Page 1

Quick Start Guide

HPX Base Assembly

Mounting Surface

Length of “B” varies according

to HPX base assembly

A

B

0.29” (7.3 mm) MAX

0.12” (3 mm)

4.37” (111 mm)

8.51" (216mm) for

Retractable Cable Modules

A

B

HPX Base Assembly

Mounting Surface

Length of “B” varies according

to Router Guide used

A

B

HPX-AC-TMPLT

Overview

The HPX-AC-TMPLT-600/900/1200 HydraPort® Installation Router Guides

provide an easy and accurate method of creating a hole in the installation

surface for HydraPort HPX-600, HPX-900 and HPX-1200 Connection Ports

(Base Assemblies). Use the HPX Router Gui des along with the required

accessories to create the hole in the mounting surface to install the HPX Base

Assemblies.

Specifications

Models Available:

• HPX-AC-TMPLT-600 (FG559-92) - For use with HPX-600

• HPX-AC-TMPLT-900 (FG559-93) - For use with HPX-900

• HPX-AC-TMPLT-1200 (FG559-94) - For use with HPX-1200

Dimensions:

Outside Dimensions: Horizontal: 18.90” (480 mm)

Routing Area (cutout)

Dimensions:

Thickness: 0.25” (6.35 mm)

Weight: HPX-AC-TMPLT-600: 4.60 lbs (2.09 kg)

Required Accessories

• Straight-Cut Router bit: Freud 12-128 or Whiteside 1072

(0.5” or 12mm / 12.7mm OD)

• Guide Bushing: Woodcraft 144693 (.75” or 19 mm OD)

• Bushing Lock Nut (Woodcraft 144696)

CAUTION: Only a professional, AMX-qualified installer should perform the

installation of Hydraport Base Assemblies. Installation must conform to all local

codes. These products may not be installed by the end-user.

The installation of Hydraport Base Assemblies requires specific woodwor king

skills. This installation should be performed by an experienced person,

comfortable with these type of woodwor king operations. Improper installat ion

may result in damage to the mounting surface.

Selecting a Suitable Location for the HPX Base Assembly

Care must be taken to ensure that the Hydraport system does not interfere with

the normal use of the work space. For exam ple, on a table or work surface,

ensure that the system does not interfere with the user's le gs when they are

seated at the table.

