AMT Datasouth Fastmark 400 User Manual

Fastmark 400 Series

Barcode Label Printer

User’s Guide

Part No. 110021 A

IMPORTANT SAFETY INSTRUCTIONS

AND OTHER NOTICES

This label printer complies with the requirements in Part 15 of FCC rules for a Class B or A

computing device. Operation of this equipment in a residential area may cause unacceptable

interface to radio and TV reception, requiring the operator to take whatever steps are necessary to

correct the interference.

Place the printer on a flat, firm and solid surface.

Do not place the printer near a heat source or near water.

Refer to the specification label on the bottom of this printer and ensure that your power source

exactly meets these requirements.

Do not open the printer during operation to avoid electrical shock.

Do not attempt to disassemble this printer if it malfunctions.

All rights are reserved. No part of this document may be reproduced or issued to third parties in

any form without the permission of AMT Datasouth.

The material in this document is provided for general information and is subject to change

without notice.

TRADEMARK CREDITS

PCL is a registered trademark of Hewlett-Packard Company

Windows, MS-Word and MS-DOS are registered trademarks of Microsoft Corporation

PC is a registered trademark of International Business Machines

Centronics is a registered trademark of Centronics Corporation

CodeSoft is a registered trademark of Techniques Avancees

BarTender is a registered trademark of Seagull Scientific Systems, Inc

LabelView is a registered trademark of Techniques Avancees

LabelMatrix is a registered trademark of StrandWare, Inc

User's Guide 1

CONVENTIONS

Some of the procedures in this guide contain special notices that highlight important information:

Note Indicate information that you should know to help your printer

run properly and efficiently.

Caution Indicate guidelines that, if not followed, can cause damage to

equipment.

Warning Indicate a situation where there may be a danger to you.

The use of the term's right and left assume that you are looking at the front of

the printer.

TECHNICAL SUPPORT

Please contact your local dealer first for technical support. Your dealer is knowledgeable about driver

installation, application software and general printer operation. If you still need factory technical

support after contacting your dealer, you may mail any problems through the E-mail account,

“www.amtdatasouth.com”. You can also get the most updated driver or application from the web site

“http://www.amtdatasouth.com”.

© Copyright 2001 by AMT Datasouth Corporation

First Edition: April 2001

User's Guide 2

Table of Contents

PRODUCT DESCRIPTION ...................................................................................... 6

Unpacking and Inspection.......................................................................................... 8

INSTALLATION AND CONFIGURATION .......................................................... 9

Finding a Location for the Printer............................................................................ 9

Connecting the Power Cord ................................................................................... 10

Connecting the Printer to Your Host...................................................................... 11

Loading the Ribbon................................................................................................ 12

Loading Media ....................................................................................................... 15

Loading Media when Peel and Present Option is Installed ................................... 18

Loading Media When Cutter is Equipped.............................................................. 19

OPERATING INSTRUCTIONS............................................................................. 20

Switch, Indicators and Connections....................................................................... 20

Label Sensor Calibration Procedure ...................................................................... 21

Printer's Internal Self Test Procedure and Configuration Report .......................... 22

Resetting the Printer to Factory Default Settings .................................................. 25

Entering into HEX Print mode............................................................................... 25

COMMAND QUICK REFERENCE ...................................................................... 26

Command Set for the PPLA................................................................................... 26

Command Set for the PPLB................................................................................... 33

PRINTER DRIVER.................................................................................................. 36

Driver Installation .................................................................................................. 36

How to Use the Driver ........................................................................................... 38

TROUBLESHOOTING AND MAINTENANCE.................................................. 43

Troubleshooting ..................................................................................................... 43

Recovery ................................................................................................................ 45

Preventive Maintenance......................................................................................... 46

Appendix A: Printer Specifications......................................................................... 49

Fonts, Bar Codes and Graphics.............................................................................. 50

Optional Accessories.............................................................................................. 51

Appendix B: INTERFACE SPECIFICATIONS ................................................... 52

Introduction............................................................................................................ 52

Serial ...................................................................................................................... 52

Parallel (Centronics) .............................................................................................. 54

Auto Polling ........................................................................................................... 54

Appendix C: ASCII TABLE .................................................................................... 55

Appendix D: FONTS AND BAR CODES FOR THE PPLA Emulation............. 56

User's Guide 3

Internal Fonts ......................................................................................................... 56

Courier Font Set ..................................................................................................... 61

Internal Bar Codes ................................................................................................. 65

Appendix E: FONTS AND BAR CODES FOR PPLB Emulation ...................... 69

Internal Fonts ......................................................................................................... 69

Symbol Set ............................................................................................................. 70

Internal Bar Codes ................................................................................................. 73

User's Guide 4

Table of Figures

Figure 1 - Fastmark 400 series.................................................................................................................7

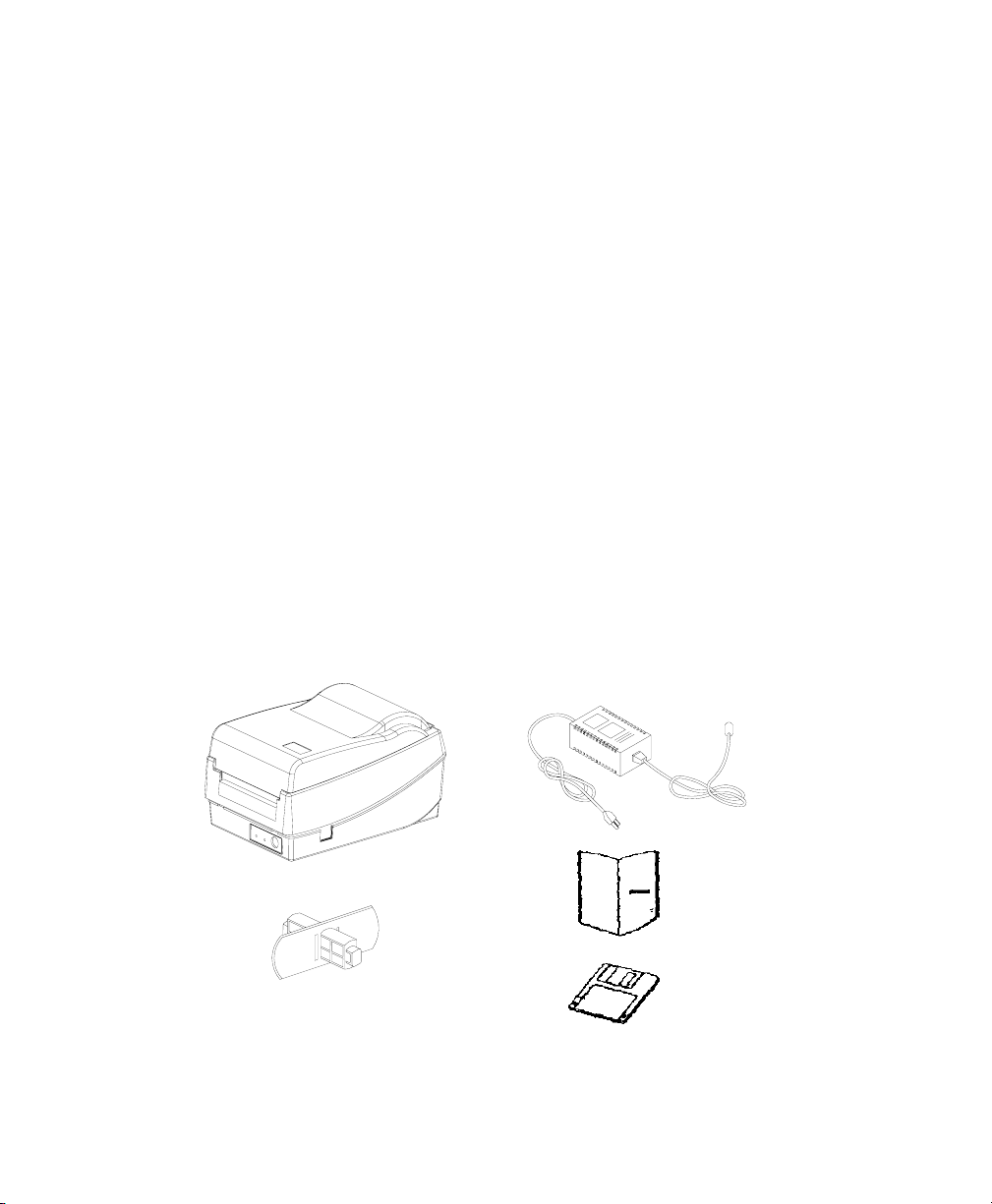

Figure 2 - Included Materials ..................................................................................................................8

