Page 1

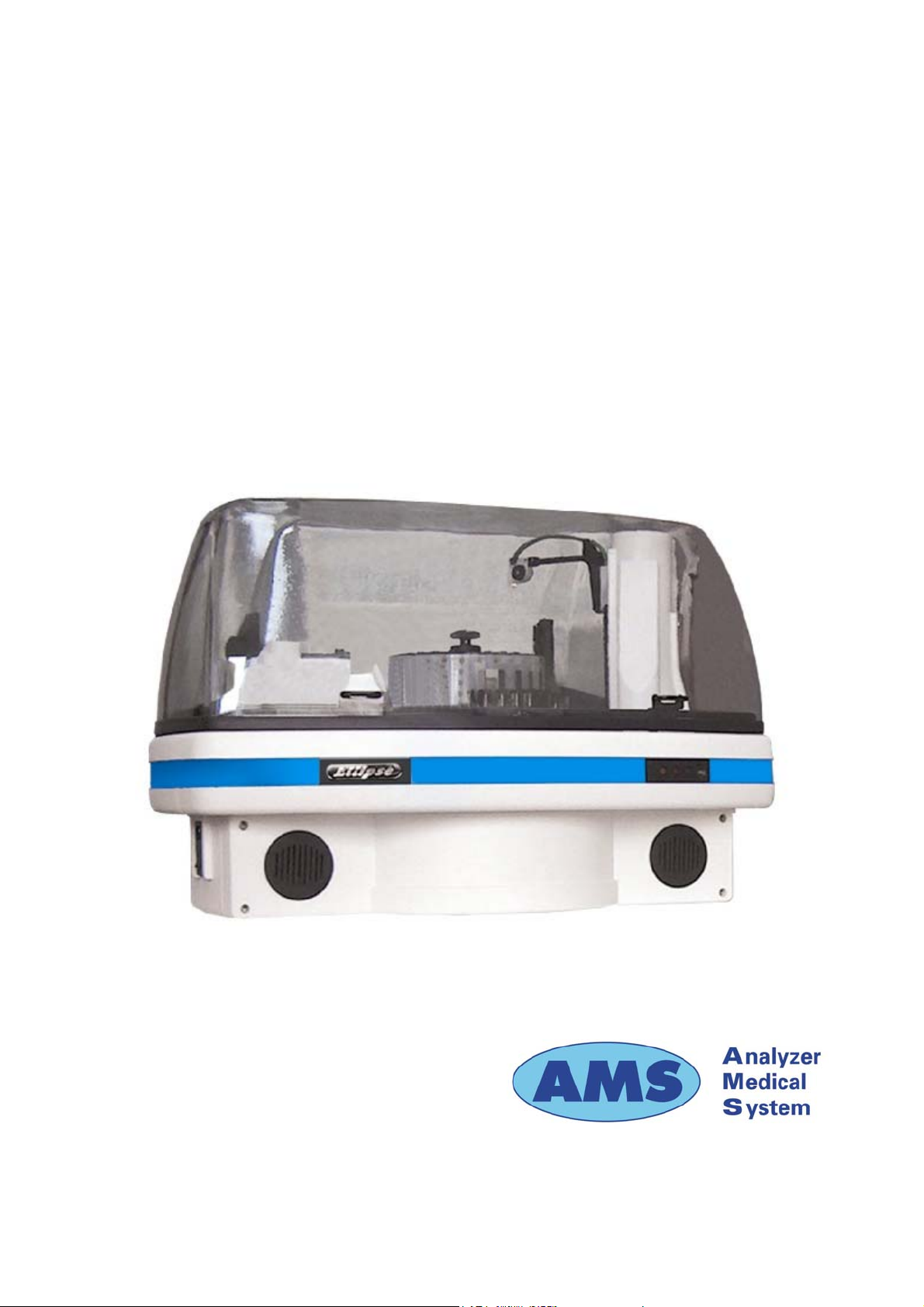

ELLIPSE

User Manual

Via E. Barsanti 17/A

00012 Guidonia – ROME (ITALY)

www.ams-analyzers.com

Page 2

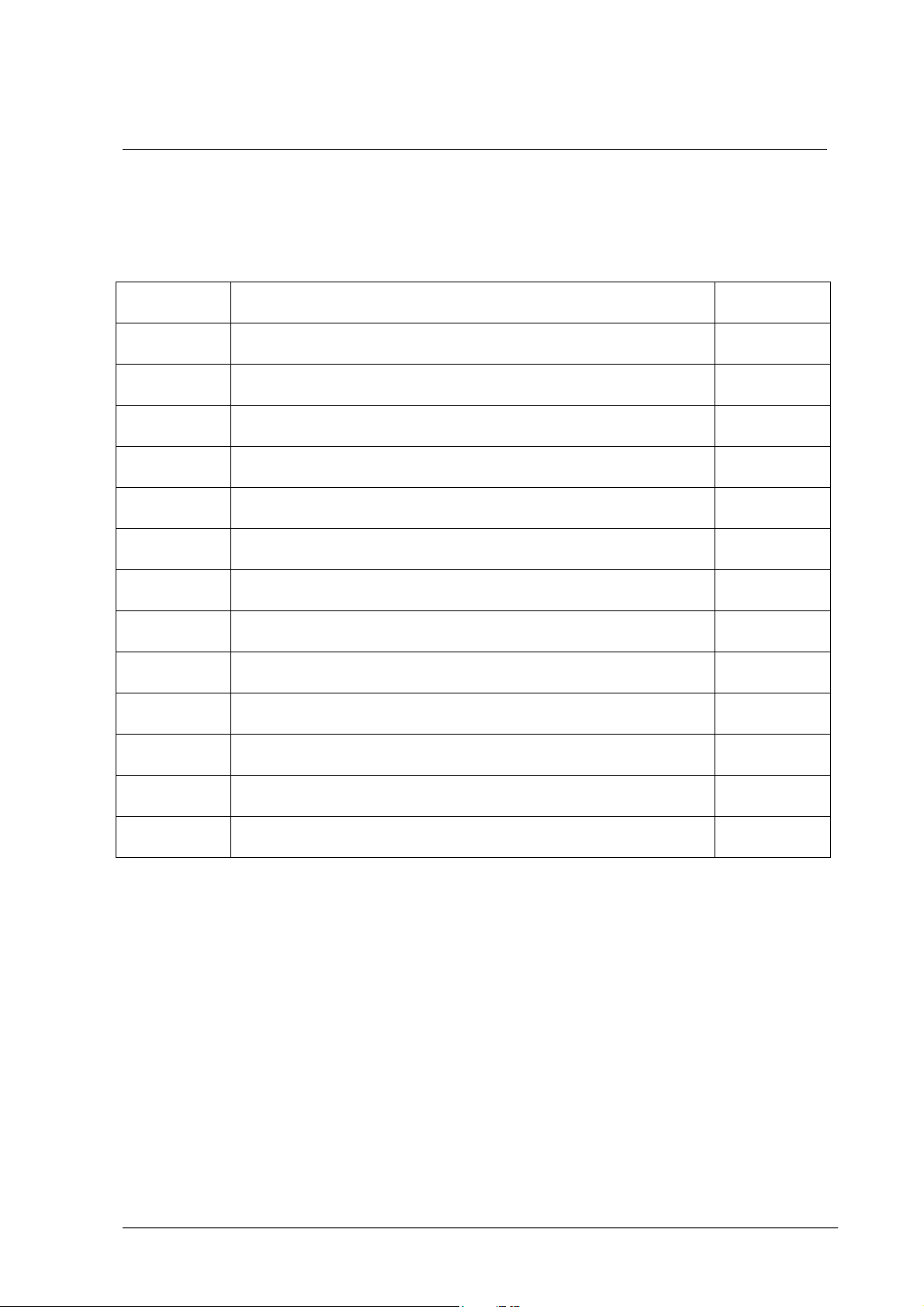

CONFIGURATION SHEET

CHAPTER DESCRIPTION REVISION

INDEX TABLE OF CONTENTS 02

01 INSTALLATION

02 GENERAL DESCRIPTION

03 SOFTWARE DESCRIPTION

04 DAILY ROUTINE

05 METHODOLOGY

06 CALIBRATION CURVES

07 MAINTENANCE

08 FORMULAS AND CALCULATION MODELS

09 ERROR SIGNALING AND TROUBLESHOOTING

10 HOST COMMUNICATION

11 PACKING LIST

02

02

02

01

01

01

02

01

02

01

01

12 DIAGNOSTIC PROGRAM

02

Ellipse User Manual Rev.02 19 October 2005 Page 1

Page 3

TABLE OF CONTENTS

Chapter 01 INSTALLATION

Chapter 02 GENERAL DESCRIPTION

Chapter 03 SOFTWARE DESCRIPTION

Chapter 04 DAILY ROUTINE

INDEX

Chapter 05 METHODOLOGY

Chapter 06 CALIBRATION CURVES

Chapter 07 MAINTENANCE

Chapter 08 FORMULAS AND CALCULATION MODELS

Chapter 09 ERROR SIGNALING AND TROUBLESHOOTING

Chapter 10 HOST COMMUNICATION

Chapter 11 PACKING LIST

Chapter 12 DIAGNOSTIC PROGRAM

Ellipse User Manual Rev.02 19 October 2005 Page 1

Page 4

Chapter 01 - INSTALLATION

CHAPTER 01 - INSTALLATION

INDEX

1.1 UNPACKING .......................................................................................................................... 2

1.2 INSTALLATION..................................................................................................................... 4

1.2.1 INSTALLATION SITE SPECIFICATIONS........................................................................... 4

1.2.2 ELECTRIC CURRENT REQUIREMENTS ........................................................................... 4

1.2.3 CONNECTION OF THE ACCESSORIES ............................................................................. 5

1.2.3.1 POWER SUPPLY .................................................................................................................... 5

1.2.3.2 COMPUTER - INSTRUMENT CONNECTION .................................................................... 6

1.2.3.3 HYDRAULIC CONNECTIONS …....……………………………………………………….6

1.2.4 ATTENTION .......................................................................................................................... 6

1.2.5 SYMBOLS ............................................................................................................................. 7

1.2.6 REGULATORY COMPLIANCE.......................................................................................... 8

1.2.7 LIMITATION OF USE........................................................................................................... 8

1.2.8 BARCODE READER............................................................................................................. 8

1.2.9 WARRANTY ……...……………………………………………………………...…………8

1.2.10 CONSUMABLES AND ACCESSORIES PARTS LIST OUT OF WARRANTY…………9

Ellipse User Manual Rev.02 19 October 2005 Page 1

Page 5

Chapter 01 - INSTALLATION

t

n

y

1.1 UNPACKING

The ELLIPSE is packed and delivered in two separate wooden crates: one contains the analyzer itself

and the other the computer, along with its accessories. In the event that the order does not include the

PC component, the packing and delivery will involve one wooden crate plus a corrugated cardboard

box. The packing has been expressly studied and designed to insure maximum protection of the

contents during shipping and handling. It is therefore extremely important that the crate(s)/box be

carefully examined upon delivery in order to ascertain their integrity. Special attention should be

dedicated to examining the color of the “Shock Watch” glued to the crates, which must show the color

‘white’. A ‘red’ “Shock Watch” indicates that the crate(s) have experienced some sort of ‘shock’

during handling, transport and/or delivery. This fact must be noted by the courier on the delivery note,

as must any and all visible external damage (for example: holes, dents, rips or tears, water marks, etc.)

evident at the moment of delivery. This will simplify matters in the event of any future claims for

damages.

