Page 1

Color Active-Matrix LCD Mini-Touch Panels

t a k e c o n t r o l

(Firmware version G2 or lower)

Instruction Manual

Page 2

Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free from defects in material and

workmanship under normal use for a period of three years from date of purchase

from AMX, with the following exceptions. Electroluminescent and LCD control

panels are warranted for a period of three years, except for the display and touch

overlay components, which are warranted for a period of one year. Disk drive

mechanisms, pan/tilt heads, codecs, power supplies, modifications, MX Series

products, and KC Series products are warranted for a period of one year. Unless

otherwise specified, OEM and custom products are covered for a period of one year.

AMX software products are warranted for a period of 90 days. Batteries and

incandescent lamps are not covered.

This warranty extends to products purchased directly from AMX or an authorized

AMX dealer. Consumers should inquire from selling dealer as to the nature and

extent of the dealer’s warranty, if any.

AMX is not liable for any damages caused by its products or for the failure of its

products to perform, including any lost profits, lost savings, incidental damages, or

consequential damages. AMX is not liable for any claim made by a third party or

made by you for a third party.

This limitation of liability applies whether damages are sought, or a claim is made,

under this warranty or as a tort claim (including negligence and strict product

liability), a contract claim, or any other claim. This limitation of liability cannot be

waived or amended by any person. This limitation of liability will be effective even

if AMX or an authorized representative of AMX has been advised of the possibility

of any such damages. This limitation of liability, however, will not apply to claims

for personal injury.

Some states do not allow a limitation of how long an implied warranty lasts. Some

states do not allow the limitation or exclusion of incidental or consequential

damages for consumer products. In such states, the limitation or exclusion of the

Limited Warranty may not apply to you. This Limited Warranty gives you specific

legal rights. You may also have other rights that may vary from state to state. You

are advised to consult applicable state laws for full determination of your rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX MAKES NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. AMX EXPRESSLY DISCLAIMS ALL WARRANTIES NOT

STATED IN THIS LIMITED WARRANTY. ANY IMPLIED WARRANTIES THAT MAY BE IMPOSED BY

LAW ARE LIMITED TO THE TERMS OF THIS LIMITED WARRANTY.

Page 3

Table of Contents

Introduction ............................................................................ 1

Overview 1

Features 2

Applications 2

What's in this Manual 3

Installing Mini-Touch Panels ................................................. 5

Overview 5

Mounting the Mini-Touch Panels 5

AXU-MCA (/PB), AXU-MCV (/PB),

and low profile back box 5

AXU-MCA (/PB), AXU-MCV (/PB),

and BB-MTP UniMount enclosure

(solid surfaces) 7

AXU-MCA (/PB), AXU-MCV (/PB), and

BB-MTP UniMount enclosure

(plasterboard) 9

AXM-MCA (/PB) or AXM-MCV (/PB)

(rack mount) 11

Wiring the Mini-Touch Panels 12

Preparing captive wires 13

Wiring guidelines 13

Using the TiltScreen mini-XLR connector

for AXlink data and power 14

Using the TiltScreen mini-XLR connector

for AXlink and an external 12 VDC

power supply 14

Using the UniMount and rack-mount

AXlink connector for data and power 15

Using the UniMount and rack-mount

AXlink connector for data and an

external 12 VDC power supply 15

Using the UniMount and rack-mount

4-pin header for mouse control 16

Cleaning the Touch Overlay 17

Color Active-Matrix LCD Mini-Touch Panels Table of Contents i

Page 4

Mini-Touch Panel Basics ..................................................... 19

Overview 19

Mini-Touch Panel Pages 19

Standard Buttons 20

General Buttons 20

Message bar 20

Editor bar 21

Selection button 21

Information button 21

Adjustment button 22

Keypad buttons 22

Page menu buttons 23

Decision buttons 23

Status buttons 24

Keyboards 24

Designing a Mini-Touch Panel Page ................................... 29

Overview 29

Activate the Editor Bar 29

Create a Page 31

Add a page 31

Go to NEW PAGE 33

Create a Button 34

Add a button 34

Resize the button 35

Button Attributes 36

Set the button attributes 36

Set the border 37

Set the channel code 38

Set the page flip 38

Add Text 39

Add text to a button 39

Create a Joy Stick 40

Add a joy stick on a page 40

Set the joy stick attributes 41

Set the level code 42

Create a Bargraph 43

Add a bargraph to a page 43

Set the bargraph attributes 44

Set the level code 45

Set the Video Display 45

ii Table of Contents Color Active-Matrix LCD Mini-Touch Panels

Page 5

Link the New Page to the Main Page 47

Close the Editor Bar 49

Exit editor mode 49

Mini-Touch Panel Program Reference................................. 51

Overview 51

Setup Page 51

Open the Setup Page 52

Buttons 52

Beep 52

LCD timer 53

Serial number, AXlink, and vX.XX 53

SmartPack 54

WAVE 55

Set time and date 57

Double beep 58

Protected setup 58

Set background 59

Brightness 60

Protected Setup Page 61

Open the Protected Setup Page 61

Protected Setup Page Buttons 62

Editor 62

Setup password 63

Auto assign 63

Set serial 64

Set device 66

Page password 67

Power up page 67

Calibrate 68

Page tracking 68

LCD timer message 69

Timer BRT 72

Editor Bar 72

Button Menu Options 73

Add 74

Move 74

Copy image 74

Delete 75

Resize 75

Edit text 76

Color Active-Matrix LCD Mini-Touch Panels Table of Contents iii

Page 6

Attributes 79

Save 83

Paste 83

Page Menu Options 83

Add 84

Copy 85

Rename 86

Delete 87

Go to 87

Passwd pg flip 88

Print 89

Page color 90

Icons Menu Options 90

Time 91

Date 91

E timer 91

16 char term 92

32 char term 92

Vertical graph 92

Icon feedback 95

Joy stick 97

Drawings 100

Brightness 100

Video Setup 101

System Menu Options 102

Clear buttons 103

Clear drawings 103

Memory 104

Send file 105

Receive file 106

Move edit bar 107

Print 107

Function map 108

Function show 109

Set Defaults 110

iv Table of Contents Color Active-Matrix LCD Mini-Touch Panels

Page 7

AXCESS Programming....................................................... 113

Overview 113

System Send_Commands 113

Color Numbers 119

Color Send_Commands 119

Variable Text Send_Commands 122

WavePack Button Attribute String_Commands124

Replacing the Lithium Batteries ........................................ 125

Overview 125

AXT-MCA (/PB) and AXT-MCV (/PB) 125

AXU-MCA (/PB), AXU-MCV (/PB),

AXM-MCA (/PB), and AXM-MCV (/PB) 127

512K Memory Upgrade ...................................................... 129

Operation 129

AXT-MCA (/PB) and AXT-MCV (/PB) 129

AXU-MCA (/PB), AXU-MCV (/PB),

AXM-MCA (/PB), and AXM-MCV (/PB) 130

Color Guidelines................................................................. 133

Overview 133

Colors 133

Specifications..................................................................... 135

Overview 135

AXT-MCA (/PB) and AXT-MCV (/PB) 135

AXU-MCA (/PB) and AXU-MCV (/PB) 136

AXM-MCA (/PB) and AXM-MCV (/PB) 137

Technical Support .............................................................. 139

Overview 139

Index.................................................................................... 141

Overview 141

Color Active-Matrix LCD Mini-Touch Panels Table of Contents v

Page 8

vi Table of Contents Color Active-Matrix LCD Mini-Touch Panels

Page 9

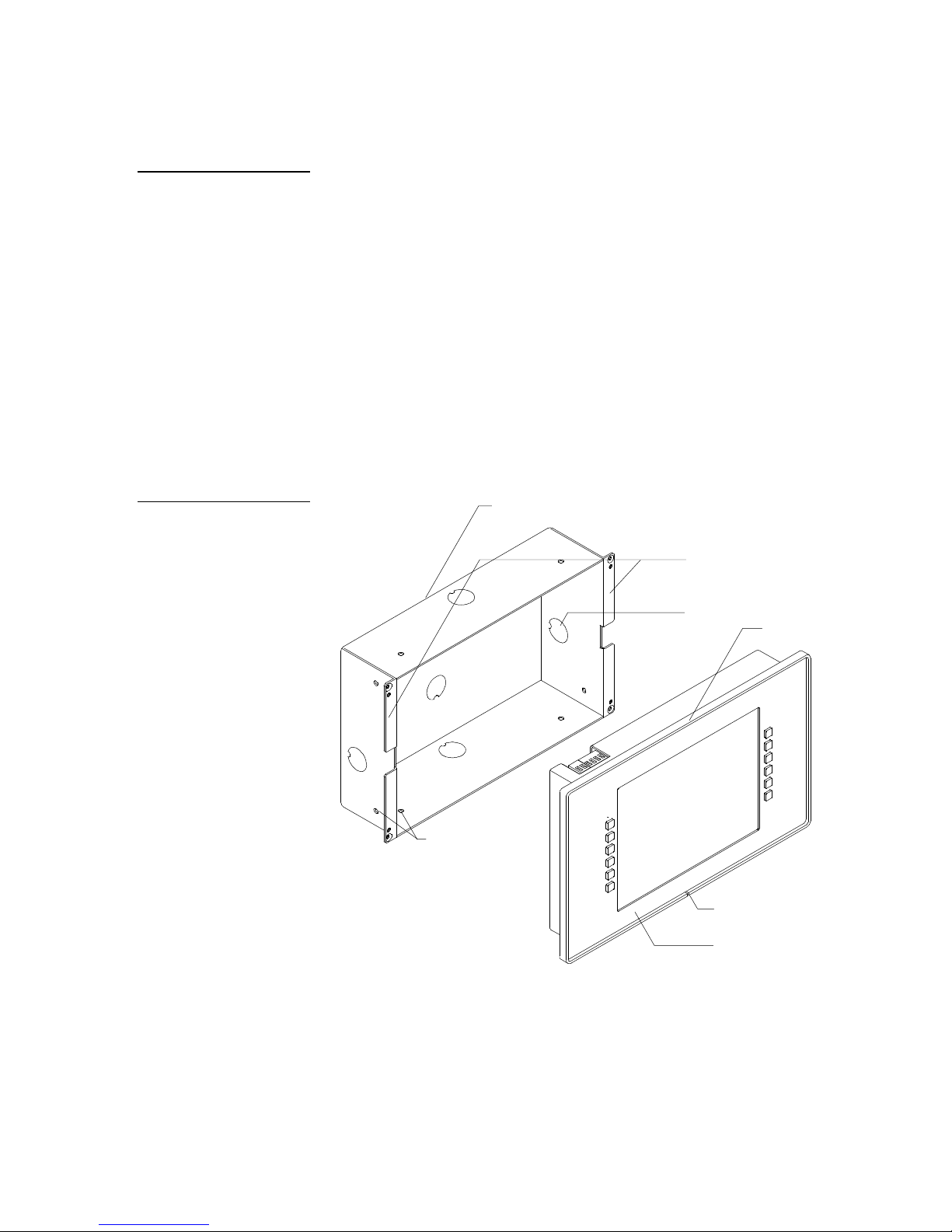

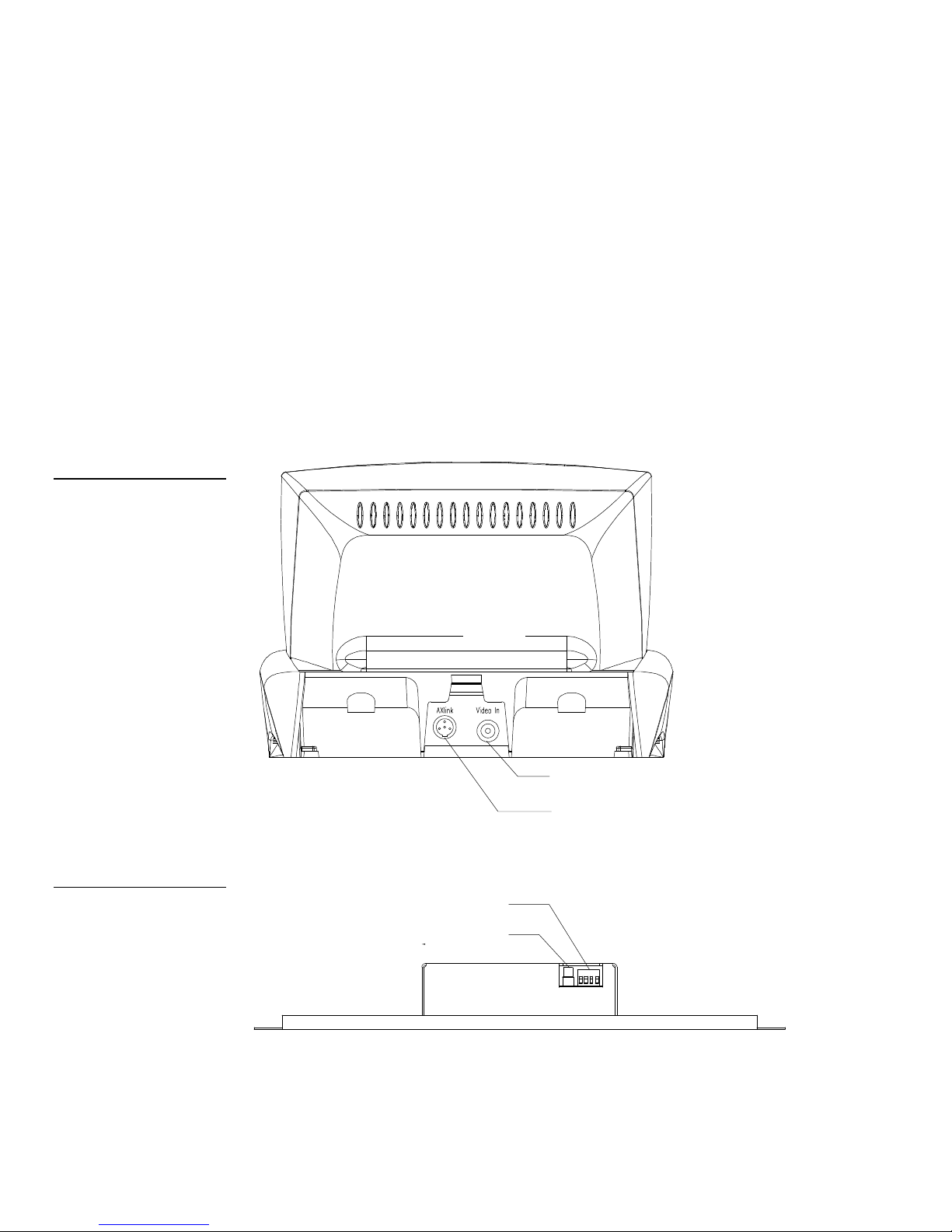

Figure 1

AXU-MCA UniMount minitouch panel

Introduction

Overview

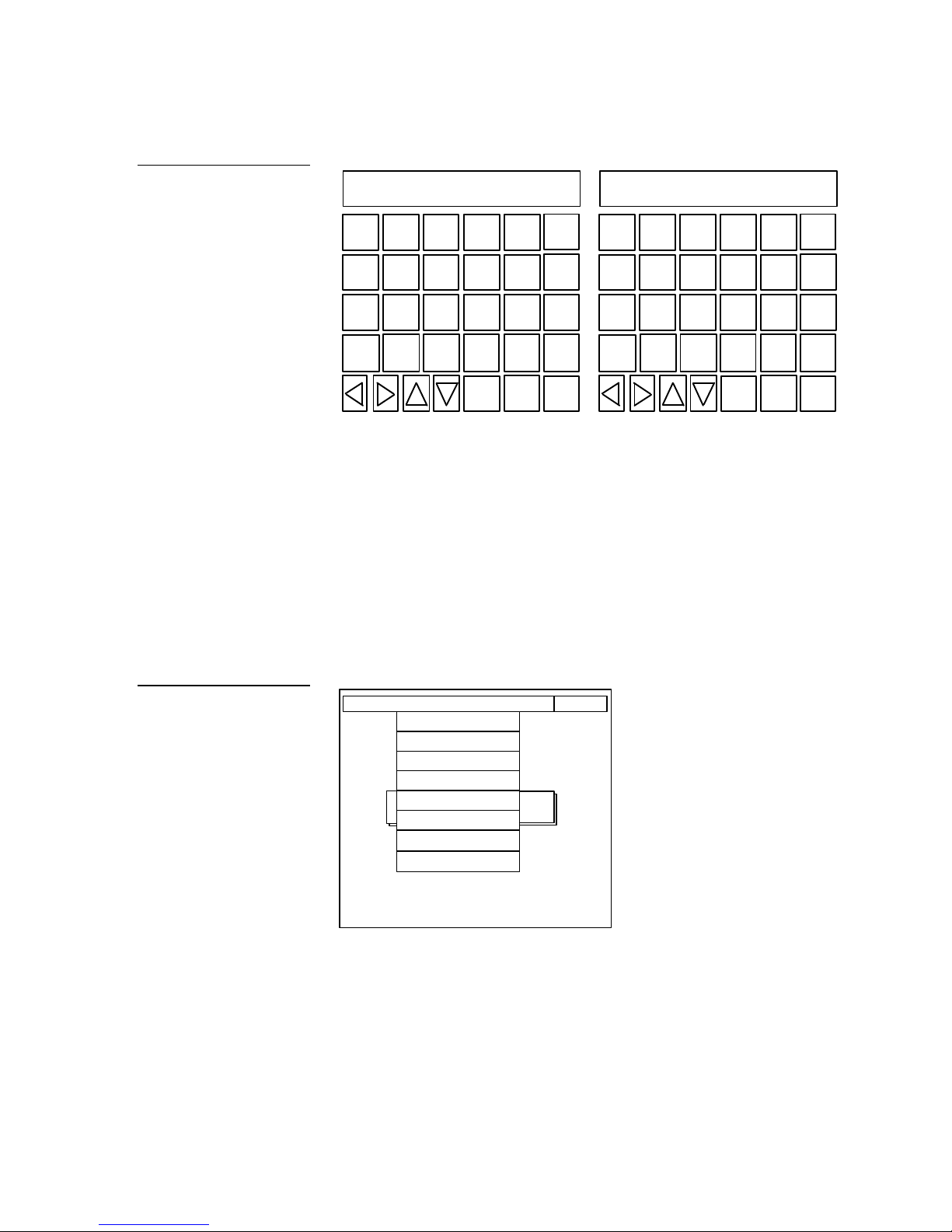

The color active-matrix mini-touch panels contain a dedicated 256-color, 320 x 240

(HV) pixel, liquid crystal display (LCD). The mini-touch panels are self-contained

enclosures that use a microprocessor to control a wide range of audiovisual

products. Special mini-touch panel options include a video input port that is PALand NTSC-compatible, and 12 pushbuttons (6 pushbuttons on each side) that can be

programmed to perform specific control operations. With the mini-touch panel

operating system, you can create custom pages with buttons, icons, sliders,

bargraphs, and imported logos and drawings. You can also use the TPDOC or

TPDesign custom touch panel design programs AMX offers to enhance your minitouch panel designs. Figure 1 shows an AXU-MCA UniMount mini-touch panel.

