AMT Datasouth 4600 User Manual

Document #140106A

March 2011

Fastmark 4600 PLUS Series

Thermal Transfer Barcode Printer

User’s Guide

1

Getting Started .................................................................................................... 2

Table of Contents

Unpacking ....................................................................................................... 2

Package Contents ........................................................................................... 3

Placing the Printer .......................................................................................... 4

Connecting the Power Cord .......................................................................... 4

Getting to Know Your Printer ............................................................................. 5

Front Panel ...................................................................................................... 5

Loading a Ribbon ......................................................................................... 15

Loading Media .............................................................................................. 18

PALTM Print and Program Overview ................................................................ 27

Traditional Printing ....................................................................................... 27

Legacy Data Stream Interpretation .............................................................. 27

Standalone/Downtime Applications ............................................................ 28

Calibration & Configuration ............................................................................. 30

Performing Calibration ................................................................................. 30

Printing a Configuration Report .................................................................. 31

Resetting to Factory Default Settings ......................................................... 32

Computer Connections .................................................................................... 33

USB Interface Requirements ....................................................................... 33

Centronics Parallel Port ............................................................................... 33

Serial (RS-232) Port ...................................................................................... 34

Ethernet 10/100 Internal Printer Server Option .......................................... 34

Ethernet Module Status Indicators .............................................................. 35

Communicating with the Printer ...................................................................... 37

Troubleshooting ................................................................................................ 44

LED and LCD Diagnosis ............................................................................... 44

Media Problems ............................................................................................ 44

Ribbon Problems .......................................................................................... 45

Other Problems ............................................................................................. 45

Light /Missing Print ...................................................................................... 46

Miscellaneous ............................................................................................... 47

Recovery ....................................................................................................... 48

Caring for Your Printer ..................................................................................... 49

Cleaning the Print Head ............................................................................... 49

Cleaning the Roller ....................................................................................... 50

Cleaning the Media Compartment ............................................................... 50

Technical Reference ......................................................................................... 51

General Specifications ................................................................................. 51

Fonts, Bar Codes and Graphics Specification ........................................... 54

Interface Specifications ............................................................................... 57

ASCII TABLE ................................................................................................. 63

2

Table of Contents

Appendix A: Printer Status .............................................................................. 64

Appendix B: Stand-alone Keyboard and Barcode Reader ............................ 65

Keyboard ....................................................................................................... 65

Form Control Functions ............................................................................... 65

Barcode Reader ............................................................................................ 69

Appendix C: Cutter Installation ....................................................................... 72

Appendix D: Dispenser Installation ................................................................. 75

Appendix E: Adjusting Ribbon Tension .......................................................... 78

Appendix F: Switching Ribbon Wound Ink-side out or Ink-side in............... 78

1

IMPORTANT SAFETY INSTRUCTIONS

AND OTHER NOTICES

This printer complies with the requirements in Part 15 of FCC rules for a

Class A computing device. Operation of this equipment in a residential area

may cause unacceptable interface to radio and TV reception, requiring the

operator to take whatever steps are necessary to correct the interference.

Place the printer on a flat, firm and solid surface.

Do not place the printer near a heat source or near water.

Refer to the specification label on the bottom of this printer and ensure that

your power source exactly meets these requirements.

Do not open the printer during operation to avoid electrical shock.

Do not attempt to disassemble this printer if it malfunctions.

All rights are reserved. No part of this document may be reproduced or

issued to third parties in any form without permission of AMT Datasouth.

The material in this document is provided for general information and is

subject to change without notice.

TRADEMARK CREDITS

Windows ® , MS-Word and MS-DOS are registered trademarks of Microsoft

Corporation

PC ® is a registered trademark of International Business Machines

Centronics ® is a registered trademark of Centronics Corporation

TM

PAL

is registered trademark of AMT Datasouth Corporation

2

Getting Started

Congratulations on choosing the AMT Datasouth Fastmark 4600 PLUS Series

industrial barcode printer. This user‟s manual describing the FM 4600 PLUS

Series printer models will help you get to know your new printer. The manual

includes a guide to operate the printer as well as related information on

troubleshooting, maintenance, and technical reference. Illustrations are provided

to help you quickly become familiar with the printer.

Unpacking

After receiving your printer, please check for possible shipping damage:

1. Inspect the outside of both the box and the printer for possible damage.

2. Open the top cover of the printer to see if the media compartments are in

order.

Note: If damage has occurred, contact your shipping company immediately to

file a claim.

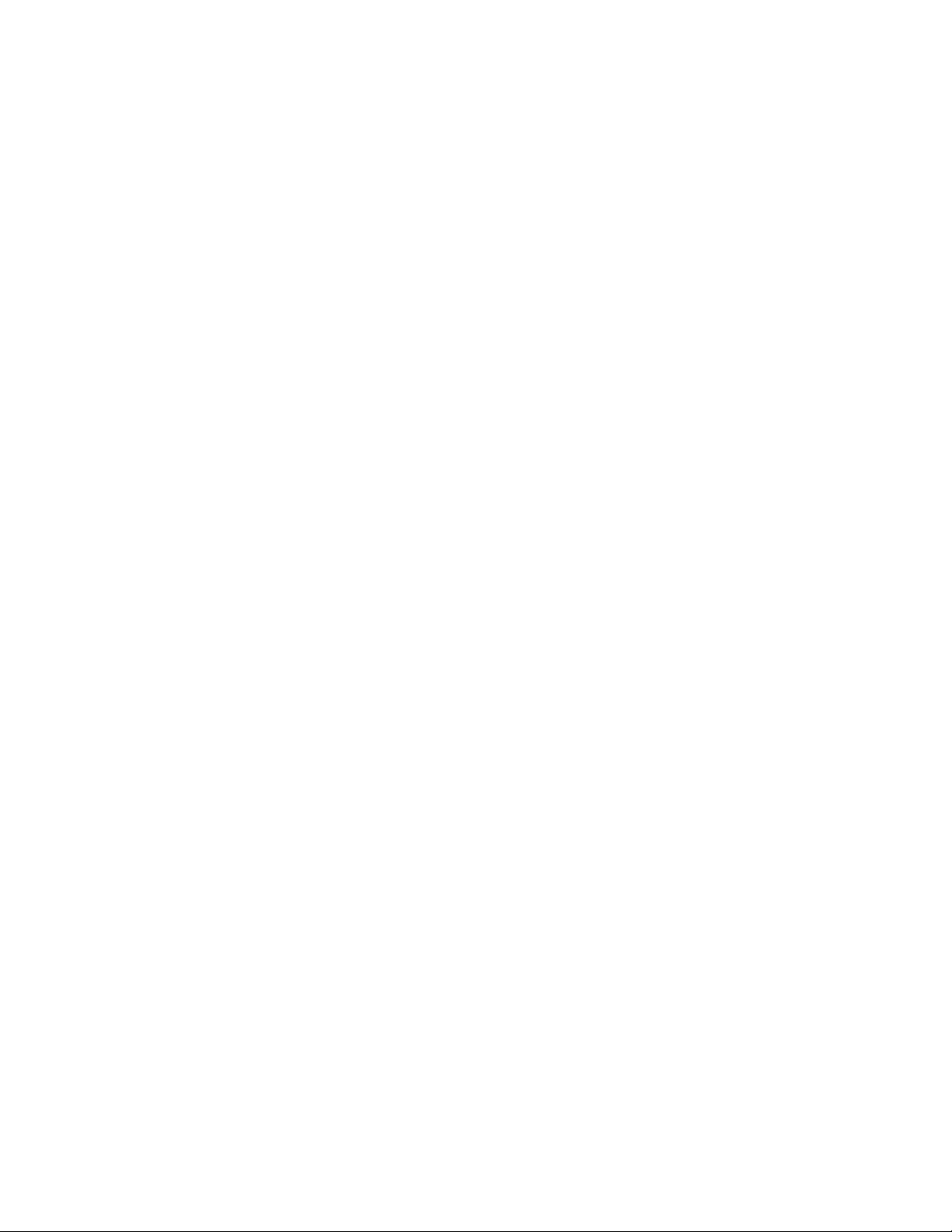

3. Check whether you have received the following accessories together with

the printer. If there are any items missing, please contact your local dealer.

