Page 1

ELLIPSE

Service Manual

Via E. Barsanti 17/A

00012 Guidonia – ROME (ITALY)

www.ams-analyzers.com

Page 2

CONFIGURATION SHEET

CHAPTER DESCRIPTION REVISION

INDEX TABLE OF CONTENTS 03

01 INTRODUCTION

02 SYSTEM DESCRIPTION

03 INSTALLATION

04 ELECTRICAL SCHEMES AND DRAWINGS

05 DIAGNOSTIC PROGRAM

06 SETTINGS AND ADJUSTMENTS

07 MAINTENANCE

08 HOST COMMUNICATION

09 ERROR SIGNALING AND TROUBLESHOOTING

03

03

03

03

03

03

03

04

03

Ellipse Service Manual Rev.04 01 October 2009 Page 1

Page 3

TABLE OF CONTENTS

Chapter 01 INTRODUCTION

Chapter 02 SYSTEM DESCRIPTION

Chapter 03 INSTALLATION

Chapter 04 ELECTRICAL SCHEMES AND DRAWINGS

INDEX

Chapter 05 DIAGNOSTIC PROGRAM

Chapter 06 SETTINGS AND ADJUSTMENTS

Chapter 07 MAINTENANCE

Chapter 08 HOST COMMUNICATION

Chapter 09 ERROR SIGNALING AND TROUBLESHOOTING

Ellipse Service Manual Rev.03 01 June 2009 Page 1

Page 4

Chapter 01 – INTRODUCTION

CHAPTER 01

- INTRODUCTION -

INDEX

1 INTRODUCTION ................................................................................................................. 1

1.1 THE AIM OF THE TECHNICAL MANUAL

1.1.2 MANUAL OUTLINE……………………………..……………………..……………..………………....2

1.2 SYSTEM INTRODUCTION ................................................................................................ 3

1.3 PRECAUTIONARY MEASURES ....................................................................................... 3

1.3.1 CHEMICAL RISKS .............................................................................................................. 5

1.3.2 ELECTRICAL RISKS........................................................................................................... 5

1.3.3 MECHANICAL RISKS......................................................................................................... 4

1.4 GUARANTEE ...................................................................................................................... 5

1.5 TECHNICAL OPERATING FEATURES………………………………………….…. ..... 6

1.5.1 COMPUTER & SOFTWARE FEATURES ........................................................................ .9

1.5.2 OPTIONS............................................................................................................................... 8

………………………………………...………..…..2

1.5.3 DIMENSIOS, WEIGHT & ENVIRONMENT.................................................................... 10

1.5.4 INSTALLATION REQUIREMENTS................................................................................ 10

Ellipse Service Manual Rev. 03 01June 2009 Page 1

Page 5

Chapter 01 – INTRODUCTION

1 INTRODUCTION

1.1 THE AIM OF THE TECHNICAL MANUAL

This manual has been written in order to supply the technical staff, the persons who are responsible

for the maintenance and for resolving instrument failures, a complete and detailed guide of the

Ellipse analyzer, in accordance with the standard UNI EN591 (which requires a manual to be

supplied with vitro diagnostic instruments for professional use).

1.1.2 MANUAL OUTLINE

The technical manual is composed of 10 chapters that not only describe the operative technical

characteristics of the system, but also the reparation and maintenance procedures to use for the

modules that they are composed of.

. Chapter 1 INTRODUCTION

The manual structure is described, and recommendations are given regarding the general

use of the analyzer. The technical characteristics of the operative system are given in this

chapter.

. Chapter 2 DESCRIPTION OF THE SYSTEM

Describes the system, in particular, the analytical cycle of the single modules and

electronic boards.

. Chapter 3 INSTALLATION

Describes the unpacking procedures and the required characteristics for the place of

installation.

. Chapter 4 ELECTRONICS SCHEMES AND DRAWINGS

Gives the electronics schemes and assembly drawings of the electronics board and the

assembly drawings of the modules that the system is composed of.

Ellipse Service Manual Rev. 03 01June 2009 Page 2

Page 6

Chapter 01 – INTRODUCTION

. Chapter 5 DIAGNOSTIC PROGRAM

Describes the folders in the Diagnostic Program that are responsible for the checks and the

calibration of the modules in the system.

. Chapter 6 SETTINGS AND ADJUSTMENTS

Gives the procedures for replacement, adjustment and check of the system modules.

. Chapter 7 MANTENANCE

Describes the routine maintenance that needs to be done on a regular basis in order to

guarantee the correct functioning of the analyzer.

. Chapter 8 COMUNICATION WITH HOST

Describes the communication protocol between the analyzer and the Host computer.

• Chapter 9 ERROR CODES AND GUIDE TO RESOLVE ANOMALIES

Lists the system’s error codes, describes the errors in the results and gives a guide for how to

implement corrective actions.

The technical staff responsible for resolving the structural anomalies is highly suggested to

thoroughly examine the contents of this manual before operating the system.

Ellipse Service Manual Rev. 03 01June 2009 Page 3

Page 7

Chapter 01 – INTRODUCTION

1.2 SYSTEM INTRODUCTION

The “Ellipse” system is a continuous-loading, random access, bench top instrument for performing

chemical and Immunoturbidimetric clinical analysis. It is totally automatic and computer

controlled.

Via E. Barsanti 17/A

00012 Guidonia – ROME (ITALY)

Ellipse Service Manual Rev. 03 01June 2009 Page 4

Page 8

Chapter 01 – INTRODUCTION

1.3 PRECAUTIONARY MEASURES

1.3.1 CHEMICAL RISKS

The individual operator is responsible for assuring that all possible precautionary measures are

taken against eventual risks associated with the use of the “Ellipse” instrument in clinical laboratory

settings. The manufacturer will provide the reagents kit and specific written information on the use

of each of the reagents.

It is important that the samples be well coagulated and then carefully centrifuged.

Samples which contain fibrinogen clots can obstruct the probe and lead to inexact sampling.

If blood samples containing gel are used, it is suggested that the manufacturer’s recommendations

be followed.

Immediately clean and remove any accidental leakage of reagent or other liquid.

1.3.2 ELECTRICAL RISKS

As with any electrical device, the risk of electric shock exists.

Is therefore necessary to take every precautionary measure possible when working with this, or any

other, electrical instrument to avoid contact with power supply wires, electrical components or

electronic boards.

1.3.3 MECHANICAL RISKS

Several precautionary measures should be taken when operating the analyzer:

avoid wearing very loose clothing or jewelry that could become tangled in the instrument’s moving

parts (e.g. the sample probe); whenever possible, operate the instrument with the main cover panel

lowered.

WARNING: Never attempt to service or substitute any part(s) of the analyzer when the

instrument is turned on.

Any and all technical repairs or servicing must be performed by specialized personnel only.

Ellipse Service Manual Rev. 03 01June 2009 Page 5

Page 9

Chapter 01 – INTRODUCTION

1.4 WARRANTY

AMS guarantees the replacement of all defective components and/or materials for a period of time

not above of 14 months starting from the date of invoicing. Saying guarantee, as well as Technical

Assistance, generally is intended furnished as net ex factory Rome.

This guarantee does not include consumable and instrument parts in contact with liquids. All

components not included in the guarantee are reported in the following table.

Besides guarantee does not cover damage caused by :

- improper use of the ELLIPSE instrument (or however not according to the Producer or

Seller instructions)

- bad transport

- insufficient (or missing) preventive maintenance by the User

In particular any damages due to the transport must be immediately reported to the carrier when he

delivers.

