Page 1

instruction manual

8.5" Color Passive

LCD Touch Panels

(Firmware version G3 or higher)

To u c h Panels and Accessories

Page 2

AMX Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free of defects in material and workmanship under normal use for

three (3) years from the date of purchase from AMX Corporation, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch

overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, MX Series products, and KC Series products are

warranted for a period of one (1) year.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX Corporation or an Authorized AMX Dealer.

AMX Corporation is not liable for any damages caused by its products or for the failure of its products to perform.

This includes any lost profits, lost savings, incidental damages, or consequential damages. AMX Corporation is not

liable for any claim made by a third party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort

claim (including negligence and strict product liability), a contract claim, or any other claim. This limitation of

liability cannot be waived or amended by any person. This limitation of liability will be effective even if AMX

Corporation or an authorized representative of AMX Corporation has been advised of the possibility of any such

damages. This limitation of liability, however, will not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or

exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of

the Limited Warranty may not apply. This Limited Warranty gives the owner specific legal rights. The owner may

also have other rights that vary from state to state. The owner is advised to consult applicable state laws for full

determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX CORPORATION MAKES NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. AMX CORPORATION

EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED WARRANTY. ANY

IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS

LIMITED WARRANTY.

Page 3

Table of Contents

Table of Contents

Product Information .................................................................................................1

Specifications .................................................................................................................... 1

Cleaning the Touch Overlay.............................................................................................. 2

Installation .................................................................................................................3

Mounting the Touch Panel ................................................................................................ 3

Decor style panels with low-profile Back Boxes....................................................................... 3

Installing touch panels and a BB-TP2 Back Box (solid surface) .............................................. 4

Installing touch panels and a BB-TP2 Back Box (plasterboard) .............................................. 6

Rack-mount panel (AXM-CP/PB) ............................................................................................. 8

Wiring the Touch Panel ..................................................................................................... 8

Preparing captive wires ............................................................................................................ 8

Wiring guidelines...................................................................................................................... 9

Using AXlink for data and power .............................................................................................. 9

Using the AXlink for data with a 12 VDC power supply ........................................................... 9

Using the (DB-9) RS-232 connector for mouse control or data ............................................. 10

Designing Touch Panel Pages ..............................................................................11

Buttons ............................................................................................................................ 11

Activating Edit Mode........................................................................................................ 12

Setting the Device Base .................................................................................................. 14

Setting the Device Used.................................................................................................. 14

Adding a Page................................................................................................................. 14

Setting the page color ............................................................................................................ 14

Adding a Button............................................................................................................... 15

Resizing a button ................................................................................................................... 15

Defining On-Screen and External Button Properties....................................................... 15

Setting the channel code........................................................................................................ 15

Setting the variable text code................................................................................................. 16

Setting the page flip ............................................................................................................... 16

Setting the button colors for channel-off conditions ............................................................... 17

Adding text, icons, and bitmaps to a button ........................................................................... 17

Using TPDesign3 to Download Bitmaps, Icons, and Fonts............................................. 17

Creating a Bargraph and Joystick ................................................................................... 18

Adding a bargraph or joystick button\..................................................................................... 18

Setting Bargraph and Joystick Properties ....................................................................... 18

Setting the level code............................................................................................................. 18

Programming ..........................................................................................................21

Color Passive-Matrix LCD Touch Panels

i

Page 4

Table of Contents

System Send_Commands .............................................................................................. 21

Programming Numbers ................................................................................................... 26

Shorthand Send_Commands.......................................................................................... 27

Color Send_Commands.................................................................................................. 31

Variable Text Send_Commands ..................................................................................... 33

Shorthand Variable Text Commands .............................................................................. 36

Button String Commands................................................................................................ 39

Upgrading the Firmware ........................................................................................41

AXT-CP EPROM Replacement....................................................................................... 41

AXM-CP (/PB) and AXD-CP (/PB) EPROM Replacement.............................................. 42

Replacing the Batteries .........................................................................................45

AXT-CP Batteries............................................................................................................ 45

AXD-CP (/PB), and AXM-CP/PB Batteries ..................................................................... 46

ii

Color Passive-Matrix LCD Touch Panels

Page 5

Product Information

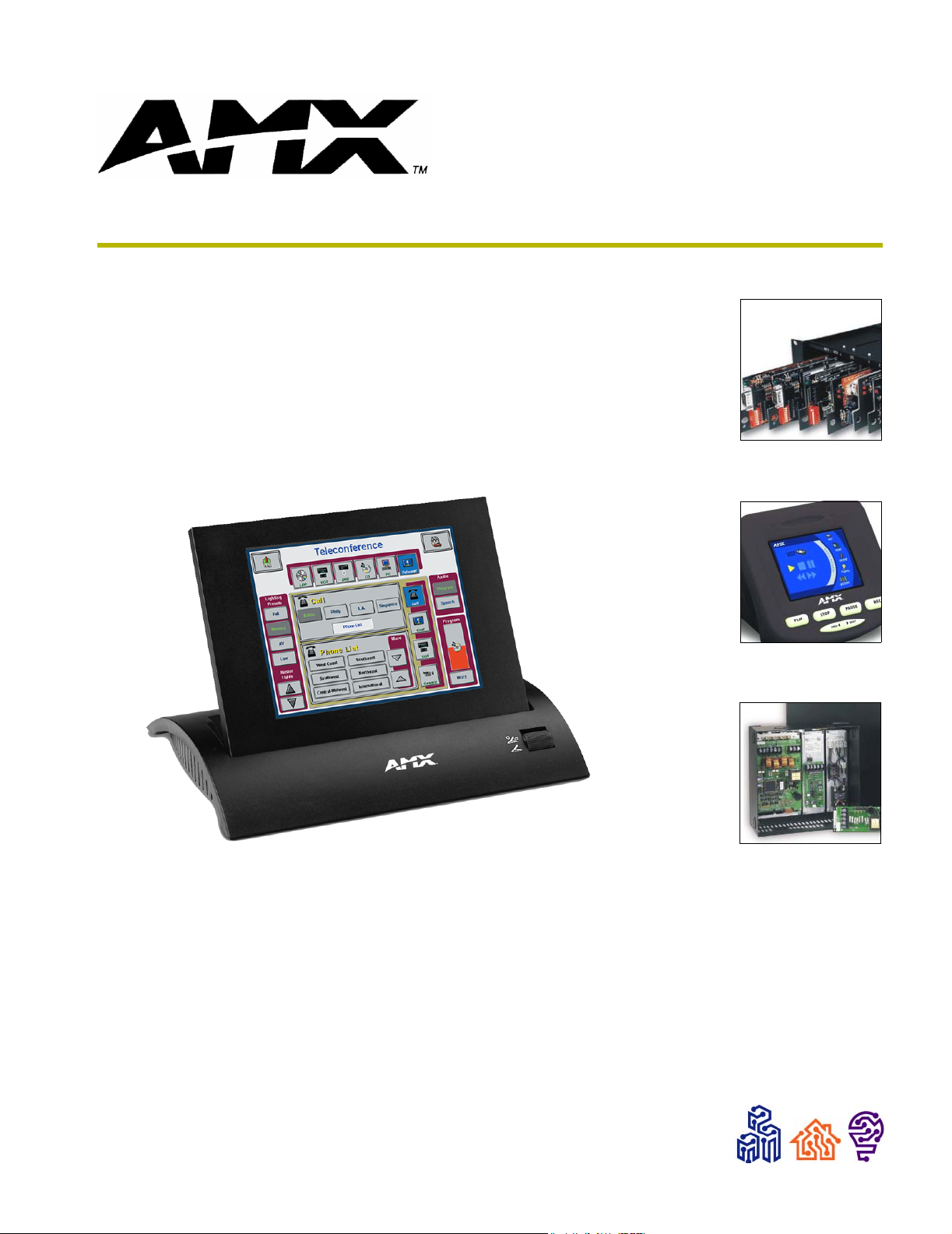

The Color Passive-Matrix touch panels contain an 8.5" (215.90 mm) 256-color passive-matrix

liquid crystal display (LCD). The self-contained enclosures use a microprocessor to control a wide

range of multimedia equipment. Using the TPDesign3 Touch Panel design program, you create

custom pages with buttons, icons, sliders, bargraphs, time displays, logos, and drawings.

8.5" Color Passive-Matrix touch panels include:

! AXD-CP (Decor-style) and AXD-CP/PB (Decor-style pushbutton)

! AXT-CP (TiltScreen) and AXT-CP/PB (TiltScreen pushbutton)

! AXM-CP (Rack-mount) and AXM-CP/PB (Rack-mount pushbutton)

Specifications

The table below lists the specifications for the AXD-CP (/PB), AXT-CP, and AXM-CP (/PB).

Specifications

Dimensions (HWD):

AXD-CP • 7.50" x 11.25" x 1.77" [low-profile Back Box] (17.48 cm x 28.58 cm x 4.5 cm)

• 7.50" x 11.25" x 2.44" [BB-TP2 Back Box] (17.48 cm x 28.58 cm x 6.2 cm)

AXT-CP • TiltScreen panel dimensions (HW): 7.10" x 9.11" (18.03 cm x 23.14 cm)

• LCD screen dimensions (HW): 4.80" x 6.40" (12.19 cm x 16.26 cm)

• Base dimensions (WD): 11.46" x 9.46" (29.11 cm x 24.03 cm)

• Adjustable display heights: 3.40" (8.64 cm) fully lowered; 8.50" (21.59 cm) fully

raised.

• Screen Dimensions (HW): 8.5" diagonal view - 4.80" x 6.40" (12.19 cm x 16.26

cm)

AXM-CP • 6.97" x 19.0" x 1.62" (low-profile Back Box) (17.70 cm x 48.26 cm x 4.11 cm)

• 6.97" x 19.0" x 2.64" (BB-TP2 Back Box) (17.70 cm x 48.26 cm x 6.71 cm)

Weight:

AXD-CP 4.5 lbs. (2.1 kg)

AXT-CP 3.6 lbs. (1.6 kg)

AXM-CP 4.4 lbs. (2.0 kg)

Power 650 mA @ 12 VDC

Display Type Color passive-matrix 256 color LCD

Screen Res. (HV) 640 x 480 pixels

Memory 1 MB

Rear Panel Connectors:

RS-232

AXlink

PWR

• DB-9 (male) connector for PC data transmission or Microsoft mouse control

• 4-pin male bus connector

• 2-pin male 12 VDC power connector

Product Information

Color Passive-Matrix LCD Touch Panels

1

Page 6

Product Information

Specifications (Cont.)

Enclosure:

AXD-CP Metal sub-plate and bezel with black or white matte finish

AXT-CP TiltScreen tabletop console; black plastic with matte finish

AXM-CP 19" (48.3 cm) Unimount; metal with black matte finish (4 rack units high)

Accessories Included • 12 VDC power supply, 1.9 A (110 VAC installations only)

• Low-profile Back Box (AXD-CP and AXM-CP only)

• 4-pin female AXlink bus connector (AXM-CP only)

• 4-pin AXlink data/power connector (AXT-CP only)

Optional Accessories • Up to 8 pushbuttons per side for the AXD-CP and AXM-CP.

• 9-pin female DB-9 connector (AXD-CP and AXT-CP only.

• PSN2.8 Power Supply

• BB-TP2 Back Box (AXD-CP)

Software • TPDesign - Windows-based (16-bit) design program (optional for the AXT-CP)

• TPDesign3 - Windows-based (32-bit) design program (optional for the AXT-CP)

AXT-CP Wireless

Options:

TiltScreen • WAV-PK WavePack

• SMT-PK SmartPack

Options:

Decor-style Panels • External pushbuttons (AXD-CP (/PB))

• UniMount Back Box (BB-TP2) and sub-plate, bezel security plates

Cleaning the Touch Overlay

You should clean the touch screen overlay after each day’s use. Always use clean cotton cloths, and

a spray bottle of cleaning solution consisting of 50% isopropyl alcohol and 50% water.

2

Color Passive-Matrix LCD Touch Panels

Page 7

Installation

Mounting the Touch Panel

The following paragraphs describe mounting the Decor and rack-mount touch panels. TiltScreen

touch panels can be placed on any flat surface.

