AMT Datasouth M5DT Plus User Manual

Fastmark M5 Plus Series

Direct Thermal Barcode Printer

User’s Guide

Document #120523 Rev-A

Contents

1. Introduction..............................................................................................1

2. Getting Started.........................................................................................1

2.1 Unpacking and Inspection....................................................................1

2.2 Equipment Checklist ............................................................................1

2.3 Printer Parts.........................................................................................3

2.3.1 Front View .....................................................................................3

2.3.2 Rear View......................................................................................3

3 Setup..........................................................................................................3

3.1 Setting Up the Printer...........................................................................3

3.2 Loading Media Stock............................................................................4

3.3 Peel-Off Module Installation (Option) ...................................................6

3.4 Loading Labels for Peel-off Mode (Option)...........................................9

3.5 External Media Roll Mount Installation (Option).................................10

3.6 Cutter Module Installation (Option).....................................................12

3.7 Loading Media in Cutter Mode...........................................................15

3.8 Internal Ethernet Print Server Module Installation (Option)................16

3.9 Diagnostic Tool ..................................................................................20

3.9.1 Start the Diagnostic Tool..............................................................20

3.9.2 Printer Function (Calibrate, Ethernet setup, RTC setup…)..........21

3.10. Install Memory Card........................................................................21

4. Power on Utilities...................................................................................23

4.1 Gap/Black Mark Sensor Calibration...................................................23

4.2 Gap/Black Mark Calibration, Self-test, Dump Mode...........................24

4.3 Printer Initialization.............................................................................27

4.4 Black Mark Sensor Calibration...........................................................28

4.5 Gap Sensor Calibration......................................................................28

4.6 PAL application program....................................................................28

5. Maintenance...........................................................................................29

5.1 Cleaning.............................................................................................29

6. Troubleshooting.....................................................................................31

6.1 LED Status.........................................................................................31

6.2 Print Quality........................................................................................32

7. LED and Button Operation....................................................................33

7.1 LED....................................................................................................33

7.2 Button Operation................................................................................33

Revise History............................................................................................37

i

1. Introduction

Thank you for purchasing the AMT Datasouth M5 DT PLUS Direct Thermal Bar Code Printer .

Although the printer takes only a small amount of space, it delivers reliable, superior

performance.

This printer provides direct thermal printing at user selectable speeds of: 2.0, 3.0, 4.0 or 5.0

inches per second. It accepts roll feed, die-cut, and fan-fold labels for printing media. All

common bar codes formats are available. Fonts and bar codes can be printed in 4 directions,

8 different alphanumeric bitmap fonts and a build-in true type font capability. You will enjoy

high throughput for printing labels with this printer.

2. Getting Started

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during shipping. Please

carefully inspect the packaging and printer upon opening and prior to installation. Please

retain the packaging materials in case you need to reship the printer.

2.2 Equipment Checklist

Printer

User CD Disk (BarTender Ultralite, Printer User Manuals & Diagnostic Software)

Quick start guide

USB port cable

External universal switching power supply

Power Cord

Label Spindle

Fixing tab x2

1.5” core adapter x2

If any parts are missing, please contact the Customer Service Department of your

purchased reseller or distributor.

1

Optional Configurations

Peel off module assembly.

Guillotine cutter

Full cut:

Paper thickness: 0.06~ 0.19mm, 500,000 cuts

Partial cut:

