Page 1

instruction manual

CP4/A - 4" Color Touch

Panels with Audio

(Firmware version G3)

To u c h Panels and Accessories

Page 2

AMX Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free of defects in material and workmanship under normal use for three

(3) years from the date of purchase from AMX Corporation, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch

overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, and MX Series products are warranted for a period of one

(1) year.

• AMX Lighting products are guaranteed to switch on and off any load that is properly connected to our lighting

products, as long as the AMX Lighting products are under warranty. AMX Corporation does guarantee the

control of dimmable loads that are properly connected to our lighting products. The dimming performance or

quality cannot be guaranteed due to the random combinations of dimmers, lamps and ballasts or transformers.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• AMX Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX Corporation or an Authorized AMX Dealer.

All products returned to AMX require a Return Material Authorization (RMA) number. The RMA number is

obtained from the AMX RMA Department. The RMA number must be clearly marked on the outside of each box.

The RMA is valid for a 30-day period. After the 30-day period the RMA will be cancelled. Any shipments received

not consistent with the RMA, or after the RMA is cancelled, will be refused. AMX is not responsible for products

returned without a valid RMA number.

AMX Corporation is not liable for any damages caused by its products or for the failure of its products to perform.

This includes any lost profits, lost savings, incidental damages, or consequential damages. AMX Corporation is not

liable for any claim made by a third party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort

claim (including negligence and strict product liability), a contract claim, or any other claim. This limitation of

liability cannot be waived or amended by any person. This limitation of liability will be effective even if AMX

Corporation or an authorized representative of AMX Corporation has been advised of the possibility of any such

damages. This limitation of liability, however, will not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or

exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of

the Limited Warranty may not apply. This Limited Warranty gives the owner specific legal rights. The owner may

also have other rights that vary from state to state. The owner is advised to consult applicable state laws for full

determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX CORPORATION MAKES NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. AMX CORPORATION

EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED WARRANTY. ANY

IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS

LIMITED WARRANTY.

Page 3

Table of Contents

Table of Contents

Product Information .................................................................................................1

Specifications ................................................................................................................ 1

Cleaning the Touch Overlay.............................................................................................. 5

AC-CP4A/WRB Water-Resistant Faceplate for AXD-CP4/A............................................. 5

Specifications ....................................................................................................................... 6

Installation .................................................................................................................7

Mounting the AXD Wall Mount Panels .............................................................................. 7

Wall Mount installation using a pre-wall CB-CP4/A Conduit Box............................................. 7

Wall Mount panel installation into Drywall using Expansion Clips ......................................... 10

Wall Mount panel installation onto a flat surface using solid-surface screws......................... 13

Installation of the AC-CP4A/WRB Faceplates................................................................. 16

Drywall Surface upgrade installation ...................................................................................... 17

Solid Surface upgrade installation.......................................................................................... 18

Removing the AXT Faceplate/Bezel ............................................................................... 19

Removing and replacing AXT pushbuttons............................................................................ 20

Wiring the Touch Panel ................................................................................................... 21

Wiring guidelines.................................................................................................................... 21

Wiring the CP4/A terminal connectors and cables................................................................. 22

Additional CP4/A wiring configurations .................................................................................. 23

Using the CP4/A Programming Jacks ............................................................................. 25

Designing Touch Panel Pages ..............................................................................27

Buttons ............................................................................................................................ 27

Activating Edit Mode........................................................................................................ 28

Setting the Device Base .................................................................................................. 29

Setting the Device Used.................................................................................................. 30

Adding a Page................................................................................................................. 30

Setting the page color ............................................................................................................ 30

Adding a Button............................................................................................................... 30

Resizing a button ................................................................................................................... 31

Defining On-Screen Button Properties............................................................................ 31

Setting the channel code........................................................................................................ 31

Setting the variable text code................................................................................................. 32

Setting the page flip ............................................................................................................... 32

Setting the button colors for channel-off conditions ............................................................... 32

Adding text, icons, and bitmaps to a button ........................................................................... 33

4" Color Touch Panels with Audio

i

Page 4

Table of Contents

Creating a Bargraph and Joystick................................................................................... 33

Adding a bargraph or joystick button...................................................................................... 33

Setting Bargraph and Joystick Properties....................................................................... 33

Setting the level code............................................................................................................. 34

Using the Adjust Sensors Setup Page ............................................................................ 34

Using the Audio and IR Device Setup page.................................................................... 37

External PushButtons...................................................................................................... 38

Setting the pushbutton LED illumination ................................................................................ 38

Light Sensor .................................................................................................................... 39

Passive Infrared Sensor.................................................................................................. 39

IR Receiver ..................................................................................................................... 39

Audio Tones .................................................................................................................... 39

Speaker Volume.............................................................................................................. 39

Microphone ..................................................................................................................... 39

Using TPDesign3 to Download Bitmaps, Icons, and Fonts............................................. 40

Programming ..........................................................................................................41

Serial Commands............................................................................................................ 41

System Send_Commands .............................................................................................. 43

Programming Numbers ................................................................................................... 52

Shorthand Send Commands........................................................................................... 53

Color Send_Commands.................................................................................................. 58

Variable Text Send_Commands ..................................................................................... 60

Shorthand Variable Text Commands .............................................................................. 62

Button String Commands................................................................................................ 65

Upgrading the Firmware ........................................................................................67

Communication Methods for CP4/A Firmware Update ................................................... 67

Upgrading the Firmware Using NetLinx Studio ............................................................... 69

Upgrading Firmware through a COM port.............................................................................. 69

Upgrading the Firmware through an IP Address.................................................................... 71

Upgrading the Firmware Using SOFTROM .................................................................... 73

Configuration.......................................................................................................................... 73

Downloading the Firmware .................................................................................................... 74

Replacing the Battery ............................................................................................75

AXT-CP4/A Battery Replacement ................................................................................... 75

AXD-CP4/A Battery Replacement................................................................................... 77

ii

4" Color Touch Panels with Audio

Page 5

Product Information

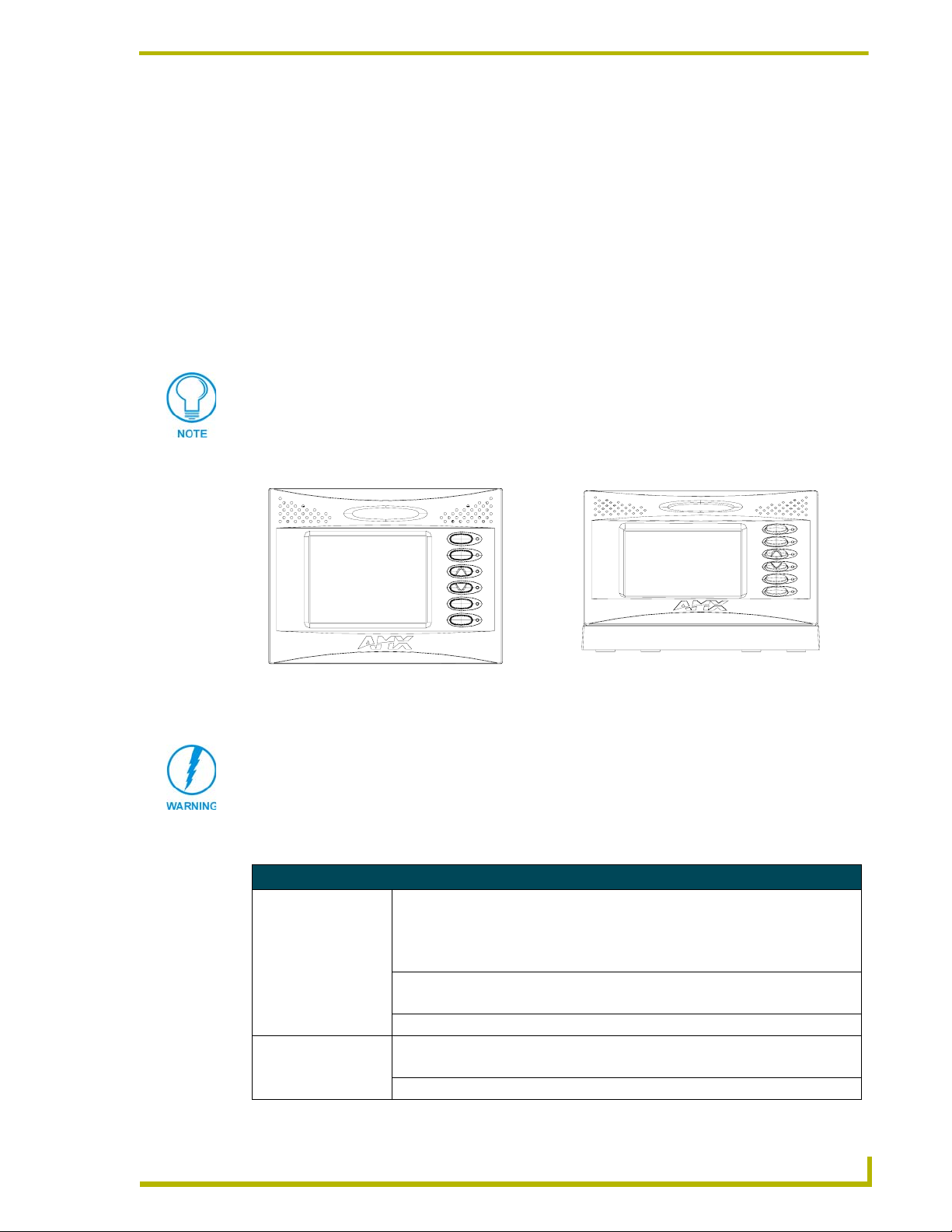

The Color Passive-Matrix Audio Mini-Touch Panels (AXD-CP4/A and AXT-CP4/A) contain a

4-inch 256-color passive-matrix liquid crystal display (LCD). These panels are equipped with an

infrared motion sensor, light sensor, IR receiver, internal audio speakers, internal microphone,

external LED buttons, and removable buttons. Using the TPDesign3 Touch Panel Design program,

you can create custom pages with buttons, icons, sliders, bargraphs, time displays, logos, and

drawings.

The AXD-CP4/A is designed for wall mounting with a Wall Mount faceplate. The AXD unit also

uses an optional CB-CP4/A conduit/wall box for "pre-wall" surfaces.

The AXD-CP4/A panels come inserted within a plastic backbox (mountable into most

surfaces) that should not be confused with the optional metal CB-CP4/A conduit box

(metallic optional component).

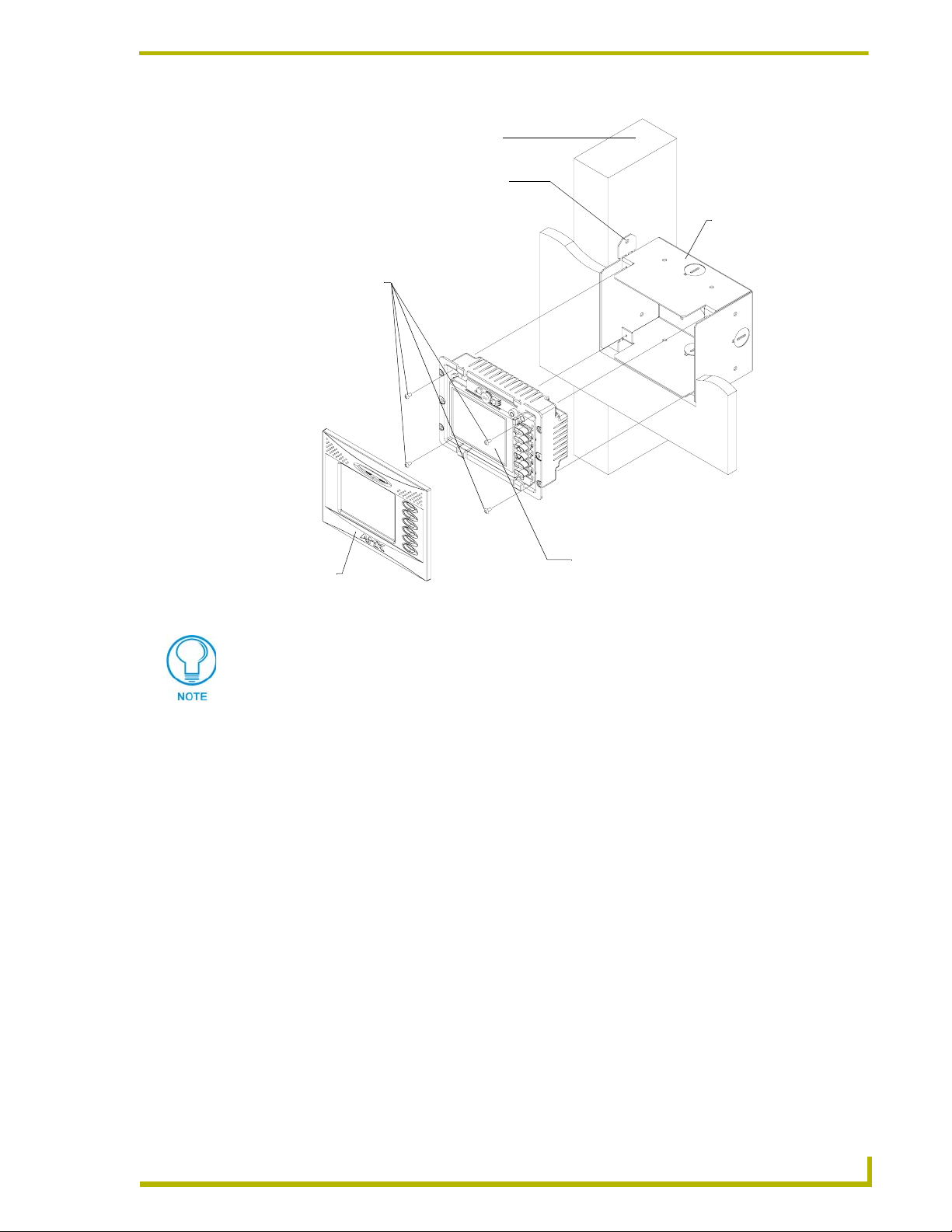

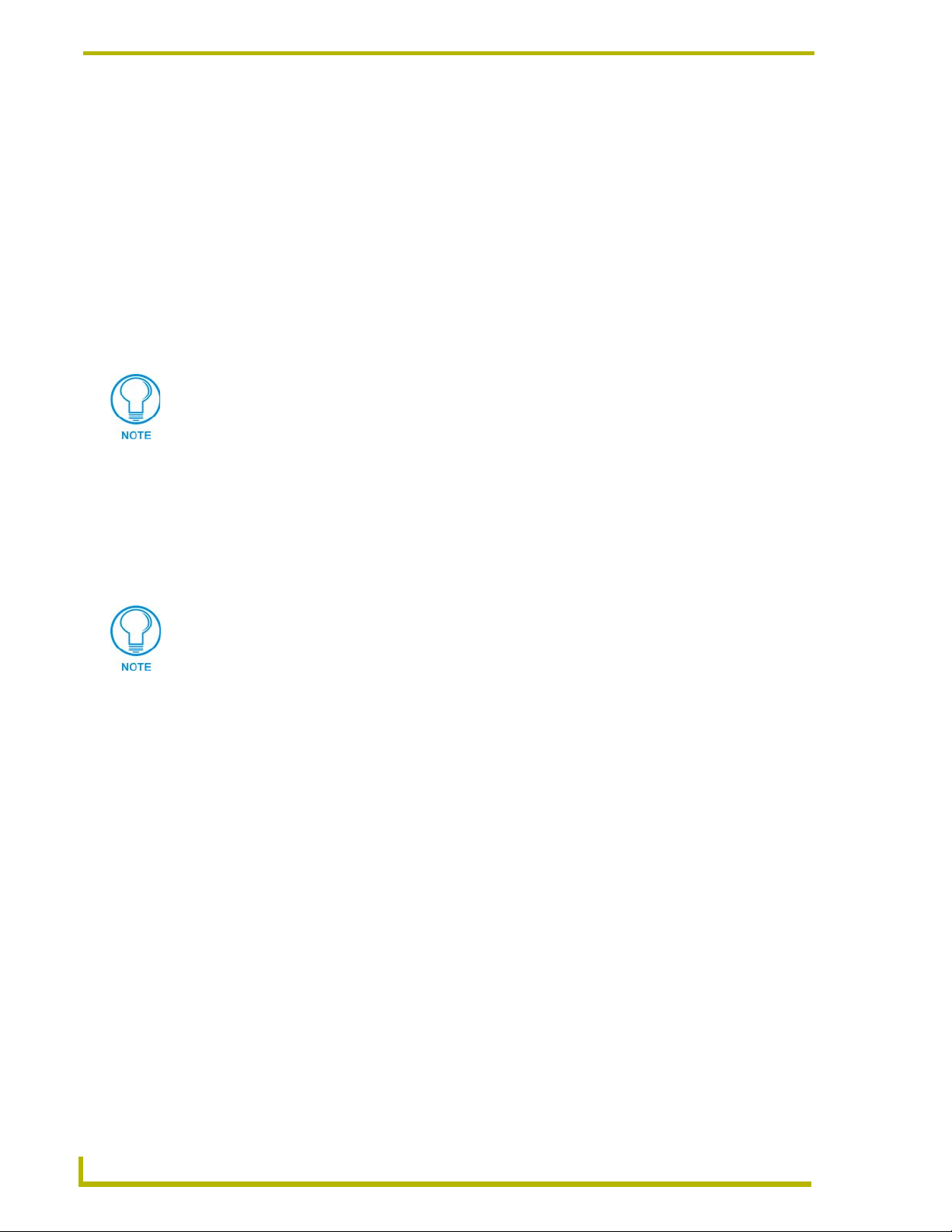

FIG. 1 shows the AXD-CP4/A and AXT-CP4/A panels.

