Page 1

www.amico.com

Installation and Maintenance Manual

Medical Gas Outlets

DISS, Ohmeda, Chemetron, Puritan-Bennett &

Oxequip / MedStar Compatible

Puritan-Bennett

Compatible

Chemetron

Compatible

Compatible

DISS Ohmeda

Oxequip/ MedStar

Compatible

Page 2

Table of Contents

Product Description 3

Cleaning and Lubricating 4

Inspection and Testing 4

Installation & Dimensions 5-7

Wall Outlet 5

Ceiling Outlet 6

Console Outlet 6

Ceiling Column Outlet 7

Service 8-13

Latch-Valve Assembly - DISS 8

Latch-Valve Assembly - Ohmeda (compatible) 9

Latch-Valve Assembly - Chemetron (compatible) 10

Latch-Valve Assembly - Puritan-Bennett (compatible) 11

Latch-Valve Assembly - Oxequip/MedStar (compatible) 12

Rough-In Assembly - Wall and Console 13

Model Numbers 14-16

Latch-Valve Assembly 14

Rough-In Assembly 15

Complete Outlets 16

Gas Indexing 17

Replacement Components 18-23

Latch-Valve Assembly - Ohmeda (compatible) 18

Latch-Valve Assembly - Chemetron (compatible) 19

Latch-Valve Assembly - DISS 20

Latch-Valve Assembly - Puritan-Bennett (compatible) 21

Latch-Valve Assembly - Oxequip/MedStar (compatible) 22

Rough-In Assembly - Wall and Console 23

2 Amico Pipeline

Page 3

Product Description

The Amico Medical Gas outlet is composed of two separate modules: the “Rough-in assembly” and the “Latch-valve

assembly”. The “Rough-in assembly” is the same for all types (DISS, Ohmeda, Chemetron, Puritan-Bennett or Oxequip/

MedStar), while the “Latch-valve assembly” determines what type of adapter the outlet will accept.

The “Rough-in assembly” consists of a brass machined body that incorporates a spring loaded check assembly. A 1/2”

OD copper pipe is silver brazed into the body for external pipeline connections. The brass body and pipe assembly are

inserted into a gas specic plate. The wall outlets can be ganged together at 5” [127mm] centers (see page 5). This makes

for a nished assembly that looks like one complete panel of outlets. The “Rough-in assembly “has a color coded label

on the front plate and the copper pipe, so that the installer can easily identify the gas that the copper pipe should be

connected to. The “Rough-in assembly” incorporates a check valve that allows the “Latch valve assembly” to be removed

for service, without requiring the pipeline to be shut down. The “Rough-in assembly” has a DUAL pin gas specic indexing

arrangement to prevent the wrong “Latch valve assembly” from being plugged into the “Rough-in assembly” (see page

17).

The “Latch-valve assembly” is manufactured in ve dierent models: DISS, Quick connect Ohmeda compatible, Quick

connect Chemetron compatible, Quick connect Puritan-Bennett compatible or Quick connect Oxequip/MedStar

compatible. The DISS “Latch-valve assembly” is permanently riveted together, so that the gas specic components cannot

be taken apart, to ensure they remain gas specic. All the servicing on the DISS outlet is done inside the connector. On the

Quick connect models the connector plate can be removed for additional O-ring servicing, but is still gas specic since the

gas specic parts are permanently riveted together. The “Latch-valve assembly” consists of: a connector with an integral

check valve, an indexing block complete with indexing pins, a color coded gas front plate and a chrome frame. The “Latchvalve assembly” is inserted into the “Rough-in assembly” and secured screws.

CAUTION: DO NOT overtighten the Latch Valve Mounting screws! Distortion of the Latch valve can occur.

The quick connect models are compatible with the Ohmeda Diamond, the Oxequip/MedStar, the Chemetron, and the

Puritan-Bennett quick connect adapters. Only the corresponding type of adapters can be used with the quick connect

outlets. The DISS outlet conforms to the CGA Pamphlet V-5 standards. Since the “Rough-in assembly” is the same for all

models of “Latch-valve assemblies”, the outlet can easily be converted from one type to another by simply replacing the

“Latch-valve assembly”.

www.amico.com 3

Page 4

Cleaning and Lubricating

The Amico Outlets are factory cleaned for oxygen service. Exposed surfaces of the outlet may be cleaned with a mild

detergent solution or wiped with a disinfectant commonly used in patient rooms, that is compatible with plastics,

anodized aluminium and die cast zinc. Lubricate elastomer seals sparingly with a silicone lubricant that is oxygen

compatible. DO NOT USE OIL.

Inspection and Testing

Medical Gas Outlets should be inspected periodically or at least once a year. The test should be in accordance with NFPA

99 “Gas and Vacuum systems” .

Test for Leaks:

Ensure that no leaks exists, with or without the adapter inserted.

Test for Indexing:

Only a mating gas specic adapter should insert smoothly into the outlet, latch and be retained.

Test for Flow:

• Gas Outlets: 120 l/min (4.2 scfm) @ 345 kPa (50 psi), maximum allowable pressure drop is 28 kPa (4 psi).

• Nitrogen Outlet: 400 l/min (14.1 scfm) @ 1,250 kPa (180 psi), maximum allowable pressure drop is 70 kPa (10

psi).

• Vacuum Outlet: 30 l/min (1.1 scfm) @ 54 kPa (16 inHg), maximum allowable pressure drop is 13 kPa (4 inHg).

Refer to the appropriate standards for the proper way of performing the ow test.

Note:

The Amico medical gas and vacuum outlets meet and exceed these requirements at the time of manufacture.

However piping source capacity, sizing and restrictions may prevent outlets from attaining these values.

4 Amico Pipeline

Page 5

Installation and Dimensions

Wall Outlets

DISS, Ohmeda compatible, Chemetron compatible, Puritan-Bennett and Oxequip/MedStar compatible

When wall outlets are ganged

together, ensure that they

are 5” from center to center.