Paper thickness: 0.06~0.12mm, 500,000 cuts

Paper thickness: 0.19mm 200,000 cuts

Main board integrated with internal Ethernet

Internal Ethernet print server module

Accessories

KP-200

KU-007 plus

External Ethernet print server

External wireless (802.11b/g) print server

External roll mount, media OD. 214 mm (8.4”) with 3” core label spindle

Contact CCD contact scanner

Long range linear image bar code scanner

2

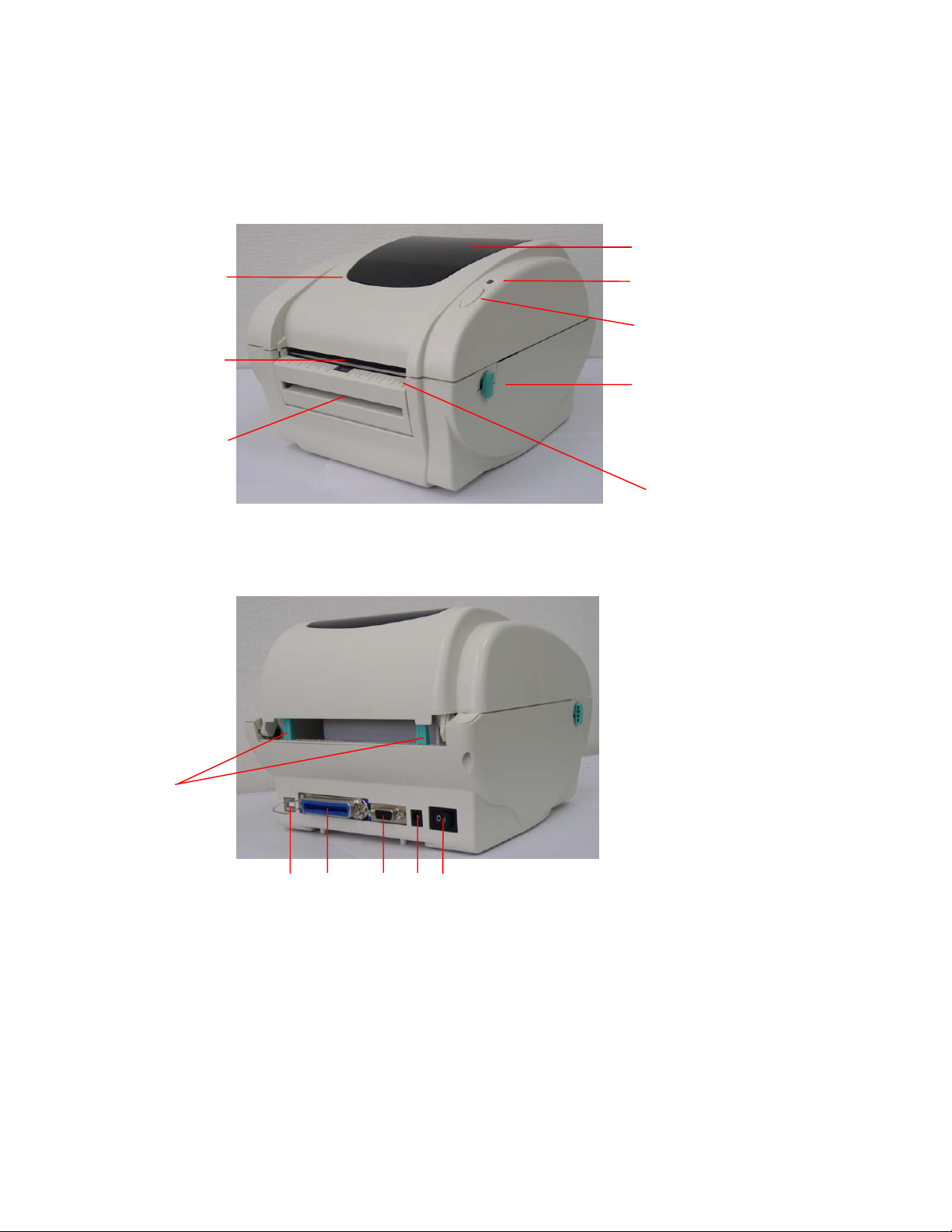

2.3 Printer Parts

2.3.1 Front View

Clear Window

Top Cover

Label Opening

Backing Paper Opening

2.3.2 Rear View

LED Indicator

Feed Button

Top Cover Open Lever

Front Panel

Fig.1 Top Front View

1. USB Interface

2. Centronics Interface

3. RS-232C DB-9 Interface

6

2

1

3

4

5

Fig.2 Rear View

3 Setup