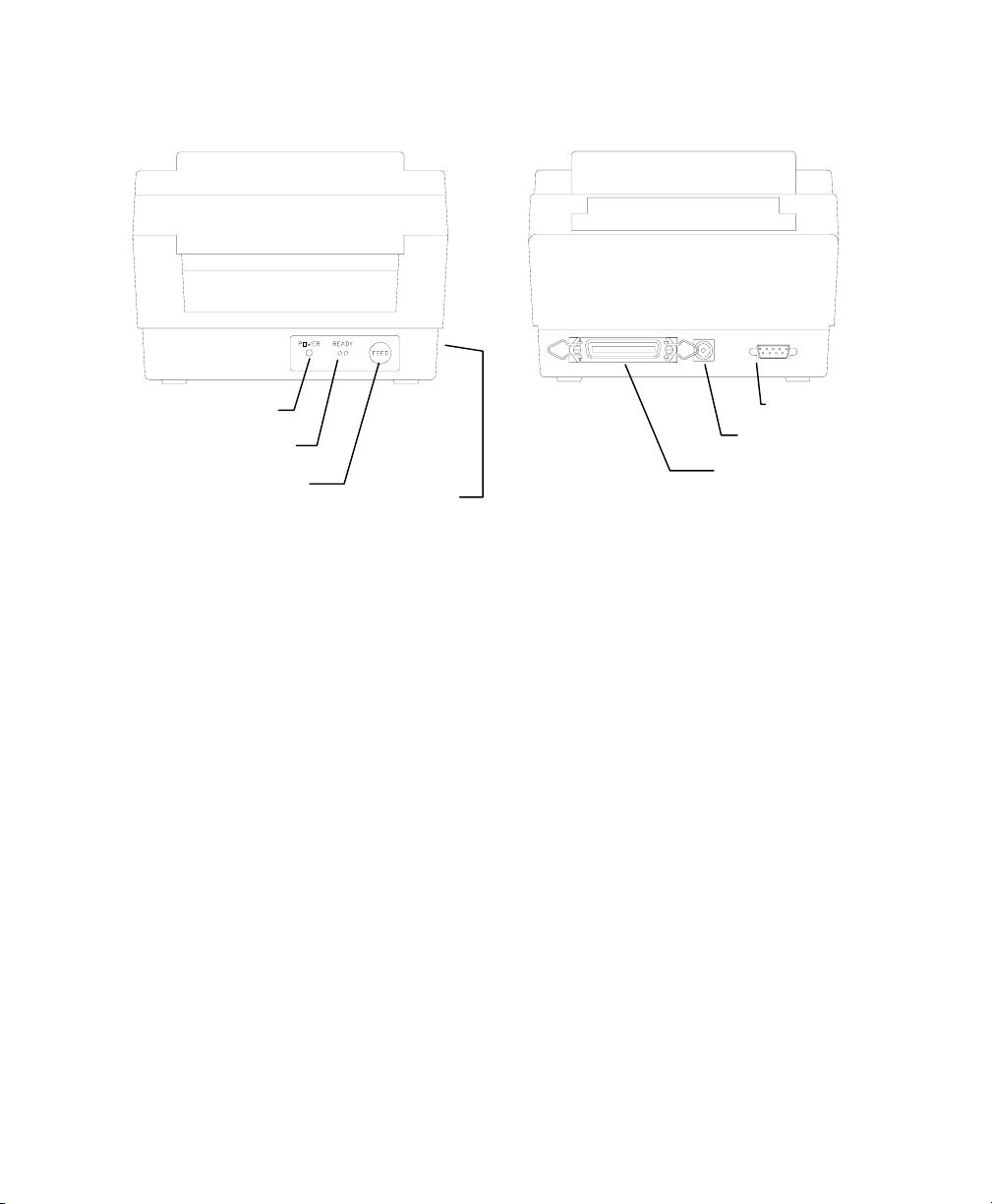

Figure 3 - Switches, Indicators and Connections ....................................................................................9

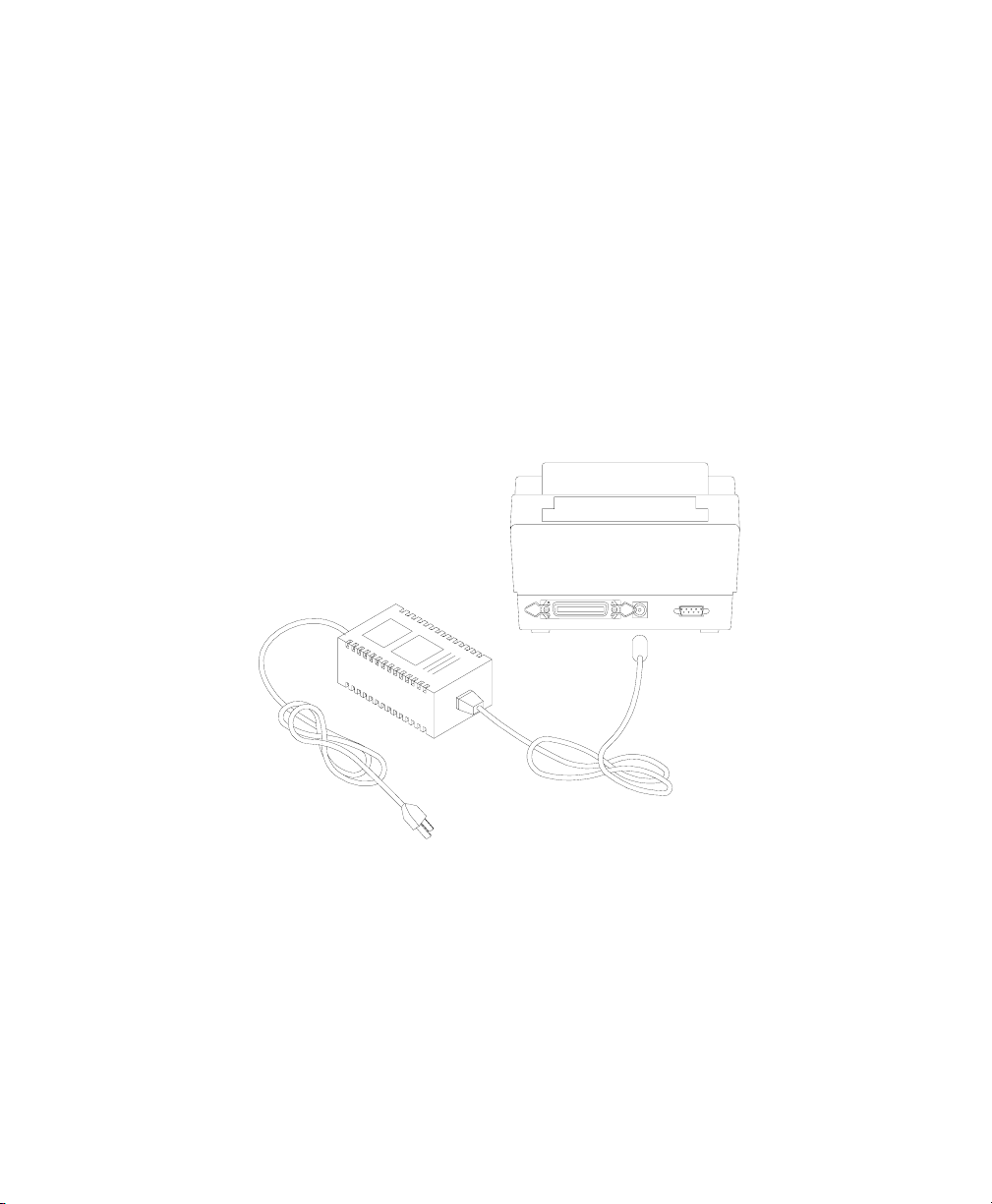

Figure 4 - Power Connection................................................................................................................. 10

