Page 1

QUICK START GUIDE

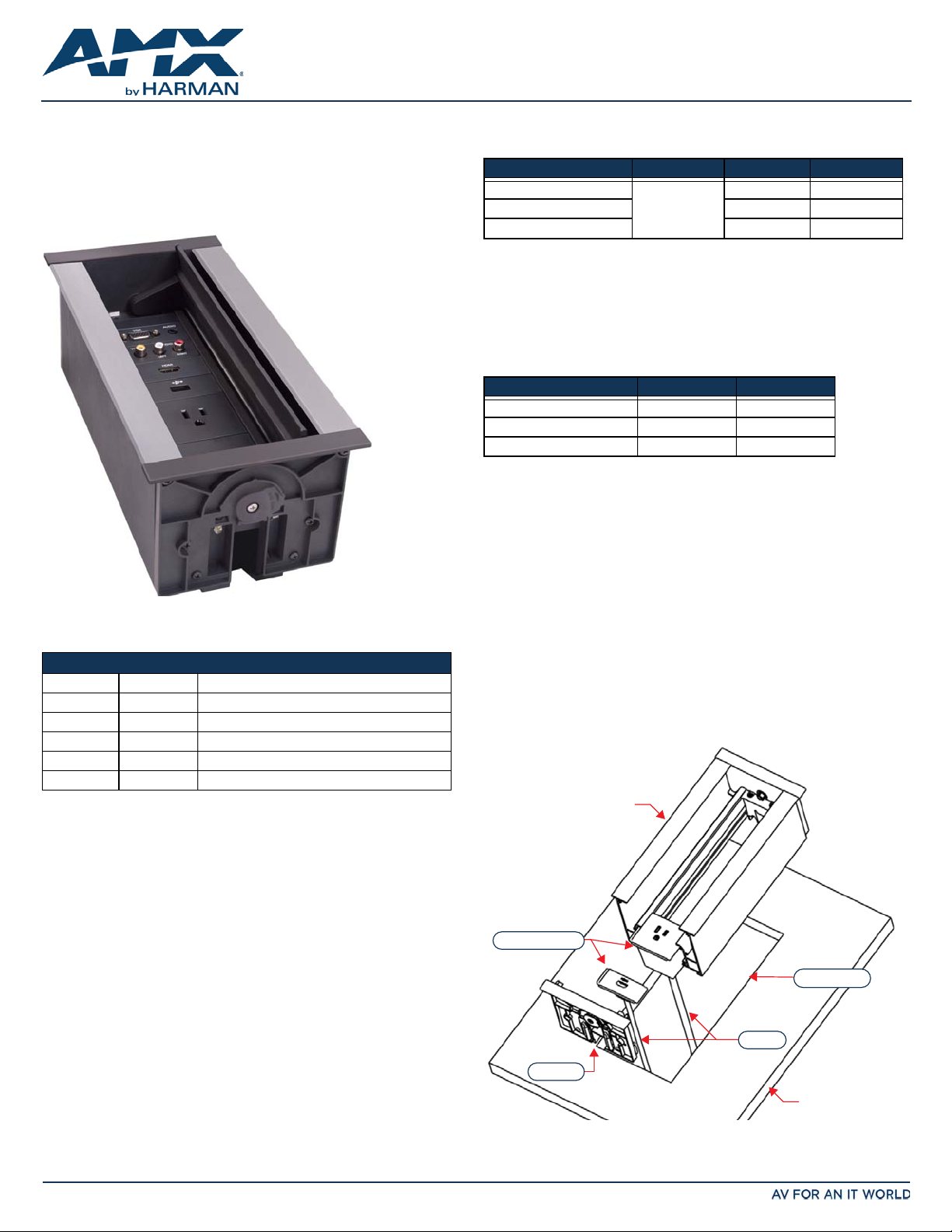

HPX-600/900/1200 6, 9,12 Module Connection Ports

Overview

The HPX-600/900/1200 family of HydraPort Connection Ports (FG560-xx-cc) are built

to accommodate the diverse connection needs of conference and meeting room

visitors. The HPX-600/900/1200 are designed to be mounted into a horizontal surface

such as a conference room table or lectern in order to provide connectivity for power,

networking, Audio/Video and control.

Specific connectivity is accomplished by populating the HydraPort Base Assembly with

various modules.