DO NOT let the notches on

the mounting plate pass the

adjacent holes on the next

mounting plate.

3/8”

[10]

1-1/16”

[27]

5”

[127]

5”

[127]

5”

[127]

1/2" [12.7 mm] O.D. (3/8” nominal) type "K"

copper pipe, rotates 360 deg.

for entry from any angle

1 7/8”

[48 ]

Inch

[mm]

Wall thickness

may vary from

3/8" to 1"

10mm to 25mm]

[

Do not bury the outlet during

the drywall and plaster application. Ensure that the cover

over the outlet is in place until the “Latch-valve assembly”

can be installed.

10”

[254]

5-3/4”

[146]

5”

[127]

OXY

3” [76]

5-27/32” [ 148]

OXYGENYGEN

OXY

NOTE:

Amico recomends that you have a blank space

between outlets and slides.

Maximum 3 outlets may be ganged together

without additional support.

5-1/2”

[140]

www.amico.com 5

Page 6

without additional support.

5

Installation and Dimensions

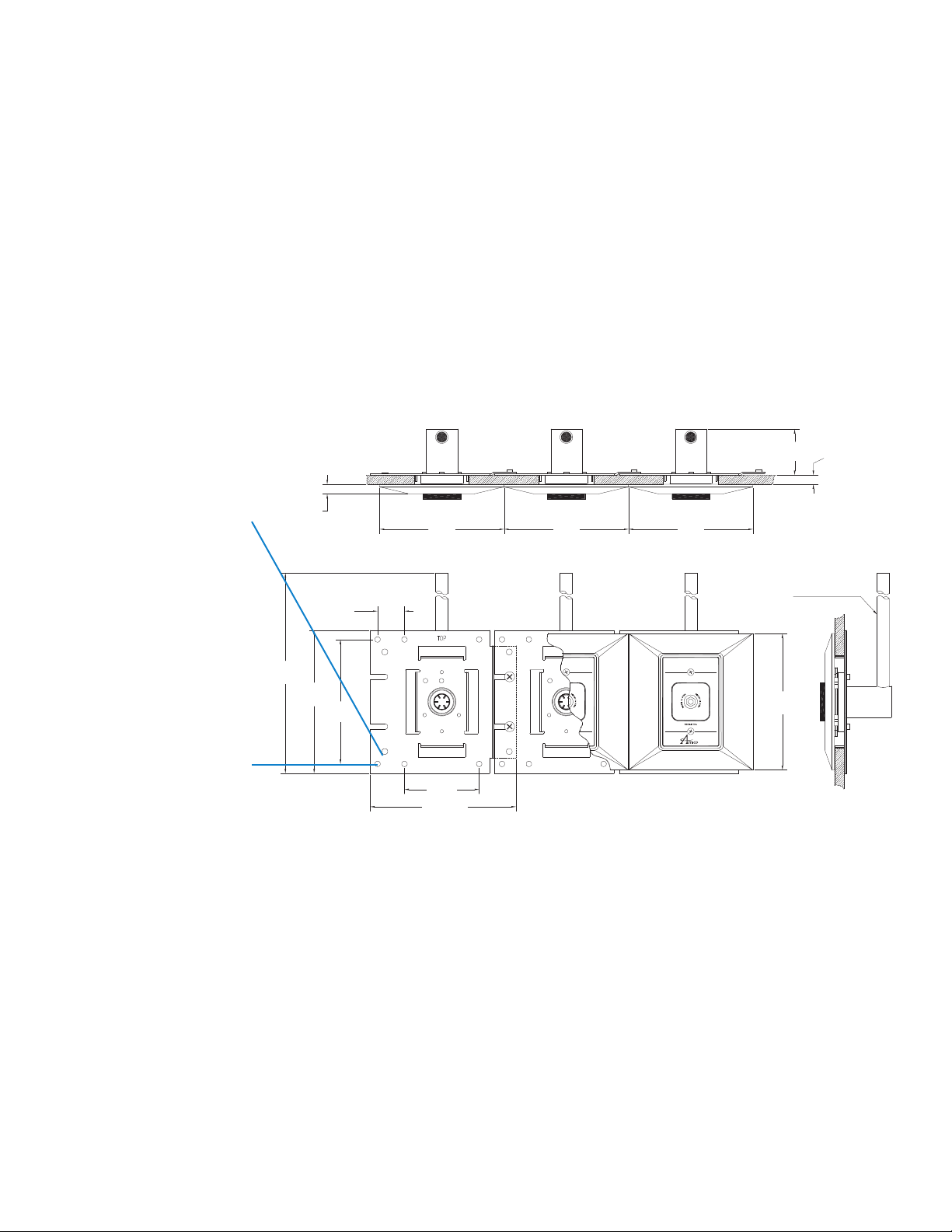

Ceiling Outlets

DISS, Ohmeda compatible, Chemetron compatible, Puritan-Bennett and Oxequip/MedStar compatible

Inch

[mm]

When wall outlets are ganged

together, ensure that they

are 5” from center to center.

DO NOT let the notches on

the mounting plate pass the

3/8”

[10]

1-1/4”

[32]

[127]

5”

[127]

5”

[127]

5”

1-7/8”

[48]

Wall thickness

may vary from

3/8” to 1”

[10mm to 25 mm]

adjacent holes on the next

mounting plate.

MEDVAC

Do not bury the outlet during

-3/4”

[146]

[127]

5”

5-1/2”

[140]

the drywall and plaster application. Ensure that the cover

over the outlet is in place until the “Latch-valve assembly”

can be installed.

3”

[76]

5-27/32”

[148]

NOTE:

Amico recommends that you have a blank space

between outlets and slides.

Maximum 3 outlets may be ganged together

Console Outlets

DISS, Ohmeda compatible, Chemetron compatible, Puritan-Bennett and Oxequip/MedStar compatible

inch

[mm]

TOP VIEW

1/2" [12.7 mm] O.D. (3/8” nominal) type "K"

copper pipe, rotates 360 deg.

for entry from any angle.

