AMT Datasouth 6000 User Manual

Fastmark 6000 Series

Barcode Label Printer

User’s Guide

Part No. 110621 A

IMPORTANT SAFETY INSTRUCTIONS

AND OTHER NOTICES

n This label printer complies with the requirements in Part 15 of FCC rules for a Class A

computing device. Operation of this equipment in a residential area may cause

unacceptable interface to radio and TV reception, requiring the operator to take whatever

steps are necessary to correct the interference.

n Place the printer on a flat, firm and solid surface.

n Do not place the printer near a heat source or near water.

n Refer to the specification label on the bottom of this printer and ensure that your power

source exactly meets these requirements.

n Do not open the printer during operation to avoid electrical shock.

n Do not attempt to disassemble this printer if it malfunctions.

n All rights are reserved. No part of this document may be reproduced or issued to third

parties in any form without the permission of AMT Datasouth.

n The material in this document is provided for general information and is subject to change

without notice.

TRADEMARK CREDITS

PCL is a registered trademark of Hewlett-Packard Company

Windows, MS-Word and MS-DOS are registered trademarks of Microsoft Corporation

PC is a registered trademark of International Business Machines

Centronics is a registered trademark of Centronics Corporation

CodeSoft is a registered trademark of Techniques Avancees

BarTender is a registered trademark of Seagull Scientific Systems, Inc.

LabelView is a registered trademark of Techniques Avancees

LabelMatrix is a registered trademark of StrandWare, Inc

Fastmark 6000 Series User's Guide 1

CONVENTIONS

Some of the procedures in this guide contain special notices that highlight important

information:

Note Indicate information that you should know to help your

printer run properly and efficiently.

Caution Indicate guidelines that, if not followed, can cause

damage to equipment.

Warning Indicate a situation where there may be a danger to you.

Important Indicate that the associated material needs to be done to

ensure proper printer operation.

The use of the term's right and left assume that you are looking at the

front of the printer.

TECHNICAL SUPPORT

Please contact your local dealer first for technical support. Your dealer is knowledgeable

about driver installation, application software and general printer operation. If you still need

factory technical support after contacting your dealer, you may mail any problems through the

E-mail account, “www.amtdatasouth.com”. You can also get the most updated driver or

application from the web site “http://www.amtdatasouth.com”.

© Copyright 2002 by AMT Datasouth Corporation

First Edition: September 2002

2 User's Guide Fastmark 6000 Series

Table of Contents

PRODUCT DESCRIPTION.......................................................................................7

OVERVIEW ................................................................................................................8

UNPACKING AND INSPECTION............................................................................9

INSTALLATION AND CONFIGURATION..........................................................10

Setting up the Printer ................................................................................................ 10

Connecting the Power Cord ..................................................................................... 12

Connecting the Printer to Your Host ......................................................................... 13

Inside the Printer ...................................................................................................... 15

Loading the Ribbon.................................................................................................. 16

Loading Media......................................................................................................... 20

Changing Position of the Media Supply Spindle......................................................... 26

Calibrating Media Sensors........................................................................................ 27

Performing the Self Test............................................................................................ 28

Resetting the Printer to Factory Default Settings ........................................................ 30

PANEL OPERATION...............................................................................................31

Front Panel.............................................................................................................. 31

LCD Display............................................................................................................ 35

Front Panel Set-up Menu ......................................................................................... 37

Procedure to Enter into Set-up Mode....................................................................... 38

Set-up Mode Selection Items ................................................................................... 39

Setting Display Language.......................................................................................... 41

Back Panel............................................................................................................... 42

Back Panel Switches................................................................................................ 44

PS/2 Keyboard I/F .................................................................................................. 46

COMMAND QUICK REFERENCE.......................................................................47

Command Set for PPLA .......................................................................................... 47

PRINTER DRIVER..................................................................................................55

Driver Installation..................................................................................................... 56

How to Use the Driver ............................................................................................. 57

TROUBLESHOOTING AND MAINTENANCE...................................................63

Troubleshooting........................................................................................................ 63

Recovery................................................................................................................. 65

Preventive Maintenance............................................................................................ 66

Fastmark 6000 Series User's Guide 3

Appendix A: Printer Specifications ...........................................................................69

General Specifications .............................................................................................. 69

Fonts, Bar Codes and Graphics................................................................................ 70

Optional Accessories................................................................................................ 70

Appendix B: INTERFACE SPECIFICATIONS......................................................71

Introduction ..............................................................................................................71

Serial....................................................................................................................... 71

Parallel (Centronics)................................................................................................. 74

Auto Polling ............................................................................................................. 74

Appendix C: PRINTER STATUS.............................................................................75

Appendix D: ASCII TABLE......................................................................................76

Appendix E: FONTS AND BAR CODES FOR PPLA............................................77

Internal Fonts........................................................................................................... 77

Courier Font Set ...................................................................................................... 78

Internal Bar Codes................................................................................................... 79

4 User's Guide Fastmark 6000 Series

Table of Figures

Figure 1 - Fastmark 6000 Series Printer..............................................................................7

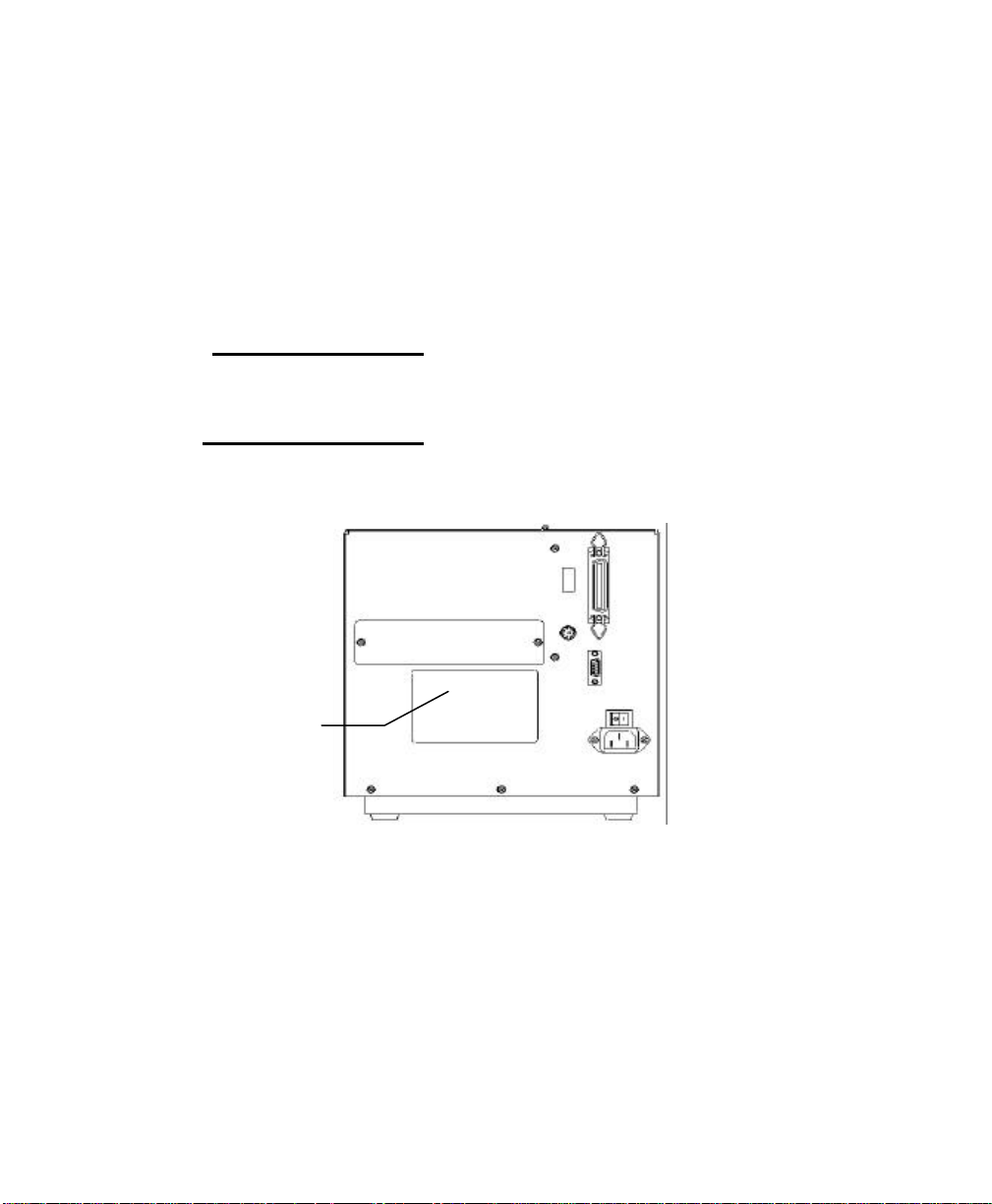

Figure 2 - Model and Serial Number Location .....................................................................8

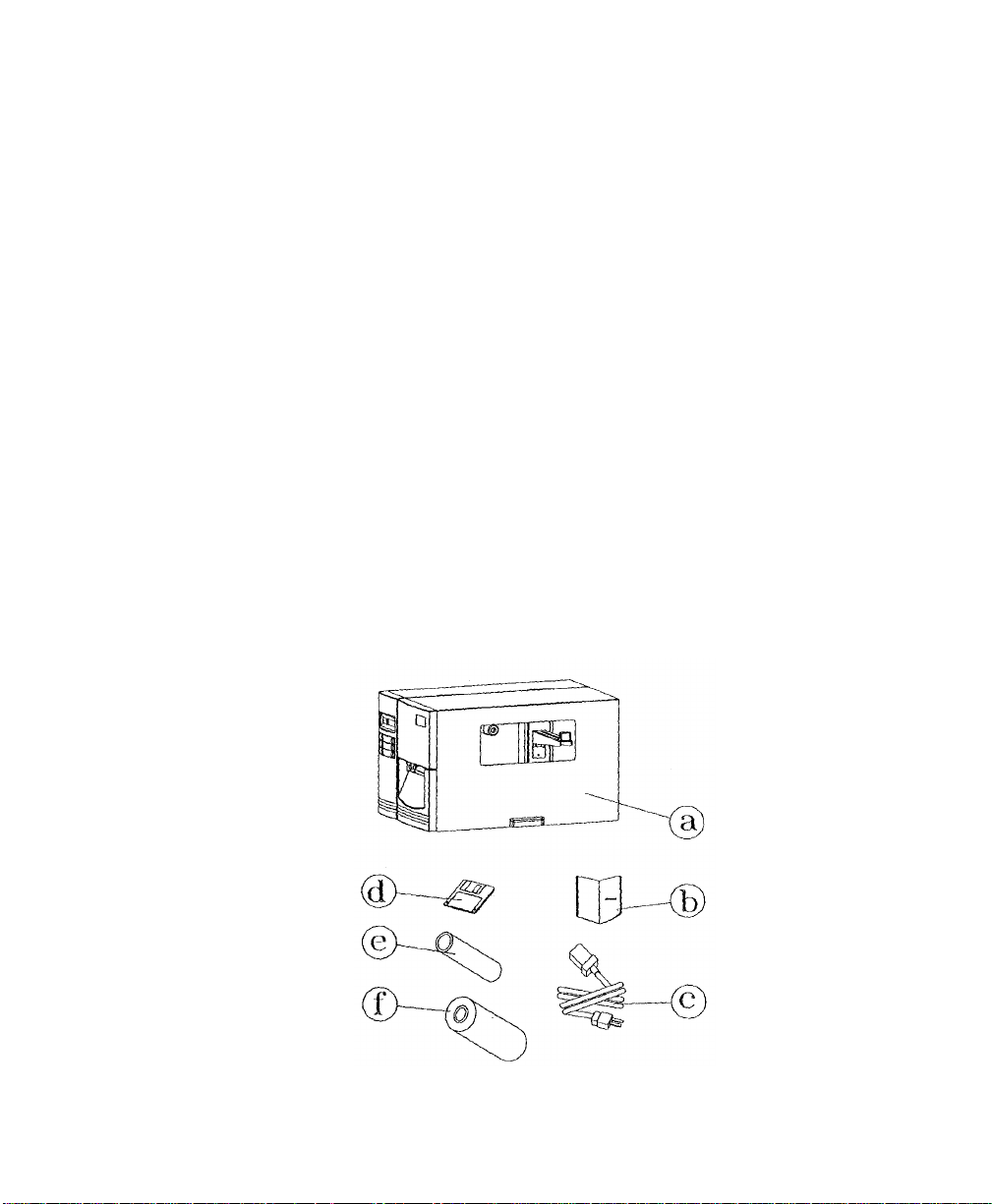

Figure 3 - Shipped with Printer...........................................................................................9

Figure 4 - Front and Side View........................................................................................ 10

Figure 5 - FM 6000 Series Back Panel............................................................................. 11

Figure 6 - Power Cord Connection ...................................................................................12

Figure 7 - Communication Cable ...................................................................................... 13

Figure 8 – Inside Printer ..................................................................................................15

Figure 9 – Printhead Mechanism...................................................................................... 15

Figure 10 - Open Top Access Cover ................................................................................16

Figure 11 - Printhead Latch and Side Access Cover.......................................................... 17

Figure 12 - Ribbon Supply ................................................................................................17

Figure 13 - Ribbon Routing.............................................................................................. 18

Figure 14 – Ribbon Take-up ............................................................................................ 18

Figure 15 - Ribbon Routing.............................................................................................. 19

Figure 16 - Open Top Access Cover ................................................................................20

Figure 17 - Printhead Latch and Side Access Cover.......................................................... 20

Figure 18 - Printhead Latch and Side Access Cover.......................................................... 21

Figure 19 - Outside Media Guide ......................................................................................22

Figure 20 - Media Sensor Adjustment............................................................................... 23

Figure 21 - Media Routing............................................................................................... 25

Figure 22 - Media Supply Spindle Location ....................................................................... 26

Figure 23 - Self Test PPLA .............................................................................................29

Figure 24 - Fastmark 6000 Series Front Panel................................................................... 31

Figure 25 - Entering into Set-up Mode .............................................................................. 38

Figure 26 - Back Panel FM6000 Series ............................................................................ 43

Figure 27 - Printhead (TPH) Maintenance ........................................................................66

Fastmark 6000 Series User's Guide 5

This page is blank

6 User's Guide Fastmark 6000 Series

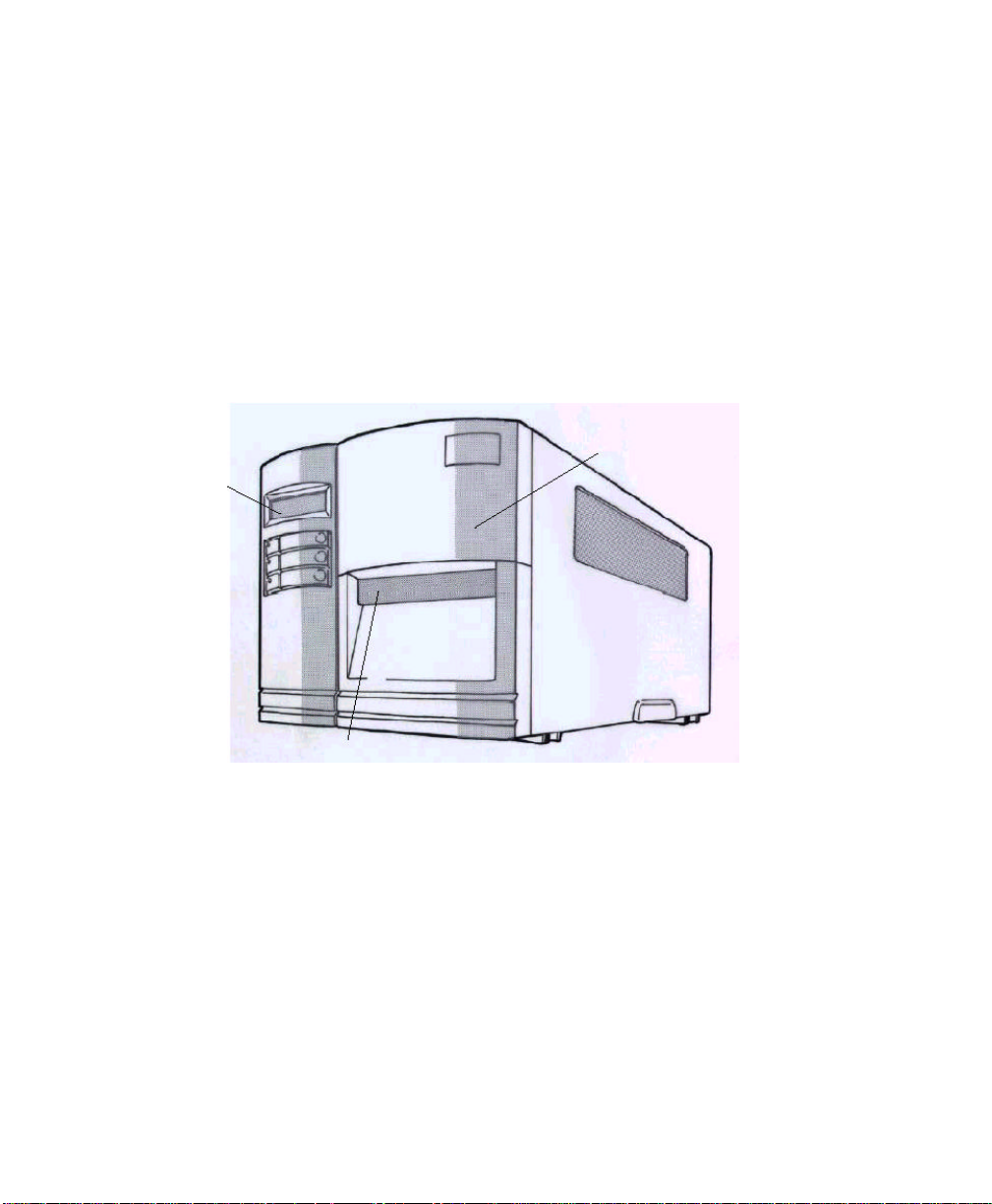

PRODUCT DESCRIPTION

This label printer is a high-performance, low-cost 6-inch wide Direct Thermal/Thermal

Transfer labeling system. Its user-friendly design and affordable price set a new standard for

the Desktop Label Printer in retail, office and industrial applications.

The printer is designed with the most efficient memory management technology - True Speed

and prints at a speed of 2 to 6 inches per second. When bundled with its smart printer driver,

the user can easily print out bar codes, texts and graphics from any editing application which

supports windows drivers under Windows 95/98/2000, and NT. All popular bar codes and

fonts are resident in the printer memory to handle versatile applications.

The solid designed mechanism allows quick and easy media (paper) and ribbon loading.

The User’s Manual will help you understand basic operations of the printer such as set-up,

installation, configuration and maintenance. Before reading the manual you should first

identify your printer model. The printer model name is located on the back of the printer on its

product label.

Figure 1 - Fastmark 6000 Series Printer

Fastmark 6000 Series User's Guide 7

OVERVIEW

The Fastmark FM6000 series is currently comprised of 1 model:

• FM6602

NOTE: The model number is printed on the compliance label attached to the

back of the printer. After un-packing please record the model number

below for reference.

MODEL No:

SERIAL No:

Model No: and

Serial No:

Figure 2 - Model and Serial Number Location

8 User's Guide Fastmark 6000 Series

UNPACKING AND INSPECTION

This section is provided to assist you in taking the printer from the shipping container to the

application environment and ready for use.

1. Remove top foam packing piece.

2. Lift printer straight up out of box carefully with adequate assistance.

3. Remove accessory kit and supplies.

4. Remove printer from plastic bag.

NOTE: Save box and all packing materials for future use, in the event the printer

needs to be shipped.

Verify that the printer box contains the following materials when unpacking:

a. Printer

b. User’s Manual

c. Power cord

d. Diskette(s) or CD for Windows 95/98/2000/NT and Label Design Software

e. Take up Core

f. A ribbon roll and a take-up ribbon core (sample roll).

g. A media roll (not pictured)

Figure 3 - Shipped with Printer

Fastmark 6000 Series User's Guide 9

INSTALLATION AND CONFIGURATION

Setting up the Printer

Before setting up the printer you should first consider the following:

• Flat stable surface with sufficient clearance to allow for interface cables and media

loading.

• Free from excessive direct sunlight, temperature, humidity, dust, dirt, and debris.

• Near a grounded AC power receptacle wired in compliance with local ordinances.

Top Access Door

LCD Display

Front Access Door

Figure 4 - Front and Side View

10 User's Guide Fastmark 6000 Series

PS/2, Keyboard

Serial No.

Interface

External Label

Feed Slot

Switches

Parallel Port

Serial Port

Model No. and

Power

Switch

AC Inlet Receptacle

Figure 5 - FM 6000 Series Back Panel

Fastmark 6000 Series User's Guide 11

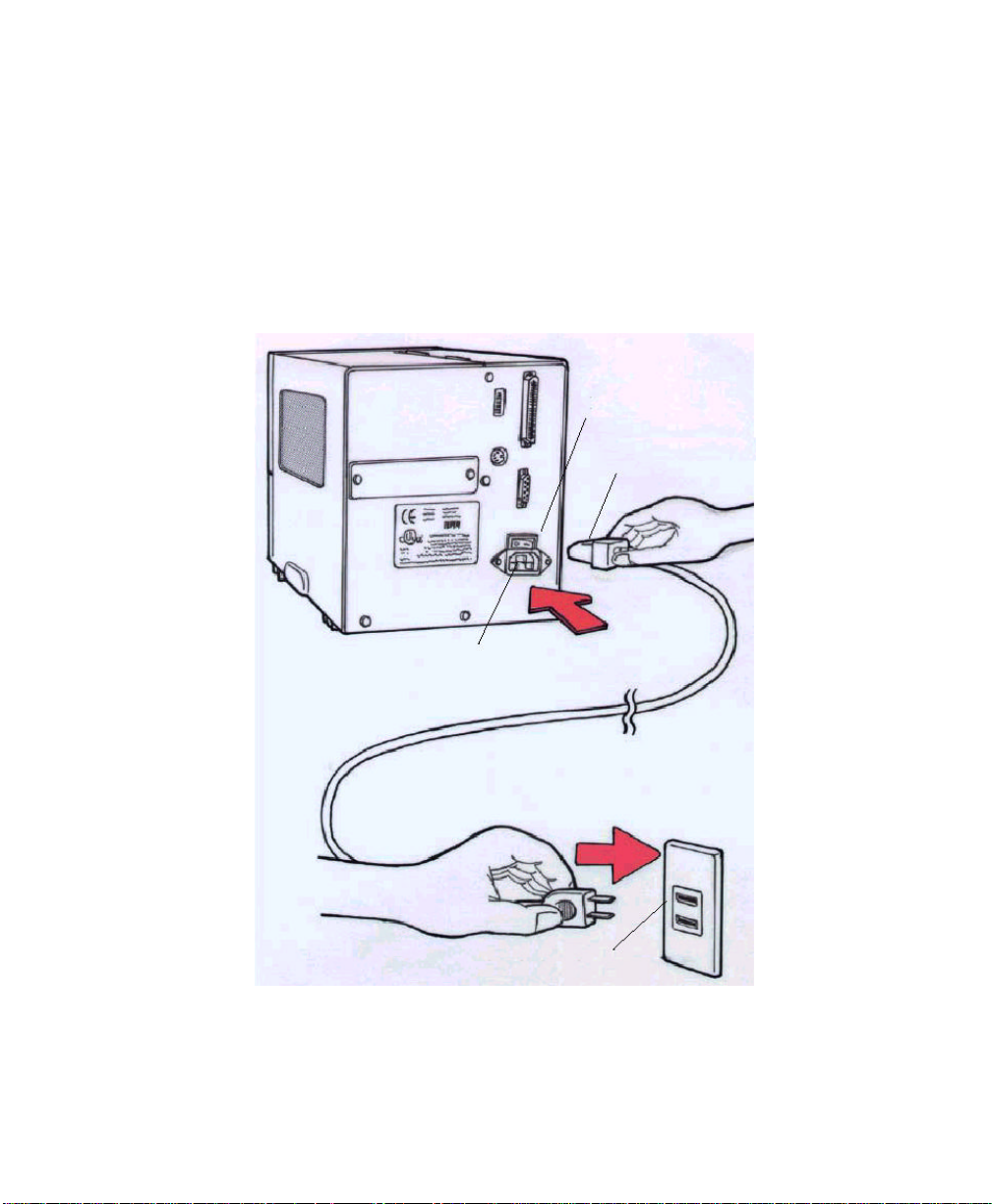

Connecting the Power Cord

1. Ensure printer Power Switch is off "0".

2. Remove the yellow voltage setting label from the AC Inlet Receptacle.

3. Connect the power cord to the AC Inlet Receptacle located on the back of the printer.

4. Connect AC power plug to a suitable AC source.

Power Switch

AC Power Connector

AC Inlet Receptacle

AC Electrical Source

Figure 6 - Power Cord Connection

12 User's Guide Fastmark 6000 Series

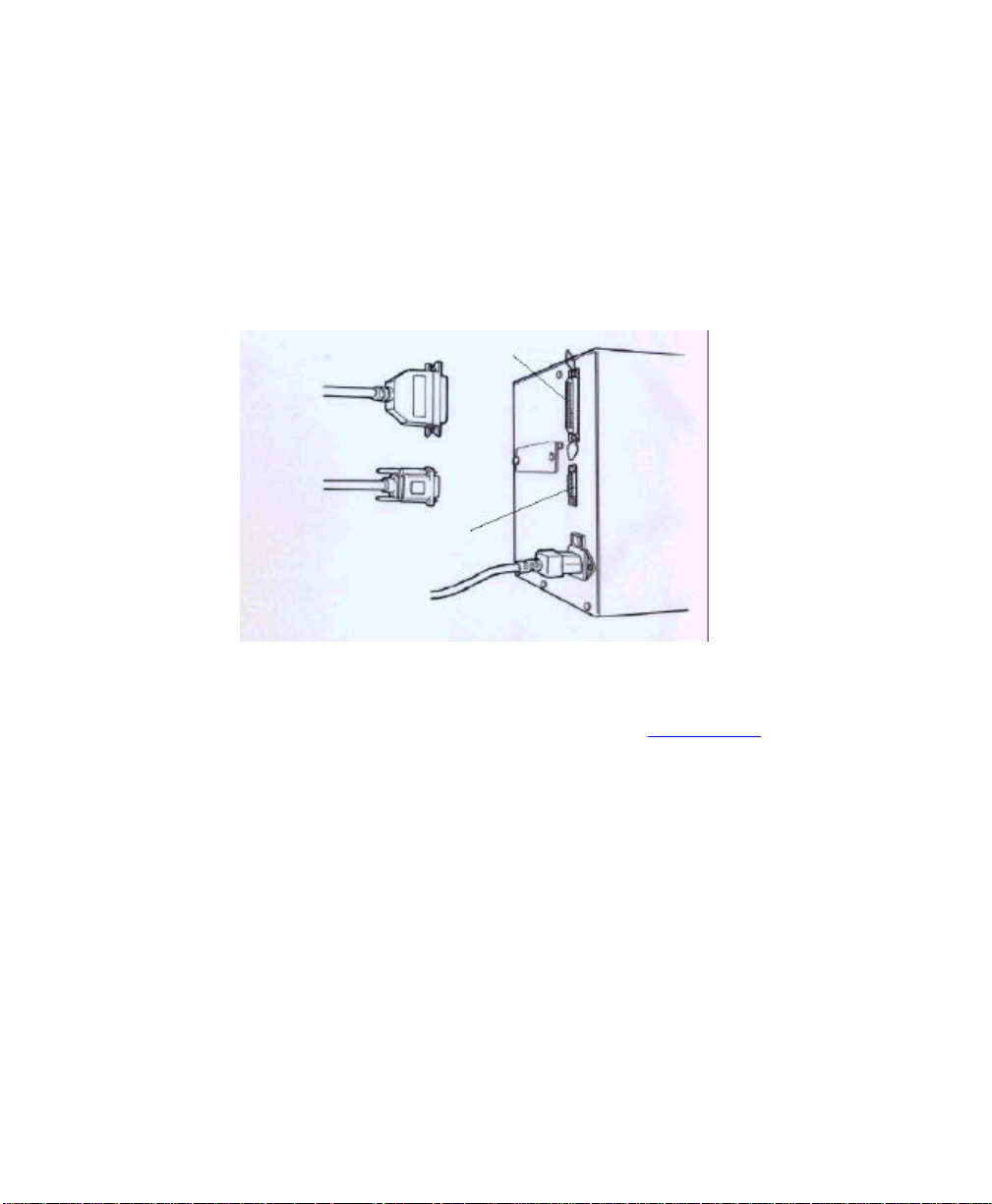

Connecting the Printer to Your Host

Parallel Port

RS-232 Serial

PC

PC

1. You can connect the printer with any standard Centronics cable to the parallel port of the

host computer.

2. Or, you can connect the printer with a serial cable to the RS-232C port of your computer

or terminal. (For PC compatibles, the RS-232C port is COM1, COM2 or COM3.)

Note : Using Centronics allows for a much higher communication speed

than serial.

Figure 7 - Communication Cable

3. If you use the serial port with your own cable, refer to the Appendix B and check the pin

connection. Be sure that the speed (baud rate) and protocol are the same between printer

and host.

Caution: Pin 9 on the serial port is directly connected to +5volts DC. It

is suggested that this pin be not connected in your cable, unless

required.

To change the Baud Rate:

FM6602: The switches on the back control Baud Rate. See the Back

Panel Switches section for more details

Fastmark 6000 Series User's Guide 13

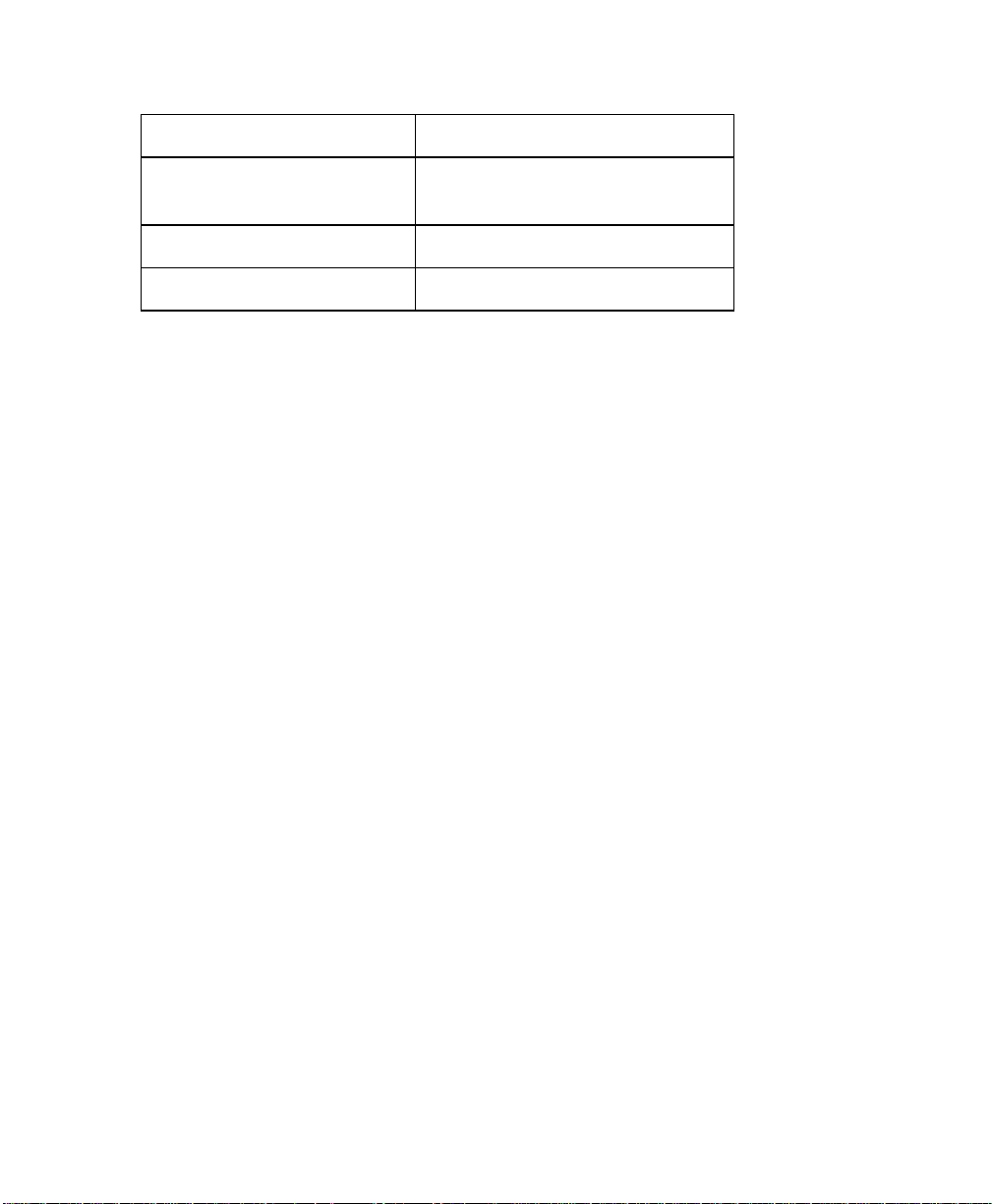

The factory default parameters of serial port are:

Speed (baud rate) 9600

Data format 1 start bit, 8 data bits and1 stop

bit.

Parity None

Handshaking (Flow control) XON/XOFF as well as RTS/CTS

Note: It is not necessary to set a switch or send a command for the

parallel and serial port selection. The printer automatically detects

the active port.

Print a SELF-TEST to review serial settings.

14 User's Guide Fastmark 6000 Series

Inside the Printer

Opening of the Top Access Door allows access to the internal user side of the printer. The

printer should be opened when:

• Installation of a Ribbon (Thermal Transfer Mode)

• Installation of Media

• Routine Maintenance

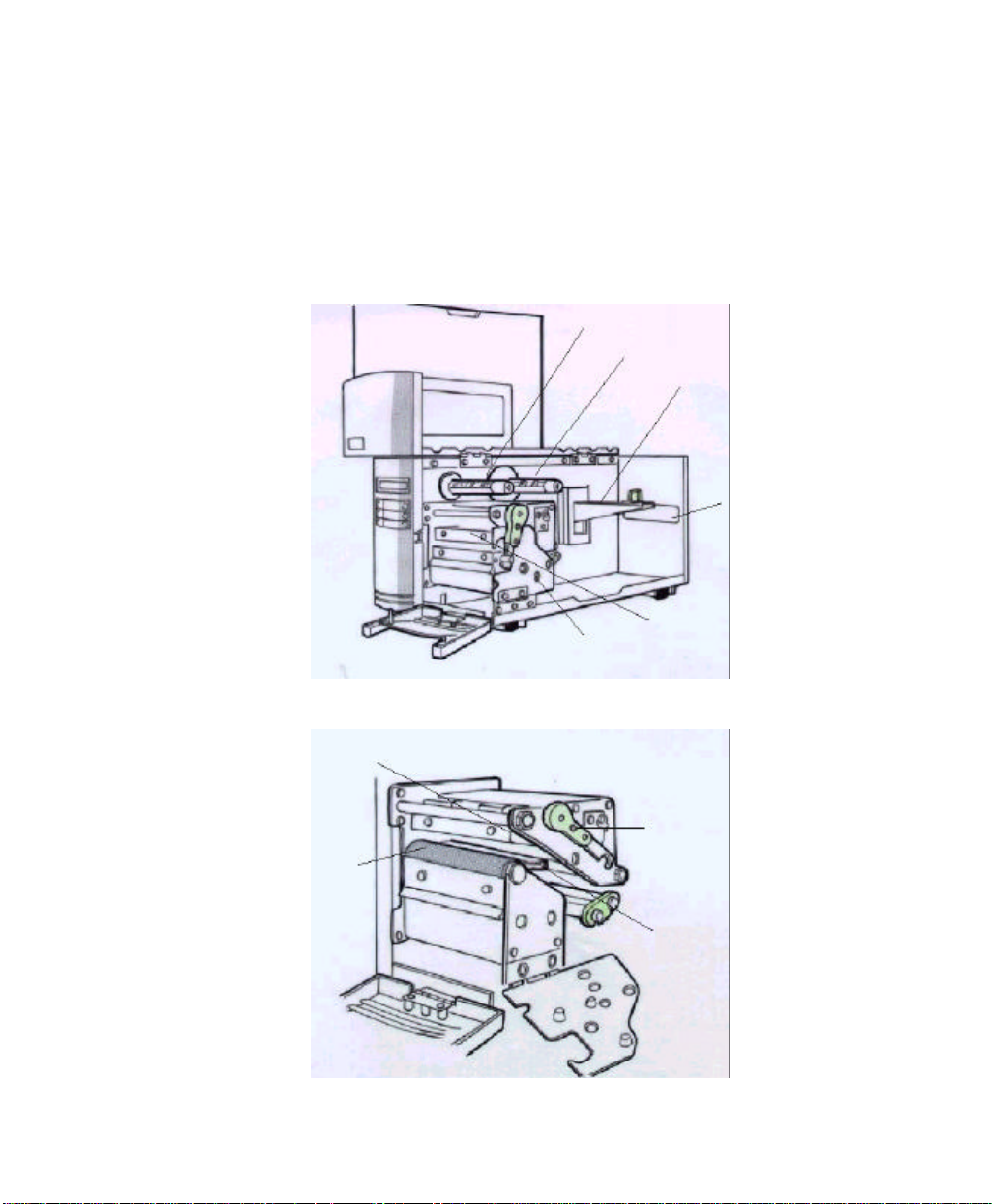

Ribbon Take-Up Spindle

Ribbon Supply Spindle

Media Supply Spindle

External Label

Feed Slot

Thermal Printhead

Side Access Door

Figure 8 – Inside Printer

Thermal Printhead

Printhead Latch Lever

Platen Roller

Paper Sensor Guide

Figure 9 – Printhead Mechanism

Fastmark 6000 Series User's Guide 15

Loading the Ribbon

Thermal Transfer Media only

If Direct Thermal Media is used, skip to the section Loading Media.

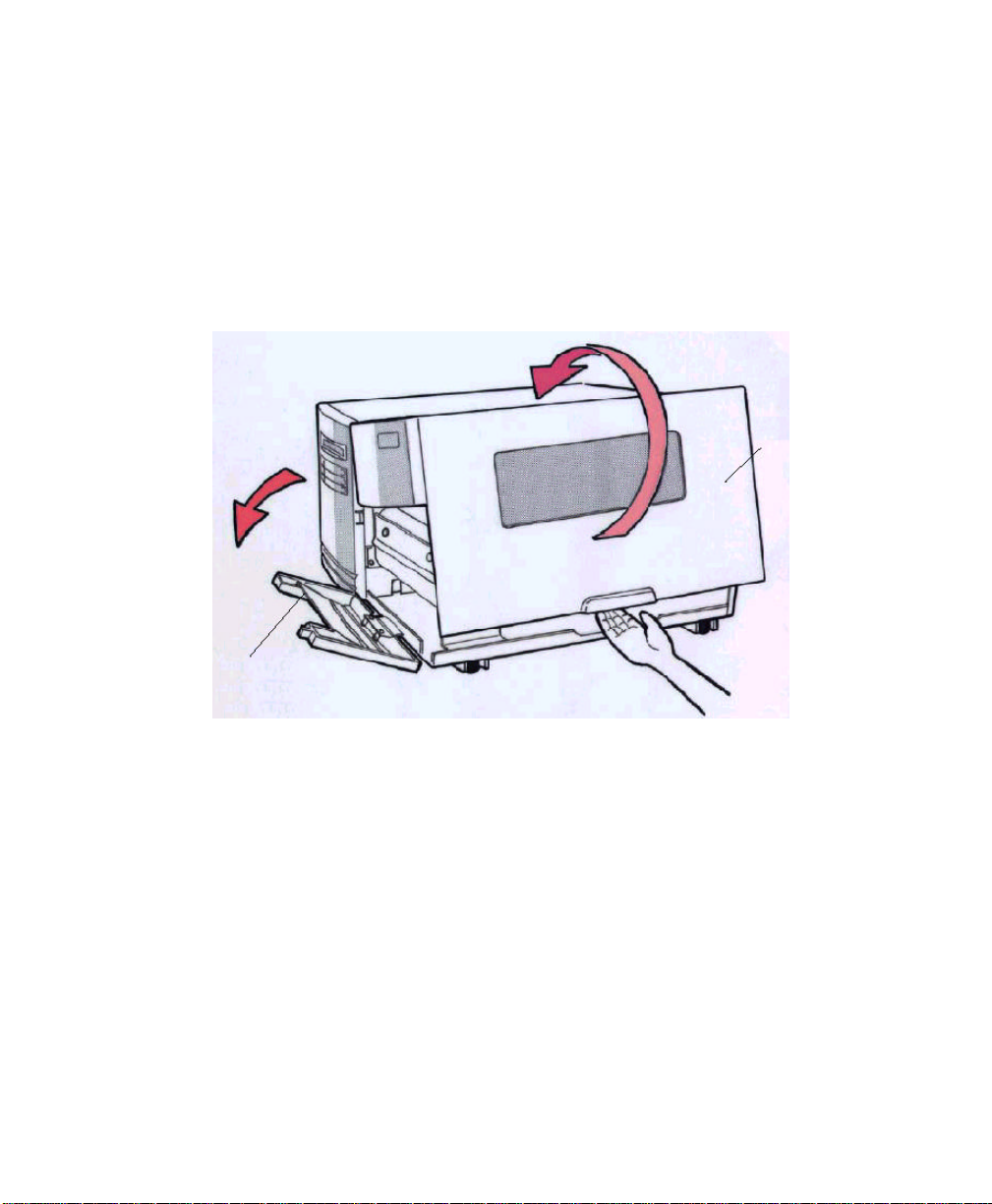

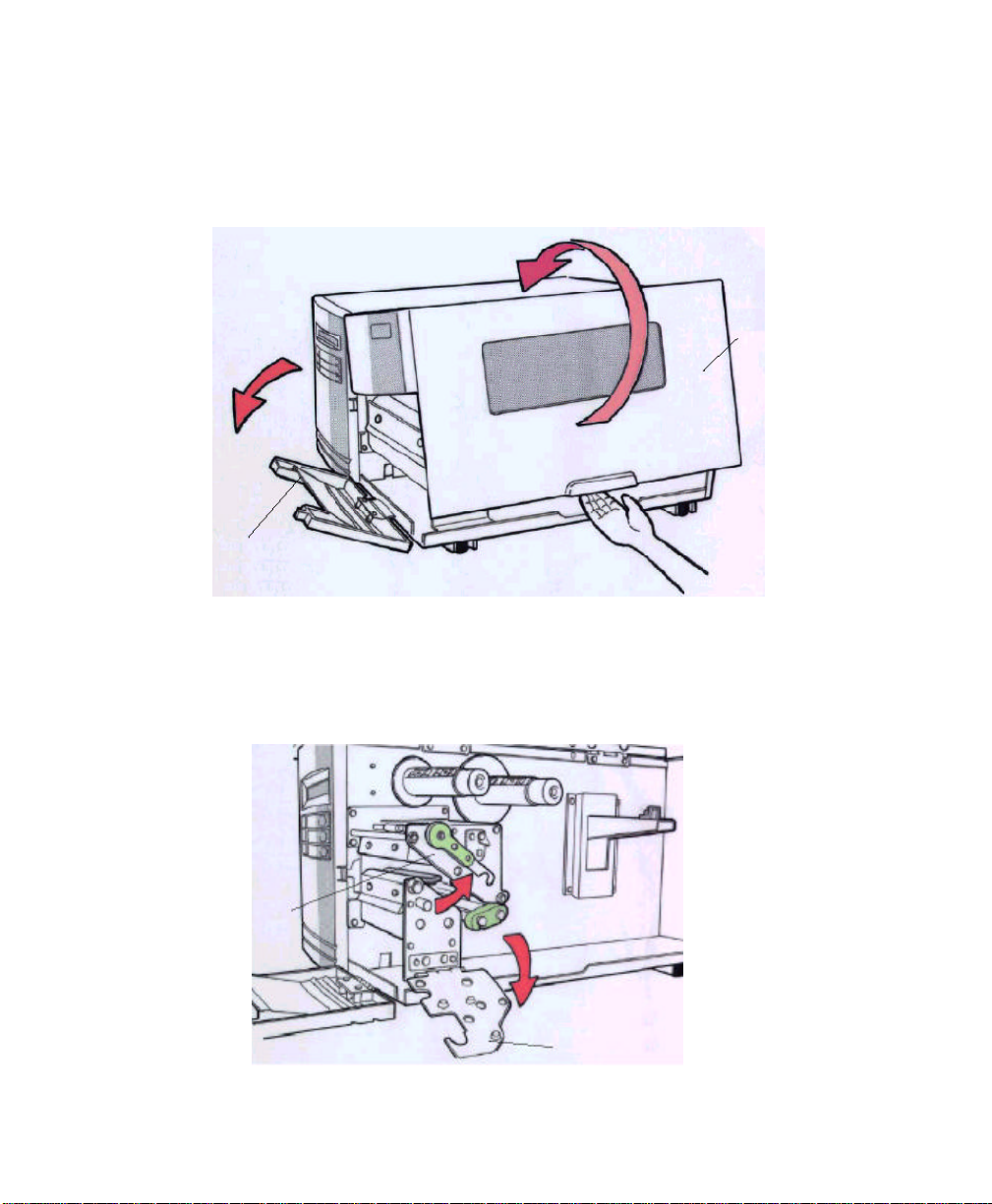

1. Open the Media Access Cover by lifting it up until it rests upon the top of the printer.

2. Open the Front Access Door by rotating it down.

Top Access

Door

Front Access

Door

Figure 10 - Open Top Access Cover

16 User's Guide Fastmark 6000 Series

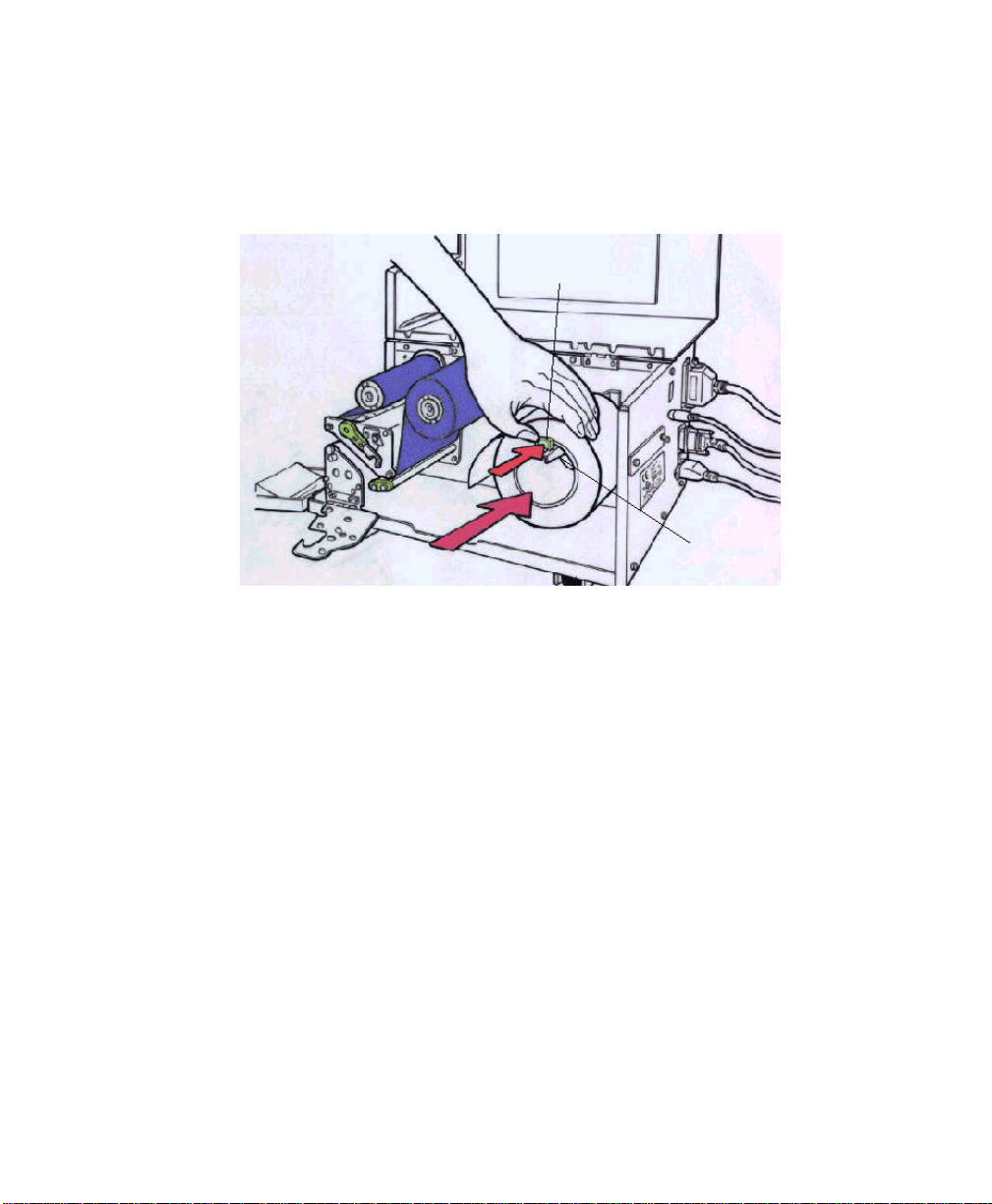

3. Rotate the Green Printhead latch counter-clockwise to open the printhead module.

4. Rotate the Side Access Door down to allow the ribbon to be loaded under the printhead

module. This will allow you to slide the ribbon under the printhead without having to

thread it under the module.

Printhead Latch

Side Access Latch

Figure 11 - Printhead Latch and Side Access Cover

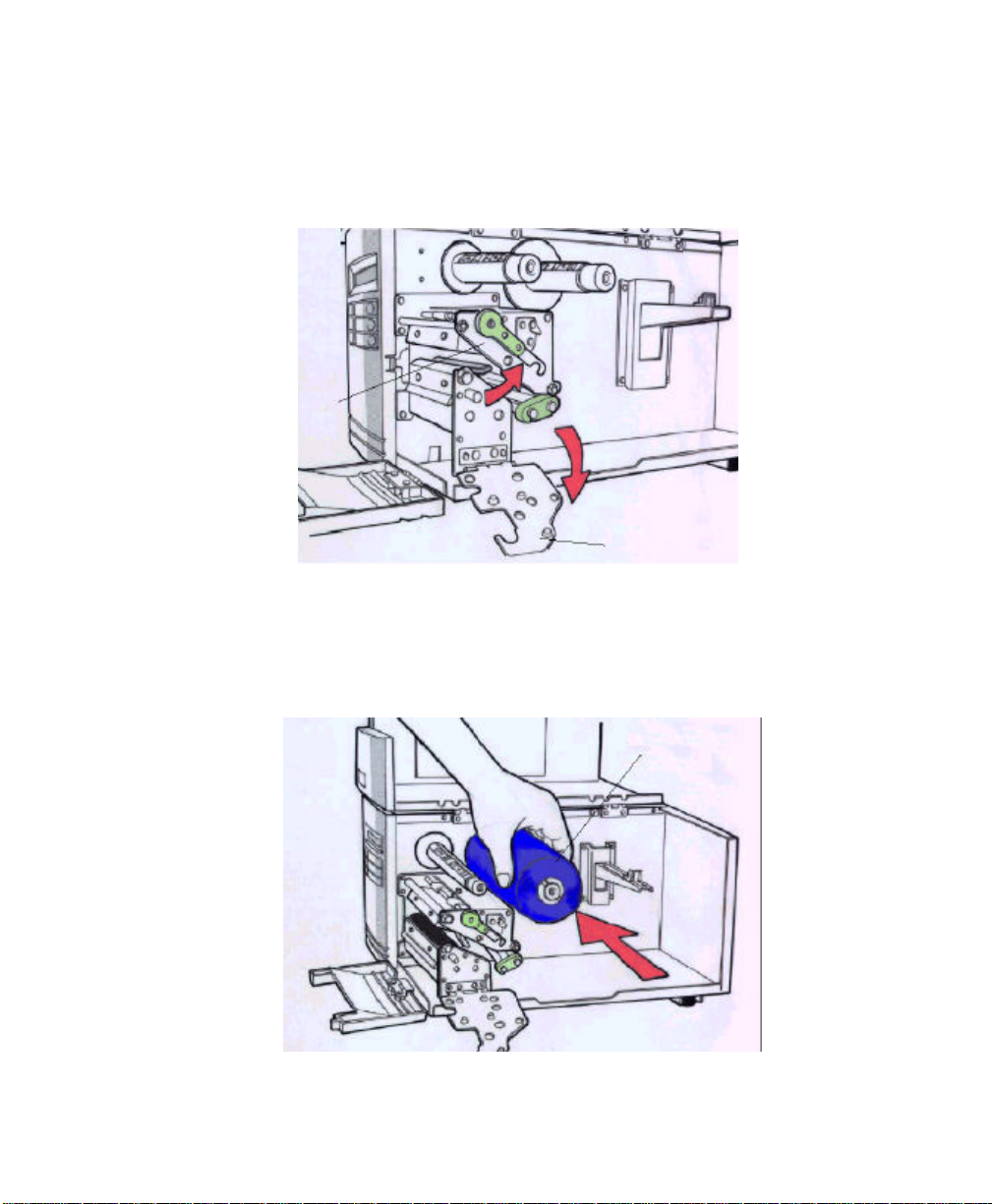

5. Unwrap the ribbon and place the Ribbon Supply Roll on the Ribbon Supply Spindle

located towards back of printer.

Ribbon Supply

Figure 12 - Ribbon Supply

Fastmark 6000 Series User's Guide 17

6. Route the ribbon under the print mechanism an onto an empty Take-up Core.

Printhead

Ribbon Take-up Core

Figure 13 - Ribbon Installing

7. Important: Route ribbon as shown in the Ribbon Routing (Figure 13) before

attaching it to the Ribbon Take-Up core using tape or adhesive leader.

Ribbon Take-up Spindle

Figure 14 – Ribbon Take -up

8. Place the Ribbon Take-up core on the Ribbon Take-Up Spindle located towards the

front of the printer.

18 User's Guide Fastmark 6000 Series

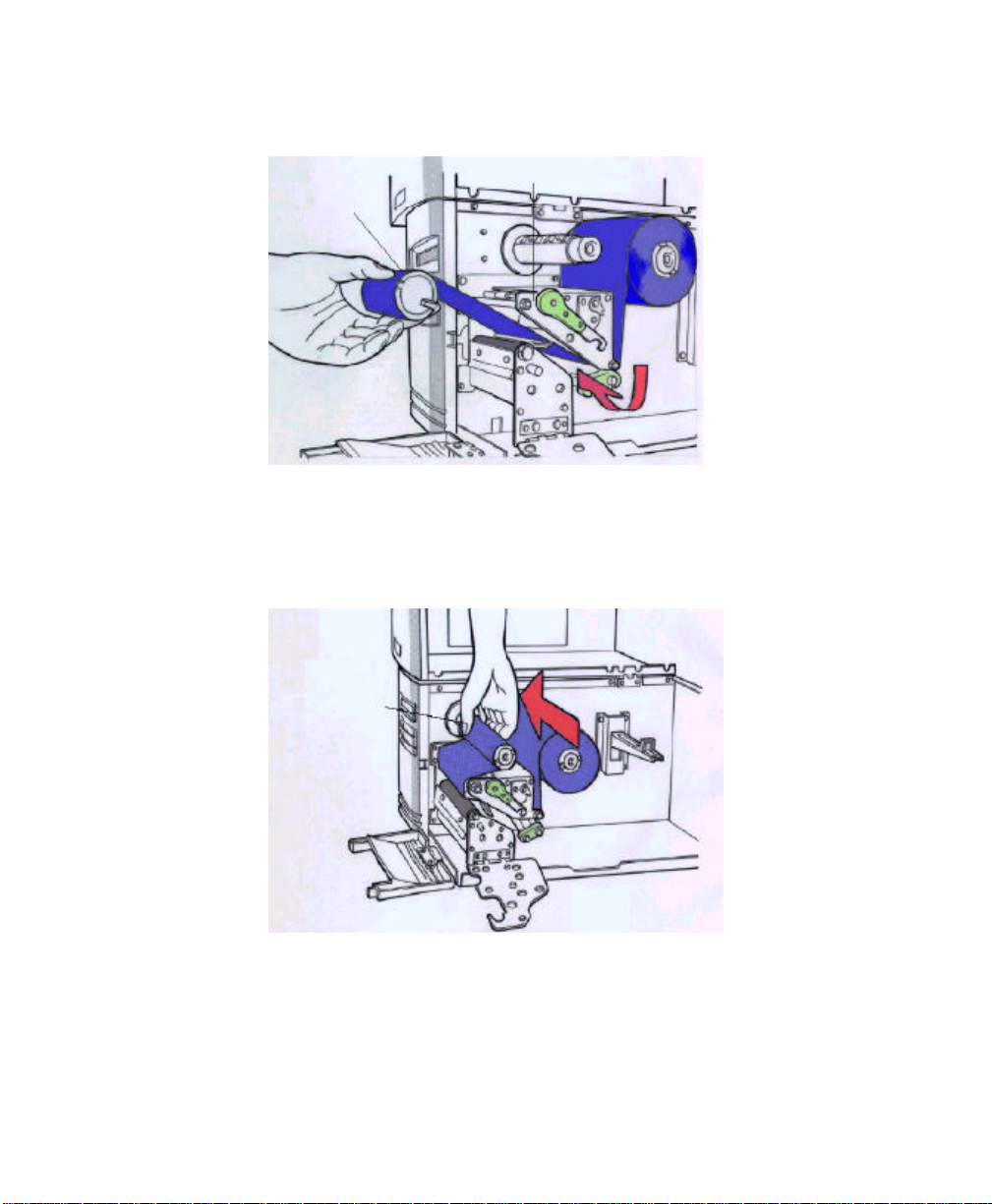

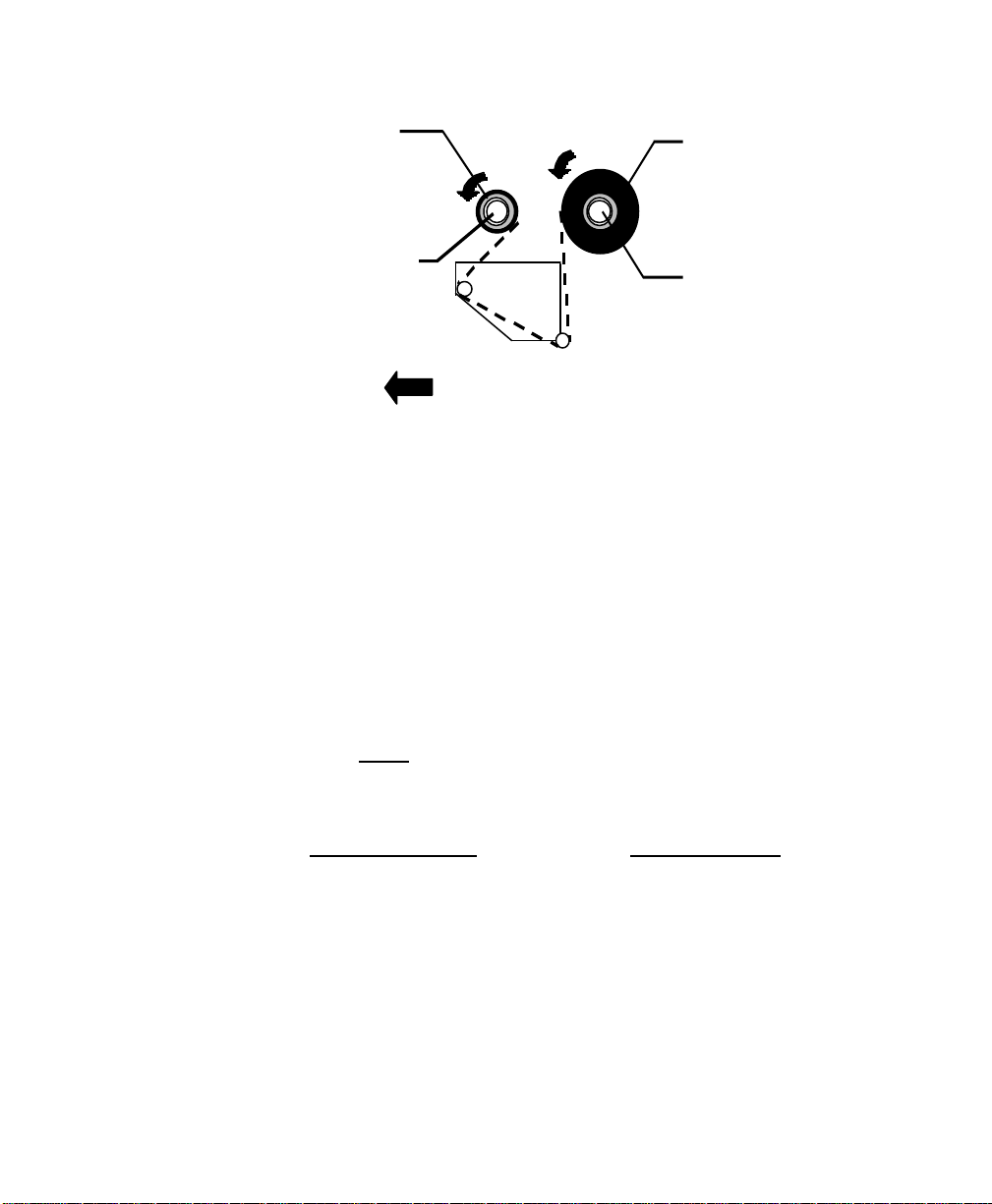

9. Tighten ribbon by manually rotating the Take-up Core counter-clockwise.

Ribbon Take-Up Roll

Ribbon Take-Up Spindle

Front of Printer

Ribbon Supply Roll

Ribbon Supply Spindle

Figure 15 - Ribbon Routing

10. Make sure that both cores are completely in line with each other. This is normally

towards the center of the printer.

11. Important: To ensure proper ribbon operation complete the following checklist:

q Ribbon is wound ink in and feeding off the top of the Ribbon Supply Roll.

q Ribbon is wound on Take Up Roll in the proper direction.

q Ribbon is routed above the Upper Media Sensor Arm. Only the media should

be below this arm.

q When properly loaded both the Ribbon Supply and Ribbon Take-Up Rolls will

be rotating counterclockwise as shown on the Ribbon Routing picture.

12. Verify the printer is set for Thermal Transfer Mode:

To verify the FM6000 series printer is set to Thermal Transfer mode, switch 1

(on the back of the printer) is set to the ON position.

Fastmark 6000 Series User's Guide 19

Loading Media

1. Fully open Top Access Cover.

2. Open the Front Access Door by rotating down.

Top

Access

Front Access

Door

Figure 16 - Open Top Access Cover

3. Rotate the green Printhead Latch counterclockwise to open the printhead.

4. Rotate the Side Access Door down to allow the media to be loaded under the printhead

module.

Printhead Latch

Side Access Latch

Figure 17 - Printhead Latch and Side Access Cover

20 User's Guide Fastmark 6000 Series

5. Slide the Media Supply Guide to the full widest position.

6. Ensure the media is face out with the labels feeding from the top of the roll. If not obtain

correctly wound media from your supplier

7. Place the media roll on the Media Supply Spindle.

Media Supply Spindle

Media Supply Guide

Figure 18 – Media Supply

8. Slide the roll fully towards the center of the printer.

9. Slide the Media Supply Guide towards the center of the printer until it is snug against

the media.

Fastmark 6000 Series User's Guide 21

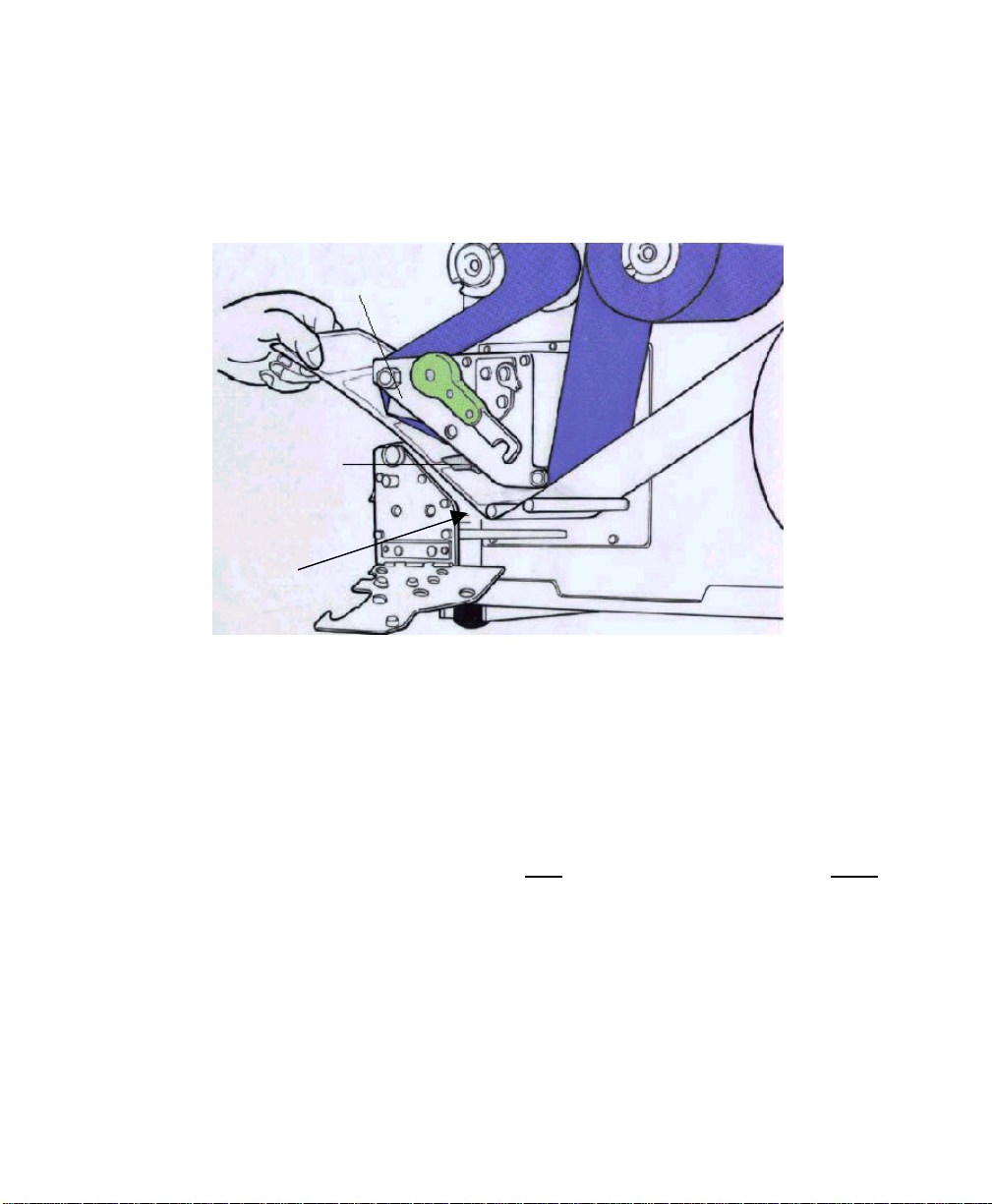

10. Slide the green Outside Media Guide off the Front and Back Media Rails by pulling

straight out.

Printhead Latch

Outside Media Guide

Ribbon

Side Support Door

Back Media Rail

Front Media Rail

Figure 19 - Outside Media Guide

11. Thread the media over the Back Media Rail and under the Front Media Rail as shown

in Figure 20.

12. Continue feeding the media through the black Upper and Lower Media Sensor Arms

located under the print module.

13. Place the green Outside Media Guide (smooth side in) back onto the Front and Back

Media Rails .

14. Slide the Outside Media Guide towards the center of the printer until it just touches but

does not buckle the media.

22 User's Guide Fastmark 6000 Series

15. Grasp the Sensor Adjust knob and sliding in or out, as needed, will move the Media

Sensor. This is required only if the sensor must be moved to a specific location on the

label to detect a notch (hole) or gap.

Printhead Module

Media Sensor Arm

Sensor Adjust knob

(under the media)

Figure 20 - Media Sensor Adjustment

16. Important: To ensure proper media feeding and sensor operation, complete the following

checklist:

q Media is wound Face Out (print side out) and feeding off the top of the roll.

q Media is routed exactly as shown over the Back Media Rail and under the

Front Media Rail.

q Media is routed between the Upper and Lower Media Sensor Arms located

under print module.

q The green Outside Media Guide has been re-installed.

q If required, the media sensor is adjusted directly over the notch (hole) or gap.

Fastmark 6000 Series User's Guide 23

24 User's Guide Fastmark 6000 Series

Loading...

Loading...