Product Information

AXD-CP4/A (Front view)

FIG. 1 Sample AXD-CP4/A and AXT-CP4/A

Verify the TPDesign3 program being used is Version 3.16 build 193 or higher.

The Updated EXE for TPDesign3 can be found at AMX.com > Tech Center >

Downloadable Files > Application FIles > TPDesign3. Earlier versions of TPD3

will not correctly function with these panels.

AXT-CP4/A (Front view)

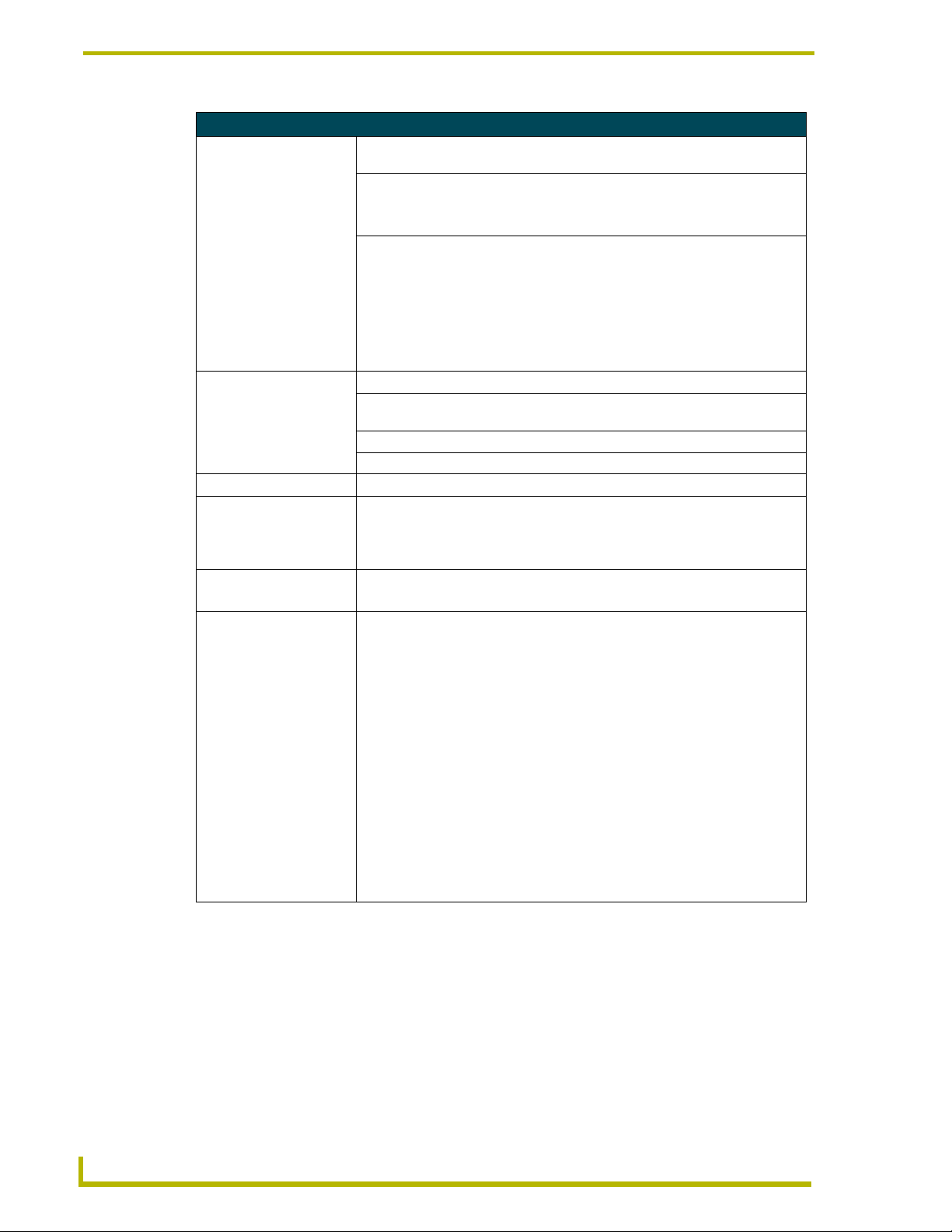

Specifications

Specifications

Dimensions (HWD):

AXD-CP4/A • Housing: 4.60" x 5.34" x 1.87" (11.68 cm x 13.56 cm x 4.75 cm)

• Faceplate: 4.60" x 6.13" x 0.35" (11.68 cm x 15.57 cm x 0.89 cm)

• CB-CP4/A Conduit/wallbox: 4.09" x 5.51" x 3.40" (10.39 cm x 13.99 cm x 8.64 cm)

AXT-CP4/A • Tabletop unit: 4.22" x 6.24" x 4.99" (10.72 cm x 15.85 mm x 12.67 mm)

• Faceplate: 4.60" x 6.13" x 0.35" (11.68 cm x 15.57 cm x 0.89 cm)

CB-CP4/A • Conduit/wallbox: 3.92" x 5.51" x 3.40" (9.96 cm x 13.99 cm x 8.64 cm)

Weight:

AXD-CP4/A 2.23 lbs. (1.02 kg)

AXT-CP4/A 2.26 lbs. (1.03 kg)

4" Color Touch Panels with Audio

1

Page 6

Product Information

Specifications (Cont.)

Enclosures:

AXD-CP4/A

(FG5921-23)

AXT-CP4/A • Table Top enclosure is available in either Dark Grey (FG5921-30) or Platinum

Power Requirements: • Constant current draw: 770 mA @ 12 VDC

Minimum power supply

required:

Memory

(factory default):

• BackBox with black matte finish

• Detachable front panel bezel are available in White (default), Black, and Beige

(FG5921-31)

• Startup current draw: 1.2 A @ 12 VDC

• PSN2.8 Power Supply (FG423-17)

- Includes U.S. power cord, with a 5mm captive-wire connector

• 512 KB of SRAM and 2 MB of Flash for a total memory of 2.5 MB.

The following is a detailed explanation of the on-board memory parameters:

• Graphics Buffer Memory:

- SGRAM

- 1 Mbit x 32 ==> 4 MByte

- Non-user accessible

- Volatile

• Flash Memory:

- CMOS Flash

- 16 MBit x 8 ==> 2 MByte

- Partially user accessible

- Non-volatile

Note: ~400 kByte is used by the firmware and is accessible only to the

firmware during both normal operation and firmware downloads.

Note: ~1600 kByte is used by the user program and is used by TPD3

designs for bitmaps, icons, and fonts. This can be cleared using either the

external "ZAP!" command or the on-panel Factory Reset button.

• RAM:

- SRAM

- 256 kByte x 16 ==> 512 kByte

- Partially user accessible

- Non-volatile via the battery backup (volatile when batteries are removed)

Note: 256 kByte is used by firmware and is accessible only to the firmware

during normal operation.

Note: 256 kByte is used by the user program and is used by TPD3 designs

for buttons, pages, and everything else not listed in the above Flash

parameter. This can be cleared using the external "ZAP!" command or

on-panel Factory Reset button.

• Clock Chip:

- RAM

- 31 Byte

- Non-user accessible

- Non-volatile via the battery backup (volatile when batteries removed)

- 31 bytes are used by the firmware to store AMX configuration information.

Note: If the battery is removed to clear the memory, it wipes out the AMX

configuration information.

•EPLD:

- EEPROM

- 32 Macrocells

- Non-user accessible

- Non-volatile

- Used by hardware for board logic (unable to clear or update)

2

4" Color Touch Panels with Audio

Page 7

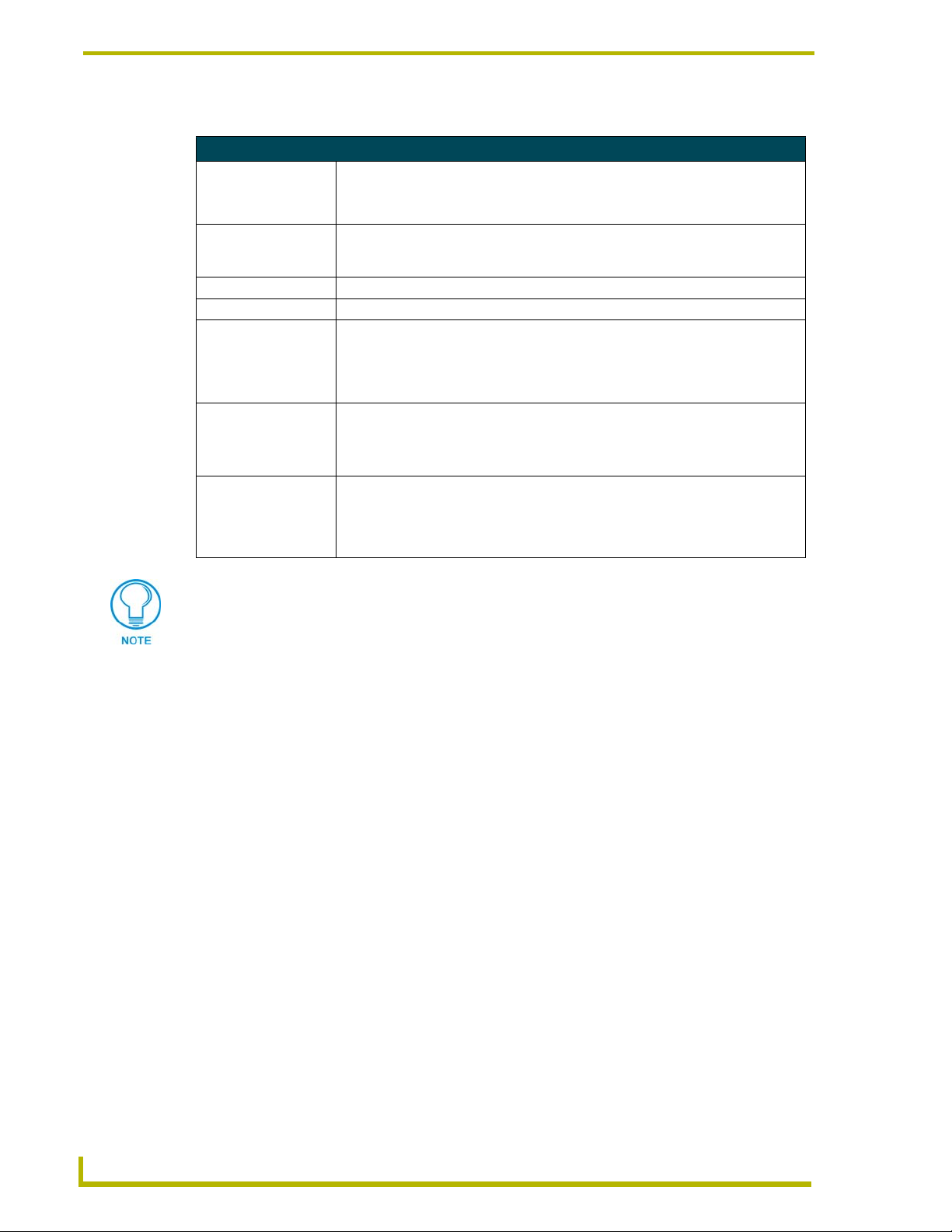

Product Information

Specifications (Cont.)

Panel LCD Parameters: • Contrast ratio: 17:1

• Display area: 3.8 inches (9.65 cm)

• Screen resolution (HV): 320 x 240 pixels

• Viewing angles (100° total viewing angle):

Horizontal: +

Ver tic a l : +

IR Reception Angle: • 45° up on the AXT (30° on the AXD) from the horizontal plane

• 15° down on the AXT (30° on the AXD) from the horizontal plane

• 40° right of the vertical plane (both AXD and AXT units)

• 40° left of the vertical plane (both AXD and AXT units)

IR Reception Range: • Maximum range - 15 feet (4.57 m) for the AXT and 22 feet (6.71 m) for the AXD

Front Panel Components:

External Buttons: • 6 inter-changeable external pushbuttons. Pushbutton assignments can include

the typical Device/Channel numbers, Flip to Page option, and String/Macro.

• Buttons are used as interface tools that operate on-screen menus or turn On/

Off the controlled equipment.

• Both AXD and AXT panels come shipped with 6 blank buttons.

External LEDs: • 6 LEDs are located alongside each external pushbutton.

• Independently operated and programmed

• Used as status indicators. Along with the buttons, these can have the following

feedback types assigned to them in TPDesign3 - Channel, Inverted Channel,

Always On, Momentary, Channel Feedback, Inverted Channel, and Blink.

• They can then be used in many of the same ways as any other on-screen

button.

Button Caps: • Set of 18 changeable button caps consisting of: 6 blanks, 2 embossed with

Up/Down arrows, and 10 pad-printed labels. These buttons match the bezel

coloring.

• Custom engraved buttons are available through your AMX sales representative

• AXD buttons: Black set (60-5921-41BK), Beige set (60-5921-41BG), and

White set (60-5921-41WH)

• AXT buttons: Dark Grey set (60-5921-37) and Platinum set (60-5921-38)

Button Labels: • 10 pad-printed labels

• These buttons contain 10 symbols covering the following functions: MENU,

LIGHTS, AUDIO, VIDEO, ENVIRONMENT, SECURITY, INTERCOM, MUTE,

DRAPES, and POWER

• Refer to the Mounting the AXD Wall Mount Panels - FIG. 10 on page 13 for

more information.

Light Detector: • Photosensitive light detector for adjustment of the panel brightness.

Motion Sensor (PIR): • Proximity Infrared Detector to wake the panel when the panel is approached.

• Activation range: +

center.

IR Receiver: • 38 KHz, one-way IR reception (for AMX codes only)

Microphone: • Used for audio conferencing applications (intercom functionality)

50° (left and right from center)

50° (up and down from center)

20° vertically from center and + 45° horizontally from

4" Color Touch Panels with Audio

3

Page 8

Product Information

Specifications (Cont.)

Front Panel Components

(Cont.):

Speakers: • Frequency response 450 Hz - 7 KHz

• 8 ohm

• 1 watt

Audio Levels: • Microphone output:

Line level audio

Differential drive

Programmable gain from 7dB to 50db in 31 steps of 1.5 db (linear taper)

• Audio input:

Line level audio

Differential drive

Programmable gain from -26dB to +34 dB in 31 steps of 2dB each.

