Page 1

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

D’INSTALLATION, D’OPÉRATION ET DE MAINTENANCE INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN, OPERACIÓN Y MANTENIMIENTO

1400 Division Road, West Warwick, RI 02893 T: 401.884.6300 F: 401.885.2567 www.amtrol.com

Champion® Family / 100 PSIG

Pre-pressurized Water System Well Tanks

Réservoirs de puits de système d’eau à pressurisation initiale

Tanques hidroneumáticos prepresurizados para sistemas de agua

Les modèles incluent: À support

WARNING: REVIEW ALL GENERAL SAFETY AND PRODUCT INFORMATION ON PAGE 2 PRIOR TO INSTALLATION.

AVERTISSEMENT: EXAMINER TOUTES LES INFORMATIONS GÉNÉRALES DE SÉCURITÉ ET DE PRODUIT DE

LA PAGE 5 AVANT L’INSTALLATION.

ADVERTENCIA: ANTES DE INSTALAR, REPASE TODA LA INFORMACIÓN GENERAL DE SEGURIDAD Y DEL

PRODUCTO QUE SE ENCUENTRA EN LA PÁGINA 8.

Your well tank by AMTROL has been carefully assembled and factory tested. To enjoy the full service your well tank can provide,

you should read and follow all of the instructions in this manual. When all installation steps have been completed, make sure you also

follow the enclosed post-installation and start-up checklists before using your AMTROL product. You should also read carefully the

sections describing proper product maintenance, and follow the required procedures as you use your well tank. Return this booklet

to its original envelope, and keep it with the well tank. This manual may become out-of-date by later amendments. Check our web

site, www.amtrol.com, or ask your AMTROL supplier for any updates relating to your product. This product comes with a limited

five (5) year warranty, see AMTROL Limited Warranty for details. Our goal is to ensure you are fully satisfied with your new well

tank. If any questions or concerns arise, call Technical Service at 401-535-1216.

Ce réservoir de puits AMTROL a été assemblé et testé à l’usine avec soin. Pour utiliser toute sa fonctionnalité, veuillez lire et suivre

toutes les instructions de ce manuel. Après avoir effectué toutes les étapes de l’installation, il faut s’assurer de suivre aussi les listes

ci-jointes de contrôle après installation et de démarrage avant d’utiliser ce produit AMTROL. Lire aussi avec soin les sections décrivant

la maintenance appropriée à ce produit et suivre les procédures requises pour l’utilisation du réservoir de puits. Remettre en place

ce livret dans sa pochette d’origine et le conserver avec le réservoir. Ce manuel peut être l’objet de révisions ultérieures. Consulter

notre site Internet à www.amtrol.com ou demander au fournisseur AMTROL les mises à jour concernant ce produit. Ce produit est

vendu avec une garantie limitée de cinq (5) ans. Voir la garantie limitée d’AMTROL pour de plus amples informations. Notre

but est d’assurer l’entière satisfaction pour ce nouveau réservoir de puits. Pour toute question ou problème, contacter le Service

technique au 401-535-1216.

Models Include: Stand

Los modelos incluyen: Base

Su tanque hidroneumático fabricado por AMTROL ha sido cuidadosamente ensamblado y probado en fábrica. Para que pueda

disfrutar por completo el servicio que su tanque hidroneumático le puede proveer, le recomendamos que lea y siga todas las

instrucciones que hay en este manual. Cuando complete todos los pasos de instalación, cerciórese de haber seguido también las

listas de verificación pos instalación y de puesta en marcha, antes de usar su producto AMTROL. Asimismo, le recomendamos que lea

cuidadosamente las secciones que describen el mantenimiento apropiado del producto, y que al usar su tanque hidroneumático siga

los procedimientos requeridos. Vuelva a colocar este folleto en su sobre original y téngalo junto a su tanque. Este manual puede

quedar desactualizado por enmiendas posteriores, por lo que le recomendamos que verifique en nuestro sitio de Web, www.amtrol.

com, o que le pregunte a su proveedor de productos AMTROL, si hay alguna actualización para su producto. Este producto tiene

una garantía limitada de cinco (5) años; para mayor información remitirse a la Garantía Limitada de AMTROL. Nuestra meta

es asegurar su completa satisfacción con su nuevo tanque hidroneumático. Si tiene alguna pregunta o inquietud, llame al Servicio

Técnico al 401-535-1216

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL PERSONAL INJURY AND

OTHER HAZARDS. OBEY ALL SAFETY MESSAGES THAT FOLLOW THIS SYMBOL TO REDUCE THE RISK OF

POSSIBLE INJURY AS WELL AS PROPERTY DAMAGE.

VOICI LE SYMBOLE D’ALERTE DE SÉCURITÉ. IL EST UTILISÉ POUR SIGNALER LES RISQUES D’ACCIDENT OU AUTRES

DANGERS. IL FAUT RESPECTER TOUS LES MESSAGES DE SÉCURITÉ QUI SUIVENT CE SYMBOLE AFIN DE RÉDUIRE LES

RISQUES POTENTIELS DE BLESSURE OU DE DOMMAGE MATÉRIEL.

ESTE ES EL SÍMBOLO DE ALERTA DE SEGURIDAD. SE USA PARA ALERTARLE DE POSIBLES LESIONES Y OTROS

PELIGROS. PARA REDUCIR EL RIESGO LESIONES, ASÍ COMO DE DAÑOS MATERIALES, OBEDEZCA TODOS LOS

MENSAJES DE SEGURIDAD QUE ACOMPAÑAN A ESTE SÍMBOLO.

Part #(Pièce N°,Parte #): 9015-610 (02/11)

Page 2

1. GENERAL SAFETY INFORMATION

THIS TANK, LIKE MOST TANKS UNDER PRESSURE, WILL OVER TIME CORRODE OR FAIL AND/OR MAY BURST AND/OR LEAK OR

TO MINIMIZE RISK, A LICENSED PROFESSIONAL MUST INSTALL AND PERIODICALLY INSPECT AND SERVICE THE UNIT. A DRIP PAN, CONNECTED TO AN

ADEQUATE DRAIN MUST BE INSTALLED IF LEAKING OR FLOODING CAN CAUSE PROPERTY DAMAGE.

OR PROPERTY DAMAGE, AND WILL VOID THE PRODUCT WARRANTY. THIS PRODUCT MUST BE INSTALLED BY A QUALIFIED

PROFESSIONAL. FOLLOW ALL APPLICABLE LOCAL AND STATE CODES AND REGULATIONS, IN THE ABSENCE OF SUCH CODES,

FOLLOW THE CURRENT EDITIONS OF THE NATIONAL PLUMBING CODE AND NATIONAL ELECTRIC CODE, AS APPLICABLE.

YOU MAY WISH TO TAKE TO SAFELY DISINFECT YOUR HOME’S PLUMBING SYSTEM.

EXPLOSION, SERIOUS OR FATAL PERSONAL INJURY AND PROPERTY DAMAGE.

SYSTEM PRESSURE.

FLOOD (AND IN RARE CASES EXPLODE) WHICH CAN CAUSE SERIOUS OR FATAL PERSONAL INJURY AND PROPERTY DAMAGE.

READ CAREFULLY THE PRODUCT INSTALLATION, OPERATING AND MAINTENANCE MANUAL. FAILURE TO

FOLLOW THE INSTRUCTIONS AND WARNINGS IN THE MANUAL MAY RESULT IN SERIOUS OR FATAL INJURY AND/

AS IN ALL PLUMBING PRODUCTS AND WATER STORAGE VESSELS, BACTERIA CAN GROW IN YOUR WELL TANK,

ESPECIALLY DURING TIMES OF NON-USE. CONSULT YOUR LOCAL PLUMBING OFFICIAL REGARDING ANY STEPS

FOLLOW ALL OF THE INSTRUCTIONS AND RECOMMENDATIONS CONTAINED IN THIS MANUAL, AND THE

FOLLOWING ADDITIONAL SPECIFIC WARNINGS. FAILURE TO DO SO IS UNSAFE AND CAN CAUSE SERIOUS

EXPLOSION OR RUPTURE HAZARD. THE WELL TANK MUST BE OPERATED SO THAT THE MAXIMUM SYSTEM

PRESSURE DOES NOT EXCEED 150 PSI OR LOCAL CODE REQUIREMENTS WHICHEVER IS LESS.

A RELIEF VALVE WITH A MAXIMUM RELIEF PRESSURE OF 125 PSI MUST BE INSTALLED IN THE SYSTEM. THE

RELIEF VALVE MUST BE CAPABLE OF DISCHARGING THE RATED CAPACITY OF THE PUMP AT THE MAXIMUM

FAILURE TO UTILIZE A PROPERLY SIZED WELL TANK (BASED ON THE FOLLOWING SIZING INSTRUCTIONS) WILL

FLOODING AND PROPERTY DAMAGE.

POSSIBLY CAUSING SERIOUS OR FATAL PERSONAL INJURY AND/OR PROPERTY DAMAGE.

FAILURE TO FOLLOW INSTRUCTIONS BELOW CAN CAUSE A RUPTURE OR EXPLOSION, POSSIBLY CAUSING SERIOUS OR FATAL

PERSONAL INJURY, AND/OR PROPERTY DAMAGE. DO NOT ADJUST OR ADD PRESSURE IF THERE HAS BEEN A LOSS OF AIR. DO NOT

ADJUST THE PRE-CHARGE PRESSURE IF THERE IS VISIBLE EXTERIOR CORROSION. DO NOT ADJUST THE PRE-CHARGE PRESSURE

IF THERE HAS BEEN A REDUCTION OF THE PUMP CYCLE TIME OR THE PRE-CHARGE PRESSURE COMPARED TO ITS INITIAL SETTING.

THIS IS BECAUSE REDUCTION IN PUMP CYCLE TIME CAN RESULT FROM LOSS OF TANK AIR PRESSURE WHICH IN TURN CAN MEAN

THERE MAY BE INTERNAL CORROSION AND ANY RE-PRESSURIZATION OR ADDITIONAL PRESSURE COULD RESULT IN RUPTURE OR

EXPLOSION.