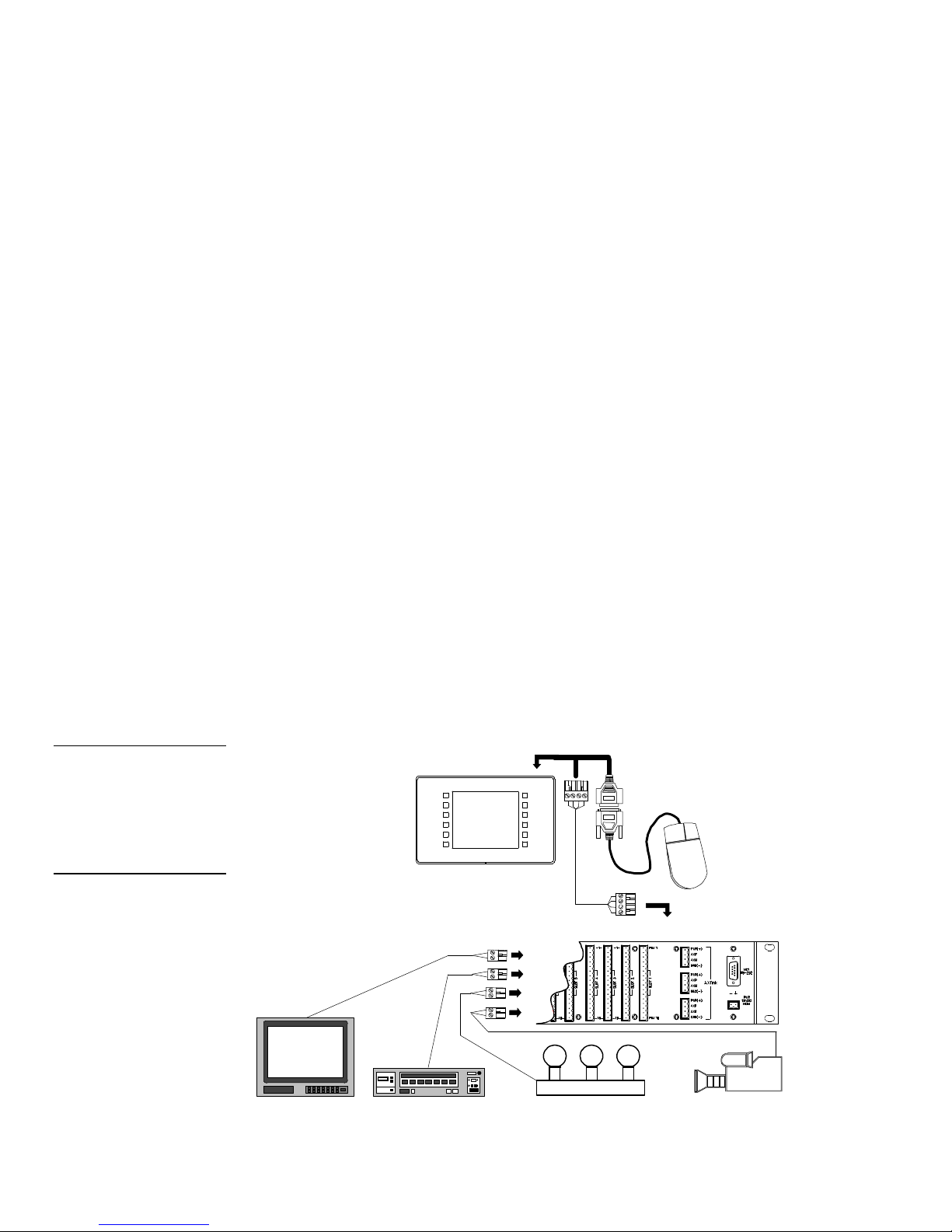

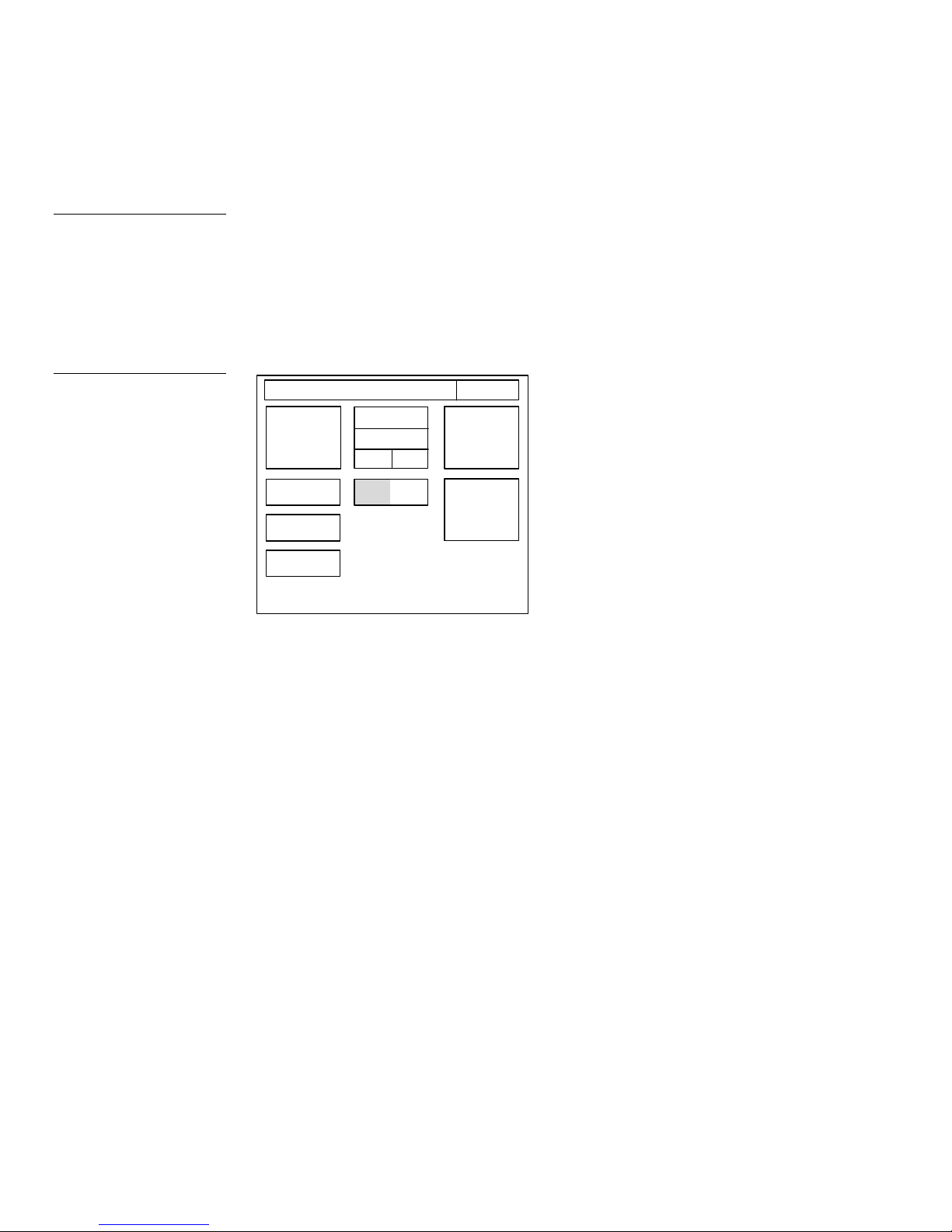

Figure 2

Color mini-touch panel types

and product names

Color Active-Matrix LCD Mini-Touch Panels Introduction 1

Figure 2 lists the mini-touch panel types and product names described in this

manual.

Color mini-touch panel types and product names

Non-Video Panels Video Panels

Panel types Standard Pushbuttons Standard Pushbuttons

TiltScreen AXT-MCA AXT-MCA/PB AXT-MCV AXT-MCV/PB

UniMount AXU-MCA AXU-MCA/PB AXU-MCV AXU-MCV/PB

Rack mount AXM-MCA AXM-MCA/PB AXM-MCV AXM-MCV/PB

Page 10

Features

Lighting

Mini-touch panel features include:

• 5" diagonal display—2.8" x 3.9" (71 mm x 97 mm)

• 256-color active matrix 320 x 240 (HV) pixel LCD

• 12 programmable pushbuttons (6 on each side)

• Microsoft or Logitech mouse compatible (UniMount and rack-mount models

only)

• Panel programming, screens, and drawings that can be uploaded and

downloaded with TPDOC (MS-DOS) or TPDesign (Windows) touch panel

software programs.

• PAL- and NTSC-compatible video input port (optional)

• Internal 4-pin header for mouse control (UniMount and rack-mount models

only)

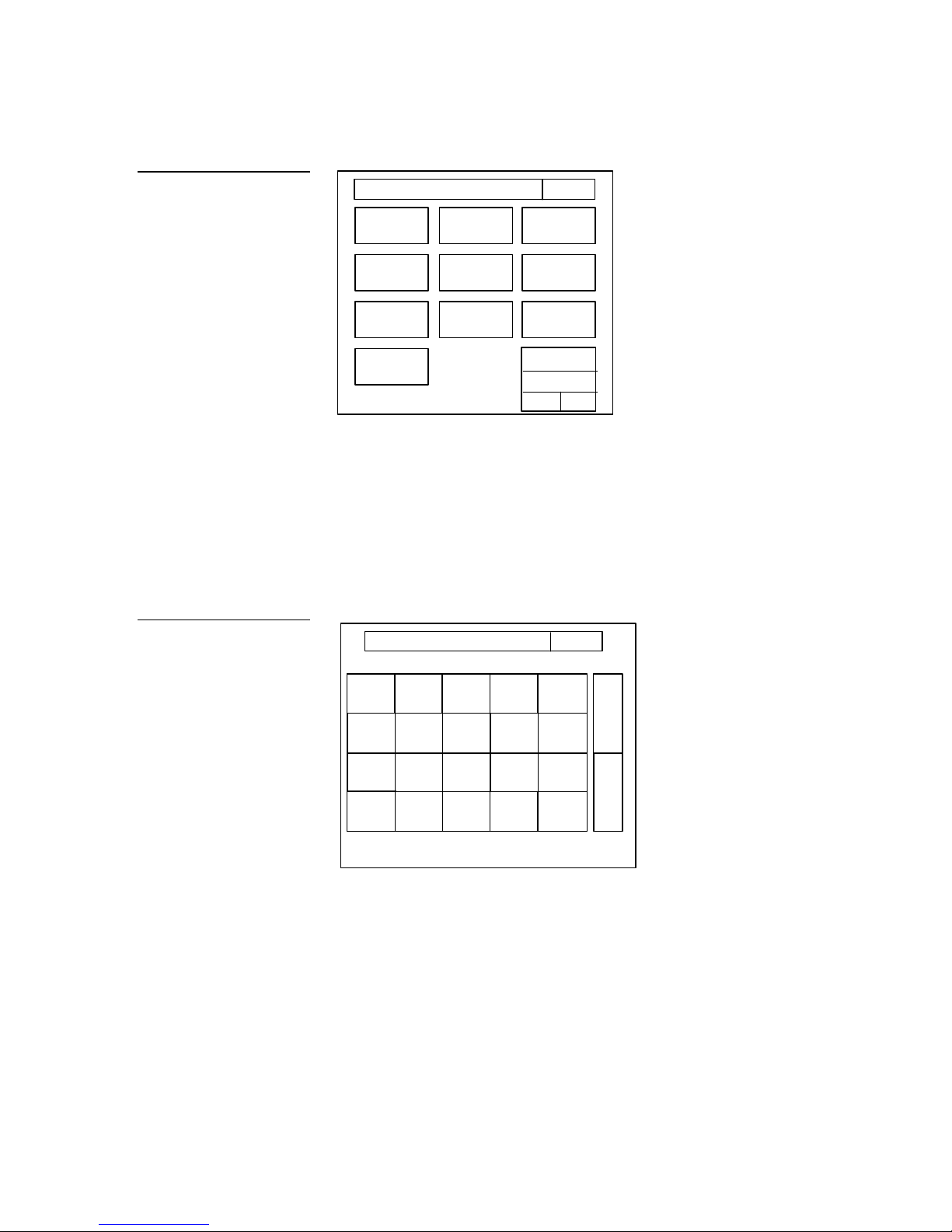

Applications

The mini-touch panels can control a wide variety of equipment connected to an

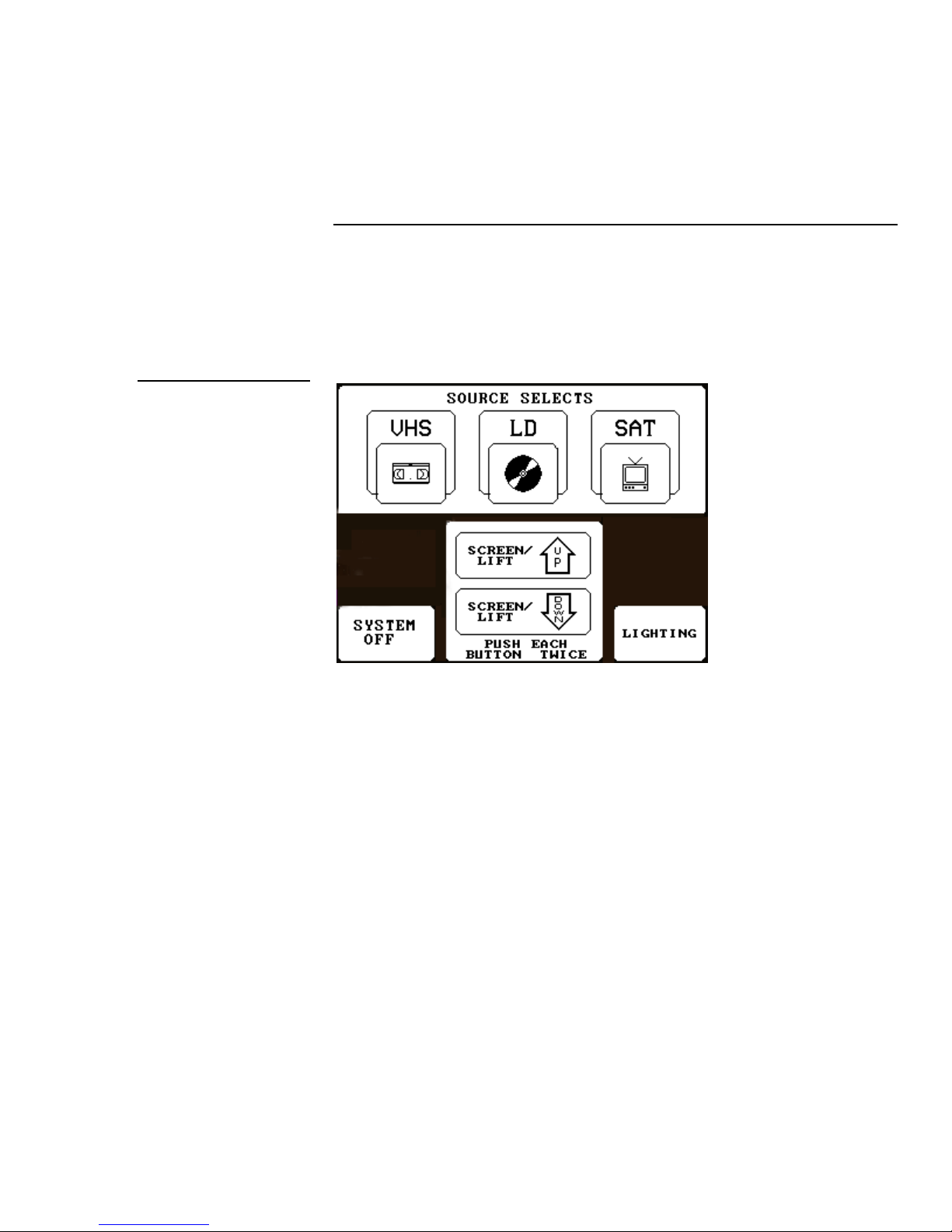

AXCESS Control System, serial mouse, or a combination of both. Figure 3 shows

how you can use the AXU-MCA control capabilities with an AXCESS Control

System. The mouse shown in Figure 3 is optional.

Figure 3

Sample AXU-MCA and

AXCESS Control System

Note

The mouse can be used to

design mini-touch panel pages

and then removed prior to

installation.

Television VCR

2 Introduction Color Active-Matrix LCD Mini-Touch Panels

AXU-MCA

Mouse (optional)

port

AXlink cable

AXCESS CardFrame

Camera

Page 11

What's in this Manual

This manual provides basic instructions on how to use the mini-touch panel

operating system, and installation, basic elements, basic page designs, reference

information, AXCESS programming, battery replacement procedures, 512K memory

upgrade, color guidelines, specifications, and technical support information. If you

are not familiar with the AMX mini-touch panel operating system, read through the

Mini-Touch Panel Basics section and create touch panel pages and objects. If you are

an experienced AMX touch panel page designer, read through the Mini-Touch Panel

Program Reference section for complete descriptions of all mini-touch panel

operations. Section titles and descriptions contained in this manual include:

• Installing the Mini-Touch Panel Installation, wiring, and cleaning

instructions.

• Mini-Touch Panel Basics Basic elements associated with the mini-touch

panel operating system such as button types, message and editor selection

bars, and keyboards.

• Designing a Mini-Touch Panel Page Step-by-step instructions to create a

mini-touch panel page, button, joy stick, and bargraph.

• Mini-Touch Panel Program Reference Describes all mini-touch panel

operations.

• AXCESS Programming Lists AXCESS system commands used to integrate

mini-touch panel features such as color settings, page flips, and variable text

into an AXCESS Control System.

• Replacing the Lithium Batteries Shows how to replace the lithium

batteries in the mini-touch panel.

• 512K Memory Upgrade Step-by-step instructions to install an optional

512K integrated circuit (IC) into the mini-touch panel.

• Color Guidelines Helpful hints you can use to choose the best mini-touch

panel colors.

• Specifications Mini-touch panel dimensions, LCD screen dimensions,

weight, power, memory, enclosure type and color, accessories, and software

programs.

Color Active-Matrix LCD Mini-Touch Panels Introduction 3

Page 12

• Technical Support Helpful hints you can use to check panel wiring, correct

a software program problem, and the numbers to call for AMX technical

support.

