Page 1

&RORU $FWLYH00DWUL[ /&' 7RXFK 3DQHOV

+)LUPZDUH YHUVLRQ *6 RU KLJKHU,

,QVWUXFWLRQ 0DQXDO

;18¨ 7RXFK 3DQHOV DQG $FFHVVRULHV

Page 2

Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free from defects in material and

workmanship under normal use for a period of 3 years from date of purchase from

AMX, with the following exceptions: Electroluminescent and LCD control panels

are warranted for a period of 3 years, except for the display and touch overlay

components, which are warranted for a period of 1 year. Disk drive mechanisms,

pan/tilt heads, power supplies, modifications, MX Series products, and KC Series

products are warranted for a period of 1 year. Unless otherwise specified, OEM

and custom products are covered for a period of 1 year. AMX software products are

warranted for a period of 90 days. Batteries and incandescent lamps are not

covered.

This warranty extends to products purchased directly from AMX or an authorized

AMX dealer. Consumers should inquire from selling dealer as to the nature and

extent of the dealer’s warranty, if any.

AMX is not liable for any damages caused by its products or for the failure of its

products to perform, including any lost profits, lost savings, incidental damages,

or consequential damages. AMX is not liable for any claim made by a third party or

made by you for a third party.

This limitation of liability applies whether damages are sought, or a claim is made,

under this warranty or as a tort claim (including negligence and strict product

liability), a contract claim, or any other claim. This limitation of liability cannot be

waived or amended by any person. This limitation of liability will be effective even

if AMX or an authorized representative of AMX has been advised of the possibility

of any such damages. This limitation of liability, however, will not apply to claims

for personal injury.

Some states do not allow a limitation of how long an implied warranty lasts. Some

states do not allow the limitation or exclusion of incidental or consequential

damages for consumer products. In such states, the limitation or exclusion of the

Limited Warranty may not apply to you. This Limited Warranty gives you specific

legal rights. You may also have other rights that may vary from state to state. You

are advised to consult applicable state laws for full determination of your rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX MAKES NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. AMX EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN

THIS LIMITED WARRANTY. ANY IMPLIED WARRANTIES THAT MAY BE

IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS LIMITED

WARRANTY.

Page 3

Table of Contents

Introduction ...........................................................................1

Overview 1

Features 2

Applications 3

What’s in this Manual 3

What’s New 4

Installing Touch Panels..........................................................5

Overview 5

Mounting the Touch Panels 5

AXU-CV(/PB), AXU-CA(/PB), and

low-profile back box 5

AXU-CV(/PB) or AXU-CA(/PB) and

BB-TP1 (solid surfaces) 7

AXU-CV(/PB) or AXU/CA(/PB) and

BB-TP1 (plasterboard) 10

AXM-CV(/PB) or AXM-CA(/PB) (rack-mount) 12

Wiring the Touch Panels 13

Preparing captive wires 13

Wiring guidelines 14

Using the AXlink connector for data and power 15

Using the AXlink connector with an

external 12 VDC power supply 15

Using the UniMount and rack-mount

four-pin header for mouse control 16

Cleaning the Touch Overlay 17

Touch Panel Basics .............................................................19

Overview 19

Touch Panel Pages 19

Standard Buttons 20

General Buttons 20

Selection buttons 20

Information buttons 21

Adjustment buttons 21

Keypad buttons 21

Color Active-Matrix LCD Touch Panels Table of Contents i

Page 4

Decision buttons 22

Status buttons 22

Designing a Touch Panel Page............................................ 23

Overview 23

Activating the Edit Button 23

Creating a Page 27

Adding a page 27

Setting the page color 29

Creating a Button 30

Adding a button 30

Resizing a button 32

Button Properties 33

Setting the button properties 33

Setting the border 34

Setting the channel code 35

Setting the variable text code 35

Setting the page flip 36

Setting the button colors for

channel-off conditions 37

Adding text to a button 38

Button Properties for External Buttons 41

Creating a Joystick 41

Adding a joystick to a page 41

Setting the joystick properties 45

Setting the channel code 46

Setting the level code 47

Setting the joystick colors for

channel-off conditions 47

Create a Bargraph 48

Adding a bargraph to a page 49

Setting the bargraph properties 51

Setting the channel code 51

Setting the level code 52

Setting the bargraph colors for

channel-off conditions 52

Linking the New Page to the Main Page 53

Exiting Edit Mode 57

Touch Panel Program Reference ......................................... 59

Overview 59

ii Table of Contents Color Active-Matrix LCD Touch Panels

Page 5

Setup Page 59

Beep 60

LCD timer 60

Set time and date 61

Double beep 62

AXlink, serial number, and vX.XX 62

Set brightness 63

Protected Setup 63

Show palette 63

Wireless settings (optional WAV-PKM) 64

Wireless settings (optional SMT-PK) 66

Protected Setup Page 67

Baud 68

Device base 68

Device used 69

Setup password 69

Mouse button 69

Power up page 70

Wake up message 71

Auto assign 71

Page password 72

Calibrate 72

Power up message 73

System page 73

Editor 76

Page tracking 77

Sleep message 77

Function show 78

Edit button 78

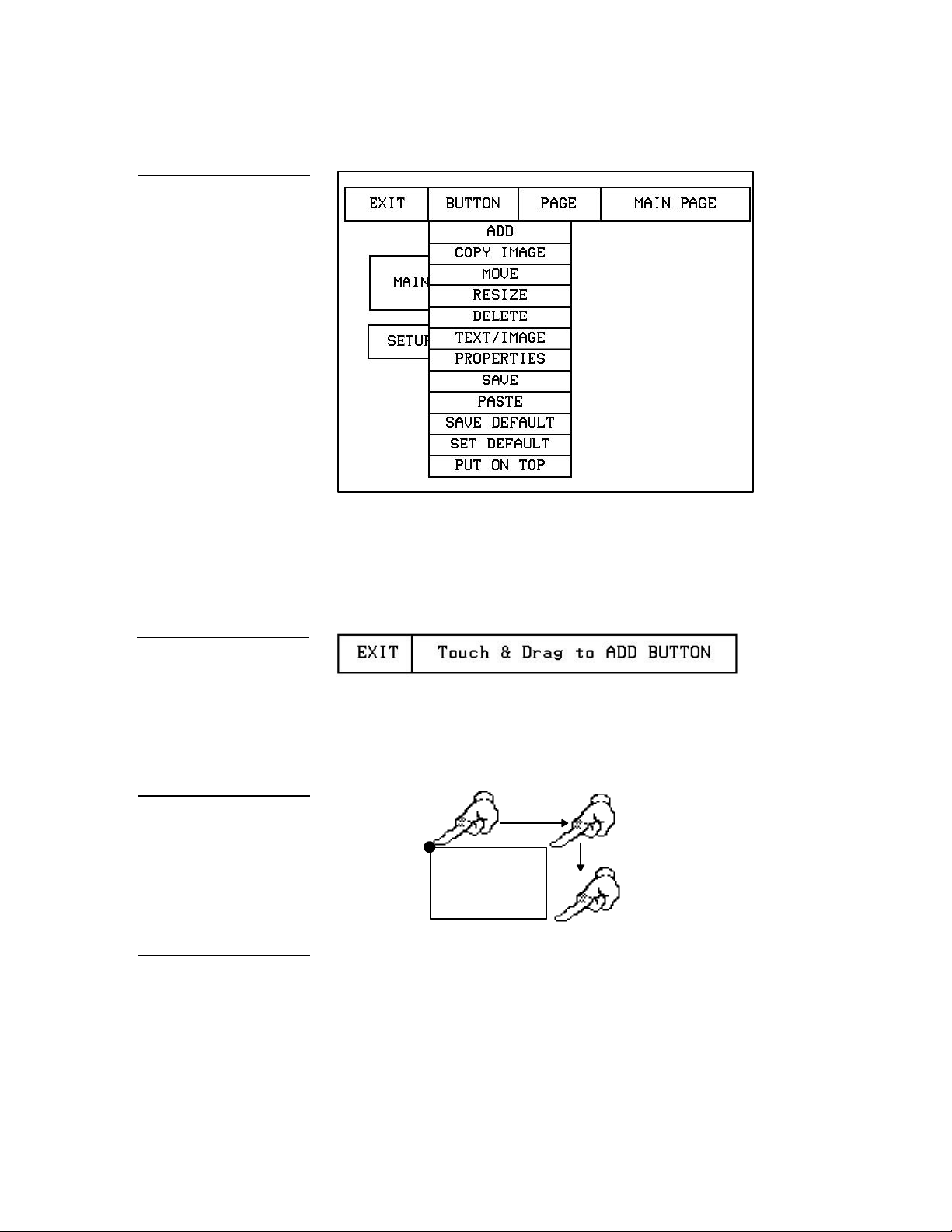

Edit Bar — Button Menu Options 80

Add 80

Copy image 81

Move 81

Resize 81

Delete 82

Text/Image 82

Properties 87

Save 95

Paste 95

Save default 96

Color Active-Matrix LCD Touch Panels Table of Contents iii

Page 6

Set default 97

Put on top 97

Properties Page — Button Type: General 97

Properties Page — Button Type: Joystick 101

Properties Page — Button Type: Vertical Bargraph 105

Properties Page — Button Type: Horizontal Bargraph 107

Edit Bar — Page Menu Options 109

Add 110

Copy 111

Rename 111

Delete 111

Page Color 112

Go to 113

Popup On 114

Popup Off 115

Move Edit 116

Snap Grid 117

AXCESS Programming .......................................................119

Overview 119

System Send_Commands 119

Colors and Programming Numbers 125

Font Styles and Programming Numbers 126

Border Styles and Programming Numbers 126

Shorthand Send_Commands 127

Color Send_Commands 132

Variable Text Send_Commands 134

Shorthand Variable Text Commands 137

Button String Commands 141

Firmware Upgrades............................................................143

Overview 143

AXT-CV and AXT-CA 143

AXU-CV(/PB), AXU-CA(PB), AXM-CV(/PB),

and AXM-CA(PB) 144

EXM-1MB Memory Upgrade................................................147

Operation 147

AXT-CV and AXT-CA 147

AXU-CV(/PB) and AXM-CV(/PB) 148

iv Table of Contents Color Active-Matrix LCD Touch Panels

Page 7

Color Guidelines ................................................................ 151

Overview 151

Colors 151

Specifications .................................................................... 153

Overview 153

AXT-CA and AXT-CV 153

AXU-CA(/PB) and AXU-CV(/PB) 154

AXM-CA(/PB) and AXM-CV(/PB) 155

Technical Support.............................................................. 157

Overview 157

Index .................................................................................159

Color Active-Matrix LCD Touch Panels Table of Contents v

Page 8

vi Table of Contents Color Active-Matrix LCD Touch Panels

Page 9

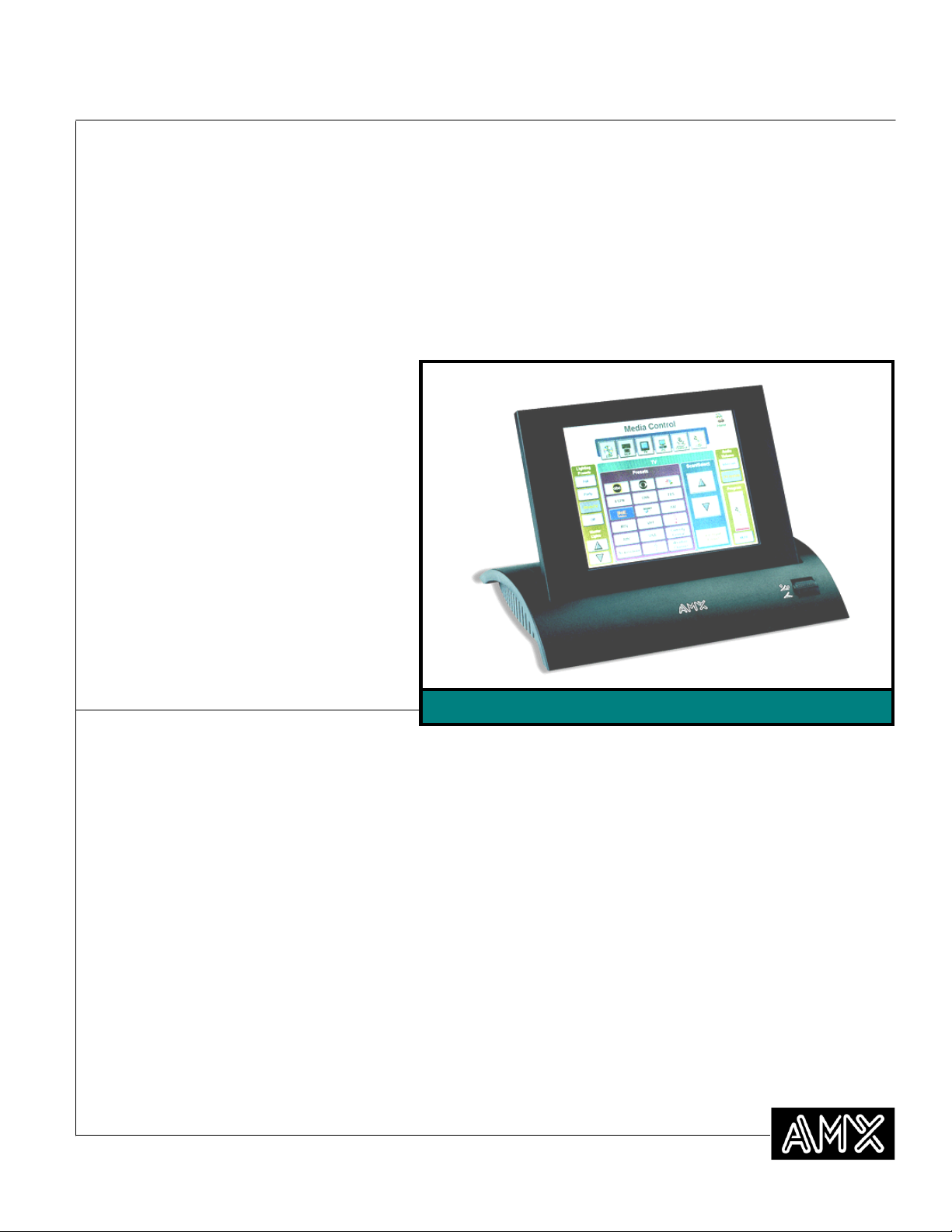

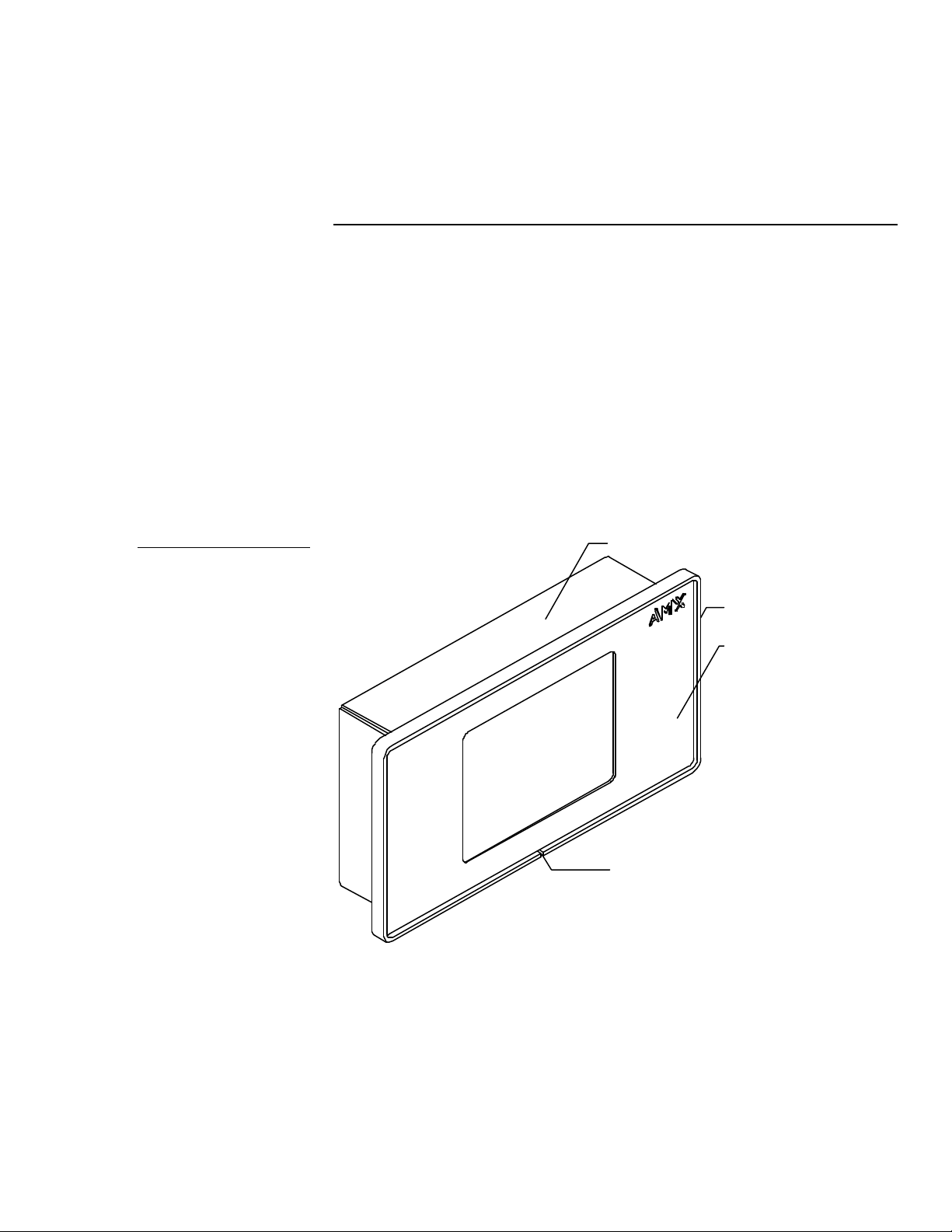

Figure 1

Color Active-Matrix

TiltScreen

Introduction

Overview

This manual describes procedures and software related to the new G3 firmware

installed in these panels. The Color Active-Matrix Touch Panels (CATPs) contain a

640 x 480 (HV) pixel, dedicated 256-color active-matrix liquid crystal display

(LCD). These self-contained enclosures use a microprocessor to control a wide

range of audiovisual products. With the TPDesign 3 custom Touch Panel design

program, you can create custom pages with buttons, icons, sliders, bargraphs, and

imported logos and drawings. Figure 1 shows an AXT-CA Color Active-Matrix

TiltScreen.

Figure 2 lists the panel types and product names described in this manual.

