Page 1

instruction manual

AXB-PT10/15/30

PosiTrack Camera Controllers

Camera Controllers

Page 2

AMX Limited Warranty and Disclaimer

AMX Corporation warrants its products to be free of defects in material and workmanship under normal use for

three (3) years from the date of purchase from AMX Corporation, with the following exceptions:

• Electroluminescent and LCD Control Panels are warranted for three (3) years, except for the display and touch

overlay components that are warranted for a period of one (1) year.

• Disk drive mechanisms, pan/tilt heads, power supplies, MX Series products, and KC Series products are

warranted for a period of one (1) year.

• Unless otherwise specified, OEM and custom products are warranted for a period of one (1) year.

• Software is warranted for a period of ninety (90) days.

• Batteries and incandescent lamps are not covered under the warranty.

This warranty extends only to products purchased directly from AMX Corporation or an Authorized AMX Dealer.

AMX Corporation is not liable for any damages caused by its products or for the failure of its products to perform.

This includes any lost profits, lost savings, incidental damages, or consequential damages. AMX Corporation is not

liable for any claim made by a third party or by an AMX Dealer for a third party.

This limitation of liability applies whether damages are sought, or a claim is made, under this warranty or as a tort

claim (including negligence and strict product liability), a contract claim, or any other claim. This limitation of

liability cannot be waived or amended by any person. This limitation of liability will be effective even if AMX

Corporation or an authorized representative of AMX Corporation has been advised of the possibility of any such

damages. This limitation of liability, however, will not apply to claims for personal injury.

Some states do not allow a limitation of how long an implied warranty last. Some states do not allow the limitation or

exclusion of incidental or consequential damages for consumer products. In such states, the limitation or exclusion of

the Limited Warranty may not apply. This Limited Warranty gives the owner specific legal rights. The owner may

also have other rights that vary from state to state. The owner is advised to consult applicable state laws for full

determination of rights.

EXCEPT AS EXPRESSLY SET FORTH IN THIS WARRANTY, AMX CORPORATION MAKES NO

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. AMX CORPORATION

EXPRESSLY DISCLAIMS ALL WARRANTIES NOT STATED IN THIS LIMITED WARRANTY. ANY

IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW ARE LIMITED TO THE TERMS OF THIS

LIMITED WARRANTY.

Page 3

Table of Contents

Table of Contents

Introduction ...............................................................................................................1

Specifications .................................................................................................................... 2

Lens Control Modes .......................................................................................................... 3

Servomotor Mode..................................................................................................................... 3

Motor Mode .............................................................................................................................. 4

Pan and Tilt Control........................................................................................................... 4

Zoom, Focus, and Iris Control........................................................................................... 4

Sample Product Application .............................................................................................. 5

Pre-Installation ..........................................................................................................7

Configuration Settings ....................................................................................................... 7

Setting zoom, focus, and iris switches to servomotor or motor mode...................................... 8

Setting the RS-232 DIP switch (S2) ......................................................................................... 8

Setting the AXlink Device DIP switch (S5) ............................................................................... 9

Accessing the AXB-PT10 and AXB-PT15 Internal Jumpers ........................................... 10

Accessing the AXB-PT30 Internal Jumpers .................................................................... 11

Setting the Internal Jumper Communication Mode ......................................................... 12

Configuring An External Camera/Lens Power Supply..................................................... 13

Installation ...............................................................................................................15

Mounting the PT10, PT15, and PT30.............................................................................. 15

PT10 and PT15 Camera/Lens Mounting and Balancing................................................. 16

PT30 Camera/Lens Mounting and Balancing.................................................................. 19

Wiring the Connectors..................................................................................................... 20

Wiring Guidelines ............................................................................................................ 21

Preparing captive wires .......................................................................................................... 22

Using the AXlink connector for data and power ..................................................................... 22

Using the AXlink connector with an external RS-232 control device or PC (Stand-Alone only) 23

Using the RS-232 DB-9 connector ......................................................................................... 23

Preparing the PosiTrack Controllers for communication ........................................................ 23

Using the lens control DB-15 HD (high density) connector .................................................... 24

Pan Characteristics ......................................................................................................... 25

Setting the adjustable pan-limit stops .................................................................................... 25

Tilt Characteristics........................................................................................................... 26

Setting the adjustable tilt-limit stops ....................................................................................... 26

XB-PT10/15/30 PosiTrack Camera Controllers

i

Page 4

Table of Contents

Programming ..........................................................................................................27

Configuration Commands ............................................................................................... 27

Channel Commands ....................................................................................................... 35

Pan/tilt functions..................................................................................................................... 35

Motor mode lens functions ..................................................................................................... 36

Preset functions .................................................................................................................... 36

Levels.............................................................................................................................. 38

Level applications................................................................................................................... 38

Send_Commands ........................................................................................................... 38

Diagnostic error values .......................................................................................................... 41

Preset parameters and commands ........................................................................................ 42

RS-232 commands ................................................................................................................ 44

RS-232 Send_Strings ............................................................................................................ 46

Stand-Alone RS-232 Protocol ......................................................................................... 46

Response mask ..................................................................................................................... 48

Upgrading the Firmware ........................................................................................49

Upgrading the Firmware Using NetLinx Studio ............................................................... 49

Upgrading Firmware on Axcess Systems .............................................................................. 49

Upgrading the Firmware Using SOFTROM .................................................................... 50

Configuration.......................................................................................................................... 50

Downloading the Firmware .................................................................................................... 50

ii

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 5

Introduction

The AXB-PT10 PosiTrack 10, AXB-PT15 PosiTrack 15, and AXB-PT30 PosiTrack 30 Camera

Controllers (FIG. 1) are camera/lens controllers used for precise camera-positioning applications.

Each PosiTrack unit supports both AXlink and RS-232 control protocols and connects directly to

an AXlink network. All controllers contain on-board intelligence for consistent motion and lens

control. The AXB-PT10 and AXB-PT15 Camera Controllers use identical connectors and camera

mounts but support different camera/lens weights (refer to the Specifications section for more

detailed information).

PosiTrack 10

LENS POWER

PANJA

CAM

RS-232

LENS

AXlink

Introduction

Dual Camera/

Lens Cradle

Assembly

(PT15 uses the

PosiTrack 30

same camera mount

as the PT10)

MT

RS-232

LENS

LENS POWER

CAM

AMX

AXlink

Single

Camera/Lens

Cradle

FIG. 1 AXB-PT10 and AXB-PT30 PosiTrack Camera Controllers (side views)

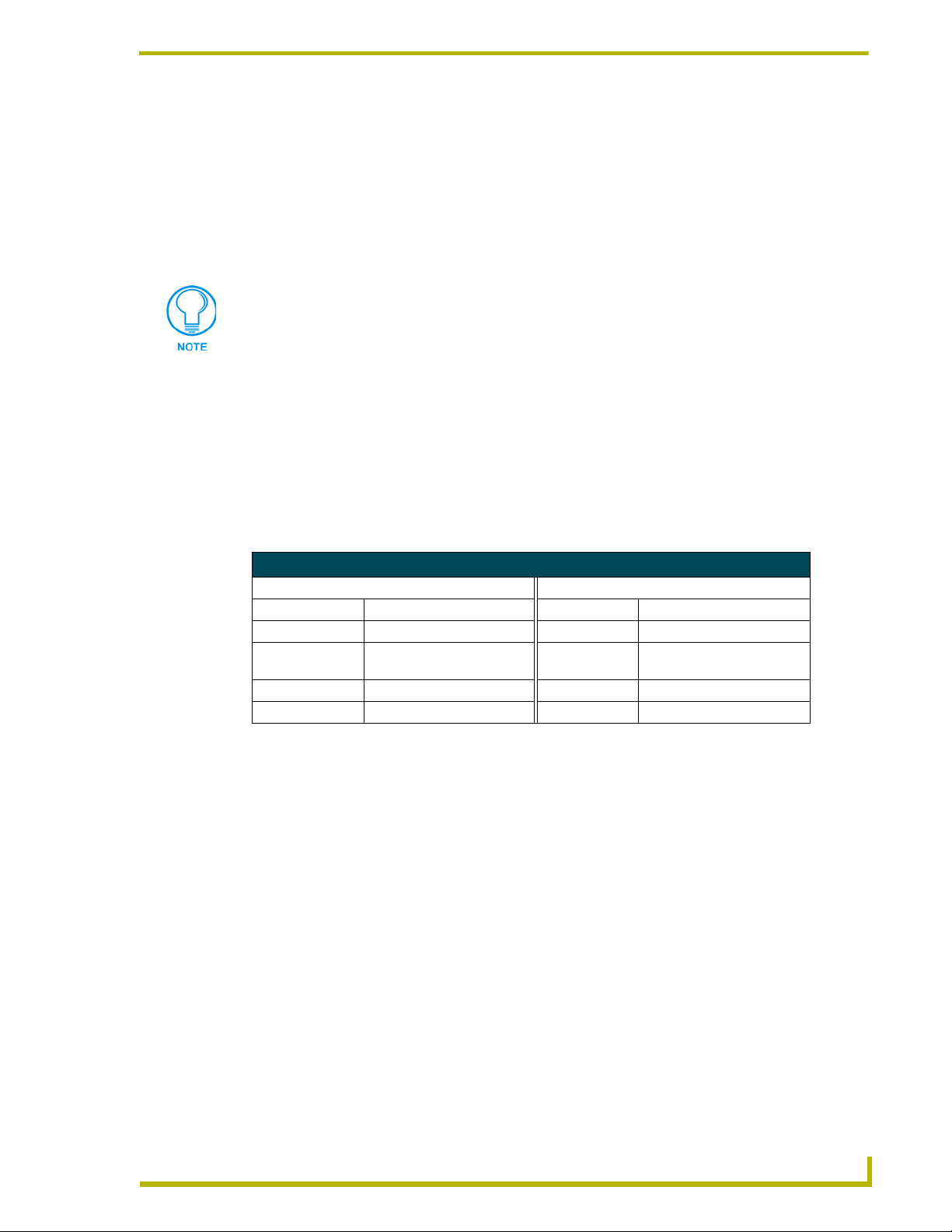

The following table shows the PosiTrack unit lens compatibility.

PosiTrack Unit Lens Compatibility

Fujinon Lenses Canon Lenses

MD KTSA

BMD RGE PZF

AMSR R

MPX REA

SNPY REA-IA

MDM REA-IA PZF

SNDS RGE

AXB-PT10/15/30 PosiTrack Camera Controllers

1

Page 6

Introduction

Specifications

The following table lists the specifications for all PosiTrack units.

Specifications

Dimensions (HWD):

AXB-PT10 Camera controller: 5.85" x 5.20" x 4.92" (14.86 cm x 13.22 cm x 14.70 cm)

Camera mount: 0.65" x 2.26" x 3.23" (1.75 cm x 5.74 cm x 8.21 cm)

Cradle support bracket: 3.64" x 5.50" x 0.20"

(9.25 cm x 13.97 cm x 0.51 cm)

Dimensions (HWD):

AXB-PT15 Camera controller: 6.43" x 5.61" x 5.38"

(16.32 cm x 14.25 cm x 13.67 cm)

Camera mount: 0.65" x 2.26" x 3.23" (1.75 cm x 5.74 cm x 8.21 cm)

Cradle support bracket: 3.64" x 5.50" x 0.20"

(9.25 cm x 13.97 cm x 0.51 cm)

Dimensions (HWD)

AXB-PT30 Camera Controller: 7.10" x 5.70" x 4.65" (18.03 cm x 14.49 cm x 11.81 cm)

Camera Cradle: 4.75" x 3.75" x 6.25" (120.67 mm x 95.28 mm x 158.75 mm)

Power Consumption:

AXB-PT10

AXB-PT15

AXB-PT30

Weight:

AXB-PT10

AXB-PT15

AXB-PT30

Angular Travel: Pan ± 179° (358° total)

Maximum Speed:

AXB-PT10 • Pan 45°/sec.

