Page 1

Operation/Reference Guide

VG Series Modero® Touch Panels

NXD/T-1200VG 12" Modero Touch Panel

NXD/T-1500VG 15" Modero Touch Panel

NXD/T-1700VG 17" Modero Touch Panel

Touch Panels

Last Revised: 9/9/2011

Page 2

AMX Limited Warranty and Disclaimer

This Limited Warranty and Disclaimer extends only to products purchased directly from AMX or an AMX Authorized Partner which

include AMX Dealers, Distributors, VIP’s or other AMX authorized entity.

AMX warrants its products to be free of defects in material and workmanship under normal use for three (3) years from the date of

purchase, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch overlay components are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, and MX Series products are warranted for a period of one (1) year.

• AMX lighting products are guaranteed to switch on and off any load that is properly connected to our lighting products, as long

as the AMX lighting products are under warranty. AMX also guarantees the control of dimmable loads that are properly connected to our lighting products. The dimming performance or quality there of is not guaranteed, impart due to the random combinations of dimmers, lamps and ballasts or transformers.

• AMX software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

• AMX AutoPatch Epica, Modula, Modula Series4, Modula CatPro Series and 8Y-3000 product models will be free of defects in

materials and manufacture at the time of sale and will remain in good working order for a period of three (3) years following the

date of the original sales invoice from AMX. The three-year warranty period will be extended to the life of the product (Limited

Lifetime Warranty) if the warranty card is filled out by the dealer and/or end user and returned to AMX so that AMX receives it

within thirty (30) days of the installation of equipment but no later than six (6) months from original AMX sales invoice date. The

life of the product extends until five (5) years after AMX ceases manufacturing the product model. The Limited Lifetime Warranty

applies to products in their original installation only. If a product is moved to a different installation, the Limited Lifetime Warranty

will no longer apply, and the product warranty will instead be the three (3) year Limited Warranty.

All products returned to AMX require a Return Material Authorization (RMA) number. The RMA number is obtained from the AMX

RMA Department. The RMA number must be clearly marked on the outside of each box. The RMA is valid for a 30-day period. After

the 30-day period the RMA will be cancelled. Any shipments received not consistent with the RMA, or after the RMA is cancelled, will

be refused. AMX is not responsible for products returned without a valid RMA number.

AMX is not liable for any damages caused by its products or for the failure of its products to perform. This includes any lost profits, lost

savings, incidental damages, or consequential damages. AMX is not liable for any claim made by a third party or by an AMX Authorized Partner for a third party.

This Limited Warranty does not apply to (a) any AMX product that has been modified, altered or repaired by an unauthorized agent or

improperly transported, stored, installed, used, or maintained; (b) damage caused by acts of nature, including flood, erosion, or earthquake; (c) damage caused by a sustained low or high voltage situation or by a low or high voltage disturbance, including brownouts,

sags, spikes, or power outages; or (d) damage caused by war, vandalism, theft, depletion, or obsolescence.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort claim (including

negligence and strict product liability), a contract claim, or any other claim. This limitation of liability cannot be waived or amended by

any person. This limitation of liability will be effective even if AMX or an authorized representative of AMX has been advised of the

possibility of any such damages. This limitation of liability, however, will not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of the Limited Warranty may not

apply. This Limited Warranty gives the owner specific legal rights. The owner may also have other rights that vary from state to state.

The owner is advised to consult applicable state laws for full determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX MAKES NO OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. AMX

EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED WARRANTY. ANY IMPLIED WARRANTIES THAT

MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS LIMITED WARRANTY. EXCEPT AS OTHERWISE LIMITED

BY APPLICABLE LAW, AMX RESERVES THE RIGHT TO MODIFY OR DISCONTINUE DESIGNS, SPECIFICATIONS, WARRANTIES, PRICES, AND POLICIES WITHOUT NOTICE.

Page 3

AMX Software License and Warranty Agreement

• LICENSE GRANT. AMX grants to Licensee the non-exclusive right to use the AMX Software in the manner described in this

License. The AMX Software is licensed, not sold. This license does not grant Licensee the right to create derivative works of the

AMX Software. The AMX Software consists of generally available programming and development software, product documentation, sample applications, tools and utilities, and miscellaneous technical information. Please refer to the README.TXT file on

the compact disc or download for further information regarding the components of the AMX Software. The AMX Software is subject to restrictions on distribution described in this License Agreement. AMX Dealer, Distributor, VIP or other AMX authorized

entity shall not, and shall not permit any other person to, disclose, display, loan, publish, transfer (whether by sale, assignment,

exchange, gift, operation of law or otherwise), license, sublicense, copy, or otherwise disseminate the AMX Software. Licensee

may not reverse engineer, decompile, or disassemble the AMX Software.

• ACKNOWLEDGEMENT. You hereby acknowledge that you are an authorized AMX dealer, distributor, VIP or other AMX authorized entity in good standing and have the right to enter into and be bound by the terms of this Agreement.

• INTELLECTUAL PROPERTY. The AMX Software is owned by AMX and is protected by United States copyright laws, patent

laws, international treaty provisions, and/or state of Texas trade secret laws. Licensee may make copies of the AMX Software

solely for backup or archival purposes. Licensee may not copy the written materials accompanying the AMX Software.

• TERMINATION. AMX RESERVES THE RIGHT, IN ITS SOLE DISCRETION, TO TERMINATE THIS LICENSE FOR ANY REASON UPON WRITTEN NOTICE TO LICENSEE. In the event that AMX terminates this License, the Licensee shall return or

destroy all originals and copies of the AMX Software to AMX and certify in writing that all originals and copies have been

returned or destroyed.

• PRE-RELEASE CODE. Portions of the AMX Software may, from time to time, as identified in the AMX Software, include PRERELEASE CODE and such code may not be at the level of performance, compatibility and functionality of the GA code. The

PRE-RELEASE CODE may not operate correctly and may be substantially modified prior to final release or certain features may

not be generally released. AMX is not obligated to make or support any PRE-RELEASE CODE. ALL PRE-RELEASE CODE IS

PROVIDED "AS IS" WITH NO WARRANTIES.

• LIMITED WARRANTY. AMX warrants that the AMX Software (other than pre-release code) will perform substantially in accordance with the accompanying written materials for a period of ninety (90) days from the date of receipt. AMX DISCLAIMS ALL

OTHER WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WITH REGARD TO THE AMX SOFTWARE. THIS LIMITED WARRANTY GIVES LICENSEE SPECIFIC LEGAL RIGHTS. Any supplements or updates to the AMX SOFTWARE,

including without limitation, any (if any) service packs or hot fixes provided to Licensee after the expiration of the ninety (90) day

Limited Warranty period are not covered by any warranty or condition, express, implied or statutory.

• LICENSEE REMEDIES. AMX's entire liability and Licensee's exclusive remedy shall be repair or replacement of the AMX Software that does not meet AMX's Limited Warranty and which is returned to AMX in accordance with AMX's current return policy.

This Limited Warranty is void if failure of the AMX Software has resulted from accident, abuse, or misapplication. Any replacement AMX Software will be warranted for the remainder of the original warranty period or thirty (30) days, whichever is longer.

Outside the United States, these remedies may not available. NO LIABILITY FOR CONSEQUENTIAL DAMAGES. IN NO

EVENT SHALL AMX BE LIABLE FOR ANY DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION, DAMAGES

FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, OR ANY OTHER

PECUNIARY LOSS) ARISING OUT OF THE USE OF OR INABILITY TO USE THIS AMX SOFTWARE, EVEN IF AMX HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. BECAUSE SOME STATES/COUNTRIES DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO LICENSEE.

• U.S. GOVERNMENT RESTRICTED RIGHTS. The AMX Software is provided with RESTRICTED RIGHTS. Use, duplication, or

disclosure by the Government is subject to restrictions as set forth in subparagraph ©(1)(ii) of The Rights in Technical Data and

Computer Software clause at DFARS 252.227-7013 or subparagraphs ©(1) and (2) of the Commercial Computer Software

Restricted Rights at 48 CFR 52.227-19, as applicable.

• SOFTWARE AND OTHER MATERIALS FROM AMX.COM MAY BE SUBJECT TO EXPORT CONTROL. The United States

Export Control laws prohibit the export of certain technical data and software to certain territories. No software from this Site may

be downloaded or exported (i) into (or to a national or resident of) Cuba, Iraq, Libya, North Korea, Iran, Syria, or any other country to which the United States has embargoed goods; or (ii) anyone on the United States Treasury Department's list of Specially

Designated Nationals or the U.S. Commerce Department's Table of Deny Orders. AMX does not authorize the downloading or

exporting of any software or technical data from this site to any jurisdiction prohibited by the United States Export Laws.

This Agreement replaces and supersedes all previous AMX Software License Agreements and is governed by the laws of

the State of Texas, and all disputes will be resolved in the courts in Collin County, Texas, USA. For any questions concerning this Agreement, or to contact AMX for any reason, please write: AMX License and Warranty Department, 3000 Research

Drive, Richardson, TX 75082.

Page 4

FCC Information

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received; including interference

that may cause undesired operation.

Federal Communications Commission (FCC)

Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy, and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC RF Radiation Exposure Statement

This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter. This

equipment complies with FCC RF radiation exposure limits set forth for an uncontrolled environment. This equipment

should be installed an operated with a minimum distance of 20 centimeters between the radia tor and your body.

Page 5

Table of Contents

i

VG-Series Modero Touch Panels

Table of Contents

Introduction ........................................................................................................1

Multimedia Streaming Video Touch Panels (VG-Series) ............................................ 1

Product Specifications (NXD-1200VG and NXT-1200VG) ............................................... 2

Product Specifications (NXD-1500VG and NXT-1500VG) ............................................... 5

Product Specifications (NXD-1700VG and NXT-1700VG) ............................................... 8

NXA-RGB Supported Resolutions and Formats............................................................. 11

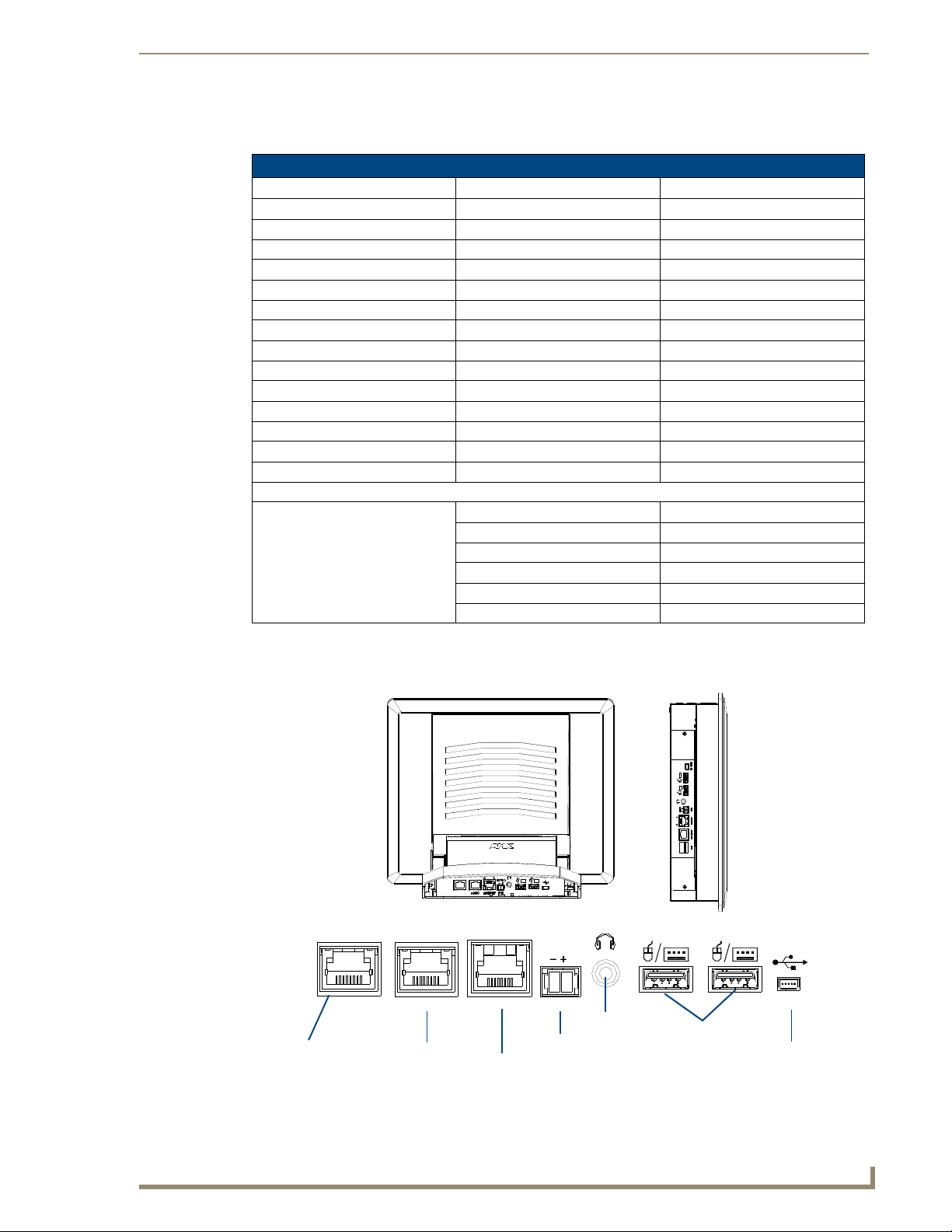

VG-Series Modero Connectors ............................................................................... 11