Rear Connectors:

AXlink/PWR: • 4-pin 3.5 mm mini-Phoenix connector for communication to the AMX Central

Controller providing both data and power

Audio: • 8-pin 3.5 mm mini-Phoenix connector for audio input/output

Programming Port: • 2.5 mm stereo conductor jack (side mounted)

Compatibility: • Axcess, NetLinx, and Landmark systems

Character Support: • Unicode

• Characters for middle-eastern languages such as Arabic are not supported

Operating / Storage

Environment:

Included Accessories: • Installation Kit for AXD panels (KA5921-02)

• Indoor Operating Temperature: 10° C (50° F) to 40° C (104° F)

• Indoor Operating Humidity: 5% to 90% RH (non-condensing)

• Installation Kit for AXT panels:

®

character support for far-eastern languages such as Chinese.

within the Unicode fonts because they are bi-directional. Buttons with Unicode

fonts can only be created and edited using TPDesign3.

- 2.5 mm stereo conductor programming cable (FG10-817)

- 4-pin 3.5 mm mini-Phoenix data/power connector (41-5047)

- 8-pin 3.5 mm mini-Phoenix audio connector (41-5083)

- Drywall clip set:

2 -drywall clamps and 2- #6 (2" long) screws (62-5924-05)

- 6 included blank buttons (pre-mounted into the AXD chassis)

- One bag containing 12 custom buttons (2 embossed/10 pad-printed)

(65-6004)

- Set of three Detachable Faceplates with corresponding buttons:

- White faceplate (60-5921-40WH) and White button set (60-5921-41WH)

- Black faceplate (60-5921-40BK) and Black button set (60-5921-41BK)

- Beige faceplate (60-5921-40BG) and Beige button set (60-5921-41BG)

- 2.5 mm stereo conductor programming cable (FG10-817)

- 6 included blank buttons (pre-mounted into the AXT chassis)

- 10’ (3.05 m) custom Table Top cable (CA5921-01)

- One bag containing 12 custom buttons (2 embossed/10 pad-printed)

4

4" Color Touch Panels with Audio

Page 9

Product Information

Specifications (Cont.)

Optional Accessories: • AC-CP4A/WRB, Water resistant bezel set for AXD-CP4/A (beige, black, white)

(FG5921-24)

• Axcess programming cable (DB9 to DB9) (FG10-727)

• CB-CP4/A (FG033-10) Conduit/wallbox (includes drywall clips and screws for

installation to studs during the construction phase).

- Conduit/Wallbox should only be mounted to a beam before a drywall is

installed (pre-wall).

• PSN2.8 Power Supply (12 VDC) (FG423-17)

• PSN6.5 Power Supply (12 VDC) (FG423-41)

(recommended for use on the CP4/A)

Cleaning the Touch Overlay

You should clean the touch screen overlay often. Always use clean cotton cloths, and a spray bottle

of cleaning solution consisting of 50% isopropyl alcohol and 50% water.

AC-CP4A/WRB Water-Resistant Faceplate for AXD-CP4/A

AMX now offers a new option - a set of water-resistant bezels for AXD-CP4/A touch panels:

AC-CP4A/WRB (FIG. 2). The faceplate set includes all three (3) color configurations - beige,

black, and white - covered with a thin transparent water-resistant film that covers the entire surface

of the bezel including the touch screen, sensor lens, and pushbuttons. It also includes a rubber-foam

gasket to "seal" the gap between the bezel, the back box and the wall. It is a perfect solution that

brings the power of AMX touch panels into wet and splashy environments inside your house or

office building.

FIG. 2 Sample AXD-CP4/A and AXT-CP4/A

4" Color Touch Panels with Audio

AC-CP4A/WRB faceplates (Beige, Black, and White)

FG5921-24

5

Page 10

Product Information

Specifications

Specifications (Cont.)

Dimensions (HWD):

AC-CP4A/WRB

Foam Insulation

Description: • Water- resistant faceplate for existing AXD-CP4/A touch panels. This faceplate

Compatibility: • All AXD-CP4/A (Wall Mount) Touch Panels

Weight: • 75 grams

Features: • Faceplate mounts to any existing AXD-CP4/A.

Included

Accessories:

Operating /Storage

Environments:

• 4.59" x 6.13" x 0.35" (11.66 cm x 15.57 cm x 1.27 cm)

• Thickness: 0.125" (3.12 mm)

covers the LCD and buttons. The included foam insulation is placed around and

behind the edges of the AXD housing (along the screw locations).

• Provides three different faceplate colors (Beige/Black/White).

• Foam insulation protects the internal circuitry from moisture and the elements.

• Insulator cutouts fit perfectly around existing housing screws.

• Three (3) faceplates: Beige (60-5921-44BG), Black (60-5921-44BK), and White

(60-5921-44WH)

• One strip of foam insulation (with screw cutouts) that mounts around the inside

border of the AXD housing

• Operating Temperature: 10° C (50° F) to 40° C (104° F)

• Operating Humidity: 20 - 100% RH

• Storage Temperature: -20° C (-4° F) to 60° C (140° F)

• Storage Humidity: 5 - 85% RH

NOTE: The AC-CP4A/WRB is intended for installation to AXD units.

The two main installation environments where this accessory can be used are: Solid

surface (using four #4-40 solid surface screws) and Drywall surface

(using 2 - #6 drywall clips and screws).

6

4" Color Touch Panels with Audio

Page 11

Installation

Mounting the AXD Wall Mount Panels

The following paragraphs describe mounting the touch panel directly into a drywall, solid surface,

and into a Conduit Box. Wall Mount panels (AXDs) are contained within a plastic back box. This

back box is not removed in either the Conduit Box (CB-CP4/A) or solid surface installation

methods.

The CP4/A has a 4-pin mini-Phoenix AXlink connector (for data and power) and 8-pin

mini-Phoenix Audio connector (for audio/microphone communication) locations on the rear of the

unit. The AXT-CP4/A comes shipped with a pre-wired tabletop cable (CA5921-01). Manual wiring

of the connector ports is recommended for any AXD or custom installations.

The AXD and AXT CP4/A touch panels have different IR reception angle

specifications based on either their location, elevation, and/or distance from the IR

transmission source.

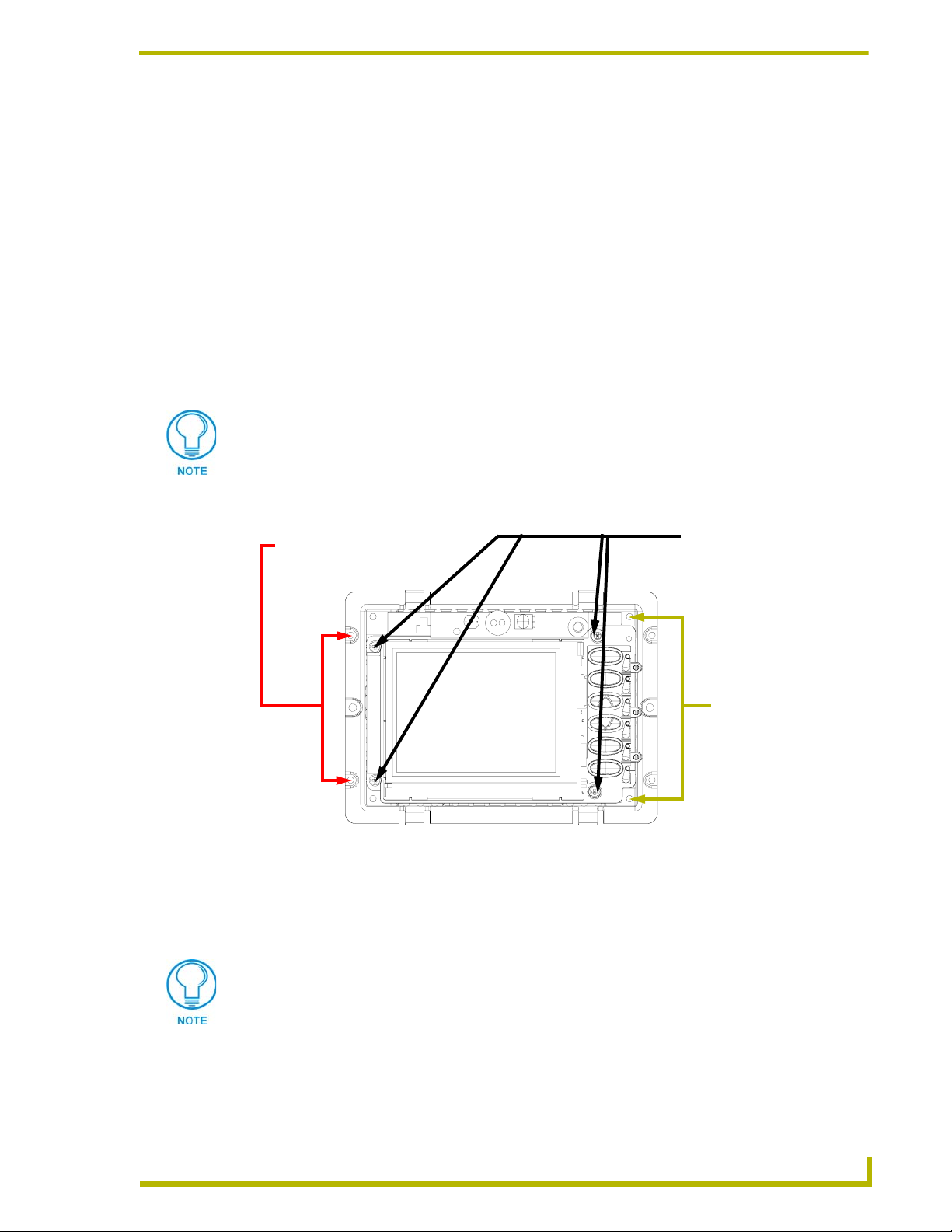

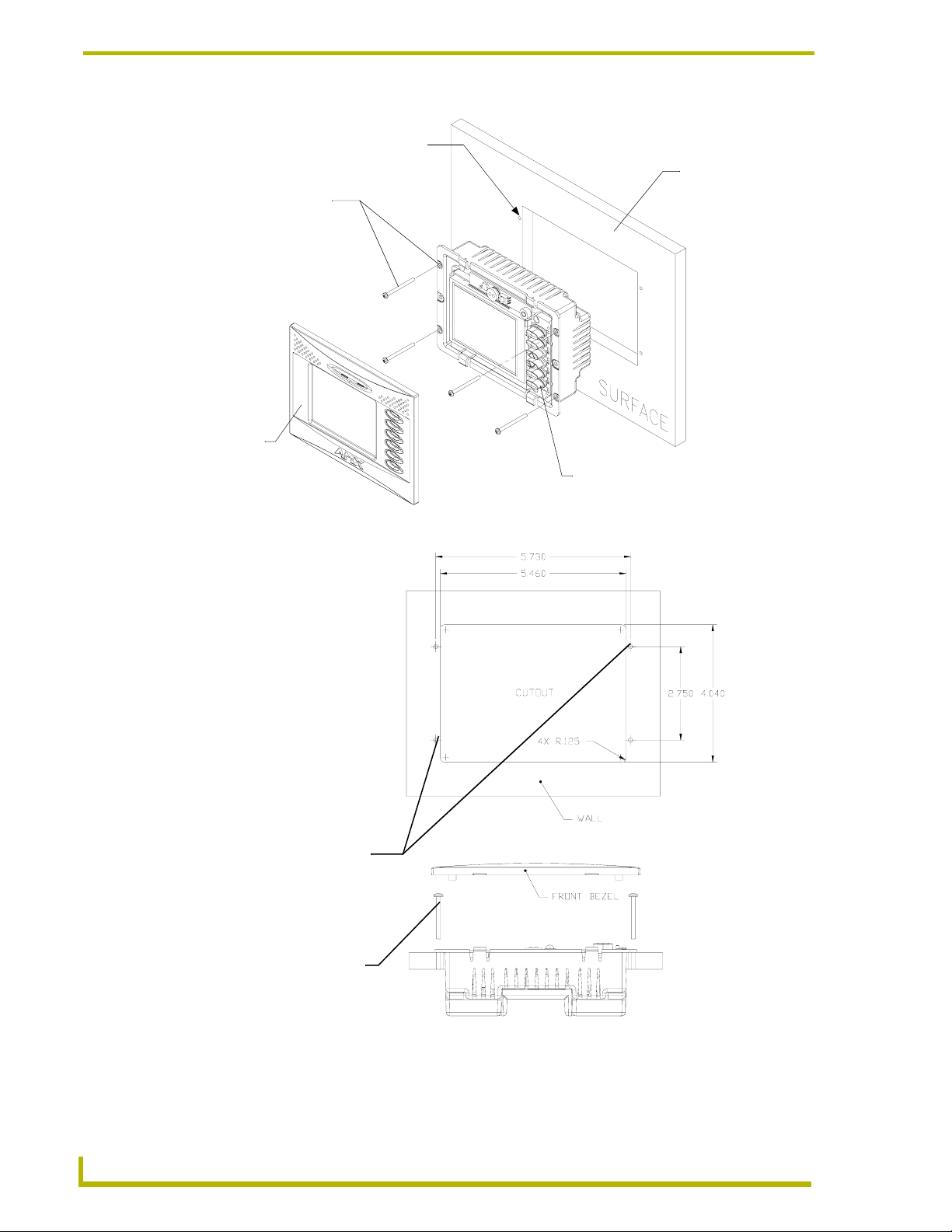

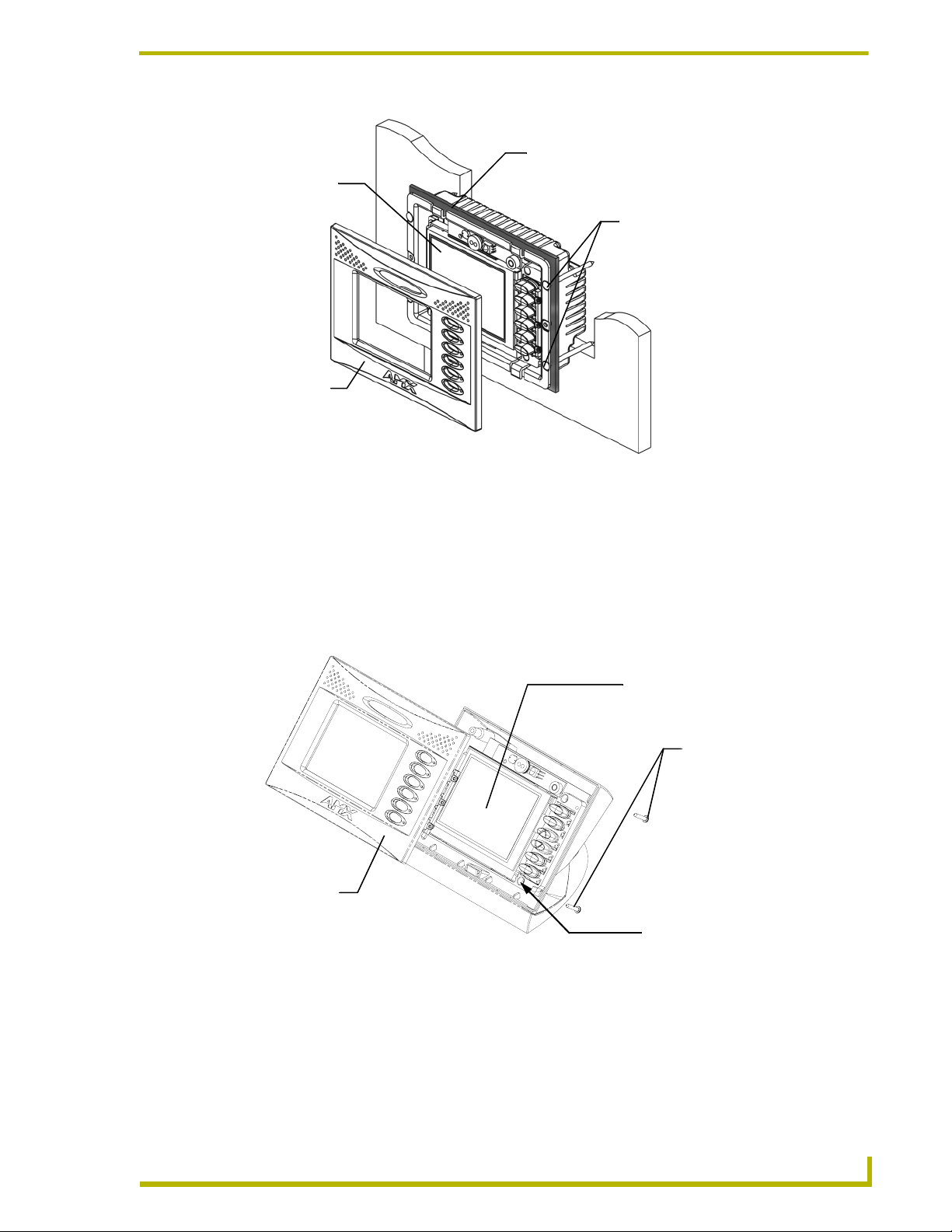

The following graphic (FIG. 3) indicates the locations of the different Wall Mount screw types.