Ellipse Service Manual Rev. 03 01June 2009 Page 6

Page 10

Chapter 01 – INTRODUCTION

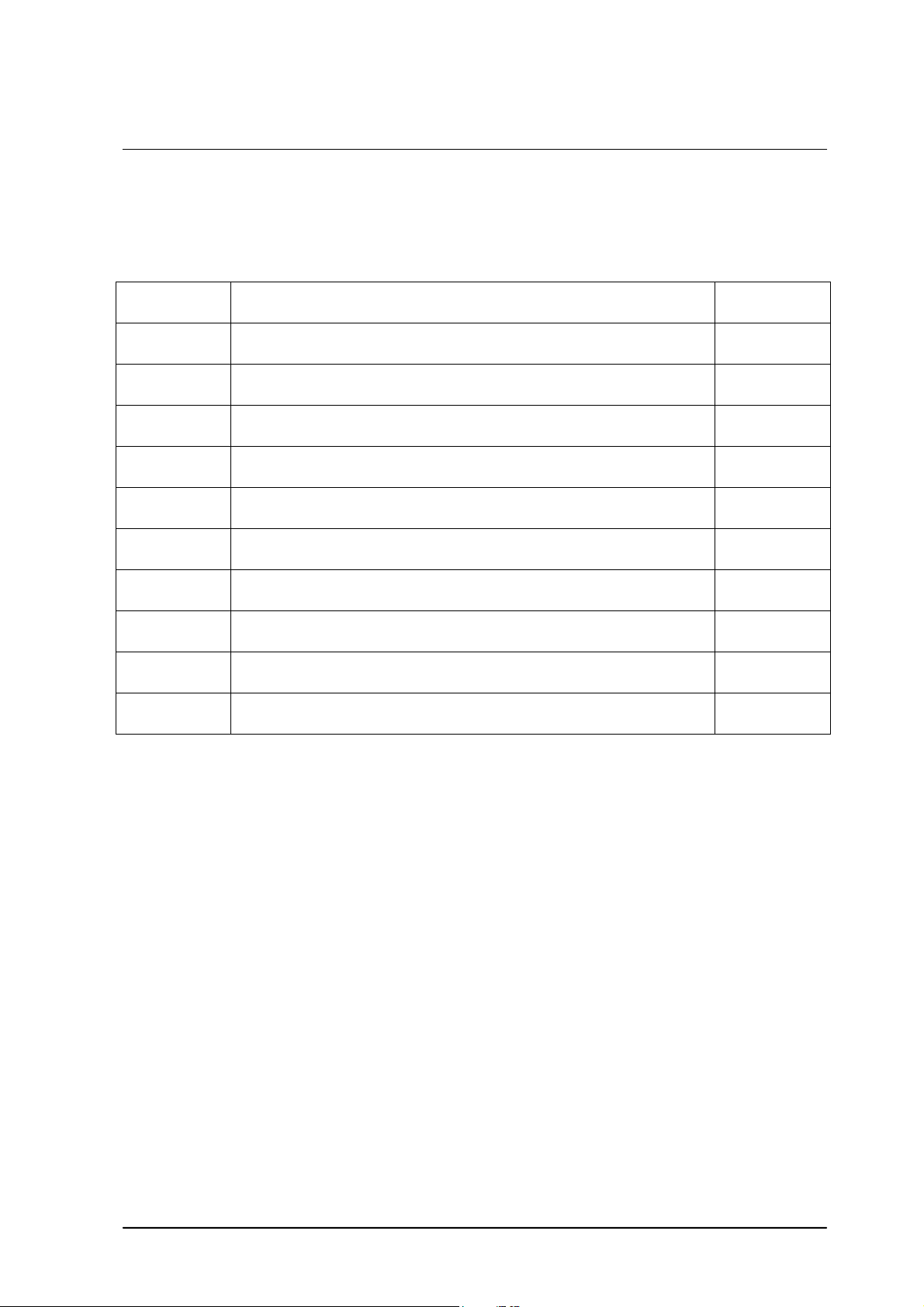

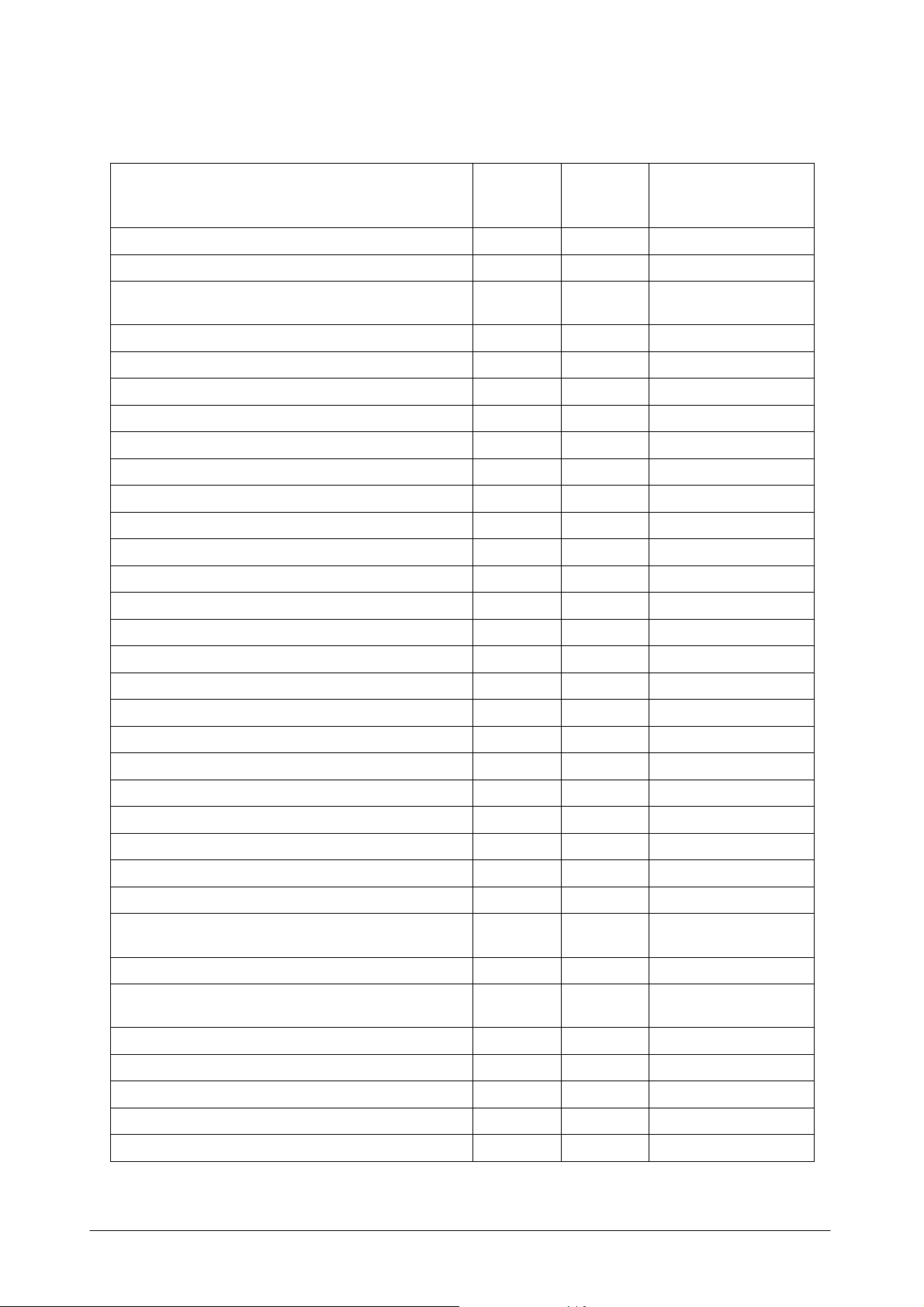

CONSUMABLES AND ACCESSORIES PARTS LIST OUT OF GUARANTEE

Description

Type Quantity Code

Reagents containers 35 ml 12 pieces C101-00190-00

Reagents containers 6 ml 12 " C101-00191-00

Samples cups 0.8 ml

1000 "

AS-65-0002

Short samples cups 1 ml 1000 " AS-65-0100

Adapter for short samples cups 1 " 9-01-0609-00

Reaction sectors 6 " C101-00217-00

Washing solution bottle 2 lt 1 " 9-35-0041-00

Bottle level sensor 1 " 9-05-0078-00

Tubing Kit for peristaltic pump 2 " 65-01835-00

Tubing Kit – complete 1 " 65-01836-00

Cleaning solution 250 ml 2 " ASRN0020

Rinse solution 50 ml 1 " ASRN0021

Sampling probe (internal needle) 1 " 05-00707-00

Complete Sampling probe 1 " 10-00703-00

Drying Pad 1 " 10-01920-00

Halogen Lamp (6 V - 10 W) 1 " 9-35-0016-00

Interferential filters Kit 1 " 9-65-0029-00

Fuse 6,3 A-T 5x20 10 " C130-01238-08

Inlet/outlet fitting for Rinse & Clean conts 1 " 01-01224-00

Cuvettes protection cover 1 " 05-01249-00

Reagent protection cover 1 " 10-00584-00

Reagent plate 1 " 10-00585-00

Samples rack 1 " 05-01829-00

Washing station, first or second cannulas (A) 1 05-01633-00

Washing station, third cannula (B) 1 05-01633-01

Washing station, fourth cannula (C)

1

05-01638-00

Washing station, fifth cannula without pad (D) 1 05-01919-00

Diluter Micro-Pump

1 " 05-01710-40

Air Micro-Pump (µP 6) 1 " 05-01711-20

Micro-Pump (µP 2 ÷5) 1 " 05-01826-16

Predilution rack 1 " 05-01735-00

Solenoid Valve –2 way 1 " 9-35-0035-00

Solenoid Valve –3 way 1 " 9-35-0036-00

Ellipse Service Manual Rev. 03 01June 2009 Page 7

Page 11

Chapter 01 – INTRODUCTION

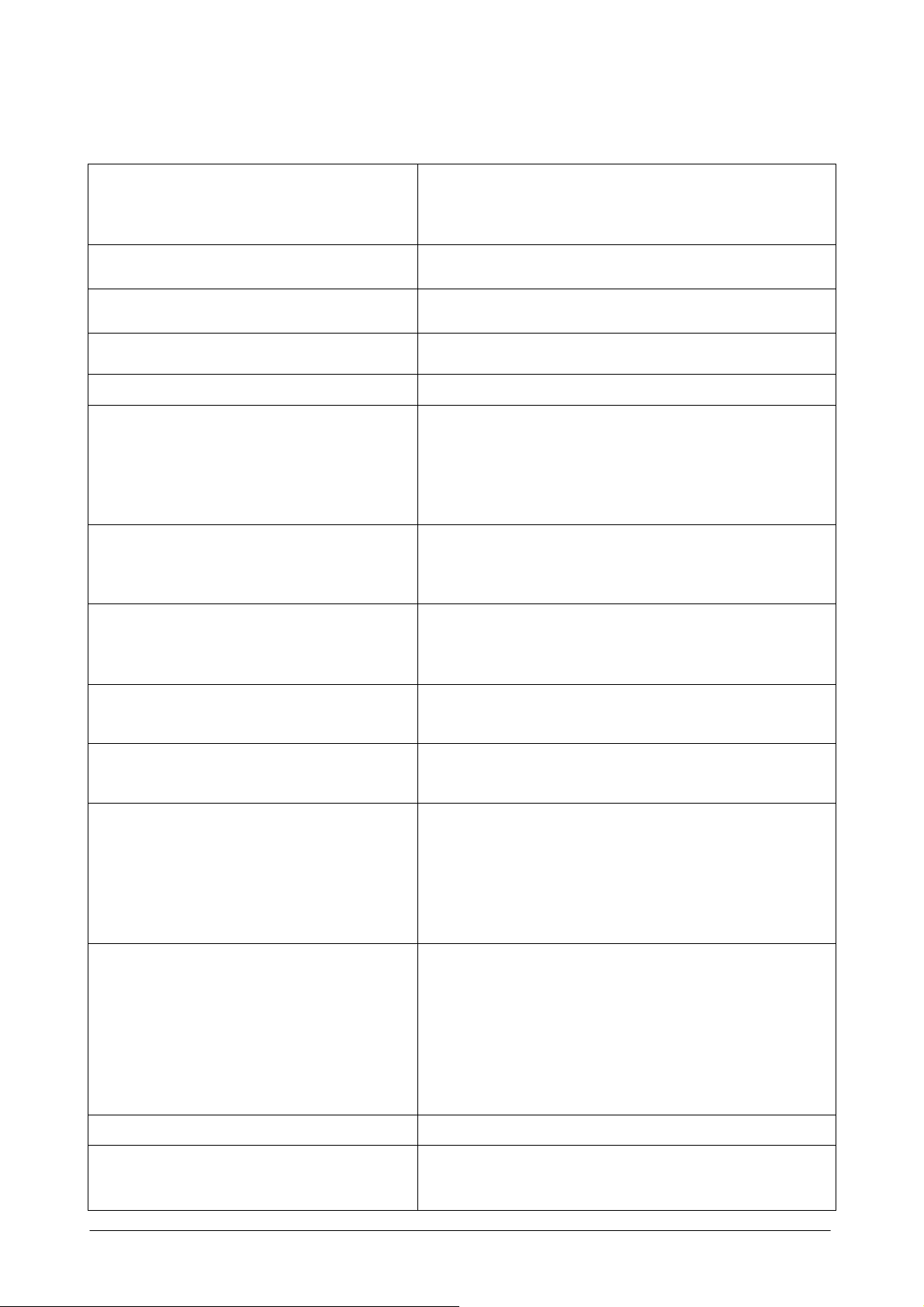

1.5 TECHNICAL OPERATING FEATURES

DESCRIPTION

ASSAY TYPE

TEST ENTRY MODE

THROUGHPUT

♦ Fully automatic, random access, continuous loading,

benchtop analyzer for clinical chemistry and

immunoturbidimetric assays;

♦ End Point, Initial Rate, Kinetic, Bichromatic, Differential;

♦ Selective, Batch, Profiles, STAT

♦ 138 tests per hour

WORKING TEMPERATURE ♦ 37° C

♦ 24 removable containers by 40 ml and 6 ml;

ON LINE REAGENTS

♦ 12 positions for Controls and Standards;

♦ Positive identification by a Bar Code Reader

♦ Primary tubes (diameter from 8 to 16 mm; height up to

100 mm) cups from 1 to 4 ml;

SAMPLE CONTAINERS

♦ 4 racks, each having 8 positions for continuous sample

loading

SAMPLE LOADING

♦ Positive identification by a Bar Code Reader

MINIMUM REACTION VOLUME

MAXIMUM REACTION VOLUME

SAMPLING ARM

DILUTER

PRECISION

♦ 220 µl

♦ 550 µl

♦ A single mechanical arm provides all the sampling

operations and is equipped with:

• Capacitive liquid level sensing

• Reagent pre-warming at 37° C

• Automatic probe washing

♦ Integrated syringe-free module having the following

specifications:

• Sample volume: 2 µl ÷ 99 µl (1 µl incr.)

• Reagent 1 volume: 3 µl ÷ 500 µl (1 µl incr.)

• Reagent 2 volume: 3 µl ÷ 330 µl (1 µl incr.)

• Reagent 3 volume: 3 µl ÷ 330 µl (1 µl incr.)

♦ CV < 1 % at 2 µl

READING SYSTEM

♦ Direct reading

Ellipse Service Manual Rev. 03 01June 2009 Page 8

Page 12

Chapter 01 – INTRODUCTION

♦ Photometer: double beam, interferential filters

♦ Wavelength: 8 narrow band interferential filters

OPTIC SYSTEM

from 340 nm to 620 nm , plus one available

optional filter position

♦ Light source: 6V/10 W halogen bulb

♦ Linearity range: up to 3,500 Abs

♦ Resolution: 0.0005 Abs

OPTICAL PATH

WASHING STATION

REACTION PLATE

1.5.1. COMPUTER & SOFTWARE FEATURE

TYPE

CPU

MEMORY

♦ 6 mm.

♦ Composed of five probes that empty, wash and

dry the reaction cuvettes.

♦ 6 singular replaceable racks with 20 cuvettes

each

♦ Cuvettes Q.C. continuously computer controlled

♦ Incubation temperature: 37°C

MINIMUM REQUIREMENTS

♦ IBM Compatible

♦ Pentium IV 500 MHz, 512 Kb Cache

♦ RAM 256 Mb

♦ Hard Disk 20 Gb

♦ Floppy Disk 3 1/2” 1.44 Mb

♦ Colour SVGA 15’’ low radiation

MONITOR

Resolution 800 x 600 pixels;

max number of colors 65536 (16 bit)

PRINTER

INTERFACE

SOFTWARE

AVAILABLE LANGUAGES

♦ 80 Columns impact graphic (EPSON LX 300)

♦ One Bi-directional RS 232C serial ports and one

parallel (one second serial port for the Host link)

♦ Multitasking WINDOWS XP Home edition

♦ Italian, English, Chinese, Czech. Software to be

released soon in these languages: Russian, Portuguese,

French, Polish. Upon request it is possible to release

the software in other languages.