Connecting and Using USB Input Devices............................................................... 12

Cleaning the Touch Overlay.................................................................................... 12

Touch Panel Accessories ...................................................................................13

Overview ................................................................................................................ 13

NXA-AVB/RGB Breakout Box (FG2254-11)............................................................. 13

Product Specifications .................................................................................................. 14

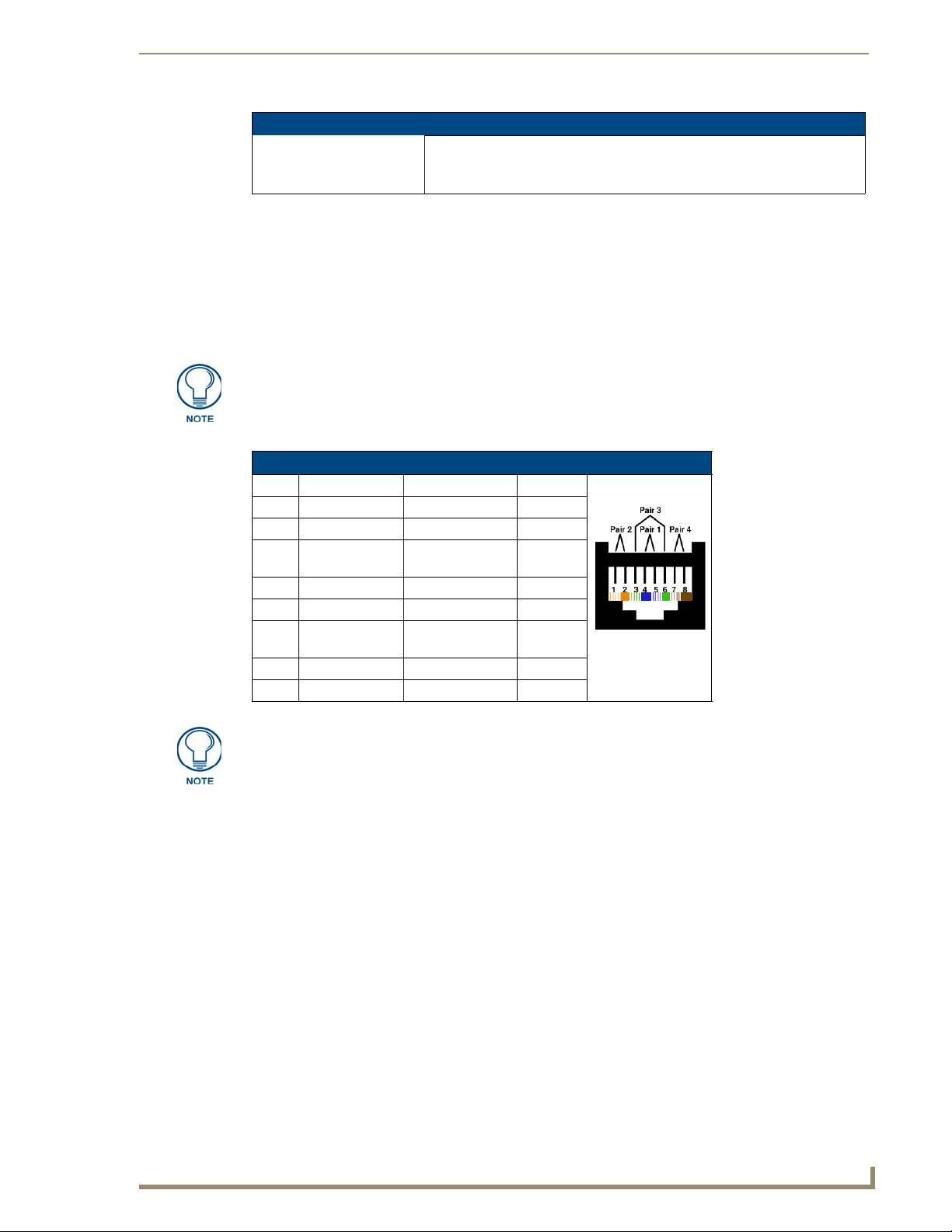

RGB RJ-45 connection and wiring information.............................................................. 15

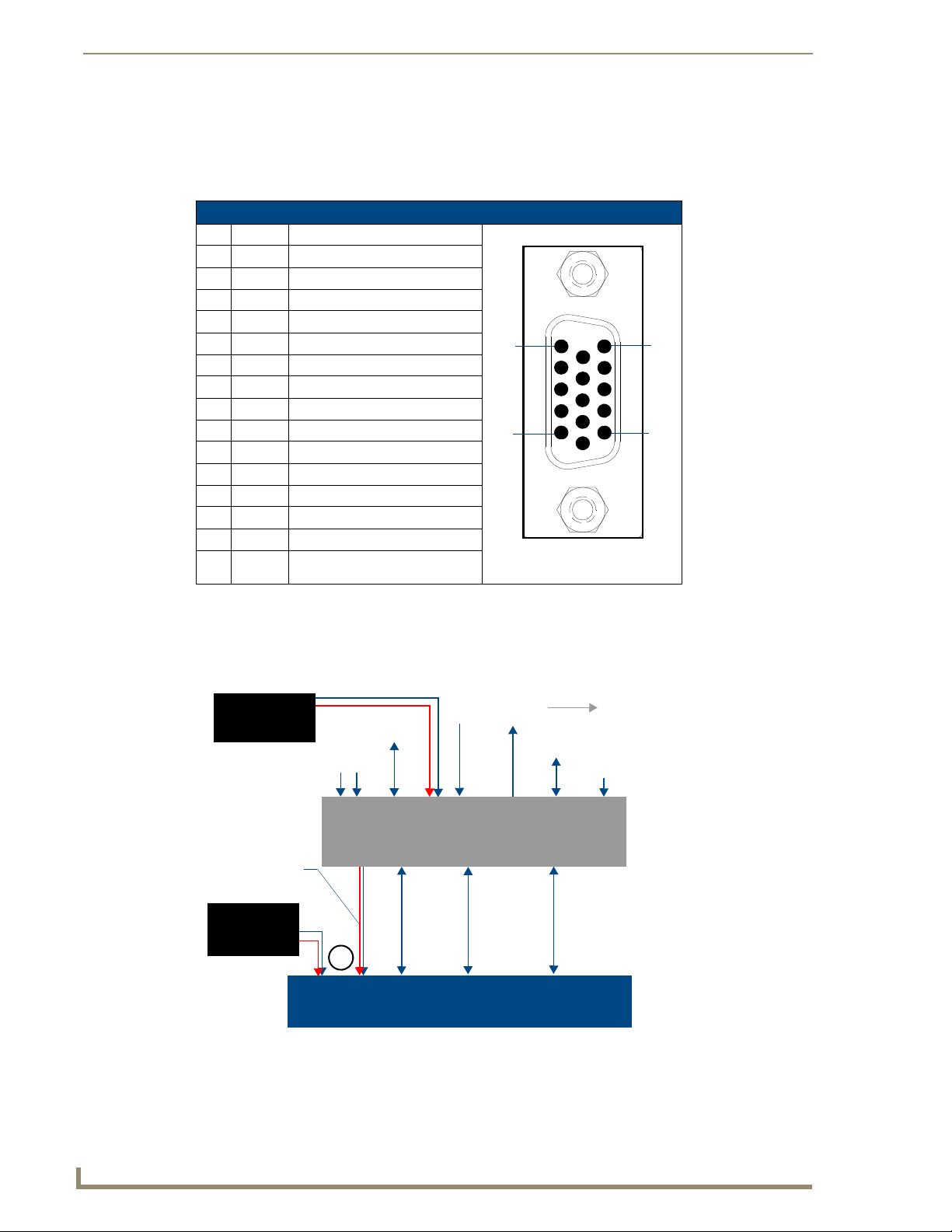

Using the HD-15 high-density connector ...................................................................... 16

Installing the NXA-AVB/RGB ......................................................................................... 16

Wiring the NXA-AVB/RGB connectors and cables......................................................... 17

Wiring the NXA-AVB/RGB for Unbalanced Audio ......................................................... 18

Wiring the NXA-AVB/RGB for Balanced Audio ............................................................. 19

Preparing your panel for Pass-Thru Control (using the NXA-AVB/RGB Breakout Box) . 19

Wiring for Pass-Thru Computer Control ........................................................................ 20

NXA-MTC/RGB Combo Table Top Cable (CA2250-70) ........................................... 22

Product Specifications ................................................................................................ 22

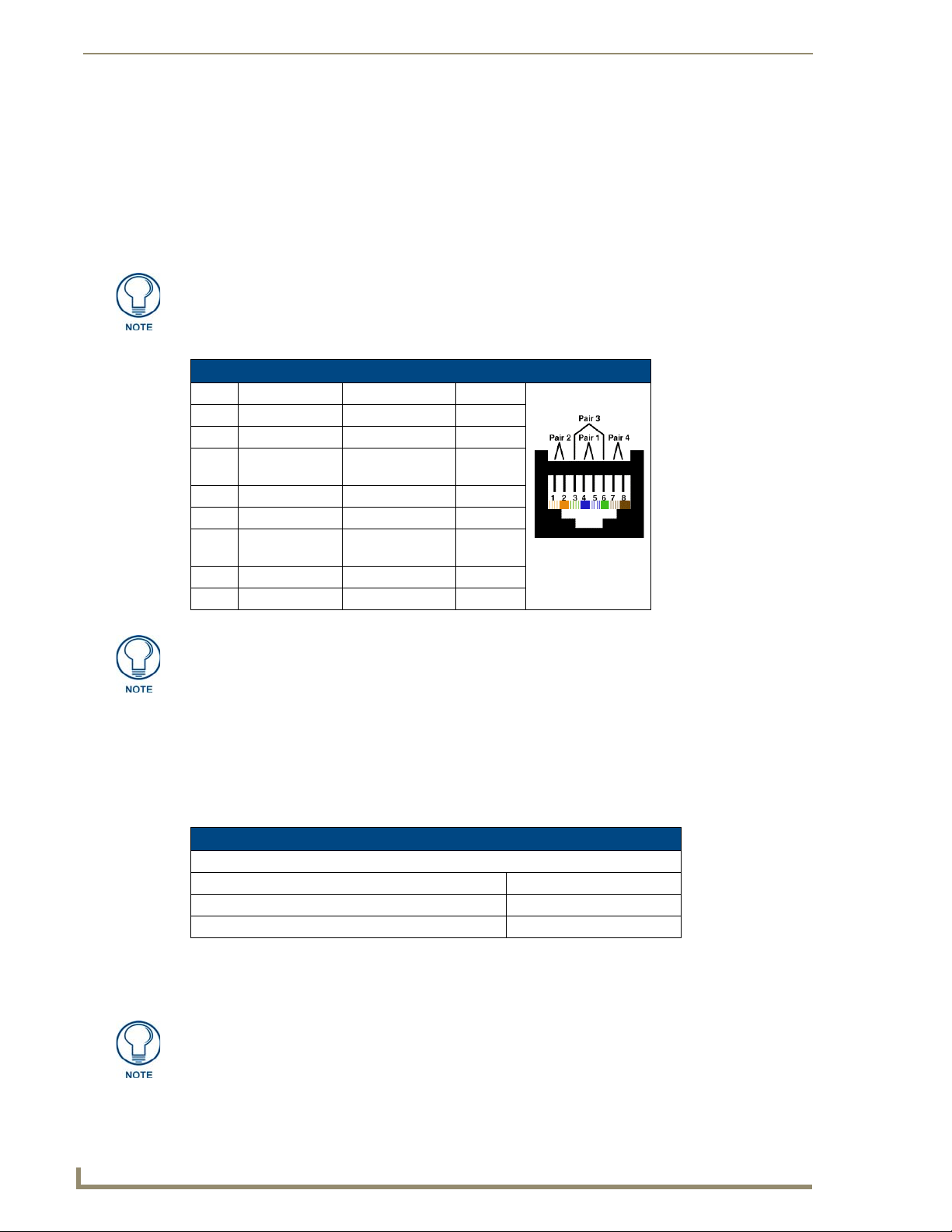

Wiring and Connection Information .............................................................................. 23

Installing CAT5 Suppression Ferrites............................................................................. 24

NXA-RGB RGB/VGA Interface Card (FG2260) ........................................................ 25

Product Specifications .................................................................................................. 26

Supported Component/VGA Video Resolutions and Formats ...................................... 27

RGB RJ-45 connection and wiring information.............................................................. 28

NXA-CFTP Compact Flash (FG2116-22).................................................................. 28

NXA-PCI80211G Wireless Card (FG2255-04).......................................................... 29

Installation and Upgrade of the Internal NXT Components .................................... 32

Product Specifications ............................................................................................... 30