FRONT VIEW

BACK

ASSEMBLY

8-7/8"

[225]

3-9/16"

[91]

1-13/16"

[46]

3-9/32"

[83]

OXY

FRONT VIEW

FRONT

ASSEMBLY

OXYGEN

OXY

2-7/16"

[62]

3-3/4"

[95]

SIDE VIEW

FRONT

ASSEMBLY

2-7/16"

[62]

SIDE VIEW

6 Amico Pipeline

Page 7

Installation and Dimensions

Ceiling Column Outlets

DISS, Ohmeda compatible, Chemetron compatible, Puritan-Bennett and Oxequip/MedStar compatible

1/2" [12.7 mm] O.D. (3/8” nominal) type "K"

copper pipe, rotates 360 deg.

for entry from any angle.

9-1/4"

[235]

inch

[mm]

FRONT VIEW

FRONT

ASSEMBLY

OXYGEN

OXY

2-7/16"

[62]

3-3/4"

[95]

SIDE VIEW

FRONT

ASSEMBLY

SIDE VIEW

2-7/16"

[62]

3-9/16"

[91]

FRONT VIEW

BACK

ASSEMBLY

OXY

1-13/16"

[46]

3-9/32"

[83]

On all outlets (wall and console) the connecting pipe can swivel a full 360 deg. for easy connection to the gas pipe.

When soldering the pipe connection take care not to heat up the body, since that could damage the secondary check

valve.

It is very important to keep the protective cover (wall outlets only) in place during construction, to ensure that no debris

or dirt get into the outlet.

When installing the “Latch-valve assembly”, remove the protective cover and inspect for dirt or debris in the outlet body.

Clean out the contaminants, if required.

The “Latch-valve assembly” should slide in smoothly into the “Rough-In assembly”, if not, check that there is no damages to

the indexing pin arrangements. If the indexing pins are bent or damaged, replace the “Latch-valve assembly”.

DO NOT PRESSURE TEST THE PIPELINE OVER 100 PSI [690 kPa] IF THE “LATCH-VALVE ASSEMBLY” HAS BEEN

INSTALLED.

All “Rough-in assemblies” can be pressure tested up to a maximum of 200psi without the “Latch-valve assembly” attached

to it.

All “Latch-valve assemblies” with the exception of Nitrogen DISS have a Maximum pressure rating of 100 PSI [690 kPa]. The

Nitrogen D I S S has a maximum pressure rating of 200 psi [1,380 kPa].

After installation, perform the test on page 1.

www.amico.com 7

Page 8

Service

Before performing any maintenance on the Outlet, the appropriate hospital maintenance or engineering personnel

should be notied. The “Latch-valve assembly” can be removed without interrupting the service, but when servicing

the “Rough-In assembly” the supply pressure has to be shut o.

Latch Valve Assembly DISS

23

22

20

17

13

12

16

21

Note:

Latch-Valve Assembly Model Numbers see Page 14

15

Complete Outlet Model Numbers see Page 16

11

Repair Kit Model Numbers see Page 20

1. Unscrew the two retaining screws (12) until the Latch Valve Assembly (11) can be removed from the outlet.

2. Remove the O-Ring seal (16) from the front and replace (NOTE: There is no O-Ring for Oxygen, Medical Air and

Carbon Dioxide).

3. Remove the retaining ring (23) using appropriate pliers. Remove the valve stem (17), O-Ring seal (20), primary

check valve (21) and spring (22). Inspect the items for wear or damage and replace if needed. Replace the O-Ring

(20).

4. Re-install all internal components and lock in place with the retaining ring (23).

5. Re-install the Latch Valve Assembly into the outlet. Coat the connector (15) with a thin coat of oxygen compatible

silicone lubricant to aid insertion. Tighten down the retaining screws (12), DO NOT over tighten, as this could

damage the Latch Valve.

6. Connect a gas specic adapter to the outlet. The connection should be smooth and hand tightening of the nut

should be sucient to allow the gas to ow without leakage. If not, replace the entire Latch Valve Assembly (11).

8 Amico Pipeline

Page 9

Latch Valve Assembly Ohmeda (Compatible)

23

22

21

20

19

18

17

13

12

Note:

Latch-Valve Assembly Model Numbers see Page 14

25

24

USE NO OIL

15

Complete Outlet Model Numbers see Page 16

16

Repair Kit Model Numbers see Page 18

14

11

1. Unscrew the two retaining screws (12) until the Latch Valve Assembly (11) can be removed from the outlet.

2. Remove the four screws (25) holding the connector retaining plate (24) in place. Remove the plate.

3. Remove the connector (17) from the valve assembly.

4. Remove the U-spring (14), inspect for wear or damage, re-install the U-spring.

5. Remove the at washer (15) and connector O-Ring (16) from the front of the connector. Inspect the items for wear

or damage and replace the O-Ring seal (16).

6. Remove the retaining ring (23) using appropriate pliers. Remove the dust cap (18), dust cap spring (19), O-Ring seal

(20), primary check valve (21) and spring (22). Inspect the items for wear or damage and replace if needed. Replace

the O-Ring (20).

7. Re-install all internal components and lock in place with retaining ring (23). Insert the Connector (17) into the gas

specic body. Check that the U-Spring (14), at washer (15) and O-Ring (16) are in place. Re-install the connector

retaining plate (24) and secure with four screws (25), do not overtighten.

8. Re-install the Latch Valve Assembly into the outlet. Coat the connector (17) with a thin coat of oxygen compatible

silicone lubricant to aid insertion. Tighten down the retaining screws (12), DO NOT over tighten, as this could

damage the Latch Valve.