HPX-600/900/1200 HYDRAPORT BASE ASSEMBLY

FIG. 1

AMX offers 6 versions of the HPX-600/900/1200 HydraPort Base Assemblies with a

variety of compatible modules:

HPX-600/900/1200 HYDRAPORT BASE ASSEMBLIES

HPX-600-BL FG560-01-BL HydraPort Base Assembly, 6M Capacity, Black Trim

HPX-600-SL FG560-01-SL HydraPort Base Assembly, 6M Capacity, Silver Trim

HPX-900-BL FG560-02-BL HydraPort Base Assembly, 9M Capacity, Black Trim

HPX-900-SL FG560-02-SL HydraPort Base Assembly, 9M Capacity, Silver Trim

HPX-1200-BL FG560-03-BL HydraPort Base Assembly, 12M Capacity, Black Trim

HPX-1200-SL FG560-03-SL HydraPort Base Assembly, 12M Capacity, Silver Trim

ATTENTION: Only a professional, AMX-qualified installer should perform this installation.

Installation must conform to all local codes. This product may not be installed by the

end-user.

Accessories

Hydraport Base assemblies come with the following accessories:

• Two Table spacers (for use in tables 0.5 - 0.75" thick) with adhesive included

• Eight Cable Routing Clips

Compatible HydraPort Modules and Panels

Please refer to the Architectural Connectivity product page at www.amx.com for a

complete listing of compatible HydraPort Connection Modules

Installation of the HydraPort Base Assembly

The following sections describe the preparation, installation and setup of the HPX-600/

900/1200 HydraPort Base Assembly. A typical installation will include several various

HydraPort modules.

Note: Refer to www.amx.com for a complete listing of compatible HydraPort Connection

Modules.

Each HydraPort module has specific instructions for terminating their connections.

Refer to each Module’s Installation Guide during the installation of the HydraPort

system.

Note: Read these instructions in their entirety before beginning the installation. The

installation requires specific steps to be performed in specific order.

CAUTION: This installation requires specific woodworking skills. This installation should

be performed by an experienced person, comfortable with these types of woodworking

operations. Improper installation may result in damage to the mounting surface. AMX is

not responsible for damage caused by improper installation.

1) Select a Suitable Location for the HydraPort Base Assembly

The following table indicates the space requirements for installing the HydraPort Base

Assembly:

MODEL HEIGHT WIDTH LENGTH

HPX-600 (Up to 6 Modules) Total Height

HPX-900 (Up to 9 Modules) 5.43” (138 mm) 11.14” (283 mm)

HPX-1200 (Up to 12 Modules) 5.43” (138 mm) 14.09” (358 mm)

• The HydraPort system requires a mounting surface from 0.5” (13mm) to 2”

(51mm) thick. Thin surfaces may require spacers.

Note: Care should also be taken to ensure that the HydraPort system does not interfere

with the normal use of the work space. For example, on a table or work surface, ensure

that the system does not interfere with the user's legs when they are seated at the table.

4.37” (111 mm)

With RCMs

11.3” (287 mm)

5.43” (138 mm) 8.19” (208 mm)

2) Cut the Hole In the Mounting Surface

The Hydraport Base Assembly comes with a paper template that can be used to locate

the perfect spot and to mark the perimeter for cutting the table surface. The following

table provides the hole cutout dimensions for the HydraPort Base Assembly:

MODEL WIDTH LENGTH

HPX-600 (Up to 6 Modules) 4.84” (123 mm) 7.64 (194 mm)

HPX-900 (Up to 9 Modules) 4.84” (123 mm) 10.59 (269 mm)

HPX-1200 (Up to 12 Modules) 4.84” (123 mm) 13.54 (344 mm)

1. Use the template or measure the tabletop or other mounting surface to locate the

desired position of the HydraPort Base Assembly.

2. Use the cutout template to mark the edges of the cutout.

Note: Very little clearance exists between the HydraPort Base Assembly and the

hole cutout in the mounting surface.

• Align the cutout carefully with the edges or other features of the mounting surface.

If the cutout is misaligned, the installed unit will be misaligned.

• Take care to ensure that the top surface of the mounting surface is not damaged

beyond the width of the trim bezel as the cutout is made.

• Use an appropriate drill and drill bit to make a starting hole within the boundary

of the cutout. Use an appropriate saw, such as a jigsaw to finish the cutout.

• Make sure cutting tool used is appropriate for the material to be cut and will not

tear or chip the top surface.

• Note that the process of making the cutout will create substantial dust and

prepare the environment appropriately.

