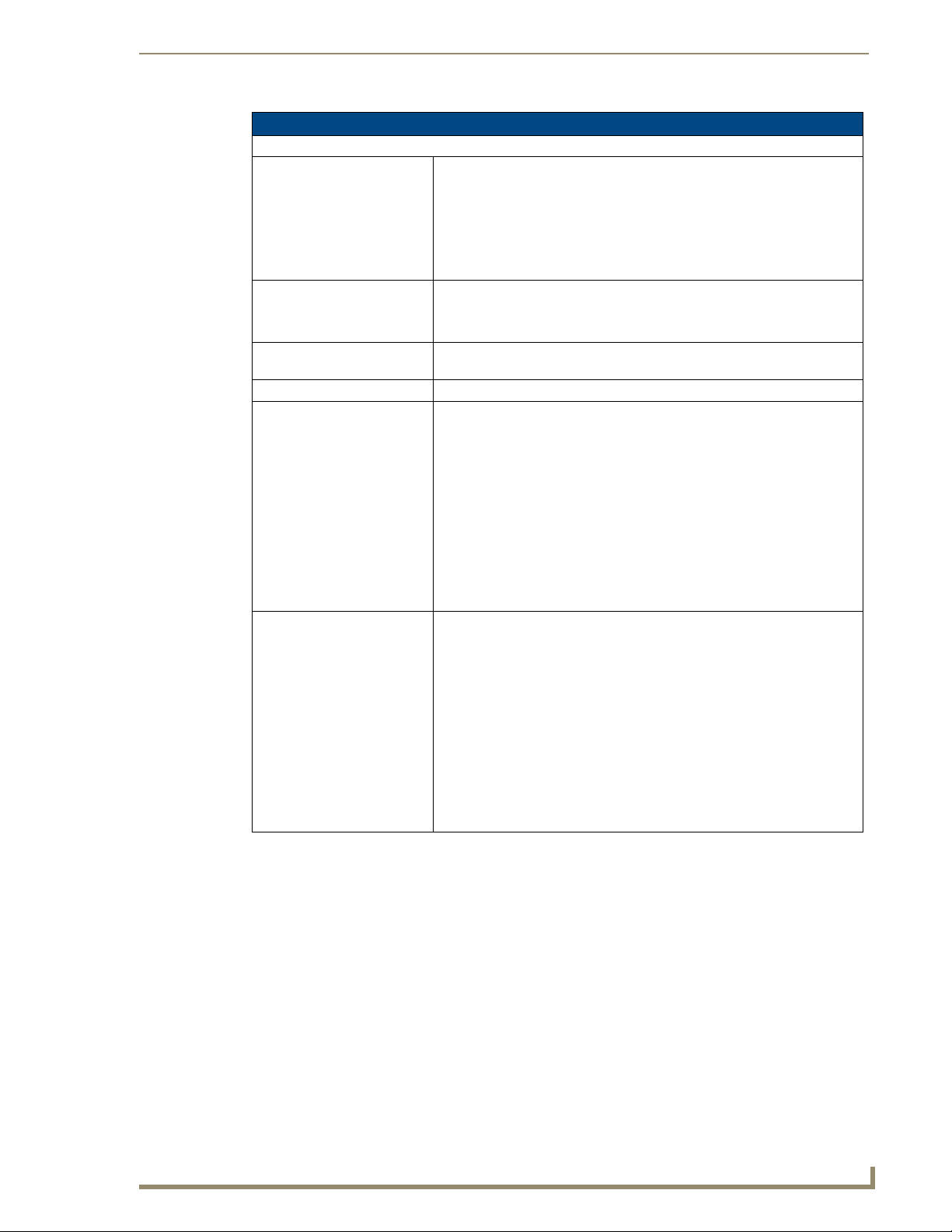

NetLinx Integrated Master Controller Features

NI-2000

(FG2105-01)

NI-3000

(FG2105-02)

NI-4000

(FG2105)

Introduction

• 1 RS-232 Program port

• 3 RS-232/RS-422/RS-485 ports

• 4 IR/Serial Output ports

• 4 Digital Input/Output ports

•4 Relays

• 1 RS-232 Program port

• 7 RS-232/RS-422/RS-485 ports

• 8 IR/Serial Output ports

• 8 Digital Input/Output ports

•8 Relays

• Support for up to 4 NetLinx control cards (such as NXC-COM2, NXC-IRS4, etc.)

• 1 RS-232 Program port

• 7 RS-232/RS-422/RS-485 ports

• 8 IR/Serial Output ports

• 8 Digital Input/Output ports

•8 Relays

These NI Controllers are Duet-compatible and can be upgraded via firmware. Duet is a dual-interpreter

firmware platform from AMX which combines the proven reliability and power of NetLinx with the

®

extensive capabilities of the Java

2 MicroEdition (J2ME) platform. Duet simplifies the programming of

a system that includes the NI-900 and other third party devices by standardizing device and function

definitions, defaulting touch panel button assignments, and controlling feedback methods. Dynamic

Device Discovery makes integration even easier by automatically identifying and communicating with

devices which support this new beaconing technology.

These NI Controllers use a combination lithium battery and clock crystal package called a Timekeeper.

Only one Timeke eper unit is installed within a given NI controller. The battery can be expected to have

up to 3 years of usable life under very adverse conditions. Actual life is appreciably longer under normal

operating conditions. This calculation is based on storing the unit without power in 50° C (120° F)

temperature until battery levels are no longer acceptable. The part number for a replacement battery is

57-0032.

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

1

Page 6

Introduction

NI-2000 Specifications

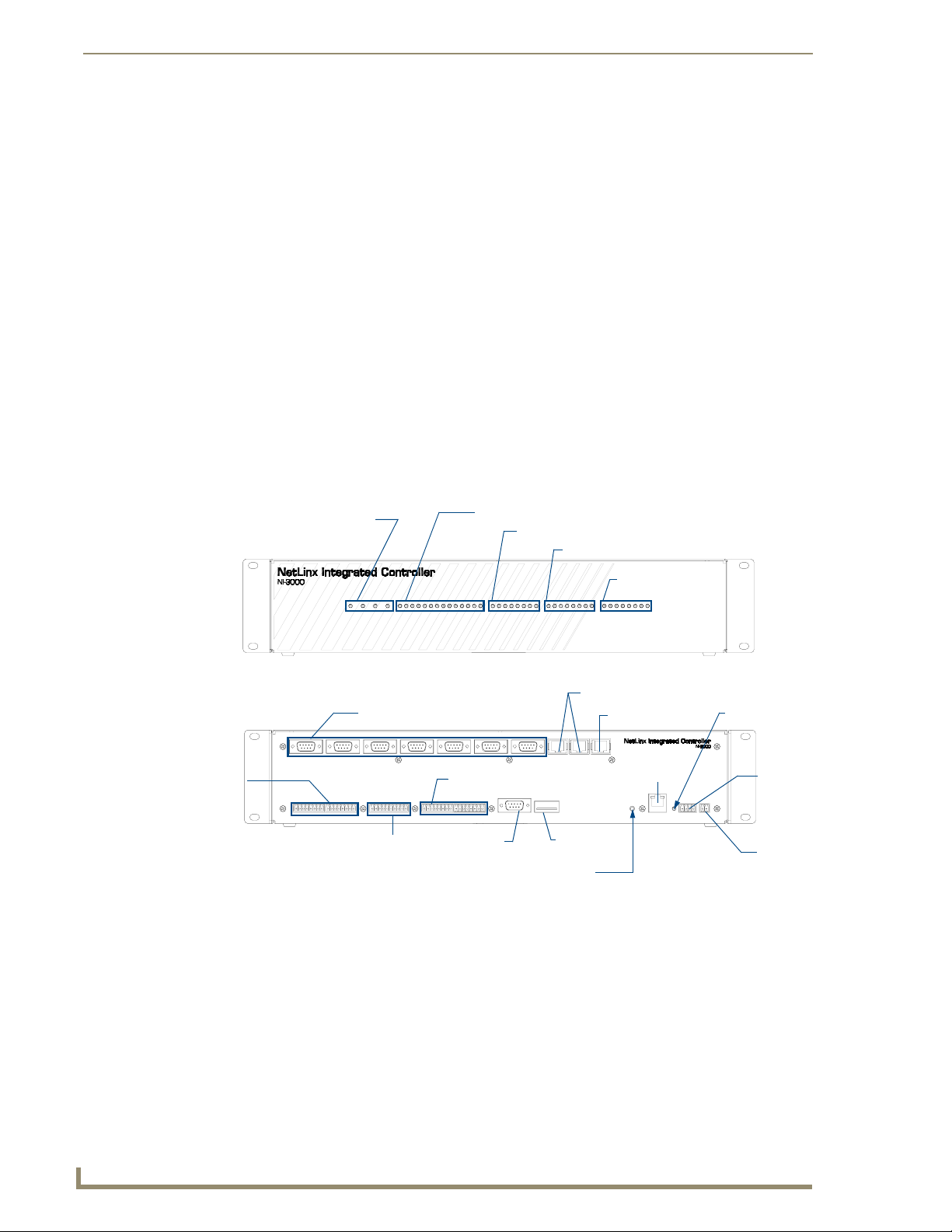

The front panel LEDs (FIG. 1) are grouped by control type and are labeled according to their

corresponding port (connector) numbers on the rear of the unit. The back of the unit contains three

RS-232/422/485, one Relay, one IR/Serial and one I/O connectors. In addition, this unit provides an ID

pushbutton, AXlink LED, and other related connectors. FIG. 2 s hows th e fr ont a nd r ear o f th e NI -20 00.

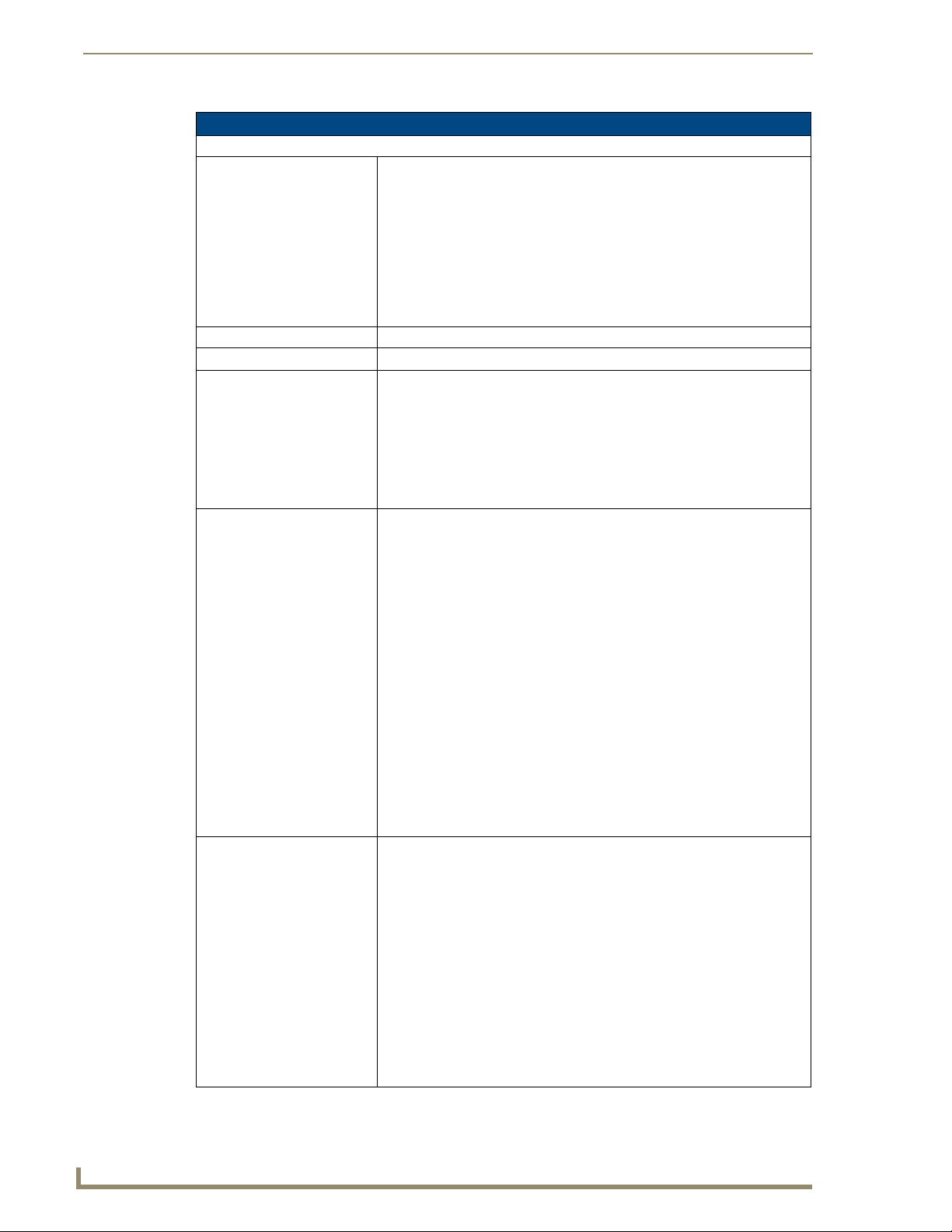

FIG. 1 NI-2000 NetLinx Integrated Controller (front view)

RS-232/422/485 TX/RX LEDs (red/yellow)

Link/Active-Status-Output-Input

Relay LEDs (red)

IR/Serial LEDs (red)

Front

Rear

Relays

(Port 4)

FIG. 2 NI-2000 front and rear panel components

RS-232/422/485 (Ports 1-3)

IR/Serial (Ports 5-8)

I/O (Port 9)

Program

port

ICSNet (2)

DIP

switch

ID Pushbutton

I/O LEDs

(yellow)

ICSHub Out

Ethernet

AXlink LED

(green)