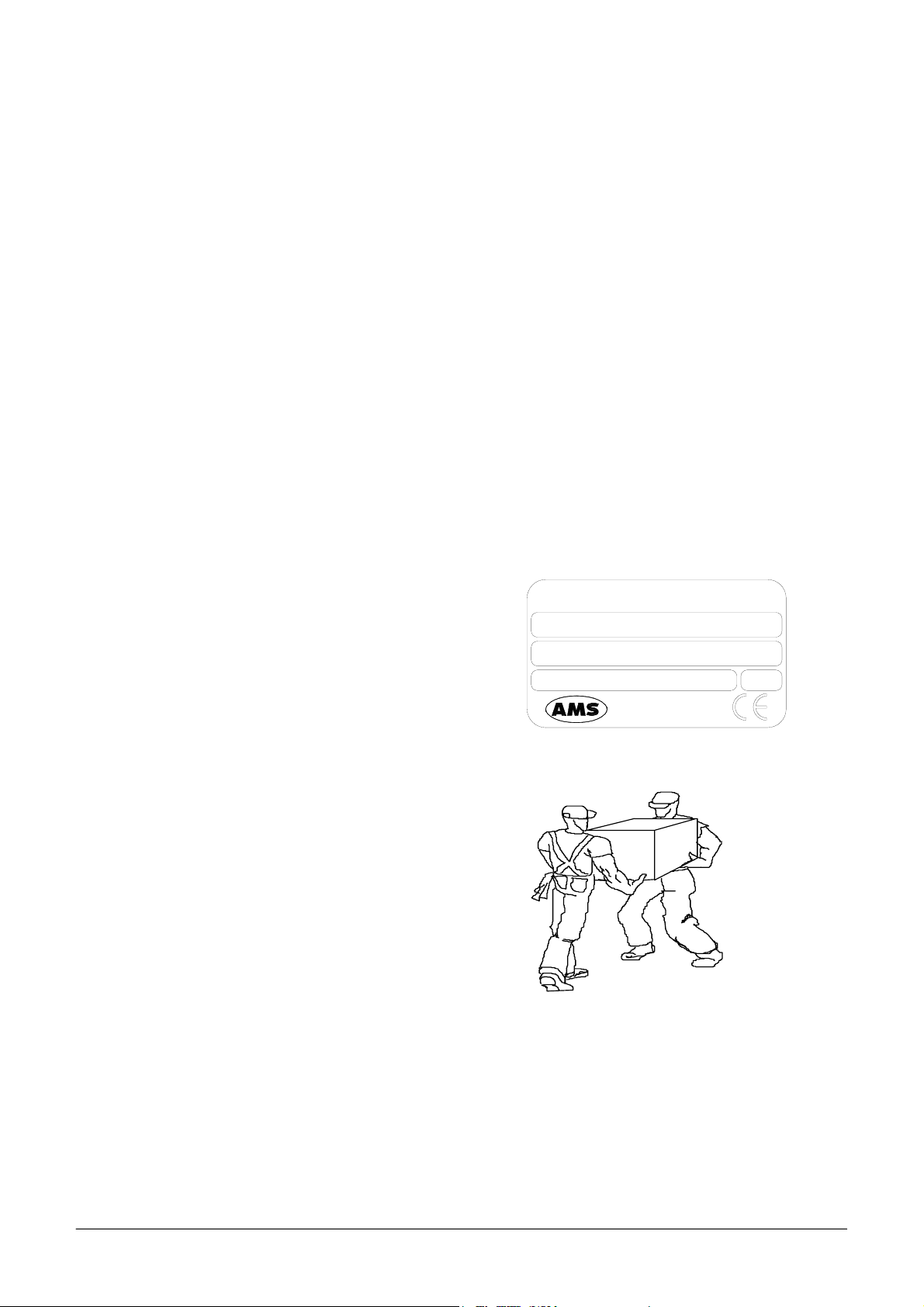

Upon arrival of the crate(s)/box, take out the

delivery note and make sure that all the items

on the packing list are included in the crates

and are undamaged. Make sure the series

number on the delivery note/packing lis

corresponds to that impressed on the plate o

the left side of the instrument.

Open the crate(s)/box from the top and ver

carefully take out:

- the instrument;

- the computer and accessories.

ELLIPSE

S/N

P/N

100 ÷ 230Vac 47 ÷ 63Hz

Analyzer

Medical

System

300W

Rome-Italy

MAKE SURE THAT THE UNPACKING IS CARRIED OUT BY TWO PEOPLE.

Ellipse User Manual Rev.02 19 October 2005 Page 2

Page 6

Chapter 01 - INSTALLATION

Do not discard the delivery crate(s)/box or the packing material until the correct functioning of the

instrument has been ascertained.

Remove all the items from the crate(s)/box very carefully.

Before connecting the "Ellipse", remove the protective packing material placed under the sampling

arm and under the wash station group.

Warning: in the event that it is necessary to repack any or all of the delivered item(s), the following

procedures must be carefully followed:

Reposition the protective packing material under the sampling arm and under the wash station

group.

Tape down (using masking tape if possible) the cover of the samples and reagents housing, the

front panels, and the samples and reagents racks.

Remove the probe from the sampling arm and place it inside a primary tube. Then cap the tube

and tape the cap down.

Be very careful to not bend the wash station cannulas when repositioning the protective packing

material.

Fill the empty spaces around the accessories packed in the crate using “pluriballs” or other

suitable packing material.

Ellipse User Manual Rev.02 19 October 2005 Page 3

Page 7

Chapter 01 - INSTALLATION

1.2 INSTALLATION

The ELLIPSE must only be installed by a qualified technician who has been authorised and trained to

do so. During its installation the system will be checked once again to ensure correct functioning. The

persons who are required to operate the ELLIPSE system must have received the adequate training.

This should also include the "know-how" of the normal maintenance for the instrument. A description

of the maintenance will be found in Chapter 7 of this manual.

ELLIPSE is a complex system, and it is therefore extremely important that it is correctly installed in

order to fully guarantee fine performance. If the installation and use directions, given in this manual,

are not correctly followed and/or safety indications are not respected, AMS cannot guarantee correct

functioning of the instrument. Apart from this, the safety of the operator could be placed at risk.

1.2.1 INSTALLATION SITE SPECIFICATIONS

Ascertain that the ELLIPSE system is not exposed to direct sunlight, draughts, dust or strong magnetic

fields. In addition, please take note of the following conditions required for the location of the

installation:

USE

DEGREE OF POLLUTION

INSULATION CLASS

INSTALLATION CATEGORY

TEMPERATURE

HUMIDITY

ALTITUDE

In covered and dry place

2

I

II

Between 18°- 30°C

20% ÷ 85%

Max 3000 m

Shelf or table with a minimum surface of 75 x 60 cm stable

LOCATION

and free of vibration

Leave a minimum distance of 10 cm around the instrument to

VENTILATION

permit air circulation. Make sure that the front and rear holes

are not blocked by any object

1.2.2 ELECTRIC CURRENT REQUIREMENTS

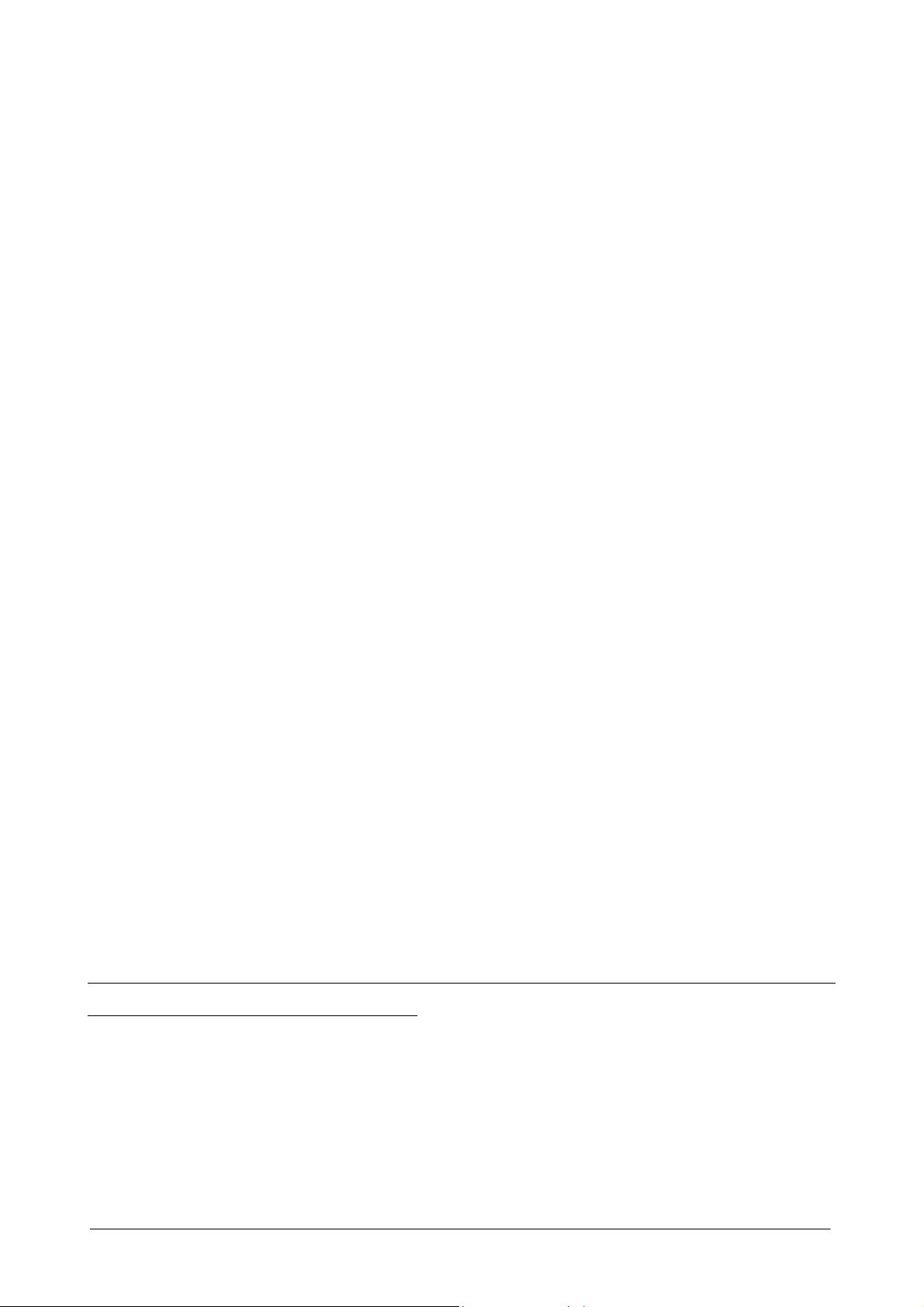

The power voltages to which the instrument is adapted are indicated on the left-hand side

(see fig. 1). It must be plugged into a plug of the correct voltage.

VOLTAGE

FUSES

100÷ 230 Vac 47/63 Hz ± 10%

6.3 A /T - 5 x 20

Ellipse User Manual Rev.02 19 October 2005 Page 4

Page 8

Chapter 01 - INSTALLATION

NOTE: IT IS ADVISABLE TO MAINTAIN THE MAXIMUM STABILITY OF THE ELECTRICAL CURRENT IN THE

LABORATORY

SUPPLEMENTARY DEVICES IS RECOMMENDED

. WHERE THIS IS NOT POSSIBLE OR ASCERTAINABLE, USE OF THE FOLLOWING

:

ELECTRONIC STABILIZER

Used to stabilise the electric voltage in the laboratory. Any stabiliser with a power potential

greater than 0.5 KW, currently available on the market, can be used.

NO-BREAK MODULE UPS - (Uninterrupted Power Supply)

This module provides two important functions:

- stabilises the main-line power

- supplies current to the instrument in case of a main-line power failure.