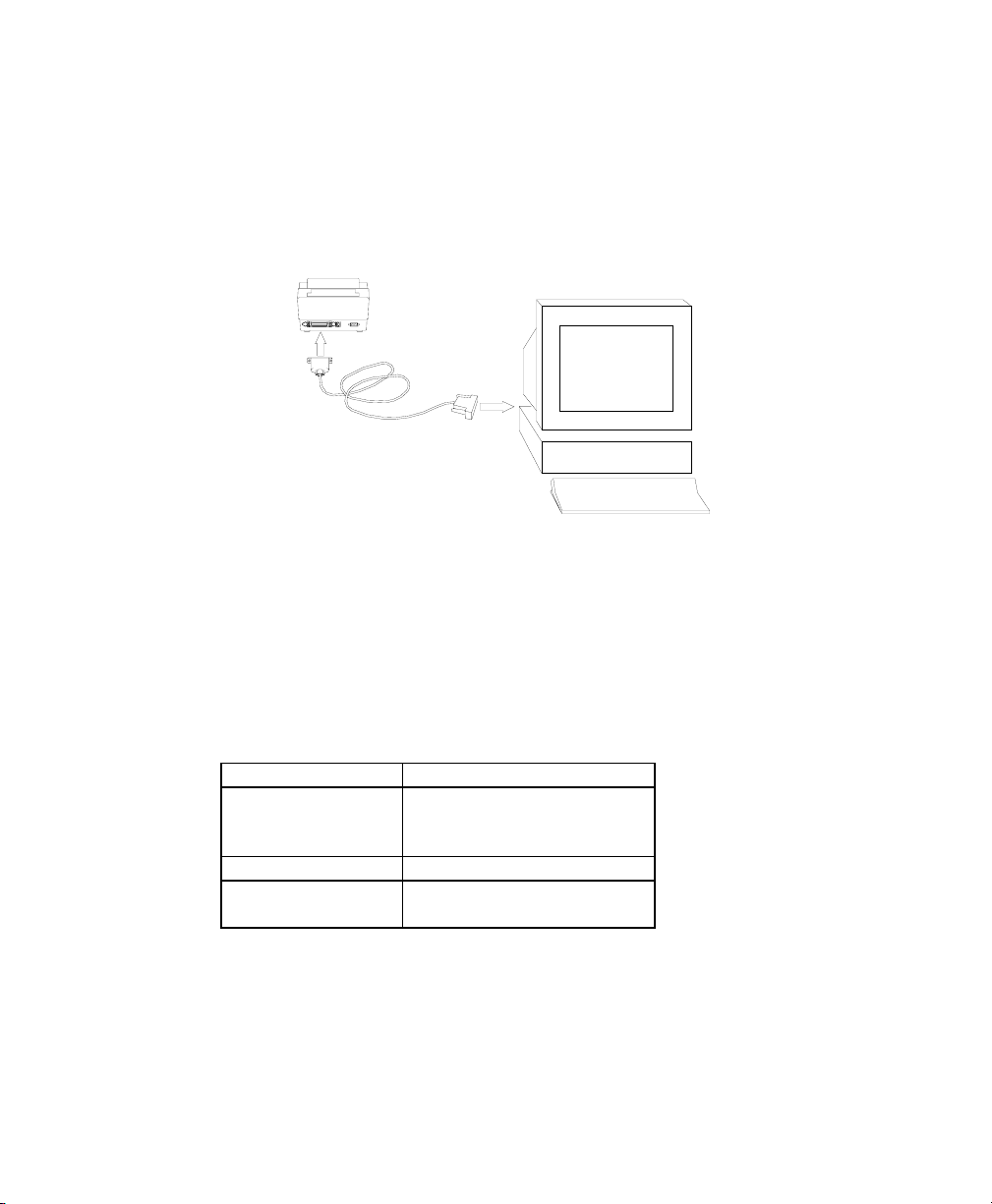

Figure 5 - Printer to Host....................................................................................................................... 11

Figure 6 - Printhead Latches.................................................................................................................. 12

Figure 7 - Ribbon Core Notch Location ................................................................................................ 13

Figure 8 - Ribbon Loading ....................................................................................................................14

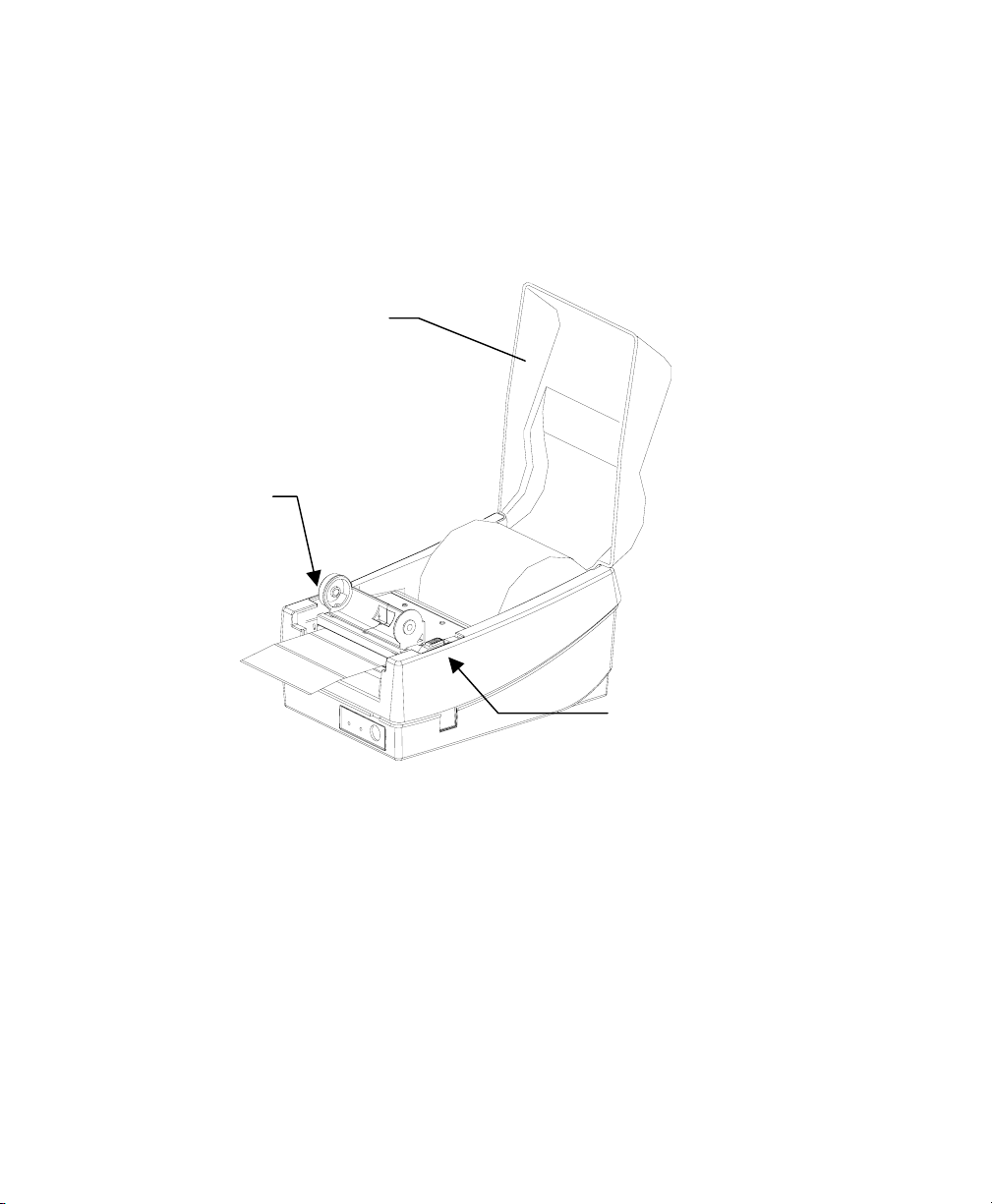

Figure 9 - Open Printhead Module ........................................................................................................ 15