AXlink

port

PWR

2

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 7

Introduction

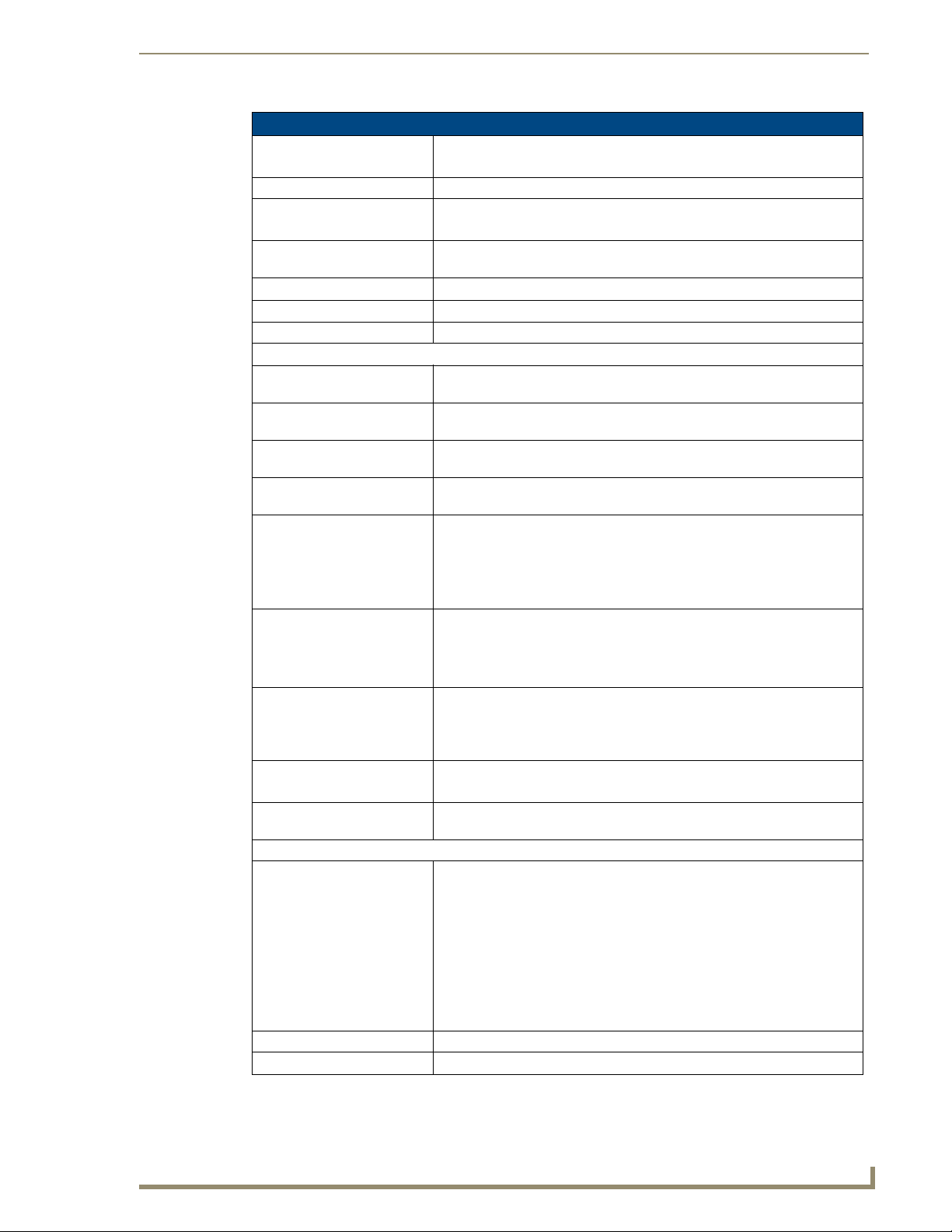

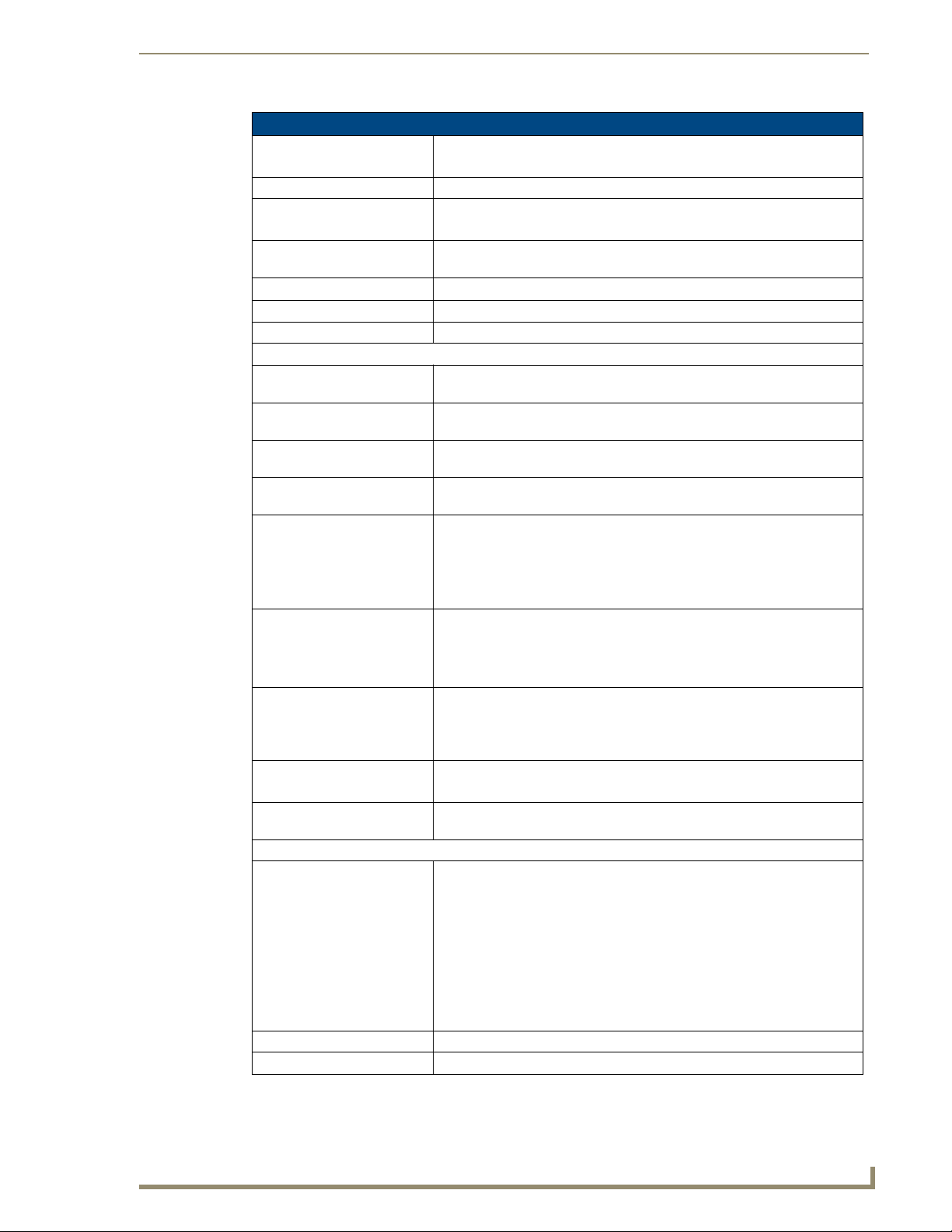

NI-2000 Specifications

Dimensions (HWD): • 3.47" x 17.00" x 3.47" (8.81 cm x 43.18 cm x 8.82 cm)

• 2 RU (rack unit) high

Power Requirement: • 700 mA @ 12 VDC

Memory: • 32 MB SDRAM

• 1 MB of Non-volatile Flash

Compact Flash: • 32 MB Card (upgradeable). Refer to the Other AMX Equipment section on

page 5 for more information.

Weight: • 4.50 lbs (2.04 kg)

Enclosure: • Metal with black matte finish

Certifications: • FCC Part 15 Class B and CE

Front Panel Components:

LINK/ACT • Green LED blinks when the Ethernet cable is connected and an active link

is established. This LED also blinks when receiving Ethernet data packets.

Status • Green LED blinks to indicate that the system is programmed and

communicating properly.

Output • Red LED blinks when the Controller transmits data, sets channels On/Off,

sends data strings, etc.

Input • Yellow LED blinks when the Controller receives data from button pushes,

strings, commands, channel levels, etc.

RS-232/422/485 LEDs • Three sets of red and yellow LEDs light to indicate the rear DB9 Ports 1 - 3

Relay LEDs • Four red LEDs light to indicate the rear relay channels 1 - 4 are active

IR/Serial LEDs • Four red LEDs light to indicate the rear IR/Serial channels 1 - 4 are

I/O LEDs • Four yellow LEDs light when the rear I/O channels 1 - 4 are active

Rack-mount brackets • Provide an installation option for the Integrated Controller to be mounted

Rear Panel Connectors:

RS-232/422/485 (Ports 1 -3) • Three RS-232/422/485 control ports using DB9 (male) connectors with

ICSNet • Tw o RJ-45 connectors for ICSNet interface

ICSHub Out • RJ-45 connector provides data to another Hub connected to the Controller

are transmitting or receiving RS-232, 422, or 485 data:

- TX LEDs (red) light when transmitting data

- RX LEDs (yellow) light when receiving data

- LED activity reflects transmission and reception activity

(closed).

• These LEDs reflect the state of the relay on Port 4

• If the relay is engaged = LED On and if the relay is Off = LED Off

transmitting control data on Ports 5 - 8

• LED indictor for each IR port remains lit for the length of time that IR/Serial

data is being generated

• LED indicator for each I/O port reflects the state of that particular port

into an equipment rack, when used with the Installation Kit (KA2105-01).

XON/XOFF (transmit On/transmit Off), CTS/RTS (clear to send/ready to

send), and 300-115,200 baud.

• Channel range = 1-255

• Channels 1-254 provide feedback

• Channel 255 (CTS Push channel): Reflects the state of the CTS Input if a

'CTSPSH' command was sent to the port

• Output data format for each port is selected via software

• Three DB9 connectors provide RS-232/422/485 termination

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

3

Page 8

Introduction

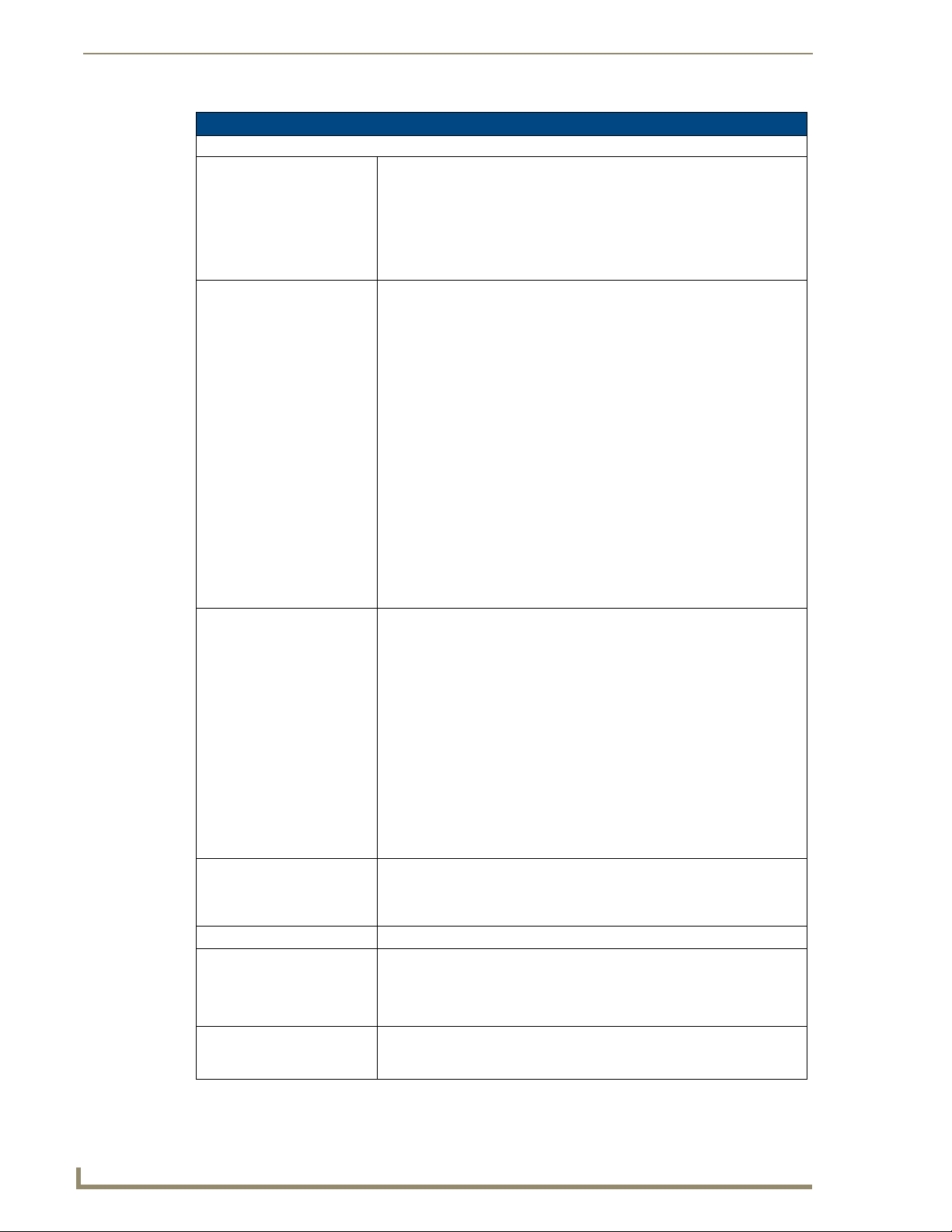

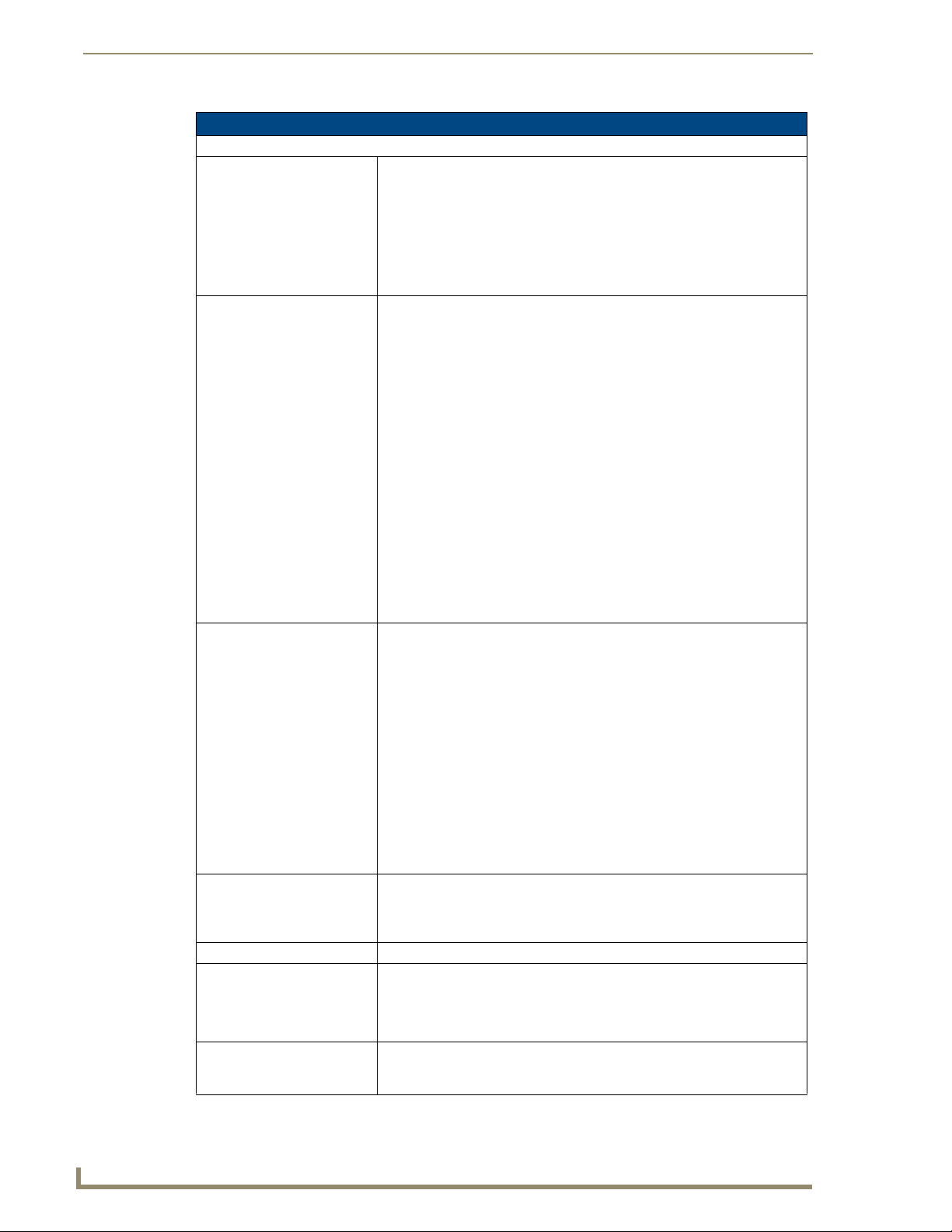

NI-2000 Specifications (Cont.)