4 Introduction Color Active-Matrix LCD Mini-Touch Panels

Page 13

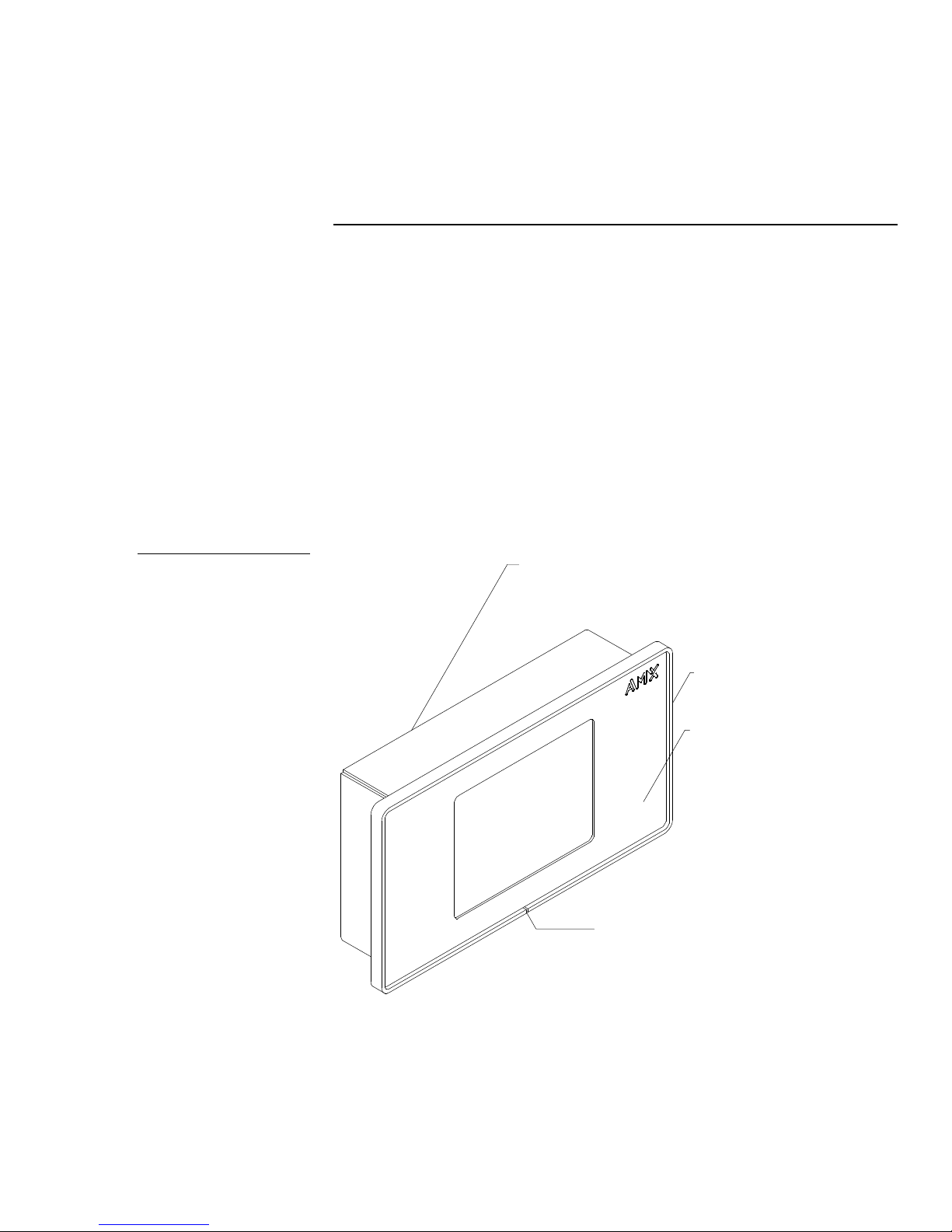

Installing Mini-Touch Panels

Overview

The section describes how to mount, wire, and clean mini-touch panels.

Mounting the Mini-Touch Panels

The following describes how to mount the UniMount and rack mount mini-touch

panels. The TiltScreen mini-touch panel can be mounted on any flat surface.

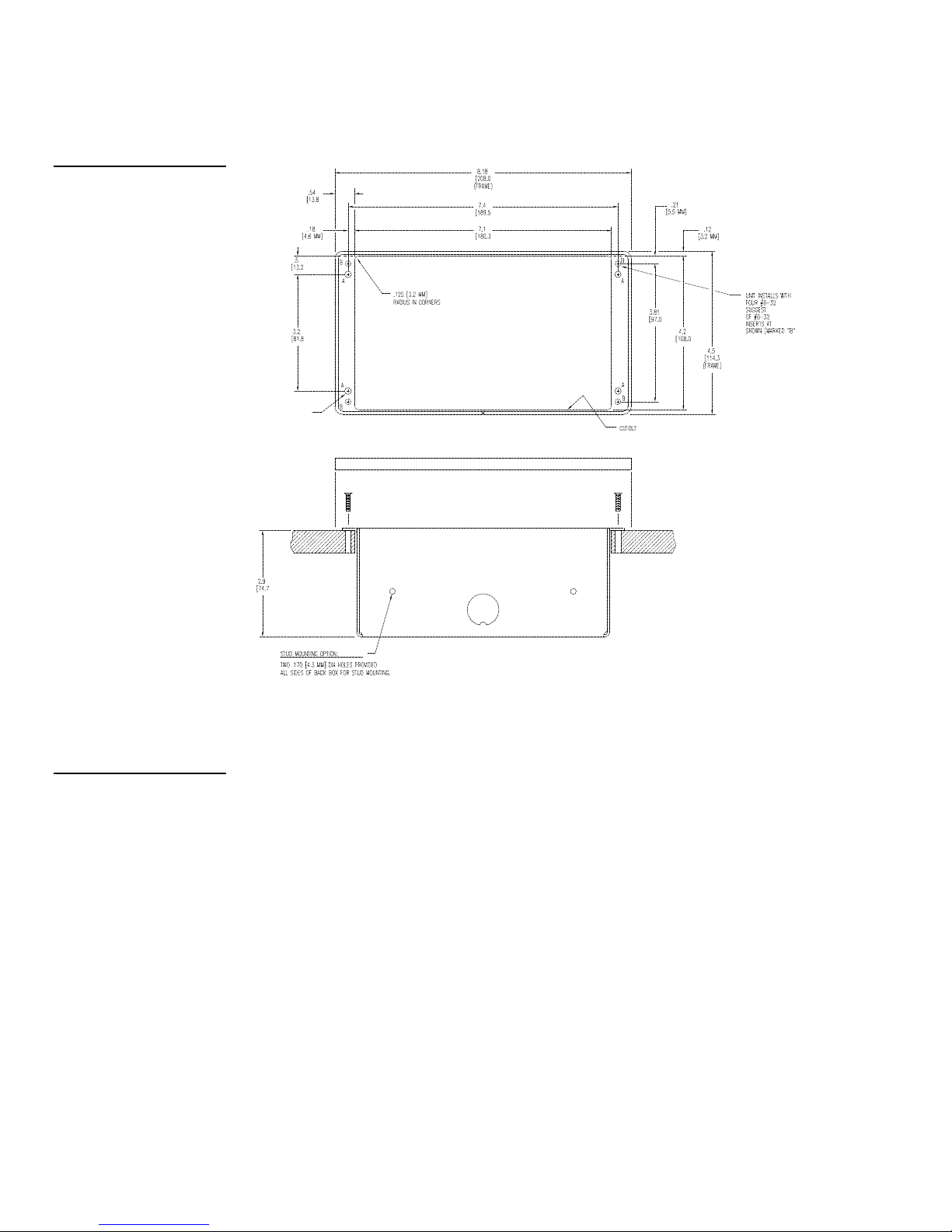

AXU-MCA (/PB), AXU-MCV (/PB), and low profile back box

Mount the AXU-MCA (/PB), AXU-MCV (/PB), and low profile back box. Figure 4

shows the AXU-MCA and low profile back box.

Figure 4

AXU-MCA and low profile back

box

Low profile back box

AXU-MCA bezel

Engraved overlay

Release slot

Color Active-Matrix LCD Mini-Touch Panels Installing Mini-Touch Panels 5

Page 14

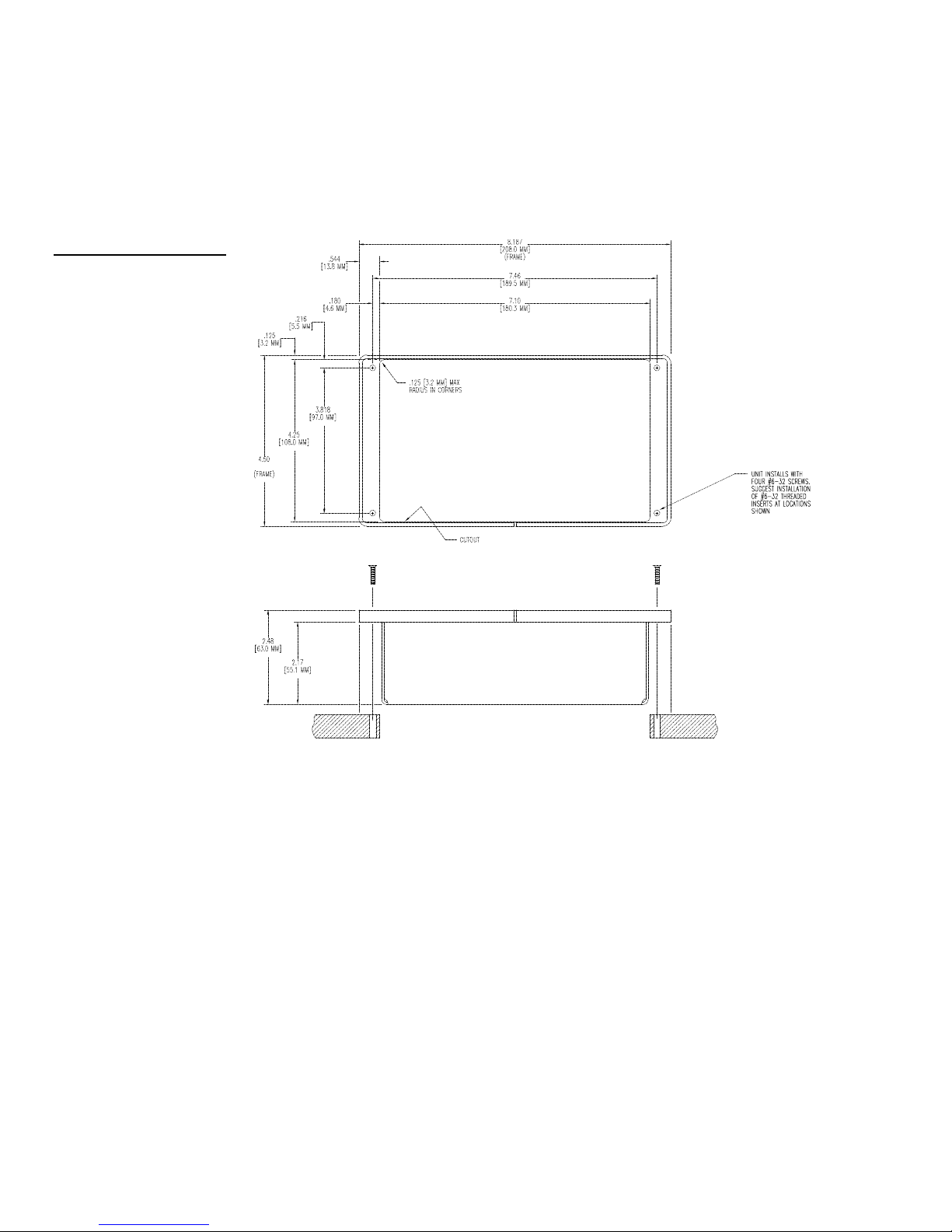

Figure 5

AXU-MCA (/PB), AXU-MCV

(/PB), and low profile back box

cutout dimensions

1. Make a cutout in the surface according to the dimensions shown in Figure 5 for

a low profile back box.

2. Insert a flat-blade screwdriver into the release slot on the mini-touch panel's

bezel and remove the engraved overlay.

3. Place the mini-touch panel into the cutout and mark the screw insert positions

as shown in Figure 5.

4. Remove the mini-touch panel and drill four #6-32 insert holes. Then, place a

threaded insert into each hole.

5. Attach the AXlink and optional RCA video connectors to the mini-touch panel.

Refer to Wiring the Mini-Touch Panels for wiring diagrams and pinout

descriptions.

6 Installing Mini-Touch Panels Color Active-Matrix LCD Mini-Touch Panels

Page 15

Release slot

BB-MTP UniMount enclosure

holes

Note

The mini-touch panel must be

installed with the release slot

located at the bottom.

Figure 6

6. Fasten the mini-touch panel and low profile back box to the surface using the

#6-32 machine screws supplied with the enclosure.

7. Insert the engraved overlay back into the bezel.

8. Connect the AXlink wiring to the AMX Control System, and the optional video

wiring to the video source. The mini-touch panel will beep when you apply

power.

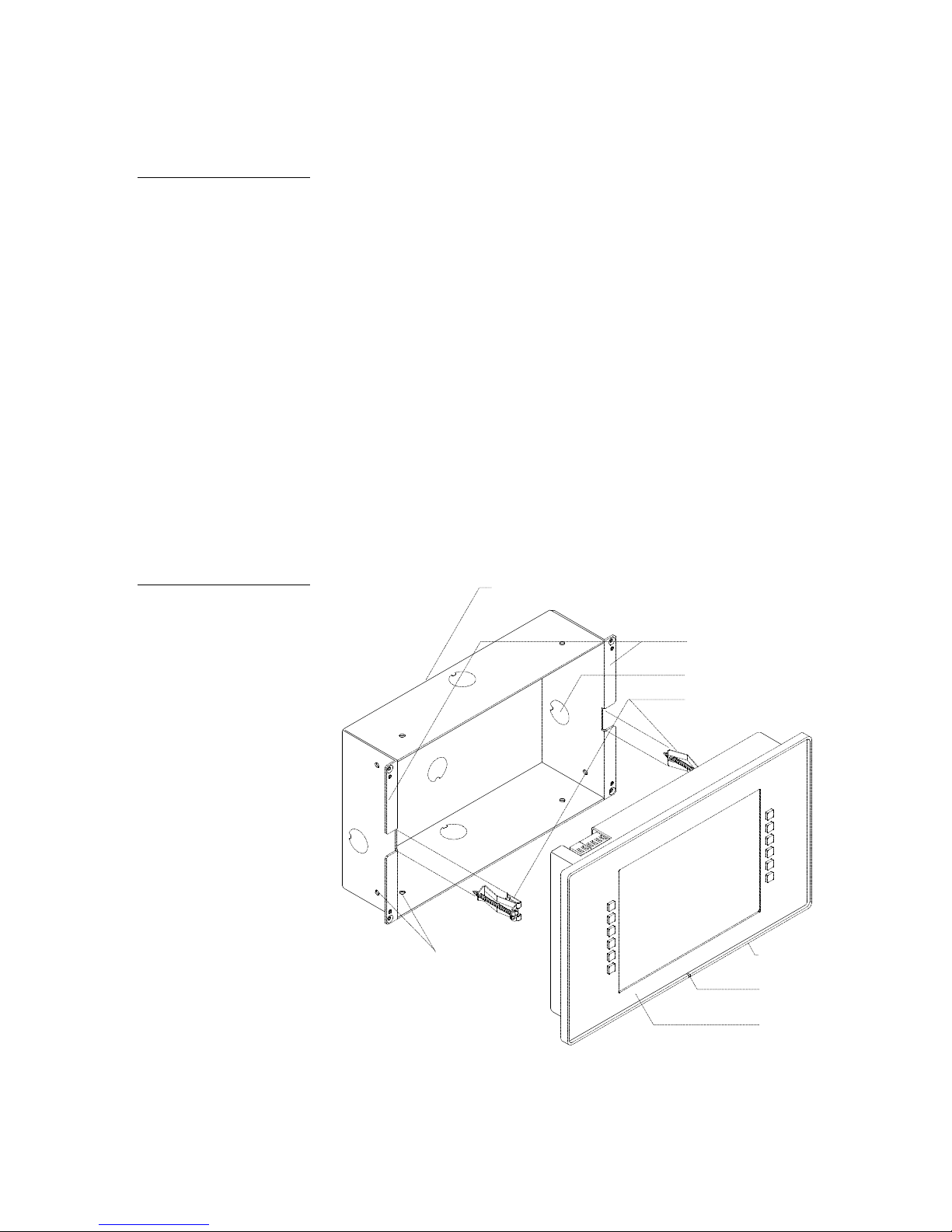

AXU-MCA (/PB), AXU-MCV (/PB), and BB-MTP UniMount enclosure (solid

surfaces)

Mount the AXU-MCA (/PB), AXU-MCV (/PB), and BB-MTP UniMount enclosure

into a solid surface. Figure 6 shows the AXU-MCA/PB and BB-MTP UniMount

enclosure for solid surfaces.

AXU-MCA/PB and BB-MTP

UniMount enclosure for solid

surfaces

Solid surface mounting

flanges

Knockout

AXU-MCA/PB bezel

Stud mounting

Engraved overlay

Color Active-Matrix LCD Mini-Touch Panels Installing Mini-Touch Panels 7

1. Cut the solid surface according to the cutout dimensions shown in Figure 7.

2. Insert a flat-blade screwdriver into the release slot on the mini-touch panel's

bezel and remove the engraved overlay.

Page 16

Figure 7

Mini-touch panel and BB-MTP

cutout dimensions

3. Lay the mini-touch panel facedown onto a soft cloth and remove the four screws

from the low profile back box. Remove the back box and discard.

Note

The BB-MTP can also be

mounted to wood or metal

studs using the pre-drilled stud

mounting holes.

4. Place the BB-MTP into the cutout and mark the threaded insert positions as

shown in Figure 7.

5. Remove the BB-MTP and drill eight holes as shown in Figure 7. Then, place #6-

32 threaded inserts into the four holes marked ‘B’ in the cutout dimensions

illustration.

6. Disconnect the AXlink connector from the AMX Control System, and the

optional video wiring from the video source.

7. Remove one or more knockouts to accommodate the wiring as required.

8. Thread the incoming AXlink and video wiring through the BB-MTP knockout.

8 Installing Mini-Touch Panels Color Active-Matrix LCD Mini-Touch Panels

Page 17

Release slot

BB-MTP UniMount enclosure

holes

Note

The mini-touch panel must

always be installed with the

release slot located at the

bottom.

Figure 8

9. Fasten the BB-MTP to the solid surface with the mounting screws supplied with

the enclosure.

10. Connect the AXlink and video wiring to the mini-touch panel. Refer to Wiring

the Mini-Touch Panels for wiring diagrams and pinout descriptions.

11. Fasten the mini-touch panel to the BB-MTP with the #6-32 screws provided with

the enclosure.

12. Insert the engraved overlay back into the bezel.

13. Connect the AXlink wiring to the AMX Control System, and video wiring to the

video source. The mini-touch panel will beep when you apply power.