9. Connect a gas specic adapter into the outlet. The connection should be smooth and the adapter should lock and

remain in place allowing gas to ow. If not replace the entire Latch Valve Assembly (11).

www.amico.com 9

Page 10

Latch Valve Assembly Chemetron (Compatible)

23

22

21

20

19

18

17

12

LIOONESU

Note:

Latch-Valve Assembly Model Numbers see

Page 14

25

24

Complete Outlet Model Numbers see Page

16

11

1. Unscrew the three retaining screws (12) until the Latch Valve Assembly (11) can be removed from the outlet.

2. Remove the four screws (25) holding the connector retaining plate (24) in place. Remove the plate.

3. Remove the connector (17) from the valve assembly.

4. Remove the connector O-Ring (16) from the front of the connector. Inspect the items for wear or damage and

replace the O-Ring seal (16).

5. Remove the retaining ring (23) using appropriate pliers. Remove the dust cap (18), dust cap spring (19), O-Ring seal

(20), primary check valve (21) and spring (22). Inspect the items for wear or damage and replace if needed. Replace

the O-Ring (20).

6. Re-install all internal components and lock in place with retaining ring (23). Insert the Connector (17) into the gas

specic body. Check that the O-Ring (16) is in place. Re-install the connector retaining plate (24) and secure with

four screws (25), do not overtighten.

16

Repair Kit Model Numbers see Page 19

7. Re-install the Latch Valve Assembly into the outlet. Coat the connector (17), with a thin coat of oxygen compatible

silicone lubricant to aid insertion. Tighten down the retaining screws (12), DO NOT over tighten, as this could

damage the Latch Valve.

8. Connect a gas specic adapter into the outlet. The connection should be smooth and the adapter should lock and

remain in place allowing gas to ow. If not replace the entire Latch Valve Assembly (11).

10 Amico Pipeline

Page 11

Latch Valve Assembly Puritan-Bennett (Compatible)

20

18

17

16

P

R

E

S

E

S

S

E

T

L

O

E

R

12

R

E

O

L

T

E

S

S

E

S

E

R

P

USE NO OIL

Note:

Latch-Valve Assembly Model

Numbers see Page 14

19

Complete Outlet Model Numbers

see Page 16

Repair Kit Model Numbers see

11

14

15

Page 21

1. Unscrew the two retaining screws (12) until the Latch Valve Assembly (11) can be removed from the outlet.

2. Remove the two screws (20), holding the round retaining ring (19) in place. Remove the plate.

3. Remove the gas connector (18) from the valve assembly.

4. Remove the Body Seal (15) and Poppet (16) from the front of the Gas Connector (18). Inspect the items for wear or

damage and replace the Body Seal (15).

5. Remove the Gas or Vacuum Spring (17), to inspect for wear or damage. Re-install the Gas or Vacuum Spring.

6. Re-install all internal components into the Gas Connector (18). Check that the Gas or Vacuum Spring (17), Body Seal

(15) and Poppet (16) are in place. Re-install the round retaining plate (19) and secure with two screws (20), do not

overtighten.

7. Re-install the Latch Valve Assembly into the outlet. Coat the connector (18) with a thin coat of oxygen compatible

silicone lubricant to aid insertion. Tighten down the retaining screws (12), DO NOT over tighten, as this could

damage the Latch Valve.

8. Connect a gas specic adapter into the outlet. The connection should be smooth and the adapter should lock and

remain in place allowing gas to ow. If not, replace the entire Latch Valve Assembly (11).

www.amico.com 11

Page 12

Latch Valve Assembly Oxequip/MEDSTAR (Compatible)

21

20

18

17

16

10

9

15

19

8

7

6

7

12

Note:

14

11

Latch-Valve Assembly Model Numbers see Page 14

Complete Outlet Model Numbers see Page 16

Repair Kit Model Numbers see Page 22

1. Unscrew the two retaining screws (12) until the Latch Valve Assembly (11) can be removed from the outlet.

2. Locking Mechanism Repair

Unscrewing the rst screw (7) and remove item (6). Then unscrew the second set of screws (7), this will give you

access to items (8), (9) and (10). Inspect all three items for wear or damage, replace if needed.

3. Outlet Gas Connector Repair.

While holding the round retaining ring (19) in place, remove the two screws (20). Remove the retaining ring (19)

and gas connector (18). Then remove the Body Seal (15), the Poppet (16) and the Gas or Vacuum Spring (17).

Inspect for wear or damage, replace components if needed.

Re-install the Gas or Vacuum Spring (17), the Poppet (16) and the Body Seal (15) into the gas connector (18).

Re-install gas connector (18) and retaining plate (19), secure with two screws (20). DO NOT OVERTIGHTEN.

4. Re-install the Latch Valve Assembly into the outlet. Coat the connector (18) with a thin coat of Oxygen compatible

silicone lubricant to aid insertion. Tighten down the retaining screws (12), DO NOT over tighten, as this could

damage the Latch Valve.

5. Connect a gas specic adapter into the outlet. The connection should be smooth and the adapter should lock

and remain in place allowing gas to ow. If not, replace the entire Latch Valve Assembly (11).