♦ Disable all the energy saving options

SETTINGS

♦ Disable the screen saver

♦ Select English “USA” as language, dot as decimal

symbol and date and time in Regional setting

Ellipse Service Manual Rev. 03 01June 2009 Page 9

Page 13

Chapter 01 – INTRODUCTION

NOTE: Even though the computers demonstrate the same technical and operative characteristics,

some of these could have different hardware installed.

This could cause problems for the Ellipse software when running tests (A message appears

indicating “Random” error or blocks the program).

Therefore, if the PC is bought separately/locally, it is highly recommended to test the system at

your offices before preceding with the installation at the final client’s.

Consequently, AMS denies any responsibility for software problems that are due to buying the

computer separately from the instrument.

1.5.2 OPTIONAL MODULES

♦ POSITIVE BARCODE READER

1.5.3 DIMENSIONS, WEIGHT & OPERATING ENVIRONMENT

DIMENSIONS

WEIGHT

OPERATING ENVIRONMENT

1.5.4 INSTALLATION REQUIREMENTS

POWER REQUIREMENTS

♦ Height: 53 cm

♦ Depth: 57 cm

♦ Length: 75 cm

♦ 35 Kilos

♦ Temperature: 18°C ÷ 30°C.

♦ Relative humidity: 20% ÷ 85%

♦ Input Voltage 90 ÷ 250 Vac

♦ Input Frequency: 47 ÷ 63 Hz

♦ Power consumption:

♦ 300 W for the analytical unit

♦ 400 W for the work station

♦ EN 61010-1:1993 +A2:1995

(IN COMPLIANCE WITH THE MAIN

SAFETY REGULATIONS

EUROPEAN DIRECTIVES 73/23/CEE AND

93/68/EEC REGARDING SAFETY)

Ellipse Service Manual Rev. 03 01June 2009 Page 10

Page 14

Chapter 01 – INTRODUCTION

♦ EMC 89/336/EEC – 92/31/EEC Directives

♦ EN 55011, Class B, Group 1

♦ EN 50081-1:1992 EMC

ELECTROMAGNETIC

COMPATIBILITY

♦ EN 55022

♦ ENV 50140 – ENV 50141

♦ EN 60601-1-2

♦ EN 61000-4

Warning: A steady power supply (+ 10%) must be provided for the instrument.

If it is not, the manufacturer highly recommends the use of:

♦ UPS Uninterruptible Power Supply ( No-break module)

♦ ELECTRONIC STABILIZER

Ellipse Service Manual Rev. 03 01June 2009 Page 11

Page 15

Chapter 02 – SYSTEM DESCRIPTION

CHAPTER 02

– SYSTEM DESCRIPTION -

INDEX

2 DESCRIPTION OF THE SYSTEM ................................................................................................ 2

2.1 ANALYSES CYCLE......................................................................................................................... 3

2.1.1 REACTION PLATE ......................................................................................................................... 3

2.1.2 REACTION PLATE CYCLE .......................................................................................................... 3

2.2 SAMPLING ARM - OPERATIONAL SEQUENCE .................................................................... 3

2.3 WASH STATION............................................................................................................................... 6

2.3.1 WASH STATION CYCLE ............................................................................................................... 6

2 DESCRIPTION OF THE SYSTEM......................................................................................... 2

2.1 ANALYSES CYCLE................................................................................................................ 3

2.1.1 REACTION PLATE .................................................................................................................3

2.1.2 REACTION PLATE CYCLE.................................................................................................. 3

2.2 SAMPLING ARM - OPERATIONAL SEQUENCE............................................................... 3

2.3 WASH STATION..................................................................................................................... 6

2.3.1 WASH STATION CYCLE.......................................................................................................6

2.4 ELECTRONIC DESCRIPTION...............................................................................................7

2.4.1 INTRODUCTION ....................................................................................................................7

2.4.2 ANALYTICAL CONTROL BOARD (C.P.U.) [P/N: 30-01283-01]...................................... 7

2.4.3 STEPPER MOTORS DRIVER BOARD [P/N: 30-01284-01]............................................... 8

2.4.4 PLATE INTERFACE BOARD (Sx) [P/N: 30-01281-01].......................................................9

2.4.5 ARM INTERFACE BOARD (Dx) [P/N: 30-01282-01] .........................................................9

2.4.6 ELECTROVALVES CONTROL BOARD [P/N: 30-01626-00] ...........................................10

2.4.7 PRE-AMPL/ADC [P/N: 30-00107-00; P/N: 30-00107-03]..................................................10

2.4.8 PHOTOMETER LAMP BOARD [P/N: 30-01576-00] .........................................................11

2.4.9 CONTROL PANEL BOARD [P/N: 30-01850-00] ............................................................... 11

2.4.10 LEVEL SENSOR ASSY [P/N: 10-01478-00]....................................................................... 11

Ellipse Service Manual Rev. 03 01 June 2009 Page 1

Page 16

Chapter 02 – SYSTEM DESCRIPTION

2 DESCRIPTION OF THE SYSTEM

"Ellipse" is a random access, computer controlled, counter-top, clinical analysis instrument. The

system can perform 138 tests per hour and has a machine cycle of 26 seconds. Its execution time

ranges from a minimum of 18 seconds to a maximum of 1032, depending on the analysis method

chosen.

The first time the system is used for laboratory analyses, the operator must configure the system

based on the specific needs of that laboratory; i.e.: the chemistry parameters and the reagents racks,

along with the normal ranges, calibrated and control values, must all be defined.

The daily routine analyses will be carried out according to patient sample arrival in a sequential and

continuous, non-stop manner.

The work list is organized using a loading rack holding up to 8 patient samples. Rack loading is

non-stop.

The racks can accommodate both test tubes and micro cups. The bar code for primary tubes and

reagent containers is an optional feature.

When the system, the analytical unit and the computer, is turned on the color-meter lamp is supplied

with low voltage power (1.2 volts), the sampling arm pre-heater remains turned off, while instead

the reaction plate heater, the reagents refrigerating unit (optional module) and the electronic

components are turned on.

In this phase, the "Stand-by" light, placed on the front panel, will flash until the reaction plate

reaches a temperature of 36° C. When this temperature is reached, the "Stand-by" light will stop

flashing and will remain constantly lit.

In the case of system failure or malfunction, the "Ready" light, situated on the front panel of the

instrument, will light up red.

In order to access the main program, double click on the "Ellipse" icon on the computer desktop.

The main menu - "System Monitor" - will appear.

Whenever any system function is launched, the color-meter lamp and the sampling arm pre-heater

will receive regular power.

Ellipse Service Manual Rev. 03 01 June 2009 Page 2

Page 17

Chapter 02 – SYSTEM DESCRIPTION

2.1 ANALYSES CYCLE

2.1.1 REACTION PLATE

The reaction plate of the "Ellipse" system contains 6 disposable racks with 20 reaction cuvettes

each.

The racks can be removed individually.

The basic operating cycle of the reaction plate takes 26 seconds. This cycle includes: optic reading

of the cuvettes in incubation, aspiration and dispensing of the reagents and the samples by the arm,

along with the relative positioning of the plate .

The reactions take place at 37° C. This temperature is maintained constant by a controlled heating

unit placed under the reaction plate .

2.1.2 REACTION PLATE CYCLE

After reagents and samples have been placed in cuvette #1, the reaction plate will rotate 40

positions counter-clockwise, so as to bring the first cuvette to be analyzed in front of the color-

meter for reading with either one or two wavelengths, as required.

The plate will then, moving counter-clockwise, carry out all the readings of any other prepared

cuvettes. After having effectuated all the readings, the plate will move counter-clockwise to its

initial position minus one cuvette, ready for a new dispensing.

In this manner, the reaction cuvettes move clockwise 1 - 2 - 3 – 4 for dispensing, washing and for

their relative readings.

2.2 SAMPLING ARM - OPERATIONAL SEQUENCE

1. The sampling arm lifts up from the wash well and carries out a wash cycle;

2. The arm moves toward the specific reagent container, while the diluter aspirates an air

bubble to separate the rinse column from the reagent;

3. The arm lowers itself into the reagent, below the level indicated by the sensor, and aspirates

the required quantity of reagent. If the method requires a Rinse (used in order to reduce the

possibility of negative contamination between the water column and the reagent) an extra

amount of reagent (not used in the analysis) will be aspirated before the quantity of reagent

necessary for the analysis, along with another air bubble for their separation;

Ellipse Service Manual Rev. 03 01 June 2009 Page 3

Page 18

Chapter 02 – SYSTEM DESCRIPTION

4. While the diluter aspirates a second air bubble, the arm rises and then lowers into the wash

well so that it can be washed externally, to minimize cross contamination;

5. The arm moves to the specified sample and aspirates a third air bubble;

6. Once the level sensor has indicated the presence of the liquid, the arm stops and aspirates

the sample;

7. The arm once again is raised, while the diluter aspirates a fourth air bubble to prevent

sample loss;

8. At this point, the arm returns to the wash well in order to clean the outside of the probe and

aspirates a fifth air bubble;

9. The arm moves to the reaction PLATE , dispenses, and mixes the reagent and sample in the

reaction cuvette for incubation and reading;