AXU-MCA (/PB), AXU-MCV (/PB), and BB-MTP UniMount enclosure

(plasterboard)

Mount the AXU-MCA (/PB), AXU-MCV (/PB), and BB-MTP into a plasterboard

surface (or equivalent). Figure 8 shows the AXU-MCA/PB and BB-MTP UniMount

enclosure for plasterboard.

AXU-MCA/PB and BB-MTP

UniMount enclosure for

plasterboard

Stud mounting

Plasterboard surfacemounting flanges

Knockout

Expansion clips

AXU-MCA/PB bezel

Engraved overlay

Color Active-Matrix LCD Mini-Touch Panels Installing Mini-Touch Panels 9

Page 18

Figure 9

Mini-touch panel and BB-MTP

cutout dimensions

1. Cut the surface according to the cutout dimensions shown in Figure 9.

2. Insert a flat-blade screwdriver into the release slot on the mini-touch panel’s

bezel and remove the engraved overlay.

3. Lay the mini-touch panel facedown onto a soft cloth and remove the four screws

from the low profile back box. Remove the back box and discard.

4. Place the BB-MTP into the cutout and mark the threaded insert positions as

shown in Figure 9.

5. Remove the BB-MTP and drill four #6-32 insert holes. Then, place a threaded

insert into each hole.

10 Installing Mini-Touch Panels Color Active-Matrix LCD Mini-Touch Panels

Page 19

6. Disconnect the AXlink connector from the AMX Control System, and the

optional video wiring from the video source.

7. Thread the incoming AXlink and video wiring through the BB-MTP knockout.

Note

The mini-touch panel must be

installed with the release slot

located at the bottom.

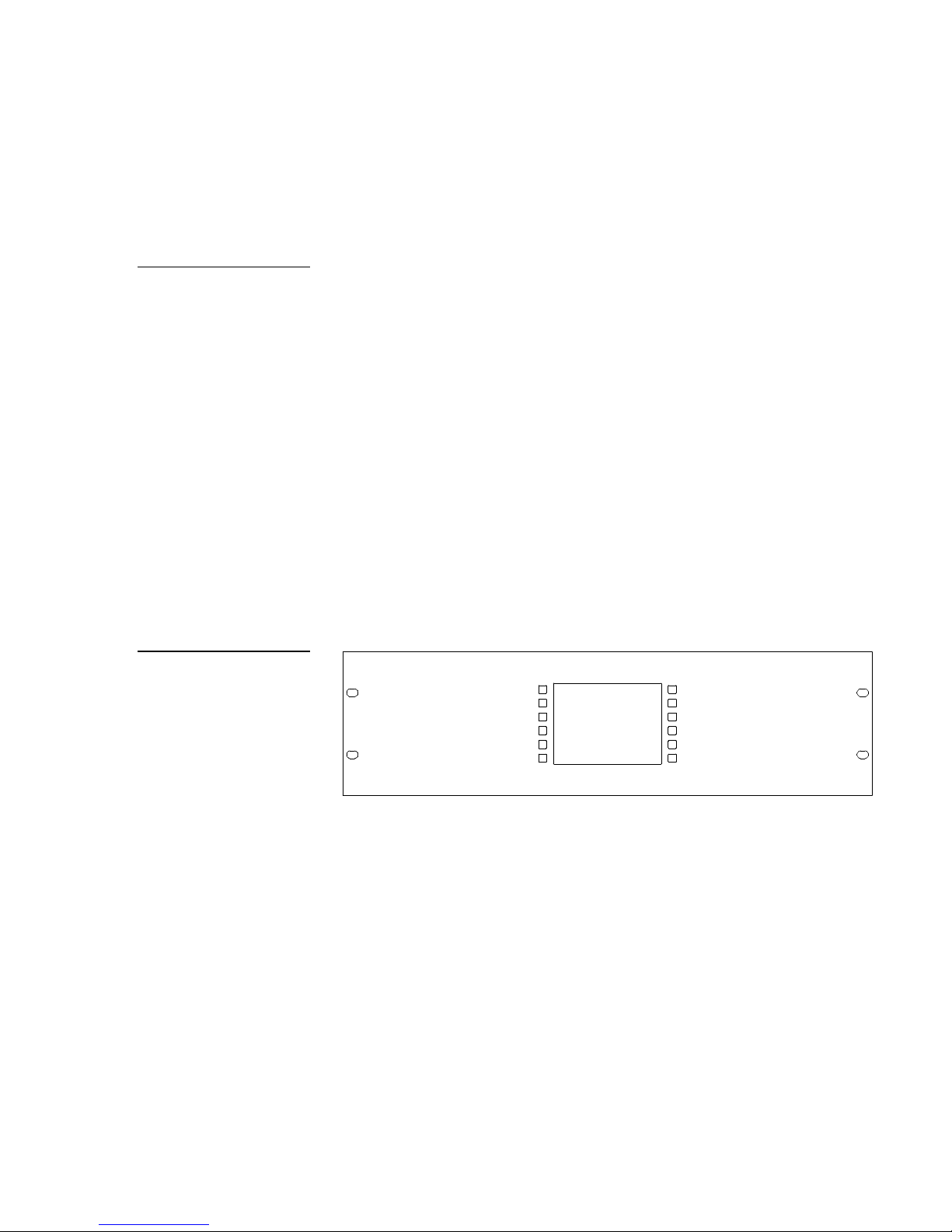

Figure 10

AXM-MCA/PB and AC-RK

rack kit for an electronic

equipment rack

8. Fasten the BB-MTP to the plasterboard using the expansion screws supplied

with the enclosure.

9. Connect the AXlink and video wiring to the mini-touch panel. Refer to Wiring

the Mini-Touch Panels for wiring diagrams and printout descriptions.

10. Fasten the mini-touch panel to the BB-MTP with the #6-32 screws supplied with

the enclosure.

11. Insert the engraved overlay back into the bezel.

12. Connect the AXlink wiring to the AMX Control System, and video wiring to the

video source. The mini-touch panel will beep when you apply power.

AXM-MCA (/PB) or AXM-MCV (/PB) (rack mount)

Mount the AXM-MCA (/PB), AXM-MCV (/PB), and AC-RK rack kit into an

electronic equipment rack. Figure 10 shows the AXM-MCA/PB and AC-RK

Accessory Rack Kit for an equipment rack.

Color Active-Matrix LCD Mini-Touch Panels Installing Mini-Touch Panels 11

1. Thread the incoming AXlink and video wiring through the opening in the

equipment rack.

2. Disconnect the AXlink connectors from the AMX Control System, and the

optional video wiring from the video source.

3. Connect the AXlink and video wiring to the mini-touch panel circuit card. Refer

to Wiring the Mini-Touch Panels for wiring diagrams and pinout descriptions.

4. Insert the mini-touch panel into the equipment rack. Line up the top-left and

bottom-right screw holes and start the #6-32 screws. Then, start the bottom-left

and top-right screws. Tighten all the screws after you start all the screws.

Page 20

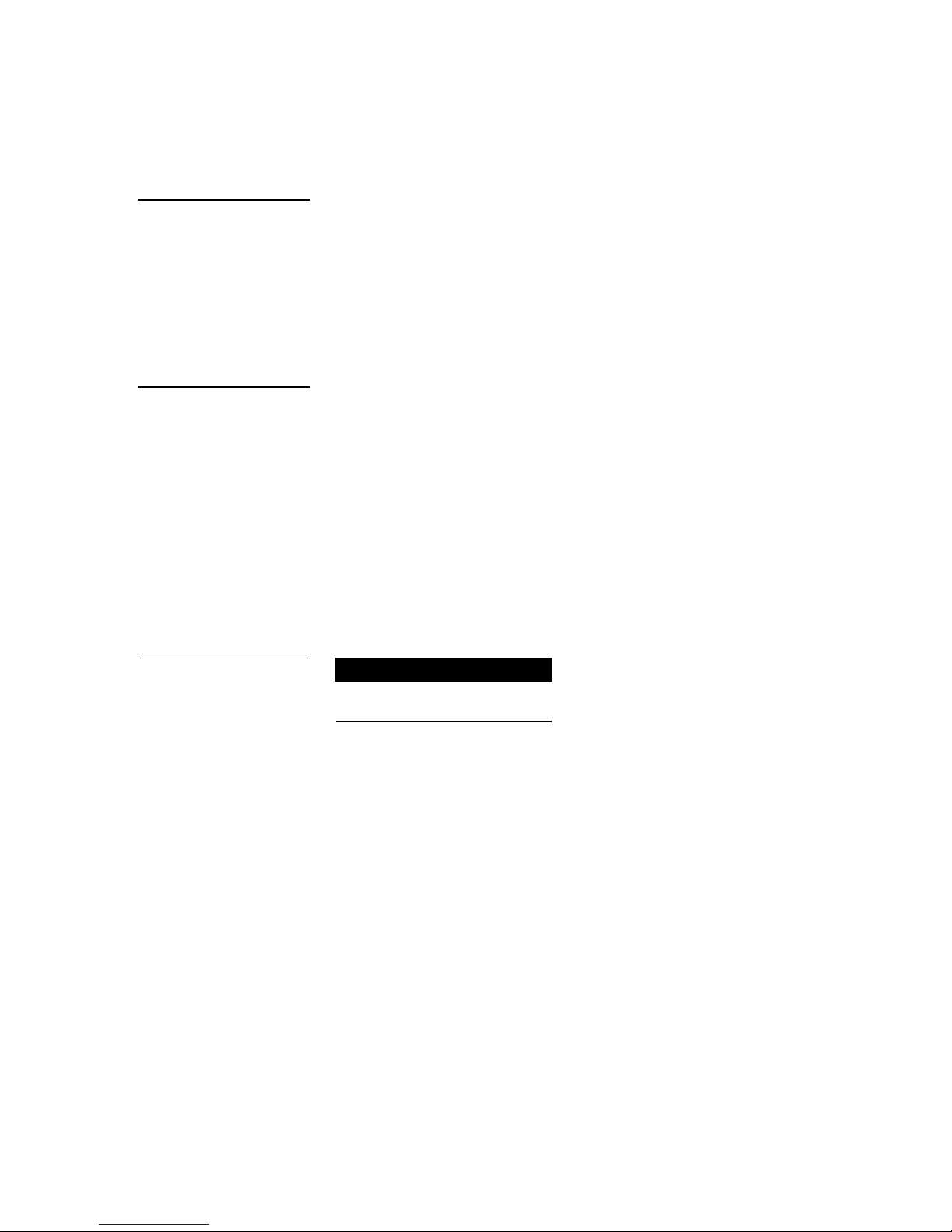

Figure 11

TiltScreen mini-touch panel

connectors (rear view)

5. Connect the AXlink wiring to the AMX Control System, and video wiring to the

video source. The mini-touch panel will beep when you apply power.

Wiring the Mini-Touch Panels

The TiltScreen mini-touch panels use a mini-XLR (male) connector for power and

data communications, and an optional RCA connector to display PAL- and NTSCcompatible video. The UniMount and rack-mount mini-touch panels use a 4-pin

(male) AXlink connector for power and data, and an optional RCA connector to

display PAL- and NTSC-compatible video. Figure 11 shows the rear panel AXlink

and optional RCA connectors on the TiltScreen mini-touch panels. Figure 12 shows

the rear panel AXlink and optional RCA connector on the rack-mount mini-touch

panel.

Figure 12

Rack-mount mini-touch panel

connectors (top view)

Rear view

RCA video connector (optional)

Mini-XLR 4-pin (male) AXlink and

power connector

4-pin (male) AXlink connector

RCA video connector (optional)

Top view

12 Installing Mini-Touch Panels Color Active-Matrix LCD Mini-Touch Panels

Page 21

Preparing captive wires

Caution

Do not connect power to the

mini-touch panel until the wiring

is complete. If you are using a

12 VDC power supply, apply

power to the mini-touch panel

only after installation is

complete.

Caution

Do not over-torque the screw.

Doing so can bend the seating

pin and damage the connector.

You will need a wire stripper, soldering iron, and flat-blade screwdriver to prepare

and connect the captive wires.

1. Strip 0.25 inch of wire insulation off all wires and apply a light coat of solder to

the ends using a soldering iron.

2. Insert each wire into the appropriate opening on the connector according to the

wiring diagrams and connector types described in this section.

3. Turn the flat-blade screws clockwise to secure the wire in the connector.

Wiring guidelines

Mini-touch panels require regulated 12 VDC power to operate properly. The

AXCESS Control System supplies power via the AXlink cable. The maximum wiring

distance between the control system and mini-touch panel is determined by power

consumption, supplied voltage, and the wire gauge used for the cable. Figure 13 lists

wire sizes and the maximum lengths allowable between the mini-touch panel and

control system. The maximum wiring lengths for using AXlink power are based on a

minimum of 13.5 volts available at the control system’s power supply.

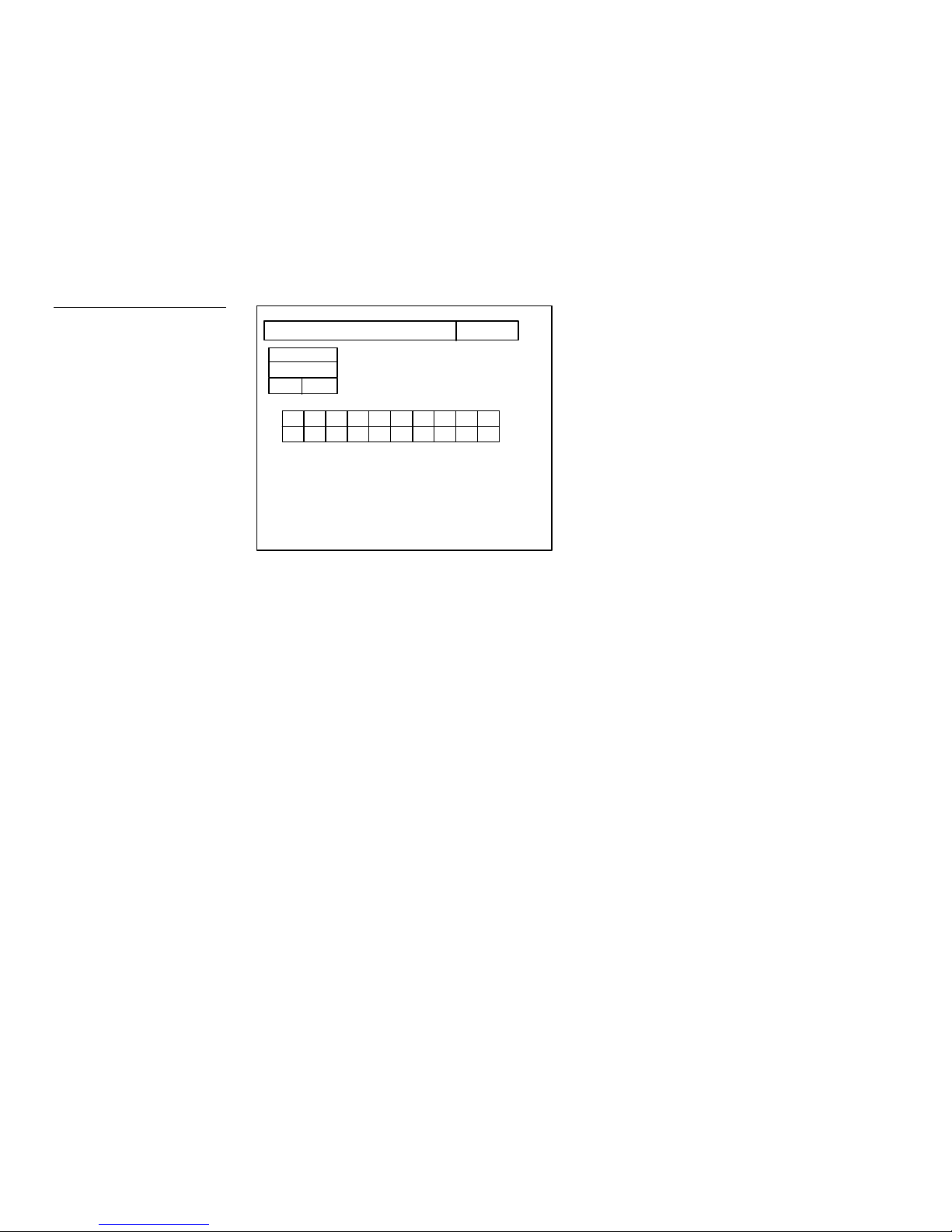

Figure 13

Wiring guidelines

Wiring guidelines

Wire size Maximum wiring

length

18 AWG 167 feet

20 AWG 106 feet

22 AWG 66 feet

24 AWG 41 feet

If you install the mini-touch panel farther away from the control system than

recommended in Figure 13, connect an external 12 VDC power supply to the

TiltScreen, UniMount, and rack-mount mini-touch panels according to the wiring

diagrams and pinout descriptions in this section.

Color Active-Matrix LCD Mini-Touch Panels Installing Mini-Touch Panels 13

Page 22

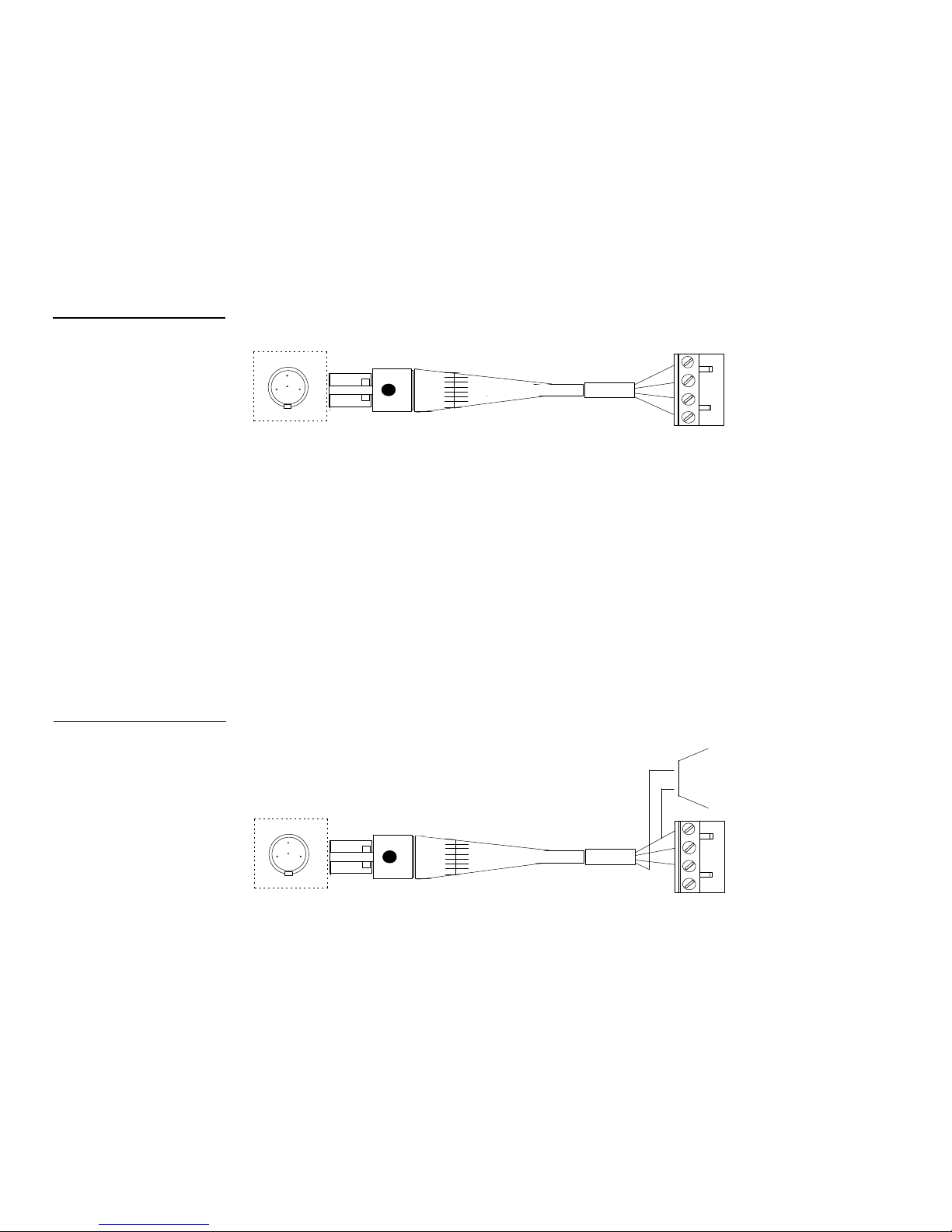

Using the TiltScreen mini-XLR connector for AXlink data and power

2

1

PWR + (RED)

3

4

234

1 - GND - (BLK)

2 - AXM (GRN)

2

1

AXM (GRN)

AXP (WHT)

3

4

PWR + (RED)

234

2 - AXM (GRN)

GND - (BLK)

Connect the control system’s AXlink connector to the mini-XLR connector (male) on

the rear panel of the TiltScreen mini-touch panel for data and 12 VDC power as

shown in Figure 14.