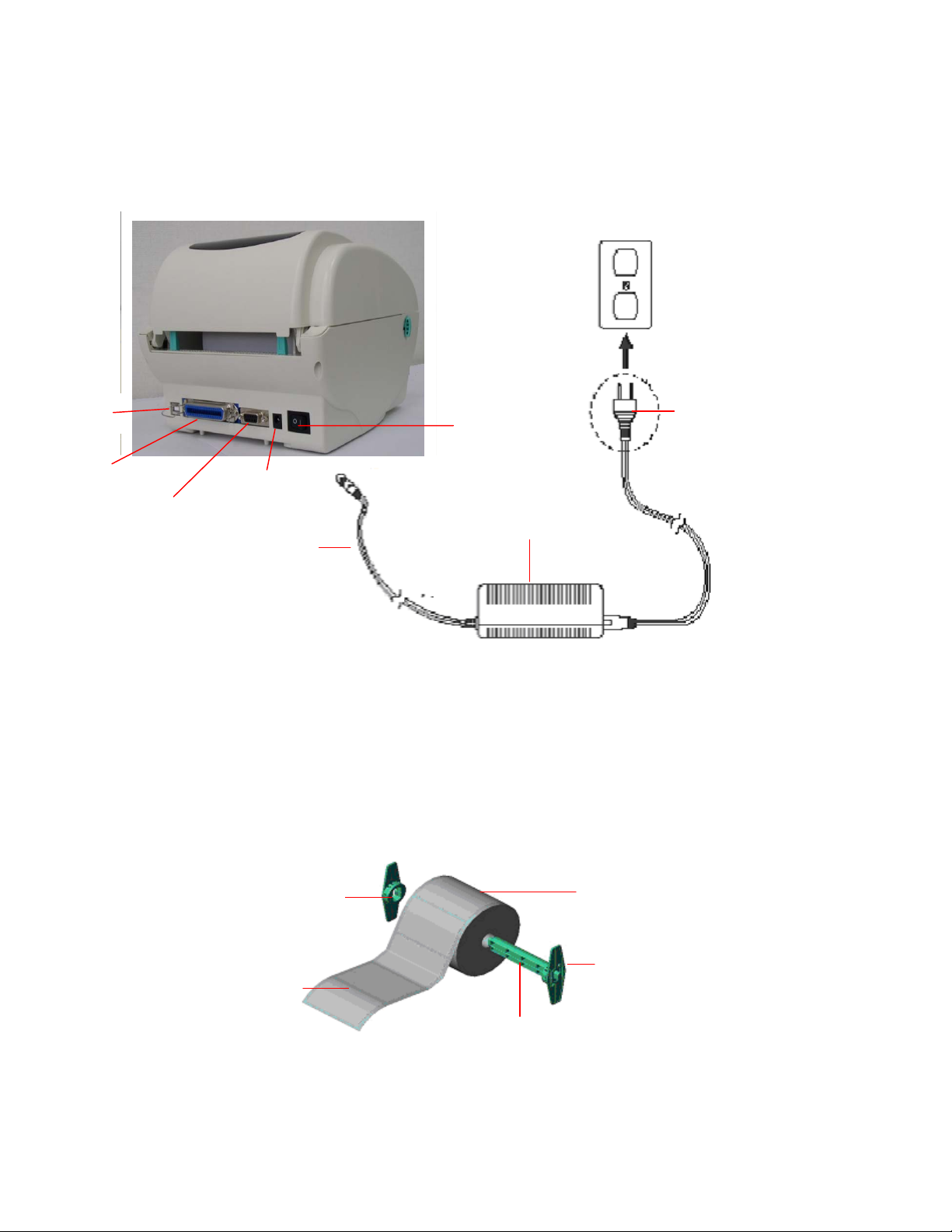

3.1 Setting Up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3

4. Power Jack

5. Power Switch

6. Rear Label Guide

3. Connect the printer to the computer with the Centronics or USB cable.

r

4 Plug the DC power cord into the power jack at the rear of the printer, and then plug

the AC power cord into a properly grounded receptacle.

USB

Centronics

3.2 Loading Media Stock

1. Insert spindle into a media roll (If your media core is 1 inch, remove the 1.5 inch core

RS-232C

Power Jack

Power Cord

Fig. 5 Attach a power supply to a printer

adapter from the fixing tab).

Plug

Power Switch

Power Supply

1.5” Core Adapte

Printing Side Face up

1” Media Spindle

Media Roll

Fixing Tab

Fig 6 Media roll installation (I)