3

4 5 3

2

1

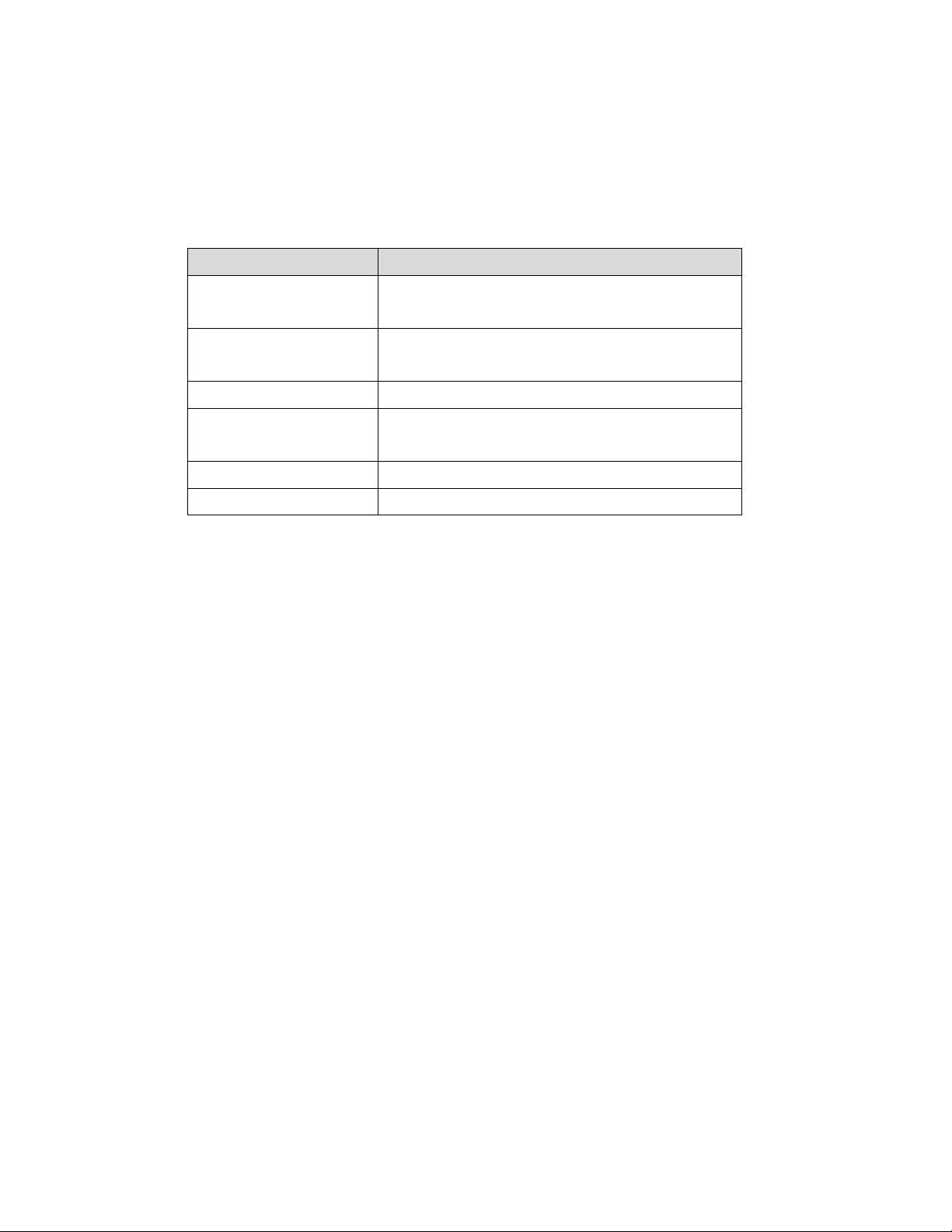

Package Contents

1. 4600 PLUS Series Printer

2. Installation Quick Start Guide

3. CD Rom (User Guides, Utility Software & Drivers)

4. AC Power Cord

5. Sample Ribbon

4

Placing the Printer

| |

Before setting up and connecting the printer you should consider the following.

WARNING! Do not operate the printer in an area where it might get wet.

Find a solid flat surface with adequate room for the printer and enough

space above for media and ribbon access.

Place the printer within cable distance of the host and printer (serial or

parallel cable.)

Isolate the power cord from other electrical cables.

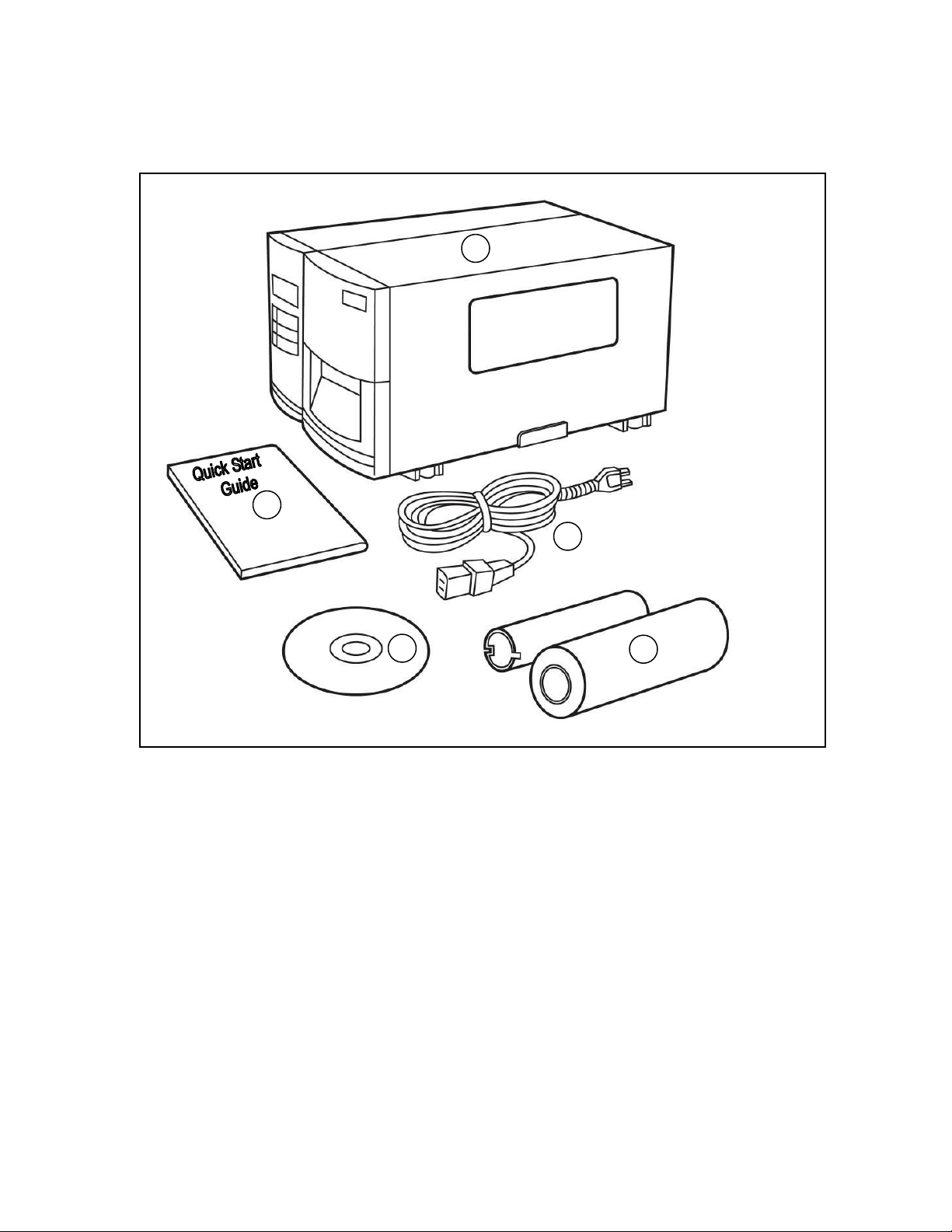

Connecting the Power Cord

Connect the power cord as below.

5

Getting to Know Your Printer

Control Panel

LED‟s and

Switches

LCD Message

Display

Top Access

Door

Front Access

Door

The front panel includes:

3 LED indicators (READY, MEDIA and RIBBON)

3 buttons (FEED, PAUSE and CANCEL)

LCD display

Top Access Door

Front Access Door

Printer Models:

TIA-200V (FM 4602 PLUS / 203dpi)

TIA-230E (FM 4602 PLUS / Int. Ethernet 203dpi)

TIA-320 (FM 4603 PLUS / 300dpi)

TIA-320E (FM 4603 PLUS / Int. Ethernet 300dpi)

The illustrations below describe parts and features of the FM 4600 PLUS Series

printer.

Front Panel

6

LED Indicators

READY

On – Normal operation

Off – Printer error

MEDIA

On – Normal operation

Blinking – Install new media

Printhead overheat

The printer is paused,

RIBBON

On – thermal transfer mode with ribbon installed

Off – direct thermal mode ( no ribbon installed )

Blinking – Install a new ribbon

For the FM 4602 PLUS Series, and the FM

4603 PLUS Series models, modes of thermal

transfer and direct transfer can be set via the

printer panel or Utility software.

Button

Function 1

(Press the button)

Function 2

(Press the button and

power switch together)

FEED/

CONFIG

Feed a label

Perform self test & print

configuration report

PAUSE/

CALIBR

Pause printing

Press again to resume printing

Perform a media calibration

CANCEL/

RESET

Interrupt and delete a print task

Force printer to continue after an

error is solved.

Reset FLASH settings

There are three LED indicators on the front panel, READY, MEDIA and RIBBON.

These indicators display the operation status of the printer.

Buttons

There are three buttons, each with two basic functions.