Installation

Four Solid Surface

screws are used here

to secure the

housing/unit to a solid

surface

FIG. 3 Wall Mount panel (AXD) showing the secure locations for all screws types

Four (4) #4-20 screws

(thread-forming screws)

- these are used to secure

the internal components

to the housing

Four (4) #4-40 screws

(machine screws)

- these are used to

secure the housing to

a CB-CP4/A

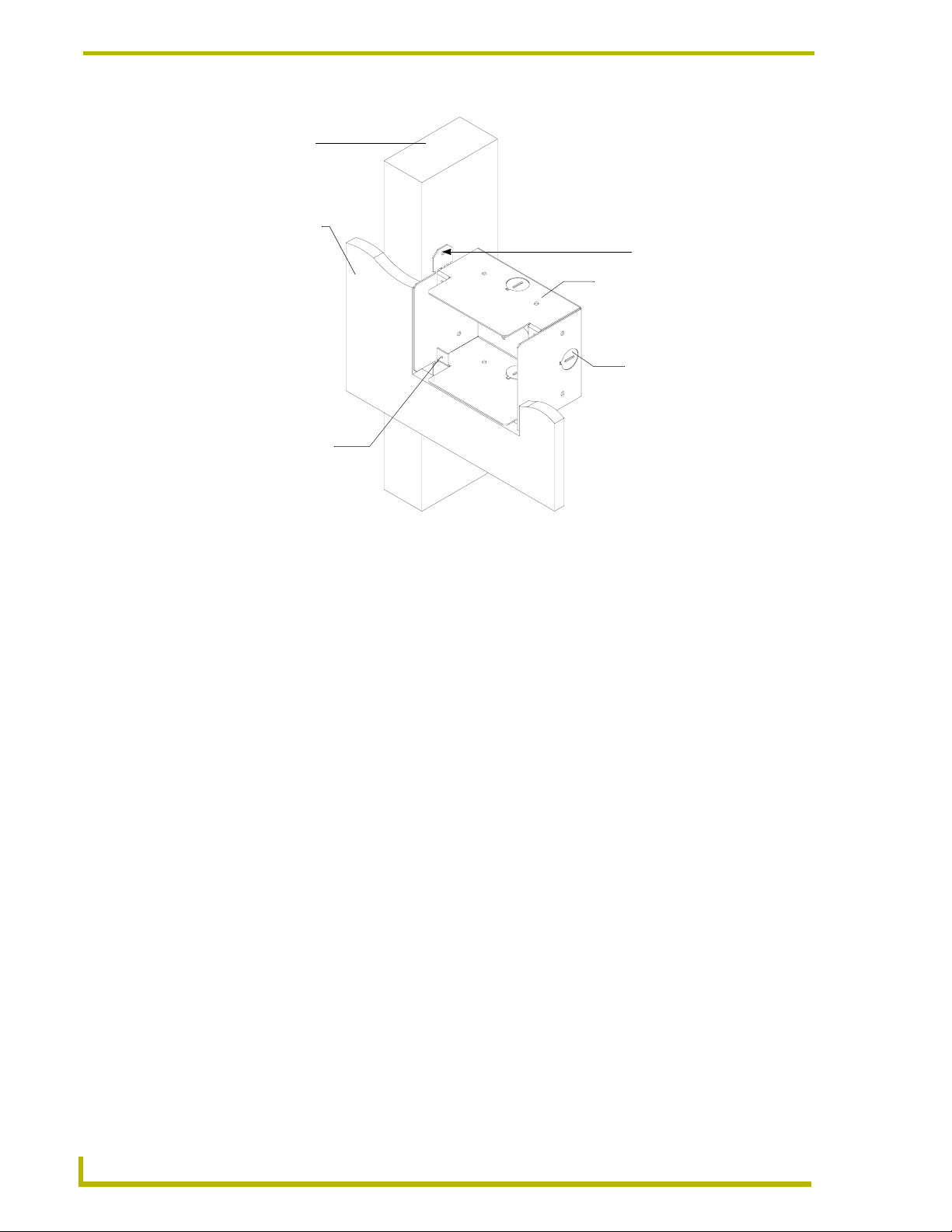

Wall Mount installation using a pre-wall CB-CP4/A Conduit Box

The CP4/A Conduit/wallbox is an optional metallic housing that is installed onto a beam in a

pre-wall setting. The touch panels are housed in a default backbox that ships with each unit.

This installation (using the CB-CP4/A) must be done prior to any wall

installation.

To install a Wall Mount touch panel into a conduit/wallbox for pre-mounted surfaces:

1. Fasten the CB-CP4/A to the stud through the stud fastening holes shown in FIG. 4 on page 8.

The wallbox can be secured to the stud by using either nails or screws.

4" Color Touch Panels with Audio

7

Page 12

Installation

Stud

Surface

Stud fastening holes

CB-CP4/A Conduit Wallbox

Knockouts

AXD-CP4/A touch

panel housing secure

locations using four

#4-40 screws

Do not use these tabs

to mount a Conduit/

Wallbox

FIG. 4 Screw location for attachment on a sample conduit box for a drywall installation

2. Remove any necessary wiring knockouts from the pre-installed (optional) conduit box

(C in FIG. 4 on page 8) where the necessary cables are threaded through for connection to the

touch panel and external devices. The snaps located along the side of the conduit/wallbox can

be snapped off or used to mount the unit to a hard surface (like a wooden beam).

3. Carefully remove the attached AMX faceplate/bezel (A in FIG. 5) from the main AXD unit

(B in FIG. 5) by gripping the faceplate from the notches (located along the underside of the

plate) and pulling with gentle force.

4. Thread the incoming 4-pin mini-AXlink and 8-pin mini-Audio wiring through the cutout

opening in the wall.

5. Test the wiring by connecting the 4-pin mini-Phoenix connector from the rear AXlink

connector to a PSN6.5 power supply or Central Controller. Verify that the panel is receiving

power and functioning properly to prevent repetition of the installation.

6. Connect both the AXlink and Audio connectors to the rear of the touch panel. Refer to the

Wiring the Touch Panel section on page 21 for more detailed wiring instructions.

7. Disconnect the power connector from the PSN6.5 or Central Controller until the installation is

complete.

8

4" Color Touch Panels with Audio

Page 13

Attachment site for beam

Install the (4) #4-40

machine screws into

into the places

indicated

Installation

Stud beam

C - Optional CB-CP4/A

conduit/wallbox

SURFACE

A - Faceplate

(bezel)

FIG. 5 Wall Mount panel installation configuration for pre-existing conduit/wall box in a pre-wall construction

B - Main AXD unit consists of

the touch panel and backbox housing

Don’t disconnect the connectors from the touch panel. The unit must be installed with

the necessary connectors before being inserted into the drywall. Verify that the panel

is receiving power and functioning properly to prevent repetition of the installation.

8. Fasten the CB-CP4/A to the stud through the tabs shown in FIG. 5. The wallbox can be secured

to the stud by using either nails or screws. This installation must be done prior to any wall

installation.

9. Carefully slide the main unit (B in FIG. 5) into the conduit/wallbox (C in FIG. 5) until it slides

in completely and flush against the wallbox.

10. Use the four (4) securing screws (#4-40 screws) to attach the main AXD unit to the conduit

wallbox. Refer to B in FIG. 5 on page 9 for more information.

11. Use a grounded Phillips screwdriver to tighten the screws in a clockwise direction

12. Fasten the main AXD unit to the surface using the four (4) surface screws (not provided with

unit) until the housing is securely fastened and flush against the wall.

13. Carefully remove any of the blank pre-installed plastic pushbuttons by pushing the top rim of

the button towards the LCD panel and applying a small amount of force.

14. Carefully insert the six (6) desired replacement pushbuttons (up to 12 other pre-labeled buttons

come in the accessory button kit) by grabbing the button at either sides, inserting the

attachment pegs into their respective connector holes, and pressing down firmly (FIG. 6 on

page 10).