Rear Panel Connectors (Cont.):

Relay (Port 4) • Four-channel single-pole single-throw relay ports

• Each relay is independently controlled.

• Supports up to 4 independent external relay devices

• Channel range = 1-4

• Each relay can switch up to 24 VDC or 28 VAC @ 1 A

• 8-pin 3.5 mm mini-Phoenix (female) connector provides relay termination

Digital I/O (Port 9) • Four-channel binary I/O port for contact closure

• Each input is capable of voltage sensing. Input format is software

selectable.

• Interactive power sensing for IR ports

• Channel range = 1-4

• All inputs are assigned to respective IR/Serial ports for "automatic" power

control through the use of software commands. Power control is provided

via commands such as: ’PON’, ’POF’, ’POD’, ’DELAY’, I/O Link etc.).

• Contact closure between GND and an I/O port is detected as a PUSH

• When used as voltage input - I/O port detects a low signal (0- 1.5 VDC) as

a PUSH and a high signal (3.5 - 5 VDC) as a RELEASE

• When used as an output - each I/O port acts as a switch to GND and is

rated at 200 mA @ 12 VDC

• 6-pin 3.5 mm mini-Phoenix (female) connector provides I/O port

termination

Note: This IO port uses 5V logic but can handle up to 12V without harm. It

can handle up to 12V on the input. At higher voltages you run a higher risk of

surge damage.

IR/Serial (Ports 5-8) • Four IR/Serial control ports support high-frequency carriers of up to

1.142 MHz.

• Each output is capable of three electrical formats: IR, Serial, and Data

• Four IR/Serial data signals can be generated simultaneously.

• Channel range = 1-32,767

• Channels 1-128 (output): IR commands

• Channels 129-253: used as reference channels

• Channel 254 (feedback): Power Fail (used with 'PON' and 'POF'

commands)

• Channel 255 (feedback): Power status (when IO Link is set)

• IR ports support data mode (at limited baud rates and wiring distances).

• 8-pin 3.5 mm mini-Phoenix (female) connector provides IR/Serial port

termination

Program port • RS-232 DB9 connector (male) can be connected to a DB9 port on a

computer; used with serial commands, NetLinx programming commands,

other DB9 capable devices, and to upload/download information from the

NetLinx Studio 2.4 program.

Configuration DIP switch • Sets the communication parameters for the Program port.

ID pushbutton • Provides the NetLinx ID (Device only) assignment for the device.

• The D notation is used to represent a device number.

• Refer to the NetLinx Integrated Controller WebConsole & Programming

Guide for details.

Ethernet port • RJ-45 port for 10/100 Mbps communication. This port automatically

negotiates the connection speed (10 Mbps or 100 Mbps) and whether to

use half duplex or full duplex mode.

4

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 9

Introduction

NI-2000 Specifications (Cont.)

Rear Panel Connectors (Cont.):

Ethernet Link/Activity LED • LEDs show communication activity, connection status, speeds, and mode

information:

SPD (speed) - Yellow LED lights On when the connection speed is 100

Mbps and turns Off when the speed is 10 Mbps.

L/A (link/activity) - Green LED lights On when the Ethernet cables are

connected/terminated correctly, and blinks when receiving Ethernet data

packets.

AXlink LED • Green LED indicates the state of the AXlink connector port.

• Normal AXlink activity = 1 blink/second

• Abnormal AXlink activity = cycle of 3 consecutive blinks and then Off

AXlink port • 4-pin 3.5 mm mini-Phoenix (male) connector provides data and power to

external control devices.

Power port • 2-pin 3.5 mm mini-Phoenix (male) connector

Included Accessories: • 2-pin 3.5 mm mini-Phoenix (female) PWR connector (41-5025)

• 4-pin 3.5 mm mini-Phoenix (female) AXlink connector (41-5047)

• 6-pin 3.5 mm mini-Phoenix (female) I/O connector (41-5063)

• 8-pin 3.5 mm mini-Phoenix (female) Relay connector (41-5083)

• Installation Kit (KA2105-01):

8-pin Relay Common Strip

Four rack mount screws

Four washers

• NI-2000 Quick Start Guide

• Two CC-NIRC IR Emitters

• Two removable rack ears (62-2105-07)

Other AMX Equipment: • 2-pin 3.5 mm mini-Phoenix male connector (41-5026)

• CC-NIRC IR cables (FG10-000-11)

• CC-NSER IR/Serial cables (FG10-007-10)

• CSB Cable Support Bracket (FG517)

• NCK, NetLinx Connector Kit (FG2902)

• STS, Serial To Screw Terminal (FG959)

• Upgrade Compact Flash (factory programmed with firmware):

NXA-CFNI64M - 64 MB compact flash card (FG2116-31)

NXA-CFNI128M - 128 MB compact flash card (FG2116-32)

NXA-CFNI256M - 256 MB compact flash card (FG2116-33)

NXA-CFNI512M - 512 MB compact flash card (FG2116-34)

NXA-CFNI1G - 1 GB compact flash card (FG2116-35)

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

5

Page 10

Introduction

NI-3000 Specifications

The front LEDs (FIG. 3) are grouped by control type and are labeled according to their corresponding

port (connector) numbers on the rear of the unit. The back of the this unit contains RS-232/422/485,

Relay, IR/Serial and I/O connectors. In addition, this unit provides an ID pushbutton, AXlink LED, and

other related connectors. FIG. 4 shows the front and rear of the

NI-3000.

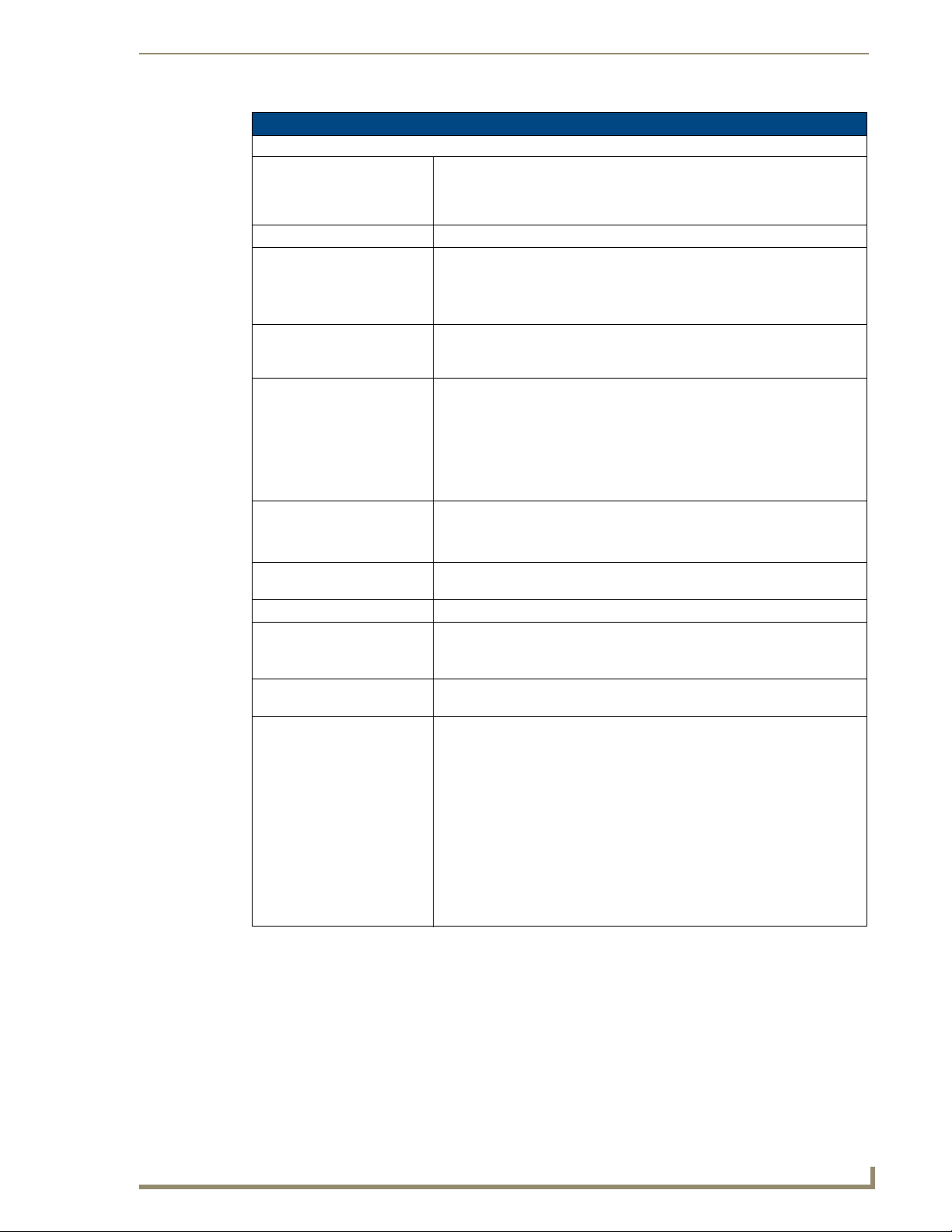

FIG. 3 NI-3000 NetLinx Integrated Controller (front view)

Link/Active-Status-Output-Input

Front

Rear

Relays

(Port 8)

FIG. 4 NI-3000 front and rear panel components

RS-232/422/485 (Ports 1-7)

I/O (Port 17)

RS-232/422/485 TX/RX LEDs (red/yellow)

Relay LEDs (red)

IR/Serial LEDs (red)

I/O LEDs (yellow)

ICSNet (2)

ICSHub Out

IR/Serial (Ports 9-16)

Program

port

DIP

switch

ID Pushbutton

Ethernet

AXlink LED

(green)

AXlink

port

PWR

6

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 11

Introduction

NI-3000 Specifications

Dimensions (HWD): • 3.47" x 17.00" x 3.47" (8.81 cm x 43.18 cm x 8.82 cm)

• 2 RU (rack unit) high

Power Requirement: • 900 mA @ 12 VDC

Memory: • 32 MB SDRAM

• 1 MB of Non-volatile Flash

Compact Flash: • 32 MB Card (upgradeable). Refer to the Other AMX Equipment section on

page 9 for more information.

Weight: • 4.55 lbs (2.06 kg)

Enclosure: • Metal with black matte finish

Certifications: • FCC Part 15 Class B and CE

Front Panel Components:

LINK/ACT • Green LED lights when the Ethernet cable is connected and an active link

is established. This LED also blinks when receiving Ethernet data packets.

Status • Green LED lights to indicate that the system is programmed and

communicating properly.

Output • Red LED lights when the Controller transmits data, sets channels On/Off,

sends data strings, etc.

Input • Yellow LED lights when the Controller receives data from button pushes,

strings, commands, channel levels, etc.

RS-232/422/485 LEDs • Seven sets of red and yellow LEDs light to indicate the rear DB9 Ports 1-7

Relay LEDs • Eight red LEDs light to indicate the rear relay channels 1-8 are active

IR/Serial LEDs • Eight red LEDs light to indicate the rear IR/Serial channels 1-8 are

I/O LEDs • Eight yellow LEDs light when the rear I/O channels 1-8 are active

Rack-mount brackets • Provide an installation option for the Integrated Controller to be mounted

Rear Panel Connectors:

RS-232/422/485 (Ports 1 -7) • Seven RS-232/422/485 control ports using DB9 (male) connectors with

ICSNet • Tw o RJ-45 connectors for ICSNet interface

ICSHub Out • RJ-45 connector provides data to another Hub connected to the Controller

are transmitting or receiving RS-232, 422, or 485 data:

- TX LEDs (red) light when transmitting data

- RX LEDs (yellow) light when receiving data

- LED activity reflects transmission and reception activity

(closed)

• These LEDs reflect the state of the relay on Port 8

• If the relay is engaged = LED On and if the relay is Off = LED Off

transmitting control data on Ports 9-16

• LED indictor for each IR port remains lit for the length of time that IR/Serial

data is being generated

• LED indicator for each I/O port reflects the state of that particular port

into an equipment rack, when used with the Installation Kit (KA2105-01).

XON/XOFF (transmit on/transmit off), CTS/RTS (clear to send/ready to

send), and 300-115,200 baud.

• Channel range = 1-255

• Channels 1-254 provide feedback

• Channel 255 (CTS Push channel): Reflects the state of the CTS Input if a

'CTSPSH' command was sent to the port

• Output data format for each port is selected via software

• Seven DB9 connectors provide RS-232/422/485 termination

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

7

Page 12

Introduction

NI-3000 Specifications (Cont.)

Rear Panel Connectors (Cont.):

Relay (Port 8) • Eight-channel single-pole single-throw relay ports

• Each relay is independently controlled.

• Supports up to 8 independent external relay devices

• Channel range = 1-8

• Each relay can switch up to 24 VDC or 28 VAC @ 1 A

• Two 8-pin 3.5 mm mini-Phoenix (female) connectors provide relay

termination

Digital I/O (Port 17) • Eight-channel binary I/O port for contact closure

• Each input is capable of voltage sensing. Input format is software

selectable.

• Interactive power sensing for IR ports

• Channel range = 1-8

• All inputs are assigned to respective IR/Serial ports for "automatic" power

control through the use of software commands. Power control is provided

via commands such as: ’PON’, ’POF’, ’POD’, ’DELAY’, I/O Link etc.).

• Contact closure between GND and an I/O port is detected as a PUSH

• When used as voltage input - I/O port detects a low signal (0- 1.5 VDC) as

a PUSH and a high signal (3.5 - 5 VDC) as a RELEASE

• When used as an output - each I/O port acts as a switch to GND and is

rated at 200 mA @ 12 VDC

• 10-pin 3.5 mm mini-Phoenix (female) connector provides I/O port

termination

Note: This IO port uses 5V logic but can handle up to 12V without harm. It

can handle up to 12V on the input. At higher voltages you run a higher risk of

surge damage.

IR/Serial (Ports 9-16) • Eight IR/Serial control ports support high-frequency carriers up to

1.142 MHz

• Each output is capable of three electrical formats: IR, Serial, and Data

• Eight IR/Serial data signals can be generated simultaneously.

• Channel range = 1-32,767

• Channels 1-128 (output): IR commands

• Channels 129-253: used as reference channels

• Channel 254 (feedback): Power Fail (used with 'PON' and 'POF'

commands)

• Channel 255 (feedback): Power status (when IO Link is set)

• IR ports support data mode (at limited baud rates and wiring distances).

• Two 8-pin 3.5 mm mini-Phoenix (female) connectors provide IR/Serial port

termination

Program port • RS-232 DB9 connector (male) can be connected to a DB9 port on a

computer; used with serial commands, NetLinx programming commands,

other DB9 capable devices, and to upload/download information from the

NetLinx Studio 2.4 program.

Configuration DIP switch • Sets the communication parameters for the Program port.