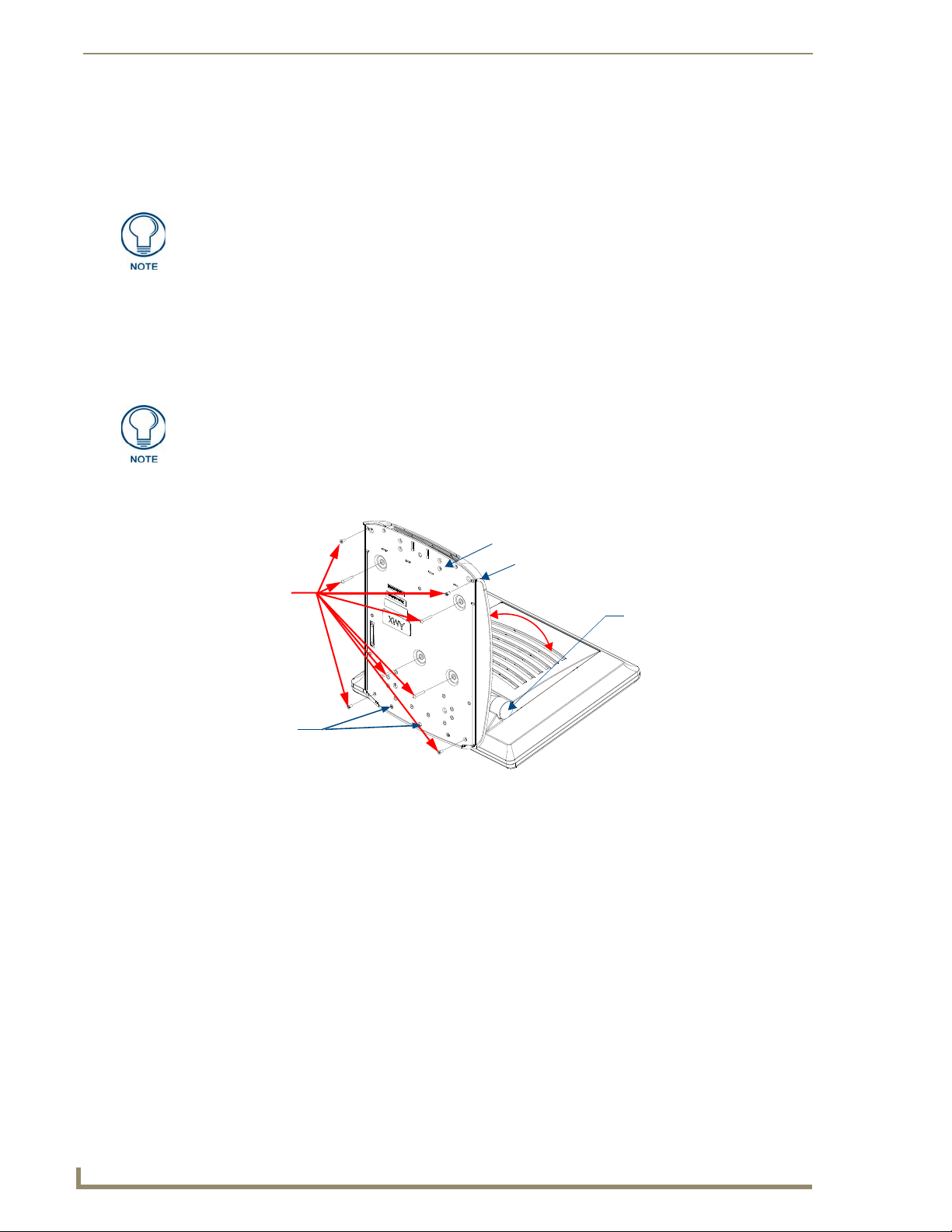

Step 1: Remove the existing NXT Outer Housing ......................................................... 32

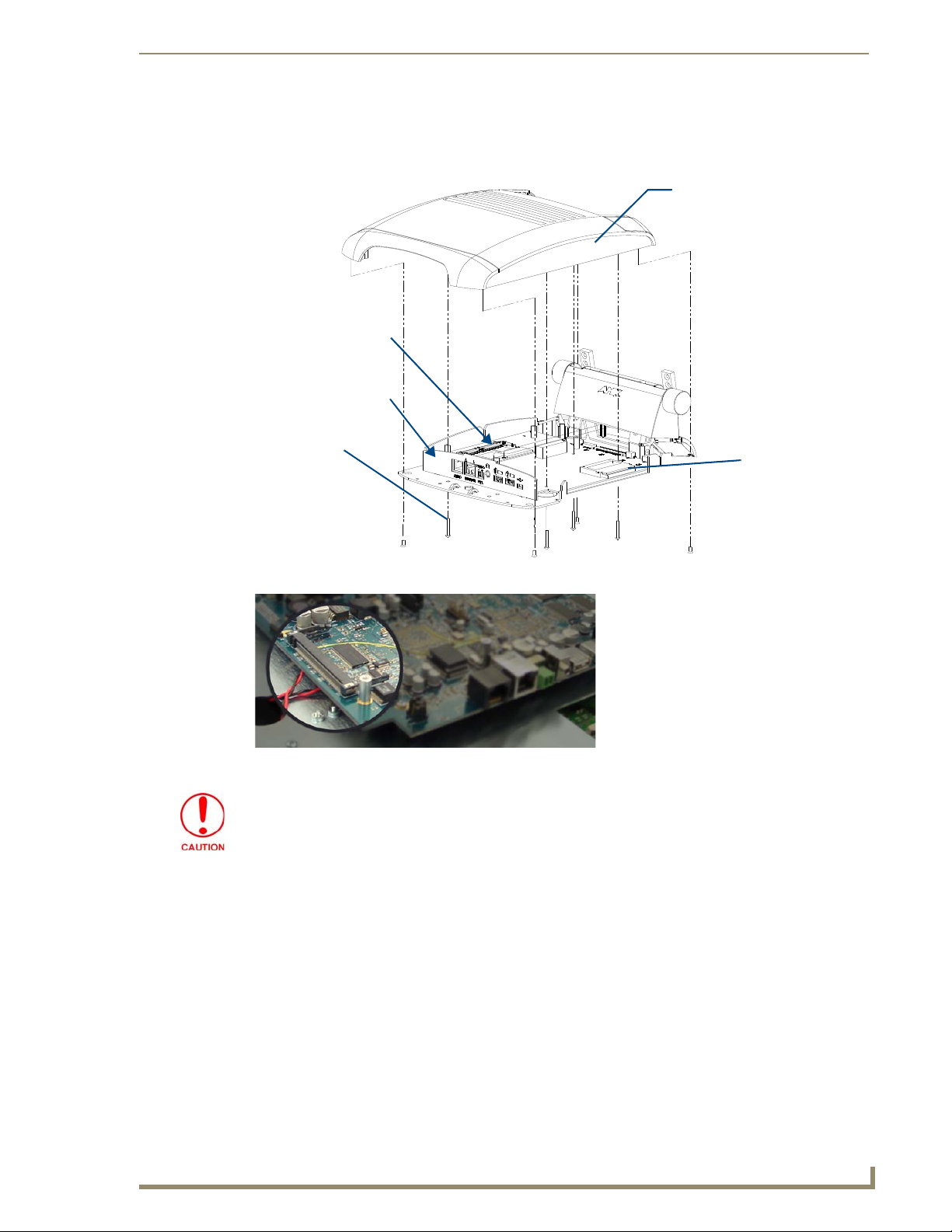

Step 2: Install the 802.11g mini-PCI Wireless Card ....................................................... 33

Step 3: Install the NXA-RGB Card Component (NXT).................................................... 34

Step 4: Install the Compact Flash Memory Card upgrade............................................. 35

Page 6

ii

VG-Series Modero Touch Panels

Table of Contents

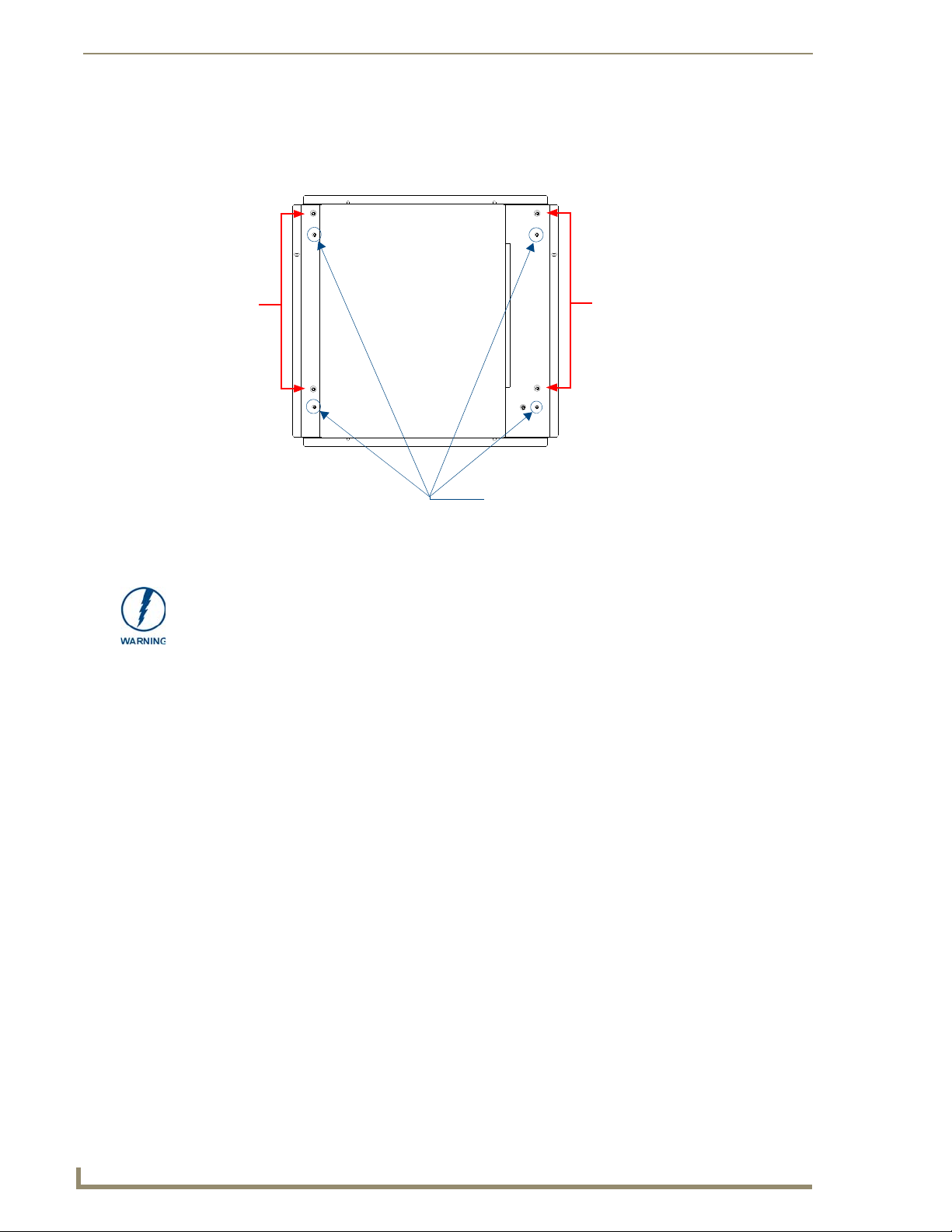

Step 5: Close and Resecure the NXT Panel Enclosure................................................... 36

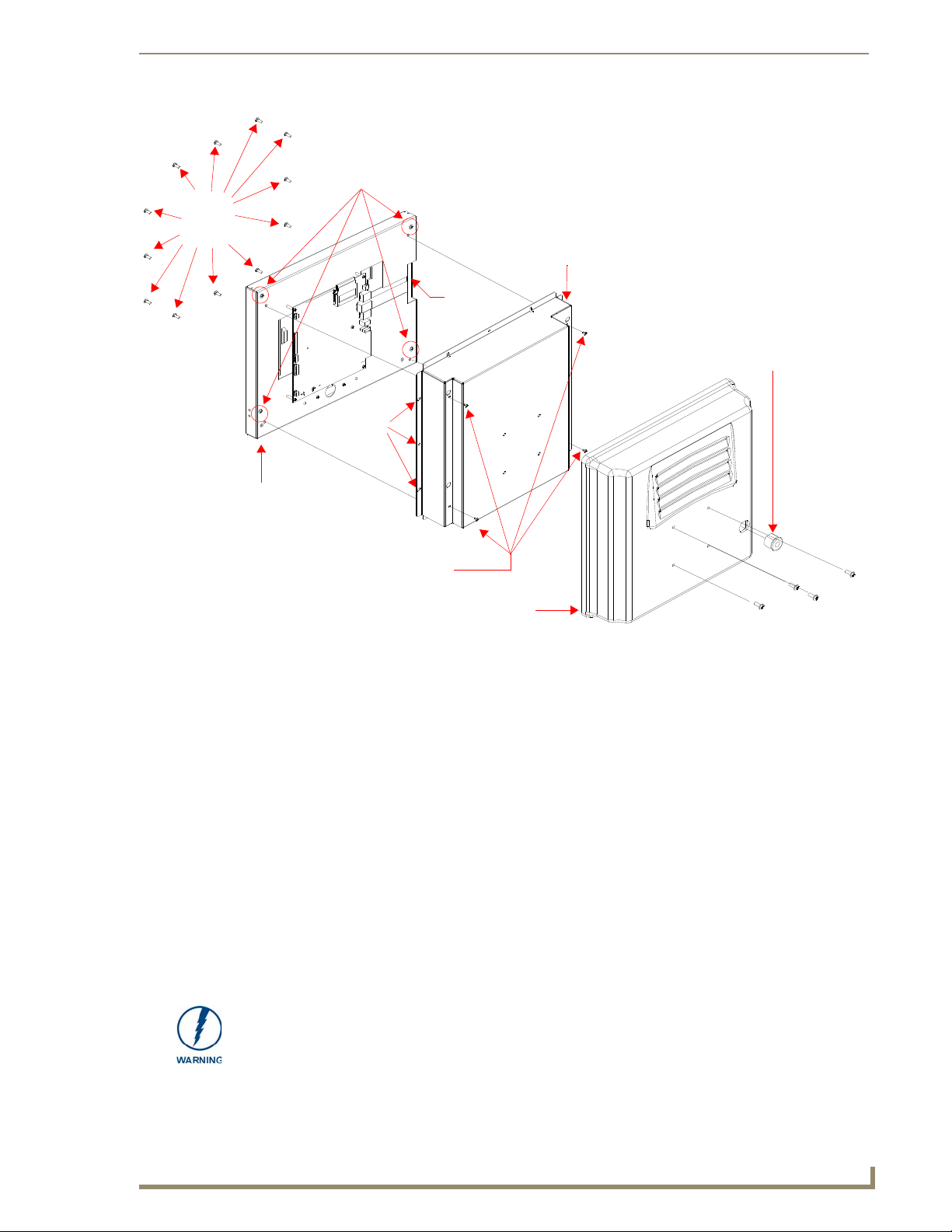

Installation and Upgrade of the Internal NXD Components ................................... 36