4" Color Touch Panels with Audio

9

Page 14

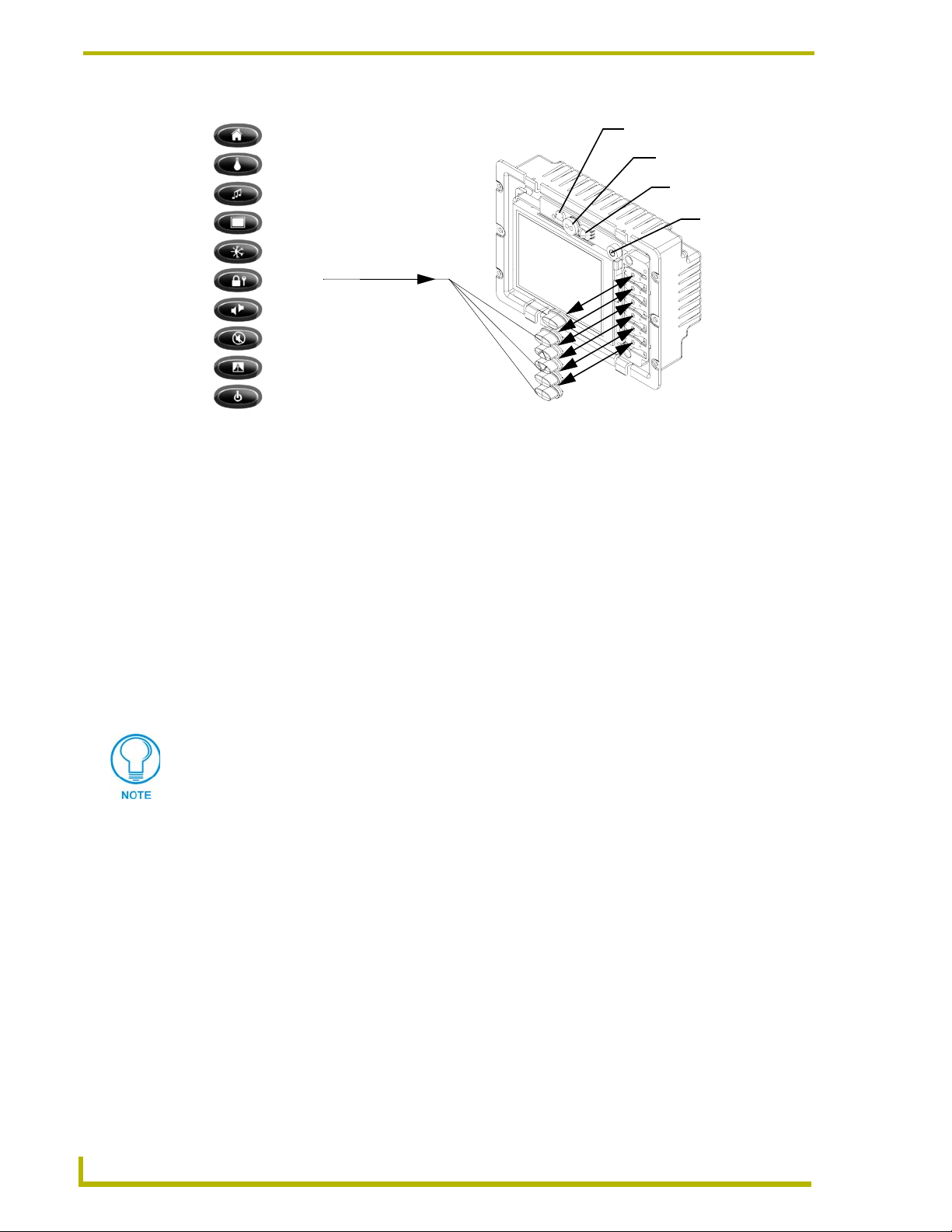

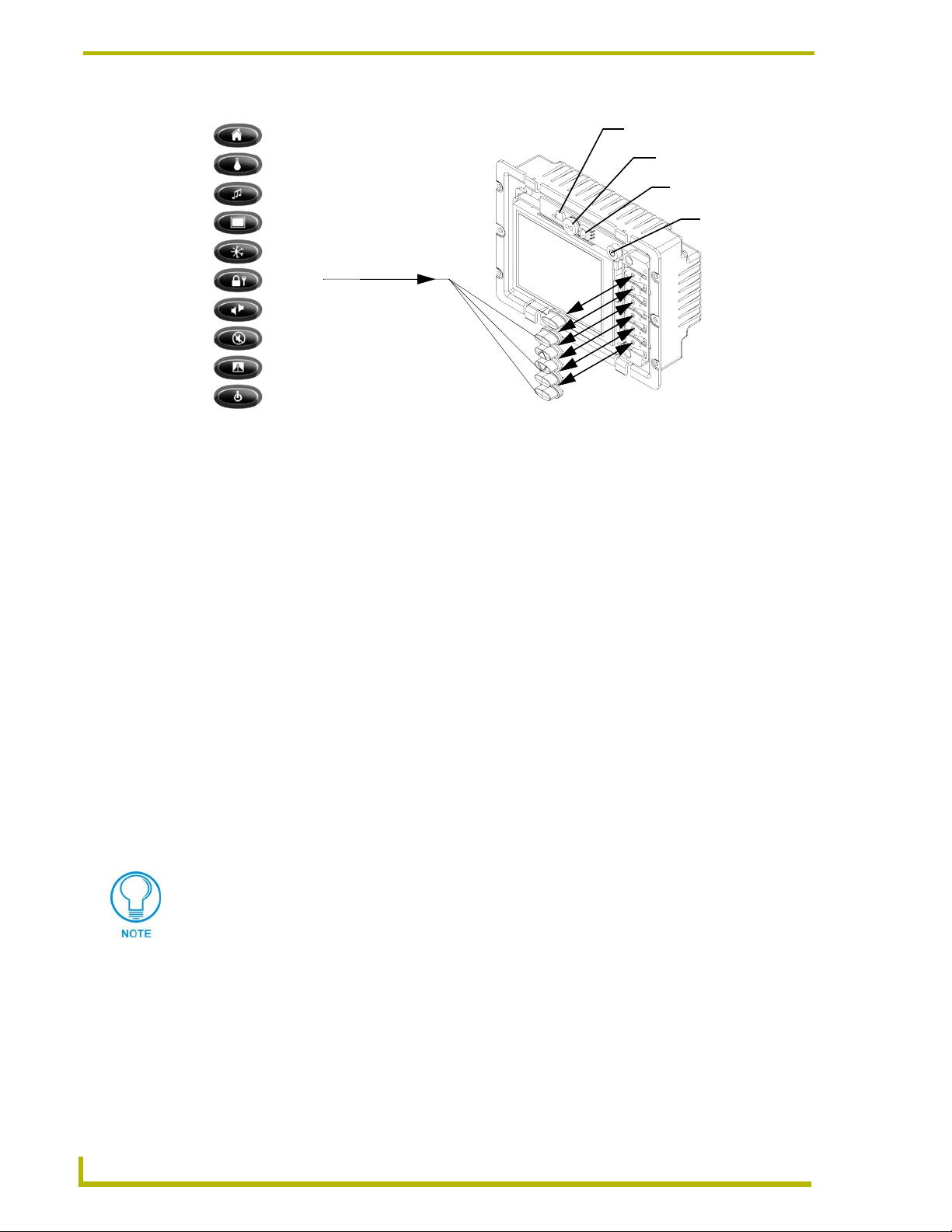

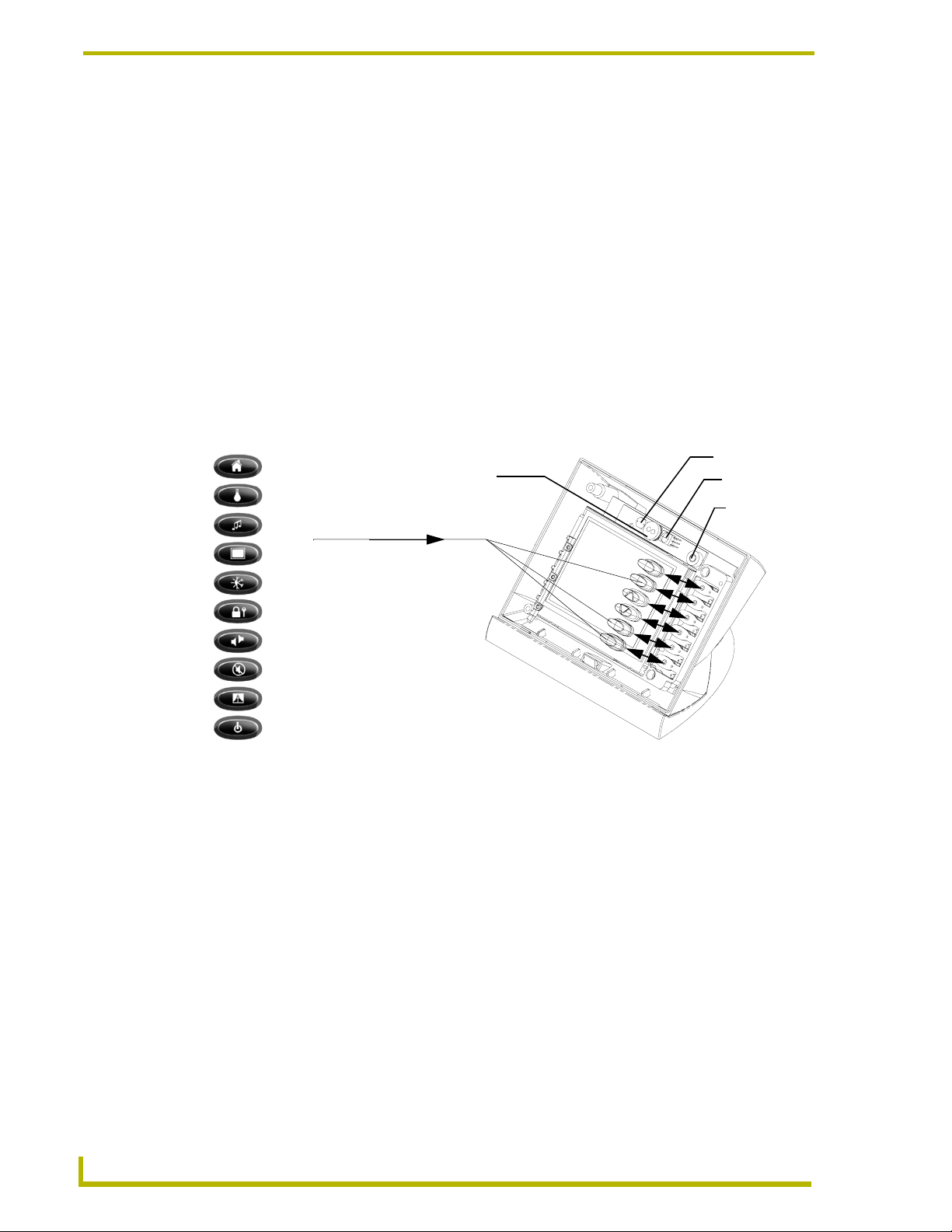

Installation

Menu

Lights

Audio

Video

Environment

Security

Intercom

Mute

Drapes

Powe r

FIG. 6 Plastic pushbutton replacement locations

Standard pushbutton

icons (come in 3 colors

Black, Beige, and White)

Light Sensor

PIR (Passive Infrared)

Sensor

IR Receiver

Microphone

15. Place the faceplate (A in FIG. 5 on page 9) onto the main AXD unit (B in FIG. 5 on page 9) by

gripping the object at both sides, resting the top rim of the faceplate to the top rim of the

housing, then applying gentle downward force. Make sure to align the Light, IR receiver, and

PIR Motion sensor locations to their respective openings on the front bezel/faceplate. Make

sure the buttons are flush against the faceplate.

16. Reconnect the audio wiring to its respective terminal locations on the selected external audio

equipment for use in conferencing.

17. Reconnect the 4-pin mini-AXlink connector from the panel to the Central Controller and

provide power to the unit.

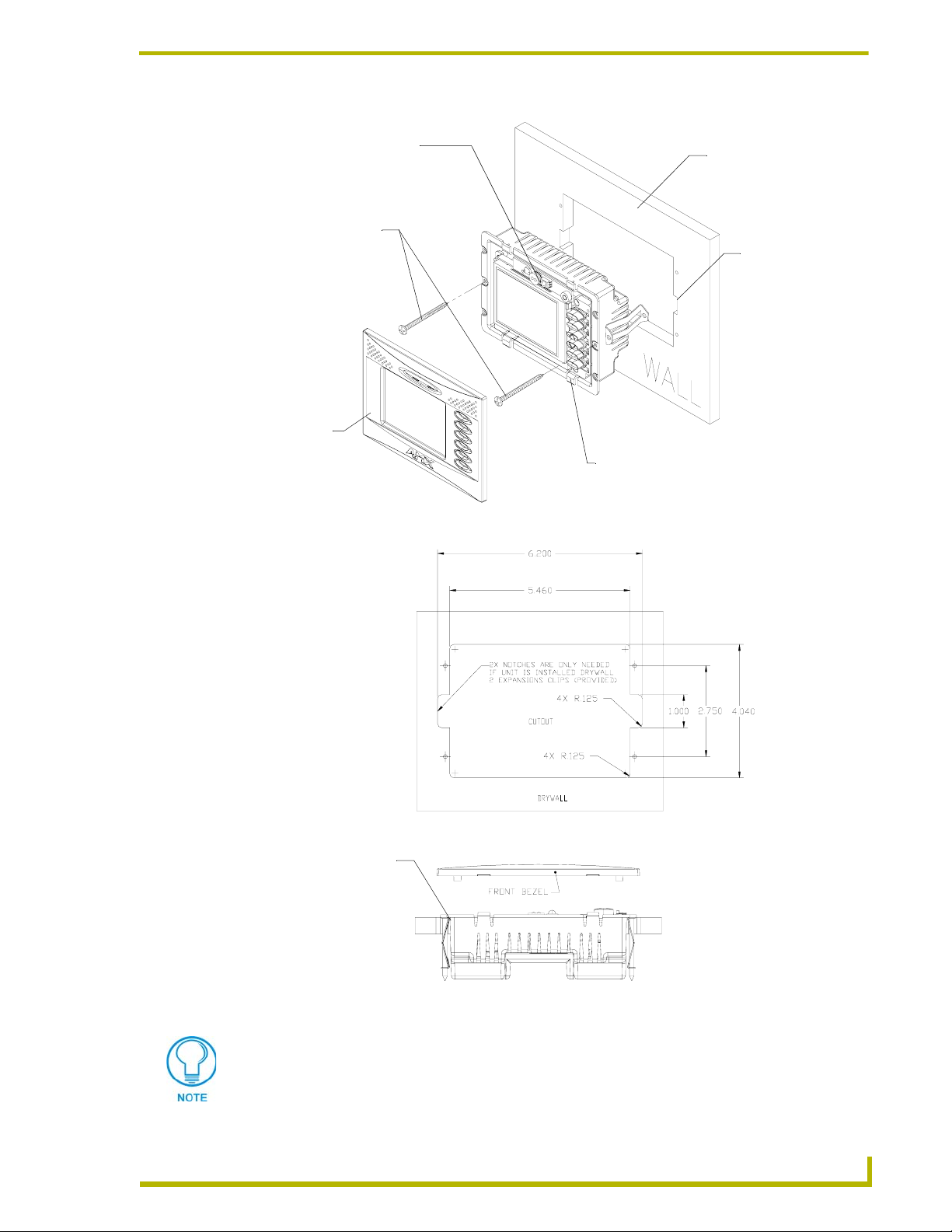

Wall Mount panel installation into Drywall using Expansion Clips

To install Wall Mount touch panels into plasterboard/drywall:

Expansion clips are mounted through pre-drilled notches located at the sides of the

panel. These clips are one-time use pieces. If and error occurs during the installation

process, a replacement clip must be ordered through your AMX representative.

1. Carefully remove the attached AMX faceplate/bezel (A in FIG. 7 on page 11) from the main

AXD unit (B in FIG. 7 on page 11) by gripping the faceplate from the notches (located along

the underside of the plate) and pulling with gentle force.

2. Cut out the install surface using the dimensions shown in FIG. 8 on page 11. Cut out the two

notches along-side the CP4/A to accommodate the two provided drywall expansion clips.

3. Thread the incoming 4-pin mini-AXlink and 8-pin mini-Audio wiring through the cutout

opening in the wall.

4. Test the wiring by connecting the 4-pin mini-Phoenix connector from the rear AXlink

connector to a PSN6.5 power supply or Central Controller. Verify that the panel is receiving

power and functioning properly to prevent repetition of the installation.

5. Connect both the AXlink and Audio connectors to the rear of the touch panel. Refer to the

Wiring the Touch Panel section on page 21 for more detailed wiring instructions.

10

4" Color Touch Panels with Audio

Page 15

Installation

PIR, Microphone, IR and

Light Sensor locations

Install the 2-#6 drywall

clips and screws

(included) into the

the holes

A - Faceplate

(bezel)

B - Main AXD unit consists of the touch

panel, internal components, and housing

FIG. 7 Wall Mount panel (AXD) installation configuration for drywall surfaces

Flat surface

(can include a

wall, podium, or

other level

surface)

2 notches are

required if the unit

is installed into a

drywall using the (2)

provided clips.

Drywall clip set (clip and

screw) for installation

to plasterboard/drywall

FIG. 8 Wall Mount panel installation configuration for plasterboard

Don’t disconnect the connectors from the touch panel. The unit must be installed with

the necessary connectors before being inserted into the drywall. Verify that the panel

is receiving power and functioning properly to prevent repetition of the installation.

4" Color Touch Panels with Audio

surfaces

11

Page 16

Installation

6. Disconnect the power connector from the PSN6.5 or Central Controller until the installation is

complete.

7. Insert the #6 drywall screws and clips into the two notch locations along the side edges of the

Wall Mount housing as shown in both FIG. 7 on page 11 and in FIG. 8 on page 11.

8. Carefully insert the main unit (with expansion clips) into the cutout until the rim of the AXD

unit lies flush with the wall and the unit is firmly positioned.

9. Use a grounded Phillips screwdriver to tighten the #6 drywall screws in a clockwise direction

(FIG. 7 on page 11).

10. Fasten the main AXD unit to the surface using the two (2) drywall clip sets (consisting of

screws and clips) supplied with the enclosure until the housing is securely fastened and flush

against the wall (FIG. 9).

As the screw is tightened, the clip bends toward the insertion hole and into the wall. This

bending creates a "grip" on the wall by either pressing onto the wall or by securing the drywall

between the housing and the drywall clip.

B - Main

AXD unit

Interchangeable

plastic pushbuttons

Dry wall clips and 2- #6 screws

are inserted through the

notches cut out in the wall

A - Faceplate

(bezel)

FIG. 9 Screw and clip locations for plasterboard (dry wall) mounting of main AXD unit

11. Carefully remove any of the blank pre-installed plastic pushbuttons by pushing the top rim of

the button towards the LCD panel and applying a small amount of force.

12. Carefully insert the six (6) desired replacement pushbuttons (up to 12 other pre-labeled buttons

come in the accessory button kit) by grabbing the button at either sides, inserting the

attachment pegs into their respective connector holes, and pressing down firmly (FIG. 10 on

page 13).

12

4" Color Touch Panels with Audio

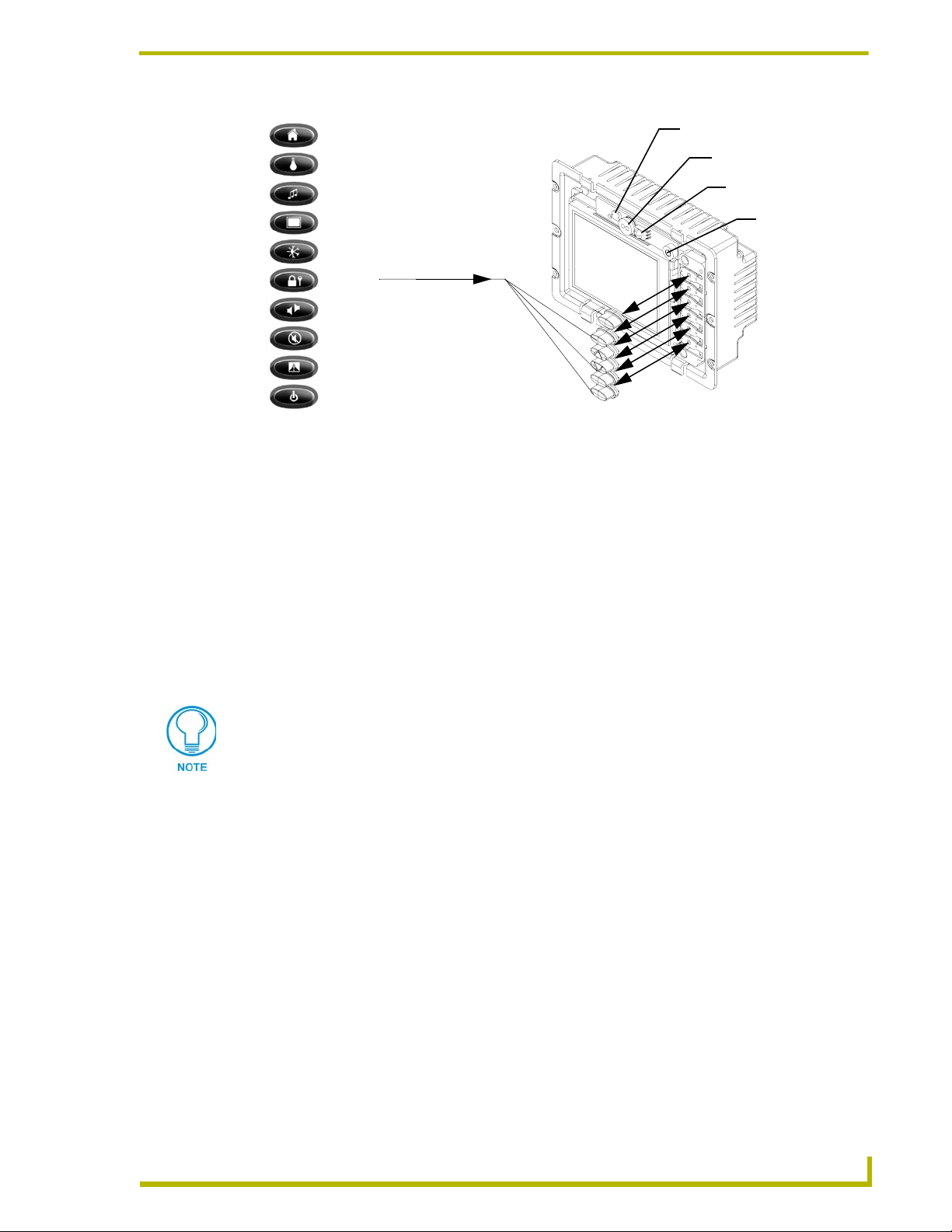

Page 17

Installation

Menu

Lights

Audio

Video

Environment

Security

Intercom

Mute

Drapes

Powe r

FIG. 10 Plastic pushbutton replacement locations

Standard pushbutton

icons (come in 3 colors

Black, Beige, and White)

Light Sensor

PIR (Passive Infrared)

Sensor

IR Receiver

Microphone

13. Place the faceplate (A in FIG. 9 on page 12) onto the main AXD unit (B in FIG. 9 on page 12)

by gripping the object at both sides, resting the top rim of the faceplate to the top rim of the

housing, then applying gentle downward force. Make sure to align the Light, IR receiver, and

PIR Motion sensor locations to their respective openings on the front bezel/faceplate. Make

sure the buttons are flush against the faceplate.