CONTAMINANTS, INCLUDING CHLORINE AND TREAT YOUR WATER APPROPRIATELY TO INSURE SATISFACTORY PERFORMANCE

AND PREVENT PREMATURE FAILURE. FOR YOUR SAFETY, THE INFORMATION IN THIS MANUAL MUST BE FOLLOWED TO MINIMIZE

THE RISK OF ELECTRIC SHOCK, PROPERTY DAMAGE OR PERSONAL INJURY. PROPERLY GROUND TO CONFORM WITH ALL

GOVERNING CODES AND ORDINANCES.

RESULT IN EXCESSIVE STRAIN ON THE PUMP AND MAY ULTIMATELY LEAD TO PRODUCT FAILURE, LEAKING OR

DANGER! EXPLOSION HAZARD. IF YOU ADJUST THE PRE-CHARGE PRESSURE OR ADD PRESSURE TO A TANK

THAT IS CORRODED OR DAMAGED OR WITH DIMINISHED INTEGRITY THE TANK CAN BURST OR EXPLODE,

• ONLY ADJUST THE PRE-CHARGE AS DESCRIBED IN THIS MANUAL WHEN THE TANK IS NEW OR WHEN THE

INTEGRITY OF THE TANK AND LACK OF INTERNAL OR EXTERNAL CORROSION IS CONFIRMED.

• ONLY QUALIFIED PROFESSIONALS SHOULD CHECK, ADJUST OR RE-CHARGE THE PRE-CHARGE OF TANKS.

DANGER! EXPLOSION HAZARD. WHEN THE WELL TANK HAS BEEN IN SERVICE AND A CHANGE TO A HIGHER

PRE-CHARGE PRESSURE IS NECESSARY DUE TO A REQUIRED CHANGE IN THE PRESSURE SWITCH SETTING,

CHLORINE & AGGRESSIvE WATER: THE WATER QUALITY CAN SIGNIFICANTLY INFLUENCE THE LIFE OF THIS

PRODUCT. YOU SHOULD TEST FOR CORROSIVE ELEMENTS, ACIDITY, TOTAL SOLIDS AND OTHER RELEVANT

INSTALL OR STORE WHERE TANK WILL NOT BE EXPOSED TO TEMPERATURES BELOW FREEZING OR ABOVE

100ºF. WATER FREEZING IN THE SYSTEM WILL BREAK IT. DO NOT ATTEMPT TO TREAT WATER OVER 100°F.

USE ONLY LEAD-FREE SOLDER AND FLUX FOR ALL SWEAT-SOLDER CONNECTIONS, AS REQUIRED BY STATE

AND FEDERAL CODES.

NOTE: INSPECT FOR SHIPPING DAMAGE AND NOTIFY FREIGHT CARRIER OR STORE WHERE PURCHASED IMMEDIATELY IF DAMAGE

IS PRESENT. TO AVOID RISK OF PERSONAL INJURY AND PROPERTY DAMAGE, IF THE PRODUCT APPEARS TO BE MALFUNCTIONING

OR SHOWS SIGNS OF CORROSION, CALL A QUALIFIED PROFESSIONAL IMMEDIATELY. CURRENT COPIES OF THE PRODUCT MANUAL

CAN BE VIEWED AT WWW.AMTROL.COM. USE PROPER SAFETY EQUIPMENT WHEN INSTALLING.

FAILURE TO FOLLOW THE ABOVE WARNINGS MAY RESULT IN SERIOUS OR FATAL PERSONAL INJURY OR DEATH AND/

OR PERSONAL PROPERTY DAMAGE, AND WILL VOID THE WARRANTY.

-2-

Page 3

2. LIMITED WARRANTY

Products covered: all Products manufactured by AMTROL Inc. (“AMTROL”) .

This warranty cannot be transferred – it is extended only to the original Purchaser or First User of the Product. By accepting and keeping this Product

you agree to all of the warranty terms and limitations of liability described below.

IMPORTANT WARNING – READ CAREFULLY THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL (“MANUAL”) to

avoid serious personal injury and/or property damage and to ensure safe use and proper care of this product

Who Receives AMTROL’s Product Warranty

All purchasers or first users of the new Product. The Warranty is non-transferable.

What is covered by this Warranty

AMTROL warrants to the purchaser or first user of the new Product that at the time of manufacture, the Product is free from defects in material and

workmanship. Any warranty claim must be made within one (1) year unless another time period is set forth in the Manual, measured from

the time the Product was purchased.

What AMTROL Will Do If You Have a Covered Warranty Claim

In the event of a breach of the foregoing warranty, AMTROL will at its option either make repairs to correct any defect in material or workmanship or

supply and ship either new or used replacement parts or products. AMTROL will not accept any claims for labor or other costs.

What This Warranty Does Not Cover - Exclusions and Limitations

This Warranty does not cover any failure or problem unless it was caused by a defect in material or workmanship. In addition, this Warranty shall not

apply:

• if the Product is not correctly installed, operated, repaired or maintained as described in the Manual provided with the Product;

• to any failure or malfunction resulting from abuse (including freezing); improper or negligent: handling, shipping (by anyone other than AMTROL),

storage, use, operation, accident; or alteration, lightning, flood or any other environmental condition;

• to any failure or problem resulting from the use of the Product for any purpose other than those specified in the accompanying Manual or alteration

of any part of the product;

• this Warranty does not cover labor costs, shipping charges, service charges, delivery expenses, administrative fees or any costs incurred in

removing or reinstalling the Product;

• this Warranty does not cover any claims submitted to AMTROL or an AMTROL-authorized distributor or retailer more than 30 days after expiration

of the applicable warranty time period described in this Warranty;

• this Warranty also does not cover repair or replacement costs not authorized in advance by AMTROL.

Additional Warranty Limitations

ALL IMPLIED WARRANTIES, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE SPECIFICALLY DISCLAIMED.

Limitations of Remedies

THE REMEDIES CONTAINED IN THIS WARRANTY ARE THE PURCHASER’S OR FIRST USER’S EXCLUSIVE REMEDIES. IN NO

CIRCUMSTANCES WILL AMTROL BE LIABLE FOR MORE THAN, AND PURCHASER-FIRST USER’S REMEDIES SHALL NOT EXCEED, THE

PRICE PAID FOR THE PRODUCT. IN NO CASE SHALL AMTROL BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, WHETHER RESULTING FROM NON-DELIVERY OR FROM THE USE, MISUSE, OR INABILITY TO USE THE PRODUCT OR FROM

DEFECTS IN THE PRODUCT OR FROM AMTROL’S OWN NEGLIGENCE OR OTHER TORT. This exclusion applies regardless of whether such

damages are sought for breach of warranty, breach of contract, negligence, strict liability, in tort or under any other legal theory. Such damages include,

but are not limited to, inconvenience, loss or damage to property, mold, loss of profits, loss of savings or revenue, loss of use of the Products or any

associated equipment, facilities, buildings or services, downtime, and the claims of third parties including customers.

What To Do If You Have a Problem Covered By This Warranty

Any covered Warranty service must be authorized by AMTROL. Contact the person from whom you purchased the Product, who must

receive authorization from an AMTROL distributor or AMTROL. If you do not receive a prompt response, call AMTROL directly at

877-517-9673. Notice of a Warranty claim should be submitted by the authorized distributor to AMTROL at the following address:

AMTROL Inc., Warranty Claim Dept.

1400 Division Road, West Warwick, RI 02893

Before AMTROL determines to provide any replacement part or Product, it may as a pre-condition to making such a determination require that the

warranty claimant ship the Product, postage prepaid to an authorized AMTROL distributor, or to AMTROL and provide proof of purchase evidenced

by the original sales receipt or Product registration.

Replacement Product Warranty

In case of replacement of a Product or any component part, AMTROL reserves the right to make changes in the design, construction, or material of the

substitute components or products, which shall be subject to all of the terms and limitations of this Warranty, except that the applicable warranty periods

shall be reduced by the amount of time the warranty claimant owned the product prior to submitting notification of the warranty claim.

Revised 01/11

AMTROL Inc. • 1400 Division Road • W. Warwick, Rhode Island 02893 • Telephone 401-884-6300 • Fax 401-885-2567

The AMTROL logo, AMTROL, Well-X-Trol, Champion, Wel-Flo, Extrol, Fill-Trol, Therm-X-Trol, and BoilerMate are registered trademarks of AMTROL Inc. and its affiliates in the U.S. and elsewhere.

All rights reserved.