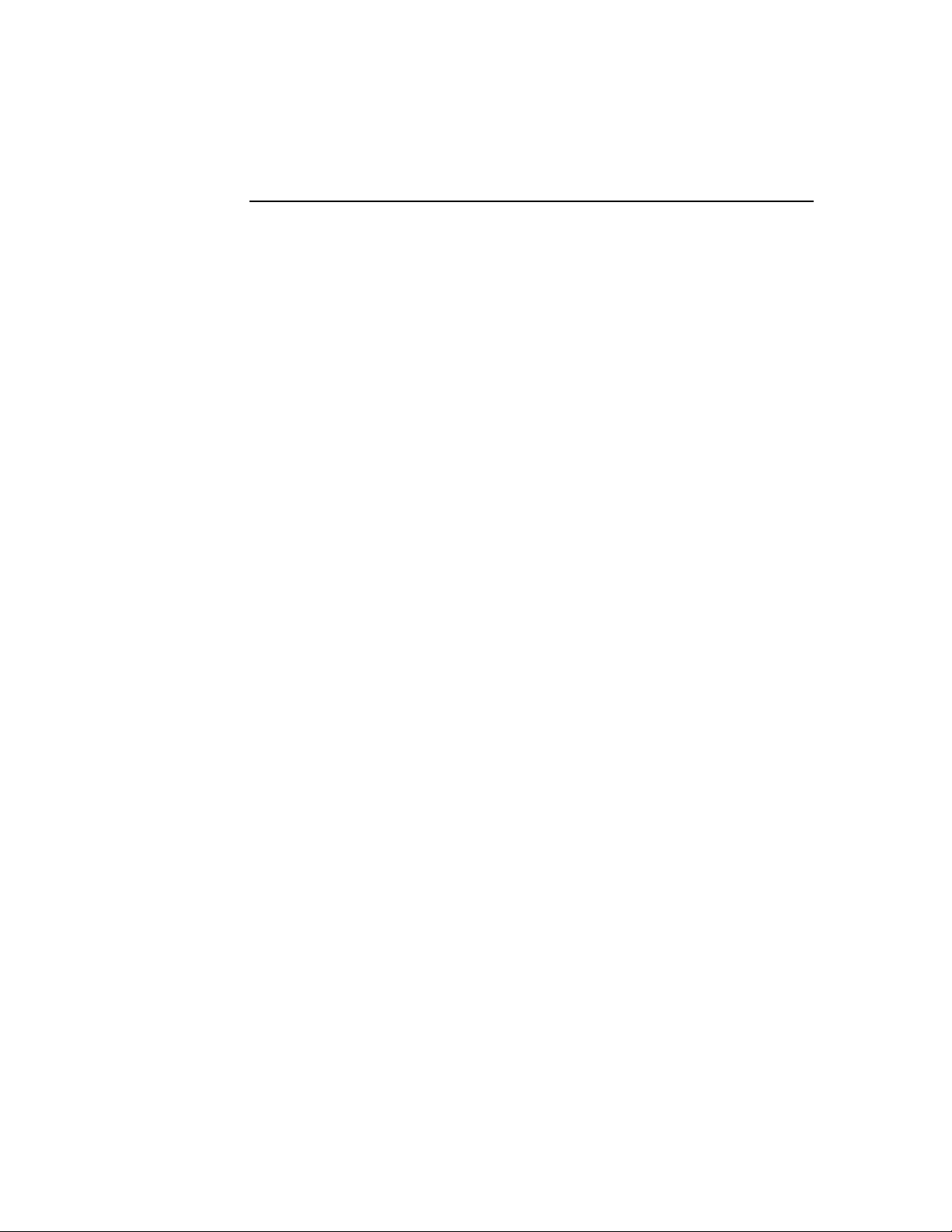

Figure 2

Color Active Touch Panel

types and product names

Color Active-Matrix LCD Touch Panels Introduction 1

Color Active Touch Panel types and product names

Panel types Product names

Standard Video Pushbutton

TiltScreen AXT-CA AXT-CV (not used)

UniMount AXU-CA AXU-CV AXU-CV/PB

AXU-CA/PB

Rack-mount AXM-CA AXM-CV AXM-CV/PB

AXM-CA/PB

Page 10

Features

and edited within TPDesign 3.

Touch Panel features include:

• 5.25" x 6.96" (133.45 mm x 176.89 mm) visible screen

• 256-color active-matrix 640 x 480 (HV) pixel LCD

• 12 programmable pushbuttons (8 on each side - except for the AXT series)

• Microsoft® mouse compatible (UniMount and rack-mount models only)

• Panel programming, screens, and drawings that can be archived with

TPDOC (MS-DOS) or designed with TPDesign 3 (Windows) touch panel

software program

• PAL- and NTSC-compatible video input port (optional)

• Optional two-way WavePack or one-way SmartPack modules for wireless

control (TiltScreen enclosure)

Note

These buttons with Unicode

Fonts can only be created

• Internal four-pin header for mouse control (UniMount and rack-mount

models only)

• Unicode Font support for Chinese and Arabic characters

2 Introduction Color Active-Matrix LCD Touch Panels

Page 11

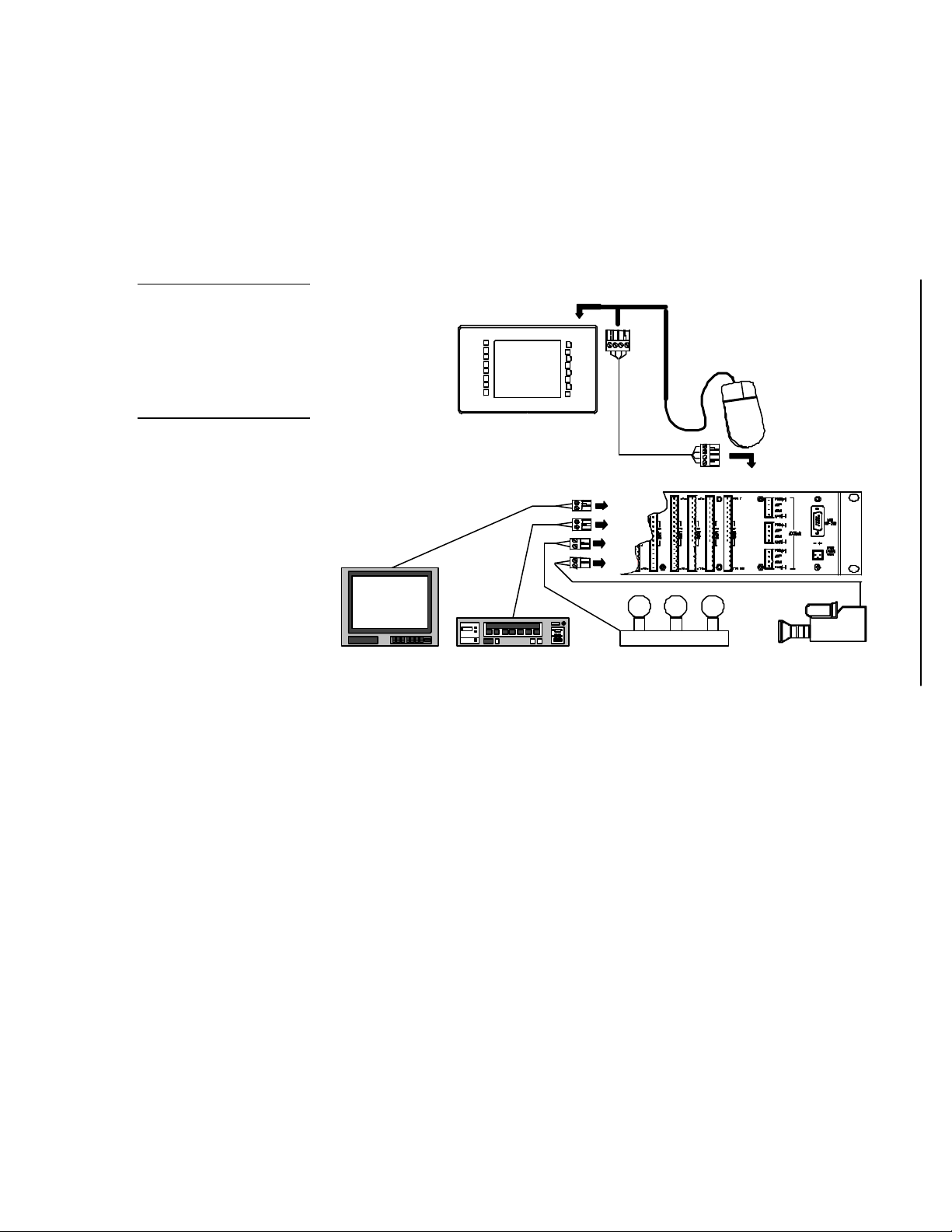

AXU-CA

(optional)

AXlink cable

AXCESS CardFrame

Television

VCR

Lighting

Camera

<<<< Factory installed connection

Figure 3

before installation.

Sample AXU-CA Touch Panel

and AXCESS Control System

Note

The optional mouse can be

used to design Touch Panel

pages and then removed

Applications

The AMX Color Active-Matrix Touch Panels control a wide variety of equipment

connected to an AXCESS Control System. Figure 3 shows a sample AXU-CA Touch

Panel and AXCESS Control System configuration.

Serial Mouse

What’s in this Manual

This manual contains the following sections:

• Installing the Touch Panel Includes installation, wiring, and cleaning

instructions.

• Touch Panel Basics Describes elements associated with the Touch Panel

operating system such as button types, message, and editor selection.

• Designing a Touch Panel Page Lists step-by-step instructions on how

to create a Touch Panel page, button, joystick, and bargraph.

• Touch Panel Program Reference Describes Touch Panel operations.

Color Active-Matrix LCD Touch Panels Introduction 3

Page 12

• AXCESS Programming Describes commands used to integrate Touch

Panel features into an AXCESS Control System.

• Replacing the Lithium Batteries Shows how to replace the lithium

batteries in the CATP.

• EXM-1MB Memory Upgrade Gives step-by-step instructions to install the

required EXM-1MB Memory Upgrade integrated circuits (ICs) in the CATP.

• Color Guidelines Provides helpful hints you can use to choose the best

Touch Panel colors.

• Specifications Describes the physical and operating characteristics of the

Touch Panels.

• Technical Support Identifies regions for technical support and provides

telephone numbers for each region.

What’s New

New sections added to this manual include:

• • Touch Panel Basics

• • Designing a Touch Panel Page

• • Touch Panel Program Reference

• • AXCESS Programming

All other revisions are identified by vertical margin bars as shown adjacent to this

paragraph.

4 Introduction Color Active-Matrix LCD Touch Panels

Page 13

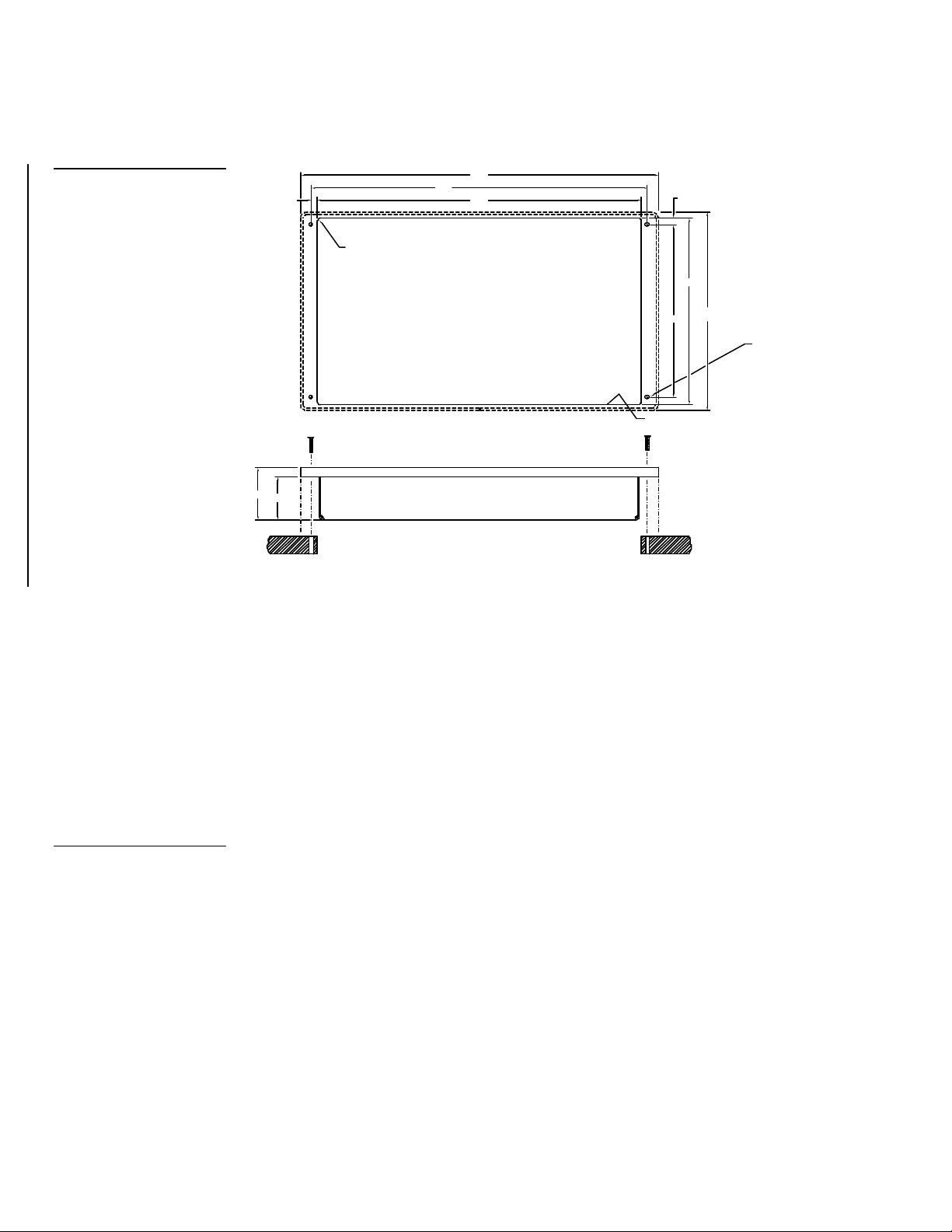

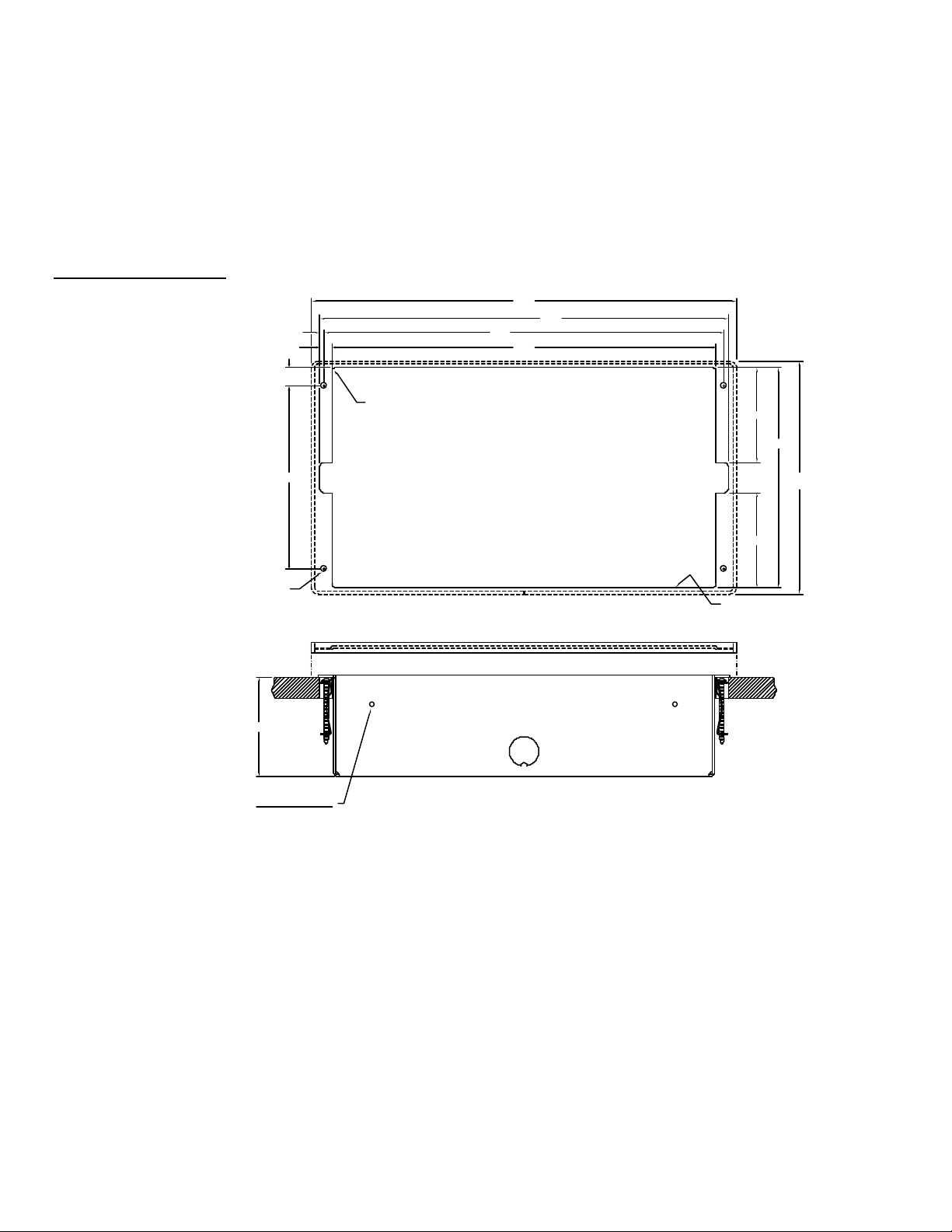

Low-profile back box

Release slot

Engraved

Figure 4

Installing Touch Panels

Overview

The section describes how to mount, wire, and clean Touch Panels.

Mounting the Touch Panels

The following paragraphs describe how to mount the UniMount and rack-mount

Touch Panels. The TiltScreen Touch Panel can be placed on any flat surface.

AXU-CV(/PB), AXU-CA(/PB), and low-profile back box

Mount the AXU-CV(/PB), AXU-CA(/PB), and low-profile back box (Figure 4):

AXU-CV(/PB) or AXUCA(/PB) and low-profile back

box

AXU-CV(/PB) or

AXU-CA(/PB)

bezel

1. Make a cutout in the surface according to the dimensions shown in Figure 5

for a low-profile back box.

Color Active-Matrix LCD Touch Panels Installing Touch Panels 5

Page 14

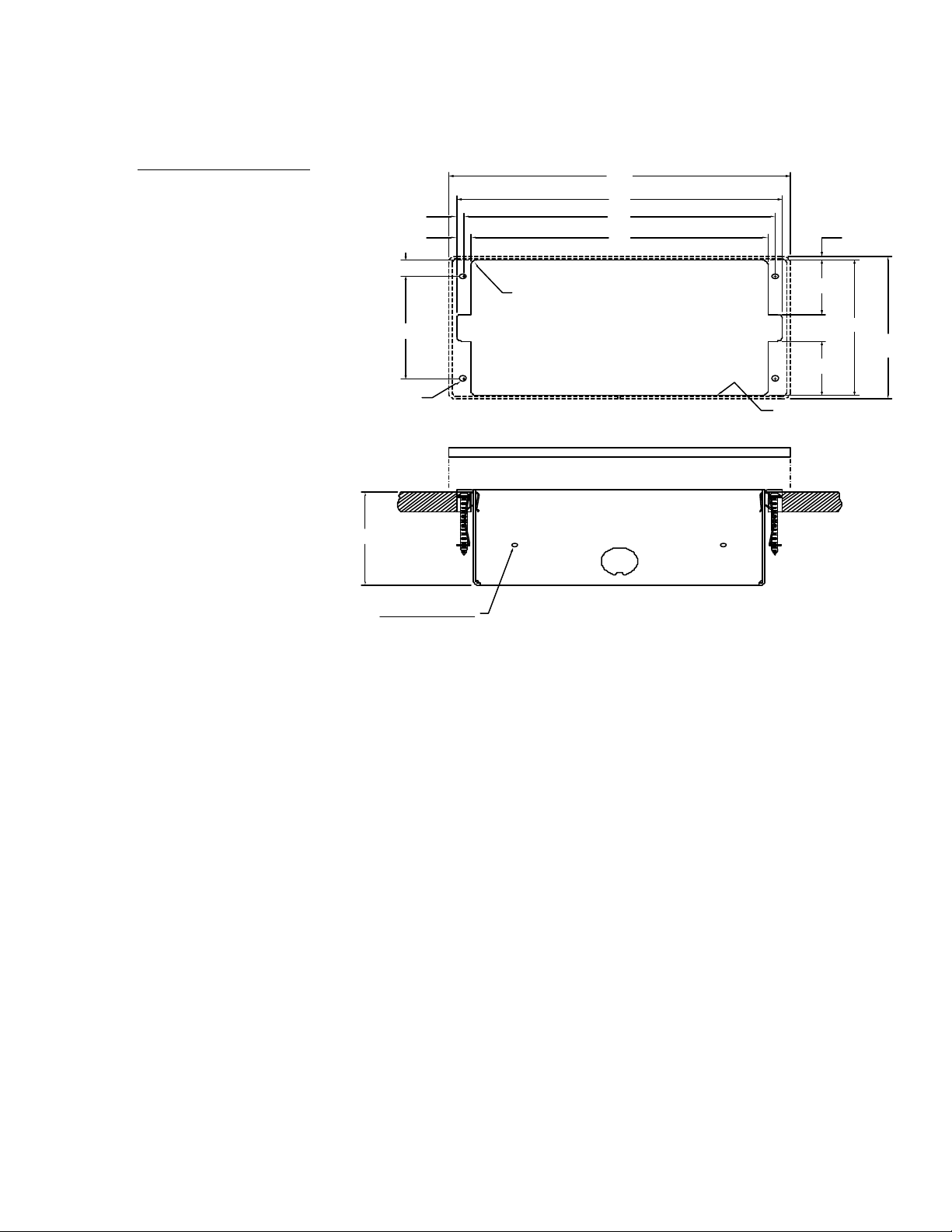

INSTALLATION METHOD

Figure 5

located at the bottom

AXU-CV(/PB) or AXUCA(/PB) and low-profile back

box cutout dimensions

12.60

(FRAME)

.23

.125 MAX RADIUS

IN CORNERS

1.79

1.48

11.85

11.40

CUTOUT

.25

6.50

6.88

(FRAME)

6.00

USE WHEN INSTALLING UNIT ON SOLID

SURFACES (PODIUM, DESK ETC.). FACE

FRAME AND LOW PROFILE BACKBOX

INSTALLED AS SINGLE "DROP-IN"

ASSEMBLY.