14. Reconnect the audio wiring to its respective terminal locations on the selected external audio

equipment for use in conferencing.

15. Reconnect the 4-pin mini-AXlink connector from the panel to the Central Controller and

provide power to the unit.

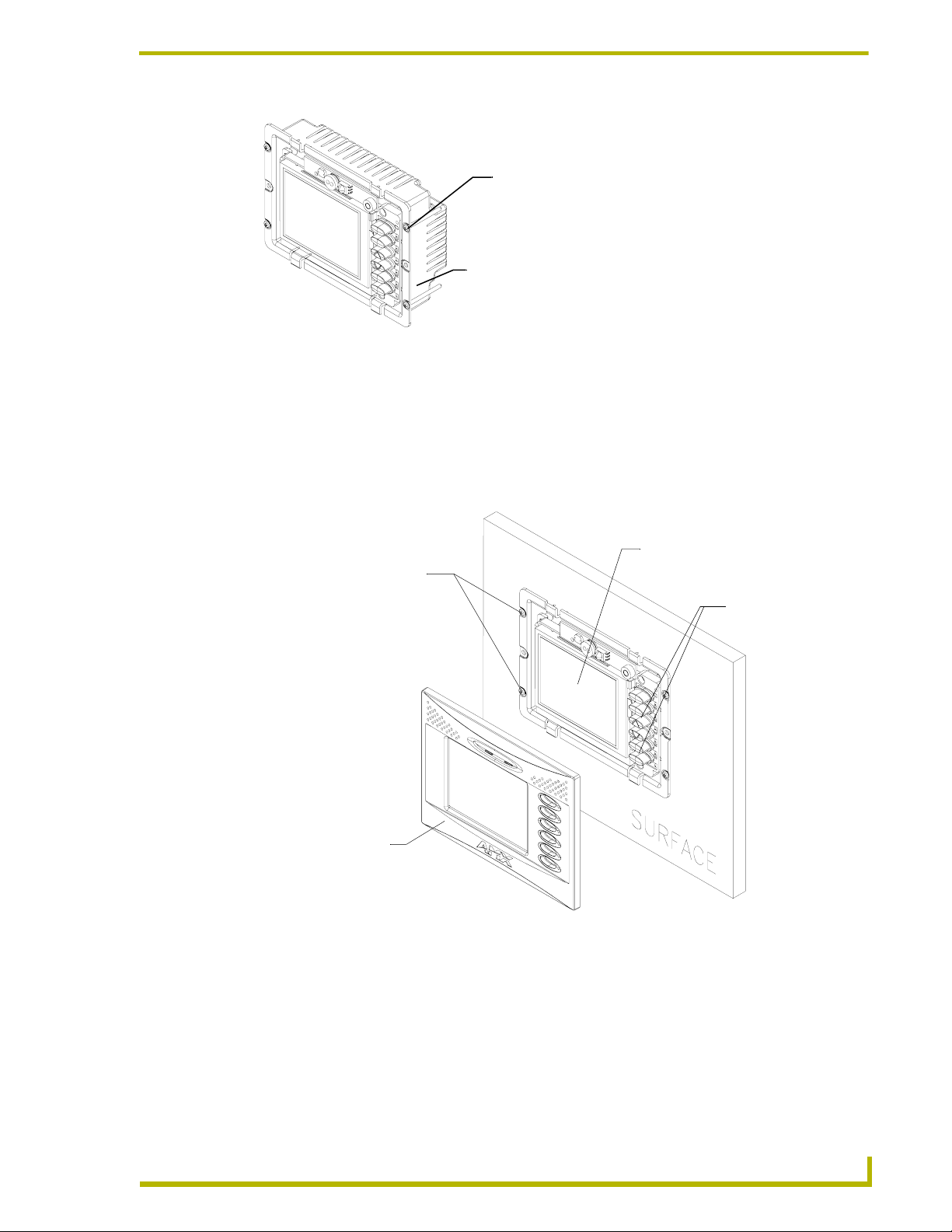

Wall Mount panel installation onto a flat surface using solid-surface screws

Mounting screws are secured through four (4) pre-drilled holes located at the left and

right sides of the panel.

1. Carefully remove the attached AMX faceplate/bezel (A in FIG. 11) from the main AXD unit

(B in FIG. 11) by gripping the faceplate from the notches (located along the underside of the

plate) and pulling with gentle force.

2. Cut out the surface using the dimensions shown in FIG. 12 on page 14. Be sure not to cut out

notches for the expansion clips (only used when mounting the panel in plasterboard).

3. Thread the incoming 4-pin mini-AXlink and 8-pin mini-Audio wiring through the cutout

opening in the wall.

4. Test the wiring by connecting the 4-pin mini-Phoenix connector from the rear AXlink

connector to a PSN6.5 power supply or Central Controller. Verify that the panel is receiving

power and functioning properly to prevent repetition of the installation.

5. Connect both the AXlink and Audio connectors to the rear of the touch panel. Refer to the

Wiring the Touch Panel section on page 21 for more detailed wiring instructions.

6. Disconnect the power connector from the PSN6.5 or Central Controller until the installation is

complete.

4" Color Touch Panels with Audio

13

Page 18

Installation

Install the four (4)

solid surface screws

into the holes

(screws not included)

shown below.

Screw length

depends on the

installation surface.

A

- Decor

faceplate

Attachment is done

along the edges of

the cutout

Flat/Solid surface

(can include a

wall, podium, or

other level

surface)

B - Main AXD unit consists of the

touch panel, internal components,

and housing

FIG. 11 Wall Mount panel installation configuration for flat /solid surfaces

These four holes are only

required when mounting

to a solid surface. Secure

the unit with solid surface

screws using #4-40 threaded

inserts at these four locations

Solid surface screw inserts

(4 screws) for mounting to a

flat surfaces (provided by

installer)

14

FIG. 12 Wall Mount panel installation configuration for flat surface mounting

7. Insert the four solid surface screws into the four threaded insert locations along the side edges

of the Wall Mount housing as shown in both FIG. 13 on page 15.

4" Color Touch Panels with Audio

Page 19

Installation

Solid surface mounting screws (4)

are inserted through the

outer holes along the plastic housing

Main AXD unit consists of

internal components, CP4/A, and

plastic housing

FIG. 13 Screw locations for plasterboard mounting of the main AXD unit

8. Carefully insert the main unit (with surface screws) into the cutout until the rim of the AXD

unit lies flush with the wall and the unit is firmly positioned.

9. Use a grounded Phillips screwdriver to tighten the solid surface screws in a clockwise direction

(FIG. 13 on page 15).

10. Fasten the main AXD unit to the surface using the four (4) solid surface screws (not provided

with unit) until the housing is securely fastened and flush against the wall (FIG. 14).

Solid surface mounting screws

are inserted through the

openings along the side of

the Wall Mount panel

A - Faceplate

(bezel)

FIG. 14 Mounting screw locations for solid-surface mounting of main AXD unit

B - Main

AXD unit

Interchangeable

plastic pushbuttons

11. Carefully remove any of the blank pre-installed plastic pushbuttons by pushing the top rim of

the button towards the LCD panel and applying a small amount of force.

12. Carefully insert the six (6) desired replacement pushbuttons (up to 12 other pre-labeled buttons

come in the accessory button kit) by grabbing the button at either sides, inserting the

attachment pegs into their respective connector holes, and pressing down firmly (FIG. 15 on

page 16).

4" Color Touch Panels with Audio

15

Page 20

Installation

Menu

Lights

Audio

Video

Environment

Security

Intercom

Mute

Drapes

Powe r

FIG. 15 Plastic pushbutton replacement locations

Standard pushbutton

icons (come in 3 colors

Black, Beige, and White)

Light Sensor

PIR (Passive Infrared)

Sensor

IR Receiver

Microphone

13. Place the faceplate (A in FIG. 14) onto the main AXD unit (B in FIG. 14) by gripping the

object at both sides, resting the top rim of the faceplate to the top rim of the housing, then

applying gentle downward force. Make sure to align the Light, IR receiver, and PIR Motion

sensor locations to their respective openings on the front bezel/faceplate. Make sure the buttons

are flush against the faceplate.

14. Reconnect the audio wiring to its respective terminal locations on the selected external audio

equipment for use in conferencing.

15. Reconnect the 4-pin mini-AXlink connector from the panel to the Central Controller and

provide power to the unit.

Installation of the AC-CP4A/WRB Faceplates

AMX now offers a new option - a set of water-resistant bezels for AXD-CP4/A touch panels:

AC-CP4A/WRB. This faceplate set includes all three (3) color configurations - beige, black, and

white - covered with a thin transparent water-resistant film that covers the entire surface of the

bezel including the touch screen, sensor lens, and pushbuttons. It also includes a rubber-foam

gasket to "seal" the gap between the bezel, the back box and the wall. It is a perfect solution that

brings the power of AMX touch panels into wet and splashy environments inside your house or

office building.

The AC-CP4A/WRB is intended for installation to AXD units.

The two main installation environments where this accessory can be used are: Solid

surface (using four #4-40 solid surface screws) and Drywall surface

(using 2 - #6 drywall clips and screws).

16

4" Color Touch Panels with Audio

Page 21

Installation

Drywall Surface upgrade installation

Expansion clips are mounted through pre-drilled notches located at the sides of the

panel. These clips are one-time use pieces. If and error occurs during the installation

process, a replacement clip must be ordered through your AMX representative.

1. Carefully remove the attached AMX faceplate/bezel (A in FIG. 16) from the main AXD unit

(B in FIG. 16) by gripping the faceplate from the notches (located along the underside of the

plate) and pulling with gentle force.

2. Locate the 2 drywall screws located along both sides of the AXD unit.

3. Use a grounded Phillips screwdriver to slightly loosen the #6 drywall screws in a counter-

clockwise direction.

The purpose of only slightly loosening the drywall screws is NOT to remove the unit

but to provide enough slack so that there is enough room between the AXD housing

and the drywall to wrap the foam insulation around the back of the housing for

insulation purposes.

4. Unscrew the drywall screws enough to where there is a 0.125" gap between the edge of the

AXD housing and the drywall.

5. Install the foam insulation by inserting the left side of the foam between the drywall and the

rear of the housing.

6. While still holding the insulation, gently pull the other side of the foam over the opposite side

of the housing (FIG. 16) until the entire foam strip is now located behind the outer rim of the

AXD housing.

B - Main unit

(with LCD)

A - Faceplate

(bezel)

Foam Insulation strip

Two #6 drywall

clips and screws

FIG. 16 Foam insulation location on a drywall mounted AXD

7. Verify the alignment of the center foam cutouts over the two side drywall screws (FIG. 16).

8. Carefully begin tighten the #6 drywall screws in a clockwise direction. Slight adjustments to

the position of the foam insulation can be necessary.

4" Color Touch Panels with Audio

17

Page 22

Installation

9. Perform a visual inspection of the insulation seal around the rim of the AXD housing. There

should be no visible gaps between the rim of the housing and the surface of the drywall.

10. Finish the securing process of the AXD back to the drywall by tightly turning the drywall

screw in a clockwise direction to guarantee a tight seal.

11. Place the new AC-CP4A/WRB water-resistant faceplate onto the main AXD unit

(B in FIG. 16) by gripping the object at both sides, resting the top rim of the faceplate to the

top rim of the housing, then applying gentle downward force.

12. Make sure to align the Light, IR receiver, and PIR Motion sensor locations to their respective

openings on the front bezel/faceplate. Make sure the buttons are flush against the faceplate.

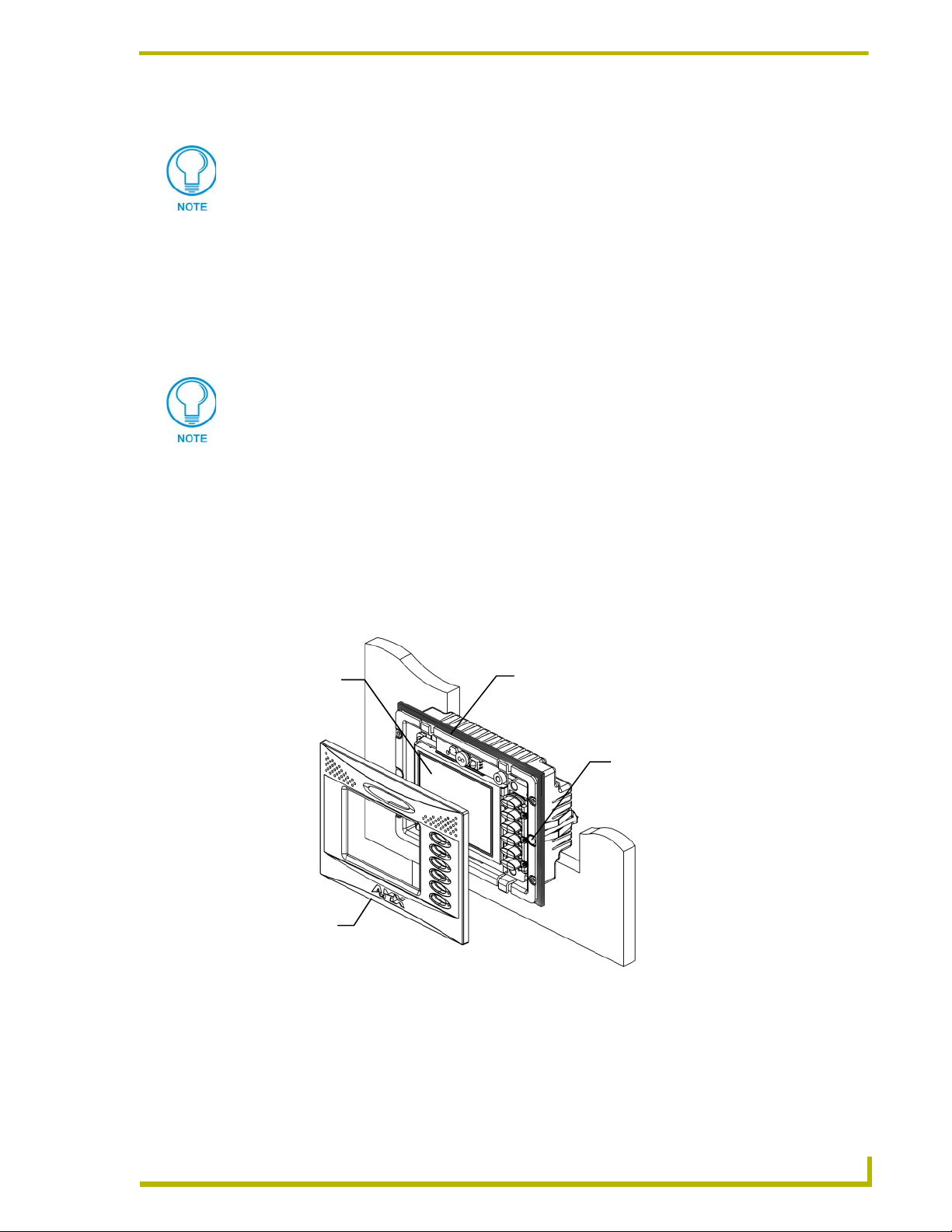

Solid Surface upgrade installation

Expansion clips are mounted through pre-drilled notches located at the sides of the

panel. These clips are one-time use pieces. If and error occurs during the installation

process, a replacement clip must be ordered through your AMX representative.