-3-

Page 4

3. PRE-INSTALLATION CHECKLIST

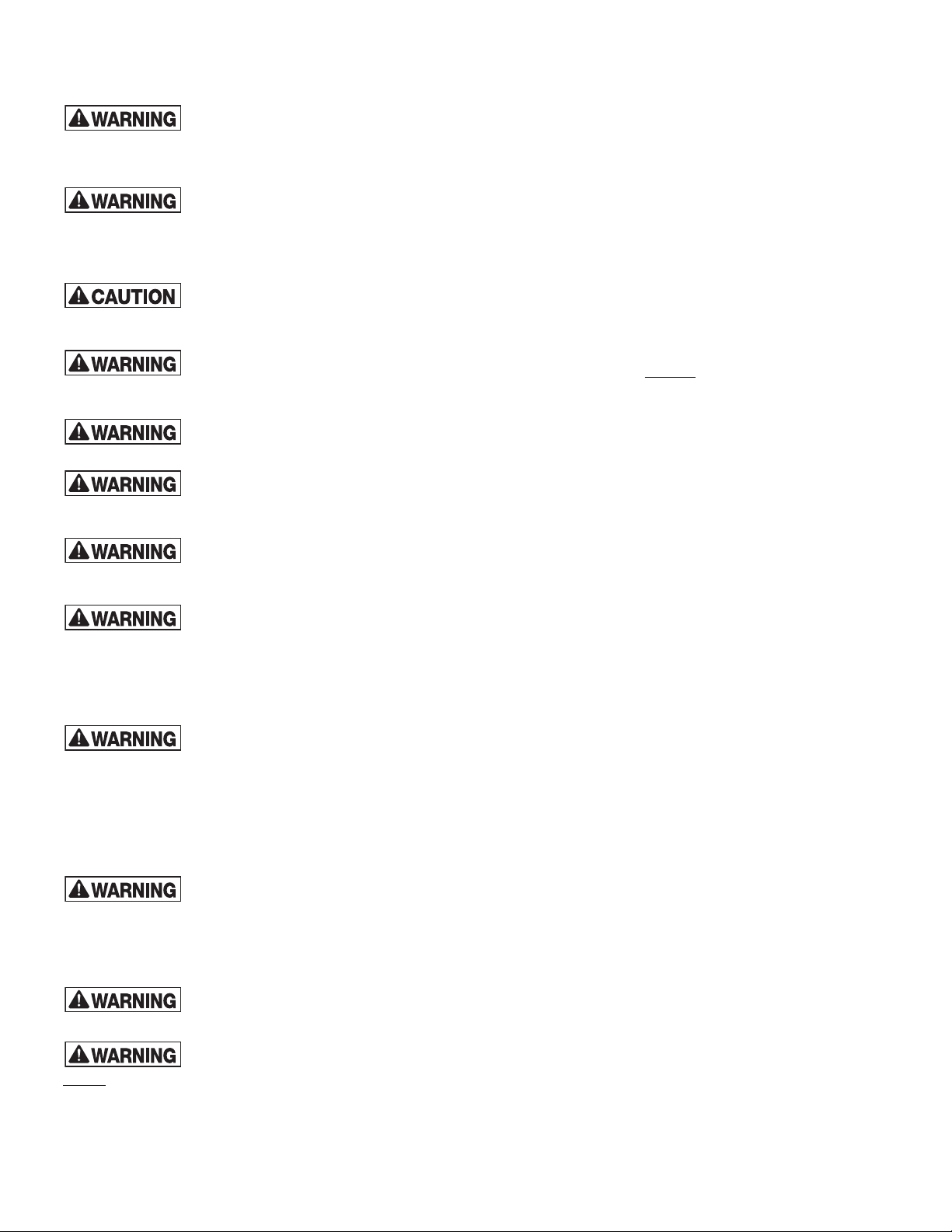

AIR VA L V E

LABEL

AIR

VA L V E

CAP

AIR VA LVE LABEL

IN POSITION

OVER CAP

FIGURE 1

IMPORTANT STEPS AND DECISIONS

REQUIRED BEFORE INSTALLATION

THIS PRODUCT MUST BE INSTALLED AND

j

MAINTAINED BY A LICENSED PROFESSIONAL. IN

ADDITION TO THE INSTRUCTIONS IN THIS MANUAL,

FOLLOW ALL APPLICABLE LOCAL AND STATE

CODES OR IN THE ABSENCE OF SUCH CODES, THE

CURRENT EDITIONS OF THE NATIONAL PLUMBING

CODE AND THE NATIONAL ELECTRIC CODE.

DRIP PAN AND DRAIN: To avoid leaking and/or flooding

j

damage, install with a drip pan connected to an adequate

working drain kept clear at all times.

4. REQUIRED COMPONENTS AND

ACCESSORIES CHECKLIST

VERTICAL STAND MODELS

1. PRESSURE SWITCH

j

2. RELIEF VALVE

j

3. 1 UNION

j

4. 1 SHUT OFF VALVE

j

5. VALVE DRAIN

j

6. PRESSURE GAUGE

j

7. TANK-TEE

j

the maximum working pressure for the well tank line.

Location

Proper well tank Location

The well tank should be installed as close as possible to the

pressure switch. This will reduce the adverse effects of added

friction loss and pressure switch bouncing, and the difference in

elevation between well tank and switch.

A HIGHER PRE-CHARGE PRESSURE IS NECESSARY DUE TO A REQUIRED

CHANGE IN THE PRESSURE SWITCH SETTING, FAILURE TO FOLLOW

INSTRUCTIONS BELOW CAN CAUSE A RUPTURE OR EXPLOSION, POSSIBLY

CAUSING SERIOUS OR FATAL INJURY, AND/OR PROPERTY DAMAGE.

• DO NOT ADJUST OR ADD PRESSURE IF THERE HAS BEEN A LOSS OF

• DO NOT ADJUST THE PRE-CHARGE PRESSURE IF THERE IS VISIBLE

• DO NOT ADJUST THE PRE-CHARGE PRESSURE IF THERE HAS BEEN A

Adjusting Precharge

Prior to Installation

All well tanks are shipped with a standard precharge

of 38 psig.

Step 1. Remove protective air valve cap

Step 2. Check precharge pressure should be + or -

Step 3. Release or add air as necessary to make

Step 4. Replace protective air valve cap. Peel off

MAXIMUM WORKING PRESSURES

Every well tank is air tested to 100 psig,

5. INSTALLATION INSTRUCTIONS

DANGER! EXPLOSION HAZARD. WHEN THE WELL

TANK HAS BEEN IN SERVICE AND A CHANGE TO

AIR.

EXTERIOR CORROSION.

REDUCTION OF THE PUMP CYCLE TIME OR THE PRE-CHARGE PRESSURE

COMPARED TO ITS INITIAL SETTING. THIS IS BECAUSE REDUCTION IN PUMP

CYCLE TIME CAN RESULT FROM LOSS OF TANK AIR PRESSURE WHICH

IN TURN CAN MEAN THERE MAY BE INTERNAL CORROSION AND ANY

RE-PRESSURIZATION OR ADDITIONAL PRESSURE COULD RESULT IN

RUPTURE OR EXPLOSION.

10% of the factory setting)

the precharge pressure 2 psig below

the pressure switch pump cut-in setting.

(Example, if you have a well tank with

a precharge of 38 psig, and you have

a pressure switch setting of 30/50 psig,

adjust precharge of your well tank from 38

psig to 28 psig.)

backing of label and apply over air valve

cap.

RELIEF VALVE RECOMMENDED

be installed which is set to open at excessive pressures (75

psig or more). This will protect your well tank and other system

components should the pressure switch malfunction and fail to

shut the pump off. The relief valve should be installed at the

connection of your well tank to the system piping and have a

discharge equal to the pump’s capacity at 75 psig.

rupture or explosion possibly causing serious or fatal

injury, flooding, and / or property damage.

It is recommended that a relief valve

Explosion Hazard. Failure to follow

these instructions can cause a

System Connection

1. Locate your well tank in the final desired location.

2. Level as necessary.

3. To eliminate friction loss, do not reduce the pipe size from the

pump to the well tank.

Start Up

Fine Tuning Procedures

Many times the actual pressure switch will vary from the standard

pressure range indicated. These variations could cause a momentary

lag of water delivery, as the pressure switch is not “tuned to the well tank

precharge pressure”.

1. Fill the system and well tank until pump cuts off.

2. Open one or more fixtures to drain the well tank.

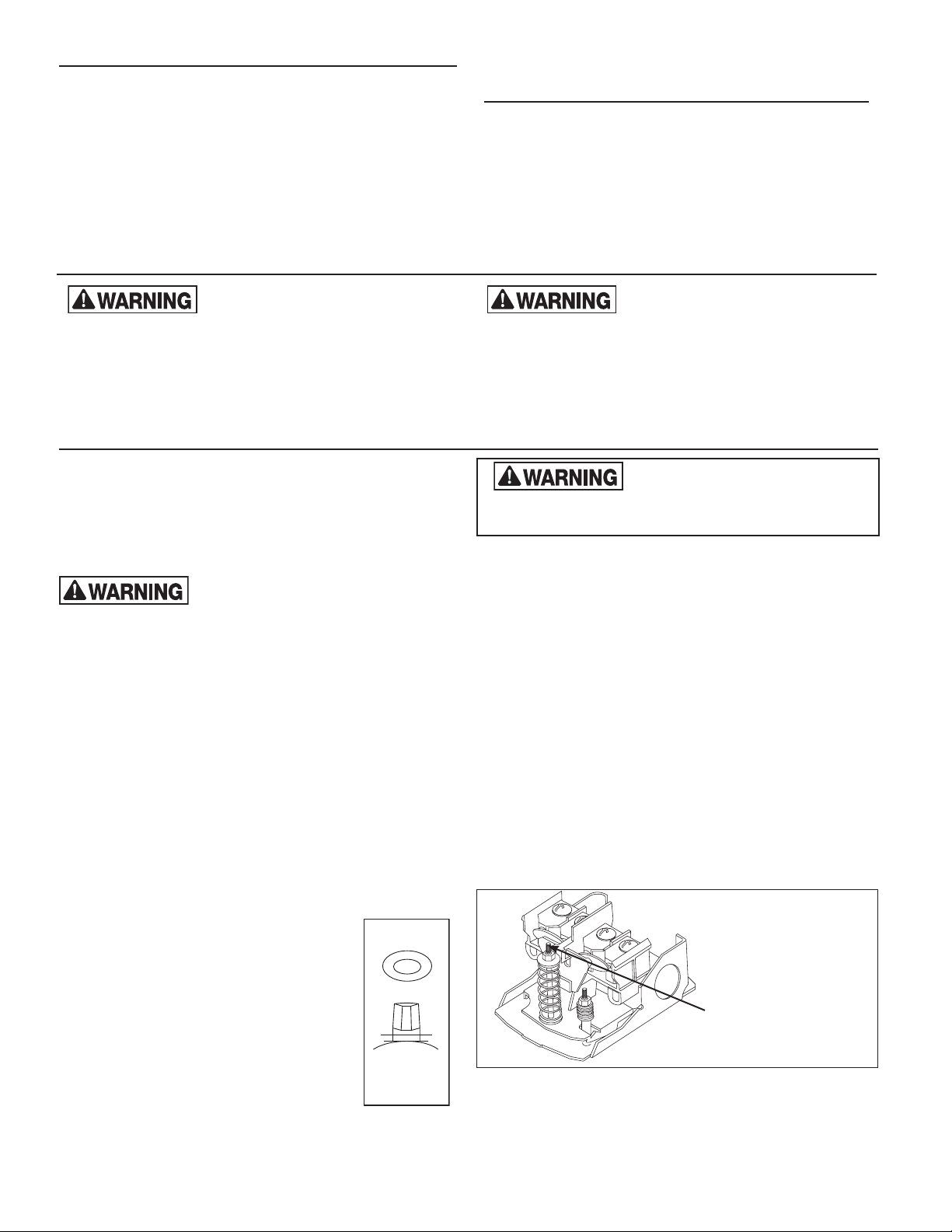

3. If there is a momentary pause in the water flow from the time the well

tank is emptied and the pump starts, adjust pump cut-in setting clockwise slightly (see figure 2).

4. Close fixtures and refill well tank to pump cut off. Check time to fill.

5. Open fixtures and see if pause in water is eliminated. If not, con-

tinue adjusting pressure switch.