1.2.3 CONNECTION OF THE ACCESSORIES

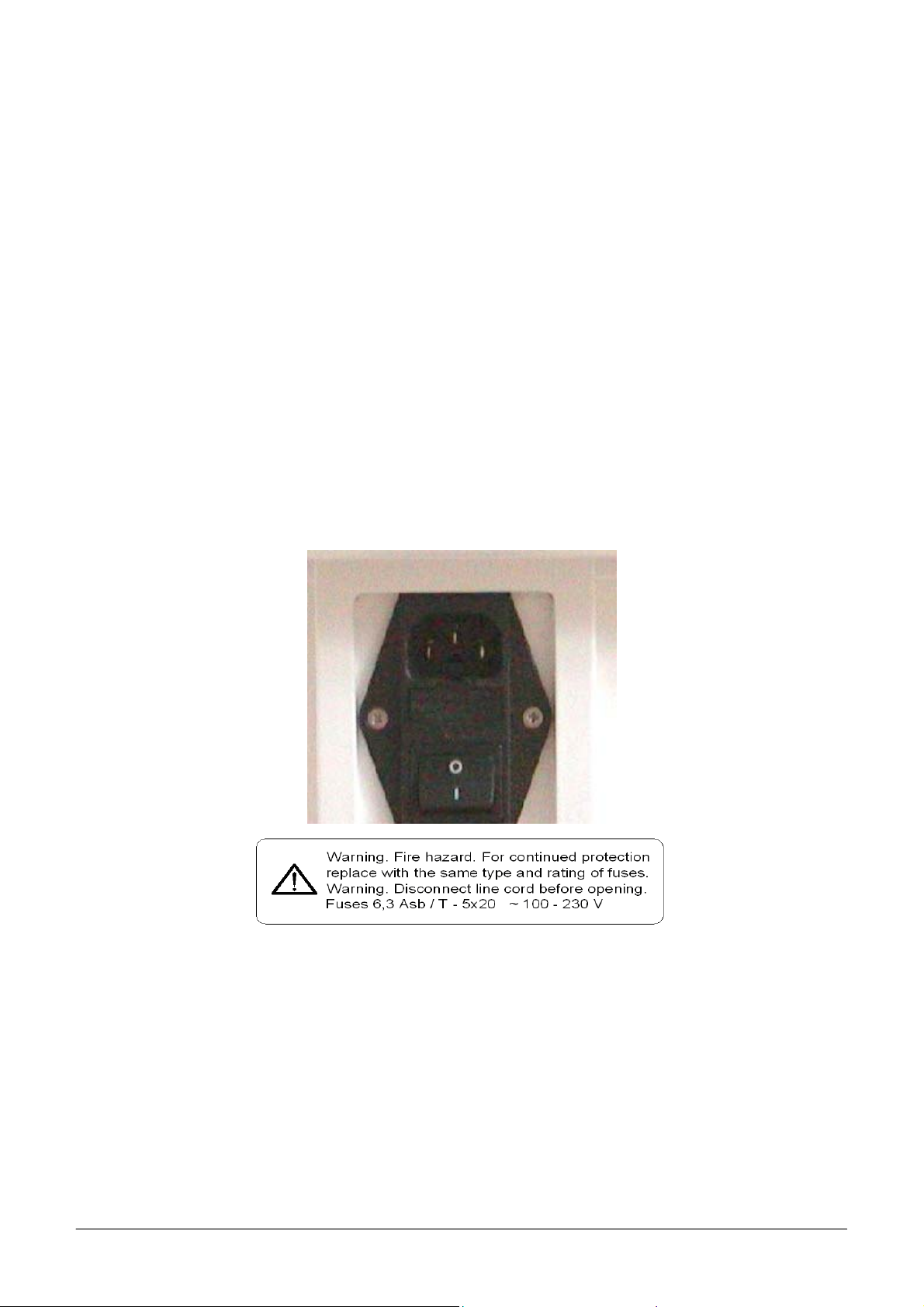

1.2.3.1 POWER SUPPLY

Fig. 1 – Plug (use the feeder cable supplied with the instrument).

The sticker below the plug in indicates the power supply voltage and the values of the fuses.

Ellipse User Manual Rev.02 19 October 2005 Page 5

Page 9

Chapter 01 - INSTALLATION

1.2.3.2 COMPUTER - INSTRUMENT CONNECTION

The instrument and the Personal Computer are connected by one serial RS232 standard cable

(Cod. 9-35-0055-01), which provides the hardware support for the communication.

1.2.3.3 HYDRAULIC CONNECTIONS

The instrument uses Cleaning solution and distilled water for reaction cuvettes cleaning; it uses Rinse

solution for sampling probe cleaning and cuvette blank determination (WBL). A second Rinse

hydraulic line is used for cuvettes quality control checking after washing.

For connecting said solution there are four inlet on the instrument left side identified by roman

numbers as here below specified:

• I Rinse solution (green color)

• II Rinse solution (yellow color)

• III Distilled water (blue color)

• IV Cleaning solution (red color)

The waste hydraulic lines are located on the instrument right side

Further information can be taken on the Hydraulic diagram (SI 16 00571 01 Service manual -chapter

04).

1.2.4 ATTENTION

The following label is found at the rear of the instrument.

CAUTION

TO PREVENT ELECTRIC SHOCK

DO NOT REMOVE BACK PANEL.

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVING TO QUALIFIED

SERVICE PERSONNEL

NOTE: THE REAR PANELS OF THE INSTRUMENT MUST NEVER BE OPENED WITHOUT HAVING FIRST

SWITCHED THE INSTRUMENT OFF AND DISCONNECTED THE ELECTRICITY CABLE

Ellipse User Manual Rev.02 19 October 2005 Page 6

.

Page 10

Chapter 01 - INSTALLATION

THE MAINTENANCE AND CLEANING PROCEDURES FOUND IN CHAPTER 07 OF THIS MANUAL MUST BE

RESPECTED AT ALL TIMES

BEFORE INSTRUMENT MAINTENANCE OPERATION

. REMEMBER TO FOLLOW THE DECONTAMINATION PROCEDURE WHEN REQUIRED

(SEE CHAPTER 07).

1.2.5 SYMBOLS

ATTENTION: READ THE INSTRUCTIONS IN THE USER MANUAL

TERMINAL OF TOTAL MASS PROTECTION (CONDUCTOR)

BIOLOGICAL HAZARD

(LOCATED NEAR THE REACTION PLATE AREA)

Carefully manipulate all the consumables and the wastes produced during the

analysis routines. Use appropriate protective garment. Disposal of wastes must

be done in compliance with applicable regulation. It is recommended to

periodically check the level in the waste container, in order to avoid overflow.

INDICATES THE BOTTLES CONNECTION

I RINSE SOLUTION

II

III

IV

STAND-BY BUTTON

RINSE SOLUTION

DISTILLED WATER

CLEANING SOLUTION

BUZZER FORCE OFF BUTTON

Ellipse User Manual Rev.02 19 October 2005 Page 7

Page 11

Chapter 01 - INSTALLATION

BARCODE READER BUTTON

1.2.6 REGULATORY COMPLIANCE

The ELLIPSE instrument complies with:

• European Directive 98/79/CE for In Vitro Diagnostic Devices

1.2.7 LIMITATION OF USE

The ELLIPSE can not be used by blind operators because the user interface with the system requires a

monitor.

Furthermore the ELLIPSE must be used with particular caution by color blind operators because the

graphic interface displays different colors with different meaning.

1.2.8 BARCODE READER

A bar code reader can be optionally installed on the ELLIPSE. The barcode reader has a laser micro-

scanner classified as Class II laser device. It is compliant with applicable safety regulations.

WARNING TURN OFF ALWAYS THE INSTRUMENT before removal of those panels and

covers that protect from any interference and/or exposure to the laser beam active during sample

identification.

1.2.9 WARRANTY

AMS guarantees the substitution of all defective components and/or materials for a period of time not

above of fourteen months starting from the date of invoicing. Saying warranty, as well as Technical

Assistance, generally is intended furnished as net ex factory Rome.

This warranty does not include consumable and instrument parts in contact with liquids. All

components not covered by the warranty are reported in the table on the next page.

Besides warranty does not cover damage caused by:

- improper use of the ELLIPSE instrument (or however not according to the Producer or Seller

instructions)

- bad transport

- insufficient (or missing) preventive maintenance by the User

In particular any damages due to the transport must be immediately reported to the carrier when he

delivers.

Ellipse User Manual Rev.02 19 October 2005 Page 8

Page 12

Chapter 01 - INSTALLATION

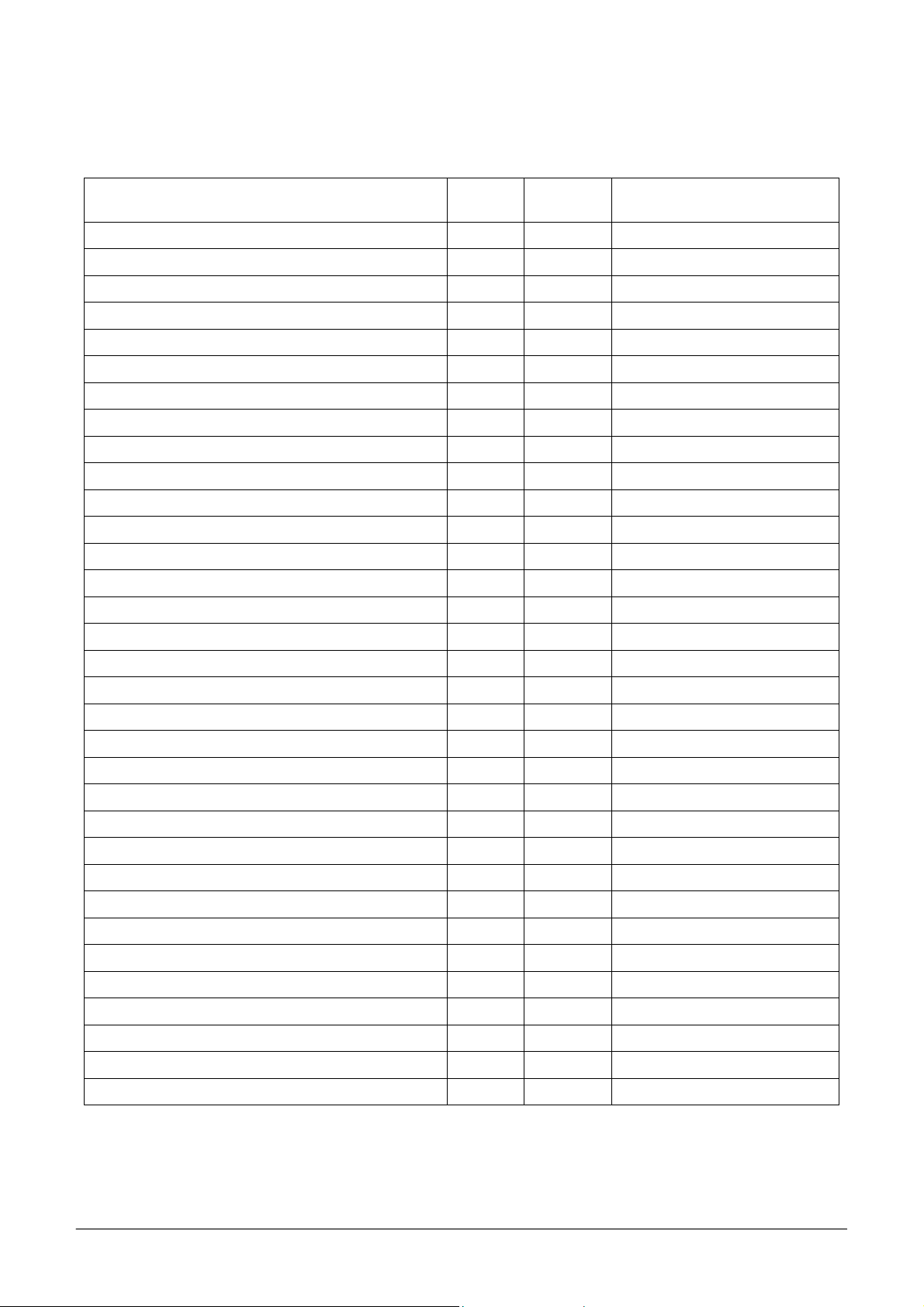

1.2.10 CONSUMABLES AND ACCESSORIES PARTS LIST OUT OF WARRANTY

Description Type

Quantity

(Pieces)

Code

Reagents containers 35 ml 12 C101-00190-00

Reagents containers 6 ml 12 C101-00191-00

Samples cups 0.8 ml 1000 AS650002

Short samples cups 1 ml 1000 AS650100

Adapter for short samples cups 1 9-01-0609-00

Reaction sectors 6 C101-00217-00

Washing solution bottle 2 lt 1 9-35-0041-00

Bottle level sensor 1 9-05-0078-00

Tubing Kit for peristaltic pump 2 65-01835-00

Tubing Kit – complete 1 65-01836-00

Cleaning solution 250 ml 2 ASRN0020

Rinse solution 50 ml 1 ASRN0021

Sampling probe (internal needle) 1 05-00707-00

Complete Sampling probe 1 10-00703-00

Drying Pad 1 01-01920-00

Halogen Lamp (6 V - 10 W) 1 9-35-0016-00

Interferential filters Kit (Stablife) 1 65-02017-00

Fuse 6,3 A-T 5x20 10 C132-01238-08

Inlet/outlet fitting for Rinse & Clean conts 1 01-01224-00

Cuvettes protection cover 1 05-01249-00

Reagent protection cover 1 10-00584-00

Reagent plate 1 10-00585-00

Samples rack 1 05-01829-00

Washing station, first or second cannulas (A) 1 05-01633-00

Washing station, third cannula (B) 1 05-01633-01

Washing station, fourth cannula (C) 1 05-01638-00

Washing station, fifth cannula without pad (D) 1 05-01919-00

Diluter Micro-Pump 1 05-01710-40

Air Micro-Pump (µP 6) 1 05-01711-20

Micro-Pump (µP 2 ÷5) 1 05-01826-16

Predilution rack 1 05-01735-00

Solenoid Valve –2 way 1 9-35-0035-00

Solenoid Valve –3 way 1 9-35-0036-00

Ellipse User Manual Rev.02 19 October 2005 Page 9

Page 13

Chapter 02 - GENERAL DESCRIPTION

CHAPTER 02 – GENERAL DESCRIPTION

INDEX

2.1 INTENDED USE AND SYSTEM DESCRIPTION........................................................... 2

2.2 ANALYSES CYCLE .......................................................................................................... 3

2.2.1 REACTION PLATE ........................................................................................................... 3

2.2.2 REACTION PLATE CYCLE ............................................................................................. 3

2.2.3 SAMPLING ARM - OPERATIONAL SEQUENCE ......................................................... 4

2.2.4 SAMPLING SYSTEM........................................................................................................ 5

2.2.5 WASH STATION ............................................................................................................... 6

2.2.6 WASH STATION CYCLE ................................................................................................. 6

2.3 TECHNICAL-OPERATIVE SPECIFICATIONS............................................................... 7

2.3.1 SOFTWARE AND COMPUTER SPECIFICATIONS....................................................... 8

2.3.2 OPTIONAL MODULES .....................................................................................................9

2.3.3 DIMENSIONS, WEIGHT AND OPERATING ENVIRONMENT.................................... 9

2.3.4 INSTALLATION SPECIFICATIONS................................................................................9

Ellipse User Manual Rev.02 19 October 2005 Page 1

Page 14

Chapter 02 - GENERAL DESCRIPTION

2.1 INTENDED USE AND SYSTEM DESCRIPTION

The “Ellipse” is a random access, computer controlled, counter-top, clinical analysis instrument.