ID pushbutton • Provides the NetLinx ID (Device only) assignment for the device.

• The D notation is used to represent a device number.

• Refer to the NetLinx Integrated Controller WebConsole & Programming

Guide for details.

Ethernet port • RJ-45 port for 10/100 Mbps communication. This port automatically

negotiates the connection speed (10 Mbps or 100 Mbps) and whether to

use half duplex or full duplex mode.

8

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 13

Introduction

NI-3000 Specifications (Cont.)

Rear Panel Connectors (Cont.):

Ethernet Link/Activity LED • LEDs show communication activity, connection status, speeds, and mode

information:

SPD (speed) - Yellow LED lights On when the connection speed is 100

Mbps and turns Off when the speed is 10 Mbps.

L/A (link/activity) - Green LED lights On when the Ethernet cables are

connected/terminated correctly, and blinks when receiving Ethernet data

packets.

AXlink LED • Green LED indicates the state of the AXlink connector port.

• Normal AXlink activity = 1 blink/second

• Abnormal AXlink activity = cycle of 3 consecutive blinks and then Off

AXlink port • 4-pin 3.5 mm mini-Phoenix (male) connector provides data and power to

external control devices.

Power port • 2-pin 3.5 mm mini-Phoenix (male) connector

Included Accessories: • 2-pin 3.5 mm mini-Phoenix (female) PWR connector (41-5025)

• 4-pin 3.5 mm mini-Phoenix (female) AXlink connector (41-5047)

• 10-pin 3.5 mm mini-Phoenix (female) I/O connector (41-5107)

• Installation Kit (KA2105-01):

8-pin Relay Common Strip

Four rack mount screws

Four washers

• NI-3000 Quick Start Guide

• Two 8-pin 3.5 mm mini-Phoenix (female) Relay connectors (41-5083)

• Two CC-NIRC IR Emitters

• Two removable rack ears (62-2105-07)

Other AMX Equipment: • 2-pin 3.5 mm mini-Phoenix male connector (41-5026)

• CC-NIRC IR cables (FG10-000-11)

• CC-NSER IR/Serial cables (FG10-007-10)

• CSB Cable Support Bracket (FG517)

• NCK, NetLinx Connector Kit (FG2902)

• STS, Serial To Screw Terminal (FG959)

• Upgrade Compact Flash (factory programmed with firmware):

NXA-CFNI64M - 64 MB compact flash card (FG2116-31)

NXA-CFNI128M - 128 MB compact flash card (FG2116-32)

NXA-CFNI256M - 256 MB compact flash card (FG2116-33)

NXA-CFNI512M - 512 MB compact flash card (FG2116-34)

NXA-CFNI1G - 1 GB compact flash card (FG2116-35)

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

9

Page 14

Introduction

NI-4000 Specifications

The front LEDs (FIG. 5) are grouped by control type, and are labeled according to their corresponding

port (connector) numbers on the rear of the unit. The back of the this unit contains RS-232/422/485,

Relay, IR/Serial and I/O connectors. In addition, this unit provides an ID pushbutton, AXlink LED,

NetLinx Card slots, and other related connectors. FIG. 6 shows the front and rear of the NI-4000.

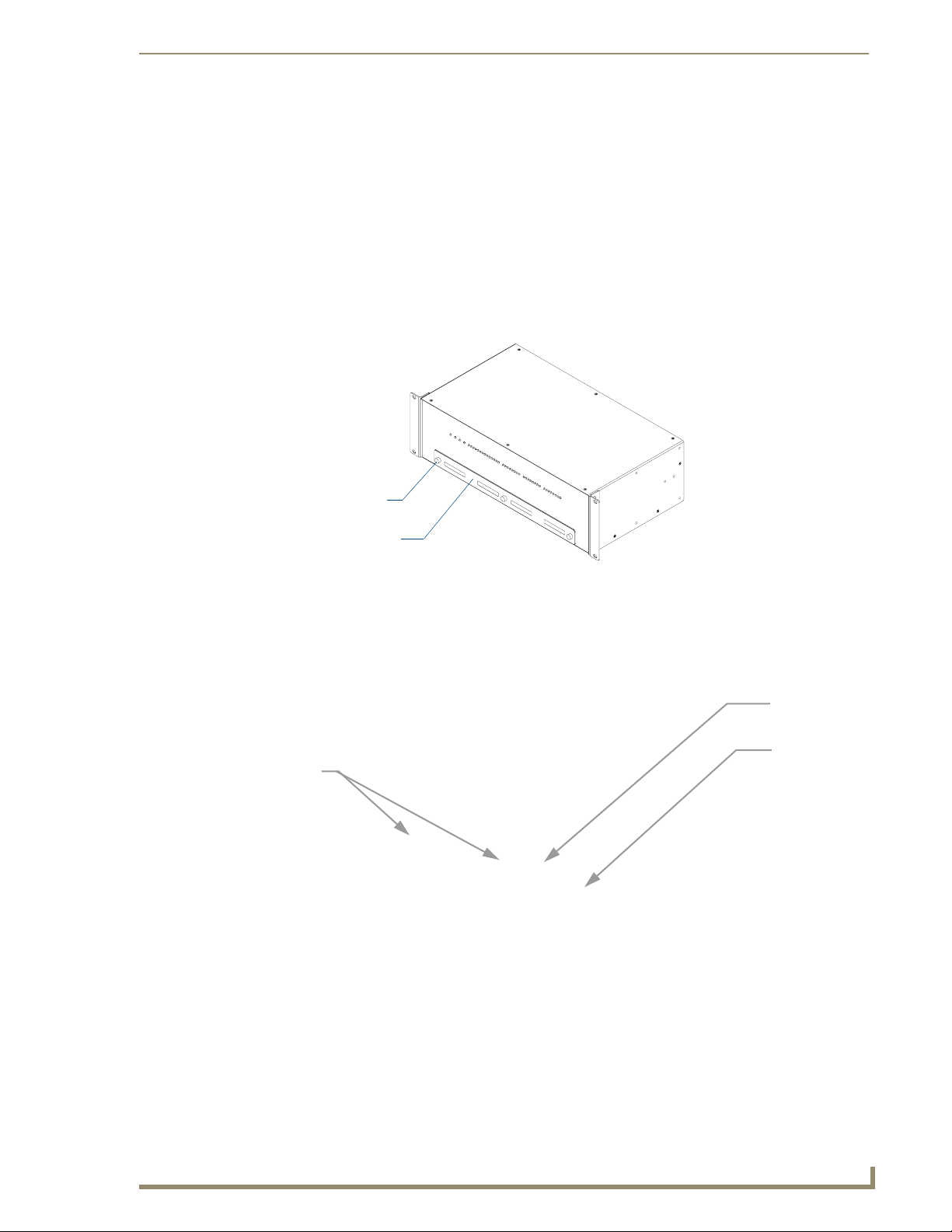

FIG. 5 NI-4000 NetLinx Integrated Controller (front view)

Link/Active-Status-Output-Input

NetLinx

Card

slots

(1-4)

Front

Rear

Relays

(Port 8)

CardFrame DIP

switch

FIG. 6 NI-4000 front and rear panel components

RS-232/422/485 (Ports 1-7)

I/O (Port 17)

Slot 1-4 connectors

RS-232/422/485 TX/RX LEDs (red/yellow)

Relay LEDs (red)

IR/Serial LEDs (red)

I/O LEDs (yellow)

ICSNet (2)

ICSHub Out

DIP

switch

Ethernet

IR/Serial (Ports 9-16)

Program port

ID Pushbutton

AXlink LED

(green)

AXlink

port

PWR

10

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 15

Introduction

NI-4000 Specifications

Dimensions (HWD): • 5.21" x 17.00" x 9.60" (13.23 cm x 43.18 cm x 24.27 cm)

• 3 RU (rack unit) high

Power Requirement: • 900 mA @ 12 VDC (no cards)

Memory: • 32 MB SDRAM

• 1 MB of Non-volatile Flash

Compact Flash: • 32 MB Card (upgradeable). Refer to the Other AMX Equipment section on

page 14 for more information.

Weight: • 9.15 lbs (4.15 kg)

Enclosure: • Metal with black matte finish

Certifications: • FCC Part 15 Class B and CE

Front Panel Components:

LINK/ACT • Green LED lights when the Ethernet cable is connected and an active link is

established. This LED also blinks when receiving Ethernet data packets.

Status • Green LED lights to indicate that the system is programmed and

communicating properly.

Output • Red LED lights when the Controller transmits data, sets channels On/Off,

sends data strings, etc.

Input • Yellow LED lights when the Controller receives data from button pushes,

strings, commands, channel levels, etc.

RS-232/422/485 LEDs • Seven sets of red and yellow LEDs light to indicate the rear DB9 Ports 1-7

Relay LEDs • Eight red LEDs light to indicate the rear relay channels 1-8 are active

IR/Serial LEDs • Eight red LEDs light to indicate the rear IR/Serial channels 1-8 are

I/O LEDs • Eight yellow LEDs light when the rear I/O channels 1-8 are active

NetLinx Control

Card slots 1- 4

Rack-mount brackets • Provide an installation option for the Integrated Controller to be mounted

are transmitting or receiving RS-232, 422, or 485 data:

- TX LEDs (red) light when transmitting data

- RX LEDs (yellow) light when receiving data

- LED activity reflects transmission and reception activity

(closed)

• These LEDs reflect the state of the relay on Port 8

• If the relay is engaged = LED On and if the relay is Off = LED Off

transmitting control data on Ports 9-16

• LED indictor for each IR port remains lit for the length of time that IR/Serial

data is being generated

• LED indicator for each I/O port reflects the state of that particular port

Accepts up to 4 compatible NetLinx Control Cards:

• NXC-COM2 Dual COM Port Control Card (FG2022)

• NXC-I/O10 Input/Output Control Card (FG2021)

• NXC-IRS4 4-Port IR/S Control Card (FG2023)

• NXC-REL10 Relay Control Card (FG2020)

• NXC-VAI4 Analog Voltage Control Card (FG 2025)

• NXC-VOL4 Volume Control Card (FG2024)

into an equipment rack, when used with the Installation Kit (KA2105-01).

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

11

Page 16

Introduction

NI-4000 Specifications (Cont.)

Rear Panel Connectors:

RS-232/422/485 (Ports 1 -7) • Seven RS-232/422/485 control ports using DB9 (male) connectors with

XON/XOFF (transmit on/transmit off), CTS/RTS (clear to send/ready to

send), and 300-115,200 baud.

• Channel range = 1-255

• Channels 1-254 provide feedback

• Channel 255 (CTS Push channel): Reflects the state of the CTS Input if a

'CTSPSH' command was sent to the port

• Output data format for each port is selected via software

• Seven DB9 connectors provide RS-232/422/485 termination

ICSNet • Tw o RJ-45 connectors for ICSNet interface

ICSHub Out • RJ-45 connector provides data to another Hub connected to the Controller

Relay (Port 8) • Eight-channel single-pole single throw relay ports

• Each relay is independently controlled.

• Supports up to 8 independent external relay devices

• Channel range = 1-8

• Each relay can switch up to 24 VDC or 28 VAC @ 1 A

• Two 8-pin 3.5 mm mini-Phoenix (female) connectors provide relay

termination

Digital I/O (Port 17) • Eight-channel binary I/O port for contact closure

• Each input is capable of voltage sensing. Input format is software

selectable.

• Interactive power sensing for IR ports

• Channel range = 1-8

• All inputs are assigned to respective IR/Serial ports for "automatic" power

control through the use of software commands. Power control is provided

via commands such as: ’PON’, ’POF’, ’POD’, ’DELAY’, I/O Link etc.).

• Contact closure between GND and an I/O port is detected as a PUSH

• When used as voltage input - I/O port detects a low signal (0- 1.5 VDC) as a

PUSH and a high signal (3.5 - 5 VDC) as a RELEASE

• When used as an output - each I/O port acts as a switch to GND and is

rated at 200 mA @ 12 VDC

• 10-pin 3.5 mm mini-Phoenix (female) connector provides I/O port

termination

Note: This IO port uses 5V logic but can handle up to 12V without harm. It

can handle up to 12V on the input. At higher voltages you run a higher risk of

surge damage.

IR/Serial (Ports 9-16) • Eight IR/Serial control ports support high-frequency carriers of up to 1.142

MHz.

• Each output is capable of three electrical formats: IR, Serial, and Data

• Eight IR/Serial data signals can be generated simultaneously.

• Channel range = 1-32,767

• Channels 1-128 (output): IR commands

• Channels 129-253: used as reference channels

• Channel 254 (feedback): Power Fail (used with 'PON' and 'POF'

commands)

• Channel 255 (feedback): Power status (when IO Link is set)

• IR ports support data mode (at limited baud rates and wiring distances).

• Two 8-pin 3.5 mm mini-Phoenix (female) connectors provide IR/Serial port

termination

12

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 17

Introduction

NI-4000 Specifications (Cont.)

Rear Panel Connectors (Cont.):

Program port • RS-232 DB9 connector (male) can be connected to a DB9 port on a

computer; used with serial commands, NetLinx programming commands,

other DB9 capable devices, and to upload/download information from the

NetLinx Studio 2.4 program.

Configuration DIP switch • Sets the communication parameters for the Program port.

ID pushbutton • Provides the NetLinx ID (Device only) assignment for the device.

• The D notation is used to represent a device number.

• Refer to the NetLinx Integrated Controller WebConsole & Programming

Guide for details.

Ethernet port • RJ-45 port for 10/100 Mbps communication. This port automatically

negotiates the connection speed (10 Mbps or 100 Mbps) and whether to

use half duplex or full duplex mode.

Ethernet Link/Activity LED • LEDs show communication activity, connection status, speeds, and mode

AXlink LED • Green LED indicates the state of the AXlink connector port.

AXlink port • 4-pin 3.5 mm mini-Phoenix (male) connector provides data and power to

Power port • 2-pin 3.5 mm mini-Phoenix (male) connector

CardFrame Number

DIP switch

NetLinx Control Card

connectors (1-4)

Included Accessories: • 2-pin 3.5 mm mini-Phoenix (female) PWR connector (41-5025)

information:

SPD (speed) - Yellow LED lights On when the connection speed is 100

Mbps and turns Off when the speed is 10 Mbps.

L/A (link/activity) - Green LED lights On when the Ethernet cables are

connected/terminated correctly, and blinks when receiving Ethernet data

packets.

• Normal AXlink activity = 1 blink/second

• Abnormal AXlink activity = cycle of 3 consecutive blinks and then Off

external control devices.

• Sets the starting address for the Control Cards in the CardFrame.(Factory

default CardFrame DIP switch value = 0).

• The Control Card address range is 1-3064.

• Four 20-pin (male) connectors that bridge the gap between the Control

Cards in the CardFrame and external equipment.

• 4-pin 3.5 mm mini-Phoenix (female) AXlink connector (41-5047)

• 10-pin 3.5 mm mini-Phoenix (female) I/O connector (41-5107)

• Installation Kit (KA2105-01):

8-pin Relay Common Strip

Four rack mount screws

Four washers

• NI-4000 Quick Start Guide

• Two 8-pin 3.5 mm mini-Phoenix (female) Relay connectors (41-5083)

• Two CC-NIRC IR Emitters

• Two removable rack ears (62-2105-07)

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

13

Page 18

Introduction

NI-4000 Specifications (Cont.)