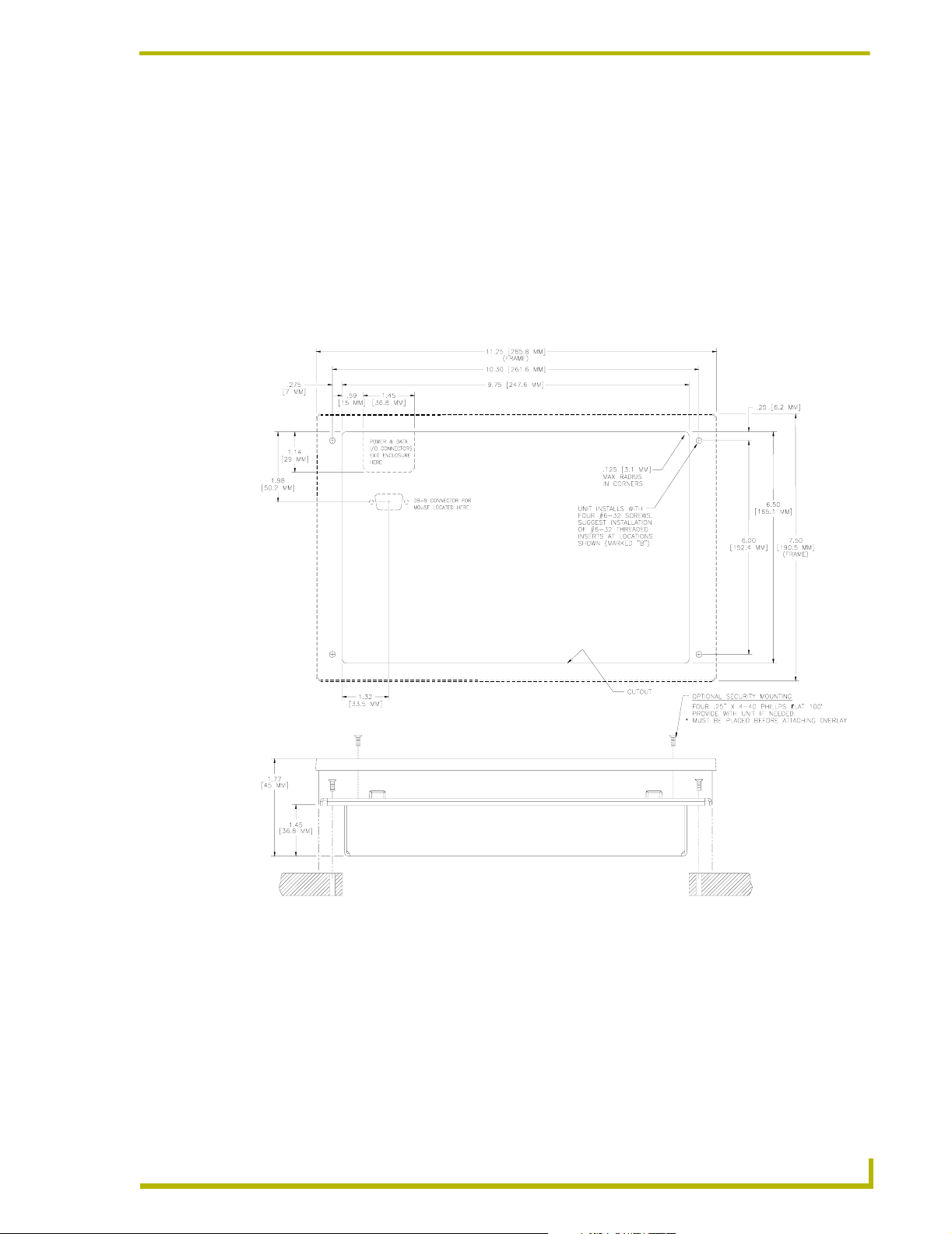

Decor style panels with low-profile Back Boxes

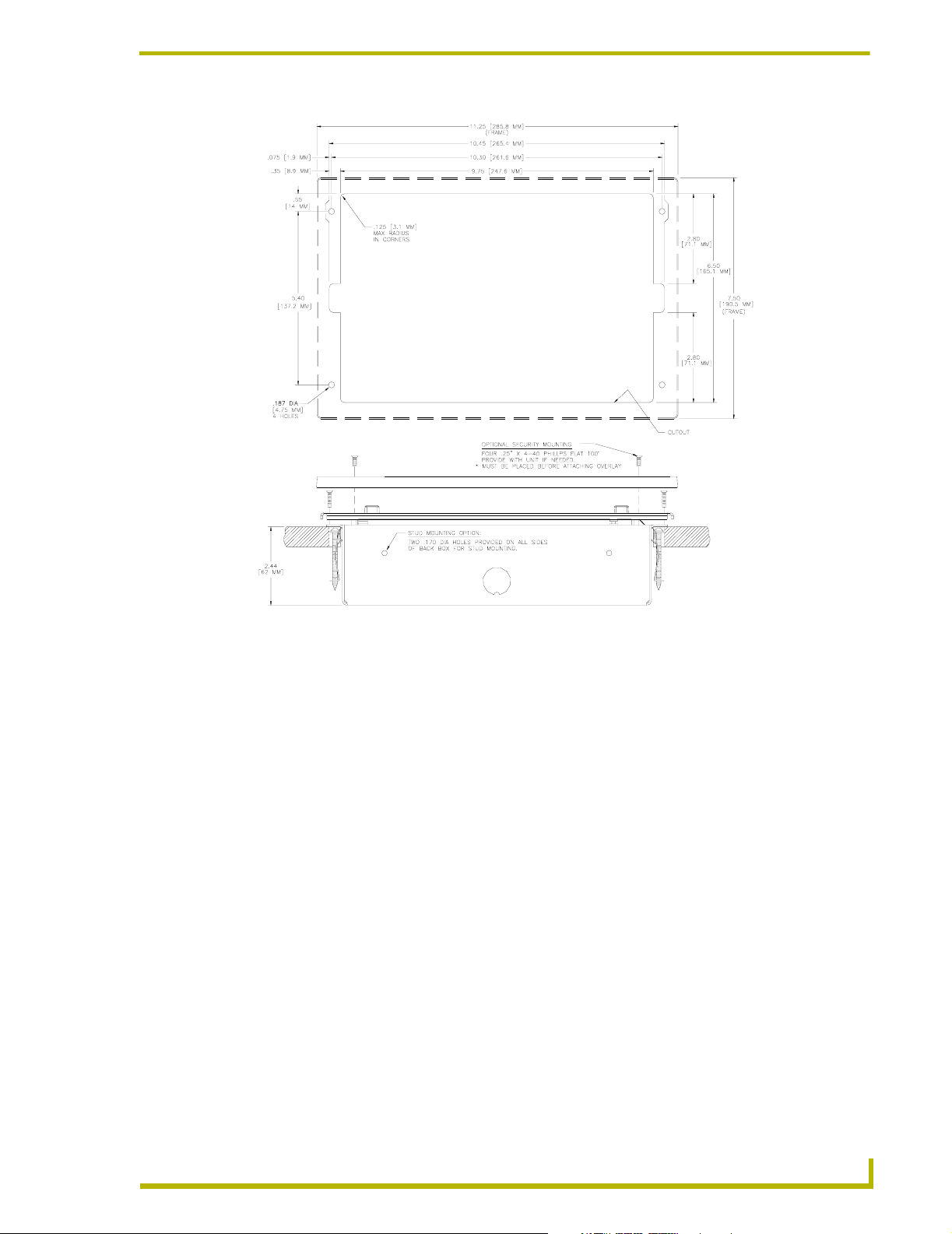

1. Cut out the surface using the dimensions shown in FIG. 1.

Installation

FIG. 1 Decor style and low-profile Back Box output dimensions

2. Carefully insert a flat-blade screwdriver into the release slot on the touch panel's faceplate and

remove the engraved overlay.

3. Place the touch panel into the cutout and mark the screw insert positions as shown in FIG. 1.

4. Remove the touch panel and drill four #6-32 insert holes. Then, place a threaded insert into

each hole.

5. Disconnect the AXlink connector from the Central Controller. Then, disconnect the optional

RS-232 wiring from the external RS-232 device connected to the touch panel.

Color Passive-Matrix LCD Touch Panels

3

Page 8

Installation

6. Fasten the low-profile Back Box to the surface using the #6-32 machine screws supplied with

the enclosure.

7. Attach the data and power wiring to the touch panel.

8. Test the connection by reconnecting the AXlink connector to the Central Controller and

optional RS-232 wiring to the source equipment. Before continuing, disconnect all connections

until panel installation is complete. Once attached to the Decor style faceplate, the security

screws can’t be replaced without removing the overlay.

9. Fasten the touch panel and low-profile Back Box using the #6-32 machine screws supplied

with the enclosure panel.

10. Place the faceplate onto the bezel. You can also secure the faceplate to the bezel using the four

Phillips flat-head security screws.

11. Insert the engraved overlay back into the bezel.

12. Remove the backing from the adhesive tape strips located on the front of the touch panel; press

the engraved overlay onto the faceplate.

13. Reconnect the AXlink wiring to the Central Controller and RS-232 wiring (optional) to the

external RS-232 device. The touch panel beeps when you apply power.

Installing touch panels and a BB-TP2 Back Box (solid surface)

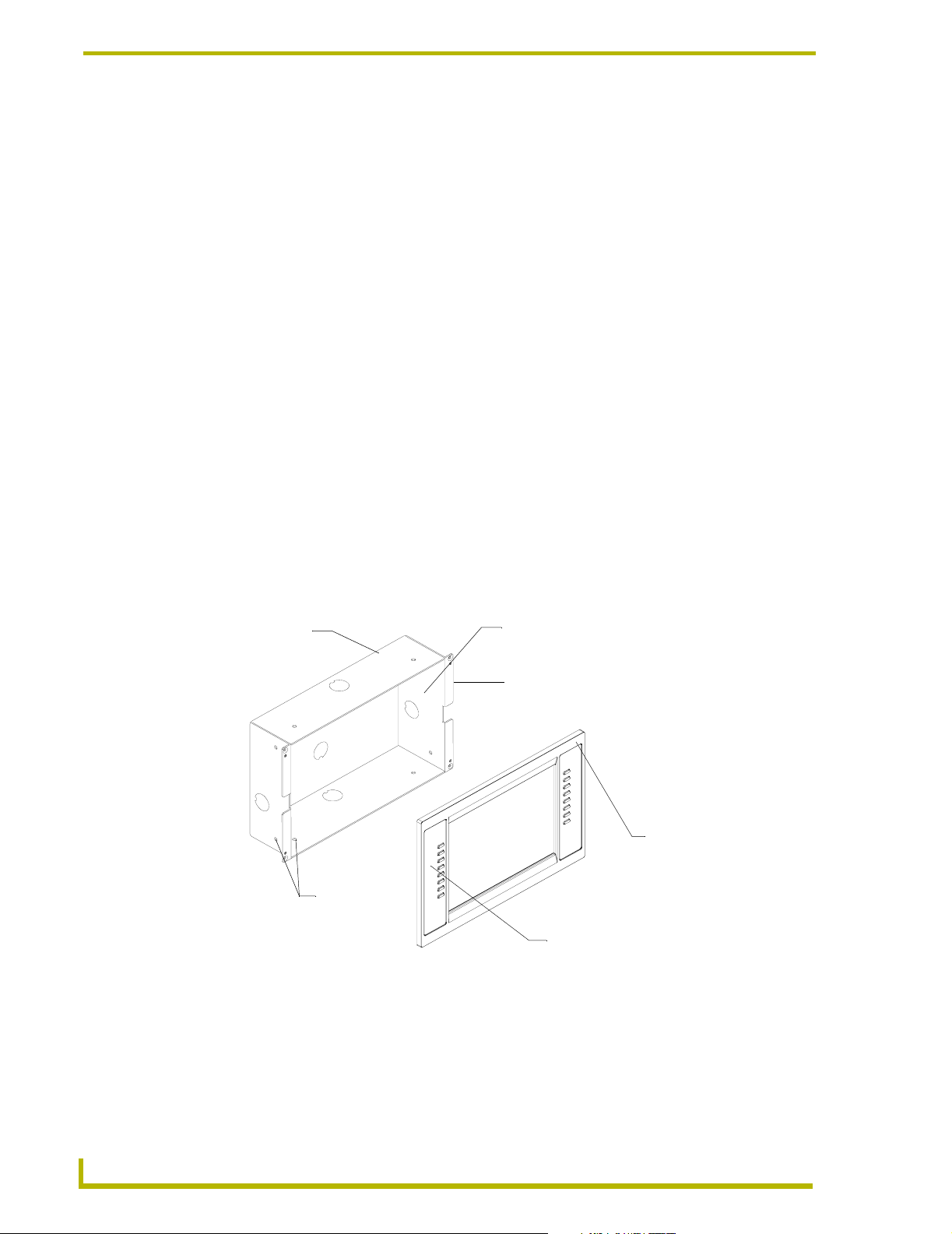

FIG. 2 shows a sample AXD-CP/PB and BB-TP2 Back Box for solid surfaces.

The BB-TP2 can also be mounted to wood or metal studs using the pre-drilled stud mounting holes.

BB-TP2 Unimount

Backbox enclosure

Stud mounting

holes

FIG. 2 AXD-CP/PB and BB-TP2 Back Box (solid surfaces)

Knockout

Solid surface mounting flanges

AXD-CP/PB

faceplate

Engraved overlay

1. Cut out the surface using the dimensions shown in FIG. 3.

4

Color Passive-Matrix LCD Touch Panels

Page 9

Installation

FIG. 3 Decor style (AXD) and BB-TP2 cutout dimensions

The touch panel must always be installed with the release slot located at the bottom.

2. Carefully insert a flat-blade screwdriver into the release slot on the touch panel’s bezel and

remove the engraved overlay.

3. Lay the touch panel facedown onto a soft cloth and remove the four screws from the low-

profile Back Box. Remove the Back Box and discard.

4. Place the BB-TP2 into the cutout and mark the threaded insert positions as shown in FIG. 3.

5. Remove the BB-TP2 and drill holes (A and B) for the panel (FIG. 3). Then, place #6-32

threaded inserts into the four holes marked 'B' in the cutout dimensions illustration.

6. Disconnect the AXlink connector from the Central Controller. Then, disconnect the optional

RS-232 wiring from the external RS-232 device connected to the touch panel.

7. Remove one or more knockouts to accommodate the wiring as required.

8. Thread the incoming AXlink and RS-232 wiring through the knockouts. Refer to theWirin g the

Touch Panel section on page 8 for additional wiring information.

9. Fasten the BB-TP2 to the solid surface using the supplied mounting screws.

10. Connect the AXlink and RS-232 wiring to the touch panel.

Color Passive-Matrix LCD Touch Panels

5

Page 10

Installation

s

B

11. Test the connection by reconnecting the AXlink connector to the Central Controller and the

optional RS-232 wiring to the source equipment. The panel beeps upon power-up. Before

continuing, disconnect all connections until panel installation is complete.

12. Fasten the touch panel to the BB-TP2 using the #6-32 screws supplied with the panel.

13. Place the Decor-style faceplate onto the bezel. You can also secure the faceplate to the bezel

using the four Phillips flat-head security screws.

14. Remove the backing from the adhesive tape strips on the touch panel; press the engraved

overlay onto the faceplate. Once attached to the faceplate, the security screws cannot be

replaced without removing the battery.

15. Reconnect the AXlink wiring to the Central Controller and RS-232 wiring (optional) to the

external RS-232 device. The touch panel will beep when you apply power.