AXB-PT15 • Pan 55°/sec.

AXB-PT30 • Pan 35°/sec.

Weight Capacity:

AXB-PT10

AXB-PT15

AXB-PT30

Repeatability:

AXB-PT10

AXB-PT15

AXB-PT30

2.6 A max @ 12 VDC

4 A max @ 12 VDC

6 A max @ 12 VDC

8.00 lbs. (3.63 kg)

10.51 lbs. (4.77 kg)

13.05 lbs. (5.92 kg)

Tilt ± 90° (180° total)

• Tilt 45°/sec.

• Tilt 55°/sec.

• Tilt 35°/sec.

10 lbs. (4.54 kg) balanced lens/camera weight (maximum)

15 lbs. (6.80 kg) balanced lens/camera weight (maximum)

30 lbs. (13.6 kg) balanced lens/camera weight (maximum)

± 5 arc minutes

± 3 arc minutes

± 5 arc minutes

2

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 7

Introduction

Specifications (Cont.)

DIP Switches: • (S2) - RS-232 communication (baud rate)

• (S5) - AXlink communication (device #)

Presets: Stores up to 255 presets for pan, tilt, zoom, focus, and iris operations; 127 of

those presets return a status when queried.

Relays: Solid-state relays for servomotor lens mode control (zoom/focus speed/position

and iris local/auto)

Optical Centerline: Optical centerline is between 1/2" and 5" above the mounting plane of the cam-

era/lens (this allows the mounting of the camera/lens so that the tilt axis is

capable of going through the optical axis of the camera)

Environmental Parameters: 32° F to 120° F (0° C to 48.8° C) ambient temperature range

Enclosure: Metal with enamel and anodized matte finish

Control Panel: • RS-232 DB-9 connector (300 baud - 38.4 KB communication for camera

Battery: Lithium battery to protect preset memory (up to 10 years)

Connectors: • 4-pin captive wire (AXlink)

Optional Accessories: • CC-CAM lens control cable (specify make and model)

control)

• DB-15 high density connector (lens control)

• Lens power switch (powers or isolates the camera lens)

• AXlink 4-pin connector (provides AXlink, RS-232 stand-alone

communication, and power connection points)

• DB-15 HD 15-pin high-density (female) for lens control

• DB-9 9-pin D-sub (male) for RS-232 camera control

• CC-CAM RS-232 camera control cable (specify make and model)

• Pedestal mount (PM-CAM, PosiTrack Pedestal Mount)

• PSN2.8 Power Supply (for use with the PT10 Camera Controller)

• PSN6.5 Power Supply (for use with the PT10/15/30 Camera Controllers)

- This power supply can be used with ALL PosiTrack units

• Tripod mount (TM-CAM, PosiTrack Tripod Mount Adapter)

• Wall-mount bracket (WM-CAM, PosiTrack Wall Mount)

Lens Control Modes

The Servomotor and Motor modes are two Analog Voltage Control methods available on the

PosiTrack units.

Servomotor Mode

This method is generally used in broadcast or videoconference-style lenses. The voltage range used

for servomotor style lenses is +2.5 to +7.5 VDC. These lenses can be controlled in two different

modes: positional mode and speed mode.

Positional mode is the most common Servomotor mode. When voltage changes, the lens

moves and remains still until the voltage changes again. For example, if a lens receives a

voltage of +3 VDC, the lens moves to the corresponding position and stays there as long

as the voltage remains at +3 VDC. The movement speed of the lens motor is a function of

the PosiTrack unit’s analog output. The lens servomotor receives the preset voltage when

a preset is recalled in the positional mode.

AXB-PT10/15/30 PosiTrack Camera Controllers

3

Page 8

Introduction

Speed mode moves the lens when the voltage deviates from the center point of its range.

The farther the voltage moves away from the center point of reference, the faster the lens

motor moves. The lens must have POT outputs when recalling a preset in this mode,. The

outputs pass to the PosiTrack unit, and when the received voltage level matches the level

stored in the preset, the voltage returns to zero. Servomotor speed mode lenses not

having POT outputs do not have preset recall capability.

Motor Mode

Motor mode is used when the lens requires the motors be directly driven from an external source.

The standard voltage ranges are ± 6 VDC or ± 12 VDC with a center (no motion) of 0 VDC. Unlike

servomotor lenses, these only operate in speed mode.

The lens moves in relation to the voltage offset from zero. The farther the voltage moves away from

the center point, the faster the lens motor moves. The lens must have POT outputs when recalling a

preset in this mode, these outputs are then passed to the PosiTrack unit. When the received voltage

level matches the level stored in the preset, the voltage returns to zero. Motor mode lenses not

having POT outputs do not have preset recall capability.

Pan and Tilt Control

Presets and travel limit stops are based on encoder counts from a home position index, located at

the center of each axis’ range of motion.

Zoom, Focus, and Iris Control

Each PosiTrack unit delivers a low voltage pulse-width-modulated output for zoom, focus, and iris

functions for motor mode lenses. These units are also capable of receiving reference voltage rails

and sending zoom, focus, and iris control signals in response to these rails. In this setting (slide-

switch configured), no active control signals will reach the lens before power (+ 12 VDC and

GND) is supplied to the lens. This motor mode applies to the control of the Fujinon and Canon

teleconferencing lenses. During preset recall operation, these outputs are synchronized with the pan

and tilt motions. Refer to the PosiTrack Unit Lens Compatibility table on page 1. Four solid state

relays are also provided to control the zoom, focus, and iris speed/position mode selection and iris

local/auto selection on the Fujinon MD series and Canon KTSA series lenses.

4

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 9

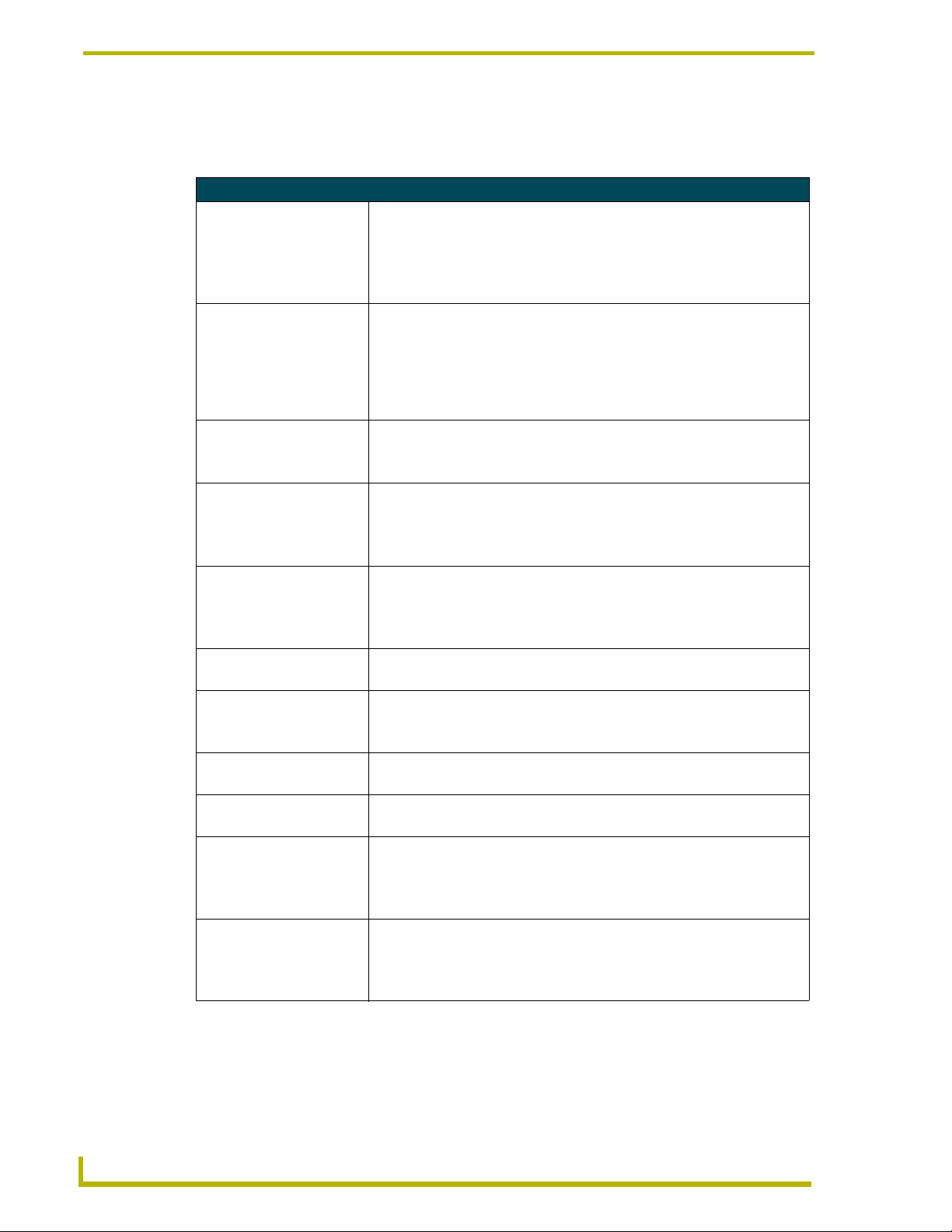

Sample Product Application

FIG. 2 shows a sample camera control application using the AXB-PT10.

Application #1 - AXlink

AMX AXB-PT10

AMX Local

Power Supply

Introduction

AMX AXP-PLV

PWR cable

AXlink

AMX AXB-EM232 (rear view)

V

CTS2

RTS2

GND

485EN

RX2

TX2

RS-232

GND

RX

TX

TX

RX

TX1

RX1

RS-232 / 422 AXlink PWR

AXlink

AMX ABS (AXlink Bus Strip)

AMX PS2.8

Powe r S up pl y

PWR cable

Application #2 - RS-232

AMX AXB-PT10

AMX Local

Power Su pp l y

PWR cable

FIG. 2 Sample AXB-PT10 camera product application

Use a separate power supply to power each PosiTrack unit. Power to the PosiTrack

unit is supplied from the external power supply to the unused power pin on the

PosiTrack unit’s AXlink connector.

The AXB-PT10 unit requires a PSN2.8 or PSN6.5 power supply.

The AXB-PT15 and AXB-PT30 units require a PSN6.5 power supply.

12VDC

AXM

AXP

GND

PWR

PC or other

RS-232

controller

AXB-PT10/15/30 PosiTrack Camera Controllers

5

Page 10

Introduction

6

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 11

Pre-Installation

There are four SPDT slide switches in the lens control section (FIG. 3). Three of the switches

toggle the lens control selection between servomotor or motor mode hardware for control of zoom,

focus, and iris. The fourth selects between ± 6 VDC and ± 12 VDC control for motor mode lens

functions.

An SPDT switch is a Single Pole-Double Throw switch. This switch is completed at

both positions. An example is the Volt switch that is active in both the 6 and 12

positions.

Each PosiTrack unit consists of two main Printed Circuit Boards (PCBs):

PosiTrack Processor PCB (PosiTrack Mother Board) contains the main processor, 2MB

FlashROM, and 2MB SRAM.

PosiTrack Power Management PCB (PosiTrack Daughter Board) contains power

conditioning circuitry, control outputs/inputs to the pan/tilt drives, and zoom/focus/iris

outputs, and inputs to the lenses.

Pre-Installation

The following table shows the necessary tools when working on the PosiTracks.

Necessary Tools

AXB-PT10/15 AXB-PT30

3/32 HEX KEY Anti-Rotation Pin 5/64 HEX KEY Cover Screws

3/16 HEX KEY Camera Mount Screw 1/16 HEX KEY Bezel and Connector Screws

1/16 HEX KEY Cover Screws and Connector

Bezel

5/64 HEX KEY Tilt Arm Screws 5/64 HEX KEY Tilt Arm Screws

3/32 HEX KEY Camera Mount ADJ. Screws 3/32 HEX KEY Camera Mount ADJ. Screws

3/32 HEX KEY Camera Mount ADJ. Screws

Configuration Settings

Both PosiTrack units contain switches for setting the control mode, lens control voltage, RS-232

baud rate, and AXlink address. Before installing the PosiTrack unit, you must set the DIP switches,

lens control mode switches, and lens control voltage switch.

AXB-PT10/15/30 PosiTrack Camera Controllers

7

Page 12

Pre-Installation

AXlink

S6 VOLT

6 12

S1 ZOOM

S M

S3 FOCUS

S M

S4 IRIS

S M

FIG. 3 Lens control section (back panel)

LED

RS-232

AXlink

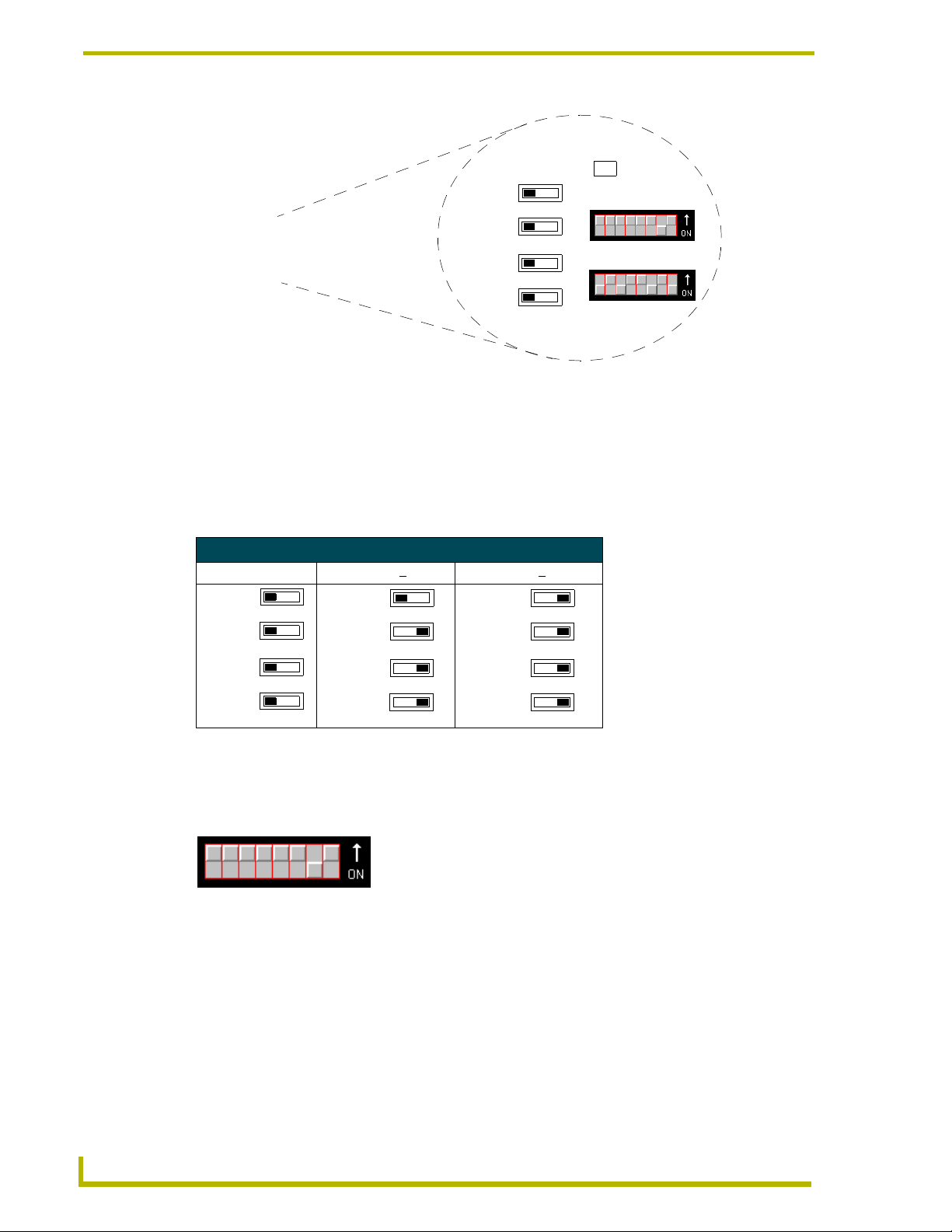

Setting zoom, focus, and iris switches to servomotor or motor mode

Both PosiTrack units support servomotor (+2.5 to +7.5 VDC operating range) and direct-drive

motor (± 6 VDC or ± 12 VDC operating range) lens control. The table below shows how to set the

switches for servomotor mode (S) or motor mode (M). If you are using a direct-drive lens, refer to

the manufacturer's literature to set the VOLT switch for ± 6 or ± 12 VDC control.

Servomotor and Motor Voltage Switch Settings

Servomotor mode Motor mode (+ 6 VDC) Motor mode (+ 12 VDC)

VOLT

6 12

ZOOM

S M

FOCUS

S M

IRIS

S M

VOLT

ZOOM

FOCUS

IRIS

6 12

S M

S M

S M

VOLT

6 12

ZOOM

S M

FOCUS

S M

IRIS

S M

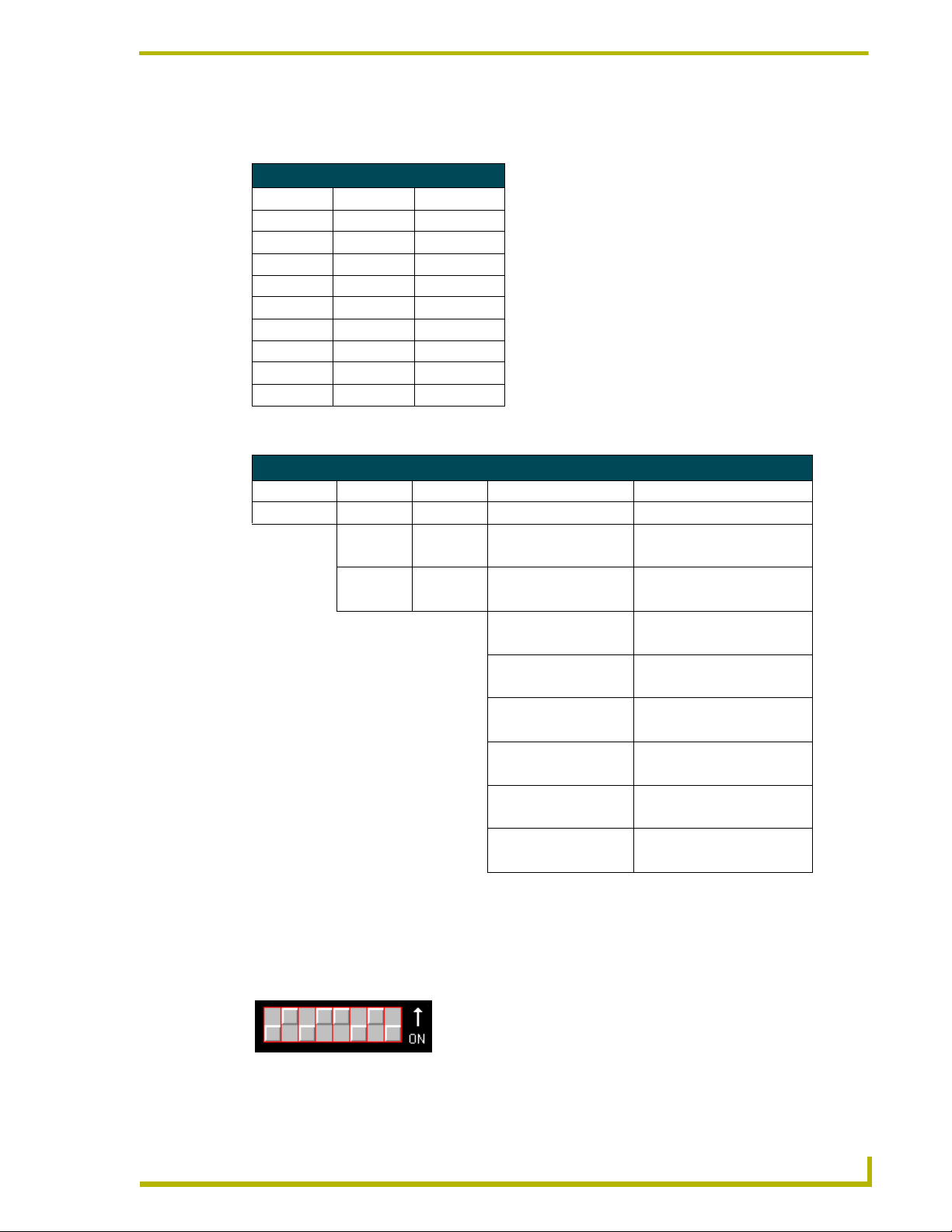

Setting the RS-232 DIP switch (S2)

The RS-232 DIP switch (S2) positions 1 and 2 set the stop and data bits, positions 3 through 5 set

the parity, and positions 6 through 8 set the baud rate. FIG. 4 shows the RS-232 DIP switch.

RS-232

DIP switch

(S2)

1 2 3 4 5 6 7 8

FIG. 4 RS-232 communications parameters DIP switch (S2) (default setting)

The PosiTrack units contain one EIA RS-232C standard port for equipment that requires RS-232

control. The following communication protocols are supported:

300, 600, 1200, 2400, 4800, 9600, 19200, and 38400 baud

7, 8, or 9 Data bits

1 or 2 Stop bits

Even, Odd, and None parity settings

8

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 13

Pre-Installation

The RS-232 factory default communications settings are: 9600 baud, No Parity, 8 bits, and 1 stop

bit. The following table lists the RS-232 Port DB-9 (male) pinouts.

RS-232 Port DB-9 (male) Pinouts

Pin Signal Function

1N/AN/A

2RXDRXD

3TXDTXD

4N/AN/A

5GNDGND

6N/AN/A

7RTSRTS

8CTSCTS

9N/AN/A

The following table lists the RS-232 DIP switch settings.

RS-232 DIP Switch (S2) Settings

Position 1 2 3 4 5 6 7 8

Function Stop Bits Data Bits Parity Baud Rates

Off Off Off Off Off Off Off Off

2 bits 7 bits Unused 300

On On On Off Off On Off Off

1 bit 8 bits Unused 600

Off On Off Off On Off

Unused 1,200

On On Off On On Off

Unused 2,400

Off Off On Off Off On

Unused 4,800

On Off On On Off On

Even 9,600

Off On On Off On On

Odd 19,200

On On On On On On

None 38,400

Setting the AXlink Device DIP switch (S5)

The eight-position Device DIP switch (S5), shown in FIG. 5, must match the number assigned in

the Axcess software program. The Device DIP switch example is set to 90 (2 + 8 + 16 + 64 = 90),

the factory default setting.

1 2 3 4 5 6 7 8

FIG. 5 AXlink device DIP switch (S5) (default value of 90)

AXB-PT10/15/30 PosiTrack Camera Controllers

AXlink

DIP switch

(S5)

9

Page 14

Pre-Installation

The AXlink device number range is 1-255. The Device DIP switch positions determines their

values, based on the following table:

Device DIP Switch (S5) Settings and Values

Position 12 34567 8

Value 1 2 4 8 16 32 64 128

After setting the AXlink device number, remove and reconnect the AXlink connector on the

PosiTrack unit to save the new number.

Accessing the AXB-PT10 and AXB-PT15 Internal Jumpers

Jumpers J6 through J8, located on the circuit board inside the PT10 and PT15, set the

communication mode to AXlink (factory default) or RS-232.

You need a 5/64" (1.98 mm) and 1/16" (1.59 mm) Allen wrench to open the unit, and a pair of non-

conducting pliers to set the jumpers using the following steps.

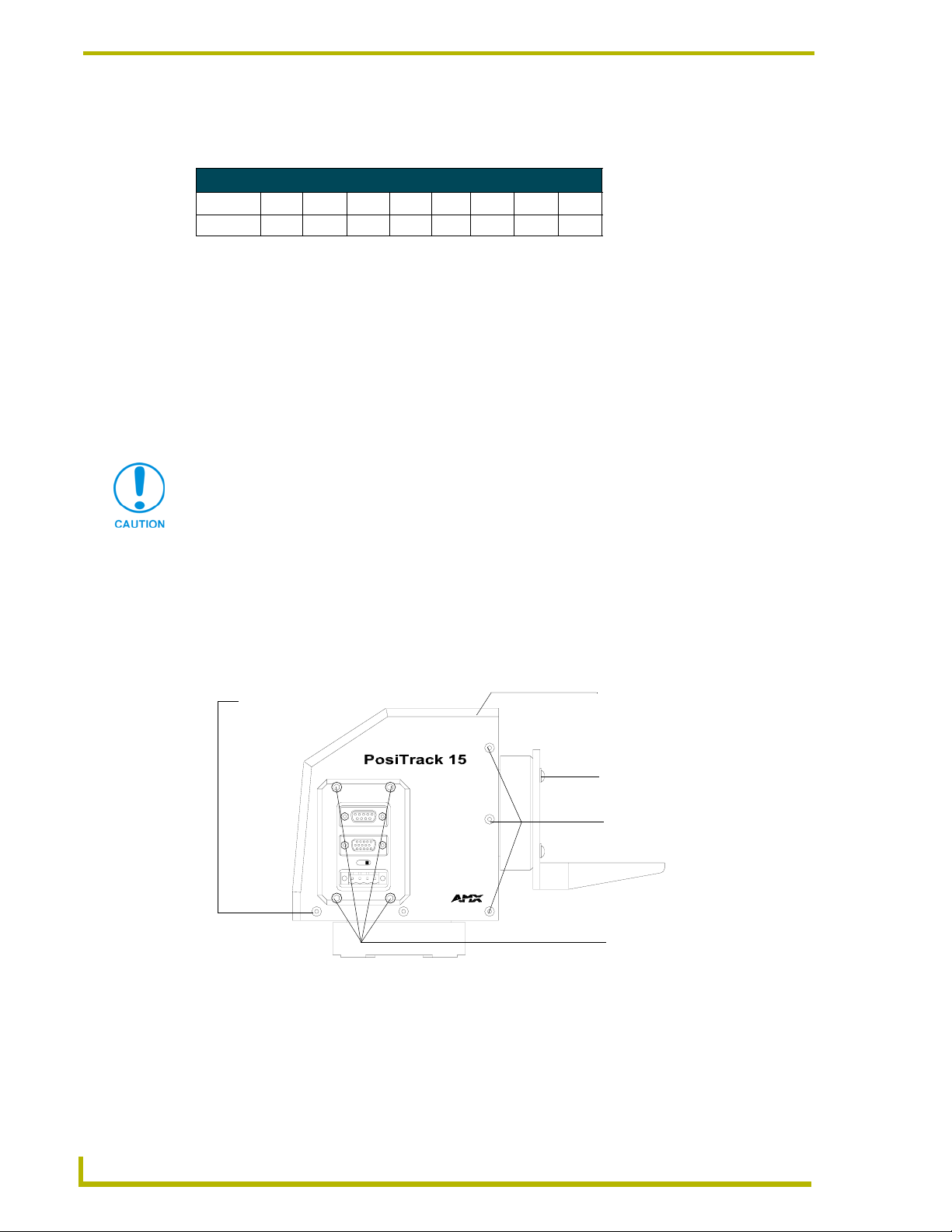

Remove the control panel before you remove the cover, in order to avoid any damage

to the unit.

1. Discharge any accumulated static electricity from your body before removing the enclosure.

Remove the static electricity by touching a grounded metal object.

2. Unplug all connectors from the rear panel of the PosiTrack unit.

3. Remove the four screws, located around the connector panel (FIG. 6), by using the 1/16" Allen

wrench. BHSC is the abbreviation for the Button Head Socket Cap screws.

BHSC screws

(two screws

in rear)

LENS POWER

AMX

FIG. 6 Pan-head screw locations

RS-232

LENS

CAM

AXlink

BHSC screws

(two screws on top)

Tilt-head screws (four

screws available)

BHSC screws

(five screws on each side)

Connector panel

(four screws)

10

4. Carefully pull the connector panel away from the main unit until the bottom edge of the cover

clears the connector panel. Be careful not to damage the pins attached to the connector panel.

FIG. 7 illustrates how to remove the control panel.

5. Using the 1/16" Allen wrench, remove the 14 BHSC screws, from the left, right, top, and back

sides of the PosiTrack unit.

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 15

Pre-Installation

Pins that connect

the control panel

to the motherboard

FIG. 7 Control panel removal for PT10 and PT15

6. Carefully pull the cover straight up from the main unit, until the bottom edge of the cover

clears the connector panel and then slide it backwards (as seen in FIG. 8).

FIG. 8 Removing cover on the PT10 and PT15

Accessing the AXB-PT30 Internal Jumpers

Jumpers J6 - J8, located on the circuit board inside the AXB-PT30, set the communication mode to

AXlink (factory default) or RS-232.

You need a 5/64" (1.98 mm) and 1/16" (1.59 mm) Allen wrench to open the unit, and a pair of non-

conducting pliers to set the jumpers using the following steps.

1. Discharge any accumulated static electricity from your body before removing the enclosure.

Remove the static electricity by touching a grounded metal object.

2. Unplug all connectors from the rear panel of the AXB-PT30.

3. Using the 1/16" Allen wrench, remove the four #4-40 socket head screws located around the

connector panel (FIG. 9), by using.

4. Remove the 16 BHSC screws, using the 5/64" Allen wrench, from the left, right, top, and back

sides of the AXB-PT30. A sample view of the screw locations is shown in FIG. 9.

5. Carefully pull the cover straight up from the main unit, until the bottom edge of the cover

clears the connector panel, and place the cover aside (see FIG. 8).

AXB-PT10/15/30 PosiTrack Camera Controllers

11

Page 16

Pre-Installation

BHSC screws

(two screws on top)

Connector panel

(four screws)

BHSC screws

(six screws on

each side)

BHSC screws

(two on the rear)

PosiTrack 30

LENS POWER

AMX

CAM

RS-232

LENS

AXlink

FIG. 9 Pan-head screw locations

Setting the Internal Jumper Communication Mode

1. Locate jumpers J6, J7, and J8 communication mode jumpers on the Mother PCB (FIG. 10).

The connectors and the main board are mounted onto the pan base.

2. Set the jumpers for either AXlink or RS-232 communication.

Jumper

locations

(3 pair)

J8

J6

J6, J7, and J8

communication

mode settings

Lens control

section

FIG. 10 Communication mode jumpers J6, J7, and J8 (factory default set to AXlink)

3. Set the jumpers for either AXlink or RS-232 communication.

Jumper Settings (top view)

AXlink (pins 1 & 2) RS-232 (pins 2 & 3)

RS-232

AXlink

AXlink

RS-232

12

Jumper 8

Jumper 7

Jumper 6

Pin #s 1 2 3

MOTOR

Jumper 8

Jumper 7

Jumper 6

Pin #s 1 2 3

MOTOR

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 17

Pre-Installation

For RS232 stand-alone mode, the 8-position AXlink Device DIP switch must be set to

all off (down position).

4. Carefully place the cover back onto the main unit by sliding it over the internal gears and

motherboard.

5. Align the Control panel screw holes. Make sure the cables are not pinched in the back panel or

drive gears.

6. Insert the 14 BHSC screws and tighten securely using the 1/16" Allen wrench.

Steps 6 and 7 apply to the AXB-PT10/PT15 units where the removal of the Control

Panel differs from the PT30.

7. Carefully insert the connector panel, on the PT10/15, into the opening on the side of the unit

and connect it to the motherboard located inside the unit.

8. Firmly secure the control panel to the motherboard.

9. Using the 1/16" Allen wrench, insert the four BHSC screws, located around the connector

panel.

10. Use the wire tie-mount to secure connector cables.

Configuring An External Camera/Lens Power Supply

The camera/lens power switch, located between the AXlink and DB-15 connectors, regulates the

power to the camera/lens from the PosiTrack unit. The power switch, seen in FIG. 6 and FIG. 9,

Opens (turns Off) or Closes (turns On) the circuit feeding power to the camera/lens assembly. Refer

to the Wiring the Connectors section on page 20 for more information about the control panel.

Flip the Lens Power switch to the left if you are only providing power to the camera/lens

assembly through the PosiTrack unit.

Flip the Lens Power switch to the right if you are providing external power to the camera/

lens assembly. By turning the switch Off, the dedicated +12 VDC stops providing

additional power to the camera/lens; preventing damage to power supplies and noise in

the video cables.

AXB-PT10/15/30 PosiTrack Camera Controllers

13

Page 18

Pre-Installation

14

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 19

Installation

IMPORTANT! READ THIS DOCUMENT BEFORE MOUNTING CAMERA.

Proper balance of the camera mount (with camera/lens/cradle) will result in optimal

performance. Follow these balancing instructions prior to operation. Failure to

balance the camera mount can result in poor performance.

The PosiTrack units enable pan and tilt functionality for mounted camera/lens assemblies and

provides lens control functions for teleconferencing lenses. Digital encoders are installed on both

the pan and tilt drives, allowing positional feedback for presets, and to provide accurate speed

control. Software adjustable stop limits are used on the pan and tilt drives to limit the range of

motion.

Do not mount a PosiTrack unit in any location where the motion of the camera/lens is

obstructed by any object.

Installation

Mounting the PT10, PT15, and PT30

Mount the PosiTrack units to a flat horizontal surface, either upright or inverted.

1. Select a surface that can support the combined weight of the PT10/ PT15/PT30, the

camera/lens, and control cables. Some support surfaces include the WM-CAM,

PM-CAM, and TM-CAM mounts available for use with these units.

2. Locate the external white position markers located on the pan and tilt axis. The position

markers must align with the pan and tilt axis in order to be considered in the home position.

FIG. 11 shows the camera cradle attachment in the center position.

Tilt Hub

Central tilt-axis

Camera cradle

mounting holes

Camera points this way

Position markers, located on the

outer surfaces, mark the center for

the vertical range of camera motion

Pan hub (mounting plate)

FIG. 11 Center position for the camera cradle attachment

3. Mount the PosiTrack unit to a flat surface by drilling four holes, according to the mounting-

plate dimensions shown in FIG. 12. Secure the unit to the surface using four 1/4" x 20 machine

bolts and lock washers. Ensure that the external white position marker, on the pan drive

hub, is inside the desired camera rotation range.

AXB-PT10/15/30 PosiTrack Camera Controllers

15

Page 20

Installation

)

Position marker

(on the outer surface)

Ø 3.453"

87.7 mm

FIG. 12 Tilt Hub (Mounting plate) dimensions

Camera points this way when the pan drive is in

the center of its range of motion (Home position)

3.00 BHC"

76.20 mm

3.45"

(87.7mm)

Each PosiTrack unit can be mounted to camera mounts such as the TM-CAM, WM-CAM, and

PM-CAM as shown in FIG. 13.

Cradle support bracket

Camera mount assembly

PM-CAM (Pedestal mount

Wire

tie-mount

FIG. 13 Pedestal mount

The camera/lens cradle can be mounted on either side of the cradle support bracket.

PT10 and PT15 Camera/Lens Mounting and Balancing

The camera/lens assembly should be mounted so the tilt axis is capable of going through the optical

axis of the camera, assuming the optical centerline is between 1/2" (12.70 mm) and 5" (127.00 mm)

above the mounting plane of the camera lens. The mounting platform (camera cradle) allows the

camera/lens to be mounted with its center of gravity on the tilt axis. The maximum weight of the

camera/lens assemblies on the PT10 is 10 lbs. (4.54 kg) and on the PT15 is 15 lbs. (6.80 kg). The

camera cradle is mounted to the Tilt Hub (FIG. 14).

16

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 21

Installation

e

0.750"

19.05 mm

0.750"

19.05 mm

0.250"

6.35 mm

0.250"

6.35 mm

0.750"

19.05 mm

FIG. 14 Tilt Hub dimensions for the PT10/15 units

0.00"

0.00"

0.750"

19.05 mm

Position

markers

Camera points

in this direction

0.56"

39.62 mm

Do not lift the PosiTrack unit by the Camera/Lens cradle as this procedure could

damage internal components.

To mount and balance the camera/lens:

1. Separate the camera mount and the cradle support bracket by removing the two 1/2" screws on

the underside of the assembly (see FIG. 15) using a 3/32" Allen wrench.

2. Install the camera alignment peg to the mount at the position that best fits the camera/lens.

3. Secure the camera/lens to the mount (at the camera alignment peg) with the 1/2" screw and

1/10" thick washer supplied (see FIG. 15).

Mounting holes (three sets)

Camera mount

(underside view)

Camera alignment peg

FIG. 15 Camera bracket assembly

Cradle support brack

Camera/Lens cradle

assembly (side view)

4. Place the assembly on a balancing beam and while maintaining the cradle centered on the pipe,

slide the camera along the cradle’s groves until the camera and cradle remain balanced on the

beam (see FIG. 16). Verify balance with a spirit level.

5. Mount the camera as close to the Tilt Hub as possible to obtain a true center of gravity. The

center of gravity is the location on the long axis of the camera/lens assembly around which the

camera and mount balances.

AXB-PT10/15/30 PosiTrack Camera Controllers

17

Page 22

Installation

s

cradle

(bottom view)

FIG. 16 Balancing the camera/lens cradle assembly

balancing beam

6. Re-attach the camera mount (with camera/lens) to the cradle support bracket using the two 1/2"

screws.

7. Take the entire camera/mount and cradle assembly and align the lens with the Tilt Hub so that

the vertical-axis intersects the center of the camera’s iris, as shown in FIG. 17.

Marker points

Iris

Vertical tilt-axi

FIG. 17 Iris alignment with vertical tilt-axis

8. Mark the position of the cradle support bracket on the Tilt Hub (for later attachment).

9. Remove the camera/lens and mount piece from the support bracket by unscrewing the two 1/2"

screws on the underside of the camera mount.

10. Secure the support bracket to the Tilt Hub (at the same position marked for the iris alignment)

on the PosiTrack unit with some or all of the four 1/2" screws and washers.

11. Secure the camera/mount to the support bracket by using the two 1/2" screws.

12. Support the weight of the camera cables with a wire tie attached to the wire tie mount on the

lower corner of the face of the PosiTrack unit (FIG. 13).

The camera/lens cradle can be mounted on either side of the cradle support bracket.

18

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 23

Installation

IMPORTANT! READ THIS DOCUMENT BEFORE MOUNTING CAMERA.

Proper balance of the camera mount (with camera/lens/cradle) will result in optimal

performance. Follow these balancing instructions prior to operation. Failure to

balance the camera mount can result in poor performance.

PT30 Camera/Lens Mounting and Balancing

The camera/lens assembly should be mounted so the tilt axis is capable of going through the optical

axis of the camera, assuming the optical centerline is between 1/2" (12.70 mm) and 5" (127.00 mm)

above the mounting plane of the camera lens. The mounting platform (camera cradle) allows the

camera/lens to be mounted with its center of gravity on the tilt axis. The maximum camera/lens

weight supported is 30 lbs. (13.6 kg). The camera cradle is mounted to the Tilt Hub (FIG. 18).

0.984"

24.99 mm

0.984"

24.99 mm

0.328"

8.33 mm

0.00"

0.328"

8.33 mm

0.984"

24.99 mm

FIG. 18 Tilt Hub dimensions for the PT30

0.00"

0.984"

24.99 mm

Position

markers

Camera points

in this direction

Ø 3.500"

88.97 mm

Do not lift the PT30 by the Camera/lens cradle as this procedure could damage

internal components.

To mount and balance the assembly:

1. Remove the four 1/2" screws and washers securing the camera cradle to the pan/tilt head.

2. Obtain a camera and a balancing beam, such as a pipe. The pipe is used to balance the camera/

lens on the cradle assembly.

3. Mount the camera to the camera/lens cradle assembly (FIG. 19).

4. Attach the camera/lens to the cradle with a fastener recommended by the camera manufacturer.

Allow the camera to slide along the horizontal grooves without sliding off.

5. Place the assembly on the balancing beam and while maintaining the cradle centered on the

pipe, slide the camera along the cradle’s grooves until the camera and cradle remain balanced

on the beam (FIG. 20). Verify the balance with a spirit level.

6. Mount the camera as close to the Tilt Hub as possible to obtain a true center of gravity. The

center of gravity is the location on the long axis of the camera/lens assembly around which the

camera and mount balances.

AXB-PT10/15/30 PosiTrack Camera Controllers

19

Page 24

Installation

Camera/lens

cradle assembly

FIG. 19 Camera/lens cradle assembly mounting

Tilt-axis

mount slots

FIG. 20 Balancing the camera/lens cradle assembly

7. Secure both the camera mounting and tilt-axis screws.

8. Take the entire camera/lens assembly and slide it along the Tilt Hub until the vertical-axis of

the PT30 intersects the center of the camera’s iris. Refer to the PT10 and PT15 Camera/Lens

Mounting and Balancing section on page 16 for more information on alignment.

9. Mark the position of the white tilt-axis marker on the camera/lens cradle (use this position for

later attachment of the camera/lens assembly to the Tilt Hub).

10. Remove the camera/lens from the cradle.

11. Secure the camera/lens assembly to the Tilt Hub by using the lens centerline markings for the

camera as a reference (see previous step) with the eight 32x 3/4" screws and washers removed

in step 1.

12. Re-attach the camera to its previous position on the cradle.

Wiring the Connectors

Each PosiTrack Controller has an RS-232 DB-9 connector, lens control DB-15 high-density

connector, and an AXlink 4-pin connector. Always provide enough cable to accommodate the

desired range of motion for the PosiTrack units and their camera/lenses. The Lens Power switch on

the control panel, removes any power noise on the incoming video by turning power On/Off to

Pin 1 of the DB-15 lens control connector.

20

The LENS POWER switch can turn power Off to the DB-15 pin 1 when the camera/

lens is powered from a separate supply.

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 25

Installation

FIG. 21 shows the location of each connector on the AXB-PT10/15.

AXB-PT10 (side view)

Camera control RS-232

DB-9 (male) connector

Lens control DB-15

high density (female)

connector

Lens Power switch

Pin 1 power switch for

DB-15 connector

AXlink 4-pin (male)

connector

Wire tie-mount

FIG. 21 Control panel location on the AXB-PT10/15

Control panel

LENS POWER

AMX

CAM

The PosiTrack Controller receives all power from the +12 VDC and GND connections on the four-

pin AXlink connector.

When applying power to the AXB-PT10/15, adjust the soft-set pan/tilt limit stops to a

safe position to prevent camera or PosiTrack damage.

Wiring Guidelines

In most installations, the PosiTrack Controllers require local +12 VDC power to operate properly.

The maximum wiring distance between the power supply and the PosiTrack Controller is

determined by power consumption, supplied voltage, and the wire gauge used for the cable. The

following wiring table lists wire sizes and the maximum lengths allowable between the PosiTrack

units and the power supply. The maximum wiring lengths are based on a minimum of 13.5 VDC,

available at the power supply output.

The AXB-PT10 power rating is 2.6 A @ 12 VDC.

The AXB-PT15 power rating is 4 A @ 12 VDC.

The AXB-PT30 power rating is 6 A @ 12 VDC.

To reduce the possible effects of ground loop noise in the video, use a single-source power supply

mounted within distances specified in the following table.

Wiring Guidelines - PT10, PT15, PT30 (Based on a +12VDC Power Supply)

Wiring Guidelines - PT10 (2.6 A) Wiring Guidelines - PT15 (4 A) Wiring Guidelines - PT30 (6 A)

Wire size Max. wiring length Wire size Max. wiring length Wire size Max. wiring length

18 AWG 45.14 ft (13.76 m) 18 AWG 29.34 ft (8.94 m) 18 AWG 19.56 ft (5.96 m)

20 AWG 28.56 ft (8.71 m) 20 AWG 18.56 ft (5.66 m) 20 AWG 12.38 ft (3.77 m)

22 AWG 17.80 ft (5.43 m) 22 AWG 11.57 ft (3.53 m) 22 AWG 7.72 ft (2.35 m)

24 AWG 11.22 ft (3.42 m) 24 AWG 7.30 ft (2.22 m) 24 AWG 4.86 ft (1.48 m)

AXB-PT10/15/30 PosiTrack Camera Controllers

21

Page 26

Installation

Preparing captive wires

You will need a wire stripper and flat-blade screwdriver (approximately 1/8") to prepare and

connect the captive wires.

Never pre-tin wires for compression-type connections.

1. Strip 0.25 inch (6.35 mm) of insulation off all wires.

2. Insert each wire into the appropriate opening on the connector, according to the wiring

diagrams and connector types described in this section.

3. Turn the screws clockwise to secure the wire in the connector. Do not tighten the screws

excessively; doing so may strip the threads and damage the connector.

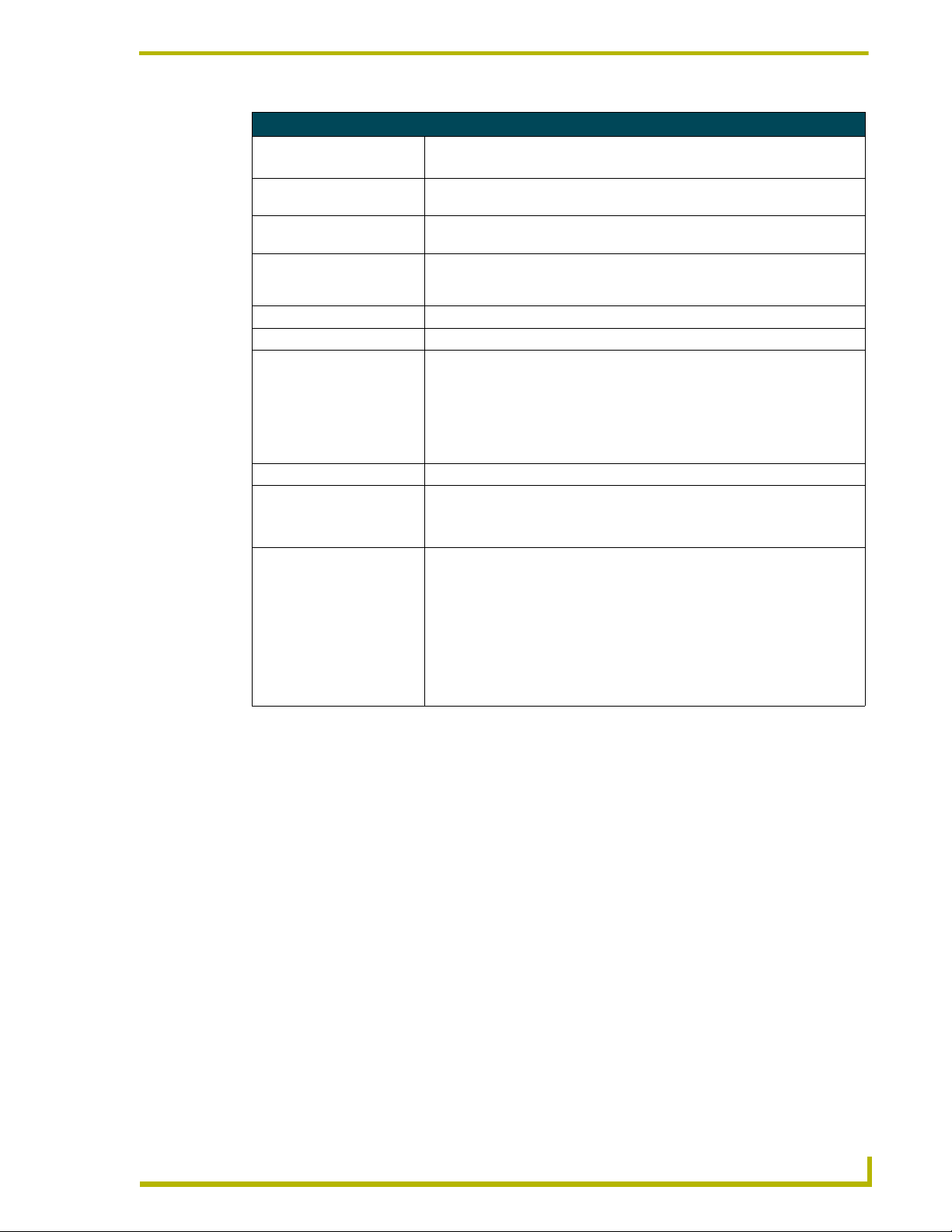

Using the AXlink connector for data and power

To use the AXlink 4-pin connector for data communication with the Central Controller and power

transfer from the local power supply (PSN), the incoming PWR and GND cable from the local

power supply must be connected to the AXlink cable connector going to the PosiTrack Controller.

FIG. 22 shows how the power cable from the local power supply is used to power the PosiTrack

Controller and the GND cable is connected onto the existing GND cable on the AXlink cable

coming from the Central Controller. Always use a local power supply to power the PosiTrack unit.

PWR (+)

GND (-)

PWR +

AXP/TX

AXM/RX

GND -

To the PosiTrack unit

FIG. 22 AXlink connector and local +12 VDC power supply wiring diagram

Do not connect the wire from the PWR terminal on the Central Controller to the PWR

terminal on the PosiTrack unit when you connect an external power supply. Make

sure to connect only the AXM, AXP, and GND wires on the PosiTrack unit’s Axlink

connector when using a local power supply.

Local +12 VDC power supply

(coming from the PSN power supply)

PWR +

AXP/TX

AXM/RX

GND -

To the Central Controller

1. Unscrew the PWR and GND wires on the terminal end of the PSN’s 2-pin cable.

2. Pair the GND wires from the PSN and the Central Controller AXlink connectors together and

insert them into the clamp position for GND on the PosiTrack unit’s AXlink connector.

3. Tighten the clamp to secure the two GND wires.

4. Place the PWR wire from the PSN into the open clamp position for PWR on the PosiTrack

unit’s AXlink connector.

22

5. Tighten the clamp to secure the PWR wire.

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 27

Installation

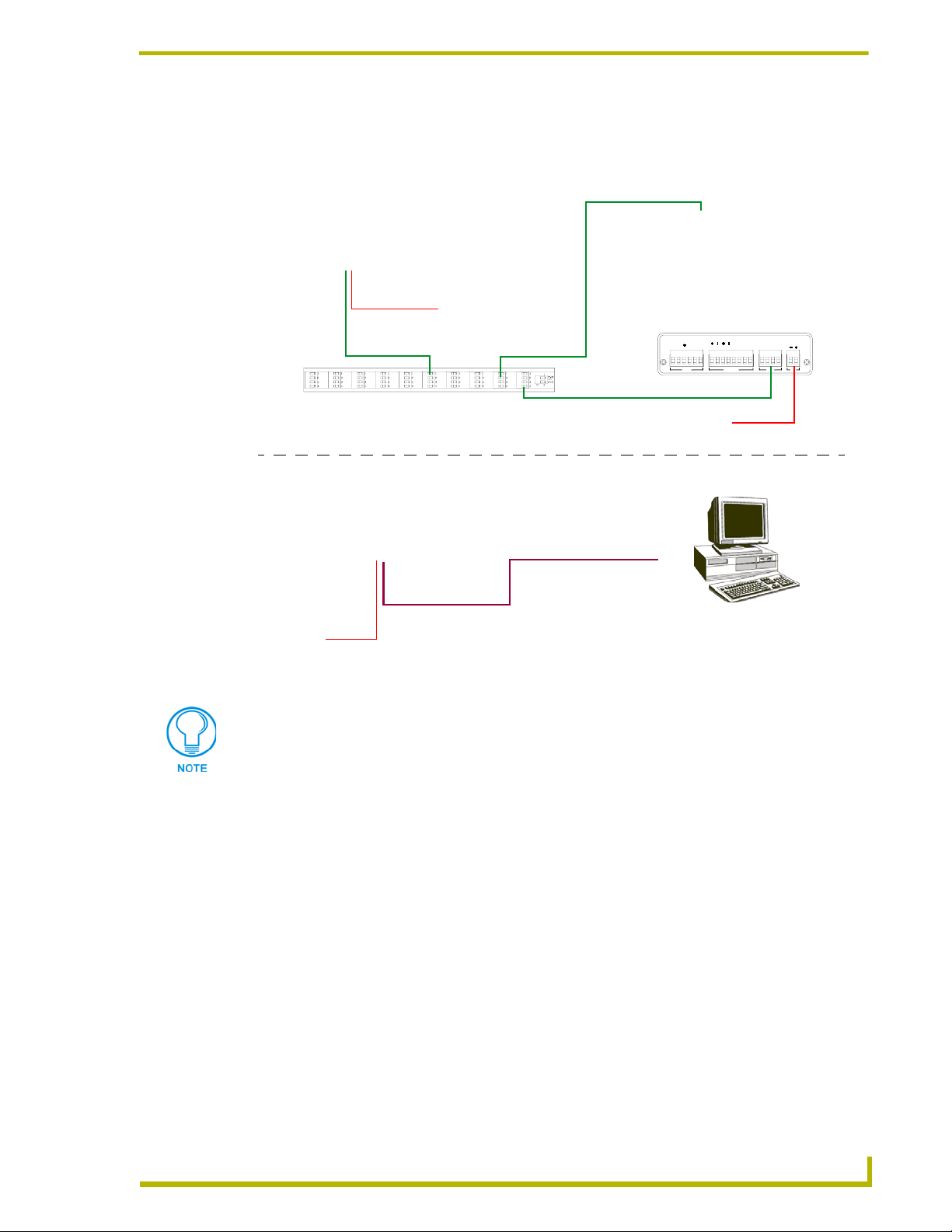

Using the AXlink connector with an external RS-232 control device or PC (StandAlone only)

To use the AXlink 4-pin connector with a PC or other RS-232 controller, wire the AXlink

connector to a DB-9 female connector, as shown in FIG. 23. Connector pins 2, 3, and 5 are used for

data and ground. For some applications requiring hardware handshaking, it may be necessary to

strap pins 7 (request to send) and 8 (clear to send) together.

PWR (+)

GND (-)

PWR +

AXP/TX

AXM/RX

GND -

PosiTrack unit

AXlink connector

FIG. 23 External RS-232 control device or PC wiring diagram

2 (RXD)

3 (TXD)

5 (GND)

External RS-232

DB-9 connector

(female)

For RS232 stand-alone mode, the 8-position AXlink Device DIP switch (S5) positions

1 thru 8 must all be set to Off (all down) and the internal communication jumpers must

be set to RS232 mode. For more information, refer to the Jumper Settings (top

view) table on page 12.

Using the RS-232 DB-9 connector

The RS-232 DB-9 (male) connector on the PosiTrack units connect to the camera head’s RS-232

connector. The following table shows the (DB-9) RS-232 connector wiring diagram.

(DB-9) RS-232 Connector Pinouts

Pin Signal Function

1 N/A Not used

2 RXD Receive data

3 TXD Transmit data

4 DTR Data terminal ready (not used)

5 GND Signal ground

6 DSR Data set ready (not used)

7 RTS Request to send (not used)

8 CTS Clear to send (not used)

9 N/A Not used

9

8

7

6

Female

5

4

3

2

1

Male

9

8

7

6

Preparing the PosiTrack Controllers for communication

The AXlink Device DIP switch is located beneath the round cover on the back of the PT10, PT15

and PT30. Set these switches to the desired device value based on the number of PosiTrack units

being used in a particular system. The initial unit is defaulted with a device number of #90. Any

additional units must have values that do not conflict with other PosiTrack units being used. Refer

to the Setting the AXlink Device DIP switch (S5) section on page 9 for more information.

AXB-PT10/15/30 PosiTrack Camera Controllers

23

Page 28

Installation

Pin 1Pin 5

Using the lens control DB-15 HD (high density) connector

The PosiTrack Controllers are designed to control servomotor and motor mode camera lenses. See

the Pre-Installation section on page 7 to set the lens switches for servomotor or motor mode.

FIG. 24 shows the DB-15 HD connector pin numbers.

Pin 10

Pin 15

FIG. 24 Lens control DB-15 HD connector (female) wiring pinouts

Lens control DB-15 HD

(female) connector

wiring pinouts

Pin 6

Pin 11

DO NOT connect the motor-mode outputs to servo-mode lenses. This can result in

lens damage.

The following table lists the pinouts for motor mode lenses. Pin1 provides lens power from the

PosiTrack’s own power supply when the lens power switch is set to AMX (left).

Lens Control DB-15 HD Connector Pinouts for Motor Mode

Pin

1 +12 VDC Output Motor Power

2 GND Output Lens common

3 Zoom-drive Output Zoom motor

4 Focus-drive Output Focus motor

5 Iris-drive Output Iris motor

12 POT-REF+ (+5 VDC) Output POT-high side

13 POT-REF - (GND) Output POT-low side

14 Zoom-wiper Input Zoom-POT wiper

15 Focus-wiper Input Focus-POT wiper

PosiTrack DB-15 HD

connector functions

Direction Lens function

24

Motor driven outputs are intended to drive conventional motors. These outputs can deliver up to

100 mA of current. The outputs use Pulse Width Modulation (PWM) for speed control. The output

voltage values are ± 6 VDC or ±12 VDC. Speed is controlled by varying the duty cycle of the

output.

Lens Control DB-15 HD Connector Pinouts for Servomotor Mode

Pin

PosiTrack DB-15 HD

connector functions

1 +12 VDC Output Motor Power (see following note)

2 GND Output Lens common

3 Zoom-drive Output Zoom motor

4 Focus-drive Output Focus motor

5 Iris-drive Output Iris motor

Direction Lens function

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 29

Lens Control DB-15 HD Connector Pinouts for Servomotor Mode (Cont.)

Pin

Pin 1 is not required if the lens is powered independently. This feature is controlled by

the AMX/CAM switch on the connector panel. Pins 12-15 are required for Speed

mode but are not required for Positional mode.

PosiTrack DB-15 HD

connector functions

6 Zoom-speed/position Output Zoom-positional/speed mode

7 Focus-speed/position Output Focus-positional/speed mode

8 Iris-local/auto Output Iris-local/auto select

9 Iris-speed/position Output Iris-positional/speed mode

10 VREF-A (+7.5V) Input VREF-A (+7.5 V). The reference voltage must be

11 VREF-B (+2.5 V) Input VREF-B (+2.5 V). The reference voltage must be

12 POT-REF+ (+5 VDC) Output POT-high side

13 POT-REF- (GND) Output POT-low side

14 Zoom-wiper (0-5 VDC) Input Zoom-POT wiper

15 Focus-wiper (0-5 VDC) Input Focus-POT wiper

Direction Lens function

present to operate correctly in servomotor mode.

present to operate correctly in servomotor mode.

Installation

Servomotor driven outputs are intended to drive servo-type motors only. The outputs have very low

current (milliampere range) capability. DO NOT attempt to drive conventional motors with these

outputs or you may damage the output drivers. If you are not sure about the motor type, refer to the

Specifications section on page 2 for more information.

Pan Characteristics

The pan drive has a maximum pan range of ± 179° (358° total). Pan travel is capable of being

limited to a restricted range around the center of pan travel by software limits adjustable by the

programmer/end user. Pan limits refer to the horizontal range of motion available to the PosiTrack

unit. These limits are set via the Axcess program. The center position marks the center of the range.

Setting the adjustable pan-limit stops

The Central Controller should be programmed by an AMX Axcess programmer before beginning.

Refer to the Specifications section on page 2 for more information on programming devices. To set

the adjustable pan-limit stops:

1. Ensure that there is enough slack in the lens, camera, and PosiTrack units’ AXlink cables to

accommodate the full range of pan motion.

2. Confirm that the necessary programming has been done to the system before beginning the

installation process.

3. Mount the camera controller to the desired horizontal surface.

4. Pan the unit as far to the left as desired and enter this position into the Axcess program as the

left pan-limit stop. The LEFT limit stop MUST be set left of the Home position.

5. Pan the unit as far to the right as desired and enter this position into the Axcess program as the

right pan-limit stop. The Right limit stop MUST be set right of the Home position.

6. Pan to both programmed stop positions and ensure the pan-limit stops are set correctly.

AXB-PT10/15/30 PosiTrack Camera Controllers

25

Page 30

Installation

Tilt Characteristics

The tilt drive is factory set to a maximum tilt range of ± 90° (for a total of 180°). Tilt limit stops

refer to the vertical range of motion available to the PosiTrack unit and are set via the Axcess

program. The center position marks the center of the range.

Setting the adjustable tilt-limit stops

The Central Controller should be programmed before beginning. Refer to the Specifications section

on page 2 for more information on programming devices. To set the adjustable tilt-limit stops:

1. Ensure that there is enough slack in the lens, camera, and PosiTrack controller AXlink cables

to accommodate the full range of tilt motion.

2. Mount the PosiTrack Controller to the desired surface.

3. Tilt the unit as far up as desired and enter this position into the Axcess program as the upper

tilt-limit stop. The UP limit stop MUST be set above the Home position.

4. Tilt the unit as far down as desired and enter this position into the Axcess program as the lower

tilt-limit stop. The DOWN limit stop MUST be set below the Home position.

5. Tilt to both stop positions and ensure the tilt-limit stops are set correctly.

If you have problems setting the range of motion on either PosiTrack units, you may be setting both

limits on the same side of the Home position. You may need to set a new Home position before

proceeding.

See the Configuration Commands table on page 28 for details on the SET HOME command.

26

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 31

Programming

The AXB-PT10, AXB-PT15, and AXB-PT30 control capabilities for camera functions include:

• Pan • Focus (servomotor; speed)

• Tilt • Focus (motor drive)

• Zoom (servomotor; positional) • Iris (servomotor; positional)

• Zoom (servomotor; speed) • Iris (servomotor; speed)

• Zoom (motor drive) • Iris (motor drive)

• Focus (servomotor; positional)

The PosiTrack Controllers are controlled with device-specific channel settings and Axcess

Send_Commands. You create the software programs with the Axcess programming software. Use

the programming information in this section, with the Axcess Programming Guide to create a

program to control the PosiTrack Camera Controllers. The program resides in the Axcess or

NetLinx Central Controller.

Programming

The commands for ZOOM, FOCUS, and IRIS output to servomotor or motor mode

MUST be configured to match the switch settings.

Configuration Commands

The following table lists in detail the different variables used in the Configuration Commands.

These variables consist of parameters which the commands must adhere to.

Variables for the Configuration Commands

Parameters Description

Outputs 1—PAN

2—TILT

3—ZOOM

4—FOCUS

5—IRIS

Level 0 (lowest) to 255 (highest) or 0% to 100%

On pan, tilt, and PWM drives for zoom, focus, and iris, level 128 will be OFF.

Level 129 and above are for the forward direction. Level 127 and below are

for the reverse direction.

Time (optional) If specified, 0 to 255 in tenths of a seconds; if not specified, at current rate.

Position 0 to 255; value of POT input. Corresponds to a position of the unit. 0 is one

end of the POT and 255 is the other end. Not directly related to an output

level voltage.

AXB-PT10/15/30 PosiTrack Camera Controllers

27

Page 32

Programming

Variables for the Configuration Commands (Cont.)

Parameters Description

Speed 0 to 127; where 0 is the slowest and 127 is the fastest (default).

Deviation 0 to 127; where 0 is most accurate but can have some jitter. Default is 2,

meaning the position can be within +

Distance 0 to 127; distance from the specified position.

Ramp Time 1 to 255; time in 10ms increments it takes the motor drives to ramp up to

speed.

2 from the specified position.

All presets are cleared when any limits are set.

Configuration commands configure the manner in which the PosiTrack operates.

Configuration Commands

ACCEL

CONTROL=ON

Enables acceleration

control for pan/tilt

(default).

ACCEL

CONTROL=OFF

Disables acceleration

control for pan/tilt.

BUTTON PRESS

Executes a series of

preset 10-degree

movements for both

directions of pan/tilt.

CHAN PRESET=ON

Enables preset recalls

by turning ON the

preset channels

101-228.

CHAN PRESET=OFF

Switches back

channels 101-228 to

feedback only mode.

(default).

CLEAR ERRORS

Clears all of the error

messages obtained by

using the

STATUS

the Terminal Emulator

mode.

DEVICE

command in

Syntax:

SEND_COMMAND CAM,"’ACCEL CONTROL=ON’"

Pan/Tilt movement speeds up and slows down based on PANACC, TILTACC,

and PRESET ACCEL values. This affects all pan/tilt movements and results in

smoother, dampened operation.

Syntax:

SEND_COMMAND CAM,"’ACCEL CONTROL=OFF’"

Pan/Tilt movement start and stop immediately. This results in more responsive

operation, although changes in speed may result in rough movements.

Syntax:

SEND_COMMAND CAM,"’BUTTON PRESS’"

The PosiTrack moves up, home (stops), left, then stops at home. This is

designed to test the functionality of the PosiTrack’s field of movement.

Syntax:

SEND_COMMAND CAM,"’CHAN PRESET=ON’"

The default mode of operation for these channels is feedback ONLY.

Syntax:

SEND_COMMAND CAM,"’CHAN PRESET=OFF’"

Syntax:

SEND_COMMAND CAM,"’CLEAR ERRORS’"

Refer to the Diagnostic error values section on page 41 for detailed information.

28

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 33

Configuration Commands (Cont.)

CLEAR HOME

Clears the current

home position and

goes to the default

setting and clears

presets.

CLEAR LIMIT ALL

Clears all of the limits.

CLEAR LIMIT DOWN

Clears the tilt-down

limit.

CLEAR LIMIT LEFT

Clears the pan-left limit.

CLEAR LIMIT RIGHT

Clears the pan-right

limit.

CLEAR LIMIT UP

Clears the tilt-up limit .

CURRENT SPEED

PRIORITY=CHANNEL

Changes the

operational mode of

channels 31, 32, 35,

and 36.

CURRENT SPEED

PRIORITY=LEVEL

Changes the operational mode of channels

31, 32, 35, and 36.

Syntax:

SEND_COMMAND CAM,"’CLEAR HOME’"

This command also clears all presets.

Syntax:

SEND_COMMAND CAM,"’CLEAR LIMIT ALL’"

Syntax:

SEND_COMMAND CAM,"’CLEAR LIMIT DOWN’"

Syntax:

SEND_COMMAND CAM,"’CLEAR LIMIT LEFT’"

Syntax:

SEND_COMMAND CAM,"’CLEAR LIMIT RIGHT’"

Syntax:

SEND_COMMAND CAM,"’CLEAR LIMIT UP’"

Syntax:

SEND_COMMAND CAM,"’CURRENT SPEED PRORITY=CHANNEL’"

Does NOT allow pan/tilt movement from levels until channels 31, 32, 35 and 36

are turned Off.

Setting this priority puts the unit in CaMatrix compatible mode. The CaMatrix is a

third-party RS232 control program that runs on a PC.

Syntax:

SEND_COMMAND CAM,"’CURRENT SPEED PRORITY=LEVEL’"

Allows pan/tilt movement from levels even if these channels are still On.

Setting this priority makes the move at current speed channels operate like the

other axis movement channels.

Programming

DEFAULT ACCEL

Sets the Pan and Tilt

acceleration to the

default value of 90

degrees/(second

squared).

FIND HOME

Runs a series of pan/tilt

movements to

recalibrate its

mechanical home.

FOCUS PRESET=POS

Sets the FOCUS

voltage output to recall

positional presets

(default).

Syntax:

SEND_COMMAND CAM,"’DEFAULT ACCEL’"

Syntax:

SEND_COMMAND CAM,"’FIND HOME’"

After the mechanical recalibration, the unit moves to the location set via the

"SET HOME" command (if applicable).

This is applicable only if the FOCUS SIGNAL=S command is in effect, and the

FOCUS switch is set to the S position (servomotor mode).

Syntax:

SEND_COMMAND CAM,"’FOCUS PRESET=POS’"

The command for FOCUS output to servomotor mode or motor mode MUST be

configured to match the switch settings.

AXB-PT10/15/30 PosiTrack Camera Controllers

29

Page 34

Programming

Configuration Commands (Cont.)

FOCUS

PRESET=SPEED

Sets the FOCUS

voltage output to recall

speed presets.

FOCUS SIGNAL=M

Sets the FOCUS output

to be a motor output.

FOCUS SIGNAL=S

Sets the Focus output

to be a servomotor

output.

FP

Sets the lens’ Focus

mode to positional

(default).

FS

Sets the lens’ Focus

mode to speed.

GET STATUS

(version 3.00 or

higher)

Displays the current

firmware version (Boot

and Download) on the

terminal along with

additional status

information.

This is applicable only if the FOCUS SIGNAL=S command is in effect, and the

FOCUS switch is set to the S position (servomotor mode).

Syntax:

SEND_COMMAND CAM,"’FOCUS PRESET=SPEED’"

The command for FOCUS output to servomotor mode or motor mode MUST be

configured to match the switch settings.

This setting corresponds to the M position (motor mode) setting on the FOCUS

switch.

Syntax:

SEND_COMMAND CAM,"’FOCUS SIGNAL=M’"

The command for FOCUS signal must be configured to match the switch settings.

This setting corresponds to the FOCUS switch in the S position.

Syntax:

SEND_COMMAND CAM,"’FOCUS SIGNAL=S’"

The command for FOCUS signal must be configured to match the switch settings.

Syntax:

SEND_COMMAND CAM,"’FP’"

This command can be used only for servomotor mode.

It causes a logic high (VREF-A) on Pin 7 of the lens control connector. This puts

a servomotor lens into positional focus mode.

Syntax:

SEND_COMMAND CAM,"’FS’"

This command can be used only for servomotor mode.

It causes a logic low (0 V) on Pin 7 of the lens control connector. This puts a servomotor lens into speed focus mode.

The returned boot version is determined by checking the version in flash memory.

Syntax:

SEND_COMMAND CAM,"’GET STATUS’"

This command is issued from Terminal Emulator mode. When using a NetLinx

master, the ’MSG ON’ command must first be issued to see the status. Besides

the boot and download versions, it also displays the following information:

• Presets - predifined camera positions

• Channel preset - On or Off.

• Current speed - pan, tilt, zoom, focus, and iris speeds

• Current acceleration - a value between 0-255 on an acceleration curve applied

to the movement of the unit from one position to another.

• Acceleration control - On or Off.

• Mode - settings for the camera (servomotor or motor modes)

• Deviation - numeric value corresponding to how far-off from the center point of

your preset you want the camera to be when it finally stops on that preset.

• Speed Priority - level or channel

30

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 35

Configuration Commands (Cont.)

GET VERSION

(version 3.00 or

higher)

Displays the current

firmware version (Boot

and Download) on the

terminal.

HOME

Goes to the location set

previously via the SET

HOME command.

IA

Sets the lens’ Iris mode

to auto (default).

IL

Sets the lens’ Iris mode

to local.

IP

Sets the lens’ Iris mode

to positional (default).

IRIS PRESET=POS

Sets the Iris voltage

output to recall

positional presets

(default).

IRIS PRESET=SPEED

Sets the Iris voltage

output to recall speed

presets.

IRIS SIGNAL=M

Sets the Iris output to

be a motor output.

The Boot version sent back is determined by checking the version in flash

memory.

Syntax:

SEND_COMMAND CAM,"’GET VERSION’"

This command is issued from Terminal Emulator mode. When using a NetLinx

master, the ’MSG ON’ command must first be issued to see the status.

If there is no user-defined HOME position, then the PosiTrack goes to the

mechanical home position.

Syntax:

SEND_COMMAND CAM,"’HOME’"

This differs from the FIND HOME command in that HOME does not involve a

re-calibration of the PosiTrack’s mechanical position.

Syntax:

SEND_COMMAND CAM,"’IA’"

This command causes pin 8 of the lens connector to float open. A Servomotor

lens will internally pull this signal high. In this mode, the iris signal from the PosiTrack (pin 5) will be ignored. Instead, the camera has full control of the lens iris,

typically used for Auto Iris mode (if the camera supports it).

Syntax:

SEND_COMMAND CAM,"’IL’"

This command applies Ground (0 V) to pin 8 of the lens connector. It allows iris

control from the PosiTrack.

Syntax:

SEND_COMMAND CAM,"’IP’"

This command can be used only for servomotor mode.

This command causes a logic high (VREF-A) on pin 9 of the lens control connector. This puts the servomotor lens into Positional Iris mode.

This is only applicable if the IRIS SIGNAL=S command is in effect, and the IRIS

switch is set to the S position (servomotor mode).

Syntax:

SEND_COMMAND CAM,"’IRIS PRESET=POS’"

The command for IRIS output to servomotor mode or motor mode MUST be

configured to match the switch settings.

This is applicable only if the IRIS SIGNAL=S command is in effect, and the IRIS

switch is set to the S position (servomotor mode).

Syntax:

SEND_COMMAND CAM,"’IRIS PRESET=SPEED’"

The command for IRIS output to servomotor mode or motor mode MUST be

configured to match the switch settings.

This setting corresponds to the M position (motor mode) setting on the IRIS

switch.

Syntax:

SEND_COMMAND CAM,"’IRIS SIGNAL=M’"

The command for IRIS output to servomotor mode or motor mode MUST be

configured to match the switch settings.

Programming

AXB-PT10/15/30 PosiTrack Camera Controllers

31

Page 36

Programming

Configuration Commands (Cont.)

IRIS SIGNAL=S

Sets the Iris output to

be a servomotor output.

IS

Sets the lens’ Iris mode

to speed.

LENS=SERVO

Sets the lens settings to

servomotor mode style.

LENS=STANDARD

Sets the lens settings to

standard motor mode

style.

PANACC

Sets the acceleration

rate of the pan axis, for

manual movements.

POWER UP

HOME=ON

Enables the unit to reestablish the mechanical HOME position

position at each

power-up (default).

POWER UP

HOME=OFF

Prevents the

mechanical HOME

process at power-up.

PRESET ACCEL

Sets the acceleration

rate of the pan and tilt

axes for preset recall

movements.

This setting corresponds to the S position (servomotor mode) setting on the IRIS

switch.

Syntax:

SEND_COMMAND CAM,"’IRIS SIGNAL=S’"

The command for IRIS output to servomotor mode or motor mode MUST be

configured to match the switch settings.

Syntax:

SEND_COMMAND CAM,"’IS’"

This command can be used only for servomotor mode.

This command causes a logic low (0 V) on pin 9 of the lens control connector.

This puts the servomotor lens into Speed Iris mode.

Syntax:

SEND_COMMAND CAM,"’LENS=SERVO’"

This macro command sends the ZP, FP, IP, ZOOM PRESET=POS, ZOOM

SIGNAL=S, FOCUS PRESET= POS, FOCUS SIGNAL=S, IRIS PRESET=POS,

IRIS SIGNAL=S commands at one time.

Syntax:

SEND_COMMAND CAM,"’LENS=STANDARD’"

This macro command sends the ZS, FS, IS, ZOOM PRESET=SPEED, ZOOM

SIGNAL=M, FOCUS PRESET= SPEED, FOCUS SIGNAL=M, IRIS

PRESET=SPEED, IRIS SIGNAL=M commands at one time.

Syntax:

"'PANACC <acceleration rate 0-127>’"

Examples:

SEND_COMMAND CAM,"’PANACC22’"

A value of zero sets acceleration to 2.25 degrees per second squared and 127

sets acceleration to 135 degrees per second squared. There is a linear

relationship for values between 0 and 127. The command DEFAULT ACCEL

sets both the pan and tilt acceleration to the default value of 90 degrees/(second

squared).

Syntax:

SEND_COMMAND CAM,"’POWER UP HOME=ON’"

The unit performs a mechanical "homing" calibration on power-up. This process

takes approximately 30 seconds to complete.

Syntax:

SEND_COMMAND CAM,"’POWER UP HOME=OFF’"

During the power-up process, the unit stays in the same position it was before it

lost power. It is immediately ready for use in this mode.

In order to force a recalibration and homing sequence, use the FIND HOME

command.

Syntax:

SEND_COMMAND CAM,"’PRESET ACCEL <acceleration rate

0-127>’"

Examples:

SEND_COMMAND CAM,"’PRESET ACCEL 22’"

A value of zero sets acceleration to 2.25 degrees per second squared and 127

sets acceleration to 135 degrees per second squared. There is a linear

relationship for values between 0 and 127.

32

AXB-PT10/15/30 PosiTrack Camera Controllers

Page 37

Programming

Configuration Commands (Cont.)

READ ALL Forces the device to read and update levels to the Central Controller.

Syntax:

SEND_COMMAND CAM,"’READ ALL’"

RUN TESTS Runs and checks error values 244 and 245 to see if the gears are properly

SET HOME

Sets a new home

position.

SET LIMIT DOWN

Sets the down tilt limit

value given.

SET LIMIT LEFT

Sets the left pan limit

value given.

SET LIMIT RIGHT

Sets the right pan limit

value given.

SET LIMIT UP

Sets the up tilt limit

value given.

TILTACC

Sets the acceleration

rate of the tilt axis, for

manual movements.

TILT CURVE=

NORMAL

Adjusts Tilt Up/Down

speed curves for

normal mounting

position.

TILT CURVE= INVERT

Adjusts Tilt Up/Down

speed curves for

inverted mounting

position.

aligned to their respective grooves.

Syntax:

SEND_COMMAND CAM,"’RUN TESTS’"

Refer to the Diagnostic error values section on page 41 for more detailed

information. Make sure there are no obstructions while the PosiTrack performs

the full range of the following movements: Up, Down, Home, Left, Home.

Syntax:

SEND_COMMAND CAM,"’SET HOME’"

Warning! This command clears all presets.

Syntax:

SEND_COMMAND CAM,"’SET LIMIT DOWN’"

Warning! This command clears all presets.

Syntax:

SEND_COMMAND CAM,"’SET LIMIT LEFT’"

Warning! This command clears all presets.

Syntax:

SEND_COMMAND CAM,"’SET LIMIT RIGHT’"

Warning! This command clears all presets.

Syntax:

SEND_COMMAND CAM,"’SET LIMIT UP’"

Warning! This command clears all presets.

Syntax:

"’TILTACC <acceleration rate 0-127>’"

Examples:

SEND_COMMAND CAM,"’TILTACC103’"

A value of zero sets acceleration to 2.25 degrees per second squared and 127

sets acceleration to 135 degrees per second squared. There is a linear

relationship for values between 0 and 127. The command DEFAULT ACCEL

sets both the pan and tilt acceleration to the default value of 90 degrees/(second

squared).

Syntax:

SEND_COMMAND CAM,"’TILT CURVE=NORMAL’"

This keeps the up and down tilts moving at the same rate for a given speed.

(Added v1.10) Sets the tilt curve to normal, for normal installation position.

This command DOES NOT reverse the direction of the pan/tilt motors.

Syntax:

SEND_COMMAND CAM,"’TILT CURVE=INVERT’"

This keeps the up and down tilts moving at the same rate for a given speed.

(Added v1.10)

Sets the tilt curve to inverted, for inverted installation position. This command

reverses the direction of the tilt motor.

AXB-PT10/15/30 PosiTrack Camera Controllers

33

Page 38

Programming

Configuration Commands (Cont.)

ZAP!

Initializes all memory in

the unit.

ZOOM PRESET=POS

Sets the Zoom voltage

output to recall

positional presets

(default).

ZOOM

PRESET=SPEED

Sets the Zoom voltage

output to recall speed

presets.

ZOOM SIGNAL=S

Sets the Zoom output

to be a servomotor

output.

ZOOM SIGNAL=M

Sets the Zoom output

to be a motor output.

ZP

Sets the lens’ Zoom

mode to positional

(default).

ZS

Sets the lens’ Zoom

mode to speed.

Syntax:

SEND_COMMAND CAM,"’ZAP!’"

This includes speed settings, deviation settings, configuration settings, and all

presets.

Warning! This command clears all user-defined settings.

Syntax:

SEND_COMMAND CAM,"’ZOOM PRESET=POS’"

This is applicable only if the ZOOM SIGNAL=S command is in effect, and the

ZOOM switch is set to the S position (servomotor mode). The command for

ZOOM output to servomotor mode or motor mode MUST be configured to match

the switch settings.

Syntax:

SEND_COMMAND CAM,"’ZOOM PRESET=SPEED’"

This is applicable only if the ZOOM SIGNAL=S command is in effect, and the

ZOOM switch is set to the S position (servomotor mode). The command for

ZOOM output to servomotor mode or motor mode MUST be configured to match

the switch settings.

Syntax:

SEND_COMMAND CAM,"’ZOOM SIGNAL=S’"

This setting corresponds to the S position (servomotor mode) setting on the

ZOOM switch. The command for ZOOM output to servomotor mode or motor

mode MUST be configured to match the switch settings.

Syntax:

SEND_COMMAND CAM,"’ZOOM SIGNAL=M’"

This setting corresponds to the M position (motor mode) setting on the ZOOM

switch. The command for ZOOM output to servomotor mode or motor mode

MUST be configured to match the switch settings.

Syntax:

SEND_COMMAND CAM,"’ZP’"

This command can be used only for servomotor mode.

This command causes a logic high (VREF-A) on pin 6 of the lens control connector. This puts the servomotor lens into Positional Zoom mode.

Syntax:

SEND_COMMAND CAM,"’ZS’"

This command can be used only for servomotor mode.