Other AMX Equipment: • 2-pin 3.5 mm mini-Phoenix male connector (41-5026)

• CC-NIRC IR cables (FG10-000-11)

• CC-NSER IR/Serial cables (FG10-007-10)

• CSB Cable Support Bracket (FG517)

• NCK, NetLinx Connector Kit (FG2902)

• STS, Serial To Screw Terminal (FG959)

• Upgrade Compact Flash (factory programmed with firmware):

NXA-CFNI64M - 64 MB compact flash card (FG2116-31)

NXA-CFNI128M - 128 MB compact flash card (FG2116-32)

NXA-CFNI256M - 256 MB compact flash card (FG2116-33)

NXA-CFNI512M - 512 MB compact flash card (FG2116-34)

NXA-CFNI1G - 1 GB compact flash card (FG2116-35)

• NXC cards (see the Card Slot section (page 11) of this Specification table

for more detailed information)

Related Documents

For information on using the on-board Web Console, as well as NetLinx send commands and terminal

communications to configure the NI Controllers, refer to the NetLinx Integrated Controller WebConsole

& Programming Guide.

All product documentation is available to view or download from www.amx.com.

14

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 19

Installation and Upgrading

Installing NetLinx Control Cards (NI-4000 Only)

NetLinx Cards can be installed into the front card slots. The cards mount horizontally through the card

slot openings on the front of the enclosure.

1. Discharge the static electricity from your body, by touching a grounded object.

2. Remove the three screws by turning them in a counter-clockwise direction and then remove the

faceplate (FIG. 1).

Thumbscrews

Installation and Upgrading

NXC Card Slot faceplate

FIG. 1 NI-4000 front faceplate

3. Align the edges of the card with the internal guide slots and gently slide the card all the way into the

slot (FIG. 2).

Card slots

Internal Guide

Sample

NXC cards

FIG. 2 Sample NXC cards inserted into an NI-4000 unit

slots

4. Carefully apply a small amount of force to insert the cards into their respective connectors. If the

cards have LEDs on them, those LEDs will initiate a lighting sequence to indicate they are receiving

power and are communicating with the Controller.

5. Re-align the faceplate and secure it to the chassis by inserting the three screws by turning them in a

clockwise direction and securing the front plate to the Integrated Controller.

6. Install all rear connectors and apply power.

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

15

Page 20

Installation and Upgrading

If the cards do not appear in the NetLinx Studio’s Workspace window for the selected

Master System number: give the system time to detect the inserted cards (and

refresh the system) and/or cycle power to the unit.

Setting the NetLinx Control Card Addresses (NI-4000 Only)

For example:

1. Set the CardFrame Number DIP switch based on the information listed in the table below.

The 8-position CardFrame Number DIP switch (located on the rear of the NI-4000) sets the

starting address (the device number in the D:P:S specification) for the Control Cards installed

in the CardFrame. The address range is 1-3064.

The factory default CardFrame DIP switch value = 0 (all CardFrame DIP switches in the OFF

position).

The formula for setting the starting address is:

(DIP switch address x 12) + Card slot Number (1-12) = Card address

DIP switch setting, 00010101: (0 + 0 + 0 + 96 + 0 + 384 + 1536) + SLOT #(ex:1) = 2017.

A card in slot number 1 would be device address 2017.

Position 12345 6 7 8

Value 12 24 48 96 192 384 768 1536

ON position

2. Cycle power to the unit for approximately 5 seconds. This allows the unit to read the new device

number settings.

Device:Port:System (D:P:S)

A device is any hardware component that can be connected to an AXlink or ICSNet bus. Each device

must be assigned a unique number to locate that device on the bus. The NetLinx programming language

allows numbers in the range 1-32,767 for ICSNet (255 for AXlink).

Only the Device value can be set through the DIP switch settings mentioned above.

NetLinx requires a Device:Port:System (D:P:S) specification. This D:P:S triplet can be expressed as a

series of constants, variables separated by colons, or a DEV structure. For example:

STRUCTURE DEV

{

INTEGER Number // Device number

INTEGER Port // Port on device

INTEGER System // System the device belongs to

}

The D:P:S notation is used to explicitly represent a device number, port and system.

For example, 128:1:0 represents the first port on device 128 on this system.

If a device is declared in a NetLinx program with just the Device number (System and Port are

omitted), the NetLinx Compiler assumes it has a Port number of 1 and a System number of 0.

However, you should convert all existing device declarations using the D:P:S (Device:Port:System)

notation. This enables certain NetLinx specific debugging features and can help pinpoint other possibly

obscure errors.

Here's the syntax:

16

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 21

Installation and Upgrading

NUMBER:PORT:SYSTEM

where:

NUMBER: 16-bit integer represents the device number

PORT: 16-bit integer represents the port number (in the range 1 through the number of

SYSTEM: 16-bit integer represents the system number (0 = this system)

ports on the Controller or device)

Removing NetLinx Control Cards (NI-4000 Only)

To install NetLinx Control Card:

1. Discharge any static electricity from your body, by touching a grounded object and unplug all

connectors (if any) from the unit.

2. Remove the three faceplate screws by turning them in a counter-clockwise direction.

3. Remove the faceplate from the front plate (FIG. 1 on page 15).

4. Gently grasp the rear edge of the control card and gently pull it out from the unit (along the internal

guide slots).

5. Re-secure the faceplate by inserting the three faceplate screws by turning them in a clockwise

direction and securing the front plate to the Integrated Controller.

6. Re-apply power and other connections as necessary.

Compact Flash Upgrades

The NetLinx Integrated Controllers are shipped with a default 32 MB Compact Flash module.

It is recommended that ANY MEMORY UPGRADE should be done prior to any

installation. Refer to the following accessing and installation sections for more

information.

The Compact Flash card is factory programmed with specific Controller firmware. These cards can be

ordered from AMX in several different upgrade sizes (see the following table):

Optional Compact Flash Upgrades

Product Name Description

NXA-CFNI64M 64 MB compact flash card (FG2116-31)

NXA-CFNI128M 128 MB compact flash card (FG2116-32)

NXA-CFNI256M 256 MB compact flash card (FG2116-33)

NXA-CFNI512M 512 MB compact flash card (FG2116-34)

NXA-CFNI1G 1 GB compact flash card (FG2116-35)

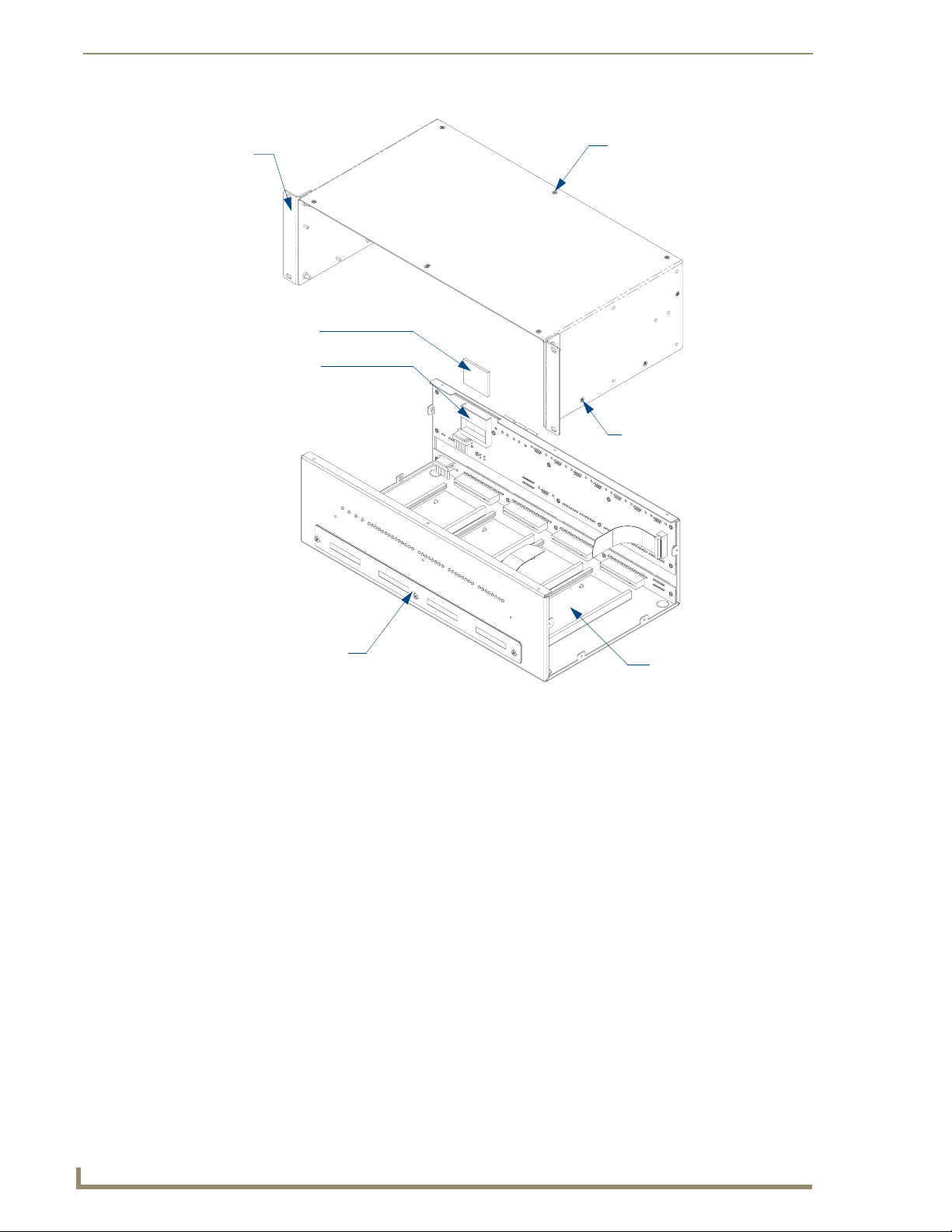

Accessing The Internal Components On An Integrated Controller

Carefully detach all connectors from the rear of the unit.

1.

2. Remove the chassis housing screws from both the sides and top of the Controller, as shown in

FIG. 3 by using a grounded screwdriver turning in a counter-clockwise rotation.

The NI-2000 and NI-3000 have six screws on top and three on each side.

The NI-4000 has six screws on top and four on each side.

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

17

Page 22

Installation and Upgrading

Mounting

Brackets

Chassis housing screws (top)

- 6 on top

- sides vary per model

Compact Flash

Compact Flash

insert location

Chassis housing screws (side)

- 4 on each side of the NI-4000

- 3 on each side of the

NI-3000/2000

NXC Card Slot

faceplate

FIG. 3 Location of the Compact Flash within a sample Integrated Controller

NXC Card Slots

3. Carefully pull-up and remove the housing up and away from the Controller to expose the internal

circuit board (FIG. 3).

4. Refer to the followingInstallation of Compact Flash Upgradesfor detailed replacement information.

Installation of Compact Flash Upgrades

Discharge any static electricity from your body by touching a grounded metal object.

1.

2. Locate the 32 MB Compact Flash card on the main board. For more detailed information on

component locations, refer to FIG. 3.

3. Insert the tip of a grounded flathead screwdriver into one of the Card Removal Grooves (located on

either side of the card), and gently pry the card out of the slot. Repeat this process on the opposite

card removal groove. This alternating action causes the card to "wiggle" away from the on-board

connector pins.

4. Slip your finger into the opening between the connector pins and the card, and push the card out to

remove it.

5. Remove the upgrade card from it’s anti-static bag.

6. Insert the upgrade card into the connector opening with the arrow facing towards the pins, then push

it in firmly until the contact pins are completely inside the flash card and securely attached to the

connector (FIG. 4).

18

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 23

Installation and Upgrading

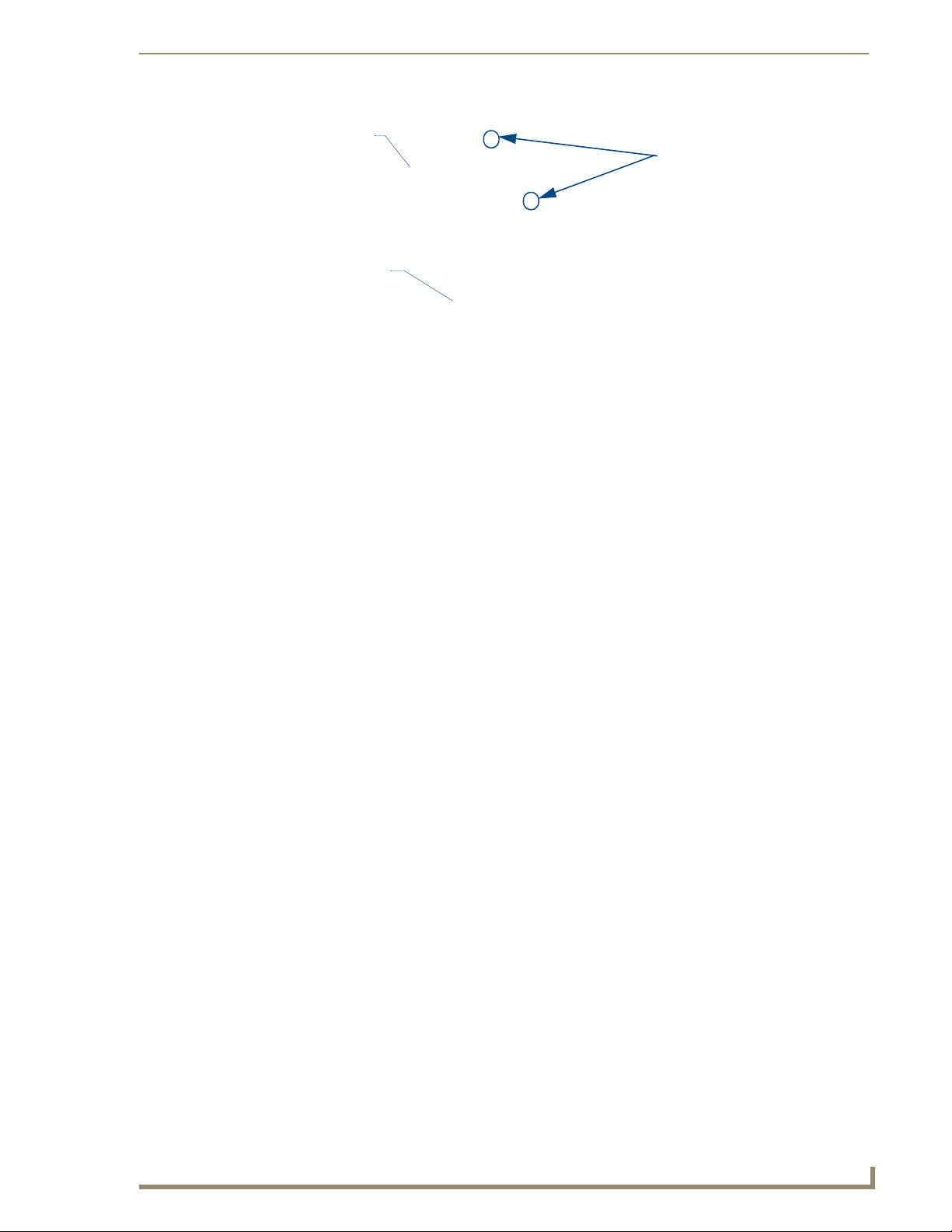

Under-side groove

located below

Insert with arrow

facing towards

the connector pins

FIG. 4 Removing the Compact Flash card

Card Removal Grooves

7. To complete the upgrade process, close and re-secure the Integrated Controller enclosure using the

procedures outlined in the following section.