Installing touch panels and a BB-TP2 Back Box (plasterboard)

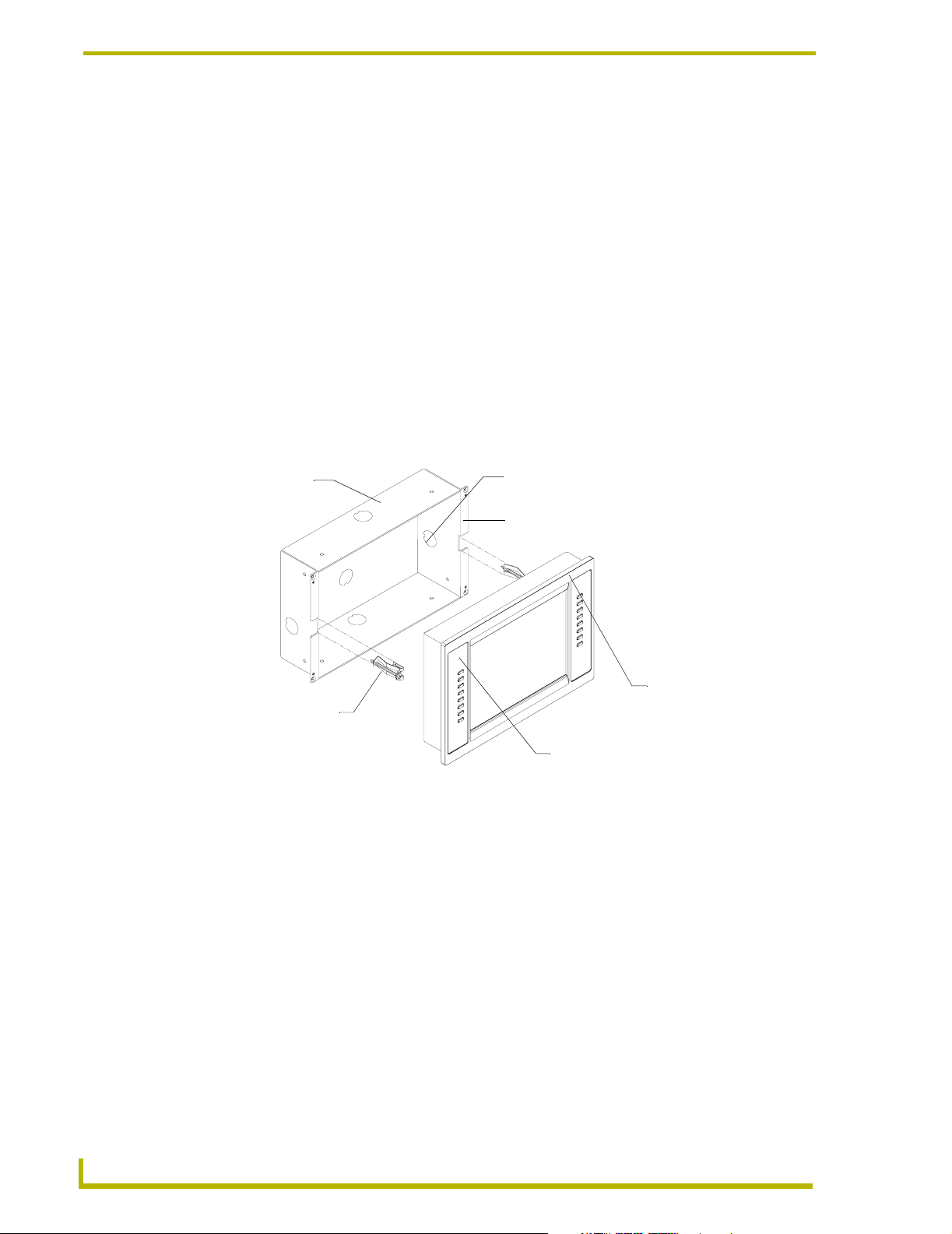

FIG. 4 shows the AXD-CP/PB and BB-TP2 Back Box for plasterboard.

BB-TP2 Unimount

Backbox enclosure

Expansion clips

FIG. 4 AXD-CP/PB and BB-TP2 Back Box (plasterboard)

Knockout

Plasterboard surface mounting flange

AXD-CP/P

faceplate

Engraved overlay

1. Cut out the surface using the dimensions shown in FIG. 5.

2. Carefully insert a flat-blade screwdriver into the release slot on the touch panel's faceplate and

remove the engraved overlay.

3. Lay the touch panel facedown onto a soft cloth and remove the screws from the low-profile

Back Box. Remove the Back Box and discard.

4. Place the BB-TP2 into the cutout and mark the threaded insert positions (FIG. 4).

5. Remove the BB-TP2 and drill four #6-32 insert holes. Then, place a threaded insert (or screw

anchor) into each hole.

6. Disconnect the AXlink connector from the Central Controller that supplies power and data to

the touch panel. Then, disconnect the optional RS-232 wiring from the external RS-232 device

connected to the touch panel.

7. Remove one or more knockouts to accommodate the wiring as required.

6

Color Passive-Matrix LCD Touch Panels

Page 11

Installation

FIG. 5 Decor style (AXD) and BB-TP2 cutout dimensions for plasterboard

8. Thread the incoming AXlink and RS-232 wiring through the BB-TP2 knockouts. Refer

toWiring the Touch Panel section on page 8 for more information.

9. Fasten the BB-TP2 to the plasterboard using the expansion screws supplied with the enclosure.

10. Connect the AXlink and RS-232 wiring to the touch panel.

11. Test the connection by reconnecting the AXlink connector to the Central Controller and the

optional RS-232 wiring to the source equipment. The panel beeps on power-up. Before

continuing, disconnect all connections until panel installation is complete.

12. Fasten the touch panel to the BB-TP2 with the #6-32 screws supplied with the en-closure.

13. Place the Decor-style faceplate onto the bezel. You can also secure the faceplate to the bezel

using the four Phillips flat-head security screws.

14. Remove the backing from the adhesive tape strips. Once attached to the faceplate, the security

screws cannot be replaced without removing the overlay.

15. Press the engraved overlay onto the faceplate.

16. Reconnect the AXlink wiring to the Central Controller and RS-232 wiring (optional) to the

external RS-232 device. The touch panel beeps on power-up.

Color Passive-Matrix LCD Touch Panels

7

Page 12

Installation

Rack-mount panel (AXM-CP/PB)

1. Thread the incoming AXlink and optional RS-232 wiring through the opening in the

equipment rack.

2. Disconnect the AXlink connector from the Central Controller and disconnect the optional RS-

232 connector from the external RS-232 device connected to the touch panel.

3. Insert the touch panel into the equipment rack. Line up the top-left and bottom-right screw

holes and start tightening the #6-32 screws. Then, tighten the bottom-left and top-right screws.

4. Connect the AXlink and RS-232 wiring (optional) to the touch panel. Refer to (DB-9) RS-232

Connector Pinouts table on page 10 for pinout descriptions. The touch panel beeps on

power-up.

Wiring the Touch Panel

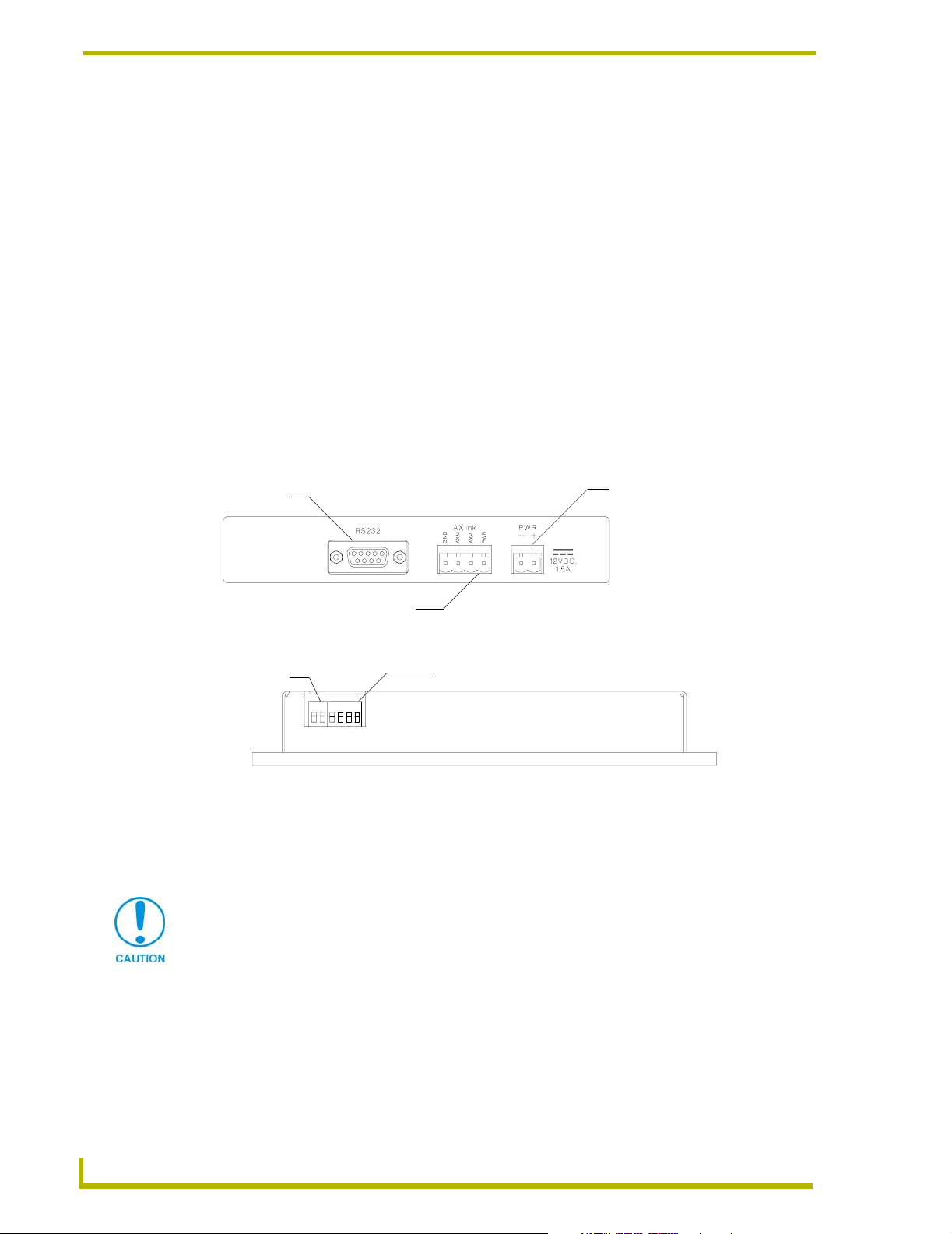

The RS-232, AXlink, and PWR (power supply) connectors are located at the rear of the AXT-CP as

shown FIG. 6. The connectors are located on the top-left corner of the rack-mount touch panels as

shown in FIG. 7.

DB-9 connector

Four-pin AXlink connector

FIG. 6 AXT-CP (rear view)

Two-pin power

connector

FIG. 7 AXD-CP (/PB) and AXM-CP (/PB) (top view)

Four-pin AXlink connector

Two-pin power connector

Preparing captive wires

You will need a wire stripper, soldering iron, and flat-blade screwdriver to prepare and connect the

captive wires.

Do not connect power to the touch panel until the wiring is complete. If you are using

a 12 VDC power supply, apply power to the touch panel only after installation is

complete.

1. Strip 0.25 inch of wire insulation off all wires and apply a light coat of solder to the ends using

a soldering iron.

2. Insert each wire into the appropriate opening on the connector according to the wiring

diagrams and connector types described in this subsection.

3. Turn the flat-blade screws clockwise to secure the wire in the connector. Do not over-torque

the screws; doing so can bend the seating pin and damage the connector.

8

Color Passive-Matrix LCD Touch Panels

Page 13

Installation

Wiring guidelines

The touch panels require 12 VDC power to operate properly. The Central Controller supplies power

via the AXlink cable or external 12 VDC power supply. The maximum wiring distance between the

Central Controller and touch panel is determined by power consumption, supplied voltage, and the

wire gauge used for the cable. The table below lists wire sizes and the maximum lengths allowable

between the touch panel and Central Controller. The maximum wiring lengths for using AXlink

power are based on a minimum of 13.5 volts available at the Central Controller's power supply.

Refer to theSpecifications section on page 1 for more information on power requirements.

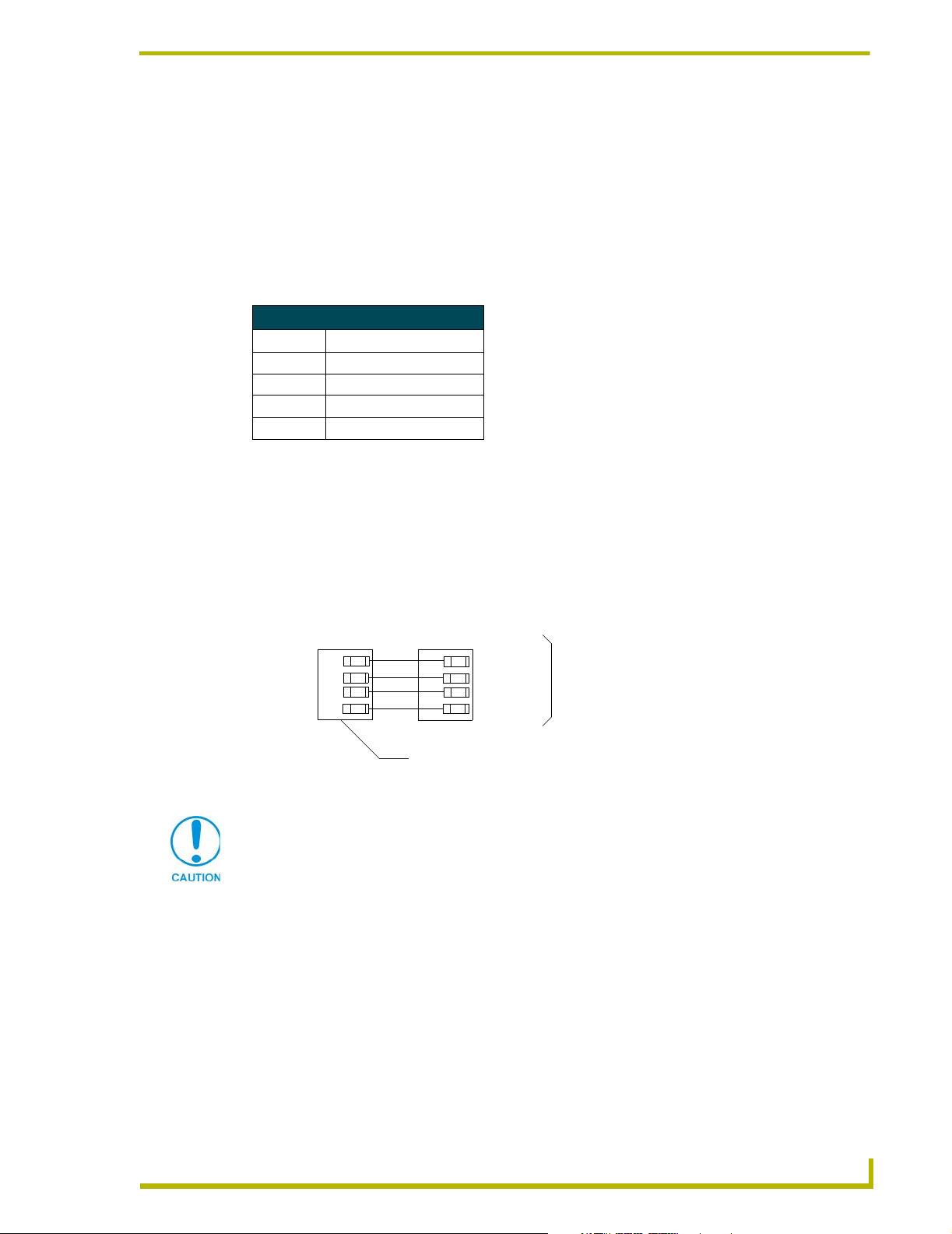

Wiring Guidelines

Wire Size Maximum Wiring Length

18 AWG 180.57 feet (55.04 m)

20 AWG 114.24 feet (34.82 m)

22 AWG 71.23 feet (21.71 m)

24 AWG 44.90 feet (13.69 m)

If you install the touch panel farther away from the control system than recommended in the Wiring

Guidelines table, connect an external 12 VDC power supply to the 2-pin PWR connector on the

touch panel.