UNIT INSTALLS WITH

FOUR #6-32 SCREWS.

SUGGEST INSTALLATION

OF #6-32 THREADED

INSERTS AT LOCATIONS

SHOWN

Note

The CATP must always be

installed with the release slot

2. Insert a flat head screwdriver into the release slot on the AXU-CV(/PB)s or

AXU-CA(/PB)’s bezel and remove the engraved overlay.

3. Place the AXU-CV(/PB) or AXU-CA(/PB) into the cutout and mark the screw

insert positions as shown in Figure 4.

4. Remove the AXU-CV(/PB) or AXU-CA(/PB) and drill four #6-32 insert holes.

Then, place a threaded insert into each hole.

5. Attach the data and power wiring to the AXU-CV(/PB) or AXU-CA(/PB). Refer

to Wiring the Touch Panels for wiring diagrams and pinout descriptions.

6. Fasten the AXU-CV(/PB) or AXU-CA(/PB) and low-profile back box to the

surface using the #6-32 machine screws supplied with the enclosure.

7. Insert the engraved overlay back into the bezel.

8. Connect the AXlink wiring to the AMX Central Controller, and RS-232 wiring

(optional) to the external RS-232 device. The AXU-CV(/PB) or AXU-CA(/PB)

will beep when you apply power.

6 Installing Touch Panels Color Active-Matrix LCD Touch Panels

Page 15

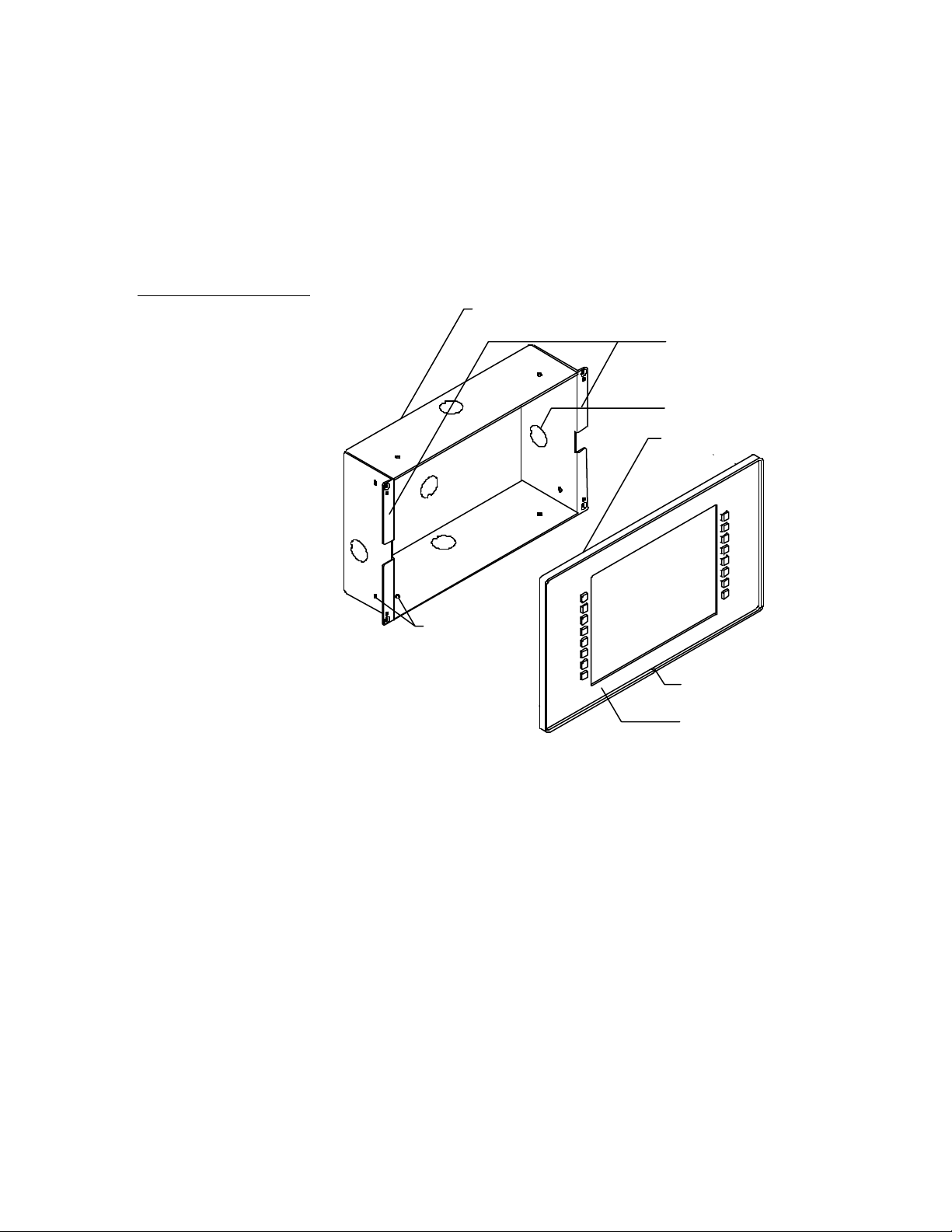

Release slot

flanges

Knockout

BB-TP1 UniMount Back Box enclosure

AXU-CA/PB bezel

Engraved overlay

holes

Figure 6

AXU-CV(/PB) or AXU-CA(/PB) and BB-TP1 (solid surfaces)

Mount the AXU-CV(/PB) or AXU-CA(/PB) and BB-TP1 (Figure 6) into a solid

surface:

AXU-CV/PB or AXU-CA/PB

and BB-TP1 UniMount Back

Box enclosure for solid

surfaces

Solid surface mounting

AXU-CV/PB or

Stud mounting

1. Cut the solid surface according to the cutout dimensions shown in Figure 7.

Color Active-Matrix LCD Touch Panels Installing Touch Panels 7

2. Insert a flat head screwdriver into the release slot on the AXU-CV(/PB) or

AXU-CA(/PB)’s bezel and remove the engraved overlay.

Page 16

THIRD ANGL

used as the basis for manufacture

INSTA

EASIL

PERM

EXPAN

SHEE

USE W

OF BACK BOX FOR STUD MOUNTING.

THIRD ANGLE

used as the basis for manufacture

INSTALLATION METH

USE WHEN INSTALLING UNIT ON SOLID

SURFACES (PODIUM, DESK ETC.). ALLO

PERMANENT INSTALLATION OF BACK B

WITH FACE FRAME AND ELECTRONICS

OF BACK BOX FOR STUD MOUNTING.

MOUNTING / MILLWORK S

AXU-CV COLOR ACTIVE W

(BACKBOX SECURED WIT

Mounting with Expansion Clips

Mounting with Screws

Figure 7

AXU-CV(/PB) or AXUCA(/PB), and BB-TP1 cutout

dimensions

12.60

(FRAME)

12.10

11.85.125

11.40.35

.55

.125 MAX RADIUS

IN CORNERS

2.80

6.50

5.40

.187 DIA

4 HOLES

2.94

STUD MOUNTING OPTION:

TWO .170 DIA HOLES PROVIDED ON ALL SIDES

.23

B

.55

A

.125 MAX RADIUS

IN CORNERS

5.40

6.88

(FRAME)

2.80

CUTOUT

WITH

NOTICE: This drawing is the property

of AMX CORPORATION. All information

contained herein that is not generally

known shall be confidential except to

the extent the information has been

previously established. This drawing

.25

6.50

may not be reproduced, copied or

6.88

(FRAME)

A RELEASED TO PRODUCTION

12.60

(FRAME)

11.85

11.40

B

A

6.00

DRAWN

CHECKED

APPD ENG

APPD QC

APPD MFG

DESCRIPTIONREV

UNIT INSTALLS WITH

FOUR #6-32 SCREWS.

SUGGEST INSTALLATION

OF #6-32 THREADED

INSERTS AT LOCATIONS

SHOWN (MARKED "B")

8 Installing Touch Panels Color Active-Matrix LCD Touch Panels

A

.187 DIA

4 HOLES

(MARKED "A")

2.94

STUD MOUNTING OPTION:

TWO .170 DIA HOLES PROVIDED ON ALL SIDES

B

A

B

CUTOUT

NOTICE: This drawing is the property

of AMX CORPORATION. All information

contained herein that is not generally

known shall be confidential except to

the extent the information has been

previously established. This drawing

may not be reproduced, copied or

EASILY REMOVABLE FOR SERVICING.

DRAWN

AM 6/21/96

CHECKED

APPD ENG

APPD QC

APPD MFG

DWG. NO.SIZE

SP094104

C

Page 17

3. Lay the AXU-CV(/PB) or AXU-CA(/PB) facedown onto a soft cloth and

remove the four screws from the low-profile back box. Remove the back box

and discard.

Note

The CATP must always be

installed with the release slot

located at the bottom.

Note

The BB-TP1 can also be

mounted to wood or metal

studs using the pre-drilled

stud mounting holes.

4. Place the BB-TP1 into the cutout and mark the threaded insert positions as

shown in Figure 7.

5. Remove the BB-TP1 and drill eight holes as shown in Figure 6. Then, place #6-

32 threaded inserts into the four holes marked ‘B’ in the cutout dimensions

illustration.

6. Disconnect the AXlink connector from the control system that supplies power

and data to the AXU-CV(/PB) or AXU-CA(/PB). Then, disconnect the DB-9

connector from the external RS-232 device connected to the AXU-CV(/PB) or

AXU-CA(/PB).

7. Remove one or more knockouts to accommodate the wiring as required.

8. Thread the incoming AXlink and RS-232 wiring through the BB-TP1 knockout.

9. Fasten the BB-TP1 to the solid surface with the mounting screws supplied with

the enclosure.

10. Connect the AXlink and RS-232 wiring to the AXU-CV(/PB) or AXU-CA(/PB)

circuit card. Refer to Wiring the Touch Panel for complete wiring information.

11. Fasten the AXU-CV(/PB) or AXU-CA(/PB) to the BB-TP1 with the #6-32

screws provided with the enclosure.

12. Insert the engraved overlay back into the bezel.

13. Connect the AXlink wiring to the AMX control system and RS-232 wiring to

the external RS-232 device. The AXU-CV(/PB) or AXU-CA(/PB) will beep

when you apply power.

Color Active-Matrix LCD Touch Panels Installing Touch Panels 9

Page 18

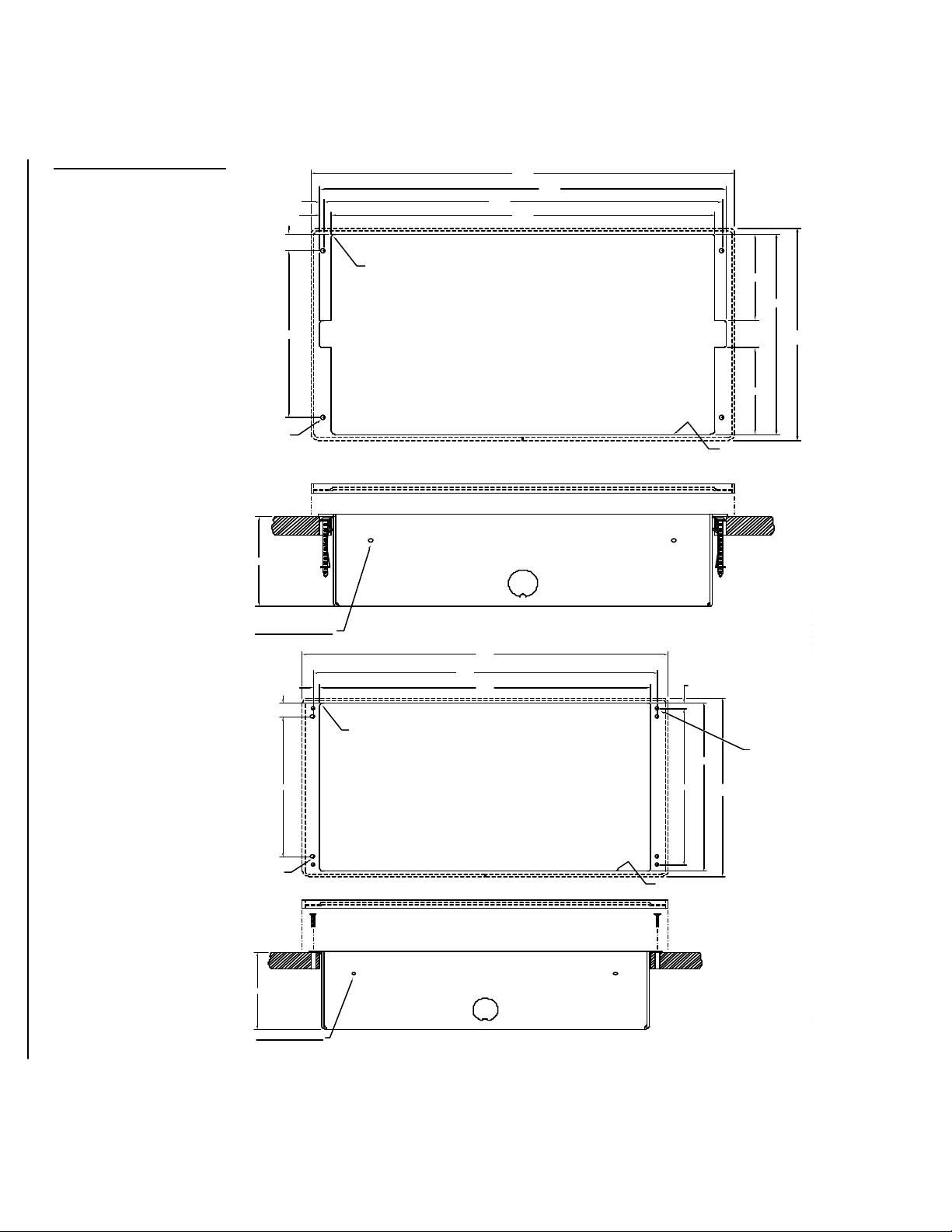

AXU-CV(/PB) or AXU/CA(/PB) and BB-TP1 (plasterboard)

OF BACK BOX FOR STUD MOUNTING.

Mount the AXU-CV(/PB) or AXU-CA(/PB) and BB-TP1 (Figure 8) into a

plasterboard surface (or equivalent).

Figure 8

AXU-CV/PB and BB-TP1 for

plasterboard

2.94

.187 DIA

4 HOLES

12.60

(FRAME)

11.85.125

.55

.125 MAX RADIUS

IN CORNERS

5.40

12.10

11.40.35

2.80

6.50

6.88

(FRAME)

2.80

CUTOUT

10 Installing Touch Panels Color Active-Matrix LCD Touch Panels

STUD MOUNTING OPTION:

TWO .170 DIA HOLES PROVIDED ON ALL SIDES

1. Cut the surface according to the cutout dimensions shown in Figure 9.

Page 19

.125 [3.2 MM] MAX

CUTOUT

TWO .170 [4.3 MM] DIA HOLES PROVIDED ON

2.94

1.70

1.70

.125

4.25

7.10

7.46

7.80

.35

.170

.52

3.22

(FRAME)

(FRAME)

[74.7 MM]

[8.9 MM]

[180.3 MM]

8.187

4.50

Figure 9

AXU-CV(/PB) or AXUCA(/PB), and BB-TP1 cutout

dimensions

2. Insert a flat head screwdriver into the release slot on the AXU-CV(/PB)’s or

AXU-CA(/PB)’s bezel and remove the engraved overlay.

3. Lay the AXU-CV(/PB) or AXU-CA(/PB) facedown onto a soft cloth and

remove the four screws from the low-profile back box. Remove the back box

and discard.

4. Place the BB-TP1 into the cutout and mark the threaded insert positions as

shown in Figure 9.

5. Remove the BB-TP1 and drill four #6-32 insert holes. Then, place a threaded

insert into each hole.

6. Disconnect the AXlink connector from the AMX Central Controller that

supplies power and data to the AXU-CV(/PB) or AXU-CA(/PB). Then,

disconnect the DB-9 connector from the external RS-232 device connected to

the AXU-CV(/PB) or AXU-CA(/PB).

7. Thread the incoming AXlink and RS-232 wiring through the BB-TP1 knockout.

Color Active-Matrix LCD Touch Panels Installing Touch Panels 11

Page 20

Note

The CATP must always be

installed with the release slot

located at the bottom.