10. The arm returns to the wash well and carries out a probe wash cycle.

Ellipse Service Manual Rev. 03 01 June 2009 Page 4

Page 19

Chapter 02 – SYSTEM DESCRIPTION

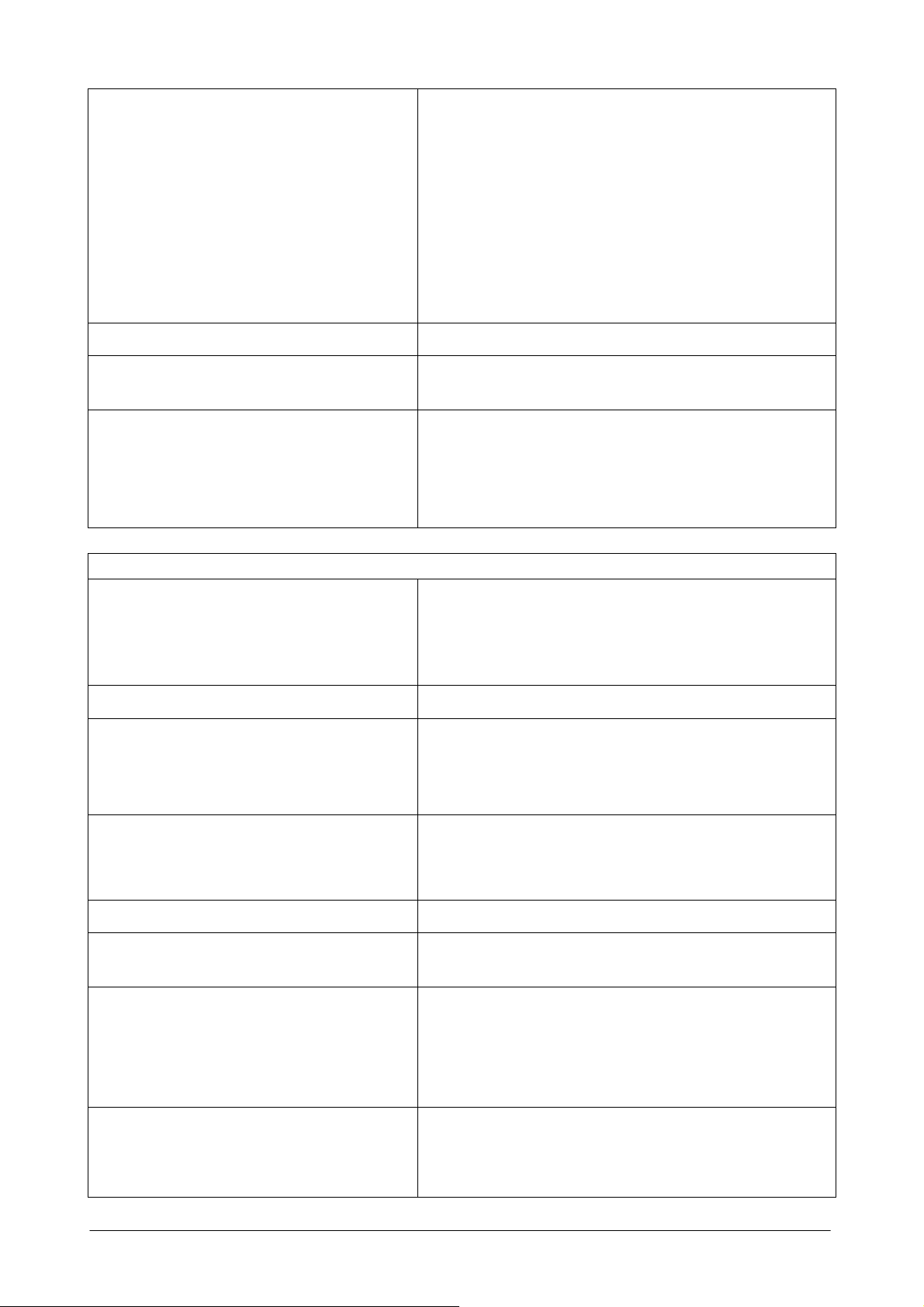

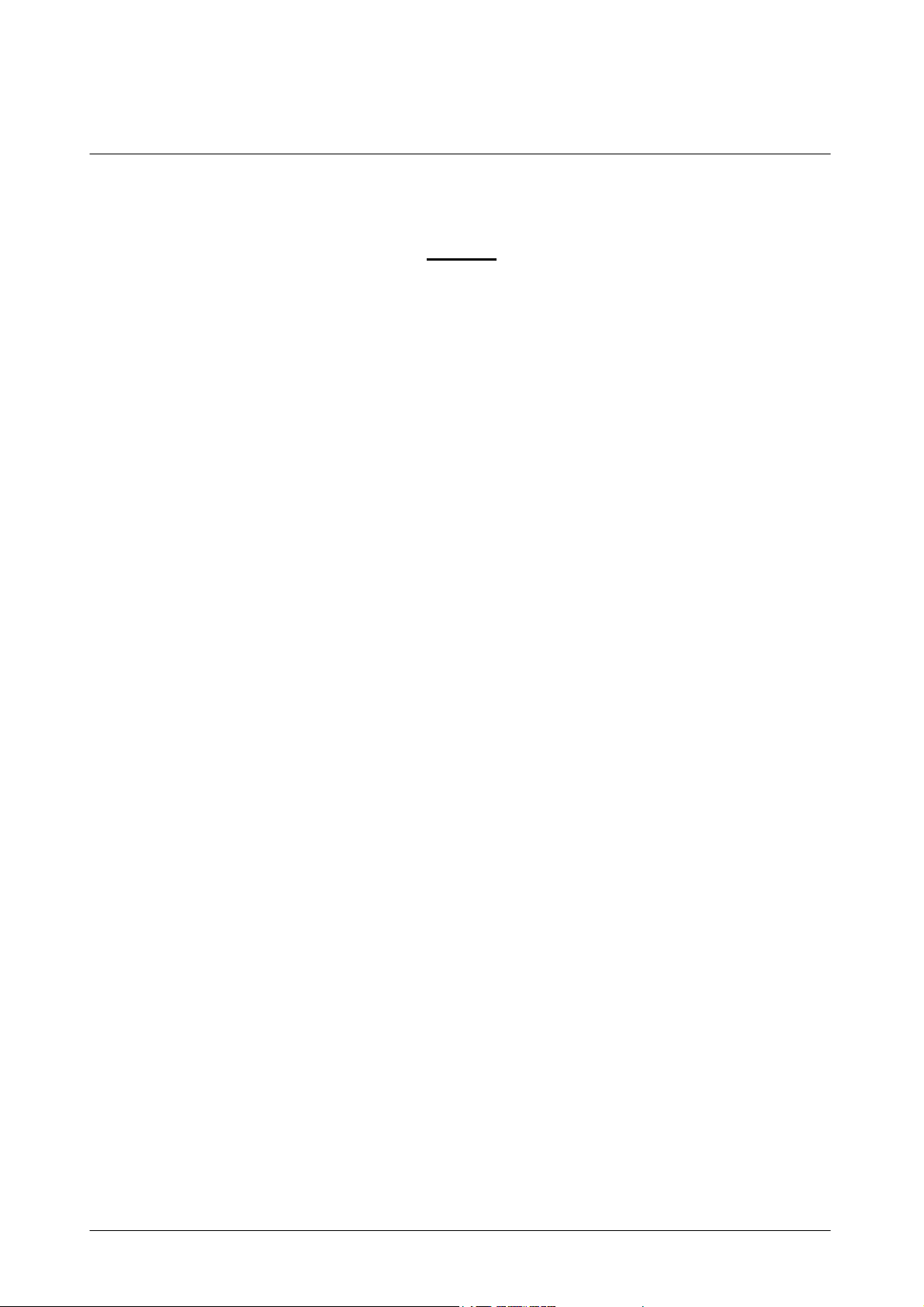

SAMPLING SYSTEM

Aspiration of Air

Aspiration of Reagent

Aspiration of Air

(To separate reagent from serum)

To wash well to clean the probe

Aspiration of air

Aspiration of serum

Aspiration of air

To wash well to clean the probe

Aspiration of air

Dispensing and mixing in cuvette

H2O

AIR

RGT

AIR

AIR

SERUM

AIR

To wash well for final wash

Ellipse Service Manual Rev. 03 01 June 2009 Page 5

Page 20

Chapter 02 – SYSTEM DESCRIPTION

2.3 WASH STATION

The reaction plate wash station is made up of a series of five small needles situated on one side of

the reaction PLATE . Said needles are opportunely connected to the valve and pump system for

emptying, washing and drying operations (please see the hydraulic diagram).

2.3.1 WASH STATION CYCLE

The wash station carries out its operations alternating upward and downward movement. In its

downward movement phase the needles are guided in such a manner as to carry out the following

operations:

• The first needle, using the central cannula, removes the reaction mix while the external

cannula dispenses, shower-like fashion, the wash solution; after that the external

cannula dispenses wash solution and then the liquid is aspirated from the central

cannula;

• The second needle operates exactly like the first but uses distilled water instead;

• The third needle operates exactly like the first but dispenses rinse solution into the

cuvette so that an optics check can be performed (if the results are negative, the cuvette

is discarded);

• The fourth needle aspirates the control water;

• The fifth needles dries the sides.

All these operations are part of the routine operation of the instrument. Every reaction cuvette is

washed at the end of each round of analysis.

The reusability (optical integrity) of each reaction cuvette is always tested before the next round of

analysis.

Ellipse Service Manual Rev. 03 01 June 2009 Page 6

Page 21

Chapter 02 – SYSTEM DESCRIPTION

2.4 ELECTRONIC DESCRIPTION

2.4.1 INTRODUCTION

The Ellipse general interconnection diagram is reported on the document having the code

SC-16-00571-XX. This document shows all the electronic boards and the links among them.

The power supply is connected through a dedicated socket to the power line. It supplies, by two

separate modules, the two requested voltages +24 VDC and +12 VDC.

All the Ellipse electronics boards are following described.

2.4.2 ANALYTICAL CONTROL BOARD (C.P.U.) [P/N: 30-01283-01]

The Analytical Control Board, integrated in the Ellipse system, is the heart of the low level, real

time and processing management. This board, on which is present the micro-controller HITACHI

H8S/2633F (U1), permits to manage all the input and output analogical and digital signals

need to the instrument functionality. The mentioned micro-controller, having 128 pin packaging and

12 ports, contains 16 KB of RAM memory and 256 KB flash memory where the firmware is

installed. The firmware writing on the flash memory is permitted by an external personal computer

by a serial transmission RS232.

The Analytical Control Board is connected to the “Stepper Motors Driver Board” by a 64 pin

frontal clutch connector from which receives all the signals for driving the motors.

The following further boards are directly connected to the Analytical Control Board, through

specific cables:

The “Plate Interface Board (Sx)” and “Arm Interface Board (Dx)” for the users

interfacing;

The “Pre-Ampl./ADC” for reading the signals from main and reference channels of the

photometer;

The “Electrovalves Control Board” for commanding all the hydraulic devices.

Besides, through two distinct and direct serial links, it manages (if present) the bar code reader and

the ISE modules.

On the board are present also the followings two leds:

o The red led (LD1) not used yet;

o The green led (LD2) is flashing when the board is powered and the firmware activated.

Ellipse Service Manual Rev. 03 01 June 2009 Page 7

Page 22

Chapter 02 – SYSTEM DESCRIPTION

The power supply, by a specific line of the power cable, supplies the board with +24 VDC and +12

VDC. Further two voltages, +5 VDC and +3,3 VDC are generated on the same board by voltage

regulators.

Components and integrated circuit dedicated to the programming communication with the micro-

controller and those for I/O ports protection, are present on the same board.

Finally, the alarmed fan needed for the electronic area cooling, composed by the Analytical Control

Board and the Stepper Motors Driver Board, is powered directly from the same board.

2.4.3 STEPPER MOTORS DRIVER BOARD [P/N: 30-01284-01]

The "Stepper Motors Driver Board" is the interface between the “Analytical Control Board” and the

stepper motors.

Besides the Analytical Control Board, there are two more boards directly linked to the Stepper

Motors Driver Board. They are the Plate Interface Board (Sx) and the Arm Interface Board (Dx)

which transmit (by specific cables) all the command signals to the nine stepper motors present in

the instrument. On the boards are present nine driver components (NMB SDI-C403 or TOSHIBA

TA8435H). Each driver, on which is installed a metal heatsink by a couple of screws, is dedicated

to drive one stepper motor as specified here below:

driver U1 Sample plate motor;

driver U7 Reagent plate motor;

driver U4 Reaction plate motor;

driver U6 Vertical sampling arm motor;

driver U3 Horizontal sampling arm motor;

driver U9 Diluter motor;

driver U2 Photometer filter wheel motor;

driver U5 Washing station motor;

driver U8 Peristaltic pump motor.

By the nine dip switches setting on the board, each motor is driven to ¼ of step unless the filter

wheel motor that is driven to

1/8

of step.

The power supply, by a specific power line cable, supplies two voltages +24 VDC and +12 VDC to

the board. The +5 VDC needed to the driver components is generated on the same board by a

voltage regulator. All the components managing the nine drivers and the relevant signals are

mounted on the same board.

Ellipse Service Manual Rev. 03 01 June 2009 Page 8

Page 23

Chapter 02 – SYSTEM DESCRIPTION

2.4.4 PLATE INTERFACE BOARD (SX) [P/N: 30-01281-01]

This board is the hardware interface between the reaction and reading sections of the instrument and

the following boards:

the Analytical Control Board which receives from the Plate Interface Board the I/O

signals for managing the relevant devices (the three independents plates home sensors,

the washing station home sensor, the photometer filter wheel home sensor, the reaction

plate N.T.C., the reaction plate heater, the lamp and the fan of the photometer);

the Stepper Motors Driver Board from which the Plate Interface Board receives the

command signals for the stepper motors of the following devices: sample plate, reagent

plate, reaction plate, washing station and photometer filter wheel;

the Photometer Lamp Board for the photometer halogen lamp checking.

There are also the following two leds:

o the yellow led (LD1) active when the reaction plate resistor is powered;

o the red led (LD2) active when there is a signal from the reaction plate leaking.

The power supply, by a specific power line cable, supplies two voltages +24 VDC and +12 VDC to

the board. The +5 VDC needed is generated on the Plate Interface Board by a voltage regulator. All

the components managing respective devices are mounted on this board.

2.4.5 ARM INTERFACE BOARD (DX) [P/N: 30-01282-01]

This board is the hardware interface between the Sampling sections of the instrument and the

following boards:

the Analytical Control Board which receives from the Arm Interface Board the I/O

signals for managing the relevant devices (the vertical sampling arm home sensor, the

horizontal sampling arm home sensor, the diluter home sensor, the diluter electrovalve

and pump, the preheater, the level sensor assembly, the temperature service probe, the

main alarmed fan, the three buttons – indicators of the Control Panel);

the Stepper Motors Driver Board from which the Arm Interface Board receives the

command signals for the stepper motors of the following relevant devices: vertical and

horizontal sampling arm, Diluter, peristaltic pump;

the Control Panel Board for the three buttons-indicators checking.

Ellipse Service Manual Rev. 03 01 June 2009 Page 9

Page 24

Chapter 02 – SYSTEM DESCRIPTION

There are also the following three led:

o the yellow led (LD1), active when the preheater is powered;

o the red led (LD2), active when there is a signal from the sampling arm leaking sensor;

o the yellow led (LD3), light on when the level sensor is activated.