7

(203, PAL/PPLZ)

(300, PAL/PPLZ)

(203, PAL/PPLZ)

<ESC> FOR KEYBD

Notes:

1. You should perform a media calibration after installation and when

changing to a different type or size of media.

2. Before calibration, you must load the media and ribbon properly and move

the label sensor to the correct position avoiding holes.

3. After calibration the printer saves parameters to FLASH. Without correct

calibration gap detection is easily lost during printing especially for small

labels (less than 1.5 inches in height).

4. After self-test, the printer is in dump mode. For normal operation, you must

press CANCEL to restart the printer.

LCD Display

The FM 4600 PLUS Series models have a LCD that shows:

printer status

printer settings

input data from a keyboard or barcode reader

The first parameter is either 203 or 300, which stands for the print resolution. The

second parameter indicates the emulation (printer language), PAL/PPLZ, PPLA,

or PPLB.

After power-on, the LCD displays the following message as examples:

FM 4602 PLUS Series

FM 4603 PLUS Series

If a keyboard is plugged in, the display shows:

FM 4602 PLUS Series

8

(300,PAL/PPLZ)

<ESC> FOR KEYBD

(203,PAL/PPLZ)

WITH B.C. READER

(300,PAL/PPLZ)

WITH B.C. READER

RIBBON OUT

LANGUAGE

ENGLISH

FM 4603 PLUS Series

If a barcode reader is connected, the display shows:

FM 4602 PLUS Series

FM 4603 PLUS Series

If an abnormal condition occurs, a related message is displayed. For example:

Setting Display Language

The printer‟s LCD display supports six languages: English, French, German,

Italian, Spanish, and Portuguese.

To select a language:

1. Press the PAUSE and CANCEL buttons at the same time.

2. Hold both buttons for about 3 seconds and release.

3. The language selection screen appears.

4. Press the FEED button for the next language.

5. Press the CANCEL button to select and set the language.

Press PAUSE or the PAUSE+CANCEL buttons to exit the language selection

screen and enter normal mode.

9

Changing Settings from the Panel

Buttons

Function

FEED+PAUSE

Press to enter setting mode.

(Don‟t press over 1 second)

FEED+CANCEL

Press to show next features.

CANCEL

Press to select desired feature.

FEED+CANCEL

To scroll through the list of values for the

chosen feature.

CANCEL

To save the currently displayed value.

PAUSE

To exit setup mode.

You may change settings using the front panel buttons of the 4600 PLUS series

printer models. In addition you may also change settings via software Utility and

data stream commands.

Setting Procedure:

To change settings using the buttons on the front panel:

1. Press PAUSE, verify mode on LCD display.

2. Press FEED and PAUSE at the same time to enter setup mode.

3. Press and hold FEED, use CANCEL to scroll through the list of features.

4. Press CANCEL to select desired feature.

5. Press and hold FEED, use CANCEL to scroll through the list of values for

the chosen feature.

6. Press CANCEL to save the currently displayed value.

7. Press PAUSE twice to exit setup mode and READY the printer.

10

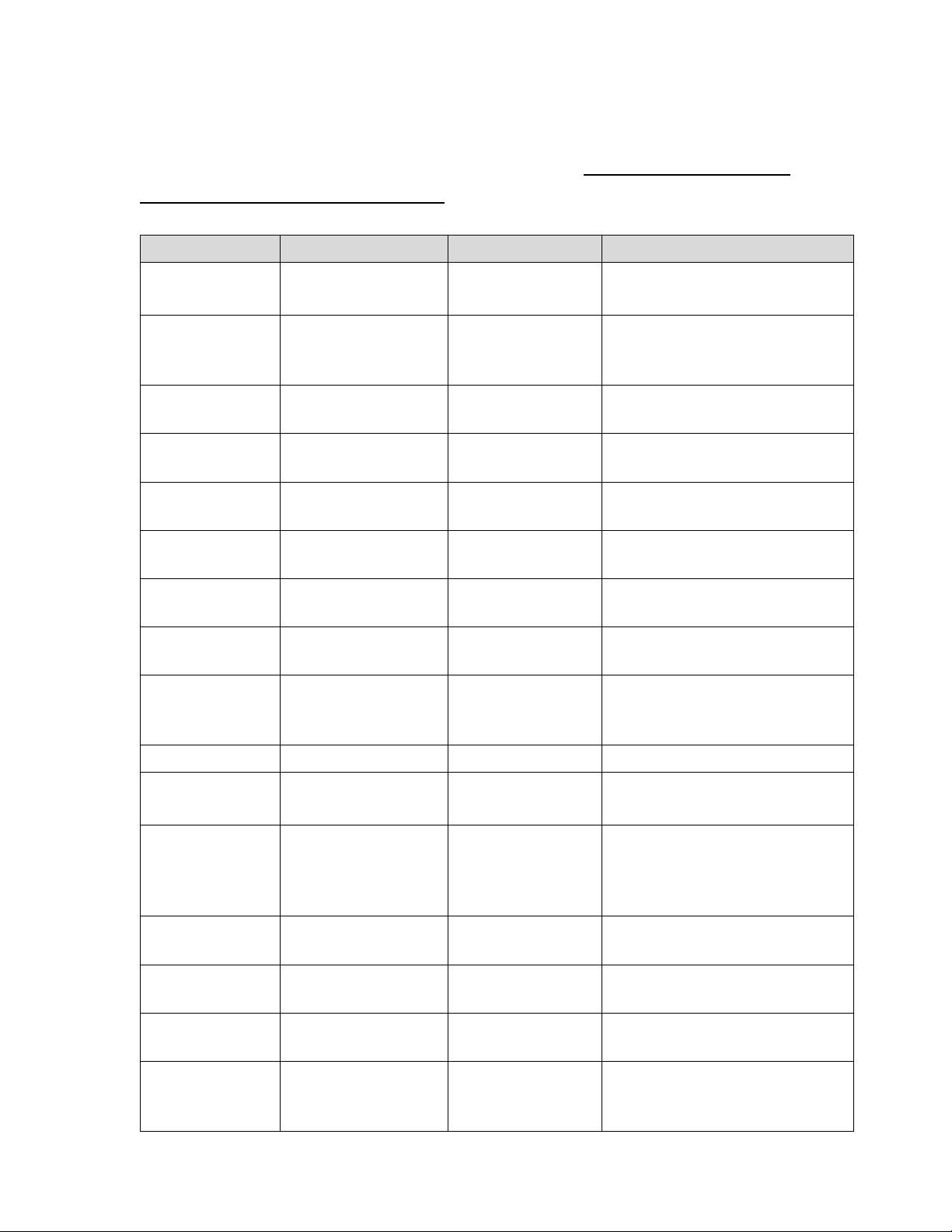

Feature

Parameter

Factory Default

Remarks

PRINT MODE

Thermal transfer /

Direct thermal

Thermal transfer

AUTO

CALIBRATE

MODE

Mode 1~4

Mode 1

Calibrates on demand.

CUT/PEEL

OFFSET

-015 ~+.050

0

Controls cut and peel

position.

TPH VERTICAL

OFFSET

-.003~+.003”

0

Offset of vertical print

position.

RECOVER

PRINT

ENABLED,

DISABLED

ENABLED

Contents reprint after media

out or ribbon-out.

CUTER

INSTALLED

YES

NO

NO

PEELER

INSTALLED

YES

NO

NO

READER

INSTALLED

YES

NO

NO

WIN. CON. LIN.

0~254

0

Only under Windows with

bundled printer driver and

continuous media.

BASE SEED

0~4 ips

0 ips

COUNTING

DOWN

UP

DOWN

DOWN

MEDIA

SENSOR TYPE

GAP

BLACK BAR

GAP

Select for media

characteristics. Once

changed make sure to

calibrate before printing.

BACKFEED

ENABLED

DISABLED

DISABLED

PRESENT

DISTANCE

.0~040”

.87”

Appears only when

BACKFEED enabled.

BASE

DARKNESS

-028~+028

0

BAUD RATE

(RS232)

600 / 1200 / 2400/

4800 / 9600 /

19200 /NONE

9600

Basic Printer Features and Parameter Settings , PPLA/PPLB.

NOTE: Features can vary based on printer model. Do not change settings

during printing or communication.