The system can perform 138 tests per hour and has a machine cycle of 26 seconds. Its execution

time ranges from a minimum of 18 seconds to a maximum of 1040, depending on the analysis

method chosen.

The first time the system is used for laboratory analyses, the operator must configure the system

based on the specific needs of that laboratory; i.e.: the chemistry parameters and the reagents racks,

along with the normal, calibrated and control values, must all be defined.

The “Ellipse” is an “OPEN” system that allows configuration with different reagents selected by

the customer in order to fit his needs.

NOTE:

In order to assure the analytical performances of the system “instrument + reagents”, it is

responsibility of the laboratory staff to use reagents, controls and calibrators validated on the

“Ellipse”, or in alternative, to qualify other reagents, controls and calibrators in compliance with

the applicable regulations.

The daily routine analyses will be carried out according to patient sample arrival in a sequential and

continuous, non-stop manner.

The work list is organized using a loading rack holding up to 8 patient samples. Rack loading is

non-stop.

The racks can accommodate test tubes or micro caps. The bar code for primary tubes and reagent

containers is an optional feature.

When the system, the analytical unit and the computer, is turned on the color-meter lamp is supplied

with low voltage power (1.2 volts), the sampling arm pre-heater remains turned off, while instead

the reaction plate heater, the reagents refrigerating unit (optional module) and the electronic

components are turned on.

In this phase, the "Stand-by" light, placed on the front panel, will flash until the reaction plate

reaches a temperature of 36° C. When this temperature is reached, the "Stand-by" light will stop

flashing and will remain constantly lit.

In the case of system failure or malfunction, the "Ready" light, situated on the front panel of the

instrument, will light up red.

In order to access the main program, double click on the "Analyzer" icon on the computer desktop.

Ellipse User Manual Rev.02 19 October 2005 Page 2

Page 15

Chapter 02 - GENERAL DESCRIPTION

The main menu - "System Monitor" - will appear.

Whenever any system function is launched, the color-meter lamp and the sampling arm pre-heater

will receive regular power.

2.2 ANALYSES CYCLE

2.2.1 REACTION PLATE

The reaction plate of the "Ellipse" system contains 6 disposable racks with 20 reaction cuvettes

each.

The racks can be removed individually.

The basic operating cycle of the reaction plate takes 26 seconds. This cycle includes: optic reading

of the cuvettes in incubation, aspiration and dispensing of the reagents and the samples by the arm,

along with the relative positioning of the plate.

The reactions take place at 37° C. This temperature is maintained constant by a controlled heating

unit placed under the reaction plate.

2.2.2 REACTION PLATE CYCLE

After reagents and samples have been placed in cuvette #1, the reaction plate will rotate 40

positions counter-clockwise, so as to bring the first cuvette to be analyzed in front of the color-

meter for reading with either one or two wavelengths, if required.

The plate will then, moving clockwise, carry out all the readings of any other prepared cuvettes.

After having effectuated all the readings, the plate will move counter-clockwise to its initial

position minus one cuvette, ready for a new dispensing.

In this manner, the reaction cuvettes move clockwise 1 - 2 - 3 - 4 for dispensing, washing and the

relative readings.

Ellipse User Manual Rev.02 19 October 2005 Page 3

Page 16

Chapter 02 - GENERAL DESCRIPTION

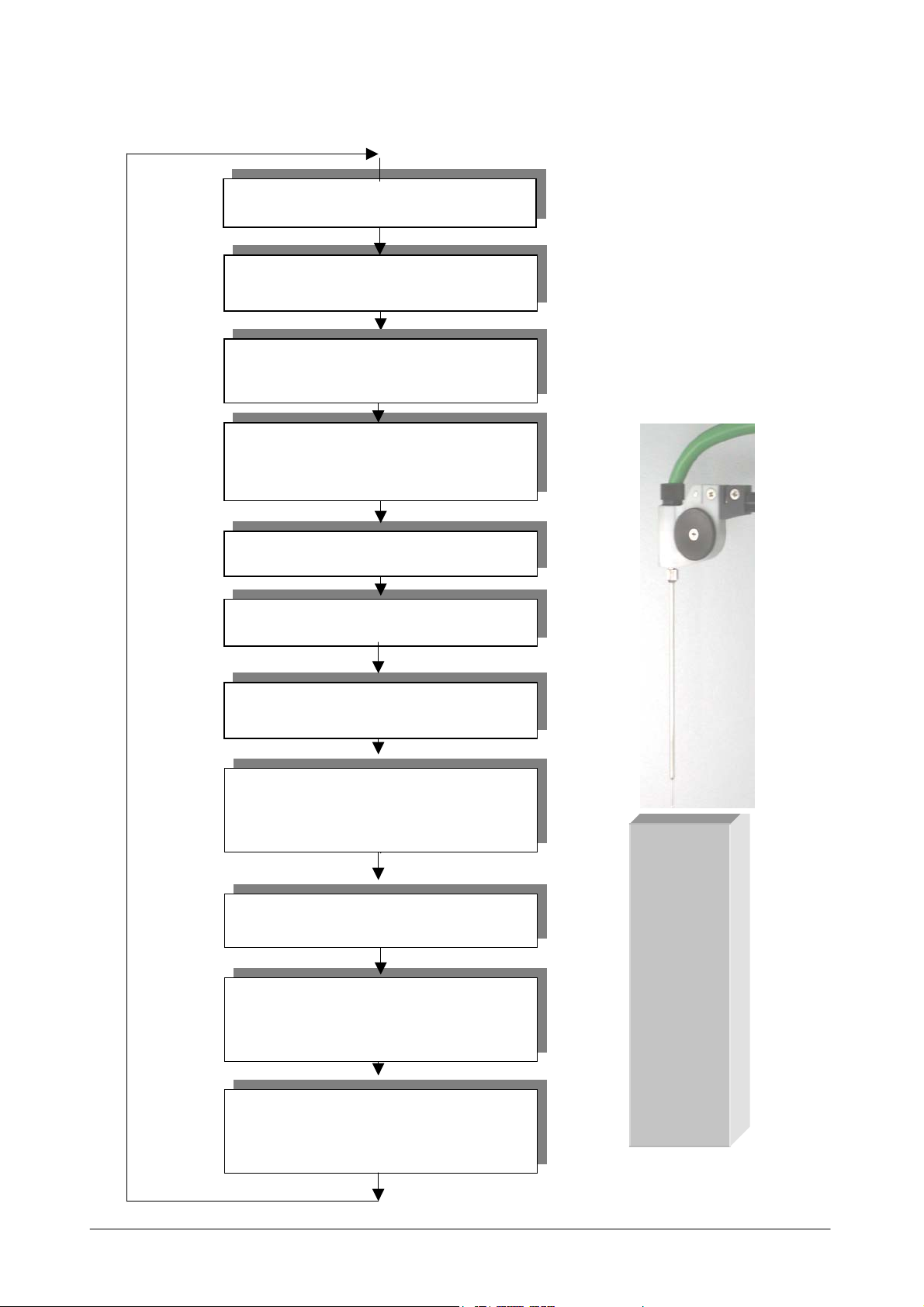

2.2.3 SAMPLING ARM - OPERATIONAL SEQUENCE

1. The sampling arm lifts up from the wash well and carries out a wash cycle;

2. The arm moves toward the specific reagent container, while the diluter aspirates an air bubble

to separate the rinse column from the reagent;

3. The arm lowers itself into the reagent, below the level indicated by the sensor, and aspirates the

required quantity of reagent. If the method requires a Rinse (used in order to reduce the

possibility of negative contamination between the water column and the reagent) an extra

amount of reagent (not used in the analysis) will be aspirated before the quantity of reagent

necessary for the analysis, along with another air bubble for their separation;

4. While the diluter aspirates a second air bubble, the arm rises and then lowers into the wash well

so that it can be washed externally, to minimize cross contamination;

5. The arm moves to the specified sample and aspirates a third air bubble;

6. Once the level sensor has indicated the presence of the liquid, the arm stops and aspirates the

sample;

7. The arm once again is raised, while the diluter aspirates a fourth air bubble to prevent sample

loss;

8. At this point, the arm returns to the wash well in order to clean the outside of the probe and

aspirates a fifth air bubble;

9. The arm moves to the reaction plate, dispenses, and mixes the reagent and sample in the

reaction cuvette for incubation and reading;

10. The arm returns to the wash well and carries out a probe wash cycle.

Ellipse User Manual Rev.02 19 October 2005 Page 4

Page 17

Chapter 02 - GENERAL DESCRIPTION

(

)

2.2.4 SAMPLING SYSTEM

Aspiration of Air

Aspiration of Reagent

Aspiration of Air

To separate reagent from serum

To wash well to clean the

probe

Aspiration of air

Aspiration of serum

Aspiration of air

To wash well to clean the

probe

Aspiration of air

Dispensing and mixing in

cuvette

To wash well for final

wash

H2O

AIR

RGT

AIR

AIR

SERUM

AIR

Ellipse User Manual Rev.02 19 October 2005 Page 5

Page 18

Chapter 02 - GENERAL DESCRIPTION

2.2.5 WASH STATION

The reaction plate wash station is made up of a series of five small needles situated on one side of

the reaction plate. Said needles are opportunely connected to the valve and pump system for

emptying, washing and drying operations (please see the hydraulic diagram).

2.2.6 WASH STATION CYCLE

The wash station carries out its operations alternating upward and downward movement. In its

downward movement phase the needles are guided in such a manner as to carry out the following

operations:

• The first needle, using the central cannula, removes the reaction mix while the external cannula

dispenses, shower-like fashion, the wash solution; after that the external cannula dispenses

wash solution and then the liquid is aspirated from the central cannula;

• The second needle operates exactly like the first but uses distilled water instead;

• The third needle operates exactly like the first but dispenses rinse solution into the cuvette so

that an optics check can be performed (if the results are negative, the cuvette is discarded);

• The fourth needle aspirates the Rinse solution used for the optic check.

• The fifth needles dries the sides.

All these operations are part of the routine operation of the instrument. Every reaction cuvette is

washed at the end of each round of analysis.

The reusability (optical integrity) of each reaction cuvette is always tested before the next round of

analysis.

Ellipse User Manual Rev.02 19 October 2005 Page 6

Page 19

Chapter 02 - GENERAL DESCRIPTION

2.3 TECHNICAL-OPERATIVE SPECIFICATIONS

♦ Completely automatic, random access, computer

DESCRIPTION

REACTION TYPES

TEST SELECTION MODES

PRODUCTIVITY

OPERATING TEMPERATURE

IN LINE REAGENTS

SAMPLE CONTAINERS

controlled, counter-top, non-stop loading clinical

chemistry and immunoturbidimetric analysis

instrument

♦ End Point, Fixed Time, Kinetic, Bichromatic,

Differential

♦ Selective, Batch, Profile, STAT

♦ 138 tests per hour

♦ 37° C

♦ 24 removable containers (capacity 35 and 6 ml)

♦ Reagent plate cooling unit (Optional)

♦ 12 positions for Controls and Standards

♦ Positive Bar Code Reader (Optional)

♦ Primary tubes (diameter from 8 to 16 mm; height

up to 100 mm) cups from 1 to 4 ml

SAMPLE LOADING

MINIMUM REACTION

VOLUME

MAXIMUM REACTION

VOLUME

SAMPLING ARM

DILUTER

♦ 4 racks, each having 8 positions for non-stop

sample loading

♦ Positive Bar Code Reader (Optional)

♦ 220 µl

♦ 550 µl

♦ A single mechanical arm performs all the sampling

operations and is equipped with:

• A volume level sensor

• Pre-heating of the reagent(s) to 37 °C

• Automatic probe washing

♦ Integrated syringe-free module having the

following specifications:

• Sample volume: 2 µl ÷ 99 µl (1 µl incr.)