The power supply, by a specific power line cable, supplies +24 VDC and +12 VDC to the board. +5

VDC needed to the Arm Interface Board is generated on the same board by a voltage regulator. All

the components managing respective devices are mounted on this board.

2.4.6 ELECTROVALVES CONTROL BOARD [P/N: 30-01626-00]

This board communicates with the Analytical Control Board all the I/O signals for managing all the

relevant devices (electrovalves and micropumps related to the washing station, the washing well

and the peristaltic pump; the bottles liquid sensors; the waste sensors; the main cover switch).

The red led (LD1) is active when there is a signal from the washing station leaking sensor;

From the Analytical Control Board the Electrovalves control board receives the +24 VDC . +5

VDC is generated from + 24VDC by a voltage regulator. All the components managing respective

devices are mounted on this board.

2.4.7 PRE-AMPL/ADC [P/N: 30-00107-00; P/N: 30-00107-03]

The Pre-Ampl/ADC board P/N: 30-00107-00 is used for reading the signals from the photometer

main channel, while the Pre-Ampl/ADC P/N: 30-00107-03 has the same function for the

photometer reference channel. They are mounted on the photometer assembly and directly linked to

the Analytical Control Board, by two distinct flat cables, for transmitting all the I/O signals. The

only difference between them is the R1 resistor value. On the boards, the (FD1) photodiode reveals

the signal arriving from the relevant reading channel; the Amplifier (U2) amplifies the signal, which

is then inputted in the serial converter ADS 1250 (U3) for its conversion A/D.

From the Analytical Control Board they receive also two continuous voltages (+VB and –VB).

All the components dedicated to the signal amplification or digital conversion are mounted on the

same boards.

Ellipse Service Manual Rev. 03 01 June 2009 Page 10

Page 25

Chapter 02 – SYSTEM DESCRIPTION

2.4.8 PHOTOMETER LAMP BOARD [P/N: 30-01576-00]

This board is linked to the Plate Interface Board (Sx) from which receives the check signal (coming

from the Analytical Control Board) to regulate the light intensity of the photometer halogen lamp

(+6V, 10W). From the interface board receives the continuous voltage (VL) which is then converted

to +6 VDC on the same board, by a voltage regulator, for powering the lamp.

2.4.9 CONTROL PANEL BOARD [P/N: 30-01850-00]

This board is linked to the Arm Interface Board (Sx) to which transmits the I/O signals from the 3

lighting buttons of the Control Panel.

From the interface board receives also the continuous voltage (VB) for the three buttons – indicators

functionality.

2.4.10 LEVEL SENSOR ASSY [P/N: 10-01478-00]

The level sensor assembly is composed by the level sensor board “A” (P/N:30-01392-00) and the

level sensor board “B” (P/N:30-01392-01).

The level sensor assembly, installed on the sampling probe head, is linked to the Arm interface

board. By a specific cable it transmits the relevant signal (the capacity variation produced by the

contact between the sampling probe and the liquid) to the Analytical Control Board.

Level sensor components and integrated circuits are mounted on the level sensor assembly.

Ellipse Service Manual Rev. 03 01 June 2009 Page 11

Page 26

Chapter 03 - INSTALLATION

CHAPTER 03 - INSTALLATION

INDEX

3.1 UNPACKING.........................................................................................................................2

3.2 INSTALLATION ...................................................................................................................4

3.2.1 INSTALLATION SITE SPECIFICATIONS ...................................................................... 4

3.2.2 ELECTRIC CURRENT REQUIREMENTS....................................................................... 4

3.2.3 CONNECTIONS TO ACCESSORIES ...............................................................................5

3.2.3.1 POWER SUPPLY/LINE INPUT...................................................................................... 5

3.2.3.2 CONNECTING THE INSTRUMENT TO THE COMPUTER .......................................6

3.2.4 ATTENTION....................................................................................................................... 6

3.2.5 SYMBOLS........................................................................................................................... 6

3.2.6 REGULATORY COMPLIANCE........................................................................................ 6

Ellipse Service Manual Rev. 03 01 June 2009 Page 1

Page 27

Chapter 03 - INSTALLATION

3.1 UNPACKING

The ELLIPSE is packed and delivered in two separate wooden crates: one contains the

analyzer itself and the other the computer, along with its accessories. In the event that the order

not include the PC component, packing and delivery will involve one wooden crate plus a

corrugated cardboard box. The packing has been expressly studied and designed to insure

maximum protection of the contents during shipping and handling. It is therefore extremely

important that the crate(s)/box be carefully examined upon delivery in order to ascertain their

integrity. Special attention should be dedicated to examining the color of the “Shock Watch”

glued to the crates, which must show the color ‘white’. A ‘red’ “Shock Watch” indicates that

the crate(s) have experienced some sort of ‘shock’ during handling, transport and/or delivery.

This fact must be noted by the courier on the delivery note, as must any and all visible external

damage (for example: holes, dents, rips or tears, water marks, etc.) evident at the moment of

delivery. This will simplify matters in the event of any future claims for damages.

Upon arrival of the crate(s)/box, take out the

delivery note and make sure that all the items

on the packing list are included in the crates

and are undamaged. Make sure the series

number on the delivery note/packing list

corresponds to that impressed on the plate on

the right side of the instrument.

S/N

P/N

ELLIPSE

90 - 250Vac 47 - 63Hz

Analyzer

Medical

System

Rome-Italy

300W

Open the crate(s)/box from the top and very

carefully take out:

- the instrument;

- the computer and accessories.

MAKE SURE THAT THE UNPACKING IS CARRIED OUT BY TWO PEOPLE.

Ellipse Service Manual Rev. 03 01 June 2009 Page 2

Page 28

Chapter 03 - INSTALLATION

Do not discard the delivery crate(s)/box or the packing material until the correct functioning of

the instrument has been ascertained.

Remove all the items from the crate(s)/box very carefully.

Remove the adhesive tape from the cover of the samples and reagents housing, from the front

panels and from the samples and reagents racks.

Before connecting the "Ellipse", remove the protective packing material placed under the

sampling arm and under the wash station group.

Warning: in the event that it is necessary to repack any or all of the delivered item(s), the

following procedures must be carefully followed:

¾ Reposition the protective packing material under the sampling arm and under the wash

station group.

¾ Tape down (using masking tape if possible) the cover of the samples and reagents housing,

the front panels, and the samples and reagents racks.

¾ Remove the probe from the sampling arm and place it inside a cuvette. Then cap the

cuvette and tape the cap down.

¾ Be very careful to not bend the wash station cannulas when repositioning the protective

packing material.

¾ Fill the empty spaces around the accessories packed in the crate using “pluriballs” or other

suitable packing material.

Ellipse Service Manual Rev. 03 01 June 2009 Page 3

Page 29

Chapter 03 - INSTALLATION

3.2 INSTALLATION

The ELLIPSE must only be installed by a qualified technician who has been authorised and

trained to do so. During its installation the system will be checked once again to ensure correct

functioning. The persons who are required to operate the ELLIPSE system must have received

the adequate training. This should also include the "know-how" of the normal maintenance for

the instrument. A description of the maintenance will be found in Chapter 7 of this manual.

ELLIPSE is a complex system, and it is therefore extremely important that it is correctly

installed in order to fully guarantee fine performance. If the installation and use directions,

given in this manual, are not correctly followed and/or security indications are not respected,

AMS cannot guarantee correct functioning of the instrument. Apart from this, the security of

the operator could be placed at risk.

3.2.1 INSTALLATION SITE SPECIFICATIONS

Ascertain that the ELLIPSE system is not exposed to direct sunlight, draughts, dust or strong

magnetic fields. In addition, please take note of the following conditions required for the

location of the installation:

USE

DEGREE OF POLLUTION

INSULATION CLASS

INSTALLATION CATEGORY

TEMPERATURE

HUMIDITY

ALTITUDE

LOCATION

In covered and dry place

2

I

II

between18°- 30°C

20% ÷ 85%

Max 3000 m

Shelf or table with a minimum surface of 75 x 60 cm

stable and free of vibration

VENTILATION

Leave a minimum distance of 10 cm around the

instrument to permit air circulation . Make sure that

the front and rear holes are not blocked by any object

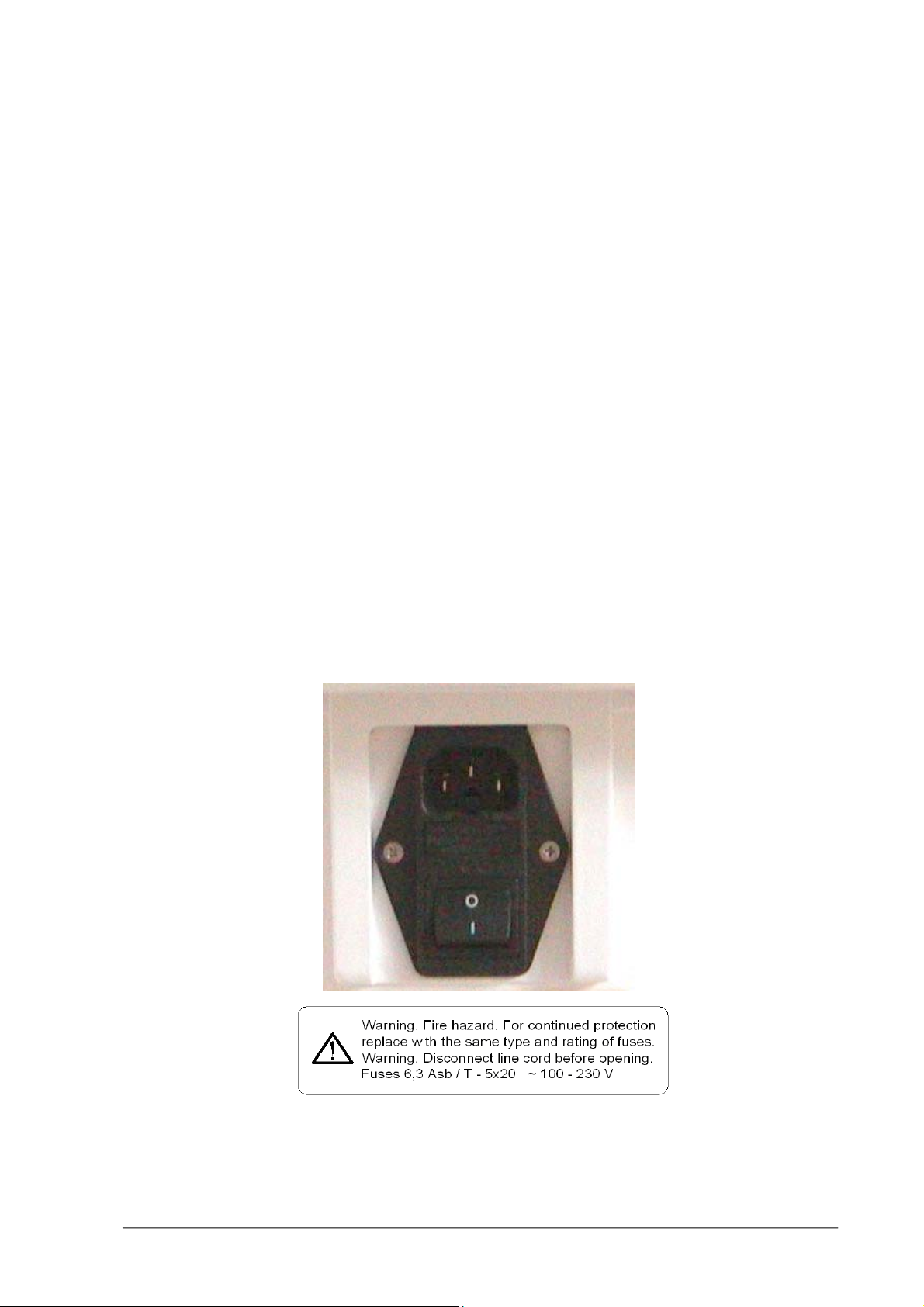

3.2.2 ELECTRIC CURRENT REQUIREMENTS

The power voltages to which the instrument is adapted are indicated on the left-hand side

(see fig. 1). It must be plugged into a plug of the correct voltage.