12 Amico Pipeline

Page 13

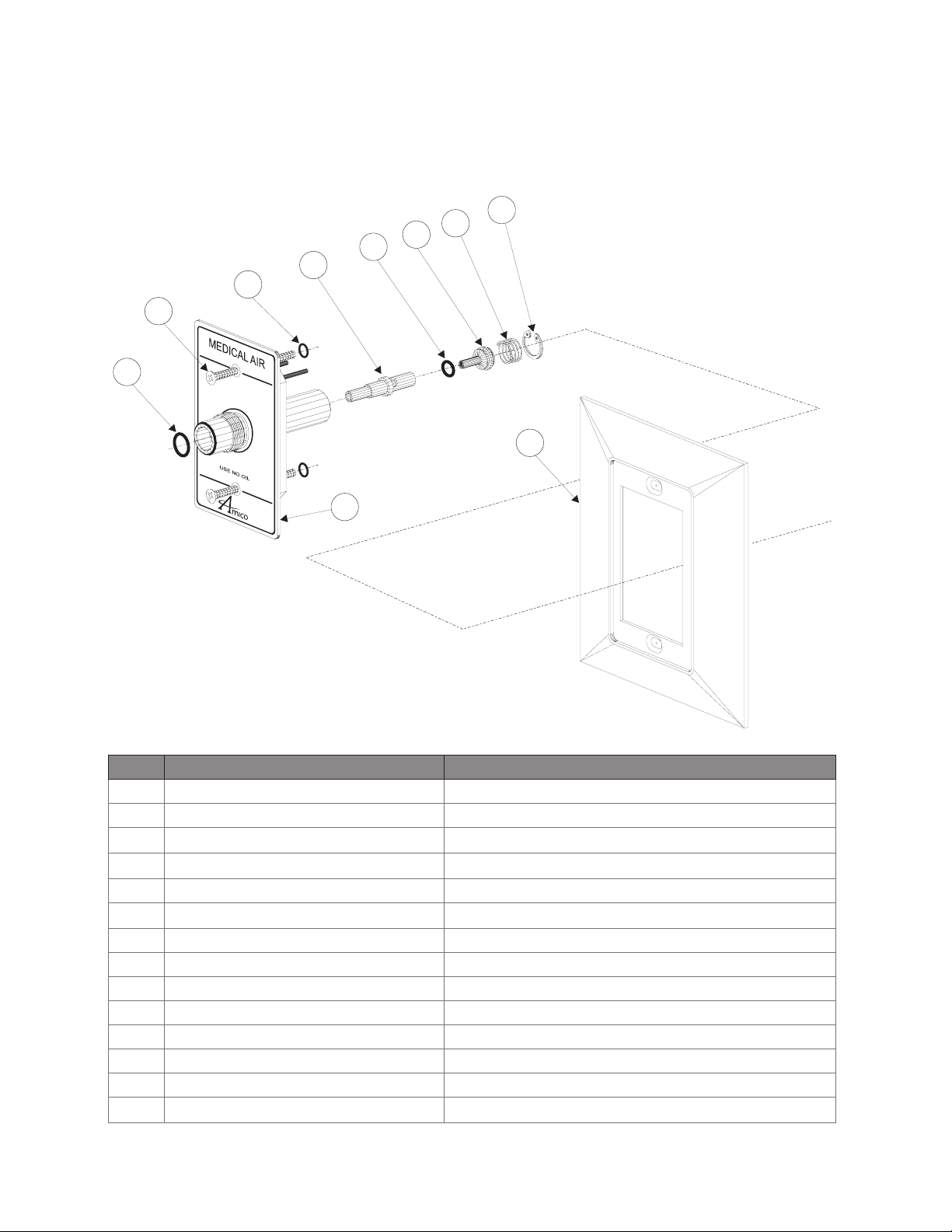

Rough-In Assembly Wall and Console

OXYGEN

1

OXYGEN

2

Note:

Rough-in Assembly Model Numbers see Page 15

Complete Outlet Model Numbers see Page 16

Repair Kit Model Numbers see Page 23

3

4

5

6

7

8

CAUTION: Ensure that the supply pressure is shut o before performing service.

Inside the “Rough-in assembly” is a secondary check valve whose function is to shut o gas ow when the “Latch-valve

assembly” is removed. This seat/seal also prevents leakage around the latch valve connector. As the secondary seal

is only a static seal, it will rarely need replacement. However, if the seat/seal does need replacement, follow the following

procedure:

1. Ensure that no pressure exists in the line by depressing the secondary check valve (5).

2. Remove the retaining ring (8) from the inside of the outlet body. Use a small screwdriver to pull the end of the

ring towards the center and then pull the ring up and out.

3. Remove the washer (7), seat/seal (6), secondary check valve (5) and secondary check valve spring (4). Inspect

items for wear or damage and replace the seat/seal (6).

4. Re-install the spring (4), secondary check valve (5), seat/seal (6) and the washer (7). Insert the retaining ring (8)

into the slot and ensure that the whole ring is seated properly.

5. Turn on the pressure and check for leaks. Re-install the “Latch Valve assembly” and perform the inspection and

test on page 1.

www.amico.com 13

Page 14

Model Numbers

Latch-Valve Assemblies

Gas Service

DISS Wall

Latch-valve assembly:

Oxygen O-FASW-DI-U-OXY O-FASW-DI-E-OXY O-FASW-DI-F-OXY

Medical Air O-FASW-DI-U-AIR O-FASW-DI-E-AIR O-FASW-DI-F-AIR

MedVac O-FASW-DI-U-VAC O-FASW-DI-E-VAC O-FASW-DI-F-VAC

Nitrous Oxide O-FASW-DI-E-N2O O-FASW-DI-E-N2O O-FASW-DI-F-N2O

Nitrogen O-FASW-DI-E-NIT O-FASW-DI-E-NIT O-FASW-DI-F-NIT

Carbon Dioxide O-FASW-DI-E-CO2 O-FASW-DI-E-CO2 O-FASW-DI-F-CO2

WAGD/AGSS O-FASW-DI-U-WAG O-FASW-DI-E-AGS O-FASW-DI-F-AGS

DISS Console Latch Valve:

For DISS Console Latch Valve replace the “W” in the O-FASW-DI-L-GAS to “C”.

For example: USA DISS Oxygen = O-FASC-DI-U-OXY

English USA English ISO French ISO

Ohmeda compatible Wall Latch Valve:

For Ohmeda compatible Wall Latch Valve replace the “DI” in the O-FASW-DI-L-GAS to “QD”.

For example: USA Ohmeda Vacuum = O-FASW-QD-U-VAC

Ohmeda compatible Console Latch Valve:

For Ohmeda compatible Console Latch Valve replace the “W” in the O-FASW-QD-L-GAS to “C”.