• Reagent 1 volume: 3 µl ÷ 500 µl (1 µl incr.)

• Reagent 2 volume: 3 µl ÷ 330 µl (1 µl incr.)

• Reagent 3 volume: 3 µl ÷ 330 µl (1 µl incr.)

Ellipse User Manual Rev.02 19 October 2005 Page 7

Page 20

Chapter 02 - GENERAL DESCRIPTION

PRECISION

READING SYSTEM

OPTIC SYSTEM

CUVETTE OPTIC LENGTH

WASHING STATION

REACTION PLATE

♦ CV < 1 % at 2 µl

♦ Direct reading

♦ Photometer: double ray, interferential filters

♦ Wavelength: 8 narrow band – from 340 nm to 620

nm – interferential filters plus one available

optional filter position

♦ Light source: 6V/10W halogen bulb

♦ Linearity range: up to 3,500 Abs

♦ Resolution: 0.0005 Abs

♦ 6 mm

♦ Composed of five probes that empty, wash and dry

the reaction cuvettes.

♦6 individually replaceable racks with 20 cuvettes

each

♦Incubation temperature: 37°C

2.3.1 SOFTWARE AND COMPUTER SPECIFICATIONS

TYPE

CPU

♦ IBM Compatible

♦ Pentium IV 500 MHz, 512 Kb Cache or plus

♦ RAM 256 Mb or plus

MEMORY

♦ Hard Disk 20 Gb or plus

♦ Floppy Disk 3 1/2” 1.44 Mb

Colour SVGA 15’’ low radiation

MONITOR

Resolution 800 x 600 pixels;

max number of colors 65536 (16 bit)

PRINTER

♦ 80 Columns impact graphic (EPSON LX 300)

KEYBOARD AND MOUSE

INTERFACE

♦ PS2

♦ One Bi-directional RS 232C serial ports and one

parallel (one second serial port for the Host link)

♦ Multitasking WINDOWS XP Home edition

SOFTWARE

AVAILABLE LANGUAGES

Ellipse User Manual Rev.02 19 October 2005 Page 8

♦ Italian, English, Chinese, Czech. Software to be released

soon in these languages: Russian, Portuguese, French,

Polish. Upon request it is possible to release the software

in other languages.

Page 21

Chapter 02 - GENERAL DESCRIPTION

♦ Disable all the energy saving options

SETTINGS

♦ Disable the screen saver

♦ Select English “USA” as language, dot as decimal

symbol and date and time in Regional setting

NOTE: Even though the computers demonstrate the same technical and operative characteristics,

some of these could have different hardware installed.

This could cause problems for the Ellipse software when running tests (A message appears

indicating “Random” error or blocks the program).

Therefore, if the PC is bought separately/locally, it is highly recommended to test the system before

proceeding with the installation at customer laboratories.

Consequently, AMS denies any responsibility for software problems that are due to buying the

computer separately from the instrument.

2.3.2 OPTIONAL MODULES

♦ POSITIVE BAR CODE READER

2.3.3 DIMENSIONS, WEIGHT AND OPERATING ENVIRONMENT

♦Height: 53 cm

DIMENSIONS

♦Width: 57 cm

♦Length: 75 cm

WEIGHT

OPERATING

ENVIRONMENT

♦35 kilos

♦Temperature: 18 °C ÷ 30 °C

♦ Relative Humidity: 20% ÷ 85%

2.3.4 INSTALLATION SPECIFICATIONS

♦Input voltage: 100 ÷ 230 Vac

♦Input frequency: 47 ÷ 63 Hz

POWER SUPPLY

♦Power consumption:

♦300 W for the analysis unit

♦400 W for the work station

Ellipse User Manual Rev.02 19 October 2005 Page 9

Page 22

Chapter 02 - GENERAL DESCRIPTION

Warning: in order to assure proper instrument functioning, the manufacturer strongly advises the

use of a stable tension supply outlet (+/-10%). If it is not possible to guarantee said stability, the

manufacturer suggests the use of:

♦ UPS (Uninterrupted Power Supply)

♦ ELECTRONIC STABILIZER

Ellipse User Manual Rev.02 19 October 2005 Page 10

Page 23

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

CHAPTER 03 - DESCRIPTION OF INSTRUMENT

SOFTWARE

INDEX

3.1 SYSTEM MONITOR………………………………...……………..…………………….………..3

Warning Lights.................................................................................................................................... …….5

Legends ........................................................................................................................................................ 7

Status Line.................................................................................................................................................... 8

Menus available under System Monitor: ..................................................................................................... 9

Command Buttons………………………………………………………………………..……………....10

Check button ..............................................................................................................................................11

Order button ............................................................................................................................................... 11

Print button................................................................................................................................................. 13

Graph button............................................................................................................................................... 13

Rerun button............................................................................................................................................... 14

Edit Results button ..................................................................................................................................... 15

Move to Archive button ............................................................................................................................. 16

Unload button............................................................................................................................................. 16

3.1.1 START WORK................................................................................................................................ 17

Wash all cuvettes........................................................................................................................................ 17

Water Blank Level ..................................................................................................................................... 18

Calibration & Quality Control.................................................................................................................... 18

Work List ................................................................................................................................................... 19

Start Running ............................................................................................................................................. 19

3.2 CHECKS ........................................................................................................................................... 20

WBL........................................................................................................................................................... 21

Main Area.............................................................................................................................................. ….21

Reagent Volume......................................................................................................................................... 23

Main Area................................................................................................................................................... 23

Details Area……………………………………………………….……………………………………...24

Reagent Configuration ............................................................................................................................... 25

Predilution Rack......................................................................................................................................... 27

3.3 ROUTINE ......................................................................................................................................... 31

Work List Setup .........................................................................................................................................32

Unassigned Sample .................................................................................................................................... 33

Saving data for more than one patient........................................................................................................ 37

Deleting a Patient………………………………………………………………………………….……...37

Ellipse User Manual Rev.02 19 October 2005 Page 1

Page 24

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

Deleting a rack…………………………………………………………………….……………………...38

Result by Patient ........................................................................................................................................ 40

Printing Data ..............................................................................................................................................43

Main Area................................................................................................................................................... 44

Precision check........................................................................................................................................... 46

Calibration & Quality Control Setup ......................................................................................................... 47

Calibration Programming........................................................................................................................... 49

Editing Calibration ..................................................................................................................................... 50

Calibration Results ..................................................................................................................................... 51

Quality Control Results.............................................................................................................................. 58

Quality Control Graphs .............................................................................................................................. 60

Receive from Host...................................................................................................................................... 61

3.4 ARCHIVE ......................................................................................................................................... 62

Patients ....................................................................................................................................................... 63

Main Area................................................................................................................................................... 63

Details Area................................................................................................................................................ 64

Calibration.................................................................................................................................................. 65

Main Area................................................................................................................................................... 66

Details Area................................................................................................................................................ 68

Backup........................................................................................................................................................ 69

Restore........................................................................................................................................................ 70

Tests Counter ............................................................................................................................................. 71

Event Log................................................................................................................................................... 72

3.5 PARAMETERS ................................................................................................................................ 73

Inserting the Password ............................................................................................................................... 74

Profiles ....................................................................................................................................................... 75

Ratio ........................................................................................................................................................... 77

Standards.................................................................................................................................................... 82

Controls...................................................................................................................................................... 87

Options ....................................................................................................................................................... 91

Print Order.................................................................................................................................................. 92

Report Options ........................................................................................................................................... 93

Password Setting ........................................................................................................................................ 94

3.6 HELP................................................................................................................................................. 96

Guide F1.................................................................................................................................................... 97

Software versions ....................................................................................................................................... 98

3.7 SHUT DOWN................................................................................................................................... 99

Ellipse User Manual Rev.02 19 October 2005 Page 2

Page 25

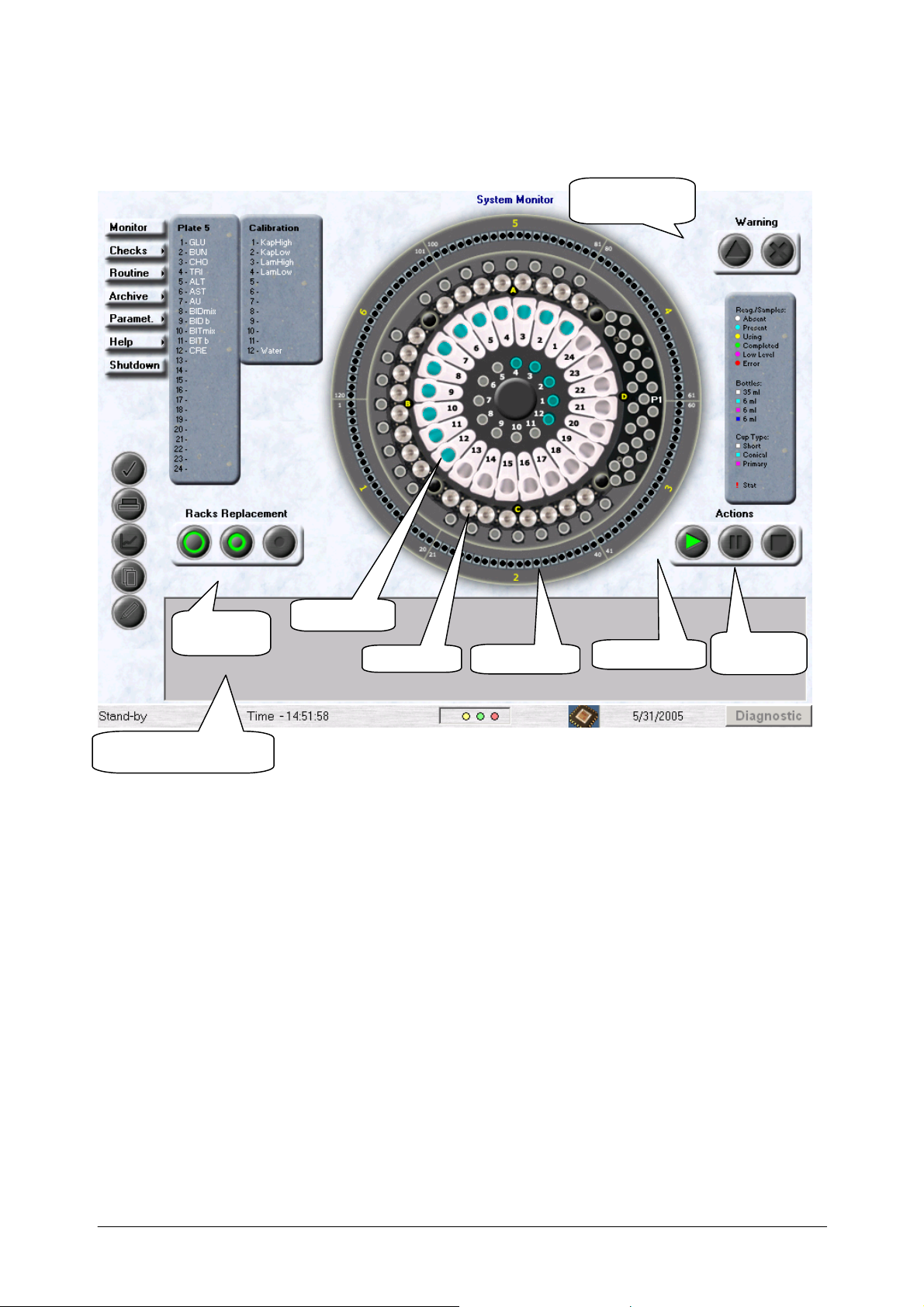

y

3.1 SYSTEM MONITOR

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

Warning Lights

Operative

Buttons

Reagent tray

Sample tra

Reaction tray

Desk Top area

Operative

View Data/Details Area

The system’s management software is extremely user-friendly and, moreover, allows maximum

flexibility in its use.

The operator can access the management software by simply turning on the instrument. If the last

instrument Shut Down was due to a Fatal Error or if the Analyzer is at the time turned off, the user

must double click on the Analyzer icon located on the computer Desk Top.