1. Carefully remove the attached AMX faceplate/bezel (A in FIG. 17) from the main AXD unit

(B in FIG. 17) by gripping the faceplate from the notches (located along the underside of the

plate) and pulling with gentle force.

2. Locate the 4 solid-surface screws located along both sides (2 per side) of the AXD unit.

3. Use a grounded Phillips screwdriver to slightly loosen the screws in a counter-clockwise

direction.

The purpose of only slightly loosening the surface screws is NOT to remove the unit

but to provide enough slack so that there is enough room between the AXD housing

and the surface to wrap the foam insulation around the back of the housing for

insulation purposes.

4. Unscrew the screws enough to where there is a 0.125" gap between the edge of the AXD

housing and the surface.

5. Install the foam insulation by inserting the left side of the foam between the surface and the

rear of the housing.

6. While still holding the insulation, gently pull the other side of the foam over the opposite side

of the housing (FIG. 17) until the entire foam strip is now located behind the outer rim of the

AXD housing.

7. Verify the alignment of the center foam cutouts over the four side solid-surface screws

(FIG. 17).

8. Carefully begin tighten the screws in a clockwise direction. Slight adjustments to the position

of the foam insulation can be necessary.

9. Perform a visual inspection of the insulation seal around the rim of the AXD housing. There

should be no visible gaps between the rim of the housing and the surface.

18

10. Finish the securing process of the AXD back to the surface by tightly turning the surface screw

in a clockwise direction to guarantee a tight seal.

11. Place the new AC-CP4A/WRB water-resistant faceplate onto the main AXD unit (B in

FIG. 17) by gripping the object at both sides, resting the top rim of the faceplate to the top rim

of the housing, then applying gentle downward force.

4" Color Touch Panels with Audio

Page 23

Installation

Foam Insulation strip

B - Main unit

(with LCD)

4 - #4-40 solid

surface screws

A - Faceplate

(bezel)

FIG. 17 Foam insulation location on a solid surface mounted AXD

12. Make sure to align the Light, IR receiver, and PIR Motion sensor locations to their respective

openings on the front bezel/faceplate. Make sure the buttons are flush against the faceplate.

Removing the AXT Faceplate/Bezel

Whereas the AXD faceplate is removable by gripping the faceplate from the notches and pulling

outwards, the AXT faceplate is secured to the enclosure via four (4) #4-40 phillips-head screws

located along the rear corners of the panel (FIG. 18).

B - Main AXT unit consists of

the touch panel, internal components

and enclosure

Remove/Install the four (4)

#4-20 screws from/into the

location indicated

A - Faceplate

(bezel)

Securing screws (4) #4-20

FIG. 18 AXT faceplate removal and screw locations

1. Flip the AXT panel over and place the LCD onto a soft cloth to prevent scratching during the

removal process.

2. Locate the four (4) phillips-head #4-20 screws on the rear of the enclosure.

3. Remove the screws by inserting a grounded Phillips screwdriver into the screw holes and turn

the screws counter-clockwise.

4" Color Touch Panels with Audio

19

Page 24

Installation

4. Remove all screws from the rear of the unit (B in FIG. 18 on page 19).

5. Firmly grab the front and rear of the panel and flip it back to where the entire unit is lying flat

on a level surface.

6. Carefully pull the faceplate (A in FIG. 18 on page 19) outwards until it comes away from the

rest of the main AXT unit (B in FIG. 18 on page 19).

Refer to the following section for more information on removing/replacing the pushbuttons and

reconnecting the faceplate/bezel to the main AXT unit

Removing and replacing AXT pushbuttons

1. Carefully remove any of the blank pre-installed plastic pushbuttons by pushing the top rim of

the button towards the LCD panel and applying a small amount of force.

2. Carefully insert the desired replacement pushbutton (up to 12 other pre-labeled buttons come

in the accessory button kit) by grabbing the button at either sides, inserting the attachment pegs

into their respective connector holes, and pressing down firmly (FIG. 19).

Menu

Lights

Audio

Video

Environment

Security

Intercom

Mute

Drapes

Powe r

FIG. 19 Plastic pushbutton replacement locations on AXT

Standard pushbutton

icons (come in 3 colors

Black, Beige, and White)

PIR (Passive

Infrared Sensor

Light Sensor

IR Receiver

Microphone

3. Carefully place the faceplate (A in FIG. 18) back onto the Main AXT unit (B in FIG. 18).

Make sure to align the Light, IR receiver, and PIR Motion sensor locations to their respective

openings on the front bezel/faceplate.

4. Firmly grab the front and rear of the panel and flip the AXT panel over.

5. Place the LCD back onto a soft cloth to prevent scratching during the removal process.

20

6. Insert all screws back into the screw holes on the rear of the unit (B in FIG. 18).

7. Secure the screws by inserting a grounded Phillips screwdriver into the screw holes and turn

the screws clockwise.

8. Firmly grab the front and rear of the panel and flip it back to where the entire unit is lying flat

on a level surface.

4" Color Touch Panels with Audio

Page 25

Installation

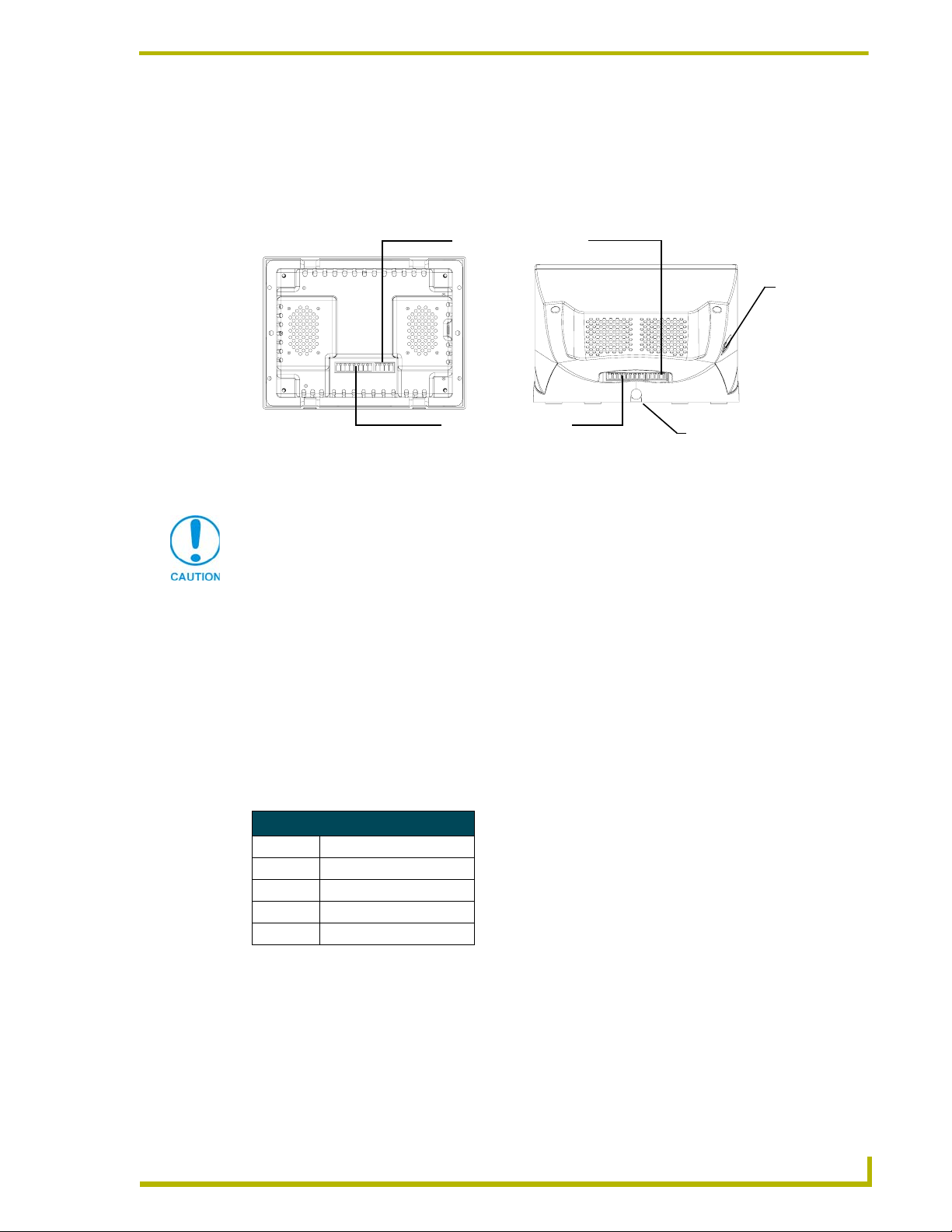

Wiring the Touch Panel

The CP4/A touch panels use a 4-pin 3.5 mm mini-Phoenix AXlink connector (male) for both power

and data and an 8-pin 3.5 mm mini-Phoenix connector for audio input/output (FIG. 20). This same

figure shows the rear connector locations on both AXD and AXT panels.

4-pin

3.5 mm mini-Phoenix

AXlink connector

Programming

jack

8-pin

3.5 mm mini-Phoenix

Audio connector

AXD-CP4/A (Rear view)

FIG. 20 Rear views of the AXD and AXT touch panels

AXT-CP4/A (Rear view)

Cable clip

Do not connect power to the touch panel until wiring is complete. If you are using a

12 VDC power supply, apply power to the touch panel only after installation is

complete.

Wiring guidelines

CP4/A touch panels require 12 VDC power to operate properly. These panel can use either a

PSN2.8 or a PSN6.5 power supply. The Central Controller supplies power via the AXlink cable.

The maximum wiring distance between the Central Controller and touch panel is determined by

power consumption, supplied voltage, and the wire gauge used for the cable. The table below lists

wire sizes and maximum lengths allowable between the touch panel and Central Controller. The

maximum wiring lengths for using AXlink power are based on a minimum of 13.5 volts available at

the Central Controller’s power supply. Refer to the Specifications section on page 1 for more

information.

Wiring Guidelines at 770 mA

Wire Size Maximum Wiring Length

18 AWG 152.43 feet (46.46 m)

20 AWG 96.44 feet (29.39 m)

22 AWG 60.13 feet (18.33 m)

24 AWG 37.90 feet (11.55 m)

4" Color Touch Panels with Audio

21

Page 26

Installation

Wiring the CP4/A terminal connectors and cables

You will need a wire stripper and Phillips screwdriver to prepare and connect the captive wires.

Power and Audio connectors are wired and attached to the rear of the CP4/A. FIG. 21 provides a

layout of the wiring connection into both the AXD and AXT touch panels. This diagram is intended

for use in wiring the terminal ends of the 4-pin and 8-pin cables.

Microphone (-)

Microphone (+)

Mic GND

3.5 mm Audio Connector

Terminal connections are

dependent on the system configuration

FIG. 21 CP4/A terminal connector pinout and wiring diagram

8-pin

4-pin

3.5 mm mini-AXlink

Audio Right (+)

Audio Right (-)

Audio GND

Audio Left (+)

Audio Left (-)

GND

AXM

AXP

PWR

AXD/T-CP4/A

Rear

Front

Touch

Panel

On an AXT-CP4/A panel, these terminal connections are already wired to the

appropriate connectors. To wire the terminal end of the AXT panel, connect the

connectors to the rear of the panel as shown in FIG. 21 and thread the tabletop cable

(CA5921-01) through the cable support clip located at the base of the panel (rear).

1. Loosen the screws on both the 4-pin and 8-pin connectors before insertion.

2. Strip 0.25 inch of wire insulation off all wires.

3. Insert the incoming PWR, AXP, AXM, and GND wires from the Controller’s AXlink

connector into the respective openings on the terminal 4-pin 3.5 mm mini-Phoenix AXlink

connector locations shown in FIG. 21.

4. Insert the outgoing microphone and incoming audio wires from the existing audio system into

the respective openings on the terminal 8-pin 3.5 mm mini-Phoenix audio connector locations

shown in FIG. 21.

5. Secure the connections by using a grounded Phillips screwdriver to turn the screws clockwise.

Do not over-torque the screws; doing so can bend the seating pin and damage the connector.

6. Insert the wired connectors to the rear of the CP4/A touch panel.

Do not connect power to the touch panel until wiring is complete. If you are using a

12 VDC power supply, apply power to the touch panel only after installation is

complete.

7. Unscrew the two (2) screws that attach the clip to the underside of the AXT.

8. Thread the tabletop cable through the cable-clip opening at the rear of the AXT unit

(FIG. 20 on page 21).

22

4" Color Touch Panels with Audio

Page 27

Installation

9. Flip the AXT panel over and place the LCD onto a soft cloth to prevent scratching during the

removal process.

10. Screw the two (2) screws that attach the clip to the underside of the AXT.

11. Firmly grab the front and rear of the panel and flip it back to where the entire unit is lying flat

on a level surface.

Additional CP4/A wiring configurations

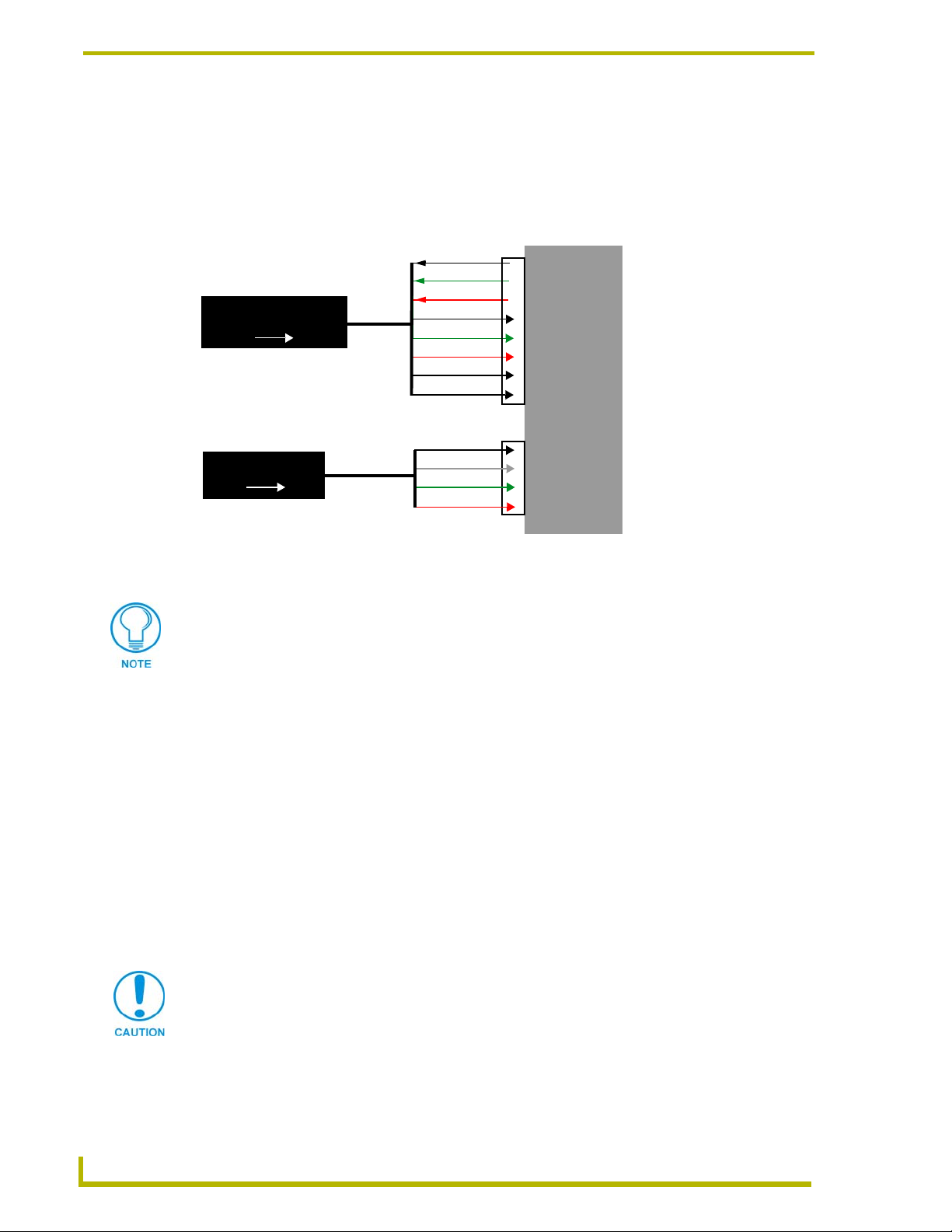

FIG. 22 provides a layout of the wiring connection used for multiple CP4/A panels wired to both a

Central Controller and an Audio switch. This diagram is intended for use in general wiring amongst

the various components of this system. The audio and microphone termination connectors are

dependent on the switch itself.