FIGURE 2

Pressure Adjustment Clockwise

To Increase Cut-Out Pressure

Counter Clockwise To

Decrease Cut-Out Pressure

Adjusting Precharge After Installation

Step 1. Drain tank of all water. Check precharge pressure in the

Step 2. Release or add air as necessary to make the precharge

-4-

well tank.

pressure 2 psig below the pressure switch pump cut-in setting.

Page 5

1. INFORMATIONS GÉNÉRALES DE SÉCURITÉ

COMME LA PLUPART DES RÉSERVOIRS SOUS PRESSION, CE RÉSERVOIR SE CORRODERA OU SE ROMPRA AU BOUT D’UN

CAS RARES, IL POURRA EXPLOSER), QUI POURRAIT CAUSER DES BLESSURES GRAVES OU LA MORT, AINSI QUE DES DOMMAGES MATÉRIELS. POUR

RÉDUIRE LES RISQUES AU MINIMUM, UN SPÉCIALISTE HABILITÉ DOIT INSTALLER ET, PÉRIODIQUEMENT, INSPECTER ET FAIRE L’ENTRETIEN DE

L’APPAREIL. UNE CUVE D’ÉGOUTTEMENT RACCORDÉE À UNE ÉVACUATION ADÉQUATE DOIT ÊTRE INSTALLÉE SI LES FUITES OU L’INONDATION

PEUVENT CAUSER DES DOMMAGES MATÉRIELS.

TUYAUTERIE POUR DÉTERMINER LES MESURES À PRENDRE POUR DÉSINFECTER EN TOUTE SÉCURITÉ LE SYSTÈME DE TUYAUTERIE RÉSIDENTIEL.

À UNE EXPLOSION SÉRIEUSE, DES BLESSURES GRAVES OU LA MORT, ET DES DOMMAGES MATÉRIELS.

CONDUIRE À LA DÉFAILLANCE, AUX FUITES OU À L’INONDATION DU PRODUIT ET À DES DOMMAGES MATÉRIELS.

CE QUI POURRAIT CAUSER DES BLESSURES GRAVES OU MORTELLES ET/OU DES DOMMAGES MATÉRIELS.

• AJUSTER SEULEMENT LA PRESSION DE CHARGE INITIALE COMME INDIQUÉ DANS CE MANUEL LORSQUE LE RÉSERVOIR EST NEUF OU LORSQUE SON

INTÉGRITÉ ET L’ABSENCE DE CORROSION INTERNE OU EXTERNE ONT ÉTÉ CONFIRMÉES.

• SEULS LES PROFESSIONNELS QUALIFIÉS PEUVENT VÉRIFIER, AJUSTER OU RECHARGER LA PRÉCHARGE DES RÉSERVOIRS.

PRESSOSTAT, SI LES INSTRUCTIONS CI-DESSOUS NE SONT PAS SUIVIES, CELA PEUT CAUSER UNE RUPTURE OU UNE EXPLOSION, ET POURRAIT

ENTRAÎNER DES BLESSURES GRAVES OU MORTELLES ET/OU DES DOMMAGES MATÉRIELS.

• NE PAS AJUSTER NI AUGMENTER LA PRESSION SI DE L’AIR S’EST ÉCHAPPÉ.

• NE PAS AJUSTER LA PRESSION DE CHARGE INITIALE S’IL EXISTE DES SIGNES DE CORROSION À L’EXTÉRIEUR.

• NE PAS AJUSTER LA PRESSION DE CHARGE INITIALE EN CAS DE RÉDUCTION DU TEMPS DE CYCLE DE LA POMPE OU DE LA PRESSION DE CHARGE

INITIALE PAR RAPPORT À SA VALEUR D’ORIGINE. EN EFFET, LA RÉDUCTION DU TEMPS DE CYCLE DE LA POMPE PEUT ÊTRE DUE À LA PERTE DE

PRESSION D’AIR DANS LE RÉSERVOIR, LAQUELLE PEUT ÊTRE CAUSÉE PAR LA CORROSION INTERNE, ET DANS CE CAS LA REMISE SOUS PRESSION OU

L’AUGMENTATION DE LA PRESSION POURRAIT CONDUIRE À UNE RUPTURE OU À UNE EXPLOSION.

SOLIDES ET AUTRES CONTAMINANTS APPROPRIÉS, Y COMPRIS LE CHLORE, ET LA TRAITER D’UNE FAÇON ADÉQUATE POUR ASSURER UNE BONNE

PERFORMANCE ET EMPÊCHER LES PANNES PRÉMATURÉES.

NATURE. SI L’EAU GÈLE DANS LE SYSTÈME, CE DERNIER TOMBERA EN PANNE. NE PAS ESSAYER DE TRAITER L’EAU À UNE TEMPÉRATURE SUPÉRIEURE

À 37,8°C (100°F).

REMARQUE : INSPECTER POUR DÉCELER LES DOMMAGES ÉVENTUELS D’EXPÉDITION ET AVISER LE TRANSPORTEUR OU LE MAGASIN DE VENTE

IMMÉDIATEMENT SI DES DOMMAGES EXISTENT.

REMARQUE : VEUILLEZ LIRE DANS LEUR ENTIER LE MANUEL DU PROPRIÉTAIRE ET LES INSTRUCTIONS D’INSTALLATION AVANT D’INSTALLER CE

NOUVEAU PRODUIT AMTROL. SAUVEGARDER TOUS LES DOCUMENTS ET MANUELS POUR QU’ILS SERVENT DE RÉFÉRENCE ULTÉRIEURE.

REMARQUE : UTILISER UN ÉQUIPEMENT DE SÉCURITÉ APPROPRIÉ POUR L’INSTALLATION.

REMARQUE : IL FAUT RESPECTER TOUS LES CODES DE PLOMBERIE.

REMARQUE : SI LES AVERTISSEMENTS CI-DESSUS NE SONT PAS RESPECTÉS, CELA PEUT CONDUIRE À DES BLESSURES SÉRIEUSES OU MORTELLES

ET/OU DES DOMMAGES MATÉRIELS, ET CAUSERA L’ANNULATION DE LA GARANTIE.

SI LES AVERTISSEMENTS CI-DESSUS NE SONT PAS RESPECTÉS, CELA POURRA CONDUIRE À DES BLESSURES GRAVES OU LA MORT ET/OU DES

DOMMAGES MATÉRIELS, ET ANNULERA LA GARANTIE

CERTAIN TEMPS, ET/OU IL POURRA ÉCLATER ET/OU PRÉSENTER DES FUITES OU CAUSER UNE INONDATION (ET, DANS DES

COMME DANS TOUS LES PRODUITS DE TUYAUTERIE ET LES RÉSERVOIRS DE STOCKAGE D’EAU, DES BACTÉRIES PEUVENT SE

FORMER DANS LE RÉSERVOIR DE PUIT, SURTOUT QUAND IL N’EST PAS UTILISÉ. CONSULTER UN SPÉCIALISTE LOCAL DE

SUIVRE TOUTES LES INSTRUCTIONS ET RECOMMANDATIONS CONTENUES DANS CE MANUEL ET LES AVERTISSEMENTS

SPÉCIFIQUES ADDITIONNELS CI-DESSOUS. SINON, CELA CRÉERAIT UNE CONDITION D’INSÉCURITÉ QUI POURRAIT CONDUIRE

RISQUE D’EXPLOSION OU DE RUPTURE. UNE SOUPAPE DE DÉTENTE DOIT ÊTRE INSTALLÉE POUR EMPÊCHER LES

PRESSIONS SUPÉRIEURES À 8,8 KG/CM2 (125 PSIG) OU À LA VALEUR MAXIMALE EXIGÉE PAR LE CODE LOCAL

(SI INFÉRIEURE).

RISQUE D’EXPLOSION OU DE RUPTURE. LE RÉSERVOIR DE PUIT DOIT ÊTRE UTILISÉ DE FAÇON QUE LA PRESSION NE

DÉPASSE PAS 125 PSIG.

SI UN RÉSERVOIR DE PUIT DIMENSIONNÉ CORRECTEMENT (EN FONCTION DES INSTRUCTIONS DE DIMENSIONNEMENT

CI-DESSOUS) N’EST PAS UTILISÉ, LA POMPE SERA SOUMISE À UNE CHARGE EXCESSIVE, CE QUI POURRAIT FINALEMENT

DANGER ! RISQUE D’EXPLOSION. SI ON AJUSTE LA PRESSION DE PRÉCHARGE OU ON AUGMENTE LA PRESSION D’UN

RÉSERVOIR CORRODÉ OU ENDOMMAGÉ OU DONT L’INTÉGRITÉ EST RÉDUITE, LE RÉSERVOIR PEUT ÉCLATER OU EXPLOSER,

DANGER ! RISQUE D’EXPLOSION. LORSQUE LE RÉSERVOIR DE PUIT A ÉTÉ EN SERVICE PENDANT UN CERTAIN TEMPS ET

LA PRESSION DE CHARGE INITIALE DOIT ÊTRE AUGMENTÉE À CAUSE D’UN CHANGEMENT NÉCESSAIRE DU RÉGLAGE DU

LA QUALITÉ DE L’EAU PEUT AFFECTER CONSIDÉRABLEMENT LA DURÉE DE SERVICE DU PRODUIT. IL FAUT TESTER L’EAU

POUR DÉCELER LES ÉLÉMENTS CORRODANTS ÉVENTUELS, MESURER SON ACIDITÉ, LA CONCENTRATION TOTALE DES

INSTALLER OU STOCKER DANS UN ENDROIT OÙ LE RÉSERVOIR NE SERA PAS EXPOSÉ AUX TEMPÉRATURES INFÉRIEURES À

LA TEMPÉRATURE DE CONGÉLATION OU SUPÉRIEURES À 37,8°C (100°F), NE PAS EXPOSER AUX INTEMPÉRIES DE TOUTE

UTILISER UNIQUEMENT DE LA SOUDURE ET UN FLUX SANS PLOMB POUR TOUTES LES CONNEXIONS DE SOUDURE PAR

RESSUAGE, COMME REQUIS PAR LES CODES RÉGIONAUX ET NATIONAUX.

-5-

Page 6

2. GARANTIE LIMITÉE DE PRODUIT AMTROL

Produits couverts : tous les produits fabriqués par AMTROL Inc. (“AMTROL”).

Cette garantie ne peut pas être cédée – elle est offerte uniquement à l’Acheteur initial ou au Premier Utilisateur du Produit. En acceptant et en

conservant ce Produit, vous convenez de toutes les dispositions et limitations de responsabilité de la garantie décrites ci-dessous.

