AMS Neve 4081 User Manual

NEVE

4081

Quad Mic Preamp

User Manual

for

Software V1.02 or later

Issue 2

4081 User Manual Issue 2

Health & Safety Notice

FOR YOUR OWN SAFETY AND THE PROTECTION OF OTHERS,

PLEASE OBSERVE THE FOLLOWING HEALTH AND SAFETY INSTRUCTIONS

[ READ THESE INSTRUCTIONS AND KEEP THEM HANDY

[ HEED ALL SAFETY WARNINGS

[ DO NOT USE NEAR WATER

[ CLEAN ONLY WITH A DRY CLOTH

[ DO NOT INSTALL NEAR HEAT SOURCES

[ DO NOT BLOCK VENTILATION OPENINGS

[ PROTECT THE POWER CORD

[ USE ONLY ACCESSORIES SPECIFIED BY THE MANUFACTURER

[ UNPLUG WHEN UNUSED FOR LONG PERIODS OF TIME

[ REFER ALL SERVICING TO QUALIFIED PERSONNEL ONLY

[ NO USER SERVICEABLE PARTS INSIDE

FAILURE TO FOLLOW THESE PROCEDURES AND RECOMMENDATIONS

COULD INVALIDATE THE MANUFACTURER'S WARRANTY

© ® 2008 AMS Neve Ltd own the copyright of all information and figures contained in this manual which are not to be copied or

reproduced by any means or disclosed in part or whole to any third party without written permission.

As part of our policy of continual product improvement, we reserve the right to alter specifications without notice but with due regard to

all current legislation.

Disclaimer: The information in this manual has been carefully checked and is believed to be accurate at the time of publication.

However, no responsibility is taken by AMS-Neve for inaccuracies, errors or omissions nor any liability assumed for any loss or damage

resulting either directly or indirectly from use of the information contained within.

Trademarks: All trademarks are the property of their respective owners and are hereby acknowledged.

- 2 -

4081 User Manual Issue 2

Table of Contents

Health & Safety Notice.....................................................................................................................................2

Introduction........................................................................................................................................................4

Channel Controls..............................................................................................................................................5

Rear Connectors...............................................................................................................................................6

Installing the software – PC............................................................................................................................10

USB Driver.............................................................................................................................10

4081 Software........................................................................................................................11

Standalone Control Setup – PC.....................................................................................................................13

Communications Port..............................................................................................................14

MIDI Port Setup.....................................................................................................................15

Reset Current Rack / Reset All Racks.........................................................................................15

Checkboxes...........................................................................................................................15

Installing the software – Mac.........................................................................................................................17

Pro Tools Control Setup...................................................................................................................................19

Technical / Physical Information...................................................................................................................23

Dimensions.......................................................................................................................................................23

Power Requirements.......................................................................................................................................23

Audio Specification........................................................................................................................................23

Head Office:

AMS Neve

Billington Road

Burnley

Lancashire

England

BB11 5UB

- 3 -

Phone: +44 (0) 1282 457 011

Fax: +44 (0) 1282 417 282

London Office:

+44 (0) 2074 323 858

Email:info@ams-neve.com

Web:

www.ams-neve.com

Support: www.ams-neve.info/ftp/

4081 User Manual Issue 2

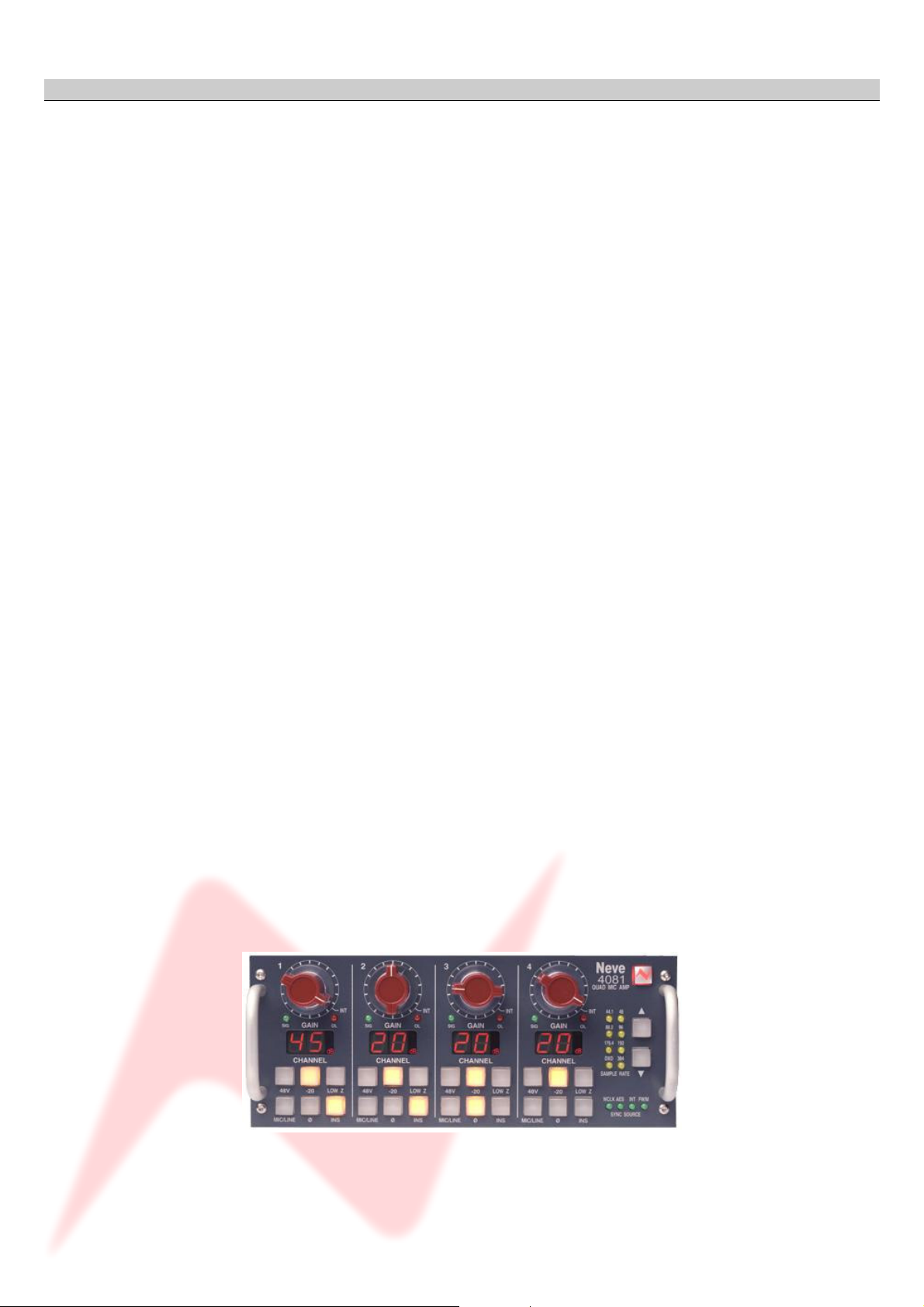

Introduction

The 4081 Quad Mic Preamp builds on the incredible success of the 1081 and 1081R modules and

provides both powerful control and legendary Neve sound.

Perfect for vocals, ADR and Foley recording, the 4081 features make it the number one choice for any

studio, OB truck or live stage environment.

Every function of the 4081 can be controlled directly from the front panel or by remote control using a

Mac or Intel based computer with Neve Remote Control software.

This provides a simple and elegant solution for users of ProTools, Nuendo, Cubase and similar DAW

systems.

Multiple 4081 units can be linked together to create up to 64 independent channels of Mic Preamps or

Line Level inputs, all controlled from a single point.

An optional Digital module provides a Firewire/AES interface with four channels of A/D and D/A

conversion to either AES or Firewire.

An Insert point is available before the A/D converter on each channel to allow external, analogue

outboard equipment to be switched into the signal path.

• Legendary Neve microphone preamp design.

• Four genuine 1081 Mic preamp channels in a single 8.5” wide unit.

• Two units can be fastened together to provide 8-channels in a single 19” unit.

• Remote control using a Mac/Intel computer and the Neve remote control software.

• XLR Mic input can be switched between Mic and electronically balanced Line.

• Switchable 48V Phantom power supply.

• Digital I/O Option:

• Firewire/AES interface with four channels of A/D conversion to either AES or Firewire and 4 channels

of D/A conversion.

• Analogue Insert (pre A/D converter) per channel.