The user interface screen is subdivided into two main areas:

the Desk Top area

the View Data/Details Area

The Desk Top area is a graphic illustration of the instrument that allows the operator to easily

identify each

single item and its status. It includes:

√ A reagent tray with twenty-four reagents and twelve Standards and Controls positions;

√ A Samples tray composed by four racks with eight positions each.

Ellipse User Manual Rev.02 19 October 2005 Page 3

Page 26

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

√ A reaction tray composed by six racks with twenty cuvettes each.

View Data/Details Area

Located in the lower section of the System Monitor mask, the View Data/Details Area contains

precise, detailed information concerning the item selected (Cuvette, Samples, Reagents, Standards

and Controls).

It is possible to view data details regarding single items by clicking on them whenever the mouse

pointer turns into a question mark as it passes over that particular element.

• If the operator selects a given position on the Reaction Plate, by placing the mouse pointer

over the required item:

a table containing the WBL values of the cuvette selected (both the main channel and the

reference channel values) will be viewed. The Print button will also be activated.

• If the operator selects a given position on the Samples Rack, by placing the mouse pointer

over the required item:

a table listing the tests programmed to be run on that sample will appear in the lower

portion of the window and information regarding the sample itself (patient name, sample

ID, rack and position) will appear in the upper portion of the window.

• If the operator selects a given position on the Reagents Rack, by placing the mouse pointer

over the required item, the below-illustrated table will appear allowing the user to view

information regarding the selected Reagent.

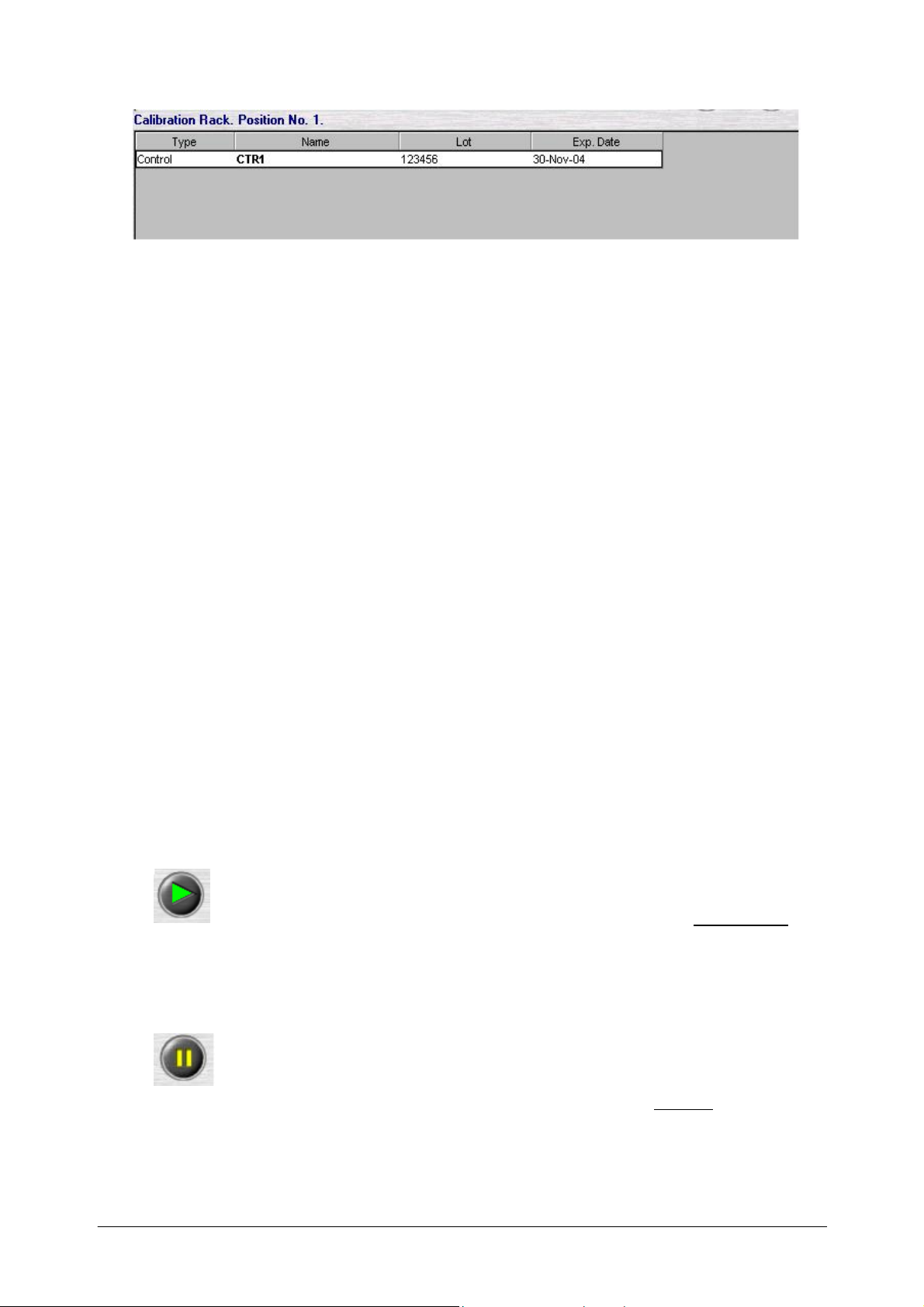

• If the operator selects a given position on the Controls or Standards, by placing the mouse

pointer over the required item, the below-illustrated table will appear allowing the user to

view information regarding the selected Control or Standard.

Ellipse User Manual Rev.02 19 October 2005 Page 4

Page 27

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

WARNING LIGHTS

There are two types of alarms:

• The first type is a brief visual text message, which appears in the lower, left-hand portion

of the screen, up to the operative buttons. It can inform the operator that either there is “no

instrument connection”, or the “cover is open”, or that a “remote link” is in operation.

• The second are Warning Buttons (located in the upper, right portion of the mask) and they

can be:

- either a “Warning” represented by a triangle that lights up yellow. If the operator clicks

on this button, it is possible to view in the Details Area those events which caused the

warning (e.g.: liquid(s) finished).

- or a “Fatal Error” represented by an X that lights up red. Whenever a fatal error is

signalled, only those readings that have already been carried out will be saved; those

operations being carried out at the time are interrupted (e.g.: incubation). After every

“Fatal Error”, the user must have the instrument carry out a Wash cuvette cycle. If the

operator clicks on this button, it is possible to view in the Details Area those events that

caused the warning (e.g.: temperature error).

At this point, it can be useful for the operator to consult Event Log, listed under the

Archive menu, where all instrument status information is memorized, in order to have

more information regarding the occurrence.

Operative Buttons “Actions”:

START (green triangle): allows the operator to access the Start Work mask

where it is possible to start the running of the various tests and of any other operation regarding

the instrument.

PAUSE: temporarily interrupts only the sampling process. It does not interrupt

incubation, nor the reading of already dispensed samples. To restart, press START

.

Ellipse User Manual Rev.02 19 October 2005 Page 5

Page 28

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

STOP: halts instrument functioning - the sampled tests are lost.

Operative Buttons “Racks Replacement”:

Change cuvettes: allows the operator to change cuvettes rack. Clicking on it, the

following dialog box will automatically open and rack selection to be replaced can be done

clicking on the pull-down menu from 1 to 6.

Clicking on “OK” the instrument pass to the Priming and then in Stand-By condition while the

reaction plate turns up to bring the selected position in front of the operator to allow the cuvette

rack replacement.

Click on “OK” into the message that appears after reaction plate positioning to confirm the

happened replacement.

Cuvettes rack can be changed only when the instrument is not performing any operation or

procedure. In such condition, the button is made disable.

Whenever one or more cuvettes illustrated in the Reaction Plate are coloured Red, it is because the

instrument cannot perform the required readings on them due to the fact that they are not perfectly

transparent, or rather; their transparency is below the minimum or above the maximum limit

acceptable to the instrument program. If the operator wishes to view the filter readings, he/she can

do so from within the Details Area.

Whenever a cuvettes rack is inserted for the first time in the Reaction Plate, it is indicated in red

under System Monitor because the instrument does not have that data necessary for the

mathematical equations needed to calculate test results. Therefore, it is necessary to carry out a

WBL for that cuvettes rack (auto-zeroing) in order to be able to use it.

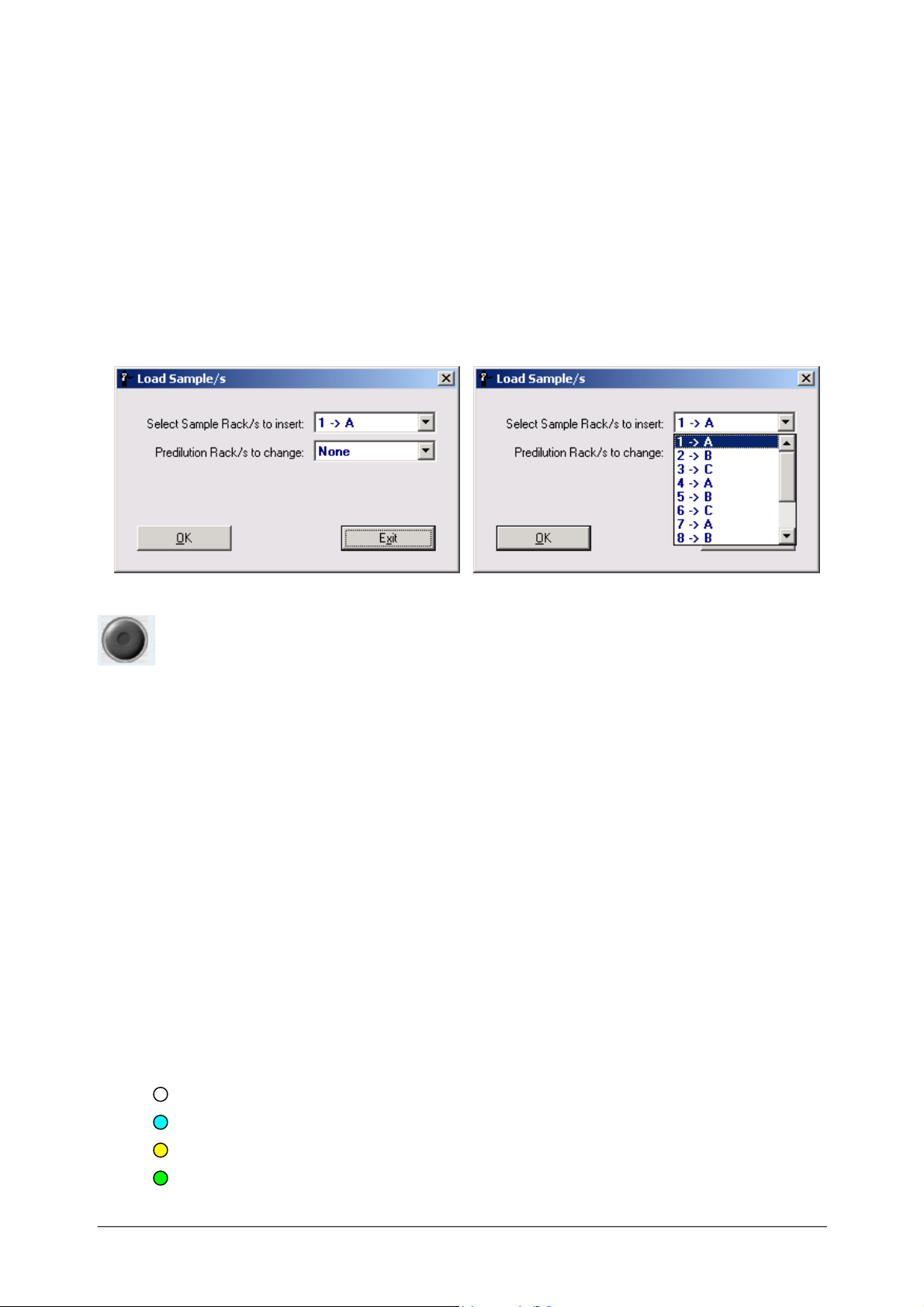

Load Sample/s: allows the operator to load samples rack. Clicking on it, the following

dialog box will automatically open and rack selection to be replaced can be done on the pull-down

menu, among those programmed, in the reported position A, or B, or C or D, defined by the

instrument.

Ellipse User Manual Rev.02 19 October 2005 Page 6

Page 29

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

Clicking on “OK”, the sample plate turns up to bring the selected position in front of the operator,

to allow the sample rack loading.

Click on “OK” into the message that appears after sample plate positioning to confirm the

happened loading.

Samples rack can be loaded at any time, even if the instrument is in running condition.

In this case, pushing the loading operative button, the instrument pass from the Running to the

Pausing and then to the Pause condition, to allow the selected rack loading.