11

Feature

Parameter

Factory Default

Remarks

PARITY

(RS232)

NONE

EVEN

ODD

NONE

LENGTH

(RS232)

8 DATA BITS

7 DATA BITS

8 DATA BITS

CLEAR FLASH

YES/NO

NO

PRINTERS WITH ETHERNET

DHCP

ENABLE

DISABLE

ENABLE

IP ADDRESS

###.###.###.###

SUBNET MASK

###.###.###.###

DEFAULT

GATEWAY

###.###.###.###

MAC

ADDRESS

####.####.####

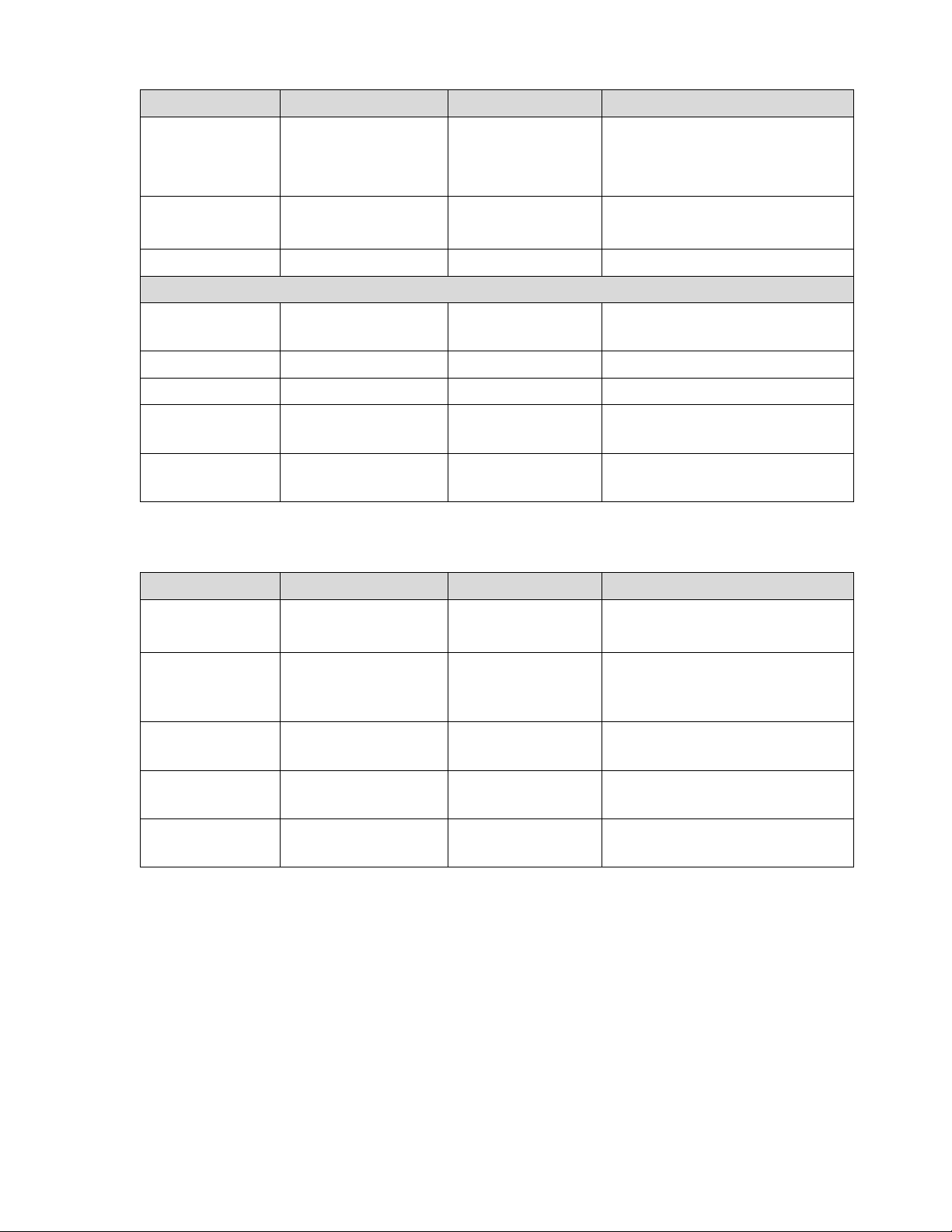

Feature

Parameter

Factory Default

Remarks

PRINT MODE

Thermal transfer /

Direct thermal

Thermal transfer

AUTO

CALIBRATE

MODE

Mode 1~4

Mode 1

Calibrates on demand.

CUT/PEEL

OFFSET

-015 ~+.050

0

Controls cut and peel

position.

TPH VERTICAL

OFFSET

-.003~+.003”

0

Offset of vertical print

position.

RECOVER

PRINT

ENABLED,

DISABLED

ENABLED

Contents reprint after media

out or ribbon-out.

Printer Features and Parameter Settings, PAL/PPLZ

12

Feature

Parameter

Factory Default

Remarks

PEELER

INSTALLED

YES

NO

NO

COUNTING

UP

DOWN

DOWN

MEDIA

SENSOR TYPE

GAP

BLACK BAR

GAP

Select for media

characteristics. Once

changed make sure to

calibrate before printing.

PRESENT

DISTANCE

.0~040”

.87”

Appears only when

BACKFEED enabled.

ABS

DARKNESS

0~30

0

Setting darkness

TRIM

DARKNESS

-30~30

0

Fine-tuning darkness

BAUD RATE

(RS232)

600 / 1200 / 2400/

4800 / 9600 /

19200 /NONE

9600

PARITY

(RS232)

NONE

EVEN

ODD

NONE

LENGTH

(RS232)