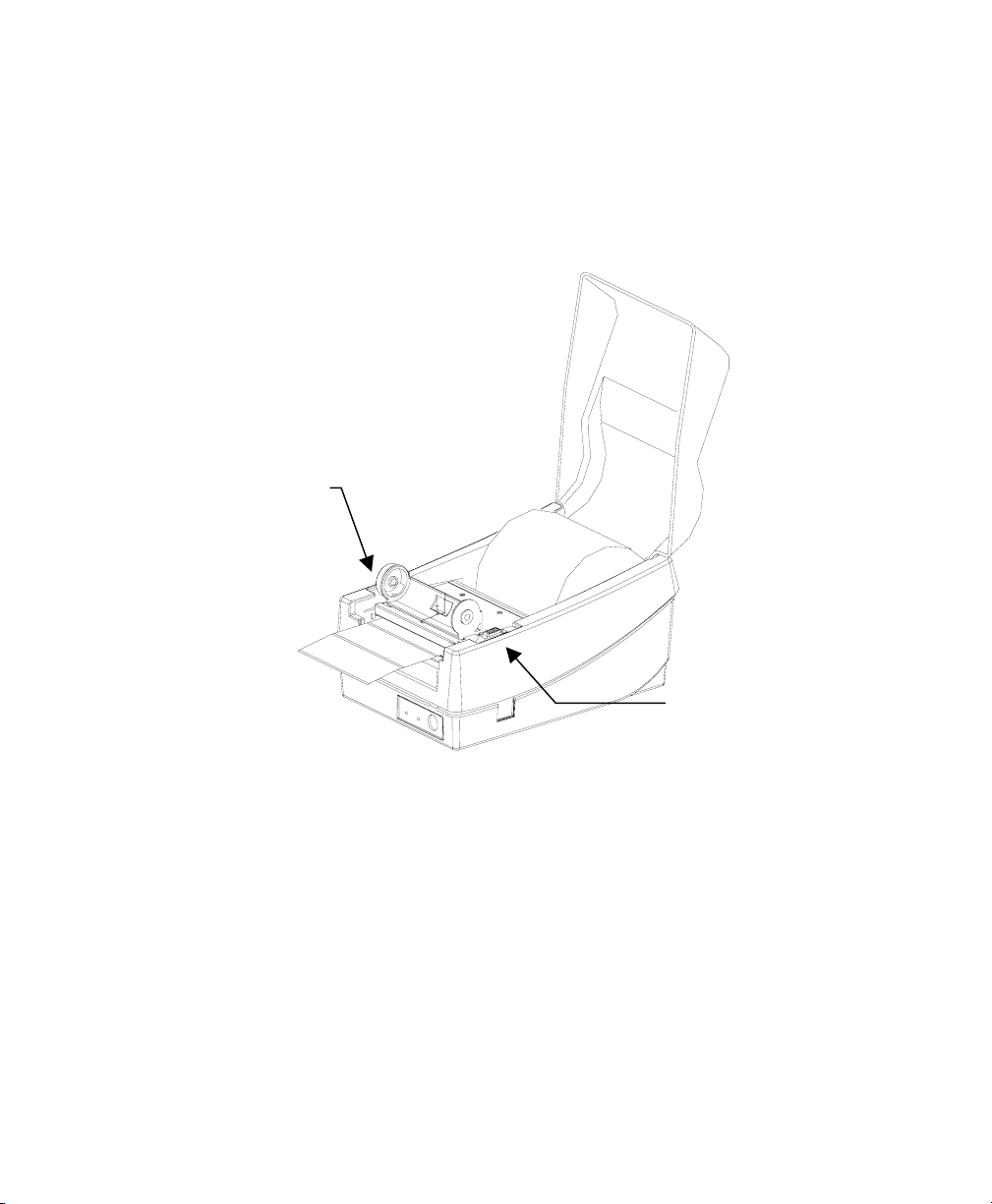

Figure 10 - Media Spindle and Retainer Disk .......................................................................................16

Figure 11 - Loading Media.................................................................................................................... 16