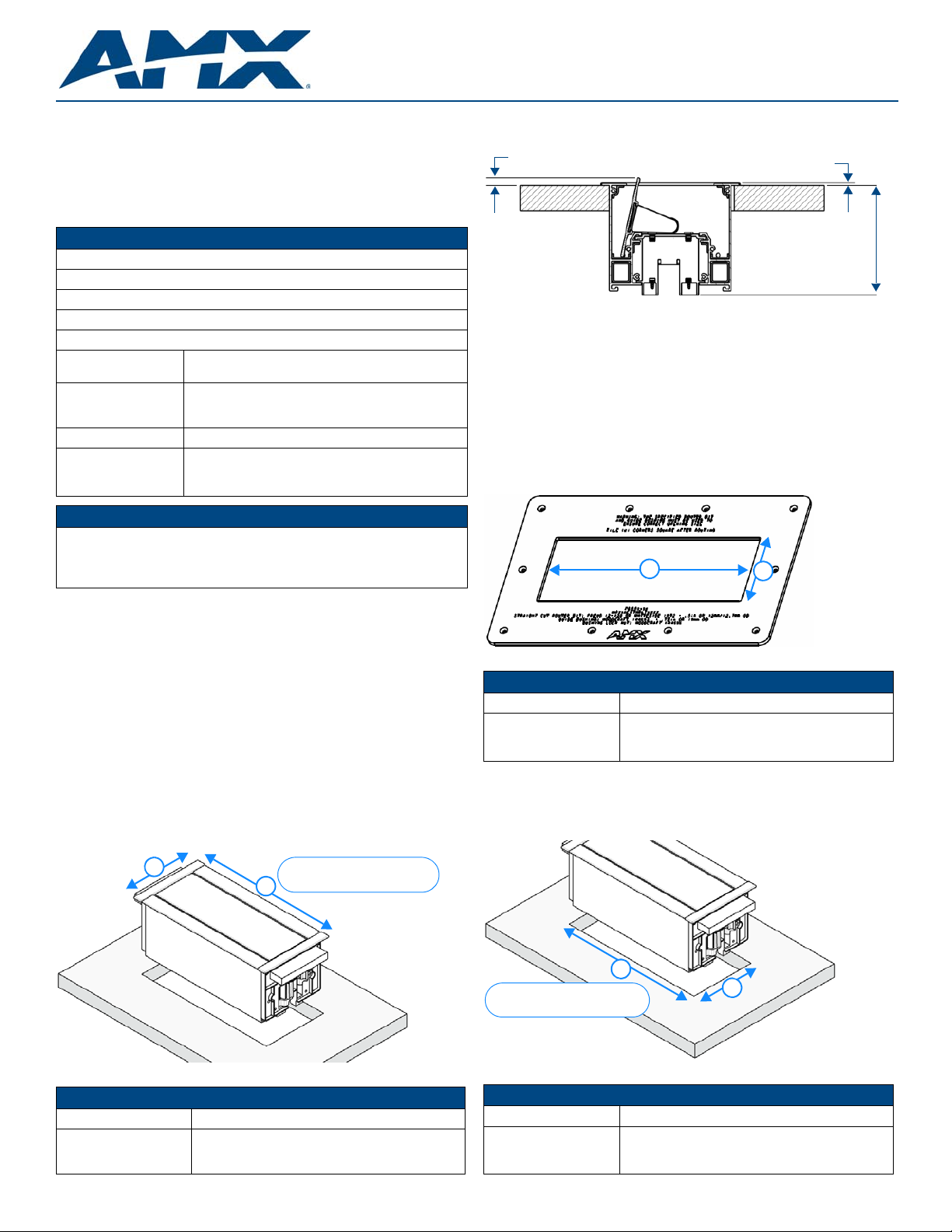

Above-Surface Dimensions of HPX Base Assemblies

Refer to FIG. 1 and the following table for the ab ove-surface dimensions of the

HPX-600/900/1200 Base Assemblies:

Vertical: 11.61” (295 mm)

These dimensions vary for each template.

Refer to the Routing Area Dimensions for

HPX-AC-TMPLT Router Guides section for details.

HPX-AC-TMPLT-900: 4.25 lbs (1.93 kg)

HPX-AC-TMPLT-1200: 3.85 lbs (1.75 kg)

HPX-600/900/1200 Installation Router Guides

FIG. 2 indicates th e below-surface dimensions requi red for the HPX-600/900/

1200 Base Assemblies:

FIG. 2 Dimensions of the HPX Base Assembly (below the table)

• The Hydraport system requires a mounting surface from 0.5” (13 mm) to

2” (51 mm) thick.

• The Hydraport base assembly will have a total depth of 4.37" (111 mm).

Note: For installations with Retrac table Cable Modules, the Hydraport syst em

will have a total assembly depth of 8.51" (216 mm).

Routing Area Dimensions for HPX-AC-TMPLT Router Guides

Refer to FIG.3 and the following table for the dimensions of the routing area

(template cutout) of the HPX-AC-TMPLT Router Guides:

FIG. 3 HPX-AC-TMPLT Router Guides - Routing Area

Dimensions of Routing Area for HPX-AC-TMPLT Router Guides

Length of “A”: 5.05” (128.25 mm)

Length of “B”: HPX-AC-TMPLT-600: 7.85” (199.35 mm)

HPX-AC-TMPLT-900: 10.78” (274.25 mm)

HPX-AC-TMPLT-1200: 13.75” (349.25 mm)

Hole Cutout Dimensions for the Mounting Surface

Refer to FIG. 4 and the following table for the dimensions of the actual hole cut

out in the mounting surface, resulting from using the Router Guides and required

accessories:

FIG. 1 Above-Surface Dimensions of HPX Base Assemblies

Dimensions of HPX Base Assemblies

Length of “A”: 5.43” (138 mm)

Length of “B”: HPX-600: 8.19” (208 mm)

FIG. 4 Hole Cutout Dimensions for the Mounting Surface

Hole Cutout Dimensions for the Mounting Surface

HPX-900: 11.14” (283 mm)

HPX-1200: 14.09” (358 mm)

Length of “A”: 4.84” (123 mm)

Length of “B”: HPX-AC-TMPLT-600: 7.64” (194 mm)

HPX-AC-TMPLT-900: 10.59” (269 mm)

HPX-AC-TMPLT-1200: 13.54” (344 mm)

Page 2

93-0559-92 REV: B

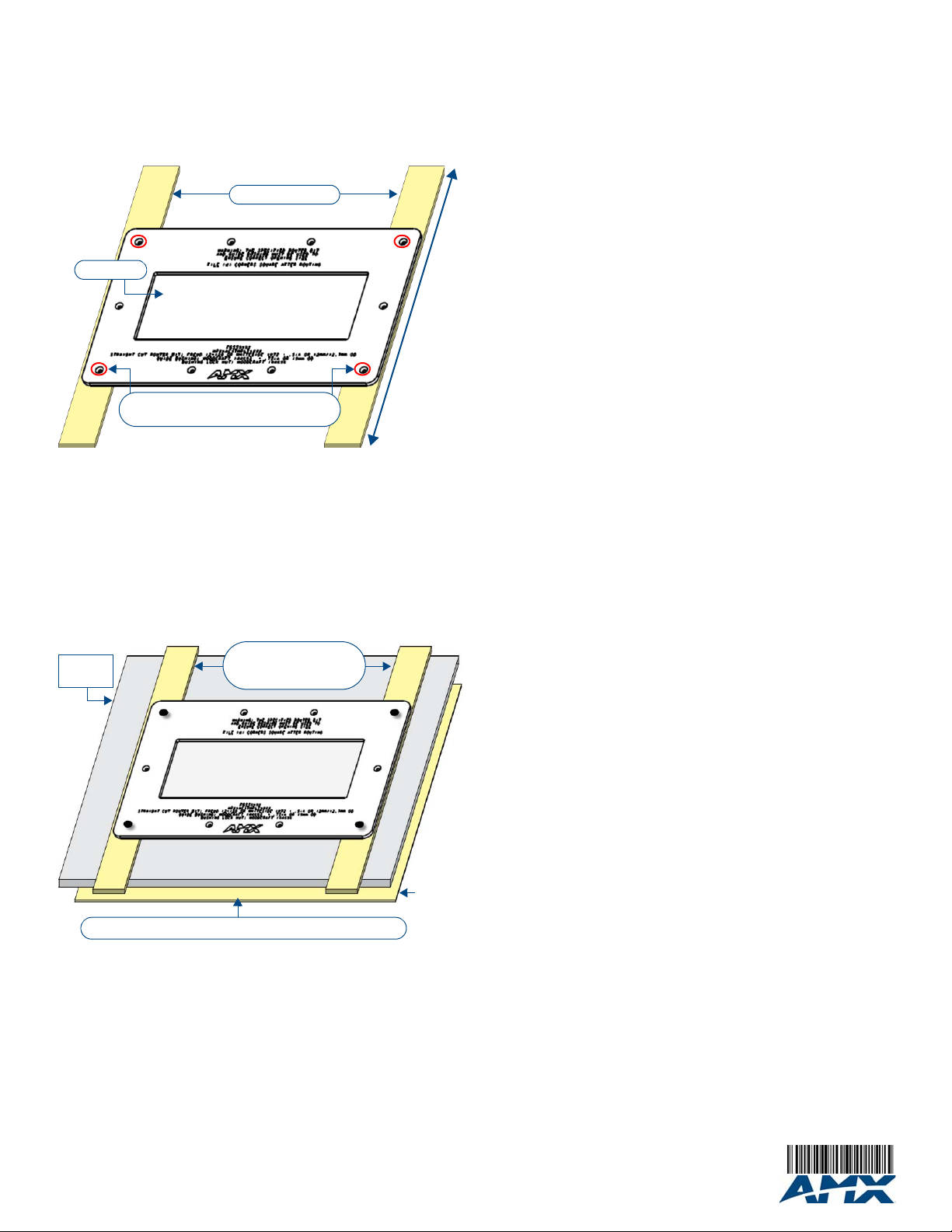

Preparing the HPX Installation Router Guide

1/2” x 4” wood strips

Wood strips

should span

the width of

the mounting

surface

Use a minimum of four short screws to

secure the Router Guide to the wood strips

Routing area

Wood strips secur ed to

the Router Guide with

at least four screws

Mounting

surface

Sandwich the mounting surface between soft wood for protection

soft wood

(under surface)

1. Cut two 1/2-inch x 4-inch strips of soft, finished wood. The wood strips

should be long enough to span the distance from the installation

location to the edges of the mounting surface.

2. Use four or more short lock nut screws to secure the router guide to the

wood strips (FIG.5):

FIG. 5 Securing the router guide

CAUTION: To avoi d d amagi ng the mount ing s urfac e, do no t allow the s crew s to

protrude through the bottom of the wood strips.

Preparing the Mounting Surface

1. Mark the desired mounting location on the mounting surface.

2. Place the router guide/wood strip assembly on the mounting surface, and

center the assembly on the mounting location.

3. Position a sheet of soft wood beneath the mounting surface to “sandwich”

the mounting surface with soft wood. Thi s will protect both sides of the

mounting surface during installation (FIG.6):

Cutting the Hole In the Mounting Surface

CAUTION: Wear safety glasses when operating the router. Failure to comply

may result in eye injury.

Use the specified guide bushing and router bit:

• Guide Bushing: Woodcraft 144693 (.75” or 19 mm OD)

• Router Bit: Straight-Cut Router bit: Freud 12-128 or Whiteside 1072

(0.5” or 12mm / 12.7mm OD)

1. Carefully measure the mounting surface to locate the desired position of