Any new internal card upgrade is detected by the Controller only after power is

cycled.

Closing and Securing the Outer Housing

Once the card has been replaced, close and re-secure the outer housing:

1. Align the cover back over the unit and gently slide-down the chassis until the openings are aligned

over their respective openings along both the sides and top of the unit.

2. Insert and secure the chassis housing screws back into their respective locations, as shown in FIG. 3

by using a grounded screwdriver.

3. Re-install all connectors and apply power to the unit.

Installing Into An Equipment Rack

Use the rack-mounting brackets (supplied) for equipment rack installations.

Remove the mounting brackets for flat surface installations.

Before completing the install process, it is recommended that you complete any

firmware upgrade of the NetLinx Control Cards. This upgrade involves physically

cycling power to the unit and can become cumbersome if the unit is already installed

into a rack. Refer to theUpgrading the NXC Card Firmware via IP (NI-4x00

ONLY) section on page 59 for more detailed information.

1. Discharge the static electricity from your body by touching a grounded object.

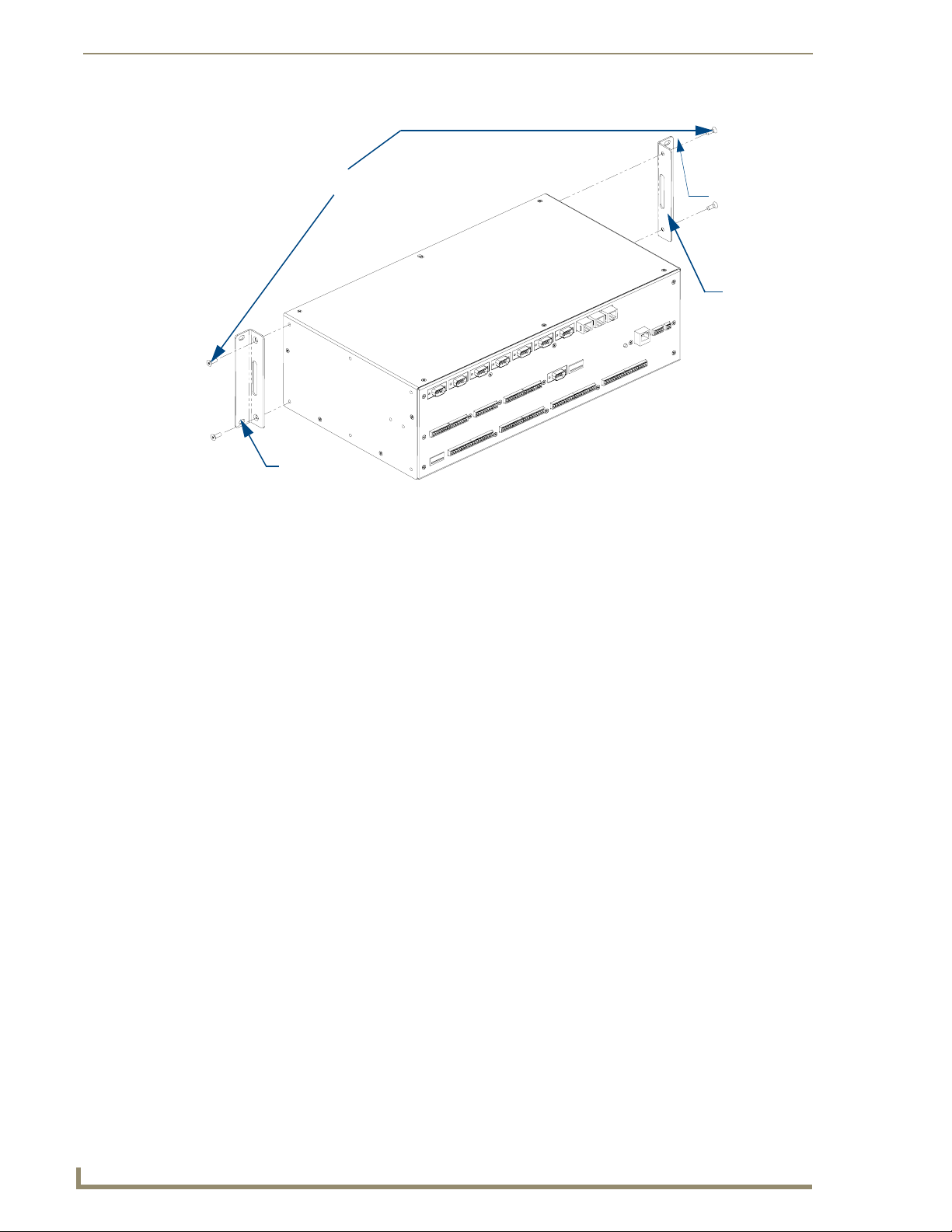

2. Position and install the mounting brackets, as shown in FIG. 5, using the screws supplied with the

unit. The mounting brackets can be rotated to accommodate your mounting needs.

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

19

Page 24

Installation and Upgrading

FIG. 5 Mounting Integrated Controller into an equipment rack

Install screws

Bracket

Rack

Mounting Holes

3. Thread the cables through the opening in the equipment rack. Allow for enough slack in the cables

to accommodate for movement during the installation process.

4. Reconnect all cables to their appropriate source/terminal locations. Refer to theConnections and

Wiring section on page 19 for more detailed wiring and connection information.

Verify that the terminal end of the power cable is not connected to the a power supply before

plugging in the 2-pin power connector.

To prevent repetition of the installation, test the incoming wiring by connecting the

Controller’s connectors to their terminal locations and applying power. Verify that the

unit is receiving power and functioning properly. Disconnect the terminal end of the

power cable from the connected 12 VDC-compliant power supply.

5. Slide the unit into the rack until the attachment holes, along both sides, align to their corresponding

locations on the mounting brackets, as shown in FIG. 5.

6. Secure the AC-RK to the rack by using the four #10-32 screws (80-0186) and four #10 washers

(80-0342) supplied in the kit.

7. Apply power to the unit to complete the installation.

20

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 25

Connections and Wiring

Setting the Configuration DIP Switch (for the Program Port)

Prior to installing the Controller, use the Configuration DIP switch to set the baud rate used by the

Program port for communication. The Configuration DIP switch is located on the front of the Integrated

Controllers.

Baud Rate Settings

Before programming the on-board Master, make sure the baud rate you set matches the communication

parameters set on both your PC’s COM port and those set through your NetLinx Studio v 2.4.

By default, the baud rate is set to 38,400 (bps).

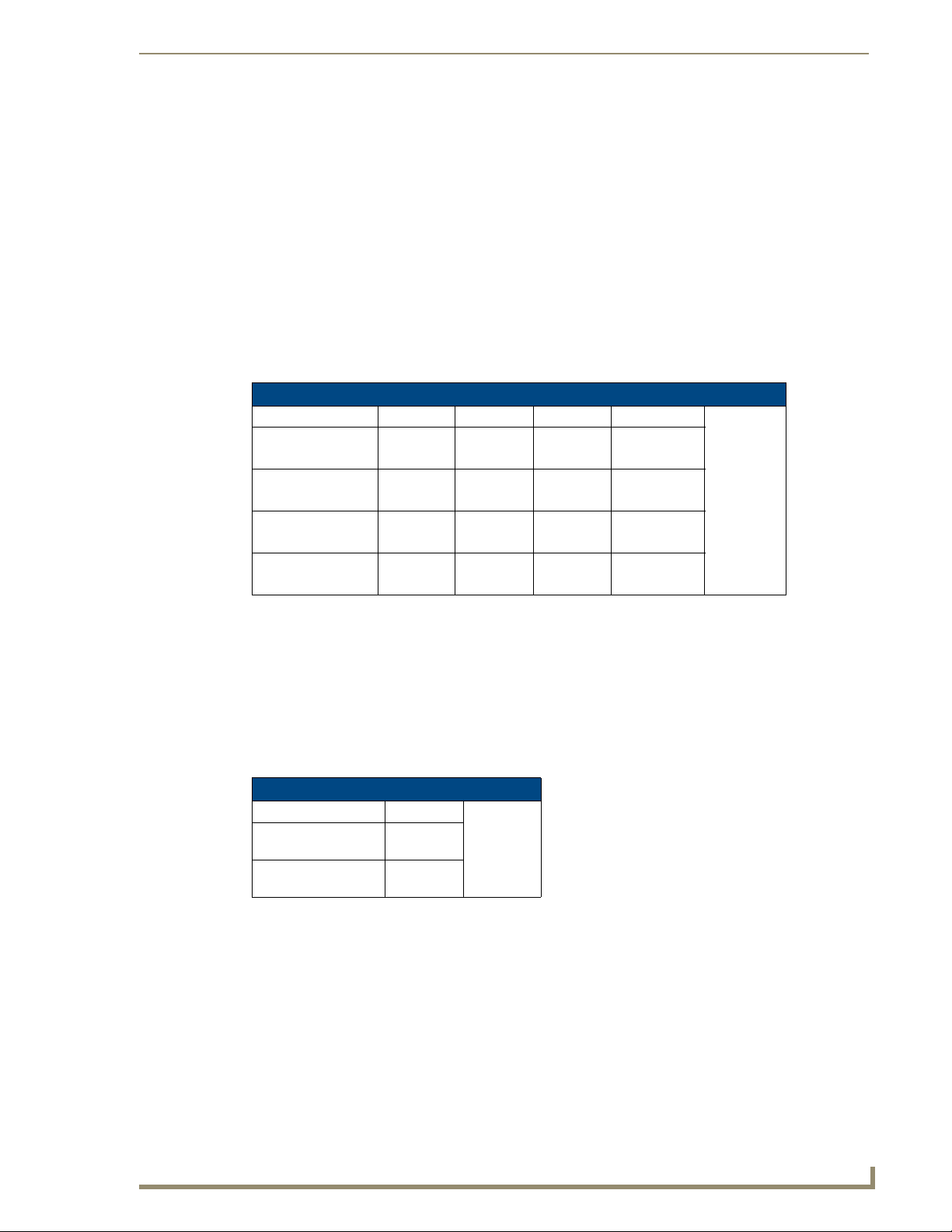

Baud Rate Settings on the Configuration DIP Switch

Baud Rate Position 5 Position 6 Position 7 Position 8

9600 bps OFF ON OFF ON

38,400 bps (default) OFF ON ON ON

Connections and Wiring

57,600 bps ON OFF OFF OFF

115,200 bps ON ON ON ON

Note the orientation of the Configuration DIP Switch and the ON position label.

DIP switches 2,3, and 4 must remain in the OFF position at all times.

Program Run Disable (PRD) Mode

You can also use the Program port’s Configuration DIP switch to set the on-board Master to Program

Run Disable (PRD) mode according to the settings listed in the table below.

PRD Mode Settings

PRD Mode Position 1

Normal mode (default) OFF

PRD Mode ON

The PRD mode prevents the NetLinx program stored in the on-board Master from running when you

power up the Integrated Controller. This mode should only be used when you suspect the resident

NetLinx program is causing inadvertent communication and/or control problems.

If necessary, place the on-board Master in PRD mode and use the NetLinx Studio v 2.4 program to

resolve the communication and/or control problems with the resident NetLinx program. Then download

the new NetLinx program and try again.

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

21

Page 26

Connections and Wiring

Think of the PRD Mode (On) equating to a PC’s SAFE Mode setting. This mode

allows a user to continue powering a unit, update the firmware, and download a new

program while circumventing any problems with a currently downloaded program.

Power must be cycled to the unit after activating/deactivating this mode on the

Program Port DIP switch #1.

Working With the Configuration DIP Switch

1.

2. Set DIP switch positions according to the information listed in theBaud Rate Settings on the

3. Reconnect the 12 VDC-compliant power supply to the 2-pin 3.5 mm mini-Phoenix PWR connector.

Setting the CardFrame DIP Switch (NI-4000 Only)

Refer to the Setting the NetLinx Control Card Addresses (NI-4000 Only) section on page 16 for a

detailed explanation on this process.

Program Port Connections and Wiring

The Integrated Controllers are equipped with a Program port located on the front of the unit. Use an

RS232 programming cable to establish a connection between this Program port to your PC's COM port.

This connection provides communication with the NetLinx Integrated Controller. Then you can

download NetLinx programs to this on-board Master using the NetLinx Studio v 2.4 software program.

Refer to the NetLinx Studio instruction manual for programming instructions. The following table shows

the rear panel Program Port connector (male), pinouts, and signals.

Disconnect the power supply from the 2-pin PWR (green) connector on the rear of the NetLinx

Integrated Controller.

Configuration DIP Switch andPRD Mode Settings tables.

Program Port, Pinouts, and Signals

Program Port Connector Pin Signal

2RX

3TX

5

4

3

2

1

Male

9

8

7

6

5GND

7RTS

8CTS

When wiring the 422/485 connections, do NOT use pre-made 9-wire cable or connect

the wire in the cable to any connection that will not be used by the DB9 serial port.

Only use wiring that connects the needed pins.

22

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 27

Connections and Wiring

Modes and Front Panel LED Blink Patterns

The following table lists the modes and blink patterns for the front panel LEDs associated with each

mode. These patterns are not evident until after the unit is powered.

Modes and LED Blink Patterns

LEDs and Blink Patterns

STATUS

Mode Description

OS Start Starting the operating system (OS). On On On

Boot On-board Master is booting. On Off On

Contacting DHCP

server

Unknown DHCP

server

Downloading Boot

firmware

No program running There is no program loaded, or the

Normal On-board Master is functioning normally. 1 blink per second Indicates

On-board Master is contacting a DHCP

server for IP configuration information.

On-board Master could not find the

DHCP server.

Downloading Boot firmware to the

Master’s on-board flash memory.

Do not cycle power during this process!

program is disabled.

(green)

On Off Fast Blink

Fast Blink Off Off

Fast Blink Fast Blink Fast Blink

On Normal Normal

OUTPUT

(red)

activity

INPUT

(yellow)

Indicates

activity

Port Assignments and Functionality

The Port Assignments are as follows:

NI-2000 Port Assignments NI-3000/4000 Port Assignments

Port ICSP Port # Port ICSP Port #

Serial Port #1 1

Serial Port #2 2

Serial Port #3 3

Relays Ports (1-4) 4

IR/Serial Port #1 5

IR/Serial Port #2 6

IR/Serial Port #3 7

IR/Serial Port #4 8

I/O Port 9

Serial Port #1 1

Serial Port #2 2

Serial Port #3 3

Serial Port #4 4

Serial Port #5 5

Serial Port #6 6

Serial Port #7 7

Relays Ports (1-8) 8

IR Serial Port #1 9

IR Serial Port #2 10

IR Serial Port #3 11

IR Serial Port #4 12

IR Serial Port #5 13

IR Serial Port #6 14

IR Serial Port #7 15

IR Serial Port #8 16

I/O Port 17

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

23

Page 28

Connections and Wiring

AXlink Port and LED

All NI units have an AXlink port and adjacent status LED (FIG. 1). This port allows the NI to support

AMX Legacy AXlink devices such as G3 touch panels (ex: CP4/A) and PosiTrack Pilot devices. A green

LED shows AXlink data activity. When the AXlink port is operating normally, blink patterns include:

FIG. 1 AXlink connector and LED

The AXlink port can be used to supply power to downstream AXlink-compatible devices as long as both

the power required is LESS THAN 2 Amps total and the external power supply feeding the NI unit has

the necessary power capability.