Figure 14

Mini-XLR connector-to-control

system wiring diagram

Figure 15

Mini-XLR connector to external

12 VDC power supply, and

control system wiring diagram

4-pin mini-XLR

connector

GND - (BLK)

1

4 - PWR + (RED)

3 - AXP (WHT)

Control system

AXM (GRN)

AXP (WHT)

Using the TiltScreen mini-XLR connector for AXlink and an external 12

VDC power supply

Connect the control system’s AXlink connector to the mini-XLR connector and

external 12 VDC power supply to the rear panel of the mini-touch panel as shown in

Figure 15.

12 VDC power supply

1

4 - PWR + (RED)

3 - AXP (WHT)

1 - GND - (BLK)

14 Installing Mini-Touch Panels Color Active-Matrix LCD Mini-Touch Panels

GND - (BLK)

PWR + (RED)

Control system

Page 23

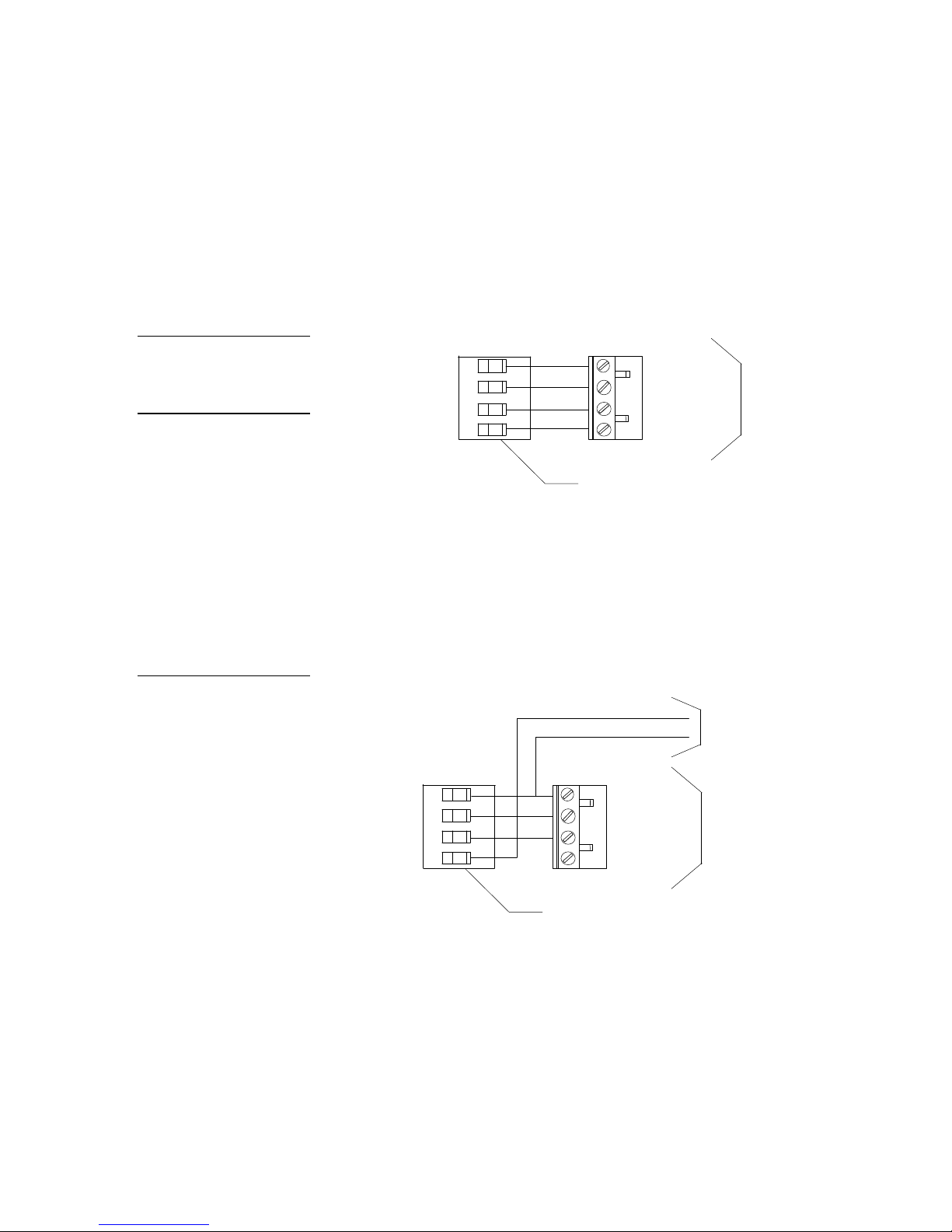

AXP (WHT)

AXM (GRN)

AXP (WHT)

AXM (GRN)

PWR + (RED)

GND - (BLK)

Figure 16

AXlink wiring diagram

Caution

If you are using power from

AXlink, disconnect the wiring

from the control system before

wiring the mini-touch panel.

Using the UniMount and rack-mount AXlink connector for data and power

Connect the control system’s AXlink connector to the AXlink connector (male) on

the rear panel of the mini-touch panel for data and 12 VDC power as shown in

Figure 16.

GND - (BLK)

AXP (WHT)

PWR + (RED)

1

2

3

4

1

GND - (BLK)

AXM (GRN)

2

3

PWR + (RED)

4

UniMount or rack-mount AXlink

connector

Control system

Using the UniMount and rack-mount AXlink connector for data and an

external 12 VDC power supply

Connect the control system’s AXlink connector to the AXlink connector on the rear

panel of the mini-touch panel as shown in Figure 17.

Figure 17

AXlink and external 12 VDC

power supply, and control

system wiring diagram

12 VDC power supply

1

GND - (BLK)

AXP (WHT)

PWR + (RED)

1

2

3

4

UniMount or rack-mount AXlink

connector

GND - (BLK)

AXM (GRN)

2

3

PWR + (RED)

4

Control system

Use an external 12 VDC power supply when the distance between the control system

and mini-touch panel exceeds the limits described in Figure 13. Make sure to connect

only the GND wire on the AXlink connector when using an external 12 VDC power

supply. Do not connect the PWR wire to the AXlink connector’s PWR (+) terminal.

Color Active-Matrix LCD Mini-Touch Panels Installing Mini-Touch Panels 15

Page 24

Using the UniMount and rack-mount 4-pin header for mouse control

Pin 4

Pin 1

Figure 18 shows the location of the 4-pin header on the UniMount and rack-mount

mini-touch panels. The 4-pin header supports Microsoft and Logitech serial mouse

control devices. Figure 19 lists the 4-pin header and DB-9 connector (male) pinouts.

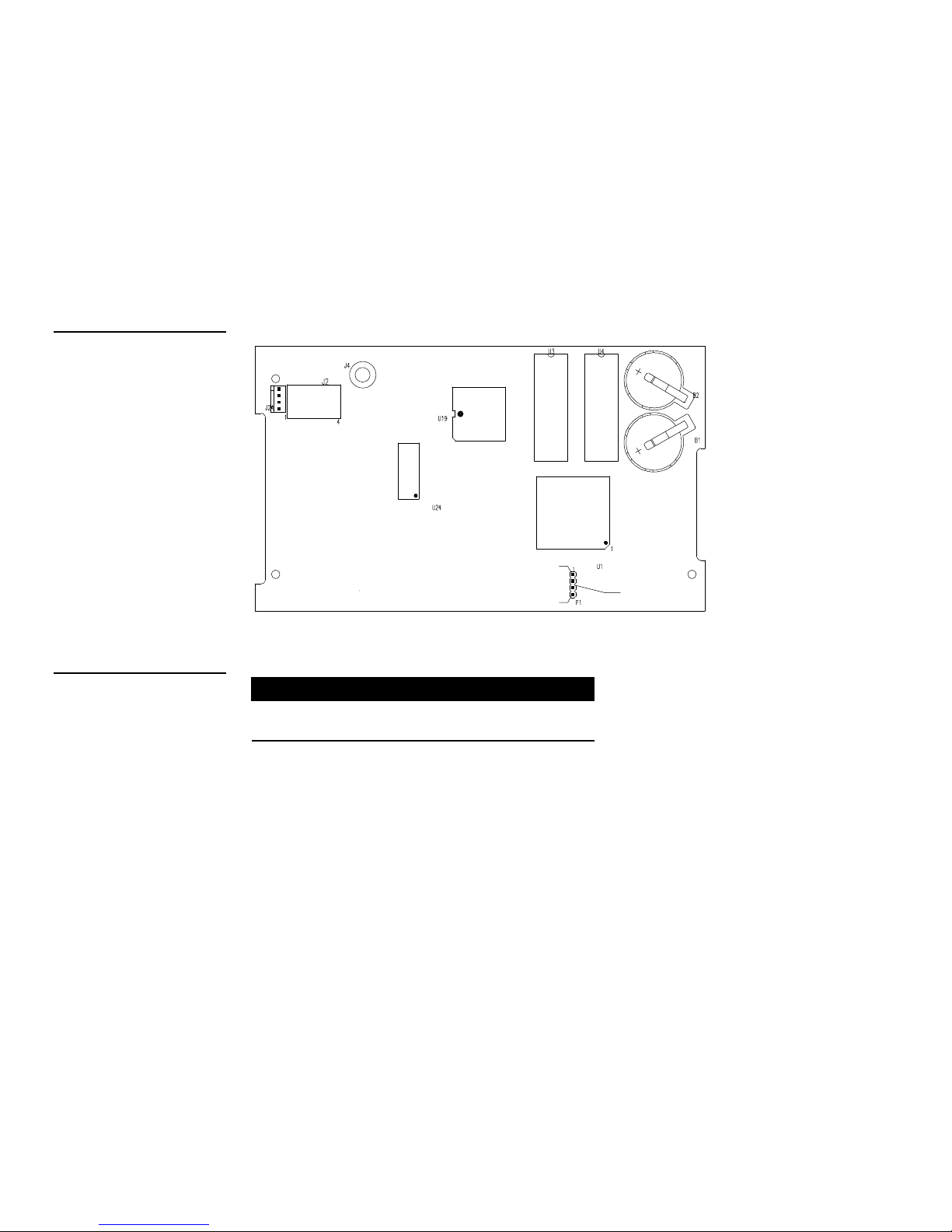

Figure 18

4-pin header location on the

UniMount and rack-mount minitouch panel circuit card

Figure 19

4-pin header and DB-9

connector pinouts

Connector side of circuit card

4-pin header and DB-9 connector pinouts

4-pin

header Signal Function

1 PWR +12 VDC power 4 and 7 (strap)

2 TXD Transmit data 3

DB-9 connector

(male) pins

4-pin

header

3 RXD Receive data 2

4 GND Ground 5

16 Installing Mini-Touch Panels Color Active-Matrix LCD Mini-Touch Panels

Page 25

Cleaning the Touch Overlay

After installing the mini-touch panel, you should clean the touch overlay. Clean the

touch overlay:

1. Disconnect the AXlink and optional video connectors from the mini-touch

panel.

2. Using a cotton cloth, spray a small amount of cleaning solution consisting of 50-

percent isopropyl alcohol and 50-percent water onto the cloth.

3. Clean the touch overlay with the damp cloth. Then, wipe the touch overlay with

a dry cloth.

4. Reconnect the AXlink and optional video connectors to the mini-touch panel.

Color Active-Matrix LCD Mini-Touch Panels Installing Mini-Touch Panels 17

Page 26

18 Installing Mini-Touch Panels Color Active-Matrix LCD Mini-Touch Panels

Page 27

Figure 20

Mini-touch panel page sample

Mini-Touch Panel Basics

Overview

This section contains descriptions and illustration examples of mini-touch panel

pages (Figure 20), buttons, message bars, keypads, and keyboards.

Mini-Touch Panel Pages

You can add objects like buttons, bargraphs, sliders, and drawings to a mini-touch

panel page, and then designate the control functions for each object. The number of

objects depends on the type and quantity of external devices you want to control

with the mini-touch panel and AXCESS Control System. When you create multiple

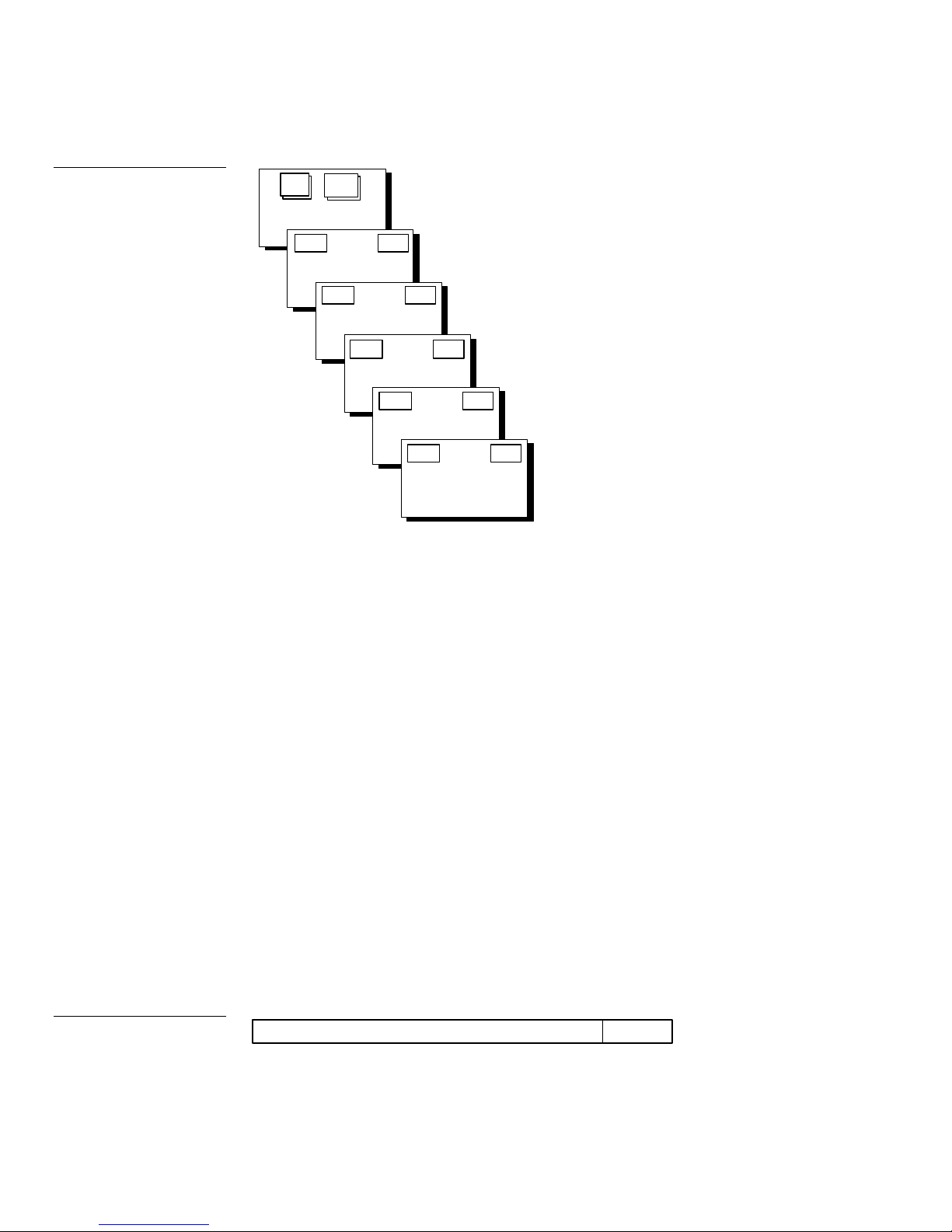

pages, you must link them with buttons. Figure 21 shows how to link five minitouch panel pages to the Main page. Note that each page contains one button that

goes to the next page, and one that goes to the previous page.

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Basics 19

Page 28

Setup

Figure 21

Mini-touch panel pages with

linked buttons

Main

Page

Main Page

Page 2 Main

Page 1

Page 3 Page 1

Page 2

Page 4 Page 2

Page 3

Page 5 Page 3

Page 4

Main Page 4

Page 5

Standard Buttons

Standard buttons are rectangles, rectangle variations, and other geometric shapes

that you can create with the mini-touch panel. You can add, revise, and delete

buttons on a mini-touch panel page using the editor bar. B uttons are set with active

attributes, which means there is a response (control system feedback) when you

touch the button.

General Buttons

General buttons are part of the mini-touch panel software program and cannot be

changed. You use general buttons to specify panel communication parameters and

create or revise pages. Some button examples include the message bar, editor bar,

selection, adjustment, keypad, page menu, decision, status, and keyboard.

Message bar

The message bar (Figure 22) appears when you press the editor bar or a menu option

for setup or installation operations. The message bar instructs you to perform an

operation. Press EXIT to return to the Editor Bar. The message portion is not active

(no feedback).