Step 1: Remove the existing NXD Outer Housing......................................................... 36

Step 2: Install the new 802.11g mini-PCI Wireless card (NXD) ...................................... 37

Step 3: Install the new RGB Card Component (NXD) .................................................... 37

Step 4: Install the new Compact Flash Memory card (NXD) .......................................... 37

Step 5: Close and Resecure the NXD Panel Enclosure .................................................. 38

NXT-BP Power Pack (FG2255-10) ........................................................................... 39

Product Specifications .................................................................................................. 39

NXA-BASE/B Battery Base Kit (FG2255K) .............................................................. 39

Product Specifications .................................................................................................. 40

Checking the NXT-BP battery charge............................................................................ 40

Installing the NXA-BASE/B to an NXT Modero Panel.................................................... 40

Installing an NXT-BP into the NXA-BASE/B................................................................... 42

Charging the NXT-BP batteries with the NXA-BASE/B ................................................. 42

NXT-CHG Battery Charger Kit (FG2255-50K) ......................................................... 43

Product Specifications .................................................................................................. 43

Powering the NXT-CHG ................................................................................................ 43

Reading NXT-CHG LED Indicator .................................................................................. 44

Charging the NXT-BP batteries using the NXT-CHG ..................................................... 44

Recalibrating the batteries ............................................................................................ 44

Installation Procedures: 12" and 15" Panels .....................................................45

Overview ................................................................................................................ 45

Unpacking the Panel ............................................................................................... 45

Installing Internal Components ............................................................................... 45

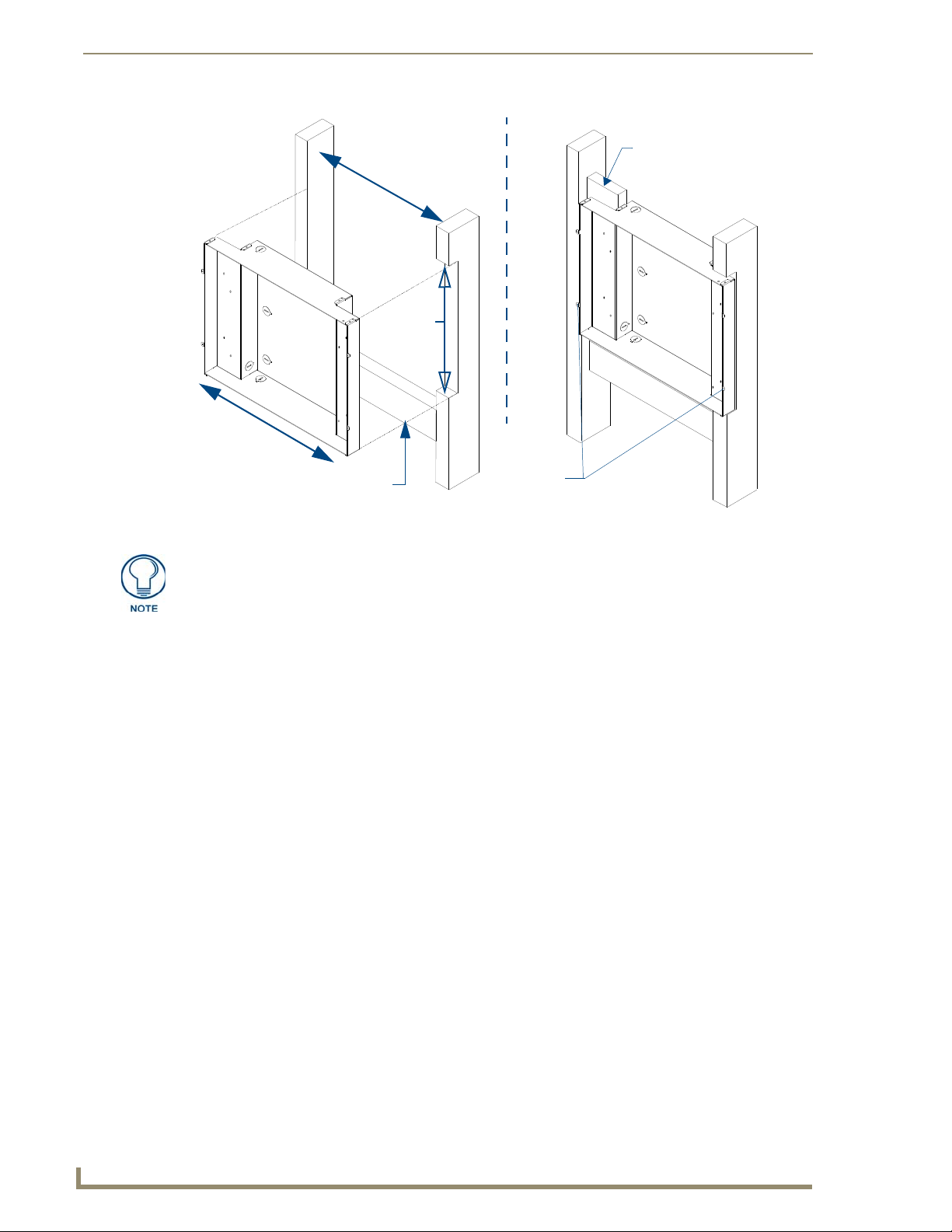

Upgrading to the MB-TP12/MB-TP15 VESA Mounting Kit ..................................... 45

Removing the Original Modero Back Box ..................................................................... 45

Installing the MP-TP12/15 Back Box.............................................................................. 46

Cable Installation for the MP-TP12/15 Back Box........................................................... 47

Finalizing the installation............................................................................................... 47

Pre-wall Installation of the Conduit Boxes .............................................................. 49

Installation of the NXD Touch Panel ....................................................................... 50

Installing the NXD panel within a Conduit Box ............................................................. 50

Installing the NXD into drywall using Expansion Clips .................................................. 52

Installing the NXD into a Flat Surface using #4 screws ................................................. 55

Installing an NXD into an (optional) Rack Mount Kit (NXA-RK12 or NXA-RK15) ........... 57

Wiring Guidelines for the 1200VG and 1500VG Panels .......................................... 59

Preparing captive wires................................................................................................. 59

Wiring a power connection ........................................................................................... 59

Audio/Video Port: Connections and Wiring ............................................................ 60

Page 7

Table of Contents

iii

VG-Series Modero Touch Panels

Ethernet/RJ-45 Port: Connections and Wiring ........................................................ 60

Installation Procedures: 17" Panels ..................................................................63

Overview ................................................................................................................ 63

Unpacking the Panel ............................................................................................... 63

Installing the Internal Components ......................................................................... 63

Upgrading the Back Box with the MB-TP17 VESA Housing.................................... 63

Removing the Original Modero Back Box ..................................................................... 63

Installing the MP-TP17 Back Box................................................................................... 64

Cable Installation for the MP-TP17 Back Box ................................................................ 65

Finalizing the installation............................................................................................... 65

Pre-wall Installation of the CB-TP17 Conduit Box ................................................... 67

Installation of an NXD-1700VG............................................................................... 69

Installing the NXD-1700VG within a CB-TP17 Conduit Box .......................................... 69

Installing the NXD-1700VG into drywall using Expansion Clips .................................... 71

Installing the NXD-1700VG into a Flat Surface using #6 screws ................................... 74

Installing an NXD into an (optional) Rack Mount Kit (NXA-RK17) ................................. 77

Wiring Guidelines for the 1700VG Panels............................................................... 78

Preparing captive wires................................................................................................. 79

Wiring a power connection ........................................................................................... 79

Audio/Video Port: Connections and Wiring............................................................ 80

Ethernet/RJ-45 Port: Connections and Wiring ........................................................ 80

Panel Calibration ..............................................................................................83

Overview ................................................................................................................ 83

Calibrating the Modero Panel................................................................................. 83

Testing your Calibration ................................................................................................ 84

Configuring Communication ............................................................................. 85

Overview ................................................................................................................ 85

Modero Setup and System Connection .................................................................. 85

Configuring and Using USB with a Virtual Master .................................................. 87

Step 1: Setting up the USB Driver on the PC ................................................................ 87

Step 2: Confirming the Installation of the USB Driver on the PC .................................. 87

Step 3: Confirm and View the current AMX USB device connections ........................... 89

Step 4: Using a USB to Configure a Virtual Master (using NetLinx Studio) ................... 90

Step 5: Confirm and View the current AMX USB device connections ........................... 91

Wireless Settings Page - Wireless Access Overview ............................................... 92

IP Routing...................................................................................................................... 92

Hot Swapping ............................................................................................................... 92

Configuring a Wireless Connection......................................................................... 93

Step 1: Configuring the Panel’s Wireless IP Settings .............................................. 93

Page 8

iv

VG-Series Modero Touch Panels

Table of Contents

Wireless communication using a DHCP Address ........................................................... 93

Wireless communication using a Static IP Address........................................................ 94

Step 2: Configuring the Card’s Wireless Security Settings ..................................... 94

Configuring the Modero’s wireless card for unsecured access to a WAP200G ............. 94

Configuring the Modero’s wireless card for secured access to a WAP200G ................. 96

Configuring multiple wireless Moderos to communicate to a target WAP200G........... 98

Configuring a Wired Ethernet Connection.............................................................. 99

Step 1: Configuring the Panel’s Wired IP Settings.................................................. 99

IP Settings section - Configuring a DHCP Address over Ethernet ................................. 99

IP Settings section - Configuring a Static IP Address over Ethernet.............................. 99

Step 2: Choosing a Master Connection Mode Setting .......................................... 100

Step 3: Configuring the Ethernet Connection Type.............................................. 100

Master Connection - Virtual Master communication over Ethernet............................. 101

Master Connection section - NetLinx Master Ethernet IP Address - URL Mode .......... 103

Master Connection section - NetLinx Master Ethernet IP Address - Listen Mode ....... 104

Master Connection section - NetLinx Master Ethernet IP Address - Auto Mode......... 104

Using G4 Web Control to Interact with a G4 Panel .............................................. 105

Using your NetLinx Master to control the G4 panels............................................ 107

Upgrading Modero Firmware .........................................................................109

Overview .............................................................................................................. 109

Upgrading the Modero Firmware via the USB port .............................................. 109

Step 1: Configure the panel for a USB Connection Type ............................................ 109

Step 2: Prepare NetLinx Studio for communication via the USB port ......................... 110

Step 3: Confirm and Upgrade the firmware via the USB port ..................................... 111

Upgrading the Modero Firmware via an IP Address............................................. 113

Step 1: Prepare the Master for communication via an IP ............................................ 113

Step 2: Prepare the panel for communication via an IP............................................... 114

Step 3: Verify and Upgrade the panel firmware via an IP ........................................... 114

Upgrading Accessory Devices via an IP Address................................................... 116

Step 1: Prepare the NXA-BASE/B for firmware transfer ............................................. 117

Step 2: Upgrade the NXA-BASE/B firmware via an IP................................................. 117

Upgrading the NXA-RGB and NXA-AVB/RGB Firmware....................................... 119

Firmware Pages and Descriptions ..................................................................121

Overview .............................................................................................................. 121

Setup Navigation Buttons..................................................................................... 121

Setup Page ........................................................................................................... 122

Panel Information Page ............................................................................................... 124

Project Information Page............................................................................................. 125

Time & Date Settings Page ......................................................................................... 126

Page 9

Table of Contents

v

VG-Series Modero Touch Panels

Audio Settings Page.................................................................................................... 128

Supported sampling rates for WAV ............................................................................ 129

Information icon .......................................................................................................... 129

Protected Setup Page ................................................................................................. 129

Video Slide-Out Menu................................................................................................. 130

Video Settings Page.................................................................................................... 130

Video - RGB Settings Page.......................................................................................... 131

Adjusting the Incoming Signal on the RGB Settings Page........................................... 134

Video - Streaming Settings Page ................................................................................ 137

Battery Base Page ....................................................................................................... 140

Protected Setup Navigation Buttons .................................................................... 142

Protected Setup Page........................................................................................... 143

Security Settings ......................................................................................................... 145

System Settings Page.................................................................................................. 147

Sensor Settings Page .................................................................................................. 149

Using the Automated Brightness Control feature (DIM Mode) ................................... 150

Calibration Page.......................................................................................................... 152

G4 Web Control Settings ............................................................................................ 153

Other Settings Slide-Out Menu................................................................................... 155

Cache Settings Page ................................................................................................... 155

Setting the image cache.............................................................................................. 157