Click on “OK” into the message that appears after sample plate positioning to confirm the

happened loading; click on the START button and confirm pushing OK in order to restart the

running.

Load Reagents: allows the operator to load reagents. The button is able in Running

condition only. Clicking on it, the following dialog box will automatically open and ALL

selection to load reagents can be done on the pull-down menu.

Clicking on “OK” the instrument pass from the Running to the Pausing and then to the Pause

condition the allow the refill of one or more then one used reagents, or one new reagent

configuration loading.

Click on “OK” into the message that appears after reagent plate positioning to confirm the

happened loading; click on the START button and confirm pushing OK in order to restart the

running.

LEGENDS

There are three legends and one symbol to be found under System Monitor and they are the

following:

• A Legend regarding the colours associated with certain visual text messages

concerning reagent and sample status: (upper right)

Reag./Samples:

White (absent)

Sky blue (present)

Yellow (in use)

Green (completed)

Ellipse User Manual Rev.02 19 October 2005 Page 7

Page 30

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

Magenta (low level)

Red (error - no sample or reagent)

• A legend regarding the various types of reagent bottles having different volume

capacities, that can be selected for use by the operator (medium right)

white 35 ml

sky blue 6 ml

magenta 6 ml

blu 6 ml

• A legend regarding the various types of test-tubes having different volume capacities,

that can be selected for use by the operator (lower right)

white (short – approximately 1 ml)

sky blue (conic– approximately 2 ml)

magenta (primary tube)

By clicking on “Options” under the “Parameters” menu, the operator can select the reagent

bottle to be used by default. The reagent code will be written in the colour of the bottle that

contains that reagent.

• A symbol regarding STAT

Samples having this symbol will be processed first of all the other programmed

and loaded samples.

STATUS LINE

The Status Line, lower left, contains information regarding the functioning condition of the

instrument. Said information allows the operator to follow and check the status of instrument

operation.

Stand By

Stop

Washing

Running WBL

Ellipse User Manual Rev.02 19 October 2005 Page 8

Page 31

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

Running

Pause

Pausing

Safe

Priming

Moreover, in the Status Line, are reported the following information:

Icon indicating a fault sample reading executed by the Bar Code reader.

If the operator places the mouse pointer on this icon, it is possible to view the Firmware

version.

MENUS AVAILABLE UNDER SYSTEM MONITOR:

⇒ Monitor

⇒ Checks

⇒ Routine

⇒ Archive

⇒ Parameters

⇒ Help

⇒ Shut Down

Ellipse User Manual Rev.02 19 October 2005 Page 9

Page 32

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

COMMAND BUTTONS

The Command Buttons are automatically activated as needed and have the following functions:

Make validated the results of a given Test (Check button);

Reorder the viewed data (Order button);

Print the viewed data (Print button);

View an absorbance graph (Graph button);

Repeat an already run test (Rerun button);

Modify the results of a test (Edit button)

Save and File results in the Archive (Move to Database button);

Send the data to the remote computer (Unload button)

The various icons are activated in accordance with the mask being used. It is possible to recognize

an inactive button by its opaque colouring or by the fact that it cannot be viewed. If the user places

the mouse pointer over an icon, a visual text message will appear describing the corresponding

function.

Ellipse User Manual Rev.02 19 October 2005 Page 10

Page 33

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

CHECK BUTTON

Working within the Patient Results window and within the Test Results window (even under

System Monitor), the operator has the possibility to verify, select and confirm the results of the

tests by using the Check button located on the Desk Top. By selecting, from the offered list, a row

containing a result deemed correct (e.g.: the same test repeated for the same patient), the operator

can, by clicking on this command, make the selected test “valid”. The system will automatically

show the examined data in bold print, in order to make it more readily visible to the user.

ORDER BUTTON

Whenever the operator looks over the results of any one of the various operations carried out,

he/she may find it necessary to Re-order that list in a manner judged by him/her to be simpler and

more useful. This procedure is described in the following paragraph. The Order command can be

applied to the visualization of the various results listed here below:

Patients Results;

Test Results;

Quality Control Results;

Archive – Patients;

Archive – Calibration;

Tests Counter.

This re-ordering can be requested via the Order button located on the Desk Top, and can be

viewed (or rather, is activated) only during the visualization of those lists whose contents can be

re-ordered.

Re-ordering can also be requested directly from the area involved, by clicking on the small

triangle symbol that appears in the field heading. After clicking on the symbol, the user need only

select to have an alphanumerical order either ascending or descending.

How to Re-order

In order to carry out a re-ordering of viewed data, the operator must first select a row from the

required list and then click on the above-described Order button. The below-illustrated mask will

automatically open, allowing the user to select from the offered options and perform the operation.

Ellipse User Manual Rev.02 19 October 2005 Page 11

Page 34

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

The Order Data mask contains: a “Keys” area where the operator can select which field(s) in the

List he/she wants to re-order; options concerning which type of Order is to be effectuated; another

” Sort Key List” area where those field(s) to be re-ordered, selected from the Key area, are listed;

plus the various buttons necessary for carrying out the procedures.

The operator must first click on the name of that field, within the “Keys” area,

which is to be re-ordered and then click on “Set”. The selected field will automatically be listed in

the “Sort Key List” area, ready to be re-ordered.

Once a given field (or fields) has been selected from the “Key” area and is

listed in the “Re-order List” area, the operator can change his/her mind and decide to delete one or

more fields from this list to be re-ordered. He/she need only click on the required field and then

click on “Remove”. The Remove button is activated only after at least one field has been selected

from the “Key” area.

For each individual field that is to be re-ordered the operator can choose from two Order options,

Ascending or Descending, located between the “Key” area and the “Re-order List” area.

After all the above-described selections have been made, the operator need

simply click on “OK” to have the instrument carry out the Order procedure. The Order Data

mask will automatically close and the List will now be viewed according to the order requested by

the user. To annul the operation and exit the Order Data mask, click on “Exit”.

Following are two examples, which could be useful for a better understanding of the abovedescribed procedure and also helpful in carrying out the Re-order operation.

Ellipse User Manual Rev.02 19 October 2005 Page 12

Page 35

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

The two illustrations provided below are ordered according to two different criteria. The

“Position” (Pos) has been selected in the first illustration and an “Ascending” order has been

designated.

The second illustration, instead, exemplifies the selection of the “Sample ID” and the designation

of a “Descending” order.

PRINT BUTTON

In order to print the data viewed in a given mask, the operator must first select those rows that are

to be printed and then click on the “Print” button, located on the Desk Top.

GRAPH BUTTON

In order to view the reaction graph, or rather, the Graph of the Optical Densities obtained and the

reading times expected (as given under Methods) for the result selected, the user need simply

select the row in the Details Area containing the results he/she is interested in and then either

double click on it with the mouse or click on the “Graph” button located on the Desk Top.

This Graph button is activated only when the Details Area contains at least one row of data.

Ellipse User Manual Rev.02 19 October 2005 Page 13

Page 36

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

Exit

To exit the Graph mask, click on “Exit”.

RERUN BUTTON

Whenever it is deemed necessary to rerun a test (e.g.: the sample appears too concentrated, the

quantity of reagent seems insufficient, etc.), the operator can do so by using this “Rerun”

procedure – the relative button is located on the Desk Top.

Select the required row and then click on “Rerun”. The previously illustrated window will

automatically appear within which the operator can reprogram the required test. In order to carry

out the operation, the relative command, under the Start Work mask must be activated. All those

Ellipse User Manual Rev.02 19 October 2005 Page 14

Page 37

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

fields, which may be of help to the user in the reprogramming of the test, can be viewed in this

mask. Among them:

Item Selected: indicates the name of the Test the operator has selected to be rerun, if only one

type of test has been selected. If more than one type of test has been selected, the window will

show “Multiple Selection”;

Total Selection: allows the operator to view the total number of reruns requested for the required

Test(s);

Dilution Ratio: allows the operator to decide, using a pull-down menu, the dilution ratio for that

test. This is possible only when one single type of test has been selected to be rerun, and not when

the operator has requested a Multiple Selection rerunning or when the sample volume permits to

do so (Sample volume more than four microliters).

By clicking on “OK”, the operator confirms the operation. Clicking on Exit, instead, annuls the

selection, as well as the operation.

EDIT RESULTS BUTTON

This button allows the operator to edit the results of the tests performed. To perform this

operation, first select the required row from the Details Area and click on the Edit button located

on the Desk Top. The below-illustrated window will open, containing two buttons: “OK” and

“Exit”.

Insert the new value for the test result and click on OK. The new value will automatically be

registered and will appear in the Results field of the relative test. At the same time, the Flags

column will show an E in the relative field (see the illustration below), indicating an Edit (see

Result Flags).

The window’s Exit button allows the operator to annul the editing operation.

Ellipse User Manual Rev.02 19 October 2005 Page 15

Page 38

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

MOVE TO ARCHIVE BUTTON

The results of all those operations carried out under Start Work can be recorded and saved, along

with the patient data contained in the “Work List”, in a Archive. First, select the record to be saved

in the Archive from the Main Area and then click on “Move”, located on the Desk Top. The

following window will automatically come up:

This window contains a pull-down menu in the field labeled “Results to move” where the

operator can choose to save either the individual records selected from the Main Area or an entire

Rack. To confirm the move, click on “OK” and the selected data will automatically be moved and

thereby recorded in the Archive.

The Exit button annuls the move and the operation.

Data can be moved to the Archive only if the patient has been assigned tests and the tests have

been performed (and therefore have results). If the operator tries to confirm, “OK”, the movement

of data to the Archive when no results or tests are available for that patient, the program will

automatically annul the operation and the user will be informed via a visual text information

message to that effect.

The centred portion of this window contains the number of records moved, deleted or pending for

both Patients and Results. All this saved and filed data (“moved” data) can be consulted under

Archive – Patients.

UNLOAD BUTTON

This command makes it possible to activate data transmission to the Host. To carry out this

Transmission, select one or more rows from the Main Area of the Result by Patient window in

the Routine menu and then click on “Unload button” (located on the Desk Top only if Host

Connection selection has been made active in the Option Menu). In order to view this command

(not automatically shown on the Desk Top), the operator must have selected at least one record

under Patient Results.

T

he program will guide the operator during the data transmission, via a series of visual text

messages.

Ellipse User Manual Rev.02 19 October 2005 Page 16

Page 39

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

3.1.1 START WORK

The START WORK button (green triangle) allows the operator to open the Start Work

window where he/she can select, as needed, the below-illustrated operations:

Wash all cuvettes

“Wash all Cuvettes” is the first option offered. Here, the user can select which cuvettes rack

contained in the Reaction Plate is to be washed. To do so, the operator must select, from the field’s

pull-down menu, one of the following: All, Rack 1, Rack 2, Rack 3, Rack 4, rack 5, Rack 6. If

he/she selects All, the programme will automatically wash all the cuvettes in the Reaction Plate,

while remain selections permit washing of the selected rack only.

Whenever this option is highlighted in red and is accompanied by a visual text information

message, viewed at the bottom of the Start Work mask, it means that the instrument is in the

condition to warrant cuvette washing. Therefore, the programme notifies the user to this effect and

suggests that said operation (“Wash all Cuvettes”) be carried out before performing any other

operation.

Ellipse User Manual Rev.02 19 October 2005 Page 17

Page 40

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

WATER BLANK LEVEL

The second option, “WBL”, allows the user to activate a pull-down menu where he/she can

choose those cuvettes racks to be subjected to a water blank level reading, auto-zeroing. The

options offered are the following: All, Rack 1, Rack 2, Rack 3, Rack 4, rack 5, Rack 6.

All carry out WBL readings on all the cuvettes racks contained in the Reaction Plate, while remain

selections permit WBL readings on the selected rack only.

The WBL operation (auto-zeroing of the cuvettes) must be carried out daily, before running the

Work List tests. Each cuvette is filled with approximately 400 micro-liters of Rinse solution and

read for all the wavelengths of the eight filters. These readings are fundamental to determining

cuvette quality and for instrument auto-zeroing, necessary for subsequent numeric calculations.

The user can view the obtained WBL readings in the “Water Blank Level” mask.

The resulting WBL values will be used by the system to calculate the concentration of the tested

analita.

The reading system (Photometer) reads light intensity that passes through photodiodes. The

analogical values expressed in millivolt read by the photodiodes are then digitally

transformed into logical data expressed in “Counts” from 0 to 65553.