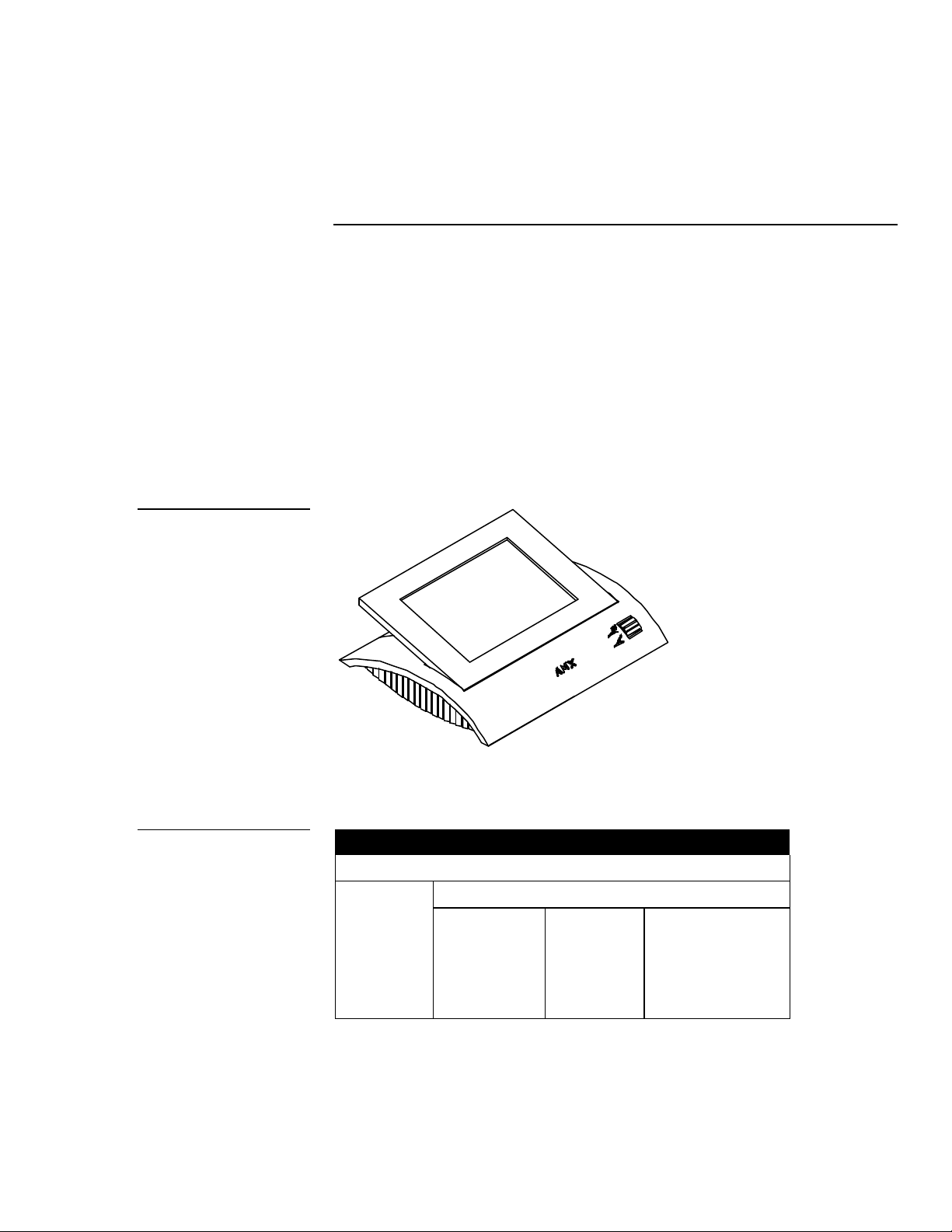

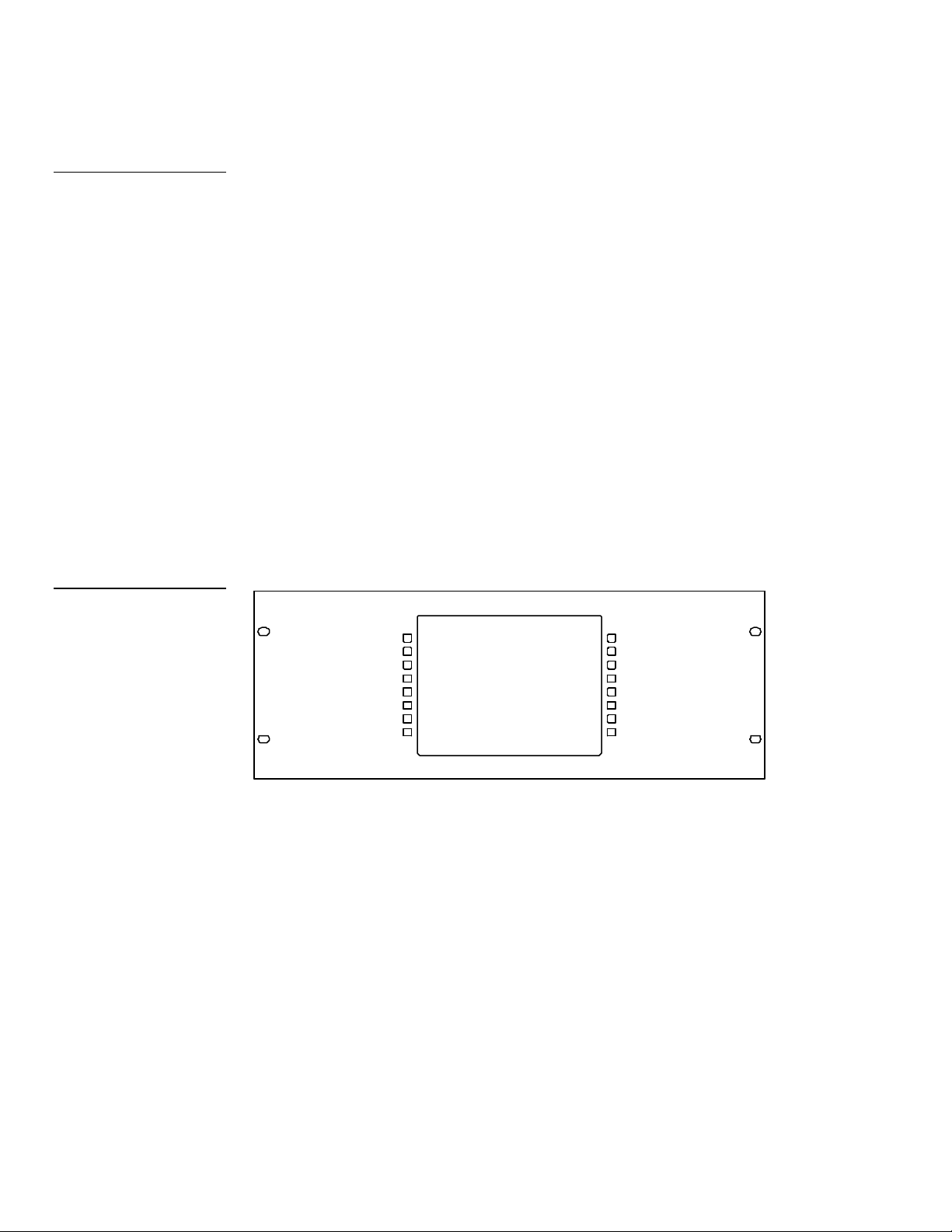

Figure 10

AXM-CV(/PB) or AXMCA(/PB) Rack-Mount CATP

8. Fasten the BB-TP1 to the plasterboard using the expansion screws supplied

with the enclosure.

9. Connect the AXlink and RS-232 wiring to the AXU-CV(/PB) or AXU-CA(/PB)

circuit card. Refer to Wiring the Touch Panel for complete wiring information.

10. Fasten the AXU-CV(/PB) or AXU-CA(/PB) to the BB-TP1 with the #6-32

screws supplied with the enclosure.

11. Insert the engraved overlay back into the bezel.

12. Connect the AXlink wiring to the AMX Central Controller and RS-232 wiring

to the external RS-232 device. The AXU-CV(/PB) or AXU-CA(/PB) will beep

when you apply power.

AXM-CV(/PB) or AXM-CA(/PB) (rack-mount)

Mount the AXM-CA(/PB) or AXM-CA(/PB) (Figure 10) rack-mount into an

electronic equipment rack.

1. Thread the incoming AXlink and RS-232 (optional) wiring through the

opening in the equipment rack.

2. Disconnect the AXlink connector from the AMX Central Controller that

supplies power and data to the AXM-CV(/PB) or AXM-CA(/PB). Then,

disconnect the DB-9 connector from the external RS-232 device connected to

the AXU-CV(/PB) or AXM-CA(/PB).

3. Connect the AXlink and RS-232 wiring to the AXM-CV(/PB) circuit card. Refer

to Wiring the Touch Panel for complete wiring information.

12 Installing Touch Panels Color Active-Matrix LCD Touch Panels

Page 21

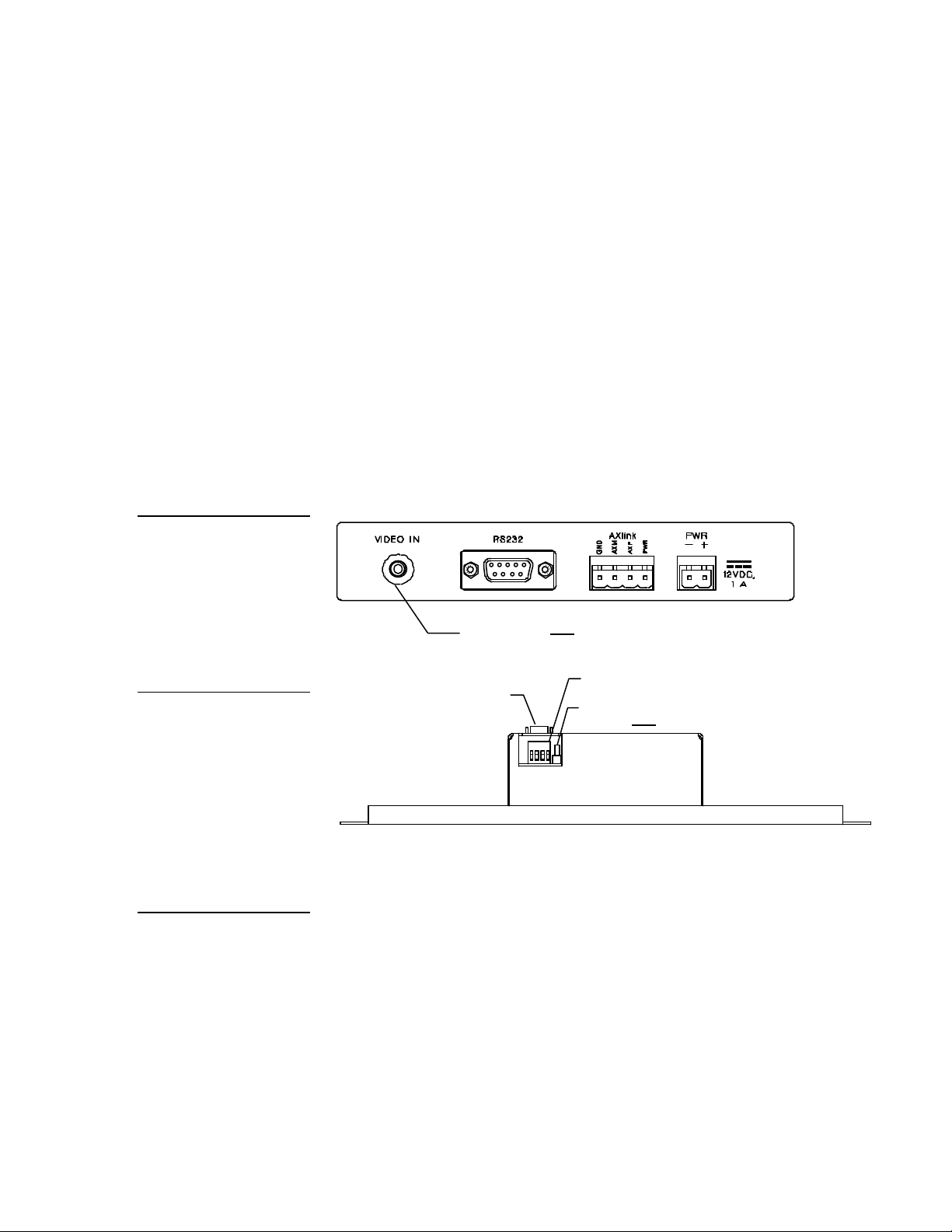

Rear view

Video models only

Top view

4-pin (male) AXlink connector

RS-232 (male) connector

models only

Figure 11

(rear view)

complete.

TiltScreen Color and Video

Touch Panel connectors

4. Insert the AXM-CV(/PB) or AXM-CA(/PB) into the rack. Line up the top left

and right screw holes and start the #6-32 screws. Then, start the bottom left

and right screws. Tighten all the screws after you start all the screws.

5. Connect the AXlink wiring to the AMX Central Controller and RS-232 wiring

to the external RS-232 device. The AXM-CV(/PB) or AXM-CA(/PB) will beep

when you apply power.

Wiring the Touch Panels

The CATPs use a four-pin AXlink connector for power and data. Figure 11 shows

the rear panel AXlink connector on the TiltScreen color active and color video

touch panels. Figure 12 shows the rear panel AXlink connector on the UniMount

and rack-mount color active and color video touch panels.

Figure 12

Rack-Mount CATP

connectors (top view)

Caution

Do not connect power to the

Touch Panel until the wiring is

complete. If you are using a

12 VDC power supply, apply

power to the Touch Panel

only after installation is

RCA Video connector - video

Preparing captive wires

You will need a wire stripper and flat-blade screwdriver to prepare and connect

the captive wires.

1. Strip 0.25 inch (6.35 mm) of wire insulation off all wires.

Color Active-Matrix LCD Touch Panels Installing Touch Panels 13

Page 22

2. Insert each wire into the appropriate opening on the connector according to

the connector.

Specifications section.

the wiring diagrams and connector types described in this section.

Caution

Do not over-torque the

screw. Doing so can bend

the seating pin and damage

Figure 13

Wiring guidelines 800 mA.

See the Specifications

section for power information.

Note

For information on the maximum power consumption of

each device, see the

3. Turn the flat-blade screws clockwise to secure the wire in the connector.

Wiring guidelines

Touch Panels require regulated 12 VDC power to operate properly. The AXCESS

Central Controller supplies power via the AXlink cable. The maximum wiring

distance between the control system and Touch Panel is determined by power

consumption, supplied voltage, and the wire gauge used for the cable. Figure 13

lists wire sizes and the maximum lengths allowable between the Touch Panel and

control system. The maximum wiring lengths for using AXlink power are based on

a minimum of 13.5 volts available at the control system’s power supply.

Wiring guidelines for Touch Panel (800 mA)

Wire size Maximum wiring length

18 AWG 146.71 feet (44.71 m)

20 AWG 92.8 feet (28.29 m)

22 AWG 57.9 feet (17.65 m)

24 AWG 34.5 feet (10.52 m)

If you install the Touch Panel farther away from the control system than

recommended in Figure 13, connect an external 12 VDC power supply as shown in

the wiring diagrams in this section.

14 Installing Touch Panels Color Active-Matrix LCD Touch Panels

Page 23

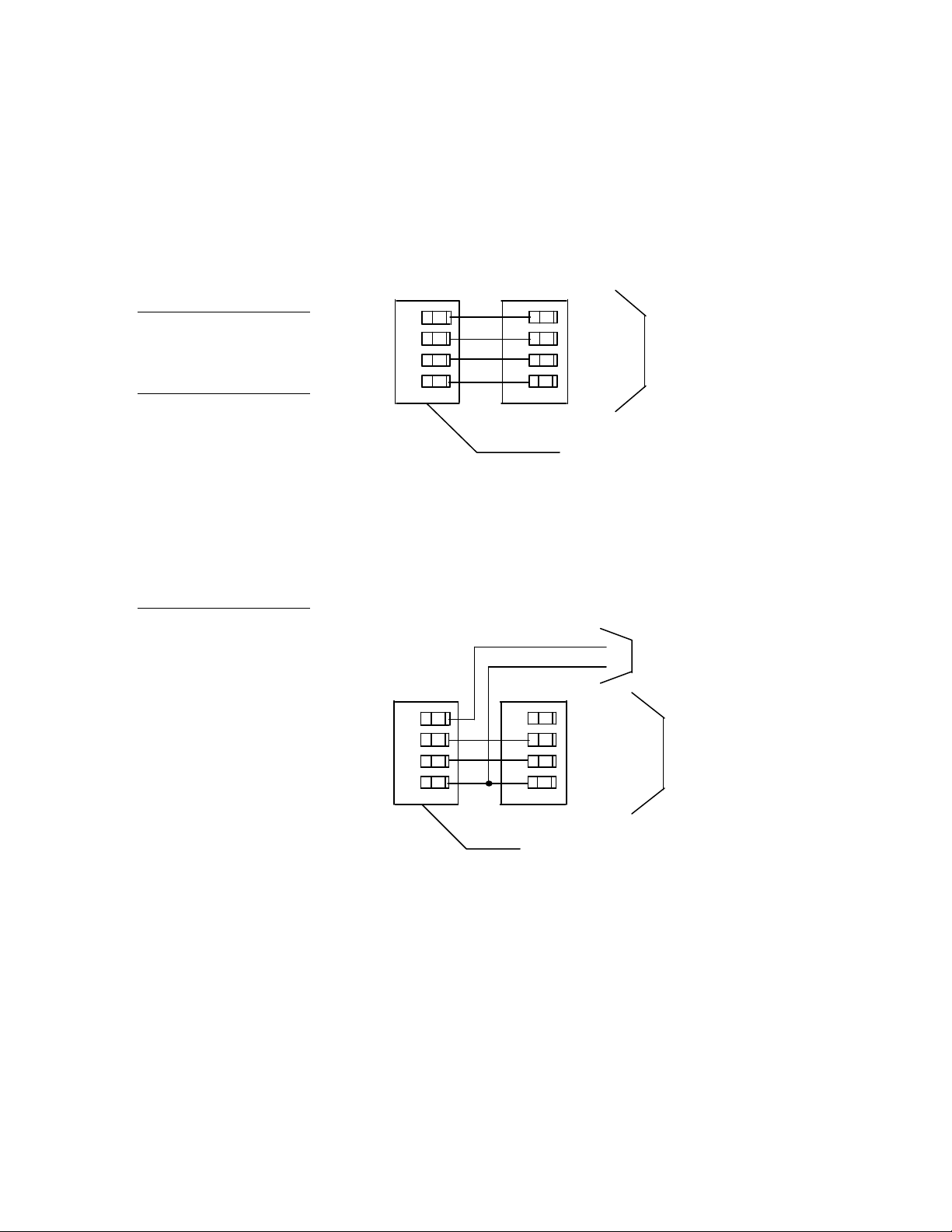

PWR (+)

AXM

AXP

GND (-)

Control system

PWR (+)

AXM

AXP

GND (-)

PWR (+)

AXM

AXP

GND (-)

PWR (+)

AXM

AXP

GND (-)

Control system

12 VDC power supply

PWR (+)

GND (-)

Touch Panel.

Figure 14

AXlink wiring diagram

Caution

Using the AXlink connector for data and power

Connect the control system’s AXlink connector to the AXlink connector on the rear

of the Touch Panel for data and 12 VDC power as shown in Figure 14.

If you are using power from

AXlink, disconnect the wiring

from the AXCESS Central

Controller before wiring the

Figure 15

AXlink and external 12 VDC

power supply wiring diagram

AXlink connector

Using the AXlink connector with an external 12 VDC power supply

Connect the control system’s AXlink connector to the AXlink connector on the rear

panel of the Touch Panel as shown in Figure 15.

AXlink connector

Use an external 12 VDC power supply when the distance between the control

system and Touch Panel exceeds the limits described in Figure 13. Make sure to

connect only the GND wire on the AXlink connector when using an external 12

VDC power supply. Do not connect the PWR wire to the AXlink connector’s PWR

(+) terminal.