For example: USA Oxygen = O-FASC-QD-U-OXY

Chemetron compatible Latch Valve:

For Chemetron compatible Wall Latch Valve replace the “DI” in the O-FASW-DI-L-GAS to “CH”.

For example: Chemetron USA Vacuum = O-FASW-CH-U-VAC

Chemetron compatible Console Latch Valve:

For Chemetron compatible Console Latch Valve replace the “W” in the O-FASW-CH-L-GAS to “C”.

For example: Chemetron USA Oxygen = O-FASC-CH-U-OXY

Puritan-Bennett compatible Latch Valve:

For Puritan-Bennett compatible Wall Latch Valve replace the “DI” in the O-FASW-DI-L-GAS to “PB”.

For example: Puritan-Bennett USA Vacuum = O-FASW-PB-U-VAC

Puritan-Bennett compatible Console Latch Valve:

For Puritan-Bennett compatible Console Latch Valve replace the “W” in the O-FASW-PB-L-GAS to “C”.

For example: Puritan-Bennett USA Oxygen = O-FASC-PB-U-OXY

14 Amico Pipeline

Page 15

Model Numbers

Oxequip Compatible Latch Valve:

For Oxequip compatible Wall Latch Valve replace the “DI” in the O-FASW-DI-L-GAS to “OX”.

For Example: Oxequip USA Oxygen = O-FASW-OX-U-OXY

Oxequip Compatible Console Latch Valve:

For Oxequip compatible Console Latch Valve replace the “W” in the O-FASW-OX-L-GAS to “C”.

For Example: Oxequip USA Oxygen = O-FASC-OX-U-OXY

Rough-In Assemblies

Gas Service

Wall Rough-In:

Oxygen O-BAKW-U-OXY O-BAKW-E-OXY O-BAKW-E-OXY

Medical Air O-BAKW-U-AIR O-BAKW-E-AIR O-BAKW-E-AIR

MedVac O-BAKW-U-VAC O-BAKW-E-VAC O-BAKW-E-VAC

Nitrous Oxide O-BAKW-E-N20 O-BAKW-E-N2O O-BAKW-E-N2O

Nitrogen O-BAKW-E-NIT O-BAKW-E-NIT O-BAKW-E-NIT

Carbon Dioxide O-BAKW-E-CO2 O-BAKW-E-CO2 O-BAKW-E-CO2

WAGD/AGSS O-BAKW-U-WAG O-BAKW-E-AGS O-BAKW-E-AGS

Console Rough-In:

For Console Rough-in replace the “W” in the O-BAKW-L-GAS to “CON”.

For example: USA Oxygen = O-BAKCON-U-OXY

Ceiling Rough-In:

For Ceiling Rough-in replace the “W” in the O-BAKW-L-GAS to “CEI”.

For example: USA Nitrogen = O-BAKCEI-E-NIT

English USA English ISO French ISO

Ceiling Column Rough-In:

For Ceiling Column Rough-in replace the “W” in the O-BAKW-L-GAS to “CCOL”.

For example: USA Nitrous Oxide = O-BAKCCOL-E-N2O

www.amico.com 15

Page 16

Model Numbers

Complete Outlets

Gas Service

DISS Wall:

Oxygen O-DISWAL-U-OXY O-DISWAL-E-OXY O-DISWAL-F-OXY

Medical Air O-DISWAL-U-AIR O-DISWAL-E-AIR O-DISWAL-F-AIR

MedVac O-DISWAL-U-VAC O-DISWAL-E-VAC O-DISWAL-F-VAC

Nitrous Oxide O-DISWAL-E-N2O O-DISWAL-E-N2O O-DISWAL-F-N2O

Nitrogen* O-DISWAL-E-NIT O-DISWAL-E-NIT O-DISWAL-F-NIT

Carbon Dioxide** O-DISWAL-E-CO2 O-DISWAL-E-CO2 O-DISWAL-F-CO2

WAGD/AGSS O-DISWAL-U-WAG O-DISWAL-E-AGS O-DISWAL-F-AGS

* DISS Only

**Not Available for Puritan-Bennett

DISS Console Outlet:

For DISS Console outlet replace the “WAL” in the O-DISWAL-L-GAS to “CON”.

For example: DISS Console USA Nitrogen = O-DISCON-E-NIT

DISS Ceiling Outlet:

For DISS Ceiling outlet replace the “WAL” in the O-DISWAL-L-GAS to “CEI”.

English USA English ISO French ISO

For example: DISS Ceiling USA Nitrogen = O-DISCEI-E-NIT

DISS Ceiling Column Outlet:

For DISS Ceiling Column outlet replace the “WAL” in the O-DISWAL-L-GAS to “CCOL”.

For example: DISS Ceiling Column USA Vacuum = O-DISCCOL-U-VAC

Ohmeda compatible Outlet:

For Ohmeda compatible outlet replace the “DIS” in any of the above examples, O-DISWAL-L-GAS to “QD”.

For example: Ohmeda compatible Wall USA Oxygen = O-QDWAL-U-OXY

Chemetron compatible Outlet:

For Chemetron compatible outlet replace the “DIS” in any of the above examples, O-DISWAL-L-GAS to “CH”.

For example: Chemetron compatible Console USA Oxygen = O-CHCON-U-OXY

Puritan-Bennett compatible Outlet:

For Puritan-Bennett compatible outlet replace the “DIS” in any of the above examples, O-DISWAL-L-GAS to “PB”.

For example: Puritan-Bennett compatible Console USA Oxygen = O-PBCON-U-OXY

Oxequip Compatible Outlet:

For Oxequip compatible outlet replace the “DIS” in any of the above examples, O-DISWAL-L-GAS to “OX”.