Figure 22

Message bar example

20 Mini-Touch Panel Basics Color Active-Matrix LCD Mini-Touch Panels

TOUCH BUTTON TO CHANGE ATTRIBUTES EXIT

Page 29

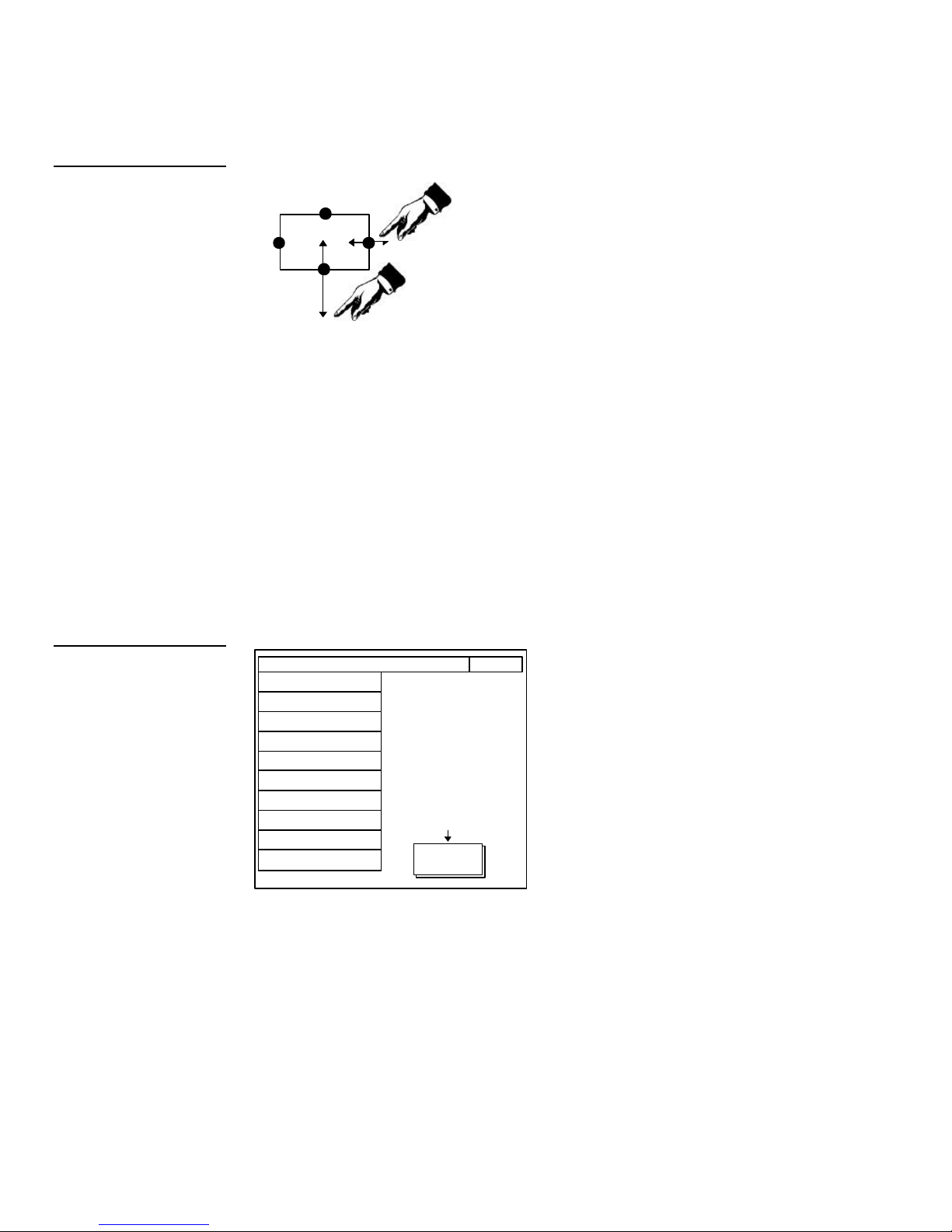

Editor bar

PAGE

The editor bar (Figure 23) is a variation of the message bar. It appears whenever the

editor mode is active in the mini-touch panel. Each one of the editor bar menu

options is active. If you press a menu option, a drop-down menu appears.

Figure 23

Editor bar and menu options

Editor bar

BUTTON PAGE

MAIN

ICONS

VERTICAL GRAPH

ICON FEEDBACK

SYSTEM

TIME

DATE

E TIMER

16 CHAR TERM

32 CHAR TERM

JOY STICK

DRAWINGS

BRIGHTNESS

VIDEO SETUP

EXIT

Selection button

Selection buttons (Figure 24) appear throughout the mini-touch panel software

program to open pages, activate YES/NO prompt messages, or set communication

parameters.

Figure 24

Selection button example

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Basics 21

PROTECTED

SETUP

Information button

Information buttons contain serial numbers and firmware version information.

Figure 25 shows the serial number information button in the Setup Page.

Page 30

Figure 25

Information button example

SERIAL NO.

924-00-0000

Adjustment button

You can use the UP and DN buttons to set an adjustment button. The adjustment

button example in Figure 26 sets the RS-232 baud rate for serial mouse control

(UniMount and rack-mount models only).

Figure 26

Adjustment button example

Figure 27

Keypad example

BAUD

19.2

UP DN

Button title

Variable data

Keypad buttons

The keypad button opens a keypad (Figure 27) so you can enter a password or value

assignment. All keypad buttons are active except for the entry display.

Entry display

0

0

1 2 3

SET TIME SET

4 5

Keypad entry (0 - 9)

6

7 8 9

CLEAR ENTER

0

CLEAR – Resets entry to 0

ENTER – Processes entry if correct

22 Mini-Touch Panel Basics Color Active-Matrix LCD Mini-Touch Panels

Page 31

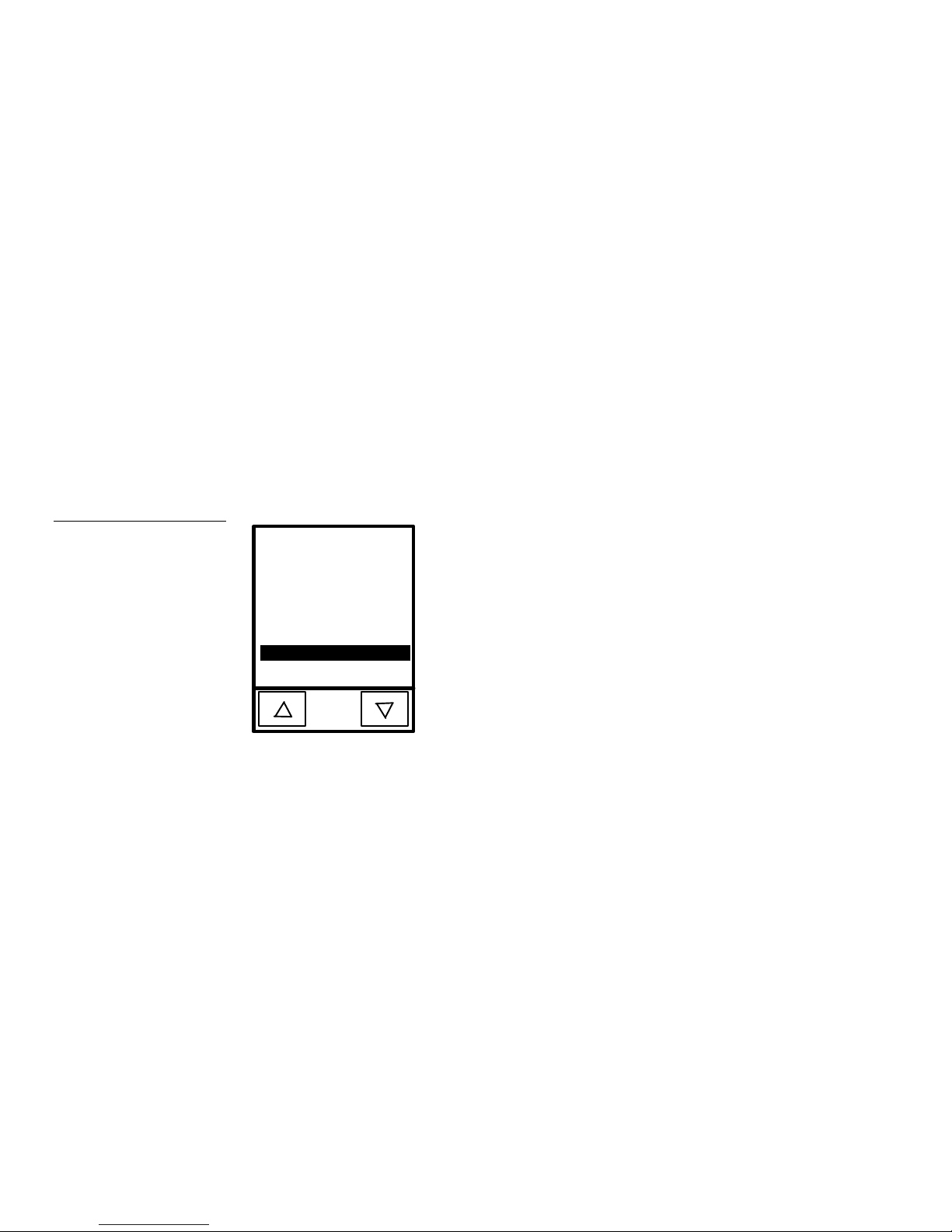

Page menu buttons

The page menu button (Figure 28) appears when you need to go to a page, designate

a startup page, or assign a page attribute to a button.

Figure 28

Go to page menu button

example

* * NONE * *

* * PREVIOUS *

NEW PAGE

MAIN PAGE

ENTER

*

List of pages

Up and down buttons

ENTER – Accepts entry

The up, down, and ENTER buttons are active. Use the up and down buttons to scroll

through the list of page names. The highlight bar marks the page name as you scroll

through the list. Press the ENTER button to designate the Go To page or Startup

page.

Decision buttons

Decision buttons ( Figure 29) appear when an operation has two options.

Figure 29

Decision button example

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Basics 23

YESNO"Decision Text Goes Here"

Decision buttons appear when y ou exit the editor bar, send or receive a drawing,

designate a communication protocol, or make an operation error.

Page 32

Status buttons

LOCK

–

SAVE

LOCK

SAVE

Status buttons (Figure 30) appear when you try to perform operations that do not

function correctly.

Figure 30

Status button example

Figure 31

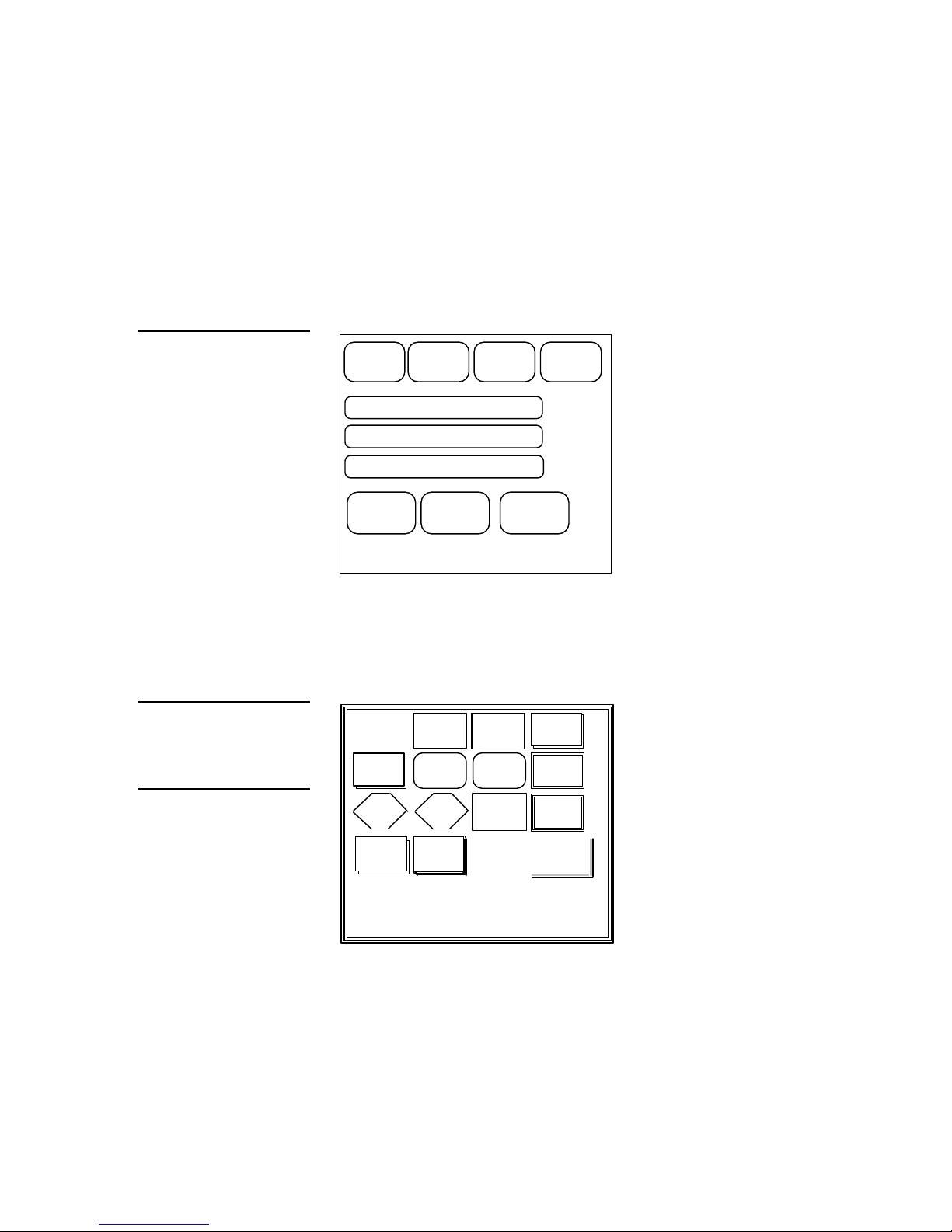

Keyboard page 1 and 2

example

NO COMMUNICATION

TOUCH SCREEN TO CONTINUE

Keyboards

Keyboards (Figure 31) appear so you can type text strings.

Q W E R T

A S D F G

Z X C V

CAP

INTNL

CHARS

SHIFT

SPACE ALT

FONT ABORT

BACK

SPACE

ENTER

DEL

MORE

KEYS

EXIT

Y U I O P

H J K L

N M

B

CAP

INTNL

SPACE ALT

CHARS

:

< >

SHIFT

FONT ABORT

BACK

SPACE

ENTER

DEL

MORE

KEYS

EXIT

Press the MORE KEYS button to toggle between keyboard pages 1 and 2. You use

the keyboard pages during initial setup if you change the time-out message or

power up message. The keyboard pages also appear when you add new pages, type

text output strings, and select the editor bar.

24 Mini-Touch Panel Basics Color Active-Matrix LCD Mini-Touch Panels

Page 1 Page 2

Page 33

Keyboard features and functions include:

• BACK SPACE Moves the cursor back one space to the left.

• ENTER Adds a return to the current line and then moves the cursor to the

next line.

• DEL Deletes the character above the cursor.

• MORE KEYS Toggles between keyboard pages 1 and 2 and the alternate

keyboard pages 1 and 2.

• CAP LOCK Locks all text characters in uppercase. The default mode is CAP

LOCK on.

• INTNL CHARS Changes the keyboard to two additional pages of

international characters for the character set (font) in use.

• SPACE Inserts a space character in your line of text .

• SHIFT Shifts text characters between upper case and lowercase.

• ALT Changes the keyboard to alternate keyboard pages 1 and 2 that contain

additional numbers and punctuation characters .

• Direction arrows Moves the cursor left, right, up, and down within a line or

page of text.

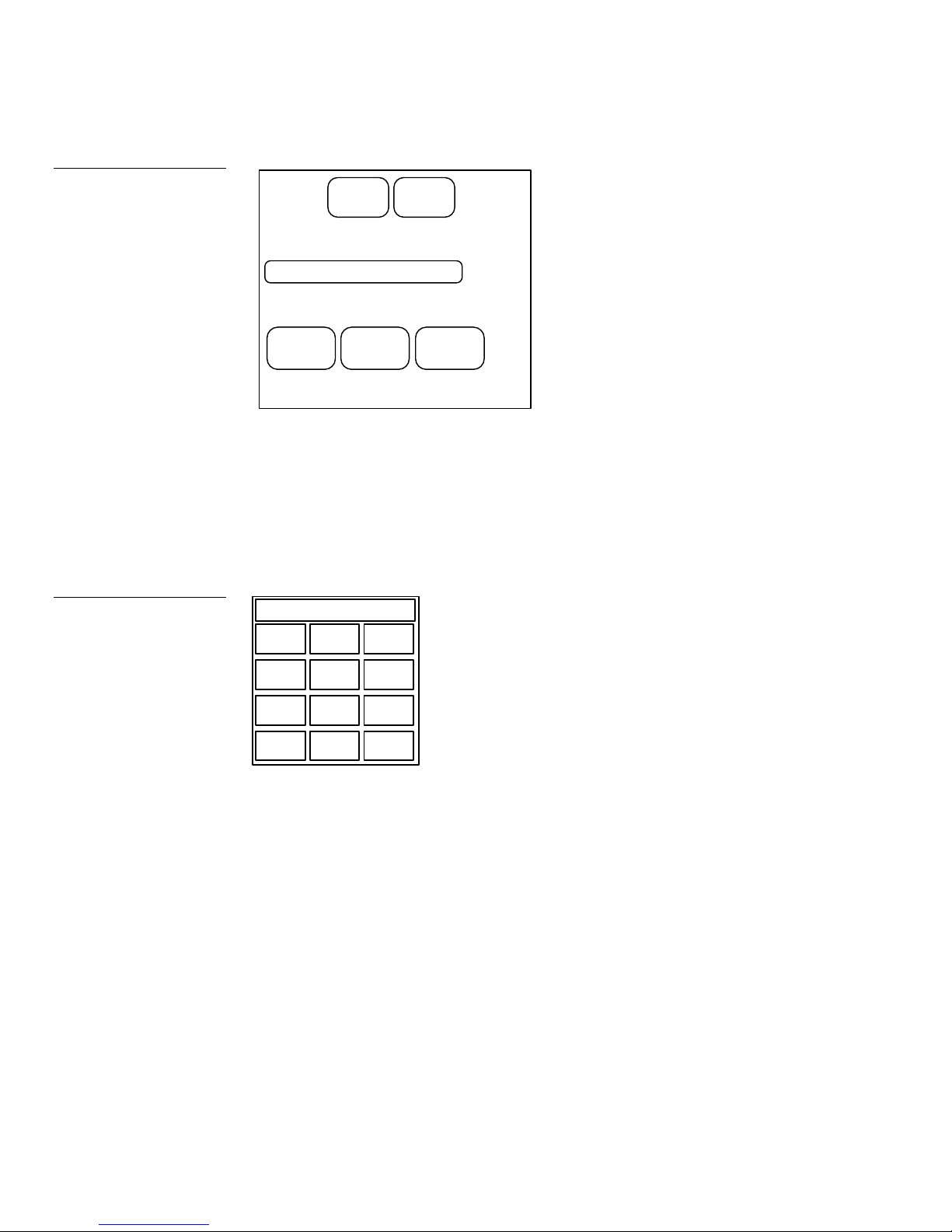

• FONT Opens the font page (Figure 32), which contains five standard fonts,

four outline fonts, and two symbol buttons . You can use the FIXED SYMBOLS

and VARIABLE SYMBOLS for buttons, sliders, and bargraphs.