AVERTISSEMENT IMPORTANT – LIRE AVEC SOIN LE MANUEL D’INSTRUCTIONS D’INSTALLATION, FONCTIONNEMENT ET MAINTENANCE

(le “MANUEL”) pour éviter les blessures graves et/ou les dommages matériels et pour s’assurer de la sécurité d’utilisation et du bon entretien de

ce produit.

®

Qui reçoit la garantie de produit d’AMTROL

Tous les acheteurs ou les premiers utilisateurs du Produit neuf. La garantie n’est pas cessible.

Qu’est-ce qui est couvert par cette Garantie

AMTROL® garantit à l’acheteur ou au premier utilisateur du Produit neuf que, au moment de sa fabrication, le Produit était dépourvu de vice de

matériau ou de fabrication. Toute réclamation de garantie doit être déposée dans un délai d’un (1) an après la date d’achat du Produit, sauf si d’autres

délais sont précisés dans le Manuel.

Ce que fera AMTROL en cas de réclamation couverte par la garantie

En cas de violation de la garantie ci-dessus, AMTROL choisira soit d’effectuer des réparations afin de corriger tout vice de matériau ou de fabrication

soit de fournir et d’expédier des pièces ou des produits de rechange, neufs ou non. AMTROL n’acceptera pas de réclamation pour les dépenses de

main d’œuvre ou autres.

Ce que cette Garantie ne couvre pas - Exclusions et Limitations

Cette Garantie ne couvre pas les défaillances ou les problèmes qui n’ont pas été causés par un vice de matériau ou de fabrication. En outre, cette

Garantie n’est pas applicable:

• Si le Produit n’a pas été correctement installé, utilisé, réparé ou maintenu comme indiqué dans le Manuel fourni avec le Produit ;

• À toute panne ou défaillance causée par un abus (y compris le gel) ; une manutention, expédition (par un tiers autre que Amtrol), stockage, utilisation,

opération, accident inappropriés ou négligents; ou une altération, la foudre, l’inondation ou toute autre condition environnementale;

• À toute panne ou problème causé par l’utilisation du Produit pour toute raison autre que celles spécifiées dans le Manuel joint ou par l’altération

d’une partie quelconque du produit ;

• Si le Produit est utilisé dans tout endroit autre qu’aux États-Unis, ses territoires ou possessions, ou au Canada;

• Cette Garantie ne couvre pas les coûts de main d’œuvre, les frais d’expédition, les commissions, les frais de livraison, les frais administratifs ou toute

autre dépense subie pour reprendre ou réinstaller le Produit ;

• Cette Garantie ne couvre aucune réclamation déposée auprès de Amtrol ou d’un concessionnaire ou détaillant autorisé de Amtrol plus de 30

jours après l’expiration de la période applicable de garantie décrite dans cette Garantie;

• Cette Garantie ne couvre pas non plus les frais de réparation ou de remplacement qui n’ont pas été autorisés au préalable par AMTROL.

Limitations de garantie supplémentaires

TOUTES LES GARANTIES TACITES, INCLUANT LES GARANTIES TACITES DE QUALITÉ MARCHANDE ET D’APTITUDE À UN USAGE

PARTICULIER, SONT SPÉCIFIQUEMENT REJETÉES.

Limitations des remèdes

LES REMEDES CONTENUS DANS CETTE GARANTIE REPRESENTENT LES REMEDES EXCLUSIFS DE L’ACHETEUR OU DU PREMIER

UTILISATEUR. AMTROL NE SAURAIT EN AUCUN CAS ETRE RESPONSABLE POUR UNE SOMME SUPERIEURE AU PRIX D’ACHAT DU

PRODUIT, ET LES REMEDES DE L’ACHETEUR/PREMIER UTILISATEUR NE DEPASSERONT PAS CE PRIX. AMTROL NE SERA EN AUCUN CAS

TENU RESPONSABLE POUR TOUS DOMMAGES-INTERETS SPECIAUX, INDIRECTS, FORTUITS OU ACCESSOIRES, QU’ILS RESULTENT

OU NON DE LA NON-LIVRAISON OU DE LA NON-UTILISATION, LA MAUVAISE UTILISATION OU L’IMPOSSIBILITE D’UTILISATION DU

PRODUIT, OU DE DEFAUTS DU PRODUIT OU DE LA NEGLIGENCE OU AUTRE FAUTE DE AMTROL. Cette exclusion est applicable, que les

dommages-intérêts soient ou non demandés pour violation de garantie, rupture de contrat, négligence, responsabilité stricte, dans le cadre d’un délit

civil ou selon toute autre théorie juridique. Ces dommages-intérêts incluent, sans pour autant que cette énumération soit limitative, l’incommodité, les

pertes ou les dommages matériels, les moisissures, les pertes de bénéfice, les pertes d’argent économisé ou les pertes de chiffre d’affaires, les

pertes d’utilisation des Produits ou de tout équipement, installation, immeuble ou service associé, les temps morts et les réclamations de tiers, incluant

les clients.

Que faut-il faire en cas de problème couvert par cette Garantie

Toute réparation couverte par la Garantie doit être autorisée par AMTROL. Contacter la personne auprès de laquelle le Produit a été acheté, et qui doit

recevoir l’autorisation d’un concessionnaire AMTROL ou l’autorisation de AMTROL. Si la réponse se fait attendre, contacter AMTROL directement

au numéro 877-517-9673. La notification de réclamation de garantie doit être soumise par le concessionnaire autorisé de AMTROL à l’adresse

ci-dessous:

AMTROL Inc.

Warranty Claim Dept.

1400 Division Rd.

West Warwick, RI 02893 USA

Avant que AMTROL ne décide de fournir une pièce ou un Produit de rechange, il peut exiger, en tant que condition préalable à cette prise de décision,

que le demandeur de garantie envoie le Produit en port payé chez un concessionnaire AMTROL autorisé ou chez AMTROL et fournisse un justificatif

d’achat sous forme du récépissé de vente d’origine ou de l’enregistrement du Produit.

Garantie du Produit de rechange

En cas de remplacement d’un Produit ou de toute autre pièce, AMTROL se réserve le droit d’apporter des modifications à la conception, la

construction ou les matériaux des pièces ou des produits de substitution, lesquels seront soumis à toutes les dispositions et limitations de cette

Garantie, sauf que les périodes de garantie applicables seront réduites par la période au cours de laquelle le demandeur de garantie avait possédé le

produit avant de soumettre la notification de réclamation de garantie.

Le symbole AMTROL, Well-X-Trol, Champion, Wel-Flo, Extrol, Fill-Trol, Therm-X-Trol et BoilerMate sont des marques déposées de AMTROL Inc. et ses usines affiliés

aux États-Unis et mondiales. Tous droits réservés.

-6-

Revised 02/11

Page 7

3. LISTE DE CONTRÔLE AVANT

ÉTIQUETTE DE

SOUPAPE À AIR

CAPUCHON DE

SOUPAPE À AIR

ÉTIQUETTE DE

SOUPAPE À AIR

EN POSITION SUR

LE CAPUCHON

FIGURE 1

L’INSTALLATION

ÉTAPES ET DÉCISIONS IMPORTANTES ET

NÉCESSAIRES AVANT L’INSTALLATION

j CE PRODUIT DOIT ÊTRE INSTALLÉ ET MAINTENU PAR UN

SPÉCIALISTE HABILITÉ. EN PLUS DES INSTRUCTIONS DE CE

MANUEL, SUIVRE TOUS LES CODES LOCAUX ET RÉGIONAUX

APPLICABLES OU, DANS LEUR ABSENCE, LES DERNIÈRES

VERSIONS DU CODE NATIONAL DE LA TUYAUTERIE ET DU

CODE NATIONAL DE L’ÉLECTRICITÉ

j BAC D’ÉGOUTTEMENT ET ÉVACUATION : Pour éviter les

dommages causés par les fuites et/ou l’inondation, installer un bac

d’égouttement raccordé à une évacuation opérationnelle adéquate,

dégagée en permanence.

PRESSIONS MAXIMALES DE

MARCHE

Chaque réservoir de puits est testé à 100 psig pression, de marche

maximale de la conduite du réservoir.

5. INSTRUCTIONS D’INSTALLATION

4. LISTE DE CONTRÔLE DES PIÈCES

ET ACCESSOIRES REQUIS

MODÈLES À SUPPORT VERTICAL

j 1. PRESSOSTAT

j5. ÉVACUATION DE

SOUPAPE

j2. SOUPAPE DE DÉTENTE

j6. MANOMÈTRE

j3. 1 RACCORD UNION

j7. RACCORD EN T DE

j4. 1 SOUPAPE D’ARRÊT

SOUPAPE DE DÉTENTE

RECOMMANDÉE

Il est recommandé d’installer une soupape de détente réglée pour s’ouvrir

aux pressions excessives (75 psig et plus). Cela protègera le réservoir

de puits et les autres composants du système au cas où le pressostat ne

fonctionnerait pas correctement et n’arrêterait pas la pompe. La soupape

de détente doit être installée au niveau du raccordement du réservoir à la

tuyauterie du système, et doit avoir une pression de refoulement égale à

la capacité de la pompe, soit 75 psig.

RÉSERVOIR

Emplacement

Emplacement approprié du réservoir de puits

Le réservoir de puits doit être installé aussi près que possible

du pressostat. Cela réduit les effets nuisibles des pertes dues à

l’augmentation des frottements, des mouvements du pressostat

et de la différence de hauteur entre le réservoir et le pressostat.

DANGER ! RISQUE D’EXPLOSION.

LORSQUE LE RÉSERVOIR DE PUITS A ÉTÉ EN SERVICE PENDANT UN

CERTAIN TEMPS ET LA PRESSION DE CHARGE INITIALE DOIT ÊTRE

AUGMENTÉE À CAUSE D’UN CHANGEMENT NÉCESSAIRE DU RÉGLAGE DU

PRESSOSTAT, LE NON-RESPECT DES INSTRUCTIONS CI-DESSOUS PEUT

CAUSER UNE RUPTURE OU UNE EXPLOSION POUVANT CONDUIRE À DES

BLESSURES GRAVES OU LA MORT, ET/OU DES DOMMAGES MATÉRIELS.