Off - No power, or the controller is not functioning properly

1 blink per second - Normal operation.

3 blinks per second - AXlink bus error. Check all AXlink bus connections.

Wiring Guidelines

The Integrated Controllers use a 12 VDC-compliant power supply to provide power through the rear 2pin 3.5 mm mini-Phoenix PWR connector. Use the power requirements referenced in the product’s

Specifications table to determine the power draw.

The incoming PWR and GND cable from the power supply must be connected to the corresponding

locations within the PWR connector.

This unit should only have one source of incoming power.

Using more than one source of power to the Controller can result in damage to the

internal components and a possible burn out.

Apply power to the unit only after installation is complete.

Wiring length guidelines

Refer to the following tables for the wiring length information used with the different types of NetLinx

Integrated Controllers:

Wiring Guidelines - NI-2000 (@ 700 mA)

Wire size Maximum wiring length

18 AWG 154.83 feet (47.19 meters)

20 AWG 98.30 feet (29.96 meters)

22 AWG 63.40 feet (19.32 meters)

24 AWG 38.68 feet (11.79 meters)

24

Wiring Guidelines - NI-3000 & NI-4000 (@ 900) mA

Wire size Maximum wiring length

18 AWG 120.41 feet (39.70 meters)

20 AWG 76.45 feet (23.30 meters)

22 AWG 49.36 feet (15.04meters)

24 AWG 30.08 feet (9.17 meters)

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 29

Connections and Wiring

Preparing Captive Wires

You will need a wire stripper and flat-blade screwdriver to prepare and connect the captive wires.

Never pre-tin wires for compression-type connections.

1. Strip 0.25 inch (6.35 mm) of insulation off all wires.

2. Insert each wire into the appropriate opening on the connector (according to the wiring diagrams

and connector types described in this section).

3. Tighten the screws to secure the wire in the connector. Do not tighten the screws excessively doing

so may strip the threads and damage the connector.

Wiring a Power Connection

To use the 2-pin 3.5 mm mini-Phoenix connector with a 12 VDC-compliant power supply, the incoming

PWR and GND cables from the external source must be connected to their corresponding locations on

connector (FIG. 2).

1. Insert the PWR and GND wires on the terminal end of the 2-pin 3.5 mm mini-Phoenix cable. Match

the wiring locations of the +/- on both the power supply and the terminal connector.

2. Tighten the clamp to secure the two wires. Do not tighten the screws excessively; doing so may strip

the threads and damage the connector.

3. Verify the connection of the 2-pin 3.5 mm mini-Phoenix to the external 12 VDC-compliant power

supply.

PWR +

GND -

To the Integrated Controller

FIG. 2 2-pin mini-Phoenix connector wiring diagram (direct power)

Power Supply

Using the 4-Pin Mini-Phoenix Connector For Data and Power

Connect the 4-pin 3.5 mm mini-Phoenix (female) captive-wire connector to an external NetLinx device

as shown in FIG. 3.

To the Integrated Controller’s

AXlink/PWR connector

Top view

GND -

FIG. 3 Mini-Phoenix connector wiring diagram (direct data and power)

AXP/TX

PWR +

AXM/RX

To the external AXlink device

Top view

GND -

AXP/TX

AXM/RX

PWR +

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

25

Page 30

Connections and Wiring

Using the 4-pin Mini-Phoenix Connector For Data With External Power

To use the 4-pin 3.5 mm mini-Phoenix (female) captive-wire connector for data communication and

power transfer, the incoming PWR and GND cable from the 12 VDC-compliant power supply must be

connected to the AXlink cable connector going to the Integrated Controller. FIG. 4 shows the wiring

diagram. Always use a local power supply to power the Integrated Controller unit.

To the Integrated Controller’s

AXlink/PWR connector

Top view

GND -

AXM/RX

AXP/TX

FIG. 4 4-pin mini-Phoenix connector wiring diagram (using external power source)

PWR (+)

GND (-)

Local +12 VDC

power supply

(coming from

an external

power supply)

To the external AXlink device

Top view

GND -

AXP/TX

AXM/RX

When you connect an external power supply, do not connect the wire from the PWR

terminal (coming from the external device) to the PWR terminal on the Phoenix

connector attached to the Controller unit. Make sure to connect only the AXM, AXP,

and GND wires to the Controller’s Phoenix connector when using an external power

supply.

Make sure to connect only the GND wire on the AXlink/PWR connector when using a separate 12 VDC

power supply. Do not connect the PWR wire to the AXlink connector’s PWR (+) opening.

DB9 Device Port: Connections and Wiring

FIG. 5 shows the connector pinouts for the rear RS-232/RS-422/RS-485 (DB9) Device Ports.

These ports support most standard RS-232 communication protocols for data transmission. This figure

gives a visual representation of the wiring specifications for the RS-232/422/485 Device connectors.

Refer to the rear of the unit for more detailed connector pinout information.

26

DB9 Serial Port pinouts (male connector)

5

4

3

2

1

Male

FIG. 5 RS-232/422/485 DB9 (male) connector pinouts for the rear Device Ports

9

8

7

6

RS-232

Pin 2: RX signal

Pin 3: TX signal

Pin 5: GND

Pin 7: RTS

Pin 8: CTS

RS-422

Pin 1: RX Pin 4: TX +

Pin 5: GND

Pin 6: RX +

Pin 9: TX -

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

RS-485

Pin 1: A (strap to 9)

Pin 4: B (strap to 6)

Pin 5: GND

Pin 6: B (strap to 4)

Pin 9: A (strap to 1)

Page 31

Connections and Wiring

The table below provides information about the connector pins, signal types, and signal functions. This

table’s wiring specifications are applicable to the rear RS-232/422/485 Device Port connectors on the:

NI-2000 (Ports 1-3)

NI-4000/NI-3000 (Ports 1-7)

RS-232/422/485 Device Port Wiring Specifications

Pin Signal Function RS-232 RS-422 RS-485

1 RX- Receive data XX (strap to pin 9)

2 RXD Receive data X

3 TXD Transmit data X

4 TX+ Transmit data XX (strap to pin 6)

5 GND Signal ground XX

6 RX+ Receive data XX (strap to pin 4)

7 RTS Request to send X

8 CTS Clear to send X

9 TX- Transmit data XX (strap to pin 1)

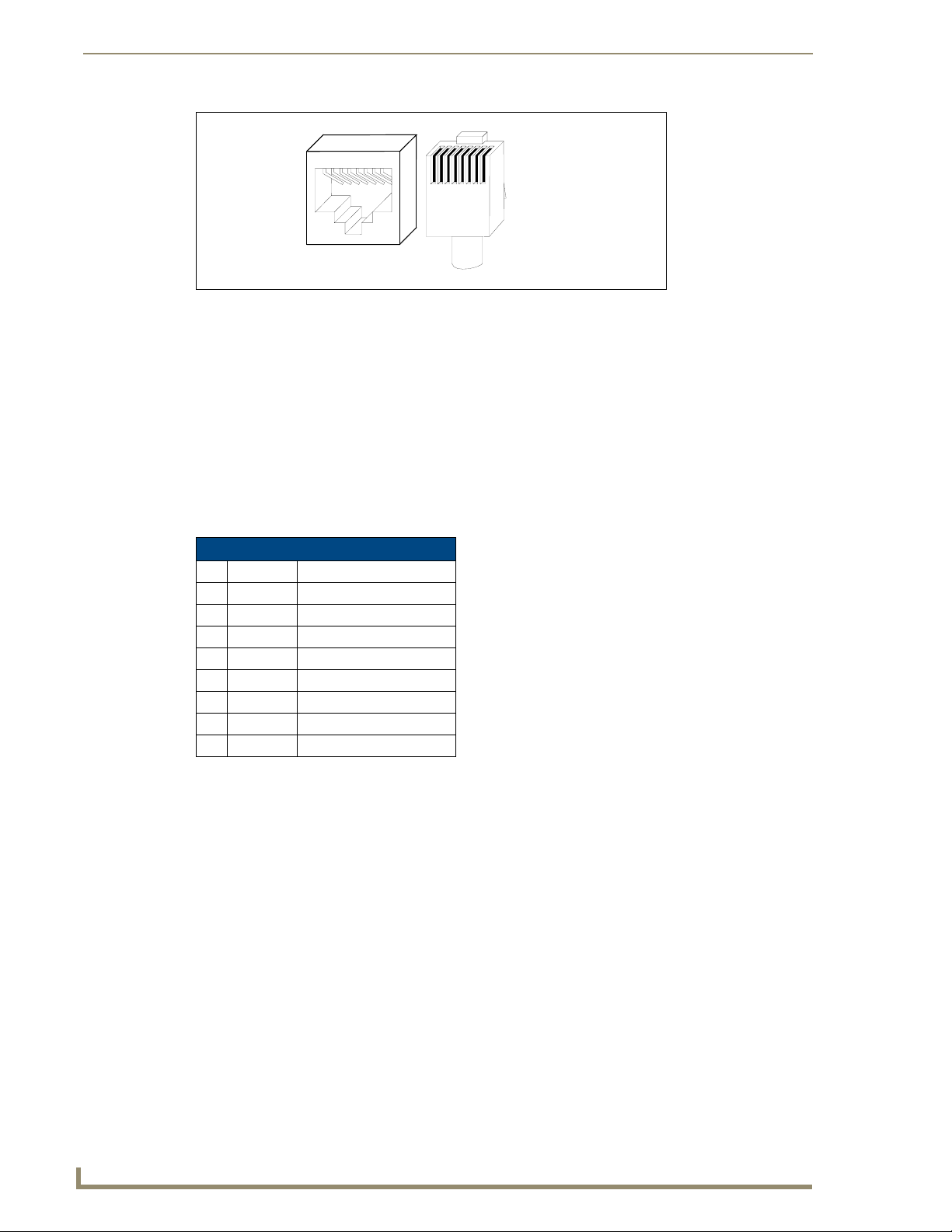

ICSNet Port: Connections and Wiring

The NI Controller must be equipped with the available ICSNet connectors for this functionality to be

active. The following tables show the signal and pinouts/pairing information:

ICSNet RJ-45 Signals

Pin Signal-Master Signal-Device

1 TX + RX +

2 TX - RX -

3N/A N/A

4GND GND

5N/A N/A

6N/A N/A

7 RX + TX +

8RX - TX -

RJ-45 Pinout Information (EIA/TIA 568 B)

Pin Wire Color Polarity Function

1 Orange/White + Transmit

2 Orange - Transmit

3 Green/White - Mic

4Blue - Ground

5 White/Blue + 12 VDC

6 Green + Mic

7 White/Brown + Receive

8Brown - Receive

TIA 568B

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

27

Page 32

Connections and Wiring

Unlike the ICSNet ports, the ICSHub connections require a specific polarity. The

IN/OUT configuration, on the hub ports, was implemented to use the same cables as

ICSNet, but these ports need TX and RX crossed. You must connect an OUT to an

IN, or an IN to an OUT port.

This is done simply to keep the polarity straight. The Hub bus is still a bus. All Hub

connections are bi-directional.

ICSHub OUT Port: Connections and Wiring

The NI Controller must be equipped with the available ICSNet connectors for this functionality to be

active. The following table describes the pinout/signal information for the ICSHub OUT port located on

the rear panel of the Integrated Controller.

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

(female) (male)

RJ-45 connector - pin configurations

ICSHub OUT Pinouts and Signals

Pin Signal Color

1 RX + orange-white

2 RX - orange

3 ------ ------

4 ------ ------

5 ------ ------

6 ------ ------

7 TX + brown-white

8TX -brown

Relay Port: Connections and Wiring

You can connect up to 8 independent external relay devices on both the NI-4000 and NI-3000 units (4 on

the NI-2000) to the Relay connectors on the Integrated Controller.

Connectors labeled A are for common; B are for output.

Each relay is isolated and normally open.

A metal commoning strip is supplied with each Integrated Controller to connect multiple

relays.

Relay Connections

Use A for common and B for output (FIG. 6). Each relay is isolated and normally open. A metal

connector strip is also provided to common multiple relays.

28

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 33

Connections and Wiring

NI-2000 relay connector

configuration (Port 4)

FIG. 6 RELAY connector (male)

NI-4000/NI-3000 relay connector

configuration (Port 8)

Input/Output (I/O) Port: Connections and Wiring

The I/O port responds to either switch closures, voltage level (high/low) changes, or it can be used for

logic-level outputs.

NI-2000 I/O connector

configuration (Port 9)

FIG. 7 INPUT/OUTPUT (I/O) connector (male)

A contact closure between the GND and an I/O port is detected as a Push.

When used for voltage inputs, the I/O port detects a low signal (0 - 1.5 VDC) as a Push, and a

high signal (3.5 - 5 VDC) as a Release (this IO port uses 5V logic but can handle up to 12V

without harm).

When used for outputs, the I/O port acts as a switch to GND and is rated for 200mA

@ 12 VDC.

The NI-2000 can use up to 4 I/O ports

The NI-3000 and NI-4000 can use up to 8 I/O ports

The PWR pin provides +12 VDC @ 200 mA and is designed as a power output for the PCS

Power Current Sensors, VSS2 Video Sync Sensors (or equivalent).

The GND connector is a common ground and is shared by all I/O ports. A common ground is

shared with I/O ports 1 - 8 (NI-3000/NI-4000) or with I/O ports 1 - 3 (NI-2000).