Clearing the image cache ............................................................................................ 157

Checking image cache status ...................................................................................... 157

Password Settings Page .............................................................................................. 158

Tools Slide-out Menu .................................................................................................. 159

Panel Connection Logs ................................................................................................ 159

Checking the Panel Connection Logs .......................................................................... 160

Refreshing the Panel Connections Log........................................................................ 160

Clearing the Panel Connections Log ........................................................................... 160

Panel Statistics ............................................................................................................ 161

Checking the Panel Statistics ...................................................................................... 162

Refreshing the Panel Statistics .................................................................................... 162

Clearing the Panel Statistics ........................................................................................ 162

Connection Utility ....................................................................................................... 163

Using the Connection Utility ....................................................................................... 164

Wireless Settings Page................................................................................................ 165

Displaying Stream Content ............................................................................. 169

Overview .............................................................................................................. 169

Requirements for Receiving Streamed Content.................................................... 170

Setting up a Modero Panel to Receive and Display a Stream............................... 171

Page 10

vi

VG-Series Modero Touch Panels

Table of Contents

Step 1: Obtaining the IP Address of the target panel................................................. 171

Step 2: Configuring the MAX-CSE for communication ................................................ 171

Step 3: Configuring the MAX-CSE audio/video inputs ................................................ 173

Step 4: Setup a streaming page within TPDesign4 ..................................................... 174

Step 5: Establishing the final connection between the two units ................................ 177

Programming ..................................................................................................179

Overview .............................................................................................................. 179

Button Assignments ............................................................................................ 179

Page Commands ................................................................................................... 179

@APG...................................................................................................................................... 179

@CPG...................................................................................................................................... 179

@DPG...................................................................................................................................... 180

@PDR ...................................................................................................................................... 180

@PHE ...................................................................................................................................... 180

@PHP ...................................................................................................................................... 180

@PHT ...................................................................................................................................... 180

@PPA ...................................................................................................................................... 181

@PPF....................................................................................................................................... 181

@PPG ...................................................................................................................................... 181

@PPK ...................................................................................................................................... 181

@PPM...................................................................................................................................... 182

@PPN ...................................................................................................................................... 182

@PPT....................................................................................................................................... 182

@PPX ...................................................................................................................................... 182

@PSE....................................................................................................................................... 182

@PSP....................................................................................................................................... 183

@PST ....................................................................................................................................... 183

PAGE ...................................................................................................................................... 183

PPOF....................................................................................................................................... 183

Programming Numbers......................................................................................... 184

RGB triplets and names for basic 88 colors ................................................................ 184

PPOG ...................................................................................................................................... 184

PPON ...................................................................................................................................... 184

Font styles and ID numbers ......................................................................................... 186

Border styles ............................................................................................................... 186

"^" Button Commands ......................................................................................... 188

^ANI ....................................................................................................................................... 188

^APF ....................................................................................................................................... 188

^BAT....................................................................................................................................... 189

^BAU ...................................................................................................................................... 189

^BCB....................................................................................................................................... 189

^BCF ....................................................................................................................................... 190

^BCT ....................................................................................................................................... 190

^BDO...................................................................................................................................... 190

^BFB ....................................................................................................................................... 191

^BIM ....................................................................................................................................... 191

Page 11

Table of Contents

vii

VG-Series Modero Touch Panels

^BLN ....................................................................................................................................... 191

^BMC ...................................................................................................................................... 192

^BMF....................................................................................................................................... 192

^BMI........................................................................................................................................ 194

^BML....................................................................................................................................... 194

^BMP ...................................................................................................................................... 194

^BNC....................................................................................................................................... 195

^BNN ...................................................................................................................................... 195

^BNT ....................................................................................................................................... 195

^BOP....................................................................................................................................... 195

^BOR....................................................................................................................................... 196

^BOS....................................................................................................................................... 196

^BPP........................................................................................................................................ 197

^BRD ....................................................................................................................................... 197

^BSF........................................................................................................................................ 197

^BSM....................................................................................................................................... 197

^BSO....................................................................................................................................... 198

^BVL........................................................................................................................................ 198

^BVN....................................................................................................................................... 198

^BVP ....................................................................................................................................... 198

^BVT ....................................................................................................................................... 198

^BWW ..................................................................................................................................... 199

^CPF........................................................................................................................................ 199

^DPF ....................................................................................................................................... 199

^DTO....................................................................................................................................... 199

^ENA....................................................................................................................................... 200

^FON ...................................................................................................................................... 200

^GDI........................................................................................................................................ 200

^GIV ........................................................................................................................................ 200

^GLH ....................................................................................................................................... 201

^GLL........................................................................................................................................ 201

^GRD....................................................................................................................................... 201

^GRU....................................................................................................................................... 201

^GSC ....................................................................................................................................... 201

^GSN....................................................................................................................................... 202

^ICO........................................................................................................................................ 202

^JSB ........................................................................................................................................ 203

^JSI ......................................................................................................................................... 203

^JST ........................................................................................................................................ 204

^MBT....................................................................................................................................... 204

^MDC...................................................................................................................................... 204

^SAV ....................................................................................................................................... 204

^SHO....................................................................................................................................... 204

^SKT........................................................................................................................................ 205

^STO ....................................................................................................................................... 205

^TEC........................................................................................................................................ 205

^TEF........................................................................................................................................ 205

^TOP ....................................................................................................................................... 205

Text Effect Names ................................................................................................ 206

Page 12

viii

VG-Series Modero Touch Panels

Table of Contents

^TXT ....................................................................................................................................... 206

^UNI ....................................................................................................................................... 206

^VTO ...................................................................................................................................... 206

Button Query Commands ..................................................................................... 207

?BBV ....................................................................................................................................... 208

?BCB ....................................................................................................................................... 208

?BCF ....................................................................................................................................... 209

?BCT ....................................................................................................................................... 209

?BMP ...................................................................................................................................... 210

?BOP....................................................................................................................................... 210

?BRD ....................................................................................................................................... 211

?BRT........................................................................................................................................ 211

?BWW ..................................................................................................................................... 211

?CHR....................................................................................................................................... 212

?DTO....................................................................................................................................... 212

?FBC ....................................................................................................................................... 212

?FON ...................................................................................................................................... 212

?ICO........................................................................................................................................ 213

?JSB ........................................................................................................................................ 213

?JSI ......................................................................................................................................... 214

?JST ........................................................................................................................................ 214

?MAC ...................................................................................................................................... 214

?MUT ...................................................................................................................................... 215

?PIF......................................................................................................................................... 215

?STA........................................................................................................................................ 215

?TEC........................................................................................................................................ 216

?TEF........................................................................................................................................ 216

Panel Runtime Operations .................................................................................... 217

?TXT........................................................................................................................................ 217

?VOL ....................................................................................................................................... 217

?WIF........................................................................................................................................ 217

ABEEP..................................................................................................................................... 218

ADBEEP .................................................................................................................................. 218

@AKB ...................................................................................................................................... 218

AKEYB .................................................................................................................................... 218

AKEYP..................................................................................................................................... 218

AKEYR..................................................................................................................................... 218

@AKP ...................................................................................................................................... 219

@AKR ...................................................................................................................................... 219

BEEP ....................................................................................................................................... 219

BRIT ........................................................................................................................................ 219

@BRT....................................................................................................................................... 219

DBEEP..................................................................................................................................... 219

@EKP ...................................................................................................................................... 220

PKEYP ..................................................................................................................................... 220

@PKP ...................................................................................................................................... 220

SETUP ..................................................................................................................................... 220

SHUTDOWN ........................................................................................................................... 220

SLEEP...................................................................................................................................... 220

Page 13

Table of Contents

ix

VG-Series Modero Touch Panels

Input Commands................................................................................................... 221

@SOU ...................................................................................................................................... 221

@TKP ....................................................................................................................................... 221

TPAGEON ............................................................................................................................... 221

TPAGEOFF .............................................................................................................................. 221

@VKB....................................................................................................................................... 221

WAKE ...................................................................................................................................... 221

^CAL ....................................................................................................................................... 222

^KPS........................................................................................................................................ 222

^MPS....................................................................................................................................... 222

Embedded Codes ................................................................................................. 223

^SLT ........................................................................................................................................ 223

^VKS ....................................................................................................................................... 223

Panel Setup Commands ........................................................................................ 224

^MUT ...................................................................................................................................... 225

@PWD ..................................................................................................................................... 225

^PWD...................................................................................................................................... 225

@RPP ....................................................................................................................................... 225

^VOL ....................................................................................................................................... 225

Dynamic Image Commands................................................................................... 225

^BBR ....................................................................................................................................... 226

^RAF ....................................................................................................................................... 226

^RFR........................................................................................................................................ 226

^RAF, ^RMF - Embedded Codes ................................................................................ 227

^RMF....................................................................................................................................... 227

^RSR........................................................................................................................................ 227

Escape Sequences ....................................................................................................... 228

$DV ......................................................................................................................................... 228

$SY .......................................................................................................................................... 228

$IP ........................................................................................................................................... 228

$HN......................................................................................................................................... 228

$MC......................................................................................................................................... 228

$ID........................................................................................................................................... 228

$PX.......................................................................................................................................... 228

$PY.......................................................................................................................................... 228

$ST .......................................................................................................................................... 228

$AC ......................................................................................................................................... 228

$AP.......................................................................................................................................... 228

$CC ......................................................................................................................................... 228

$CP.......................................................................................................................................... 228

$LC .......................................................................................................................................... 228

$LP .......................................................................................................................................... 228

$BX.......................................................................................................................................... 228

$BY.......................................................................................................................................... 228

$BN ......................................................................................................................................... 228

Troubleshooting .............................................................................................231

Overview .............................................................................................................. 231

Page 14

x

VG-Series Modero Touch Panels

Table of Contents

Appendix ........................................................................................................235

Text Formatting Codes for Bargraphs/Joysticks................................................... 235

Text Area Input Masking....................................................................................... 236

Input mask character types ......................................................................................... 236

Input mask ranges ....................................................................................................... 237

Input mask next field characters.................................................................................. 237

Input mask operations................................................................................................. 237

Input mask literals ....................................................................................................... 237

Input mask output examples ....................................................................................... 238

URL Resources ...................................................................................................... 238

Special escape sequences ........................................................................................... 239

Page 15

1

VG-Series Modero Touch Panels

Introduction

The VG Series of Modero® Touch Panels offer streaming MPEG video, high-definition Component RGB

input and display, USB support for extended input devices, and panel programming via a mini-USB port.

The new G4 graphics and Video/RGB technology is supported by the release of the latest TPDesign4 Touch

Panel Design Program. These video-capable panels support several video formats: NTSC, SECAM, and PAL

(Color Active (CA) panels don’t support video).

Multimedia Streaming Video Touch Panels (VG-Series)

Although these panels are similar to the 1200V models, in that they both share connectors for USB

communication and Audio/Video distribution; the VG-Series far exceed those panels by additionally providing

RGB Component video display, MPEG streaming technology, and pass-thru computer control.

These panels are capable of NTSC/PAL/SECAM video formats within variable sized video windows. These

VG-Series panels display HDTV Component video (fed from an external NXA-AVB/RGB Breakout Box and

then through an internal NXA-RGB card). In addition to composite video support, the new VG-Series of

panels now feature USB connectivity for mouse and keyboard, and pre-installed antennas for all Table Top

models.

Powered by a cutting-edge DSP core, the VG-Series has the muscle to handle digital streaming

(both video and audio), in wired or wireless configurations. These Moderos feature full support for standard

MPEG-2 streaming video as well as MP3 and AAC streaming audio.

The NXA-AVB/RGB Breakout Box (FG2254-11) facilitates the installation and distribution of video

(Composite and Component), data, audio, and pass-thru Computer Control to Modero touch panels located up

to 200 feet (60.96 m) from the NXA-AVB/RGB box.

The VG-Series of touch panels can be fitted for either Video (Composite) or RGB (Component) via the use of

two Kit configurations: Video Kit and RGB Kit. Each kit comes with its own group of standard components

that are specific to its configuration. Although a panel can be order with either of these kits; a previously fitted

Video Kit panel can be later upgraded to accept and display RGB Component via the use of an RGB upgrade

package called the NXA-RGBKIT (FG2255-11). This upgrade kit supplements the existing Video fitted panel

(FG225X-XXV) with such things as an internal NXA-RGB interface card and an external NXA-AVB/RGB

Breakout Box.

The Video Kit fitted units can accept either Composite or S-Video from standard video devices. These

Composite video panels include those listed below:

Modero Multimedia Touch Panels (VG-Series with Video Kits)

NXD-1200VG (FG2251-61V) 12" Modero Multimedia WallMount Touch Panel with Video Kit.

NXT-1200VG (FG2250-61V) 12" Modero Multimedia Table Top Touch Panel with Video Kit.

NXD-1500VG (FG2253-61V) 15" Modero Multimedia WallMount Touch Panel with Video Kit.

NXT-1500VG (FG2252-61V) 15" Modero Multimedia Table Top Touch Panel with Video Kit.

NXD-1700VG (FG2256-61V) 17" Modero Widescreen WallMount Touch Panel with Video Kit.

NXT-1700VG (FG2257-61V) 17" Modero Widescreen Table Top Touch Panel with Video Kit.

Introduction

The Video Kits include the following components:

Modero VG-Series Touch Panel (NXD or NXT) (FG225X-XXV)

Modero 10’ foot Table Top Cable (CA2250-50)

NXA-AVB/ETHERNET Breakout Box (FG2254-10)

These panels are capable of displaying both Composite video and High-Definition Component RGB, bringing

together both Video and RGB capability together into one panel.