8 DATA BITS

7 DATA BITS

8 DATA BITS

CLEAR FLASH

YES/NO

NO

PRINTERS WITH ETHERNET

DHCP

ENABLE

DISABLE

ENABLE

IP ADDRESS

###.###.###.###

SUBNET MASK

###.###.###.###

DEFAULT

GATEWAY

###.###.###.###

MAC

ADDRESS

####.####.####

13

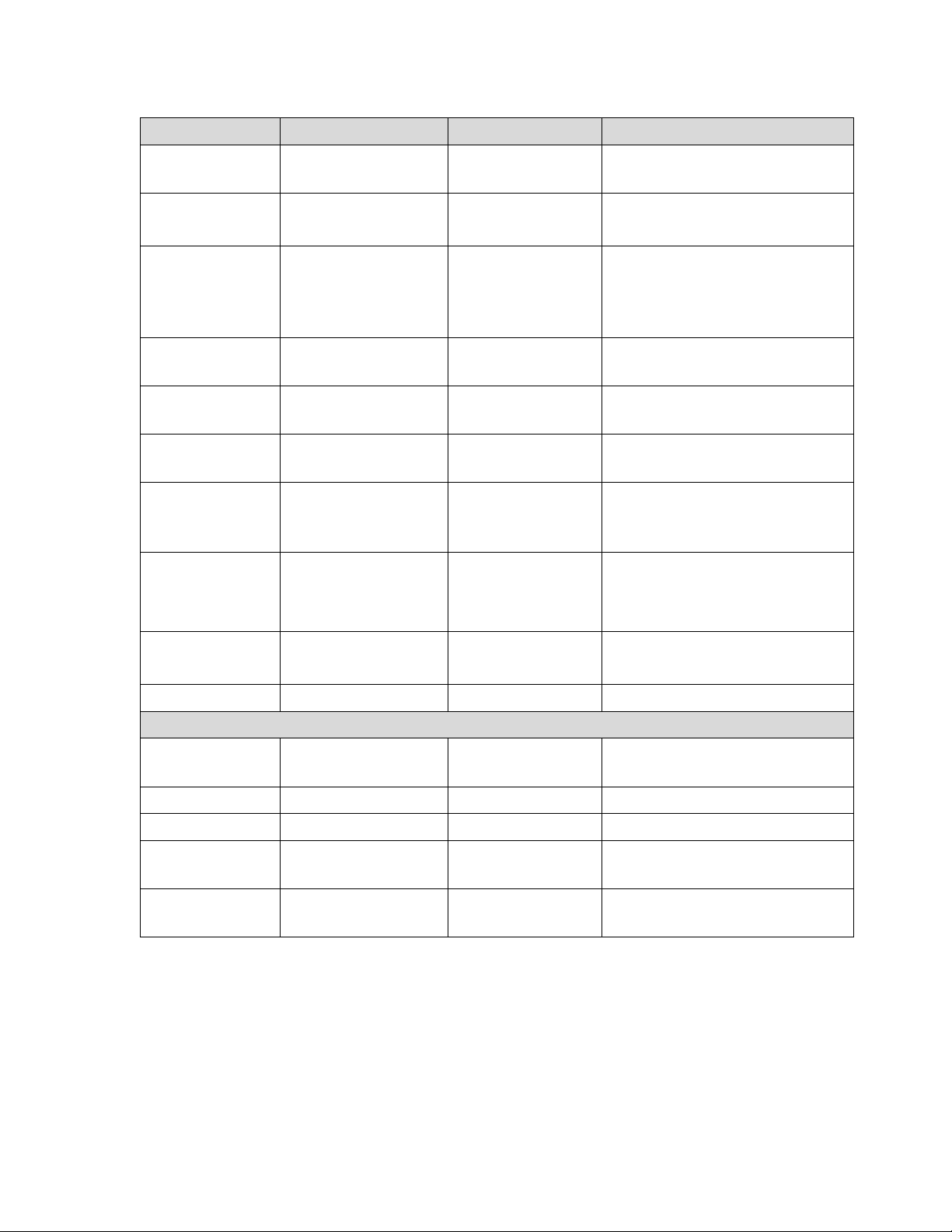

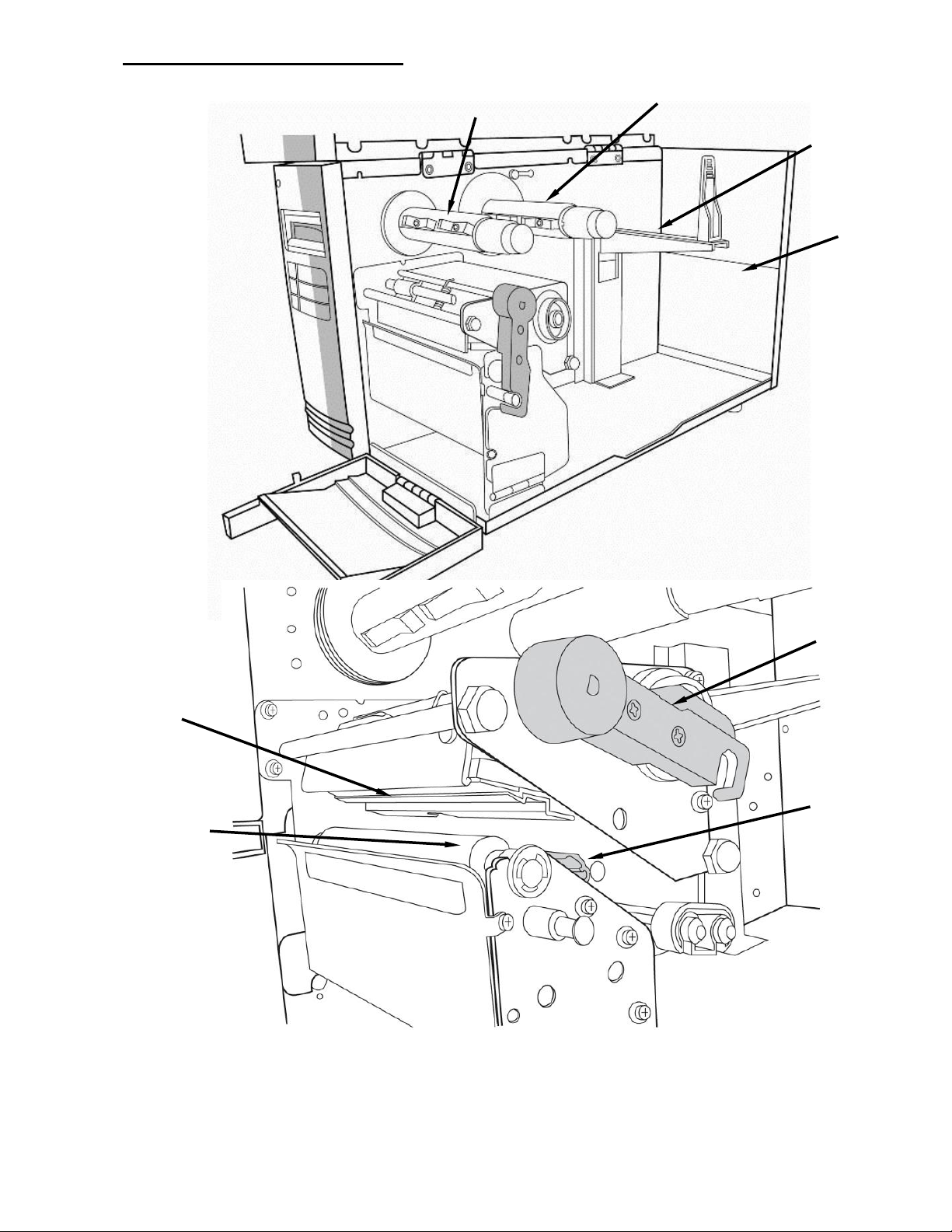

Ribbon Pick-up Spindle

Ribbon Supply Spindle

Media Supply Spindle

Rear

Feed Slot

Head Latch

Thermal Printhead

Paper Sensor

Guide

Internal Parts and Features

Paper Drive Roller

14

Cutter Module

Peeler Option

15

1

Front Access

Loading Ribbon and Media

This section describes how to load ribbon and media.

Loading a Ribbon

Note: This section can be referred to, when transfer thermal printing is used.

The steps below are based on ribbon wound ink-side in as an example.