NI-4000/NI-3000 I/O connector

configuration (Port 17)

I/O Port Wiring Specifications

NI-4000 and NI-3000

Pin Signal Function Pin Signal Function

1 GND Signal GND 1 GND Signal GND

2 I/O 1 Input/Output 2 I/O 1 Input/Output

3 I/O 2 Input/Output 3 I/O 2 Input/Output

4 I/O 3 Input/Output 4 I/O 3 Input/Output

5 I/O 4 Input/Output 5 I/O 4 Input/Output

6 I/O 5 Input/Output 6 12 VDC PWR

7 I/O 6 Input/Output

8 I/O 7 Input/Output

9 I/O 8 Input/Output

10 12 VDC PWR

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

I/O Port Wiring Specifications NI-2000

29

Page 34

Connections and Wiring

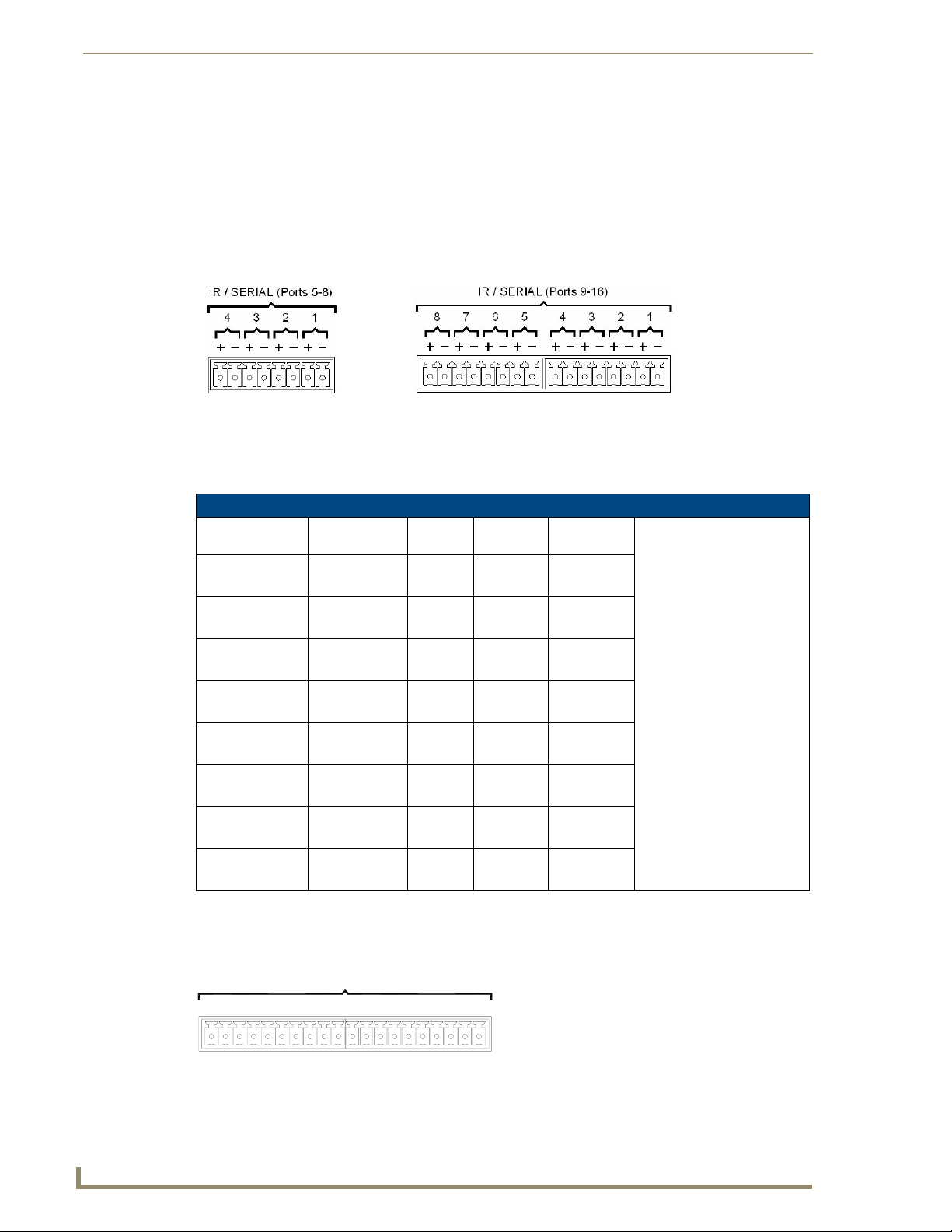

IR/Serial Port: Connections and Wiring

You can connect up to eight IR- or Serial-controllable devices to the IR/Serial connectors on the rear of

the NI-4000 and NI-3000 and up to four on the NI-2000 (FIG. 8).

These connectors accept an IR Emitter (CC-NIRC) that mounts onto the device's IR window, or a miniplug (CC-NSER) that connects to the device's control jack. You can also connect a data 0 - 5 VDC

device.

These units come with two CC-NIRC IR Emitters (FG10-000-11).

NI-2000 IR/Serial connector

configuration (Port 5-8)

FIG. 8 IR/SERIAL (male)

NI-4000/NI-3000 IR/Serial connector

configuration (Port 9-16)

The IR/Serial connector wiring specifications are listed in the following table.

IR/Serial Connector Wiring Specifications (per Port)

Number of

IR connections

1 9 5 GND (-)

2 10 6 GND (-)

3 11 7 GND (-)

4 12 8 GND (-)

5 13 N/A GND (-)

6 14 N/A GND (-)

7 15 N/A GND (-)

8 16 N/A GND (-)

NI-4000/3000

Port #

NI-2000

Port #

Signal Function

Signal GND

Signal 1 (+)

Signal 2 (+)

Signal 3 (+)

Signal 4 (+)

Signal 5 (+)

Signal 6 (+)

Signal 7 (+)

Signal 8 (+)

IR/Serial data

Signal GND

IR/Serial data

Signal GND

IR/Serial data

Signal GND

IR/Serial data

Signal GND

IR/Serial data

Signal GND

IR/Serial data

Signal GND

IR/Serial data

Signal GND

IR/Serial data

12 3 45 6 7 8

12 3 45 6 7 8

30

NetLinx Control Card Slot Connector (NI-4000 only)

FIG. 9 shows the 20-pin (male) connector that provides connection to the NetLinx Control Cards.

SLOT 1

1820 19 151716 610

NetLinx Control Card 20-pin connector

FIG. 9

111312

987

5

432114

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 35

Connections and Wiring

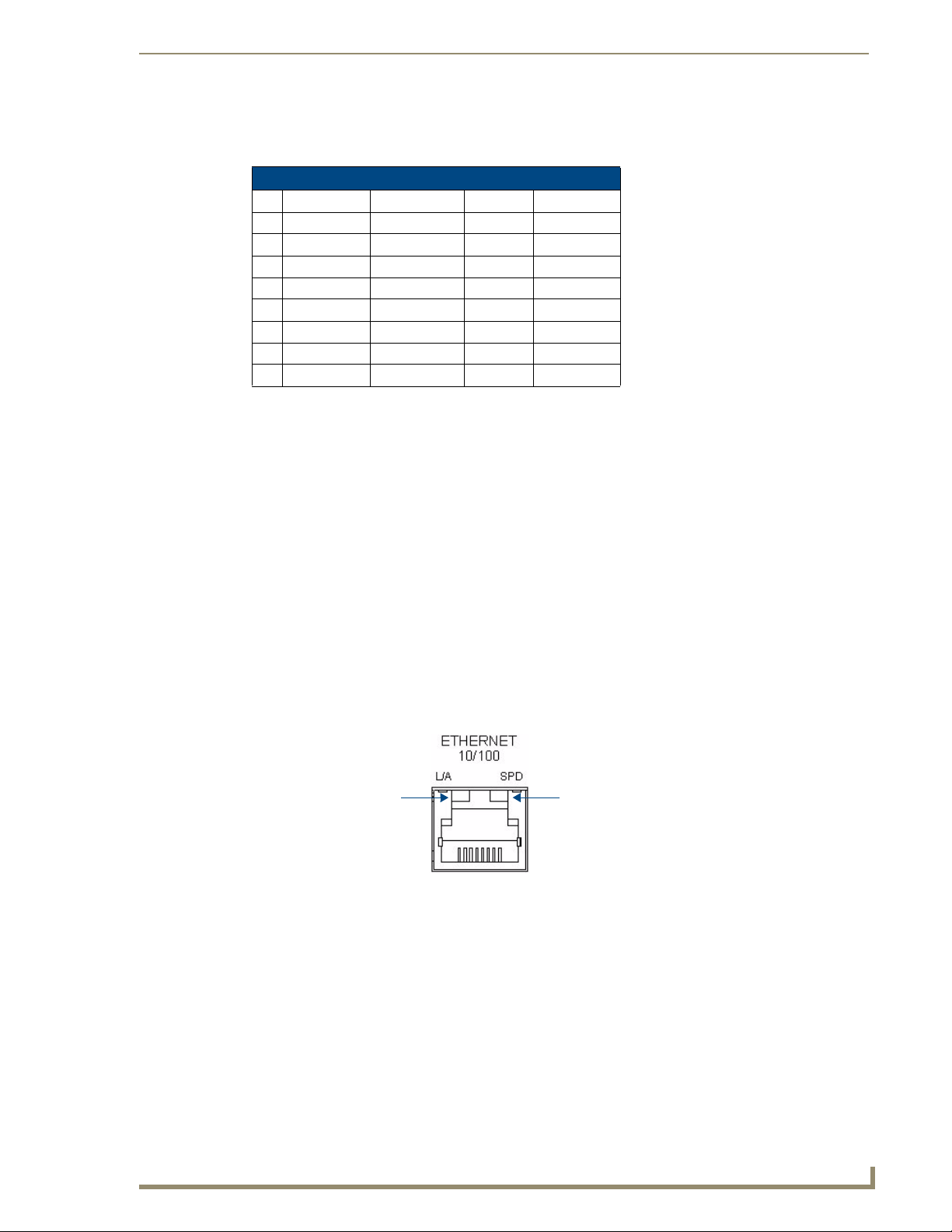

Ethernet/RJ-45 Port: Connections and Wiring

The following table lists the pinouts, signals, and pairing for the Ethernet connector.

Ethernet RJ-45 Pinouts and Signals

Pin Signals Connections Pairing Color

1 TX + 1 --------- 1 1 --------- 2 Orange-White

2 TX - 2 --------- 2 Orange

3 RX + 3 --------- 3 3 --------- 6 Green-White

4 no connection 4 --------- 4 Blue

5 no connection 5 --------- 5 Blue-White

6 RX - 6 --------- 6 Green

7 no connection 7 --------- 7 Brown-White

8 no connection 8 --------- 8 Brown

FIG. 10 diagrams the RJ-45 pinouts and signals for the Ethernet RJ-45 connector and cable.

FIG. 10

RJ-45 wiring diagram

Ethernet LEDs

L/A - Link/Activity LED

lights (green) when the

Ethernet cables are

connected and terminated

FIG. 11 Ethernet LEDs

correctly.

SPD - Speed LED

lights (yellow) when the

connection speed is 100 Mbps

and turns Off when speed is

10 Mbps.

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

31

Page 36

Connections and Wiring

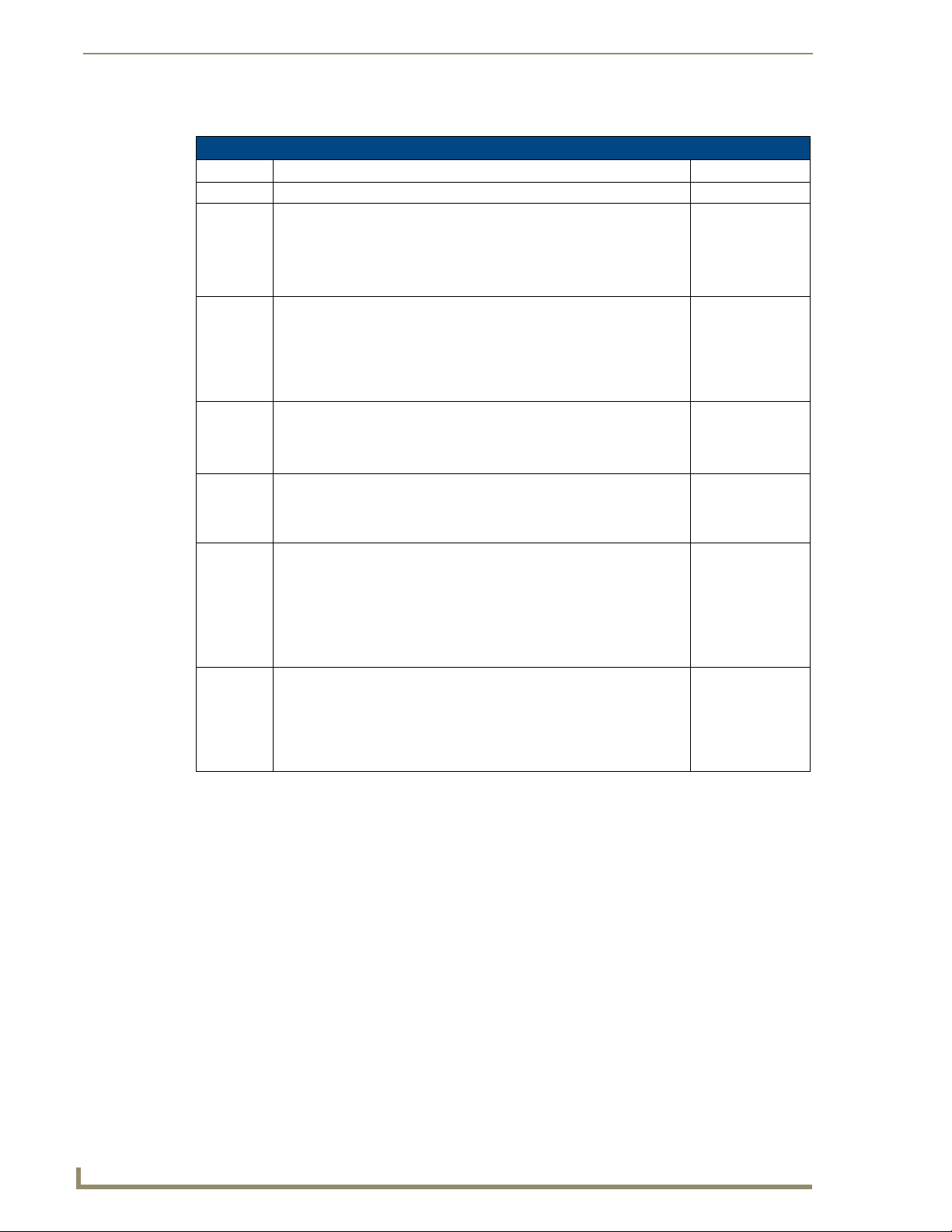

Ethernet Ports Used By the Integrated Controller

Ethernet Port Descriptions

Port type Description Standard Port #

FTP The on-board Master has a built-in FTP server. 21/20 (TCP)

SSH The SSH port functions using the same interface as Telnet but over a

Telnet The NetLinx Telnet server provides a mechanism to configure and

HTTP The Master has a built-in web server that complies with the HTTP 1.0

HTTPS/SSL This port is used by a web browser to securely communicate between the

ICSP Peer-to-peer protocol used for both Master-to-Master and Master-to-

integration!

Solutions

secure shell where it uses SSL as a mechanism to configure and diagnose

a NetLinx system.

This port value is used for secure Telnet communication.

Note: SSH version 2 is only supported.

diagnose a NetLinx system.

For maximum flexibility, the Master can be configured to utilize a different

port than 23, or disable Telnet completely from either Telnet or the Program Port located on the rear of the Master itself. Once disabled, the only

way to enable Telnet again is from the Master’s Program port.

specification and supports all of the required features of HTTP v1.1.

This port is used for unsecure HTTP Internet communication between the

web browser’s UI and the target Master.

web server UI and the target Master. This port is also used to

simultaneously encrypt this data using the SSL certificate information on

the Master as a key.

device communications.

For maximum flexibility, the Master can be configured to utilize a different

port than 1319, or disable ICSP over Ethernet completely from either

Telnet or the Program Port located on the rear of the Master itself.

This type of communication is used by the various AMX product for

communication amongst themselves.

This feature on the Master uses, by default, port 10500 for the XML based

communication protocol. This port is connected to by the client web

browser’s JVM when integration! Solutions control pages are retrieved

from the on-board Master’s web server.

For maximum flexibility, the on-board Master can be configured to utilize a

different port than 10500 or to disable integration! Solutions completely.

22 (TCP)

23 (TCP)

80 (TCP)

443 (TCP)

1319 (UDP/TCP)

10500 (TCP)

32

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

Page 37

Connections and Wiring

NI-2000, NI-3000, NI-4000 Hardware Reference Guide

33

Page 38

It’s Your World - Take Control™

3000 RESEARCH DRIVE, RICHARDSON, TX 75082 USA • 800.222.0193 • 469.624.8000 • 469-624-7153 fax • 800.932.6993 technical support • www.amx.com

2008 AMX. All rights reserved. AMX and the AMX logo are registered trademarks of AMX. AMX reserves the right to alter specifications without notice at any time.

©

5/08

Loading...

Loading...