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Basics 25

Page 34

Aa

Aa

Aa

AaBbCc

Aa

AaAa

Figure 32

Font page example

Figure 33

Fixed Symbol page 1

AaBb

FIXED

SYMBOLS

VARIABLE

SYMBOLS

Aa Aa

FIXED SYMBOLS Opens the Fixed Symbol pages that contain 22

control symbols. Figure 33 shows the first page of fixed symbols.

26 Mini-Touch Panel Basics Color Active-Matrix LCD Mini-Touch Panels

Page 35

Figure 34

Sample variable symbols

page

VARIABLE SYMBOLS Opens the Variable Symbols pages that can

store up to 223 symbols. Figure 34 is a variable symbol page sample.

Refer to the TPDOC or TPDesign instruction manuals to download

symbols into mini-touch panel memory.

• ABORT Closes the keyboard page without making any text or graphic

character changes.

• EXIT SAVE Closes the keyboard page and stores the text or graphic

changes to memory.

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Basics 27

Page 36

28 Mini-Touch Panel Basics Color Active-Matrix LCD Mini-Touch Panels

Page 37

Figure 35

Main page

Designing a Mini-Touch Panel Page

Overview

This section contains step-by-step instructions to create a mini-touch panel page and

a button, joy stick, bargraph, and also to set the video display. Once you understand

the basic operations, go through the Mini-Touch Panel Program Reference section to

learn about all the operations you can use to design mini-touch panel pages.

Activate the Editor Bar

Before you can design a mini-touch panel page, you need to activate the editor bar.

When you power up the panel, the first page you should see is the Main page

(Figure 35). If you have a pre-programmed panel, you may not see the Main page.

Refer to the Editor bar and Go to information in the Mini-Touch Panel Program

Reference section to access the Main page.

MAIN

PAGE

1. Press SETUP in the Main page to open the Setup page ( Figure 36).

SETUP

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 29

Page 38

1

UP

DN

UP

DN

1

UP

DN

Figure 36

Setup page

ADJUST ATTRIBUTES

BEEP

SET TIME

AND DATE

EXIT

PROTECTED

SETUP

Figure 37

Setup page and password

keypad

LCD TIMER

5 min

SERIAL NO.

924-00-0000

DOUBLE

BEEP

AXlink

vX.XX

SET

BACKGROUND

BRIGHTNESS

2. Press PROTECTED SETUP to open the password keypad shown in Figure 37.

ADJUST ATTRIBUTES EXIT

BEEP

LCD TIMER

5 min

UP DN

SERIAL NO.

924-00-0000

SET TIME

SET TIME

AND DATE

AND DATE

1 2 3

4 5

DOUBLE

DOUBLE

BEEP

BEEP

7 8 9

AXlink

CLEAR ENTER

0

AXlink

vX.XX

PROTECTED

1988

6

BACKGROUND

BRIGHTNESS

SETUP

SET

3. Type 1988, and press ENTER to open the Protected Setup page ( Figure 38). If

you enter a wrong number, press CLEAR and re-enter the number. Refer to the

Set Password subsection to change a password.

30 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 39

DN

Figure 38

Protected Setup page

ADJUST ATTRIBUTES

EDITOR CALIBRATE

SET

DEVICE

128

EXIT

Figure 39

Main page and editor bar

SETUP

PASSWORD

AUTO

ASSIGN

SET

SERIAL

PAGE

PASSWORD

POWER UP

PAGE

PAGE

TRACKING

LCD TIMER

MESSAGE

TIMER BRT

4

UP

4. Press EDITOR (Figure 39) and EXIT to close the Protected Setup page and return

to the Main page. The editor bar appears at the top of the Main page (Figure 36).

BUTTON PAGE ICONS SYSTEM EXIT

MAIN

PAGE

SETUP

Editor Bar

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 31

Create a Page

You create mini-touch panel pages using the Page menu option in the editor bar.

Add a page

1. Press PAGE on the editor bar to open the menu options shown in Figure 40.

Page 40

LOCK

–

ENTER

SAVE

Figure 40

Page menu options

Note

The message bar shows the

name of the current page.

PAGE: MAIN PAGE

MAIN

PAGE

PASSWD PG FLIP

PAGE COLOR

ADD

COPY

RENAME

DELETE

GO TO

PRINT

SETUP

EXIT

2. Press the ADD option to add a new page, and then the add page message to

open keyboard page 1 (Figure 41).

Figure 41

Add page message and

keyboard page 1

YOU MUST GIVE THE NEW PAGE A

UNIQUE NAME UP TO 20 LETTERS

TOUCH SCREEN TO CONTINUE

Q W E R T

BACK

SPACE

A S D F G

Z X C V

CAP

INTNL

CHARS

3. Type New Page (Figure 42) using keyboard pages 1 and 2. Press the MORE

KEYS button to toggle between the keyboard pages. The page name can be up to

20 letters.

SHIFTSPACE ALT

FONT ABORT

DEL

MORE

KEYS

EXIT

32 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 41

LOCK

–

SAVE

LOCK

SAVE

Page 1

Page 2

Figure 42

Add page message and

keyboard pages 1 and 2

NEW PAGE

Q W E R T

BACK

SPACE

NEW PAGE

Y U I O P

BACK

SPACE

Figure 43

Page menu options

A S D F G

Z X C V

CAP

INTNL

CHARS

SHIFT

SPACE ALT

FONT ABORT

ENTER

DEL

MORE

KEYS

EXIT

H J K L

N M

B

CAP

INTNL

CHARS

SHIFT

SPACE ALT

FONT ABORT

< >

ENTER

:

DEL

MORE

KEYS

EXIT

4. Press EXIT SAVE to add NEW PAGE to panel memory, close the keyboard, and

return to the Main page.

Go to NEW PAGE

1. Press PAGE on the editor bar to open the page menu options shown in Figure

43.

PAGE: MAIN PAGE

MAIN

PAGE

PASSWD PG FLIP

PAGE COLOR

ADD

COPY

RENAME

DELETE

GO TO

PRINT

SETUP

EXIT

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 33

2. Press the GO TO option to open the page list shown in Figure 44.

Page 42

Figure 44

Page list

* * NONE * *

* * PREVIOUS *

*

NEW PAGE

MAIN PAGE

ENTER

3. Press the up or down arrow to move the highlight bar to NEW PAGE.

4. Press ENTER to go to NEW PAGE.

Create a Button

You should be on NEW PAGE, and the editor bar should be visible before you create

a button. If not, start at the beginning of this section.

Add a button

1. Press BUTTON on the editor bar to open the button menu options shown in

Figure 45.

Figure 45

Button menu options

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

EXIT

2. Press ADD to add a button to NEW PAGE. The message bar shown in Figure 46

instructs you how to add a button. The first touch point is the upper-left corner

of the button.

34 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 43

Figure 46

Add a button message bar

Figure 47

Add a button example

TOUCH AND DRAG FOR SIZE

EXIT

3. Drag your finger horizontally across the screen and down to set the height and

width of the button as shown in Figure 47.

Width

Figure 48

Button menu options

Touch point

Height

4. Press EXIT in the message bar to exit add mode.

Resize the button

1. Press BUTTON on the editor bar again to open the menu options shown in

Figure 48.

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

Button

EXIT

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 35

2. Press the RESIZE option to resize the button when the message bar appears.

3. Touch the button and drag your finger horizontally across the screen and down

to resize the button as shown in Figure 49.

Page 44

Figure 49

Sizing a button

Touch any edge and

drag to resize.

4. Press EXIT in the message bar to exit resize mode.

Button Attributes

You can use the ATTRIBUTES option on the editor bar to set button borders, page

flips, and assign channel and level codes.

Set the button attributes

1. Press BUTTON on the editor bar to open the button menu options shown in

Figure 50.

Figure 50

Button menu options

V

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

Button

EXIT

2. Press ATTRIBUTES and the button you added to open the Attributes page

shown in Figure 51.

36 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 45

RAISED

Figure 51

Attributes page

BORDER

PAGE: NONE

STRING: NONE

FEEDBACK: CHANNEL

CHANNEL

CODE

NONE

VARIABLE

TEXT

NONE

BRING

BUTTON

TO FRONT

Figure 52

Border options page

Note

The three-dimensional border

option is available in mini-touch

panels equipped with firmware

version 2.0 or higher.

EXIT

EXIT

NO CHANGE

SET

COLORS

Set the border

1. Press BORDER to open the Border options page ( Figure 52).

NO

BORDER

DOUBLE

RAISED

SINGLE

DIAMOND

TRIPLE

SINGLE

WIDE

SINGLE

ROUNDED

DOUBLE

DIAMOND

SHADOWNOBORDER

DOUBLE

WIDE

DOUBLE

ROUNDED

TRIPLE

WIDE

SPECIAL

SINGLE

RAISED

DOUBLE

2

SINGLE

DOUBLE

3

SINGLE

THREE

DIMENSION

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 37

2. Press SHADOW to reset the button border to shadow style.

Page 46

Set the channel code

1. Press CHANNEL CODE in the Attributes page to open the channel code

keypad.

Note

The channel code for nonactive buttons is 0, and 1–255

for active buttons.

Figure 53

Page list

2. Type 255 in the keyboard. The AXCESS software program uses the channel

code number to identify the button and its operations.

3. Press ENTER to store the channel code in memory, close the keypad, and return

to the Attributes page.

Set the page flip

1. Press PAGE in the Attributes page to open the page list ( Figure 53).

* * NONE * *

* * PREVIOUS *

NEW PAGE

MAIN PAGE

ENTER

2. Press the up or down arrow to move the highlight bar to MAIN PAGE.

*

3. Press ENTER to set the page flip to the MAIN PAGE.

4. Press EXIT in the Attributes page to store the new button attributes in memory

and return to the current page.

5. Press EXIT in the editor bar to exit the attribute's mode.

38 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 47

Add Text

LOCK

–

SAVE

LOCK

SAVE

You can add text to buttons, joy sticks, and bargraphs using the BUTTON option.

Add text to a button

1. Press BUTTON on the editor bar to open the button menu options list shown in

Figure 54.

Figure 54

Button menu options

Figure 55

Edit text keyboard pages 1 and

2

V

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

Button

EXIT

2. Press EDIT TEXT to add text in the button.

3. Touch the button to open the keyboard pages 1 or 2 shown in Figure 55. Press

the MORE KEYS button to toggle between the keyboard pages.

Q W E R T

BACK

SPACE

Y U I O P

BACK

SPACE

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 39

A S D F G

Z X C V

CAP

INTNL

CHARS

SHIFT

SPACE ALT

FONT ABORT

Page 1 Page 2

ENTER

DEL

MORE

KEYS

EXIT

H J K L

N M

B

CAP

INTNL

CHARS

SHIFT

SPACE ALT

FONT ABORT

< >

ENTER

:

DEL

MORE

KEYS

EXIT

Page 48

Figure 56

Joy stick

4. Type MAIN PAGE. Press MORE KEYS to toggle between keyboard pages 1 and

2. The text appears in the message box at the top of the keyboard as shown in

Figure 55. The mini-touch panel displays an error message if you exceed the

maximum character spaces in the button. Change the size of the button or

reduce the text string to clear the error message.

5. Press EXIT SAVE to close the keyboard and return to the current page.

6. Press EXIT in the editor bar to exit edit text mode.

Create a Joy Stick

You can create a joy stick ( Figure 56) with the ICONS option in the editor bar.

Joy sticks are vertical and horizontal direction controllers you can use for camera

operations, such as pan and tilt. Before you start, make sure to connect the panel to

your AXCESS Control System. Otherwise, the joy stick may not work properly. Refer

to Mini-Touch Panel Program Reference for more information.

Figure 57

Icons menu options

Add a joy stick on a page

1. Press ICONS on the editor bar to open the icons menu options shown in

Figure 57.

BUTTON PAGE

ICONS

SYSTEM

TIME

DATE

E TIMER

16 CHAR TERM

32 CHAR TERM

VERTICAL GRAPH

ICON FEEDBACK

JOY STICK

DRAWINGS

BRIGHTNESS

VIDEO SETUP

EXIT

40 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 49

Figure 58

Add a joy stick example

2. Press the JOY STICK option to add a joy stick when the message bar appears.

3. Touch the screen to add the new joy stick to the page. Figure 58 shows the

method to add a joy stick.

Touch point

Set the joy stick attributes

1. Press BUTTON on the editor bar to open the button menu options shown in

Figure 59.

Figure 59

Button menu options

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

MAIN PAGE

EXIT

Joy stick

2. Press ATTRIBUTES to set the joy stick attributes when the message bar appears.

3. Touch the joy stick to open the Joy stick Attributes page shown in Figure 60.

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 41

Page 50

Figure 60

Joy stick Attributes page

CHANNEL

CODE

NONE

FUNCTION: JOYSTICK

LEVEL

CODE

1

Figure 61

Level code keypad

EXIT

EXIT

NO

CHANGE

SET

COLORS

Set the level code

1. Press LEVEL CODE in the Attributes page to open the level code keypad

(Figure 61).

0

1 2 3

4 5

6

7 8 9

CLEAR ENTER

0

2. Type 6 in the keyboard. The AXCESS software program uses level codes 1

through 7 to identify the joy stick and its associated operations. Refer to MiniTouch Panel Program Reference for more information.

3. Press ENTER to store the level code in memory.

4. Press EXIT in the Attributes page to store the new joy stick attributes in memory

and return to the current page.

5. Press EXIT in the editor bar to exit the attribute's mode.

42 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 51

Figure 62

Bargraph

Create a Bargraph

You can create a bargraph (Figure 62) with the ICONS option in the editor bar.

Bargraphs are level monitors and adjustable level controls you can configure to

monitor and adjust audio outputs and lighting levels. Before you start, make sure to

connect the panel to your AXCESS Control System. Otherwise, the bargraph may not

work properly. Refer to the Mini-Touch Panel Program Reference for more

information.

Add a bargraph to a page

1. Press ICONS on the editor bar to open the icons menu options shown in

Figure 63.

Figure 63

Icons menu options

BUTTON PAGE

ICONS

VERTICAL GRAPH

SYSTEM

TIME

DATE

E TIMER

16 CHAR TERM

32 CHAR TERM

ICON FEEDBACK

JOY STICK

DRAWINGS

BRIGHTNESS

VIDEO SETUP

EXIT

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 43

Page 52

Figure 64

2. Press the VERTICAL GRAPH option to add a bargraph when the message bar

appears.

3. Touch the screen to add the new bargraph to the page. Figure 64 shows the

method to add a bargraph.

Add and move a bargraph

example

Figure 65

Button menu options

Touch point

Set the bargraph attributes

1. Press BUTTON on the editor bar to open the button menu options shown in

Figure 65.

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

Bar graph

MAIN PAGE

EXIT

2. Press ATTRIBUTES to set the bargraph attributes when the message bar

appears.

44 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 53

3. Touch the bargraph to open the Attributes page shown in Figure 66.

Figure 66

Attributes page for a bargraph

EXIT

LEVEL

CODE

0

BRING

BUTTON

TO FRONT

CHANNEL

CODE

NONE

FEEDBACK: BAR GRAPH

FUNCTION: VERTICAL DISPLAY

EXIT

NO CHANGE

Set the level code

1. Press LEVEL CODE in the Attributes page to open the level code keypad.

2. Type 8 in the keyboard. The AXCESS software program uses level codes 1

through 8 to identify the bargraph and its associated operations. Refer to MiniTouch Panel Program Reference for more information.

3. Press ENTER to store the level code in memory.

4. Press EXIT in the Attributes page to store the new bargraph attributes in

memory and return to the current page.

5. Press EXIT in the editor bar to exit the attribute's mode.

Set the Video Display

After you add a Video Setup button on a page, you can open the Adjust Attributes

page that sets the incoming video signal's brightness, contrast, color, tint, and

compatible video signal. You must connect a live video source to the RCA video

port on the mini-touch panel's rear panel to perform these steps. The Video Setup

button is only available with mini-touch panels equipped with a video port. Go to

Link the New Page to the Main Page instructions if the mini-touch panel is not

equipped with a video port.

1. Press ICONS on the editor bar to open the icons menu shown in Figure 67.

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 45

Page 54

Figure 67

Icons menu

BUTTON PAGE

ICONS

VERTICAL GRAPH

SYSTEM

TIME

DATE

E TIMER

16 CHAR TERM

32 CHAR TERM

ICON FEEDBACK

JOYSTICK

DRAWINGS

BRIGHTNESS

VIDEO SETUP

EXIT

2. Press VIDEO SETUP and touch the screen to add a Video Setup button.

3. Press the VIDEO SETUP button to open the Video Setup page shown in

Figure 68. The live video appears in the video display area.

Figure 68

Video Setup page

ADJUST ATTRIBUTES EXIT

B

R

I

G

N

T

N

E

S

S

RESET

C

O

N

T

R

A

S

T

Video display area

C

O

L

O

R

NTSC

T

I

N

T

Horizontal sliders

4. Set the brightness, contrast, color, and tint with the horizontal sliders shown in

Figure 68. Set the mini-touch panel for NTSC or PAL composite video with the

button located in the bottom-right corner. The RESET button returns the video

display to factory default settings.

5. Press EXIT in the editor bar to exit the Video Setup page.

46 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 55

Link the New Page to the Main Page

You use the Attributes page to link buttons to pages.

1. Touch the MAIN PAGE button to flip to the Main page.

2. Press BUTTON on the editor bar to open the button menu options list shown in

Figure 69.

Figure 69

Button menu options

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

PAGE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

MAIN

SETUP

EXIT

3. Press EDIT TEXT to change the MAIN PAGE button text when the message bar

appears.

4. Touch the MAIN PAGE button to open the keyboard pages 1 and 2 shown in

Figure 65. Press the MORE KEYS button to toggle between the keyboard pages.

5. Press DEL four times to delete MAIN.

6. Type NEW. The revised text appears in the keyboard window as shown in

Figure 70.