Color Active-Matrix LCD Touch Panels Installing Touch Panels 15

Page 24

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNETNETNET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NETNETNETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNETNETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NETNETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNETNETNETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NETNETNET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NETNET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

VIA_PADSTACK

NET

COMPONENTCOMPONENTCOMPONENT

1411B2B1U24U1P1U3U19

U4J2J4

J2A

header

Connector side of circuit card

DB-9 connector (male)

TXD

RXD

GND

+12VDC

4 and 7 (+12)

3 (RXD)

5 (GND)

2 (TXD)

Pin 1

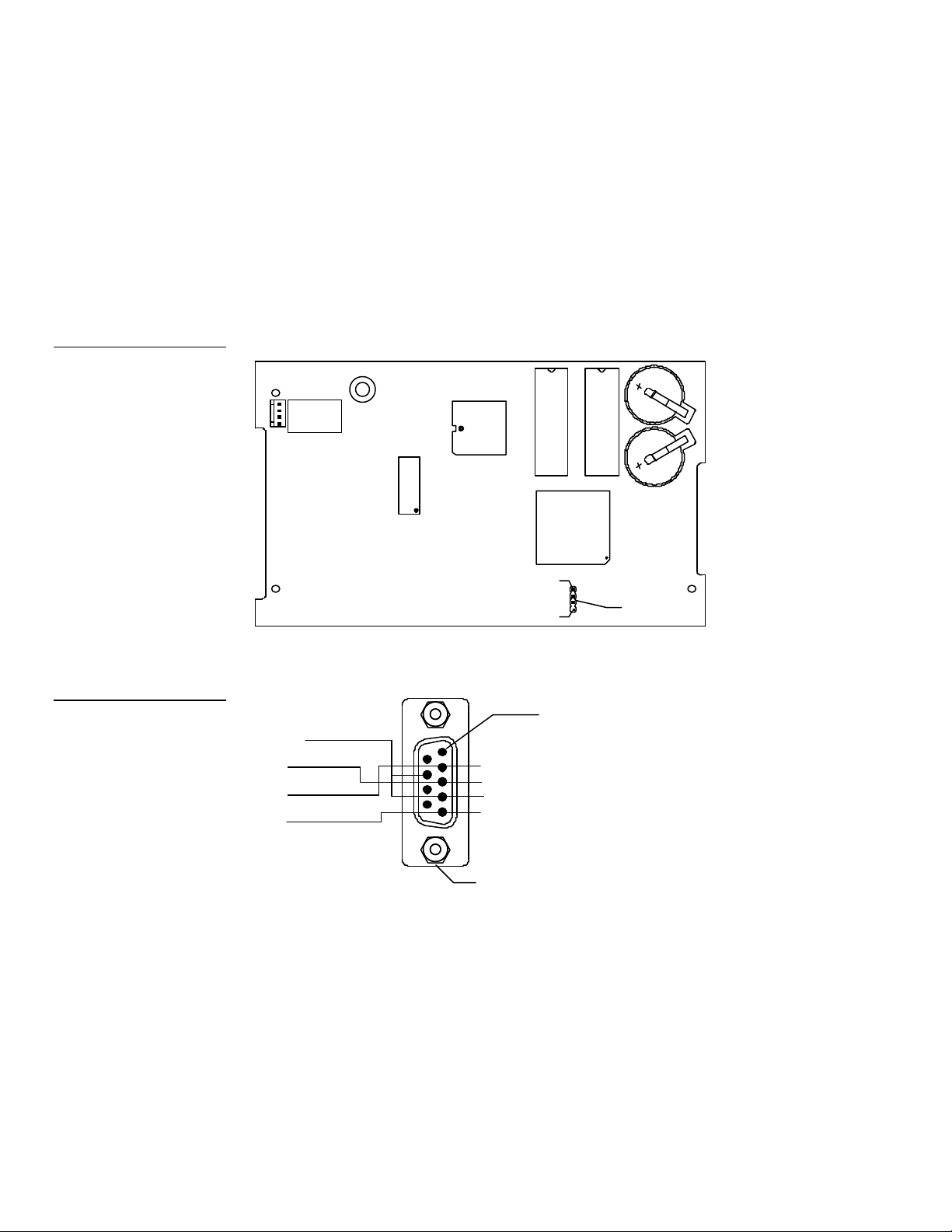

Figure 16

Four-pin header location on

the UniMount and rack-mount

Touch Panel circuit card

Using the UniMount and rack-mount 4-pin header for mouse control

Figure 16 shows the location of the four-pin header on the UniMount and rackmount Touch Panels. The four-pin header supports Microsoft serial mouse control

devices. Figure 17 for DB-9 wiring diagram. Figure 18 lists the four-pin header and

DB-9 connector (male) pinouts

4-pin

Figure 17

Circuit connector wiring

diagram

16 Installing Touch Panels Color Active-Matrix LCD Touch Panels

Page 25

Figure 18

Four-pin header and DB-9

connector pinouts

Four-pin header and DB-9 connector pinouts

Fourpin

header

Signal Function DB-9 connector (male)

pins

1 PWR +12 VDC power 4 and 7 (strap)

2 TXD Transmit data 3

3 RXD Receive data 2

4 GND Ground 5

Cleaning the Touch Overlay

After installing the Touch Panel, you should clean the touch overlay. To clean the

touch overlay:

1. Disconnect the AXlink and optional video connectors from the CATP.

2. Using a cotton cloth, spray a small amount of cleaning solution consisting of

50% isopropyl alcohol and 50% water onto the cloth.

3. Clean the touch overlay with the damp cloth. Then, wipe the touch overlay

with a dry cloth.

4. Reconnect the AXlink and optional video connectors to the CATP.

Color Active-Matrix LCD Touch Panels Installing Touch Panels 17

Page 26

18 Installing Touch Panels Color Active-Matrix LCD Touch Panels

Page 27

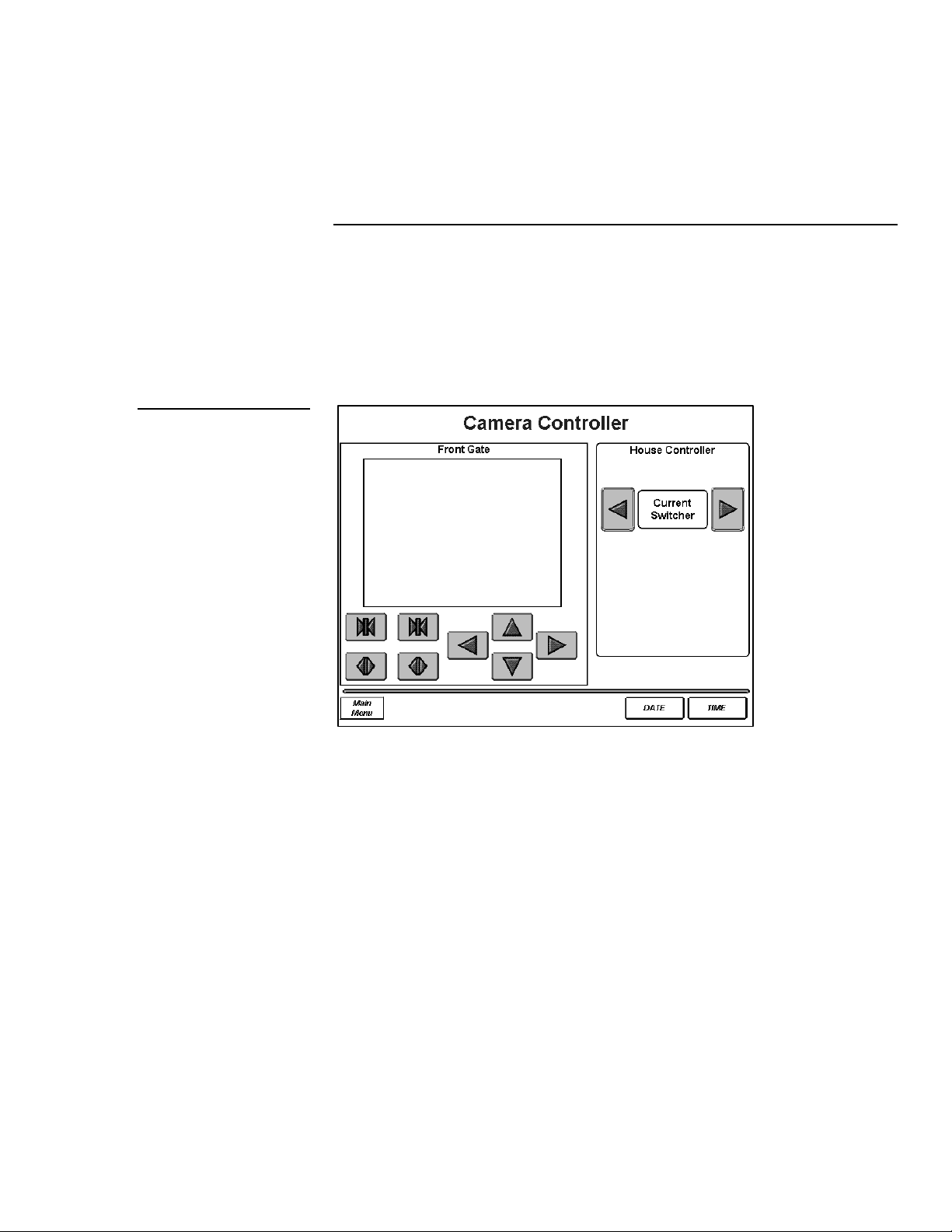

Figure 19

Sample Touch Panel page

Touch Panel Basics

Overview

This section contains descriptions and illustration examples of Touch Panel pages

(Figure 19), buttons, message bars, and keypads. You can use the Touch Panel’s

onboard editor or the TPDesign 3 software program to create custom pages.

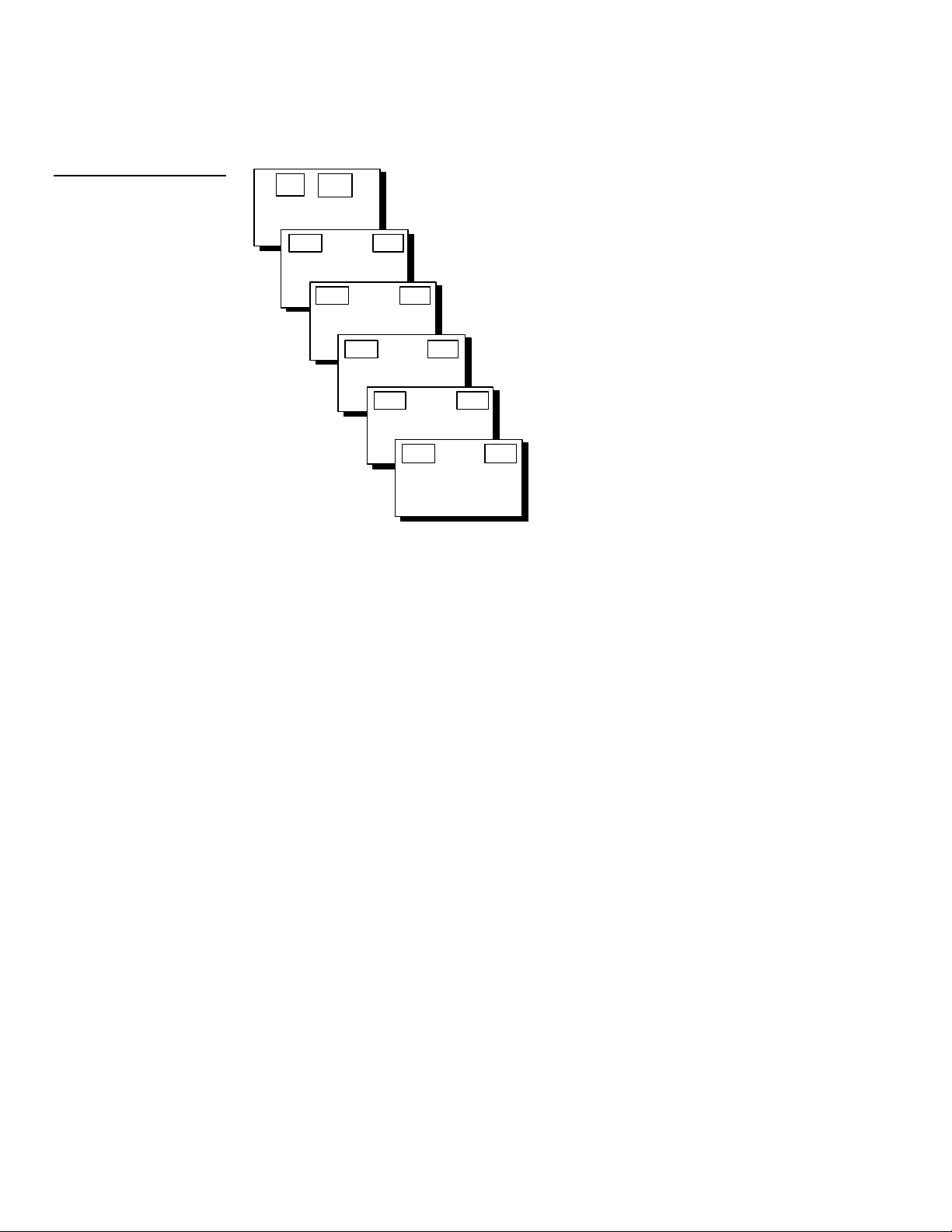

Touch Panel Pages

You can create buttons, bargraphs, sliders, and drawings with the Touch Panel

editor. The number of objects depends on the type and quantity of external devices

you want to control with the Touch Panel and AXCESS Central Controller. When

you create multiple pages, you must link them with buttons. Figure 20 shows how

five Touch Panel pages are linked to the Main page. The illustration shows how

each page has a button that flips to the next page, and one that flips back to the

previous page.

Color Active-Matrix LCD Touch Panels Touch Panel Basics 19

Page 28

Main Page

Page

Page 2

Page 3

Page 1

Page 4

Page 2

Page 5

Page 3

Page 4

Page 1

Figure 20

linked buttons

Touch Panel pages with

Main

Main

Page 1

Page 2

Page 3

Page 4

Main

Page 5

Standard Buttons

Standard buttons are rectangles, rectangle variations, and other geometric shapes

that you can create with the Touch Panel. Buttons are set with attributes, which

means that there is control system feedback when you touch the button.

General Buttons

General buttons are part of the Touch Panel program and cannot be changed. You

use general buttons to specify panel communication parameters and create or

revise pages. Some button examples include the message bar, adjustment, keypad,

page menu, decision, status, and keyboard.

Selection buttons

Selection buttons (Figure 21) appear throughout the color active and color active

video Touch Panel software program to open pages, activate YES/NO prompt

messages or set communication parameters.

20 Touch Panel Basics Color Active-Matrix LCD Touch Panels

Page 29

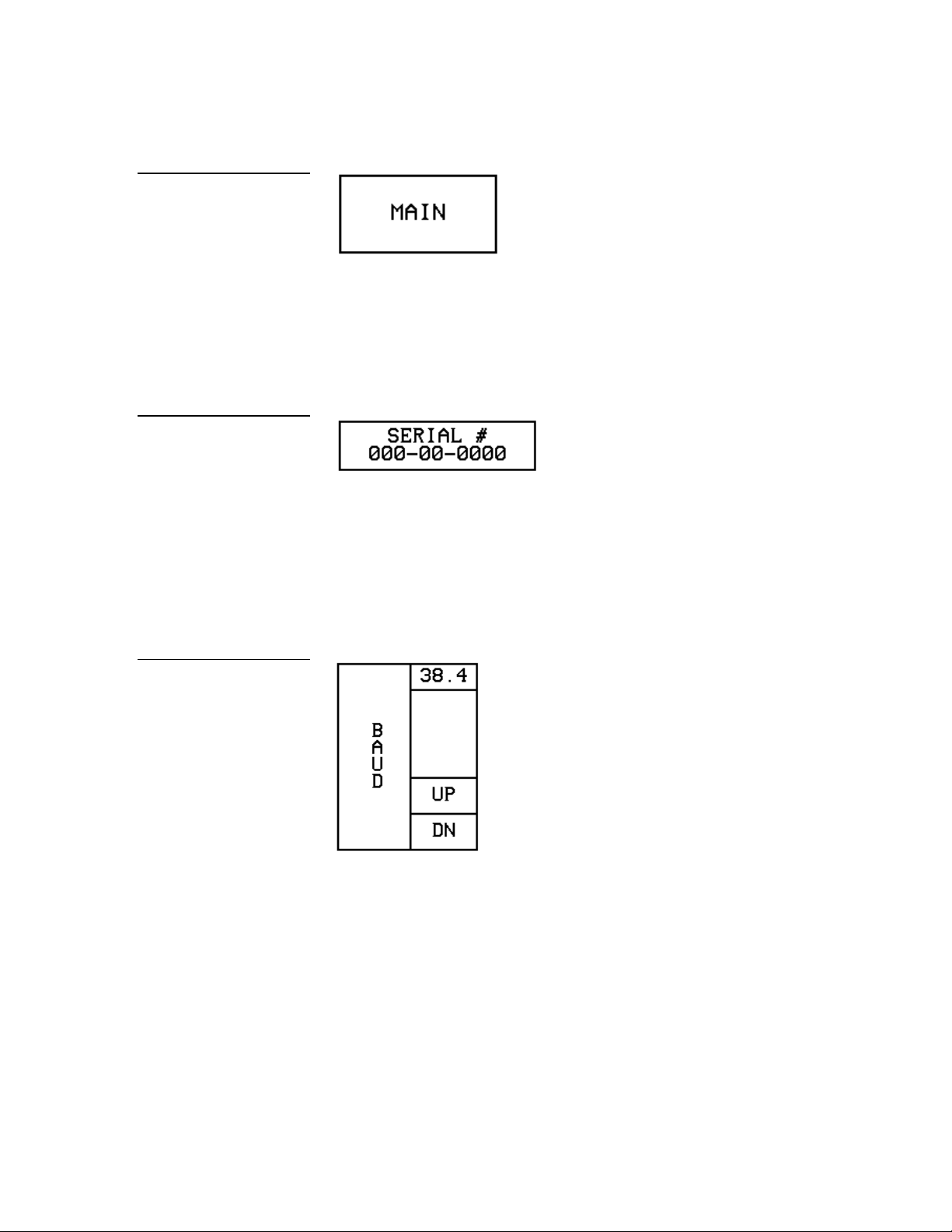

Figure 21

Selection button example

Figure 22

Information button example

Information buttons

Information buttons contain serial numbers and firmware version information.

Figure 22 shows the serial number information button in the Setup page.

Adjustment buttons

You can use the UP and DN buttons to set adjustment buttons. The adjustment

button example in Figure 23 sets the baud rate for the RS-232 connector on the

Touch Panel.

Figure 23

Adjustment button example

Keypad buttons

The keypad button opens a keypad (Figure 24) so you can enter a password or

value assignment. All keypad buttons are interactive except for the entry display.

Color Active-Matrix LCD Touch Panels Touch Panel Basics 21

Page 30

Entry display

Keypad entry (0 - 9)

CLEAR – Resets entry to 0

ENTER – Processes entry if correct

Figure 24

Decision button example

Keypad example

Figure 25

Decision buttons

Decision buttons (Figure 25) appear when an operation has two options.

Decision buttons appear when you send or receive a drawing, designate a

communication protocol or perform an operation error.

Figure 26

Status button example

Status buttons

Status buttons (Figure 26) appear when you try to perform operations that do not

function correctly.