Using AXlink for data and power

Connect the Central Controller's AXlink connector to the AXlink connector on the touch panel for

data and 12 VDC power as shown in FIG. 8.

PWR (+)

AXP

AXM

GND (-)

AXlink connector on the touch panel

FIG. 8 AXlink wiring diagram

If you are using power from AXlink, disconnect the wiring from the Central Controller

before wiring the touch panel.

PWR (+)

AXP

AXM

GND (-)

Central Controller

Using the AXlink for data with a 12 VDC power supply

Connect the Central Controller's AXlink connector to the AXlink connector on the touch panel and

external 12 VDC power supply as shown in FIG. 9.

Use an auxiliary 12 VDC power supply when the distance between the Central Controller and touch

panel exceeds the limits described in Wiring Guidelines table on page 9.

Connect only the GND wire on the AXlink connector when using a 12 VDC power supply. Do not

connect the PWR wire to the AXlink connector's PWR (+) terminal.

Color Passive-Matrix LCD Touch Panels

9

Page 14

Installation

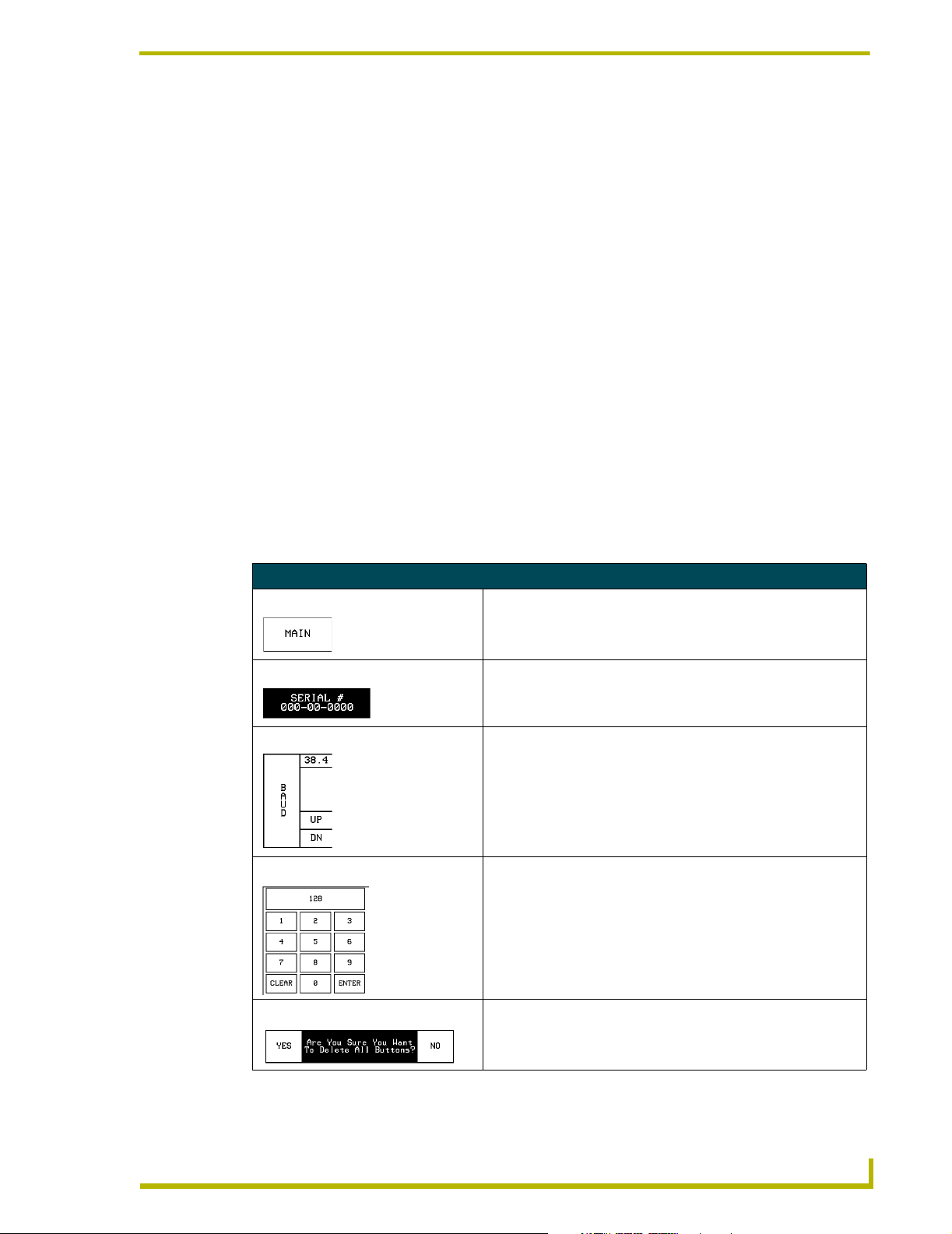

12 VDC power supply

PWR (+)

GND (-)

PWR (+)

AXP

AXM

GND (-)

AXlink connector on the touch panel

FIG. 9 AXlink and external 12 VDC power supply wiring diagram

PWR (+)

AXP

AXM

GND (-)

Central Controller

Using the (DB-9) RS-232 connector for mouse control or data

The dual-function (DB-9) RS-232 connector supports most standard serial mouse control devices

and RS-232 communication protocols for PC data transmission. Refer to the TPDesign or

TPDesign3 Touch Panel Program instruction manual for data transmission information.

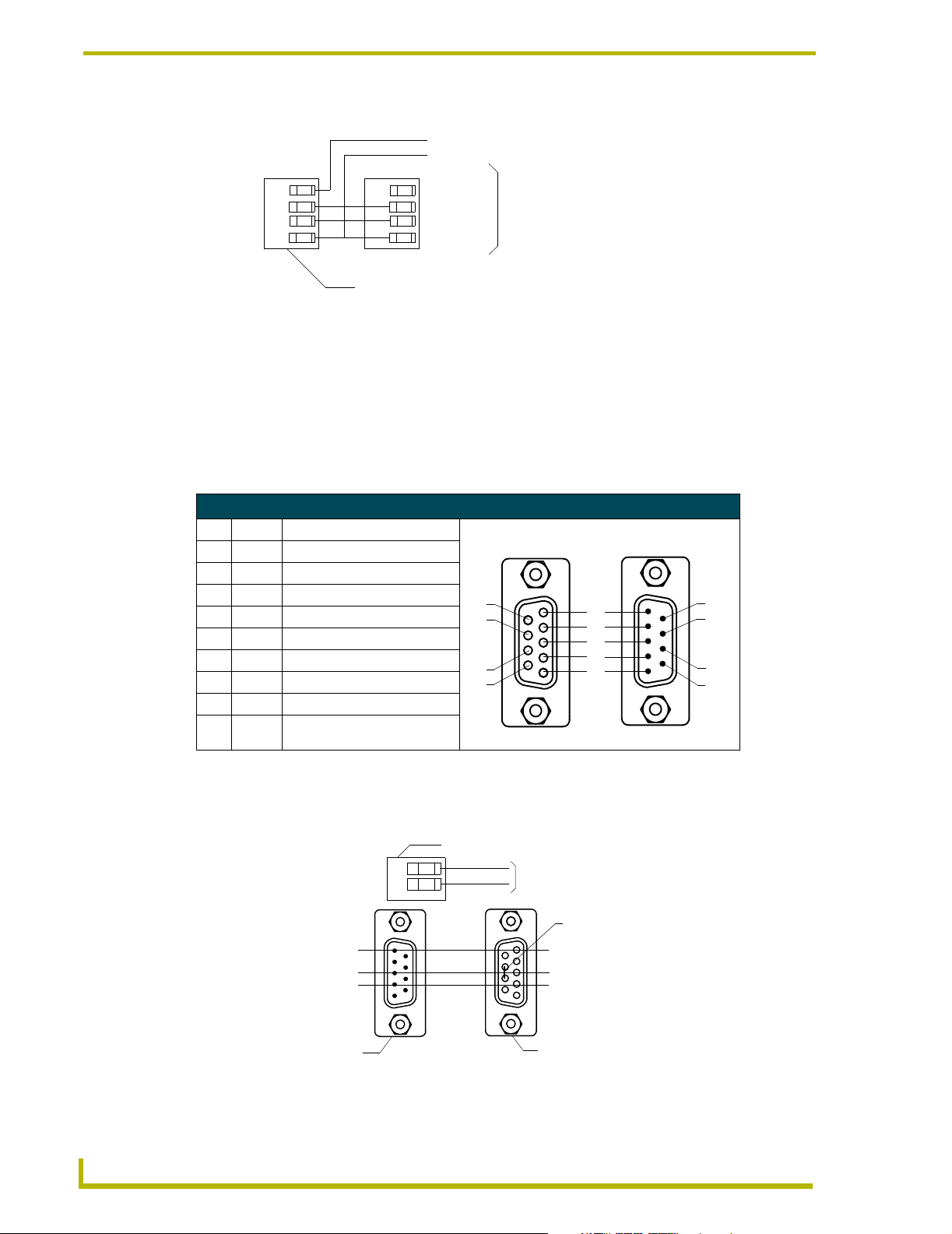

The table below lists (DB-9) RS-232 connector pinouts and FIG. 10 shows the (DB-9) RS-232

connector and power supply wiring diagram.

(DB-9) RS-232 Connector Pinouts

Pin Signal Function

5

4

3

2

1

DB-9 (male)

9

8

7

6

Male

1 N/A Not used

2 RXD Receive data

3 TXD Transmit data

4 DTR Data terminal ready (not used)

5 GND Signal ground

6 DSR Data set ready (not used)

7 RTS Request to send (not used)

8 CTS Clear to send (not used)

9 N/A Not used

DB-9 (female)

9

8

7

6

Female

10

Use connector pins 2, 3, and 5 for data and ground. For some applications, you may need to strap

pins 7 (request to send) and 8 (clear to send) together depending on the PC.

Power connector

+ (PWR)

- (GND)

5 (GND)

3 (TXD)

2 (RXD)

Touch panel

DB-9 connector

FIG. 10 DB-9 RS-232 connector and power supply wiring diagram

Male

12 VDC power supply

Optional 7 to 8-pin

connector

5 (GND)

3 (TXD)

2 (RXD)

Mouse or PC, DB-9 connector

Female

Color Passive-Matrix LCD Touch Panels

Page 15

Designing Touch Panel Pages

There are two ways to approach creating touch panel pages:

! TPDesign3 - Refer to the TPDesign3 Touch Panel Program (Version 3. 16 or higher)

Instruction Manual for more information.

! On-board editor

This document describes basic use of the on-board editor to create pages and buttons. Refer to the

G3 Firmware Design and Reference instruction manual for more detailed firmware information.

Buttons

Standard button types include rectangles and other geometric shapes you can create with the touch

panel editor. Buttons are set with attributes, meaning there is a response from the Central Controller

when you touch the button.

General buttons are part of the default touch panel program and cannot be changed. You use general

buttons to create or revise pages and specify panel communication parameters. Button examples

include selection buttons, information buttons, adjustment buttons, and operation bars. The general

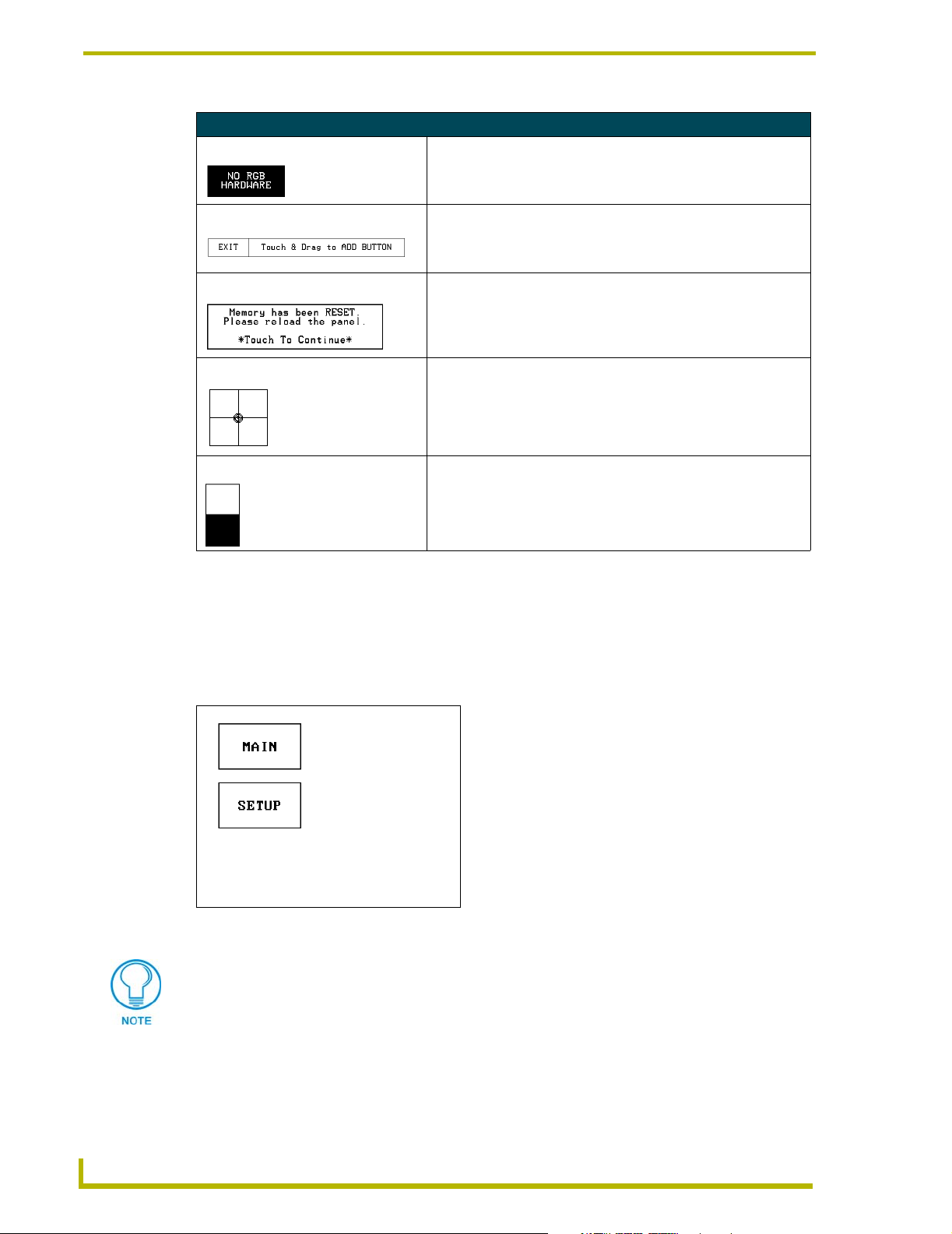

button categories are described in the table below.