As we know from Lambert/Beer law, the relationship between transmittance (Ratio between

incident light Io and transmitted light I) and absorbance is an inverse logarithmic type. In

order to obtain a linear data, proportional to the concentration of the Analita tested, the

following mathematic algorithmic is used:

- Log (I / Io) = - Log [counts(1) / counts(2)] = Abs = Σ * C * r

Where:

counts(1) = reaction reading (I)

counts(2) = cuvette containing water reading (WBL = Io)

Abs = Absorbance (optical density)

Σ = absorbivity or Coefficient of molar extinction

C = concentration

r = Optical path length

The absorbance data given in the reaction reading (see reaction graph) contains the offset value

(about 100 counts).

Possible signal variation due to the lamp or to the filters (Thermical drift) are automatically

compensated by the readings taken from the reference channel.

CALIBRATION & QUALITY CONTROL

This third option makes it possible to calibrate the methods. In order to activate this option, it is

not only necessary to select the relative field, but also to request at least one Sample Blank (RBL)

execution in the Calibration & Quality Control function under the Routine menu.

Ellipse User Manual Rev.02 19 October 2005 Page 18

Page 41

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

WORK LIST

The fourth option allows the operator to activate the work lists previously programmed.

There are four positions available for the Samples racks, identified by the “A”, “B”, “C” e “D”

characters.

By selecting the Work List option, the positions containing the previously programmed and loaded

samples rack are activate. After selection, samples racks are shown in the System Monitor in the

dedicated area. Here, the rack number is also available by assuming the colour corresponding to

the size of the liquid container. The samples are shown in sky blue colour if they are still to be run;

in yellow if they are in process and in green if they have been completed.

Note: A sample position will remain yellow coloured until all its programmed tests are completed.

Clicking on the rack number of each active position, a pull-down menu will be shown, where the

user can disable the selected rack by clicking on Nothing (when the machine is not in running). So

that, by pushing the start button, the samples will not be sampled, even if still shown on the

System Monitor.

While tests are in process, the reaction mixture in the reading will be shown on the System

monitor by changing the concerned cuvettes colour: from black to grey.

START RUNNING

To activate the carrying out of the option selected, click on “OK”. Note that the “Parameters”

menu is blocked (inactivated by the instrument itself) during the carrying out of any and all

operations. This is done in order to protect those masks that contain fields where, if the contents

were edited, the results of the operations could be compromised. When said operations have been

completed, the Parameters menu will automatically be reactivated. This reactivation can also be

obtained by clicking on “Stop” or “Pause”.

Exit

By clicking on “Exit”, the operator can exit the Start Work menu without carrying out any

operation.

N. B.:

The instrument program will carry out any automatic rerunning of the tests without the need for

the operator to intervene.

Further rerunning can be requested only after testing has been completed and preferably before

rack replacement.

Ellipse User Manual Rev.02 19 October 2005 Page 19

Page 42

3.2 CHECKS

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

“Checks” includes the entire set of masks which allow the operator to access and

activate functions, as well as view a series of data, both useful and necessary for correctly

preparing the instrument for routine operation.

Each set of data, grouped according to information category, has its own dedicated mask.

Following is a list of these masks:

Water Blank Level

control on each of the 120 cuvettes.

Reagent Volume

Configuration” mask, along with the calibration programming data (CTRL and STD).

Reagent Configuration: a necessary preliminary step before performing any analytical testing. In

this mask, the operator can assign the positions of the reagent liquids and also, if desired, that of

the controls, from among those set aside within the instrument specifically for this purpose.

Predilution

predilution as set-up in the “Reagent Configuration” mask.

: this mask contains all that data regarding the positions dedicated to sample

: contains a graphic illustration of the results of all the WBLs run as quality

: contains an organized view of all that data set-up in the “Reagent

Ellipse User Manual Rev.02 19 October 2005 Page 20

Page 43

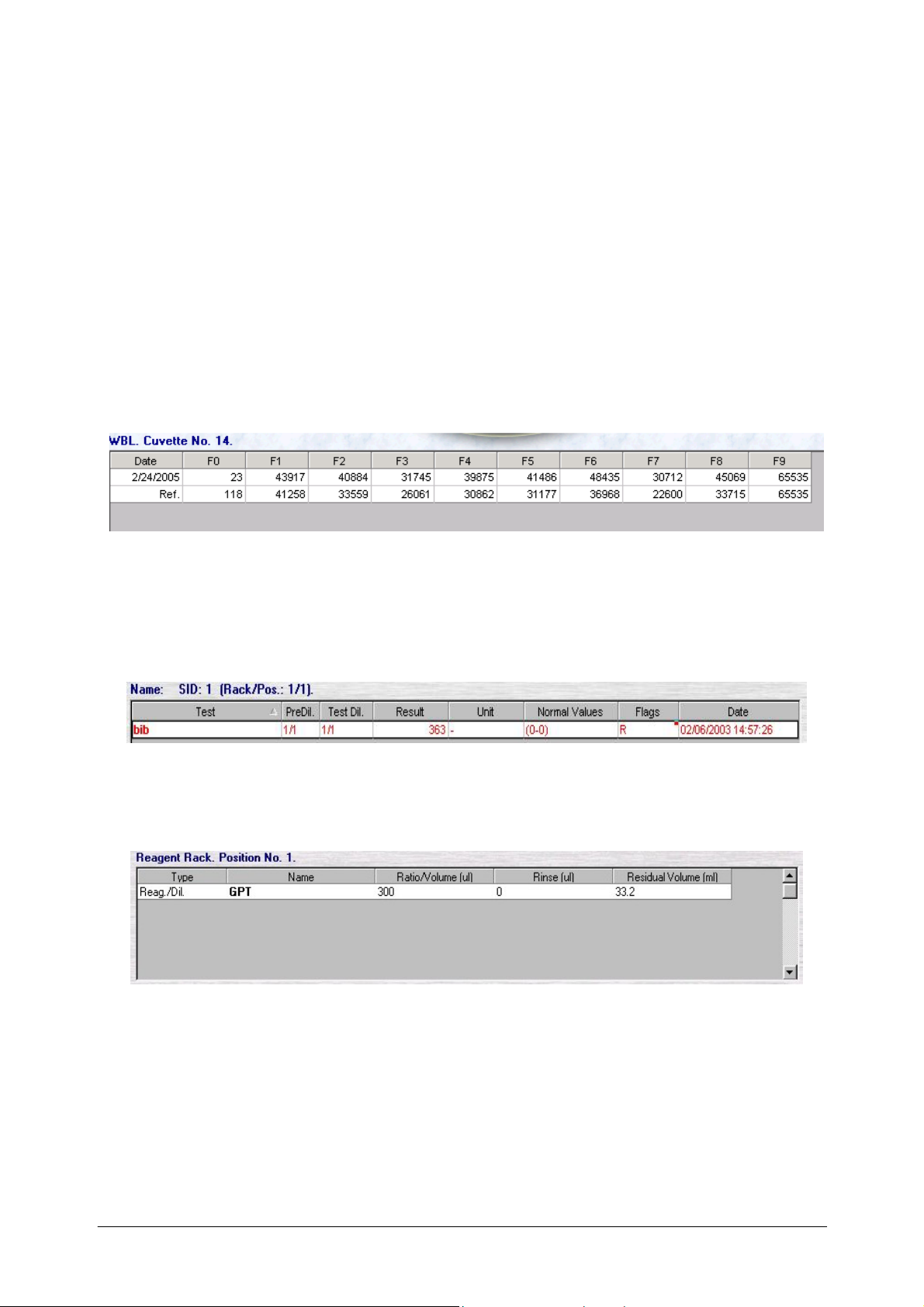

WBL

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

To access the Water Blank Level mask, first select the Checks Menu and then, from the options

listed, click on Water Blank Level.

The window that opens graphically illustrates the results of the operations carried out when the

WBL option is selected under the Start Work mask.

The values of the WBL are used in the mathematical operations for calculating test results and for

performing quality control checks on the 120 cuvettes (e.g. when checking transparency).

This window is divided into two sections, a Main Area and a Details Area, in order to facilitate

user access and comprehension.

The mask also contains buttons, which allow the operator to move on to other applications or

procedures.

MAIN AREA

The main area of the WBL mask contains a histogram of the WBL results on a scale ranging

between 28,000 and 63,000 counts.

By consulting this chart, the operator can immediately evaluate the status of the cuvettes within

this reference interval.

The histogram indicates the WBL values as explained below:

➜ The initial WBL measurement value is indicated in grey line;

➜ The penultimate WBL measurement value is indicated in matt yellow;

➜ The last WBL measurement value obtained is indicated in bright yellow.

Ellipse User Manual Rev.02 19 October 2005 Page 21

Page 44

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

PLEASE NOTE 1: the difference between the penultimate and the last WBL readings are

illustrated by the different colouring of the histogram bar (a reduction in the counts value), or by

the presence of a vertical line on the bar coloured bright yellow (an increase in the counts value).

PLEASE NOTE 2: the bar is coloured yellow for WBL values falling within the tolerance range

(28,000 – 63,000 counts). If one or more of the reported values is out-of-range, a red line will

appear next to the number of the cuvette whose reading(s) is/are out-of-range.

In the Details Area, the operator can view the Archive information regarding readings for all eight

wavelengths and for each cuvette. The Main Area will, therefore, contain only that information

regarding the reading with the Optical filter set at 340 nm, while the Details Area will show the

values relative to all the positions of the photometer filter wheel.

The Main Area’s heading contains the following fields:

Cuv.: in addition to identifying the row, this heading also indicates the number of the Cuvette to

which the thereafter-reported values (in the following fields) refer. Whenever the cuvette is judged

to be “bad”, this number will be shown in red.

D. Rel.: refers to the difference between the value of the last WBL carried out and that of the

previous one.

D. Abs.: refers to the difference between the value of the last WBL carried out and that of the first

carried out.

Initial Date: indicates the date the first WBL was carried out.

The obtained values, subdivided according to filter (fields F0 to F9), are reported in the Details

Area.

Whenever the operator selects a given row from the Main Area, the Details Area will

automatically show more specific itemized data, in chronological order, regarding the values

obtained for the cuvette indicated by that selected row.

In the column regarding the “Date” field, the row containing “Ref” values report the values

obtained using the Optical reference channel.

All the data in the various fields will be shown in red in the Details Area, whenever the cuvette(s)

selected from the Main Area is/are judged “bad”.

Details Area

Ellipse User Manual Rev.02 19 October 2005 Page 22

Page 45

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

This mask allows the operator to print the information herein contained. This is made possible via

the use of the command buttons located under System Monitor (please see the section regarding

the Command Buttons).

REAGENT VOLUME

To access the Reagent Volume mask, first select the Checks Menu and then, from the options

listed, click on “Reagent Volume”.

This mask gathers and suitably organizes all that data set-up in the Reagent Configuration mask

and in the Calibration Programming mask. In addition to the reagents contained in the reagent

housing, this mask also allows the operator to view data regarding standards and controls assigned

to the calibration procedure. This window is divided into two sections, a Main Area and a Details

Area, in order to facilitate user access and comprehension.

The Main Area is located in the upper portion of the screen and contains generalized information.

The Details Area is located in the lower portion of the screen and contains more specific, itemized

information.

MAIN AREA

Following is an illustration of the Main Area window as seen by the operator. This window

contains, in addition to those fields to be described in this paragraph, buttons that allow the user to

move on to other applications or carry out other procedures.

Ellipse User Manual Rev.02 19 October 2005 Page 23

Page 46

Chapter 03 - DESCRIPTION OF INSTRUMENT SOFTWARE

The fields, that will be herein described, are the following:

Position: allows the operator to view the position occupied in the reagents rack; there are 24

positions available;

Type: indicates the type of liquid tested;

Name: indicates the reference acronym for that liquid;

Cup/Bottle Type: allows the operator to view the format of the container to be used for the liquid

indicated. There are two bottle types configurable on the instrument, which can be chosen

according to user needs. They are:

• 35 ml;

• 6 ml;

Residual Volume (ml): quantity of reagent left in the container and available for use in other

analyses (this information is automatically updated as each test is carried out). The amount is

expressed in millilitres and is a decimal figure.

DETAILS AREA

The Details Area is located in the lower portion of the screen – above is an illustration as seen by

the user. This area allows the operator to view the specific details regarding the particular liquid

selected in the upper portion of the window (i.e. in the Main Area). A description of the more

important fields follows:

Type: indicates the type of liquid tested;

Name: indicates the full name of the liquid being tested;

Predil. Ratio/Volume (ul): if the indicated liquid is a diluent, this field expresses the predilution

ratio set-up. Otherwise, it allows the operator to view the volume of reagent necessary for each

reaction;

Rinse (ul): quantity of liquid used to avoid an intermixing (i.e. cross-contamination) of the

reagents;