NO COMMUNICATION

TOUCH SCREEN TO CONTINUE

22 Touch Panel Basics Color Active-Matrix LCD Touch Panels

Page 31

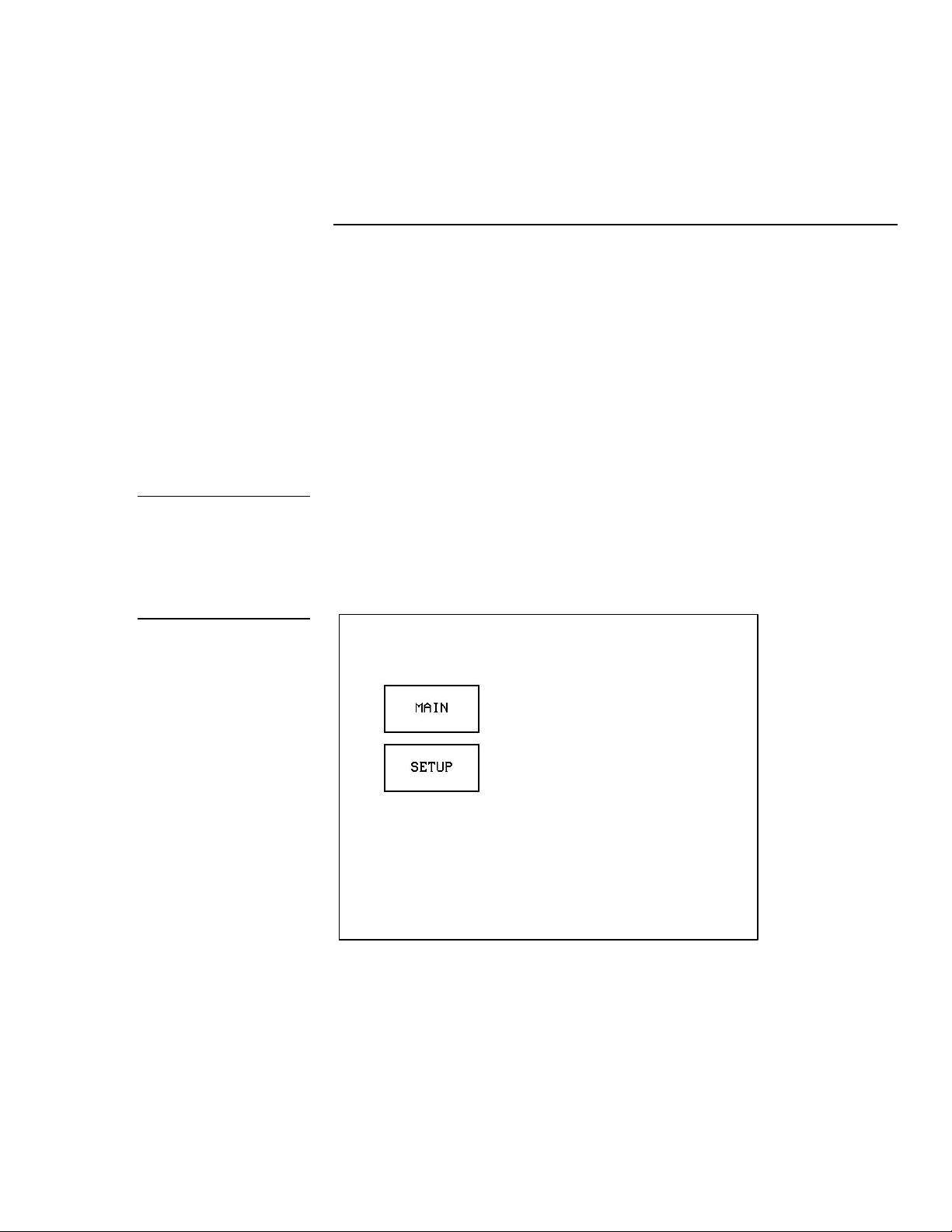

Note

not see the MAIN page.

If you have a preprogrammed panel, you may

Figure 27

Designing a Touch Panel Page

Overview

Use the step-by-step instructions to create Touch Panel pages, buttons, joysticks,

bargraphs, and set page color attributes. For in-depth information on all the

operations available on the Touch Panel, read through the Touch Panel Program

Reference section to learn about all the operations and techniques available to

design Touch Panel pages.

Activating the Edit Button

Before you design a Touch Panel page you must activate the EDIT button which

contains options to add and configure Touch Panels and buttons. When you

power up the Touch Panel, the first page you see is the MAIN page shown in

Figure 27. Refer to Edit button and Go to information in the Touch Panel Program

Reference section if the MAIN page does not appear.

MAIN page

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 23

Page 32

Figure 28

keypad

SETUP page

1. Press SETUP in the MAIN page to open the SETUP page shown in Figure 28.

2. In the above page, press PROTECTED SETUP to open the password keypad

shown in Figure 29.

Figure 29

SETUP page and password

24 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 33

Note

previous page.

If you press ENTER after

typing in an incorrect

password, you are

immediately returned to the

Figure 30

PROTECTED SETUP page

3. Type 1988 in the keypad, and press ENTER to open the PROTECTED SETUP

page (Figure 30). For information on changing the password, refer to Touch

Panel Program Reference section. If you enter a wrong number, press CLEAR

and re-enter the number.

4. Press EDITOR to enable the Editor mode. The active mode of the EDITOR

button is shown in Figure 31.

5. Press EXIT to close the PROTECTED SETUP page and return to the SETUP

page in Editor mode.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 25

Page 34

Figure 31

Active EDITOR button in the

PROTECTED SETUP page

Figure 32

6. Press EXIT twice to return to the MAIN page. The EDIT button appears at the

top of the MAIN page, indicating that the Editor mode is active (Figure 32).

MAIN page with EDIT button

7. Press the EDIT button to open the Edit bar, which appears at the top of the

page (Figure 33).

26 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 35

Edit bar

Figure 33

MAIN PAGE and Edit bar

Creating a Page

Use the PAGE menu option in the Edit bar to create Touch Panel pages.

Figure 34

PAGE menu options

Adding a page

1. Press PAGE on the Edit bar to open the Page menu options(Figure 34).

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 27

Page 36

Figure 35

as popup pages and buttons.

Keyboard

Note

Page naming does not allow

you to change the font type,

as is available for such things

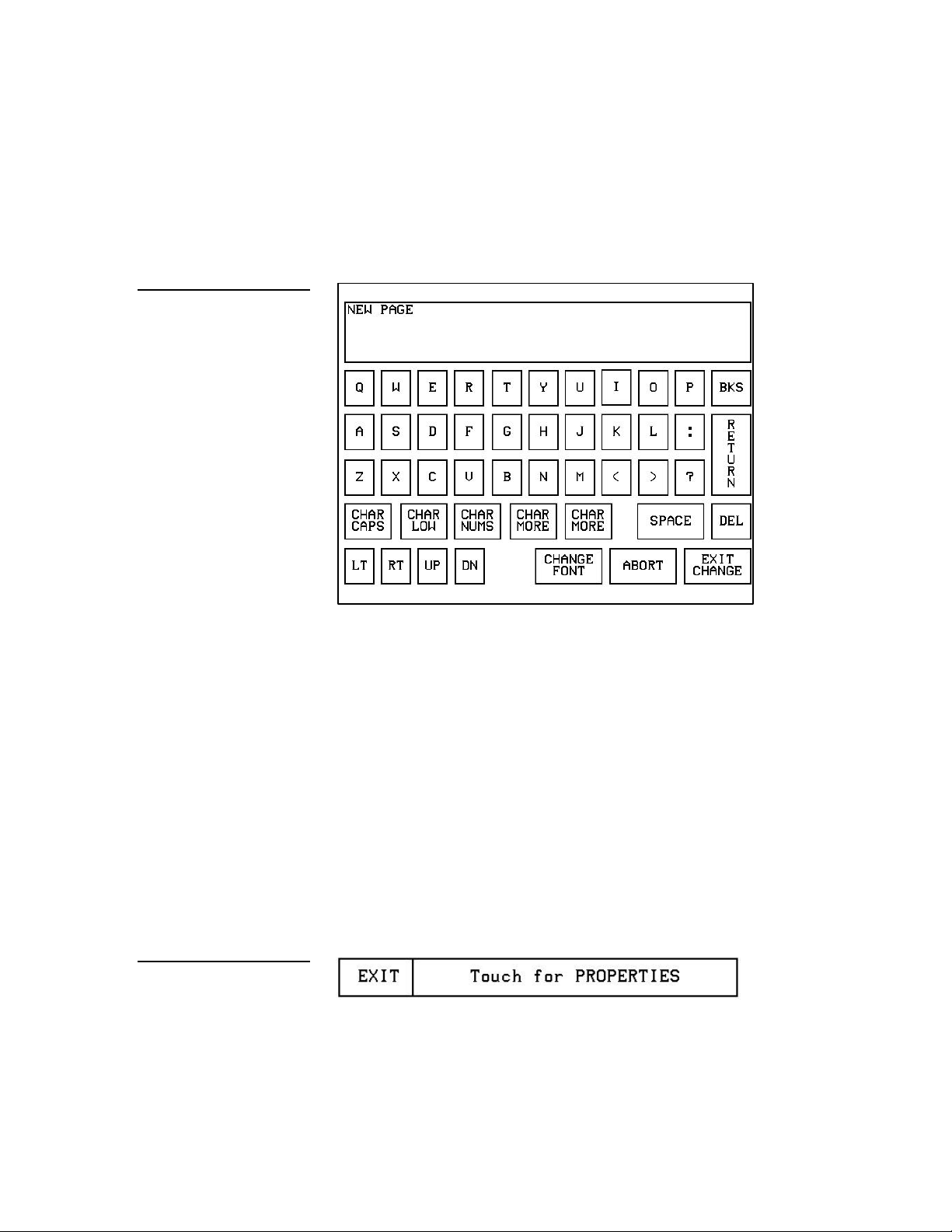

2. Press the ADD option to add a new Touch Panel page. This command opens

the keyboard (Figure 35). Use the keyboard to enter a name for the new page.

3. Type NEW PAGE (Figure 36) using the keyboard. A page name can be up to 20

characters.

Figure 36

Keyboard: NEW PAGE

28 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 37

Figure 37

Edit bar

Figure 38

PAGE menu options

4. Press EXIT CHANGE to add NEW PAGE to Touch Panel memory, close the

keyboard, and return to the NEW page.

5. Press EXIT on the Edit bar.

Setting the page color

1. Press EDIT to open the Edit bar shown in Figure 37.

2. Press PAGE on the Edit bar to open the PAGE menu options shown in

Figure 38.

3. Press the PAGE COLOR option to open the color options shown in Figure 39.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 29

Page 38

Figure 39

Color options

4. Select a page color from the palette. The page automatically changes to the new

color.

Creating a Button

Use the BUTTON menu option in the Edit bar to create Touch Panel buttons.

Adding a button

1. Press EDIT to open the Edit bar (Figure 37).

2. Press BUTTON on the Edit bar to open the BUTTON menu options shown in

Figure 40.

30 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 39

Height

Touch Point

Figure 40

ADD BUTTON message bar

button at this time.

BUTTON menu options

3. Press ADD to add a button to the new page. The message bar shown in Figure

41 appears. Touch and drag to add a button. The first touch point is the upperleft corner of the button.

Figure 41

Figure 42

Add a button example

Note

You can add more than one

4. Push on the panel and drag your finger horizontally and down across the

screen to set the height and width of the button, as shown in Figure 42.

Width

5. Release your finger from the panel to record the button dimensions into the

panel memory.

6. Press EXIT in the Edit bar.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 31

Page 40

drag to resize.

Figure 43

bar

BUTTON menu options

Resizing a button

1. Press EDIT to open the Edit bar.

2. Press BUTTON on the Edit bar to open the menu options shown in Figure 43.

Figure 44

RESIZE BUTTON message

Figure 45

Resizing a button

3. Press the RESIZE option to resize the button when the message bar (Figure 44)

appears.

4. Push the edge of the button, and drag your finger horizontally across the

screen and down to resize the button (Figure 45).

Touch any edge and

32 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 41

Figure 46

BUTTON menu options

5. Release your finger from the panel to record the button dimensions into the

panel memory.

6. Press EXIT in the Edit bar.

Button Properties

Use the PROPERTIES option of the BUTTON menu in the Edit bar to set button

borders, page flips, button colors for channel on and off conditions, and channel

and variable text codes.

Setting the button properties

1. Press EDIT to open the Edit bar (Figure 37).

2. Press BUTTON on the Edit bar to open the BUTTON menu options shown in

Figure 46.

3. Press PROPERTIES to open the Edit bar shown in Figure 47.

Figure 47

PROPERTIES message bar

4. Press the button you just added to open the BUTTON PROPERTIES page

shown in Figure 48. This page lists the properties of the selected button.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 33

Page 42

Figure 48

other button border options.

BUTTON PROPERTIES

page

Setting the border

1. Press BORDER in the BUTTON PROPERTIES page to open the BUTTON

BORDER options pages shown in Figure 49.

Figure 49

BUTTON BORDER options

pages

Note

Use the MORE button to view

34 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 43

Figure 50

CHANNEL code buttons

2. Press 3D RECTANGLE 1 to set the button border to 3D RECTANGLE 1 style.

The BORDER button in the BUTTON PROPERTIES page reflects the selected

border type. In this case, the button changes to the 3D rectangle border.

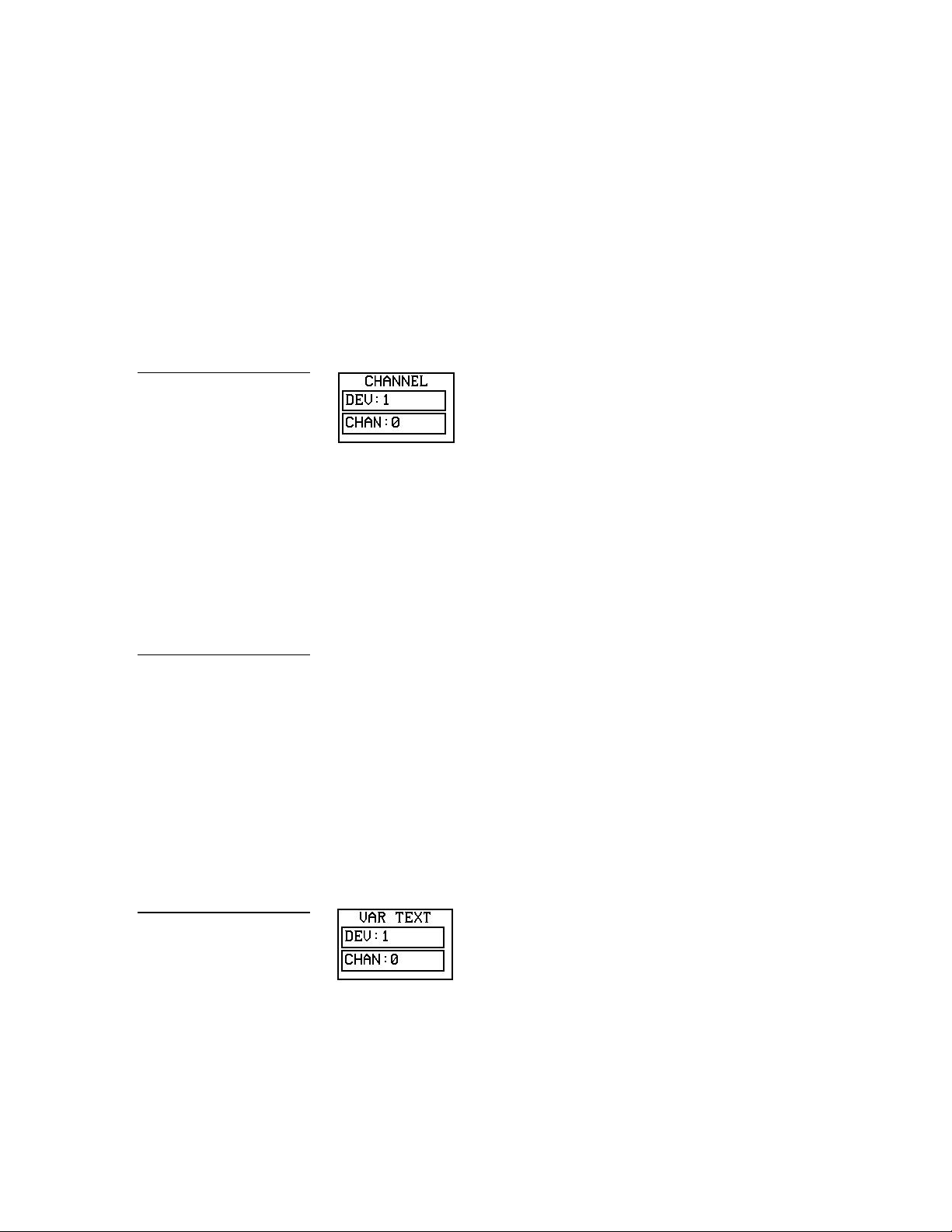

Setting the channel code

1. The two fields to be set for the button channel code are DEV (device) and

CHAN (channel) as shown in Figure 50.

2. Press DEV to open a keypad and set the device number.

3. Type 1, 2,3, or 4 in the keypad. The device number specifies the device for

which the selected channel’s feedback is displayed.

4. Press ENTER to store the device code in memory, close the keypad, and return

to the BUTTON PROPERTIES page.

5. Press CHAN to open a keypad and set the channel number.

Note

The channel code(s) for nonactive buttons is 0, and active

buttons is1 through 255.

Figure 51

VARIABLE TEXT code

buttons

6. Type a channel value of 1 to 255 in the keypad. The AXCESS software

program uses the channel code number to identify the button and its

operations.

7. Press ENTER to store the channel code in memory, close the keypad, and

return to the BUTTON PROPERTIES page.

Setting the variable text code

1. The two fields to be set for the button variable text code are DEV (device) and

CHAN (channel) as shown in Figure 51.

2. Press DEV to open a keypad and set the device number.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 35

Page 44

Flip menu button

Figure 52

appear.

Page FLIP boxes

3. Type 1, 2, 3, or 4 in the keypad. The device number specifies the device

for which the selected channel’s feedback is displayed.

4. Press ENTER to store the device number in memory, close the keypad, and

return to the BUTTON PROPERTIES page.

5. Press CHAN to open a keypad and set the channel number.

6. Type a channel value of 1 to 255 in the keypad. The AXCESS software

program uses the channel code number to identify the button and its

operations.

7. Press ENTER to store the channel code in memory, close the keypad, and

return to the BUTTON PROPERTIES page.

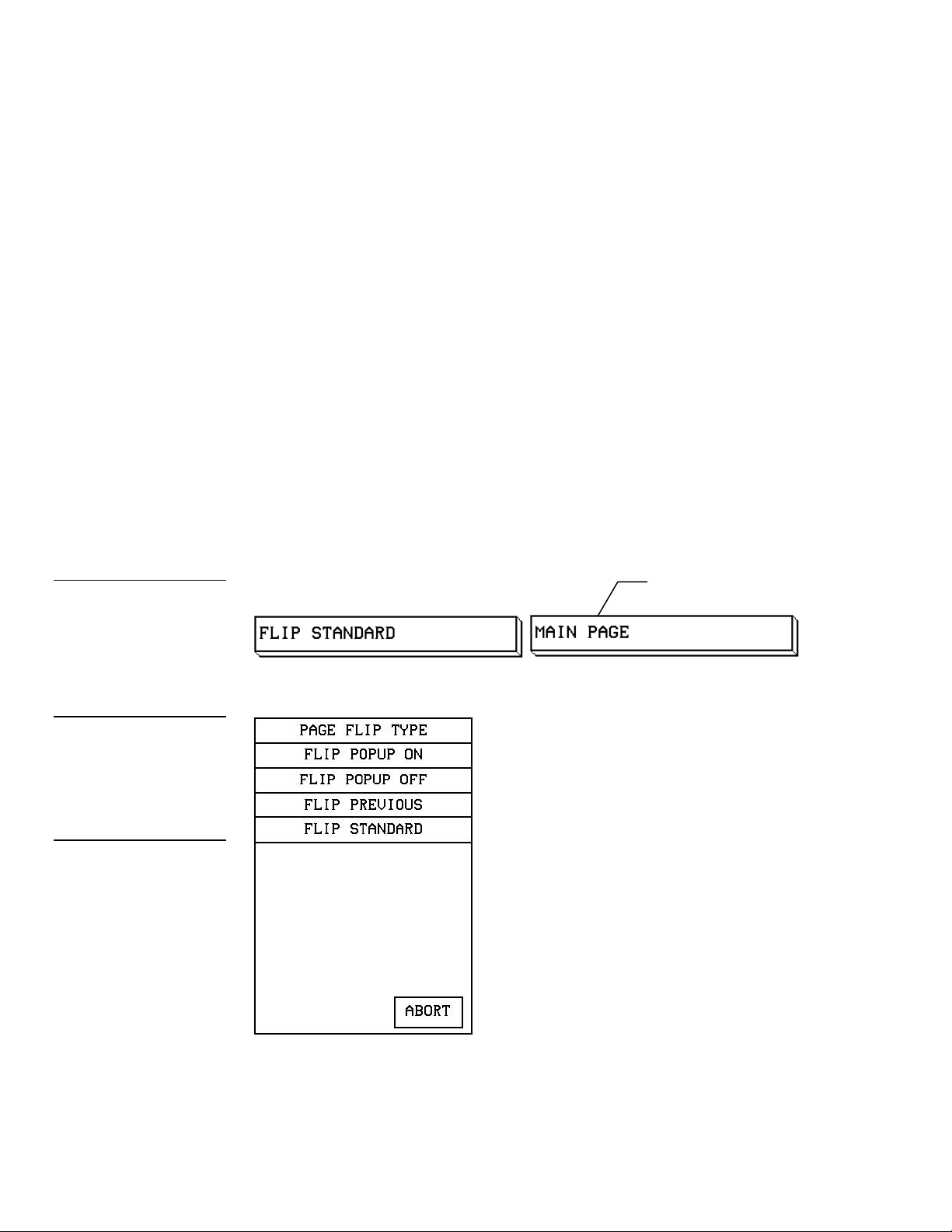

Setting the page flip

1. Press the left Page FLIP box in the Button Properties page (Figure 52) to open

the Page Flip Type list (Figure 53).