Designing Touch Panel Pages

General Button Categories

Selection buttons Selection buttons appear on touch panel pages and set communica-

tion parameters.

Information buttons Information buttons contain serial numbers and firmware version

Adjustment buttons You can use the UP and DN buttons to set adjustment buttons. The

Keypad buttons The keypad button opens a keypad so you can enter a password or

Decision buttons Decision buttons appear when an operation has two options and

information. The properties of these buttons cannot be changed.

These buttons have a black fill and yellow text.

adjustment button example sets the baud rate for the connection

from the touch panel to the computer.

value assignment. All keypad buttons are interactive except for the

entry display.

requires verification before an action is performed.

Color Passive-Matrix LCD Touch Panels

11

Page 16

Designing Touch Panel Pages

General Button Categories (Cont.)

Status buttons Status buttons always have a black fill with white letters and have no

Operation bars Operation bars appear in the place of the Editor bar, after selecting a

Touch to Continue buttons "Touch to Continue" buttons appear when an operation requires user

Joystick buttons Joysticks are vertical and horizontal direction controllers for use with

functionality except to display information.

button or page edit operation. The operation bar indicates which edit

function is currently active. When an edit operation is selected, it

remains active until you press EXIT.

acknowledgement.

pan and tilt camera controllers.

Bargraph buttons Bargraph buttons display a dynamic bargraph (vertical or horizontal).

An example is the Batter level indicator button.

Activating Edit Mode

Before designing touch panel pages and buttons, you must activate EDIT mode. Once activated, use

the EDIT button to enter Edit mode. This mode has options to add and configure touch panels and

buttons. When powering up the touch panel, the first page is the Main page (see FIG. 11). Note that

the Edit button is not available initially.

12

FIG. 11 Main Page

If you have a pre-programmed panel, you may not see the Main Page.

Color Passive-Matrix LCD Touch Panels

Page 17

Designing Touch Panel Pages

To activate edit mode:

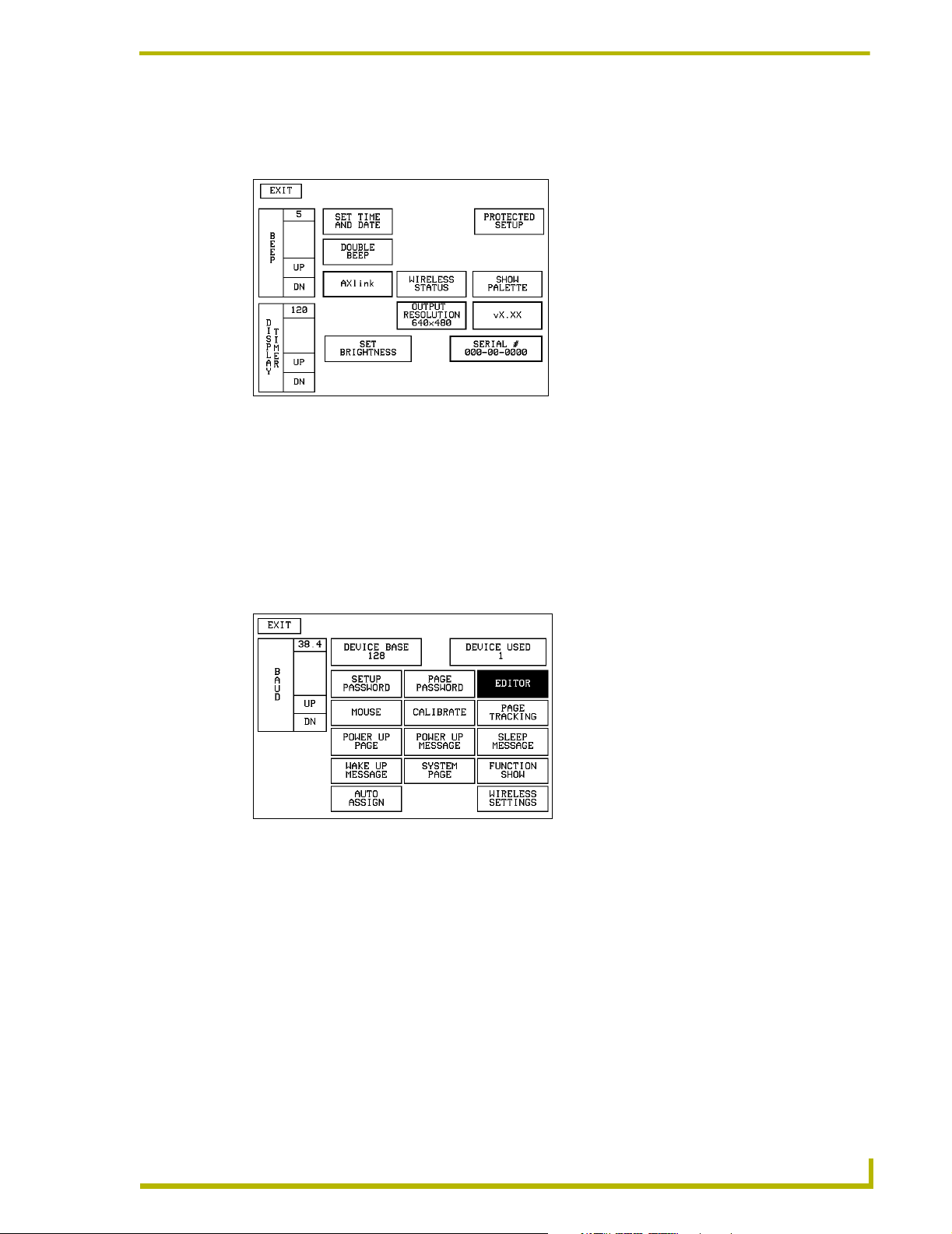

1. Press SETUP in the Main page to open the Setup page (FIG. 12).

FIG. 12 Setup page

2. Press PROTECTED SETUP to open the keypad.

3. Enter 1988 (default password) in the keypad and press ENTER to open Protected Setup page.

If you press ENTER after typing an incorrect password, you are immediately returned to the

previous page.

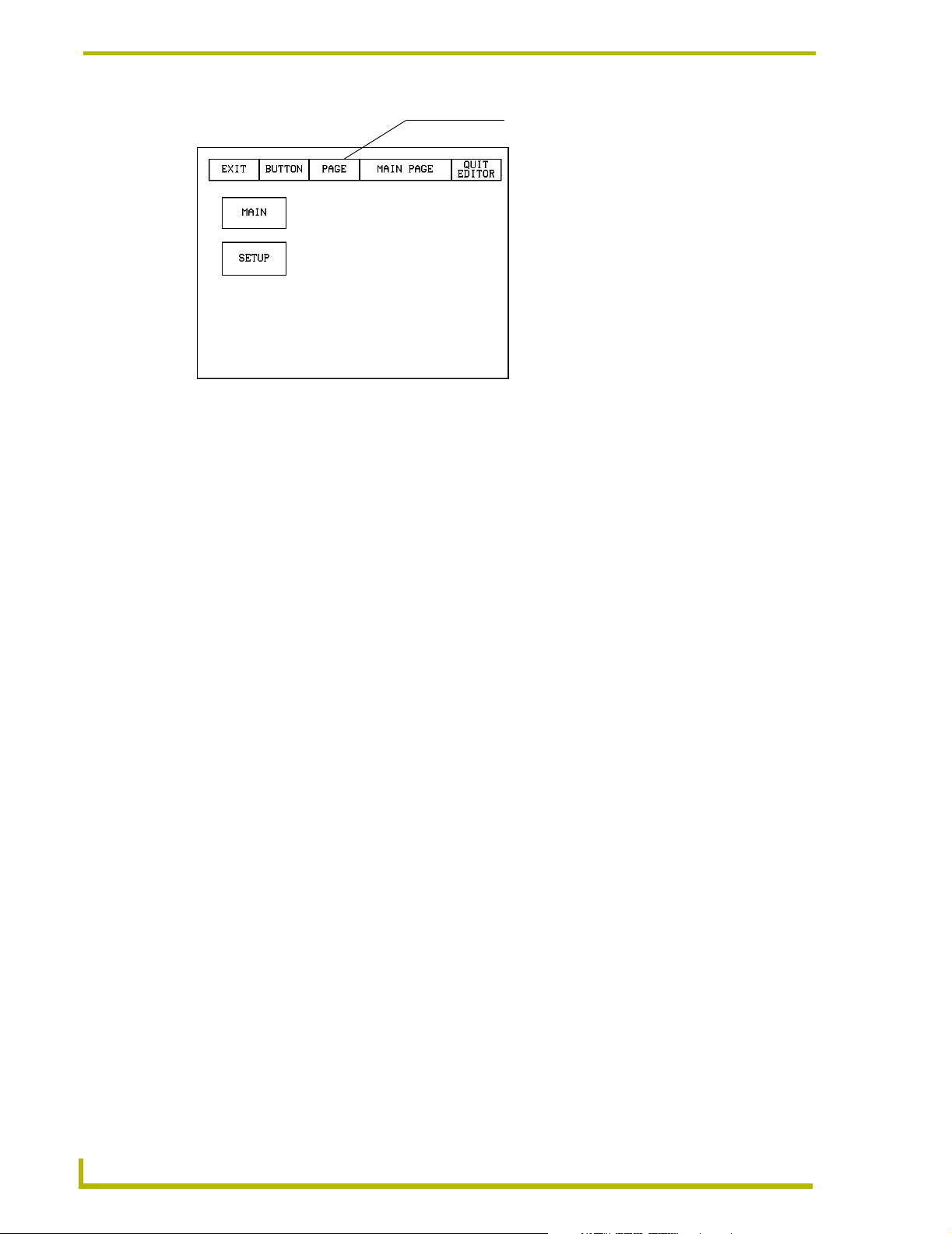

4. Press EDITOR to enable Edit mode. The EDITOR button is highlighted in the Protected Setup

page when enabled, as shown in FIG. 13.

FIG. 13 Protected Setup page with the active EDITOR button

5. Press EXIT to close the Protected Setup page and return to the Setup page (now in the Edit

mode).

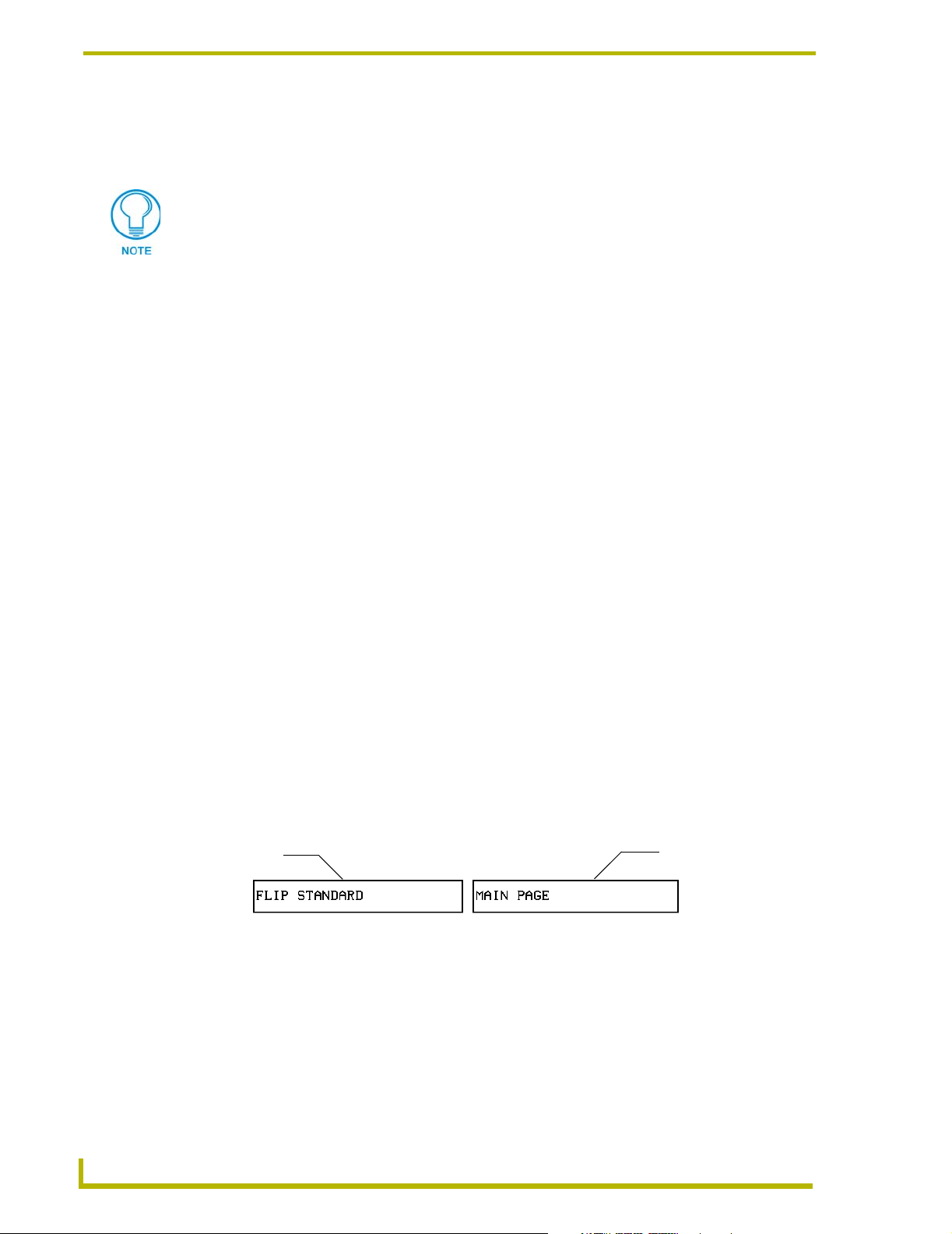

6. Press EXIT again to return to the Main page. The EDIT button appears at the top of the page

indicating that Edit mode is active.

7. Press EDIT to open the Edit bar. The BUTTON and PAGE options, in the Edit bar, (FIG. 14)

are used to design and modify button and page settings.