• NE PAS AJUSTER NI AUGMENTER LA PRESSION SI DE L’AIR S’EST

ÉCHAPPÉ.

• NE PAS AJUSTER LA PRESSION DE CHARGE INITIALE S’IL EXISTE DES

SIGNES DE CORROSION À L’EXTÉRIEUR.

• NE PAS AJUSTER LA PRESSION DE CHARGE INITIALE EN CAS DE

RÉDUCTION DU TEMPS DE CYCLE DE LA POMPE OU DE LA PRESSION

DE CHARGE INITIALE PAR RAPPORT À SA VALEUR D’ORIGINE. EN

EFFET, LA RÉDUCTION DU TEMPS DE CYCLE DE LA POMPE PEUT ÊTRE

DUE À LA PERTE DE PRESSION D’AIR DANS LE RÉSERVOIR, LAQUELLE

PEUT ÊTRE CAUSÉE PAR LA CORROSION INTERNE, ET DANS CE CAS

LA REMISE SOUS PRESSION OU L’AUGMENTATION DE LA PRESSION

POURRAIT CONDUIRE À UNE RUPTURE OU À UNE EXPLOSION.

Ajustement de la charge initiale

Avant l’installation

Tous les réservoirs de puits sont expédiés avec une charge initiale

standard de 38 psig.

Étape 1. Retirer le capuchon de protection de la

Étape 2. Vérifier la pression de charge initiale (elle

Étape 3. Retirer ou ajouter de l’air selon les besoins

Étape 4. Remettre en place le capuchon de

soupape à air

devrait être égale au réglage d’usine avec

une tolérance de + ou - 10 %)

pour amener la pression de charge initiale

à 2 psig au-dessous de la pression

d’activation de pompe du pressostat.

Exemple: pour un réservoir avec une

charge initiale de 38 psig et un réglage

de pressostat de 30/50 psig, abaisser la

charge initiale du réservoir de 38 psig à 28

psig.

protection de la soupape à air. Retirer

le dos de l’étiquette et la placer sur le

capuchon de la soupape à air.

Risque d’explosion. Si ces instructions

ne sont pas suivies, cela peut causer

une rupture ou une explosion pouvant conduire à des

blessures graves ou la mort, l’inondation et/ou les

dommages matériels.

Raccordement du système

1. Placer le réservoir de puits dans son emplacement définitif.

2. Mettre l’appareil de niveau selon les besoins.

3. Pour éliminer les pertes de friction, ne pas réduire la taille du tuyau

entre la pompe et le réservoir.

Démarrage Procédures de réglage fin

Souvent, la pression réelle du pressostat ne sera pas dans la plage de

pression nominale indiquée. Ces variations pourraient causer un retard

momentané de la livraison d’eau, car le pressostat n’est pas « accordé à

la pression de charge initiale du réservoir de puits ».

1. Remplir le système et le réservoir de puits jusqu’à ce que la

pompe s’arrête.

2. Ouvrir un ou plusieurs robinets pour vider le réservoir.

3. ISi le débit d’eau subit une interruption momentanée après que le

réservoir ait été vidé et la pompe ait démarré, ajuster le réglage

d’activation de la pompe légèrement dans le sens horaire (voir la

figure 2).

4. Fermer les robinets et remplir à nouveau le réservoir jusqu’à l’arrêt

de la pompe. Vérifier le temps nécessaire au remplissage.

5. Ouvrir les robinets et déterminer si l’interruption de l’alimentation

d’eau a été éliminée. Sinon, continuer à ajuster le pressostat.

FIGURE 2

Réglage de la pression dans le

sens horaire pour augmenter la

pression d’arrêt, dans le sens

antihoraire pour diminuer la

pression d’arrêt

Réglage de la charge initiale après

l’installation

Étape 1. Vider complètement le réservoir. Vérifier la pression de

charge initiale dans le réservoir.

Étape 2 Retirer ou ajouter de l’air selon les besoins pour amener

la pression de charge initiale à 2 psig au-dessous de la

pression d’activation de pompe du pressostat.

-7-

Page 8

1. INFORMACIÓN GENERAL DE SEGURIDAD

ESTE TANQUE, TAL COMO SUCEDE CON LA MAYORÍA DE LOS TANQUES BAJO PRESIÓN, CON EL CORRER DEL TIEMPO SE

VA A CORROER Y/O PODRÍA ESTALLAR Y/O TENER FUGAS O INUNDARSE (Y EN CASOS RAROS, EXPLOTAR), LO CUAL

UNIDAD DEBE SER INSTALADA E INSPECCIONADA Y RECIBIR MANTENIMIENTO PERIÓDICO DE UN INSTALADOR PROFESIONAL CERTIFICADO. SI EXISTE

LA POSIBILIDAD DE QUE UNA PÉRDIDA O INUNDACIÓN PUEDA CAUSAR DAÑOS MATERIALES, SE DEBE INSTALAR UNA BANDEJA RECOLECTORA DE

FUGAS, CONECTADA A UN DRENAJE ADECUADO.

LOS PASOS QUE DEBE SEGUIR PARA DESINFECTAR CON SEGURIDAD EL SISTEMA DE INSTALACIONES SANITARIAS DE SU CASA.

• SÓLO AJUSTE LA PRECARGA COMO SE DESCRIBE EN ESTE MANUAL CUANDO EL TANQUE SEA NUEVO O CUANDO SE CONFIRME SU INTEGRIDAD

Y QUE NO TENGA PÉRDIDAS INTERNAS O EXTERNAS.

• LA PRECARGA DE LOS TANQUES SÓLO DEBE SER REVISADA, AJUSTADA Y RECARGADA POR UN PROFESIONAL CALIFICADO.

• NO AJUSTE O AUMENTE LA PRESIÓN SI HA HABIDO PÉRDIDA DE AIRE.

• NO AJUSTE LA PRESIÓN DE PRECARGA SI SE OBSERVA CORROSIÓN EN EL EXTERIOR.

• NO AJUSTE LA PRESIÓN DE PRECARGA SI HUBO ALGUNA REDUCCIÓN EN EL CICLO DE OPERACIÓN DE LA BOMBA O EN LA PRESIÓN DE PRECARGA,

COMPARADA CON SU VALOR INICIAL. ESTO SE DEBE A QUE LA REDUCCIÓN DEL CICLO DE OPERACIÓN DE LA BOMBA PUEDE SER CAUSADA POR

UNA PÉRDIDA DE PRESIÓN DE AIRE DEL TANQUE, LO QUE A SU VEZ, PUEDE SER UN SÍNTOMA DE CORROSIÓN INTERNA, POR LO QUE CUALQUIER

REPRESURIZACIÓN O PRESIÓN ADICIONAL PODRÍA PRODUCIR UNA RUPTURA O EXPLOSIÓN.

PUEDE CAUSAR LESIONES PERSONALES GRAVES O FATALES Y DAÑOS MATERIALES. PARA REDUCIR ESTE RIESGO, LA

TAL COMO SUCEDE CON TODOS LOS PRODUCTOS DE INSTALACIONES SANITARIAS Y RECIPIENTES DE ALMACENAMIENTO

DE AGUA, PUEDEN DESARROLLARSE BACTERIAS EN SU TANQUE PARA SISTEMA DE AGUA,ESPECIALMENTE DURANTE

PERÍODOS DE NO FUNCIONAMIENTO. CONSULTE CON SU FUNCIONARIO DE INSTALACIONES SANITARIAS LOCAL SOBRE

SIGA TODAS LAS INSTRUCCIONES Y RECOMENDACIONES QUE HAY EN ESTE MANUAL, ASÍ COMO LAS SIGUIENTES

ADVERTENCIAS ESPECÍFICAS. EL NO HACERLO ES INSEGURO Y PUEDE CAUSAR UNA EXPLOSIÓN GRAVE, LESIONES

PERSONALES GRAVES O FATALES Y DAÑOS MATERIALES.

PELIGRO DE EXPLOSIÓN O RUPTURA. SE DEBE INSTALAR UNA VÁLVULA DE ALIVIO CON EL FIN DE EVITAR QUE

HAYA UNA PRESIÓN MAYOR QUE 125 LPPC (LIBRAS POR PULGADA CUADRADA, U 8.75 KG/CM

EL REGLAMENTO LOCAL, LO QUE SEA MENOR.

PELIGRO DE EXPLOSIÓN O RUPTURA. EL TANQUE PARA SISTEMA DE AGUA SE DEBE OPERAR DE MANERA TAL QUE

NO SE EXCEDA UNA PRESIÓN MANOMÉTRICA DE 125 LPPC (8.75 Kg/cm

LA UTILIZACIÓN DE UN TANQUE PARA SISTEMA DE AGUA QUE NO SEA DE LA DIMENSIÓN ADECUADA (CON BASE EN

LAS SIGUIENTES INSTRUCCIONES DE DIMENSIONAMIENTO) PUEDE PRODUCIR ESFUERZOS EXCESIVOS EN LA BOMBA,

QUE A SU VEZ PUEDEN CAUSAR FALLAS DEL PRODUCTO, PÉRDIDAS E INUNDACIÓN, Y DAÑOS MATERIALES.

¡PELIGRO! RIESGO DE EXPLOSIÓN. SI USTED AJUSTA LA PRESIÓN DE PRECARGA O AUMENTA LA PRESIÓN DE UN

TANQUE QUE ESTÁ CORROÍDO O DAÑADO, O CUYA INTEGRIDAD HA SIDO COMPROMETIDA, DICHO TANQUE PODRÍA

REVENTARSE O EXPLOTAR, EXISTIENDO LA POSIBILIDAD DE QUE ESTO PROVOQUE LESIONES GRAVES O FATALES Y

DAÑOS MATERIALES.

¡PELIGRO! RIESGO DE EXPLOSIÓN. SI DESPUÉS DE QUE EL TANQUE PARA SISTEMA DE AGUA HA ESTADO EN

SERVICIO, ES NECESARIO SUBIR SU PRESIÓN DEBIDO A UN CAMBIO REQUERIDO EN EL AJUSTE DEL INTERRUPTOR DE

PRESIÓN, DE NO SEGUIRSE LAS INSTRUCCIONES A CONTINUACIÓN, PODRÍA OCURRIR UNA RUPTURA O EXPLOSIÓN,

CON LA POSIBILIDAD DE QUE OCURRAN LESIONES GRAVES O FATALES Y DAÑOS MATERIALES.