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 47

Page 56

LOCK

–

SAVE

LOCK

SAVE

Figure 70

Keyboard pages 1 and 2

NEW PAGE

Q

W E R T

BACK

SPACE

NEW PAGE

Y

U I O P

BACK

SPACE

Figure 71

Button menu options

A S D F G

Z X C V

CAP

INTNL

CHARS

SHIFT

SPACE ALT

FONT ABORT

ENTER

DEL

MORE

KEYS

EXIT

H J K L

N M

B

CAP

INTNL

CHARS

SHIFT

SPACE ALT

FONT ABORT

< >

ENTER

:

DEL

MORE

KEYS

EXIT

Page 1 Page 2

7. Press EXIT SAVE to close the keyboard.

8. Press EXIT in the message bar to exit edit text mode.

9. Press BUTTON on the editor bar to open the button menu options shown in

Figure 71.

PAGE: NEW PAGE

ADD

MOVE

COPY IMAGE

DELETE

RESIZE

PAGE

EDIT TEXT

ATTRIBUTES

SAVE

PASTE

SET TO DEFAULT

MAIN

SETUP

EXIT

10. Press ATTRIBUTES and the NEW PAGE button to open the Attributes page

shown in Figure 72.

11. Press PAGE in the Attributes page to open the page list.

12. Press the up or down buttons to move the highlight bar to NEW PAGE.

48 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 57

Figure 72

Attributes page

BORDER

PAGE: MAIN PAGE

STRING: NONE

FEEDBACK: ALWAYS ON

CHANNEL

CODE

NONE

VARIABLE

TEXT

NONE

BRING

BUTTON

TO FRONT

EXIT

EXIT

NO CHANGE

SET

COLORS

13. Press ENTER to set the page flip to the NEW PAGE.

14. Press EXIT in the Attributes page to store the new button attributes in memory

and return to the current page.

15. Press EXIT in the editor bar to exit the attribute's mode.

16. Touch the NEW PAGE and MAIN PAGE buttons to flip between pages.

Close the Editor Bar

After you finish designing the mini-touch panel page, close the editor bar.

Exit editor mode

1. Touch EXIT on the editor bar ( Figure 73).

Figure 73

Main page

Color Active-Matrix LCD Mini-Touch Panels Designing a Mini-Touch Panel Page 49

BUTTON PAGE ICONS SYSTEM EXIT

NEW

PAGE

SETUP

2. Press YES on the exit decision box to close the editor bar.

Page 58

50 Designing a Mini-Touch Panel Page Color Active-Matrix LCD Mini-Touch Panels

Page 59

Figure 74

Main page

Mini-Touch Panel Program

Reference

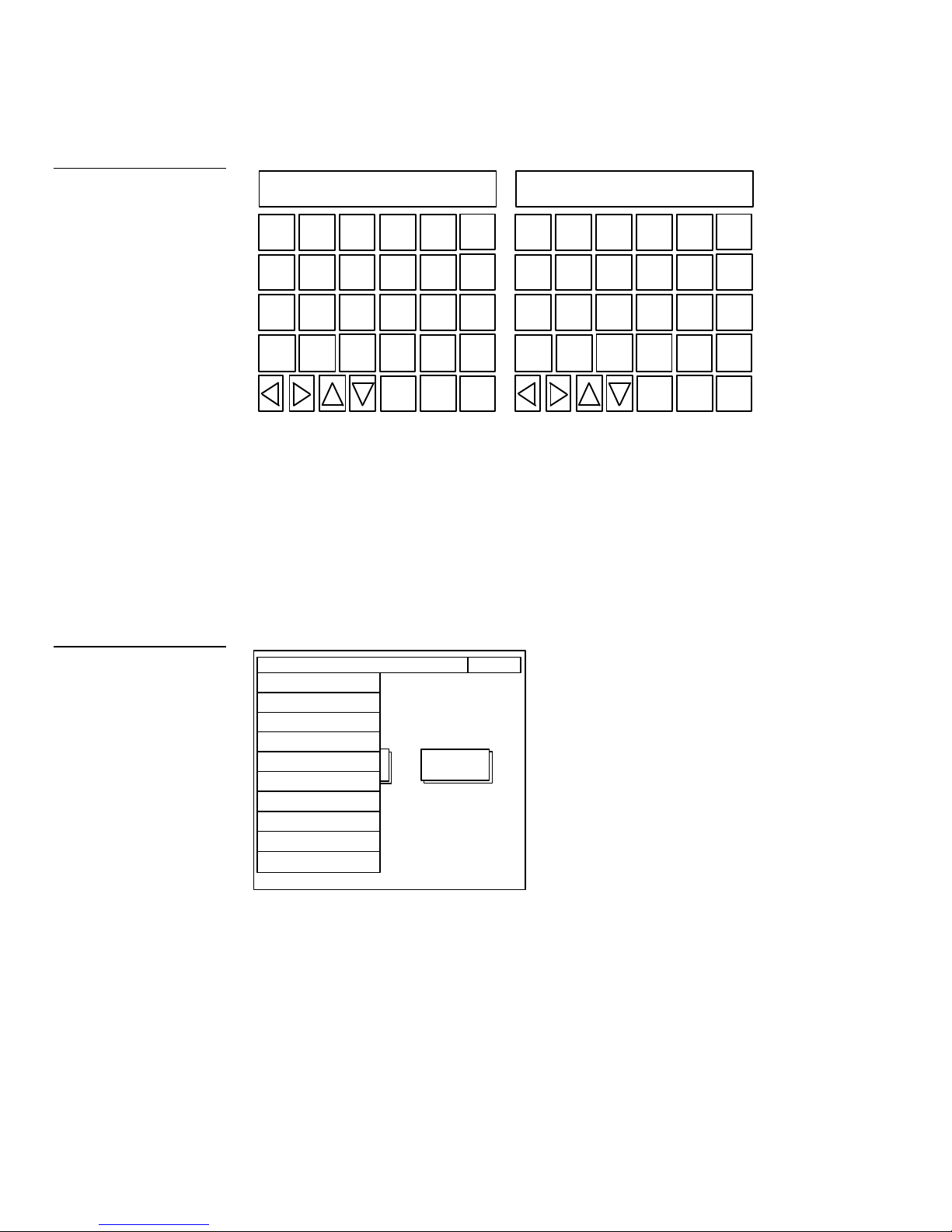

Overview

You can use the Setup page, Protected Setup page, and Editor bar operations to

create mini-touch panel pages. This section describes operations, access flowcharts,

and button options.

Setup Page

You can access the Setup page from the Main page ( Figure 74) that appears when

you power up the mini-touch panel.

MAIN

PAGE

The buttons in the Setup page set the operating parameters of the mini-touch panel.

SETUP

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Program Reference 51

Page 60

Open the Setup Page

BEEP

1

UP

DN

LCD TIMER

UP

DN

923 -00- 0001

BEEP

1

UP

DN

From the Main page, press the SETUP button to open the Setup page shown in

Figure 75.

Figure 75

Setup page

Note

The SmartPack button appears

in the Setup page when a

SMT-PKM Mini-SmartPack is

connected to the TiltScreen

mini-touch panel. The WAVE

button appears in the Setup

page when a WAV-PKM MiniWavePack is connected to the

TiltScreen mini-touch panel.

Figure 76

Setup page flowchart

ADJUST ATTRIBUTES EXIT

15

SERIAL NO.

SmartPack

WAVE

SET TIME

AND DATE

DOUBLE

BEEP

AXlink

vX.XXV

PROTECTED

SETUP

SET

BACKGROUND

BRIGHTNESS

When you select the SETUP button, it changes to a dark background. The flowchart

in Figure 76 shows the buttons you use to access the Setup page.

MAIN

PAGE

SETUP

BUTTON

Buttons

Use the Setup page buttons to configure the mini-touch panel.

Beep

The BEEP button (Figure 77) sets how long the audible beep sounds when you press

the screen.

Figure 77

BEEP button

52 Mini-Touch Panel Program Reference Color Active-Matrix LCD Mini-Touch Panels

Page 61

LCD TIMER

Note

You can override the Beep

value setting using the 'ABEEP'

and 'ADBEEP' System

Send_Commands. Refer to the

AXCESS Programming

subsection for complete

information.

Figure 78

LCD TIMER button

Set the beep value to 0 to disable the beep sound. Press the up and down buttons to

set the beep time in .10-second increments . The minimum beep time setting is 0 and

the maximum is 10 (1 second).

LCD timer

The LCD TIMER button (Figure 78) sets the length of time the mini-touch panel can

be inactive before activating screen-saver mode.

15

UP DN

When the mini-touch panel goes into screen-saver mode, the LCD is powered-down.

With a setting of 5, the panel goes into screen-saver mode if there is no activity for 5

minutes. Press the up and down buttons to change the time that the timer screen

stays on when there is no panel activity. The minimum time setting is 1 and

maximum is 150.

Figure 79

SERIAL NO., AXlink, and

vX.XX button examples

Serial number, AXlink, and vX.XX

The SERIAL NUMBER, AXlink, and vX.XX buttons shown in Figure 79 are nonactive (display only) buttons.

SERIAL NO.

923 -00- 0001

AXlink

vX.XX

The SERIAL NUMBER button shows the serial number AMX assigns to the minitouch panel. The AXlink button is an AXCESS communication indicator that blinks

once every second when the AXCESS Control System is connected to the mini-touch

panel. The vX.XX button shows the current ROM software version installed in the

mini-touch panel.

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Program Reference 53

Page 62

SmartPack

SLEEP TIME

1

UP

DN

MODULE

BATTERY

SUPPLY

BATTERY

Note

The optional Mini-SmartPack

SMT-PKM can only be used

with a TiltScreen mini-touch

panel.

Figure 80

SmartPack page

The SmartPack button appears on the Setup page when a SMT-PKM MiniSmartPack is connected to the TiltScreen mini-touch panel. The SMT-PKM provides

one-way touch panel control, and transmits RF and high-/low-frequency IR signals.

The SMT-PKM contains a lead-acid rechargeable battery that supplies independent

power to the mini-touch panel. Press the SmartPack button to open the page shown

in Figure 80.

ADJUST SMARTPACK SETTINGS

SMT-PKM

MODULE

VERSION

vX.XX

VOLTAGE

XX.XV

VOLTAGE

XX.XV

CHARGING

EXIT

RF OFF

IR 38kHz

The SmartPack page shows the module type, module version, battery voltage level,

power supply voltage level, battery charge status, and sets the sleep time, RF signal,

and IR signal.

• SMT-PKM MODULE Appears when an optional SMT-PKM is connected to

the mini-touch panel.

• MODULE VERSION vX.XX Shows the ROM firmware version installed in

the SMT-PKM Mini-SmartPack wireless power pack.

• BATTERY VOLTAGE XX.XV Shows the voltage level of the lead-acid

rechargeable battery in the SMT-PKM.

• SUPPLY VOLTAGE XX.XV Shows the voltage level of the external power

supply (optional) connected to the SMT-PKM.

54 Mini-Touch Panel Program Reference Color Active-Matrix LCD Mini-Touch Panels

Page 63

• SLEEP TIME Press the up and down buttons to set the sleep time. The

GROUP ID

1

UP

DN

MODULE

BATTERY

SUPPLY

SLEEP TIME

1

UP

DN

BATTERY

DEVICE

SERVER

DEVICE

NETWORK

RSSIRSSI

SERVER DEVICES

minimum sleep time is 0 (off) and maximum is 150 minutes. When the minitouch panel goes to sleep, all communication stops and battery discharge is

minimized. If the sleep time is set to 5, the panel goes into sleep mode if there

is no activity for 5 minutes. The mini-touch panel will wake up when you

touch the screen.

• BATTERY CHARGING/BATTERY FULLY CHARGED Battery Charging

appears when the lead-acid battery is charging. Battery Fully Charged appears

when the battery is fully charged. The shaded area in the horizontal gauge

moves from left-to-right as the battery voltage level increases.

• RF ON/RF OFF Press to set RF control signals on or off.

• IR 38 kHz/IR 455 kHz/IR OFF Press to set IR control signals to 38 kHz, 455

kHz, or off.

WAVE

Note

The optional WAV-PKM MiniWavePack can only be used

with a TiltScreen mini-touch

panel.

Figure 81

WAVE page

The WAVE button appears on the Setup page when a WAV-PKM Mini-WavePack is

connected to a TiltScreen mini-touch panel. The WAV-PKM provides wireless twoway RF spread-spectrum touch panel control. The WAV-PKM contains a lead-acid

rechargeable battery that supplies independent power to the mini-touch panel. Refer

to the AXR-WAVES Server and Wireless Power Packs instruction manual for more

information. Press the WAVE button to open the page shown in Figure 81.

ADJUST WAVE SETTINGS

WAV-PKM

MODULE

LOCKED ON

VERSION

vX.XX

VOLTAGE

XX.XV

VOLTAGE

XX.XV

CHARGING

EFFICIENCY

XX%

128, 129, 130

EXIT

VERSION

VX.XX

RANGE

XXX-XXX

EFFICIENCY

XX%

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Program Reference 55

Page 64

The WAVE page shows the module type and communication status, module

version, battery voltage level, power supply voltage level, received signal strength,

battery charge status, device efficiency, server version, device range, network

efficiency, server devices, and sets the group ID number, and sleep time.

• WAV-PKM MODULE Appears when an optional WAV-PKM is connected

to the TiltScreen mini-touch panel. LOCKED ON indicates the mini-touch

panel is locked on to the AXR-WAVES server connected to the control system.

NOT LOCKED indicates the mini-touch panel is not communicating with the

AXR-WAVES server.

• MODULE VERSION vX.XX Shows the ROM firmware version installed in

the WAV-PKM Mini-WavePack wireless power pack.

• BATTERY VOLTAGE XX.XV Shows the voltage level of the lead-acid

rechargeable battery in the WAV-PKM.

• SUPPLY VOLTAGE XX.XV Shows the voltage level of the external power

supply (optional) connected to the WAV-PKM.

• GROUP ID Sets the group ID number on the mini-touch panel to

communicate with the wireless AXR-WAVES Server with the same group ID

number. The group ID range is 0—15. The group ID setting overrides the DIP

switch setting on the WAV-PKM. Refer to the AXR-WAVES Server and Wireless

Power Packs instruction manual to set the group ID number.

• RSSI Shows the strength of the AXR-WAVES Server signal received by the

mini-touch panel. The shaded area in the horizontal gauge moves from left-toright as the RF signal intensity increases. The shaded area should fluctuate

between 50% and 100%.

• BATTERY CHARGING/BATTERY FULLY CHARGED Battery Charging

appears when the lead-acid battery is charging. Battery Fully Charged appears

when the battery is fully charged. The shaded area in the horizontal gauge

moves from left-to-right as the battery voltage level increases.

• DEVICE EFFICIENCY XX% Shows the communication efficiency of bi-

directional RF transmissions between the mini-touch panel and AXR-WAVES

Server. The efficiency percentage (0-100%) is determined by the number of

retries required to complete a panel operation.

56 Mini-Touch Panel Program Reference Color Active-Matrix LCD Mini-Touch Panels

Page 65

• SLEEP TIME Press the up and down buttons to set the sleep time. The

YEAR97UP

DN

UP

DN

HOUR

MONTH

1

UP

DN

UP

DN

MIN

DAY10UP

DN

minimum sleep time is 0 (off) and maximum is 150 minutes. When the minitouch panel goes to sleep, all communication and battery discharge stops. If

the sleep time is set to 5, the panel goes into sleep mode if there is no activity

for 5 minutes. The mini-touch panel will wake up when you touch the screen

for more than .5 seconds.

• SERVER VERSION vX.XX Shows the ROM firmware version installed in

the AXR-WAVES Server that is communicating with the mini-touch panel.

• DEVICE RANGE XXX-XXX Shows the AXlink device numbers that can

communicate with the AXR-WAVES Server. Each AXR-WAVES Server uses a

group ID number and device range to communicate with mini-touch panels

(16 maximum). Refer to the AXR-WAVES Server and Wireless Power Packs

instruction manual for more information about device and group ID settings.

• NETWORK EFFICIENCY XX% Shows the communication status of bi-

directional RF transmissions between all mini-touch panels and AXR-WAVES

Server. The percentage of efficiency (0-100%) is calculated by the number of

retries required to perform a panel operation.

• SERVER DEVICES Shows the AXlink device number of the TiltScreen mini-

touch panels communicating with the AXR-WAVES Server.

Figure 82

Set time and date page

Set time and date

Press the SET TIME AND DATE button to open the page shown in Figure 82.

SET TIME IN 24 HOUR FORMAT

5

5

DISPLAY

MONTH/DAY

EXIT

DISPLAY

12:00

Color Active-Matrix LCD Mini-Touch Panels Mini-Touch Panel Program Reference 57

Page 66

Set the year, month, day, hour, minute, clock display, and day/month display.

• YEAR Press the up and down buttons to set the year.

• MONTH Press the up and down buttons to set the month.

• DAY Press the up and down buttons to set the day.

• HOUR Press the up and down buttons to set the hour.

• MIN Press the up and down buttons to set the minute.

• DISPLAY 12:00/24:00 Press to set the clock display to a 12- or 24-hour

format. For example, the 12-hour clock format changes from 12:00 to 1:00, and

the 24-hour clock changes from 12:00 to 13:00.

• DISPLAY MONTH/DAY, DAY/MONTH Press to set the month and day

display.

Double beep

Press the DOUBLE BEEP button (Figure 83) to enable or disable the double beep

option. The double beep sounds when you press the screen. When the button

background and text is black, the double beep is enabled, and when the background

is white and text is black it is disabled.

Figure 83

DOUBLE BEEP buttons

Note

You can override the Beep

value setting using the 'ABEEP'

and 'ADBEEP' System

Send_Commands. Refer to the

AXCESS Programming

subsection for complete

information.

DOUBLE

BEEP

Enabled

DOUBLE

BEEP

Disabled

Set the BEEP button (described earlier) to 0 to disable the beep sound.

Protected setup

The Protected Setup page (Figure 84) contains various buttons you can use to set up

mini-touch panel pages.

58 Mini-Touch Panel Program Reference Color Active-Matrix LCD Mini-Touch Panels

Page 67

UP

DN

TIMER BRT

TRA

A

T

A

Figure 84

Protected Setup page

ADJUST ATTRIBUTES

EDITOR CALIBRATE

SET

DEVICE

128

EXIT

Figure 85

Set Choose Color page

SETUP

PASSWORD

AUTO

ASSIGN

SET

SERIAL

PAGE

PASSWORD

POWER UP

PAGE

PAGE

TRACKING

LCD TIMER

MESSAGE

5

Because there are so many operations associated with Protected Setup page buttons,

they are all described in the Protected Setup Page subsection.

Set background

Press the SET BACKGROUND button to open the page shown in Figure 85.

CHOOSE COLOR EXIT

DARK

BLACK

DARK

MAGENTA

MEDIUM

CREAM

GRAY

YELLOW BLUE MAGENTA CYAN WHITE

RED

DARK

CYAN

MICROSOFT

MOUSE

DARK

GREEN

LIGHT

GRAY

DARK

GRAY

DARK

YELLOW

MONEY

GREEN

DARK

BLUE

SKY

BLUE

RED GREEN

N

S