- 4 -

4081 User Manual Issue 2

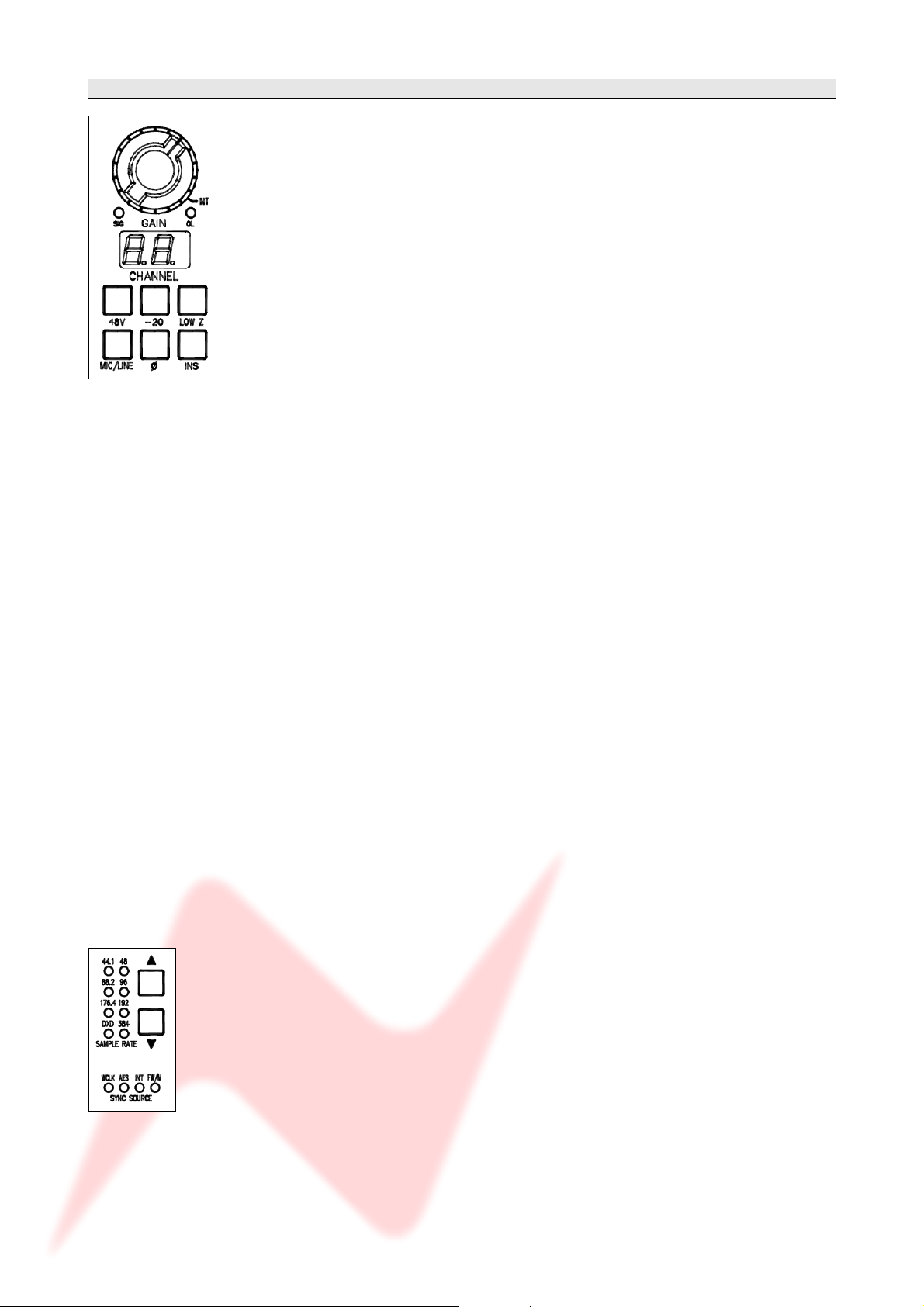

Channel Controls

The channels can be controlled from the front panel, from a remote Mac or

PC or from Pro Tools using the optional remote control software.

By default, the unit powers-up with all functions locally controllable and

settings are retained on power-down.

The unit is powered by the silver switch with the Neve logo, which will

light red once the power is on.