LA CALIDAD DEL AGUA PUEDE AFECTAR DE MANERA SIGNIFICATIVA LA VIDA DE SU PRODUCTO. USTED DEBE PROBARLA

PARA DETECTAR EN ELLA ELEMENTOS CORROSIVOS, ACIDEZ, SÓLIDOS TOTALES Y OTROS CONTAMINANTES DE

CONSIDERACIÓN, INCLUYENDO CLORO, Y TRATAR EL AGUA DE MANERA APROPIADA, A FIN DE ASEGURAR UN

DESEMPEÑO SATISFACTORIO Y DE PREVENIR FALLAS PREMATURAS.

INSTALE O ALMACENE EL TANQUE EN UN LUGAR EN EL QUE NO ESTÉ EXPUESTO A TEMPERATURAS BAJO CERO O

MAYORES QUE 100°F (38°C); NO SE EXPONGA A NINGÚN TIPO DE CLIMA EN EXTERIORES. EL CONGELAMIENTO DEL AGUA

EN EL SISTEMA LO ROMPERÁ. NO TRATE AGUA A MÁS DE 100°F (38°C).

SÓLO USE SOLDADURA Y FUNDENTE SIN PLOMO EN LAS CONEXIONES SOLDADAS, TAL COMO LO REQUIEREN LOS

REGLAMENTOS ESTATALES Y FEDERALES.

2

).

2

), O LO QUE INDIQUE

NOTA: REVISE SI EL PRODUCTO SUFRIÓ DAÑOS DURANTE LA TRANSPORTACIÓN Y, SI ESTÁ DAÑADO, NOTIFÍQUELO DE INMEDIATO AL

TRANSPORTISTA O A LA TIENDA DONDE LO ADQUIRIÓ.

POR FAVOR LEA EL MANUAL DEL PROPIETARIO Y LAS INSTRUCCIONES DE INSTALACIÓN ANTES DE INSTALAR SU NUEVO PRODUCTO AMTROL.

GUARDE LA DOCUMENTACIÓN Y LOS MANUALES PARA REFERENCIA FUTURA.DE

AL INSTALARLO, UTILICE EQUIPO DE SEGURIDAD ADECUADO.

SE DEBEN CUMPLIR TODOS LOS REGLAMENTOS DE PLOMERÍA.

EL INCUMPLIMIENTO DE LAS ADVERTENCIAS ANTERIORES PUEDE TRAER COMO CONSECUENCIA LESIONES

PERSONALES GRAVES O FATALES Y DAÑOS PERSONALES Y MATERIALES, ADEMÁS DE QUE ANULARÁ LA GARANTÍA.

DE NO SEGUIRSE LAS ADVERTENCIAS ANTERIORES, PODRÍAN PRODUCIRSE LESIONES PERSONALES GRAVES O LA MUERTE, Y/O DAÑOS MATERIALES,

Y SE ANULARÁ LA GARANTÍA.

-8-

Page 9

2. GARANTÍA LIMITADA SOBRE LOS PRODUCTOS DE AMTROL®

Productos cubiertos: todos los productos manufacturados por AMTROL Inc. (“AMTROL”).

Esta garantía es intransferible; se concede únicamente al comprador original o al primer usuario del producto. Al aceptar y conservar este producto,

usted acepta todos los términos de la garantía, así como las limitaciones de responsabilidad que se describen a continuación.

ADVERTENCIA IMPORTANTE: LEA CON ATENCIÓN EL MANUAL DE INSTRUCCIONES DE INSTALACIÓN, OPERACIÓN Y

MANTENIMIENTO (“MANUAL”) para prevenir graves lesiones personales y daños materiales, así como para asegurar la adecuada utilización y

cuidado de este producto.

Quién recibe la garantía de los productos AMTROL?

Todos los compradores o primeros usuarios de un producto nuevo. La garantía no es transferible.

Qué cubre esta garantía?

AMTROL® garantiza al comprador o al primer usuario del producto nuevo que, al momento de manufactura, dicho producto está libre de defectos

materiales y de mano de obra. Cualquier reclamación de garantía se debe efectuar en un plazo de un (1) año a partir de la fecha de compra, a

menos que en el manual se especifique un plazo distinto.

Qué hará AMTROL si usted tiene un reclamo cubierto por la garantía?

En caso de incumplimiento de la garantía anterior, AMTROL, a opción suya, efectuará las reparaciones necesarias para corregir cualquier defecto

material o de mano de obra, o suministrará y enviará piezas o productos de repuesto nuevos o usados. AMTROL no aceptará ningún reclamo por

mano de obra u otros costos.

Qué no queda cubierto por esta garantía? Exclusiones y limitaciones

Esta garantía no cubre ninguna falla ni ningún problema, a menos que haya sido causado por defectos materiales o de mano de obra. Además, esta

garantía no aplicará:

• Si el producto no ha sido instalado, operado, reparado o mantenido correctamente, según lo descrito en el manual que se suministra con él;

• A ninguna falla o funcionamiento defectuoso que resulte a consecuencia de maltrato (incluyendo congelamiento); manejo, embarque (por

terceros distintos de AMTROL), almacenamiento, utilización u operación inadecuados o negligentes; accidente; alteración; rayos; inundación;

o cualquier otra condición medioambiental;

• A cualquier falla o problema que resulte del uso del producto para cualquier fin distinto de los que se especifican en el manual adjunto, o por la

alteración de cualquier parte del producto;

• Esta garantía no cubre los costos de mano de obra, gastos de envío, costos de servicio, gastos de entrega, cargos administrativos ni ningún

otro costo en el que se incurra por remover o reinstalar el producto.

• Esta garantía no cubre ningún otro reclamo remitido a AMTROL o a un distribuidor o minorista autorizado de AMTROL más de 30 días después

del periodo aplicable de garantía que se describe en esta garantía;

• Esta garantía tampoco cubre los costos de reparación y de reemplazo no autorizados por AMTROL por adelantado.

Limitaciones adicionales de la garantía

TODAS LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO LAS GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN E IDONEIDAD PARA UN FIN

PARTICULAR, SON DENEGADAS ESPECÍFICAMENTE.

Limitaciones de los remedios

LOS REMEDIOS CONTENIDOS EN ESTA GARANTÍA SON EXCLUSIVOS PARA EL COMPRADOR O EL PRIMER USUARIO.

BAJO NINGUNA CIRCUNSTANCIA SERÁ RESPONSABLE AMTROL POR MÁS QUE EL PRECIO PAGADO POR EL PRODUCTO; DE LA MISMA

MANERA, LOS REMEDIOS DEL COMPRADOR O PRIMER USUARIO NO EXCEDERAN DICHO PRECIO. EN NINGÚN CASO SERÁ RESPONSABLE

AMTROL POR NINGÚN DAÑO ESPECIAL, INDIRECTO, INCIDENTAL O CONSIGUIENTE, SEA RESULTADO DE LA FALTA DE ENTREGA O DEL

USO, MAL USO O INCAPACIDAD PARA USAR EL PRODUCTO, NI POR DEFECTOS EN EL PRODUCTO NI POR NEGLIGENCIA PROPIA DE

AMTROL, NI POR NINGÚN OTRO AGRAVIO. Esta exclusión es aplicable sin importar si se busca la reparación de dichos daños por incumplimiento

de la garantía, incumplimiento de contrato, negligencia, responsabilidad estricta, bajo agravio o bajo cualquier otra teoría legal. Tales daños incluyen,

sin estar limitados a, inconveniencia, pérdidas o daños materiales, moho, pérdidas de ganancias, pérdida de ahorros o ingresos, pérdida del uso de

los productos o de cualquier equipo, instalaciones, edificios o servicios asociados, tiempo de baja, y las reclamaciones de terceros, incluyendo clientes.

¿Qué hacer si tiene un problema cubierto por esta garantía?

Cualquier servicio de garantía cubierto debe ser autorizado por AMTROL. Comuníquese con la persona que le vendió el producto, la cual tiene que

recibir autorización de un distribuidor de AMTROL o de AMTROL mismo. Si no recibe una respuesta pronta, llame a AMTROL directamente al

877-517-9673. El distribuidor autorizado debe remitir el aviso de un reclamo de garantía a AMTROL a la siguiente dirección:

AMTROL, Inc.

Warranty Claim Dept.

1400 Division Rd.

W. Warwick, RI 02893

Antes de que AMTROL determine proveer partes o productos de repuesto, como condición previa para tal determinación podría requerir que el

reclamante de la garantía envíe el producto, con porte prepagado, a un distribuidor autorizado de AMTROL, o a AMTROL, y que proporcione

prueba de su compra, usando como evidencia el recibo original de compra o el registro del producto.

Garantía sobre los productos de reemplazo

En caso de que se reemplace un producto o componente, AMTROL se reserva el derecho de efectuar cambios al diseño, construcción y material

de los componentes o productos de reemplazo, los cuales estarán sujetos a todos los términos y limitaciones de esta garantía, excepto que los

periodos de garantía aplicables se reducirán en un tiempo igual al tiempo que el reclamante de la garantía haya sido el propietario del producto antes

de remitir la notificación del reclamo de garantía.

El logotipo de AMTROL, AMTROL, Well-X-Trol, Champion, Wel-Flo, Extrol, Fill-Trol, Therm-X-Trol y BoilerMate son marcas registradas de AMTROL Inc. y sus afiliados

en E.U.A. y otros países. Todos los derechos reservados.

Revised 02/11

-9-

Page 10

3. LISTA DE VERIFICACIÓN

ETIQUETA DE

LA VÁLVULA DE AIRE

TA PA DE LA

VÁLVULA DE AIRE

ETIQUETA DE

LA VÁLVULA

DE AIRE EN

POSICIÓN SOBRE

LA TA P A

FIGURA 1

PREINSTALACIÓN

PASOS Y DECISIONES IMPORTANTES QUE

SE REQUIEREN TOMAR ANTES DE LA

INSTALACIÓN

ESTE PRODUCTO DEBE SER INSTALADO Y MANTENIDO

j

POR UN PROFESIONAL CERTIFICADO. ADEMÁS DE LAS

INSTRUCCIONES CONTENIDAS EN ESTE MANUAL, CUMPLA CON

TODOS LOS CÓDIGOS LOCALES Y ESTATALES APLICABLES

O, SI NO LOS HUBIERA, CON LAS EDICIONES ACTUALES DEL

CÓDIGO NACIONAL DE INSTALACIONES SANITARIAS Y EL

CÓDIGO NACIONAL ELÉCTRICO.