VOLTAGE

FUSES

100 ÷ 230 Vac 47/63 Hz ± 10%

6.3 Amp/T - 5 x 20

Ellipse Service Manual Rev. 03 01 June 2009 Page 4

Page 30

Chapter 03 - INSTALLATION

NOTE: IT IS ADVISABLE TO MAINTAIN THE MAXIMUM STABILITY OF THE ELECTRICAL CURRENT IN

THE LABORATORY

FOLLOWING SUPPLEMENTARY DEVICES IS RECOMMENDED

. WHERE THIS IS NOT POSSIBLE OR ASCERTAINABLE, USE OF THE

:

ELECTRONIC STABILIZER

Used to stabilise the electric voltage in the laboratory. Any stabiliser with a power

potential greater than 0.5 KW, currently available on the market, can be used.

NO-BREAK MODULE UPS - (Uninterrupted Power Supply)

This module provides two important functions:

- stabilises the main-line power

- supplies current to the instrument in case of a main-line power failure.

3.2.3 CONNECTION OF THE ACCESSORIES

3.2.3.1 POWER SUPPLY

Fig. 1 - – Plug (use the feeder cable supplied with the instrument).

The sticker indicates the power supply voltage and the values of the fuses.

Ellipse Service Manual Rev. 03 01 June 2009 Page 5

Page 31

Chapter 03 - INSTALLATION

3.2.3.2 COMPUTER - INSTRUMENT CONNECTION

The instrument and the Personal Computer are connected by one serial RS232 standard cable

(Cod. 9-35 0055.01), which provides the hardware support for the communication.

3.2.4 ATTENTION

The following label is found at the rear of the instrument.

NOTE: THE REAR PANELS OF THE INSTRUMENT MUST NEVER BE OPENED WITHOUT HAVING FIRST

SWITCHED THE INSTRUMENT OFF AND DISCONNECTED THE ELECTRICITY CABLE

.

THE MAINTENANCE AND CLEANING PROCEDURES FOUND IN CHAPTER 07 OF THIS

MANUAL MUST BE RESPECTED AT ALL TIMES

DECONTAMINATION PROCEDURE IN CASE OF INSTRUMENT REMOVAL

. REMEMBER TO FOLLOW THE

(SEE CHAPTER 07) .

3.2.5 SYMBOLS

ATTENTION: READ THE INSTRUCTIONS IN THE USER MANUAL

T

ERMINAL OF TOTAL MASS PROTECTION (CONDUCTOR)

REGULATORY COMPLIANCE

3.2.6

The ELLIPSE instrument complies with:

European Directive 98/79/CE for In vitro Diagnostics Devices

Ellipse Service Manual Rev. 03 01 June 2009 Page 6

Page 32

Chapter 04 – ELECTRICAL SCHEMES AND DRAWINGS

CHAPTER 04

- ELECTRICAL SCHEMES AND DRAWINGS -

INDEX

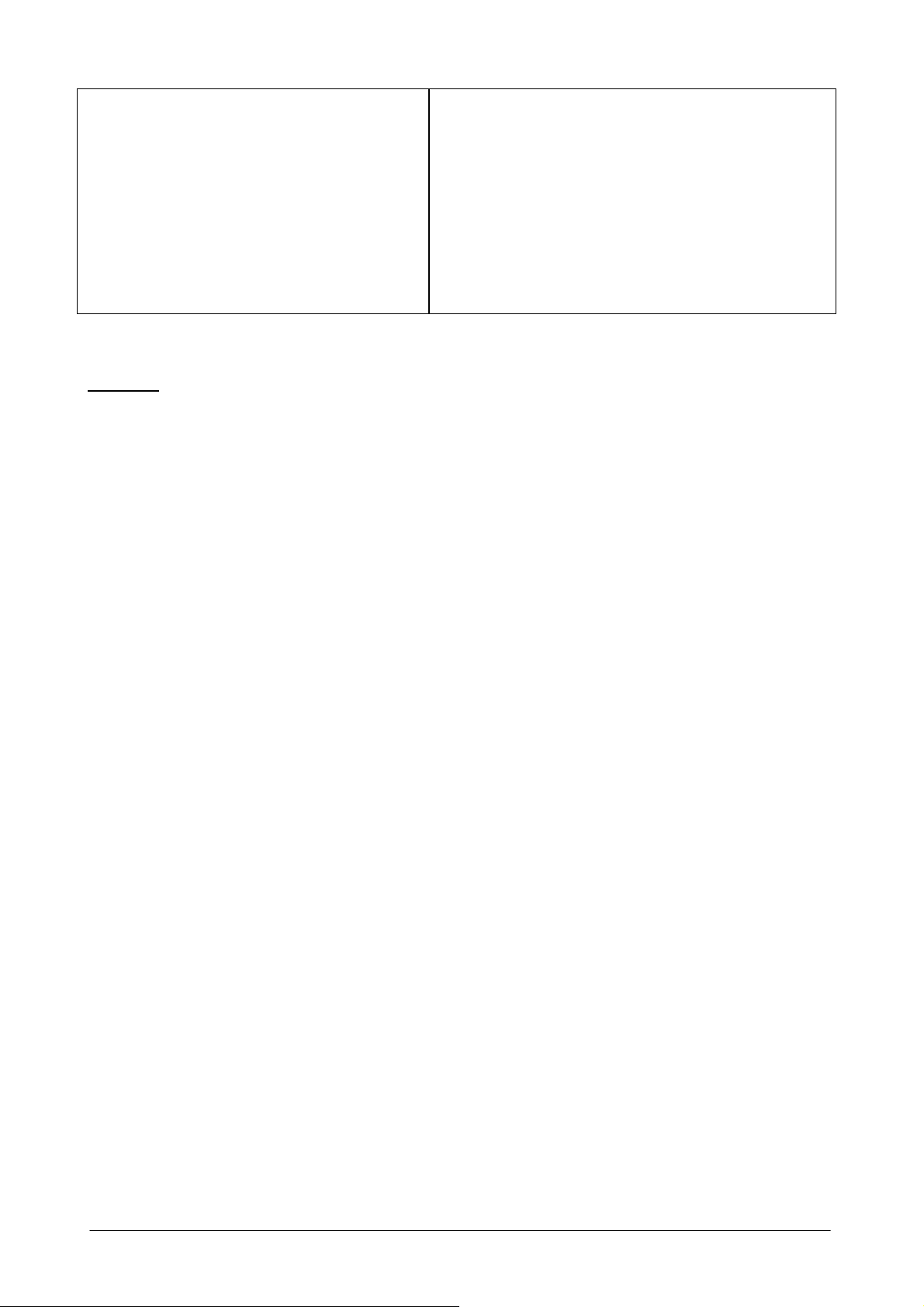

ELECTRONIC DIAGRAM ELLIPSE SC-16-00571-XX

HYDRAULIC DIAGRAM ELLIPSE SI-16-00571-XX

WIRING ME-50-01692-01

ANALYTICAL CONTROL BOARD SC02-30-01283-XX

ANALYTICAL CONTROL BOARD SE-30-01283-XX

STEPPER MOTORS DRIVER BOARD SC02-30-01284-01

STEPPER MOTORS DRIVER BOARD SE-30-01284-01

ARM INTERFACE BOARD (DX) SC02-30-01282-01

ARM INTERFACE BOARD (DX) SE-30-01282-01

PLATE INTERFACE BOARD (SX) SC02-30-01281-01

PLATE INTERFACE BOARD (SX) SE-30-01281-01

PRE-AMPL/ADC SE-30-00107-XX

PHOTOMETER LAMP BOARD SE-30-01576-00

LEVEL SENSOR ASSY SE-10-01478-00

ELECTROVALVES CONTROL BOARD SC-30-01626-00

ELECTROVALVES CONTROL BOARD SE-30-01626-00

CONTROL PANEL BOARD SE-30-01850-00

Ellipse Service Manual Rev. 03 01 June 2009 Page 1

Page 33

00012 Guidonia (Roma)

Drawn Checked

Approved

Date

Sheet

Doc.

P/N

Rev.

authorization will be prosecuted accordingly to the law.

L. Massenzi R. Cornacchia A. Gagliarducci

20/10/2005

1 of 1

SC

16

-

00571

-

XX

D

Rev. D

: emissione in riferimento

alla RMP n.268

(optional)

(Reference Channel)

18,300)

(optional)

Via E. Barsanti, 17/A

(Via Tiburtina Km

BarCode Reader

Electronic Diagram Ellipse

The present document is property of AMS, any use without

Description

30-01283-..

Analytical Control Board

(Sample Channel)

Pre-Ampl/ADC

Pre-Ampl/ADC

Page 34

Page 35

Page 36

00012 Guidonia (Roma)

Drawn Checked

Approved

Date

Sheet

Doc.

P/N

Rev.

authorization will be prosecuted accordingly to the law.

L. Massenzi R. Cornacchia A. Gagliarducci

20/10/2005

1 of 1

Analytical Control Board

30

-

01283

-

XX

A

30

-

01283

-

..

18,300)

(Sample Channel)

Pre-Ampl/ADC

(Reference Channel)

Pre-Ampl/ADC

Via E. Barsanti, 17/A

(Via Tiburtina Km

SC02

Rev. A: emissione in riferimento alla RMP n.268

The present document is property of AMS, any use without

Description

50-01692-01

ISE Module

Page 37

1

OPTOCU

OPTOCA

OPTORE

OPTOWH

WASTE1

WASTE2

LIQUID1

LIQUID2

LIQUID3

LEAKPI

RISCPI

uPSCAMB

VMVM

J20 H2X12

2

3

3V3

R2 220C6

4

X1

6,144 Mhz

10uF/25V

+

C12

3V3

5

LD1086V3.3

VM

VB

OPTOBH

OPTOBV

OPTODO

OPTOPP

PR

PG

PV

DEPR

uPACIDB

uPDOS

EVDOS

LAMPV

LAMPR

LAMPG

EV3PP

23

24

24

DIRRE

DIRCU

DIRCA

256

1Q2Q3Q

1D2D3D

347

DB0

DB1

DB2

uP1H2OPE0

uPBAND

uP2H2O

18

1Y3

1Y2

1Y1

1A3

1A2

1A1

2

PE2

PE1

0.1uF

EXTAL

C47

C46

R3 0R

XTAL

Rx1=470

se

TP1

123

IN

OUT

GND

VL

+

470uF/50V

C49

H17X2

J9

12

34

56

78

910

J8

12

34

56

78

910

uP1H2O

EV1H2O

uPBASICP

11131517192123

uP2H2O

EV2H2O

EV2PP EV1PP

uPBAND

DIRWH

DIRFO

DIRBV

DIRBH

9

1213

1617

7Q7D

5Q5D

4Q

4D

6D 6Q

8

14 15

DB3

DB4

DB5

DB6

RISCPI

CTRLAMPPE5

uPBASICP

uPSCAMB

2Y3

2Y2

2Y1

1Y4

2A3

2A2

2A1

1A4

864

11

PE3

PE6

PE4

C60 0.1uF

C5 470pF

15pF

PVCC

15pF

X1<5Mhz

1

TP-GND

C11

0.1uF

PVCC

U2

U3

6

5

4

3

2

1

1112

1314

1516

1718

1920

2122

2324

2526

2728

2930

3132

3334

1112

1314

1516

1718

1920

2122

2324

2526

SWCOP

WASTE1WASTE2

8

10121416182022

LEAKWH

DIRDO

8D 8Q

18 19

DB7

BUZZER

3579121416

20

2Y4

2A4

1

171513

PE7

R1

3V3

C7

C8

AVCC

OUT

J6 MOLEX

SLI

ARMSW

CTR1

CTR2

WDT

DACB

RISAB

TB

TA

SB

LEAKB

PWMB

EV3PP

INPUTB

H13X2

LIQUID1LIQUID2

LIQUID3

13579111315171921

13579

246810121416182022

246

LIQUID4

PVCC

1011

20

VCC

GNDCLK

ENG

U10 74HC377

1

WRL

PC1

PVCC

74HC244U15

VCC

C39 0.1uF

1OE

2OE GND

19 10

P35

P36

P37

3K3

0.1uF

3V3

0.1uF

C9

0.1uF

+

C10

10uF/25V

VB

C50

123

LM2575

IN

GND

LM7805CT

VM

D D

CTRLAMP

BUZZER

TFOPTOFO

TP

SP

LIQUID4

DACP

INPUT

WDT

OPTOWH2

CTR2

12345

EVACIDP

EVBASICP

C40 0.1uF

PVCC

PVCC

PG0

PG1

PG2

(CS2)