AXlink

AXlink

AXlink

AXlink

AXlink

AXD/T-CP4/A

Tou ch

Panel

#1

AXD/T-CP4/A

Tou ch

Panel

#2

AXD/T-CP4/A

Tou ch

Panel

#3

AXD/T-CP4/A

Tou ch

Panel

#N

Central Controller

(Master)

Microphone

Audio

Wire

termination is

switch dependent

Microphone

Audio

Microphone

Audio

Microphone

Audio

A

U

D

I

O

S

W

I

T

C

H

Wire termination are

dependent on the switch connections

FIG. 22 CP4/A wiring diagram using multiple panels routed through a Master and audio switch

In the above system, panel #1 could be configured so that a push sends a corresponding command

through the Master that sets panel #1’s microphone On and then sets all other panels (#2 - N) to

transmit the audio through their speakers.

An example of this would be if a user wants to use panel #1 to send a page throughout a

home/office: "is anyone there...". All other panels would transmit the audio being picked

up by the first panels’ microphone.

4" Color Touch Panels with Audio

23

Page 28

Installation

Another example used with this system is that a user, upon hearing the page, could press

a button "labeled" for the source room and respond: "yes, I’m here".

FIG. 23 provides a layout of the wiring connection using two directly cross-connected CP4/A

panels that use a Master. This diagram is intended for use in general wiring information amongst

the various components of this system.

Central Controller

(Master)

Mic

Speaker

AXD/T-CP4/A

Touch

Panel

#1

Audio

4-pin AXlink

8-pin AXlink

Mic

AXD/T-CP4/A

Tou ch

Panel

Audio

Mic

#2

Speaker

A

U

Wire termination of the Mic and Audio is

done using an 8-pin 3.5 mm mini-Phoenix connector

FIG. 23 CP4/A wiring diagram using two panels directly connected to each other using the CA5921-01 cable

D

I

In the above example, the Master controls the volume activity of the audio being transmitted

(through the microphone on one panel) and received (through the speakers of the other panel). The

mini 4-pin AXlink cable connects the panels to the Master and the mini 8-pin cable connects the

two panels’ audio signals.

The following bullets explain what happens on the panels during an audio transmission from both

the first and second panel.

A button push on panel #1 sends a PUSH command to the Master which then:

Increases panel #1 microphone level and mutes panel #1 speaker. This allows the

first user to transmit audio.

Decreases panel #2 microphone level and increases Panel #2 speaker volume to

default levels. This allows the second user to hear the audio being transmitted from

panel #1.

24

A button push on panel #2 sends a PUSH command to the Master which then:

Increases panel #2 microphone level and mutes panel #2 speaker. This allows the

second user to transmit audio.

Decreases panel #1 microphone level and increases Panel #1 speaker volume to

default levels. This allows the first user to hear the audio being transmitted from

panel #1.

4" Color Touch Panels with Audio

Page 29

Installation

Using the CP4/A Programming Jacks

The programming jack (located on the side of either AXT or AXD touch panels) is used for

programming/communication between the CP4/A touch panel and TPDesign3. The programming

jack uses a three-wire, 2.5 mm stereo port. The optional (female to female) Axcess programming

cable (FG10-727) is used to bridge the connection between the programming cables’ male terminal

connector and the male RS-232 port on the rear of your PC (FIG. 24).

AXT Programming

jack

Stereo plug

(male)

CP4/A panel

to DB9

programming

cable (FG10-817)

FIG. 24 Programming jack connector locations and wiring configuration to the PC

AXD Programming

jack

or

male DB9

female DB9

female DB9

Axcess Programming

cable - FG10-727

goes to your PC’s

rear male RS-232

port

To download and upload TPDesign3 touch panel pages:

1. Connect the stereo plug (male) end of the programming cable into the programming jack on

the side of the CP4/A.

2. Connect the male DB9 end of the cable into the female connector on the optional Axcess

programming cable.

3. Connect the other end of the Axcess programming cable to the male DB9 port on the back of

your computer.

4. Configure the communication parameters in TPDesign3.

For more information on CP4/A communication methods, refer to the Communication

Methods for CP4/A Firmware Update section on page 67 for additional methods and

firmware download procedures.

4" Color Touch Panels with Audio

25

Page 30

Installation

26

4" Color Touch Panels with Audio

Page 31

Designing Touch Panel Pages

There are two ways to approach creating touch panel pages:

TPDesign3 - Refer to the TPDesign3 Touch Panel Program (Version 3. 16) instruction

manual for more information.

On-board editor

This section describes the basics of using the on-board editor to create pages and buttons. For more

information, refer to the G3 Firmware Design and Reference instruction manual.

Verify the TPDesign3 program being used is Version 3.16 build 193 or higher.

The Updated EXE for TPDesign3 can be found at AMX.com > Tech Center >

Downloadable Files > Application FIles > TPDesign3. Earlier versions of TPD3

will not correctly function with these panels.

Buttons

Standard button types include rectangles and other geometric shapes you can create with the touch

panel editor. Buttons are set with attributes, meaning there is a response from the Central Controller

when you touch the button.

Designing Touch Panel Pages

General buttons are part of the default touch panel program and cannot be changed. General buttons

create or revise pages and specify panel communication parameters. The general button categories

are described in the table below.

General Button Categories

Selection buttons Selection buttons appear on touch panel pages and set

communication parameters.

Information buttons Information buttons contain serial numbers and firmware version

Adjustment buttons You can use the UP and DN buttons to set adjustment buttons. The

Keypad buttons The keypad button opens a keypad so you can enter a password or

information. The properties of these buttons cannot be changed.

These buttons have a dark fill and light text.

adjustment button example sets the baud rate for the connection

from the touch panel to the computer.

value assignment. All keypad buttons are interactive except for the

entry display.

4" Color Touch Panels with Audio

27

Page 32

Designing Touch Panel Pages

General Button Categories (Cont.)

Decision buttons Decision buttons appear when an operation has two options and

Status buttons Status buttons always have a dark fill with light letters and have no

Operation bars Operation bars appear in the place of the Editor bar, after selecting a

Touch to Continue buttons "Touch to Continue" buttons appear when an operation requires user

Joystick buttons Joysticks are vertical and horizontal direction controllers for use with

requires verification before an action is performed.

functionality except to display information.

button or page edit operation. The operation bar indicates which edit

function is currently active. When an edit operation is selected, it

remains active until you press EXIT.

acknowledgement.

pan and tilt camera controllers.

Bargraph buttons Bargraph buttons display a dynamic bargraph (vertical or horizontal).

An example is the Battery level indicator button.

Activating Edit Mode

Before designing touch panel pages and buttons, you must activate Edit mode. Once activated, use

the

EDIT button to enter Edit mode. This mode has options to add and configure touch panels and

buttons. When powering up the touch panel, the first page is the Main page (FIG. 25). Note that the

Edit button is not available initially. If you have a pre-programmed panel, you may not see the Main

page.

28

FIG. 25 Main Page

To activate Edit mode:

1. Press

2. Press

SETUP in the Main page to open the Setup page (FIG. 26).

PROTECTED SETUP to open the keypad.

4" Color Touch Panels with Audio

Page 33

Designing Touch Panel Pages

FIG. 26 Setup page

3. Enter 1988 (default password) in the keypad and press ENTER to open the Protected Setup

page. If you press ENTER after typing an incorrect password, you are immediately returned to

the previous page.

4. Press

EDITOR to enable the Edit mode. The EDITOR button is highlighted in the Protected

Setup page when enabled, as shown in FIG. 27.

FIG. 27 Protected Setup page with the active EDITOR button

5. Press

6. Press

EXIT to close the Protected Setup page and return to the Setup page (now in Edit mode).

EXIT again to return to the Main page. The EDIT button appears at the top of the page

indicating Edit mode is active.

7. Press

EDIT to open the Edit bar. The BUTTON and PAG E options, in the Edit bar (FIG. 28), are

used to design and modify button and page settings.

Setting the Device Base

Press the DEVICE BASE option, in the Protected Setup page (FIG. 27), to assign a base (starting)

device address to the touch panel.

1. Enter the base address for the touch panel. The base address range is from 1 - 255. Standard

device addresses begin at 128.

2. Press

4" Color Touch Panels with Audio

ENTER to save.

29

Page 34

Designing Touch Panel Pages

FIG. 28 Main page with Edit bar

Setting the Device Used

Use the DEVICE USED option in the Protected Setup page (FIG. 27) to assign a value for the

number of devices being controlled by the touch panel.

Edit bar

1. Press

DEVICE USED to open the keypad and enter the panel’s device number from 1 - 4. Each

device number supports up to 255 programmable channel codes. The multiple device settings

allow you to create up to four unique touch panel buttons and/or pages. This value is used to

determine the current device being used by the panel.

2. Enter the number of devices being used by the touch panel.

3. Press

ENTER to save the value.

Adding a Page

1. Press PAG E on the Edit bar to open the PA GE menu.

2. Press

3. Press

Setting the page color

1. Press

2. Press

3. Press

4. Select a color from the palette; the page automatically changes to the new color.

ADD to open the keyboard and enter a name for the new page. Page names can be up to

20 characters.

EXIT CHANGE to save, close the keyboard, and go to the new page.

EDIT to open the Edit bar on the newly created page.

PAG E on the Edit bar to open the PAG E menu.

PAG E C OL O R to open the color palette.

30

Adding a Button

To add a button to the current page:

1. Press

2. Press

BUTTON on the Edit bar to open the BUTTON menu.

ADD to open the ADD BUTTON operation bar. On the LCD screen, touch and drag to

create a button. The first touch point is the upper-left corner of the button.

4" Color Touch Panels with Audio

Page 35

Resizing a button

Designing Touch Panel Pages

1. Press

2. Press

BUTTON on the Edit bar to open the BUTTON menu.

RESIZE. Then, touch any edge of the button and drag. Removing your finger from the

panel saves the button dimensions.

Defining On-Screen Button Properties

External pushbuttons are configured with features similar to on-screen buttons. Their functionality

can be set just as any other button on the touch panel.

Use the

button colors for channel on/off conditions, channel/variable text codes, and string/macro

assignments.

Although the Border and Color sections of this page appear, they are of no use to external

pushbuttons since they do not appear on-screen.

To set button properties:

1. Press

2. Press

3. Press the new button to open the Button Properties page. This page lists the properties for the

4. Press

PROPERTIES option of the BUTTON menu in the Edit bar to set button borders, page flips,

BUTTON on the Edit bar to open the BUTTON menu options.

PROPERTIES to open the PROPERTIES operation bar.

active button.

BUTTON TYPE to open the BUTTON TYPE menu.

5. Choose a button type for the selected button to open the associated Button Properties page.

Each button type has its own Button Properties page with settings specific to the button.

6. Press

7. Select a border to set for the button and return to the Button Properties page. The

BORDER to open the Button Border page.

BORDER

button changes to show the selected border type.

Setting the channel code

The channel button sets the device and button channel codes.

Channel codes and variable text codes work the same for all button types, including

joysticks, and bargraphs.

1. In the Button Properties page, press

DEV to open the keypad and set the touch panel’s device

number.

2. Enter 1, 2, 3, or 4 in the keypad. The programming software uses device codes 1 - 4 to identify

the touch panel. Refer to the G3 Firmware Design and Reference instruction manual for more

information.

If DEVICE USED is set to 4 and Base Device Number is 128, the Controller recognizes

bus devices 128 - 131.

The panel will not allow you to enter a device number greater than the DEVICE USED

without first displaying a decision box asking if you accept the new selection or not.

3. Press

ENTER to save the device number, close the keypad, and return to the Button Properties

page.

4" Color Touch Panels with Audio

31

Page 36

Designing Touch Panel Pages

4. Press CHAN to open the keypad and enter a channel value of 1 - 255. The source code uses the

channel code number to identify the button and its programmed operations. The channel code

for non-active buttons is 0.

5. Press

ENTER to save the channel number, close the keypad, and return to the Button Properties

page.

Setting the variable text code

The variable text buttons set the device and button channel codes for the buttons.

1. Press

DEV to open the keypad and set the device number.

2. Enter 1, 2, 3, or 4 in the keypad. The source code uses device codes 1 - 4 to identify the touch

panel.

3. Press

4. Press

ENTER to save, close the keypad, and return to the Button Properties page.

CHAN to open a keypad and set the channel number.

5. Enter a channel value of 1 - 255 in the keypad. The source code uses the channel code number

to identify the button and its operations.

6. Press

ENTER to save the channel number, close the keypad, and return to the Button Properties

page.

Setting the page flip

1. Press the Page

the

PAGE FLIP TYPE menu.

Page FLIP

type button

FLIP STANDARD type button (FIG. 29) in the Button Properties page to open

Flip to Page button

FIG. 29 Page FLIP Type button

2. Select a Page Flip type. If you select

P

AGE button appears.

3. Press the

FLIP TO PAGE button (FIG. 29) to open a list of all the saved touch panel pages. If the

FLIP PREVIOUS in the PAGE FLIP TYPE menu, the FLIP TO

desired page is not present in the menu, check to verify the page has been saved.

4. Select the target page for the page flip.

Setting the button colors for channel-off conditions

1. Press any button to open the Button Properties page.

2. Press

BORDER under CHANNEL OFF in the Button Properties page. The color palette appears.

Select a color to set as the border.

3. Press the

FILL button in the Button Properties page to open the palette. Select a color to set as

the fill.

4. Press the

5. Press

TEXT button to open the palette. Select a color to use for the text.

EXIT SAVE CHANGE in the Button Properties page to save the new button properties and

return to the current page.

32

4" Color Touch Panels with Audio

Page 37

Adding text, icons, and bitmaps to a button

Designing Touch Panel Pages

1. Press

2. Press

BUTTON on the Edit bar to open the BUTTON menu.

TEXT/IMAGE to add text to the button. The TEXT/IMAGE operation bar appears.

3. Press any button to open the Text/Image page.

4. Go through each option and set as desired:

TEXT OFF and TEXT ON sets the text for the button's Off and On state.

ICON OFF and ICON ON sets the icon for the button's Off and On state.

BITMAP OFF and BITMAP ON sets the bitmap for the button's Off and On state.

MAKE ON SAME AS OFF sets the On and Off properties the same.

You cannot create or edit buttons with Unicode fonts on the panel. Any use of the

TEXT/IMAGE button to alter or create Unicode font supported buttons must be done

in the TPDesign3 Touch Panel Design Program.

5. Press

EXIT SAVE CHANGE to close the Text/Image page and return to the Main page.

Creating a Bargraph and Joystick

Bargraphs are level monitors and adjustable level controls. These levels can be configured to

monitor and adjust audio outputs and lighting levels.

Joysticks are vertical and horizontal direction controllers you can use for things such as camera pan

and tilt control. Before starting, make sure to connect the touch panel to your Controller; otherwise,

the joystick will not work properly.

Adding a bargraph or joystick button

Create a new button using the Add operation bar in the

1. Press

2. Press

BUTTON in the Edit bar to open the BUTTON menu.

PROPERTIES in the Button menu to open the PROPERTIES operation bar.

BUTTON menu.

3. Press any button to open the Button Properties page.

4. Press