4

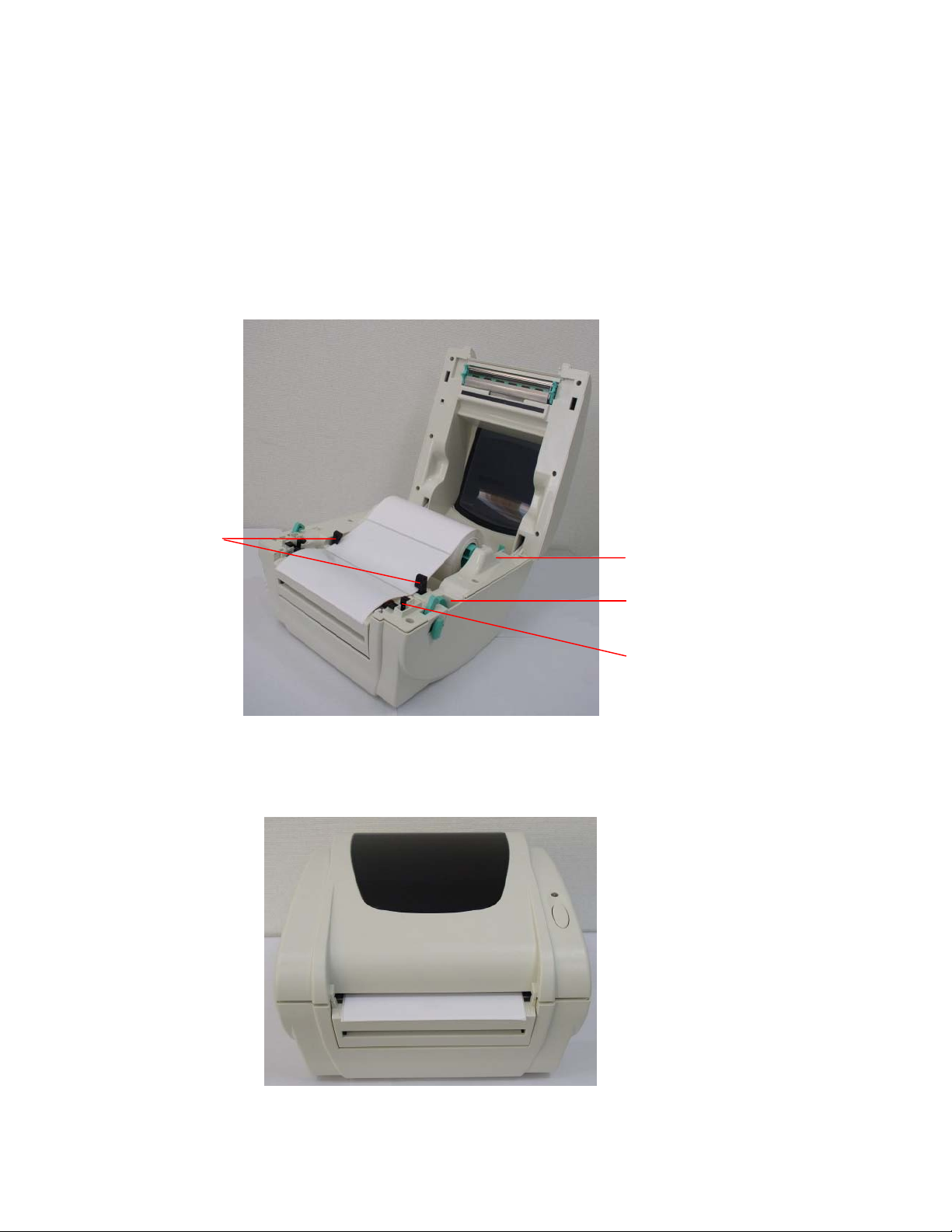

2. Open the printer’s top cover by releasing the green levers located on each side of the

printer and lifting the top cover.

3. Place a roll of media onto the internal Media Spindle.

4. Feed the media (printing side face up) under the Teflon bar and through the support

guides. The media should come to rest outside the printer. Refer to Fig #7.

5. Adjust the black center-biased media guides in or out by turning the adjustment knob so

they are slightly touching the edges of the media/backing.

Media Guide

Media Roll Mount

Adjustment Knob

Platen

Fig. 7 Media roll installation (II)

6. Close the printer top cover slowly and make sure the cover locks securely.

Note: Failure to securely close and lock the cover will result in poor print quality.