Front panel control is available on each input for:

▪ 48V: Turns on Phantom Power to the Mic (Not available for LINE)

▪ -20: Pad, attenuates the incoming Mic signal by -20dB (Not available

for LINE)

▪ LOW Z: Impedance for Ribbon Microphones (Not available for LINE)

▪ MIC/LINE: Selects between the Mic or Line input.

The button lights yellow when MIC is selected; the button will be unlit

for LINE.

▪ Ø: Swaps the incoming phase of the Mic or Line signal.

▪ INS: This function is controls the source for the A/D in the FireWire

expansion module if fitted.

When illuminated, allows an external Insert Pre- the A/D of the

expansion module.

Turning the Gain control will vary the gain as shown in the display

beneath.

The Gain level is not related to the actual position of the knob, which will

infinitely rotate.

• The MIC gain control runs from +20dB to +70dB in 5dB steps.

• The LINE gain control runs from 0dB to +20dB in 5dB steps.

Just beneath the Gain control are two leds that indicate:

• Signal Presence (lights green at approx -30dBu or greater)

• Signal overload (lights red at 2dB below clipping)

The metering point is Post- the Gain stage.

The maximum signal level is 26dBu.

The Gain knob also has a push-switch which only has a function if the unit

is attached to an AMS Neve 88R console, where it is used to interrogate

console control settings (to be implemented in V2.0 software)

If the optional Digital / Firewire hardware is fitted, the Sample Rate

leds and adjacent buttons will also function.

The unit automatically detects the type and sample rate of the incoming

sync signal if a connection is made to the WCLK I/P connector on the

rear.

The and buttons are used to step through the available sample rates

when running on internal sync.

• If running on Internal sync, the WCLK O/P BNC connector on the rear

will transmit this sync.

• If running on an External sync source, the WCLK O/P BNC connector

on the rear will transmit this sync instead.

The leds will reflect the sample rate & sync source once selected.