Figure 53

PAGE FLIP TYPE list

Note

When selecting the FLIP

PREVIOUS option in the

Page FLIP box, the POPUP

PAGE menu does not

36 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 45

2. Press FLIP STANDARD.

has not been created.

Note

The right page FLIP will

display the existing Touch

Panel pages. If the desired

page is not present, then it

Figure 54

BUTTON PROPERTIES

page

3. Press the right page FLIP box (Figure 52) to open the PAGE FLIP TYPE list

(Figure 53).

4. Press MAIN PAGE to set the page flip to the MAIN page.

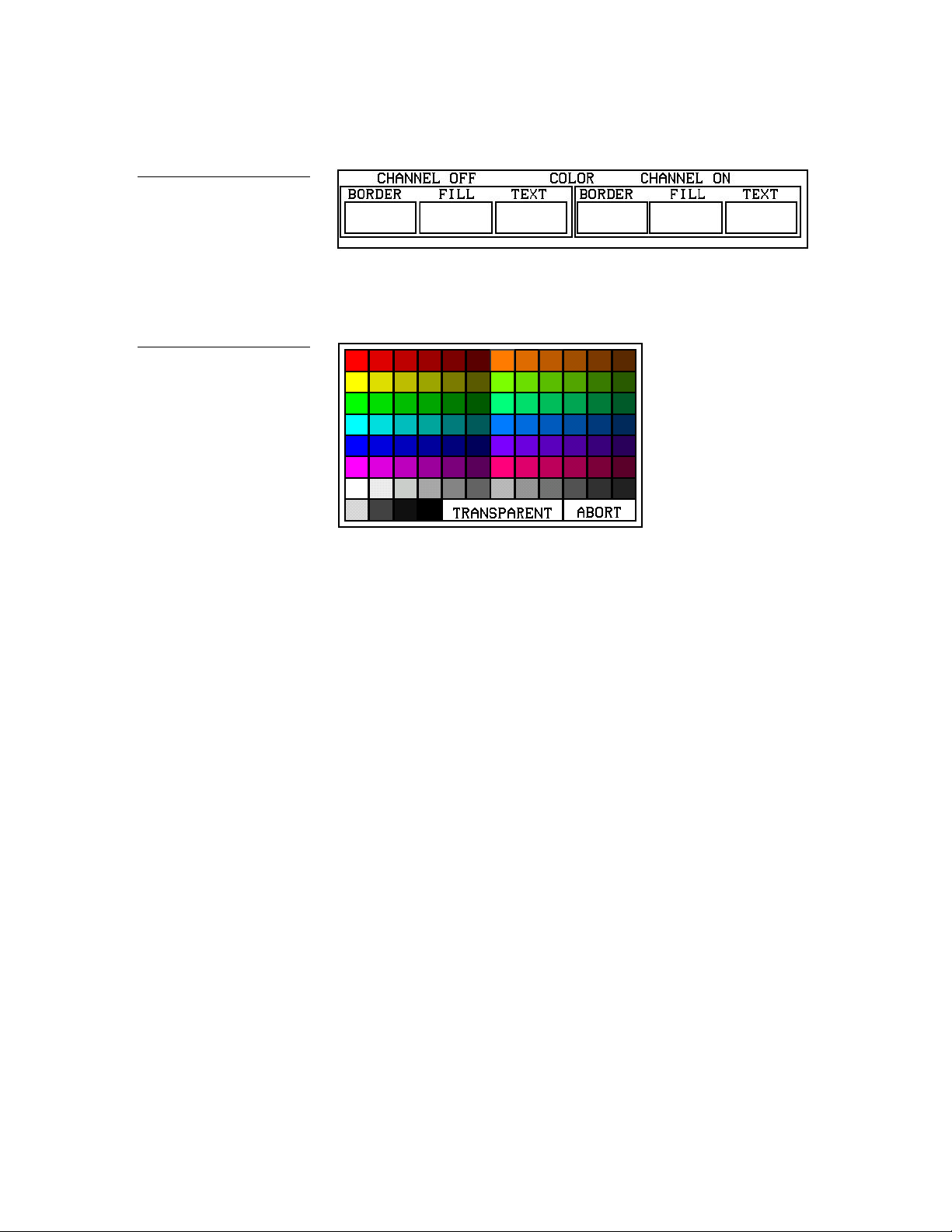

Setting the button colors for channel-off conditions

1. Press the button to open the BUTTON PROPERTIES page shown in Figure 54.

2. Press BORDER in the COLOR (CHANNEL OFF) section of the BUTTON

PROPERTIES page (Figure 55).

Figure 55

CHANNEL OFF/ON COLOR

settings box

3. The color options (Figure 56) appear.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 37

Page 46

Figure 56

Color options

4. Press black to set the border color to black.

5. Press the FILL button in the BUTTON PROPERTIES page to re-open the color

options.

6. Press white to set the fill color to white.

7. Press the TEXT button to re-open the color options.

8. Press red to set the text color to red.

9. Press EXIT SAVE CHANGE in the BUTTON PROPERTIES page to store the

new button properties in memory and return to the current page.

10. Press EXIT on the Edit bar to exit PROPERTIES mode.

Adding text to a button

Use the BUTTON OPTION in the Edit bar to add text to buttons, joysticks, and

bargraphs.

1. Press EDIT to open the Edit bar.

2. Press BUTTON on the Edit bar to open the BUTTON menu options list as

shown in Figure 57.

38 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 47

Figure 57

TEXT/IMAGE message bar

BUTTON menu options

Figure 58

3. Press TEXT/IMAGE to add text in the selected button. The message bar shown

in Figure 58 appears.

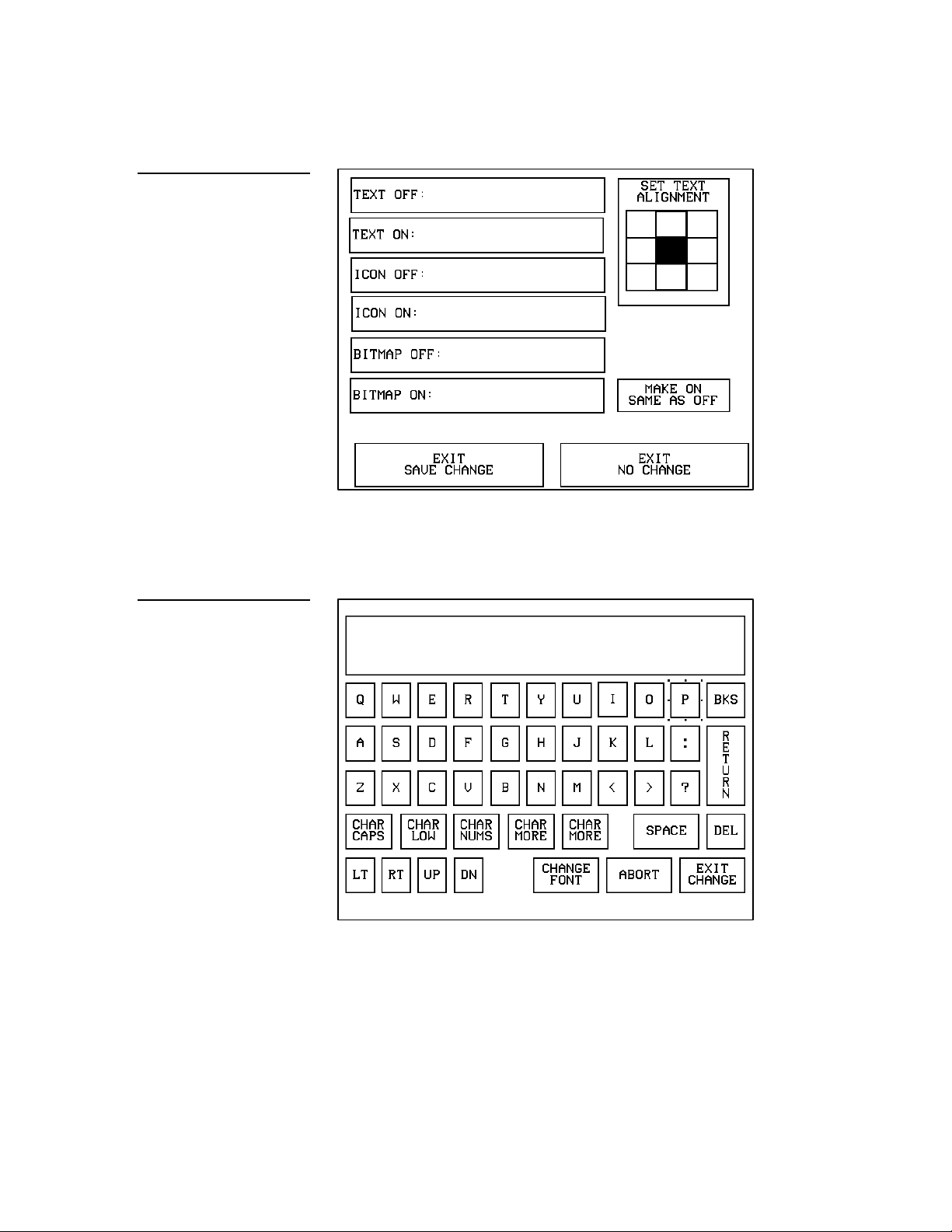

Figure 59

TEXT/IMAGE page

4. Press the on-screen button to open the TEXT/IMAGE page shown in Figure 59.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 39

Page 48

Figure 60

pages.

TPDesign 3.

Keyboard

Note

The CHANGE FONT key

only appears when changing

the font of a function button

and does not apply to popup

5. Press TEXT OFF to open the keyboard shown in Figure 60.

Note

You can not create or edit

buttons with Unicode Fonts

within the Touch Panel. Any

use of the TEXT/IMAGE

button to alter or create a

Unicode Font supported

button must be done in

6. Type MAIN PAGE. The text appears in the message box at the top of the

keyboard. If you exceed the space in the button, the Touch Panel generates an

error message. Change the size of the button or reduce the text string to clear

the error message.

7. Press EXIT CHANGE to close the keyboard and return to the TEXT/IMAGE

page.

8. Press MAKE ON SAME AS OFF to set the text for both On and Off states of the

button.

9. Press EXIT SAVE CHANGE to close the TEXT/IMAGE page and return to the

NEW page.

10. Press EXIT in the Edit bar to exit Edit Text/Image mode.

40 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 49

Button Properties for External Buttons

Type(s) sections.

Note

Although these buttons don't

appear on-screen, their

functionality can be set just

as any other button on the

Touch panel. They will have

no on-screen presence with

such things as colors,

borders, and names. For

further information on the

PROPERTIES page features

see Properties Page-Button

Figure 61

Joystick

If your Touch Panel comes with external buttons, these can be configured with

features similar to on-screen buttons, for more information see the Creating a Button

subsection. Use the PROPERTIES option to assign properties to external

pushbuttons. The BUTTON OPTIONS and VARIABLE TEXT features within the

PROPERTIES page will not appear. Although the Border and Color sections of this

page appear, they are of no use by external buttons since they do not appear onscreen.

Creating a Joystick

You can create a joystick with the BUTTON TYPE option in the BUTTON

PROPERTIES page. Joysticks (Figure 61) are vertical and horizontal direction

controllers you use for camera operations such as pan and tilt.

Before you start, make sure to connect the Touch Panel to your AXCESS Central

Controller. Otherwise, the joystick will not work properly. For more information,

refer to the Touch Panel Program Reference section in this manual.

Adding a joystick to a page

1. Create a new button using the ADD option in the BUTTON menu described in

the Creating a Button subsection.

2. Press BUTTON on the Edit bar to open the BUTTON menu options shown in

Figure 62.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 41

Page 50

Figure 62

BUTTON menu options

Figure 63

PROPERTIES message bar

3. Press the PROPERTIES option to open the message shown in Figure 63.

4. Next press the new button.

5. Press BUTTON TYPE (Figure 64) to open the BUTTON TYPE list shown in

Figure 65.

42 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 51

Figure 64

BUTTON PROPERTIES

page

Figure 65

BUTTON TYPE menu

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 43

6. Press JOYSTICK to set the selected button as a joystick.

7. Press BUTTON OPTION on the BUTTON PROPERTIES page to open the list of

joystick button options as shown in Figure 66.

Page 52

Figure 66

JOYSTICK BUTTON

OPTIONS list

8. Press CROSSHAIR CENTER to set a crosshair in the center of the joystick

button and return to the BUTTON PROPERTIES page.

9. Press EXIT SAVE CHANGE to return to the MAIN page.

44 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 53

Figure 67

BUTTON PROPERTIES

page

Setting the joystick properties

1. Press EDIT, BUTTON, and select PROPERTIES.

2. Press the new button you just created to open the Button Properties page

(Figure 67).

3. Press BUTTON TYPE to open Figure 65.

4. Press the JOYSTICK button in the BUTTON TYPE list to open the BUTTON

PROPERTIES page in Figure 68.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 45

Page 54

Figure 68

select it.

255.

BUTTON PROPERTIES

(JOYSTICK) page

Note

If you continued the

procedures from the Adding a

joystick to a page subsection,

this will be the button's

properties page when you

Setting the channel code

1. The two fields to be set for the joystick channel code are DEV (device) and

CHAN (channel) as shown in Figure 69.

Figure 69

Joystick CHANNEL code

buttons

Note

The channel code for nonactive buttons is 0, and for

active buttons it's 1 through

2. Press DEV to open a keypad and set the joystick’s device number.

3. Type 1, 2, 3, or 4 in the keypad. The device number specifies the device

number for the selected channel’s feedback is displayed.

4. Press ENTER to store the device code in memory, close the keypad, and return

to the BUTTON PROPERTIES page.

5. Press CHAN to open the keypad and set the channel number.

6. Type in a channel value of 1 to 255 in the keypad. The AXCESS software

program uses the channel code number to identify the button and programmed

operations.

46 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 55

Figure 70

from 1-7.

settings box

Level code buttons

7. Press ENTER to store the channel code in memory, close the keypad, and

return to the BUTTON PROPERTIES page.

Setting the level code

1. There are two fields in the LEVEL section: DEV (device) and NUM (number), as

shown in Figure 70.

2. Press DEV to open a keypad and set the device code.

3. Type 1, 2, 3, or 4 in the keypad. The AXCESS software program uses

device codes 1 through 4 to identify the Touch Panel. For more information,

refer to the Touch Panel Program Reference section.

4. Press ENTER to store the level device code in memory, close the keypad, and

return to the BUTTON PROPERTIES page.

Note

Each device can have from

1-8 levels except for

joysticks where the range is

Figure 71

CHANNEL OFF/ON COLOR

5. Press NUM in the LEVEL section to open a keypad and set the level number

assigned to the device.

6. Type 1 in the keypad.

7. Press ENTER to store the level number in memory, close the keypad, and

return to the BUTTON PROPERTIES page.

Setting the joystick colors for channel-off conditions

1. Press BORDER in the COLOR (CHANNEL OFF) section of the BUTTON

PROPERTIES page (Figure 71) to set the border color.

2. Press black on the color palette (Figure 72) to set the border color.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 47

Page 56

Figure 72

Color options

3. Press the FILL button in the Joystick PROPERTIES page to open the color

options again.

4. Press white to set the fill color.

5. Press the TEXT button to open the color options again.

6. Press red to set the text color.

7. Press EXIT SAVE CHANGE in the BUTTON PROPERTIES page to store the

new joystick properties in memory and return to the current page.

8. Press EXIT in the Edit bar to exit PROPERTIES mode.

Figure 73

Bargraph

Create a Bargraph

Bargraphs (Figure 73) are level monitors or adjustable level controls that you can

configure to monitor audio outputs, lighting levels, and adjusting audio line or

light levels. Before you start, make sure to connect the Touch Panel to your AXCESS

Central Controller. Otherwise, the bargraph will not work properly. Refer to the

Touch Panel Program Reference section for detailed information.

48 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 57

Figure 74

Message bar

BUTTON menu options

Adding a bargraph to a page

1. Create a new button using the ADD option in the BUTTON menu as described

earlier in this section.

2. Press EDIT to open the Edit bar (Figure 37).

3. Press BUTTON in the Edit bar to open the BUTTON menu options shown in

Figure 74.

4. Press PROPERTIES in the BUTTON menu to open the message bar shown in

Figure 75.

Figure 75

5. Press the new button to open the BUTTON PROPERTIES page shown in

Figure 76.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 49

Page 58

Figure 76

BUTTON PROPERTIES

page

Figure 77

BUTTON TYPE menu

6. Press BUTTON TYPE to open the BUTTON TYPE list shown in Figure 77.

50 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

7. Select VERTICAL BARGRAPH to open the VERTICAL BARGRAPH

PROPERTIES page shown in Figure 78.

Page 59

Figure 78

VERTICAL BARGRAPH

PROPERTIES page

Setting the bargraph properties

Use the VERTICAL BARGRAPH PROPERTIES page shown in Figure 78 to set

channel, level, and button colors.

Figure 79

Bargraph CHANNEL code

buttons

Setting the channel code

1. The two fields to be set for the bargraph channel code are DEV (device) and

CHAN (channel) as shown in Figure 79.

2. Press DEV to open a keypad and set the device number.

3. Type 1, 2, 3, or 4 in the keypad. The device number specifies the device

for which the selected channel’s feedback is displayed.

4. Press ENTER to store the device code in memory, close the keypad, and return

to the VERTICAL BARGRAPH PROPERTIES page.

5. Press CHAN to open a keypad and set the channel number.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 51

Page 60

Note

buttons.

from 1-7.

The channel code for nonactive buttons is 0, and 1

through 255 for active

Figure 80

LEVEL code buttons

6. Type in a channel value of 1 to 255 in the keypad. The AXCESS software

program uses the channel code number to identify the button and its

operations.

7. Press ENTER to store the channel code in memory, close the keypad, and

return to the VERTICAL BARGRAPH PROPERTIES page.

Setting the level code

1. There are two fields in the LEVEL selection: DEV (device) and NUM (number)

as shown in Figure 80.

2. Press DEV in the LEVEL section to open a keypad.

3. Type 1, 2, 3, or 4 in the keypad. The AXCESS software program uses

device codes 1 through 4 to identify the Touch Panel. Refer to the Touch Panel

Program Reference in this manual for more information.

Note

Each device can have from

1-8 levels except for

joysticks where the range is

4. Press ENTER to store the level device code in memory, close the keypad, and

return to the VERTICAL BARGRAPH PROPERTIES page.

5. Press NUM in the LEVEL section to open a keypad and set the level number

assigned to the device.

6. Type 1in the keypad.

7. Press ENTER to store the level number in memory, close the keypad, and

return to the VERTICAL BARGRAPH PROPERTIES page.