BANDEJA RECOLECTORA Y DRENAJE: Para evitar daños por

j

fugas y/o inundación, instale una bandeja recolectora conectada a un

drenaje que funcione adecuadamente y que se mantenga sin obstrucciones en todo momento.

PRESIONES MÁXIMAS DE

Todos los tanques hidroneumáticos son probados a una presión manométrica de

100 lppc (7 Kg/cm2), que es la presión máxima de operación para la línea del tanque

hidroneumático.

OPERACIÓN

5. INSTRUCCIONES DE INSTALACIÓN

4. LISTA DE VERIFICACIÓN DE

COMPONENTES Y ACCESORIOS

REQUERIDOS

MODELOS VERTICALES

j 1. INTERRUPTOR DE

PRESIÓN

j 5. VÁLVULA DE DRENAJE

j 6. MANÓMETRO

j 2. VÁLVULA DE ALIVIO

j 7. CONEXIÓN EN T PARA

j 3. UNA UNIÓN

EL TANQUE

j 4. UNA VÁLVULA DE

CIERRE

SE RECOMIENDA LA INSTALACIÓN

DE UNA VÁLVULA DE ALIVIO

Se recomienda la instalación de una válvula de alivio ajustada para abrirse cuando

haya presiones excesivas [presión manométrica de 75 lppc (5.25 Kg/cm2) o más].

Esto protegerá a su tanque hidroneumático y al resto de los componentes del

sistema en caso de que el interruptor de presión falle y no pare la bomba. La válvula

de alivio debería instalarse en la conexión de su tanque hidroneumático con las

tuberías del sistema, y deberá tener una descarga equivalente a la capacidad de la

bomba a una presión de 75 lppc (5.25 Kg/cm2).

Ubicación

Ubicación apropiada del tanque hidroneumático

El tanque hidroneumático deberá instalarse lo más cerca posible al

interruptor de presión. Con esto se reducirán los efectos adversos

provocados por las pérdidas por fricción y por el rebote del interruptor

de presión, así como por la diferencia de elevación entre el tanque

hidroneumático y el interruptor.

¡PELIGRO! RIESGO DE EXPLOSIÓN. SI

ESTADO EN SERVICIO, ES NECESARIO SUBIR SU PRESIÓN DEBIDO A UN

CAMBIO REQUERIDO EN EL AJUSTE DEL INTERRUPTOR DE PRESIÓN, EL

NO SEGUIR LAS INSTRUCCIONES SIGUIENTES PUEDE PROVOCAR UNA

RUPTURA O EXPLOSIÓN, POSIBLEMENTE CAUSANDO LESIONES GRAVES

O FATALES, Y/O DAÑOS MATERIALES.

• NO AJUSTE O AUMENTE LA PRESIÓN SI HA HABIDO PÉRDIDA DE AIRE.

• NO AJUSTE LA PRESIÓN DE PRECARGA SI SE OBSERVA CORROSIÓN EN

EL EXTERIOR.

• NO AJUSTE LA PRESIÓN DE PRECARGA SI HUBO ALGUNA REDUCCIÓN

EN EL CICLO DE OPERACIÓN DE LA BOMBA O EN LA PRESIÓN DE

PRECARGA, COMPARADA CON SU VALOR INICIAL. ESTO SE DEBE A

QUE LA REDUCCIÓN DEL CICLO DE OPERACIÓN DE LA BOMBA PUEDE

SER CAUSADA POR UNA PÉRDIDA DE PRESIÓN DE AIRE DEL TANQUE,

LO QUE A SU VEZ, PUEDE SER UN SÍNTOMA DE CORROSIÓN INTERNA,

POR LO QUE CUALQUIER REPRESURIZACIÓN O PRESIÓN ADICIONAL

PODRÍA PRODUCIR UNA RUPTURA O EXPLOSIÓN.

DESPUÉS DE QUE EL WELL-X-TROL HA

Ajuste de la precarga

Antes de la instalación

Todos los tanques hidroneumáticos salen de fábrica con una presión manométrica

de precarga estándar de 38 lppc (2.7 Kg/cm2).

Paso 1. Quite la tapa de protección de la válvula de aire.

Paso 2. Verifique la presión de precarga (la presión debe

Paso 3. Libere o agregue aire, según sea necesario, para

Paso 4. Vuelva a colocar la tapa de protección de la vál-

ser +/- 10% del valor de fábrica).

que la presión manométrica de precarga sea 2

lppc (0.14 Kg/cm2) menor que el ajuste del interruptor de presión para el arranque de la bomba.

(Ejemplo, si se tiene un tanque hidroneumático

con una presión manométrica de precarga de 38

lppc (2.7 Kg/cm2) y el interruptor está ajustado a

una presión manométrica entre 30 y 50 lppc (2.1

y 3.5 Kg/cm2), reduzca la precarga de su tanque

hidroneumático de 38 lppc (2.7 Kg/cm2) a 28 lppc

(2 Kg/cm2).

vula de aire. Separe el reverso de la etiqueta y

péguela en dicha tapa

Peligro de e x p l osión. Si no

se siguen estas instrucciones,

puede suceder una ruptura o explosión que puede causar

lesiones graves o fatales, inundación, y/o daños

materiales.

Conexión del sistema

1. Coloque su tanque hidroneumático en su lugar definitivo.

2. Nivélelo según sea necesario.

3. Para eliminar las pérdidas por fricción, no coloque ninguna

reducción en la tubería entre la bomba y el tanque hidroneumático.

Puesta en marcha

Muchas veces el punto de operación del interruptor de presión será

diferente de la gama de presiones indicada. Estas variaciones pueden

causar una demora momentánea en el suministro de agua, ya que el

interruptor de presión no está “sintonizado con la presión de precarga del

tanque hidroneumático”.

1. Llene el sistema y el tanque hidroneumático hasta que la bomba se

detenga.

2. Abra uno o varios grifos para drenar el tanque hidroneumático.

3. Si hubiere alguna pausa momentánea en el flujo de agua entre el

instante en que se vacíe el WELL-X-TROL y el momento en que se

ponga en marcha la bomba, ajuste ligeramente el punto de arranque

de la bomba en sentido horario (vea la figura 2).

4. Cierre los accesorios y vuelva a llenar el tanque hidroneumático

hasta que la bomba se pare. Verifique el tiempo que hace falta para

llenarlo.

5. Abra los accesorios y fíjese si se eliminó la pausa en el flujo de

agua. Si no fuese así, siga ajustando el interruptor de presión.

Procedimientos de ajuste fino

FIGURA 2

Ajuste de la presión: para

aumentar la presión de parada

de la bomba gírelo en sentido

horario; para reducir la presión

de parada de bomba, gírelo en

sentido antihorario.

Ajuste de la precarga después de la

instalación

Paso 1. Drene toda el agua del tanque. Verifique la presión de precarga

Paso 2. Libere o agregue aire, según sea necesario, para que la presión

-10-

en el tanque hidroneumático.

de precarga sea 2 lppc (0.14 Kg/cm2) menor que el ajuste del

interruptor de presión para el arranque de la bomba.

Page 11

38 IPPC

(2.7 Kg/cm2)

AL TANQUE

HIDRONEUMÁTICO

UNIÓN

VÁLVULA

DE CORTE

AL SISTEMA

INTERRUPTOR

DE PRESIÓN

TUBERÍA TÍPICA DEL COLECTOR AL TANQUE

TUBERÍA PRINCIPAL

DRENAJE

MANÓMETRO

INTERRUPTOR

DE PRESIÓN

VÁLVULA

DE ALIVIO

DRENAJE

TUBERÍAS DEL DISTRIBUIDOR

38 IPPC

(2.7 Kg/cm2)

38 IPPC

(2.7 Kg/cm2)

38 IPPC

(2.7 Kg/cm2)

6. MANIFOLD INSTALLATIONS

Minimum Manifold

Pipe Size

1

1 1/4

1 1/2

2

GPM

17

30

40

60

6. INSTALLATIONS À RAMPE DE DISTRIBUTION

Taille min de tuyau

de distribution

1

1 1/4

1 1/2

2

6. INSTALACIÓN DE COLECTORES

Tamaño mínimo

de la

1

1 1/4

1 1/2

2

Gallons/minute

17

30

40

60

Tubería del

distribuidor

17

30

40

60

-11-

Page 12

RECOMMENDED INSTALLATIONS

RELIEF VA L V E

PRESSURE SWITCH

DRAIN

PERMISSIBLE

PRESSURE

SWITCH

LOCATION

DRAIN

UNION

FROM WELL

TO SYSTEM

UNION - 2 REQUIRED

PUMP

PERMISSIBLE

PRESSURE

SWITCH

LOCATION

#161 OR

#165

PUMP

STAND

SHUT-OFF

VA L V E

ÉVACUATION

RACCORD UNION

EN PROVENANCE DU PUITS

EN PROVENANCE DU PUITS VERS LE SYSTEME

RACCORD UNION - 2 NÉCESSAIRES

POMPE

EMPLACEMENT

ACCEPTABLE DU

PRESSOSTAT E

SUPPORT DE POMPE

N˚ 161 OU N˚ 165

SOUPAPE

D'ARRÊT

EMPLACEMENT

ACCEPTABLE DU

PRESSOSTAT E

MANOMÈTRE

PRESSOSTAT

SOUPAPE

DE DÉTENTE

ÉVACUATION

VERS LE

RÉSERVO IR

DE PUITS

POMPE SUBMERSIBLE

Well tank installed on-line with

jet pump.

INSTALLATIONS RECOMMANDÉES

Réservoir de puits installé en

ligne avec pompe à jet.

Shallow well jet pump mounted

on tank.

Pompe à jet pour puits peu

profond, montée sur réservoir.

Well tank installed on-line using

submersible pump.

Réservoir de puits installé en

ligne avec pompe submersible.

Tanque hidroneumático

instalado con una bomba de

INSTALACIONES RECOMENDADAS

Bomba de chorro para pozo de

poca profundidad montada en

chorro en línea.

1400 Division Road, West Warwick, RI 02893 T: 401.884.6300 F: 401.885.2567 www.amtrol.com

el tanque

Tanque hidroneumático

instalado con una bomba

sumergible en línea.

Loading...

Loading...