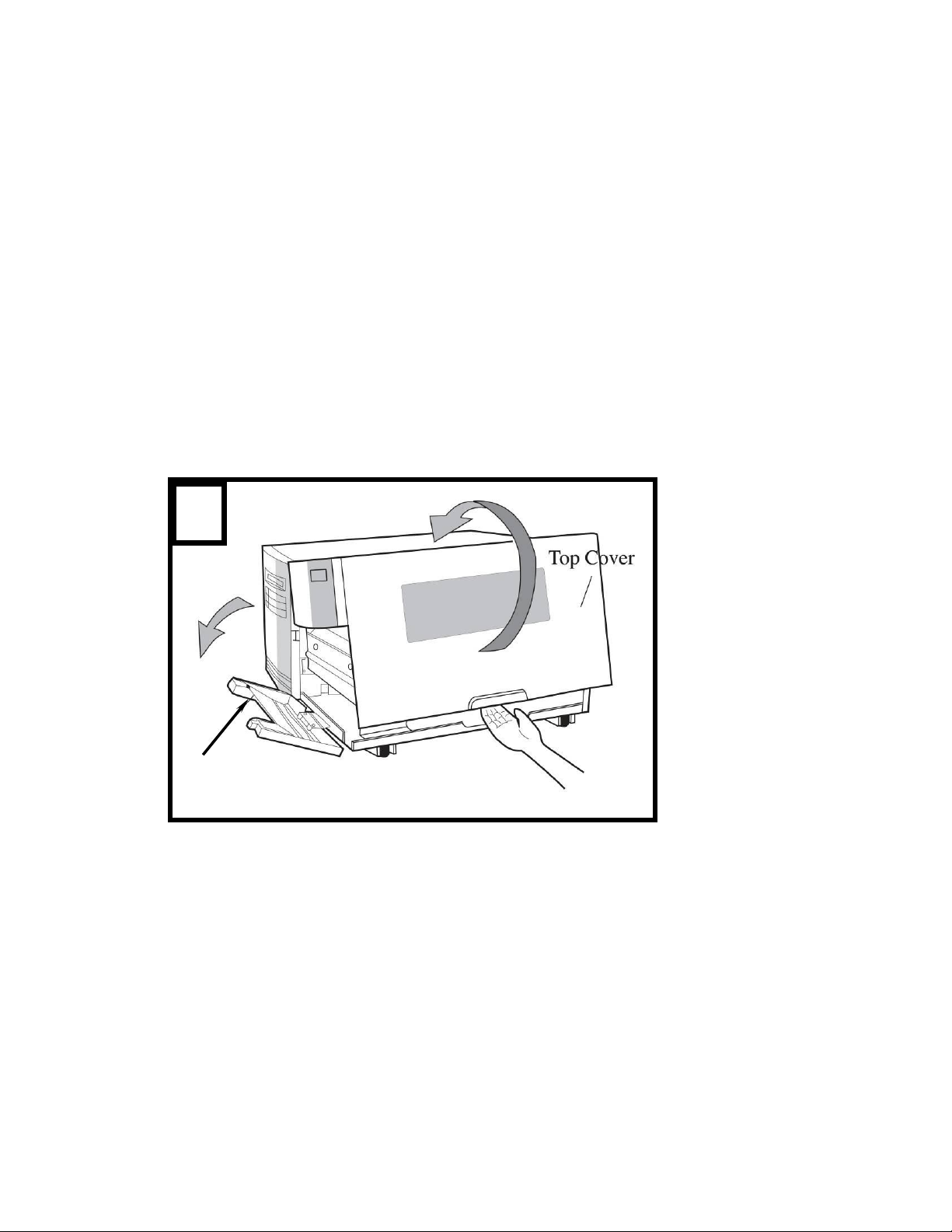

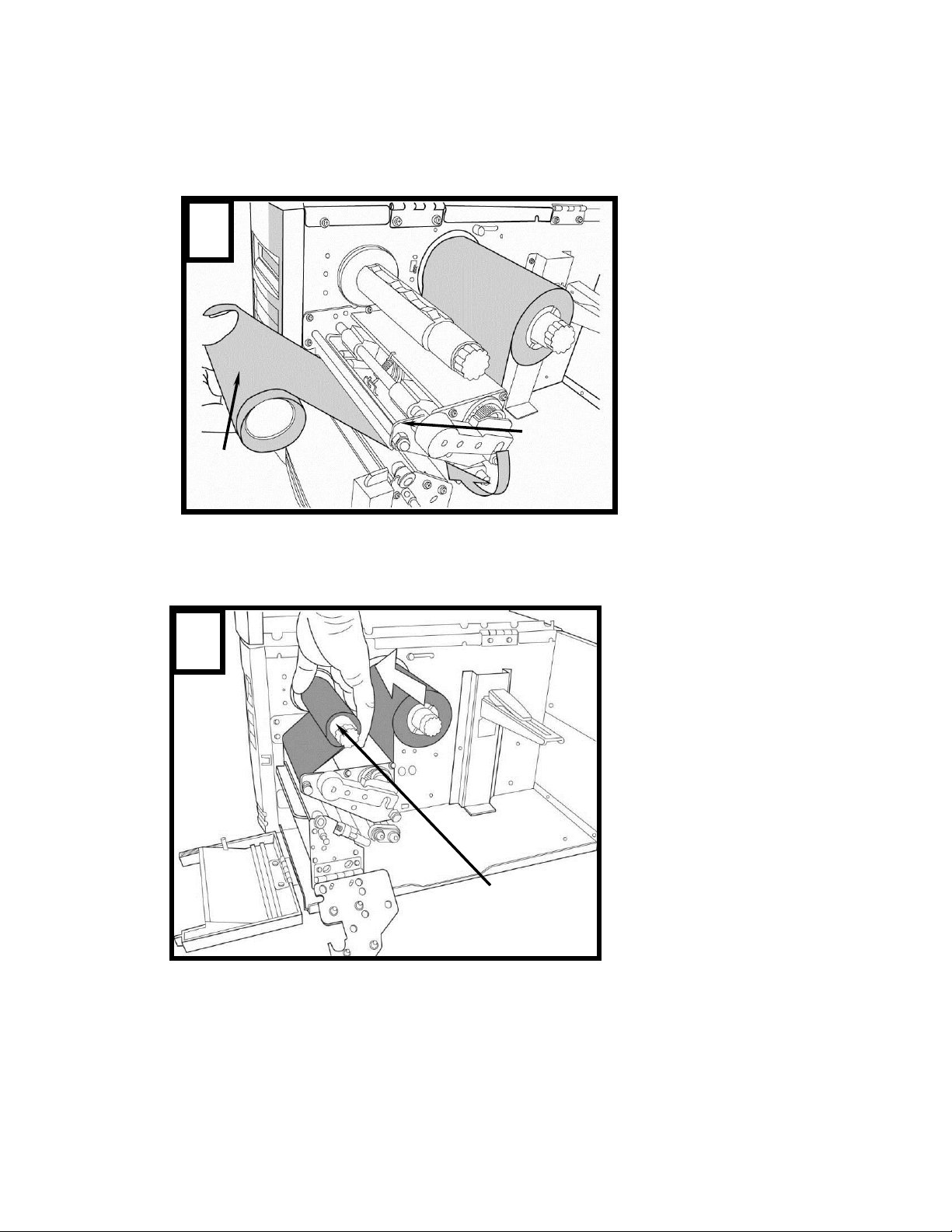

1. Lift the top cover and front access door to expose the media compartment.

(Figure 1)

16

Bracket

2

Head

Latch

3

Ribbon Supply

2. Turn the head latch counter-clockwise and open the bracket. (Figure 2)

3. Unwrap the ribbon and separate the ribbon roll from the bare core. Insert

the ribbon roll onto the ribbon supply spindle. (Figure 3)