Color Passive-Matrix LCD Touch Panels

13

Page 18

Designing Touch Panel Pages

Edit b

FIG. 14 Main page with Edit bar

Setting the Device Base

Press the DEVICE BASE option, in the Protected Setup page (FIG. 13), to assign a base (starting)

device address to the touch panel.

ar

1. Enter the base address for the touch panel. The base address range is from 1 - 255. Standard

device addresses begin at 128.

2. Press Enter to save.

Setting the Device Used

Use the DEVICE USED option in the Protected Setup page (FIG. 13) to assign a value for the

number of devices being controlled by the touch panel.

1. Press DEVICE USED to open the keypad and enter the panel’s device number from 1 - 4. Each

device number supports up to 255 programmable channel codes. The multiple device settings

allow you to create up to four unique touch panel buttons and/or pages. This value is used to

determine the current device being used by the panel.

2. Enter the number of devices being used by the touch panel.

3. Press Enter to save the value.

Adding a Page

1. Press PAGE on the Edit bar to open the PAGE menu.

2. Press ADD to open the keyboard and enter a name for the new page. Page names can be up to

20 characters.

3. Press EXIT CHANGE to save, close the keyboard, and go to the new page.

Setting the page color

14

1. Press EDIT to open the Edit bar on the newly created page.

2. Press PAGE on the Edit bar to open the PAGE menu.

3. Press PAGE COLOR to open the black and white color palette.

4. Select a color from the palette; the page automatically changes to the new color.

Color Passive-Matrix LCD Touch Panels

Page 19

Designing Touch Panel Pages

Adding a Button

To add a button to the current page:

1. Press BUTTON on the Edit bar to open the BUTTON menu.

2. Press ADD to open the ADD BUTTON operation bar. On the LCD screen, touch and drag to

create a button. The first touch point is the upper-left corner of the button.

Resizing a button

1. Press BUTTON on the Edit bar to open the BUTTON menu.

2. Press RESIZE. Then, touch any edge of the button and drag. Removing your finger from the

panel saves the button dimensions.

Defining On-Screen and External Button Properties

External pushbuttons are configured with features similar to on-screen buttons. Their functionality

can be set just as any other button on the touch panel.

Use the PROPERTIES option of the BUTTON menu in the Edit bar to set button borders, page

flips, button colors for channel on/off conditions, channel/variable text codes, and string/macro

assignments.

External button properties include only the button type, page flips, channel codes, and string/macro

assignments. Although the Border and Color sections of this page appear, they are of no use to

external pushbuttons since they do not appear on-screen.

Use the following steps to set button properties:

1. Press BUTTON on the Edit bar to open the BUTTON menu options.

2. Press PROPERTIES to open the PROPERTIES operation bar.

3. Press the new button to open the Button Properties page. This page lists the properties for the

active button.

4. Press BUTTON TYPE; this opens the BUTTON TYPE menu.

5. Choose a button type for the selected button to open the associated Button Properties page.

Each button type has its own Button Properties page with settings specific to the button type.

6. Press BORDER to open the BUTTON BORDER pages.

7. Select a border to set for the button and return to the Button Properties page. The BORDER

button changes to show the selected border type.

Setting the channel code

The channel button sets the device and button channel codes.

Channel codes and variable text codes work the same for all button types, including

joysticks, and bargraphs.

1. In the Button Properties page, press DEV to open the keypad and set the touch panel’s device

number.

Color Passive-Matrix LCD Touch Panels

15

Page 20

Designing Touch Panel Pages

2. Enter 1, 2, 3, or 4 in the keypad. The programming software uses device codes 1 - 4 to identify

the touch panel. Refer to the G3 Firmware Design and Reference instruction manual for more

information.

If DEVICE USED is set to 4 and Base Device Number is 128, the Controller recognizes

bus devices 128 - 131.

The panel will not allow you to enter a device number greater than the DEVICE USED

without first displaying a decision box asking if you accept the new selection or not.

3. Press ENTER to save the device number, close the keypad, and return to the Button Properties

page.

4. Press CHAN to open the keypad and enter a channel value of 1 - 255. The source code uses the

channel code number to identify the button and its programmed operations. The channel code

for non-active buttons is 0.

5. Press ENTER to save the channel number, close the keypad, and return to the Button Properties

page.

Setting the variable text code

The variable text buttons set the device and button channel codes for the buttons.

1. Press DEV to open the keypad and set the device number.

2. Enter 1, 2, 3, or 4 in the keypad. The source code uses device codes 1 - 4 to identify the touch

panel.

3. Press ENTER to save, close the keypad, and return to the Button Properties page.

4. Press CHAN to open a keypad and set the channel number.

5. Enter a channel value of 1 - 255 in the keypad. The source code uses the channel code number

to identify the button and its operations.

6. Press ENTER to save the channel number, close the keypad, and return to the Button Properties

page.

Setting the page flip

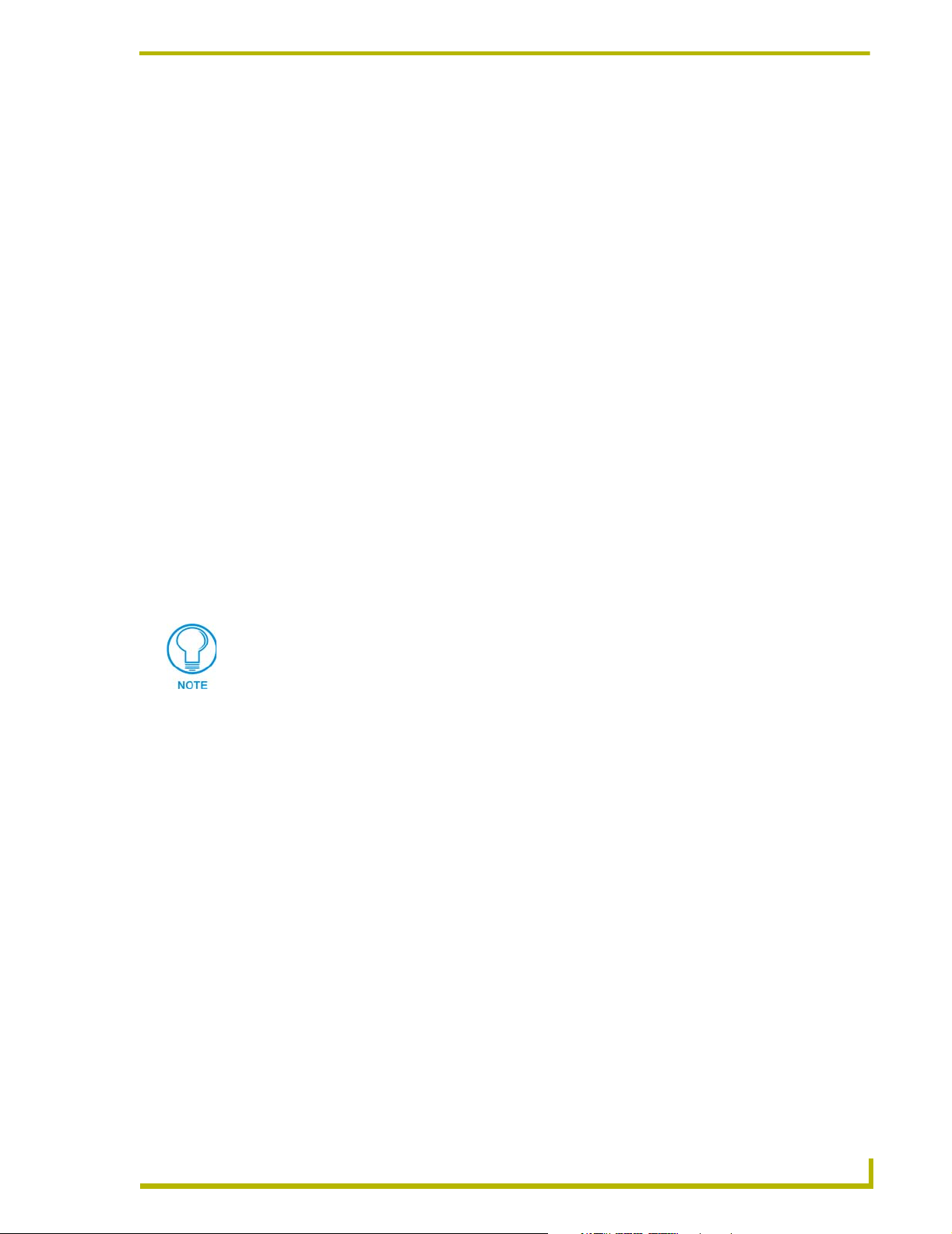

1. Press the PAGE FLIP Type button (FIG. 15) in the Button Properties page to open the Page

Flip Type menu.

Page FLIP type

button

FIG. 15 Page FLIP Type button

Flip to Page button

16

2. Select a Page Flip type. If you select FLIP PREVIOUS in the Page FLIP Type menu, the FLIP

to Page button appears.

3. Press the FLIP to Page button (FIG. 15) to open a list of all the saved touch panel pages. If the

desired page is not present in the menu, check to verify the page has been saved.

4. Select the target page for the page flip.

Color Passive-Matrix LCD Touch Panels

Page 21

Designing Touch Panel Pages

Setting the button colors for channel-off conditions

1. Press any button to open the Button Properties page.

2. Press BORDER under CHANNEL OFF in the Button Properties page. The color palette

appears. Select a color to set as the border.

3. Press the FILL button in the Button Properties page to open the palette. Select a color to set as

the fill.

4. Press the TEXT button to open the palette. Select a color to use for the text.

5. Press EXIT SAVE CHANGE in the Button Properties page to save the new button properties

and return to the current page.

Adding text, icons, and bitmaps to a button

1. Press BUTTON on the Edit bar to open the BUTTON menu.

2. Press TEXT/IMAGE to add text to the button. The TEXT/IMAGE operation bar appears.

3. Press any button to open the Text/Image page.

4. Go through each option and set as desired:

! TEXT OFF and TEXT ON sets the text for the button's Off and On state.

! ICON OFF and ICON ON sets the icon for the button's Off and On state.

! BITMAP OFF and BITMAP ON sets the bitmap for the button's Off and On state.

! MAKE ON SAME AS OFF sets the On and Off properties the same.

You cannot create or edit buttons with Unicode fonts on the panel. Any use of the

TEXT/IMAGE button to alter or create Unicode font supported buttons must be done

in the TPDesign3 Touch Panel Design Program.

5. Press EXIT SAVE CHANGE to close the Text/Image page and return to the Main page.

Using TPDesign3 to Download Bitmaps, Icons, and Fonts

TPDesign3 allows you to download bitmaps, icons, and fonts into your touch panel from an

existing touch panel program. Touch Panel programs are created in the TPDesign3 software

program. Refer to the TPDesign3 Touch Panel Program (version 3.13 or higher) instruction manual

for more information. Use the Download to Panel button to download a project file.

To download bitmaps, icons and/or fonts from an existing TPDesign3 project file:

1. Launch the TPDesign3 software program and open a project file that contains the desired

bitmaps, icons, and fonts.

2. Select File from the menu bar to open the File menu.

3. In the File menu, click on Download to Panel, this opens the Download to Panel dialog box.

4. Click on the Comm Settings tab to set the communications port, baud rate, and other

communication settings.

5. Then, click the Actions tab to set the communication mode and select which elements of the

project file you want to download to the touch panel.

Color Passive-Matrix LCD Touch Panels

17

Page 22

Designing Touch Panel Pages

6. In the What To Send area, select one or more of the available options (All Bitmaps, All Icons,

All Fonts).

7. Select the mode of communication with the touch panel (RS-232 and AXlink). Confirm that

the correct panel is selected by verifying the ID values with the Base Address assigned to the

touch panel in the Protected Setup page.

8. After clicking Connect, the Available Panels list appears in the Available Panels field. Click

Begin to start downloading the project file into the panel.

9. After completing the download, the bitmaps, icons and fonts that were downloaded are now

accessible via the BITMAPS, ICONS and FONTS menus.

Creating a Bargraph and Joystick

Bargraphs are level monitors and adjustable level controls. These levels can be configured to

monitor and adjust audio outputs and lighting levels.

Joysticks are vertical and horizontal direction controllers you can use for camera for pan and tilt

control. Before you start, make sure to connect the touch panel to your Controller; otherwise, the

joystick will not work properly.

Adding a bargraph or joystick button\

Create a new button using the ADD operation bar in the BUTTON menu.

1. Press BUTTON in the Edit bar to open the BUTTON menu.

2. Press PROPERTIES in the BUTTON menu to open the PROPERTIES operation bar.

3. Press any button to open the Button Properties page.

4. Press BUTTON TYPE to open the BUTTON TYPE menus. Choose a button type to open its

Button Properties page.

Setting Bargraph and Joystick Properties

Use the Button Properties page to set channel, level, and button colors. Refer to the Setting the

variable text code section on page 16 and the Setting the channel code section on page 15 for

further information. Refer to the Setting the button colors for channel-off conditions section on

page 17 for more information on colors for channel-off conditions.

Setting the level code

Level buttons set the device and number codes for the touch panels.

Joysticks actually use two level numbers. The first is for the X-axis and the second is

for the Y-axis. You only need to specify the first level.

18

1. Press DEV to open a keypad and set the device number.

2. Enter 1, 2, 3, or 4 in the keypad. The programming software uses device codes

1 - 4 to identify the touch panel.

3. Press ENTER to save the level device number, close the keypad, and return to the Button

Properties page.

Color Passive-Matrix LCD Touch Panels

Page 23

Designing Touch Panel Pages

4. Press NUM to open a keypad and set the level number assigned to the device.

5. Enter a number 1 – 8. Each device can have from 1 – 8 levels except joysticks, where the range

is 1 – 7.

6. Press ENTER to save, close the keypad, and return to the Button Properties page.

Color Passive-Matrix LCD Touch Panels

19

Page 24

Designing Touch Panel Pages

20

Color Passive-Matrix LCD Touch Panels

Page 25

Programming

You can program the touch panel to perform a wide variety of operations using AXCESS

Send_Commands and variable text commands. Use the commands described in this section to

program the touch panel.

System Send_Commands

System Send_Commands are stored in the Controller and direct the touch panel to perform various

operations.

System Send_Commands

ABEEP

Outputs one panel

beep even if the

beep value is set

to 0 in the Setup

page.

ADBEEP

Outputs a double

beep even if the

double beep value

is set to 0 in the

Setup page.

AKEYB

Opens the touch

panel keyboard

and initializes the

text string entry.

AKEYP

Opens the touch

panel keypad and

initializes the

number string

entry.

AKEYR

Closes/opens the

touch panel keyboard/pad.