- 5 -

4081 User Manual Issue 2

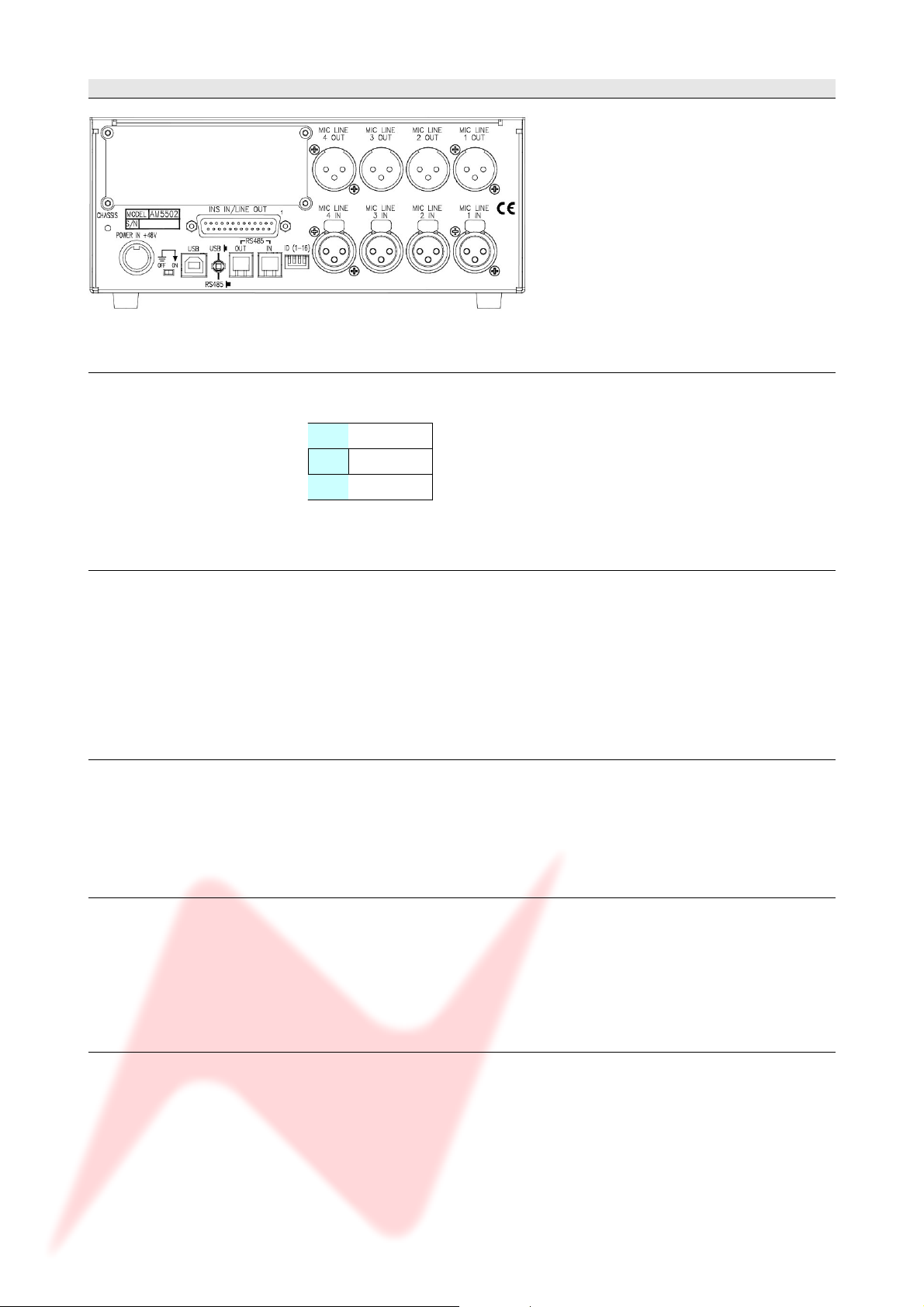

Rear Connectors

(Optional Digital Board not shown).

Mic / Line Input XLRs

Employs standard XLR wiring:

1 Screen

2 Hi

3 Lo

Mic / Line Output XLRs

Power input

INS IN / LINE OUT

These can either be used as Direct Outputs from the unit, or as Insert

Sends.

The Output is Post- the Gain control.

Pin-outs as above.

48 volts, 8-pin connector.

This connector is polarised so can only be connected in one way.

25-way D-type connector contains the Insert Return signals.

The Line Out part of this connector will have no function unless the

optional AD/DA card is fitted (see below).

USB / RS 485

It is possible to 'daisy-chain' multiple units together so they are controlled

via USB on a Mac or PC.

The first unit on the chain should be connected to the Mac or PC by a USB

cable (not supplied).

The blue USB/RS485 button on the rear of this unit should be pushed in.

Subsequent units are connected from the RS 485 OUT of the 1

st

unit, to

the IN on the 2nd; from the OUT of the 2nd to the IN of the 3rd and so on

- 6 -

4081 User Manual Issue 2

(these subsequent units should have the blue USB/RS485 button on the

rear pushed out to select RS485 control).

The RS 485 communication protocol uses standard RJ9 connectors for

connecting cables where multiple units can be chained together (cabling

not supplied).

Please note that when connecting multiple units, each 4081 should have a

unique ID as described below.

Cable Specification

The RS-422 specification recommends 24AWG twisted pair cable with a

shunt capacitance of 16 pF per foot and 100 ohm characteristic

impedance.

These recommendations should be used for RS-485 systems as well.

We also recommend using shielded cable.

There are many cables available meeting the recommendations of RS-485

made specifically for this application. Another choice is the same cable

commonly used in the twisted pair Ethernet cabling. This cable, commonly

referred to as Category 5 cable, is defined by the EIA/TIA/ANSI 568

specification.

This cable has a maximum capacitance of 17 pF/ft (14.5 pF typical) and

characteristic impedance of 100 ohms.