PG3

(CS1)

PG4

WDTOVF

RES

NMI

STBY

FWE

XTAL

EXTAL

OSC1

PF7

PF6

PF5

PF4

PF3

PF2

PF1

PF0

0.1uF

12345

470uF/50V

P96

DACB

J17

J21

uPACIDP

U1

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

D3

+

C15

H3

123

R52 1K

+

RISAB

P96

J16

H6

6

PVCC

VM

C45

0.1uF

AVCC

C4

0.1uF

P33

P34

63

64103

P33/TXD1/SCL1

P34/RXD1/SDA0AN0/P40

NC

NC

PLLVCC

PLLCAP

PLLVSS

RES

NMI

STBY

FWE

XTAL

VCC

EXTAL

VSS

OSC1

OSC2

PVCC1

PF7/CLK

VSS

PF5/RD

NC

NC

AVCC

VREF

AN1/P41

104

105

P40

P41

P42

U4

1N5818

L1

470uH

TX4

C55

H3

123

R49 1K R51 1K

P90 P91 P92

R50 1K

TA TB SB

P32

VSS

P32/SCK0/SDA1/IRQ4

P36/RXD4

P37/TXD4

PG2/CS2

PG3/CS1

PG4/CS0

WDTOVF

PF6/AS/LCAS

PF4/HWR

AN3/P43

AN2/P42

106

107

P43

P44

PVCC

RX4

1uF/50

+

C54

1uF/50

+

C53

1uF/50

+

C52

1uF/50

PVCC

P31

PD5

P30

PD6

PD7

5859606261

PVCC2

PD6/D14

PD7/D15

P30/TXD0/IRTXD

P31/RXD0/IRRXD

PG0/CAS/IRQ6

PG1/CS3/OE/IRQ7

PF3/LWR/ADTRG/IRQ3

PF2/LCAS/WAIT/BREQ0

PF1/BACK/BUZZ

PF0/BREQ/IRQ2

AN8/P90

DA1/AN7/P47

DA0/AN6/P46

AN5/P45

AN4/P44

108

109

110

111

112

P45

P46

P47

P90

P91

C13

+

470uF/50V

C14

0.1uF

5

VB

4

3

2

1

VM

P97

DACP

H3

123

J15

+

P97

DACP

J14

123

0.1uF

C44

AVCC

PVCC

0.1uF

PD2

PD0

PD1

PD4

PD3

PD3/D11

PD4/D12

PD5/D13

P35/SCK1/SCK4/SCL0/IRQ5

AN11/P93

AN10/P92

AN9/P91

113

114

115

P92

P93

P94

ISE - NO3

Module

J4 H5

PE7

PE6

51525354555657

49

50

VSS

PVCC1

PE7/D7

PD1/D9

PD0/D8

PD2/D10

DA2/AN14/P96

DA3/AN15/P97

AN13/P95

AVSS

AN12/P94

P95

CLKCU

PB0

CS4/DREQ0/TMCI011/TMRI01P70

116

117

118

119

120

121

P70

P71

P96

P97

EV2PP

CLKCA

EV1PP

EV1H2O

EV3PP

18

2Y1

1Y4

1Y3

1Y2

1Y1

2A1

1A4

1A3

1A2

1A1

864

2

11

PB1

PB3

PB2

PB5

PB4

C59

H3

R47 1KR45 1K R48 1K

SPTP

P93 P94 P95

R46 1K

TF

C3

PE5

PE4

PE5/D5

PE6/D6

SYNCI/CS6/TEND0/TMO0/P72

CS5/DREQ1/TMCI23/TMRI23/P71

122

123

P72

P73

CLKRE

EV2H2O

3579121416

2Y3

2Y2

2A3

2A2

171513

PB7

PB6

1uF/50

+

C58

1uF/50

+

C57

1uF/50

+

C56

1uF/50

PE0

PE1

PE2

PE3

P17

C51 0.1uF

H8S/2633F

39

404142434445464748

PE0/D0

PE1/D1

PE2/D2

PE3/D3

PE4/D4

P17/TIOCB2/TCKLD/PWM3

CS7/TEND1/TMO1/P73

MRES/TMO2/P74

SCK3/TMO3/P75

RXD3/P76

MD0

TXD3/P77

124

125

126

127

128

P74

P76

P75

P77

C32

0.1uF

PVCC

PVCC

20

2Y4

VCC

1OE

2A4

2OE GND

1

19 10

C C

CLKBH

18

74HC244U13

2

P10

(RD)(HWR)

PF5

PD4

PC4

PC3

CTR2

25

PC1

PC0

PC2

PF4

R41 10K

P73

C

RR4

C

RR3

P14 PE4

C

RR2

PB4

C

RR1

DB0

PVCC

181716151413121120

2345678

PD0

IRQ1/PWM2/TIOCA2/PO14/P16

38

TCKLC/TIOCB1/PO13/P15

37

NC

36

NC

35

IRQ0/TIOCA1/PO12/P14

34

A23/TCKLB/TIOCD0/PO11/P13

33

A22/TCKLA/TIOCC0/PO10/P12

32

A21/DACK1/TIOCB0/PO9/P11

31

A20/DACK0/TIOCA0/PO8/P10

30

VSS

29

SCK2/A19/PA3

28

RXD2/A18/PA2

27

TXD2/A17/PA1

26

A16/PA0

25

TIOCB5/A15/PB7

24

TIOCA5/A14/PB6

23

TIOCB4/A13/PB5

22

TIOCA4/A12/PB4

21

TIOCD3/A11/PB3

20

TIOCC3/A10/PB2

19

TIOCB3/A9/PB1

18

PVCC1

17

TIOCA3/A8/PB0

16

VSS

15

PWM1/A7/PC7

14

PWM0/A6/PC6

13

A5/PC5

12

VCC

11

A4/PC4

10

VSS

9

A3/PC3

8

A2/PC2

7

A1/PC1

6

A0/PC0

5

NC

4

NC

3

MD2

2

MD1

1

PVCC

EVACIDP

CLKBV

EVDOS

uPDOS

EVBASICP

2Y1

1Y4

1Y3

1Y2

1Y1

2A1

1A4

1A3

1A2

1A1

864

11

P12

P15

P13

P11

P14

RES

PD5

PD2

PD3

R42 10K

PE3

PE5

P13

P15

PB3

PB5

DB1

DB2

B1B2B3B4B5B6B7

A1A2A3A4A5A6A7A8G

PD2

PD1

P16

P15

P14

P13

P12

P11

P10

PA3

PA2

PA1

PA0

PB7

PB6

PB5

PB4

PB3

PB2

PB1

PB0

PC7

PC6

PC5

PC4

PC3

PC2

PC1

PC0

MD2

PVCC

CLKDO

uPACIDP

3579121416

2Y3

2Y2

2A3

2A2

171513

P17

P16

RX2

RTS

PD6

PD0 PD7

PD1

PF3

PE6

PE2

P12

P16

PB6

PB2

DB3

DB4

PD3

PD4

PVCC

C2

C1

J19

PVCC

PVCC

20

2Y4

VCC

1OE

2A4

1

19 10

3V3

11131517192123

8

101214161820222426

(CS2)

TX2

DTR#

PG2

P35

1

2

J22

DSYNC

CTR2

12

C+8 10K

3456789

PE1

PE7

PE0

12

C+8 10K

3456789

P11

P17

12

C+8 10K

3456789

PB7

PB1

PB0 P10

19

C+8 10K

8765432

DB6

DB5

DB7

B8

9191

PG3

PD5

PD7

PD6

STBY

NMI

R35 10K

R36 10K

0.1uF

PVCC

0.1uF

3V3

R40

10K

1

2

H2

C33

0.1uF

74HC244U14

2OE GND

135791113151719212325

246

PVCC

13579

2468101214161820222426

H2

PVCC

PVCC

10

VCC

PF5

PA3

R37 10K

PWDCA

256

347

DB0

J5 H13X2

DSYNC ADC

GND

DIR

U25 74HC245

PVCC

P70

P71

18

1Y1

1A1

2

INPUTB

INPUT

PC5

18

1Y1

1A1

2

DRDYAUX P32

DINDA

PWDRE

PWDCU

1Q2Q3Q

1D2D3D

DB1

DB2

CLK

G0AUX

DRDYAUX

97531

97531

108642

864

10

SCLK

DINAUX

-VB

LAMPG

LAMPV

256

1Q2Q3Q

1D2D3D

347

DB0

DB1

DB0

DB1

18

1Y1

1A1

2

P41

P40

18

1Y1

1A1

2

OPTOCA

OPTOCU

C34

CLKPP

PWMB

CLKFO

1Y4

1Y3

1Y2

1A4

1A3

1A2

864

11

P74

P73

P72

PC6

PC7

PG4

1Y4

1Y3

1Y2

1A4

1A3

1A2

864

11

DINRF

DINAUX

OPTOPP

PWDFO

PWDWH

PWDBH

9

1213

5Q5D

4Q

4D

8

14 15

DB3

DB4

DB5

CLK

G0R

G1AUX

J12 H5x2

2

DSYNC

VB

ENADO

LEDV

LEDR

LAMPR

9

1213

5Q5D

4Q

4D

8

14 15

DB5

DB4

DB3

DB2

C37

PVCC

DB2

DB3

DB4

DB5

2Y1

1Y4

1Y3

1Y2

2A1

1A4

1A3

1A2

864

11

PRPVPG

SLI

ARMSW

LEAKPI

P45

P44OPTOWH

P43

P42

2Y1

1Y4

1Y3

1Y2

2A1

1A4

1A3

1A2

864

11

OPTOBH

OPTORE

OPTOFO

0.1uF

ENAPIP77

CLKWH

ENABVWH

3579121416

20

2Y4

2Y3

2Y2

2Y1

2A4

2A3

2A2

2A1

1

171513

P76

P75

PVCC

PG0

PG1

WDT

3579121416

20

2Y4

2Y3

2Y2

2Y1

2A4

2A3

2A2

2A1

1

171513

DRDYDA

WDTOVF

DRDYRF

PVCC

PWDBV

PWDDO

1011

1617

7Q7D

6D 6Q

8D 8Q

18 19

WRL

DB6

DB7

B B

DRDYRF

97531

10

SCLK

PVCC

ENAPP

CTR1

1617

7Q7D

6D 6Q

18 19

DB6

DB7

0.1uF

DB6

DB7

3579121416

2Y3

2Y2

2A3

2A2

171513

SWCOP

ALLVENT

P47

P46

3579121416

2Y3

2Y2

2A3

2A2

171513

OPTODO

OPTOBV

PVCC

VCC

1OE

2OE GND

19 10

C36

PVCC

VCC

1OE

2OE GND

19 10

C35

PVCC

20

VCC

GNDCLK

ENG

1

PC0

G1R

97531

108642

864

DSYNC

DINRF

-VB

C41

0.1uF

PVCC

1011

20

VCC

GNDCLK

ENG

8D 8Q

1

PC3

WRL

R44 10K

PVCC

20

2Y4

VCC

1OE

2A4

2OE GND

1

19 10

ENA0

C38

PVCC

PVCC

20

2Y4

VCC

1OE

2A4

2OE GND

1

19 10

123

NME1212S

74HC244U23

0.1uF

R4 3K3

74HC244U17

D1

0.1uF

U9 74HC377

Refer to the Serigrafy

2

PF0

74HC244U19

74HC244U16

VB

1 2

RTS

CLK

G0D

G1D

DRDYDA

97531

97531

108642

J11 H5x2

864

10

SCLK

DINDA

VB

PVCC

DB0

DB1

18

1Y1

U12 74HC377

1A1

2

WASTE1

WASTE2

LOCK

uPACIDB

CTR2

PF2

18

1Y3

1Y2

1Y1

1A3

1A2

1A1

864

2

PF0

PF1

PF3

LIQUID4

0.1uF

G1R

G0R

G1D

G0D

256

9

1Q2Q3Q

1D2D3D

347

8

DB0

DB1

DB2

DB3

4

U5

0.1uF

C16

+

-VB

C18

+

10uF/25V

C17

10uF/25V

D5

4V7

R5

3K3

1N4148

PVCC

R43 10K

DTR#

PWDCA

PWDBH

ENAPI

ENABHFO

PWDFO

33343536373839404142434445464748495051525354555657585960616263

B1B2B3B4B5B6B7B8B9

A1A2A3A4A5A6A7A8A9

123456789

DIRFO

DIRCA

CLKFO

CLKBH

CLKCA

J10 H5x2

2

DSYNC

VB

-VB

C48

0.1uF

DB2

DB3

DB4

DB5

DB6

2Y2

2Y1

1Y4

1Y3

1Y2

2A2

2A1

1A4

1A3

1A2

864

11

LEAKB

LEAKWH

LIQUID3

LIQUID2

LIQUID1

SCLK

ENABHFO

P35B

3579121416

20

2Y4

2Y3

2Y2

2Y1

1Y4

2A4

2A3

2A2

2A1

1A4

1

171513

11

OPTOWH2 PF7

P77

PA0

P35

DIRPP

PWDPP

G1AUX

G0AUX

1213

1617

7Q7D

5Q5D

4Q

8D 8Q

4D

6D 6Q

14 15

18 19

DB4

DB5

DB6

DB7

MD2

RES

FWEBOOT

121314151617181920

F0F1F2F3F4F5F6

U24 16V8

I0I1I2I3I4I5I6I7I8

123456789

LOCK_IN

RESB

R6 3K3

D2

1 2

DTR

ENABHFO

1011121314151617181920212223242526272829303132

DIRBH

DB7RESA

PVCC

3579121416

20

74HC244U20

2Y4

2Y3

VCC

1OE

2A4

2A3

2OE GND

1

171513

19 10

ENA1ENA1

DEPR

C43

0.1uF

PVCC

PVCC

PVCC

74HC244U18

VCC

LD1

PVCC

U11 74HC377

ENA0

(/CS1)