Programming

Syntax:

"’ABEEP’"

Example:

SEND_COMMAND TP, "’ABEEP’"

Beeps the panel.

Syntax:

"’ADBEEP’"

Example:

SEND_COMMAND TP, "’ADBEEP’"

Double beeps the panel.

The keyboard string is set to null during power-up and is stored until power-down.

Syntax:

“’AKEYB-<text string>’"

Var iables :

text string = 0 - 59 characters

Example:

SEND_COMMAND TP, “’AKEYB-TOUCH HERE’"

Opens the touch panel keyboard with TOUCH HERE in the display.

The keyboard string is set to null during power-up and is stored until power-down for.

Syntax:

"’AKEYP-<number string>’"

Var iables :

number string = 0 - 9999

Example:

SEND_COMMAND TP,"’AKEYP-1988’"

Opens the touch panel keypad with 1988 in the display.

Syntax:

"’AKEYR’"

Example:

SEND_COMMAND TP,"’AKEYR’"

Closes the keyboard/keypad opened using the ’AKEYB’, ’AKEYP’, or ’PKEYP’ commands.

Color Passive-Matrix LCD Touch Panel

21

Page 26

Programming

System Send_Commands (Cont.)

BEEP

Gives an output of

one beep.

BRIT

Adjusts brightness

of display.

CONT

Adjusts brightness

of display.

CALIBRATE

Starts touch panel

calibration.

CLOCK

Sets the time and

date.

DBEEP

Gives a double

beep output.

MOUSE

Turns on the

Microsoft Serial

Mouse.

The Beep button in the Protected Setup page must be set from 1 - 10 for the BEEP command.

Syntax:

"’BEEP’"

Example:

SEND_COMMAND TP,"’BEEP’"

Beeps the panel if the Beep button is not set to 0.

Syntax:

"’BRIT-<level>’"

Var iables :

level = 1 - 5 (1 = minimum; 5 = maximum)

Example:

SEND_COMMAND TP,"’BRIT-5’"

Sets to highest brightness level.

Syntax:

"’CONT-<level>’"

Var iables :

level = 1 - 12 (1 = minimum; 12 = maximum)

Example:

SEND_COMMAND TP,"’CONT-12’"

Sets to highest brightness level.

Syntax:

"’CALIBRATE’"

Example:

SEND_COMMAND TP,"’CALIBRATE’"

Starts the calibration operation on the touch panel.

Syntax:

"’CLOCK <mm-dd-yy> <hh:mm:ss>’"

Var iables :

mm = 01 - 12, dd = 01 - 31, yy = 00 - 99

hh = 00 - 23, mm = 00 - 59, ss = 00 - 59

Example:

SEND_COMMAND TP,"’CLOCK 02-08-98 19:16:00’"

Sets the touch panel’s date to February 8, 1998, and time to 7:16 p.m.

This command only works if the Double Beep value in the Protected Setup page is set to

ON.

Syntax:

"’DBEEP’"

Example:

SEND_COMMAND TP,"’DBEEP’"

Double beeps the panel.

Syntax:

"’MOUSE’"

Example:

SEND_COMMAND TP,"’MOUSE’"

Activates the Microsoft Serial Mouse.

22

Color Passive-Matrix LCD Touch Panels

Page 27

System Send_Commands (Cont.)

PAG E

Flips to page with

specified page

name.

PKEYP

Displays asterisks (*) for keypad

entries.

PPOF

Closes a specific

popup page.

PPON

Opens a specific

popup page.

QBEEP

Stops all beeps.

RESET

Clears panel status (same as

power up). Saved

data is not

cleared.

SETUP

Goes to the Setup

page.

Syntax:

"’PAGE-<page name>’"

Var iables :

page name = 1 - 50 ASCII characters

Example:

SEND_COMMAND TP, "’PAGE-MAIN PAGE’"

Flips the touch panel to the page named MAIN PAGE.

Syntax:

"’PKEYP-<number string>’"

Var iables :

number string = 0 - 9999

Example:

SEND_COMMAND TP, "’PKEYP-1988’"

Displays the touch panel keypad with **** instead of 1988.

Syntax:

"’PPOF-<page name>’"

Var iables :

page name = 1 - 50 ASCII characters

Example:

SEND_COMMAND TP,"’PPOF-Popup Page 1’"

Closes Popup Page 1.

Syntax:

"’PPON-<page name>’"

Var iables :

page name = 1 - 50 ASCII characters

Example:

SEND_COMMAND TP,"’PPON-Popup Page 1’"

Opens Popup Page 1.

Syntax:

"’QBEEP’"

Example:

SEND_COMMAND TP,"’QBEEP’"

Stops all beeps.

Syntax:

"’RESET’"

Example:

SEND_COMMAND TP,"’RESET’"

Resets the touch panel.

Syntax:

"’SETUP’"

Example:

SEND_COMMAND TP, "’SETUP’"

Flips the touch panel to the Setup page.

Programming

Color Passive-Matrix LCD Touch Panel

23

Page 28

Programming

System Send_Commands (Cont.)

SLEEP

Forces the touch

panel to screen

saver mode.

$SC

Sends a serial

port

send_command

within a panel, as

if sent from

Axcess.

$ST

Sets the power

time-out for

TiltScreen panels.

TPAGEOFF

Deactivates page

tracking.

TPAGEON

Activates page

tracking.

WAKE

Deactivates

screen-saver

mode and resets

sleep timer.

ZAP!

Clears all memory; erases buttons, pages,

drawings, and

symbols.

Syntax:

"’SLEEP’"

Example:

SEND_COMMAND TP,"’SLEEP’"

Activates the screen saver mode.

Syntax:

"$SC <device offset>,"’<send_command>,<variable

text #>,<data>’""

Var iables :

device offset = Device number

variable text # = The variable text number value on the touch panel.

Example:

$SC 1,"’@TXT’,2,’TEXT’"

The string is sends the command to put text on a button with a variable text value of 2. It is

crucial that all the correct ’ and " be used with no spaces after the commas.

Example:

$SC 1,"’SLEEP’"

Sets a touch panel to sleep.

The command is followed by 1, 2, or 3 ASCII digits.

The entered number is not valid when there is no WAV-PK connected to the TiltScreen panels. The command is sent to the WAV-PK, which then sends it to the panel.

Syntax:

"’$ST <number>’"

Var iables :

number = 1 - 255 ASCII characters

Example:

SEND_COMMAND TP, "’$ST 31’"

The number entered is based on the minute increments available within the touch panel

such as 30, 60, 120 minutes. This number will be rounded down to match an increment.

Syntax:

"’TPAGEOFF’"

Example:

SEND_COMMAND TP,"’TPAGEOFF’"

Deactivates the page tracking option.

See TPAGEON on page 24 for more information.

Syntax:

"’WAKE’"

Example:

SEND_COMMAND TP,"’WAKE’"

Deactivates the touch panel screen-saver mode and resets the sleep timer.

Syntax:

"’ZAP!’"

Example:

SEND_COMMAND TP, "’ZAP!’"

Clears all memory and erases all buttons, pages, drawings, and symbols.

24

Only use the ZAP! command to erase all the saved data in the touch panel; data cannot be recovered

after it is erased.

Color Passive-Matrix LCD Touch Panels

Page 29

System Send_Commands (Cont.)

TPAGEON

Activates page

tracking.

Syntax:

"’TPAGEON’"

Example:

SEND_COMMAND TP,’TPAGEON’

DEFINE_DEVICE

TP1 = 128 (*AMX Touch Panel*)

TP2 = 129 (*AMX Touch Panel*)

DEFINE_VARIABLE

TP1_BUFFER[100] (*Buffer for TP1*)

TP2_BUFFER[100] (*Buffer for TP2*)

TRASH[50] (*For Parsing Above*)

DEFINE_START

CREATE_BUFFER TP1,TP1_BUFFER

CREATE_BUFFER TP2,TP2_BUFFER

SEND_COMMAND TP1,'TPAGEON'

SEND_COMMAND TP2,'TPAGEON'

DEFINE_PROGRAM

(* PAGE TRACKING ROUTINE *)

IF(LENGTH_STRING(TP1_BUFFER))

{

IF(FIND_STRING(TP1_BUFFER,'PAGE-',1))

{

TRASH=REMOVE_STRING(TP1_BUFFER,'PAGE-',1)

SEND_COMMAND TP2,"'PAGE-',TP1_BUFFER"

CLEAR_BUFFER TP1_BUFFER

}

IF((FIND_STRING(TP1_BUFFER,'PPON-',1))

OR(FIND_STRING(TP1_BUFFER, 'PPOF-',1)))

{

SEND_COMMAND TP2,TP1_BUFFER

CLEAR_BUFFER TP1_BUFFER

}

}

Programming

Color Passive-Matrix LCD Touch Panel

IF(LENGTH_STRING(TP2_BUFFER))

{

IF(FIND_STRING(TP2_BUFFER,'PAGE-',1))

{

TRASH=REMOVE_STRING(TP2_BUFFER,'PAGE-',1)

SEND_COMMAND TP1,"'PAGE-',TP2_BUFFER"

CLEAR_BUFFER TP2_BUFFER

}

IF((FIND_STRING(TP1_BUFFER,'PPON-',1)) OR

(FIND_STRING(TP1_BUFFER,'PPOF-',1)))

{

SEND_COMMAND TP1,TP2_BUFFER

CLEAR_BUFFER TP2_BUFFER

}

}

(* The command string is sent to the Controller in the ’PAGE-(page name)’ or ’PPON/

PPOF-(page name)’ format. The string is captured in the buffer for one panel and sent to

the other panel. If panels are combined using the DEFINE_COMBINE statement, the routine needs to be written only once, and the command is sent back to the same panel. *)

(* END OF PAGE TRACKING ROUTINE *)

25

Page 30

Programming

Programming Numbers

The following information provides the programming numbers for colors, fonts, and borders

! Colors can be used to set the colors on buttons, sliders, gauges, and pages. The lowest

color number represents the lightest color-specific display; the highest number represents

the darkest display. For example, 0 represents light red, and 5 is dark red.

Colors and Programming Numbers

Color No. Color No.

Red 0 - 5 Purple 54 - 59

Orange 6 - 11 Magenta 60 - 65

Yellow 12 - 17 Pink 66 - 71

Lime 18 - 23 White 72 - 77

Green 24 - 29 Light Gray 78 - 83

Aqua 30 - 35 Dark Gray 84 - 86

Cyan 36 - 41 Black 87

Royal 42 - 47 Transparent 255

Blue 48 - 53

! Font styles are used to program text fonts on buttons, sliders, gauges, and pages. The

programming numbers are assigned consecutively when downloaded to the touch panel.

You must import variable text fonts into a TPDesign3 project file, and download the

project file containing the fonts to the touch panel. The variable fonts are

programming numbers assigned by the touch panel during the download process.

Font Styles and Programming Numbers

No. Font styles No. Font styles

1 Extra small 5 Extra large

2 Small 6 Hollow medium

3 Medium 8 Hollow extra large

4 Large 32 - 255 Variable fonts

! Border styles can be used to program borders on buttons, sliders, and gauges.

Border Styles and Programming Numbers

No. Border styles No. Border styles

0 No border 11 Double shadow

1 No border special 20 3-dimensional rectangle 1

2 Single line 21 3-dimensional rectangle 2

3 Double line 22 3-dimensional round 1

4 Triple line 23 3-dimensional round 2

5 Single rounded 24 3-dimensional neon 1

6 Double rounded 25 3-dimensional neon 2

7 Single raised 26 3-dimensional neon blue

8 Double raised 27 3-dimensional neon green

9 Triple raised 40 Single diamond

10 Double-line two single 41 Double diamond

26

Color Passive-Matrix LCD Touch Panels

Page 31

Programming

Shorthand Send_Commands

The table below lists the shorthand Send_Commands you can use with touch panels. The shorthand

command data is 1-byte, non-ASCII format except for pages, passwords, text, and bitmap names.

Shorthand Send_Commands

@CBF

Sets the OFF

feedback border

color to the specified color.

@CBN

Sets the ON feedback border color

to the specified

color.

@CFF

Sets the OFF

feedback fill color

to the specified

color.

@CFN

Sets the ON feedback fill color to

the specified

color.

This works only if the specified background color is not the same as the current color.

Syntax:

"’@CBF’,<variable text address>,<color_number>"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’@CBF’,1,0"

Sets the OFF feedback border color to Red for the variable text button 1.

This works only if the specified background color is not the same as the current color.

Syntax:

"’@CBN’,<variable text address>,<color_number>

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’@CBN’,2,78"

Sets the ON feedback border color to Gray for variable text button 2.

This only works if the specified background color is not the same as the current color.

Syntax:

"’@CFF’,<variable text address>,<color_number>"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’@CFF’,1,72"

Sets the OFF feedback fill color to White for variable text button 1.

This only works if the specified background color is not the same as the current color.

Syntax:

"’@CFN’,<variable text address>,<color_number>"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’@CFN’,1,30"

Sets the ON feedback fill color to Aqua for variable text button 1.

Color Passive-Matrix LCD Touch Panel

27

Page 32

Programming

Shorthand Send_Commands (Cont.)

@CPG

Sets the page with

specified page

name background color to

the specified

color.

@CPP

Sets the page with

specified page

name background color to

the specified

color.

@CTF

Sets the OFF

feedback text

color to the specified color.

@CTN

Sets the ON feedback text color to

the specified

color.

@IDF

The touch panel

returns its

MS-DOS file

name in a string.

This only works if the new background color is not the same as the current color.

Syntax:

"’@CPG’,<color_number>,’<page name>’"

Var iables :

color number = See the Colors and Programming Numbers table on page 26.

page name = 1 – 50 ASCII characters

Example:

SEND_COMMAND TP,"’@CPG’,87,’Main Page’"

Sets the page title to Main Page, and the color to Black.

This only works if the specified background color is not the same as the current color.

Syntax:

"’@CPP’,<color_number>,’<pop-up page name>’"

Var iables :

color number = See the Colors and Programming Numbers table on page 26.

pop-up page name = 1 – 50 ASCII characters

Example:

SEND_COMMAND TP,"’@CPP’,54,’Audio Page’"

Sets the popup page title to Audio Page, and the color to Purple.

This only works if the specified background color is not the same as the current color.

Syntax:

"’@CTF’,<variable text address>,<color_number>"

Var iables :

variable text address = 1 – 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’@CTF’,1,48"

Sets the OFF feedback text color to Blue for variable text button 1.

This only works if the specified background color is not the same as the current color.

Syntax:

"’@CTN’,<variable text address>,<color_number>"

Var iables :

variable text address = 1 – 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’@CTN’,1,72"

Sets the ON feedback text color to White for variable text button 1.