the HPX Base Assembly.

2. Use the appropriate Installation Router Guide to mark the edges of the

cutout.

3. Carefully cut the opening in the table surface with the router.

• Note that very little clearance exists between the HPX Base Assembly and

the hole cutout in the mounting surface.

• Take care to align the cutout carefully with the edges or other appropriat e

features in the table or mounting surface.

• If the cutout is misaligned, the installed unit will be misaligned.

• Take care to ensure that the top surface of the mounting surface is not

damaged beyond the width of the trim bezel as the cutout is made.

• Use an appropriate drill and drill bit to make a starting hole within the

boundary of the cutout. Use an appropriate saw, such as a jigsaw to finish

the cutout.

• Make sure cutting tool used is appropriate for the material to be cut and will

not tear or chip the top surfa ce.

• Note that the process of making the cuto ut will create substantial dust and

prepare the environment appropriately.

4. File the four corners of the routing area square after routing.

Additional Documentation

For additional instructions and detailed installation drawings for the

HPX-600/900/1200 Base Assemblies, refer to the HPX-600/900/1200

Installation Guide (available at www.amx.com).

Detailed specifications drawings for the HPX-AC-TMPLT router guides are

available to download from www.amx.com.

FIG. 6 Position the Router Guide and protective soft wood strips for installation

Note: For additional protection of the mounting surface, place a layer of

soft, thick cloth between the wood strips and the surface.

4. Once positioned, secure the router gu ide /w o od st ri p as sembly to the

mounting surface and under-surf ace wood with C-clamps.

For full warranty information, refer to the AMX Instruction Manual(s) associated with your Product(s).

3000 RESEARCH DRIVE, RICHARDSON, TX 75082 • 800.222.0193 • fax 469.624.7153 • technical support 800.932.6993 • www.amx.com

©2015 AMX. All rights reserved. AMX and the AMX logo are registered trademarks of AMX.

AMX reserves the right to alter specifications without notice at any time.

2/15

Loading...

Loading...