For Example: Oxequip compatible Wall USA Oxygen = O-OXWAL-U-OXY

16 Amico Pipeline

Page 17

Gas Indexing

MEDVAC OXYGEN

As seen from the front of the

“Rough-In Assemblies”

NITROUS OXIDE MEDICAL AIR

NITROGEN

CARBON DIOXIDE

WAGD/AGSS

www.amico.com 17

Page 18

Replacement Components

Latch Valve Assembly Ohmeda Compatible

20

19

18

17

13

12

USENO OIL

15

14

11

25

24

23

22

21

16

26

Chrome face plate not supplied with

console or column outlets

Item Description Model Numbers

11 Ohmeda Latch-valve See above

12 Screw (2 req’d) H-1612-06-18A

13 O-ring (2 req’d) O-X-LVA-SCROR

14 Gas connector U-spring O-X-LVAQ-USPR *

15 Flat washer H-WASH-625-SS *

16 Gas connector O-ring O-X-LVAQ-ORING *

17 Gas connector O-X-LVAQ-BDY

18 Primary dust cap O-X-LVA-CAP

19 Primary dust cap spring O-X-LVA-CAPSPR *

20 Primary check valve O-Ring O-X-LVA-CHORI *

21 Primary check valve O-X-LVA-CHECK *

22a Primary check valve spring O-X-LVA-POPSPR *

22b Primary check valve spring-Vac O-X-LVA-PRSPR only for Vacuum and WAGD/AGSS *

23 C-Clip primary check valve O-X-LVA-CLIP *

24 Connector retaining plate O-X-LVA-PLATE

25 Retaining plate screws (4 req’d) H-PTPP-0606

26 Chrome face plate O-TRIM-M500C

Above parts with an “*” are found in repair kit: O-RK-LVA-QD

18 Amico Pipeline

Page 19

Replacement Components

Latch Valve Assembly Chemetron Compatible

19

17

13

12

L I O O N E S U

18

20

21

26

25

24

23

22

Chrome face plate not supplied with

console or column outlets.