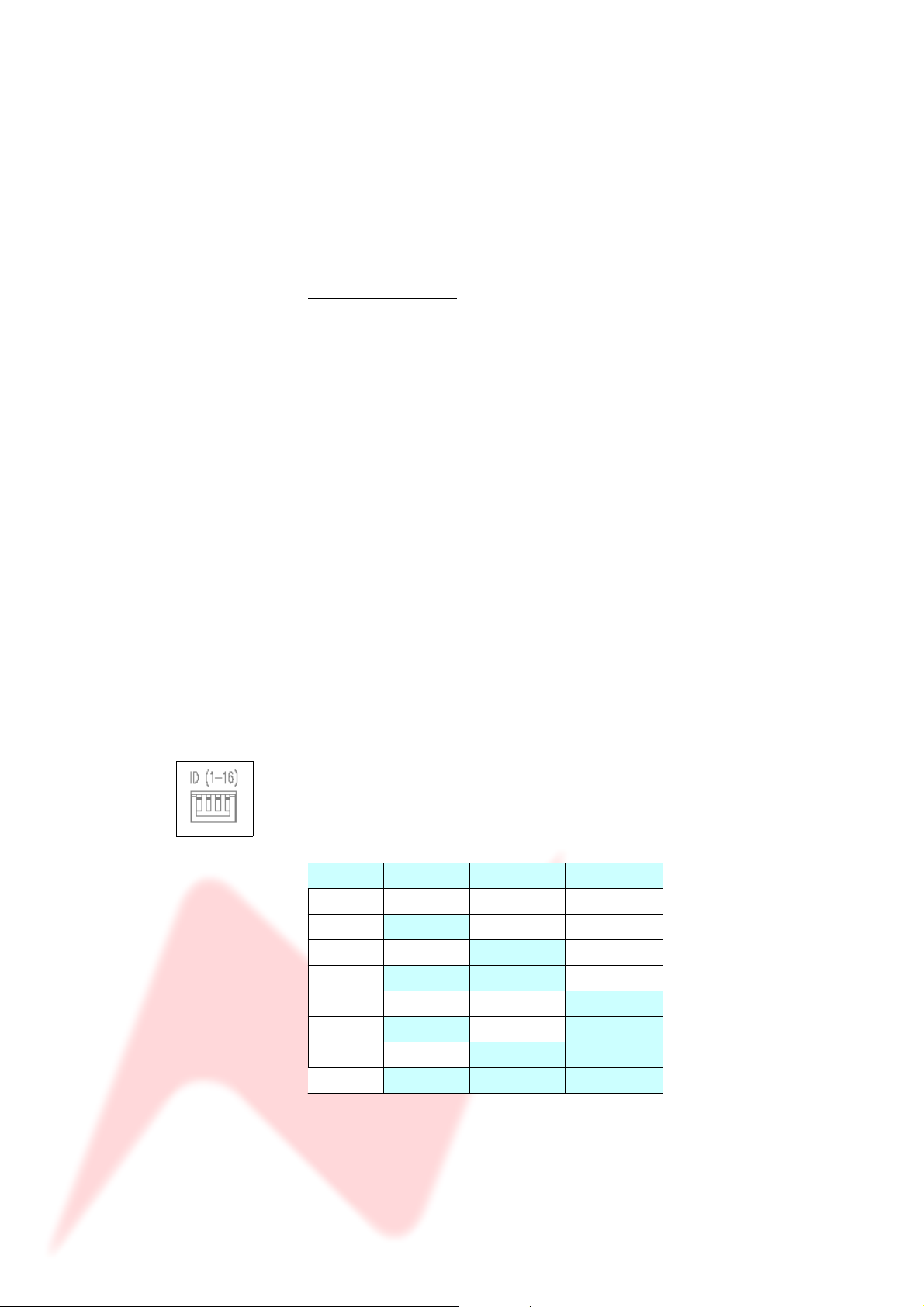

4081 unit ID dip switches

Category 5 cable is available as shielded twisted pair (STP) as well as

unshielded twisted pair (UTP) and generally exceeds the recommendations

for RS-422 making it an excellent choice for RS-422 and RS-485 systems.

When remotely controlling more than one unit, the ID dip-switches on the

rear of the unit need to be set so that each sequentially numbered unit on

the chain responds to the correct commands.

The first 3 switches from left to right are used to set the machine IDs from

1-8. These switches are On when in the down position (the right-most

switch on this block – Switch 4 - puts the unit into 'Bootloader Mode'

where the unit software can be updated via USB, so is therefore not used

to set the unit ID).

Unit ID Switch 1 Switch 2 Switch 3

1 Off Off Off

2 On Off Off

3 Off On Off

4 On On Off

5 Off Off On

6 On Off On

7 Off On On

8 On On On

Where there are more than 8 units on an RS 485 chain, the IDs for units

greater than 8 are set using a dip-switch on the switch-block labelled

SW2 inside the unit (just next to a programming connector labelled J14

on the middle left of the board).

- 7 -

Loading...

Loading...