Setting the bargraph colors for channel-off conditions

1. Press BORDER in the COLOR (CHANNEL OFF) section of the BARGRAPH

PROPERTIES page (Figure 81) to set the border color.

52 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 61

Figure 81

settings box

CHANNEL OFF/ON color

Figure 82

Color palette

2. Press black in the color palette (Figure 82) to set the border color.

3. Press the FILL button in the BARGRAPH PROPERTIES page to re-open the

color options.

4. Press white to set the fill color.

5. Press the TEXT button to re-open the color options.

6. Press red to set the text color.

7. Press EXIT SAVE CHANGE in the VERTICAL BARGRAPH PROPERTIES

page to store the new joystick properties in memory and press EXIT to return to

the current page.

Linking the New Page to the Main Page

Use the ATTRIBUTES page to link buttons to pages. This operation requires

changing the button text and setting a page flip.

1. Press the MAIN PAGE button to flip to the MAIN page.

2. Press EDIT to open the Edit bar.

3. Press BUTTON on the Edit bar to open the BUTTON menu options list as

shown in Figure 83.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 53

Page 62

Figure 83

Message bar

BUTTON menu options

Figure 84

4. Press TEXT/IMAGE to change the MAIN PAGE button text when the message

bar (Figure 84) appears.

Figure 85

TEXT/IMAGE page

5. Press the MAIN button to open the TEXT/IMAGE page shown in Figure 85.

54 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 63

Figure 86

message bar

Keyboard: New Page

6. Press TEXT OFF to open the keyboard.

7. Press DEL four times to delete MAIN.

8. Type NEW PAGE. The text appears in the keyboard window shown in Figure 86.

Figure 87

EDIT PROPERTIES

9. Press EXIT CHANGE to close the keyboard and return to the TEXT/IMAGE

page.

10. Press MAKE ON SAME AS OFF to set the text for the button’s On and Off

states.

11. Press EXIT SAVE CHANGE to close the TEXT/IMAGE page and return to the

MAIN page.

12. Press EDIT to open the Edit bar.

13. Press BUTTON to open the BUTTON OPTION menu.

14. Press PROPERTIES in the BUTTON OPTION menu to open the message bar

shown in Figure 87.

15. Press the NEW PAGE button to open the BUTTON PROPERTIES page.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 55

Page 64

Figure 88

Page FLIP buttons

Figure 89

PAGE FLIP TYPE menu

16. In the BUTTON PROPERTIES page, use the page FLIP boxes (Figure 88) to set

the page flip for the button.

17. Press the left page flip box to open the PAGE FLIP TYPE menu shown in

Figure 89.

18. Press FLIP STANDARD to set the PAGE FLIP TYPE and return to the BUTTON

PROPERTIES page.

19. Press the right page FLIP button to select a destination page (Figure 90).

56 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 65

Figure 90

Edit bar

PAGE menu

20. Press NEW PAGE to set the page flip and return to the BUTTON PROPERTIES

page.

21. Press EXIT SAVE CHANGE to save changes, close the BUTTON PROPERTIES

page, and return to the Main page.

Figure 91

22. Press EXIT to close the Edit bar.

Exiting Edit Mode

After you finish designing Touch Panel pages, exit EDIT mode.

1. Press EXIT on the Edit bar (Figure 91) to close the Edit bar.

2. Press SETUP to open the SETUP Page shown in Figure 92.

Color Active-Matrix LCD Touch Panels Designing a Touch Panel Page 57

Page 66

Figure 92

SETUP page

Figure 93

PROTECTED SETUP page

3. Press PROTECTED SETUP to open the PROTECTED SETUP page shown in

Figure 93.

4. Press EDITOR to toggle EDIT mode off.

5. Press EXIT to close the PROTECTED SETUP page and return to the SETUP

page (Figure 92).

6. Press EXIT to close the Setup page and return to the Main page (Figure 95).

58 Designing a Touch Panel Page Color Active-Matrix LCD Touch Panels

Page 67

SETUP

Figure 94

MAIN page

SETUP page flowchart

Touch Panel Program Reference

Overview

You use the SETUP and PROTECTED SETUP pages to configure the Touch Panel

operates. This section contains operation flowcharts, instructions, and menu

option descriptions. The buttons shown in Figure 94 appear when you power up

the Touch Panel.

Setup Page

The flowchart in Figure 95 shows the buttons you press to access the SETUP page.

Figure 95

MAIN

PAGE

From the MAIN page, press the SETUP button to open the SETUP page shown in

Figure 96.

Color Active-Matrix LCD Touch Panels Touch Panel Program Reference 59

Page 68

control systems.

Figure 96

page

BEEP button

section.

SETUP

Optional WIRELESS

SETTINGS button

for WAV-PK and

SMT-PK wireless

Beep

The BEEP button (Figure 97) sets the audible beep duration when you press the

screen.

Figure 97

Note

You can override the beep

value setting using the

'ABEEP' and 'ADBEEP'

Send_Commands described

in the AXCESS Programming

Set the BEEP button on 0 to disable the beep sound. Press the UP and DN buttons

to set beep time in .10-second increments. The minimum beep time setting is 0 and

the maximum is 5 (0.5 second duration).

LCD timer

The LCD TIMER button (Figure 98) sets the length of time the Touch Panel can be

idle before activating screen-saver mode.

60 Touch Panel Program Reference Color Active-Matrix LCD Touch Panels

Page 69

Figure 98

LCD TIMER button

Figure 99

When the Touch Panel goes into screen-saver mode, the LCD is powered-down.

With a setting of 5, the panel goes into screen-saver mode if there is no activity for 5

minutes. Press the UP and DN buttons to change the time that the timer screen

turns on when the Touch Panel is idle. The minimum time setting is 1 and

maximum is 120.

Set time and date

Press SET TIME AND DATE to open the page shown in Figure 99.

SET TIME AND DATE page

Set the year, hour, month, minute, day, second, clock display, and day/month

display.

• • YEAR Press the UP and DN buttons to set the year.

Color Active-Matrix LCD Touch Panels Touch Panel Program Reference 61

Page 70

• • HOUR Press the UP and DN buttons to set the hour.

DOUBLE BEEP button

section.

button examples

• • MONTH Press the UP and DN buttons to set the month.

• • MIN Press the UP and DN buttons to set the minute.

• • DAY Press the UP and DN buttons to set the day.

• • SECOND Press the UP and DN buttons to set the seconds.

• DISPLAY MONTH/DAY, DAY/MONTH Press to set the month and day

display.

• DISPLAY 12:00/24:00 Press to set the clock display to a 12- or 24-hour

format. For example, the 12-hour clock format changes from 12:00 to 1:00,

and the 24-hour clock changes from 12:00 to 13:00.

Double beep

Press the DOUBLE BEEP button (Figure 100) to toggle the double beep option on or

off. The double beep sounds when you press the screen.

Figure 100

Note

You can override the beep

value setting using the

'ABEEP' and 'ADBEEP'

Send_Commands described

in the AXCESS Programming

Figure 101

AXlink, SERIAL #, and vX.XX

Set the BEEP button (described earlier) to 0 to disable the double-beep sound.

AXlink, serial number, and vX.XX

The AXlink, SERIAL #, and vX.XX buttons shown in Figure 101 are information

buttons (display only).

The AXlink button is an AXCESS communication indicator that blinks once every

second when the AXCESS Central Controller is connected to the Touch Panel. The

62 Touch Panel Program Reference Color Active-Matrix LCD Touch Panels

Page 71

Figure 102

SET BRIGHTNESS page

SERIAL NUMBER button shows the serial number for the Touch Panel, and the

vX.XX button shows the current firmware version installed in the Touch Panel.

Set brightness

Press SET BRIGHTNESS in the SETUP page to open the page shown in Figure 102.

Press the UP and DN buttons to set the LCD brightness on the Touch Panel. The

minimum brightness level is 1 and the maximum is 8. The TRANSPARENT and

ABORT buttons are disabled on this page.

Protected Setup

The PROTECTED SETUP button opens the PROTECTED SETUP page where you

set Touch Panel passwords, mouse controls, communications parameters, etc.

Because there are so many operations associated with PROTECTED SETUP page,

they are described in the Protected Setup subsection.

Show palette

Press SHOW PALETTE in the SETUP page to open the page. This page shows the

color selections available with the Touch Panel.

Color Active-Matrix LCD Touch Panels Touch Panel Program Reference 63

Page 72

Figure 103

WAV-PK page

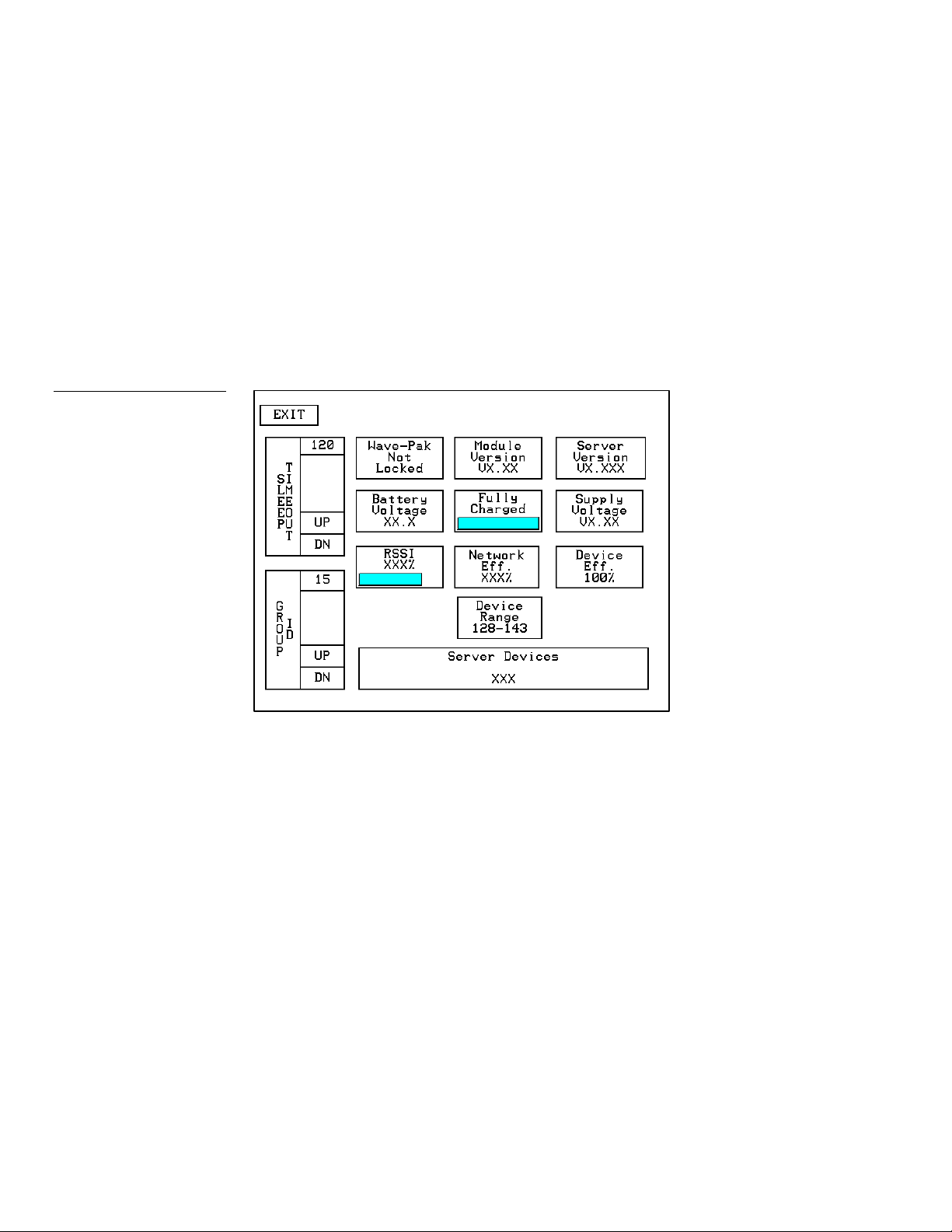

Wireless settings (optional WAV-PKM)

The WIRELESS SETTINGS button appears on the SETUP page when a WAV-PK

WavePack is connected to the Touch Panel. The WAV-PK provides wireless twoway RF spread-spectrum Touch Panel control and contains a lead-acid

rechargeable battery that supplies independent power to the panel. Refer to the

AXR-WAVES Server, WaveLink, Wireless Power Packs, Power Module AXR-WAVES

WAV-CHG instruction manual for detailed setup information Press the WIRELESS

SETTINGS button to open the optional page shown in Figure 103.

The Wave-Pack page shows the following information:

• SLEEP TIMEOUT Press the UP and DN buttons to set the sleep time. The

minimum sleep time is 0 (off) and maximum is 120 minutes. When the Touch

Panel goes to sleep, all communication and battery discharge stops. If the

sleep time is set to 5, the panel goes into sleep mode if there is no activity for

5 minutes. The Touch Panel automatically wakes up when you touch the

screen for more than .5 seconds.

• GROUP ID Sets the group ID number on the Touch Panel to communicate

with the wireless AXR-WAVES with the same group ID number. The group

ID range is 0–15. The group ID setting overrides the DIP switch setting on

the WAV-PK.

64 Touch Panel Program Reference Color Active-Matrix LCD Touch Panels

Page 73

• Wave-Pak Not Locked/Locked Appears when an optional WAV-PK is

connected to the Touch Panel. Not locked indicates the Touch Panel is not

communicating with the AXR-WAVES. Locked indicates the Touch Panel is

locked on (communicating) to the AXR-WAVES connected to the control

system.

• Battery Voltage XX.X Shows the voltage level of the lead-acid

rechargeable battery in the WAV-PK.

• Device Range Shows the device range that your server can recognize.

Devices outside that range will not be recognized

• • Server Devices XXX Shows the group address on the AXR-WAVES

communicating with the Touch Panel.

• Module Version VX.XX Shows the firmware version installed in the

WAV-PK.

• • Fully Charged/Not Charging / Charging Fully Charged appears when

the battery in the WAV-PK is fully charged. Not Charging appears when the

lead-acid battery is not charging. Charging appears when the lead-acid

battery is charging. The shaded area in the horizontal gauge button moves

from left to right as the battery voltage level increases.

• • RSSI XXX% Shows the strength of the AXR-WAVES signal received by the

Touch Panel. The signal strength fluctuates between 50% and 100%.

• Server Version Shows the firmware version installed in the AXR-

WAVES.

• • Supply Voltage VX.XX Shows the voltage level of the external power

supply (optional) connected to the WAV-PK.

• Device Eff. XXX% Shows the strength of the AXR-WAVES signal

received by the Touch Panel. The shaded area in the horizontal gauge moves

from left-to-right as the RF signal intensity increases. The shaded area

fluctuates between 50% and 100%.

Color Active-Matrix LCD Touch Panels Touch Panel Program Reference 65

Page 74

Figure 104

SMT-PK page

• Network Eff. XXX% Shows the communication efficiency of bi-directional

RF transmissions between the Touch Panel and AXR-WAVES. The efficiency

percentage (0–100%) is determined by the number of retries required to

complete a panel operation.

Wireless settings (optional SMT-PK)

The WIRELESS SETTINGS button appears on the SETUP page when a SMT-PK

SmartPack is connected to the Min-Touch. Press the WIRELESS SETTINGS button

to open the optional page shown in Figure 104.

Refer to the SmartPacks for TiltScreen Touch Panels instruction manual for detailed

information.

• SLEEP TIMEOUT Press the UP and DN buttons to set the sleep time. The

minimum sleep time is 0 (off) and maximum is 120 minutes. When the panel

goes to sleep, all communication and battery discharge stops. If the sleep

time is set to 5, the panel goes into sleep mode if there is no activity for 5

minutes. The panel wakes up when you touch the screen for more than .5

seconds.

• Smart-Pk Module Not Locked/Locked Appears when an optional

SMT-PK is connected to the panel. Not locked indicates the panel is not

66 Touch Panel Program Reference Color Active-Matrix LCD Touch Panels

Page 75

communicating with the AXR-RF RF Receiver. Locked indicates the panel is

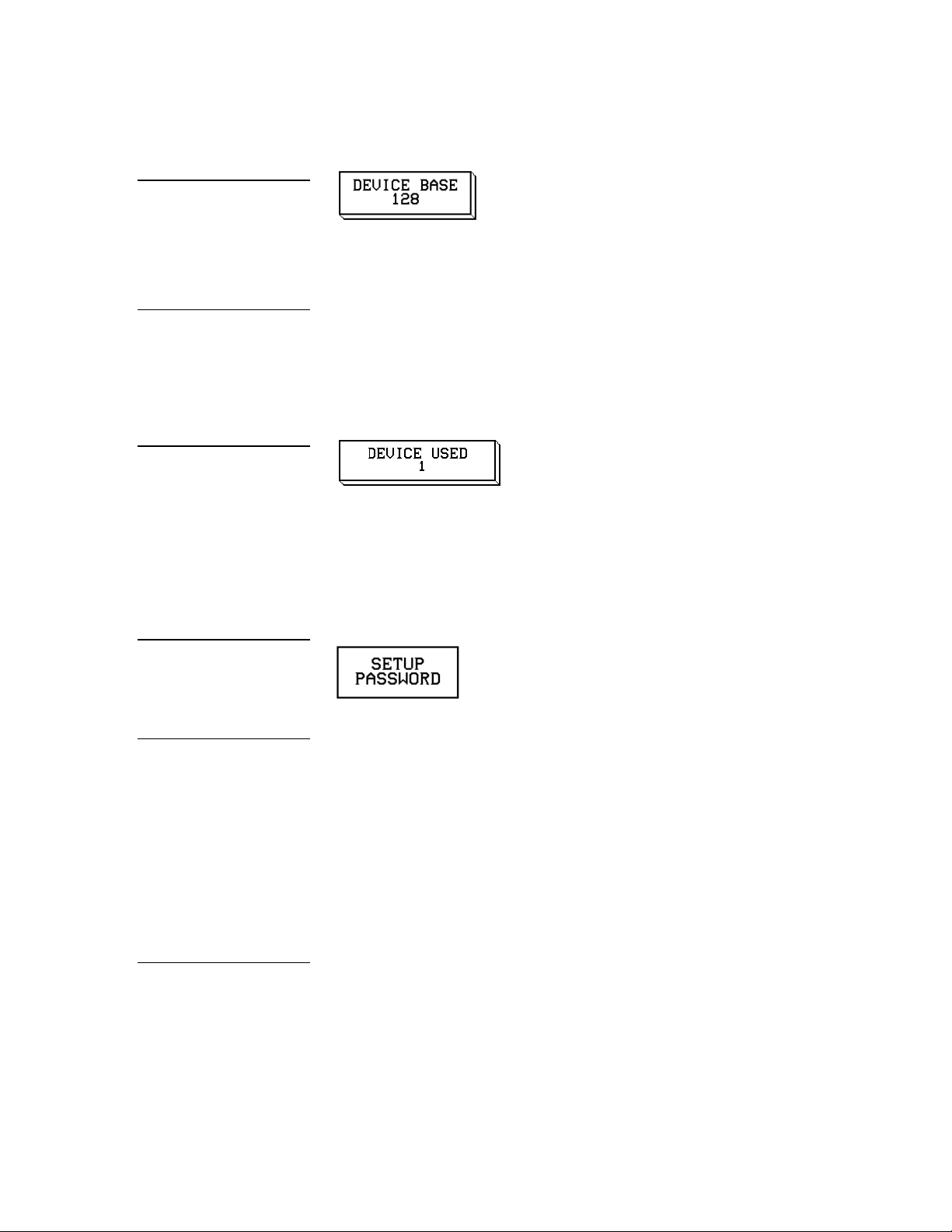

BUTTON

BUTTON

1988

PROTECTED SETUP page.

locked on to the AXR-RF connected to the control system.