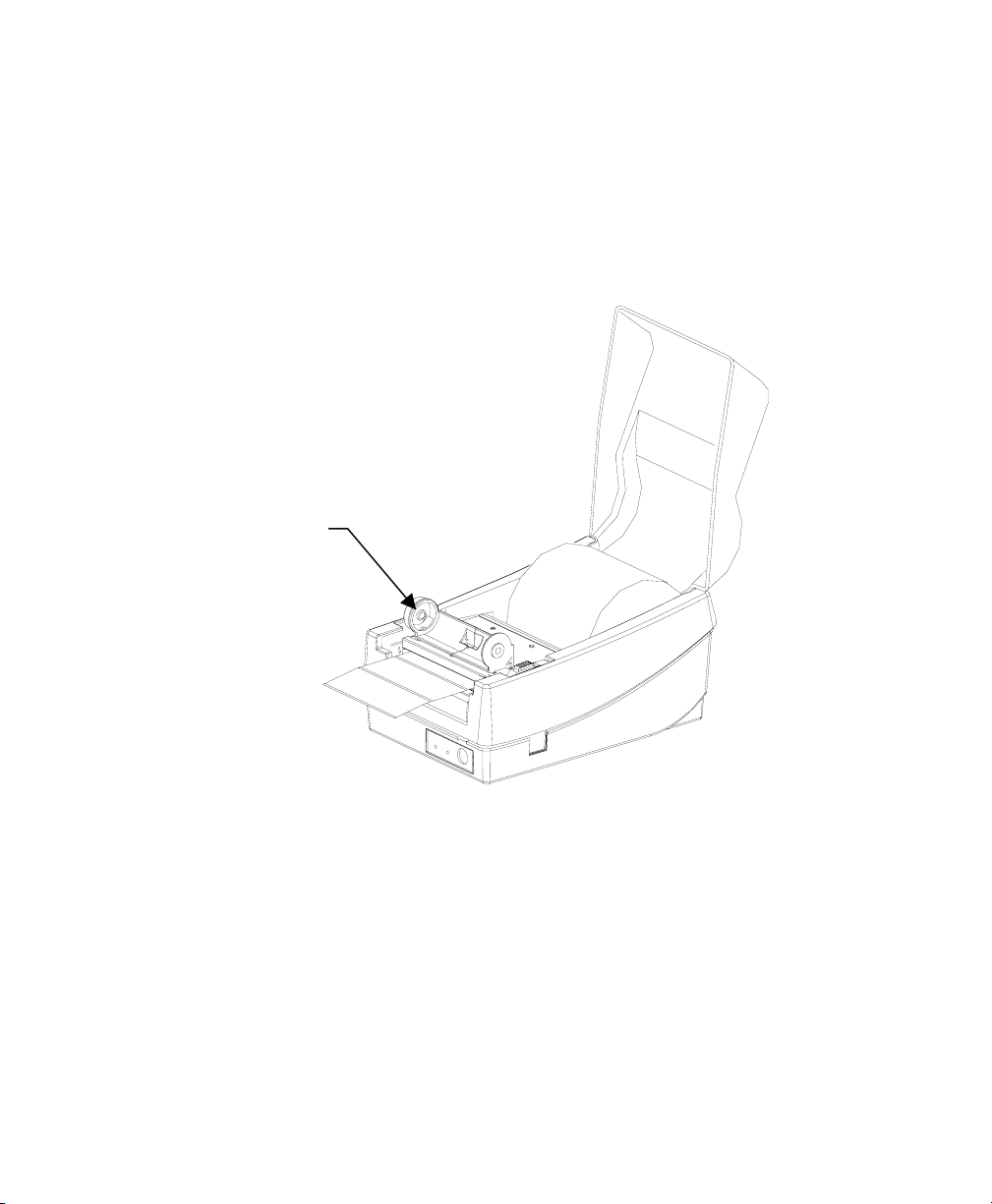

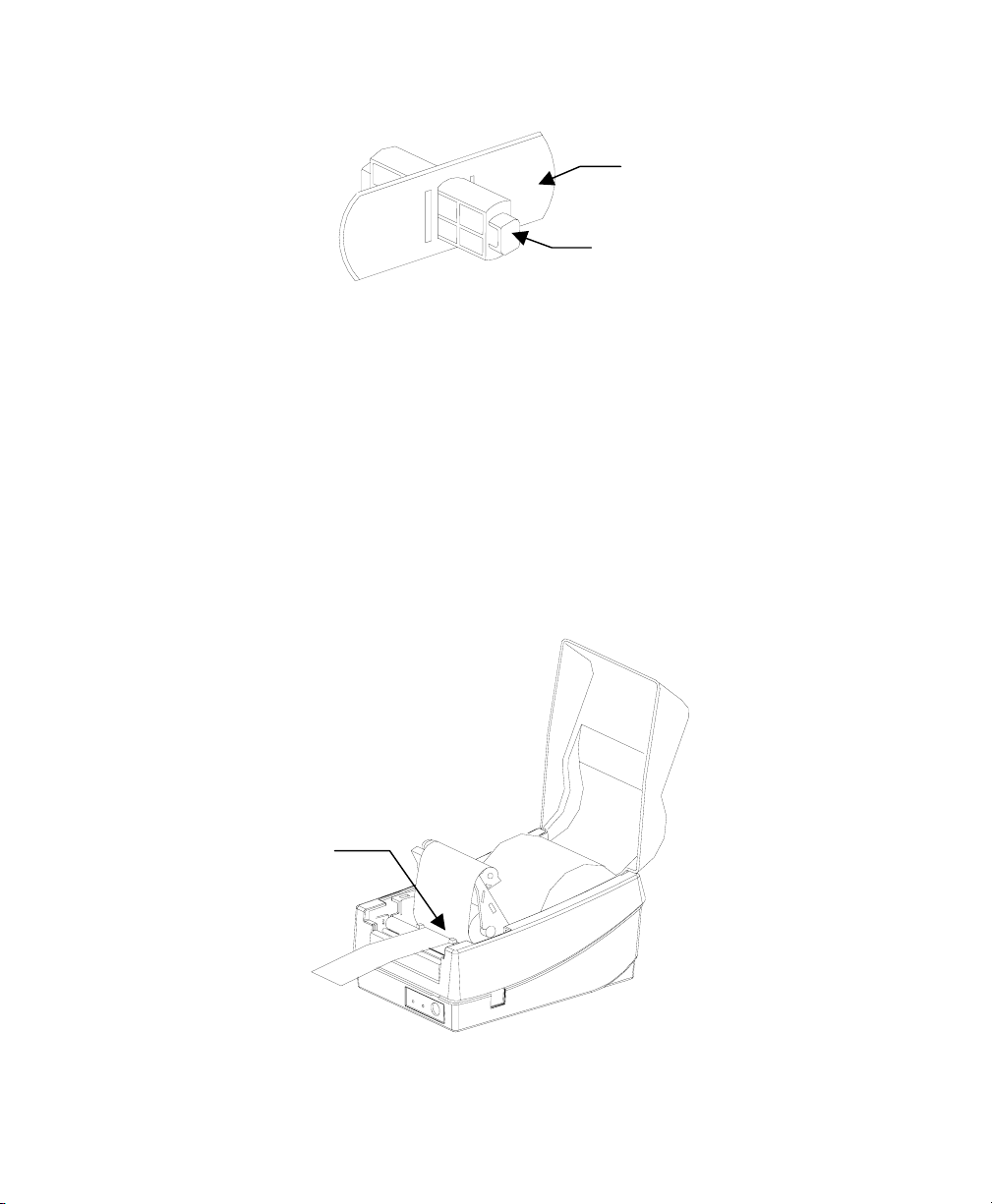

Figure 12 - Loading Media - Peal and Present ...................................................................................... 18

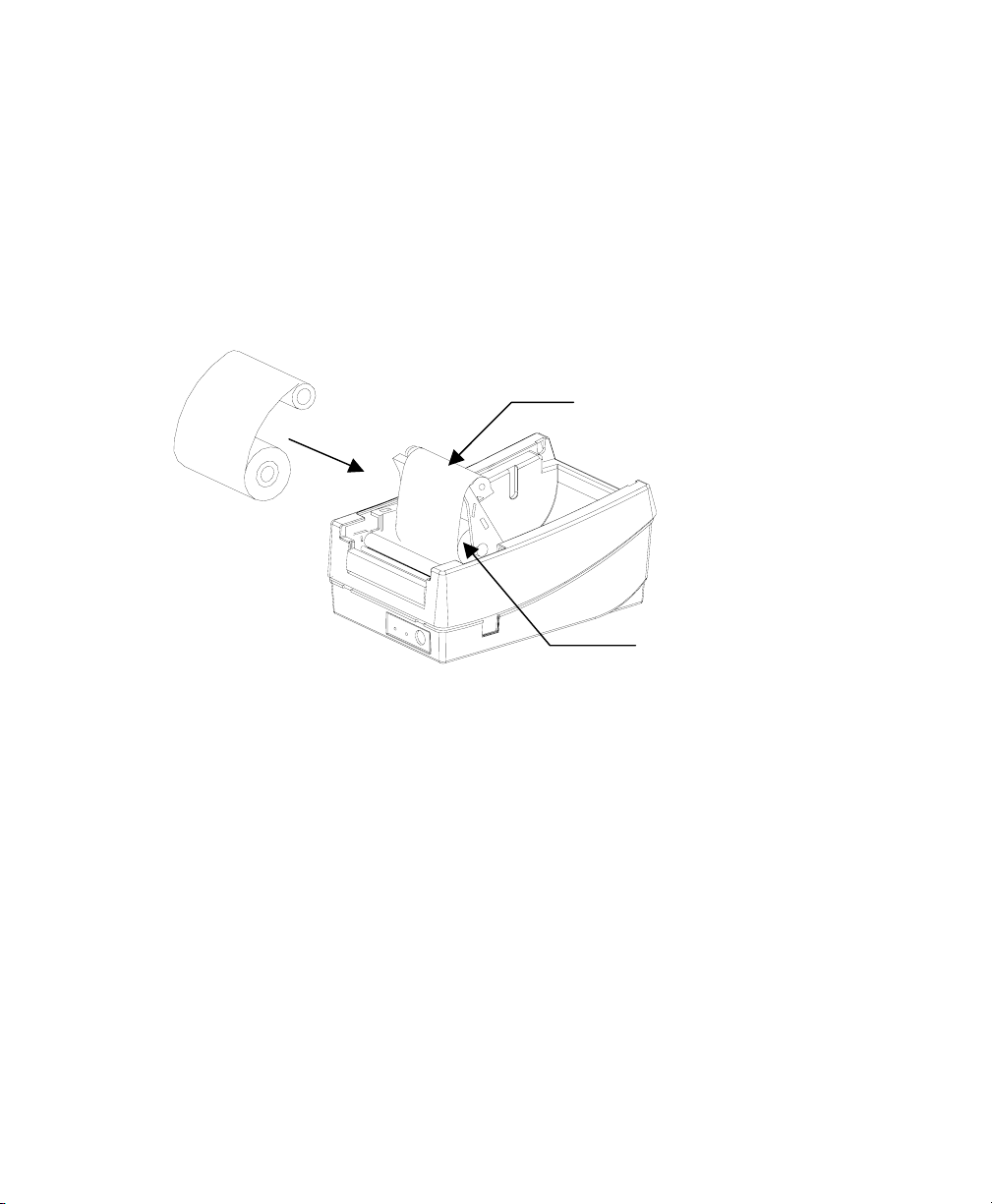

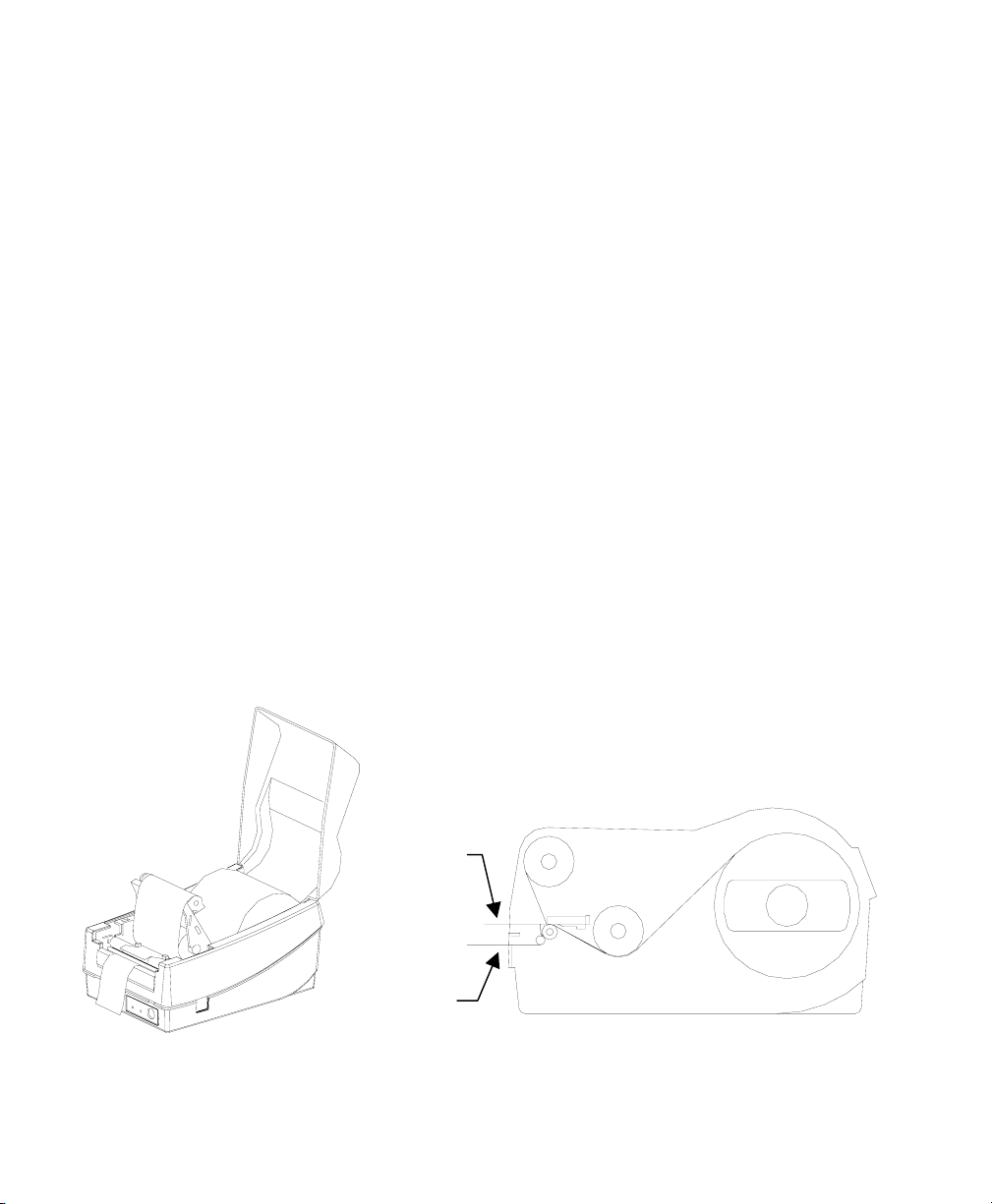

Figure 13 - Loading Media - Cutter....................................................................................................... 19

Figure 14 - Switches and Indicators ......................................................................................................20

Figure 15 - Self Test Sample - PPLA Emulation...................................................................................23

Figure 16 - Self Test Sample - PPLB Emulation...................................................................................24

Figure 17 - Printhead Location.............................................................................................................. 46

Figure 18 - Platen Roller ....................................................................................................................... 47

Figure 19 - Paper Compartment and Paper Sensor................................................................................ 48

User's Guide 5

(this page intentionally left blank)

User's Guide 6

PRODUCT DESCRIPTION

This label printer is a high-performance, low-cost direct thermal/thermal transfer labeling system. Its

user-friendly design and affordable price set a new standard for the Desktop Label Printer in retail,

office, industrial, and many other applications.

The printer is designed with the most efficient memory management technology - True Speed and

prints at a speed of 2 to 3 inches per second. When bundled with its smart printer driver, the user can

easily print out bar codes, texts and graphics from any editing application (e.g. CodeSoft, BarTender)

under Windows 95/98/2000 and NT. All popular bar codes and fonts are resident in the printer

memory to handle versatile applications.

The solidly designed mechanism allows quick and easy media (paper) and ribbon loading. The

optional Peel and Present and Cutter provide the alternatives of fan-fold label and continuous paper

handling.

This printer is a compact, highly integrated, high performance and high resolution on-site labeling

system.

The User’s Guide will help you understand basic operations of the printer such as set-up, installation,

configuration and maintenance. Before reading the manual you should first identify your printer

model. To determine the model and serial number of your printer, look at the label located on the

bottom of the printer.

Figure 1 - Fastmark 400 series

User's Guide 7

UNPACKING and INSPECTION

This printer is packed in a heavyweight carton and custom recyclable foam for environmental

protection. Inspect the shipping carton and contact the carrier directly to report any suspected damage.

Consider the following when unpacking:

♦ The container should stay right side up.

♦ Lift the printer out of the box carefully.

♦ Remove the accessory items.

♦ Set the printer on a solid, flat surface.

♦ Inspect the shipping container and printer for any damage that may have occurred during

shipping.

Verify that you have the following materials when unpacking:

Printer

a.

User’s Guide

b.

Media spindle (with retainer disk)

c.

Power adapter (AC to AC)

d.

Driver diskette for Windows 95/98/NT/2000

e.

Label Design Software.

f.

Sample Media

g.

Sample Ribbon (Thermal Transfer printers only)

h.

Printer

Media Spindle

User's Guide 8

Power Adapter

User's Guide

Diskette & Software

Figure 2 - Included Materials

INSTALLATION AND CONFIGURATION

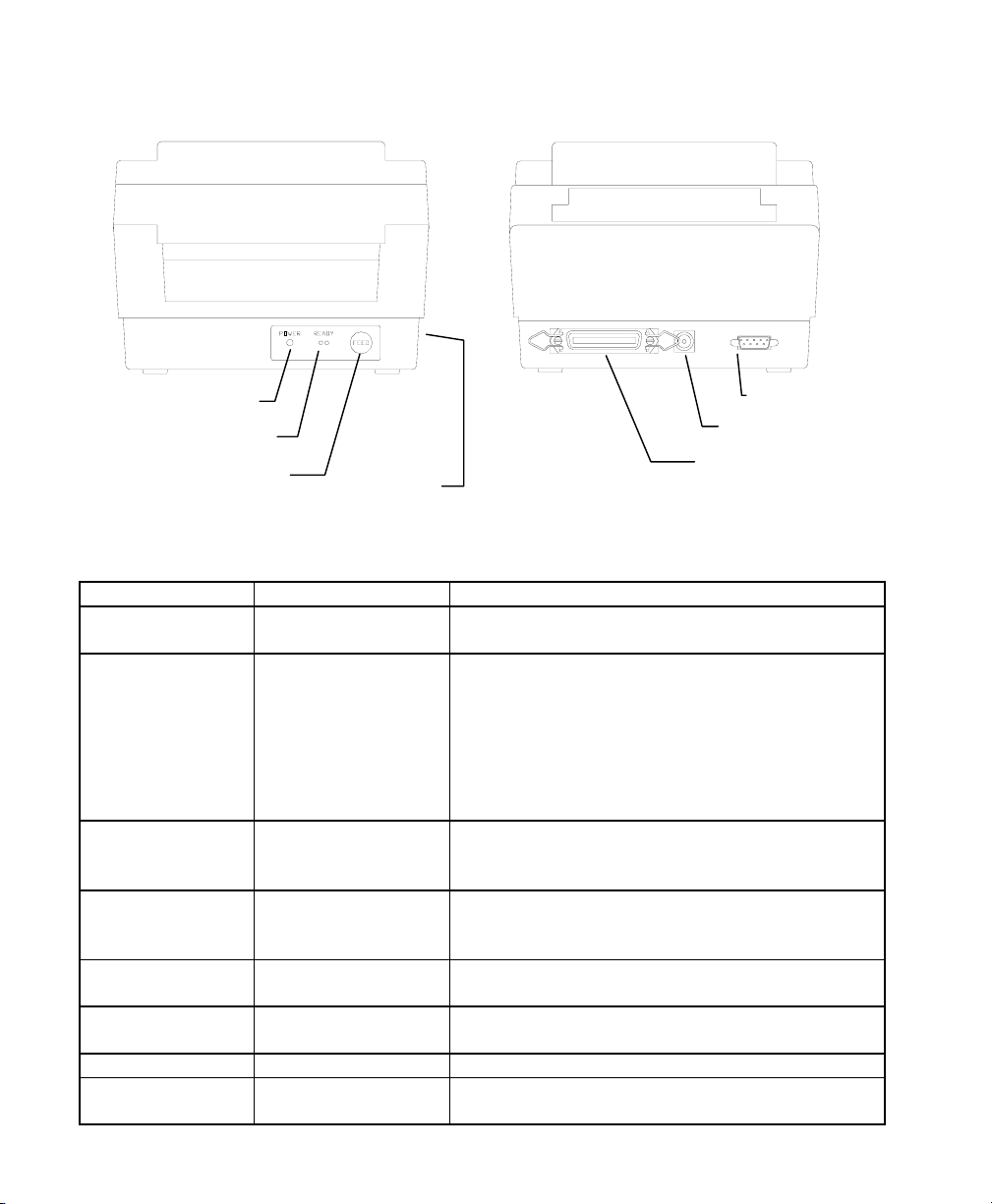

Power LED

Ready LED

Feed button

On Switch

Figure 3 - Switches, Indicators and Connections

Serial Port

Power Jack

Parallel Port

Finding a Location for the Printer

Before setting up the printer you should first consider the following:

♦ Find a solid flat surface with adequate room for the printer. Make sure there is enough room

on the top side for the media and ribbon access.

♦ The location should be near the host or terminal. Consider the distance between host and

printer for the communication cable (serial or parallel cable)

♦ The power adapter should be connected to a properly grounded and isolated electrical outlet.

♦ Away from direct sun, extreme temperatures, humidity dust and debris.

User's Guide 9

Connecting the Power Cord

1. Make sure that the source voltage matches that on the input voltage on the power adapter.

Caution: Incorrect voltage could cause damage to the printer and/or the power

adapter.

2. Make sure that the power switch is set to the Off, ”O”, position.

3. Connect the power supply plug to the power jack on the printer.

Note: When plugging into the power jack, make sure that you avoid the 36 pin

parallel connector.

4. Connect the other end of the power adapter to your AC source.

User's Guide 10

Figure 4 - Power Connection

Connecting the Printer to Your Host

1. You can connect the printer with any standard Centronics Parallel cable to the parallel port of

the host computer.

2. Alternatively you can connect the printer with a serial cable to the RS-232C port of your

computer or terminal. (For PC compatibles, the RS-232C port is COM1, COM2 or COM3.)

Figure 5 - Printer to Host

3. If you use the serial port with your own cable, refer to the Appendix A and check the pin

connection. Be sure that the speed (baud rate) and protocol are consistent between printer

and host.

Caution: Pin 9 on the serial port is directly connected to +5volts DC. It is

suggested that this pin is not connected in your cable, unless required.

The factory default parameters of serial port are:

Speed (baud rate) 9600

Data format 1 start bit,

8 data bits and

1 stop bit.

Parity None

Handshaking

(Flow control)

XON/XOFF as well as

RTS/CTS

Note: It is not necessary to set a switch or send a command for the parallel

and serial port selection. The printer automatically detects the active

port.

Print a SELF-TEST to review serial settings.

User's Guide 11

Loading the Ribbon

p

Thermal Transfer Media only

1. Lift the printer top cover and to the open position.

2. Slide the two printhead latches toward the back of the printer to unlock the printhead module.

Top Cover in

en Position

O

Printhead Latch

Printhead Latch

Figure 6 - Printhead Latches

User's Guide 12

3. Raise the printhead module to the vertical position.

4. Verify that the Supply Core and the Take-up Core have two slots on the left side of the ribbon

core when the ribbon is positioned to go into the printer. These notches will be inserted into

the notches on the Left Ribbon Holders.

Note: The notches are the drive mechanism for the ribbon. If the slots in the core are not

present or if they are in the wrong position, contact your ribbon supplier to obtain a

correct ribbon.

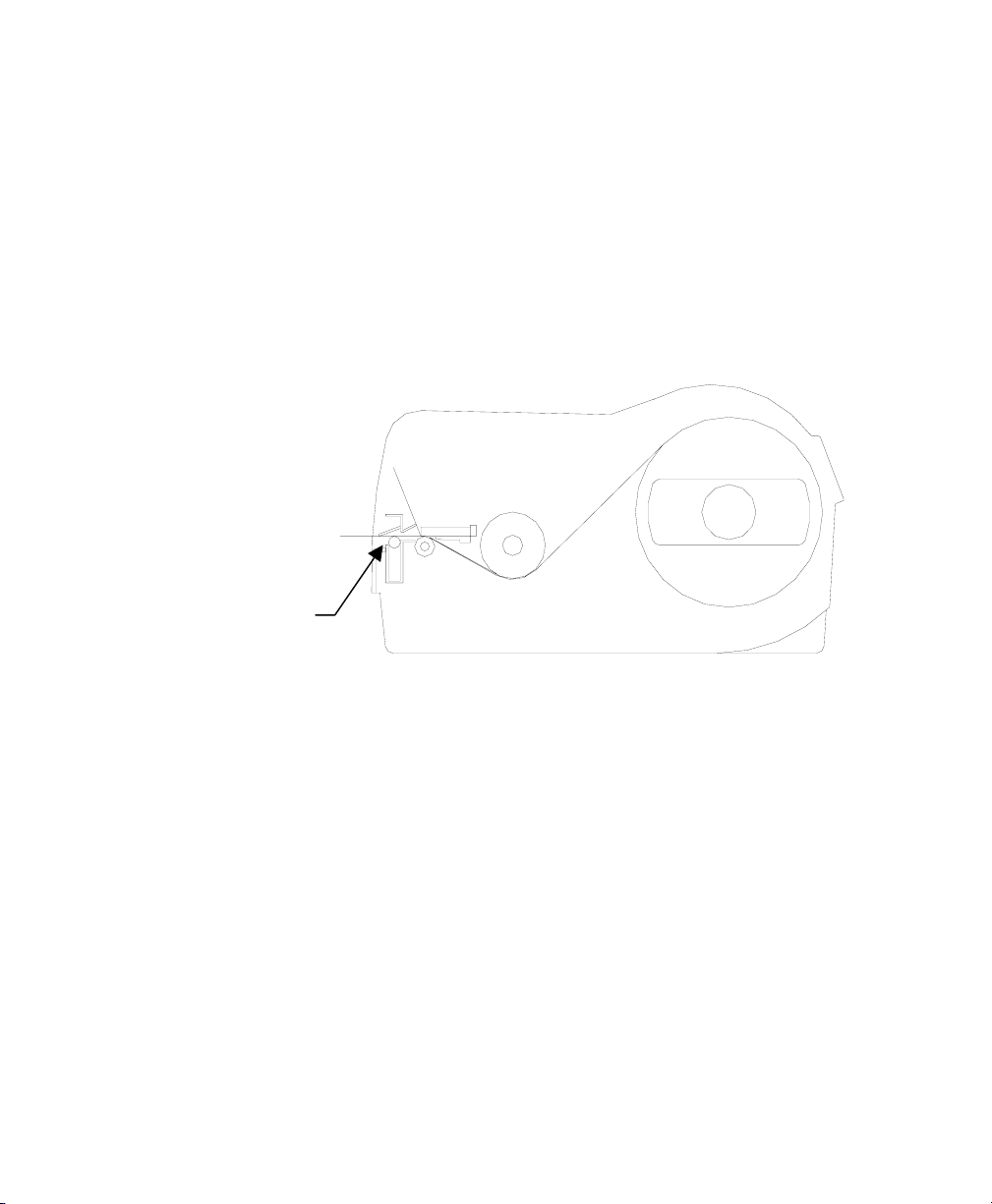

Notch

Figure 7 - Ribbon Core Notch Location

User's Guide 13

5. Unwrap the ribbon roll and place the supply roll into the supply holder of the printhead

module.

Insert the left end of the ribbon supply onto the supply holder spindle first, and then insert the

right end. Make sure that the Ribbon Core Slots match the notches on the Ribbon Drive

Mechanism.

6. Place the Take-up core into the take-up holder of the printhead module.

First insert the left end of the Take-up core into holder spindle, and then insert the other end.

Make sure that the Ribbon Core Slots match the notches on the Ribbon Drive Mechanism.

Take-up Holder

Ribbon

Supply Roll

Supply Holder

Figure 8 - Ribbon Loading

7. Manually rotate the Take-up core until the transfer (typically Black) portion of the ribbon,

from the Supply Holder starts onto the Take-up core.

8. Close and latch the Printhead module.

Note: The printer must be set to the Thermal Transfer mode to ensure the end of ribbon is

detected. This setting may be made using the Windows drivers, Utility Software, or sending

the appropriate printer commands via the host.

User's Guide 14

Loading Media

1. Lift the printer top cover to the open position.

2. Slide the two printhead latches toward the back and unlock the printhead module.

Figure 9 - Open Printhead Module

Printhead Latch

3. Raise the printhead module.

Printhead Latch

User's Guide 15

4. Insert the media spindle into core of the label media (the Retainer Disk should be on the

right).

Retainer Disk

Media Spindle

Figure 10 - Media Spindle and Retainer Disk

5. Insert the spindle and media into the slots in the printer. The media should feed from the top

of the roll.

6. Slide the media to the far left and slide in the guide until it is snug with the media.

7. Move the Right Media guide to the far right of the printer. The Right and Left Media Guides

are located under the printhead module.

Note: The Right and Left Media Guides are 'U' shaped parts and are located at the bottom of

the paper path. Only the right media guide can be moved. The media should be

snugly positioned in the 'U' portion of the guides.

Media guides

User's Guide 16

Figure 11 - Loading Media

8. Pull out 6 inches of media and thread the end of the media between the Right and Left Media

Guides.

9. Slide in the Right Media Guide until it is snug with the media.

Note: If the guides are positioned incorrectly, the media sensor may not sense

the form properly.

If too loose the media may slide out from under them, uncover the

paper out sensor and indicate a false paper out message.

If too tight so that the media may buckle and a paper jam could

occur.

10. Thread the media over the roller until approximately 2 inches of the media shows out of the

printer. (MAKE SURE THAT THE LABELS ARE FACING UP.)

11. Press the printhead module down firmly until it snaps into place.

12. Close the top cover.

13. Turn on the printer.

14. If you are using die-cut media, press the ”FEED” button to advance the first label into the

standby position.

Note: If the labels do not feed correctly, run the Label Sensor Calibration test (see the

section on Label Sensor Calibration).

Note: The first time media is loaded, the label sensor must be calibrated. After this initial

calibration, further calibration is not needed unless the media length, media changes

or irregular feeding occurs. See Label Sensor Calibration for instructions on how to

calibrate the Label sensor.

User's Guide 17

Loading Media when Peel and Present Option is Installed

1. Follow the same procedures in "Loading Media" up to closing of the Printhead Module.

2. Peel off 6 inches of labels from its backing.

3. Thread the label backing over the platen roller, over the Peel and Present Bar then back under

the Peel and Present Bar towards the platen.

4. Turn on the power to “1” position.

5. With the Printhead module still open, press “FEED” button. The printer will advance the

backing. Once the label backing comes out of the front of the printer, turn off the power to

“O” position.

6. Pull down the printhead module down and latch it closed.

7. Close the top cover.

8. Turn on the power to “1” position.

9. Press the Feed key to feed up to the first label in the printer.

Note: The printer must be configured for Peel and Present Mode. This setting may be made in

the windows driver, utility software, label design software or using printer commands

from the host.

User's Guide 18

Label

Backing

Figure 12 - Loading Media - Peal and Present

Loading Media When Cutter is Equipped

1. Follow the same procedure as “Loading Media”.

2. After you thread the media over the platen roller, thread the media through the horizontal gap

at the cutter module.

Note: The printer must be configured for Peel and Present Mode. This setting may be made

in the windows driver, utility software, label design software or using printer

commands from the host.

Cutter

Figure 13 - Loading Media - Cutter

Caution: When removing a label from a printer with the Cutter option make

sure that the cutter is not rotating before removing the label or when

manually opening the printer.

User's Guide 19

OPERATING INSTRUCTIONS

Power LED

Ready LED

Feed button

On Switch

Figure 14 - Switches and Indicators

Serial Port

Power Jack

Parallel Port

Switch, Indicators and Connections

Device name Function Usage

On/Off switch

(power switch)

FEED button

READY indicator

POWER indicator

Power jack Connected to power

RS-232 serial port Communication Connected to host (RS-232 COM port), terminal

Parallel port Communication Connected to host (Centronics )

Top cover Protects the printer

Controls printer

power

Advances the media

stock to first printing

position of next label

Shows the printer

status

Shows the power

and error status

adapter

media and ribbon

On – normal operation

Off – loading paper and ribbon

Press once to advance a label.

Press and Hold while powering on to run Label

Sensor Calibration test.

Continue to press and hold to print out the self-

test pattern and enter into Hex mode.

Press to continue, when READY LED is

blinking.

Green – printer is ready to operate

Blinking – printer is paused; press “FEED”

button to continue operation

Off – printer power off

Green – printer power on

Blinking – error has occurred

Connected with power supply transformer plug

or KDU

Lift and reach the media/ribbon compartment

User's Guide 20

Label Sensor Calibration Procedure

The Label Sensor Calibration procedure allows the printer to calibrate the Label Sensor to the media

type and length being used. The Label Sensor in this procedure looks at the back of the media sensing

for:

Black Bar Media

Gap Media

Or, Continuous Feed Media

1. Power the printer on while pressing the Feed button on the front panel.

2. When the feed motor begins moving, release the “FEED” button.

3. The printer will feed approximately 12 inches of blank media.

4. Once the printer has stopped feeding the user can, open the printhead module and manually

reverse feed the media back to the first label.

5. Press the Feed button again to align the media to the top of the next label.

Notes:

These steps are very important and must always be carried out after the first installation and

each time the media type (color, size, backing, etc) is changed. Failure to run the Label

Sensor Calibration test may result in the label registration errors and label-empty detection

being incorrect.

User's Guide 21

Printer's Internal Self Test Procedure and Configuration Report

1. Make sure that media is installed.

2. Press and hold down the Feed Button while powering on the printer.

3. The printer will begin the Label Sensor Calibration test.

4. Continue to hold the Feed button until the Self Test begins.

5. After feeding 12 inches of blank media, the printer will begin printing out the current

configuration and font list.

6. The printer will print the following information on the installed media:

Firmware version,

ROM checksum,

RS-232 settings,

Thermal transfer/Direct thermal settings,

Hardware configuration and,

Font types.

7. If the installed emulation is PPLB emulation, the printer will enter character Hex Print Mode.

8. To exit the Hex mode, press the Feed button again.

The following pages are examples of the printer's Self Test mode. The samples that you print may be

different. Before requesting service, if possible, please have this page ready.

User's Guide 22

Loading...

Loading...