17

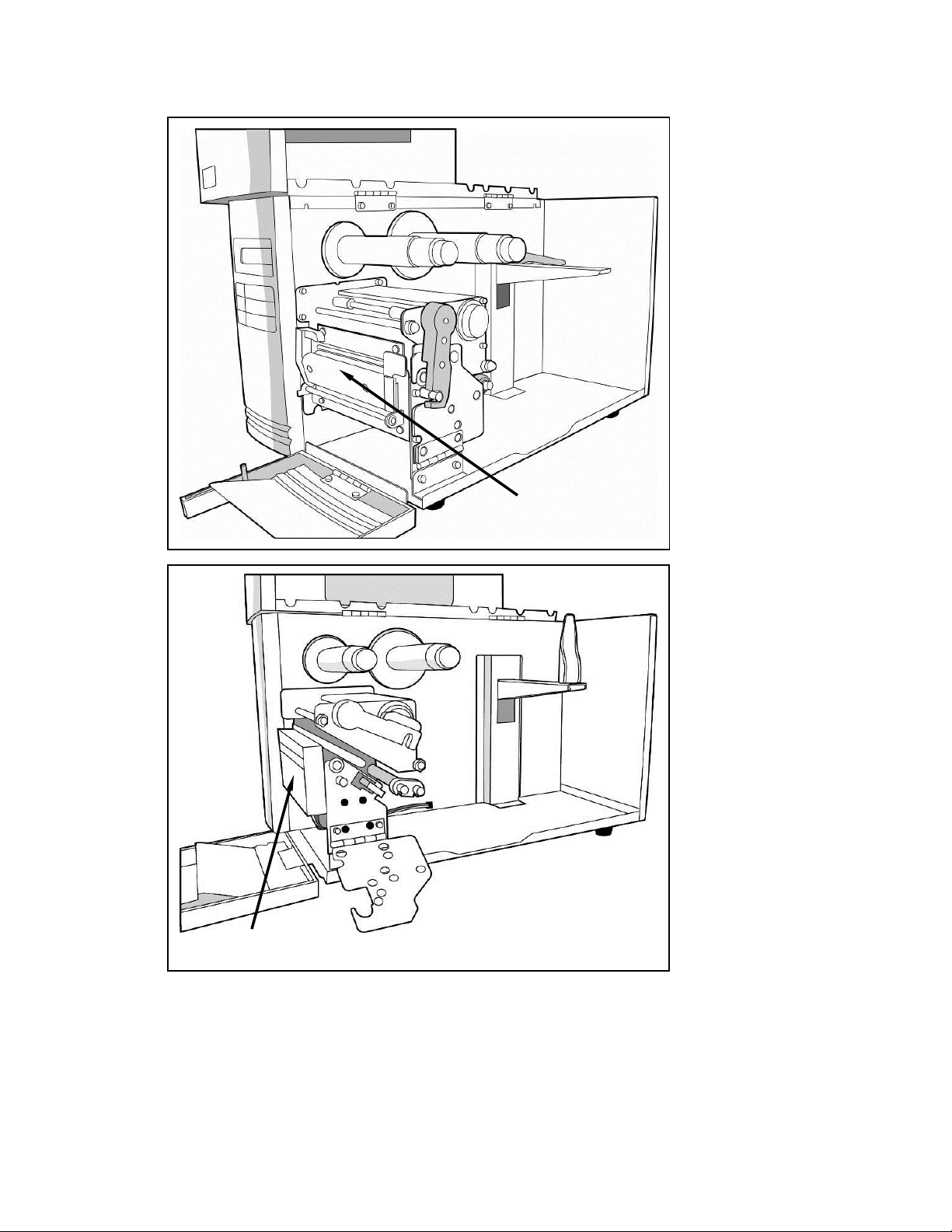

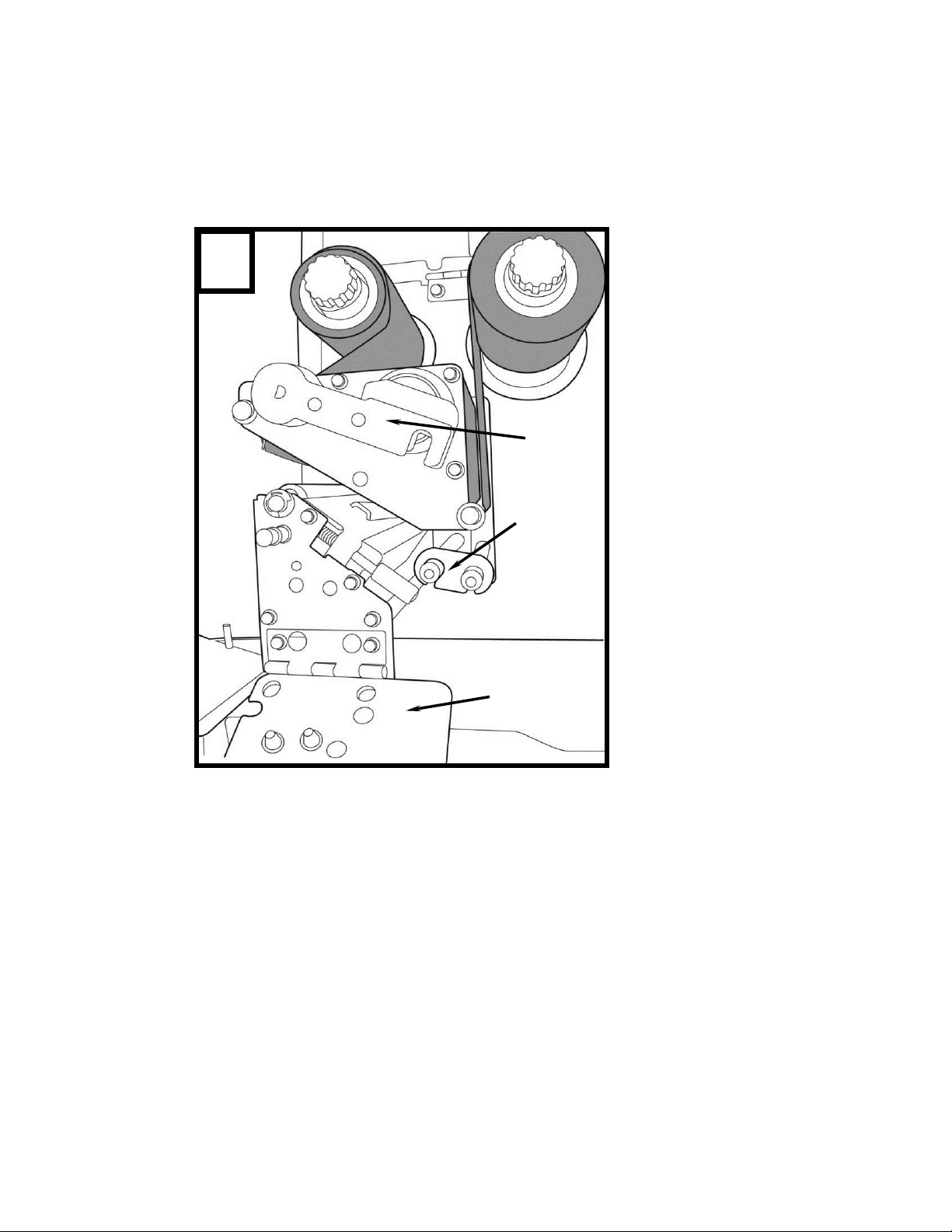

4. Lead the ribbon through the print head module. (Figure 4)

Bar Core

Print

Head

Module

4

Ribbon

Pick-up

5

Ribbon Pick-up

Spindle

5. Attach the edge of the ribbon onto the bare core and wind it a bit onto the

core. Make sure the coating side of the ribbon is face down.

6. Insert the core onto the ribbon pick-up spindle. (Figure 5)

7. Turn the pick-up spindle to ensure the ribbon is tightly wound.

18

6

Media

Guide

Media Supply

Spindle

Loading Media

The 4600 PLUS series printers offer three different loading modes: standard,

peel-off, or with a cutter.

Standard mode allows you to collect each label freely.

Peel-off mode peels backing material away from the label as it prints. After

the label is removed, the next label prints.

Cutting mode automatically cuts the label after it prints.

Standard Mode

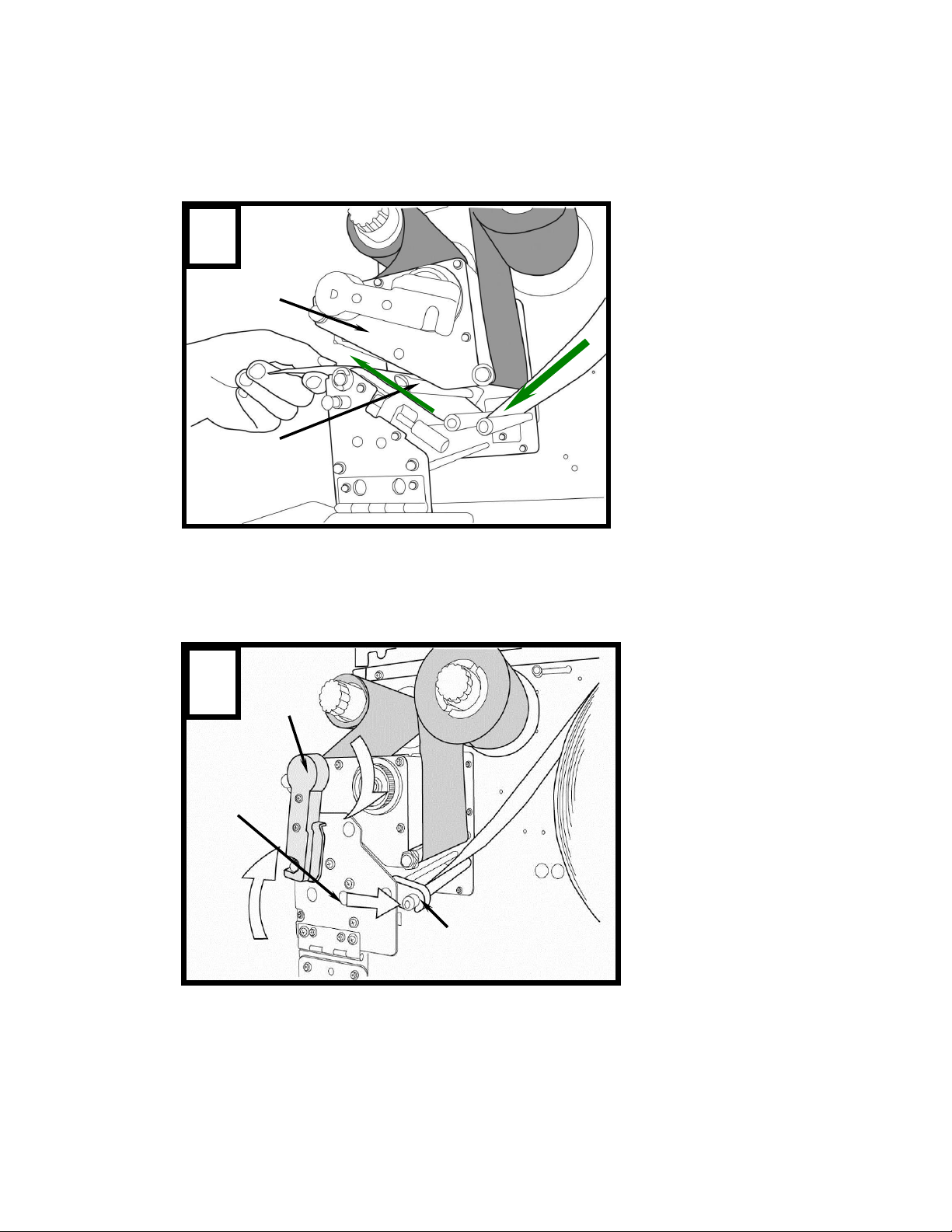

1. Insert the media roll into the media supply spindle and move the media

guide to the inside. (Figure 6)

19

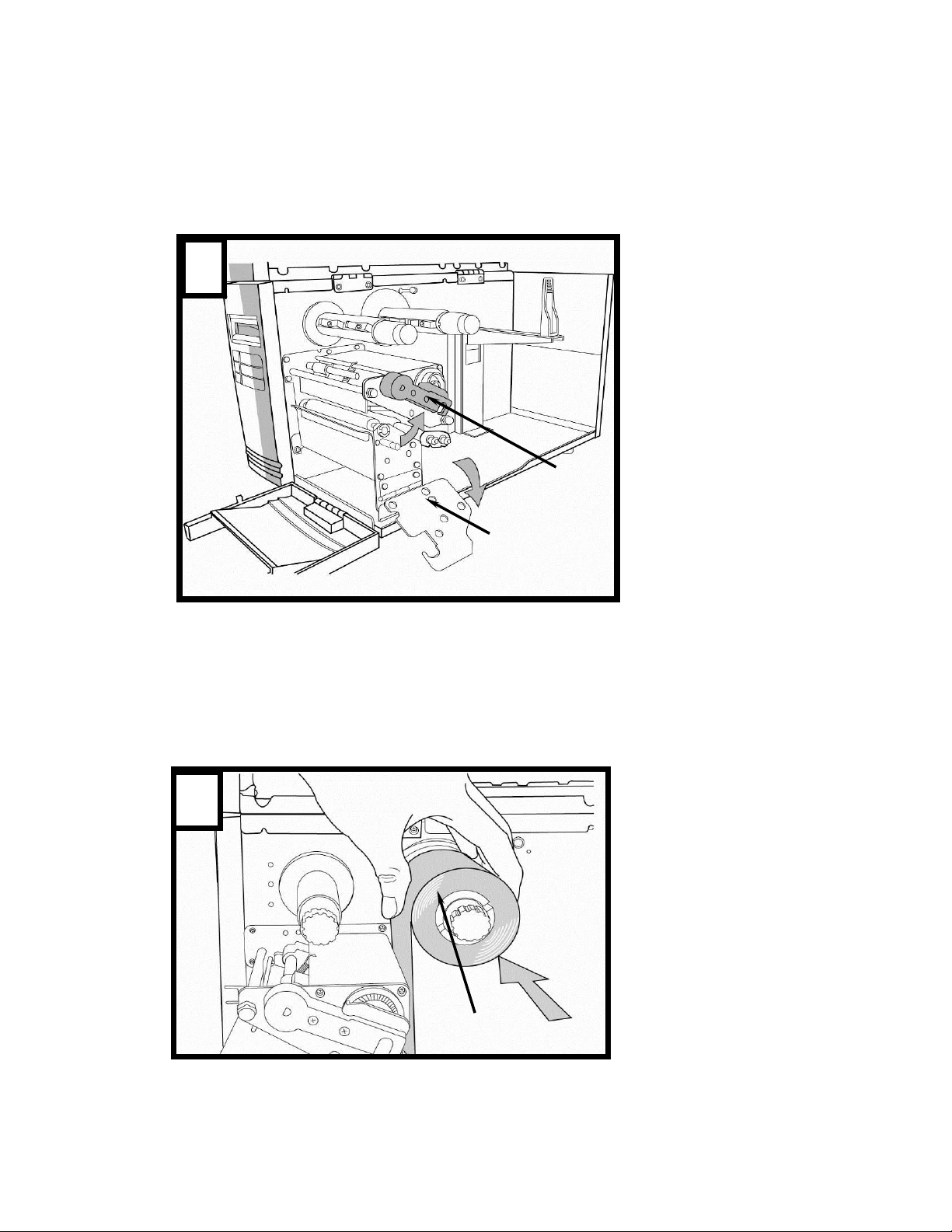

Head

Latch

Bracket

Outside

Media

Guide

7

2. Turn the head latch counter-clockwise and open the bracket. Remove the

outside media guide. (Figure 7)