16

11

Item Description Model Numbers

11 Chemtron Latch-valve See above

12 Screw (3 req’d) H-MPF-0617

13 O-ring (3 req’d) O-X-LVA-SCROR

16 Gas connector O-ring O-X-LVAQ-ORING *

17 Gas connector O-X-LVAQ-BDY

18 Primary dust cap O-X-LVA-CAP ; O-X-LVA-CAP-CVA for VAC only

19 Primary dust cap spring O-X-LVA-CAPSPR *

20 Primary check valve O-Ring O-X-LVA-CHORI *

21 Primary check valve O-X-LVA-CHECK *

22a Primary check valve spring O-X-LVA-POPSPR *

22b Primary check valve spring-Vac O-X-LVA-PRSPR only for Vacuum and WAGD/AGSS *

23 C-Clip primary check valve O-X-LVA-CLIP *

24 Connector retaining plate O-X-LVA-PLATE

25 Retaining plate screws (4 req’d) H-PTPP-0606

26 Chrome face plate O-TRIM-M500C

Above parts with an “*” are found in repair kit: O-RK-LVA-QD

www.amico.com 19

Page 20

Replacement Components

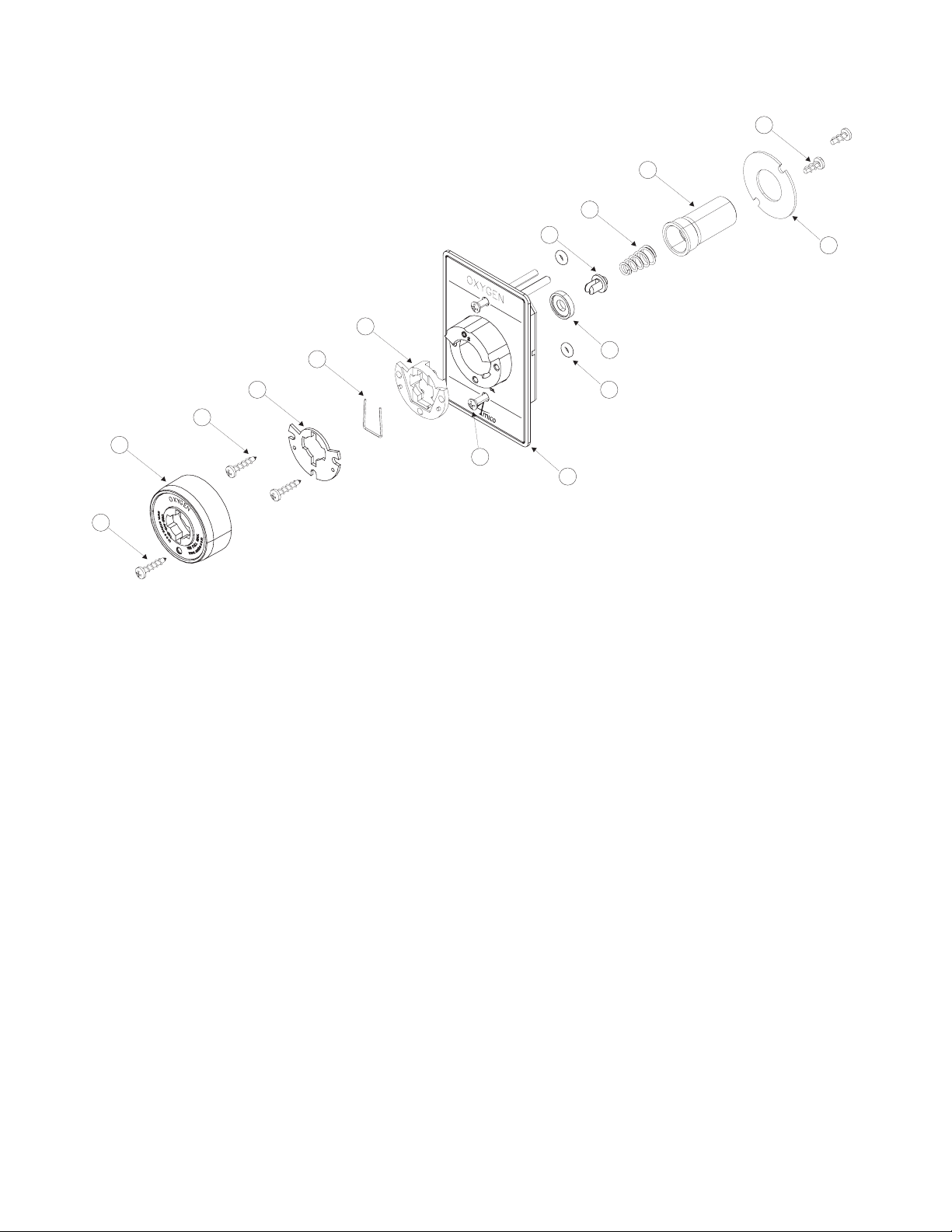

Latch Valve Assembly DISS

20

17

13

12

16

11

21

23

22

26

Chrome face plate not supplied with

console or column outlets

Item Description Model Numbers

11 DISS Latch-valve See above

12 Screw (2 req’d) H-1612-06-18A

13 O-ring (2 req’d) O-X-LVA-SCROR

16a Adapter O-ring Nit O-X-LVAD-OR-012 *

16b Adapter O-ring Vac O-X-LVAD-OR-102 *

16c Adapter O-ring N2O O-X-LVA-CHORI *

17a Valve stem DISS Gas O-X-LVAD-ST-OTH

17b Valve stem DISS Oxygen O-X-LVAD-ST-OXY

17c Valve stem DISS Vac & WAGD/AGSS O-X-LVAD-ST-VAC only for Vacuum and WAGD/AGSS

20 Primary check valve O-Ring O-X-LVA-CHORI *

21 Primary check valve O-X-LVA-CHECK *

22 Primary check valve spring O-X-LVA-PRSPR *

23 C-Clip primary check valve O-X-LVA-CLIP *

26 Chrome face plate O-TRIM-M500C

Above parts with an “*” are found in repair kit: O-RK-LVA-DIS

20 Amico Pipeline

Page 21

Replacement Components

Latch Valve Assembly Puritan-Bennett Compatible

17

16

15

21

24

12

23

P

R

E

S

E

S

S

E

T

L

O

E

R

R

E

O

L

T

E

S

S

E

S

E

R

P

USE NO OIL

13

14

Chrome face plate not supplied with

console or column outlets

11

Item Description Model Numbers

11 Puritan-Bennett Latch-valve See above

12 Mounting Screw (2 req’d) H-1612-06-18A

13 O-ring (2 req’d) O-X-LVA-SCROR

14 Body Seal O-X-LVAPB-SEAL *

15 Poppet for Body O-X-LVAPB-POPET *

16a Spring for all Gases (except Vac.) O-X-LVAPB-SPGAS *

16b Spring for Vacuum O-X-LVAPB-SPVAC *only for Vacuum and WAGD/AGSS *

17 Gas connector O-X-LVAPB-BDY

21 Chrome face plate O-TRIM-M500C

23 Retaining Ring O-X-LVAPB-WASH

24 Retaining Ring screws (2 req’d) H-MPR-0605

Above parts with an “*” are found in repair kit: O-RK-LVA-PB

www.amico.com 21

Page 22

Replacement Components

Latch Valve Assembly Oxequip/MEDSTAR Compatible

10

9

21

20

18

17

16

15

19

8

7

6

7

12

14

11

Item Description Model Numbers

6 Plastic Trimcap O-X-OXE-TRIMCAP

7 #6 x 5/8” Screws H-STSP-0606-A-SS

8 Cover Guide Plate O-X-OXE-COVPLT**

9 U-Spring O-X-OXE-USPR**

10 Cam Guide Plate O-X-OXE-CAMPLT**

11 Oxequip Latch-valve See above

12 Mounting Screw (2 req’d) H-1612-06-18A

14 O-ring (2 req’d) O-X-LVA-SCROR

15 Body Seal O-X-OXE-SEAT*

16 Poppet for Body O-X-OXE-POPET*

17a Spring for all gases (except Vac) O-X-LVAPB-SPGAS*

17b Spring for Vacuum O-X-LVAPB-SPVAC* only for Vacuum and WAGD/AGSS

18 Gas connector O-X-LVAPB-BDY

19 Retaining Ring O-X-LVAPB-WASH

20 Retaining Ring screws (2 req’) H-PTPP-0606

21 Chrome Face Plate O-TRIM-M500C

Above parts with “*” are found in repair kit: O-RK-LVA-OX-GC

Above parts with “**” are found in repair kit: O-RK-LVA-OX-LM

Both O-RK-LVA-OX-GC and O-RK-LVA-OX-LM can be ordered as one kit using O-RK-LVA-OX

22 Amico Pipeline

Page 23

Replacement Components

Rough-In Assembly

OXYGEN

1

OXYGEN

4

5

6

7

8

2

3

Item Description Model Numbers

1 Rough-In Assembly See above

2 Gas label AX-BOXLAB-L-GAS**

3 Screw (2 req’d) H-MPP-1008

4 Secondary check valve spring O-X-BAK-SPRING *

5 Secondary check valve O-X-BAK-CHECK *

6 Seat/Seal O-X-BAK-SEAT *

7 Washer H-WASH-895-SS *

8 Retaining Ring O-X-BAK-RETAI*

Above parts with an “*” are found in repair kit: O-RK-BAK

** “L” refers to langauge (U = For USA / E = For ISO)

www.amico.com 23

Page 24

www.amico.com

Amico Pipeline | www.amico.com

85 Fulton Way, Richmond Hill

Ontario, L4B 2N4, Canada

71 East Industry Court, Deer Park

NY 11729, U.S.A

Toll Free Tel: 1.877.264.2697

Toll Free Fax: 1.866.440.4986

Tel: 905.763.7778

Fax: 905.763.8587

Email: info@amico.com

C US LISTED

APE MEDGAS OUTLETS MANUAL JULY 2012

Loading...

Loading...