Modero Video/RGB-compatible panels utilize an internal NXA-RGB interface card (combined with an

external NXA-AVB/RGB Breakout Box) to accept and display high-bandwidth and high-quality RGB and

HDTV Component video signals. An existing Video Kit fitted VG-Series touch panel (Video only) can be

upgraded to display RGB input by purchasing a separate NXA-RGBKIT. These Video/RGB panels include

those listed below:

Page 16

Introduction

2

VG-Series Modero Touch Panels

Modero Multimedia Touch Panels (VG-Series with RGB Kits)

NXD-1200VG (FG2251-61RGB) 12" Modero Multimedia WallMount Touch Panel with RGB Kit.

NXT-1200VG (FG2250-61RGB) 12" Modero Multimedia Table Top Touch Panel with RGB Kit.

NXD-1500VG (FG2253-61RGB) 15" Modero Multimedia WallMount Touch Panel with RGB Kit.

NXT-1500VG (FG2252-61RGB) 15" Modero Multimedia Table Top Touch Panel with RGB Kit.

NXD-1700VG (FG2256-61RGB) 17" Modero Widescreen WallMount Touch Panel with RGB Kit.

NXT-1700VG (FG2257-61RGB) 17" Modero Widescreen Table Top Touch Panel with RGB Kit.

The RGB Kits include the following components:

Modero VG-Series Touch Panel (NXD or NXT) (FG225X-XXRGB)

NXA-AVB/RGB Breakout Box (FG2254-11)

NXA-RGB internal RGB/VGA Interface Card (FG2260) (pre-installed)

NXA-MTC/RGB Modero 10’ foot Table Top Cable (with RGB connector) (CA2250-70)

NXA-RGBCBL, 15-pin to 5X BNC RGB Breakout cable (FG2250-80)

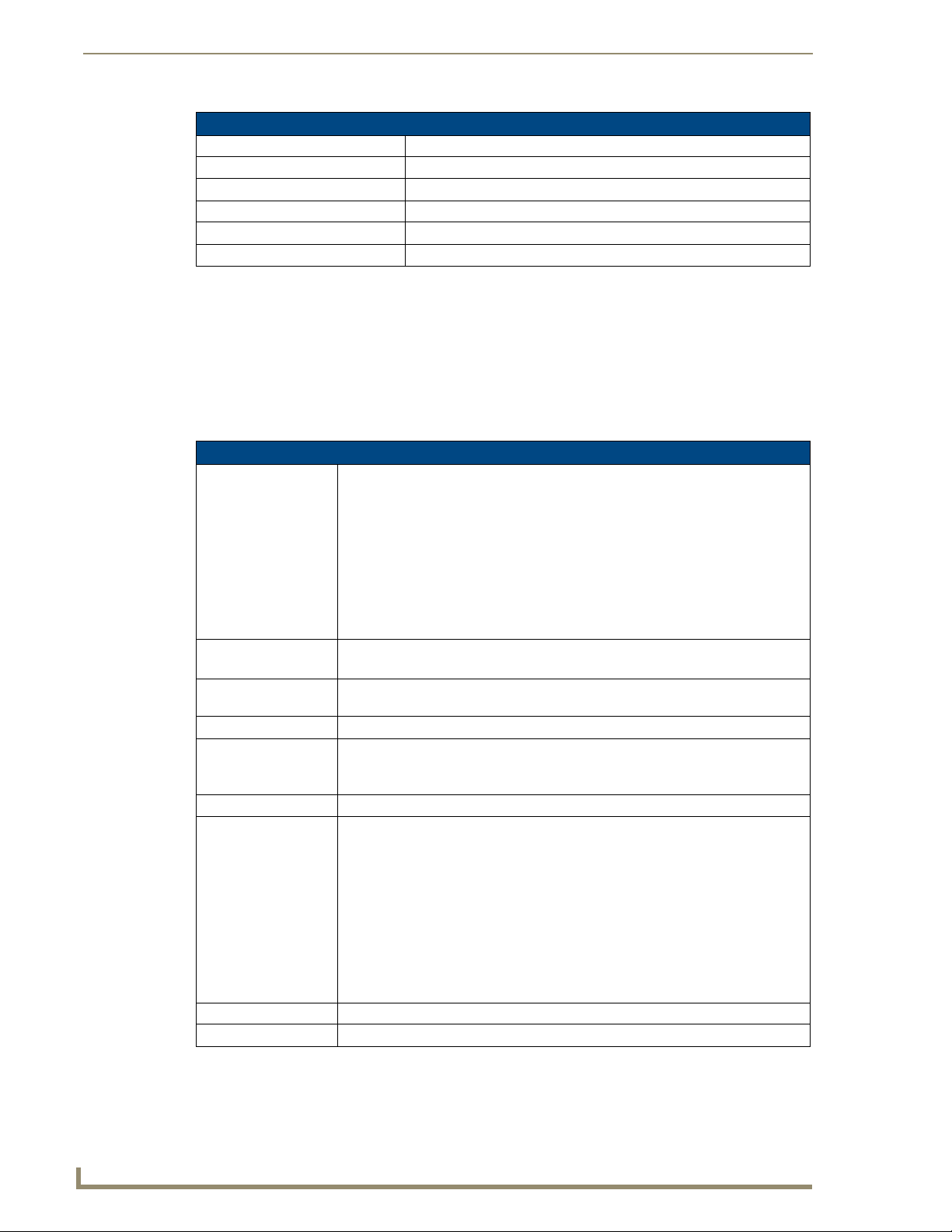

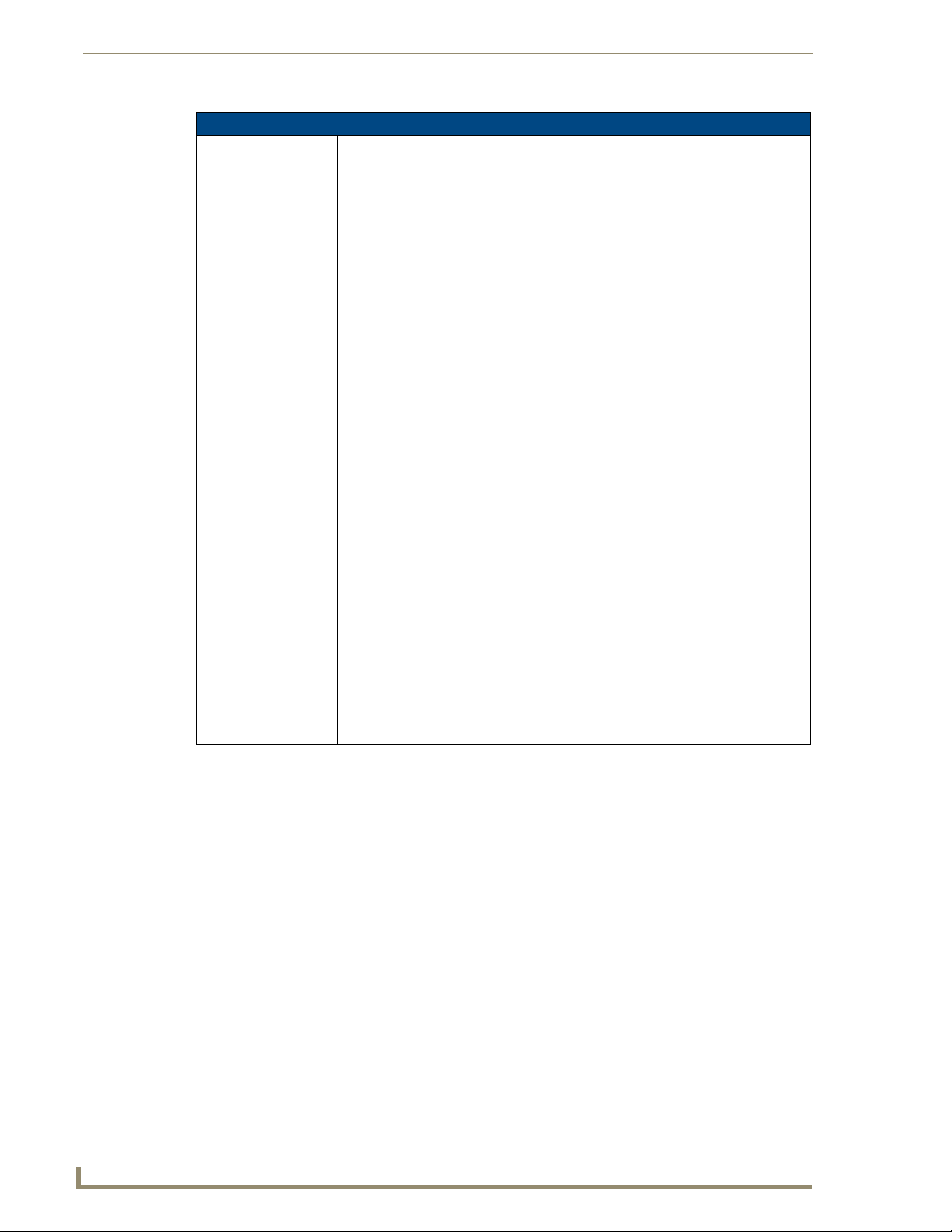

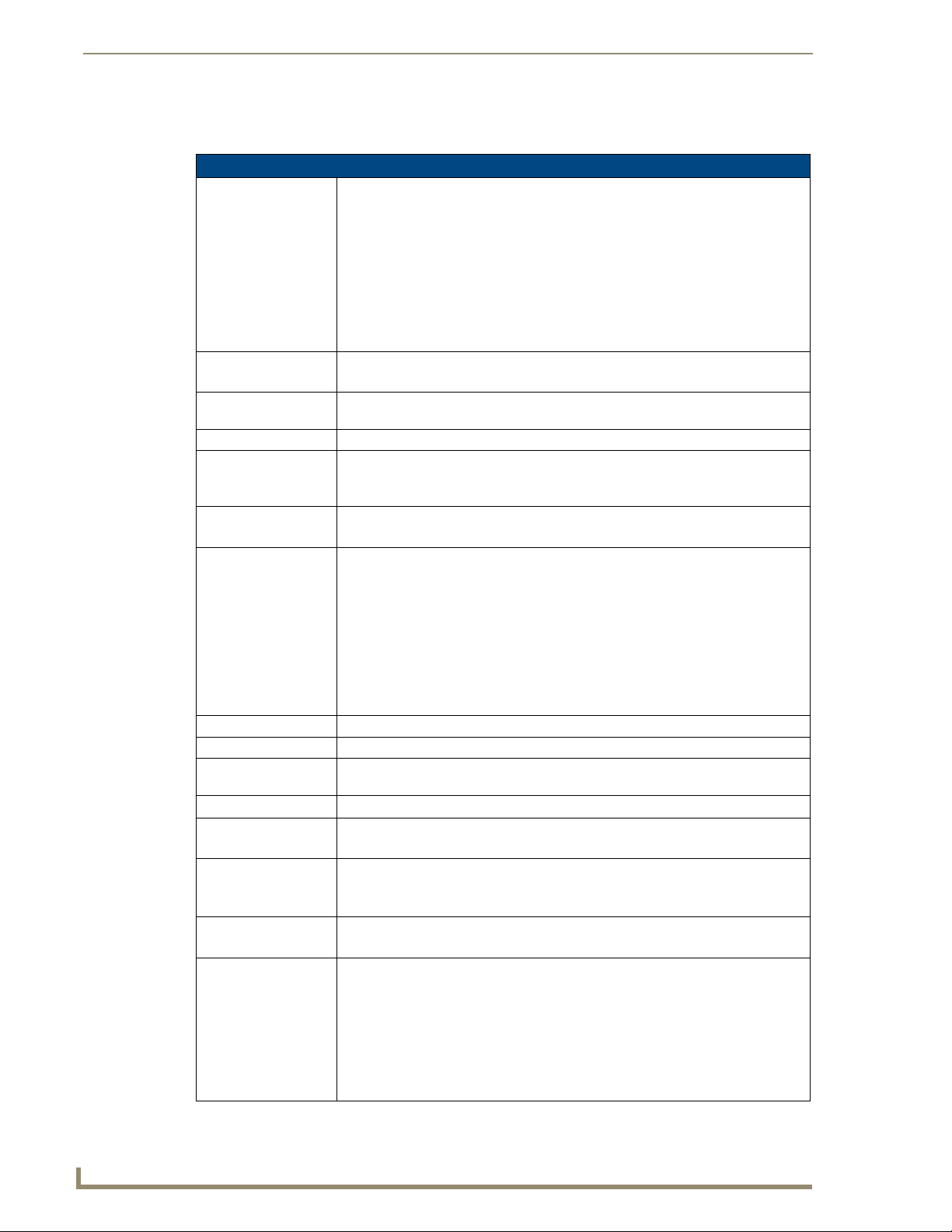

Product Specifications (NXD-1200VG and NXT-1200VG)

The following table outlines the specifications for VG-Series of 12" Modero panels.