20

3. Lead the media through the print head module and under the paper

9

Head

Latch

Outside Media Guide

Bracket

8

Print Head

Module

Paper Sensor

Guide Module

sensor guide. (Figure 8)

4. Return the outside media guide, close the bracket, and hook the head

latch. (Figure 9)

21

10

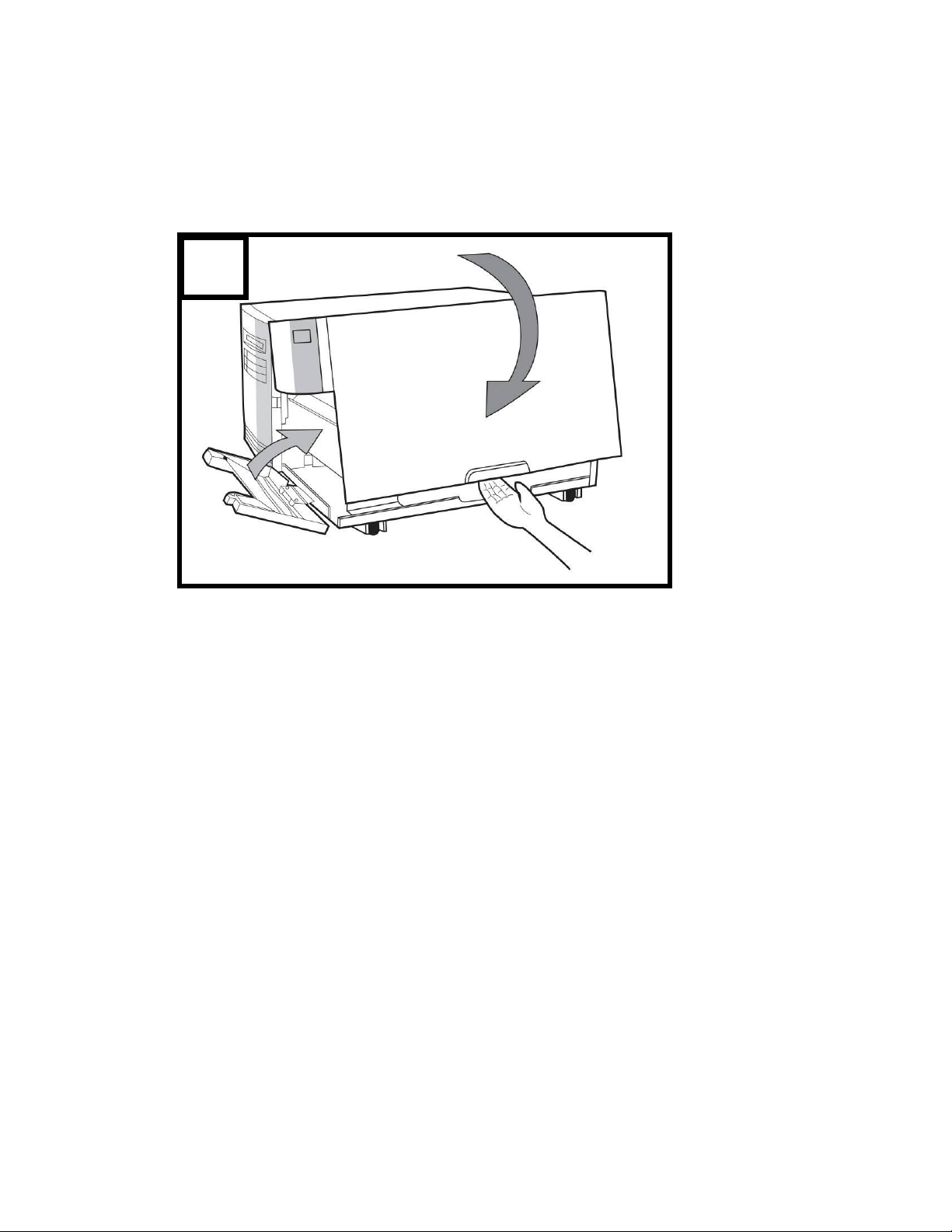

5. Close the top cover and the front access door and turn on the printer, or

press the “FEED” button if the printer is already on. (Figure 10)

22

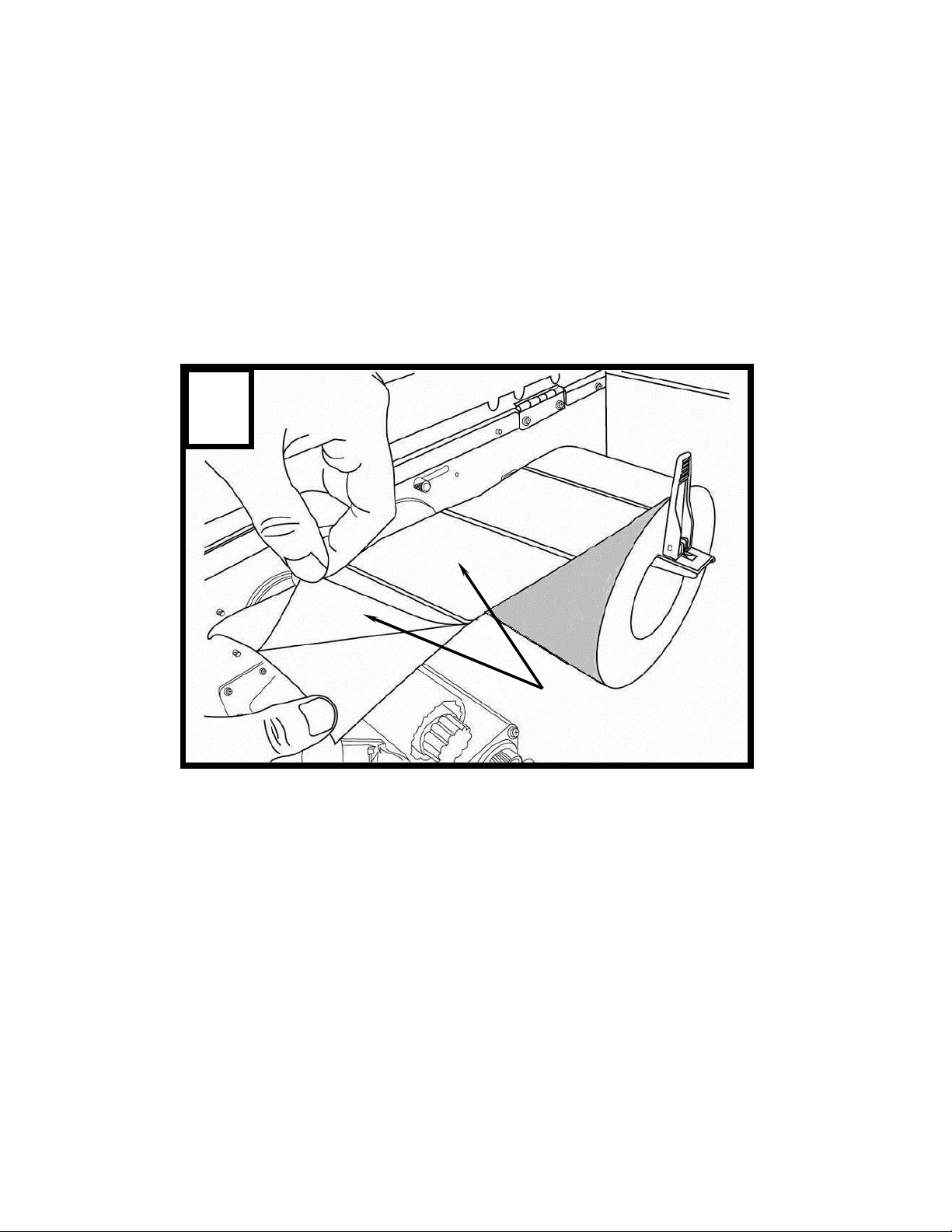

11

Remove labels

Peel Off Mode

Follow steps 1 to 3 in “Loading the Media – Standard Mode” above.

1. From the leading end of the media roll remove enough labels to expose

6-inches of backing/liner. (Figure 11)

Loading...

Loading...