PG3

4V7

PWDCU

B13

A13

CLKCU

J18

LOCK_IN

DTR#

F7

(/RD)

(/HWR)

PF4

123

RESA

PWDWH

B14

B15

A14

A15

CLKWH

LED RED

R33 4K7

LEDR

C42

0.1uF

LOCKED(ON)

1

LOCK

PVCC

10

VCC

GND

I9

11

PF5

DS1233-10

PVCC

ENABVWH

PWDBV

ENAPI

B16

B17

A16

A17

CLKBV

DIRWH

DIRCU

1OE

2OE GND

19 10

PVCC

1011

20

VCC

GNDCLK

ENG

1

PC2

WRL

FWE

WRL

PA3

PC0

D6

R7

3K3

1N4148

U6

B10

B11

B12

A10

A11

A12

Approved

L.M. 10/09/2004

A.G. 10/09/2004

R.CORNACCHIA

CheckedDescription

Drawn

Checked

Approved

RMP 224

0

PVCC

R38

PVCC

LD2

LED GREEN

R34 4K7

LEDV

PVCC

2

H2

C310.1uF

R39 10K

C19 0.1uF

PVCC

PVCC

C26

ENABVWH

B18

B19

B20

B21

A18

A19

A20

A21

DIRBV

A A

Rev.

10K

C30

U8 MAX202

C25

0.1uF

U7 MAX202

B22

B23

A22

A23

RES

DTR

RTS

Serial IN

RS232

RX2

TX2

ALLVENT

VB

PVCC

TX0 RX0

RX1TX1

VM

0.1uFC270.1uF

TX1

RX1

VCCC1+

GND

T1OUT

V+

C1-

2345678 9

C28

0.1uF

RX0

VCCC1+

GND

T1OUT

V+

C1-

2345678 9

C22

0.1uF

C23

PWDRE

PWDPP

B24

B25

B26

B27

A24

A25

A26

A27

CLKRE

CLKPP

Electronic

R1IN

C2+

R1IN

C2+

B28

A28

0

1 1

1

SE-30-01283-XX

Analytical Control Board

Title

Housing Fan

P34

P33

R1OUT

C2-

0.1uF

R8

0R

P31

P30

R1OUT

C2-

0.1uF

ENAPI

PWDDO

B29

A29

CLKDO

DIRRE

10/09/2004

A3

Size Document Number Rev

Date: Sheet of

5

4

3

2

1

J1 H5

3

2

1

8

7

6

5

4

3

2

1

P37

101112131415161

T1IN

V-

TX4

C29

PA1

101112131415161

T1IN

V-

TX2

C24

ENAPP

B30

A30

DIRPP

2

J13 H3

BarCode

J2 H8

4

3

2

1

J3 H4

Diagnostic

P36

3

T2IN

R2IN R2OUT

T2OUT

RX4

0.1uF

TX0

PA2

4

T2IN

R2IN R2OUT

T2OUT

RX2

0.1uF

5

ENADO

64

B31

B32

A31

A32

J7 DIN 64_AB-H

DIRDO

Page 38

00012 Guidonia (Roma)

Drawn Checked

Approved

Date

Sheet

Doc.

P/N

Rev.

authorization will be prosecuted accordingly to the law.

L. Massenzi R. Cornacchia A. Gagliarducci

20/10/2005

1 of 1

30

-

01284

-

01

A

Rev. A

18,300)

Via E. Barsanti, 17/A

(Via Tiburtina Km

: emissione in riferimento alla RMP n.268

30-01283-..

The present document is property of AMS, any use without

SC02

Stepper Motors Driver Board

Description

J7

U5

50-01692-01

Page 39

0

H8X2

J3

1

2

1

DOB

DOA

PPB

PPA

BVB

BVA

BHB

1

BHA

3

3

5

5

7

7

9

9

11

1314

1516

11

1314

1516

2

4

6

8

10

12

DOBN

4

DOAN

6

PPBN

8

PPAN

10

BVBN

12

BVAN

BHBN

BHAN

BHB

BHAN

BHBN

BHA

PWDCA

PWDBH

ENACA

ENAFO

ENABH

PWDFO

33343536373839404142434445464748495051525354555657585960616263

B1B2B3B4B5B6B7B8B9

A1A2A3A4A5A6A7A8A9

123456789

DIRCA

CLKFO

DIRFO

CLKBH

CLKCA

R6

1R-2W

B10

A10

1011121314151617181920212223242526272829303132

DIRBH

PWDWH

PWDCU

ENAWH

PWDBV

ENACU

ENABV

B11

B12

B13

B14

B15

B16

B17

B18

B19

B20

B21

B22

B23

B24

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

CLKCU

BVA

DIRBV

CLKBV

DIRWH

CLKWH

DIRCU

BVB

BVBN

BVAN

RESMOT

R12

ENARE

PWDRE

B25

B26

A25

A26

CLKRE

1R-2W

ENADO

PWDPP

ENAPP

PWDDO

64

B27

B28

B29

B30

B31

B32

A27

A28

A29

A30

A31

A32

J1 DIN 64_AB-H

DIRDO

CLKDO

DIRRE

DIRPP

CLKPP

DOB

R18

1R-2W

Approved

CheckedDescription

A.G. 10/09/2004

L.M. 10/09/2004

Approved

R.CORNACCHIA

Drawn

Checked

1 1

1

SE-30-01284-01

WHB

WHA

FOB

FOA

REA

CUB

CUA

CAB

CAA

2

12

34

56

78

910

1112

1314

1516

1718

1920

J2 H10X2

WHBN

WHAN

FOBN

FOAN

REBN REB

REAN

CUBN

CUAN

CABN

CAAN

C15

0.1uF

VM

+

C3100uF/50

D10

D9

24

231915

VMA

VMB

VCC

13

C14

0.1uF

CK1

72635108

RESMOT

PVCC

D11

20

FA1

FB1

FA2

RES

CK2ENDIRPDM1

CLKBH

DIRBH

D12

162118

FB2

4

PWDBH

1R-2W

R5

D22

D23

20

FA1

FB1

FA2

RES

CK2ENDIRPDM1

DIRBV

CLKBV

D24

162118

FB2

4

PWDBV

C21

VM

17

SA

SB

GNDPB

SDIC403

M2

GNDD GNDPA

OSC

9

SWBH0

SWBH1

C30

3n3

U3

1 22

D21

0.1uF

24

VMA

VMB

VCC

72635108

13

C20

0.1uF

231915

CK1

RESMOT

+

C6100uF/50

PVCC

1R-2W

R11

17

SA

SB

GNDD GNDPA

M2

OSC

9

1 22

SWBV1

SWBV0

C33

3n3

C27

VM

GNDPB

SDIC403

U6

D33C26

PVCCPVCC

D34

24

231915

VMA

VMB

VCC

CK1

72635108

13

RESMOT

0.1uF

0.1uF

+

C9100uF/50

D35

20

FA1

FB1

FA2

RES

CK2ENDIRPDM1

CLKDO

DIRDO

D36

162118

FB2

4

PWDDO

1R-2W

R17

17

SA

SB

GNDPB

SDIC403

GNDD GNDPA

M2

OSC

9

SWDO1

SWDO0

C36

3n3

U9

1 22

RMP 224

0

Rev.

SWBH0

SWBH1

4

3

SW3

1

2

SWBV0

SWBV1

4

3

SW6

SW DIP-2

1

2

SW DIP-2

Stepper Motors Driver Board

Title

SWDO0

4

SW9

1

10/09/2004

A3

Size Document Number Rev

Date: Sheet of

SWDO1

3

2

SW DIP-2

2

ENABH

FOBN

FOA

FOAN

D5

D6

24

VMA

VMB

VCC

72635108

13

C12

0.1uF

FOB

231915

20

FA1

FA2

CK1

RES

CK2ENDIRPDM1

CLKFO

RESMOT

D7

162118

FB1

PWDFO

DIRFO

R4

1R-2W

1R-2W

R3

D8

SA

SB

FB2

M2

OSC

9

4

SWFO0

SWFO1

C29

3n3

C19

0.1uF

VM

17

C5100uF/50

GNDPB

SDIC403

GNDD GNDPA

U2

1 22

1

TP1

VMVB

3

VL

PVCC

VB

TP-GND

6

5

4

3

2

1

J4 MOLEX

C40

0.1uF

C39

+

470uF/50

C38

0.1uF

C13

0.1uF

VM

+

C2100uF/50

PVCC

WHA

D17

24

+

VMA

VCC

PVCC

13

C18

0.1uF

ENABV

WHB

WHAN

WHBN

D18

D19

231915

20

162118

FA2

FB1

FA1

VMB

CK1

RES

CK2ENDIRPDM1

72635108

DIRWH

PWDWH

CLKWH

RESMOT

R10

1R-2W

1R-2W

R9

D20

17

SA

SB

FB2

GNDPB

GNDD GNDPA

OSC

M2

9

4

1 22

SWWH1

SWWH0

C32

3n3

C25

VM

SDIC403

U5

D29

0.1uF

24

+

C8100uF/50

13

C24

0.1uF

ENADO

PPB

PPBN DOBN

PPA DOA

PPAN DOAN

D31

D30

231915

20

FA2

FA1

VMB

VMA

VCC

CK1

RES

CK2ENDIRPDM1

72635108

CLKPP

RESMOT

162118

FB1

DIRPP

PWDPP

1

C+9 10K

2345678

R16

1R-2W

1R-2W

R15

D32

17

SA

SB

FB2

GNDPB

SDIC403

SW2

GNDD GNDPA

OSC

M2

9

4

SWPP0

SWPP1

C35

3n3

U8

1 22

SWWH1

SWPP1

SWPP0

SWBH1

SWBH0

SWBV1

SWWH0

SWFO1

SWFO0

4

3

1

2

SWWH1

4

3

SW5

SW DIP-2

SW DIP-2

1

2

RR2

9

10

SWDO1

SWBV0

SWDO0

3

SWPP0

SWPP1

4

3

SW8

SW DIP-2

1

2

C37

+

470uF/50

4

5

123

IN

OUT

GND

LM2940C

U10

C11

0.1uF

VM

C1100uF/50

R19

10K

RESMOT

PVCC

CAA

D1

24

+

VMA

VCC

PVCC

13

C10

0.1uF

ENAFO

CAB

CABN

CAAN

D2

D3

231915

20

162118

FA1

FB1

FA2

VMB

CK1

RES

CK2ENDIRPDM1

72635108

CLKCA

DIRCA

PWDCA

RESMOT

ENACA

ENAWH

CUB

CUAN

CUA

D14