Fig. 8 Close the top cover completely

5

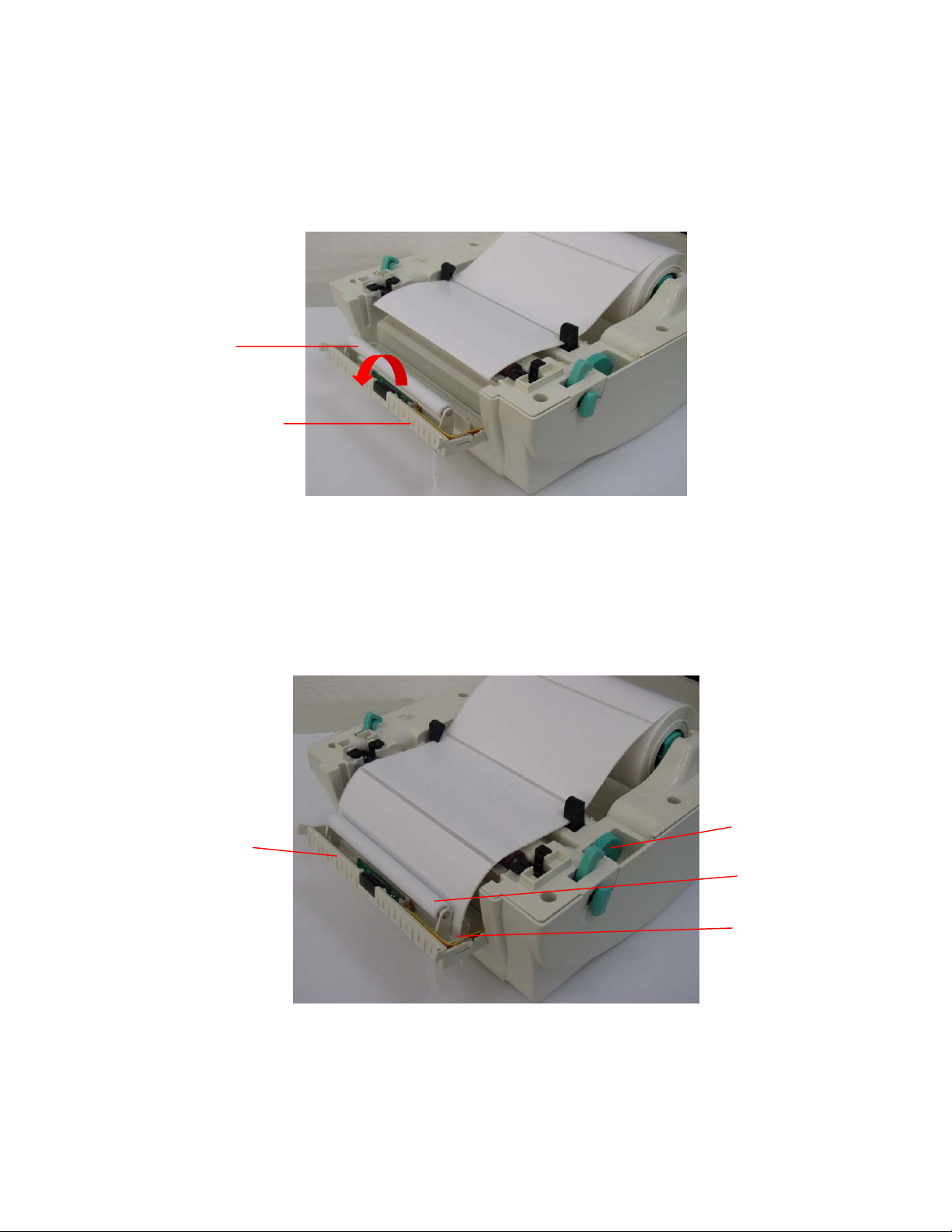

3.3 Peel-Off Module Installation (Option)

1. Open the top cover.

2. Remove the 6 screws in the lower inner cover.

Screws

3. Turn over the printer.

4. Remove two screws located near the top cover hinge.

Remove screw

Screws

Remove screw

6

5. Remove the screw at memory card cover.

6. Separate the top, inner, and the lower cover.

Screw

Lower inner

cover

Lower cover

7. Thread the cable red connector through the inner cover opening located near the front

of the printer. Insert the red cable connector into location JP17 (M5 DT) / JP19 (M5 DT

PLUS) on the main board. Install the peel-off module onto the lower inner cover slot.

7

Peel-off module

assembly

Install (2-places) one

side at a time.

8. Gently push the peel-off panel to lock onto the lower inner cover.

9. Reassemble parts in reverse procedures after installing the module.

8

3.4 Loading Labels for Peel-off Mode (Option)

1. Open the peel-off module by pulling it forward.

Peel-off Roller

Peel-off Panel

Fig. 9 Open the peel-off panel

2. Thread the label, printing side facing up, through the support guides.

3. Thread the label through the liner opening, which is beneath the roller.

4. Adjust the black center-biased media guides by turning the adjustment knob to fit the

edge of the label/backing.

Adjustment Knob

Peel-Off Panel

Roller

Liner Opening

Fig. 10 Loading Labels for peel-off mode

5. Lift the peel-off panel up and back into the closed position.

9

6. Close the top cover.

Fig. 11 Label loaded completely in peel-off mode

3.5 External Media Roll Mount Installation (Option)

1. Attach an external media roll mount on the bottom of the printer.

2. Install a roll of media on the external roll mount.

Fig. 12 External media roll mount installation (I)

Media

External Media

Roll Mount

10

Loading...

Loading...