1200VG Specifications

Dimensions (HWD): • NXD-1200VG (with faceplate): 12.38" x 12.59" x 3.25"

(31.43 cm x 31.97 cm x 8.25 cm)

• NXT-1200VG (Fully raised): 10.91" x 12.34" x 12.50"

(27.70 cm x 31.33 cm x 31.75 cm)

• NXT-1200VG (Fully lowered): 6.77" x 12.34" x 12.50"

(17.20 cm x 31.33 cm x 31.75 cm)

• CB-TP12 (conduit/wallbox): 11.52" x 11.60" x 3.50"

(29.27 cm x 29.47 cm x 8.89 cm)

• MB-TP12 (VESA mounting box): 12.37" x 12.58" x 3.52"

(31.42 cm x 31.95 cm x 8.94 cm)

Power: • Constant current draw: 2.3 A @ 12 VDC (stand-alone)

• Startup current draw: 3.5 A @ 12 VDC (stand-alone)

Minimum power

supply required:

Memory: 256 MB on-board memory

Compactflash: 2GB or greater (upgradeable to 4GB - see Other AMX Equipment).

Weight: 10.80 lbs (4.90 kg)

LCD Parameters: • Aspect Ratio: 4:3

Active Screen Area: 9.69” x 7.26” (24.60cm x 18.45cm)

Viewing Angles: Vertical: + 80° (up from center) and - 80° (down from center)

PSN4.4 Power Supply (FG423-45)

- using accessories can increase the power draw requirements

Note: AMX may increase Compactflash size at any time in response to market availability.

• Brightness (luminance): 250 cd/m2

• Channel transparency: 8-bit Alpha channel transparency

• Contrast ratio: 300:1

• Display area (HW): 183.10 mm x 247.40 mm

• Display colors: 256K (18-bit color depth)

• Dot/Pixel pitch: 0.297 mm

• Screen resolution (HV): 800 x 600 pixels

• Video formats: NTSC, PAL, and SECAM (shown within variable-size video

windows)

Page 17

3

VG-Series Modero Touch Panels

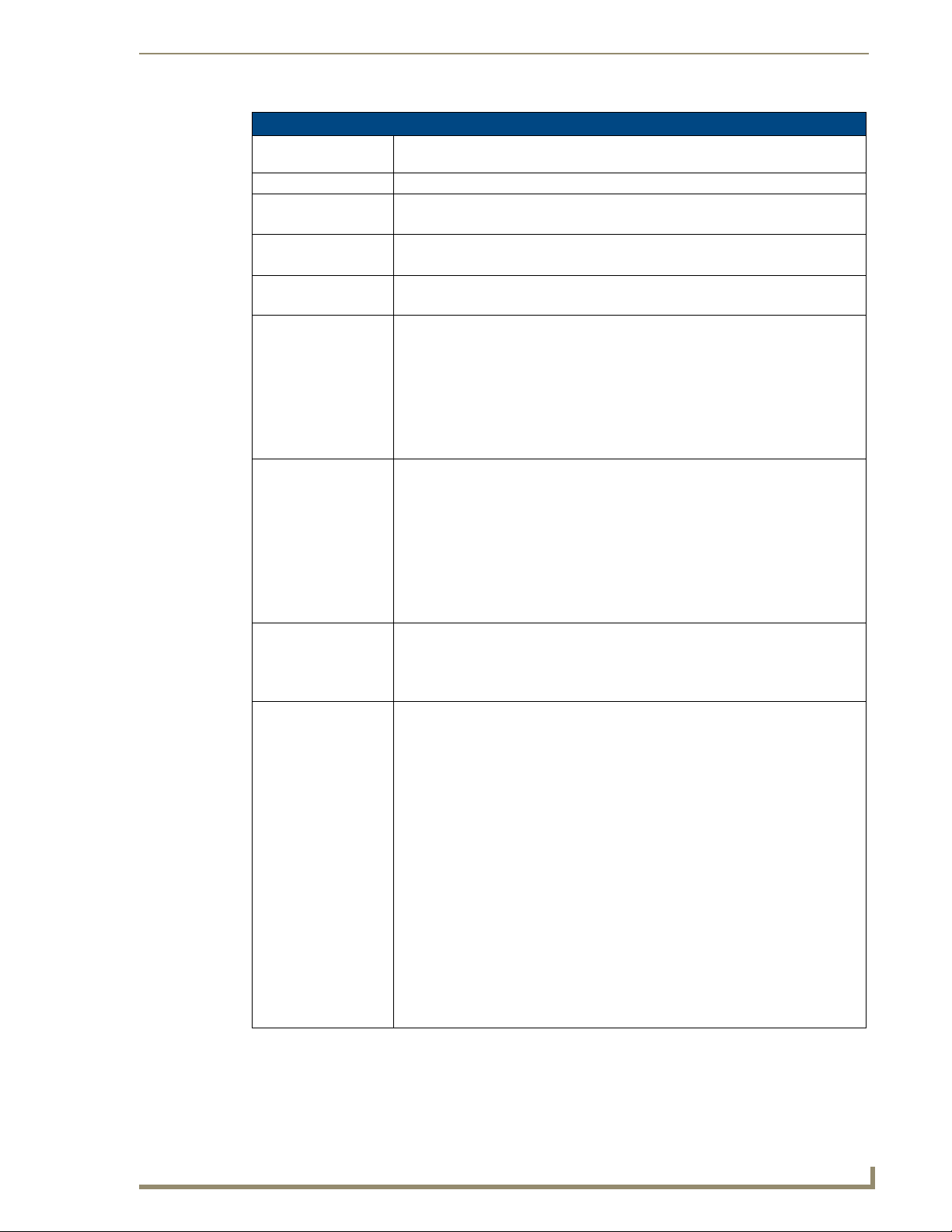

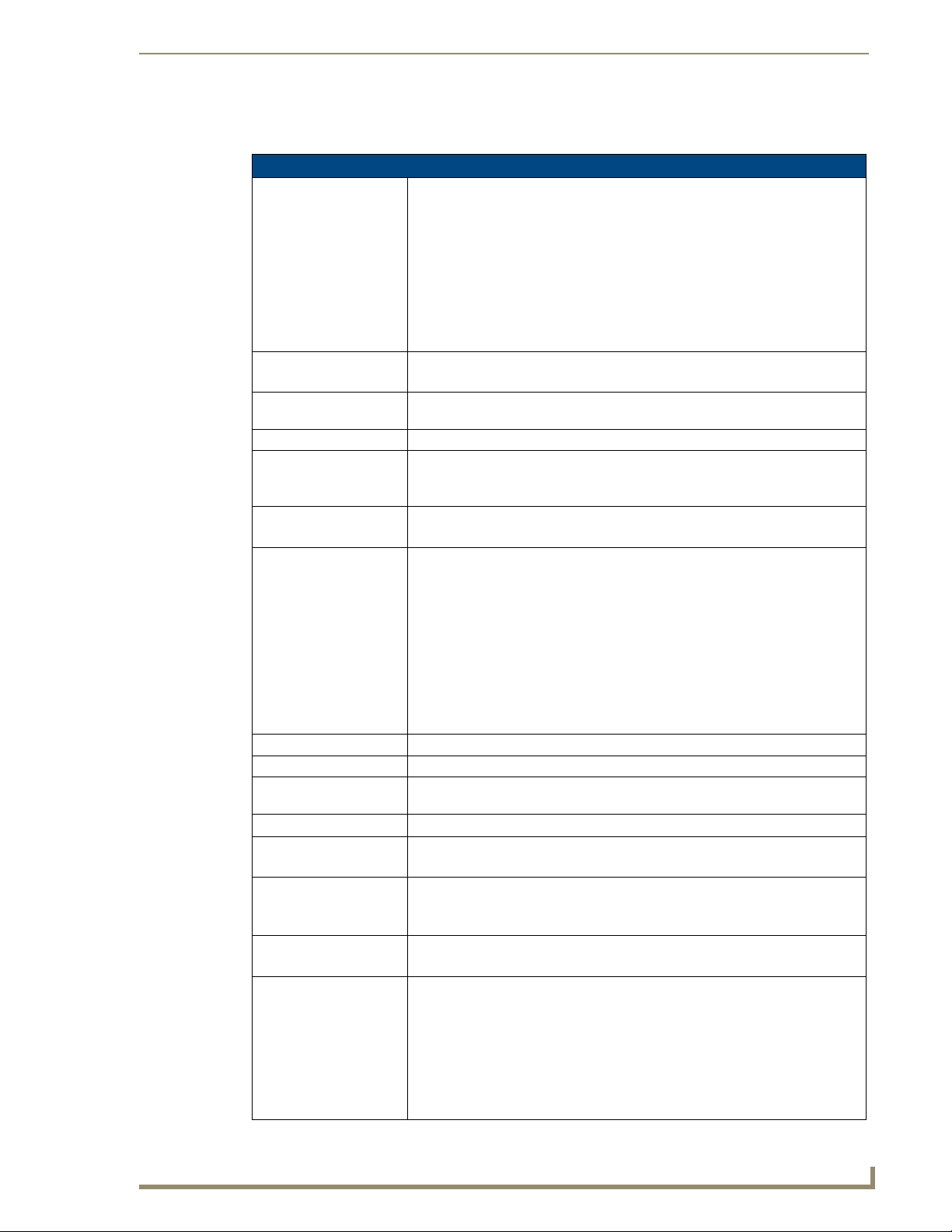

1200VG Specifications (Cont.)

Supported Audio

Sample Rates:

Certifications: FCC Part 15 Class B, CE, and EN 60950

Supported Transport

Protocols:

Supported Audio

Codecs:

Supported Video

Codecs:

Front Panel

Components:

Rear Panel

Components:

Operating / Storage

Environments:

Included

Accessories:

48000Hz, 44100Hz, 32000Hz, 24000Hz, 22050Hz, 16000Hz, 12000Hz, 11025Hz,

and 8000Hz.

• RTP (MPEG-2/MPEG-4 Transport Stream)

• UDP (MPEG-2 Transport Stream)

• Advanced Audio Coding (AAC)

• MPEG Audio Level 2 (MP2) / MPEG Audio Level 3 (MP3)

• MPEG-2

• MPEG-4

• Light Sensor: Photosensitive light detector for automatic adjustment of the panel

brightness

• Motion Sensor (PIR): Proximity Infrared Detector to wake the panel when panel is

approached

• Front Setup Access Button: Pushbutton (grey) used to either put the panel into a

"sleep" or "wake" state

• Microphone: Used for intercom applications

• Speakers: Stereo output with a frequency response of 450 Hz - 7 KHz

• RGB Connector: Made available only by using an NXA-RGB interface card

installed within the touch panel. Used with Component/RGB signals

• Audio/Video Connector: RJ-45 connector for communication of differential audio/

video signals

• Ethernet 10/100 Port: RJ-45 port for 10/100 Mbps communication

• PWR Connector: 2-pin 3.5 mm mini-Phoenix connector

• Stereo Output Connector: Stereo output through a 3.5mm mini-jack

• USB Connector: Two Type-A USB ports

• Mini-USB Connector: 5-pin Mini-USB connector

• Operating Temperature: 10° C (50° F) to 40° C (104° F)

• Operating Humidity: 20% to 85% RH

• Storage Temperature: -20° C (-4° F) to 60° C (140° F)

• Storage Humidity: 5% to 85% RH

• Installation Kit for 12" and 17" NXD panels (KA2251-01):

- 2-pin mini-Phoenix connector (41-5025)

- Four Drywall clips (62-5924-05) and #6 -metal strips (80-0192)

- One CAT5 Suppression Ferrites (04-0014)

- Three Phillips-head screws (#4-20 x 0.250 Black) (80-0114-08)

• Installation Kit for 12" NXT panels (KA2251-03):

- 2-pin mini-Phoenix connector (41-5025)

- Three Phillips-head screws (#4-20 x 0.250 Black) (80-0114-08)

- Two CAT5 Suppression Ferrites (04-0014)

• Included within the RGB Kit:

- Modero VG Touch Panel (NXD/NXT-1200/1500/1700VG)

- NXA-AVB/RGB Breakout Box (FG2254-11)

- NXA-MTC/RGB Modero 10’ foot Table Top Cable

(with RGB connector) (CA2250-70)

- NXA-RGB internal RGB/VGA Interface Card (FG2260)

- NXA-RGBCBL, 15-pin to 5X BNC RGB Breakout cable (FG2250-80)

• Included within the Video Kit:

- Modero VG Touch Panel (NXD/NXT-1200/1500/1700VG)

- Modero 10’ foot Table Top Cable (CA2250-50)

- NXA-AVB/ETHERNET Breakout Box (FG2254-10)