Syntax:

"’@IDF’"

Example:

SEND_COMMAND TP,"’@IDF’"

The touch panel returns its MS-DOS file name in a string.

28

Color Passive-Matrix LCD Touch Panels

Page 33

Shorthand Send_Commands (Cont.)

@IDP

Queries the touch

panel to return a

string with the

TPDesign3

project name.

@MOU

Sets the serial

mouse type.

@PPA

Removes all

popup pages from

a specified page.

@PPF

Deactivates a

popup page on a

touch panel page.

@PPK

Deactivates a

popup page on all

touch panel

pages.

Syntax:

"’@IDP’"

Example:

SEND_COMMAND TP,"’@IDP’"

The touch panel returns a string that contains its TPDesign3 project name.

Syntax:

"’@MOU’,<touch_type>"

Var iables :

touch_type = <Mouse Off> = 0 and <Microsoft Serial Mouse> = 1

Example:

SEND_COMMAND TP,"’@MOU’, 1"

Sets the Microsoft Serial Mouse.

If no page is specified, the active page is used.

Syntax:

"’@PPA-<page name>’"

Example:

SEND_COMMAND TP, "’@PPA-Main Page’"

If there were several popup pages on ’Main Page’ that are active, sending the previous

command would remove them all from ’Main Page’.

If a page name is empty the current page is used. If a pop-up page is part of a group, the

whole group is deactivated.

Syntax:

"’@PPF-<popup page name>; <page name>’"

Var iables :

popup page name = target popup page name

page name = target touch panel page name

Example:

SEND_COMMAND TP,"’PPF-Laser Disc 2 Transport Control;

Laser Disc Control Page’"

Deactivates the Laser Disc 2 Transport Control popup page on the Laser Disc Control

Page.

If a pop-up page is part of a group, the whole group is deactivated.

Syntax:

"’@PPK-<popup page name>’"

Var iables :

popup page name = target popup page name

page name = target touch panel page name

Example:

SEND_COMMAND TP,"’@PPK-Laser Disc 2 Transport Control’"

Deactivates the Laser Disc 2 Transport Control popup page on all touch panel pages.

Programming

Color Passive-Matrix LCD Touch Panel

29

Page 34

Programming

Shorthand Send_Commands (Cont.)

@PPN

Activates a popup

page on a touch

panel page.

@PPX

Removes all panel

popup pages.

@PRO

Sets the password

for the touch

panel Protected

Setup page.

@PWD

Sets the password

for the Page Flip

on the touch

panel.

@SSL

Changes the

Sleep string sent

to the Controller

when the touch

panel activates

sleep mode.

@SST

Changes the Startup string sent to

the Central Controller when the

touch panel powers up.

If a page name is empty the current page is used.

Syntax:

"’@PPN-<popup page name>;<page name>’"

Var iables :

popup page name = Popup page name

page name = Page name

Example:

SEND_COMMAND TP,"’@PPN-Laser Disc 2 Transport Control;

Laser Disc Control Page’"

Activates the Laser Disc 2 Transport Control popup page on the Laser Disc Control Page.

Syntax:

"’@PPX’"

Example:

SEND_COMMAND TP,"’@PPX’"

Closes all popup pages from all of the pages in the panel.

Syntax:

"’@PRO-<protected setup password>’"

Var iables :

protected setup password = 0 - 9999

Example:

SEND_COMMAND TP,"’@PRO-1988’"

Sets the touch panel’s Protected Setup page password to 1988.

Syntax:

"’@PWD-<page flip password>’"

Var iables :

page flip password = 0 - 9999

Example:

SEND_COMMAND TP,"’@PWD-1988’"

Sets the page flip password to 1988.

Syntax:

"’@SSL-<string>’"

Var iables :

string = alphanumeric characters

Example:

SEND_COMMAND TP,"’@SSL-Touch Panel Deactivated’"

Sends Touch Panel Deactivated to the Controller.

Syntax:

"’@SST-<string>’"

Var iables :

string = alphanumeric characters

Example:

SEND_COMMAND TP,"’@SST-Touch Panel Power On’"

Sends touch panel Power On to the Central Controller when the touch panel powers up.

30

Color Passive-Matrix LCD Touch Panels

Page 35

Programming

Shorthand Send_Commands (Cont.)

@SWK

Changes the

wake-up string

sent to the Controller when the

touch panel is

activated.

Syntax:

"’@SWK-<string>’"

Var iables :

string = alphanumeric characters

Example:

SEND_COMMAND TP,"’@SWK-Touch Panel Activated’"

Sends Touch Panel Activated to the Central Controller.

Color Send_Commands

Use the color Send_Commands to set the colors for text, buttons, and pages. Use the same

command for setting gray scale values only change the color number value to reflect the gray scale

(72-86) value.

Color Send_Commands

CALL

Sets the colors for

a variable text button.

CBOFF

Sets the OFF

feedback border

color to the specified color.

You must use the variable text assignments to change button colors (see the Colors and

Programming Numbers table on page 26).

Syntax:

"’CALL<variable text address>-<data>’"

Var iables :

You must have the variable text assignments to change button colors.

variable text address = 1 - 255

data = 6 color number series for:

FILL COLOR ON

FILL COLOR OFF

BORDER COLOR ON

BORDER COLOR OFF

TEXT COLOR ON

TEXT COLOR OFF

Example:

SEND_COMMAND TP,"’CALL1-87 72 87 72 72 87’"

Sets variable text button 1 to:

FILL COLOR ON = Black

FILL COLOR OFF = White

BORDER COLOR ON = Black

BORDER COLOR OFF = White

TEXT COLOR ON = White

TEXT COLOR OFF = Black

Syntax:

"’CBOFF<variable text address>-<color_number>’"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’CBOFF1-72’"

Sets the OFF feedback border color to White for the variable text button 1.

Color Passive-Matrix LCD Touch Panel

31

Page 36

Programming

Color Send_Commands (Cont.)

CBON

Sets the ON feedback border color

to the specified

color.

CFOFF

Sets the OFF

feedback fill color

to the specified

color.

CFON

Sets the ON feedback fill color to

the specified

color.

CPAGE

Sets the background page color

to the specified

color.

CTOFF

Sets the OFF

feedback text

color to the specified color.

Syntax:

"’CBON<variable text address>-<color _number>’"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’CBON1-87’"

Sets the ON feedback border color to Black for variable text button 1.

Syntax:

"’CFOFF<variable text address>-<color_number>’"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’CFOFF1-72’"

Sets the OFF feedback fill color to White for variable text button 1.

Syntax:

"’CFON<variable text address>-<color _number>’"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’CFON1-87’"

Sets the ON feedback fill color to Black for variable text button 1.

Syntax:

"’CPAGE<color_number>-<page name>’"

Var iables :

color number = See the Colors and Programming Numbers table on page 26.

page name = 1 - 50 ASCII characters (Page names are case sensitive.)

Example:

SEND_COMMAND TP,"’CPAGE255-MAIN PAGE’"

Sets the background color on the MAIN PAGE to Transparent.

Syntax:

"’CTOFF<variable text address>-<color _number>’"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’CTOFF1-87’"

Sets the OFF feedback text color to Black for variable text button 1.

32

Color Passive-Matrix LCD Touch Panels

Page 37

Color Send_Commands (Cont.)

CTON

Sets the ON feedback text color to

the specified

color.

Syntax:

"’CTON<variable text address>-<color _number>’"

Var iables :

variable text address = 1 - 255

color number = See the Colors and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’CTON1-72’"

Sets the ON feedback text color to White for variable text button 1.

Variable Text Send_Commands

Use variable text Send_Commands to set the borders, fonts, and text.

Variable Text Send_Commands

!B

Sets a specific

button to On or

Off.

BTOF

Sets a specific

button's active

state to Off.

BTON

Sets a specific

button's active

state to On.

Syntax:

"’!B’,<variable text address 1-255>,<ON/OFF 0-1>"

Var iables :

variable text address = 1 - 255

ON = 0

OFF = 1

Example:

SEND_COMMAND TP,"’!B’,128, 1"

Sets button 128 Off.

Syntax:

"’BTOF’,<variable text address>"

Var iables :

variable text address = 1 - 255

Example:

SEND_COMMAND TP,"’BTOF’,255"

Sets the state for button 255 to Off.

Syntax:

"’BTON’,<variable text address>’"

Var iables :

variable text address = 1 - 255

Example:

SEND_COMMAND TP,"’BTON’,128"

Sets the state for button 128 to On.

Programming

Color Passive-Matrix LCD Touch Panel

33

Page 38

Programming

Variable Text Send_Commands (Cont.)

!C

Sets the border,

font, and text in

one command.

!F

Shorthand version of ’FONT’

command.

FONT

Changes the font

size (or style) of

the text in a specific button.

!I

Shorthand version of 'ICON'

command.

ICON

Changes the border style of a specific button.

Syntax:

"’!C’,<variable text address>,<border style>,<font

size>,’<new button text>’"

Var iables :

variable text address = 1 - 255

border style = See the Border Styles and Programming Numbers table on page 26.

font size = See the Font Styles and Programming Numbers table on page 26.

button text = Enter button text to appear on button.

Example:

SEND_COMMAND TP,"’!C’,1,6,6,’VCR PLAY’"

Sets the variable text button one title to VCR PLAY using a hollow medium font, and

changes the border attribute to double rounded.

Syntax:

"’!F’,<variable text address>,’<font size>’"

Var iables :

variable text address = 1 - 255

font size = See the Font Styles and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’!F’,1,6"

Changes variable text button one font to hollow medium.

Syntax:

"’FONT,<variable text address>-<font size>’"

Var iables :

variable text address = 1 - 255

font size = See the Font Styles and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’FONT,1-6’"

Changes variable text button one font to hollow medium.

Syntax:

"’!I’,<variable text address>,’<border style>’"

Var iables :

variable text address = 1 - 255

border style = See the Border Styles and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’!I’,1,’6’"

Changes the variable text button one border style to double rounded.

Syntax:

"’ICON,<variable text address>-<border style>’"

Var iables :

variable text address = 1 - 255

border style = See the Border Styles and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP,"’ICON,25-6’"

Changes the variable text button 25 border style to double-rounded.

34

Color Passive-Matrix LCD Touch Panels

Page 39

Variable Text Send_Commands (Cont.)

!T

Shorthand version of 'TEXT'

command.

TEXT

Enters text on a

button.

Syntax:

"’!T’,<variable text address>,’<new button text>’"

Var iables :

variable text address = 1 - 255

new button text = 1 - 60 characters

Example:

SEND_COMMAND TP,"’!T’,1,’VCR PLAY’"

Changes the variable text button one title to VCR PLAY.

Use the | character to display text on multiple lines.

Syntax:

"’TEXT,<variable text address>-<new button text>’"

Var iables :

variable text address = 1 - 255

button text = Enter button text to appear on button

Example:

SEND_COMMAND TP,"’TEXT2-VCR|PLAY’"

Sets the VCR and PLAY text on variable button 2. The | character places VCR above

PLAY on the button.

Programming

Color Passive-Matrix LCD Touch Panel

35

Page 40

Programming

Shorthand Variable Text Commands

The table below lists the shorthand variable text commands you can use with the touch panel. The

shorthand command data is one-byte, non-ASCII format except for pages, passwords, text, and

bitmap names.

Shorthand Variable Text Commands

@BMF

Sets multiple

attributes to a button, slider, or

gauge.

This command allows you to program up to 12 attributes on one command line.

Syntax:

"’@BMF’,<variable text address>,’<attribute data>’"

Var iables :

variable text address = 1 - 255

optional data = See below

Optional data:

’%R,<left>, <top>, <right>, <bottom>’ = Sets the rectangle position.

’%B’,<border styles> = See the Border Styles and Programming Numbers table on

page 26.

’%F’,<font styles> = See the Font Styles and Programming Numbers table on page 26.

’%T’,<button text > = ASCII characters (empty is clear)

’%P’,<bitmap> = Bitmap filename (empty is clear)

’%I’,<icon> = 1 - 255 (icon numbers are assigned in TPDesign3 project file)

’%J’,<text alignment> = 1 - 9 as shown the following alignment chart

1

4

7

3

2

6

5

8

9

@BMP

Adds a bitmap file

to a button.

For %C1-%C6, see the Colors and Programming Numbers table on page 26.

’%C1’,<on-state fill color>

’%C2',<off-state fill color>

’%C3’,<on-state border color>

’%C4’,<off-state border color>

’%C5’,<on-state text color>

’%C6’,<off-state text color>

Example:

SEND_COMMAND TP,"’@BMF’,255,’%T POWER |ON’

’%B’,’4’,’%C1’,’72’"

Sets the text on button 255 to POWER ON (appears on two lines), adds a triple-line border, and sets the On-state color to White.

Bitmap files are imported into TPDesign3; the numbers are assigned by the touch panel

during the download process.

Syntax:

"’@BMP’,<variable text address>,’<bitmap>’"

Var iables :

variable text address = 1 - 255

bitmap = Bitmap

Example:

SEND_COMMAND TP, "’@BMP’,85,’Bitmap1’"

Adds the Bitmap1 file to button 85.

36

Color Passive-Matrix LCD Touch Panels

Page 41

Shorthand Variable Text Commands (Cont.)

@BOR

Sets the border

style on a button.

@ENA

Enables/Disables

buttons based on

their variable text

channel.

@FON

Sets the text font

on a button.

@ICO

Assigns an icon to

a button.

Syntax:

"’@BOR’,<variable text address>,<border style>"

Var iables :

variable text address = 1 - 255

border style = See the Border Styles and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP, "’@BOR’,65,11"

Sets the border style to Double shadow on button 65.

Syntax:

"’@ENA’,<variable text address>,<disable button on/off>

Var iables :

variable text address = 1 – 255

disable button on/off:

1 = button disabled

0 = button enabled

Example:

SEND_COMMAND TP, "’@ENA’,128,1"

Disables the button with variable text channel 128. This button will stop responding to

pushes completely, until it is sent an Enable command. Nothing short of a touch panel

Softrom firmware reload will re-enable the button. Reloading the touch panel file, reloading

the Axcess program, or resetting power on the panel or master, will not re-enable the button. It must be sent an Enable command once it has been Disabled.

Syntax:

"’@FON’,<variable text address>,<font style>"

Var iables :

variable text address = 1 - 255

font style = See the Font Styles and Programming Numbers table on page 26.

Example:

SEND_COMMAND TP, "'@FON',56,32"

Sets the text on button 56 to variable font style 32.

Syntax:

"’@ICO’,<variable text address>,<icon>"

Var iables :

variable text address = 1 - 255

icon file number = 1 - 255

Example: