AMT Datasouth 5106 User Manual

CodeWriter 5106

Technical Reference

PART NO. 108741 Rev. A

AMT Datasouth Corp.

Corporate Headquarters

4765 Calle Quetzal

Camarillo, CA 93012

(805) 388-5799 PH

(805) 484-5282 FX

Charlotte Operation

4216 Stuart Andrew Blvd.

Charlotte, NC 28217

(704) 523-8500 PH

(704) 525 6104 FX

www.amtdatasouth.com

AMT Datasouth International

Unit B, Pinnacle 15

Gowerton Rd, Brackmills

Northampton, NN4 7BW

England

+44 1604 763394 PH

+44 1604 760661 FX

AMT Datasouth CodeWriter 5106 Disclaimer of

Warranties

IMPORTANT!

READ THIS FIRST; IT LIMITS OUR LIABILITY

SOFTWARE

All software is licensed “as is” without warranty of any kind, either expressed or implied,

including but not limited to the implied warranties of merchantability and fitness for a

particular purpose. AMT Datasouth Corp. and it’s authorized sales agent have no

liability, loss, or damage caused, or alleged to have been caused directly or indirectly by

the software system (hardware, software, User’s Guide, User’s Manual, and labels), nor

for indirect, special, or consequential damages. In no event will AMT Datasouth Corp.

be liable to you for any damages, including any lost profits, savings, or other incidental or

consequential damages arising out of the use or inability to use any program produced by

AMT Datasouth Corp. or any authorized dealer advised of the possibility of such

damages occurring. No person has the authority to modify such limitations, unless

obtained in writing and signed by a corporate officer at AMT Datasouth Corp.

Acceptance of software is conditional on the acceptance of this disclaimer. Use of the

hardware/software constitutes acceptance of this disclaimer.

EXTENDED SOFTWARE SUPPORT

AMT Datasouth Corp. provides telephone support and maintenance following delivery

of your software/hardware system. Check with AMT Datasouth Corp. for details and

current pricing on extended maintenance support.

HARDWARE

Hardware provided with your system is warranted to be free from defects in

workmanship and performance by the respective manufacturers. Refer to the AMT

Datasouth Service Policy and Pricing Handbook for warranty information. Call customer

support at (800) 476-2450 for return authorization. CodeWriter is a trademark of AMT

Datasouth Corp. All other brand and product names are trademarks or registered

trademarks of their respective companies.

LABELS, TAGS AND RIBBONS

Only previously authorized label and ribbon material may be used in this printer. Due to

variations in label and ribbon quality, use of unauthorized material may void the

warranty. Check with your AMT Datasouth Dealer for a list of authorized suppliers. In

the event you require a special material for your labels, tags or ribbons you may send

samples to the manufacturer for authorization.

COPYRIGHT NOTICE

This guide is copyrighted. All rights reserved. This guide may not, in whole or part, be

reproduced, translated, stored in a retrieval system or transmitted in any forms or by any

means, electronic, mechanical, photographic, or otherwise, without the prior written

consent of AMT Datasouth Corp.

The following expressions are used to explain keyboard

operations:

• Depress [SHIFT] means: depress the [SHIFT] key.

• Depress [1] [4] [1] or [1, 4, 1] means: depress the [1], [4], then the [1] keys.

• Depress [SHIFT] + [1, 4, 1] or [R + 1, 4, 1] means: while depressing the [SHIFT]

key, depress the [1], [4], then the [1] keys.

The following abbreviations are used throughout this

documentation:

• mm = millimeter • cm = centimeter

• um = micrometer • KB = kilobyte

• MB = megabyte • ns = nanoseconds

• A = ampere • MHz = megahertz

• mV = millivolt • Vac = voltage alternating

current

• Vdc = voltage direct current • h/s screw = hexagon socket

screw

Table of Contents

1.0 GENERAL INFORMATION ...........................................................................................................................1

1.1 Features ............................................................................................................................................................ 1

1.2 5106 Overall Dimensions .............................................................................................................................2

1.3 Ribbon Specifications...................................................................................................................................2

2.0 INITIAL SETUP.................................................................................................................................................3

2.1 Assembly and Setup Procedure ...................................................................................................................3

2.2 Selection of Media Output Mode................................................................................................................3

2.3 Parameter Setting Mode................................................................................................................................4

2.4 Parameter Tree Version 1.90........................................................................................................................5

3.0 LOADING INK RIBBON AND LABEL ROLL..........................................................................................6

4.0 ADJUSTMENTS................................................................................................................................................8

4.1 Thermal Head Repla cement .........................................................................................................................8

4.2 Changing the Direction of the Take-up Roller ..........................................................................................9

4.3 Thermal Head Positioning..........................................................................................................................10

5.0 MECHANICAL ADJUSTMENTS TO THE THERMAL HEAD..........................................................11

6.0 RIBBON.............................................................................................................................................................17

6.1 Ribbon Adjustment......................................................................................................................................17

6.2 Running Condition.......................................................................................................................................19

7.0 SENSORS..........................................................................................................................................................21

8.0 SENSITIVITY ADJUSTMENT....................................................................................................................22

9.0 ELECTRICAL CIRCUITRY..........................................................................................................................24

10.0 EXTERNAL CONNECTOR AND PIN ASSIGNMENTS.......................................................................25

11.0 VOLTAGE CHECK AND ADJUSTMENT...............................................................................................26

12.0 MAIN PCB BOARD........................................................................................................................................27

13.0 TAKE-UP MOTOR CONNECTORS...........................................................................................................28

Table of Figures

Figure 1. Overall Dimensions........................................................................................................................................2

Figure 2. Ribbon Dimensions........................................................................................................................................2

Figure 3: Loading Ribbon and Label Roll...................................................................................................................6

Figure 4. Thermal Head Replacement..........................................................................................................................8

Figure 5. Thermal Head Block.....................................................................................................................................10

Figure 6. Mechanical Adjustment...............................................................................................................................11

Figure 7. Hinge of Thermal Head Lever....................................................................................................................12

Figure 8. Thermal Head Alignment ............................................................................................................................ 13

Figure 9. Thermal Head Positioning...........................................................................................................................14

Figure 10. Head Positioning.........................................................................................................................................15

Figure 11. Incline Checking of the Thermal Head...................................................................................................16

Figure 12. Ribbon Running Condition ....................................................................................................................... 18

Figure 13. Wrinkle On Ribbon .................................................................................................................................... 19

Figure 14. Ribbon Application Adjustment .............................................................................................................. 20

Figure 15. Location of Sensors and Switch...............................................................................................................21

1.0 GENERAL INFORMATION

The 5106 is a general thermal printer which offers universal printing, including various

types of barcodes. High speed and high dot density print is available which allows you to

create any label format desired through computer software generated code.

1.1 Features

• Both On-line/Off-line operation modes available

• Thermal direct and thermal transfer printing systems are adopted.

• Extremely high dot density – 203 dots/inch or 8 dots/mm.

• High speed printing – 6.00 inches/sec or 150 mm/sec.

• Most industry standard symbologies supported.

• Built-in internal and external rewind mechanism.

• Wide print width – 5.04 inches or 128 mm

1

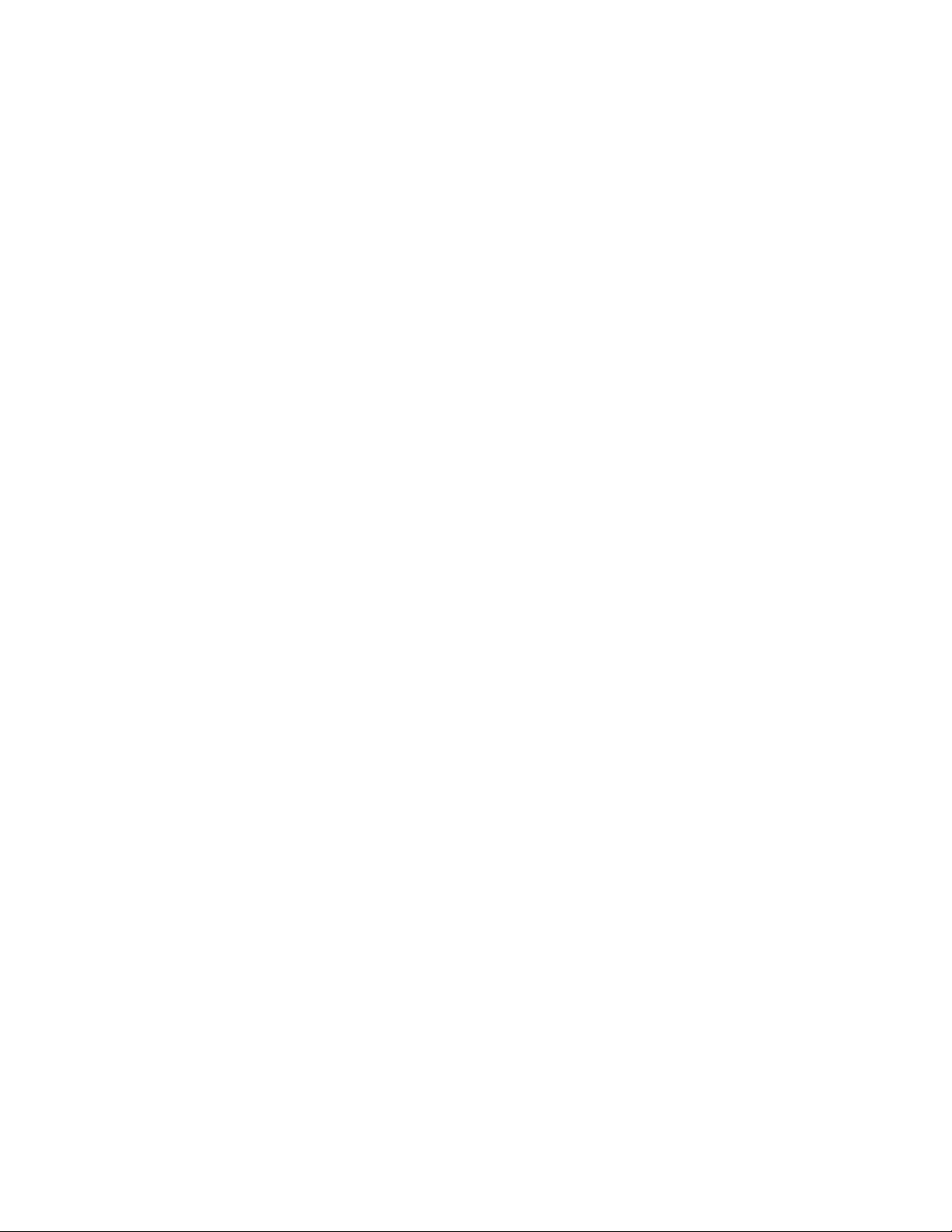

1.2 5106 Overall Dimensions

• Length: 17.3 inches/440 millimeters

• Extended Rewind: (On center from front) 4.2 inches/107 millimeters

• Height: 12.6 inches/320 millimeters

• Width: 10.7 inches/273 millimeters

Figure 1. Overall Dimensions

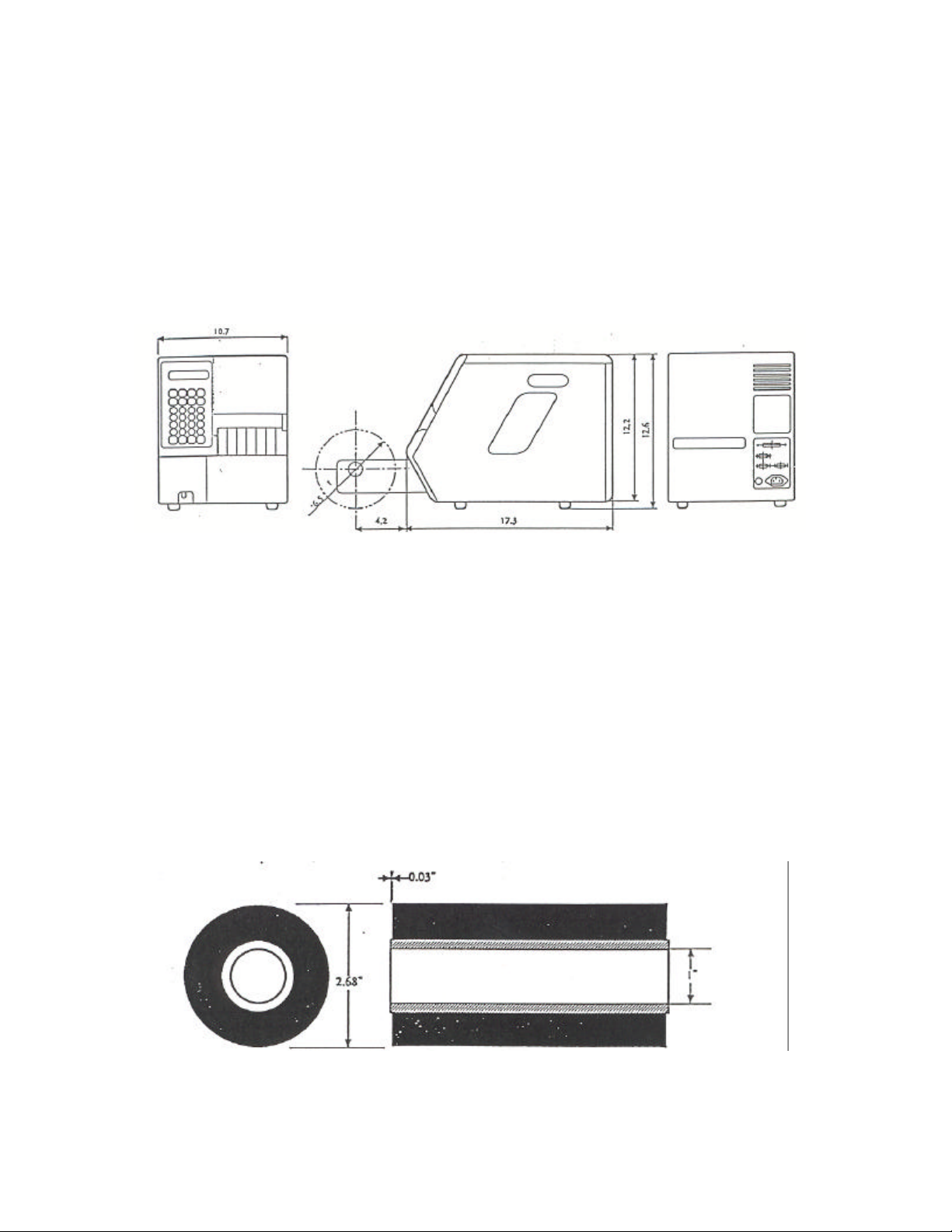

1.3 Ribbon Specifications

• Length: 984 feet/300 meters

• Ribbon Leader (Clear): 12 inches/300 millimeters

• Ribbon Trailer (Mirror coating): 6 inches/150 millimeters

• Ink Side: Outside

Figure 2. Ribbon Dimensions

2

2.0 INITIAL SETUP

2.1 Assembly and Setup Procedure

The 5106 printer provides various output modes which will correspond to the various

customer requirements. Assemble and setup the printer according to the customer

application.

2.2 Selection of Media Output Mode

Output Mode under printer parameters provides the selection. Refer to the next section

when choosing parameter settings.

Output Mode

Non-spooled

Spooled

Presentation

Optional Cutter

Function

The label is issued with the liner.

(The printer does not rewind the

label and liner). Attaching the

Tear Bar instead of the

Presentation Sensor, the label

and liner can then be torn off

together (manually)

The label is issued with liner, and

the printer rewinds both the

issued label and liner on the

Take-Up Roller (as an external

rewinder).

The labels are issued with liner

and peeled off at the dispenser

and present Label Holder. The

printer rewinds only the liner,

inside the printer.

The labels are issued with liner

and separated in the specified

timing by the Optional Cutter.

Remark

Remove label Presentation

Sensor and then attach the

Tear Bar.

Position the Take-Up

Roller on the outside of the

printer (as an external

rewinder).

Set the Take-Up Roller on

the inside of the printer.

Optional cutter mechanism

is required.

3

Loading...

Loading...