3) Prepare the Terminations

Some modules included in the final system require some type of backside termination.

Note: Refer to the installation guide for each module to determine the required backside

termination.

HydraPort Base Assembly

Interlocking tab

Table cut out

Cables

End Cap

Mounting Surface

FIG. 2 INSERTING THE MODULES INTO THE ASSEMBLY

• The backside termination for each module can and should be completed before

the module is installed into HydraPort Base Assembly.

Page 2

• For terminations for which the far end of the cable is not accessible (either

because the cable has been run under carpet, in a conduit or structure, or is

otherwise fixed), the cable must be placed through the cutout in the table prior to

installation, as indicated in FIG. 2.

4) Insert the HydraPort Modules

Note: The socket-outlet (Connection to Mains Power branch circuit) shall be installed

near the equipment and shall be easily accessible.

Note the orientation of each HydraPort Module - a small tab exists on one side of the

faceplate of each module that fits tongue in groove into the next module. Ensure all

tabs are facing the same direction (see FIG. 2).

1. Remove one end cap of the HydraPort Base Assembly by removing the six sheet

metal screws and one pivot screw and pivot pawl assembly.

2. Slide the pre-terminate modules one at a time into the HydraPort Base Assembly.

3. Rout the cables from each module out the bottom of the HydraPort Base

Assembly.

4. Use cable ties and one or more of the sliding clips to secure the cables as needed

to the HydraPort Base Assembly.

5. Reinstall the end cap of the HydraPort Base Assembly by installing the six sheet

metal screws and one pivot screw and pivot pawl assembly.

Note: Do not over-tighten the pivot pawl screw (i.e., do not use a high-powered drill

to tighten this screw).