Introduction

Page 18

Introduction

4

VG-Series Modero Touch Panels

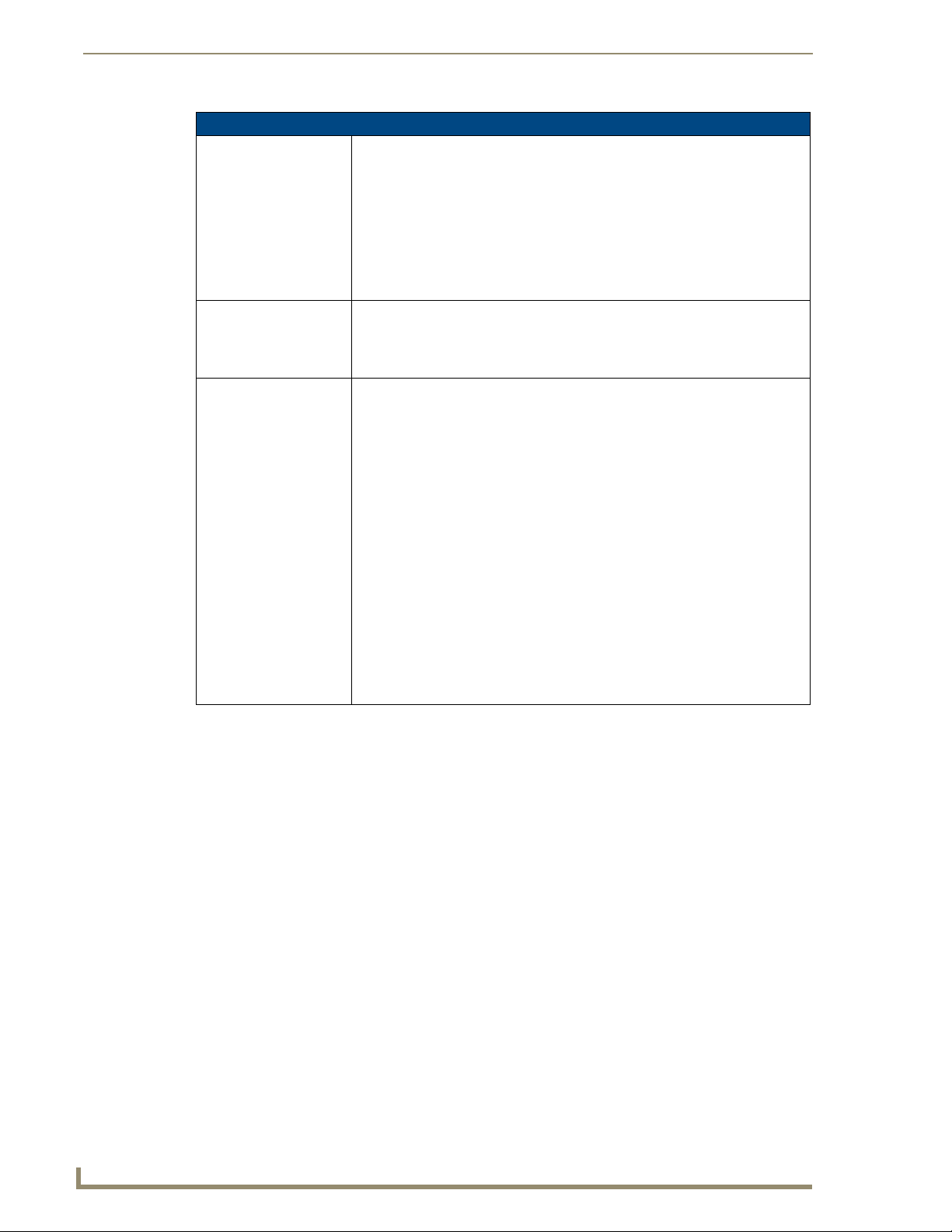

1200VG Specifications (Cont.)

Other AMX

Equipment:

• CB-TP12 Conduit/Wallbox (FG031-10)

• CC-USB (Type A) to Mini-B 5-Wire programming cable (FG10-5965)

• Kensington Lock Bracket (FG2259-10) (optional only with NXTs)

• MAX-CSE MAX Video Encoder (FG2178-70)

• MB-TP12 Universal VESA Mounting Box (FG031-50)

• NXA-AVB/ETHERNET Breakout Box (FG2254-10)

• NXA-AVB/RGB Breakout Box (FG2254-11)

• NXA-BASE/B (FG2255)

• NXA-MTC/RGB Modero 10’ foot Table Top Cable with RGB connector (CA2250-

70). This cable is not wall-rated for NXD models.

• NXA-PCI80211G Wireless Card (FG2255-04)

• NXA-RGBKIT RGB upgrade kit (FG2255-11):

- NXA-AVB/RGB Breakout Box (FG2254-11)

- NXA-MTC/RGB Modero 10’ foot Table Top Cable with RGB connector (CA2250-

70)

- NXA-RGB internal RGB/VGA Interface Card (FG2260)

- NXA-RGBCBL, 15-pin to 5X BNC RGB Breakout cable (FG2250-80)

- NXT Table Top replacement I/O plate (with RGB connector opening)

(62-2250-59)

- NXD WallMount replacement adhesive overlay for existing I/O plate

(53-2250-03)

Note: The NXT replacement I/O plate is a single piece which is meant to be

swapped-out with the pre-existing plate shipped with Composite Video panels. On

NXD panels, the RGB connector opening is pre-drilled into the I/O plate but can

only be accessed by replacing the adhesive cover and maintaining the existing

overlay. When upgrading NXD panels with this kit, don’t replace the NXD I/O plate,

only the adhesive cover.

• NXA-RGBCBL, 15-pin to 5X BNC RGB Breakout cable (FG2250-80)

• NXA-RK12 Rackmount kit for 12" Wall Mount panels (FG2904-50)

• NXT-BP (FG2250-10)

• NXT-CHG (FG2250-50)

• PSN4.4 Power Supply (12 VDC) (FG423-45)

• PSN6.5 Power Supply (12 VDC) (FG423-41)

• Upgrade Compactflash (pre-programmed with firmware):

NXA-CFTP4G, 4GB Compactflash Upgrade (FG2116-08)

Page 19

5

VG-Series Modero Touch Panels

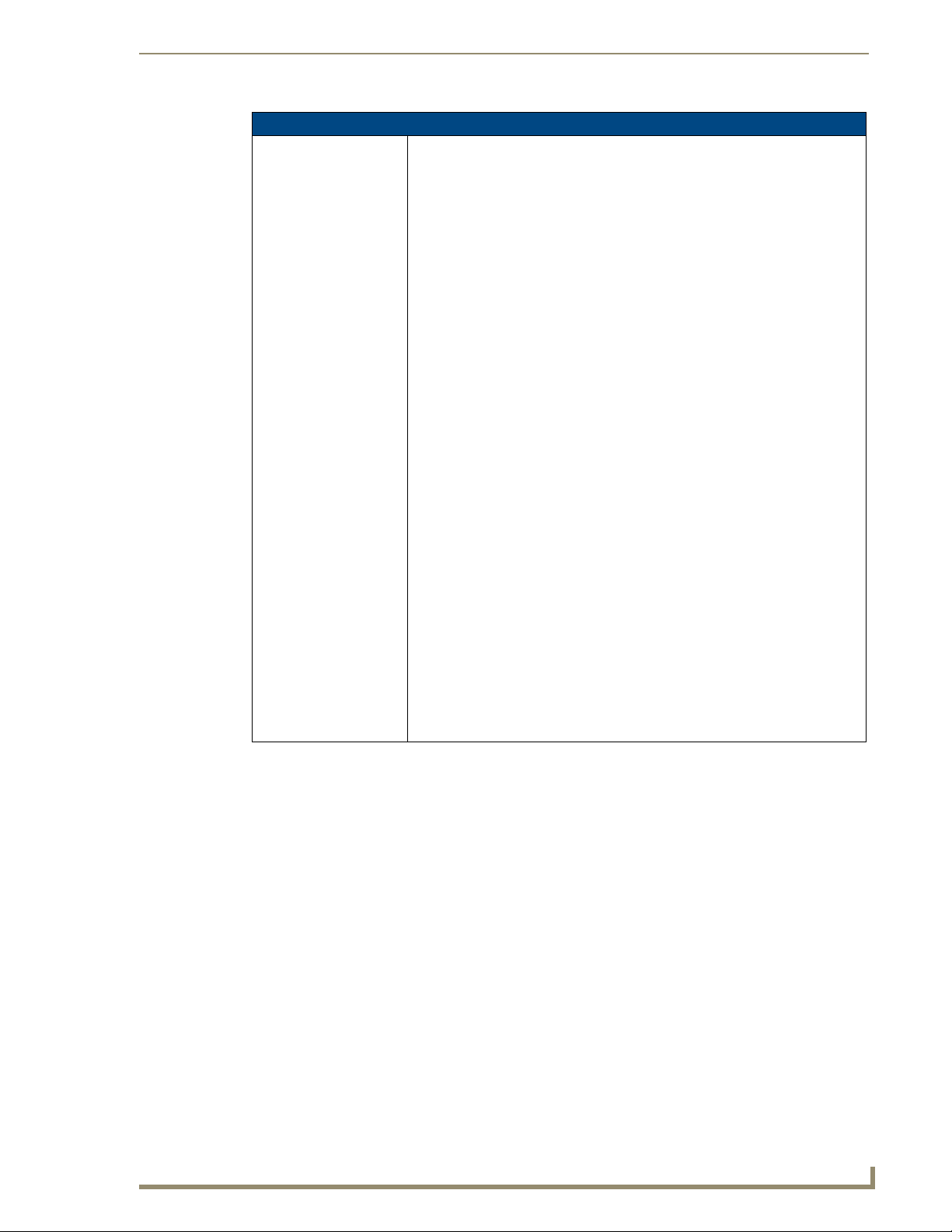

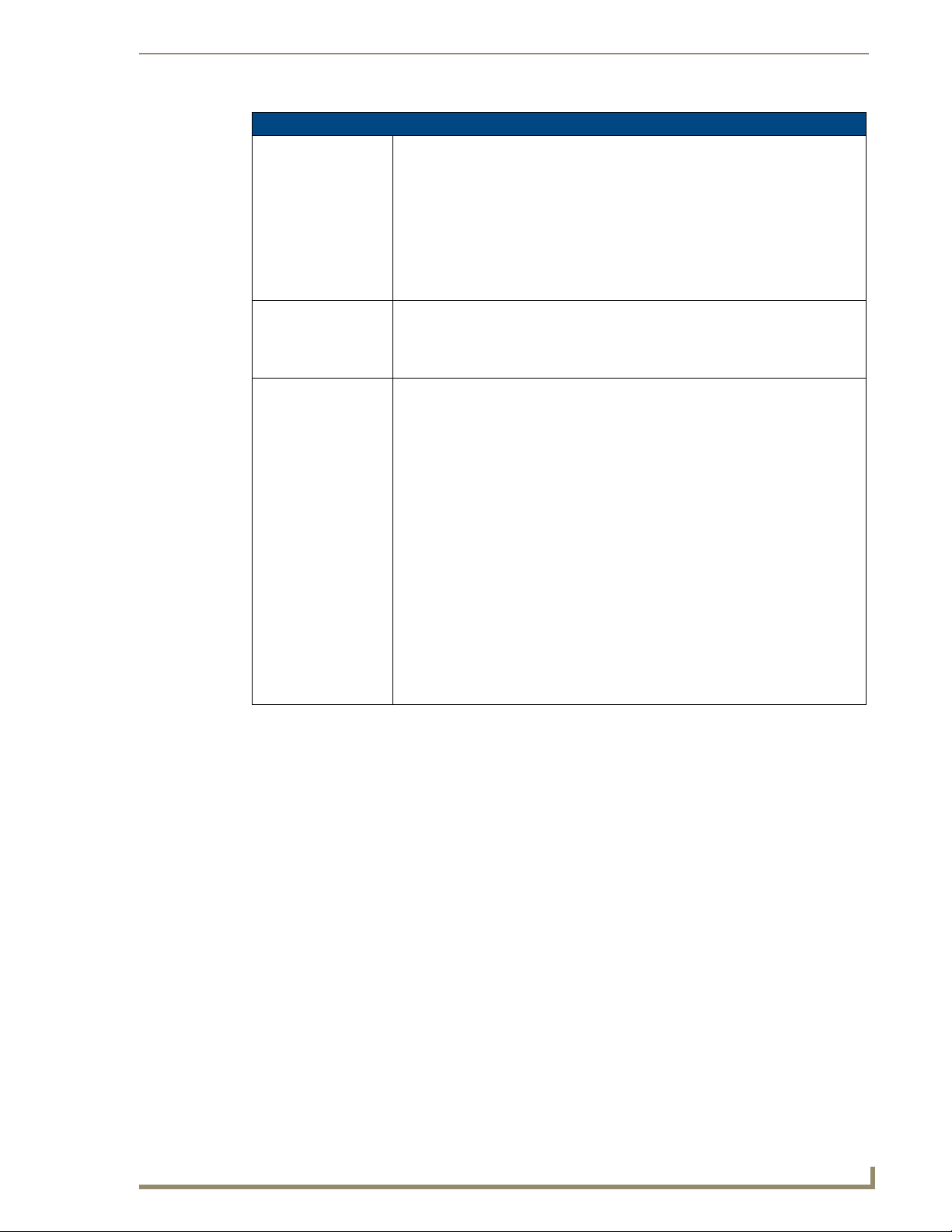

Product Specifications (NXD-1500VG and NXT-1500VG)

The following table outlines the specifications for VG-Series of 15" Modero panels.

1500VG Specifications

Dimensions (HWD): • NXD-1500VG (with faceplate): 14.37" x 15.20" x 3.31"

Power: • Constant current draw: 3.7 A @ 12 VDC (stand-alone)

Minimum power

supply required:

Memory: 256 MB on-board memory

Compactflash: 2GB or greater (upgradeable to 4GB - see Other AMX Equipment).

Weight: • NXD-1500VG: 13.45 lbs (6.10 kg)

LCD Parameters: • Aspect Ratio: 4:3

Active Screen Area: 11.97" x 8.98" (30.41cm x 22.81cm)

Viewing Angles: Vertical: + 85° (up from center) and - 85° (down from center)

Supported Audio

Sample Rates:

Certifications: FCC Part 15 Class B, CE, and EN 60950

Supported Transport

Protocols:

Supported Audio

Codecs:

Supported Video

Codecs:

Front Panel

Components:

(36.50 cm x 38.61 cm x 8.40 cm)

• NXT-1500VG (Fully raised): 12.94" x 14.95" x 11.73"

(32.87 cm x 37.97 cm x 29.78 cm)