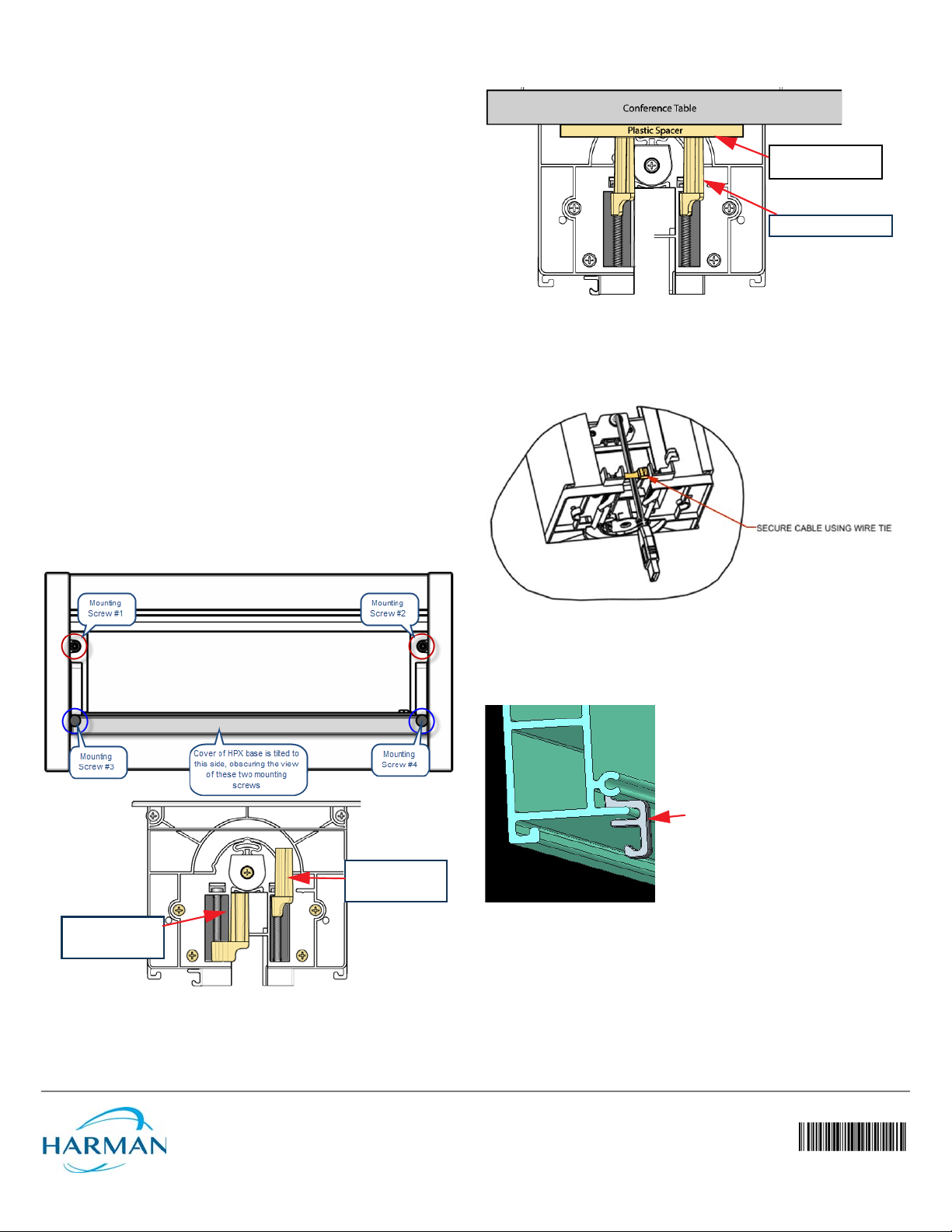

5) Install the System Into the Mounting Surface

1. Install the unit into the cutout in the mounting surface.

• Make sure that all cables from the backside terminations pass through the cutout.

• For terminations for which the far end of the cable is not accessible (either

because the cable has been run under carpet, in a conduit or structure, or is

otherwise fixed), the cable must be placed through the cutout in the table prior to

installation, as indicated in FIG. 5.

2. Open the door and rotate the four mounting screws located inside and at each

end of the HydraPort base assembly in order to rotate the retaining tabs out

under the mounting surface.

Note: Make sure that the retaining tabs are down and folded out of the way prior to

installing the unit in the mounting surface.

3. Carefully tighten the mounting screws until the mounting tabs contact the

backside of the mounting surface and torque to 8 in-lbs (FIG. 3). It will be

necessary to flip the cover to the opposite side to access the other two screws.

Note: For surfaces less than ¾" (19mm) thick, use the supplied plastic spacers by fixing

them to each end of the cutout using the supplied double sided tape (FIG. 4).

Optional Spacers

(2 Places)

Locks in Tight Position

FIG. 4 OPTIONAL SPACER AND MOUNTING TABS DEPLOYED

6) Install the System Into the Mounting Surface

1. Terminate the underside connections as required for each cable exiting the

HydraPort system.

2. Secure these cables and the power cable to either of the end caps using the

supplied wire ties (FIG. 5).

Retaining tab

shown tightened

(to secure the unit)

Retaining tab

shown loosened

(to remove the unit)

HPX BASE ASSEMBLY (SHOWN MOUNTED) - MOUNTING SCREWS LOCATIONS

FIG. 3

Note: Do not over torque screws. To avoid damaging the mounting tabs, use a hand

screwdriver or a powered screwdriver on a low torque setting.

FIG. 5 BOTTOM VIEW WITH CABLES EXITING AND SECURED

3. Secure the cables in at least one additional location after they have been secured

to the system to prevent undue stress if the cables are inadvertently kicked,

snagged or pulled. Routing clips are provided that slide into the bottom channel

of the base assembly and leave a gap to hold the cable (FIG. 6). These clips come

in two different sizes, the larger gap is for the thicker RGB+A RCM cable.

Routing Clip

FIG. 6 BOTTOM VIEW WITH CABLE ROUTING CLIP INSTALLED

Additional Documentation

For more detailed installation instructions with additional drawings, please refer to the

HPX-600/900/1200 Installation Guide, available to view or download from

www.amx.com.

Last Revised: 05/12/2016

© 2016 Harman. All rights reserved. Modero, AMX, AV FOR AN IT WORLD, HARMAN, and their respective logos are registered trademarks of

HARMAN. Oracle, Java and any other company or brand name referenced may be trademarks/registered trademarks of their respective companies.

AMX does not assume responsibility for errors or omissions. AMX also reserves the right to alter specifications without prior notice at any time.

The AMX Warranty and Return Policy and related documents can be viewed/downloaded at www.amx.com.

3000 RESEARCH DRIVE, RICHARDSON, TX 75082 AMX.com | 800.222.0193 | 469.624.8000 | +1.469.624.7400 | fax 469.624.7153

AMX (UK) LTD, AMX by HARMAN - Unit C, Auster Road, Clifton Moor, York, YO30 4GD United Kingdom • +44 1904-343-100 • www.amx.com/eu/

93-0560-01 REV: F

Loading...

Loading...